Slaughtering and producing technology of safety pigs

A production process and safe technology, applied in the direction of slaughtering, slaughtering accessories, slaughtering devices, etc., can solve the problems of large thermal energy retention, safe pork and pork are not delicious, etc., achieve the effect of small product loss, reduce heat, and reduce the formation of frost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

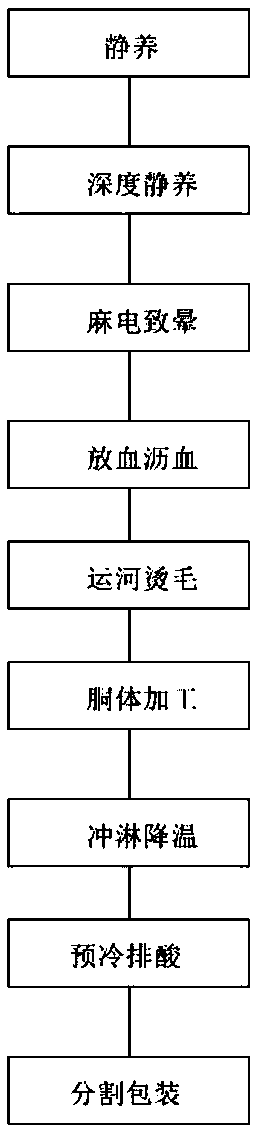

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 A safe pig slaughtering production process, comprising the following steps:

[0021] a. Resting: the pigs to be slaughtered are fed and rested for 9-21 hours, and then stopped for 3 hours, and the food is only drinking water;

[0022] b. Deep resting: After the pigs to be slaughtered are resting, rinse them with water for 3-5 minutes; when the deep resting season is summer, the water temperature is 20°C; when the deep resting season is winter, the water temperature is 38°C. ℃;

[0023] c. Electric stun;

[0024] d. Bleeding and bloodletting: the stunned pigs are tied to one hind leg with a buckle ankle chain, and the pigs are lifted into the track of the pigs' bloodletting automatic conveying line through the pig lifting device, and then stabbed with a knife for bloodletting; The time between the end time and the time of killing the pig is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com