Patents

Literature

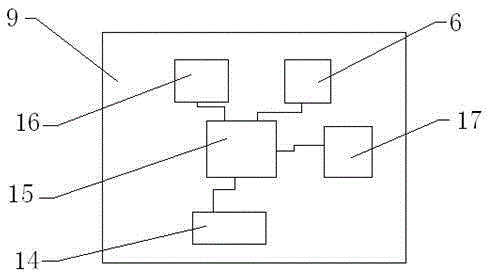

151results about "Electric current slaughtering/stunning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

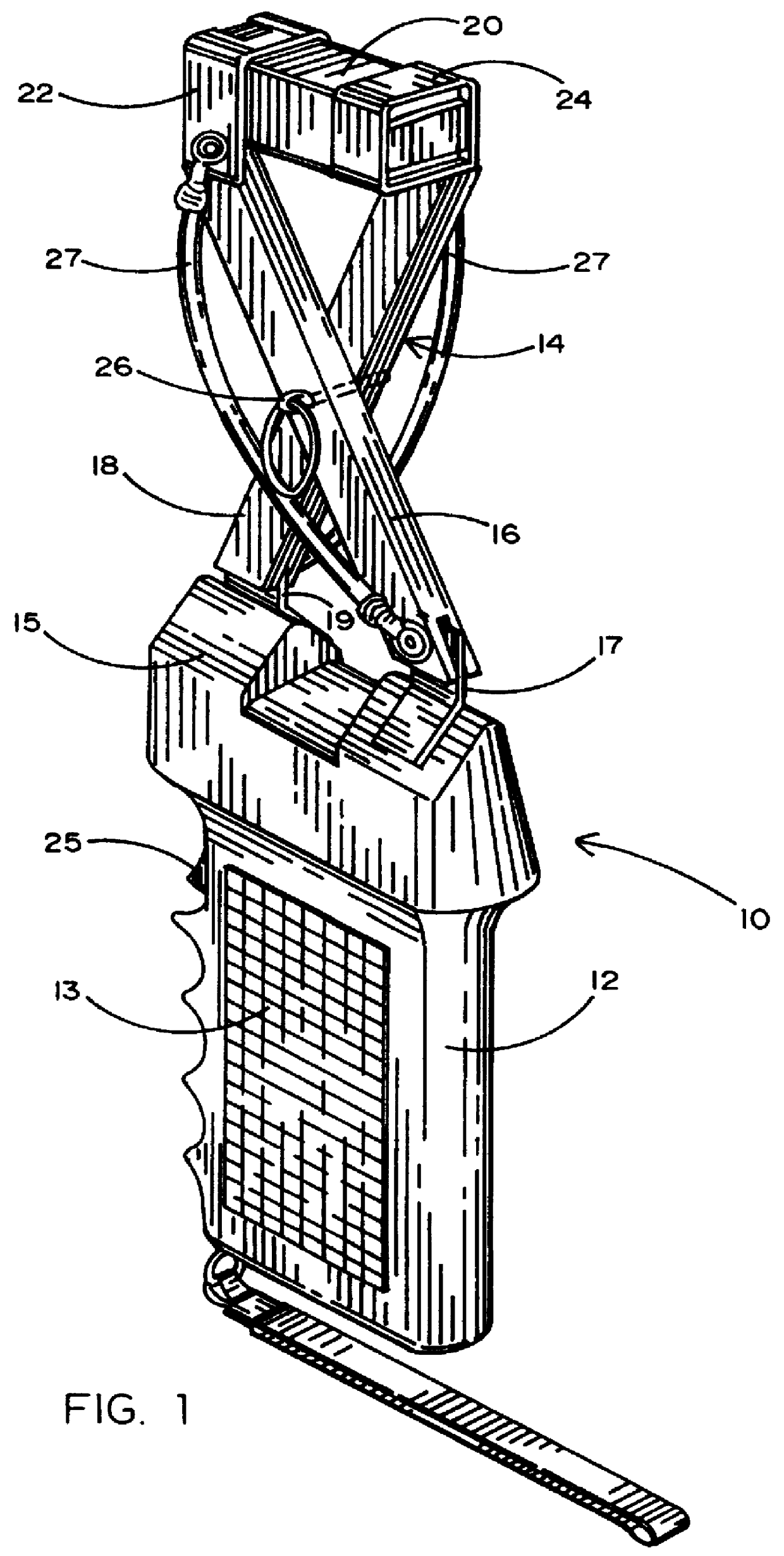

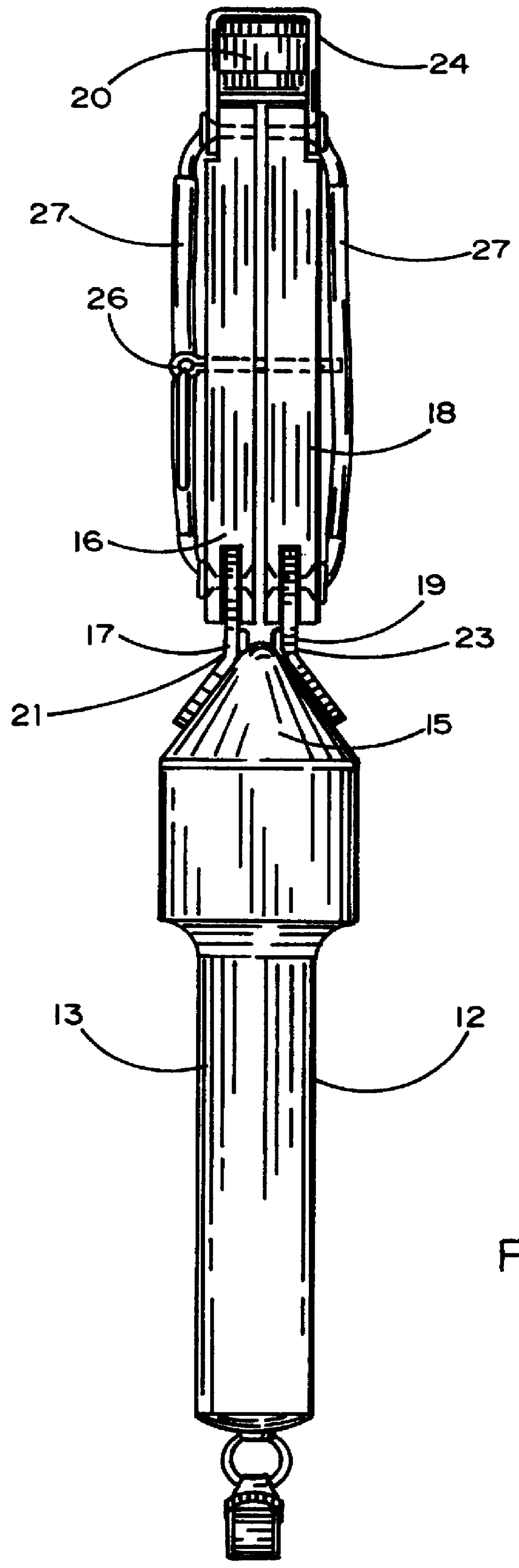

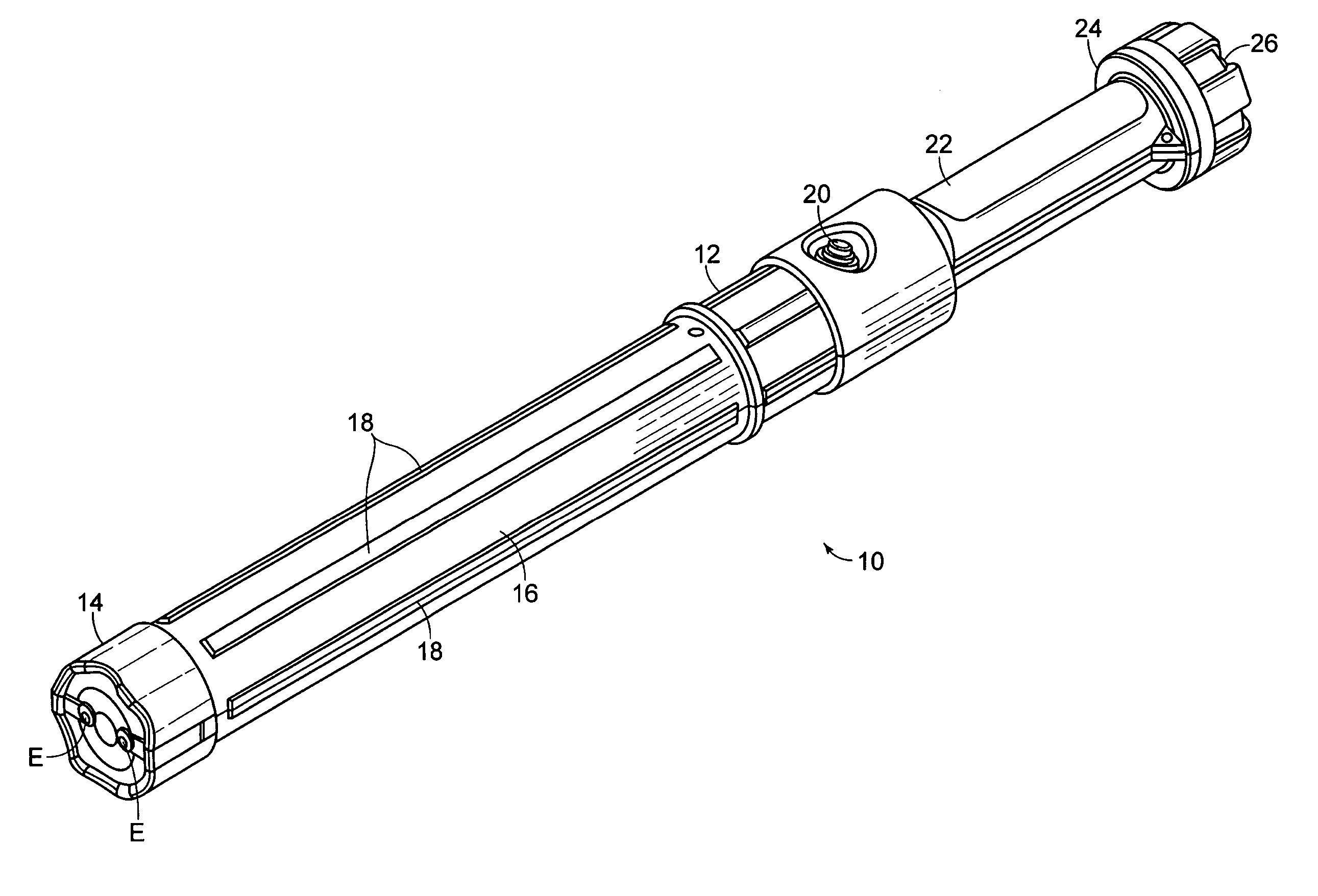

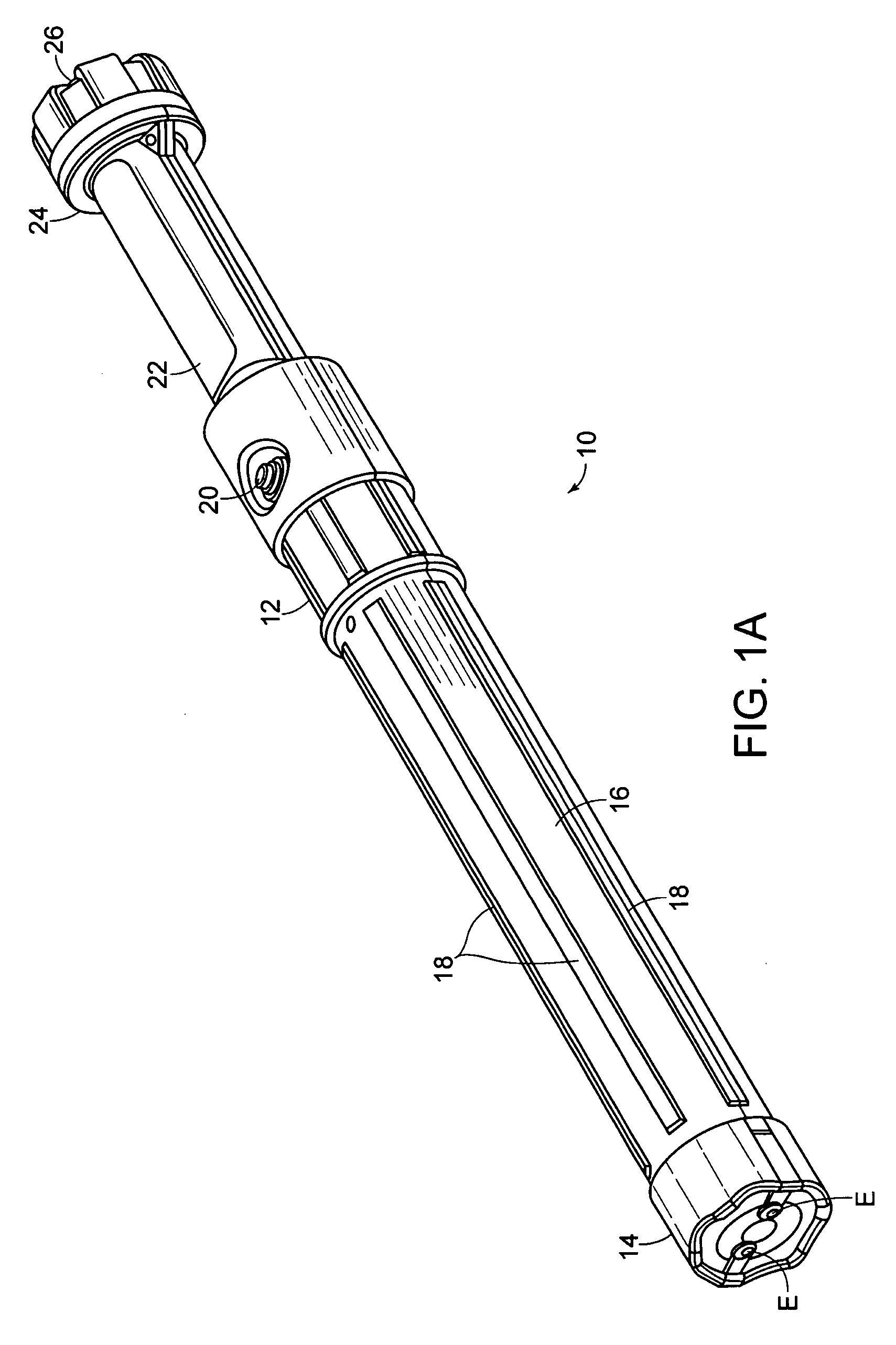

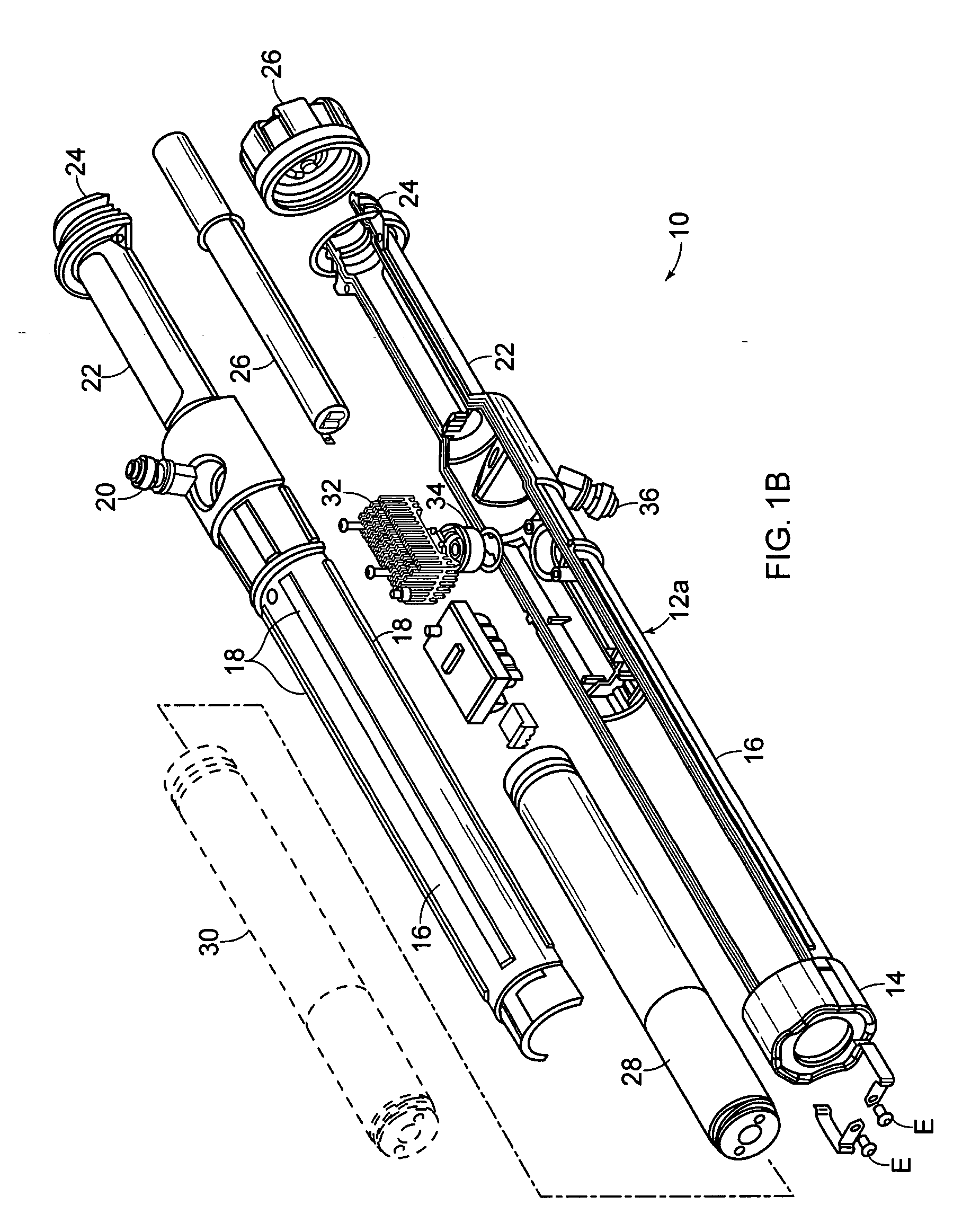

Apparatus for use with non-lethal, electrical discharge weapons

InactiveUS6053088ALong rangeLong range capabilityElectric current slaughtering/stunningElectrical apparatusEngineeringContact electrode

An addition device which permits a user of a close proximity electrical discharge weapon to modify his or her weapon by providing an improved short range capability as well as a long range capability which can be added as an after-market improvement. The invention is an apparatus designed to be mechanically and electrically attached to the device and provides a wire-tethered dart cartridge which extends above the weapon and gives the user the additional capability of contacting long range targets. The apparatus permits easy and convenient replacement of spent cartridges as well as easy and convenient connection to the close proximity device. The apparatus also improves short range performance by widening the separation of contact electrodes and by increasing the penetration voltage to increase effectiveness.

Owner:ELECTRONICS MEDICAL RES LAB

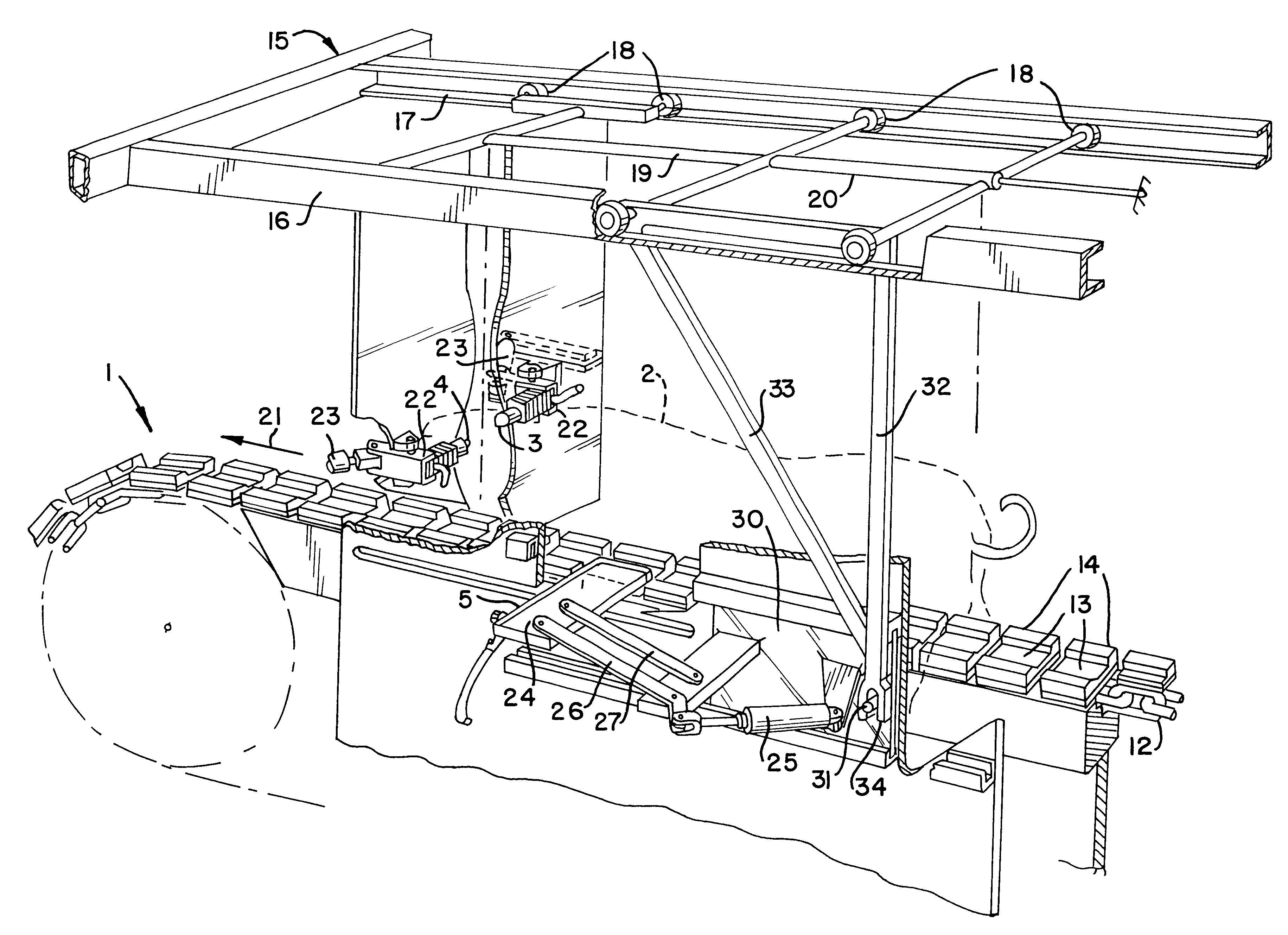

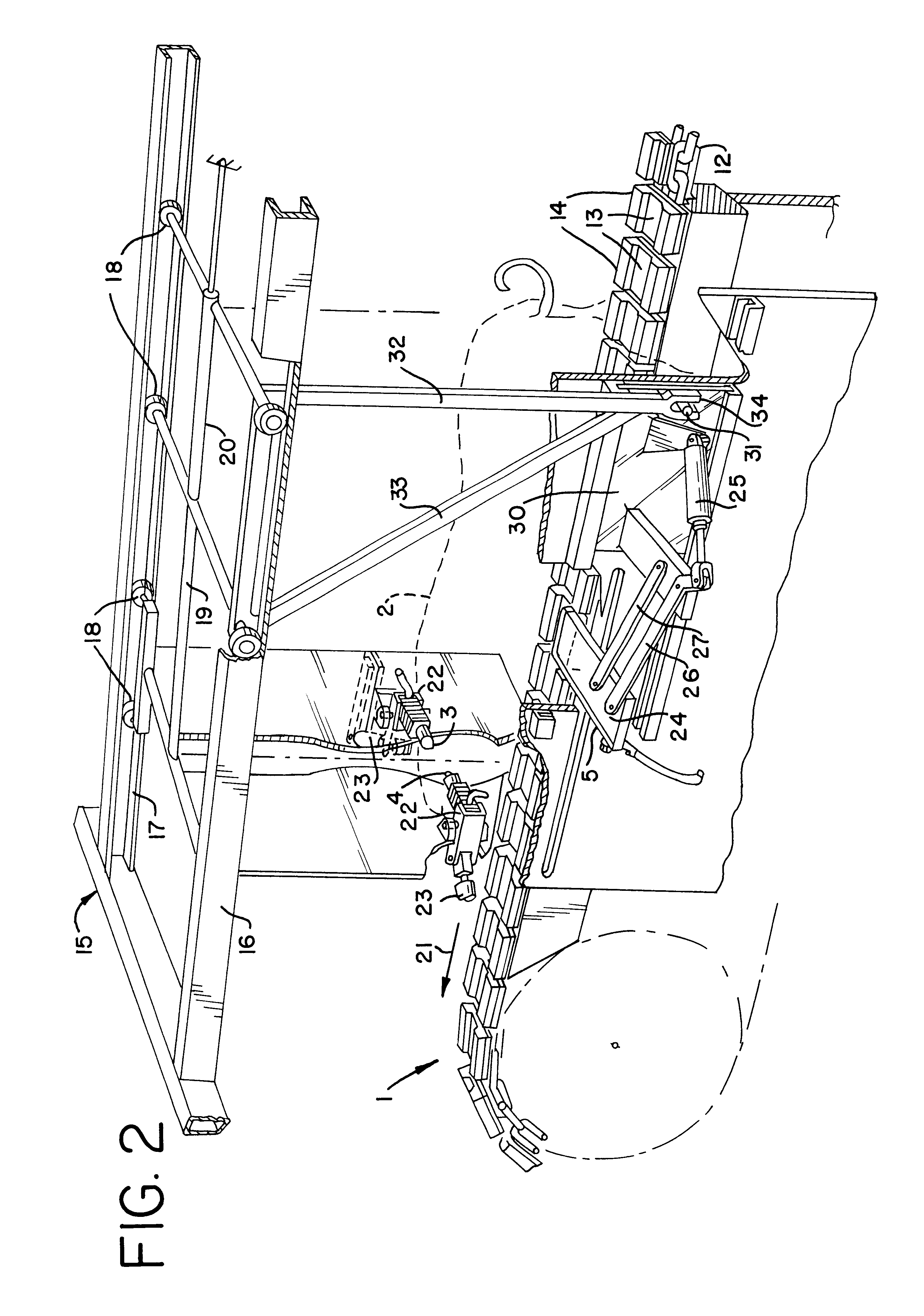

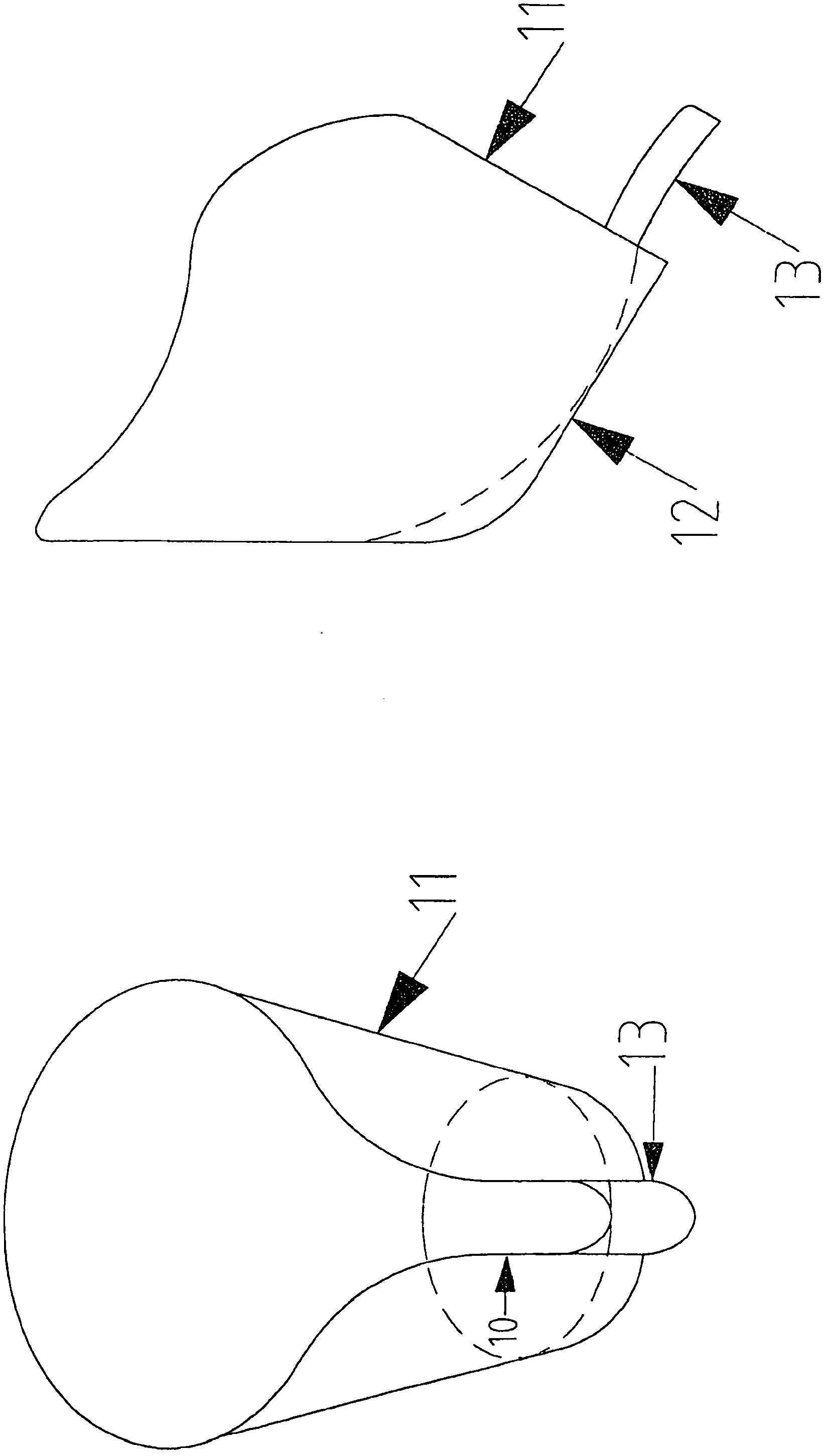

Method for processing poultry

InactiveUS7249998B2Electric current slaughtering/stunningPoultry deboningEngineeringMachining process

A method is described for processing poultry, comprising the steps of supplying live poultry, stunning the live poultry in a stunning device, placing the stunned poultry into product carriers advanced along a conveyor, killing the poultry and removing the feathers from the dead poultry in a plucking device. Downstream of the plucking device, the poultry is exposed to an electrical stimulation, an electrical voltage (V1) being applied across the carcass of the poultry. A method is further described for controlling process parameters, especially the time and duration of execution of working steps in a process of mechanized working of slaughtered poultry, the tenderness of a specified meat portion being evaluated prior to a due processing step and, after this evaluation, the important process parameters for the particular processing step being set to an optimal value.

Owner:STORK PMT

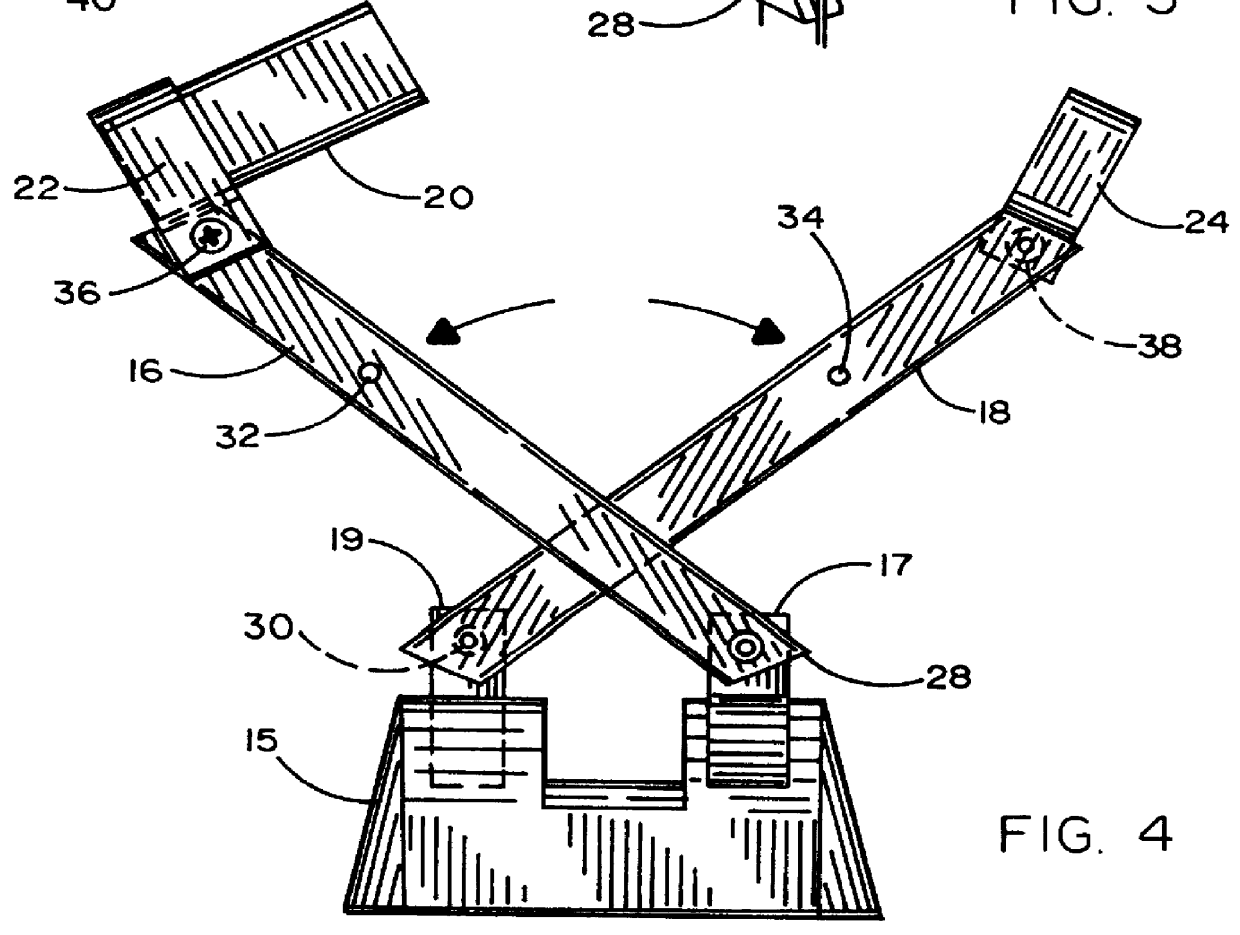

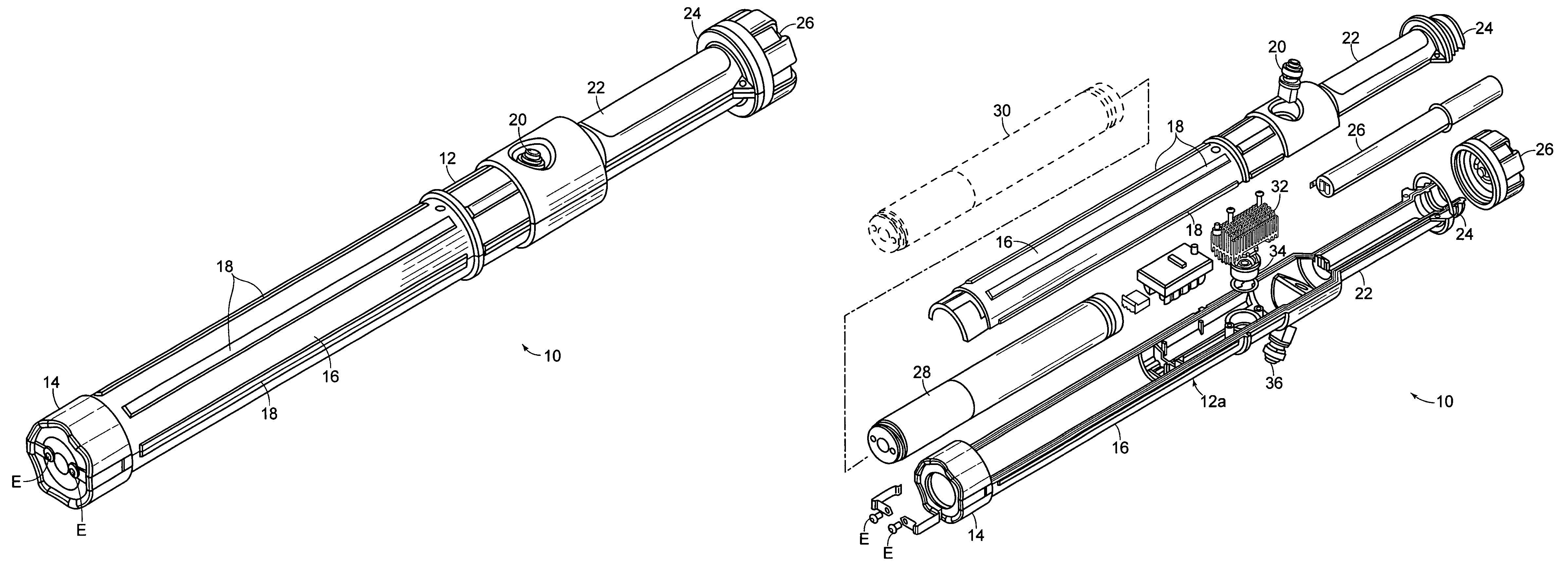

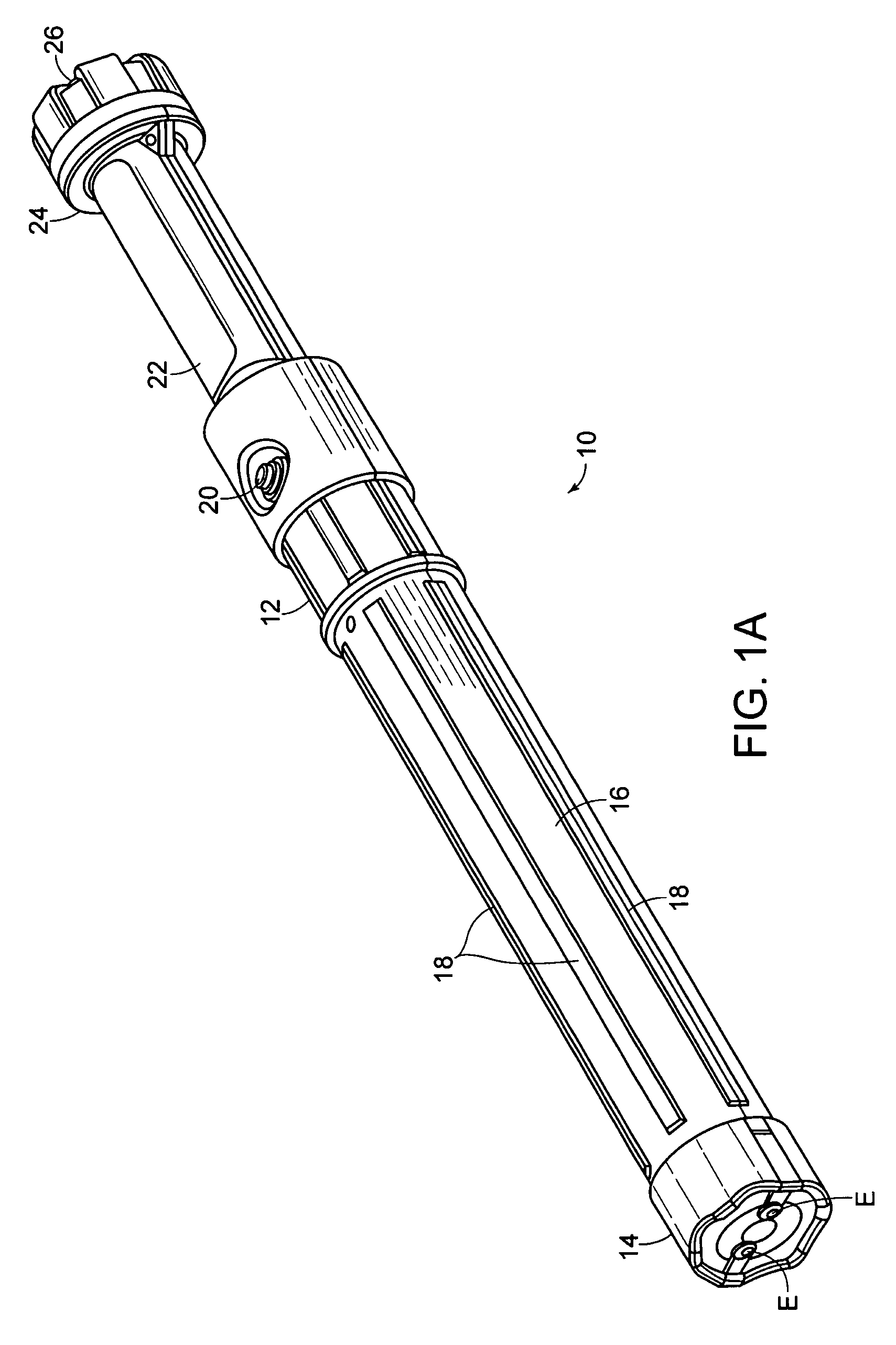

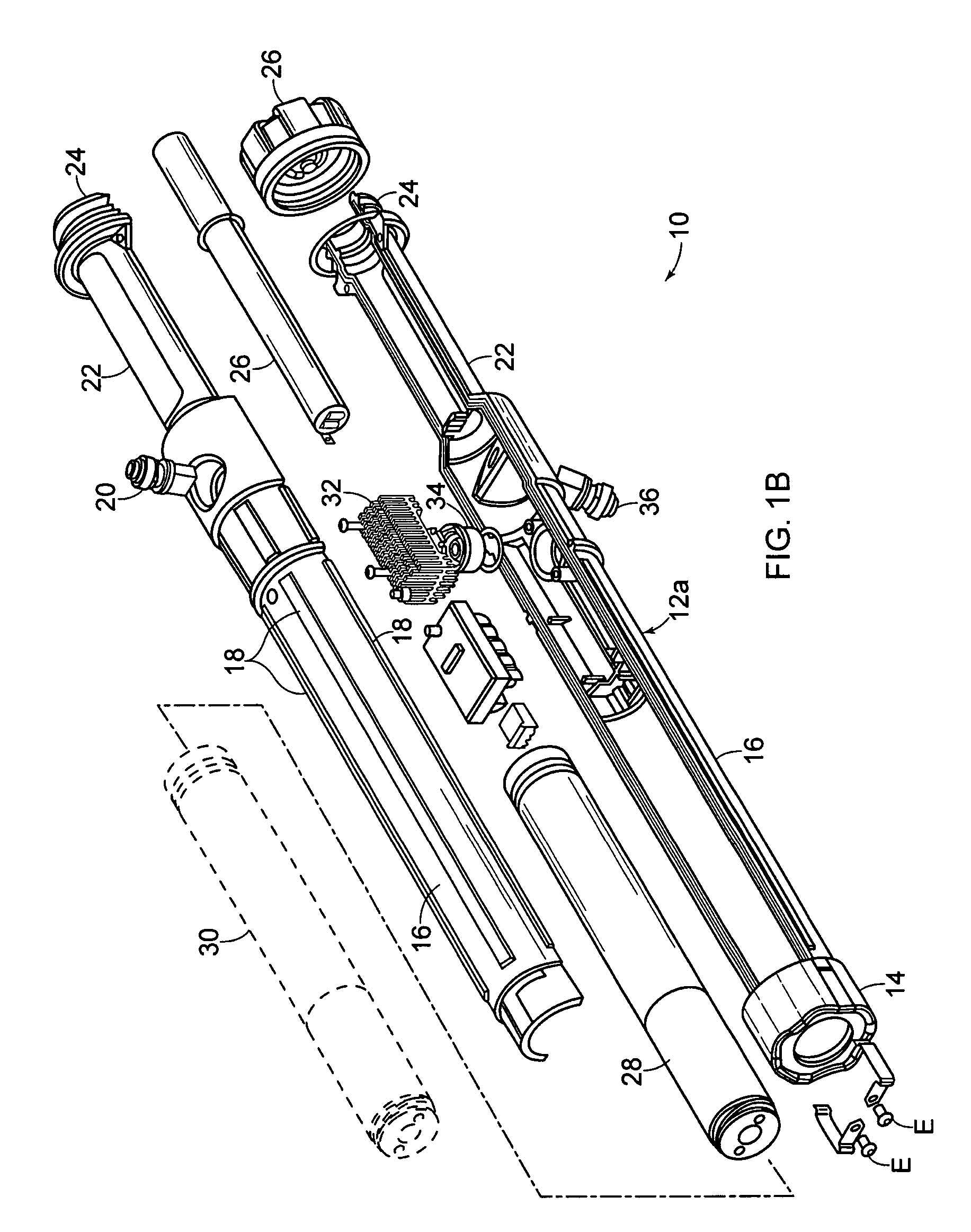

Electromuscular incapacitation device and methods

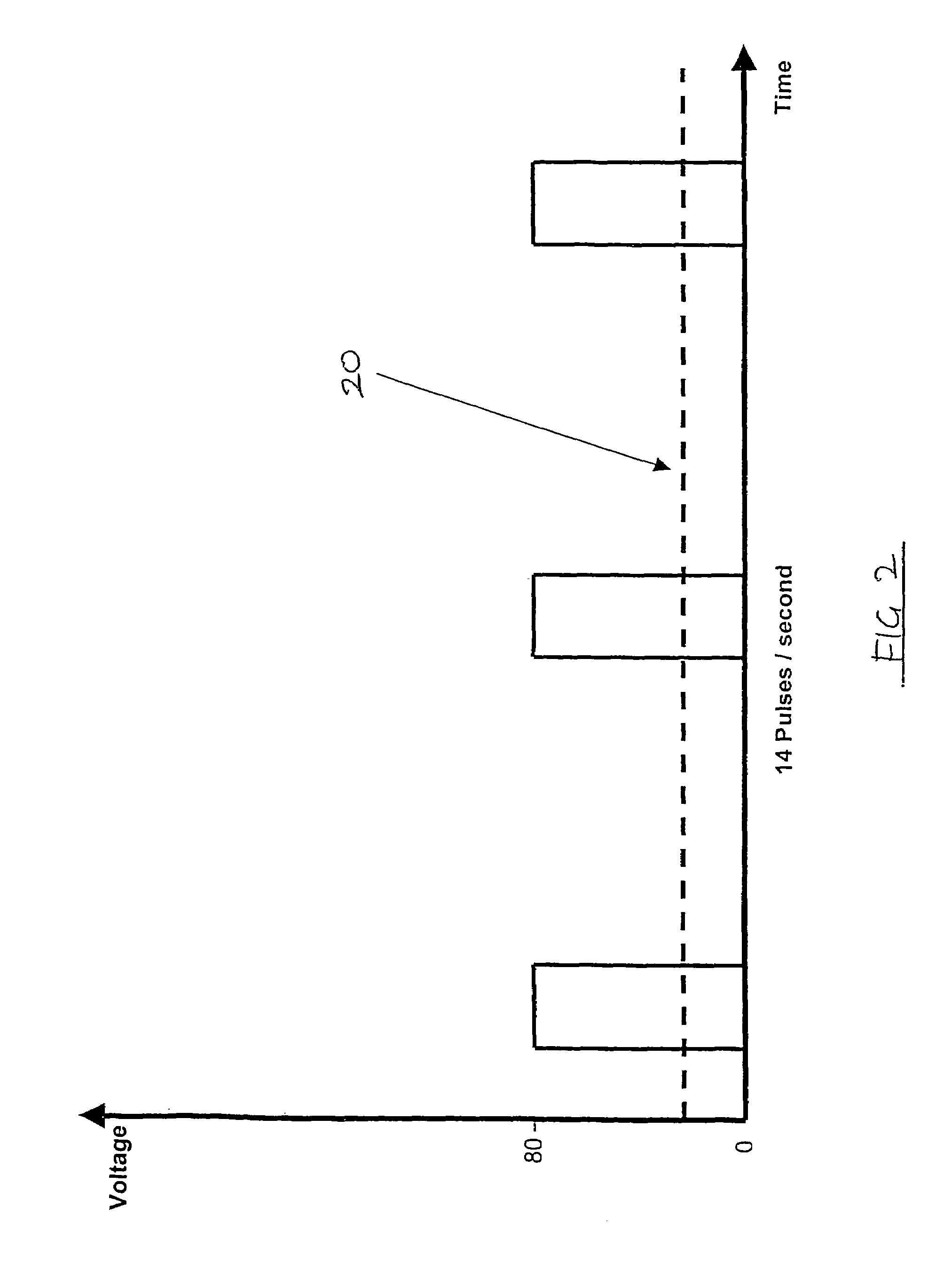

InactiveUS20070167241A1Effective and enhanced incapacitationLess chance of permanent nerveClubsElectric current slaughtering/stunningEngineeringMuscular Contractions

Incapacitation of a mammalian subject results from the application of a pulsed, low-power electric waveform. The waveform is applied to the subject at a frequency and over a time period sufficient to induce involuntary muscular contraction. Additionally, the contraction causes limited lactic acid production and is non- or minimally-injurious to the subject's tissues. A device utilizing such a waveform is designed to control or otherwise subdue an individual.

Owner:AEGIS IND INC

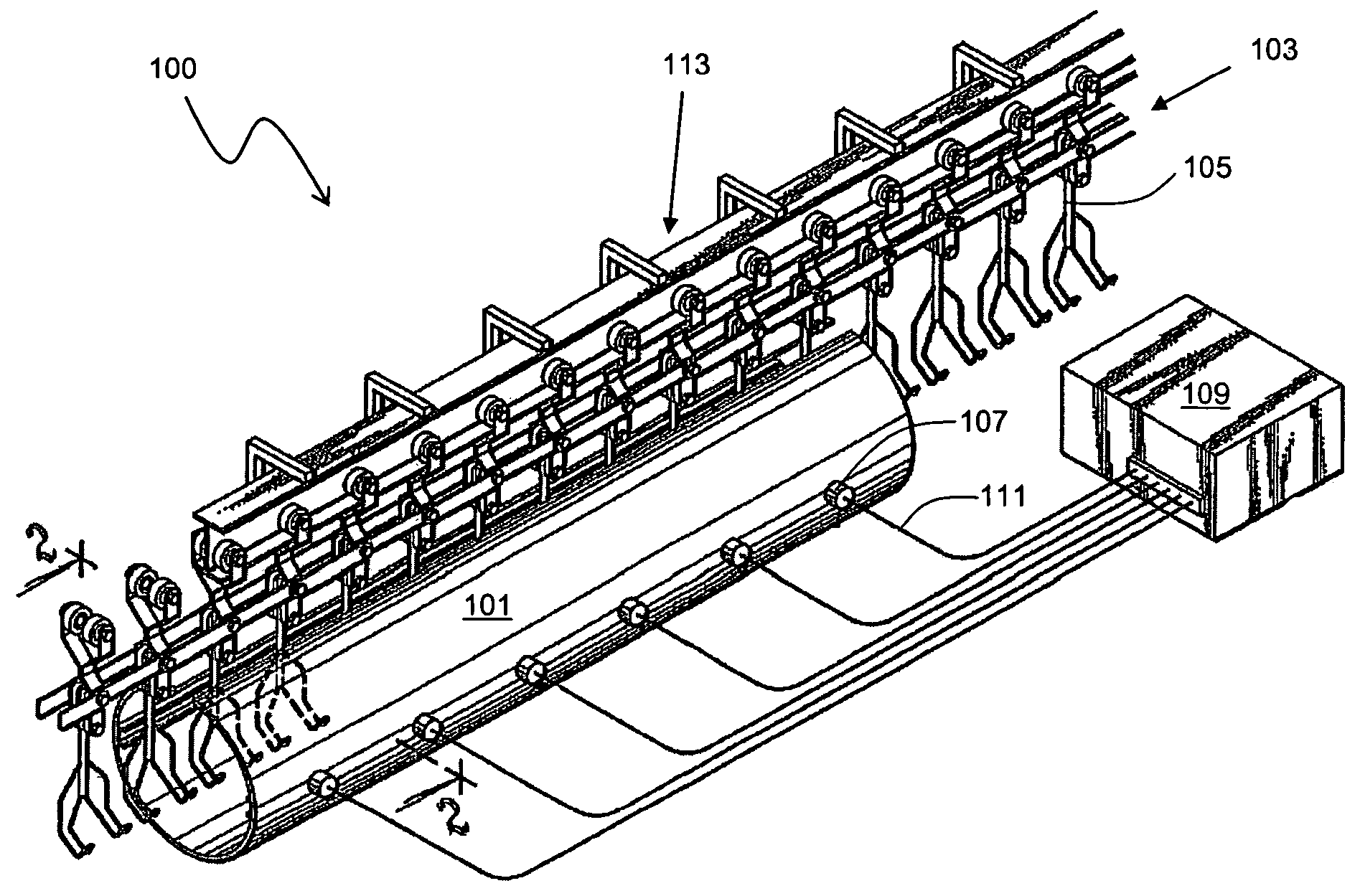

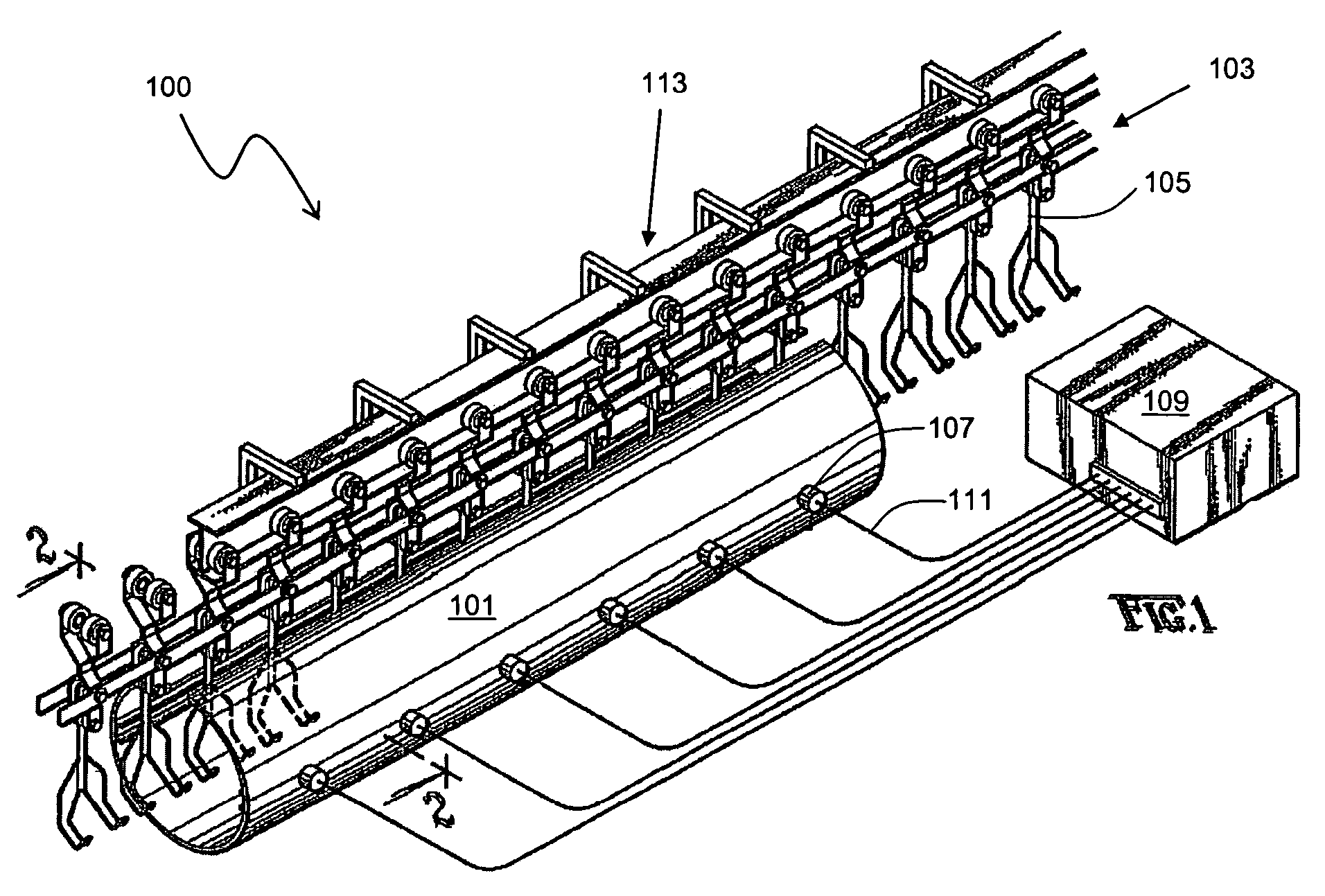

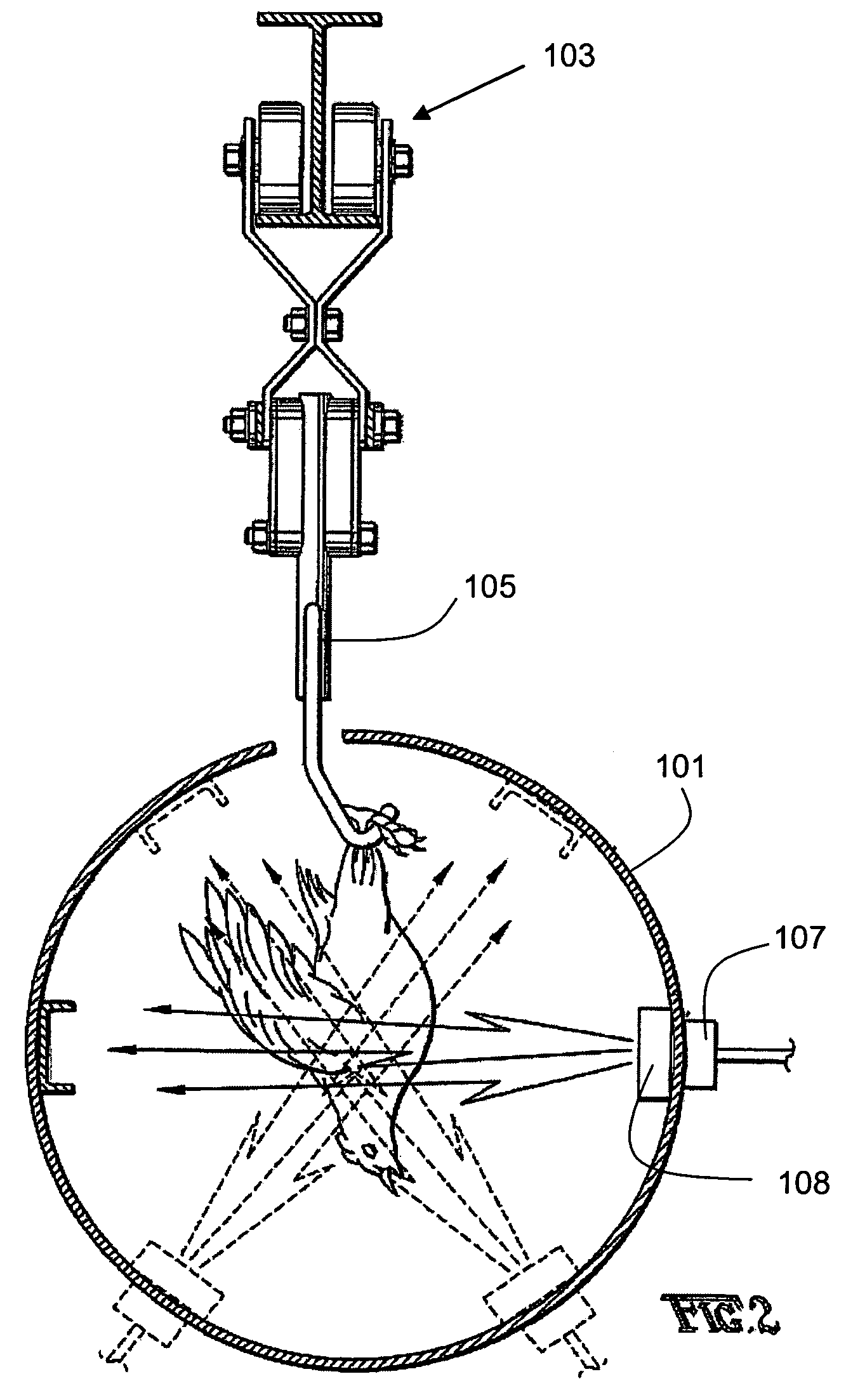

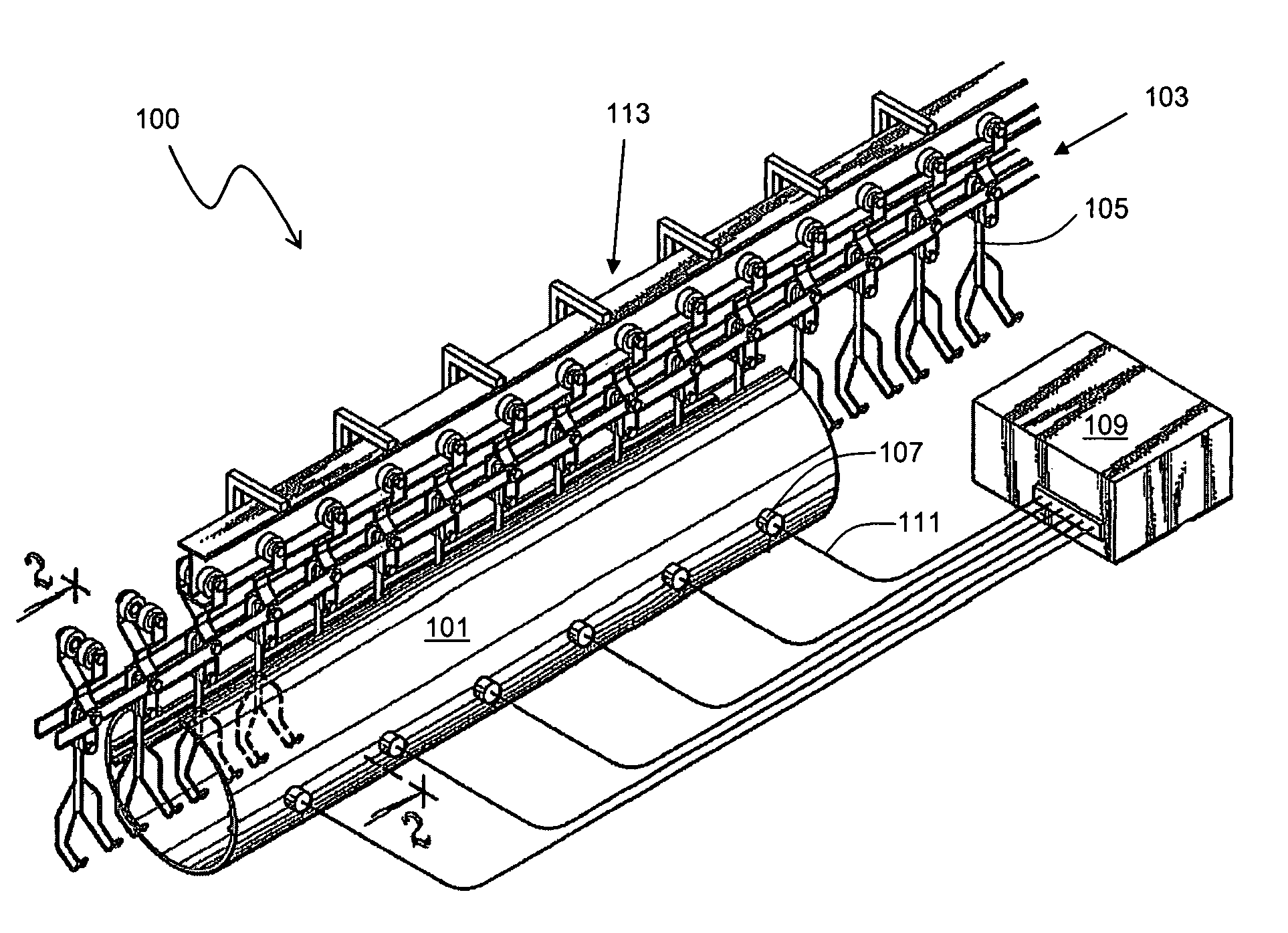

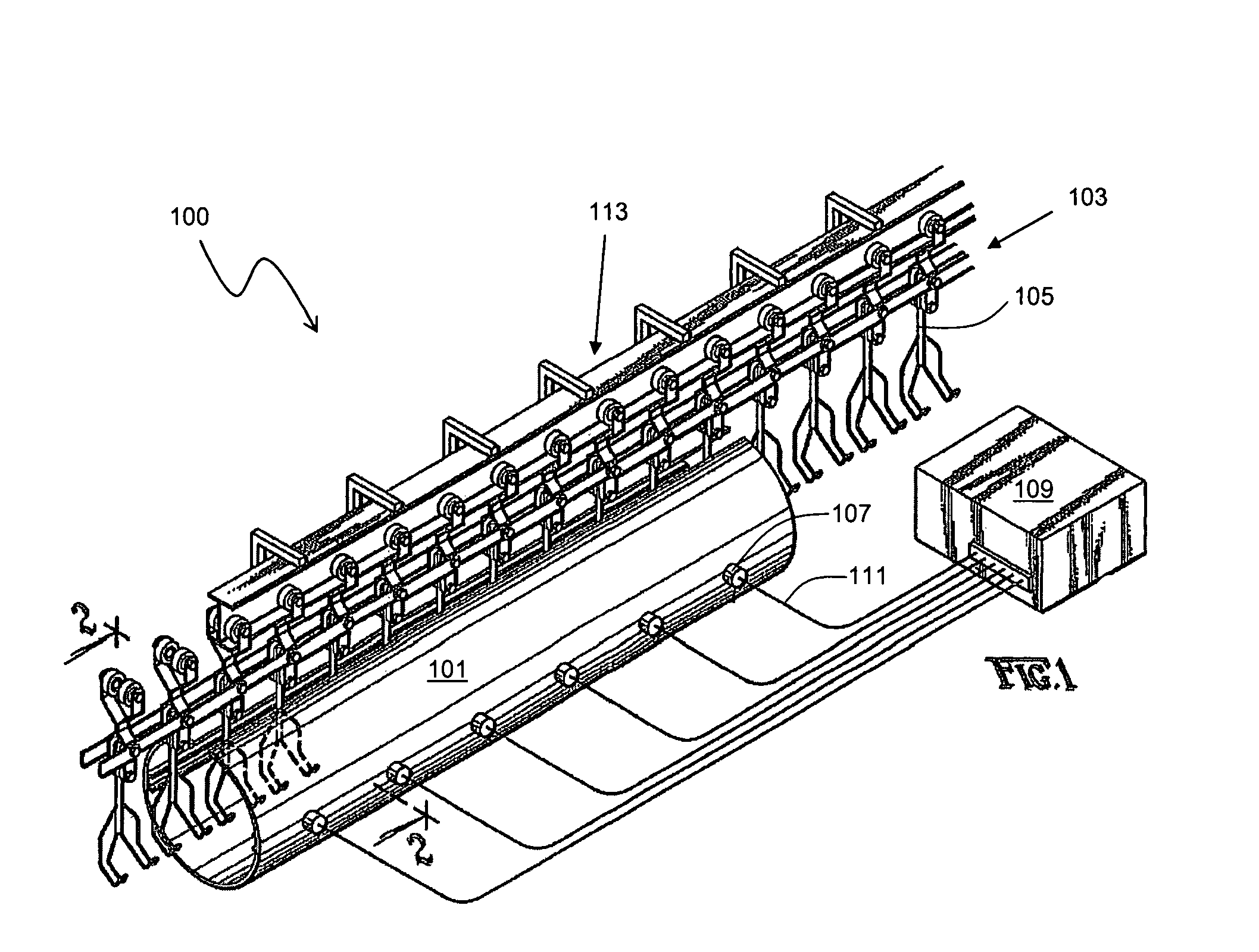

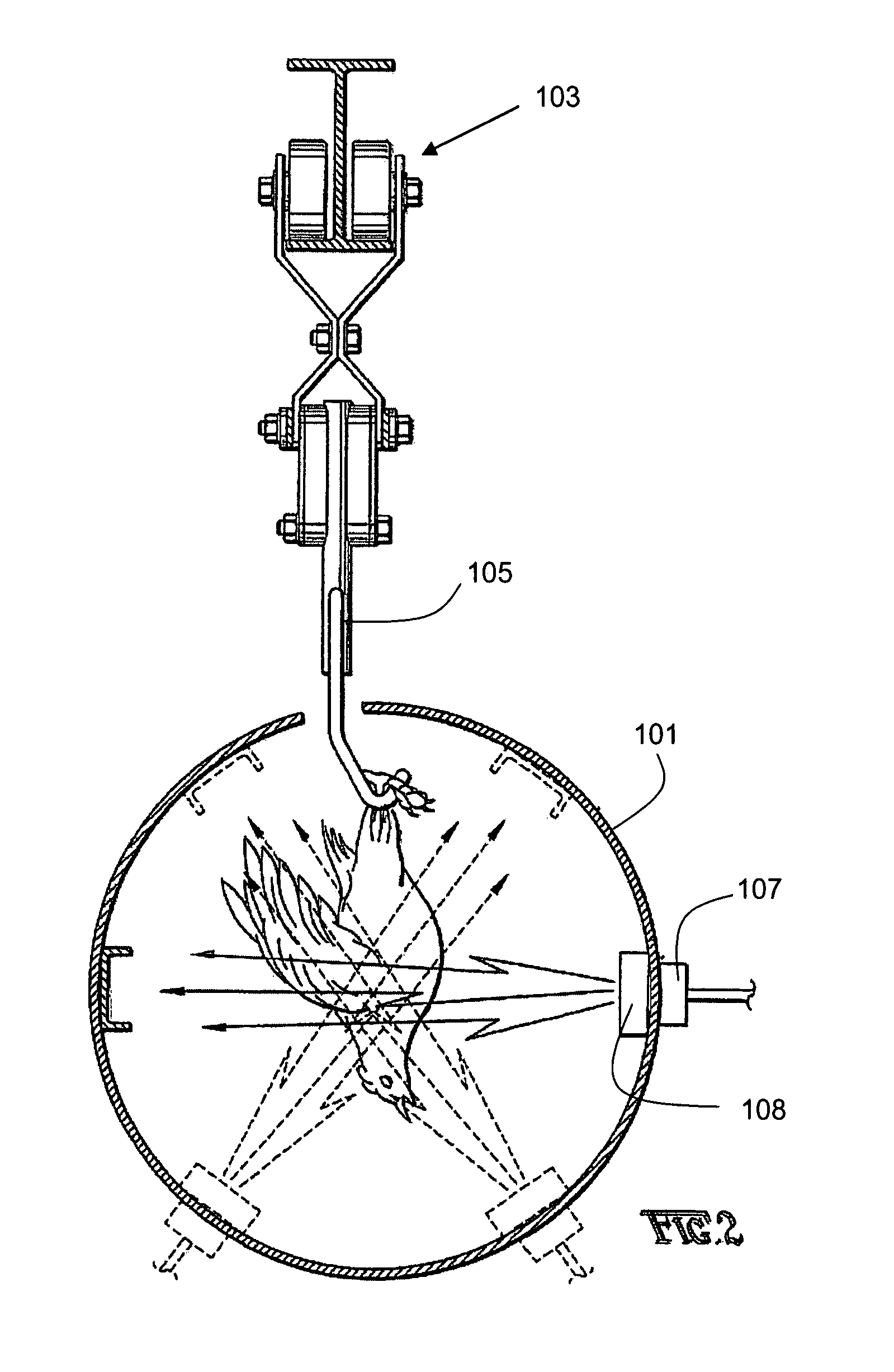

Poultry stunner

A system and method for stunning live poultry is presented. In one aspect, the system presented has a poultry stunner defining a partially enclosed passageway and at least one first conduit in fluid communication with the fluid source, configured to direct a first stream of fluid into at least a portion of the at least partially enclosed passageway. In one aspect, the system also can have at least one second conduit in fluid communication with the fluid source, configured to direct a second stream of fluid into at least a portion of the at least partially enclosed passageway. In one aspect, the system comprises an electrical power source coupled to at least one of the first conduit(s) and / or at least one of the second conduit(s). Thus, an electric circuit is formed between the first and second streams of fluid via any of the live poultry that come into contact with the first and second streams of fluid.

Owner:HARBEN GROVER

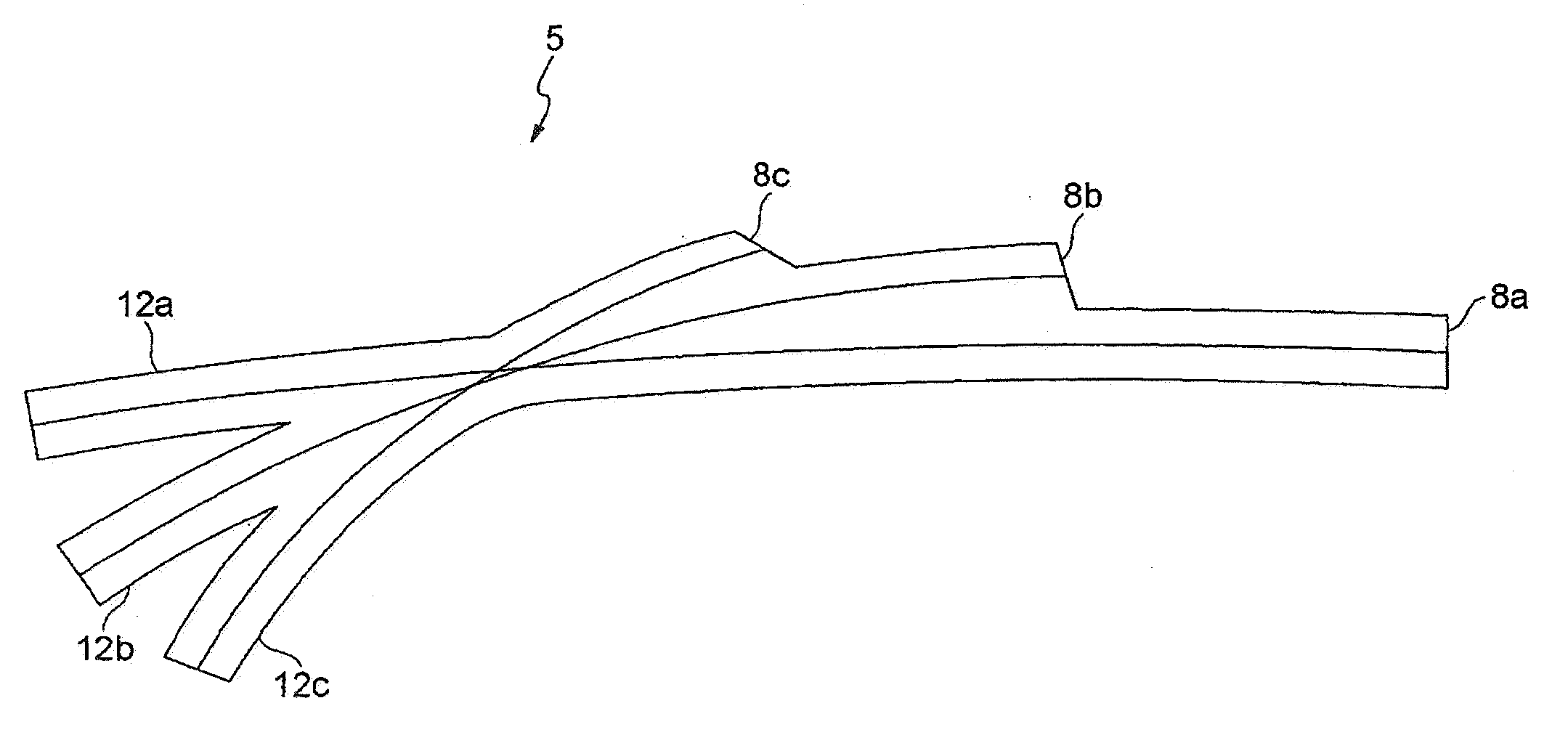

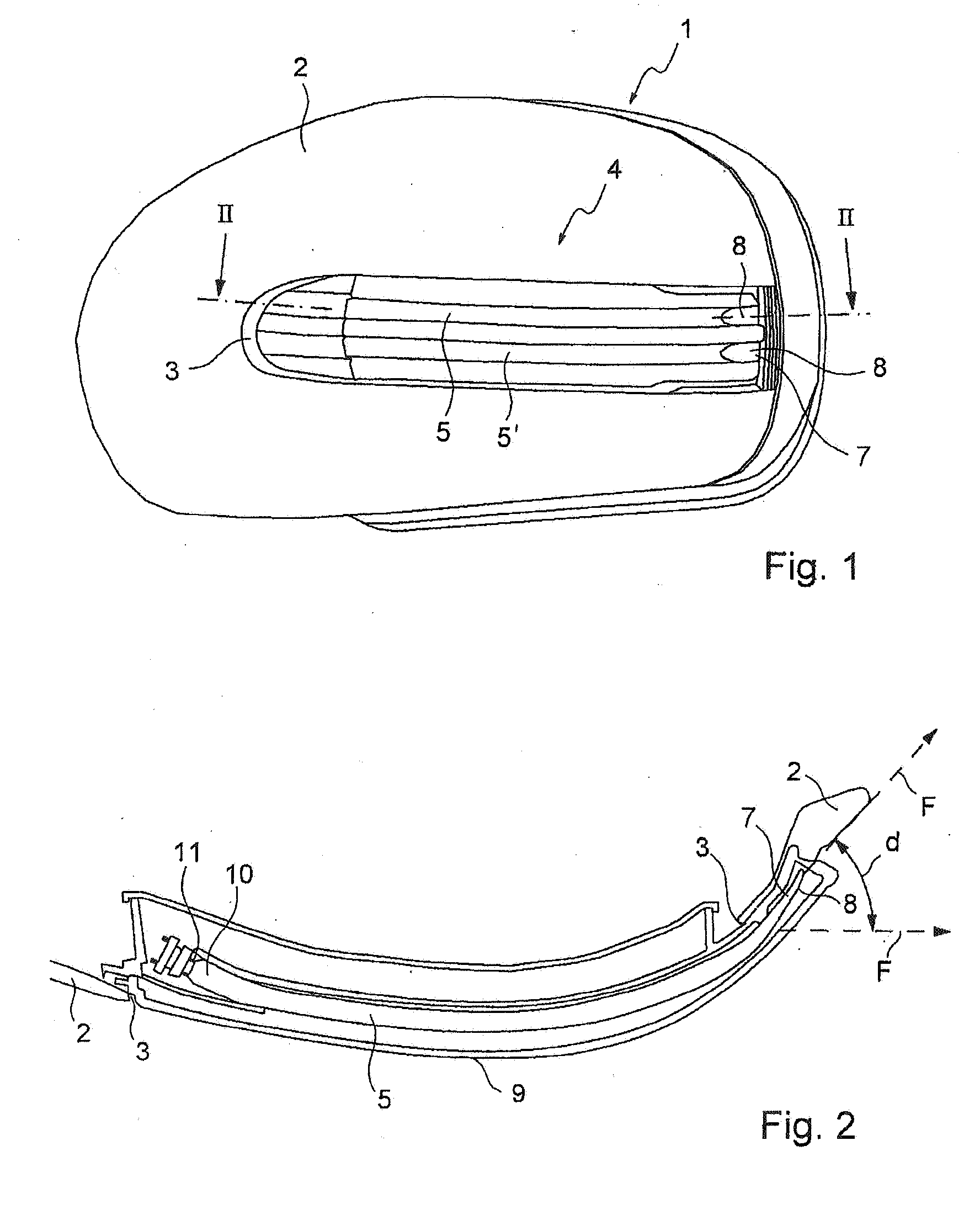

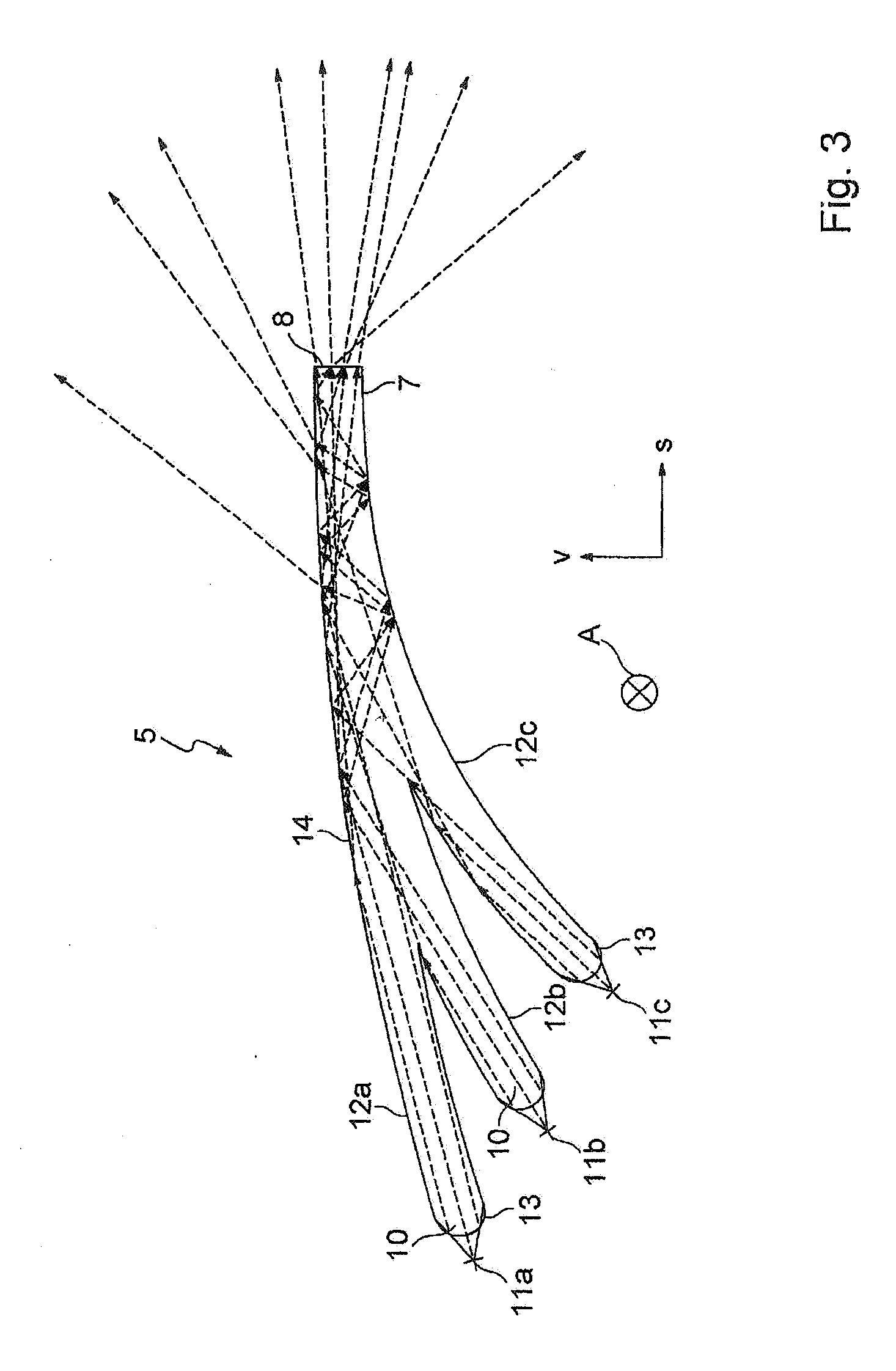

Vehicle lamp with a light guide of a multi-member configuration

InactiveUS20060234612A1Excellent luminous propertiesImprove light outputElectric current slaughtering/stunningLighting and heating apparatusLight guideEngineering

The invention concerns a vehicle lamp comprising an elongate light guide, and a light source which is arranged at one end of the light guide and whose light is coupled into the light guide and at least partially passed to an oppositely disposed coupling-out end where it is coupled-out. The light guide is of a multi-member configuration and on the side towards the vehicle has a plurality of limbs which are curved to differing degrees.

Owner:FER FAHRZEUGELEKTRIK GMBH

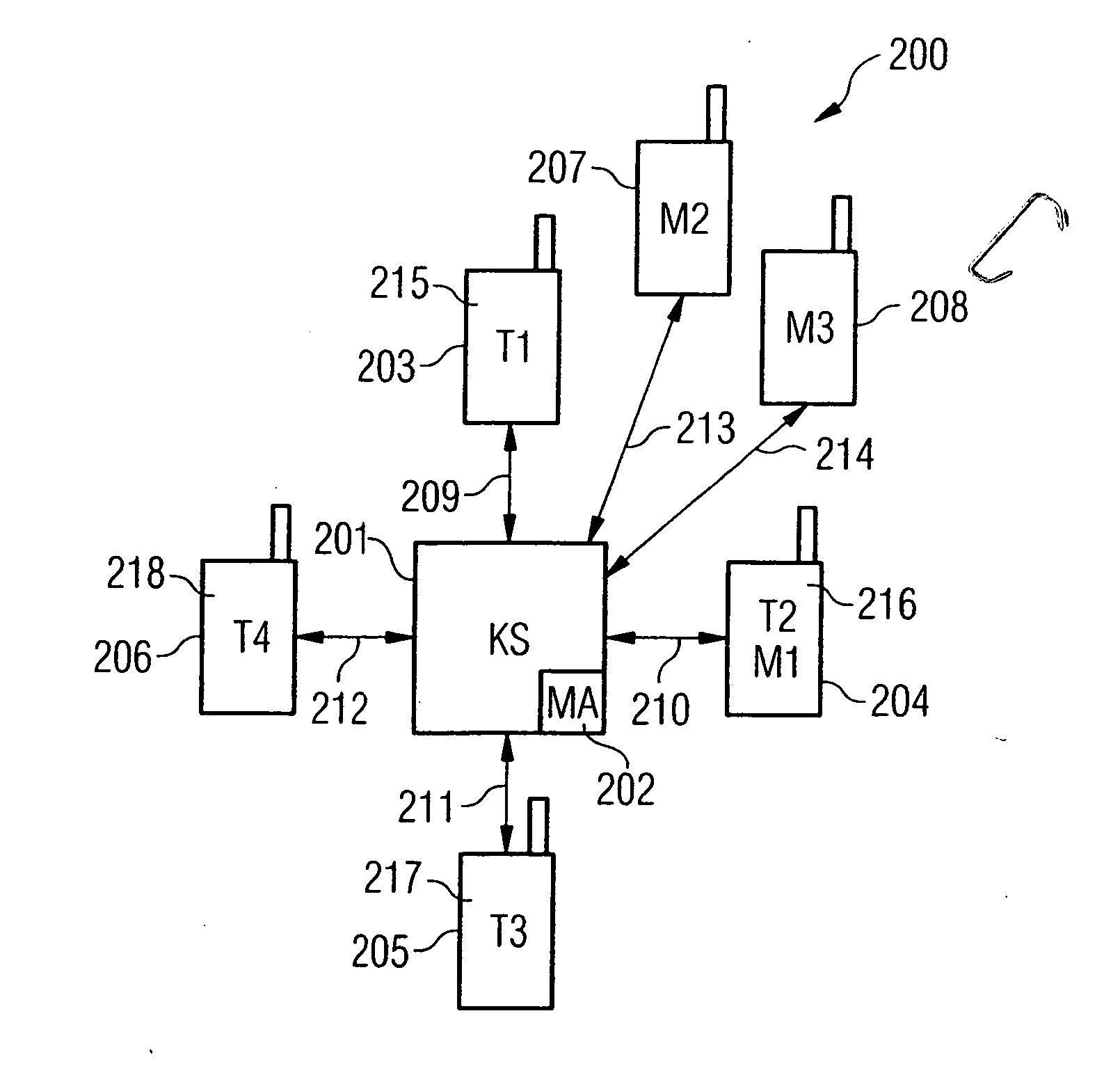

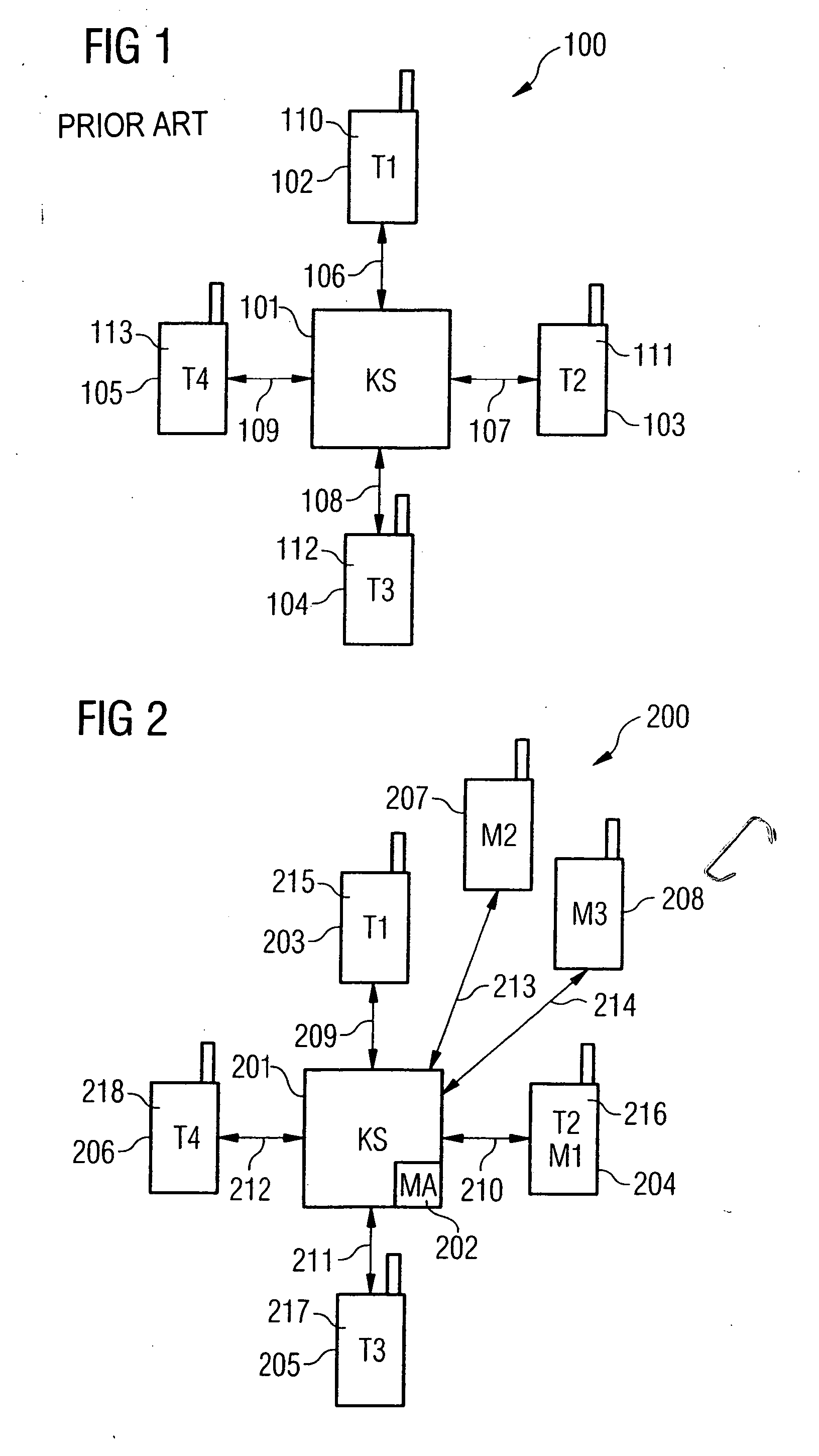

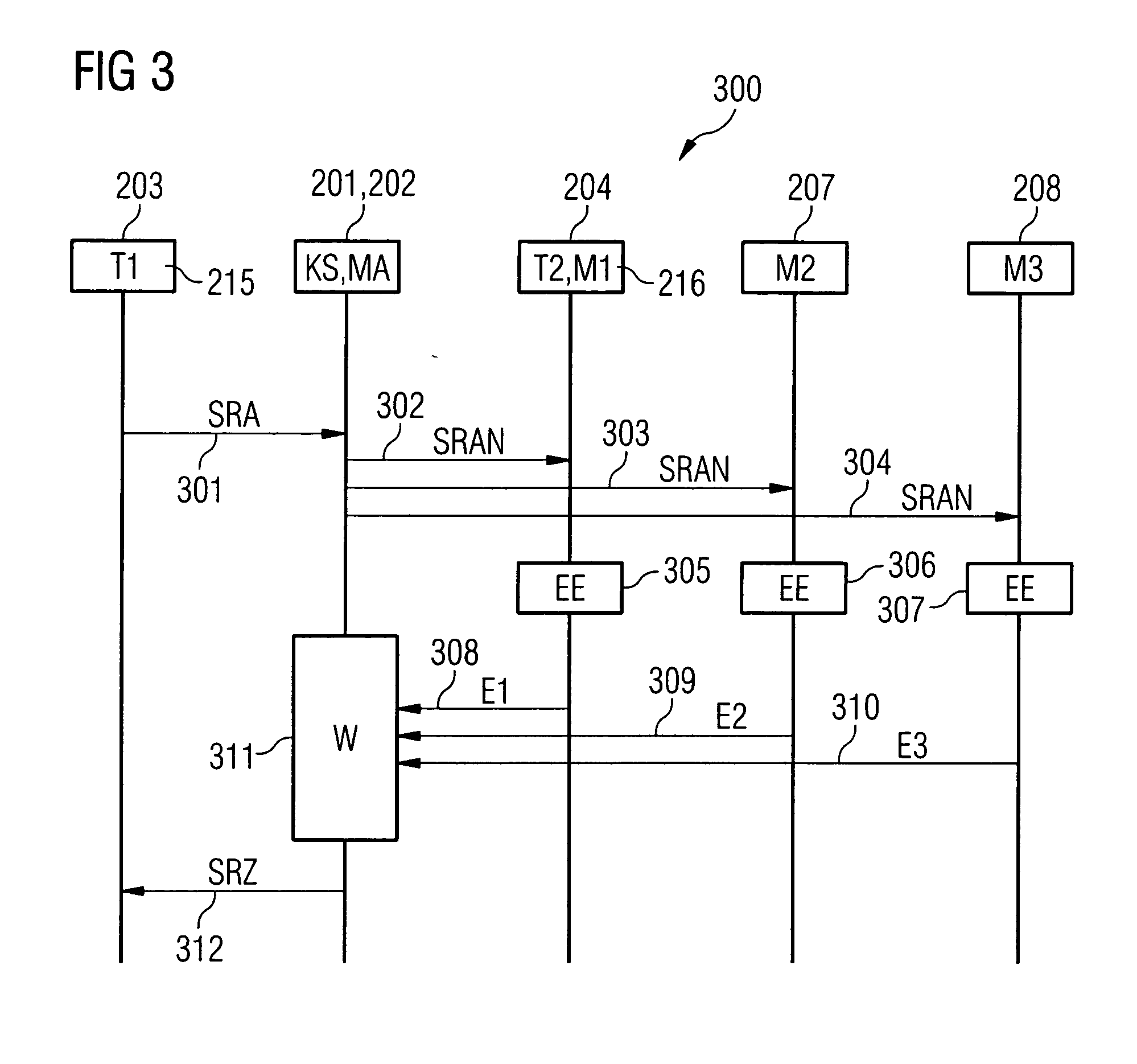

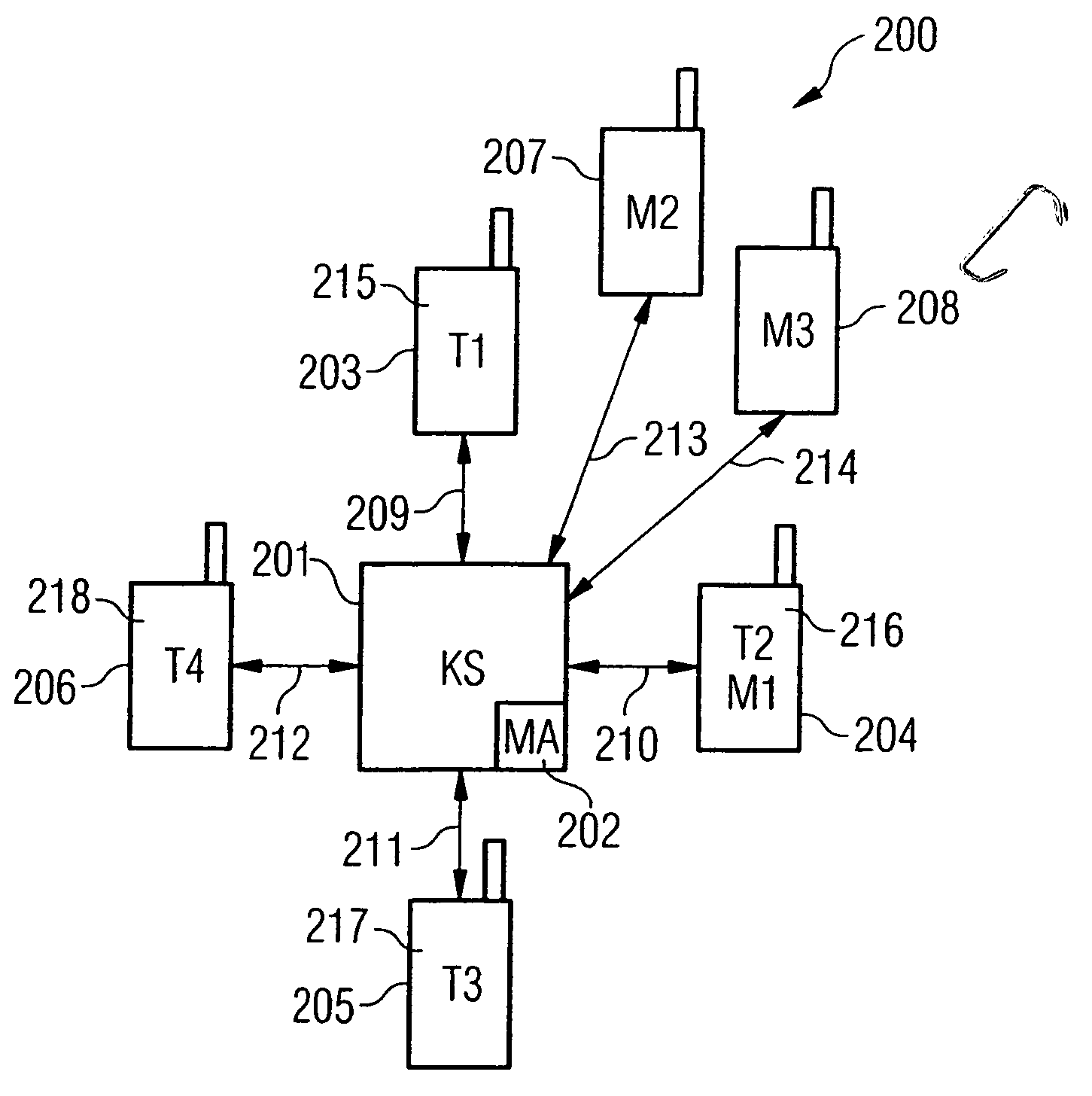

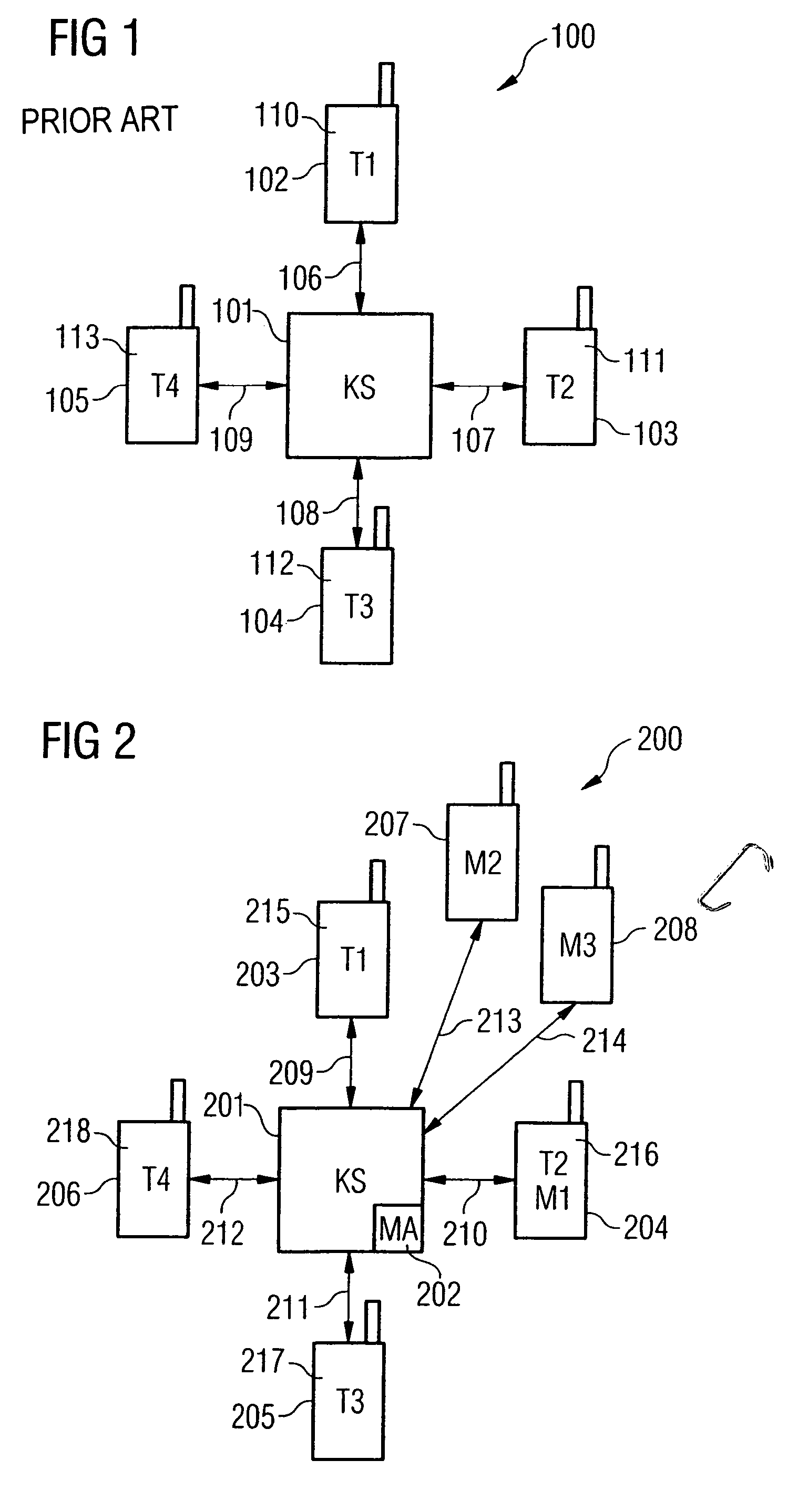

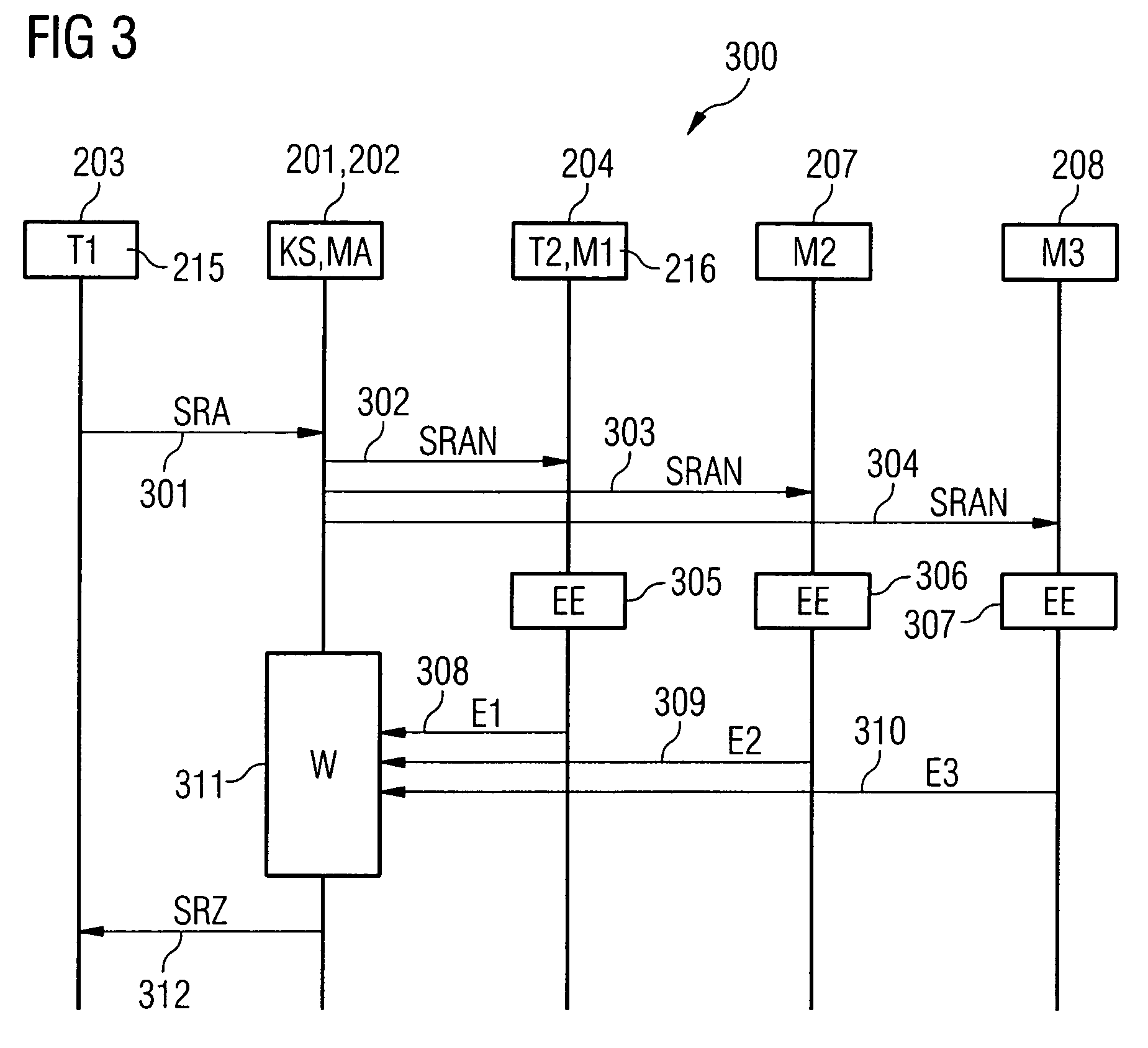

Communication system having conference server

InactiveUS20060234613A1Avoids lengthy discussionElectric current slaughtering/stunningSpecial service for subscribersControl communicationsConference control

A communication system having a conference server device, a conference control unit, a plurality of moderator units, and a plurality of telecommunication devices. The moderator units are used to control allocation of a communication right. The decisions of the moderator units regarding the allocation of the communication right are combined to form an unambiguous overall decision, and overall decision is made using a majority decision.

Owner:INTEL CORP

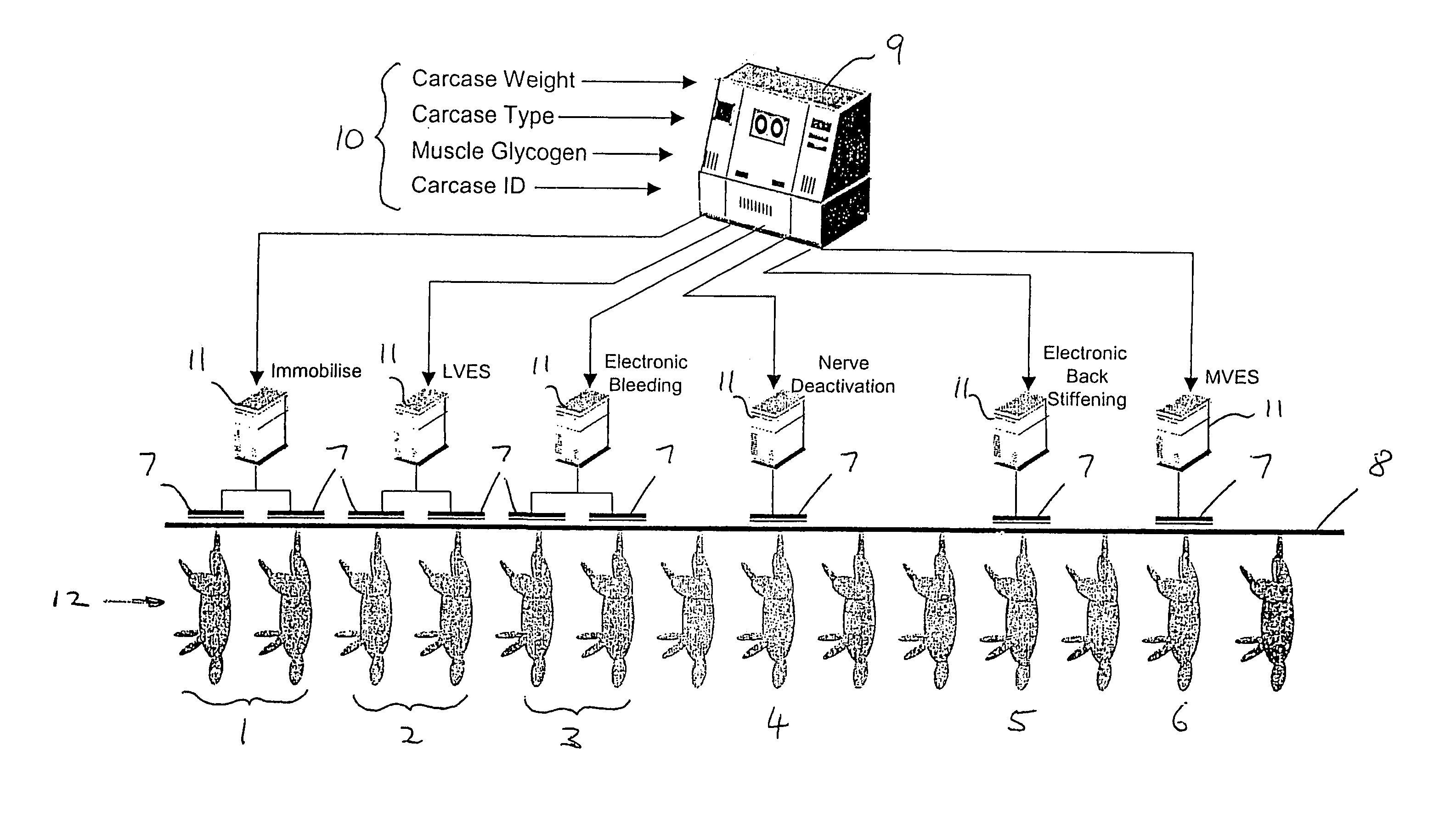

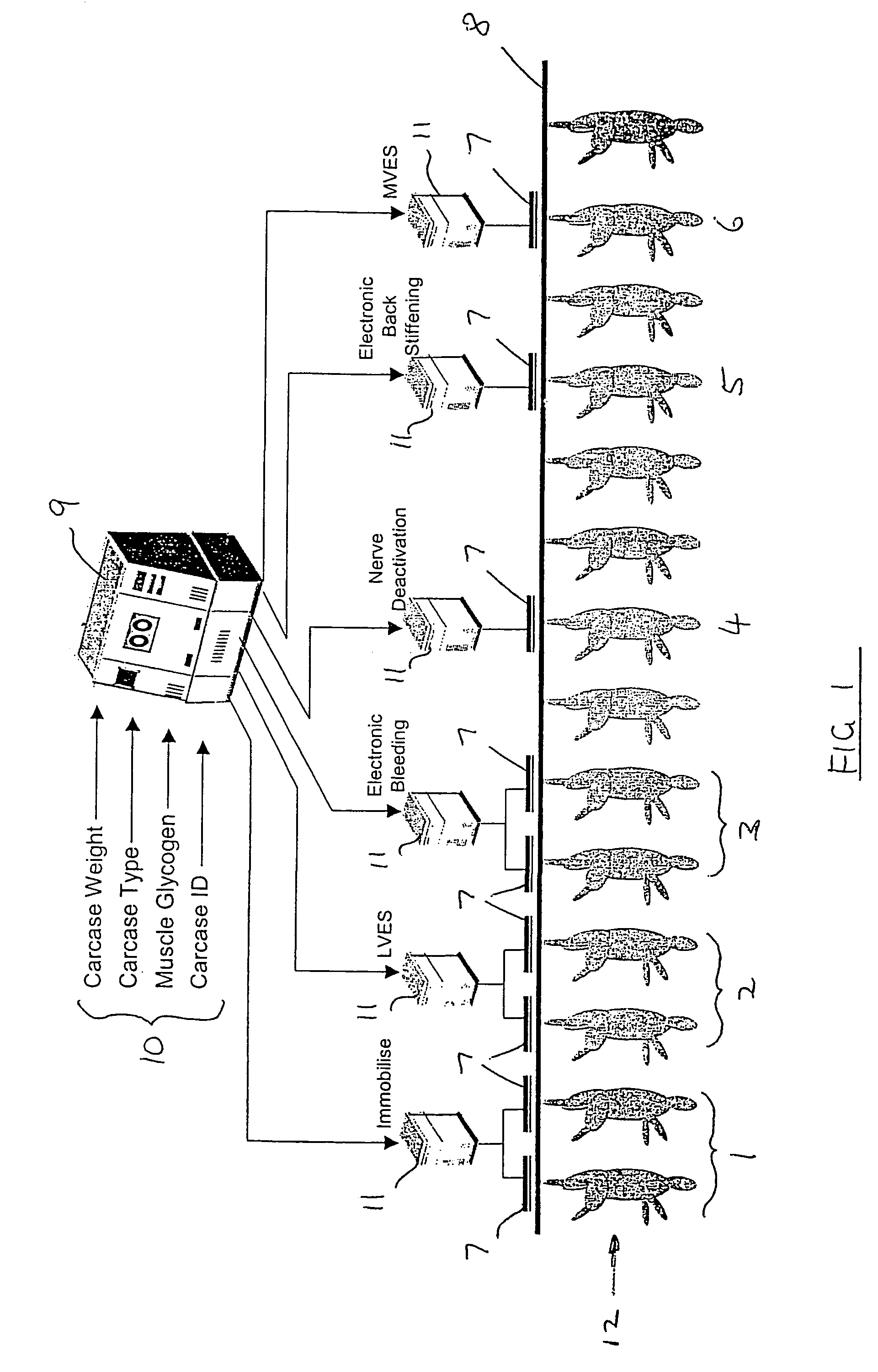

Electrical treatment of carcasses

InactiveUS7025669B2Excels in qualityIncrease productionElectric current slaughtering/stunningPoultry processingMicrocomputerPower flow

Owner:MEAT & LIVESTOCK AUSTRALIA

Slaughtering method comprehensively utilizing giant salamander resources

ActiveCN104206502ADoes not affect the tasteReduce viscosityElectric current slaughtering/stunningMeat/fish preservation by freezing/coolingSaline waterGiant salamander

The invention discloses a slaughtering method comprehensively utilizing giant salamander resources. A giant salamander is subjected to electric shock anesthetization after being temporarily cultured and cleaned, then white mucus on the body surface of the grown giant salamander is lightly scraped by a stainless steel spoon and the mucus is collected in a preservation box and is cryopreserved at the temperature of minus 20 DEG C; after collection of the mucus is finished, the processed giant salamander is soaked and washed with vinegar solution to remove residual mucus colloid, the washed giant salamander is placed on a slaughtering table, the head of the giant salamander is pressed, the head and the trunk are directly cut off and the slaughtered giant salamander is hung upside down to carry out bloodletting; after bloodletting, cutting is carried out, wherein the cutting operation comprises the following steps: (a) cutting off limbs; (b) ripping along the medioventral line to take out internal organs and peeling off livers; (c) flushing the giant salamander with salt water; (d) peeling off the skin; (e) taking out the lateral line and grease of the tail of the giant salamander; (f) separating out spine and coccyx; (g) cutting into meat slices and finally carrying out sterilization, deodorization, packaging and cryopreservation. The slaughtering method disclosed by the invention can sufficiently show edible and medicinal value of each part of the giant salamander.

Owner:CHONGQING KUIXU BIOLOGICAL SCI & TECH

Process for processing fishes cleanly in high quality

ActiveCN102160566AFull of nutritionHigh white qualityElectric current slaughtering/stunningFish processingFish processingSting fish

The invention belongs to the technical field of fish processing, and particularly relates to a process for processing fishes cleanly, which comprises the following steps of: stunning the fishes instantly, namely stunning live fishes by using rated voltage so as to allow the fishes to have heartbeat but lose memory or stunning the live fishes in a closed bag by using carbon dioxide; cutting fish gills off, namely allowing a knife to extend into the fish gills from water outlet edges of the fish gills on sides of fish cheeks to cut the fish gills on both sides off; performing bloodletting, namely hanging the fishes of which the fish gills are cut off in a mode of allowing fishtails to be upward and fish heads to be downward for bloodletting, so that fish blood flows out of fish mouths until the fish blood is discharged completely from fish gill cavities; washing, namely washing blood in fish mouth cavities cleanly by using pressurized water conveyed from the fish mouths, and washing dirt and mucus on surfaces of fish bodies cleanly; and drying, namely drying the water on the surfaces of the fish bodies by using a water absorption material. The process has the advantages that the fishes are stunned instantly, so the slaughter effect is good; the bloodletting is complete in a mode of cutting the fish gills off, so fish flesh is not polluted; and the fish bodies are hung upside down, the bloodletting is complete, and time and labor are saved, so the process is suitable for processing various fishes, particularly globefishes cleanly.

Owner:徐志敏

Poultry incapacitator and method of use

Owner:MIDDLETON

Slaughter and processing technology of special wild pigs

ActiveCN104472648AEasy dischargeImprove water retentionElectric current slaughtering/stunningSlaughterhouse arrangementsBristlePork meat

The invention provides a slaughter and processing technology of special wild pigs. The slaughter and processing technology of the special wild pigs includes following steps: driving live pigs into a slaughter house, using tingling electricity to stun the live pigs, butchering the live pigs and discharging blood of the pigs after being butchered, scalding the dead pigs and planning bristles off the dead pigs, processing carcasses, discharging acid from white bodies of the pigs, and finally cutting and packing pork of the pigs. By using the slaughter and processing technology of the special wild pigs, water holding capacity of the obtained pork is improved, nutrition ingredients in the pork are difficultly lost, and furthermore the pork is delicate in meat quality, easy to cook and easy to tender, and succulent and delicious, and not only is easy to masticate, but also improves digestion and absorption utilization rate.

Owner:四川惠远农牧科技有限公司

Poultry incapacitator and method of use

The invention relates to a method for rendering fowl insensate prior to killing and processing, by exposing the fowl to a radio frequency source producing a frequency from between approximately 5 GHz and approximately 40 GHz, with an average power density from between approximately 10 mW per square centimeter and approximately 100 mW per square centimeter, for a predetermined period of time.

Owner:MIDDLETON

Method for decreasing spastic wing activity of poultry during slaughter

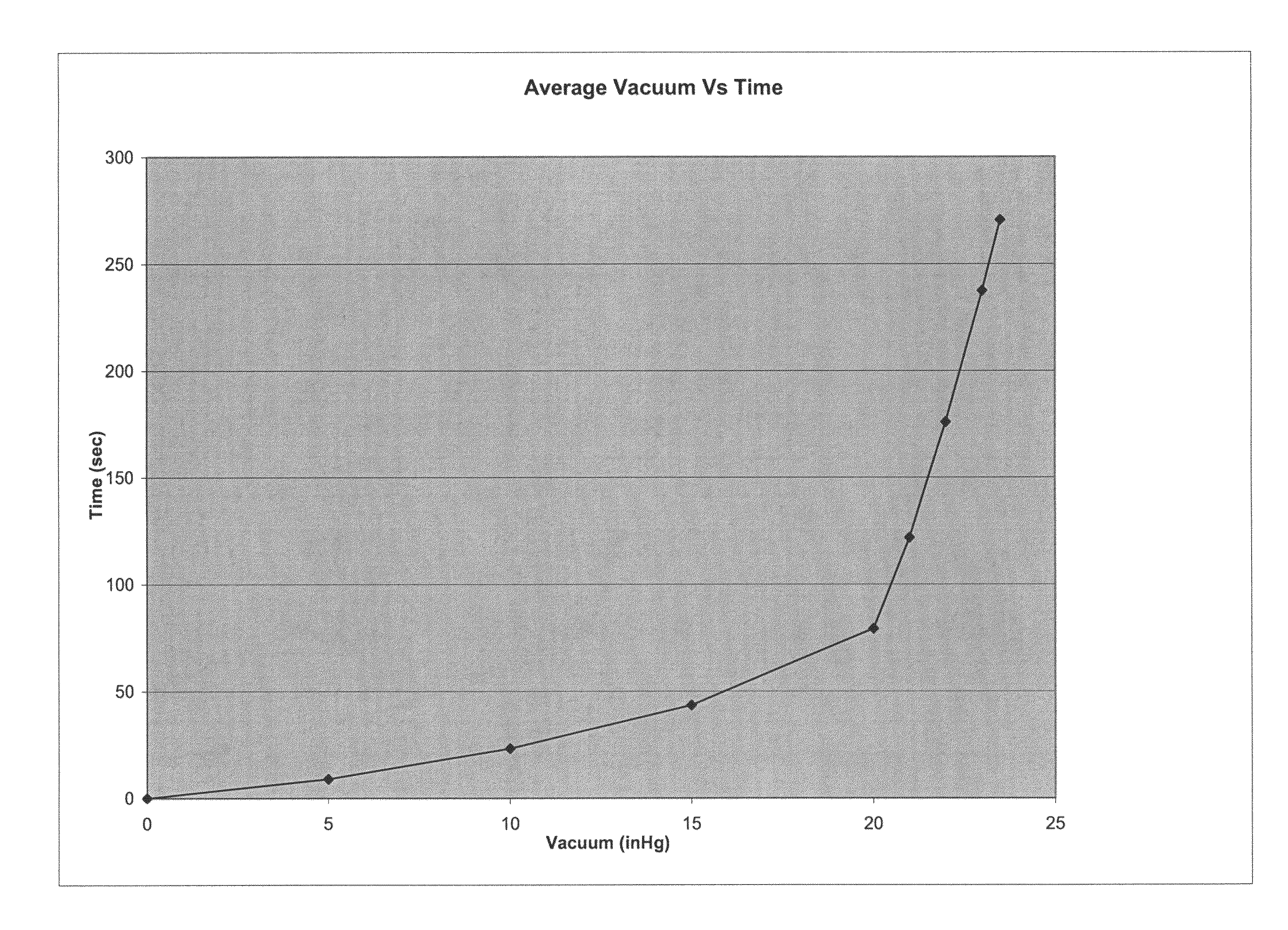

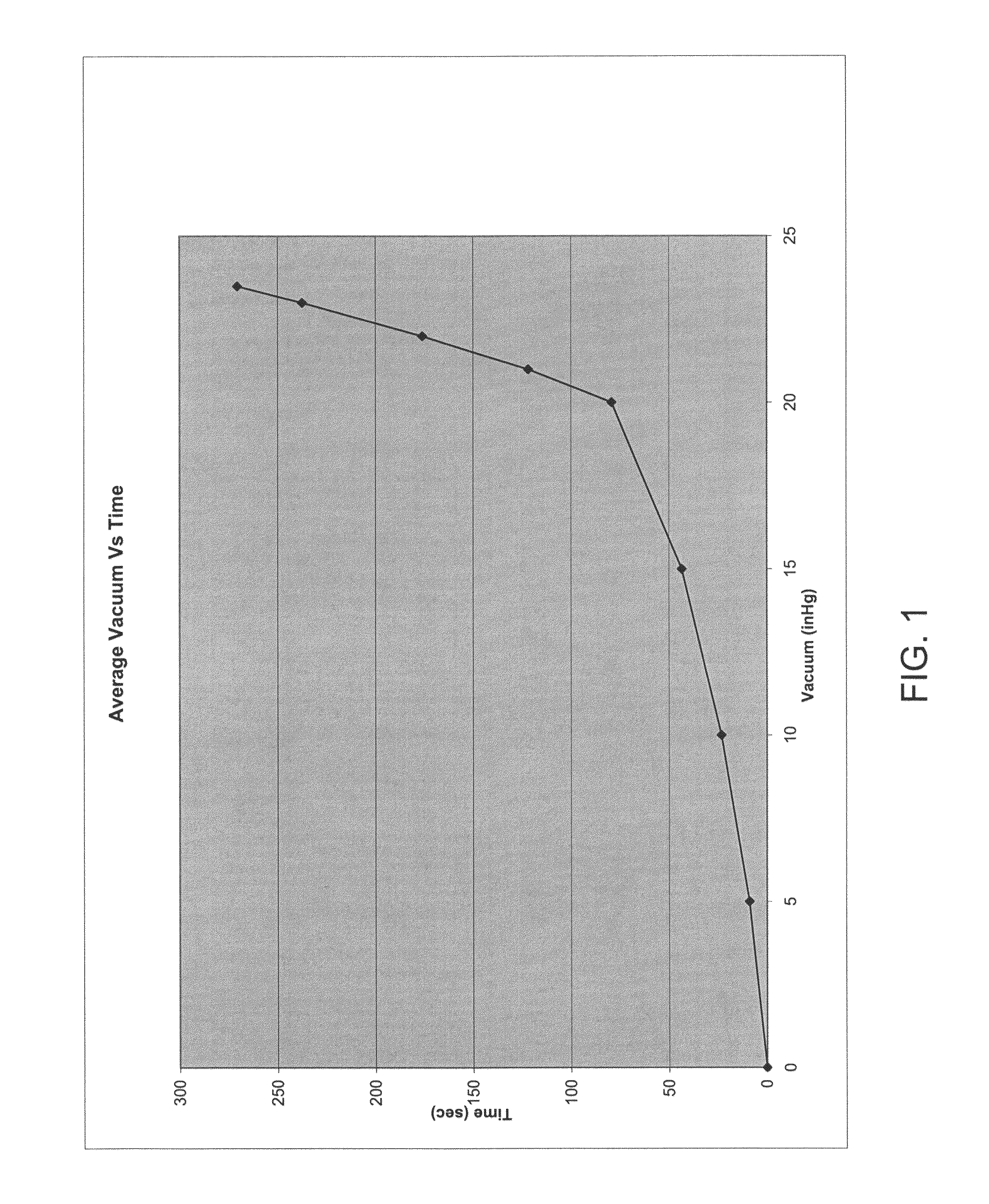

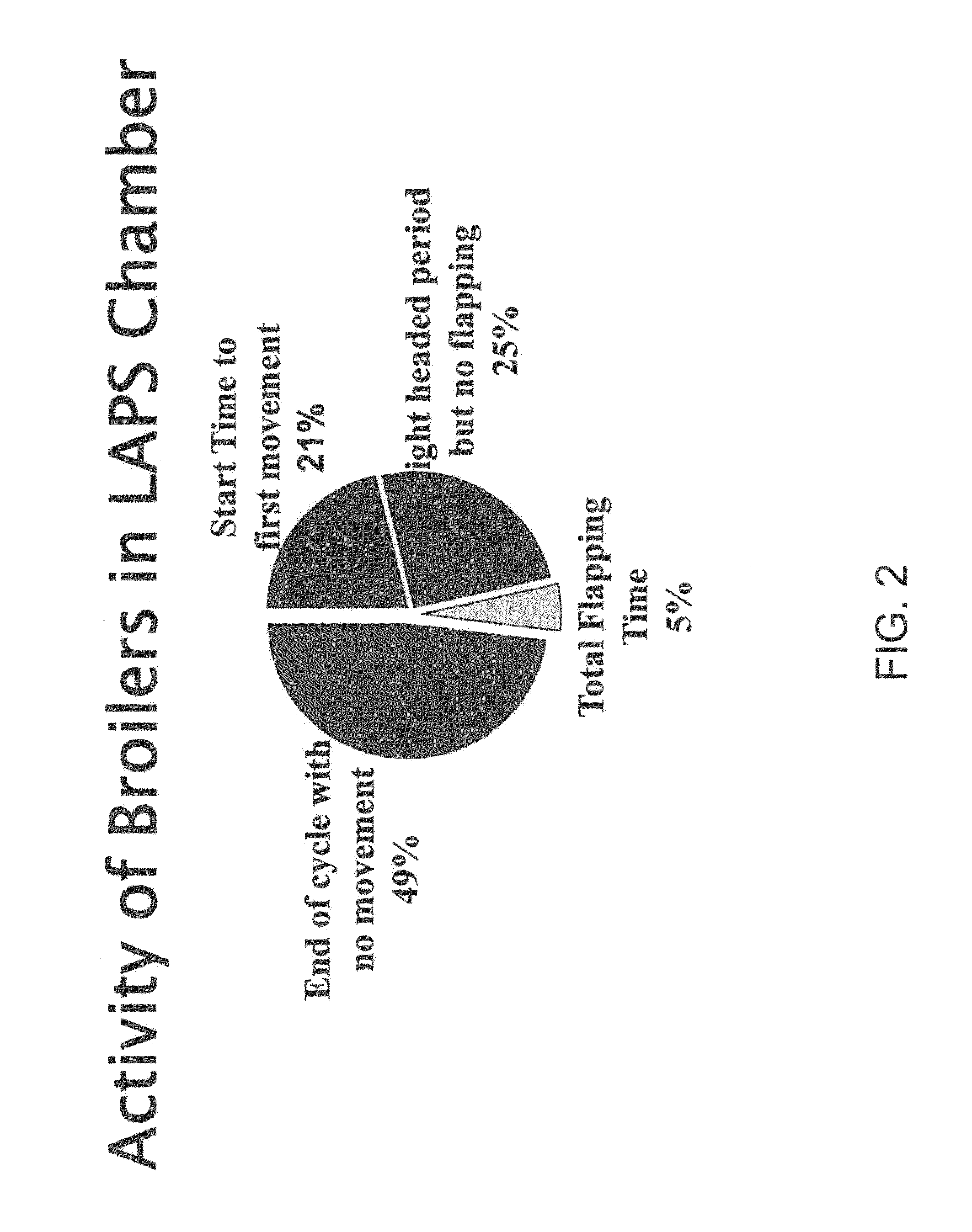

ActiveUS8113926B1Reduce the amount requiredReduced activityElectric current slaughtering/stunningBlood collection/stirring apparatusFowlAtmospheric pressure

The present disclosure generally relates to a method for humanely stunning and slaughtering poultry, and more particularly to a method for decreasing the spastic wing activity of poultry during slaughter. In particular, the birds are placed into a sealed chamber and the pressure in the chamber is reduced at a continuous rate to a target decompression pressure. The low atmospheric pressure slaughter is more humane than traditional slaughter techniques and results in less spastic wing activity.

Owner:CHEEK HOLLIS +1

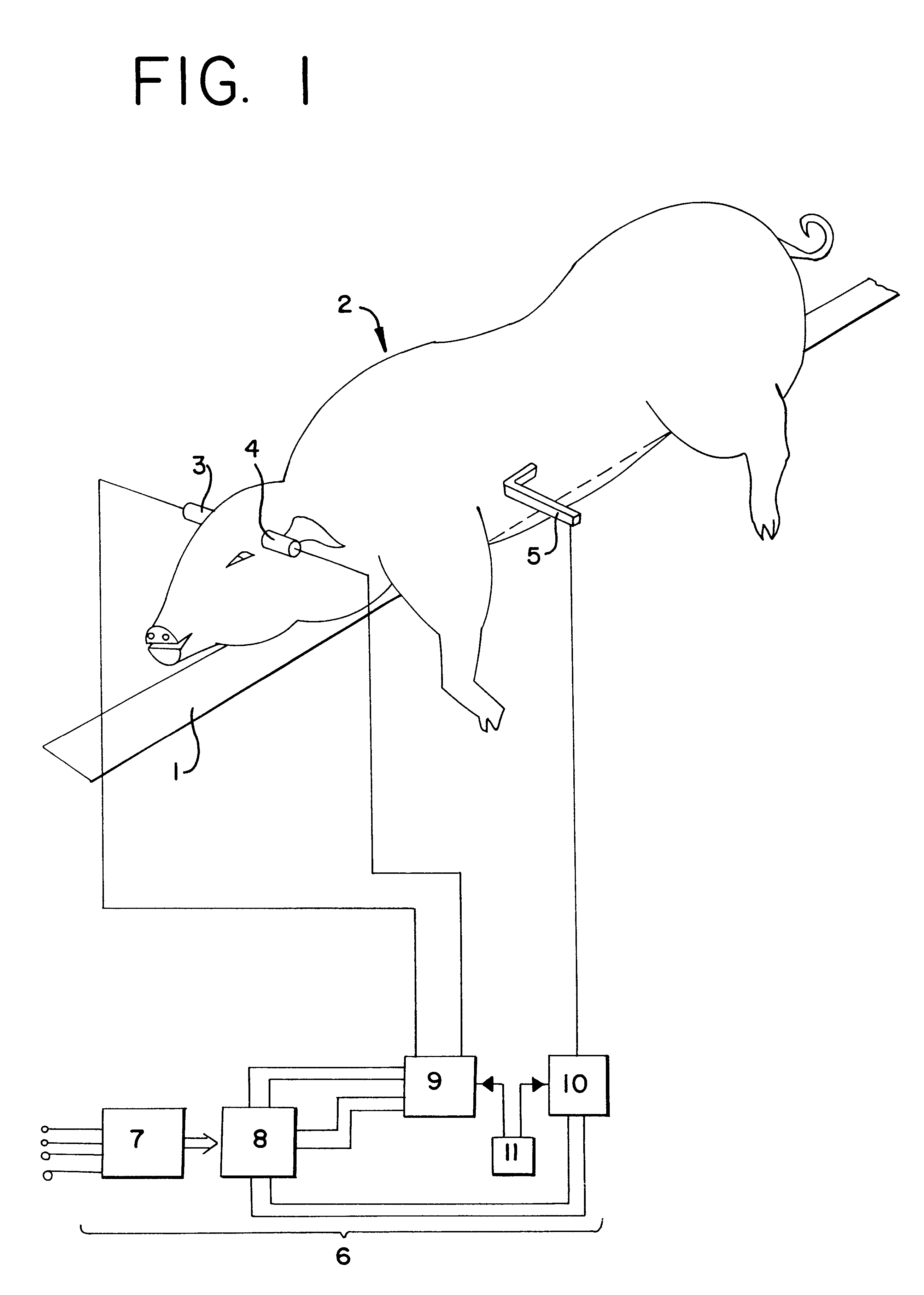

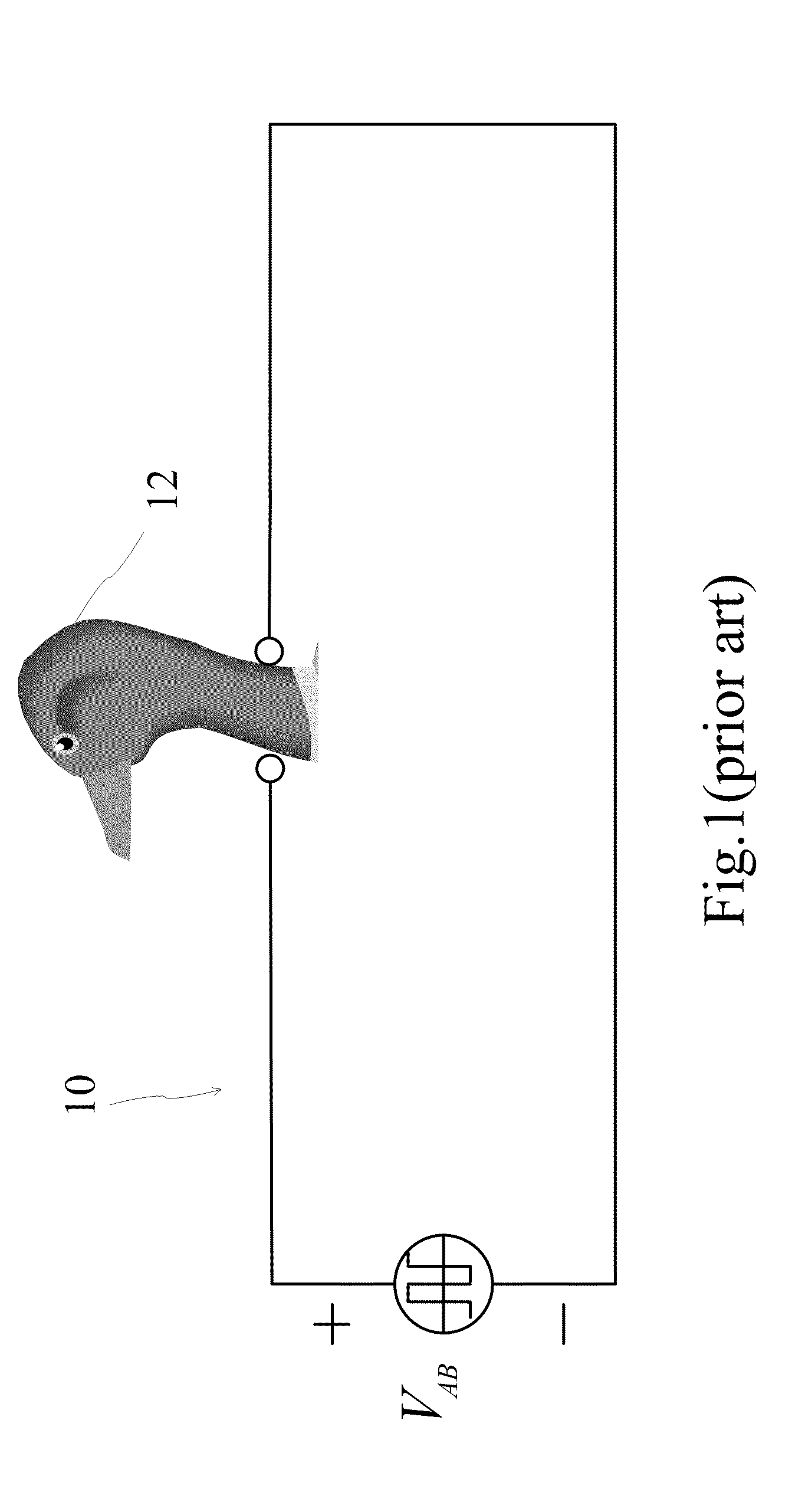

Method and device for stunning an animal for slaughter

InactiveUSRE37266E1Simple yet effectiveSuffering is preventedElectric current slaughtering/stunningCardiorespiratory arrestPower flow

A method of stunning an animal for slaughter includes the steps of providing the animal for slaughter; conveying the animal using conveying means; while conveying, causing a first current pulse having a maximum duration of 10 seconds to flow through the head and / or neck region of the animal to stun the animal; and, while conveying, causing a second current pulse to flow through the body of the animal to cause a cardiac arrest. The first and second current pulses may be applied successively or may be overlapping or partly overlapping.

Owner:STORK RMS BV

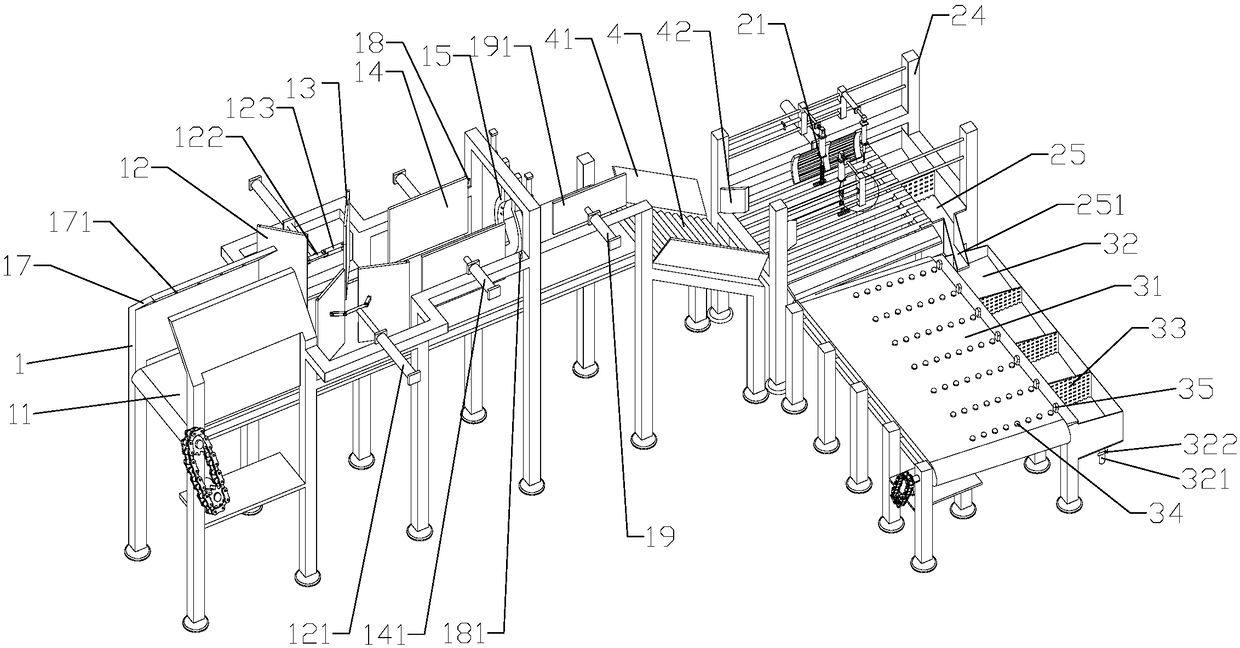

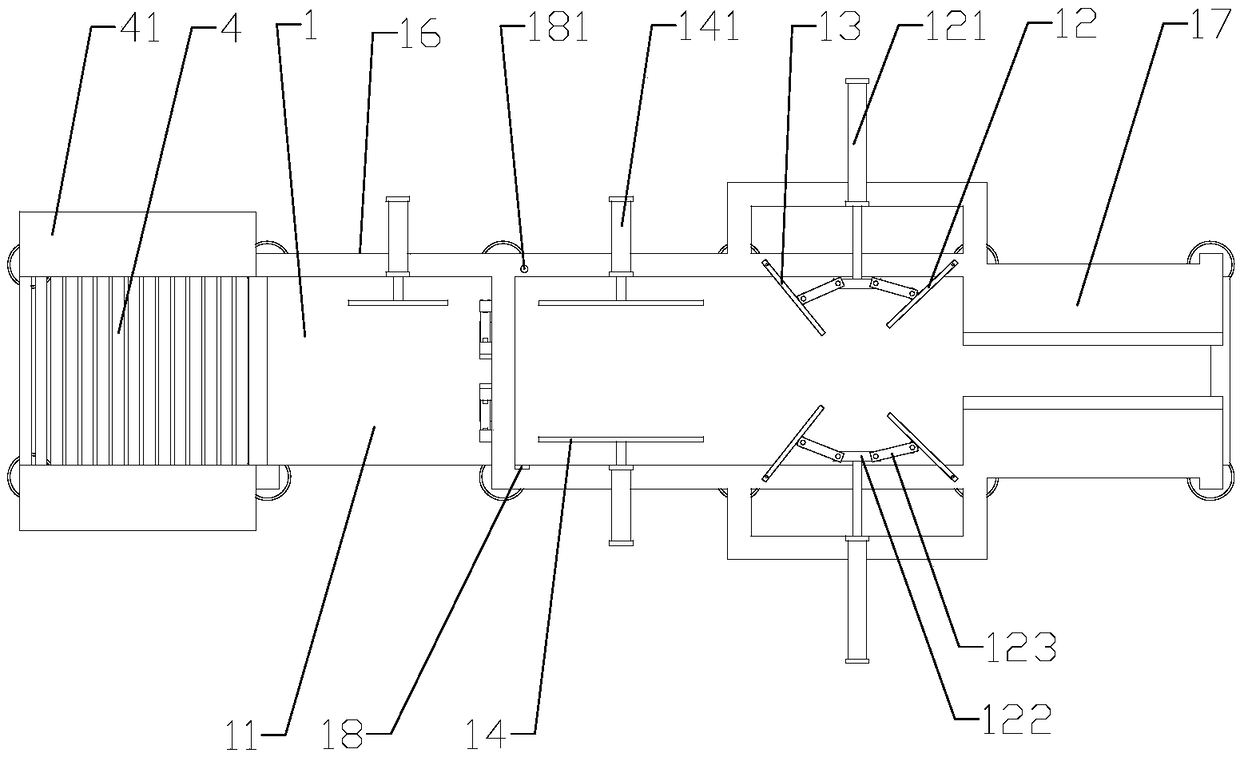

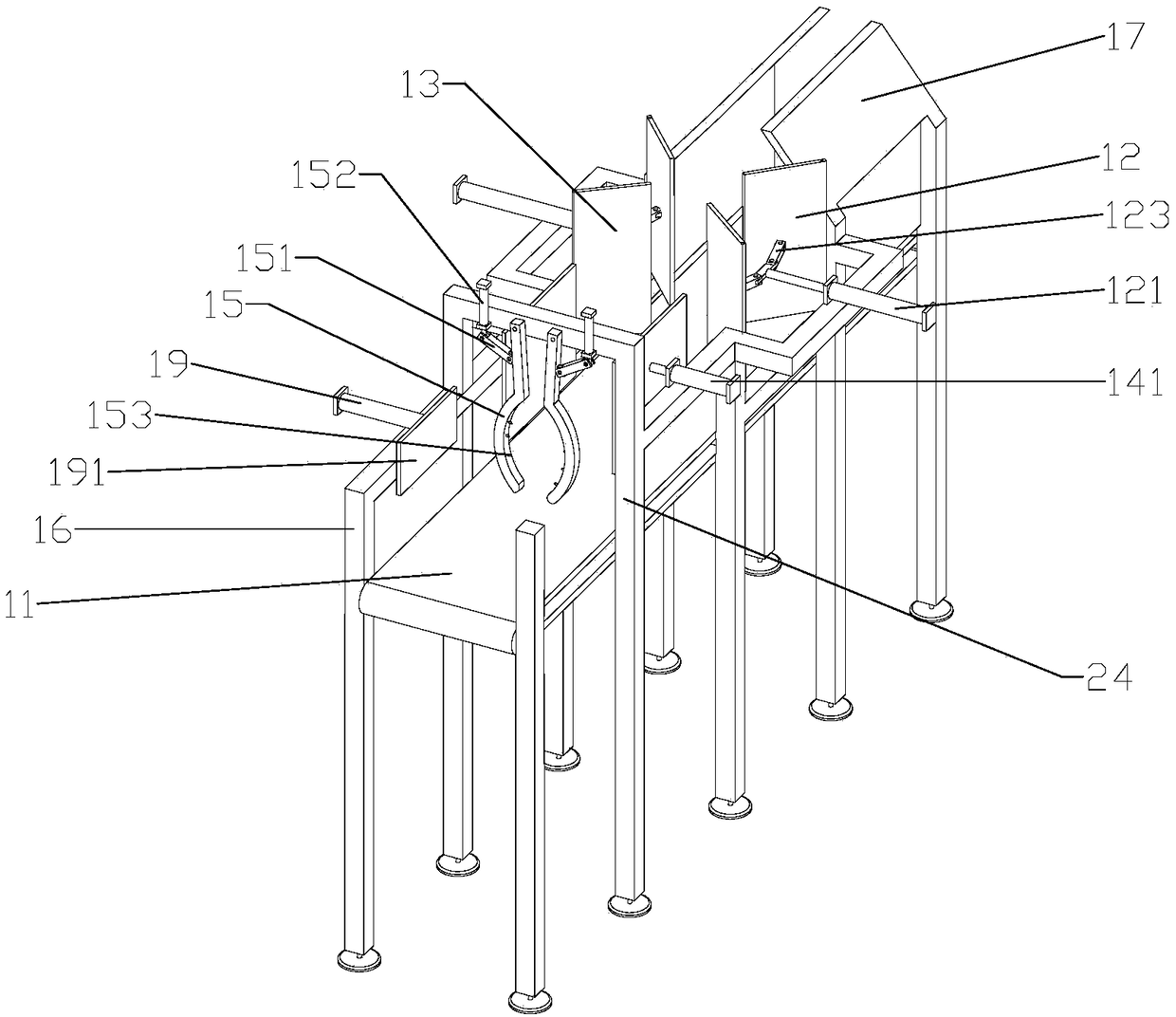

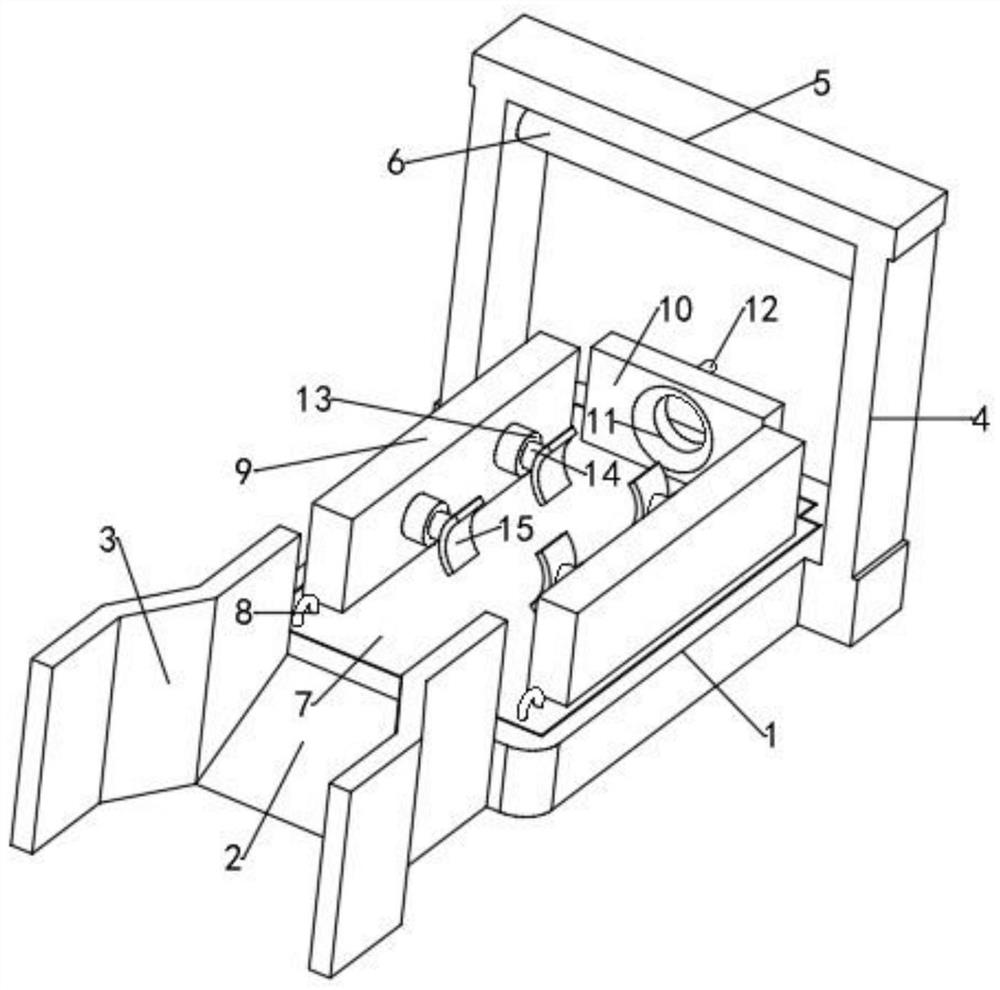

Live pig slaughtering equipment

ActiveCN109169799AEasy to collectAvoid leaningElectric current slaughtering/stunningBlood collection/stirring apparatusEngineeringSupport plane

Owner:HUBEI DAPAI FOOD

Beef cattle slaughtering method

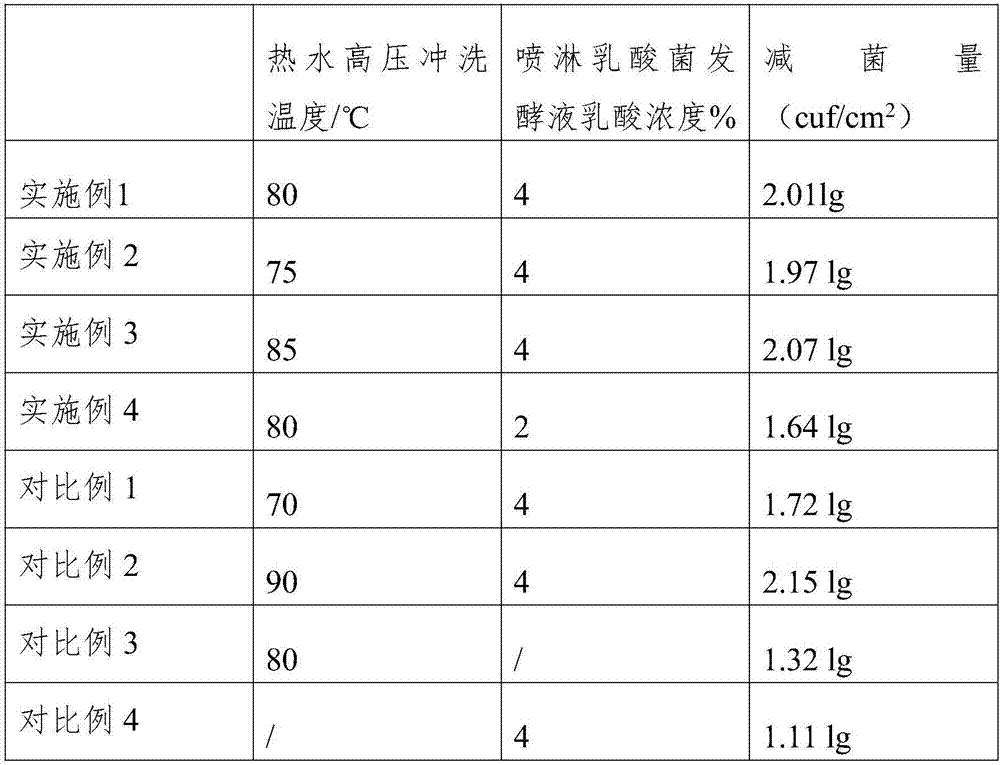

InactiveCN107087665AExtended shelf lifeHigh Bacteria ReductionElectric current slaughtering/stunningCarcasses disinfectionAgricultural scienceHigh pressure

The invention relates to the field of breeding of livestock, in particular to a beef cattle slaughtering method. According to the method, firstly beef cattle are slaughtered, hot water high-pressure rinsing is performed in the process of treating carcasses, and then sprinkling with lactic acid bacteria fermentation liquor is performed, so that disinfection and bacterium resistance are performed on beef, the total quantity of bacterial colonies of the whole carcasses of the beef is reduced, and the fresh-keeping period of the beef is prolonged.

Owner:广西山水牛畜牧业有限责任公司

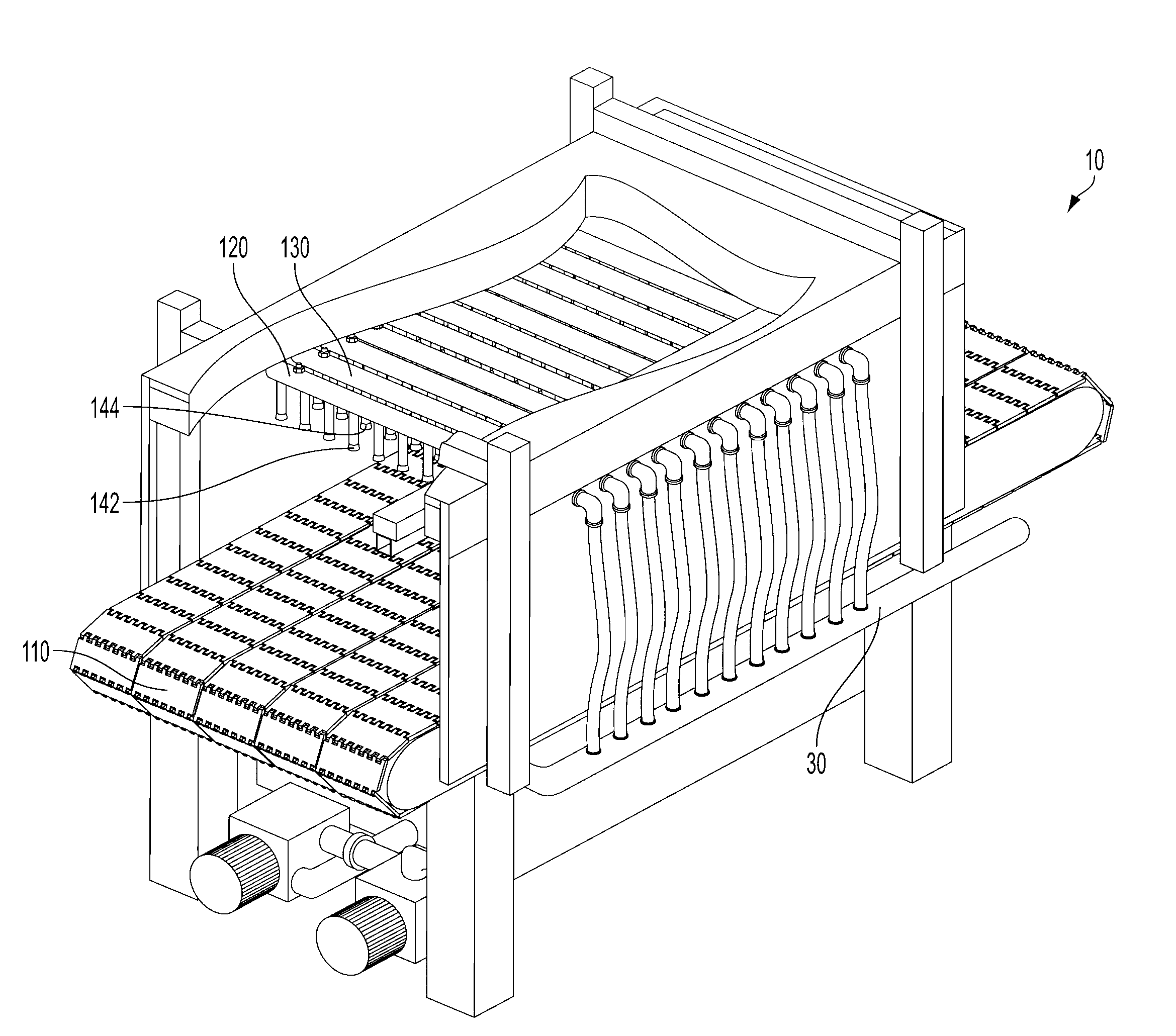

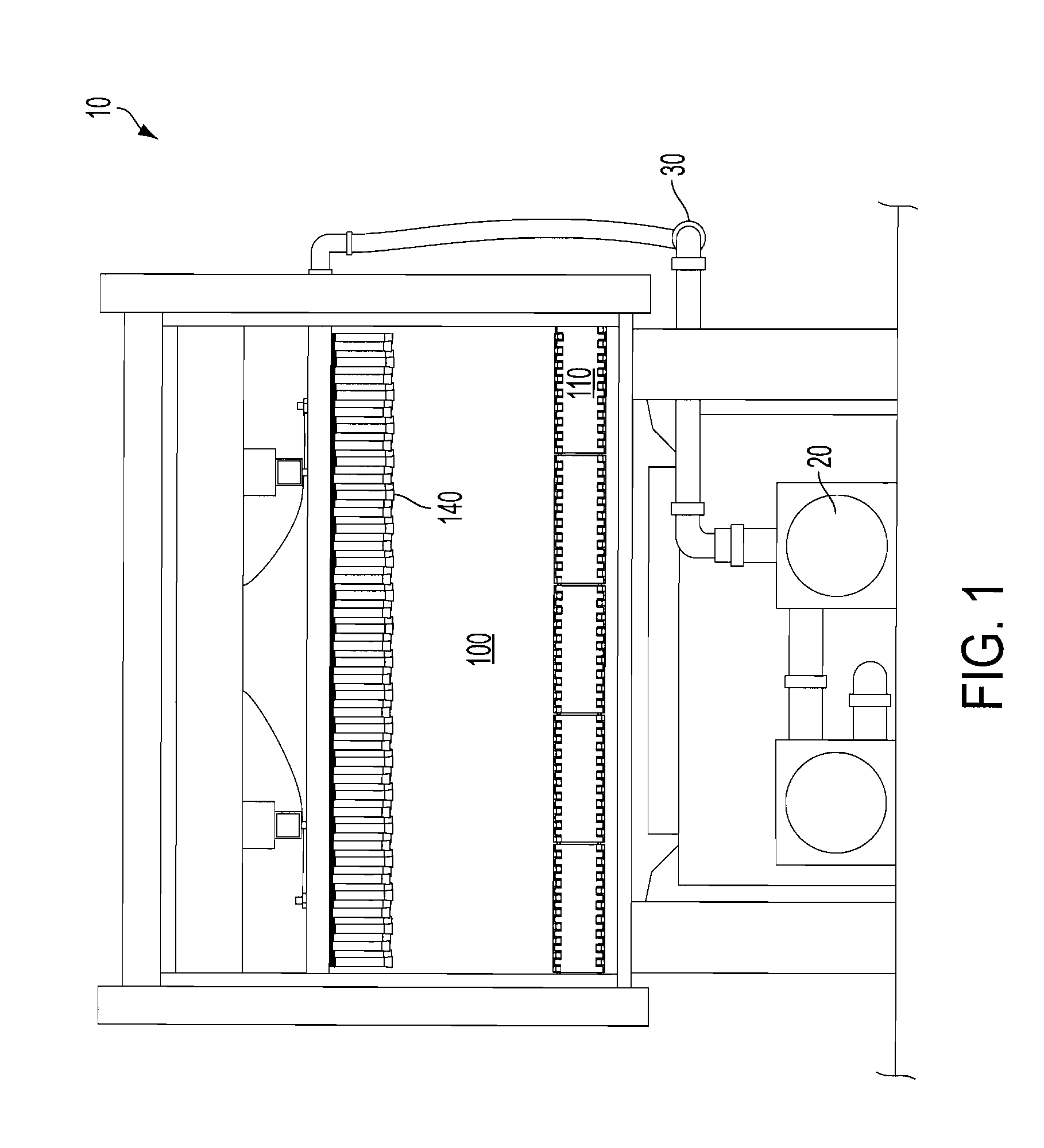

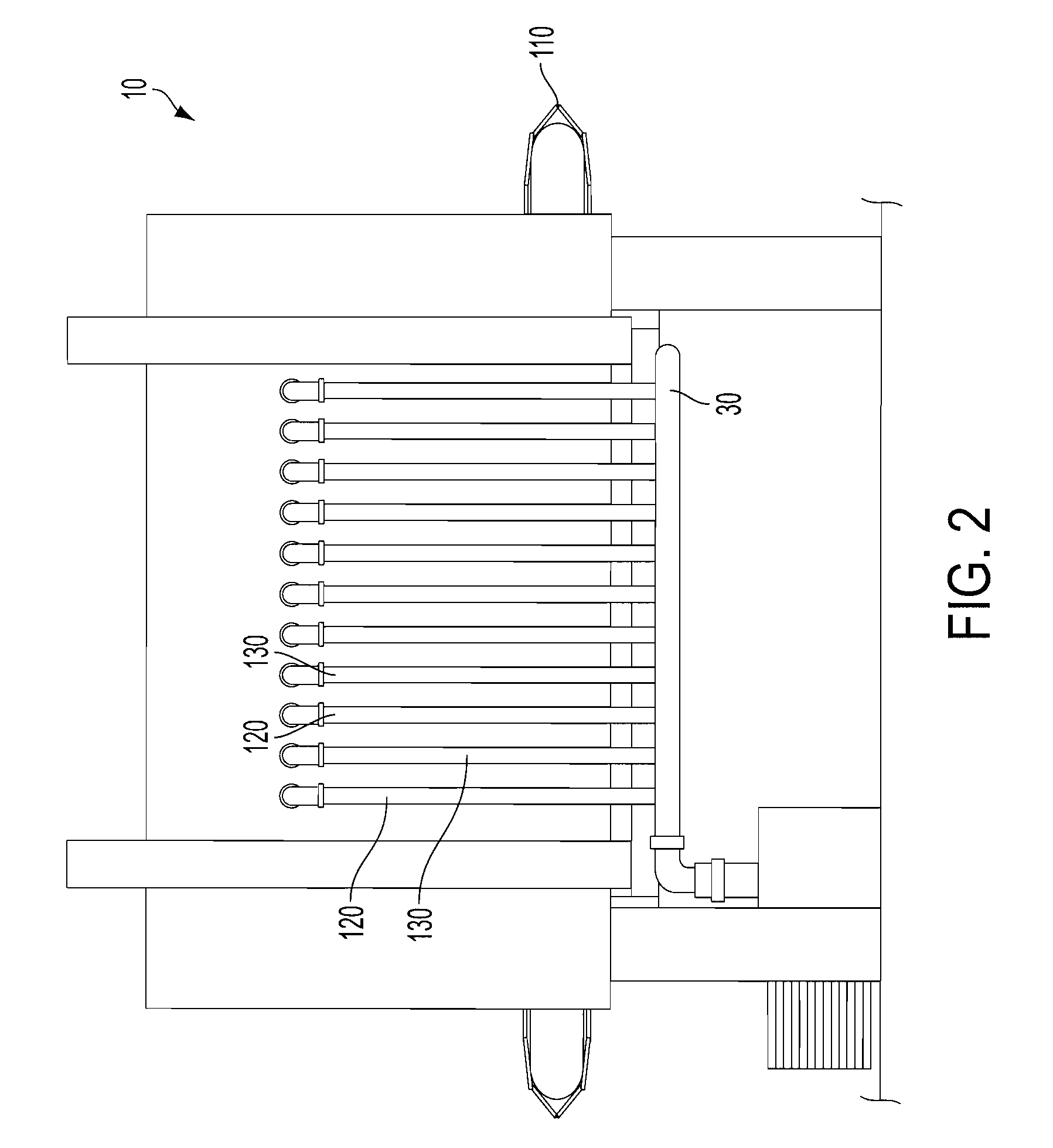

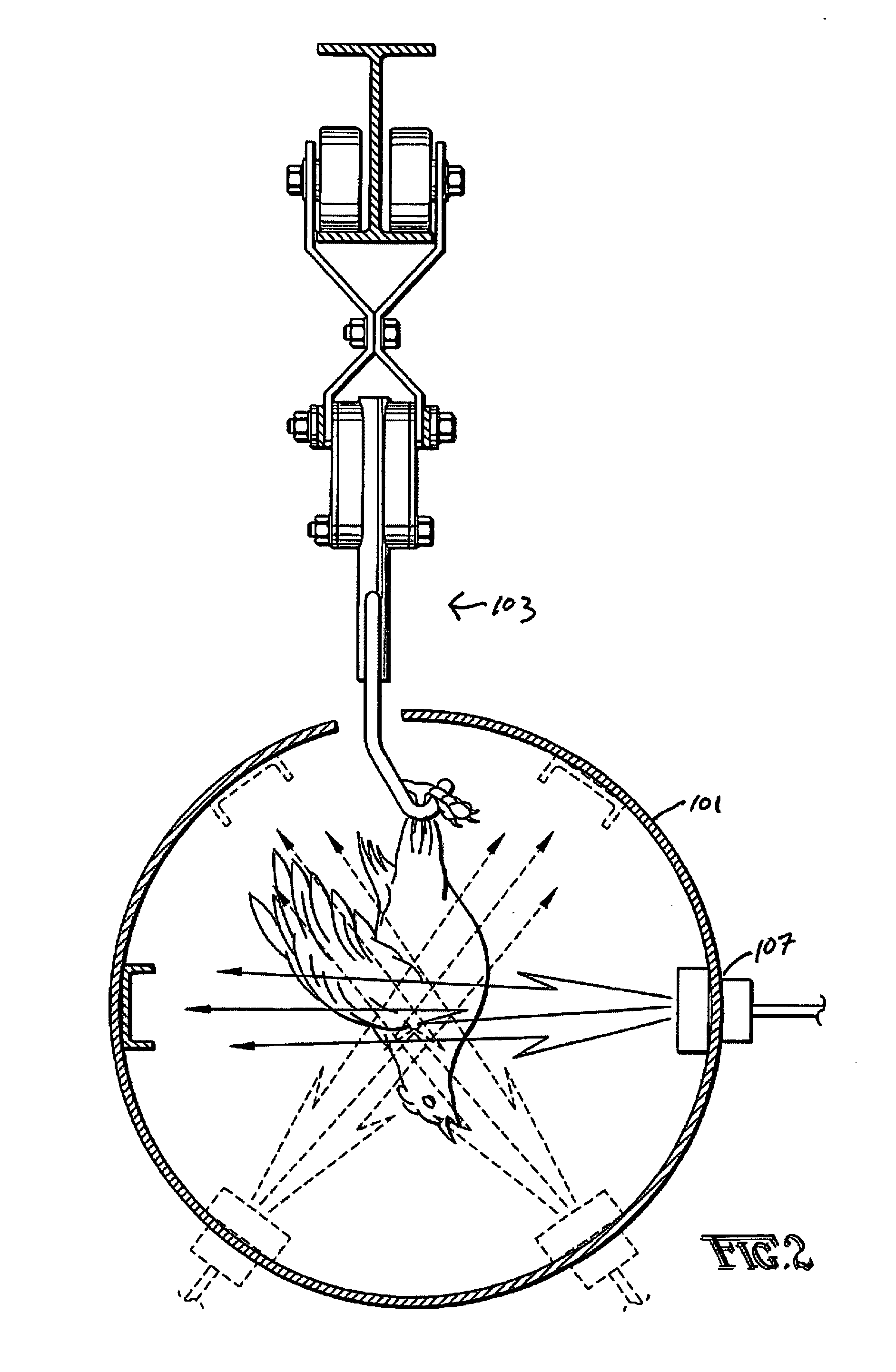

Microwave poultry processing device and method

The invention relates to a method for loosening the feathers of a fowl prior to killing and processing, by exposing the fowl to a radio frequency source producing a frequency from between approximately 5 GHz and approximately 40 GHz, with an average power density from between approximately 10 mW per square centimeter and approximately 100 mW per square centimeter, for a predetermined period of time. The invention also relates to a method for killing bacteria on the fowl prior to killing and processing.

Owner:HORST DREW +1

Communication system having conference server

InactiveUS7643628B2Avoids lengthy discussionElectric current slaughtering/stunningSpecial service for subscribersControl communicationsConference control

A communication system having a conference server device, a conference control unit, a plurality of moderator units, and a plurality of telecommunication devices. The moderator units are used to control allocation of a communication right. The decisions of the moderator units regarding the allocation of the communication right are combined to form an unambiguous overall decision, and overall decision is made using a majority decision.

Owner:INTEL CORP

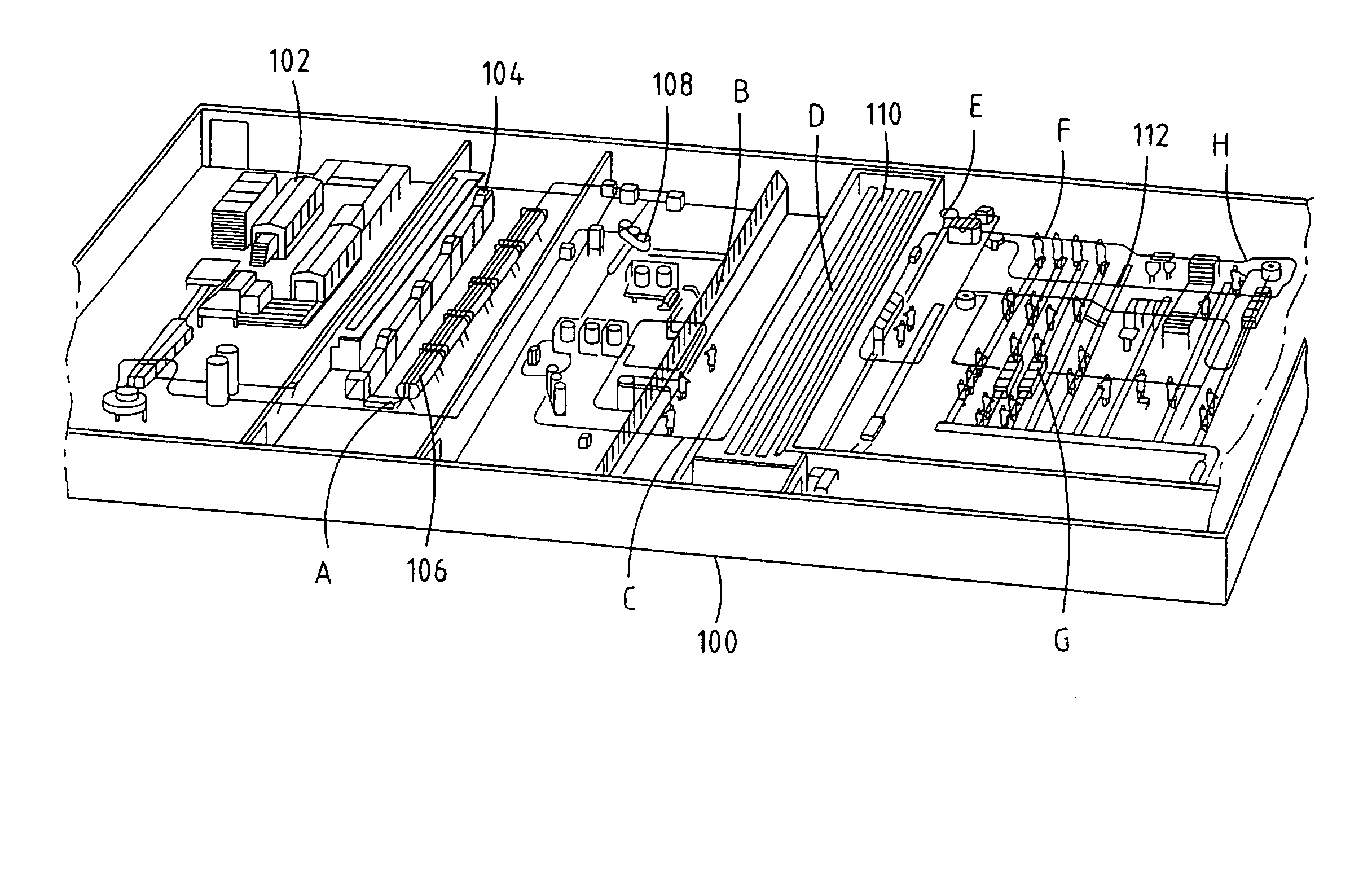

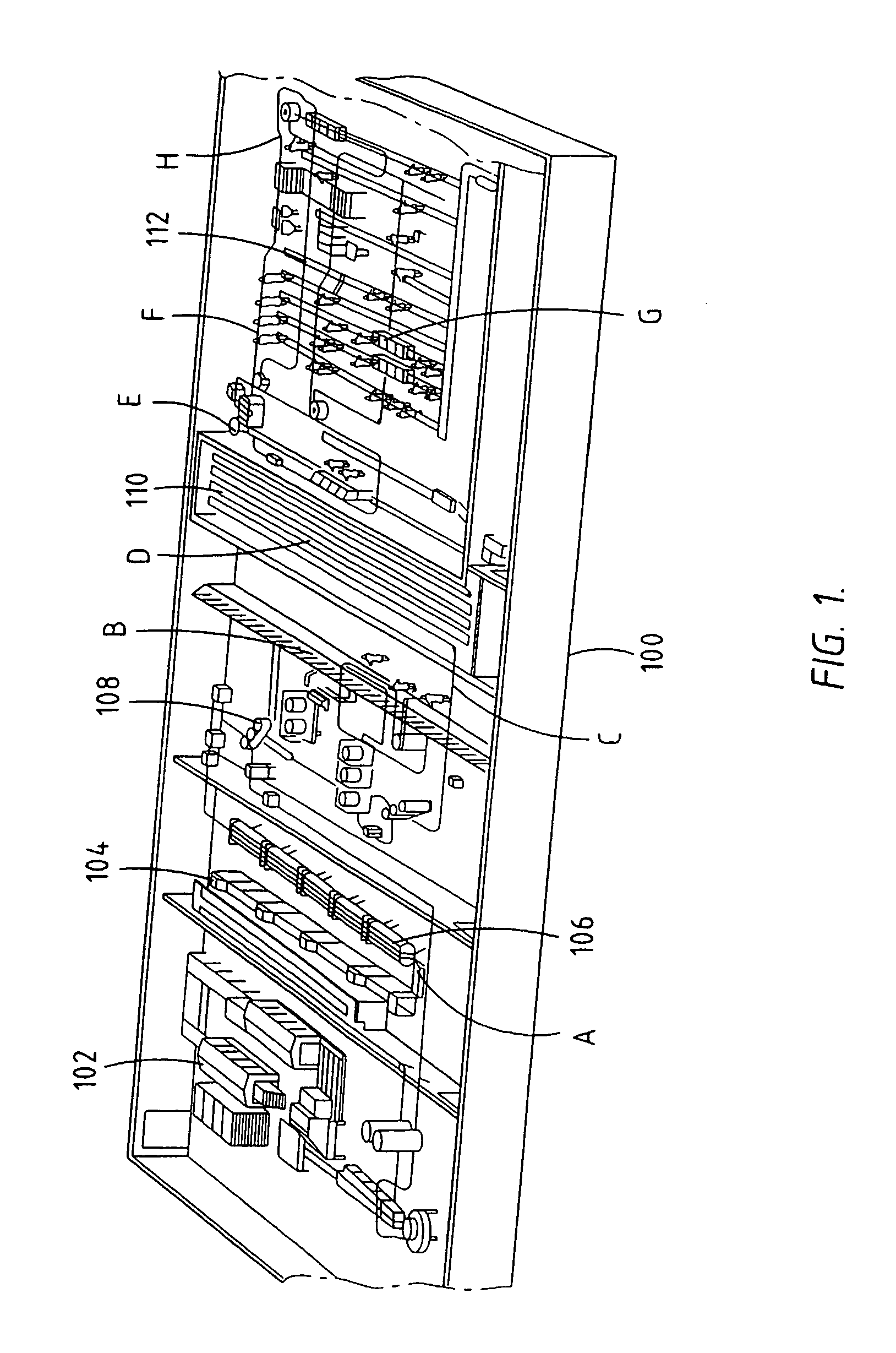

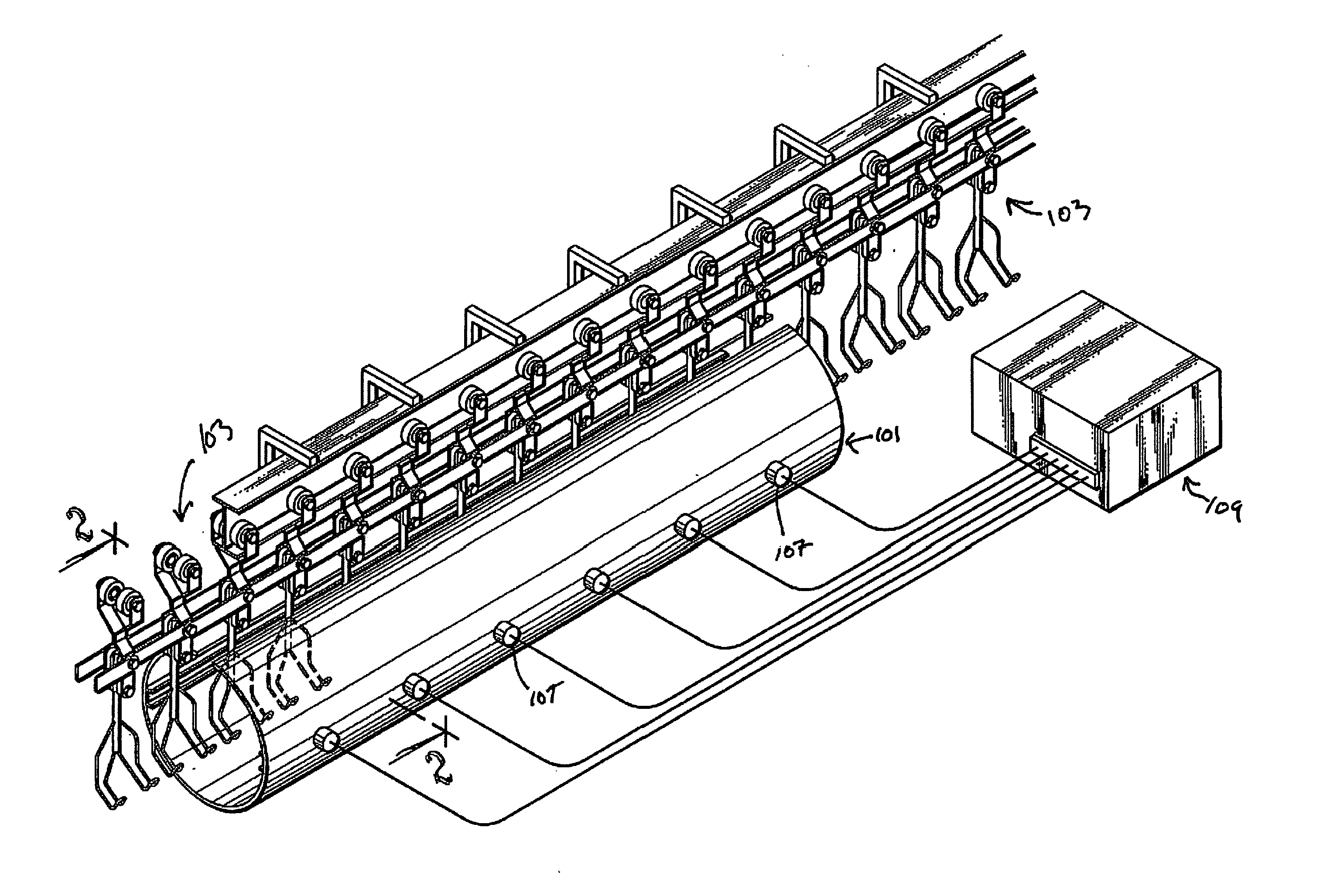

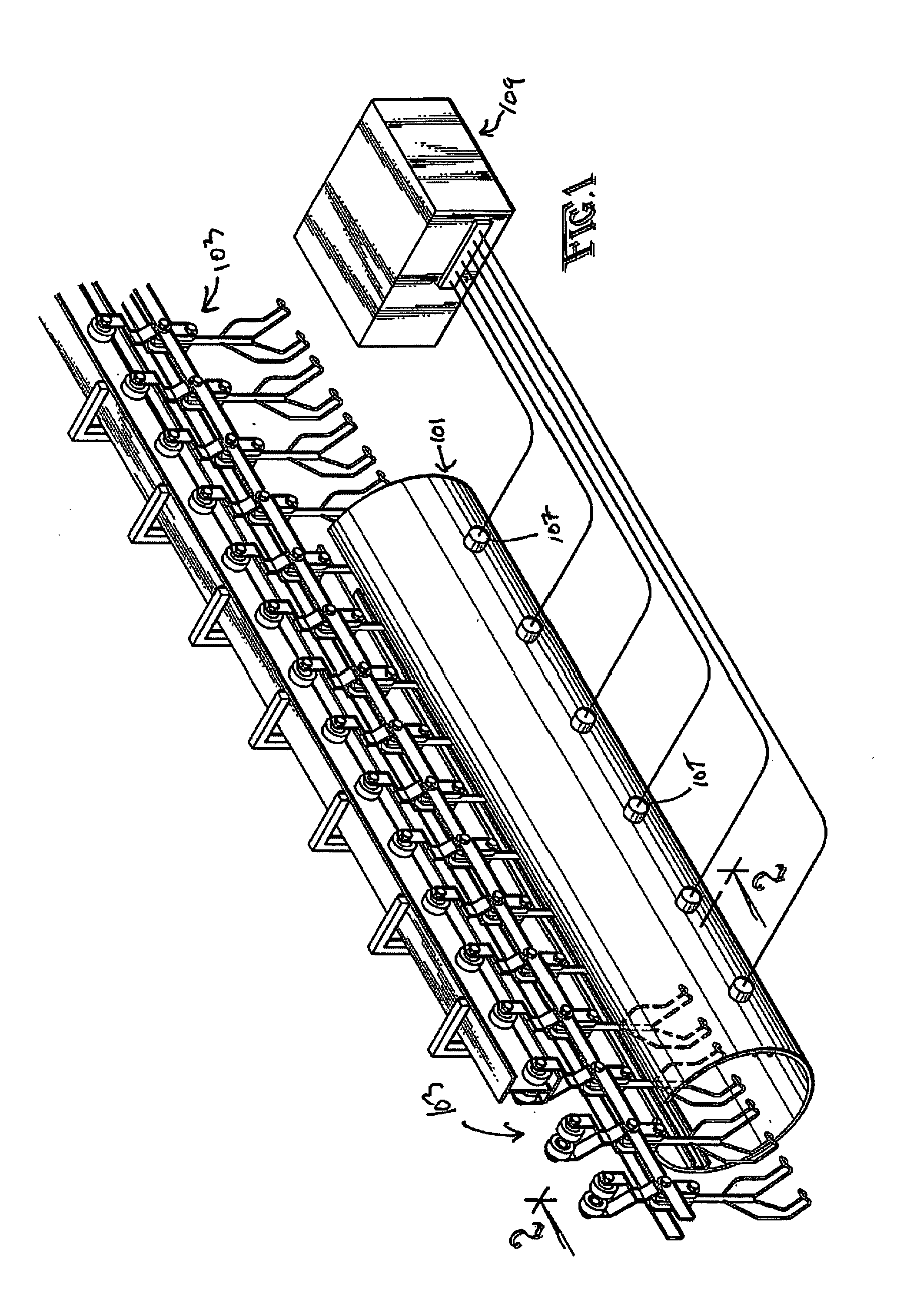

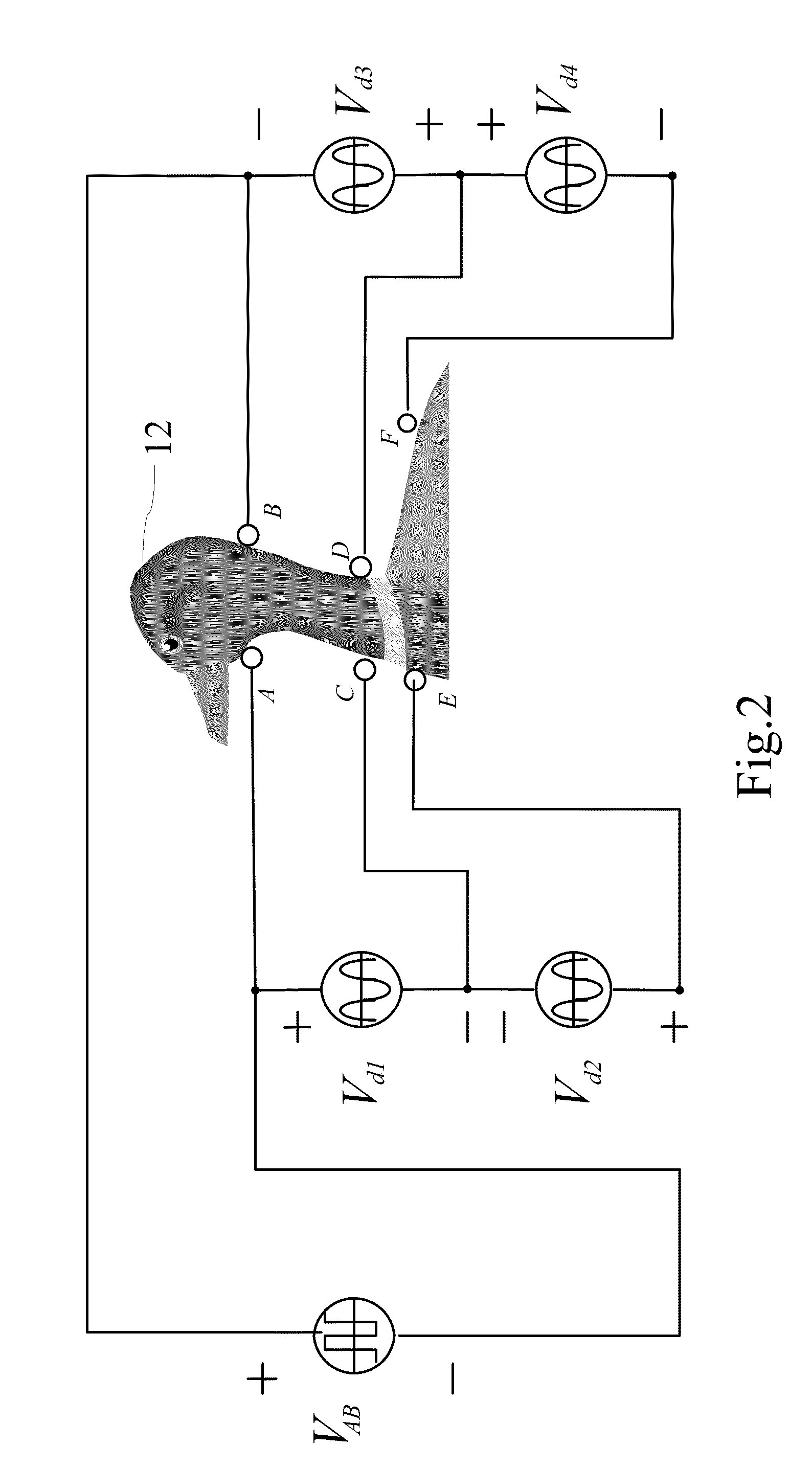

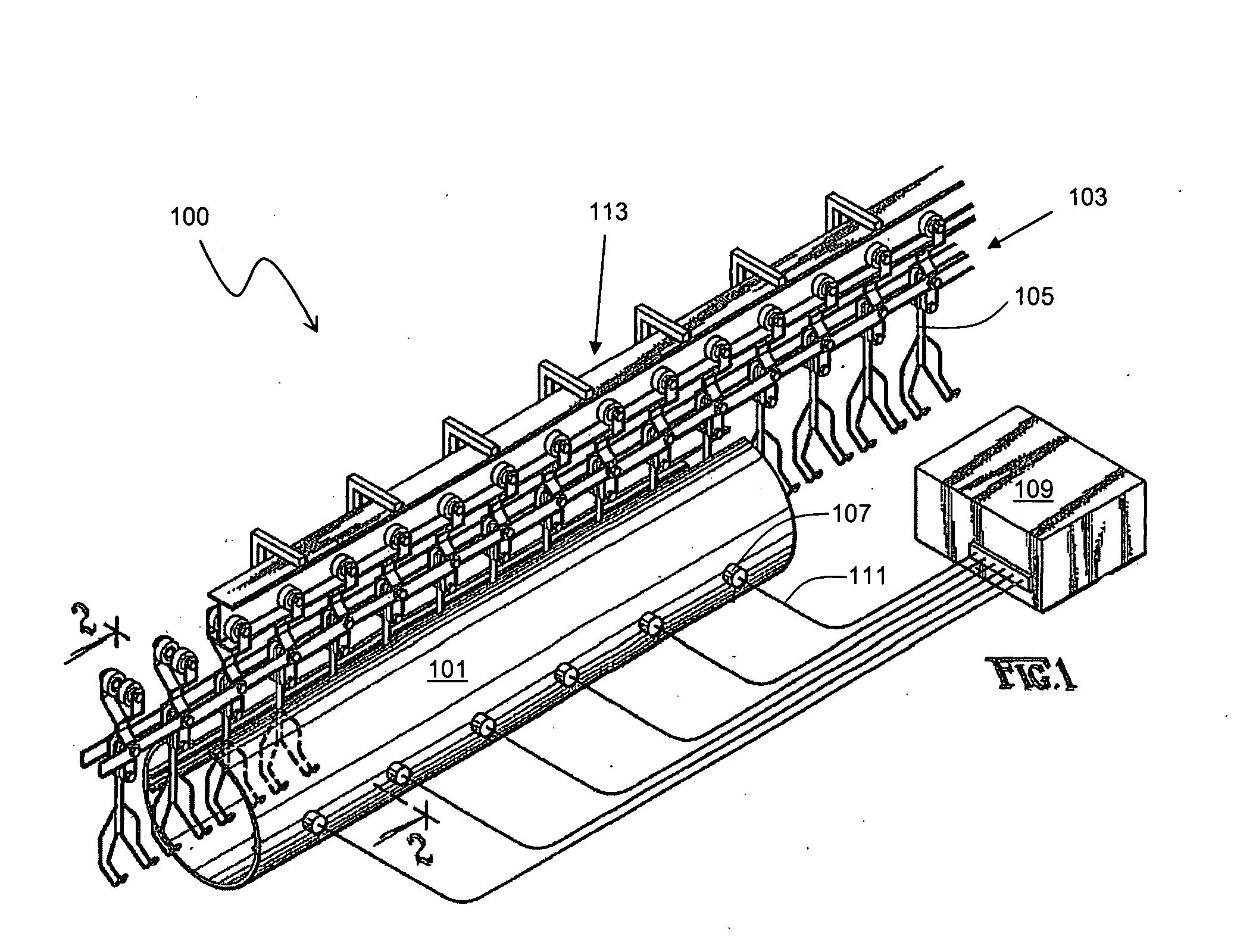

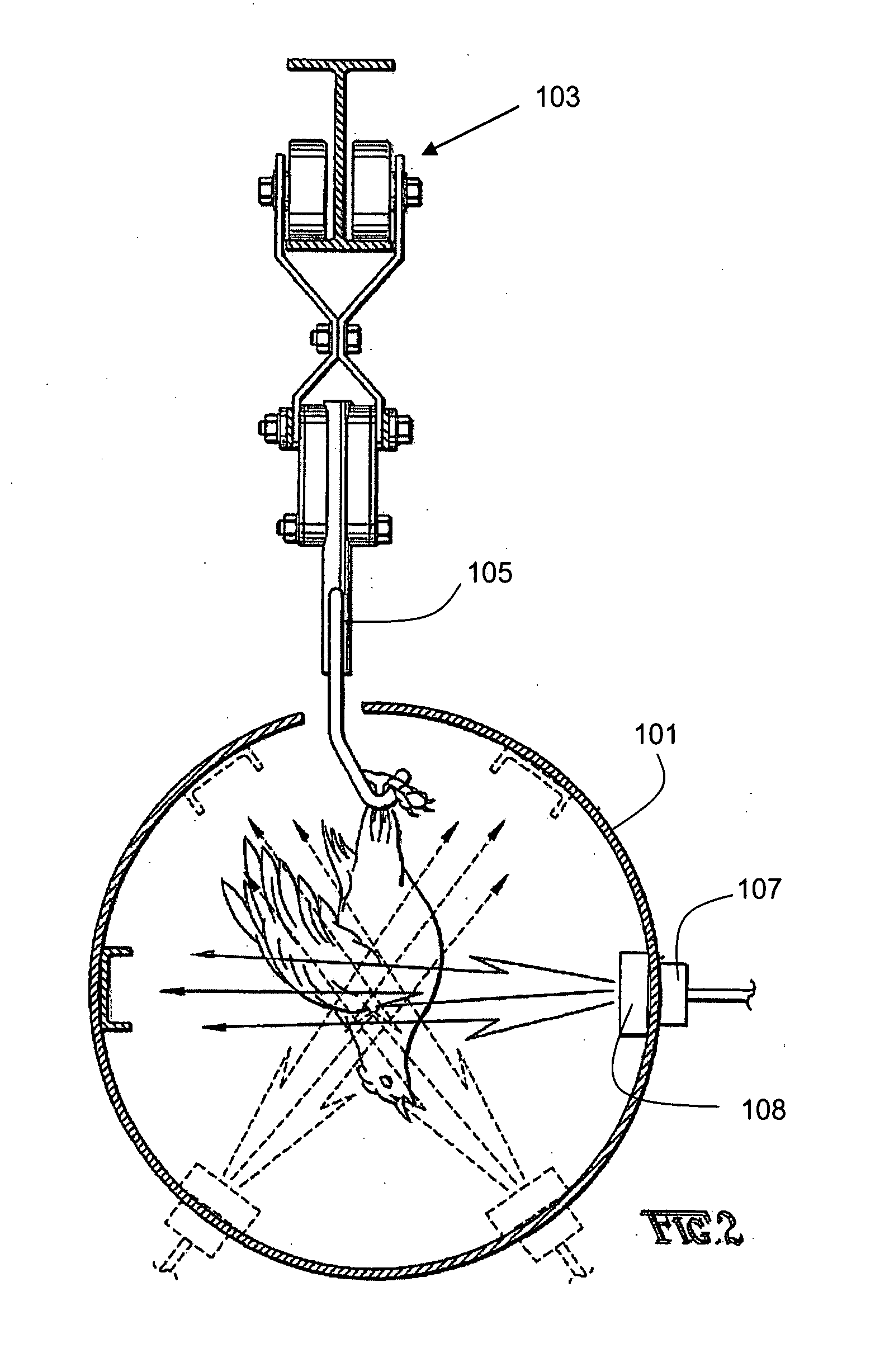

Multi-channel poultry stunner with current sharing feature

InactiveUS7841928B2Improve carcass qualitySmall sizeElectric current slaughtering/stunningEngineeringDither

A multi-channel poultry stunner with current sharing feature comprises at least two electrodes connected to at least one poultry and a current sharing circuit connected to the electrodes and a stunning voltage. The current sharing circuit generates at least four sets of dither voltages applied onto the poultry via the electrodes. The poultry is stunned by a stunning current generated on the poultry by the dither voltages and the stunning voltage. The advantages of small size and light weight can be accomplished, and very good conversion efficiency can be achieved. Moreover, a stunning current with current sharing feature can be produced to enhance poultry carcass quality.

Owner:CHANG GUNG UNIVERSITY

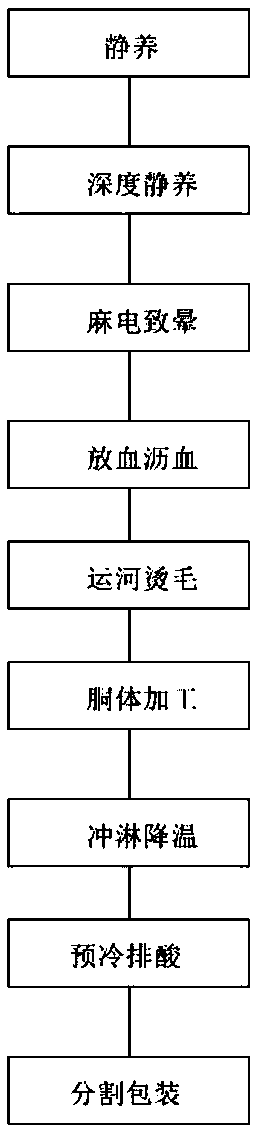

Slaughtering and producing technology of safety pigs

InactiveCN107668151AReduce formationBright colorPackaging meatElectric current slaughtering/stunningElectricityLean meat

The invention discloses a slaughtering and producing technology of safety pigs. The slaughtering and producing technology comprises the following steps of: a. performing relaxation; b. performing deeprelaxation: after the pigs to be slaughtered are in relaxation, showering the pigs with water for 3-5 minutes, wherein when the season for deep relaxation is summer, the water temperature is 20 DEG C, and when the season for deep relaxation is winter, the water temperature is 38 DEG C; c. performing electric-shock for stunning; d. performing bloodletting and bleeding; e. performing transferring and scalding; f. performing carcass processing; g. performing showering for cooling; h. performing pre-cooling and acid discharge; and i. performing segmentation and packaging: wherein in the whole segmentation process of chilled meat, the temperature of a segmentation workshop is less than or equal to 12 DEG C, the temperature of a packaging workshop is less than or equal to 10 DEG C, and the segmented chilled meat is safety pork, putting the safety pork on a tray with absorbent paper being spread, then transferring the safety pork into a packaging machine, performing overlay film packaging, and in the packaging process, charging mixed gas consisting of oxygen and carbon dioxide in the ratio of the oxygen to the carbon dioxide being 1 to 4 into an overlay film. According to the slaughtering and producing technology disclosed by the invention, the residual heat inside the product is reduced by water gradient, the product loss is smaller, and the lean meat of the product in the market isbrighter in color.

Owner:成都春源食品有限公司

Production method for giant salamander quick-frozen meat products

InactiveCN103250773AWhite fleshNutritionally completeElectric current slaughtering/stunningMeat/fish preservation by freezing/coolingBiotechnologyAnimal science

Disclosed is a production method for giant salamander quick-frozen meat products. The production method includes electrically shocking a living giant salamander to remove excretion, cutting off a carotid artery for bleeding and removing internal organs, a head and a tail, removing bones and fat in a torso part of the giant salamander, placing giant salamander meat in ice water at the temperature of 0 DEG C for soaking for 25 minutes, then soaking the giant salamander meat in ozone water at the temperature of 0-4 DEG C for 8 minutes, then placing the same into a refrigeration house at the temperature of minus 40 DEG C for 35 minutes so as to maintain the core temperature of the giant salamander meat to be < / =18 DEG C, and packaging prior to transferring the packaged giant salamander meat to the refrigeration house within 20 minutes with the temperature being controlled under minus 18 DEG C. The production method for the giant salamander quick-frozen meat products has the advantages that finished products are white in fleshcolor, glittering and transparent, fresh and tender as original when unfrozen, complete in maintenance of original nutrients, and are delicious, convenient, healthy, sanitary, nutritious and affordable like original giant salamander meat.

Owner:张家界金鲵生物工程股份有限公司

Method for improving quality of chilled fresh pork

InactiveCN103385203AKeep healthyReduced speed of breaking down toxinsElectric current slaughtering/stunningMeat/fish preservation by freezing/coolingAnimal scienceProduct gas

The invention relates to the technical field of the cooling and freshness retaining of food and particularly relates to a method for improving quality of chilled fresh pork. The method comprises the following steps of: (1) during feeding, enabling pigs to enjoy massage and music, and guaranteeing sufficient feed and water, so as to enable the pigs to live comfortably and freely; (2) before slaughtering, helping the pigs to bath in water with the temperature of 40 DEG C, carrying out comprehensive physical examination on the pigs by veterinarians, stunning the pigs by using a stunning gun after the pigs are qualified, and then, slaughtering the pigs; and (3) a freshness retaining step after slaughtering, comprising the steps of: (a) after the pigs are slaughtered, carrying out cooling and acid discharge on fresh pork for 24 h, enabling the center temperature of the fresh pork to be cooled to the temperature of 0-4 DEG C, and cutting the fresh pork into pork blocks with the weight of 100-102 g; (b) putting the pork blocks into plastic boxes, vacuumizing, then, inflating with mixed gas of 1% of nitric oxide, 50% of carbon dioxide and 49% of nitrogen gas, and packaging; and (c) preserving the packaged chilled fresh pork under the condition with the temperature of 2-4 DEG C. By using the method, the health and quality of the pigs can be guaranteed sufficiently, the blood leaking of the chilled fresh pork can be reduced through gas-conditioned packaged freshness retaining, and the freshness retaining shelf life is prolonged and can reach 20 days.

Owner:常州市汇华食品有限公司

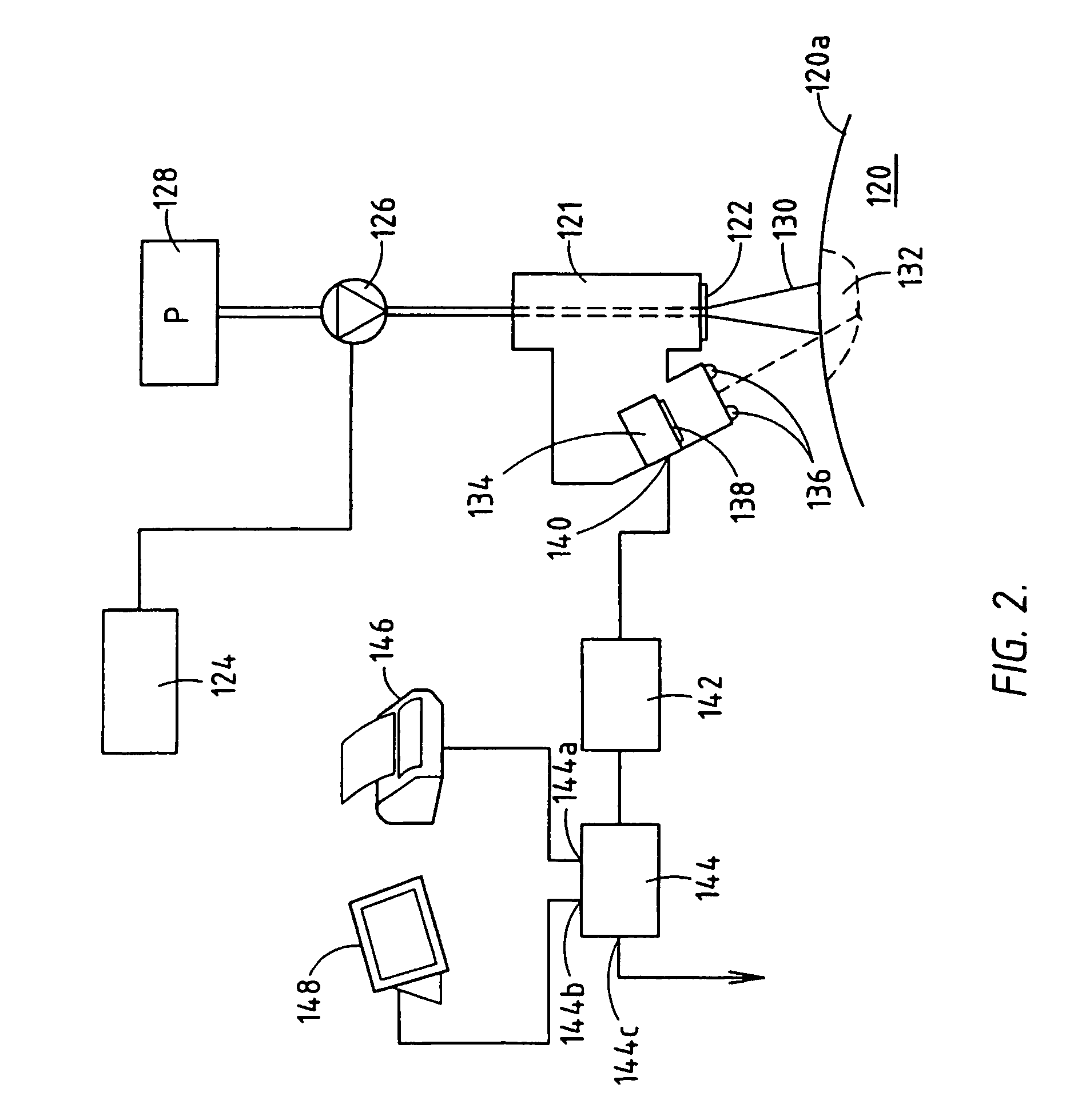

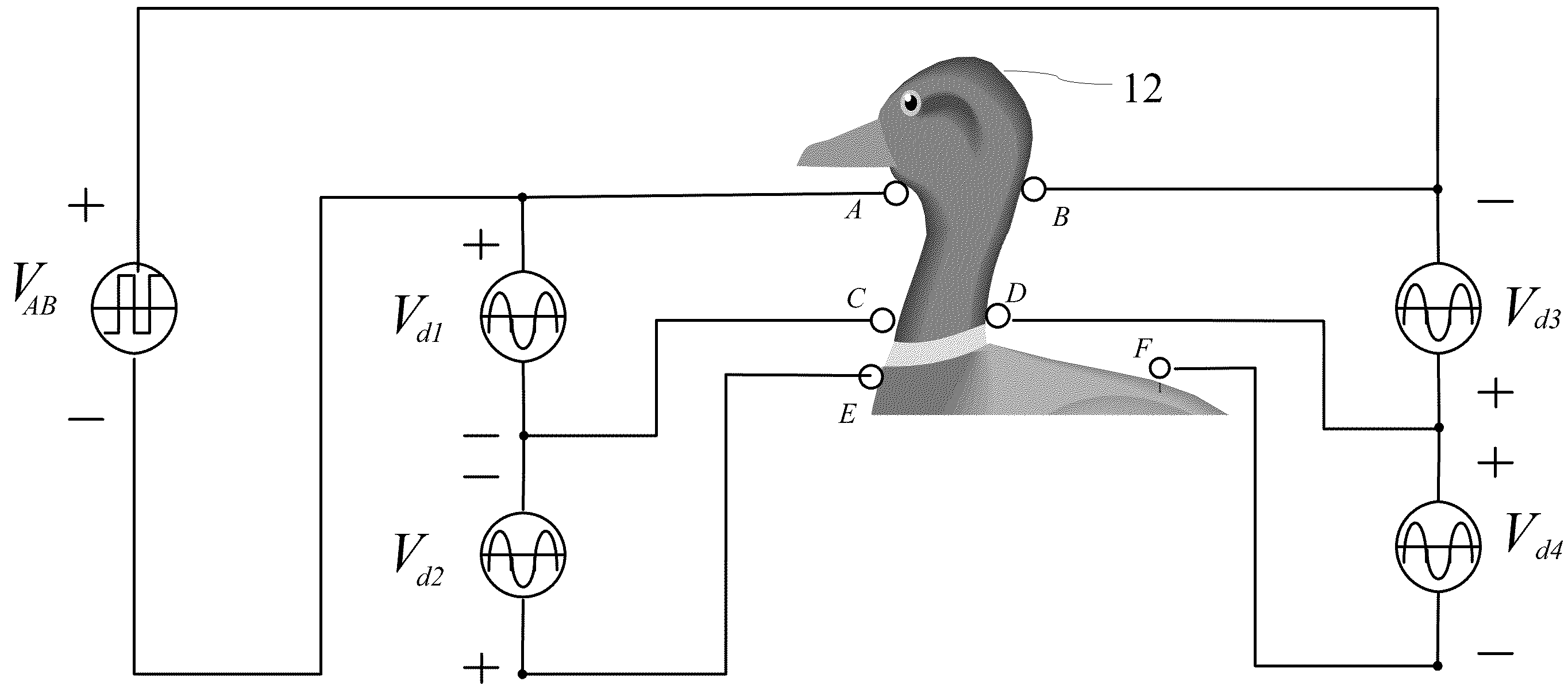

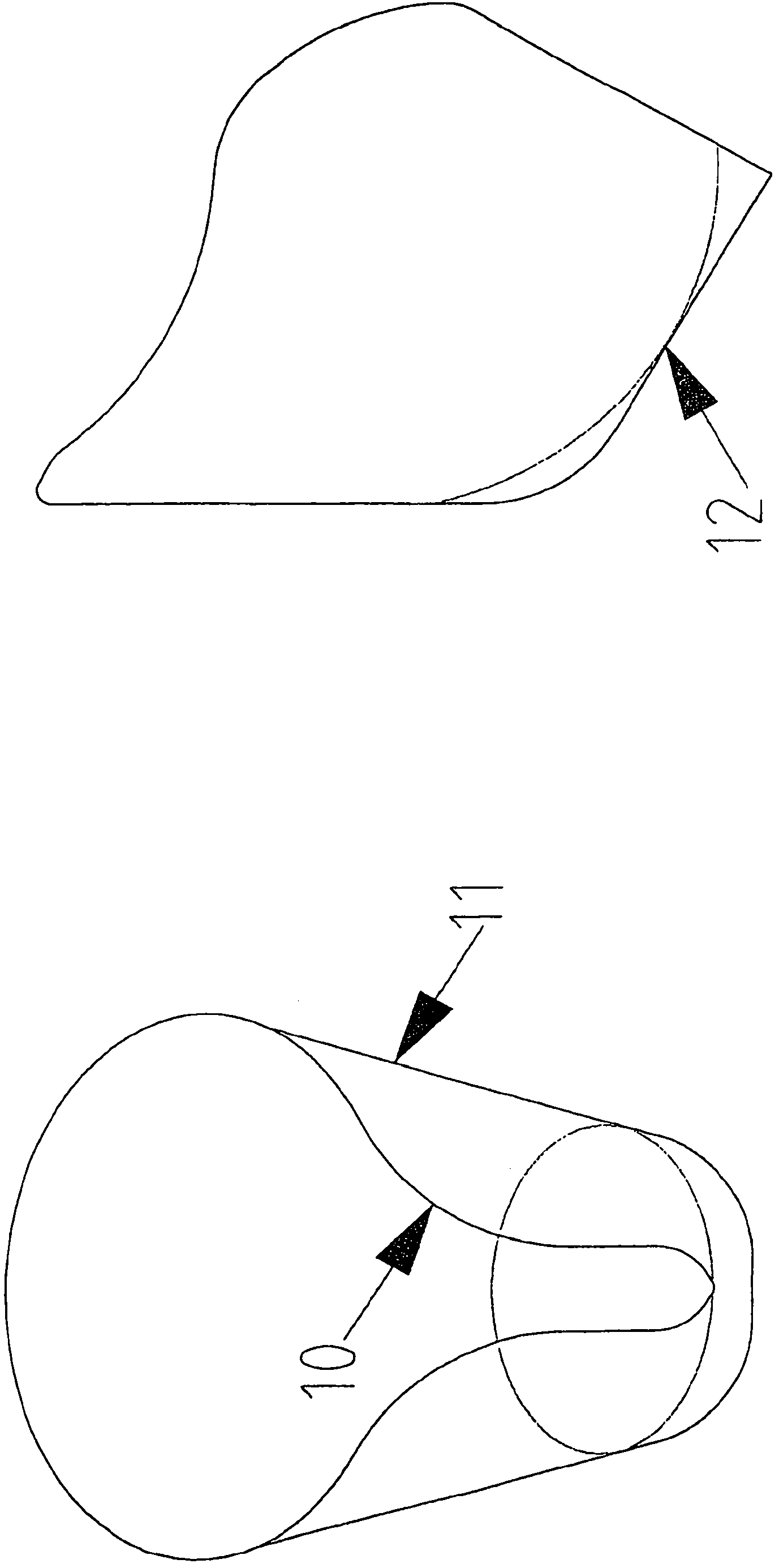

Procedure for electro-stunning and/or electro-sacrifice, for industrial application to marine inchthyological species in floating cages

InactiveUS6453596B1Acceleration in autolytical spoliationIncrease bacterial degradationElectric current slaughtering/stunningFishing netsElectricityEngineering

Procedure for electro-stunning and / or electro-sacrifice, for industrial application to marine ichthyological species in floating cages having a floating cage (12) with tuna fish (6) two divers are introduced, the hunter (1), who uses a rifle with a harpoon with a Teflon head and metallic tip (4), joined to equipment for transforming electric potential (3) on the boat (7) and also connected to a plate (5) submerged and the controller (2) that activates the equipment (3), which sends an electric stunning signal or a signal that kills the fish (6) to the two terminals of the plate (5) and tip (4), the fish is lifted from the water by the crane (10), and equipped with a collar or identifying plastic label (11), the rifle and the harpoon are recovered towards the boat (7).

Owner:GINES MENDEZ ESPANA

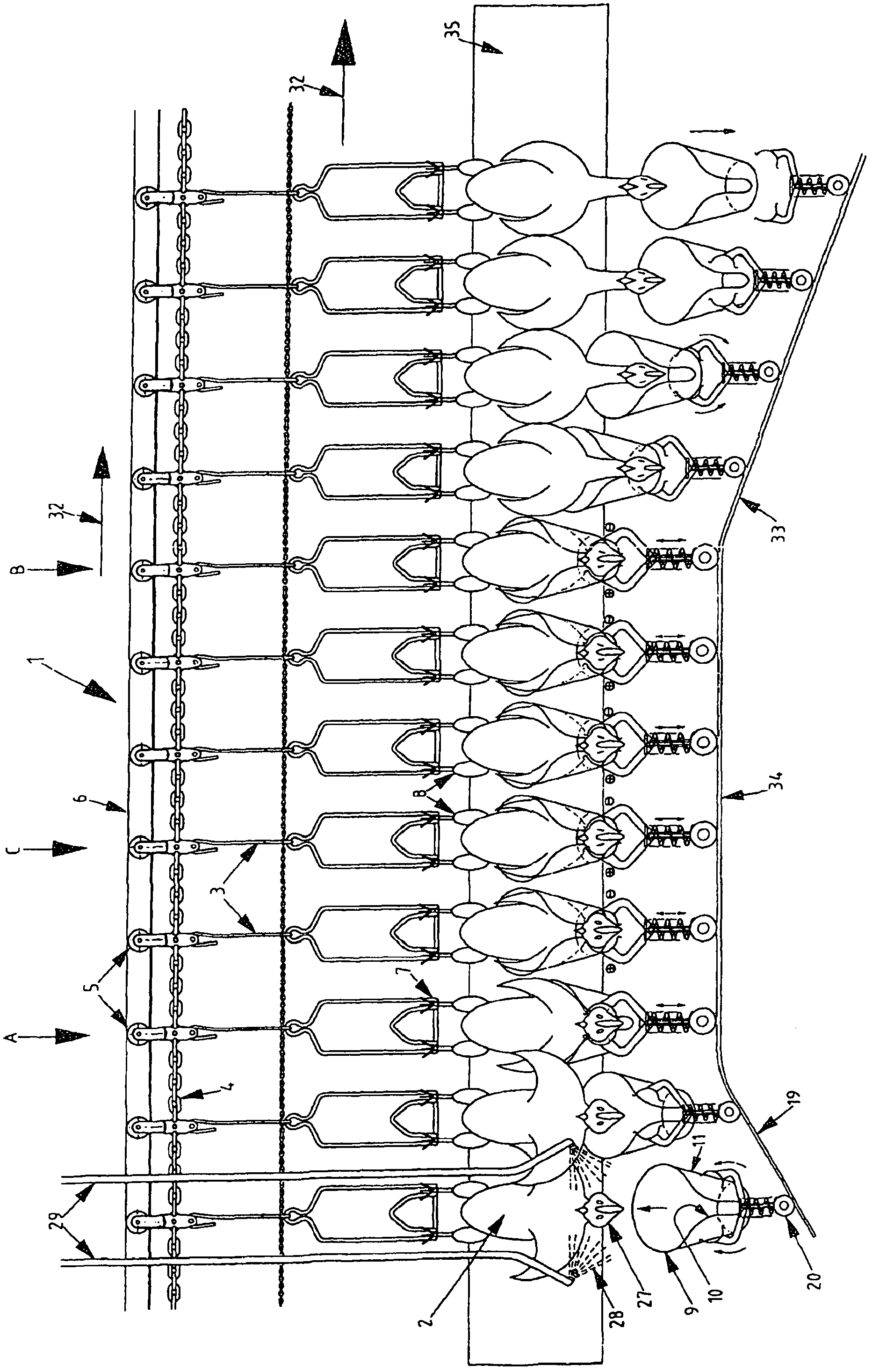

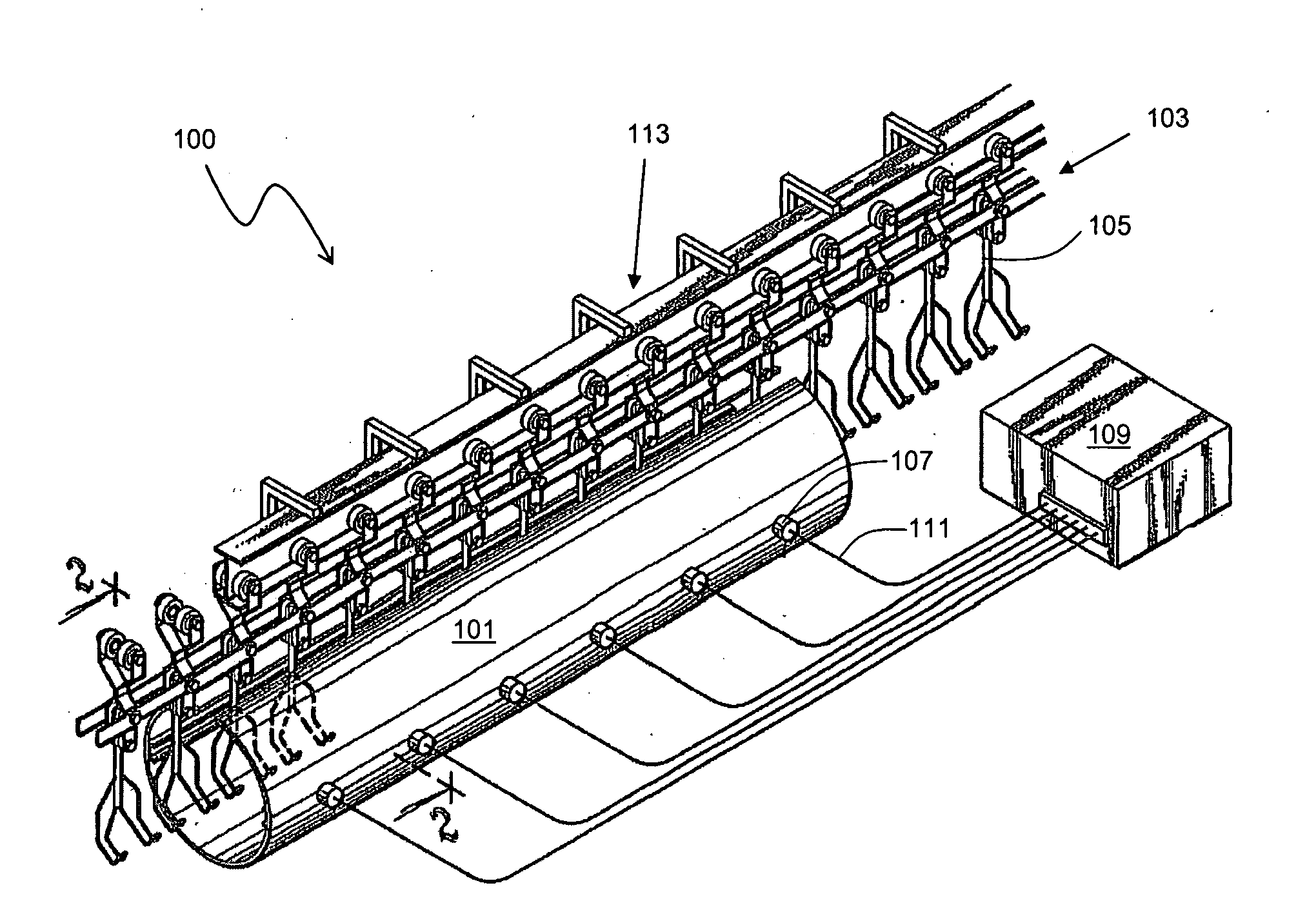

Method and installation for stunning poultry and the obtainable bleeded poultry

InactiveCN102480975AElectric current slaughtering/stunningPoultry/fish slaughtering/stunningBiologyMechanical engineering

The invention relates to a method and installation for stunning poultry, such as chicken, turkey, duck and quail, comprising the steps of : i) suspending the poultry with the poultry head down; ii) positioning the suspended poultry head; and iii) stunning the poultry via the suspended and positioned poultry head, and to obtainable debleeded poultry.

Owner:TOPKIP

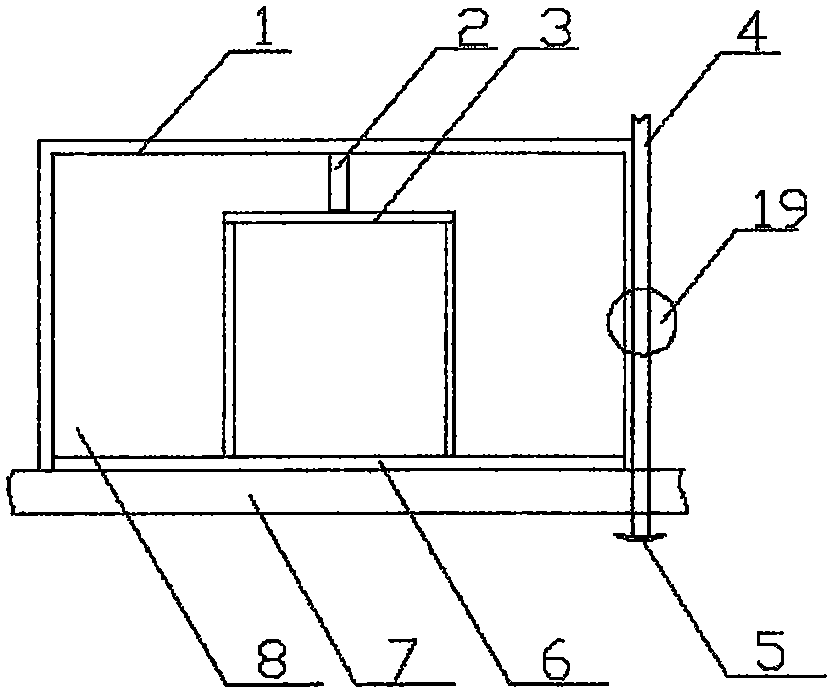

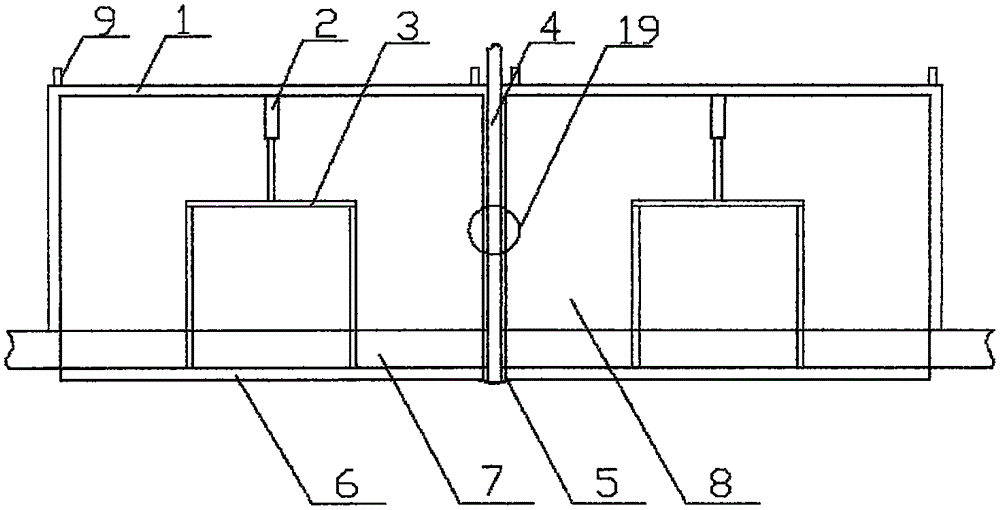

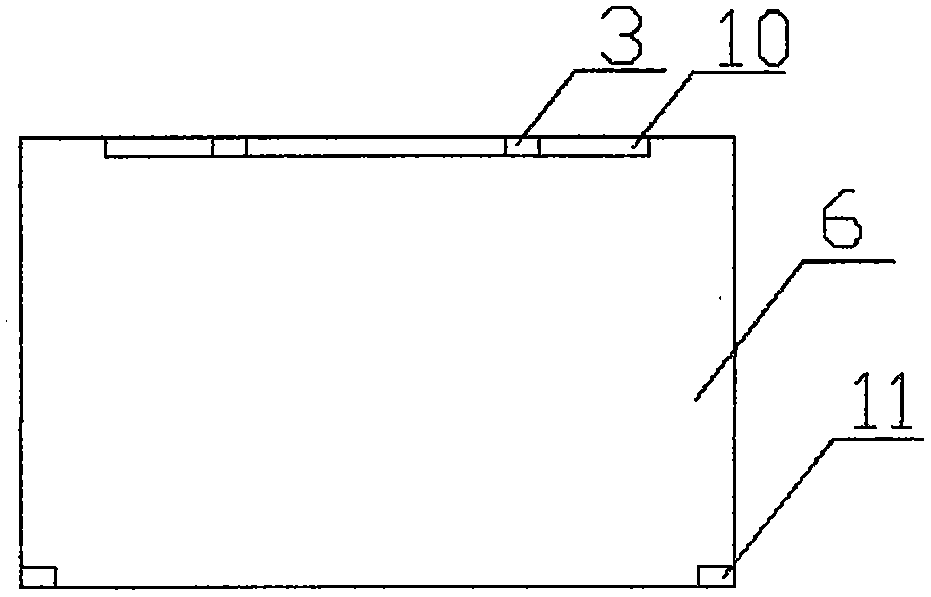

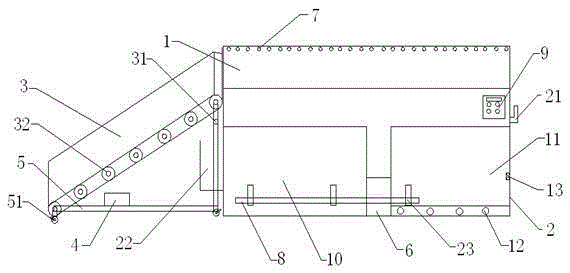

Cage device convenient for enabling chicken flocks to go out of cage and making preparations before slaughtering

ActiveCN105557554AReduced Chances of ContaminationSimple structureBiocideElectric current slaughtering/stunningEngineeringPollution

The invention provides a cage device convenient for enabling chicken flocks to go out of a cage and making preparations before slaughtering. The cage device comprises a frame, the cage and an egg conveying belt, wherein the cage adopts a cubic structure composed of a front side plate, a back side plate, a bottom plate, an upper side plate and two side plates; an air pipe is arranged at the lower part of a liquid inlet pipe on the corresponding side plate; the liquid inlet pipe is in threaded connection with a medicine pot; a collection conveying belt is arranged at the end part of the egg conveying belt; a corona device and a counter are arranged on the collection conveying belt; telescopic rods are arranged on two side walls of the corona device and driven by oil cylinders; enclasping plates are fixed at the end parts of the telescopic rods; the enclasping plates are arc-shaped plates and sponge layers are bonded in the enclasping plates; an infrared detection head is fixed on the upper wall of the corona device; the bottom of the corona device virtually presses the collection conveying belt; a rubber pipe is connected between the upper part and the bottom of the corona device in an insertion manner; a spring is connected to the exterior of the rubber pipe in a sleeving manner; and a corona head is fixed at the end part of the rubber pipe. The cage device is simple in structure and convenient to use, and has a chicken output effect; and chicken bodies and the empty cage are synchronously disinfected during chicken output, so that the probability of pathogenic bacterium pollution can be reduced and the preparations before slaughtering can be made.

Owner:HEILONGJIANG POLYTECHNIC

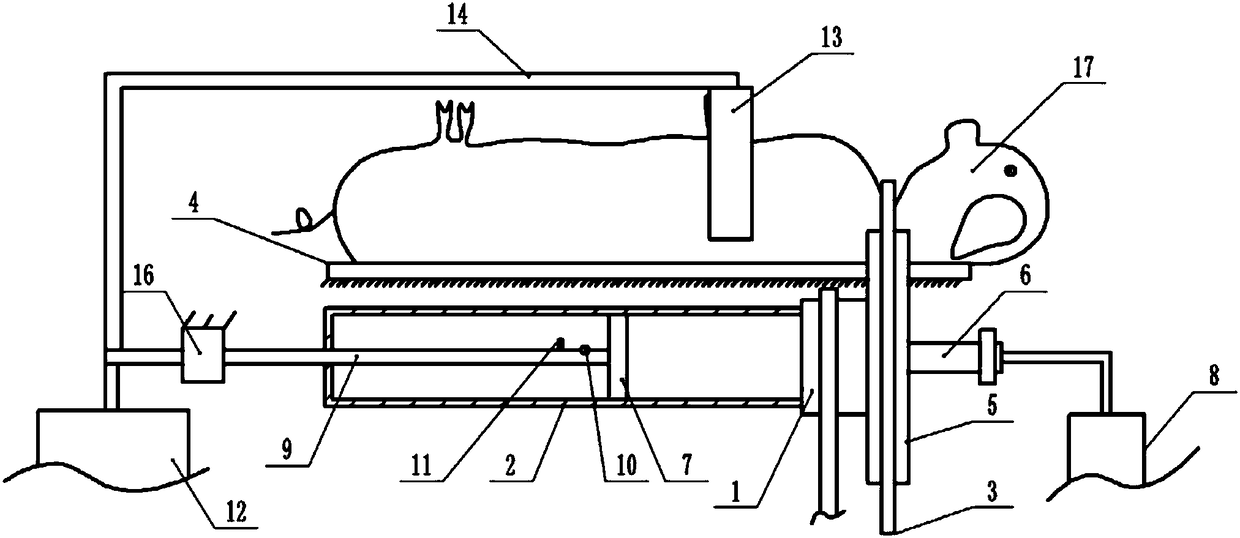

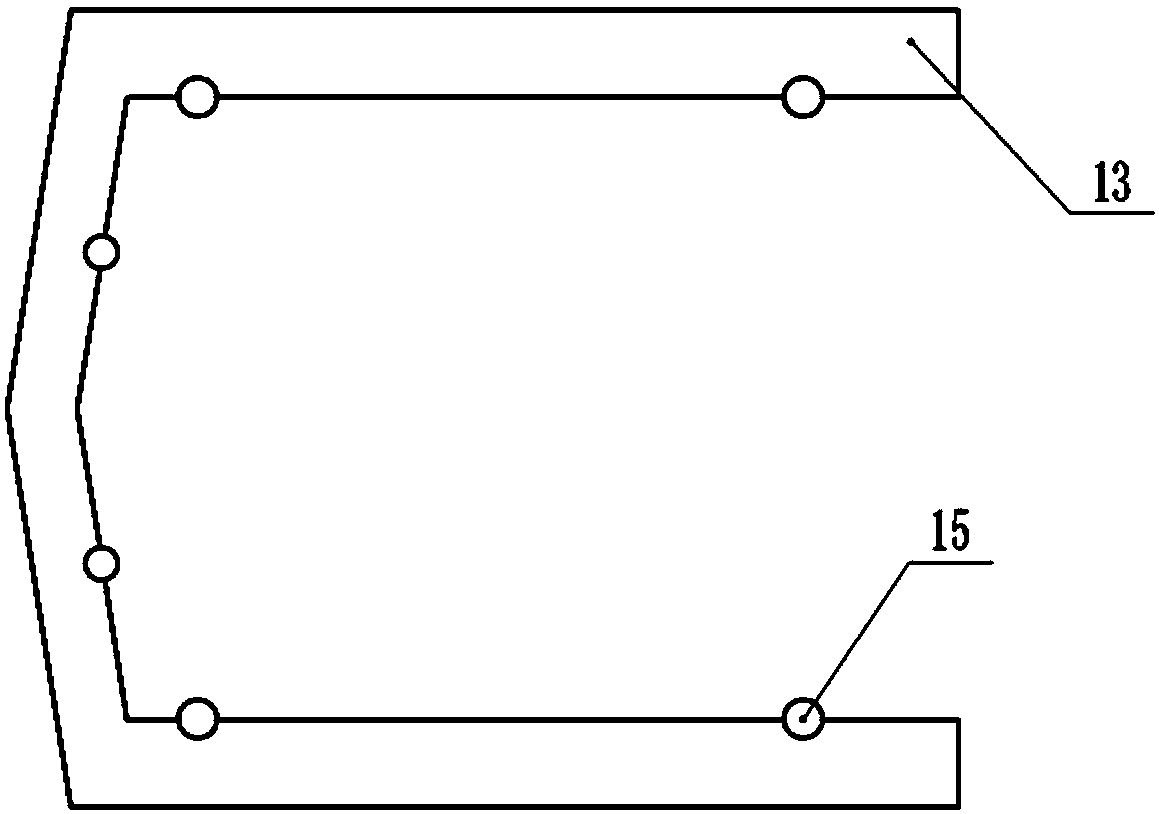

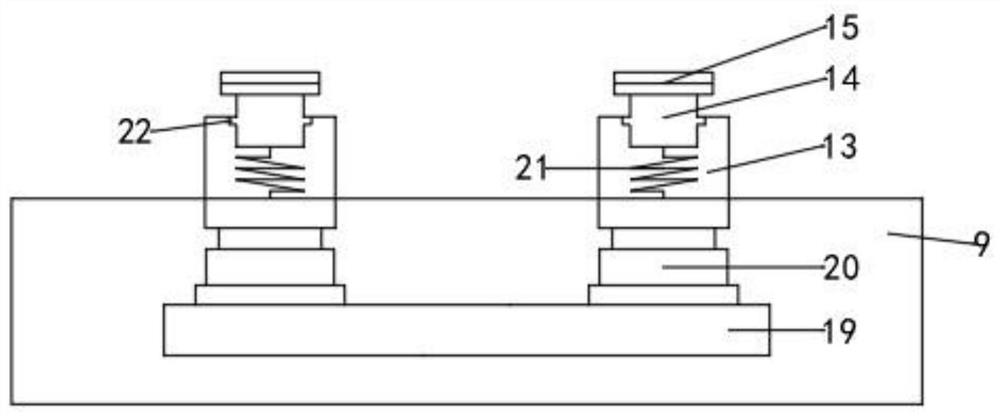

Harmless ecological live pig slaughtering equipment

PendingCN108338200AAvoid hair removal proceduresAvoid pollutionElectric current slaughtering/stunningBlood collection/stirring apparatusMotor driveBlood pump

The invention relates to the field of livestock slaughtering equipment, and particularly discloses harmless ecological live pig slaughtering equipment. The harmless ecological live pig slaughtering equipment comprises a machine frame, a motor, a belt pulley which is transmitted by a motor driving belt, a blood pumping and exhausting cylinder which is fixedly connected to one end of the belt pulley, and a slaughtering saw which is fixedly connected to the other end of the belt pulley, wherein a live pig fixing plate is arranged on the blood pumping and exhausting cylinder; a blood sucking cavity is formed in two sides of the slaughtering saw, and communicates with the blood pumping and exhausting cylinder through the belt pulley; a bloodletting pipe communicates with the free end of the blood sucking cavity; a blood pumping and exhausting plate is in threaded connection to the blood pumping and exhausting cylinder; a sliding rod is fixedly connected to one end away from the belt pulley,of the blood pumping and exhausting plate; a hair removing mechanism which can remove hair of a live pig in a sliding manner is connected to the free end of the sliding rod; a plurality of blood sucking openings are formed in the blood sucking cavity in the circumferential direction; and one-way valves are respectively arranged at joints of the bloodletting pipe and the blood sucking cavity and the blood sucking openings. Through the adoption of the harmless ecological live pig slaughtering equipment disclosed by the invention, movements of blood pumping and hair removing can be performed atthe same time; and blood sucking is started to perform when the artery of the live pig is just split, so that pollution and waste of pig blood are avoided, and the collection of blood is reinforced.

Owner:习水德康农牧有限公司

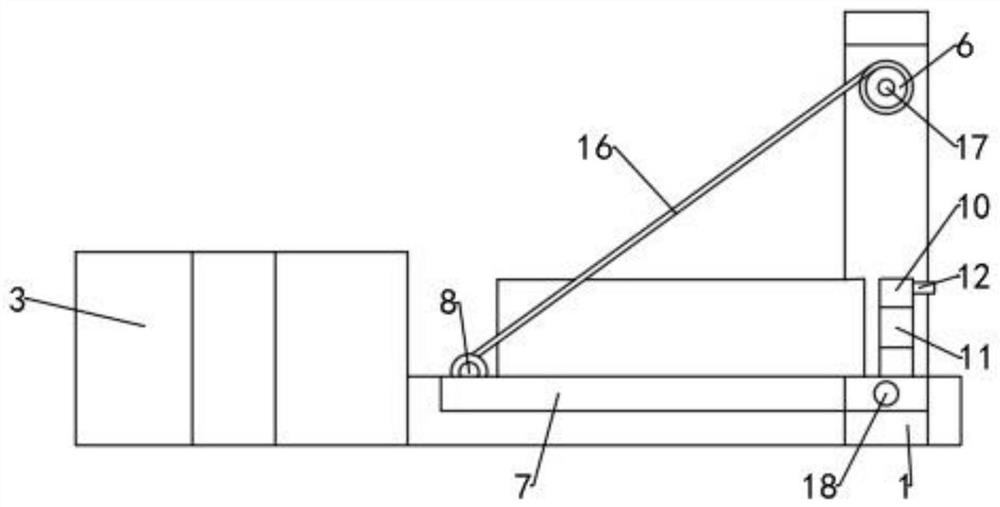

Live pig slaughter operating platform

InactiveCN105285038ASave human effortClean upElectric current slaughtering/stunningSlaughterhouse arrangementsMicrocontrollerAgricultural engineering

The present invention discloses a live pig slaughter operating platform which includes a hollow base, a cold water tank is arranged inside the left side of the hollow base, a water pump is arranged on the right side of the cold water tank, a boiling water tank is arranged on the right side of the water pump, a spraying device is arranged on one end of a table-board, the spraying device is electrically connected with the water pump, the water pump is electrically connected with a controller, the spraying device is connected with the cold water tank and the boiling water tank through water pipes, heating pipes are arranged at the bottom of the boiling water tank, a temperature sensor is arranged on the right side of the inner wall of the boiling water tank, the heating pipes and the temperature sensor are electrically connected with the controller, a conveyer belt is arranged on the left side of the base, brackets are arranged on both ends of the conveyer belt, a motor is arranged on the bracket, and the controller is electrically connected with the water pump, a temperature detecting module, a spraying module and a heating module through a single chip micyoco. The live pig slaughter operating platform is labor-saving, easy to wash and clean pig hair and less in water consumption, is health and safety, and can be operated by one person.

Owner:CHONGQING MINGGAO FOOD CO LTD

Slaughtering equipment

InactiveCN111838266AEasy accessEasy to fixElectric current slaughtering/stunningBlood collection/stirring apparatusEngineeringMechanical engineering

The invention relates to slaughtering equipment, which comprises a base, the base is movably connected with a workbench through an assembly shaft, one side of the base is fixedly connected with an inclined table, the highest point of the inclined table is flush with the base, and the two sides of the inclined table are fixedly connected with bent baffle plates; a fixing mechanism is arranged on the workbench, and a turnover mechanism is connected between the workbench and the base. According to the slaughtering equipment, a suspension pin is arranged on one side of a slaughtering table, so that the head of a live pig extends into the through hole autonomously, and fixation of the live pig is facilitated; an clamping air cylinder is used for controlling an arc-shaped current plate to stretch out and draw back, corona and fixation of live pigs are facilitated, and therefore the live pigs are prevented from struggling during slaughtering and affecting cutting of operators; a turnover shaft is connected with a lifting hook, so that the turnover shaft is conveniently driven to turn over slaughtered live pigs by a specified angle, unified recovery of pig blood is facilitated, the live pigs can conveniently walk to the workbench through the inclined table by arranging the uniform anti-skid lines on the inclined table, and the slaughtering efficiency is improved.

Owner:沈飞红

Electromuscular incapacitation device and methods

InactiveUS7736237B2Less chance of permanent nerve and muscle injuryEffective and enhanced incapacitationClubsElectric current slaughtering/stunningEngineeringMuscular Contractions

Incapacitation of a mammalian subject results from the application of a pulsed, low-power electric waveform. The waveform is applied to the subject at a frequency and over a time period sufficient to induce involuntary muscular contraction. Additionally, the contraction causes limited lactic acid production and is non- or minimally-injurious to the subject's tissues. A device utilizing such a waveform is designed to control or otherwise subdue an individual.

Owner:AEGIS IND INC

Microwave poultry processing device and method

ActiveUS20070254573A1Fish washing/descalingPoultry plucking mechanismsRadio frequencySquare Centimeter

The invention relates to a method for loosening the feathers of a fowl prior to killing and processing, by exposing the fowl to a radio frequency source producing a frequency from between approximately 5 GHz and approximately 40 GHz, with an average power density from between approximately 10 mW per square centimeter and approximately 100 mW per square centimeter, for a predetermined period of time. The invention also relates to a method for killing bacteria on the fowl prior to killing and processing.

Owner:HORST DREW +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com