Patents

Literature

38results about How to "Does not affect normal processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

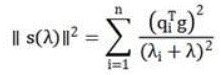

Numerically-controlled machine tool residual life real-time prediction method

ActiveCN108427841ADoes not affect dynamic characteristicsDoes not affect normal processingDesign optimisation/simulationSpecial data processing applicationsNumerical controlPredictive methods

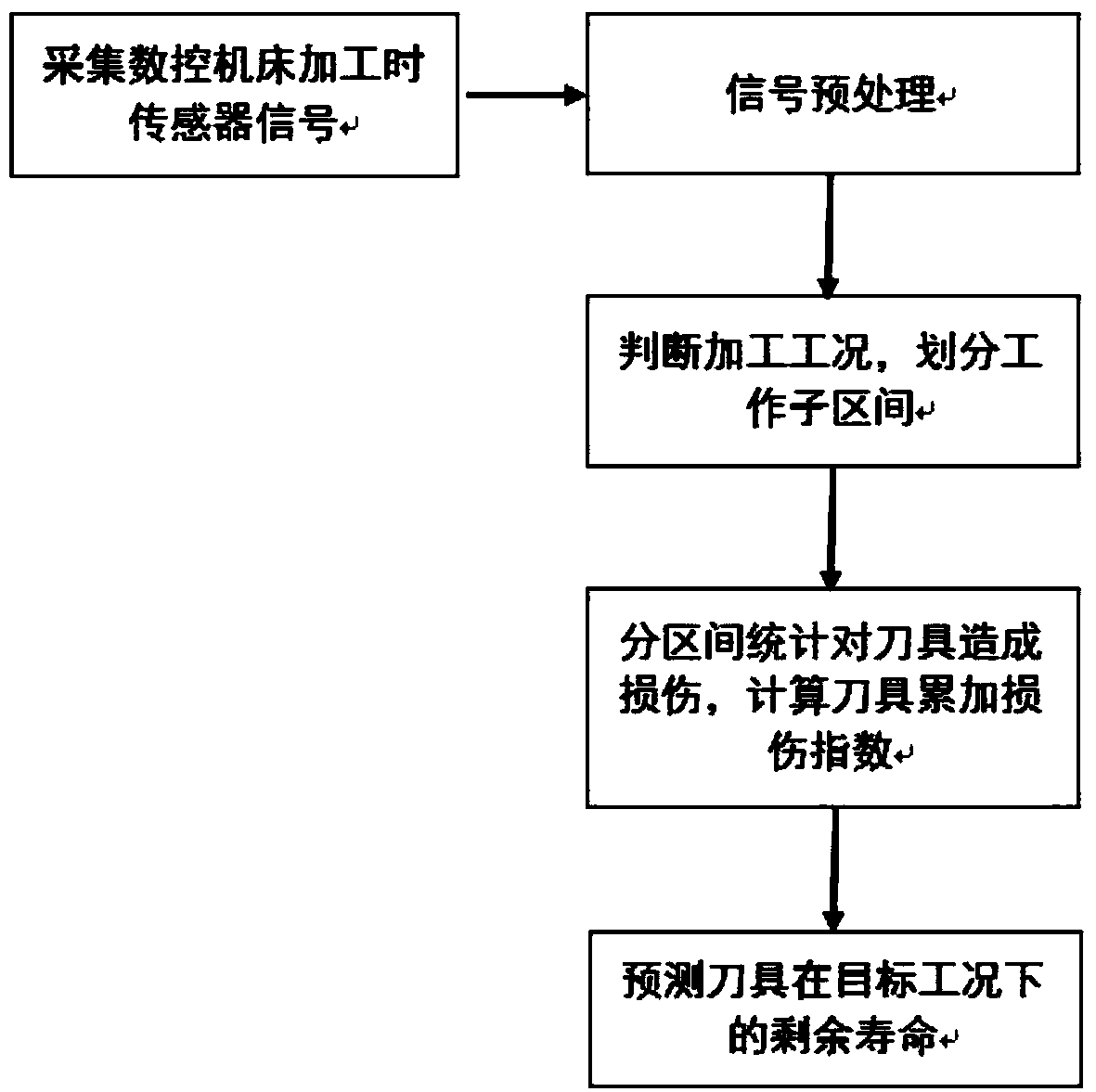

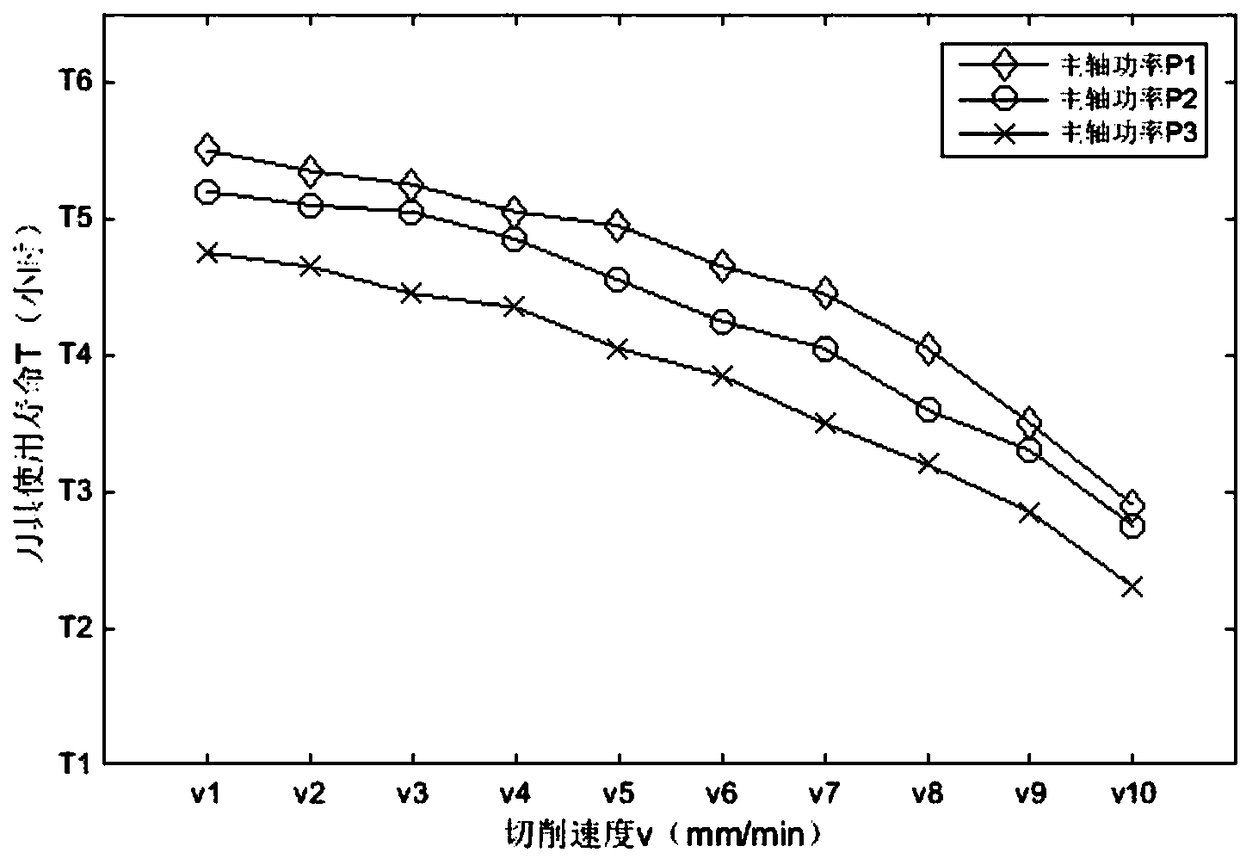

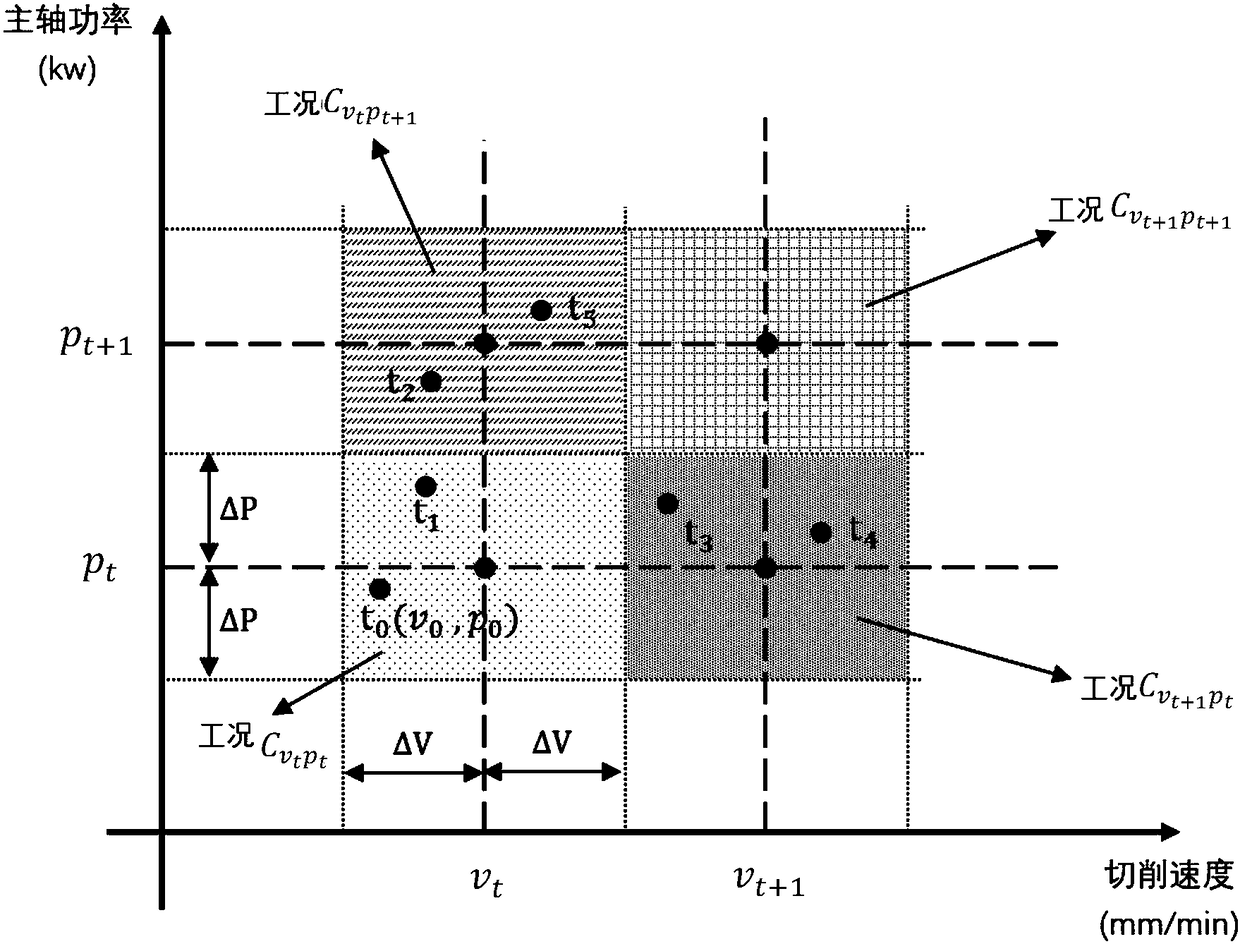

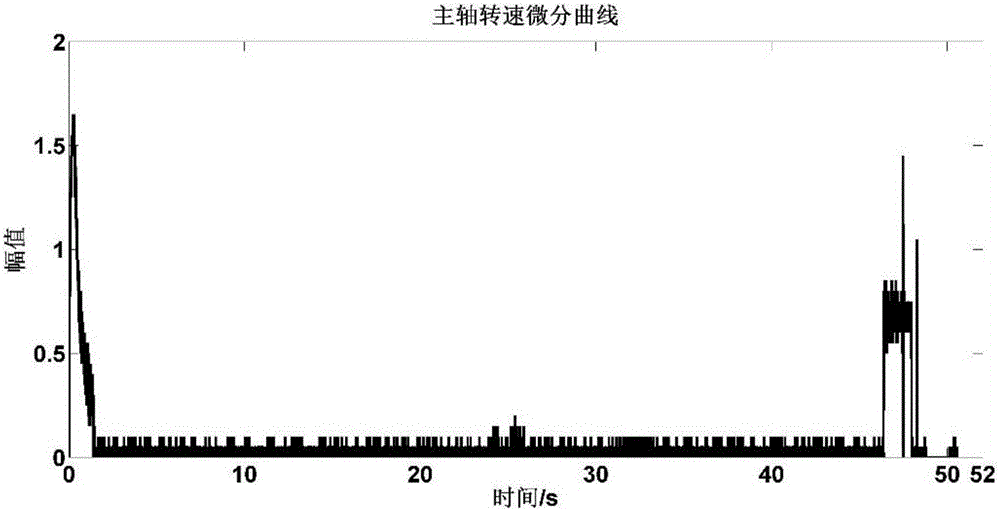

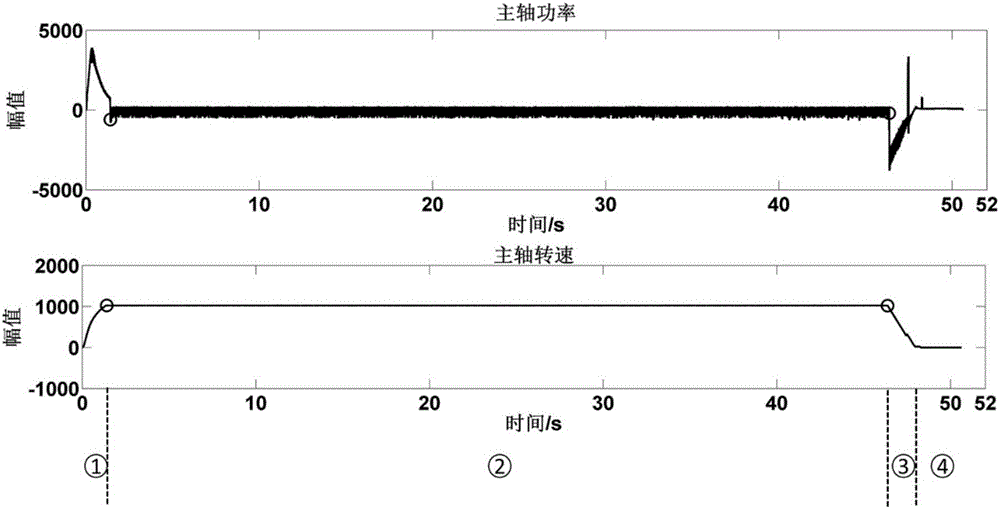

The invention belongs to the field of numerically-controlled machine tool life prediction and particularly discloses a numerically-controlled machine tool residual life real-time prediction method. The numerically-controlled machine tool residual life real-time prediction method comprises the following steps that a sensor signal during machining of a numerically-controlled machine tool is acquiredin real time and is preprocessed; the machining working condition is judged according to preprocessed signal data, and the machining process is divided into working subintervals according to different machining situations; tool damages produced in the working subintervals are accumulated to obtain accumulated tool damage indexes; real-time prediction of the residual life of a tool under the target working condition is achieved according to the accumulated tool damage indexes. The numerically-controlled machine tool residual life real-time prediction method does not need additional experimental platform erection and tool dismounting, does not affect normal machining of numerically-controlled machine tools, can achieve real-time prediction of the residual life of the numerically-controlledmachine tools and has the advantages of high prediction speed and accuracy rate.

Owner:HUAZHONG UNIV OF SCI & TECH +1

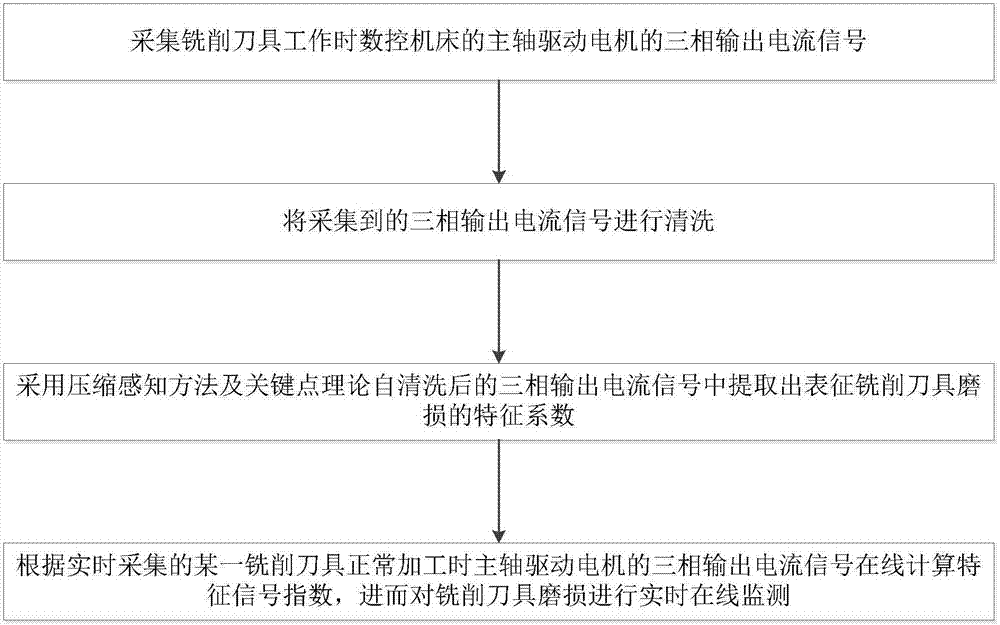

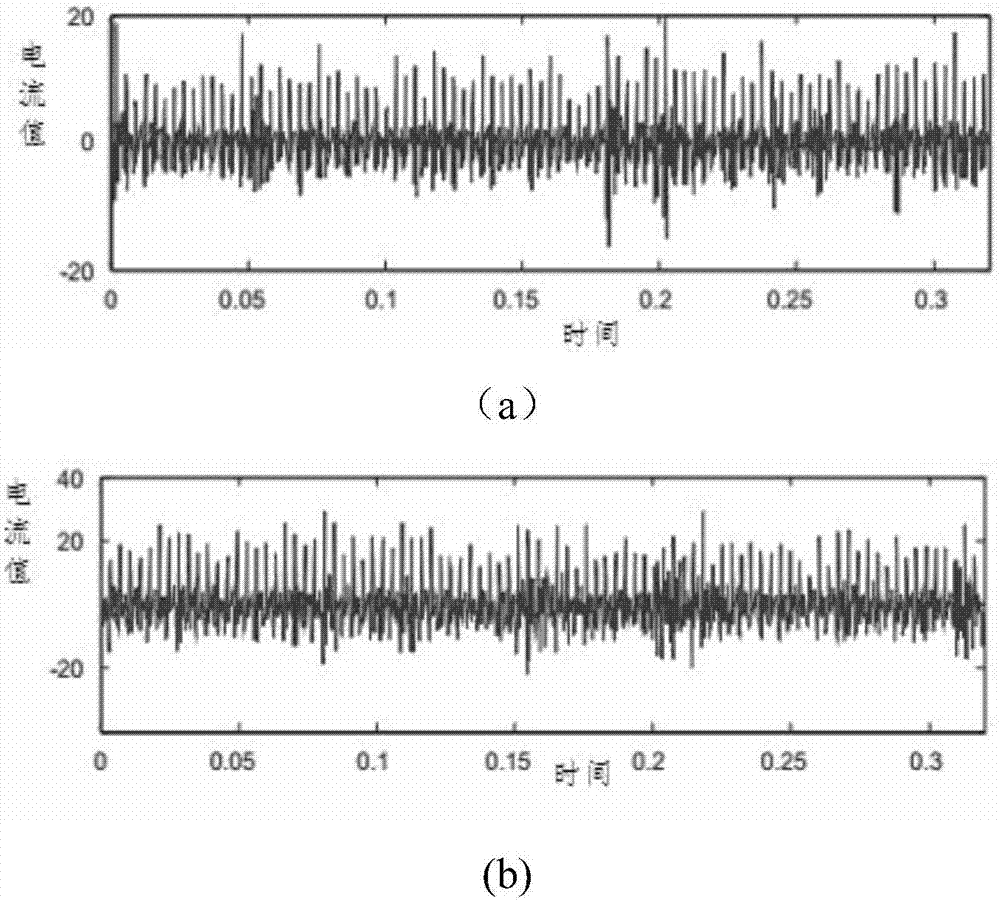

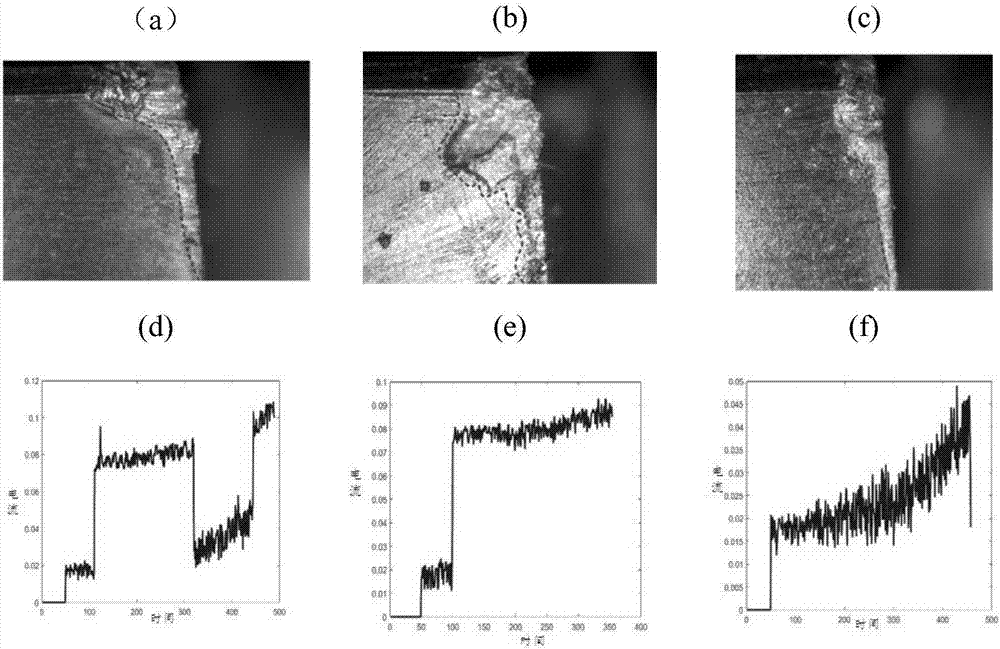

Milling tool abrasion monitoring method based on data

ActiveCN106514434ARealize real-time online predictionRealize real-time life predictionMeasurement/indication equipmentsNumerical controlPower flow

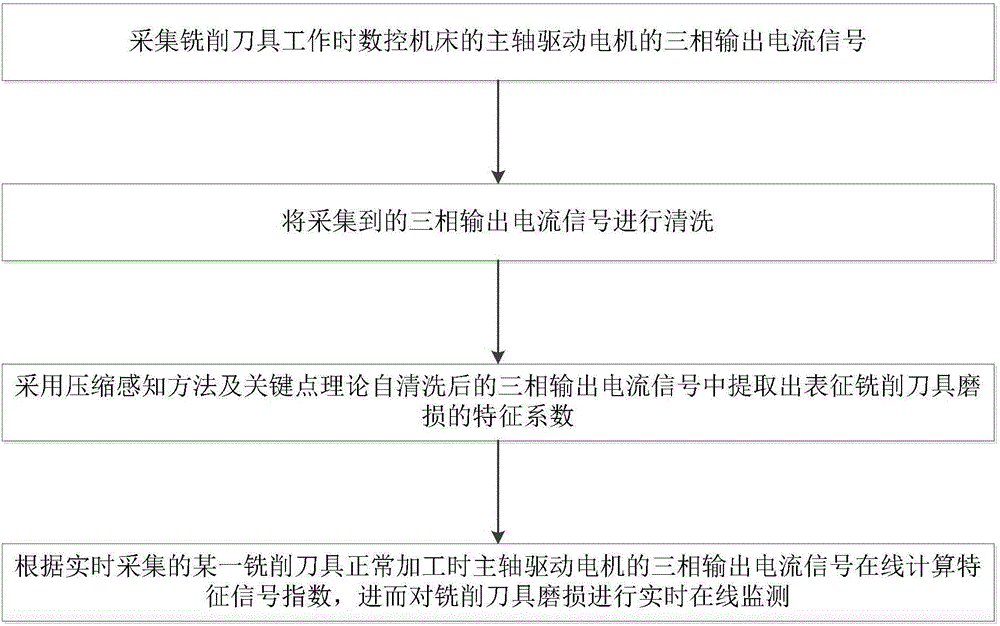

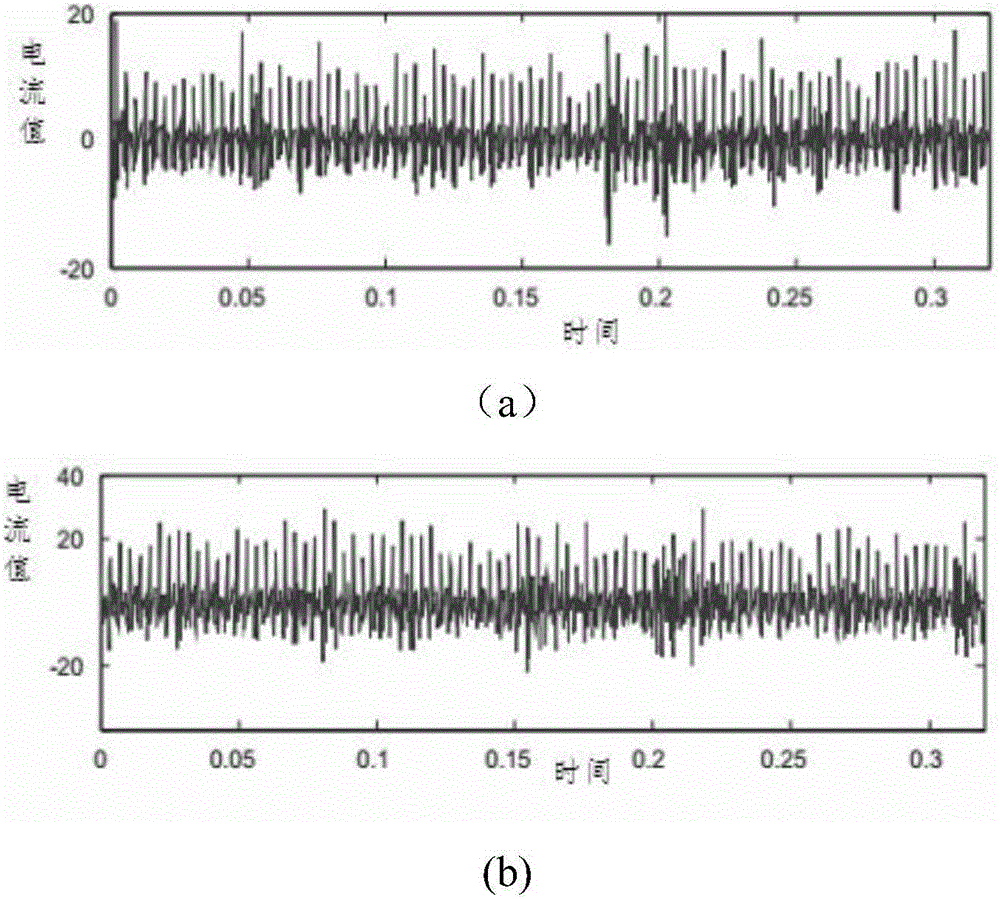

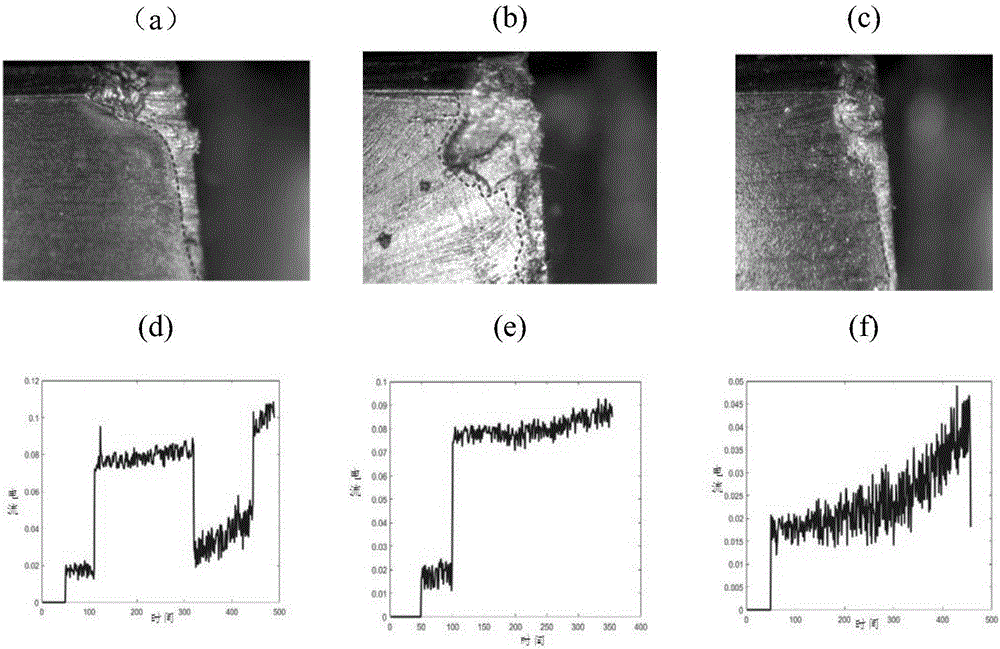

The invention belongs to the technical field relevant to tool abrasion detection and discloses a milling tool abrasion monitoring method based on data. The method comprises the following steps that (1) a three-phase output current signal of a spindle driving motor of a numerically-controlled machine tool during working of a milling tool is collected; (2) the collected three-phase output current signal is cleaned; (3) a characteristic coefficient representing milling tool abrasion is extracted from the cleaned three-phase output current signal through a compressed sensing method and the key point theory; and (4) a characteristic signal index is computed online according to the three-phase output current signal, collected in real time, of the spindle driving motor when a certain milling tool works normally, and thus milling tool abrasion is subjected to real-time online monitoring. Through the provided milling tool abrasion monitoring method based on the data, the cost is lowered, and real-time monitoring of milling tool abrasion is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Cutter breakage detection method based on internal data of numerical control system

InactiveCN106647629AGuaranteed to be authenticLow costProgramme controlComputer controlFeature vectorProduction line

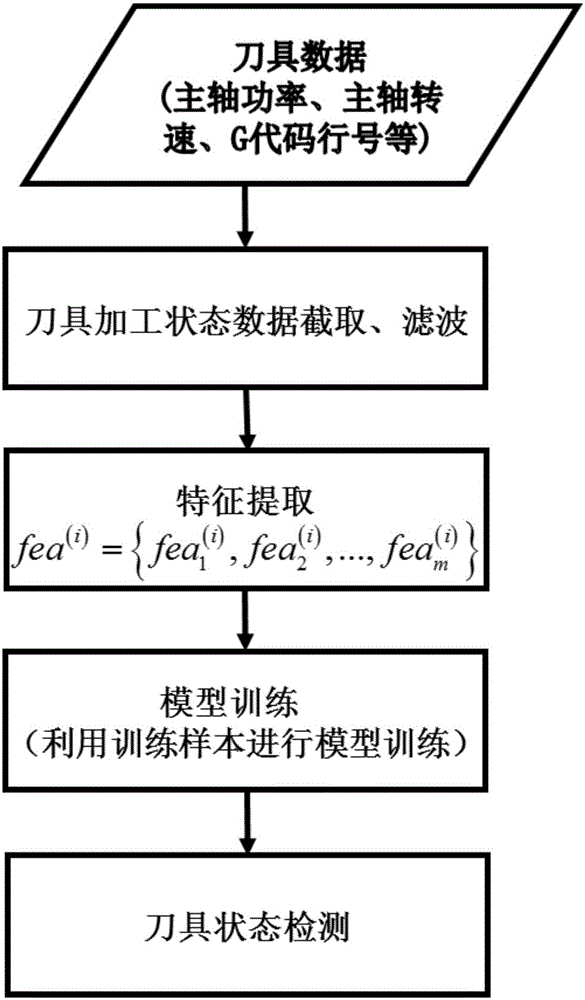

The invention discloses a cutter breakage detection method based on internal data of a numerical control system, comprising the following steps: (1) collecting the internal data of a numerical control system as cutter data, recording manufacturing resource data, and intercepting machining state data from the cutter data and pre-filtering the cutter data to get low-frequency data of cutter machining state; (2) extracting signal features characterizing cutter state according to the low-frequency data of cutter machining state to form a feature vector fea={fea<1>, fea<2>,...,fea<m>}, wherein i is the sample number of cutter data, and m is the number of feature dimensions; and (3) carrying out model training according to the feature vector and a corresponding category thereof to get a training model, judging the state of a cutter according to the training model, and completing cutter breakage detection in this way. A real-time accurate cutter breakage detection function is achieved. Subsequent scraping of cutters and parts is avoided. The first pass yield of products of an automatic production line is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

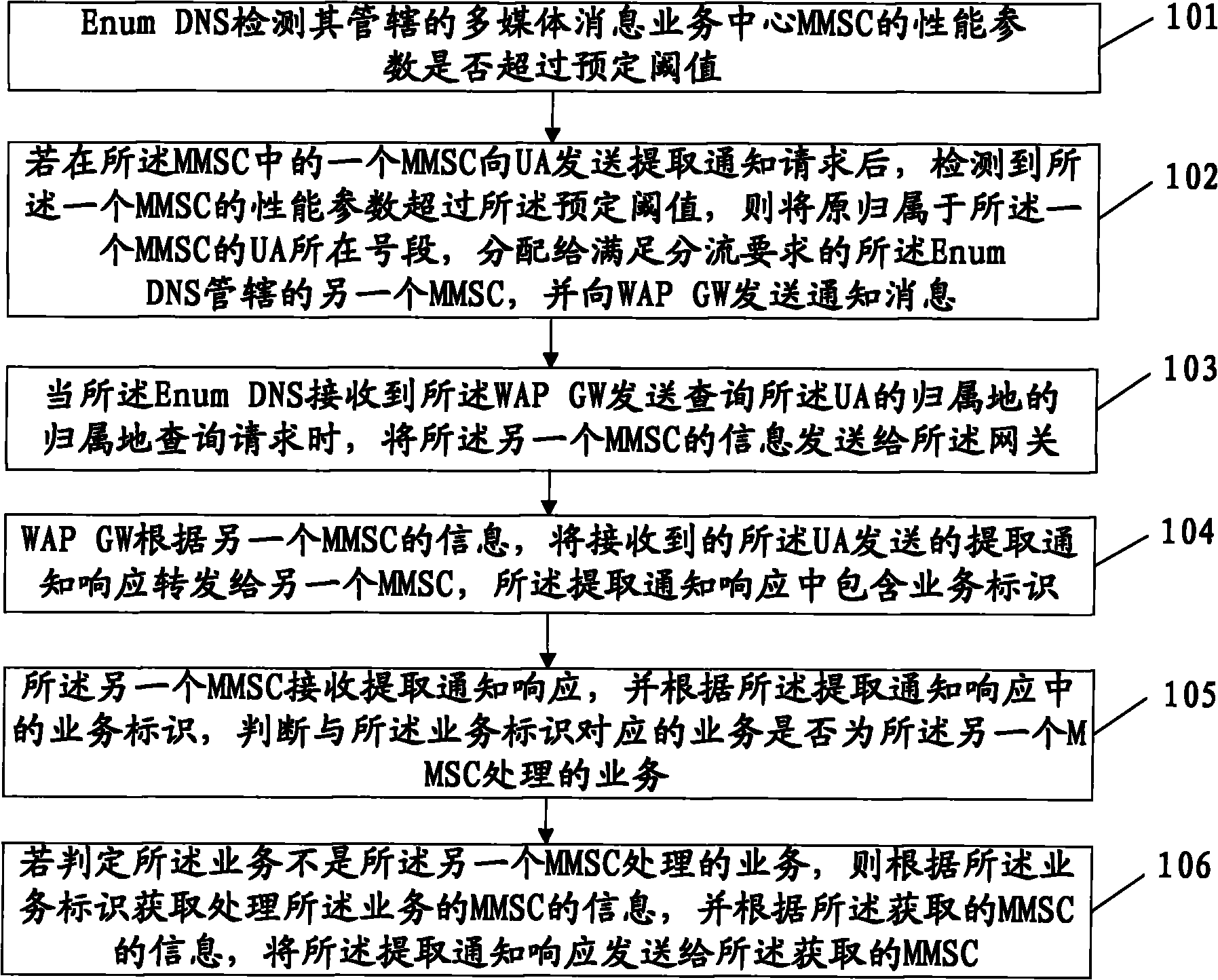

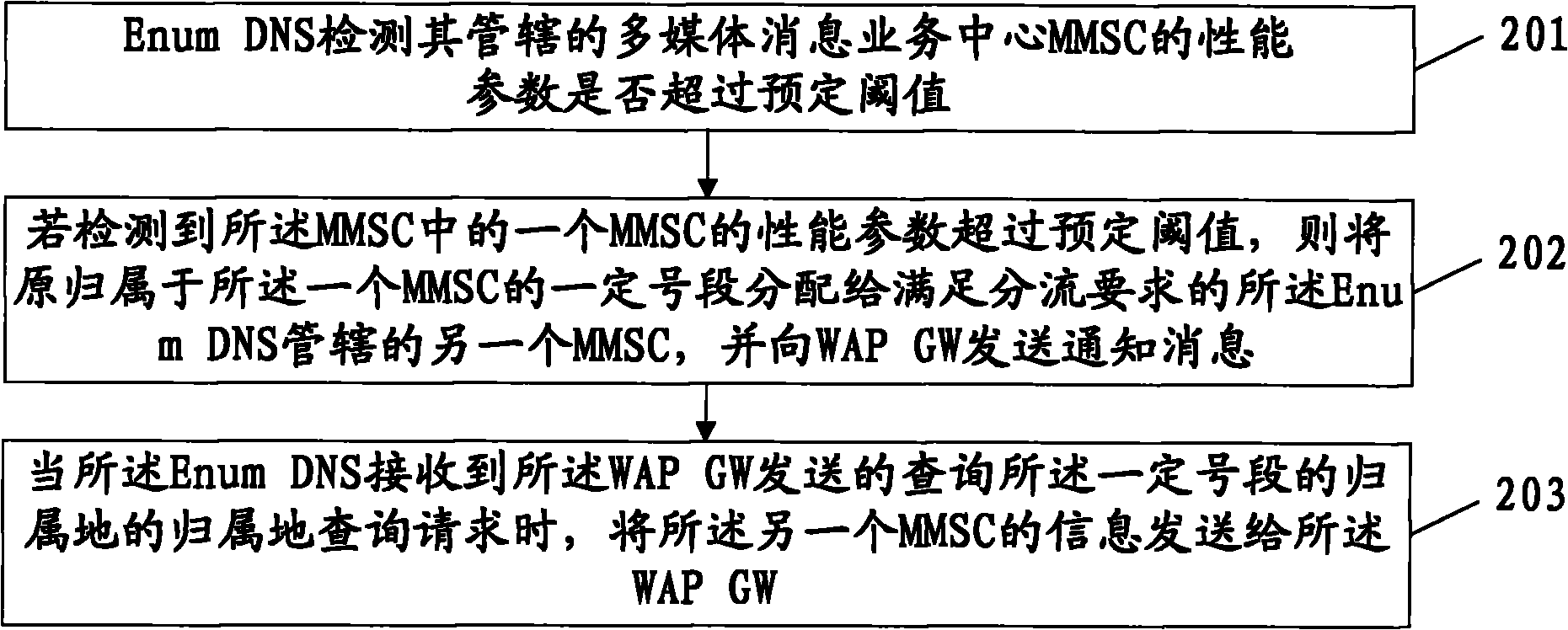

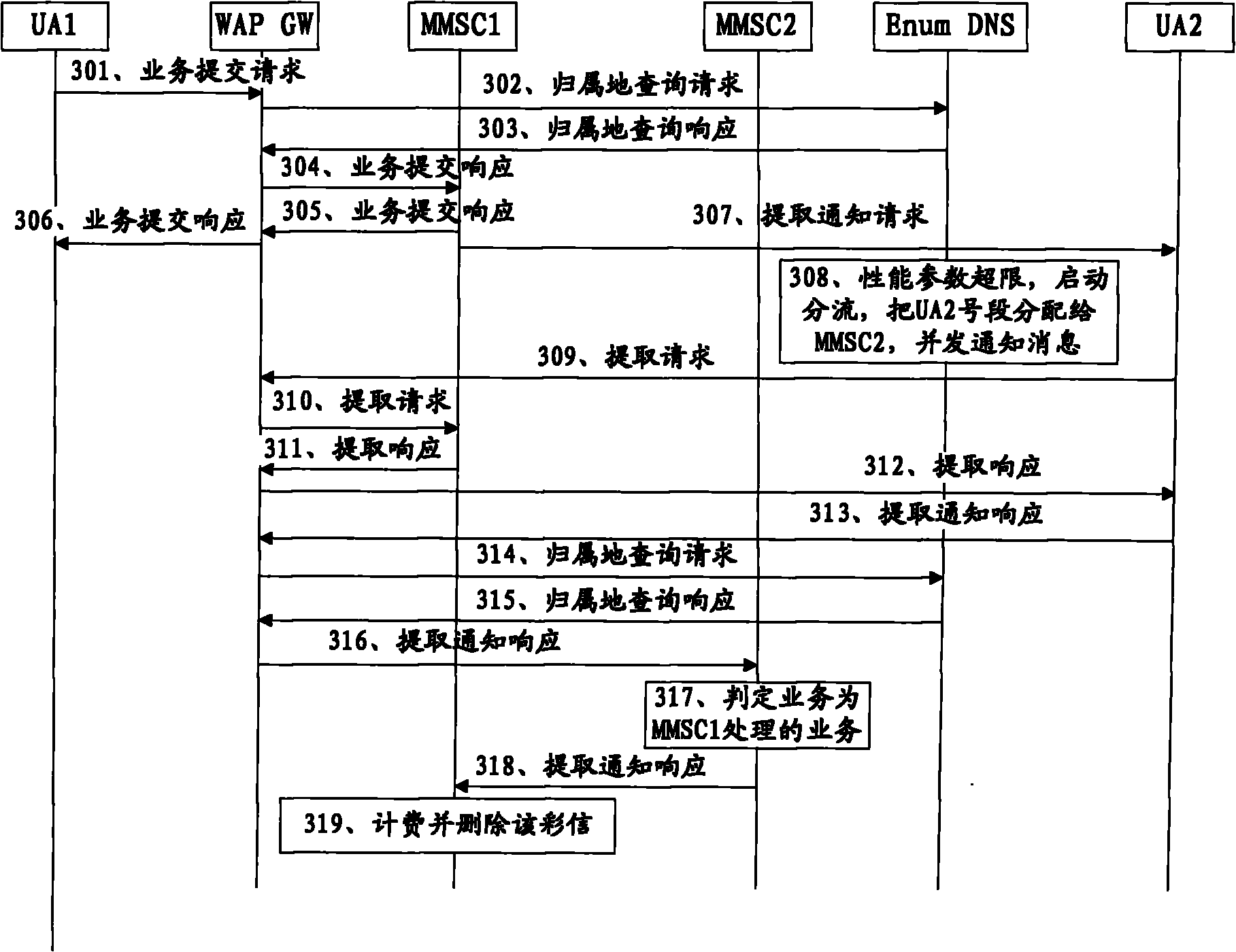

Service shunting method, device and system

InactiveCN101917679ADoes not affect normal processingImprove experienceNetwork traffic/resource managementMessaging/mailboxes/announcementsMultimedia Messaging ServiceService process

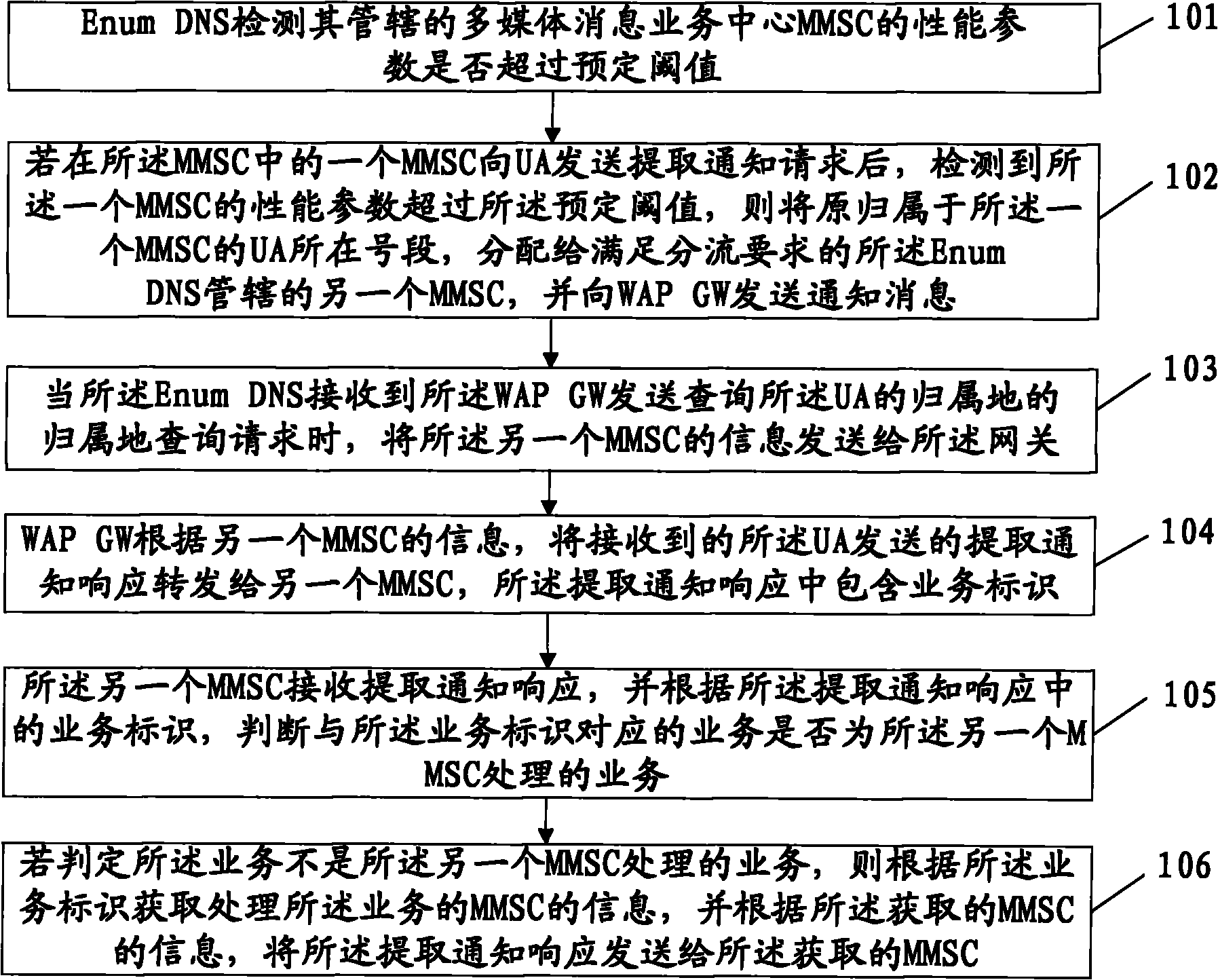

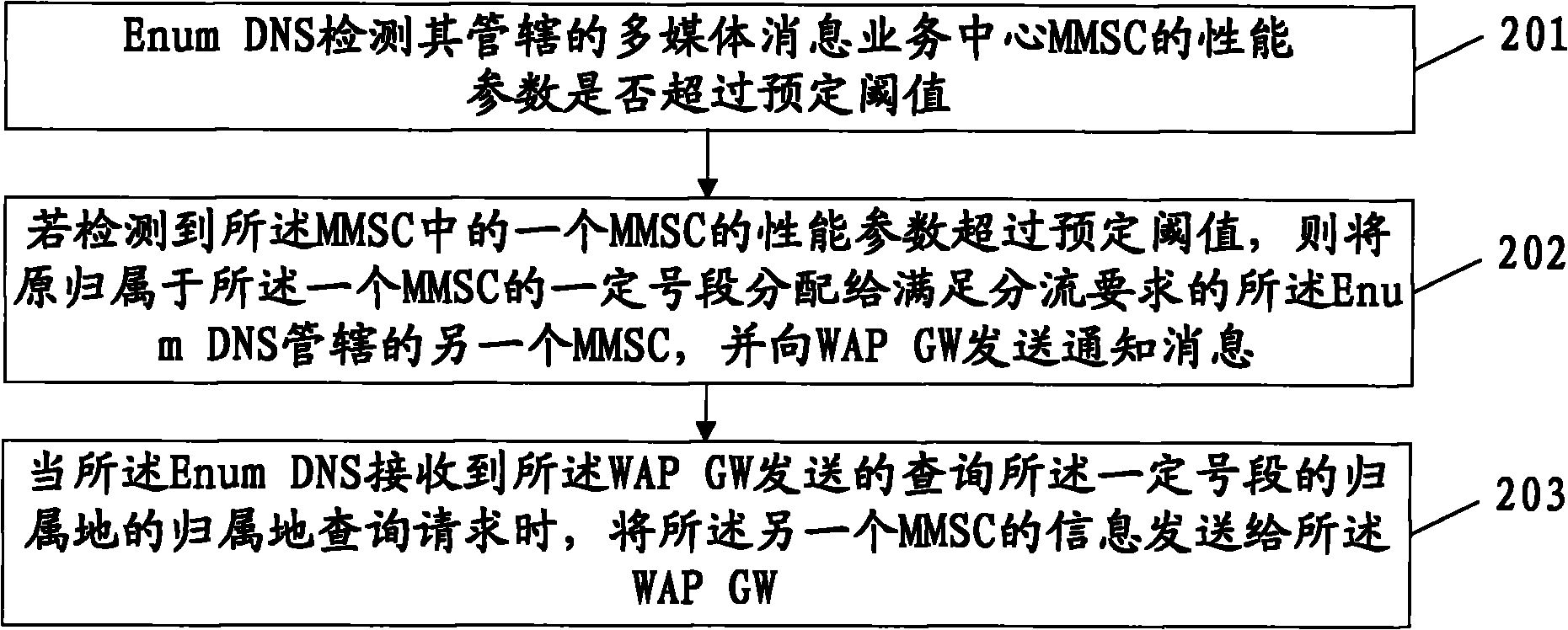

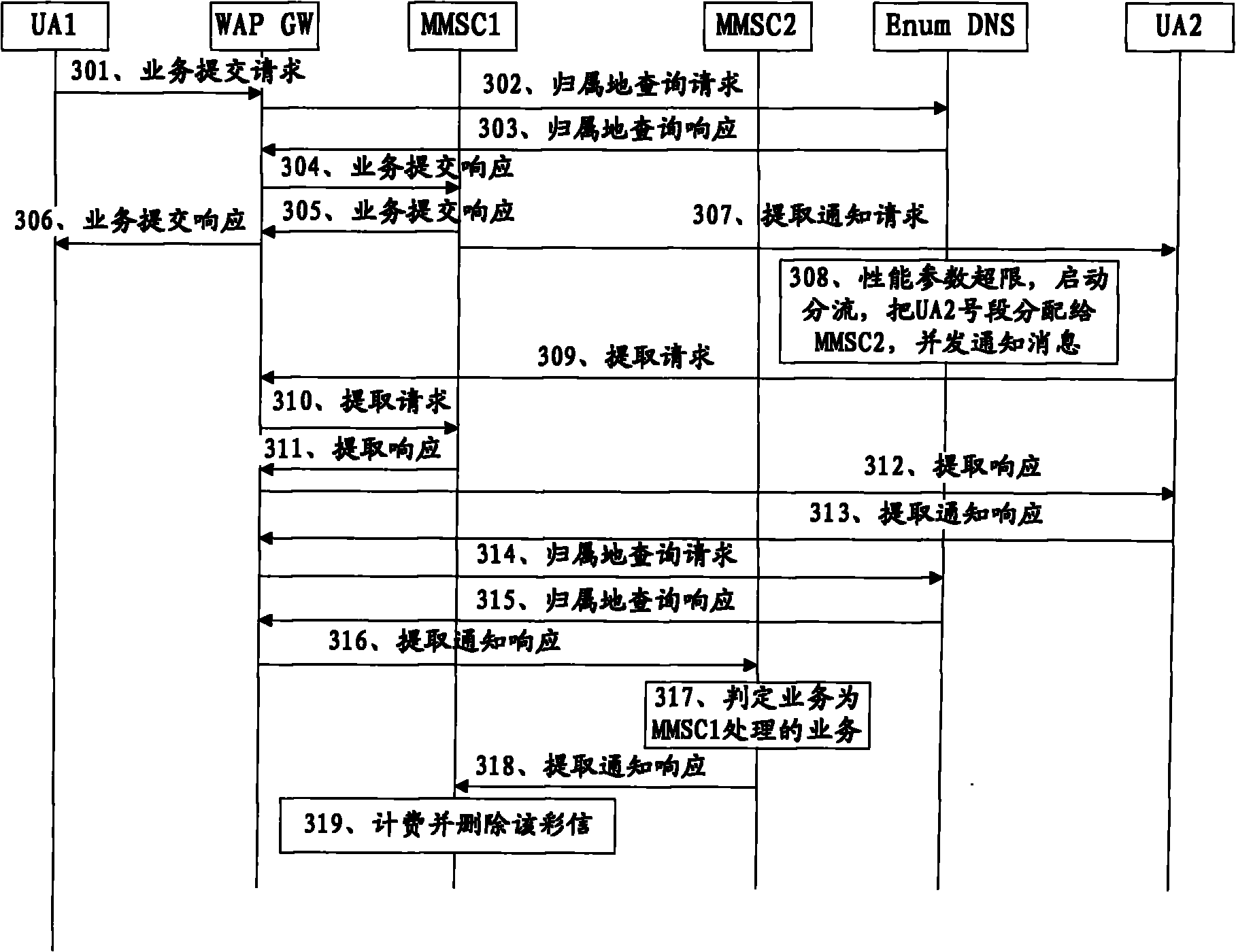

The embodiment of the invention discloses service shunting method, device and system, which relate to the field of communications. When an MMSC (Multimedia Messaging Service Center) is busy, multimedia messages can be implemented and issued; when service is shunted, the normal processing of the service is not influenced, and the user experience is further increased. The method comprises the following steps of: after sending an extraction notice request to a user agent (UA) by the MMSC, detecting that a performance parameter of the MMSC exceeds a predefined threshold by an Enum DNS (Enumeration Domain Name System), distributing UA number segments which belong to the one MMSC to the other MMSC which satisfies a shunting request; sending an extracted notice answer to the other MMSC by WAP GW(Wireless Application Protocol Gross Weight); and sending the extracted notice answer to the MMSC which is used for processing the service by judging the service is not service processed by self of the other MMSC. The embodiment is mainly used for a service shunting process.

Owner:程龙

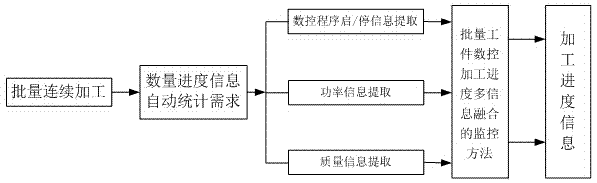

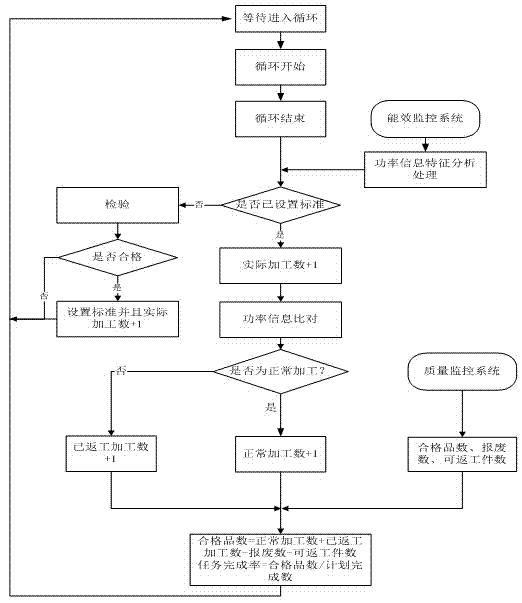

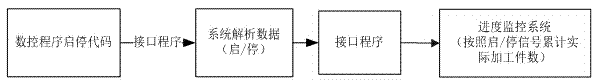

Multi-information fusion based automatic collection method for batched numerical control workpiece machining progress

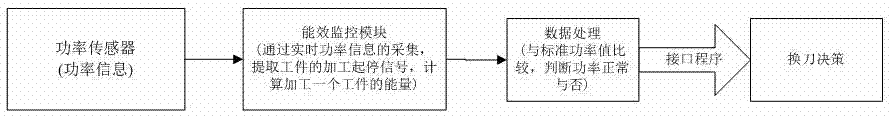

The invention provides a multi-information fusion based automatic collection method for batched numerical control workpiece machining progress. A machine tool numerical control system is connected with a computer terminal through a network cable, and machining start-stop information is read and processed through an interface program; in addition, a power sensor is introduced in between a machine tool motor and a frequency converter, the power sensor is connected with the computer terminal through an analog / digital conversion module to acquire real-time power information during machining; the power sensor acquires machining quality information during machining by communicating with a quality inspection system; progress data in the process of machining are acquired according to the machining start-stop information, the real-time power information and the machining quality information and by means of comprehensively processing the information. The method has the advantages of timely feedback, statistical accuracy, rich statistical content and the like, support is provided for improvement of management and control ability of enterprises on production fields and optimized operation of machining workshops, convenience is brought to customers to monitor executive conditions of orders anytime, and service capability for customers is improved.

Owner:CHONGQING UNIV

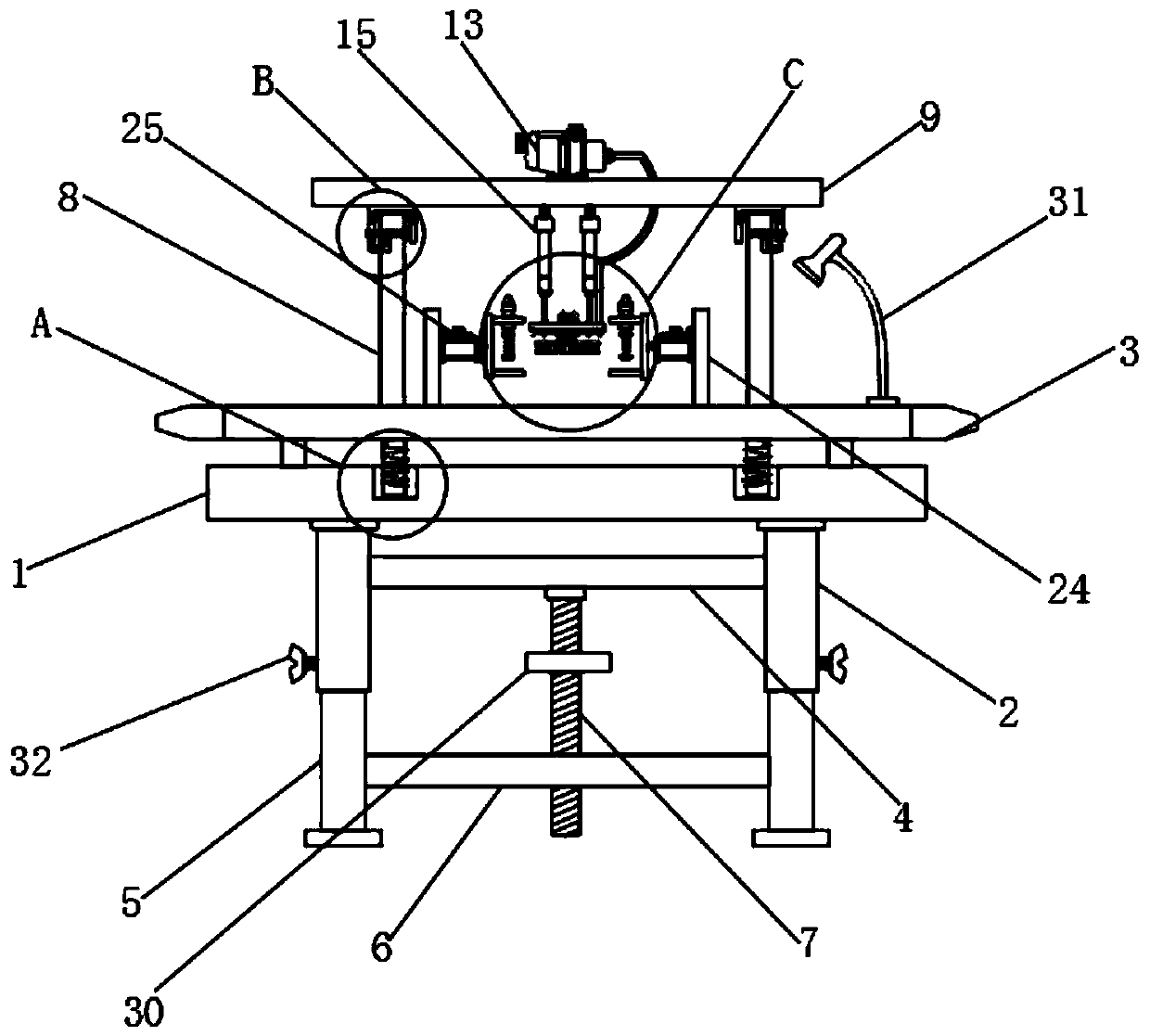

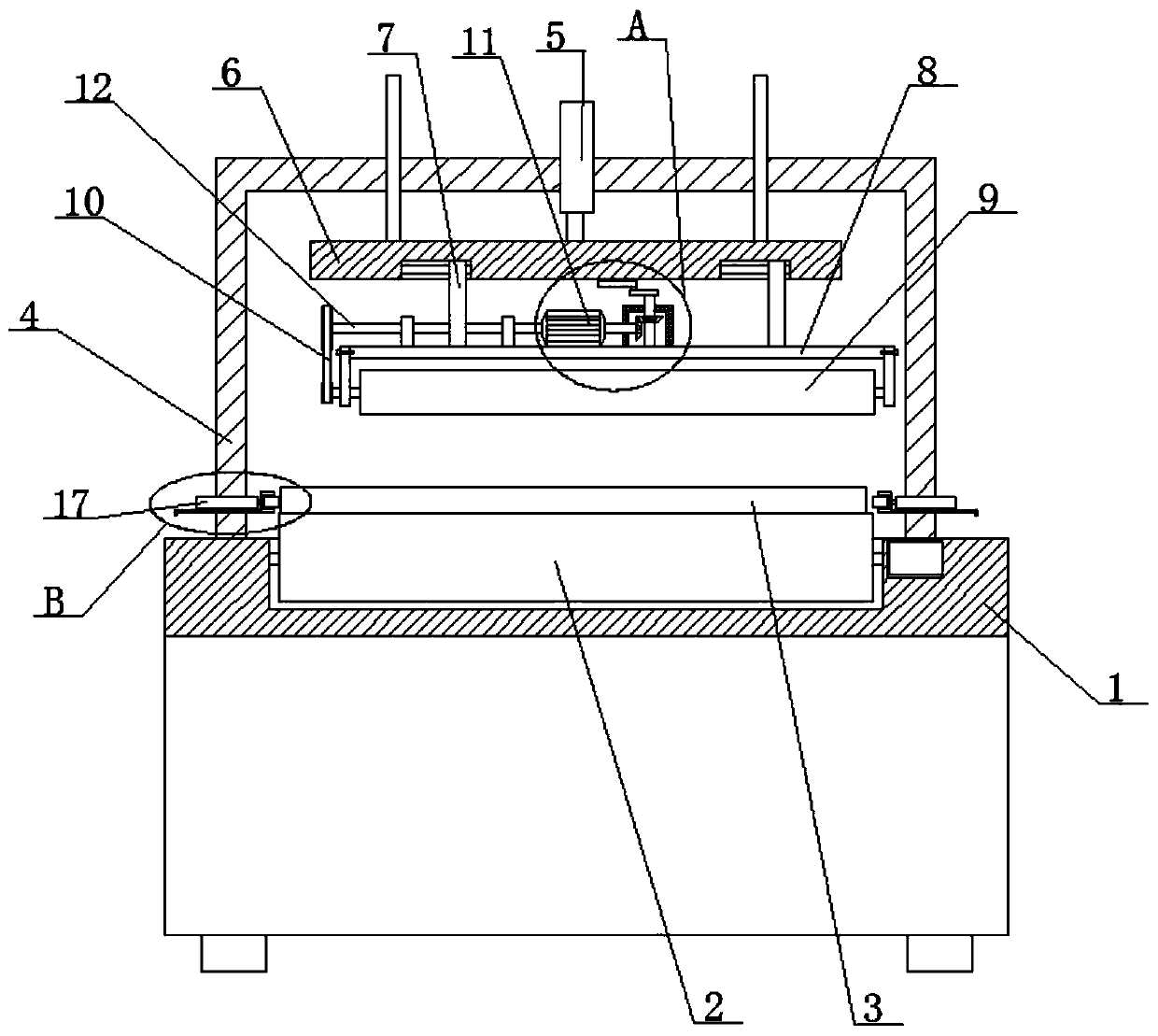

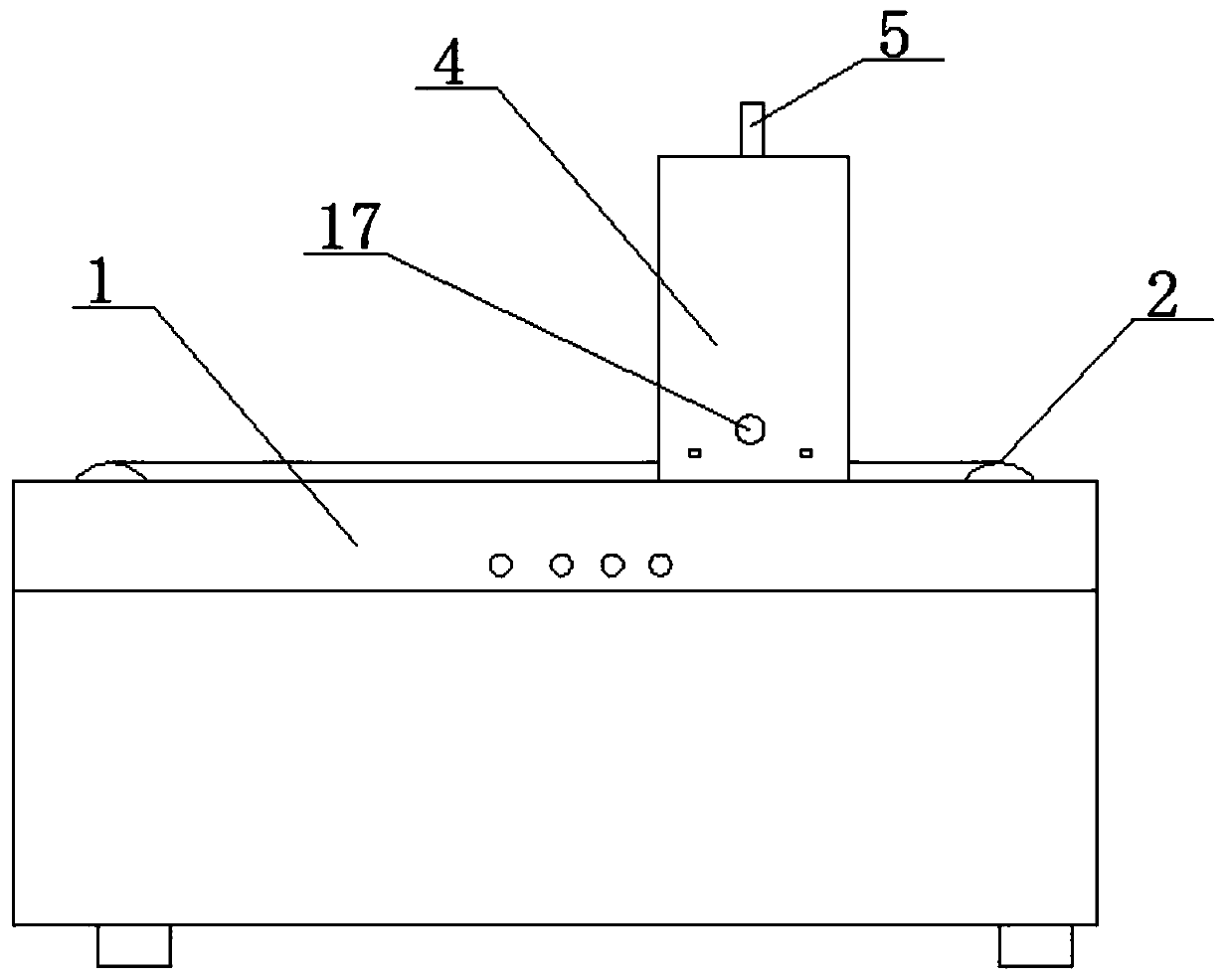

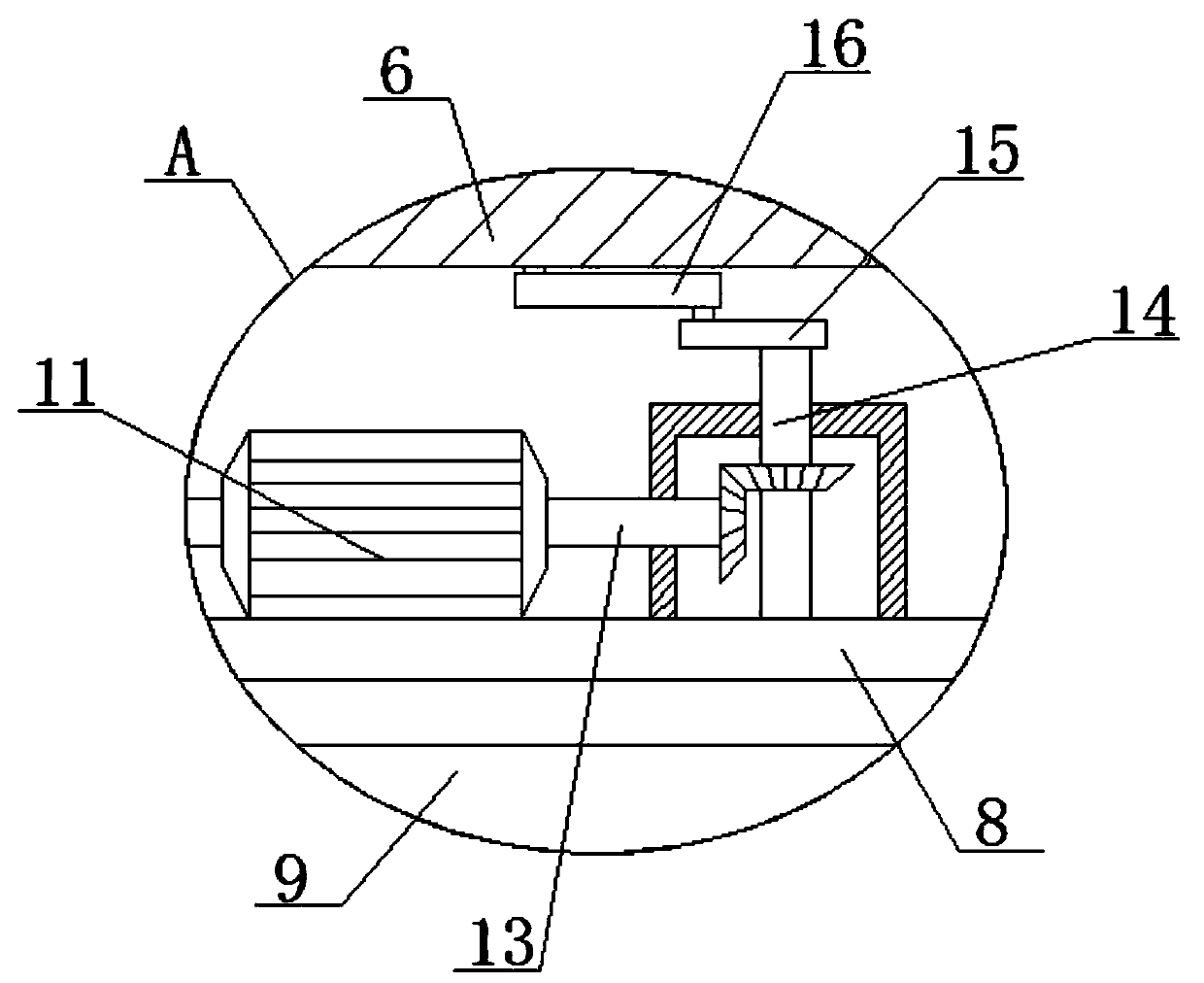

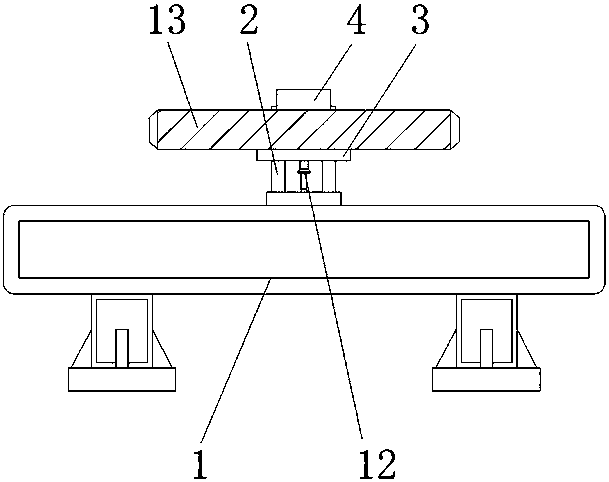

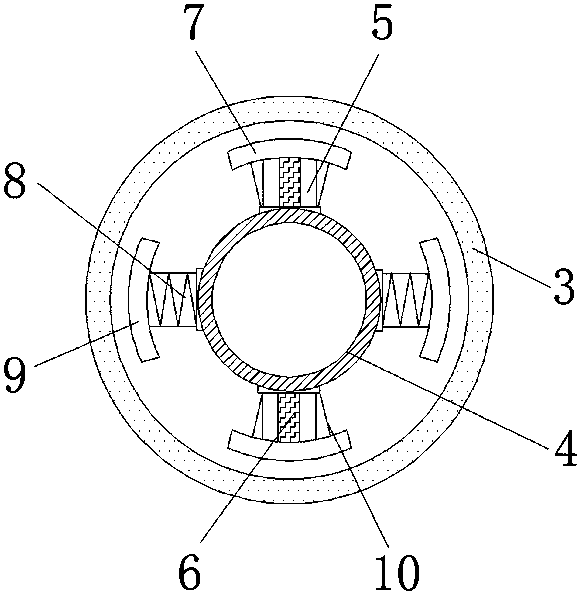

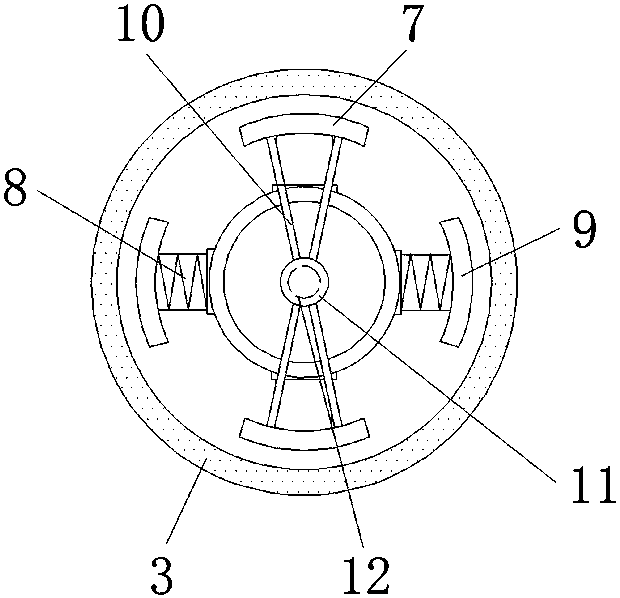

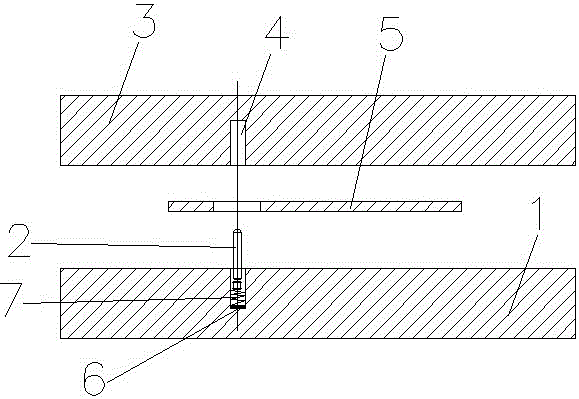

Electronic component processing platform convenient to adjust

PendingCN110788812AComfortable processingDoes not affect normal processingCleaning using toolsWork benchesEngineeringWorkbench

The invention discloses an electronic component processing platform convenient to adjust, and belongs to the technical field of electronic component processing. The electronic component processing platform includes a support plate, first support rods installed at the bottom of the support plate and a workbench installed on the upper surface of the support plate, a first connecting rod is connectedbetween the first support rods, the lower ends of the first support rods are sleeved with second support rods, a fastening bolt is installed on one side of each first support rod, a second connectingrod is connected between the second support rods, and an adjusting screw is installed between the first connecting rod and the second connecting rod. According to the electronic component processingplatform, the height of a worktable can be adjusted by installing the adjusting screw, so that workers can process electronic components at a more comfortable height; and a cleaning mechanism is arranged above the worktable detachably, the worktable can be cleaned+, the worktable can be stored when not used, and therefore normal processing of the electronic components is not influenced.

Owner:常州擎莘自动化科技有限公司

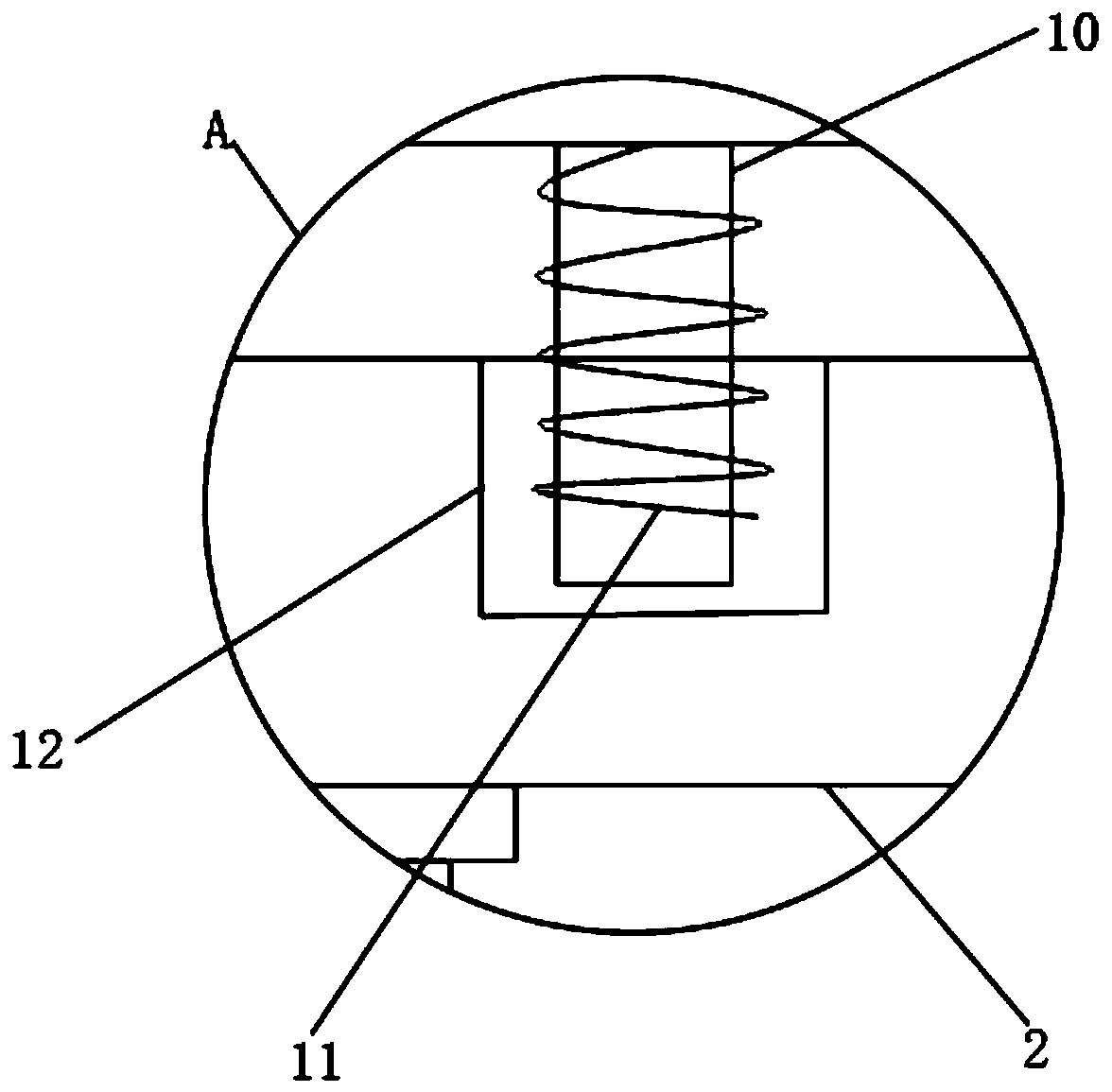

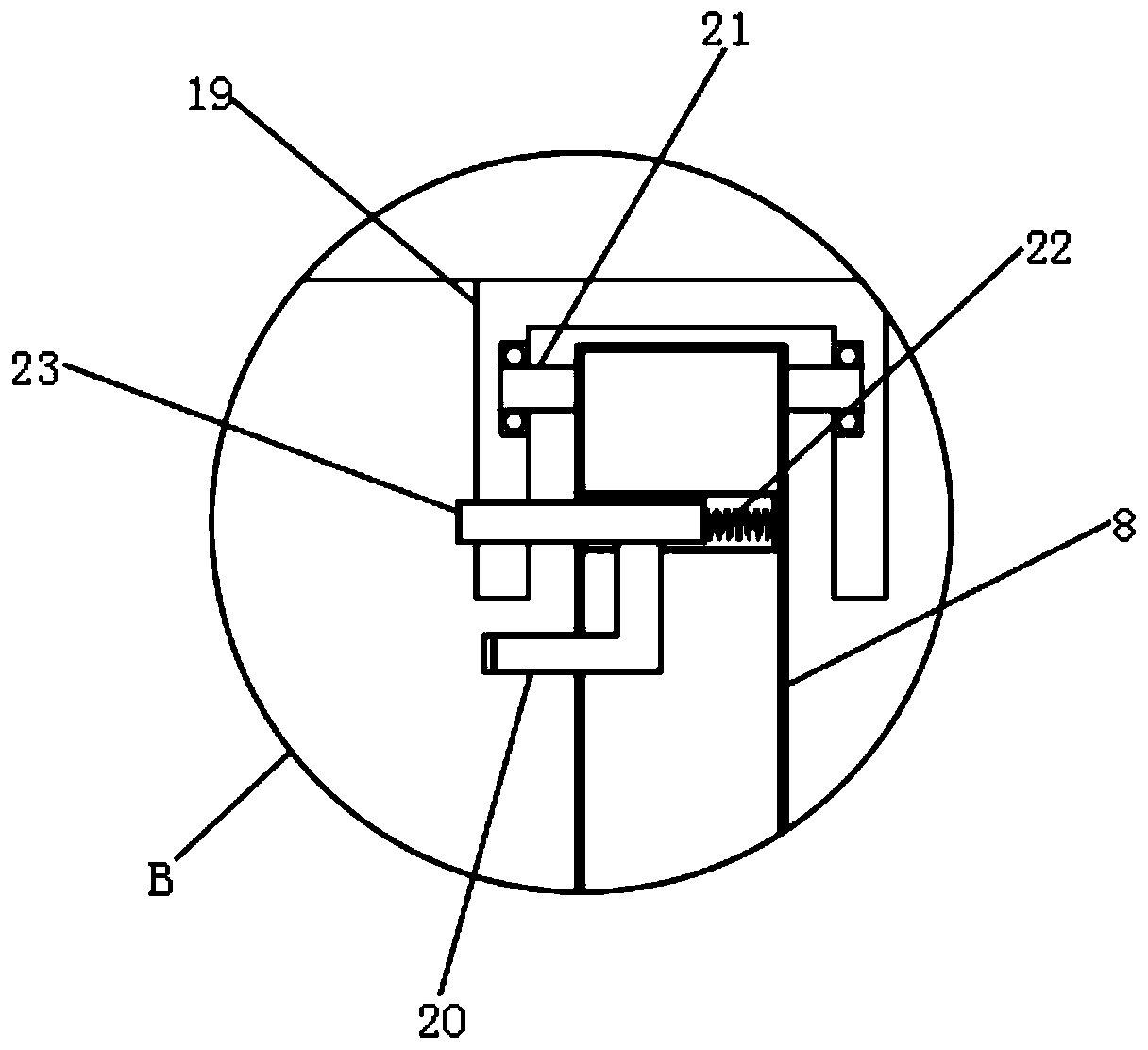

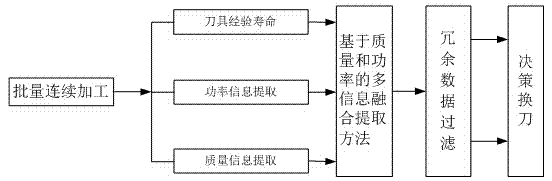

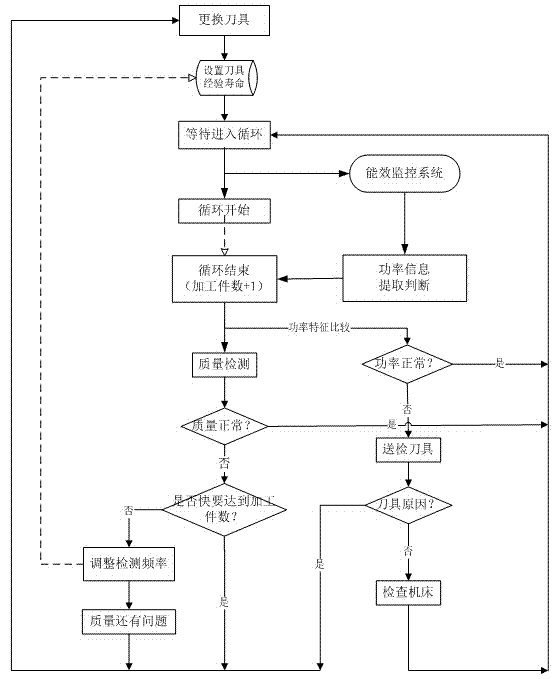

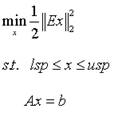

Multimodal fusion based gear machining process tool change decision method

ActiveCN104503361AThe collection method is simpleAcquisition method is stableNumerical controlQuality dataGear wheel

The invention provides a multimodal fusion based gear machining process tool change decision method. The method includes: performing multi-information fusion processing on tool experience life, power information of the machining process and quality data acquired by workpiece sampling inspection in the batch machining process of gears, and judging the current status of a tool so as to decide whether or not to change the tool. The information acquisition method is simple, stable and low in cost, and normal machining is unaffected; the acquired data are high in accuracy, response is fast, and an operator can be reminded of changing the tool in time; monitoring of machining quality, power information and tool life is combined organically, the tool can be changed under the optimum status, the machining quality is guaranteed favorably, high tool cost is lowered, and machining efficiency is increased. The method can be widely applied to gear machine tools and automatic production lines for gear machining.

Owner:CHONGQING UNIV

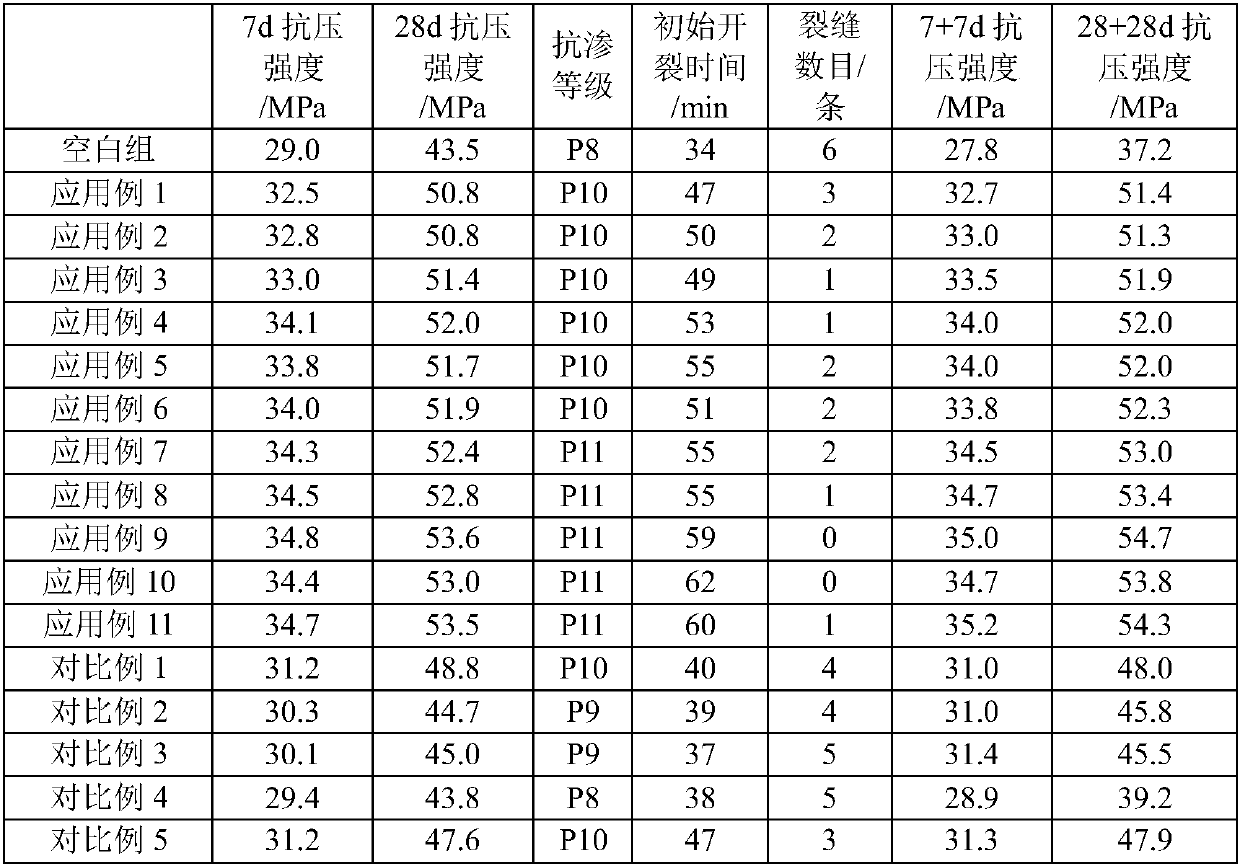

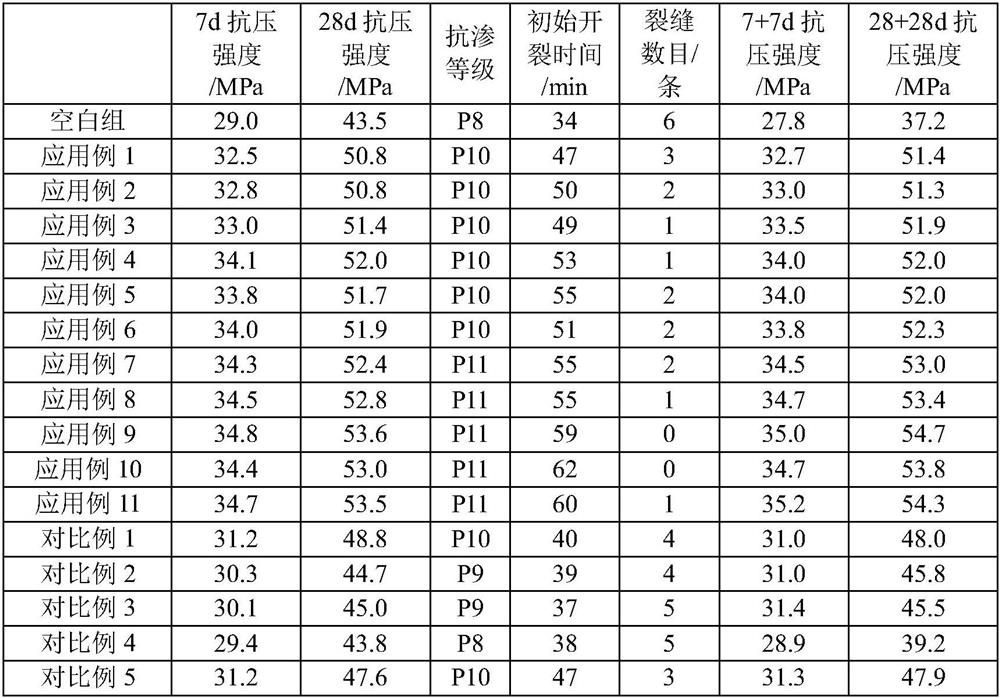

Concrete anti-crack self-repairing agent, preparation method thereof and anti-crack self-repairing concrete

The invention relates to the technical field of concrete, in particular to a concrete anti-crack self-repairing agent, a preparation method thereof and anti-crack self-repairing concrete. The concrete anti-crack self-repairing agent comprises, by weight, 35-80 parts of bulking fillers, 0.1-1 part of magnesium aluminum silicate thixotropic agents, 0.1-2 part of polyvinyl alcohol fibers, 1-3 parts of nano-scale black carbon, 2-5 parts of glucose and 3-8 parts of casein. The particle diameter of the nano-scale black carbon is 20-80nm. The anti-crack self-repairing agent is added into the concrete, the inside of a crack touching water is softened, expanded, remodeled and solidified under the action of the self-repairing agent when the surface of the concrete is cracked, so that the crack of the concrete is plugged and self-repaired, and the compressive strength of the concrete is improved. The anti-crack self-repairing agent can be mixed and stirred along with raw materials the concrete in processing and stirring process of the concrete, normal processing of the concrete cannot be affected, and the self-repairing agent is high in practicability.

Owner:东莞市冠峰混凝土有限公司

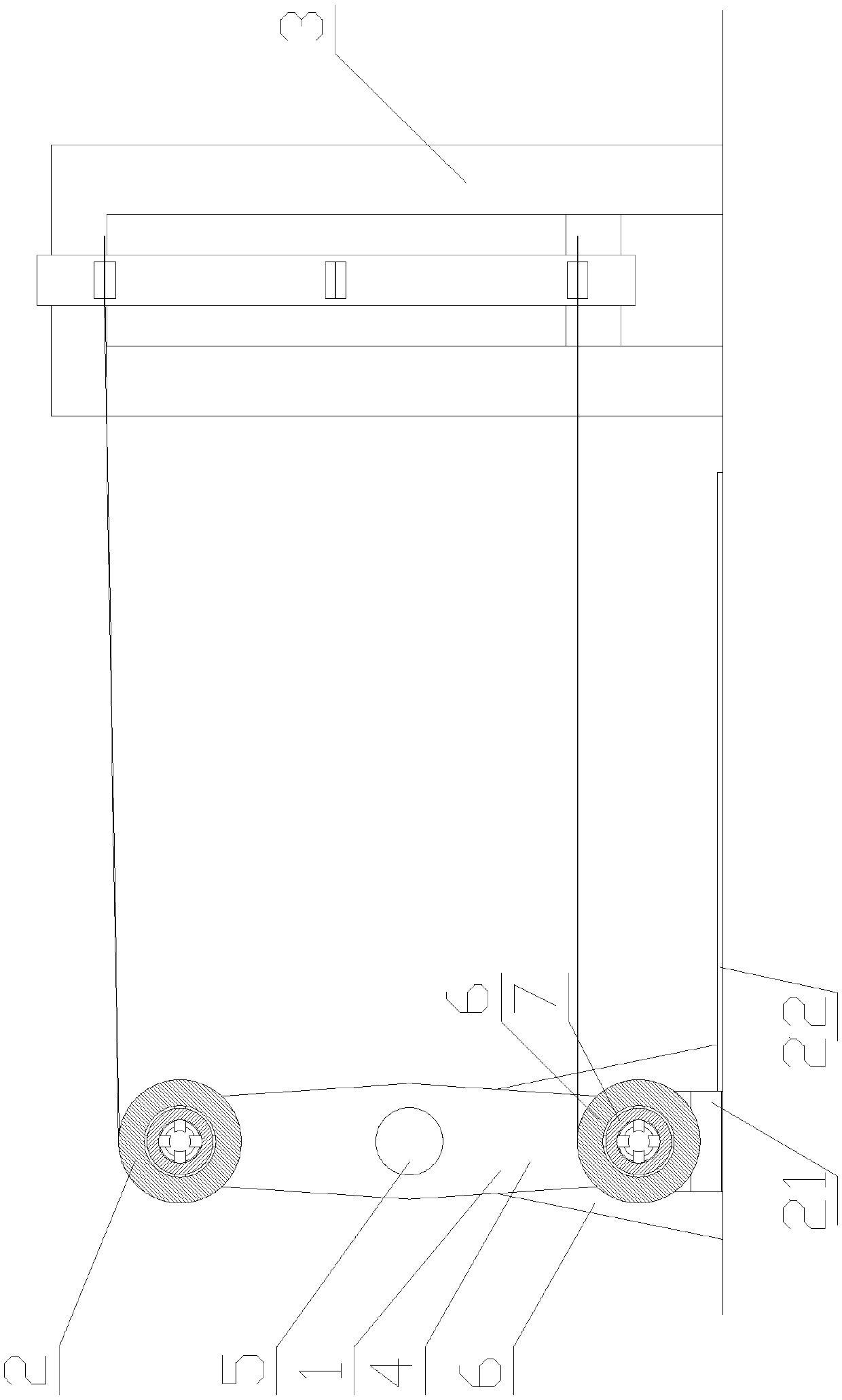

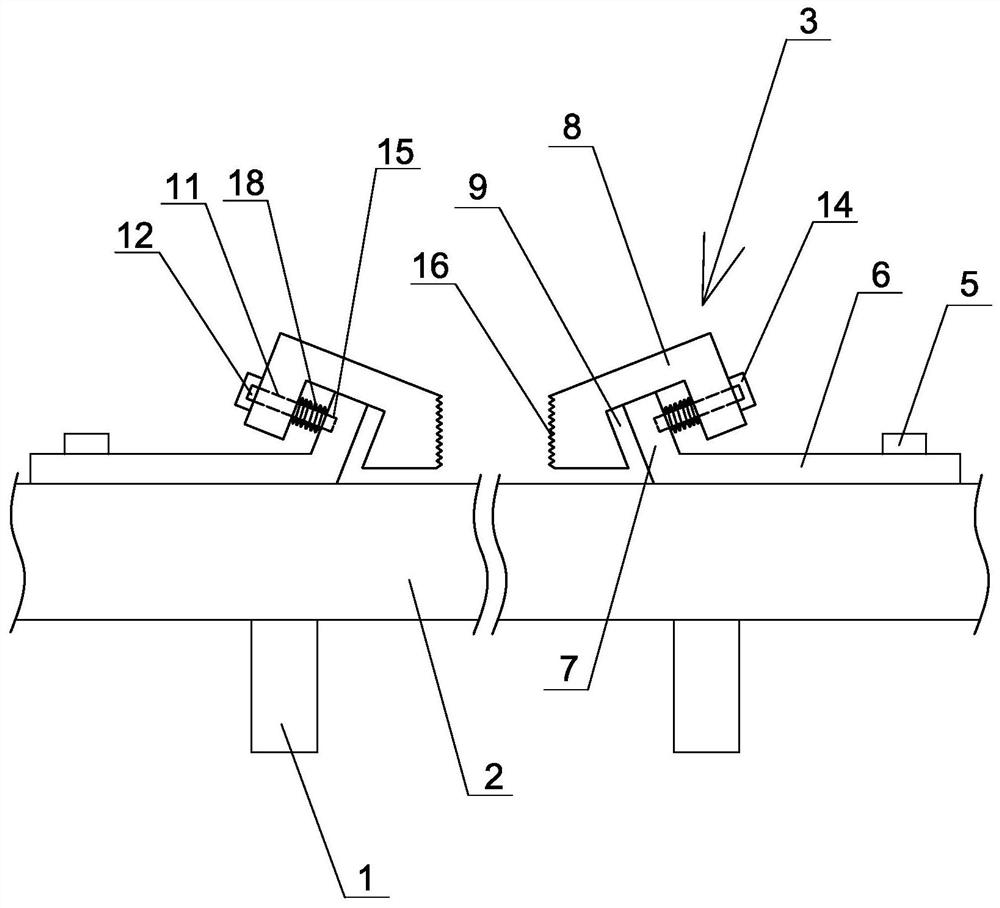

Progressive die material conveying dislocation preventing method

InactiveCN104438826AWon't breakDoes not affect normal processingShaping toolsShaping safety devicesStopped workControl system

The invention discloses a progressive die material conveying dislocation preventing method. the method comprises the steps that a detecting pin is pre-arranged on a lower die, a pin hole is formed in the corresponding position of an upper die, and in the normal feeding process, the pin hole is aligned to the hollowed position of a workpiece; when feeding is not carried out in place, the pin hole is aligned to the solid position of the workpiece, in the die assembling process, the upper die generates downward pressure on the detecting pin through the solid position of the workpiece, the detecting pin is made to move downwards, when the detecting pin moves by the set distance, the detecting pin triggers an induction switch, the induction switch is connected with a control system, and a progressive die is controlled by the control system to stop working immediately. According to the method, normal use of equipment can be effectively guaranteed, the situation that the workpiece and the equipment are bashed due to the fact that feeding is not carried out in place is avoided, and work is reliable.

Owner:黑龙江至信机械制造有限公司

Surface treatment device for vehicle carrying board producing and manufacturing

InactiveCN110814914ATurn up the effect of grinding and deburringImprove grinding efficiencyEdge grinding machinesGrinding feedersElectric machinerySurface grinding

The invention belongs to the technical field of vehicle board surface grinding, in particular to a surface treatment device for vehicle carrying board producing and manufacturing. Aiming at the problem that an existing grinding operation mode is low in efficiency, and poor in grinding quality, and a vehicle carrying board is not conveniently fixed during grinding, the following scheme is providedat present. According to the scheme, the device comprises a rack, wherein a conveying belt device is arranged on the rack, boards are arranged on the conveying belt device in a conveyed mode, a metalshell is arranged at the top of the rack, a push rod air cylinder is arranged on the metal shell, a lifting board is fixedly connected to the output end of the push rod air cylinder, two connecting rods are slidably connected to the bottom of the lifting board, the same shell is fixedly mounted at the bottom ends of the two connecting rods, a double-head motor is arranged at the top of the shell,a roller is rotationally mounted at the bottom of the shell, and a grinding sleeve is fixedly arranged at the outer side of the roller in a sleeving mode. According to the surface treatment device, the grinding efficiency and the grinding quality of the boards are improved, the boards are conveniently fixed during grinding, and normal machining is not influenced.

Owner:HEFEI WEIHUA INTELLIGENT PARKING EQUIP

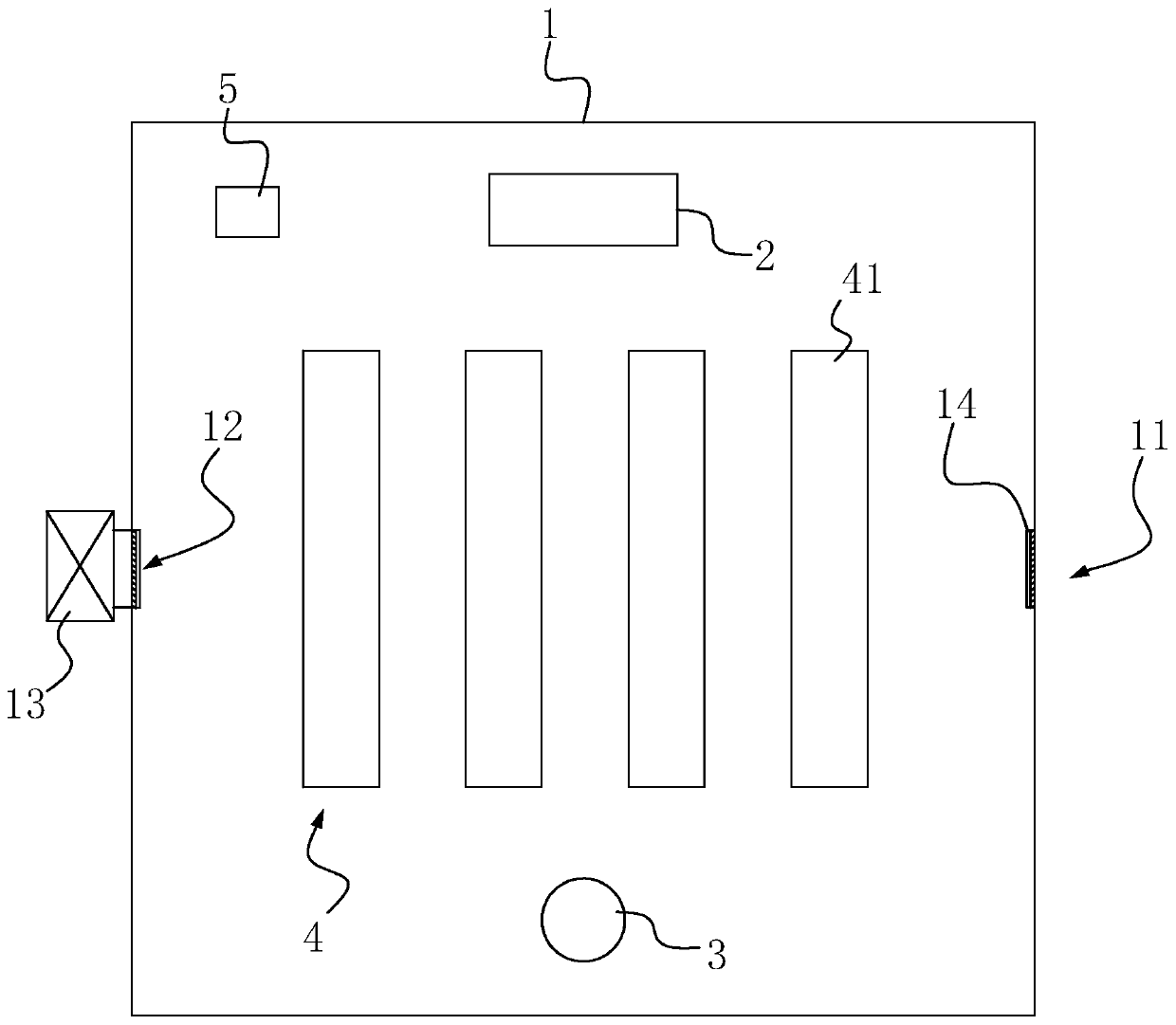

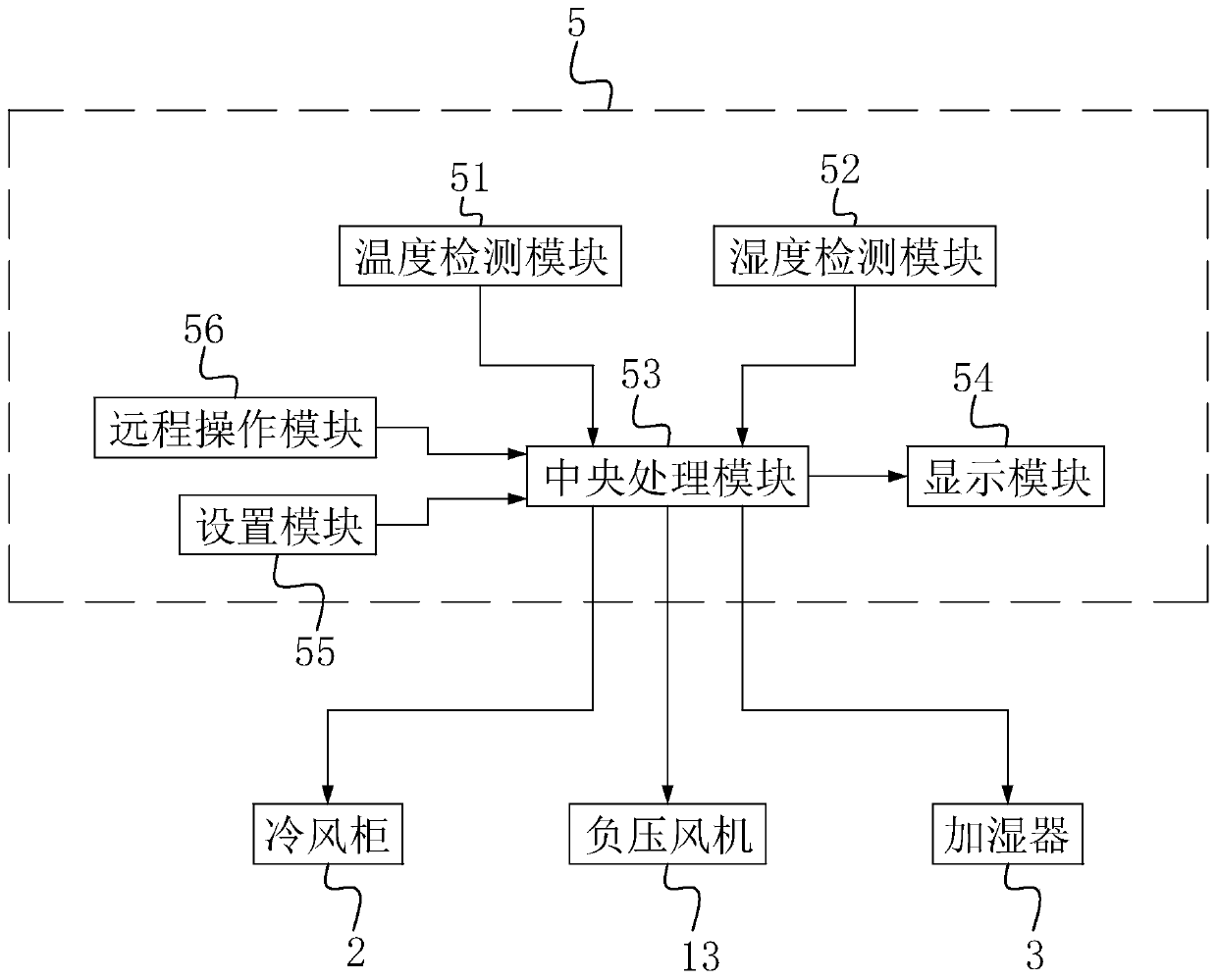

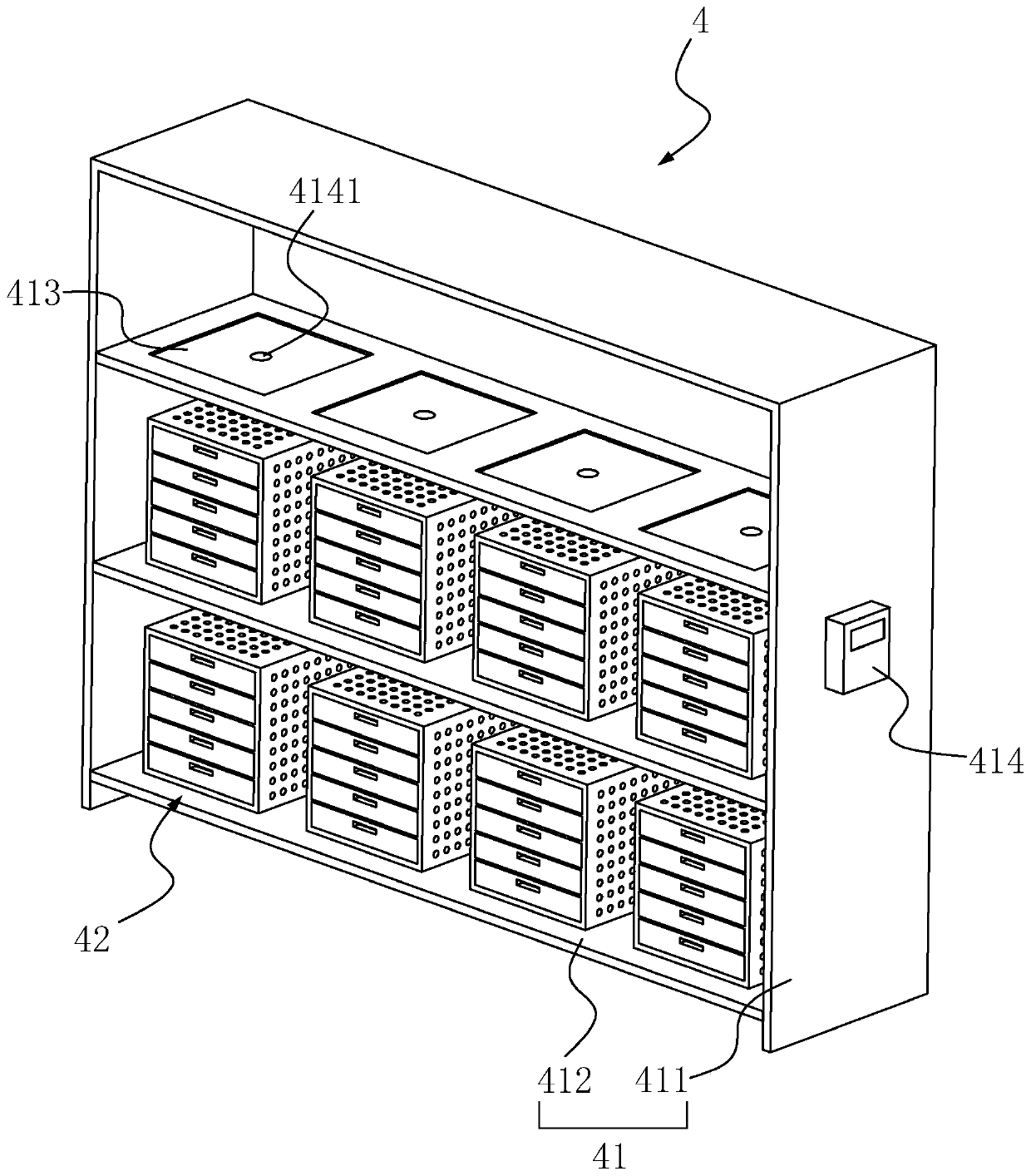

Intelligent apple refrigeration system

InactiveCN110686447AImprove ventilationWell refrigeratedLighting and heating apparatusStationary refrigeration devicesCold airCool storage

The invention relates to an intelligent apple refrigeration system, and belongs to the technical field of refrigeration systems. The main point of the technical scheme is that the intelligent apple refrigeration system comprises a refrigeration chamber, a cold air cabinet arranged in the refrigeration chamber and a plurality of apple storage devices arranged in the refrigeration chamber in a nested mode, wherein each apple storage device comprises a placement shelf and a plurality of storage boxes arranged on the placement shelf, ventilation holes which run through the peripheral wall of eachstorage box are formed in the peripheral wall of each storage box, a plurality of storage trays used for placing apples are arranged in each storage box from the top down, an air inlet communicating with the outside world is formed in a wall on one side, parallel to the placement shelves, of the refrigeration chamber, a negative pressure air outlet connected with a negative pressure draught fan isformed in a wall on one side, far away from the air inlet, of the refrigeration chamber, and sealing doors used for sealing the air inlet and the negative pressure air outlet are respectively arranged on the positions of the air inlet and the negative pressure air outlet. The intelligent apple refrigeration system can regulate ventilation conditions of apple storage according to characteristics of the apples, and can meet storage requirements of the apples different in characteristic.

Owner:栖霞德丰食品有限公司

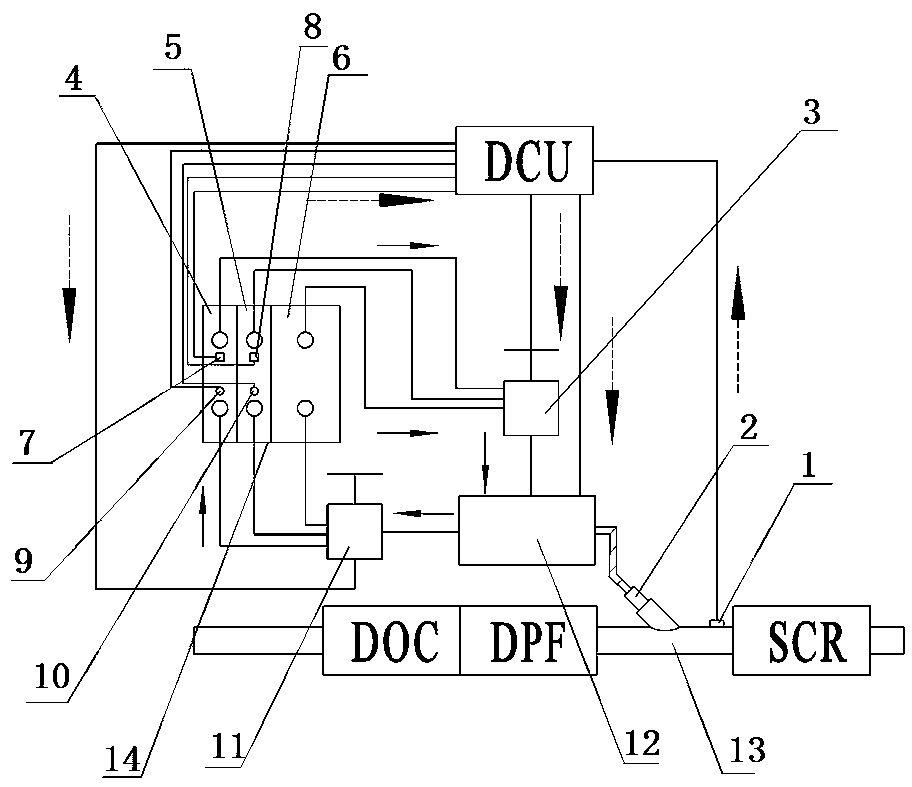

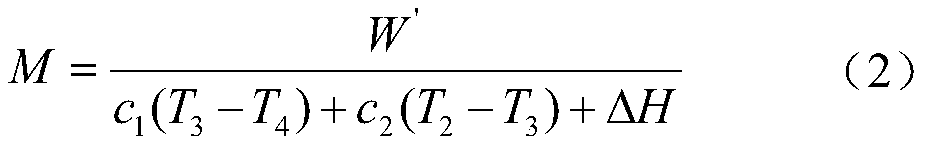

Tail gas aftertreatment device, selective catalytic reduction (SCR) front exhaust gas temperature control system and control method thereof

ActiveCN109944665ADoes not affect normal processingLow costInternal combustion piston enginesExhaust apparatusTemperature controlControl system

The invention relates to a tail gas aftertreatment device, a selective catalytic reduction (SCR) front exhaust gas temperature control system and a control method thereof. The SCR front exhaust gas temperature control system comprises a urea storage device, a urea pump, a urea supply control valve, a urea injector, an exhaust gas temperature sensor and a controller, and further comprises a coolingchannel used for connecting DPF with SCR and allowing tail gas to pass through; the urea ejector communicates with the cooling channel, the urea pump is connected with the urea storage device and theurea ejector and is connected with the controller in a controlled mode, and the urea storage device comprises a non-thermal regeneration urea storage chamber used for storing a urea solution used during non-DPF thermal regeneration and a thermal regeneration urea storage chamber used for storing a urea solution used during DPF thermal regeneration; and the concentration of the urea solution stored by the thermal regeneration urea storage chamber is lower than that of the urea solution used during non-DPF thermal regeneration. With the technical scheme, the technical problems of high complexity and high cost of an SCR front exhaust gas temperature control system in the prior art are solved.

Owner:HENAN UNIV OF SCI & TECH

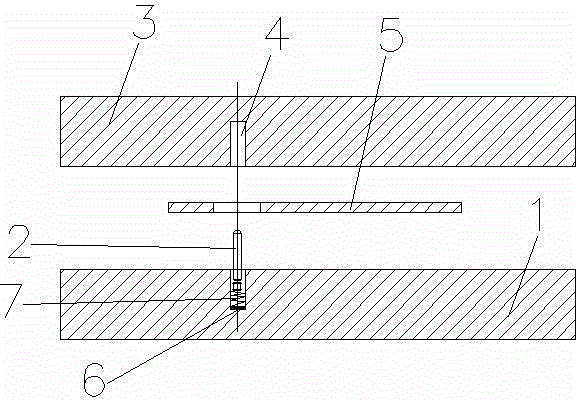

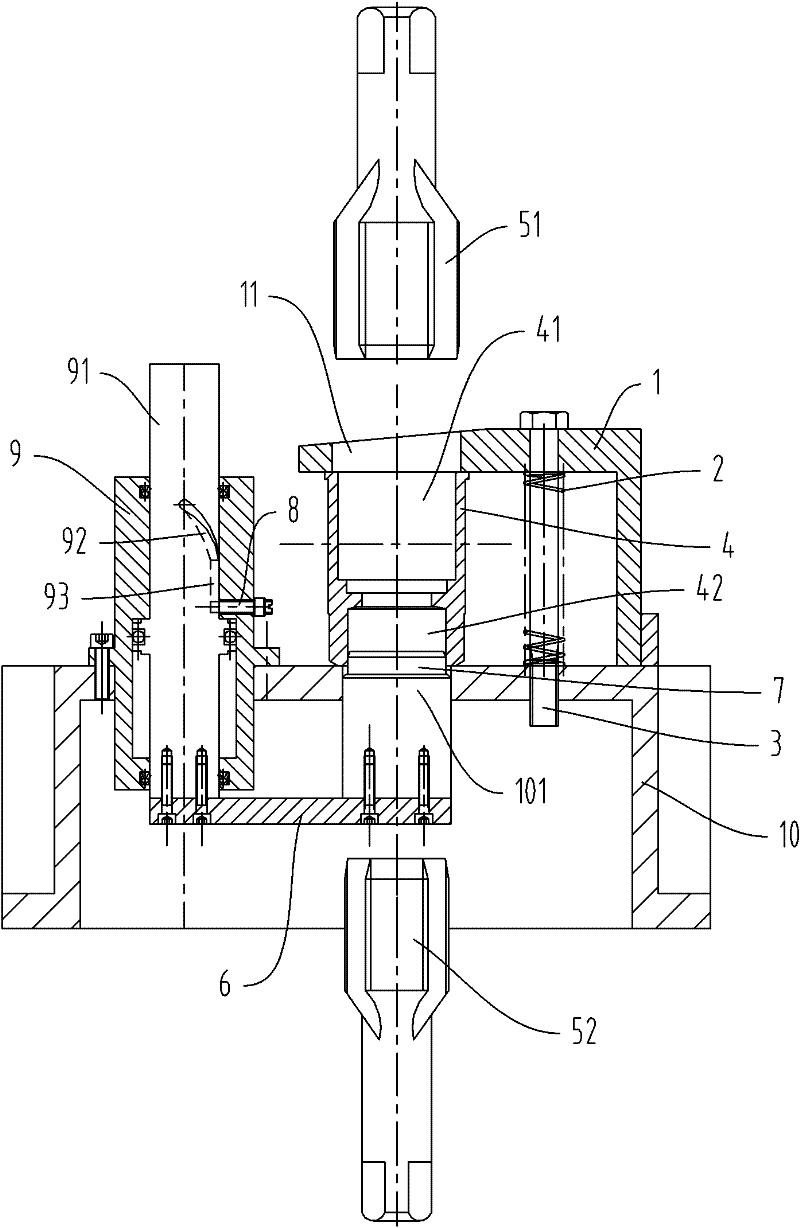

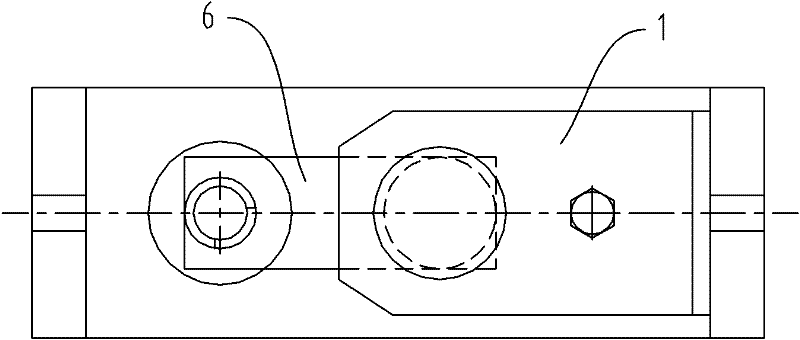

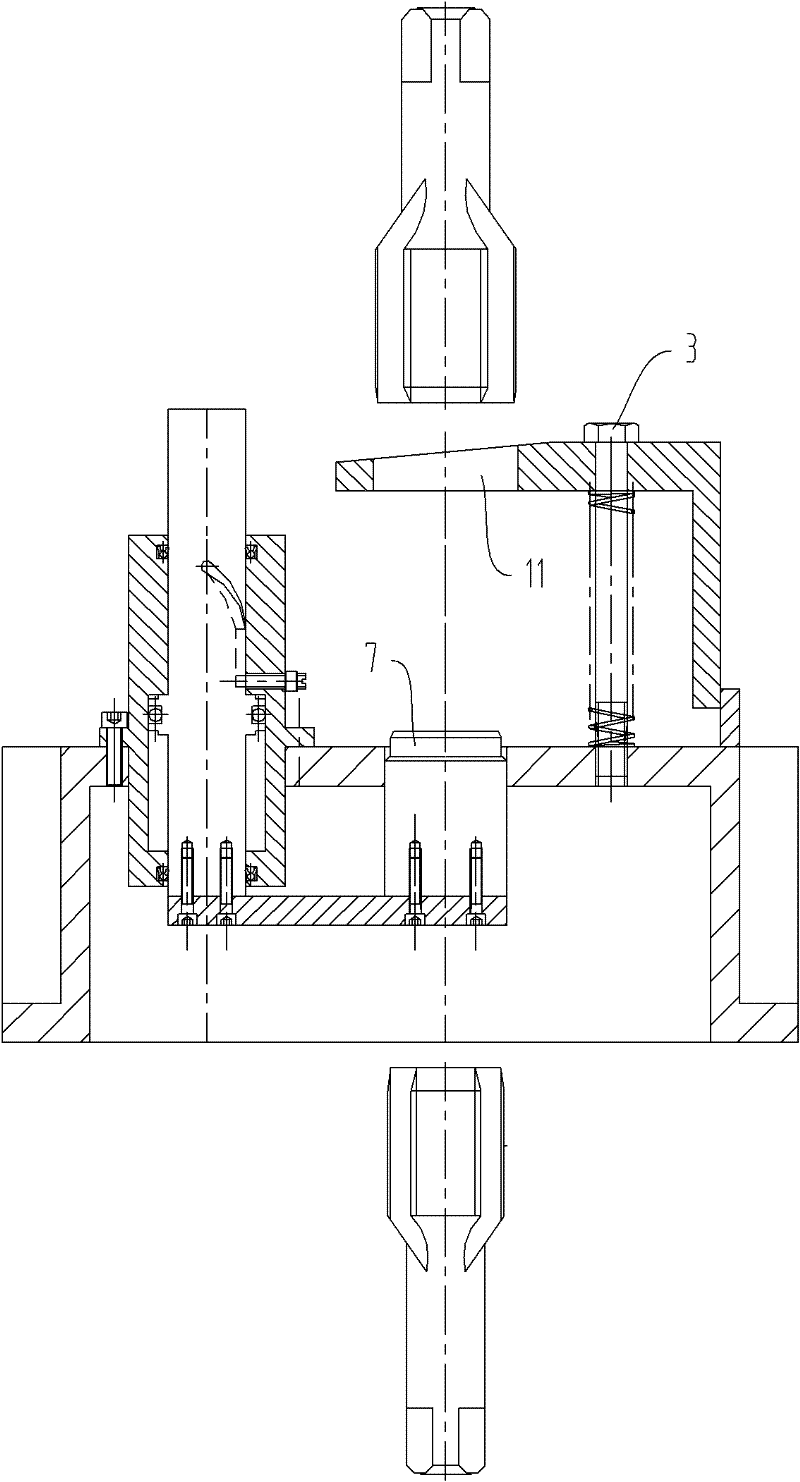

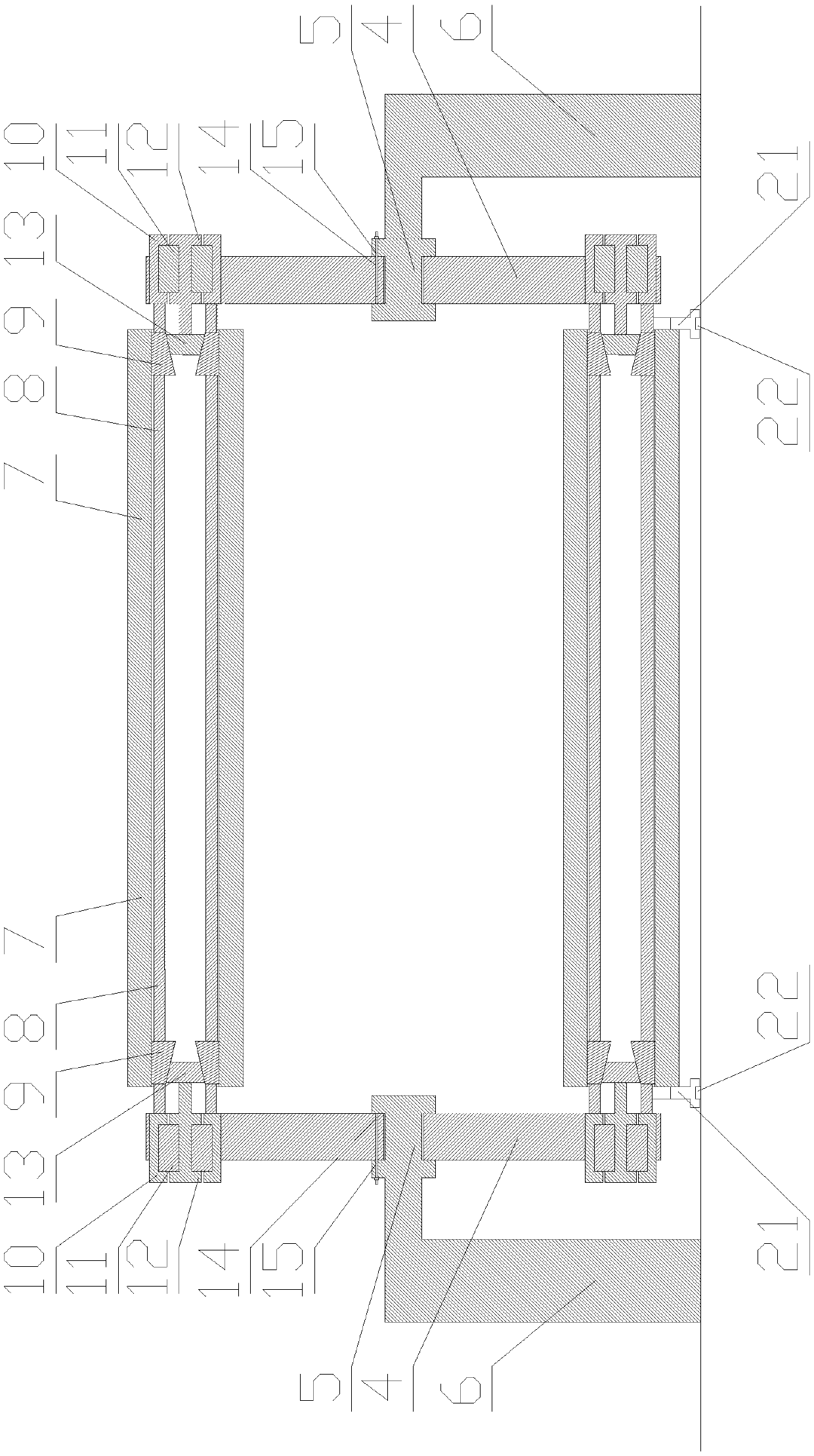

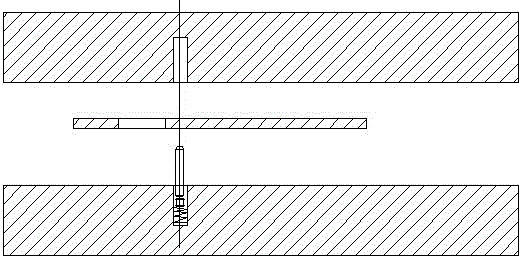

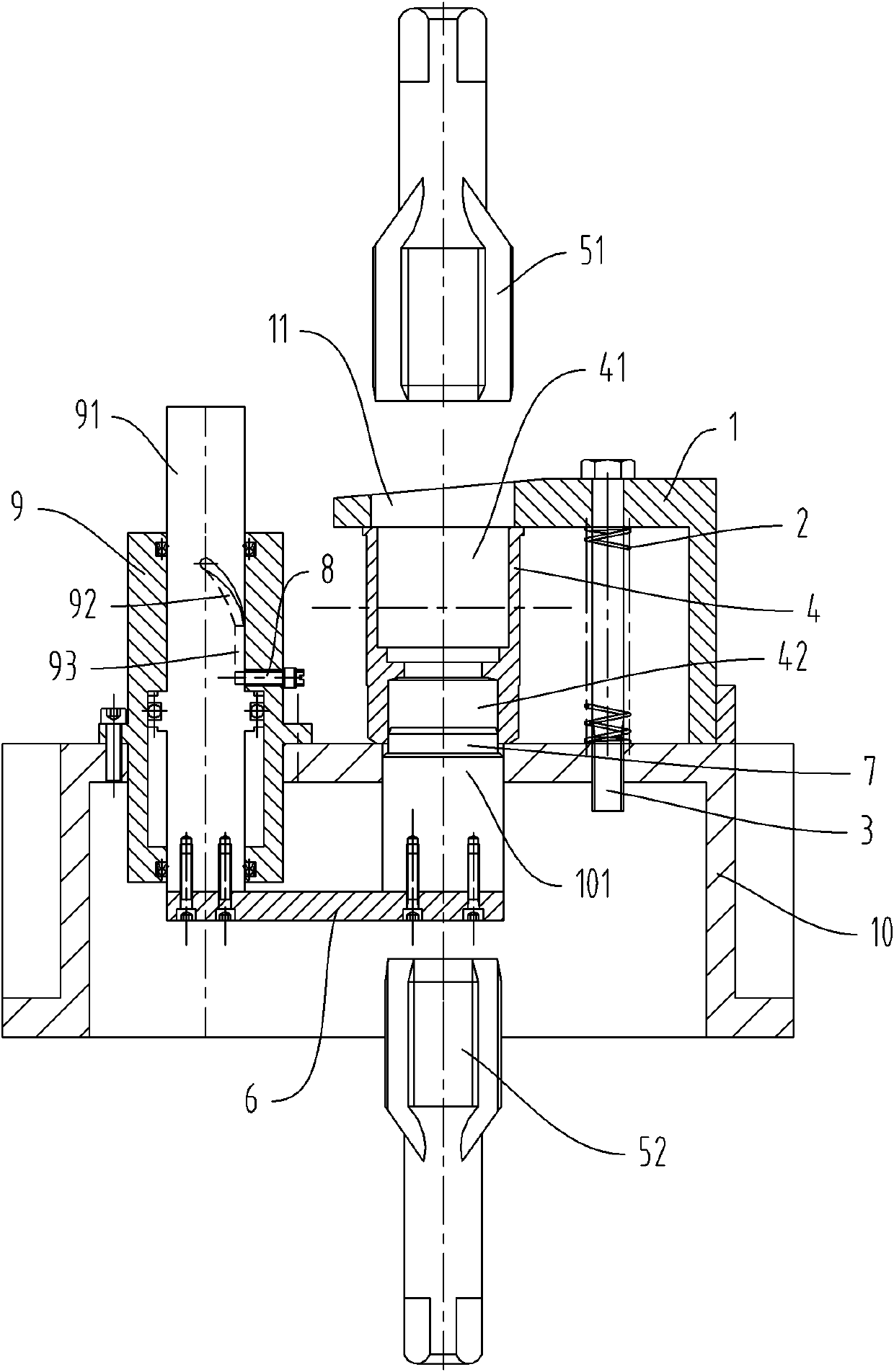

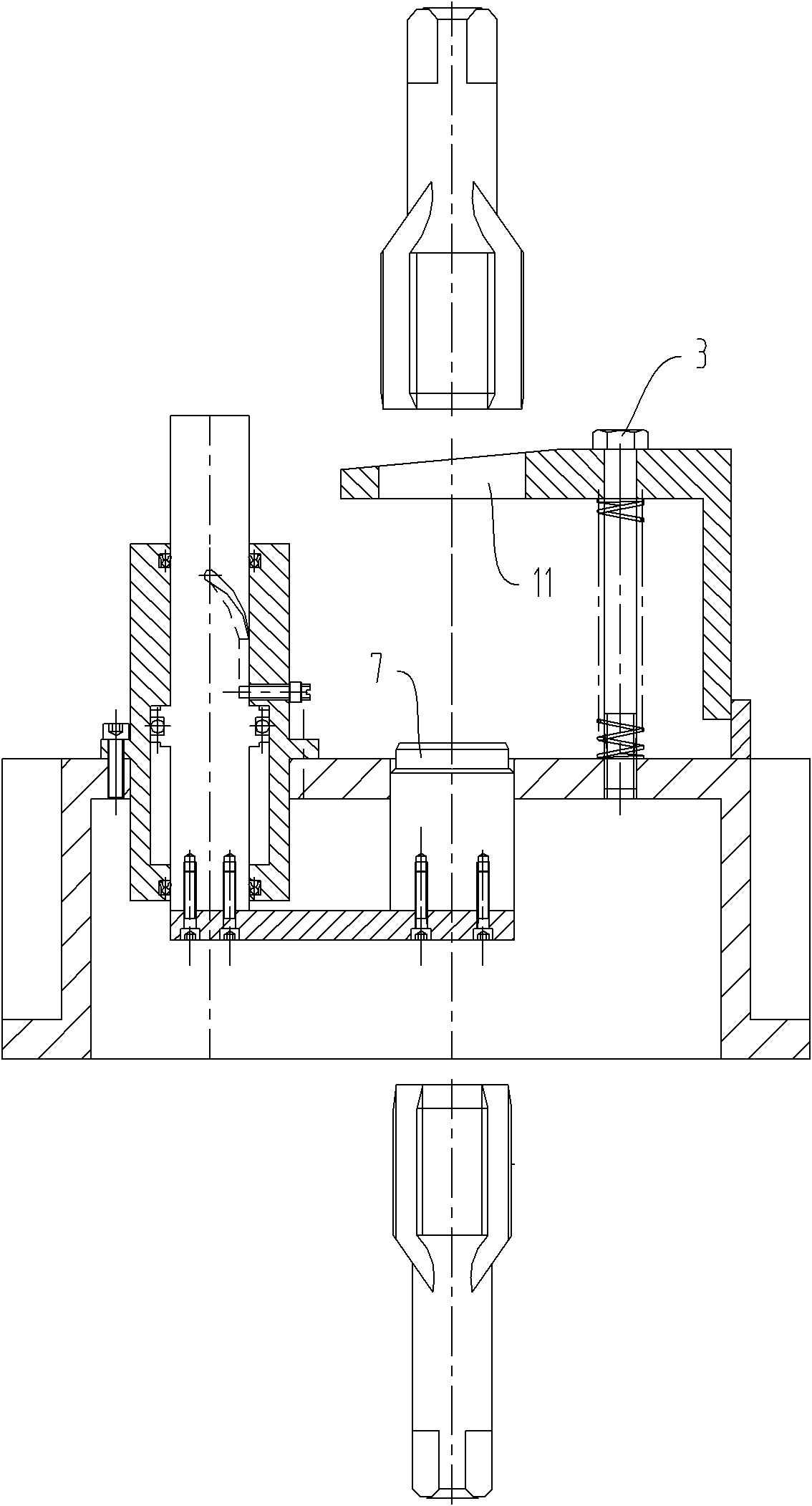

Double-headed tapping clamp

ActiveCN102528179ADoes not affect normal processingAvoid machining errorsThread cutting machinesPositioning apparatusEngineeringScrew thread

The invention provides a reasonable double-headed tapping clamp for a valve, which solves the problem of low repeated positioning precision of blanks due to scattered working procedures, and ensures product precision and processing efficiency in tapping. The double-headed tapping clamp comprises a clamp body and a pressing plate device which is arranged on the clamp body and used for clamping a workpiece needing tapping on the clamp body, and the pressing plate device comprises a pressing plate and a clamping screw rod. A lower through hole is arranged on the clamp body, an upper through holeis arranged on the pressing plate, and both the diameter of the upper through hole and the diameter of the lower through are larger than the major diameter of a screw tap for tapping. When the workpiece is clamped on the clamp body by the pressing plate device, an upper inner hole at the upper end of the workpiece needing tapping is coaxial with the upper through hole, a lower inner hole at the lower end of the workpiece needing tapping is coaxial with the lower through hole, and a cylindrical mandrel matched with the lower inner hole is coaxial with the lower through hole and is connected with a vertical movement driving device for driving the cylindrical mandrel to vertically move along the axis.

Owner:JIANGSU ZUZEM VALVES

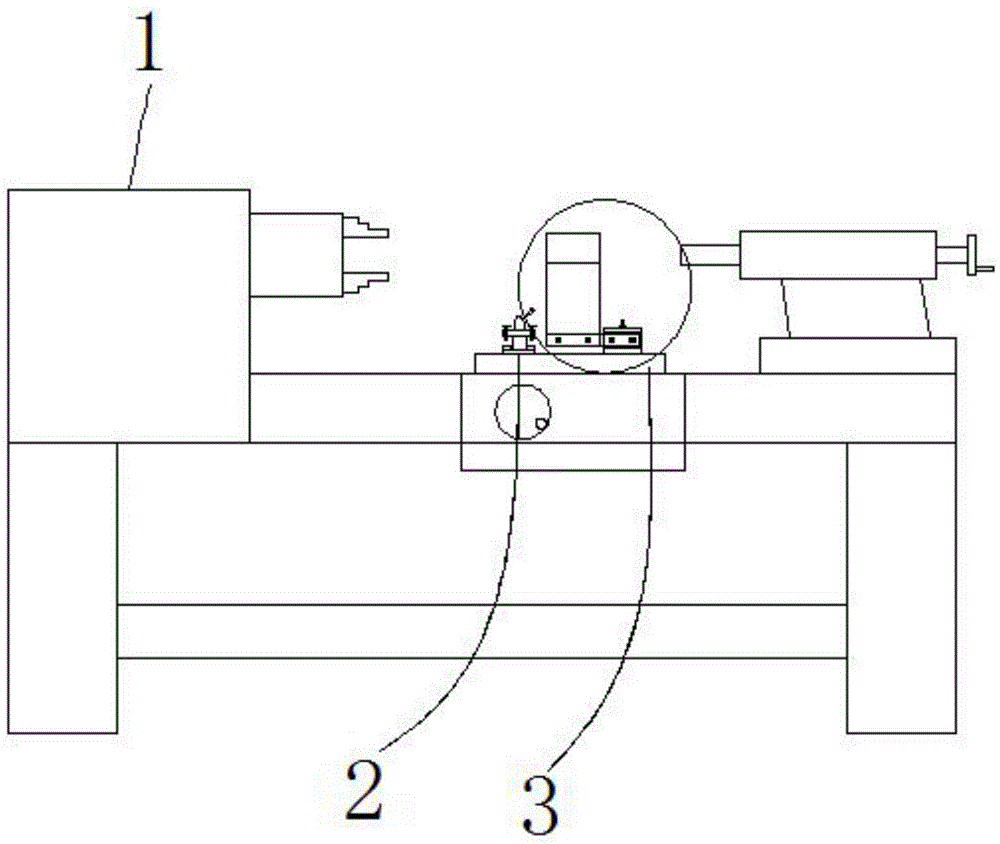

Turning protection device

The invention discloses a turning protection device. The turning protection device comprises a lathe, a tool rest and a feeding platform and further comprises a basic shaft, a rotary table, a pressing plate, a connecting plate and a protection cover. The basic shaft is located at the upper end of the feeding platform and is in threaded connection with the feeding platform. The rotary table is located at the center of the upper end of the basic shaft and is in threaded connection with the basic shaft, and the rotary table is in the shape of a cylinder. The pressing plate is located at the upper end of the rotary table and rotationally connected with the rotary table. The connecting plate is located on the side wall of the rotary table and is in threaded connection with the rotary table. The protection cover is located on the front side of the connecting plate and is in threaded connection with the connecting plate. The turning protection device can greatly protect the eyes and even the whole face of an operator against injuries. Besides, operation is simple, normal machining is not influenced, and the turning protection device has high practicality.

Owner:池州市大正机械制造有限责任公司

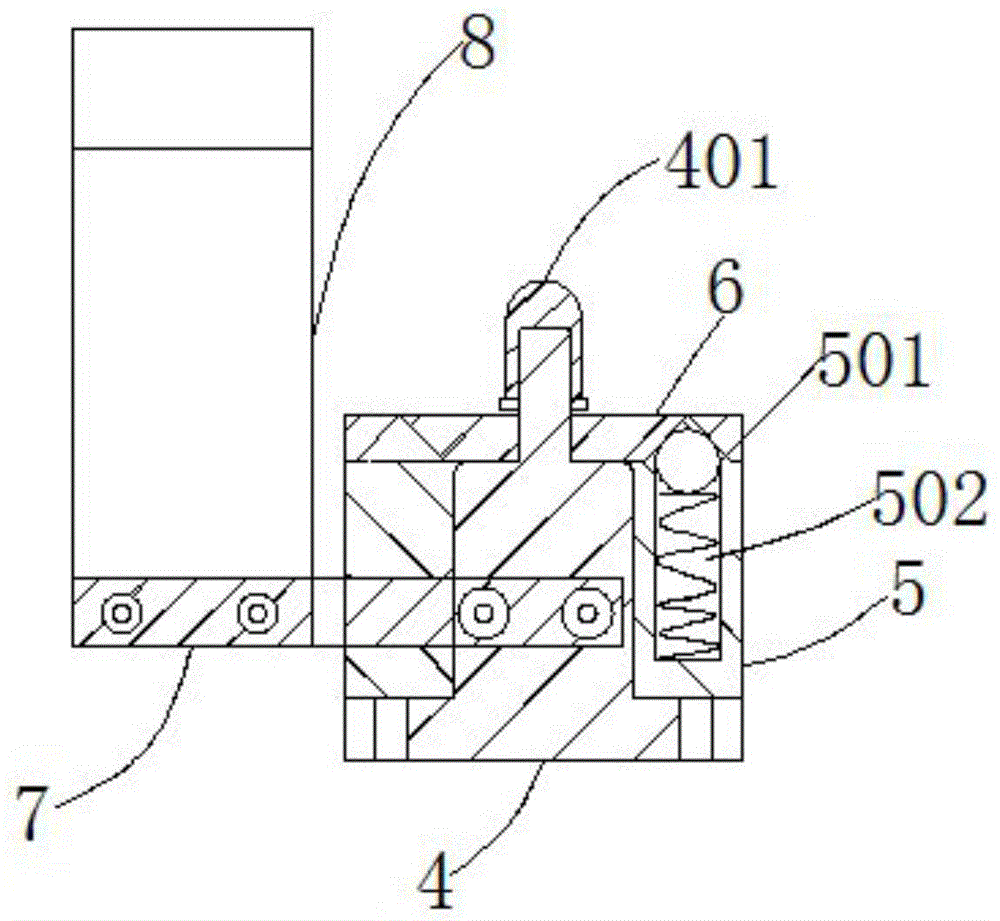

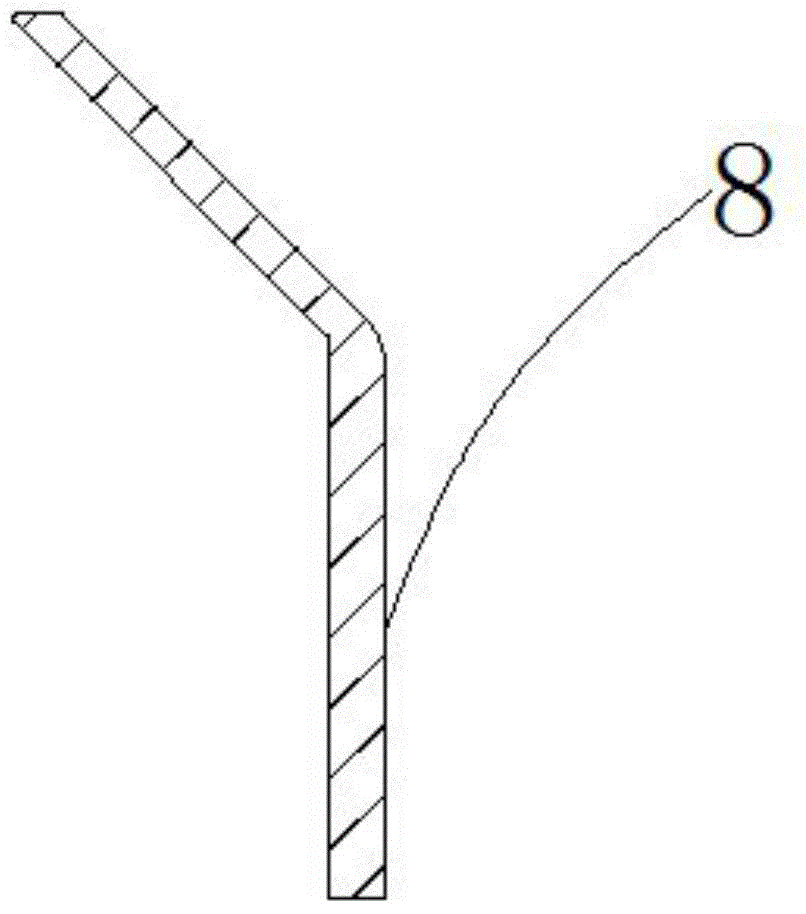

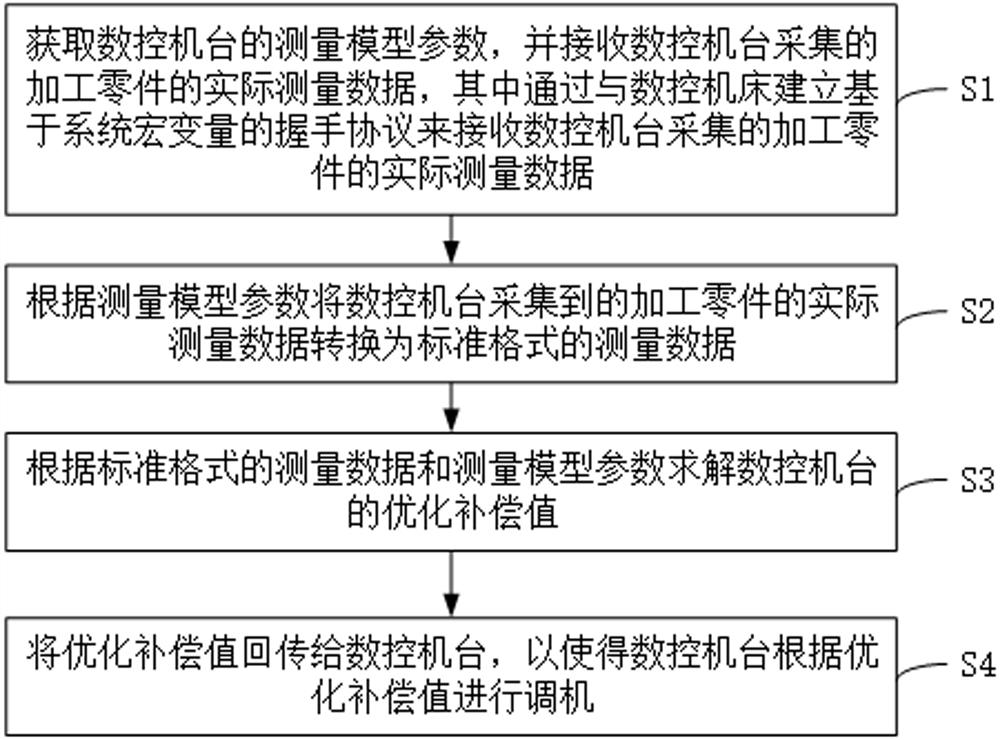

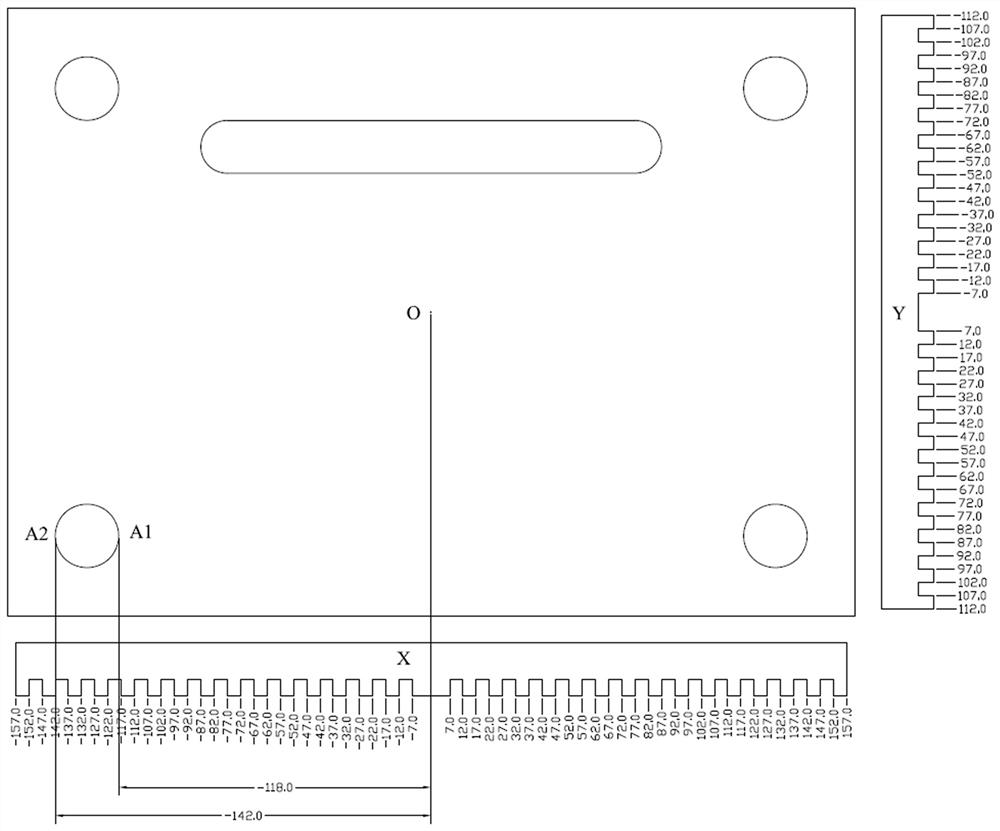

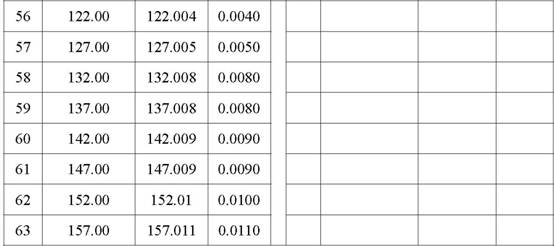

Intelligent debugging method and system based on handshake protocol

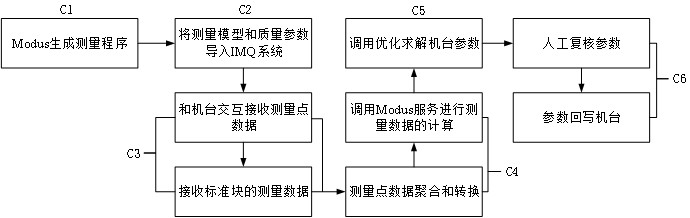

ActiveCN113589759ADoes not affect normal processingReduce machine set-up timeProgramme controlComputer controlNumerical controlMachine parts

The invention discloses an intelligent debugging method and system based on a handshake protocol, and the method is used for carrying out the intelligent debugging of at least one numerical control machine, and comprises the following steps: S1, obtaining the measurement model parameters of the numerical control machine, and receiving the actual measurement data of a machining part collected by the numerical control machine, wherein a handshake protocol based on a system macro variable is established with a numerical control machine table to receive actual measurement data, collected by the numerical control machine table, of a machined part; S2, according to the measurement model parameters, converting actual measurement data, collected by the numerical control machine, of the machined part into measurement data in a standard format; S3, solving an optimized compensation value of the numerical control machine according to the measurement data in the standard format and the measurement model parameters; and S4, transmitting the optimized compensation value back to the numerical control machine, so that the numerical control machine is adjusted according to the optimized compensation value. According to the invention, the problem of machine adjustment in the prior art is solved.

Owner:INREVO CO LTD

A data-based monitoring method for milling tool wear

ActiveCN106514434BRealize real-time online predictionRealize real-time life predictionMeasurement/indication equipmentsNumerical controlPower flow

The invention belongs to the technical field relevant to tool abrasion detection and discloses a milling tool abrasion monitoring method based on data. The method comprises the following steps that (1) a three-phase output current signal of a spindle driving motor of a numerically-controlled machine tool during working of a milling tool is collected; (2) the collected three-phase output current signal is cleaned; (3) a characteristic coefficient representing milling tool abrasion is extracted from the cleaned three-phase output current signal through a compressed sensing method and the key point theory; and (4) a characteristic signal index is computed online according to the three-phase output current signal, collected in real time, of the spindle driving motor when a certain milling tool works normally, and thus milling tool abrasion is subjected to real-time online monitoring. Through the provided milling tool abrasion monitoring method based on the data, the cost is lowered, and real-time monitoring of milling tool abrasion is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

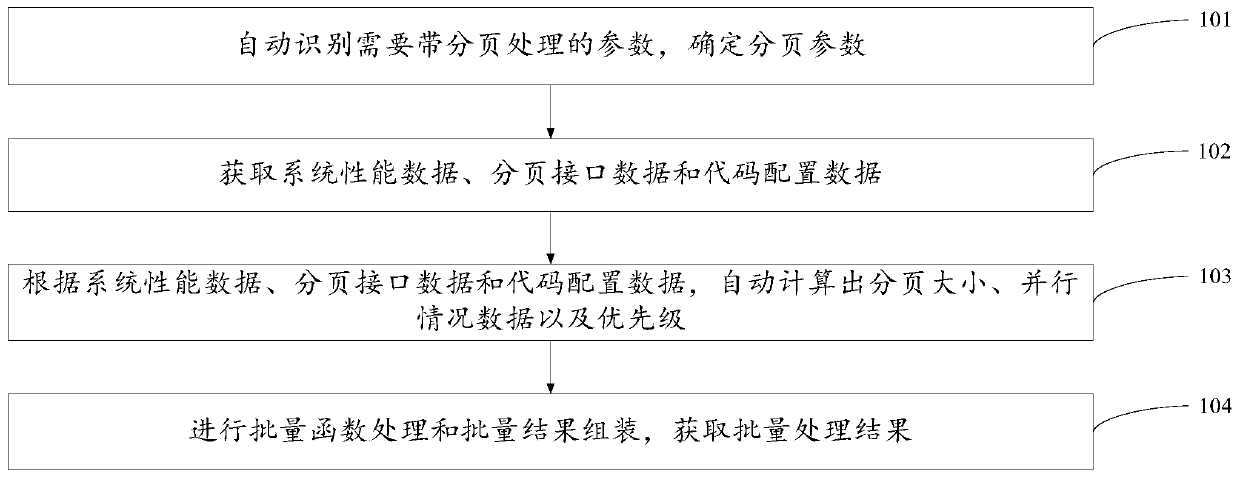

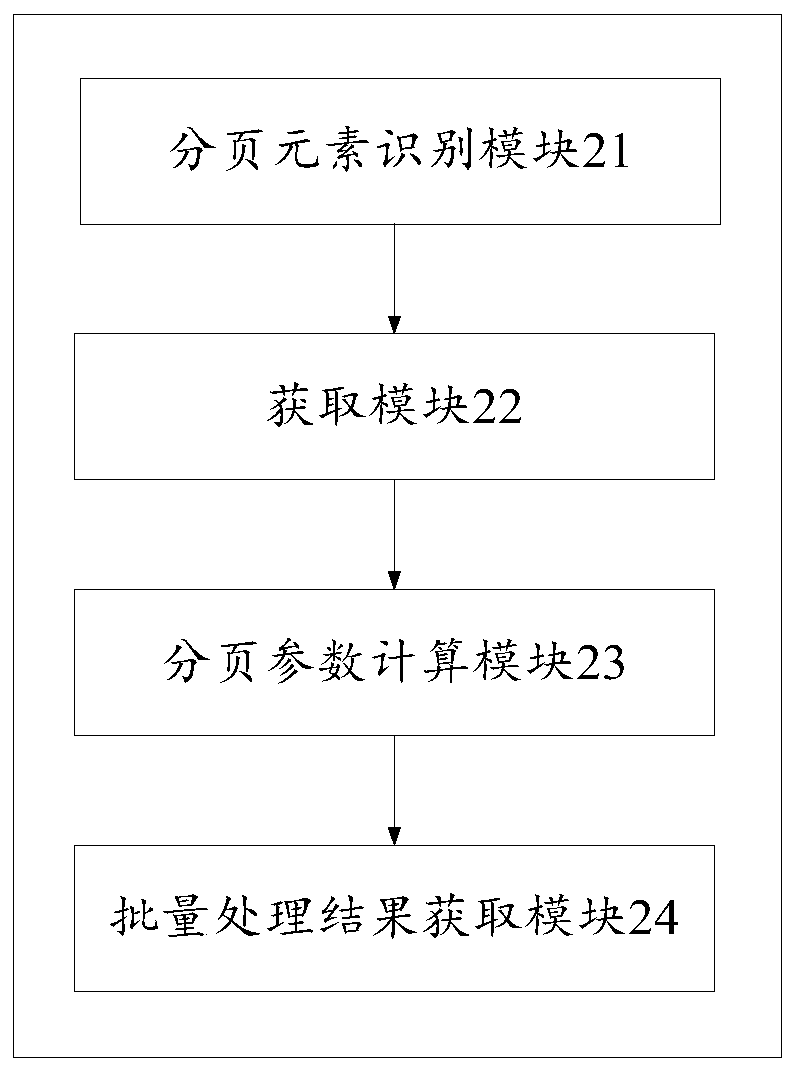

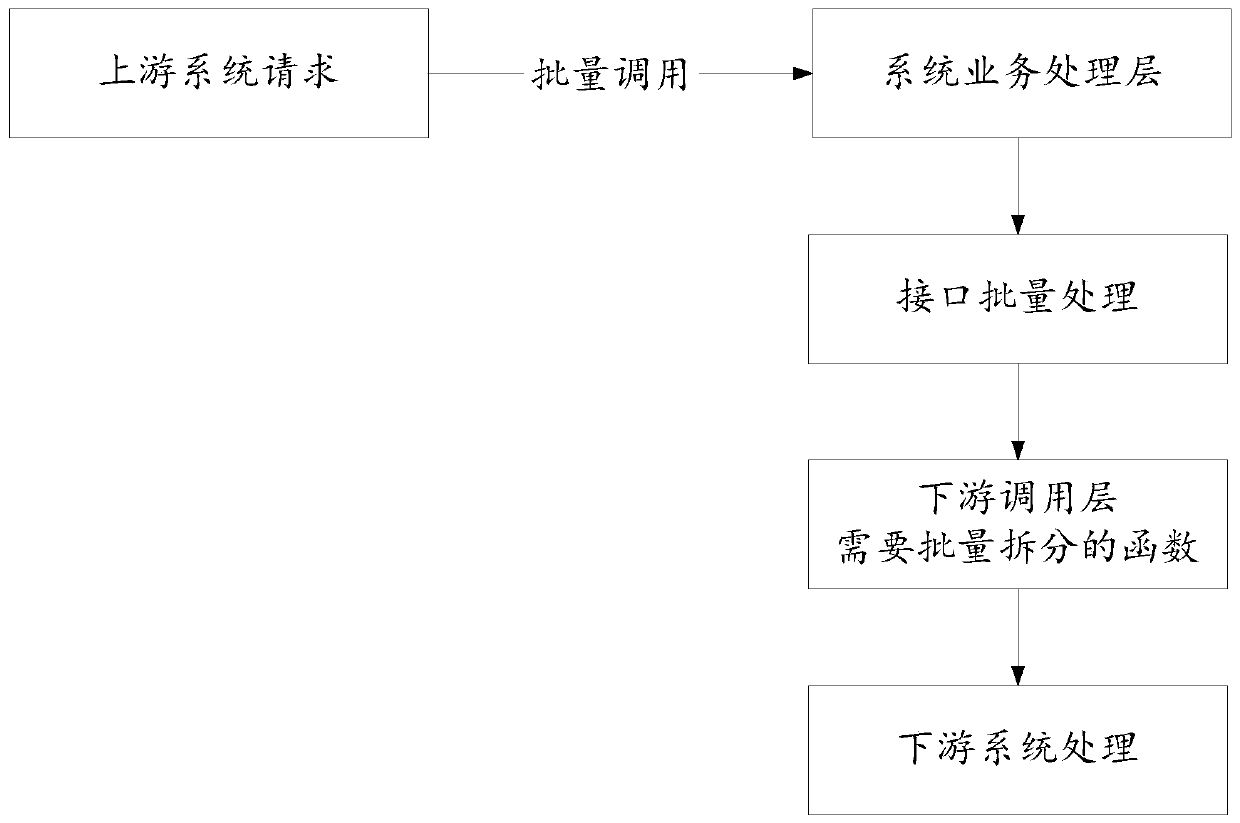

Interface batch processing method and device

PendingCN110333934ASolve the problem of refusal to processImprove development efficiencyResource allocationTransaction processingBatch processingParallel computing

The invention discloses an interface batch processing method and device, and belongs to the technical field of computers. The interface batch processing method comprises the steps: automatically recognizing parameters needing paging processing, and determining paging parameters; acquiring system performance data, paging interface data and code configuration data; according to the system performance data, the paging interface data and the code configuration data, automatically calculating the paging size, the parallel condition data and the priority; and performing batch function processing andbatch result assembly to obtain a batch processing result. According to the interface batch processing method, the problem that the downstream refuses to process due to overlarge batch data volume issolved, and the development efficiency, the processing performance and the adaptability are improved, and the processing time consumption is reduced.

Owner:南京苏宁加电子商务有限公司

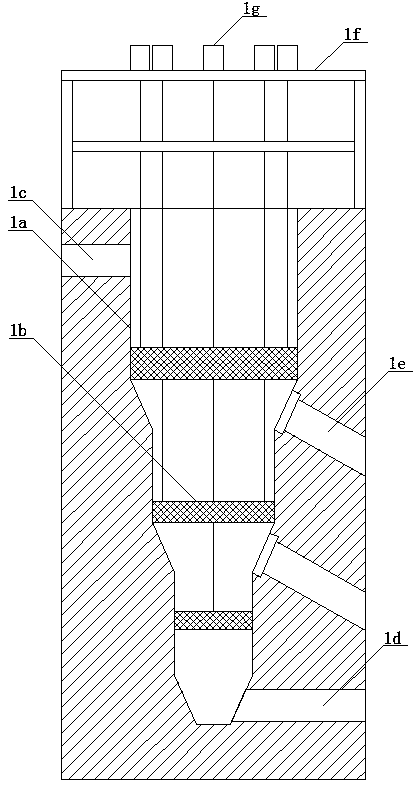

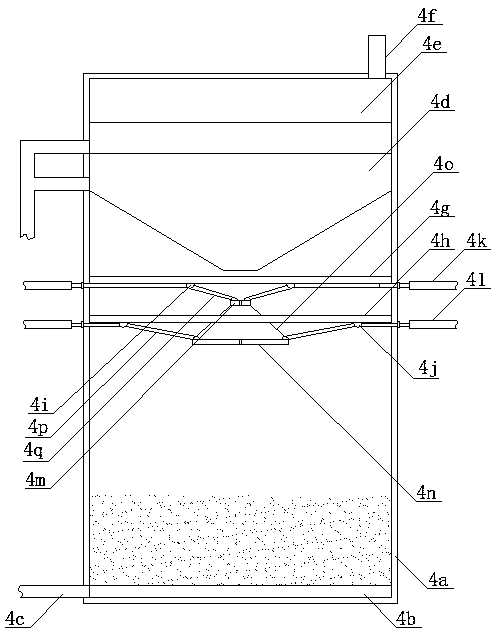

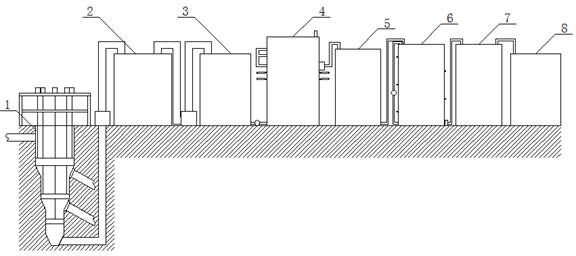

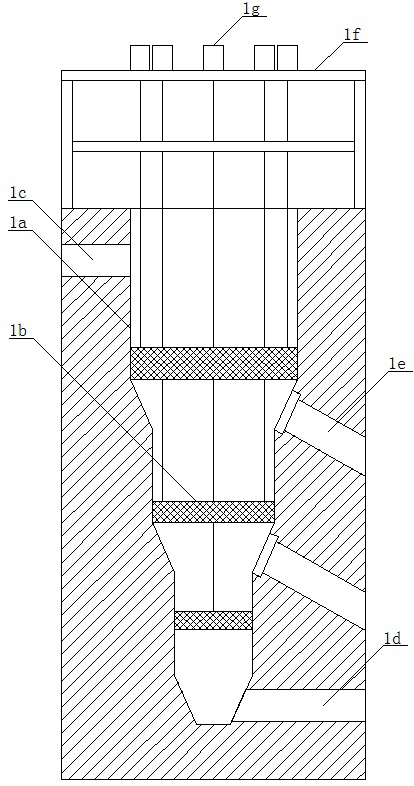

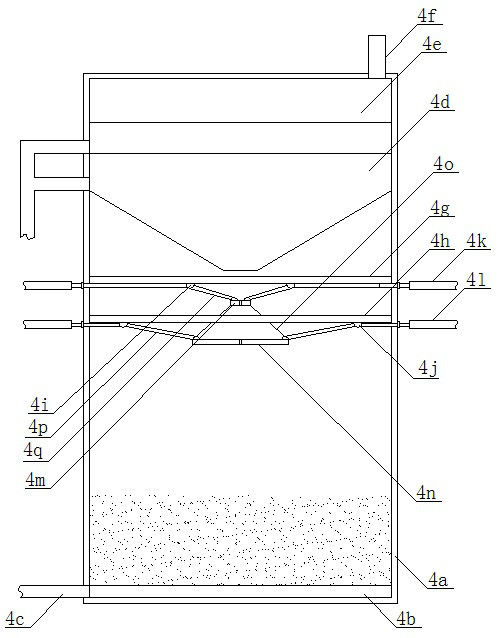

Bean product sewage treatment method and system

ActiveCN109678300AEasy to handleStabilizationTreatment using aerobic processesTreatment involving filtrationGratingMunicipal sewage

The invention discloses a bean product sewage treatment method. The bean product sewage treatment method comprises the steps of filtering bean product sewage by using a filtering grating, transportinga suspended solid and a floating object outside; preliminarily settling the filtered sewage; adding a PH regulator into a supernatant liquid; feeding the liquid into an anaerobic reaction tank to react; filtering and removing a scum of the reacted liquid, feeding the liquid into a bio-contact oxidation reaction tank to react; fluctuating and settling the reacted liquid, standing to layer, and discharging a supernatant outside. The method has the advantage of efficient and stable processing. The invention further discloses a bean product sewage treatment method, and the system comprises a sewage pretreatment device, a preliminary settling tank, a regulating tank, the anaerobic reaction tank, a filter tank, the bio-contact oxidation reaction tank, a settling tank, and a clean water tank which are sequentially connected through pipelines. The system is used for treating a large quantity of sewage, and is suitable for large-scale bean product processing enterprises and processing zones, and the treated water can be directly discharged into the municipal sewage pipe network.

Owner:云南天朗环境科技有限公司

A kind of soybean product sewage treatment method and system

ActiveCN109678300BEasy to handleStabilizationTreatment using aerobic processesTreatment involving filtrationSoybean productTreatments water

The invention discloses a soybean product sewage treatment method. The soybean product sewage is filtered with a filter grid, suspended solids and floating objects are transported outside; the filtered sewage is taken for primary precipitation; the upper layer liquid is taken and a pH regulator is added; Then the liquid is sent to the anaerobic reaction tank for reaction; the reacted liquid is filtered to remove scum, and then sent to the biological contact oxidation reaction tank for reaction; the reacted liquid is taken for flocculation and precipitation, and it is left to stand for stratification , the supernatant was drained out. The method of the invention has the advantages of efficient and stable treatment. The invention also discloses a system for treating soybean product sewage. The system of the invention includes a sewage pretreatment device, a primary sedimentation tank, a regulating tank, an anaerobic reaction tank, a filter tank, and a biological contact oxidation reaction tank connected sequentially through pipelines. , sedimentation tank, clear water tank. The system of the invention has a large amount of treated water, and is suitable for large soybean product processing enterprises and processing parks, and the treated water can be directly discharged into municipal sewage pipe networks.

Owner:云南天朗环境科技有限公司

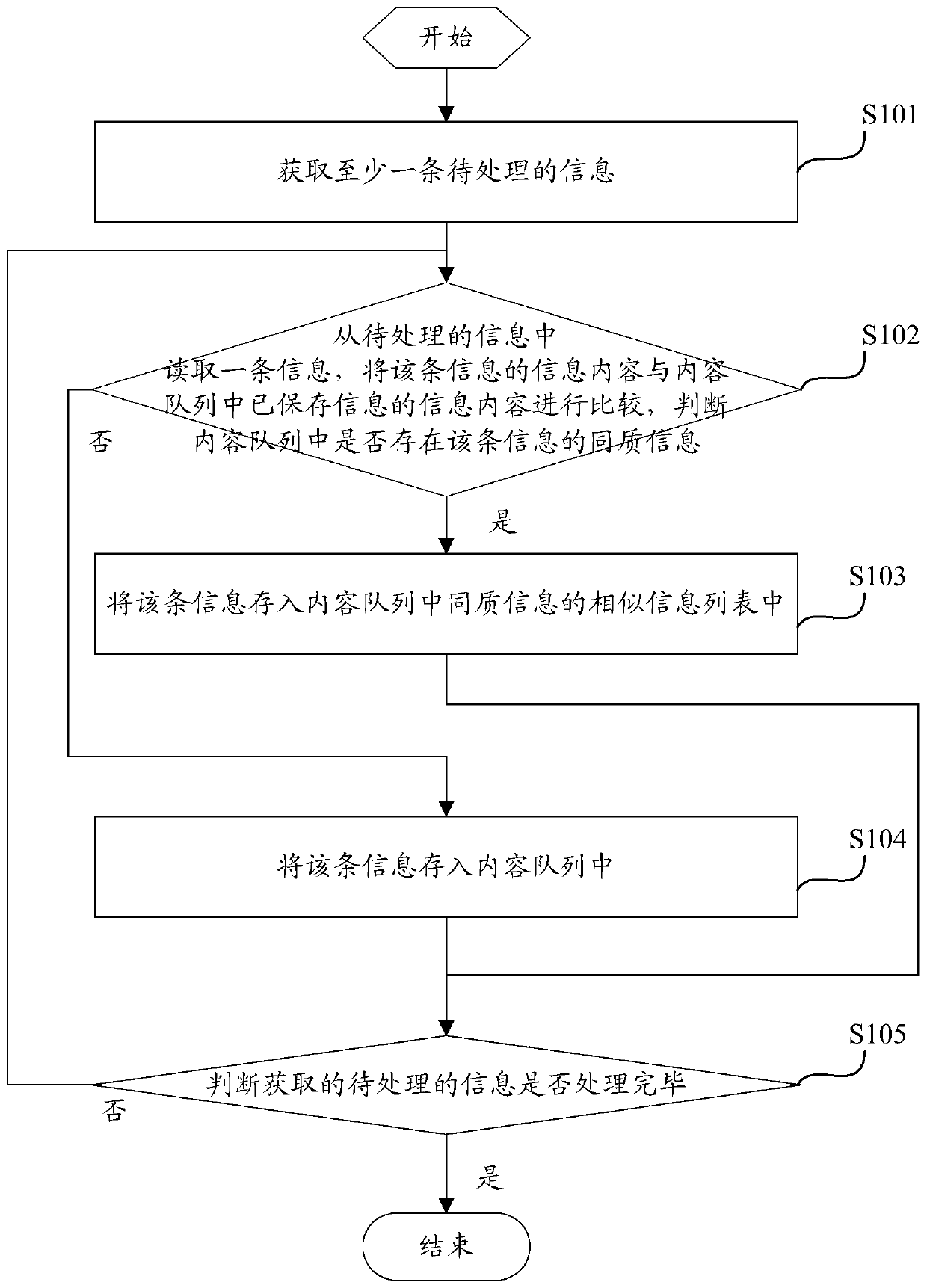

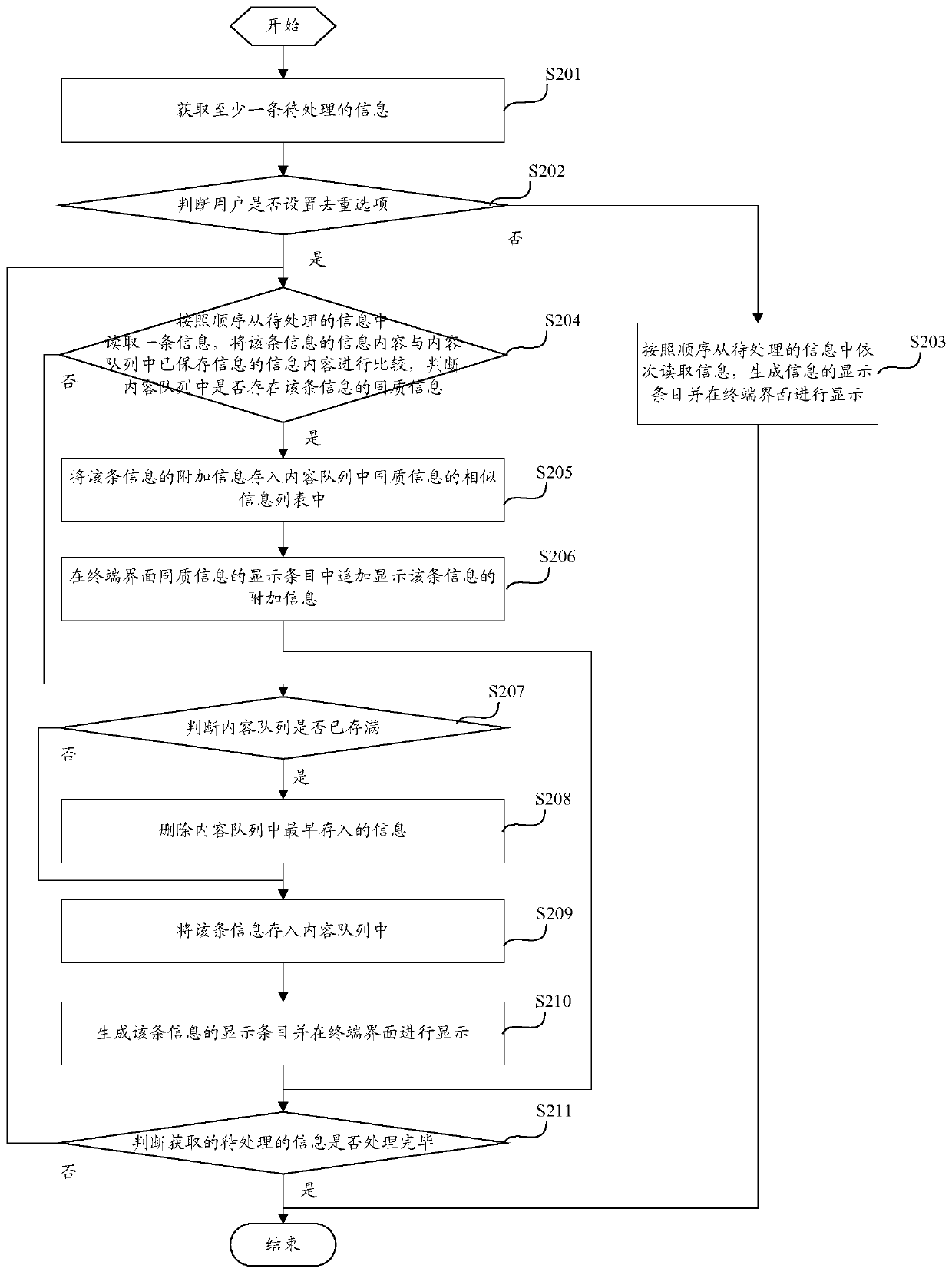

Information processing method and device applied to terminal

ActiveCN107609062BDoes not affect normal processingImprove reading experienceText database queryingSpecial data processing applicationsInformation processingEngineering

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

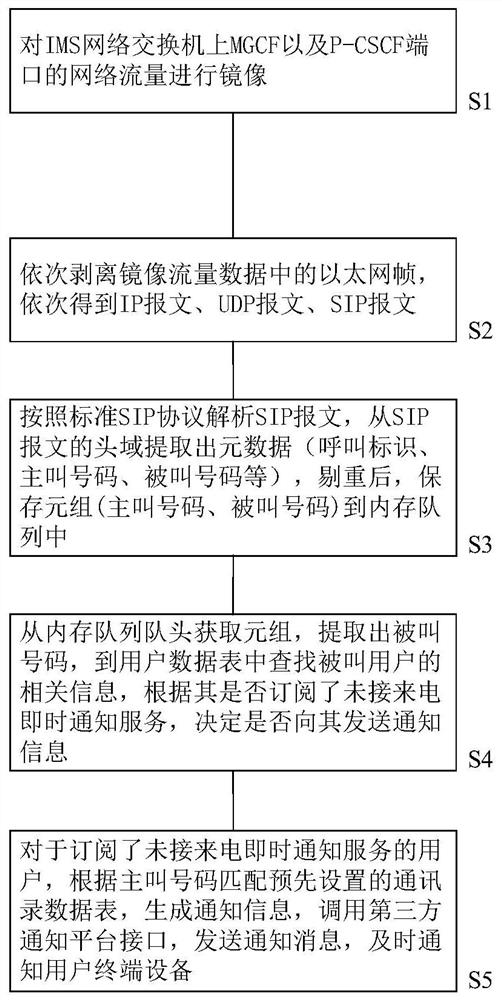

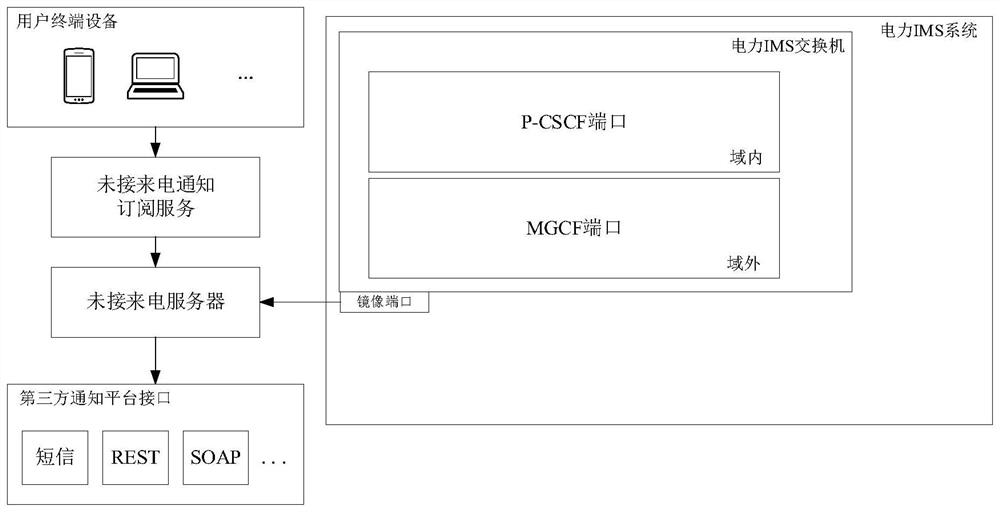

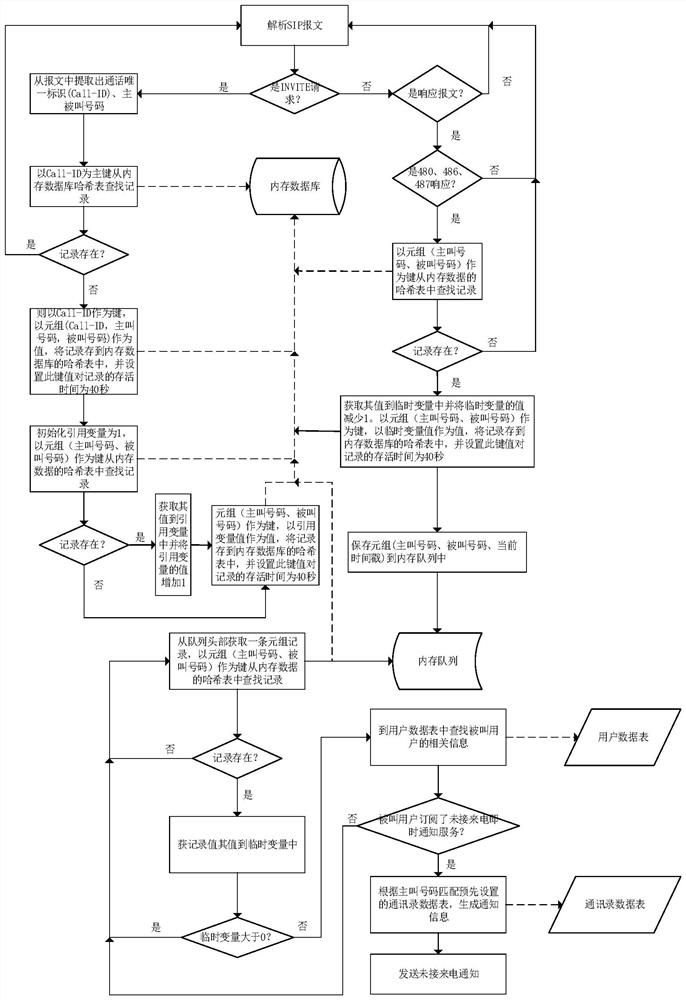

A method and system for instant notification of missed calls from multiple accounts in an IMS network

ActiveCN110912885BInstant processingComprehensive treatmentTransmissionCommunications systemOffice workers

The invention discloses an instant notification method and system for multi-account missed calls in an IMS network. The Ethernet frames in the mirrored traffic data on the IMS network switch are stripped sequentially to obtain SIP messages; the SIP messages are analyzed, and the SIP messages are obtained from The header field extracts the call ID, calling number, and called number. After deduplication, save the calling number and called number in the memory queue; obtain the calling and called numbers from the memory queue. If the called user subscribes to the Receive an instant notification service for incoming calls, and send notification messages to notify users in a timely manner. Missed calls in the IMS administrative switching network of the present invention can be processed immediately, and telephone terminal users are no longer bound by fixed telephones; integrated notifications are performed for single-user multi-account communication systems; services are only provided for subscribers, avoiding invalid notifications, Save server resources; the content of the notification message is detailed information, which is convenient for the immediate processing of the office staff.

Owner:INFORMATION & COMM BRANCH OF STATE GRID JIANGSU ELECTRIC POWER +1

Linear cutting gear-aligning clamp of reducer gear

PendingCN108380991AGuaranteed stabilityGuaranteed normal processingElectrical-based auxillary apparatusEngineeringMachining

The invention discloses a linear cutting gear-aligning clamp of a reducer gear. The linear cutting gear-aligning clamp comprises a base, connecting springs and pull rods. A supporting frame is fixed to the upper portion of the base, and a cushion block is connected to the top of the supporting frame. A mandrel is arranged in the cushion block, and connecting plates are mounted on the upper side and the lower side of the mandrel. Sliding grooves are formed in the connecting plates, and first clamping blocks are connected to the upper portions of the sliding grooves. The connecting springs and the mandrel are connected, and second clamping blocks are arranged on the left sides of the connecting springs and fixed to the tops of the pull rods. A connecting shaft is connected to the bottoms ofthe pull rods, and a connecting rod is arranged at the bottom of the connecting shaft. The gear is arranged above the cushion block. According to the linear cutting gear-aligning clamp of the reducergear, the cushion block is arranged, the diameter of the cushion block is larger than the diameter of a middle hole, namely a shaft hole, of the gear, thus the falling phenomenon can be avoided duringgear placing, and normal machining of the gear is guaranteed.

Owner:盐城市金洲机械制造有限公司

Service shunting method, device and system

InactiveCN101917679BDoes not affect normal processingImprove experienceNetwork traffic/resource managementMessaging/mailboxes/announcementsWireless Application ProtocolDomain Name System

The embodiment of the invention discloses service shunting method, device and system, which relate to the field of communications. When an MMSC (Multimedia Messaging Service Center) is busy, multimedia messages can be implemented and issued; when service is shunted, the normal processing of the service is not influenced, and the user experience is further increased. The method comprises the following steps of: after sending an extraction notice request to a user agent (UA) by the MMSC, detecting that a performance parameter of the MMSC exceeds a predefined threshold by an Enum DNS (Enumeration Domain Name System), distributing UA number segments which belong to the one MMSC to the other MMSC which satisfies a shunting request; sending an extracted notice answer to the other MMSC by WAP GW(Wireless Application Protocol Gross Weight); and sending the extracted notice answer to the MMSC which is used for processing the service by judging the service is not service processed by self of the other MMSC. The embodiment is mainly used for a service shunting process.

Owner:程龙

Intelligent tuning method and system based on handshake protocol

ActiveCN113589759BDoes not affect normal processingReduce machine set-up timeProgramme controlComputer controlNumerical controlData transformation

The invention discloses a method and system for intelligent machine tuning based on a handshake protocol, which is used for intelligent machine tuning of at least one numerical control machine. The method includes the following steps: S1: Acquiring the measurement model parameters of the numerical control machine, And receive the actual measurement data of the processed parts collected by the CNC machine, wherein the actual measurement data of the processed parts collected by the CNC machine is received by establishing a handshake protocol based on the system macro variable with the CNC machine; S2: According to the measurement Model parameters convert the actual measurement data of the processed parts collected by the CNC machine into measurement data in a standard format; S3: Solve the optimized compensation value of the CNC machine according to the measurement data in the standard format and the measurement model parameters; S4: The optimized compensation value is sent back to the numerical control machine, so that the numerical control machine performs machine adjustment according to the optimized compensation value. The invention solves the problem of "adjustment" in the prior art.

Owner:INREVO CO LTD

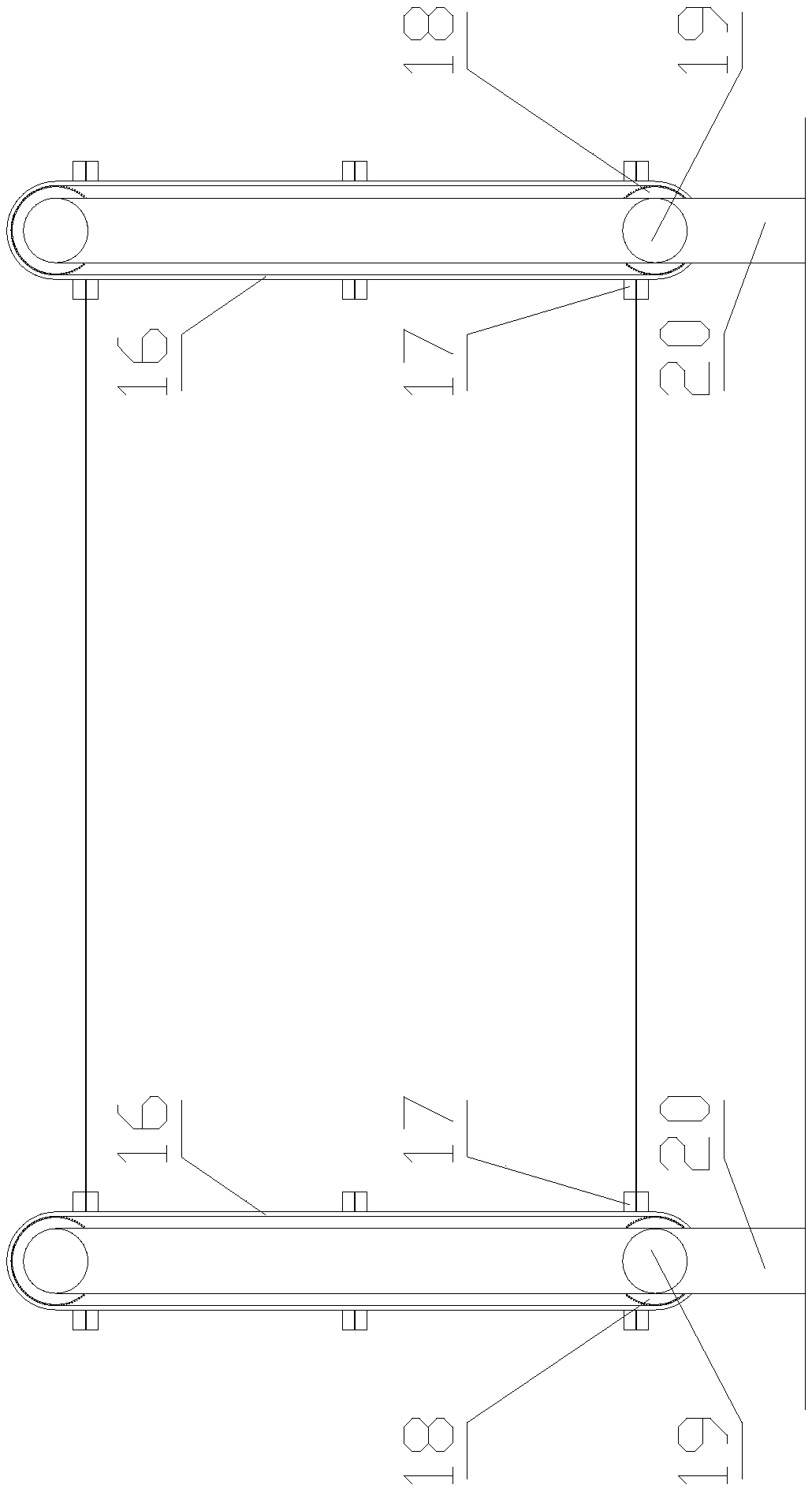

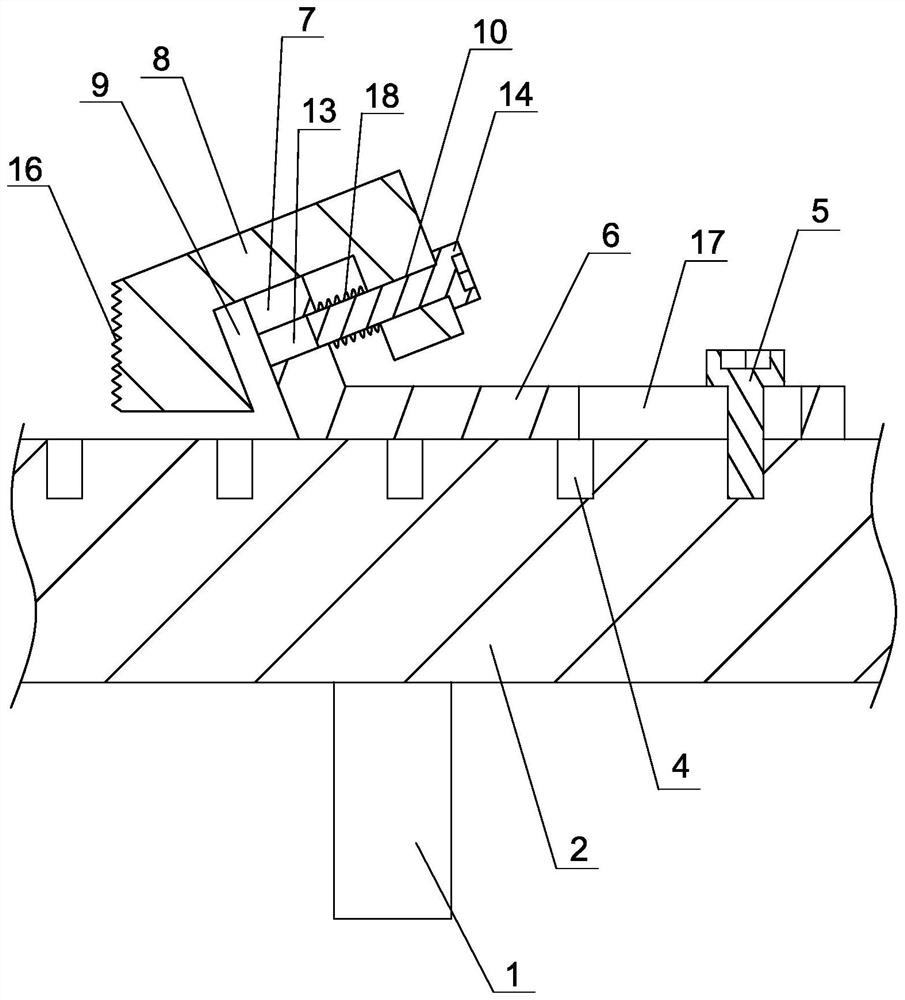

A feeding mechanism for a slitting machine

ActiveCN107161756BDoes not affect normal processingArticle deliveryWebs handlingEngineeringMachining process

The invention provides a feeding mechanism of a slitting machine. The feeding mechanism of the slitting machine comprises feeding frame assemblies, roll shaft assemblies and centering assemblies, wherein the number of the feeding frame assemblies is two; the feeding frame assemblies are symmetrically distributed at the two ends of the roll shaft assemblies and fixedly connected with the roll shaft assemblies; the number of the centering assemblies is two; the centering assemblies are located at the front ends of the feeding frame assemblies, correspond to the roll shaft assemblies in position and are symmetrically distributed on the two sides of the center of the slitting machine, and it is ensured that the center of the two centering assemblies is the center of the slitting machine; the number of the roll shaft assemblies is at least two; and the roll shaft assemblies are fixed between the two feeding frame assemblies and can freely rotate on the feeding frame assemblies. When the feeding mechanism of the slitting machine is installed, the feeding mechanism is directly aligned with the center of equipment through the centering assemblies, and manual centering is not needed; meanwhile, a plurality of rolls are adopted for feeding, and aligned products can be directly fed without halt or installation after one roll is used; and besides, in the machining process, a raw material roll can be installed continuously, and normal machining of the equipment is not affected.

Owner:苏州恒坤精密电子有限公司

Continuous die feeding and anti-dislocation method

InactiveCN104438826BWon't breakDoes not affect normal processingShaping toolsShaping safety devicesStopped workControl system

The invention discloses a progressive die material conveying dislocation preventing method. the method comprises the steps that a detecting pin is pre-arranged on a lower die, a pin hole is formed in the corresponding position of an upper die, and in the normal feeding process, the pin hole is aligned to the hollowed position of a workpiece; when feeding is not carried out in place, the pin hole is aligned to the solid position of the workpiece, in the die assembling process, the upper die generates downward pressure on the detecting pin through the solid position of the workpiece, the detecting pin is made to move downwards, when the detecting pin moves by the set distance, the detecting pin triggers an induction switch, the induction switch is connected with a control system, and a progressive die is controlled by the control system to stop working immediately. According to the method, normal use of equipment can be effectively guaranteed, the situation that the workpiece and the equipment are bashed due to the fact that feeding is not carried out in place is avoided, and work is reliable.

Owner:黑龙江至信机械制造有限公司

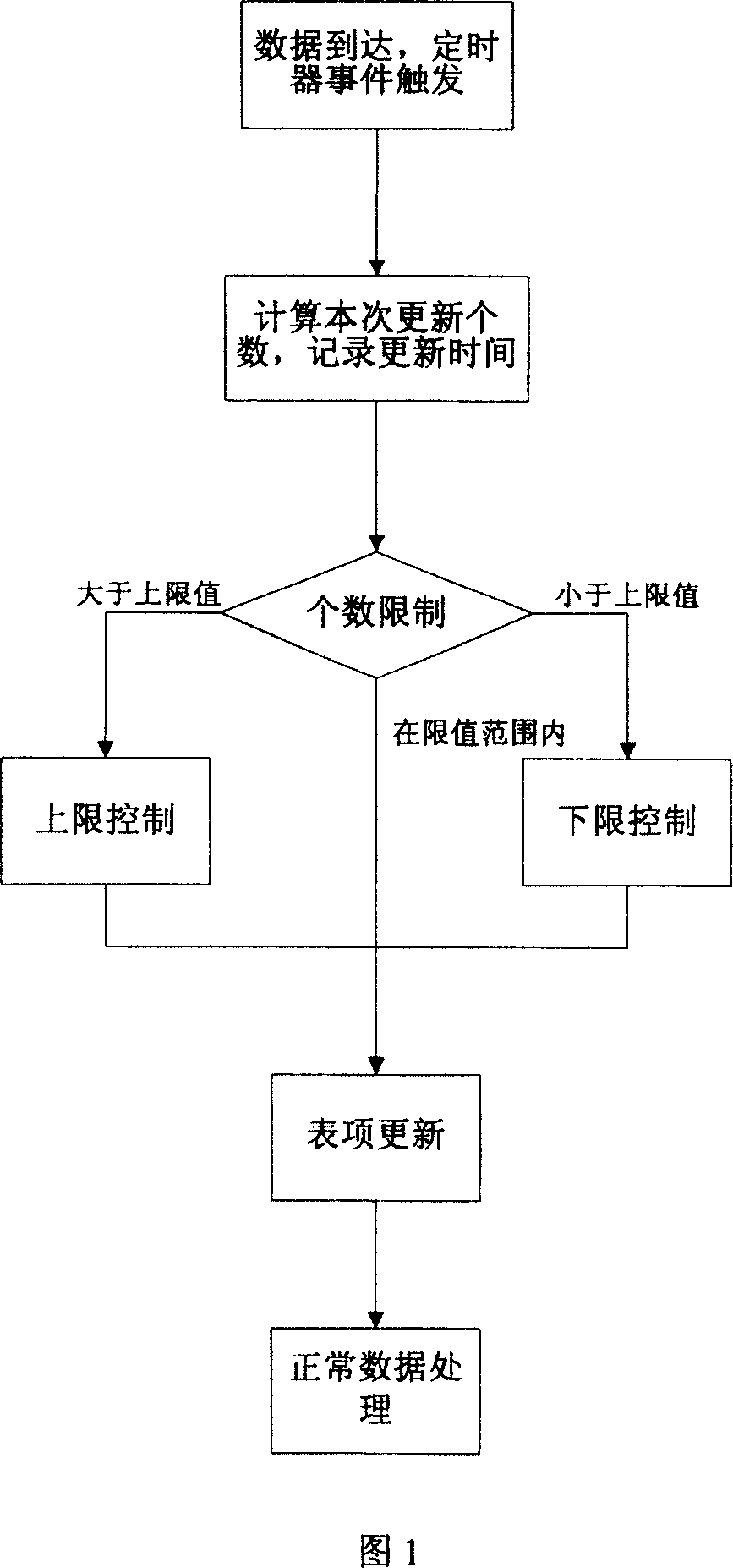

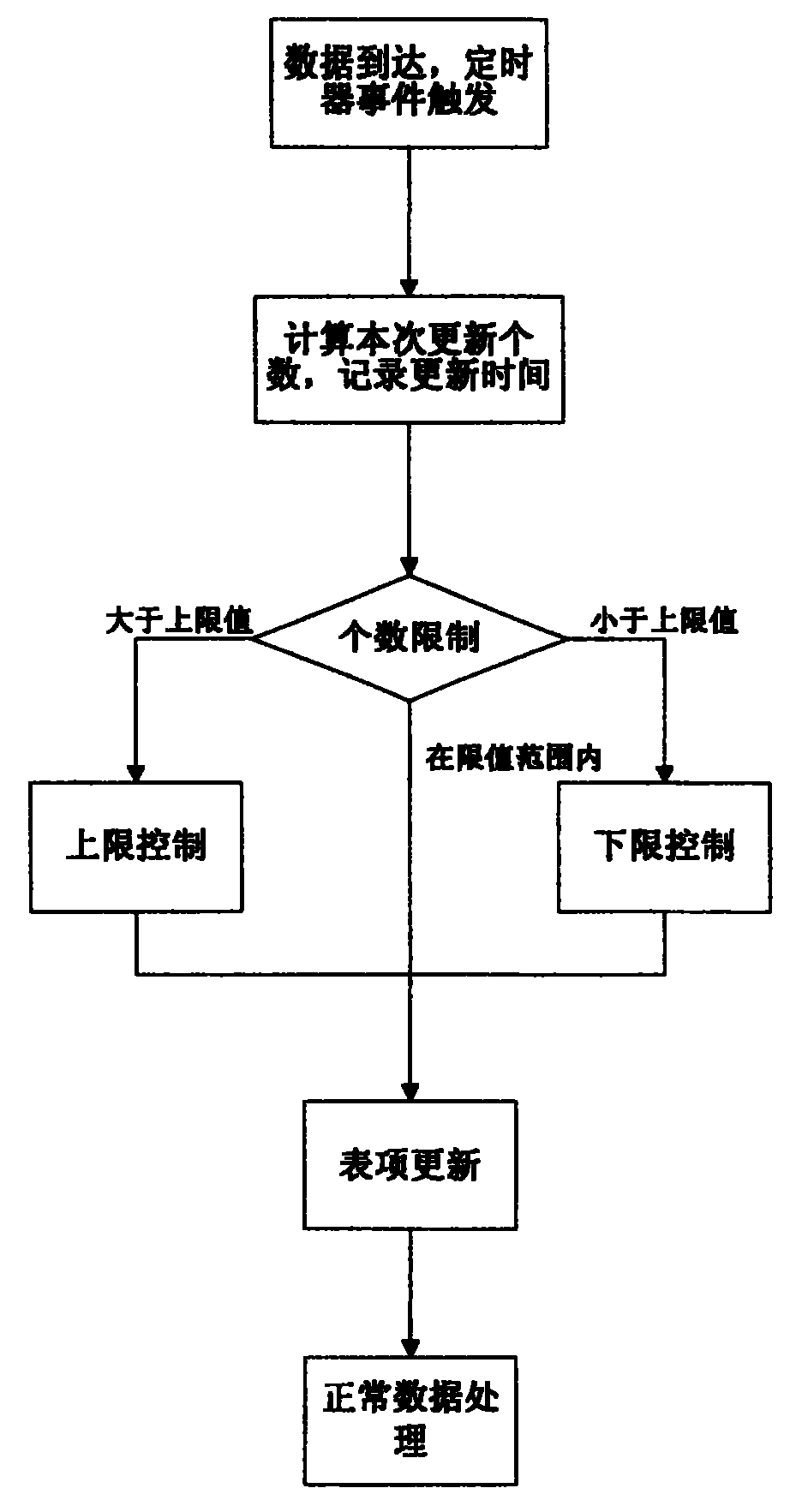

Storage table renewing method

A method for updating the storage list includes determining the average ergodic period of storage list and the upper limit of the number of list terms to be updated at the same time, receiving a data and recording its arrival time, calculating the number of list terms to be updated this time, setting up it to the upper limit if it is higher then upper limit, and updating the list term. Its advantage is equalizing system load.

Owner:ZTE CORP

Anti-cracking self-healing agent for concrete and preparation method thereof and anti-cracking self-healing concrete

Owner:东莞市冠峰混凝土有限公司

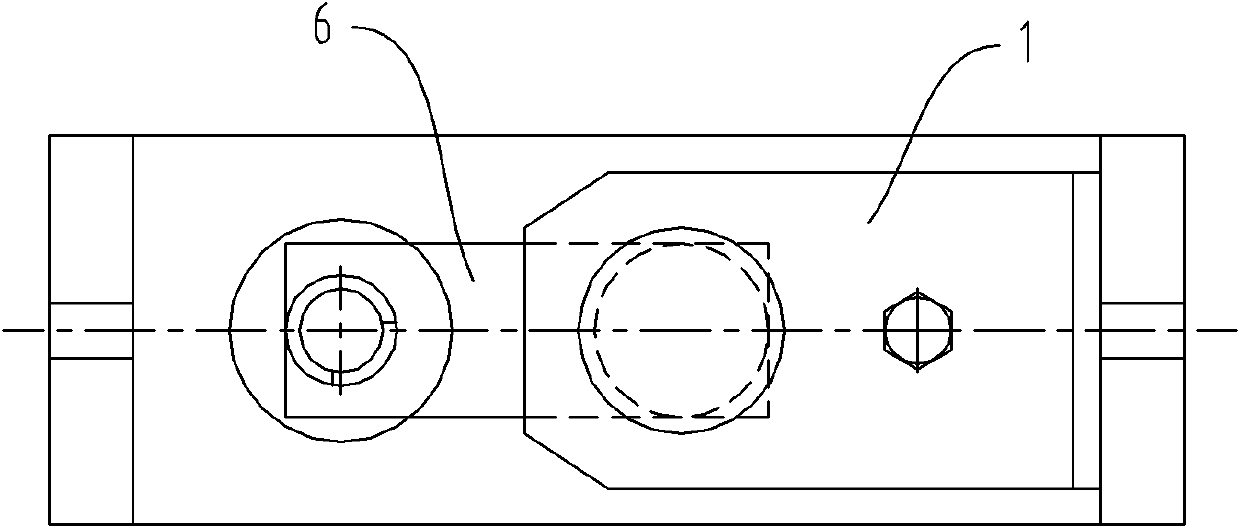

Processing positioning device and positioning method for nitrogen-containing austenite forge piece

PendingCN114290099AImprove quality and positioning efficiencyIncrease the scope of applicationPositioning apparatusMetal-working holdersForgingAustenite

The invention discloses a processing positioning device and positioning method for nitrogen-containing austenite forgings, the processing positioning device comprises a rack, a supporting table and an even number of groups of positioning mechanisms, and is characterized in that a plurality of groups of mounting screw holes are formed in the top surface of the supporting table, and each group of positioning mechanism is in threaded connection with one group of mounting screw holes through a mounting bolt; the positioning mechanism comprises a bottom connecting piece and a product limiting piece, the bottom connecting piece comprises a bottom plate and a connecting plate, the bottom face of the bottom plate abuts against the top face of the supporting table, the bottom plate is connected with the mounting screw holes in a locked mode through mounting bolts, the bottom of the connecting plate is connected with the inner end of the bottom plate, and the product limiting piece is arranged on the bottom plate. The connecting plate is inclined inwards from bottom to top; the product limiting piece is installed on the connecting plate and comprises a locking block, and the locking block is pushed by a locking bolt to move on the connecting plate. The positioning efficiency and quality are improved, and the cost is reduced.

Owner:江阴市劲松科技有限公司

Double-headed tapping clamp

ActiveCN102528179BDoes not affect normal processingAvoid machining errorsThread cutting machinesPositioning apparatusEngineeringMechanical engineering

The invention provides a reasonable double-headed tapping clamp for a valve, which solves the problem of low repeated positioning precision of blanks due to scattered working procedures, and ensures product precision and processing efficiency in tapping. The double-headed tapping clamp comprises a clamp body and a pressing plate device which is arranged on the clamp body and used for clamping a workpiece needing tapping on the clamp body, and the pressing plate device comprises a pressing plate and a clamping screw rod. A lower through hole is arranged on the clamp body, an upper through hole is arranged on the pressing plate, and both the diameter of the upper through hole and the diameter of the lower through are larger than the major diameter of a screw tap for tapping. When the workpiece is clamped on the clamp body by the pressing plate device, an upper inner hole at the upper end of the workpiece needing tapping is coaxial with the upper through hole, a lower inner hole at the lower end of the workpiece needing tapping is coaxial with the lower through hole, and a cylindrical mandrel matched with the lower inner hole is coaxial with the lower through hole and is connected with a vertical movement driving device for driving the cylindrical mandrel to vertically move along the axis.

Owner:JIANGSU ZUZEM VALVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com