Processing positioning device and positioning method for nitrogen-containing austenite forge piece

A positioning device and austenitic technology, applied in the field of forging, can solve the problems of unstable positioning quality, affecting product surface processing, high cost, etc., and achieve the effect of improving positioning efficiency and quality, improving processing efficiency, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

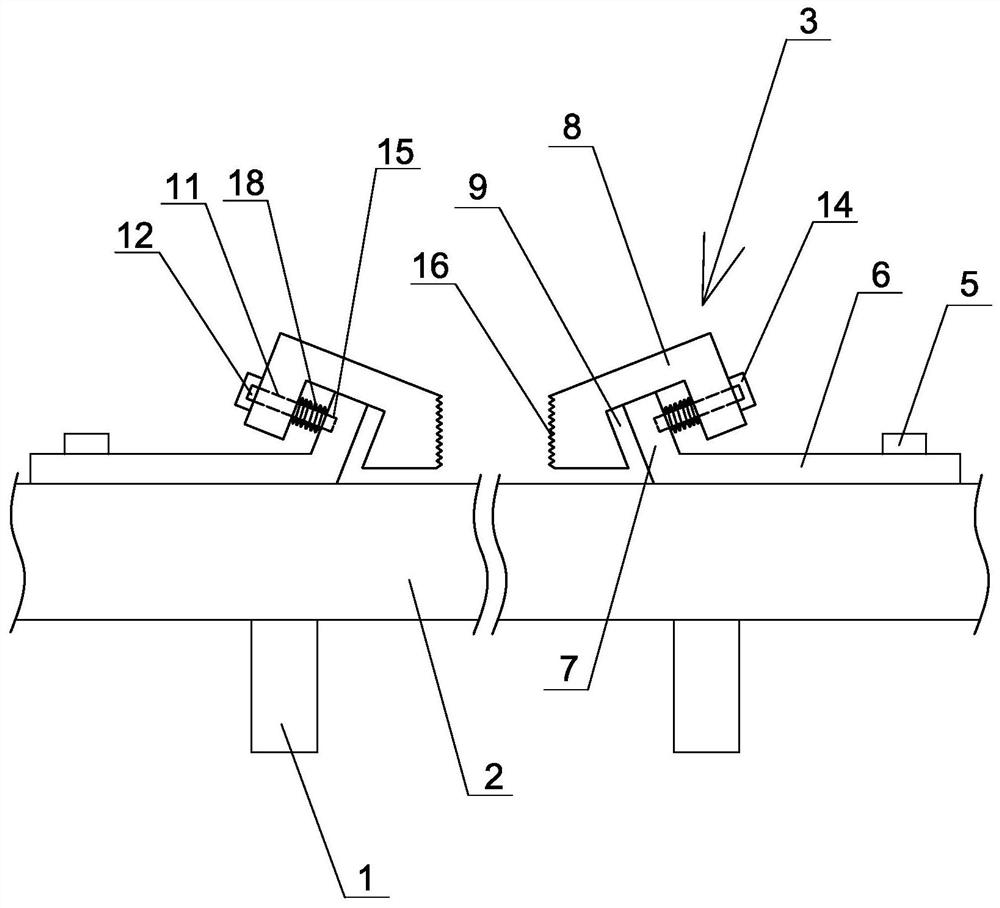

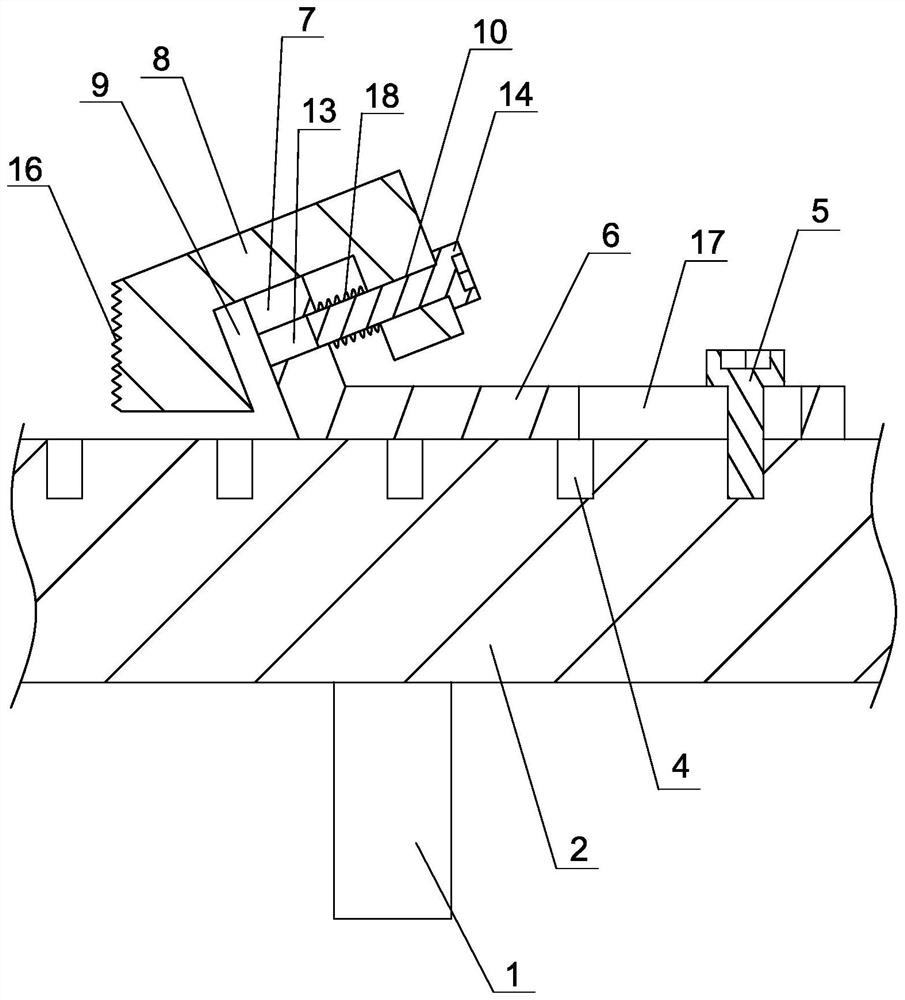

[0028] Embodiment one: see figure 1 , 2 As shown, a processing and positioning device for nitrogen-containing austenite forgings includes a frame 1, a support platform 2 arranged on the frame, and a positioning mechanism 3 arranged on the support platform. The positioning mechanisms are an even number, respectively symmetrically arranged on the left and right sides of the support platform;

[0029] The top surface of the support platform is provided with multiple sets of mounting screw holes 4, and each set of positioning mechanisms is connected to one set of mounting screw holes through a mounting bolt 5;

[0030] The positioning mechanism includes a bottom connector and a product limiter. The bottom connector includes a bottom plate 6 and a connecting plate 7. The bottom surface of the bottom plate is against the top surface of the support table. The mounting screw holes are locked and connected, the bottom of the connecting plate is connected with the inner end of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com