Machine for slaughtering ricefield eel

A technology of killing machines and rice field eels, which is applied in the direction of poultry/fish slaughtering/stunning, etc., can solve the problems of labor intensity of workers, restrict the development of rice field eels, and high labor intensity, and achieve good economic and social benefits and low processing costs , the effect of high demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

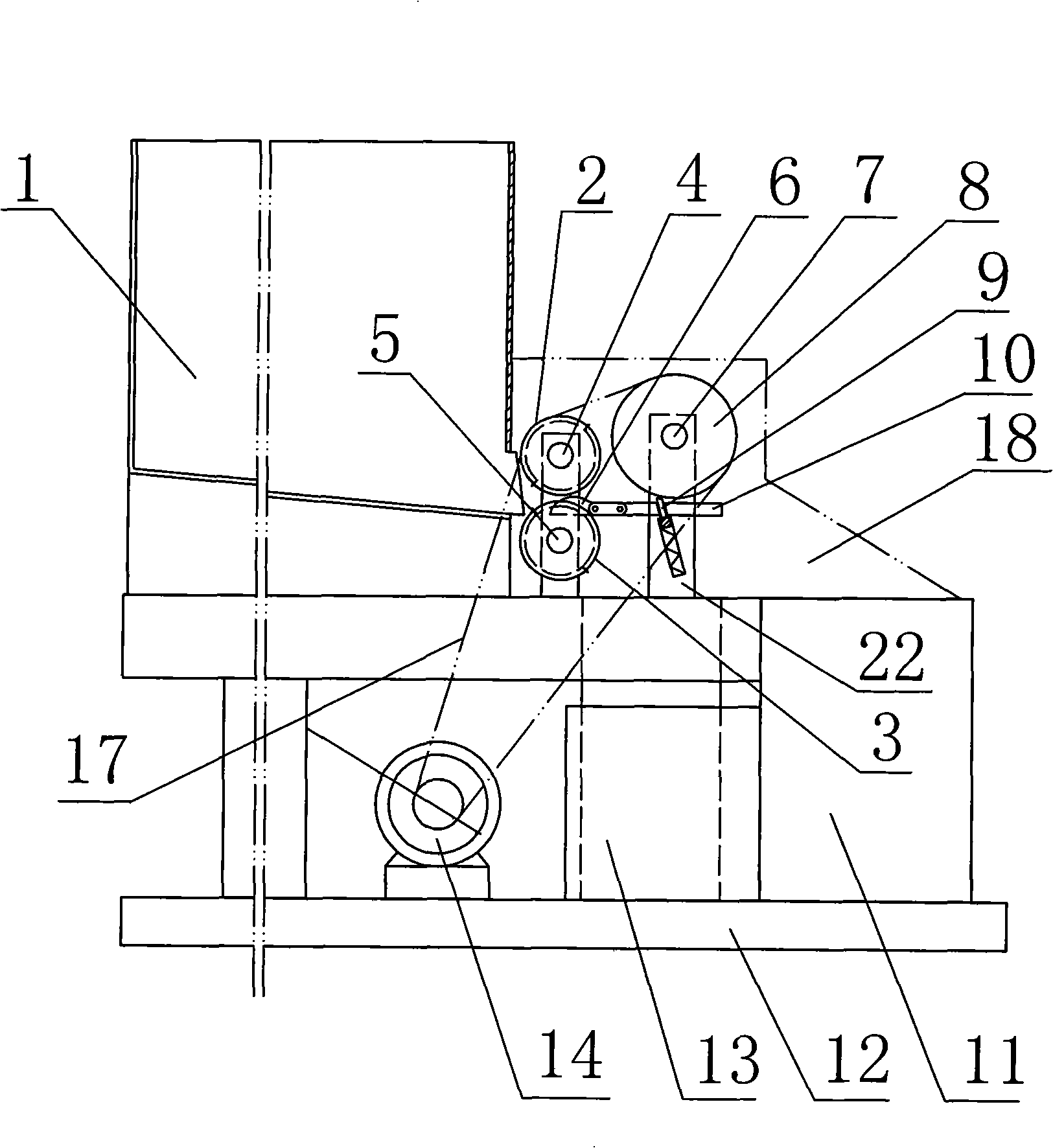

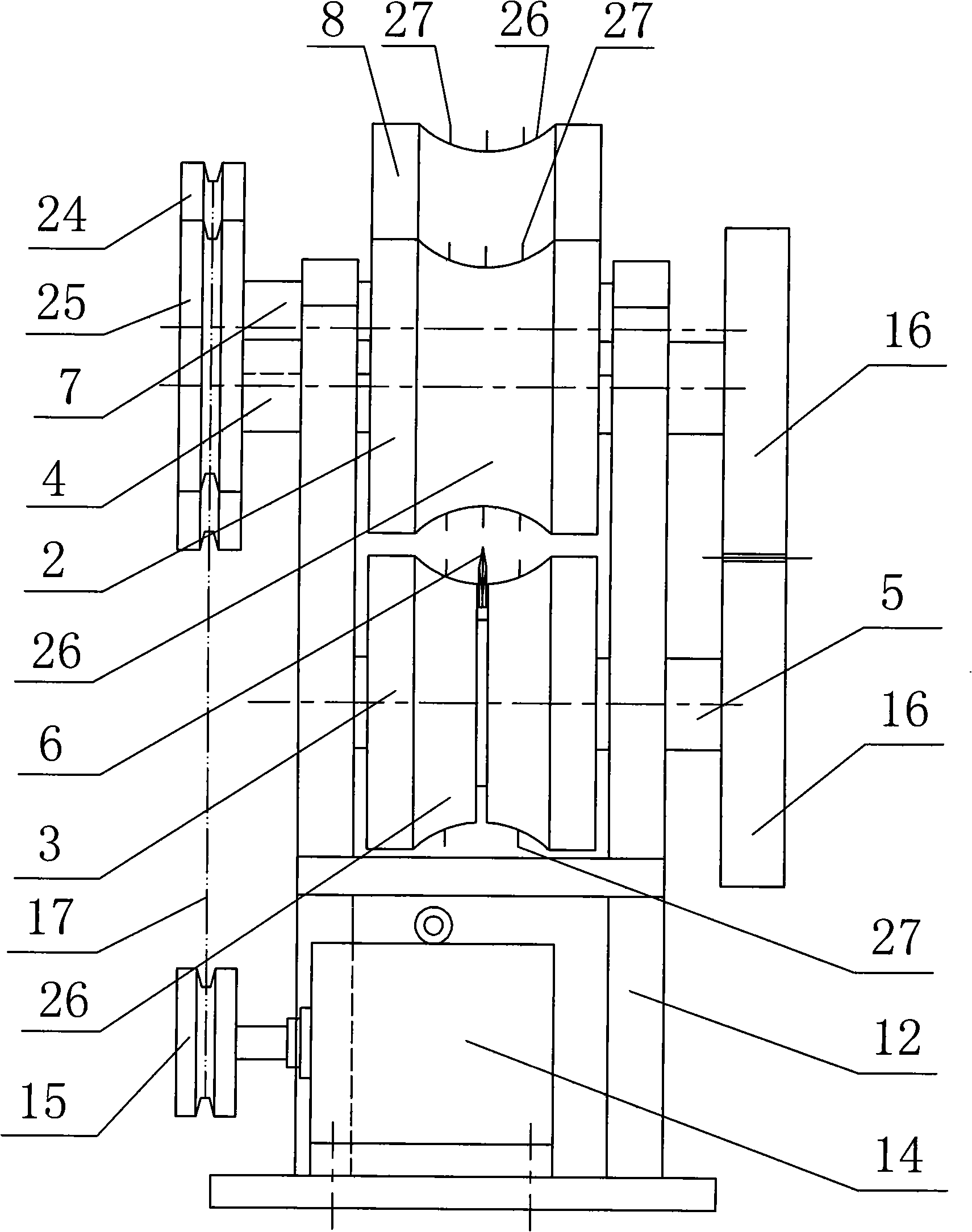

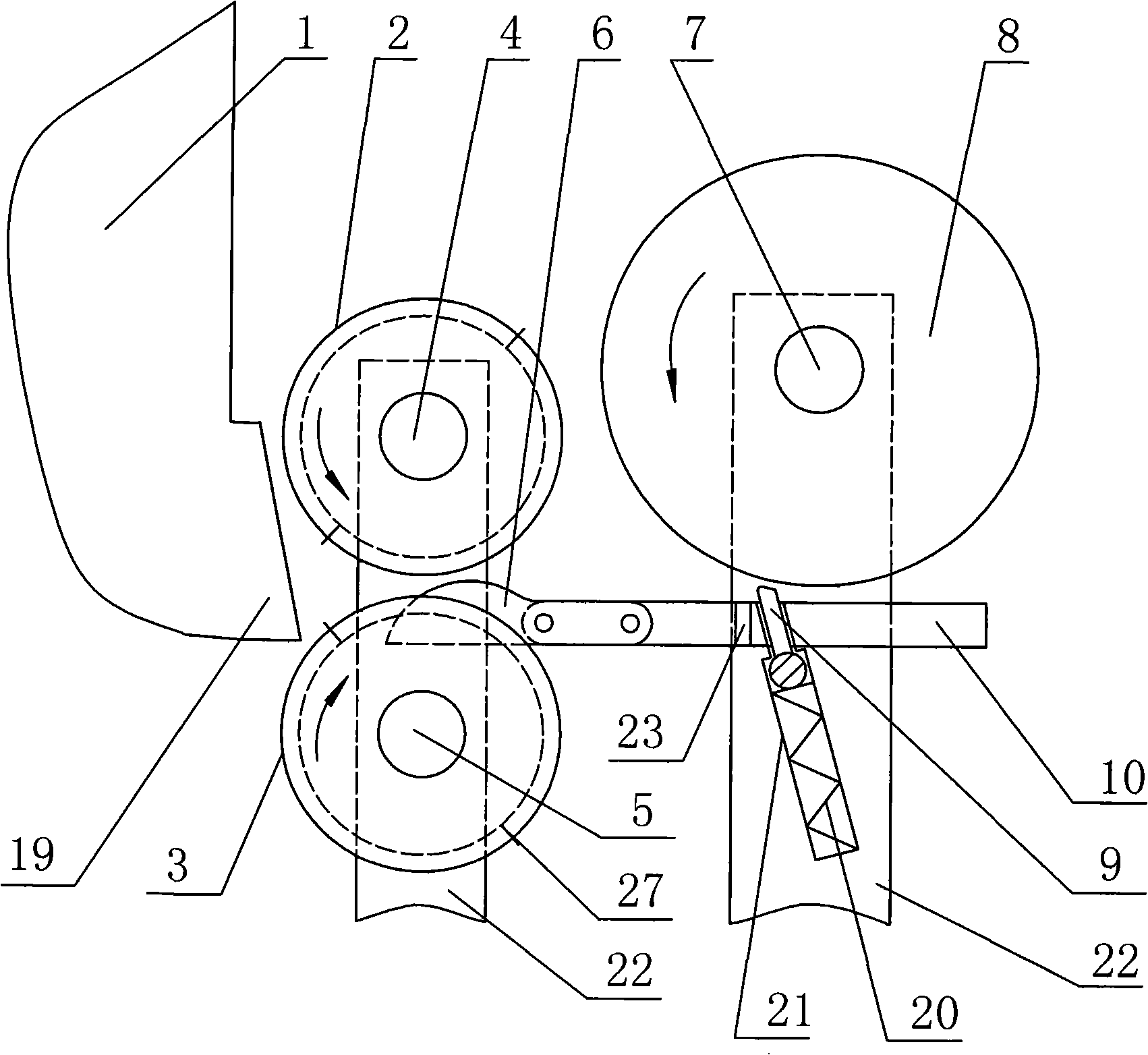

[0023] The rice field eel slaughtering machine consists of a material barrel 1, an upper pair of rollers 2, a lower pair of rollers 3, an upper pair of rollers 4, a lower pair of rollers 5, a cutting knife 6, a pressing roller 7, a pressing roller 8, a scraper 9, and a supporting plate 10 , receiving bucket 11, frame 12, waste bucket 13, motor 14, motor pulley 15, transmission gear 16, belt 17, protective cover 18, feeding hole 19, spring 20, spring seat 21, bracket 22, leakage hole 23, to rolling belt pulley 24, pressure rolling belt pulley 25, concave groove 26, steel needle 27. Composition (see attached Figure 1-3 ). One side of the worktable above the frame 12 is provided with a bucket 1, and the middle part is equipped with an upper pair of rollers 4, a lower pair of rollers 5 and a pressure roller 7 by a support 22, and the bottom of the frame 12 is equipped with a motor 14. On the same end of roller 4 and pressure roller 7 and motor 14, motor pulley 15, roller pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com