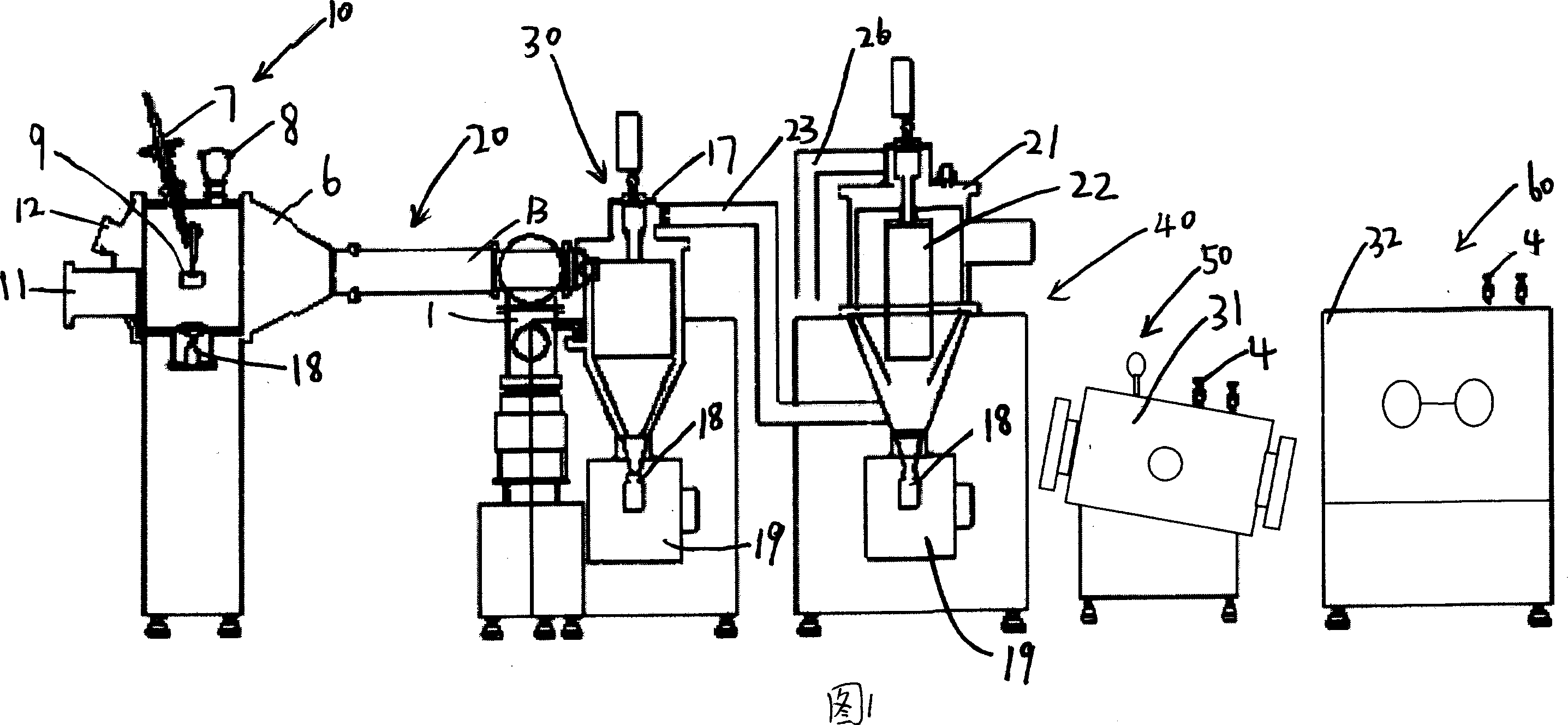

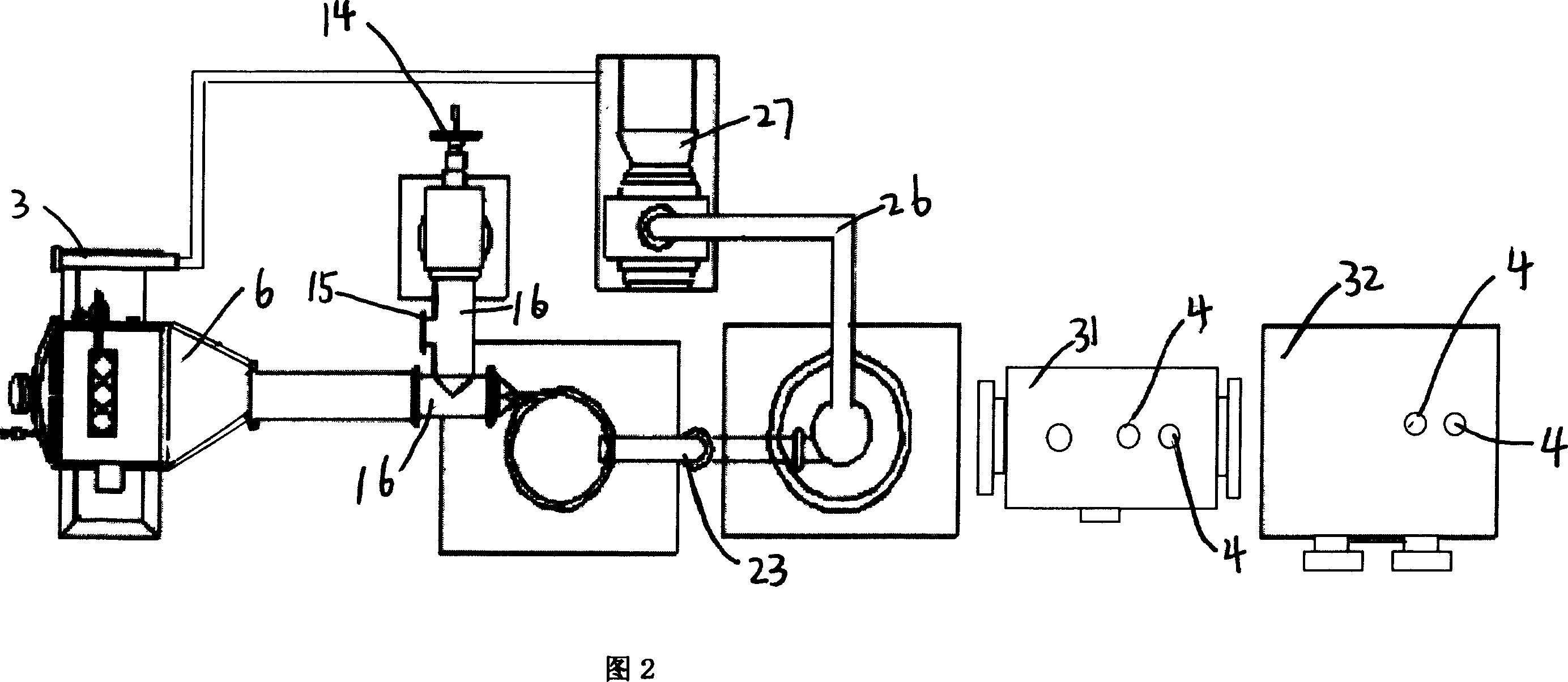

Continuous production apparatus for nano metal powder

A technology for nanometer metal powder and production equipment, which is applied in the field of preparation of nanometer metal powder, nanometer metal compound and coated nanometer metal powder, can solve the problem of poor purity of nanometer metal powder, low equipment yield and unstable arc combustion. and other problems, to achieve the effect of improving the scope of application and market competitiveness, increasing reliability and stability, and reducing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: Table 1 is the preparation experiment result of the nano Ni powder of the equipment of the present invention, compared with traditional equipment, the maximum productive rate of single gun nano Ni powder has improved 25 times.

[0067] The preparation experiment result of table 1 nanometer Ni powder

[0068] sample

Embodiment 2

[0069] Example 2: Table 2 shows the experimental results of the preparation of nano-Cu powder of the equipment of the present invention. Compared with traditional equipment, the maximum yield of single-gun nano-Cu powder is increased by 204.7 times.

[0070] The preparation experiment result of table 2 nanometer Cu powder

[0071] sample number

Embodiment 3

[0072] Embodiment 3: the preparation of highly uniform elemental mixed nano-copper-nickel composite powder, according to the following process parameters: H 2 / Ar=2 / 8, pressure=0.06MPa, electric current: 350A (nickel pole) and 300A (copper pole), the productive rate of Cu, Ni composite powder prepared by two guns is 75.1g / h, makes the powder body The average particle diameter is 54nm.

[0073] There are still many specific examples of the device of the present invention, which will not be repeated here.

[0074] The working process of the present invention is: open electrical control and pressure monitoring system:

[0075] 1. Put the metal material into the raw material storage and water-cooled crucible, purify and seal the working room, and obtain the vacuum measurement system to work to the set vacuum degree (2×10 -3 Stop after Pa);

[0076] 2. The inflation system works and fills in the selected gas (filling with Ar gas and H 2 air to 0.1-0.9 atmospheres), and hold aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com