Full-automatic finless eel or loach processing equipment

A processing equipment, fully automatic technology, applied in the direction of poultry/fish slaughtering/stunning, etc., can solve the problems of unsolved labor intensity of workers, complex structure of slaughtering devices, poor adaptability, etc., and achieve good economic and social benefits, The effect of low processing cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

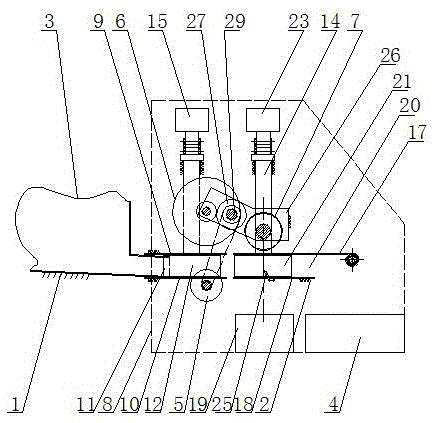

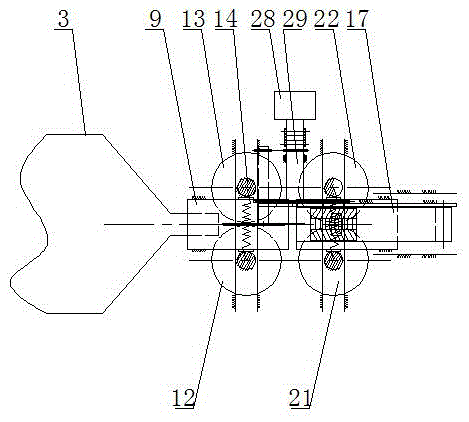

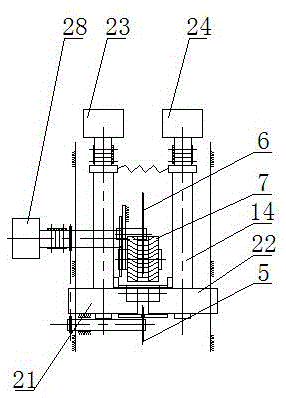

[0018] The full-automatic eel and loach processing equipment includes a fixed frame 1, an adjustable frame 2, a feed barrel 3, a discharge barrel 4, a laparotomy knife 5, a back-cut knife 6 and a hob 7. The fixed frame 1 is provided with a protective cover 8, and the fixed frame 1 in the protective cover 8 is provided with an upper fixed supporting plate 9 and a lower fixed supporting plate 10 up and down. Between the upper fixed pallet 9 and the lower fixed pallet 10 is provided a feed channel A11 formed at intervals between the upper fixed pallet 9 and the lower fixed pallet 10 .

[0019] The fixed frame 1 on one side of the feeding channel A11 is equipped with a feeding barrel 3, and the feeding barrel 3 communicates with the feeding channel A11. A feed tooth disc A12 and a feed tooth disc B13 are arranged symmetrically in the feed channel A11. The transmission shaft 14 is respectively installed on the feed tooth disc A12 and the feed tooth disc B13, and the transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com