Patents

Literature

164 results about "Particle control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

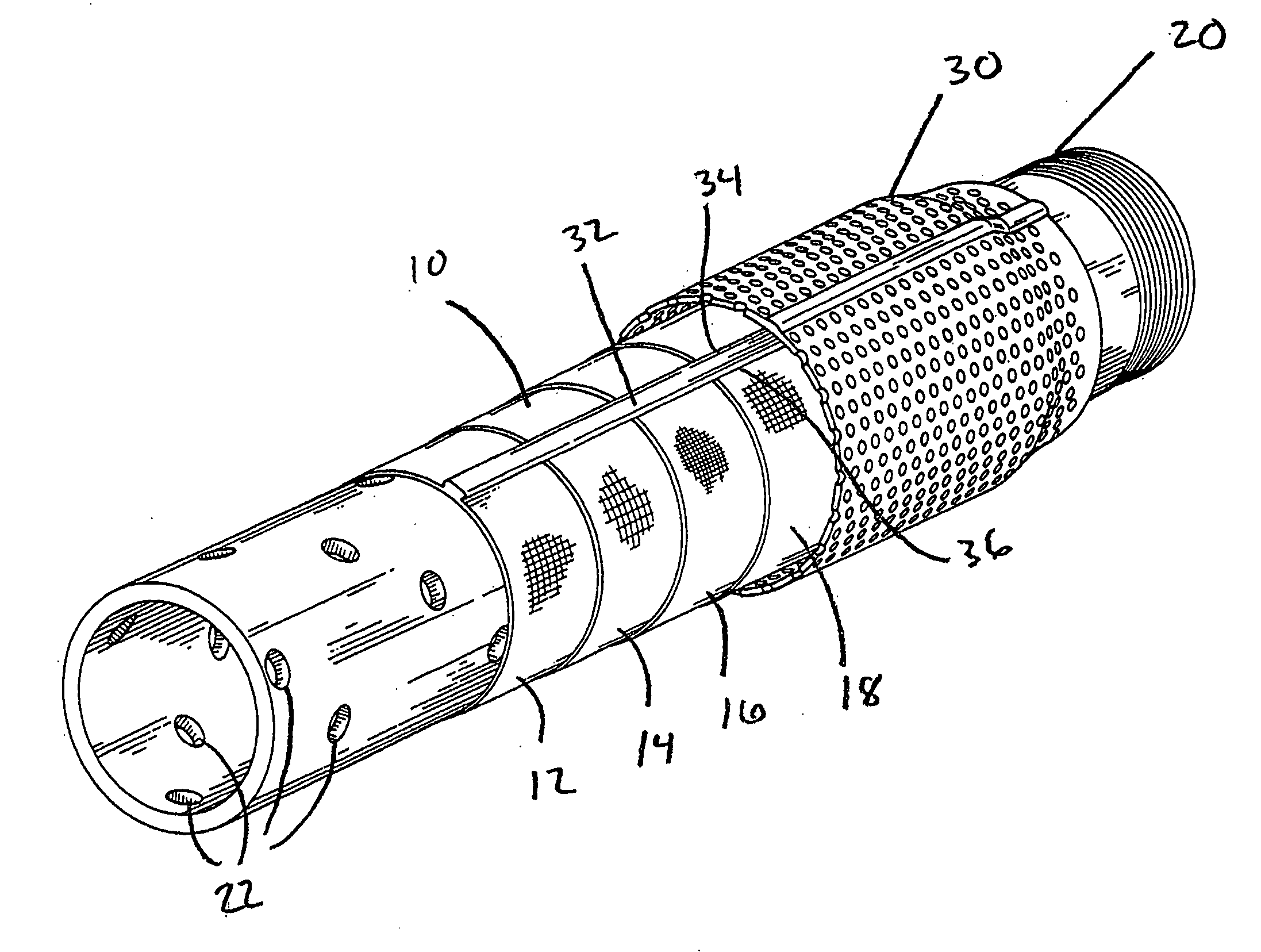

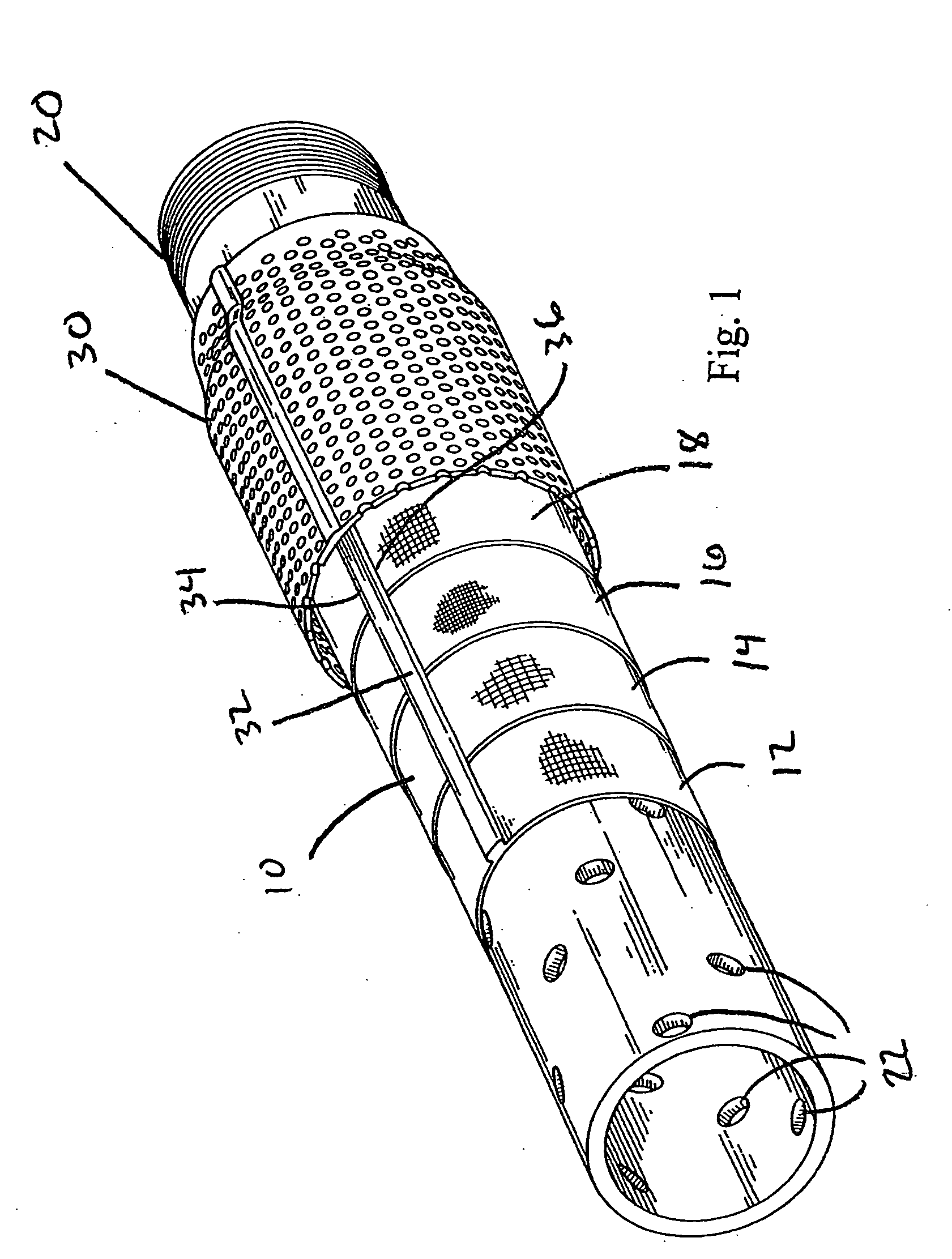

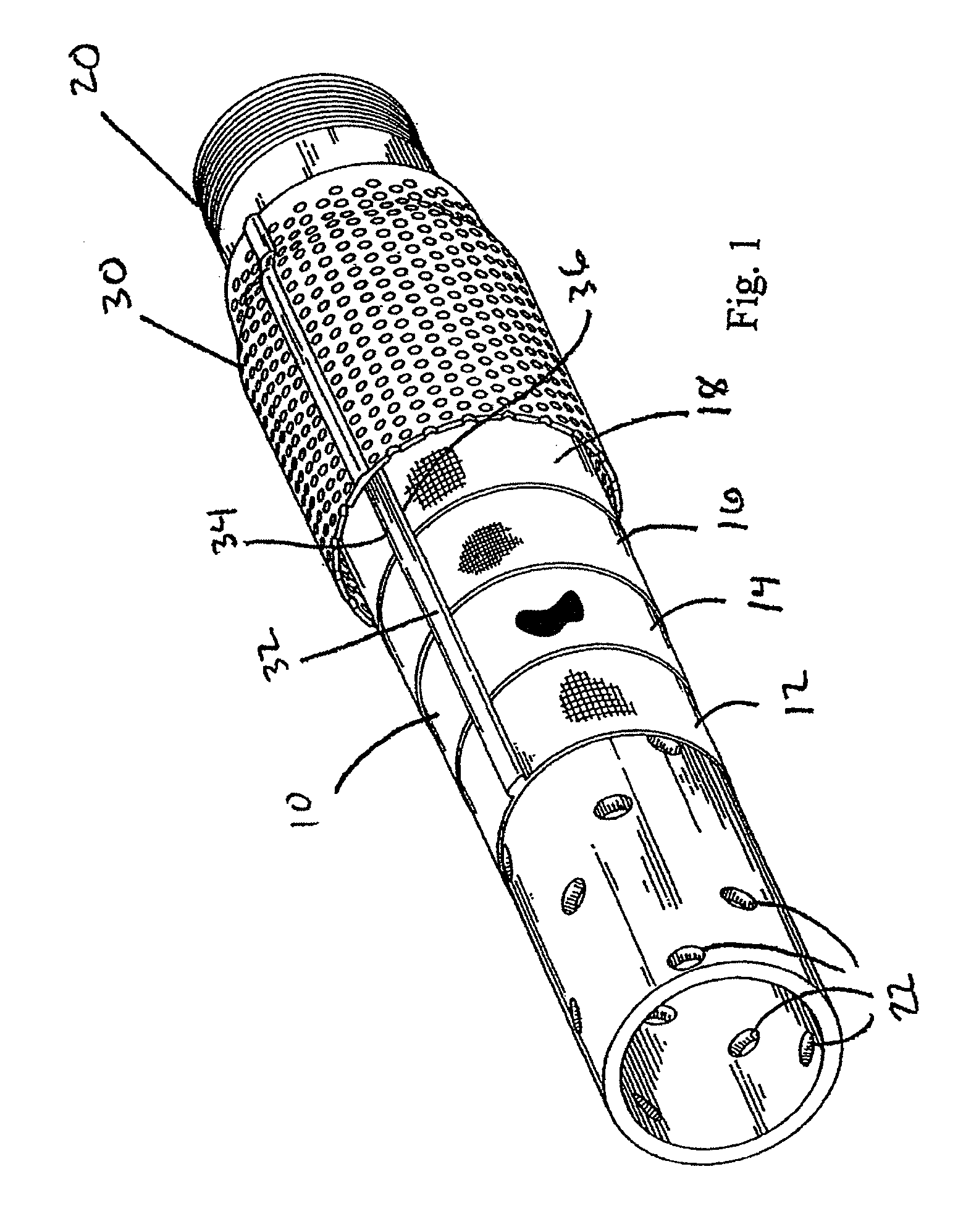

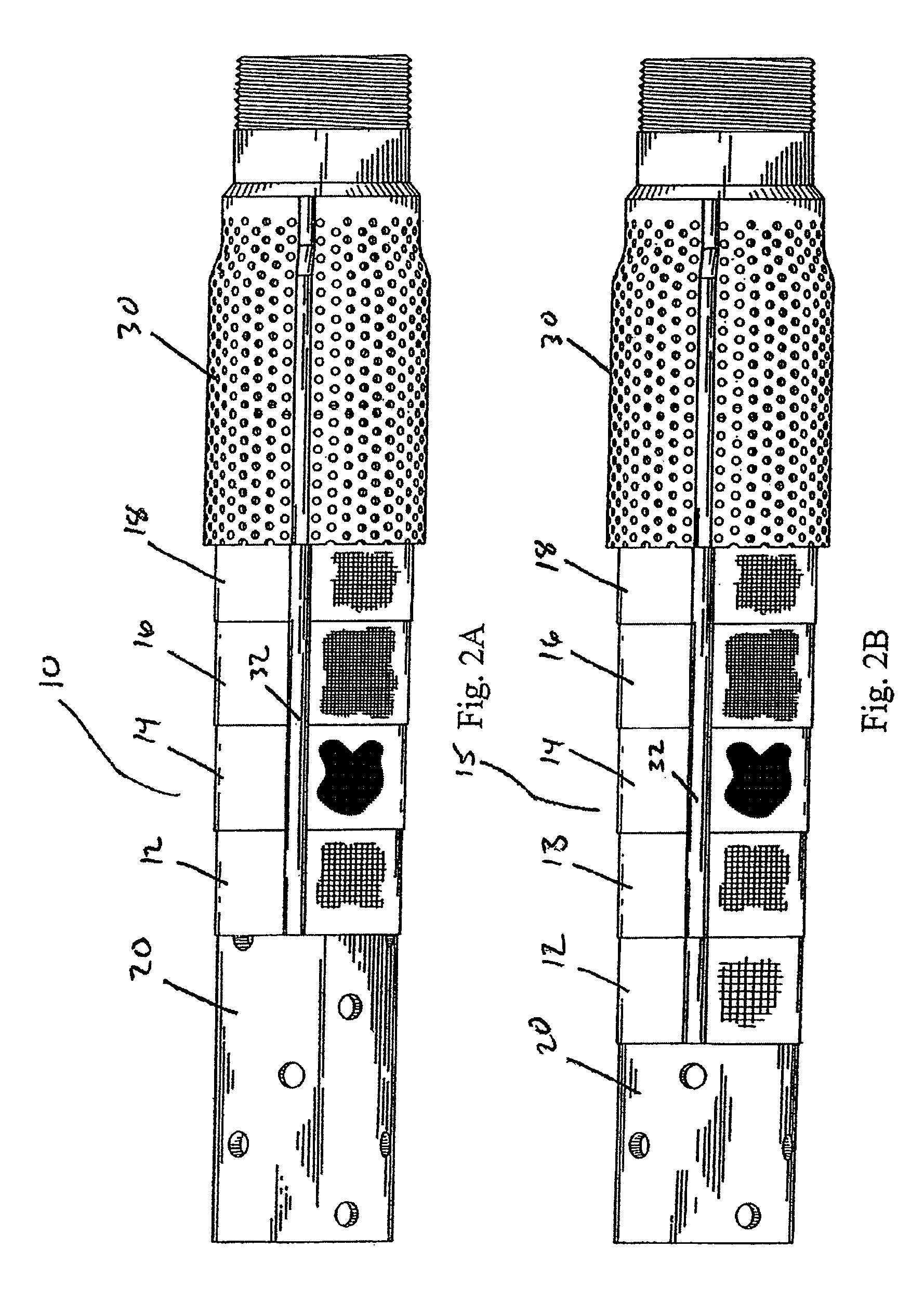

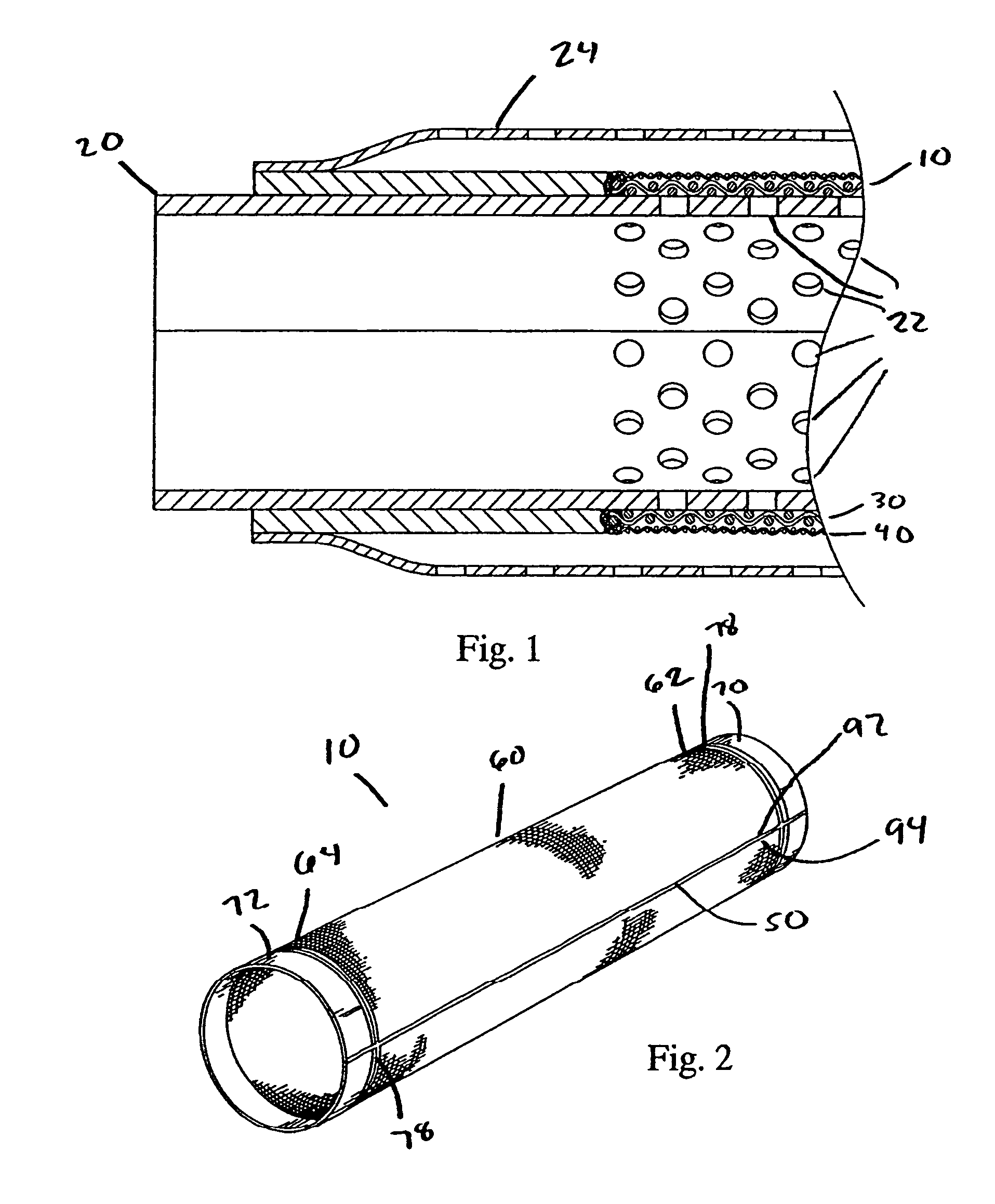

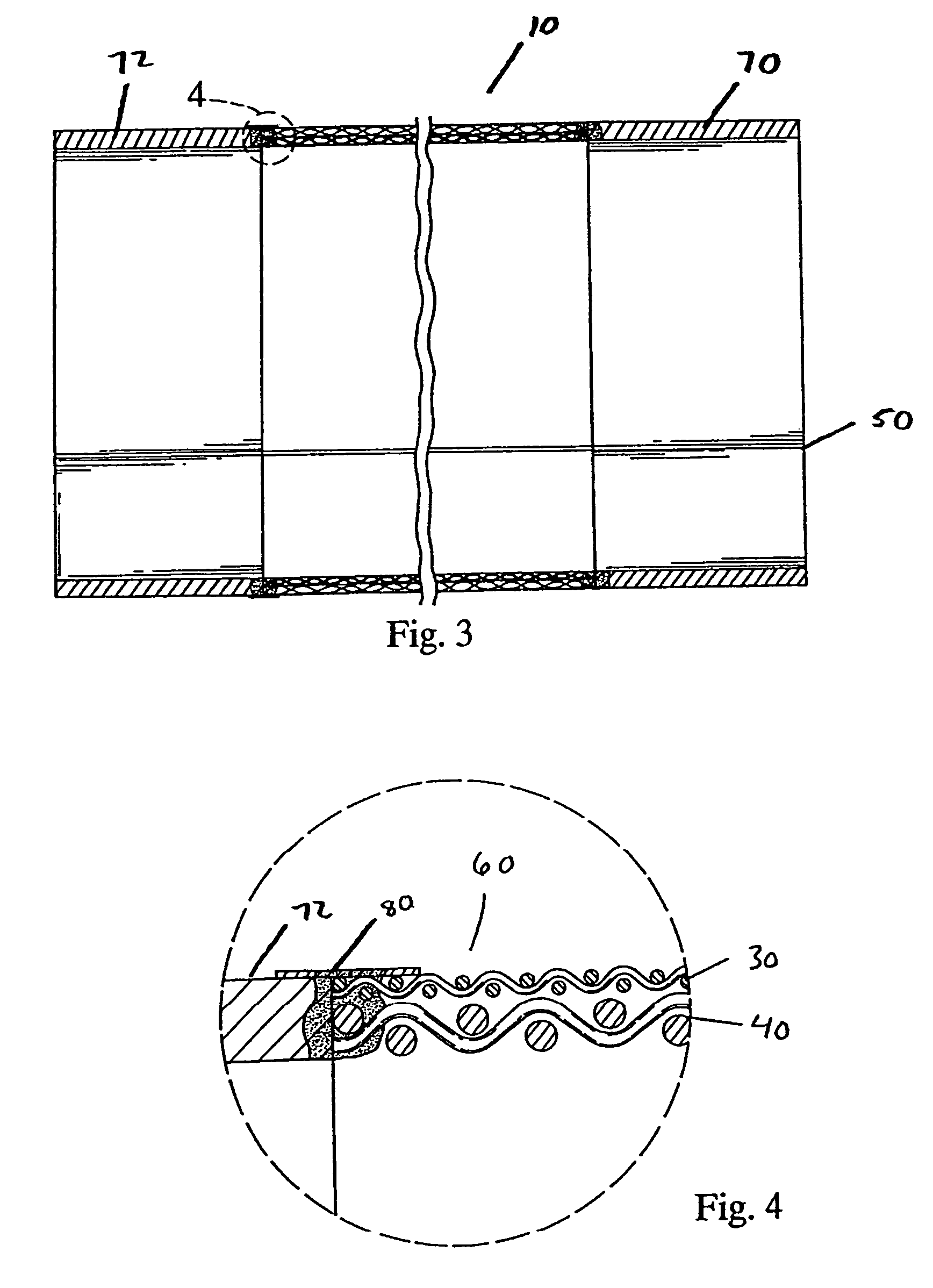

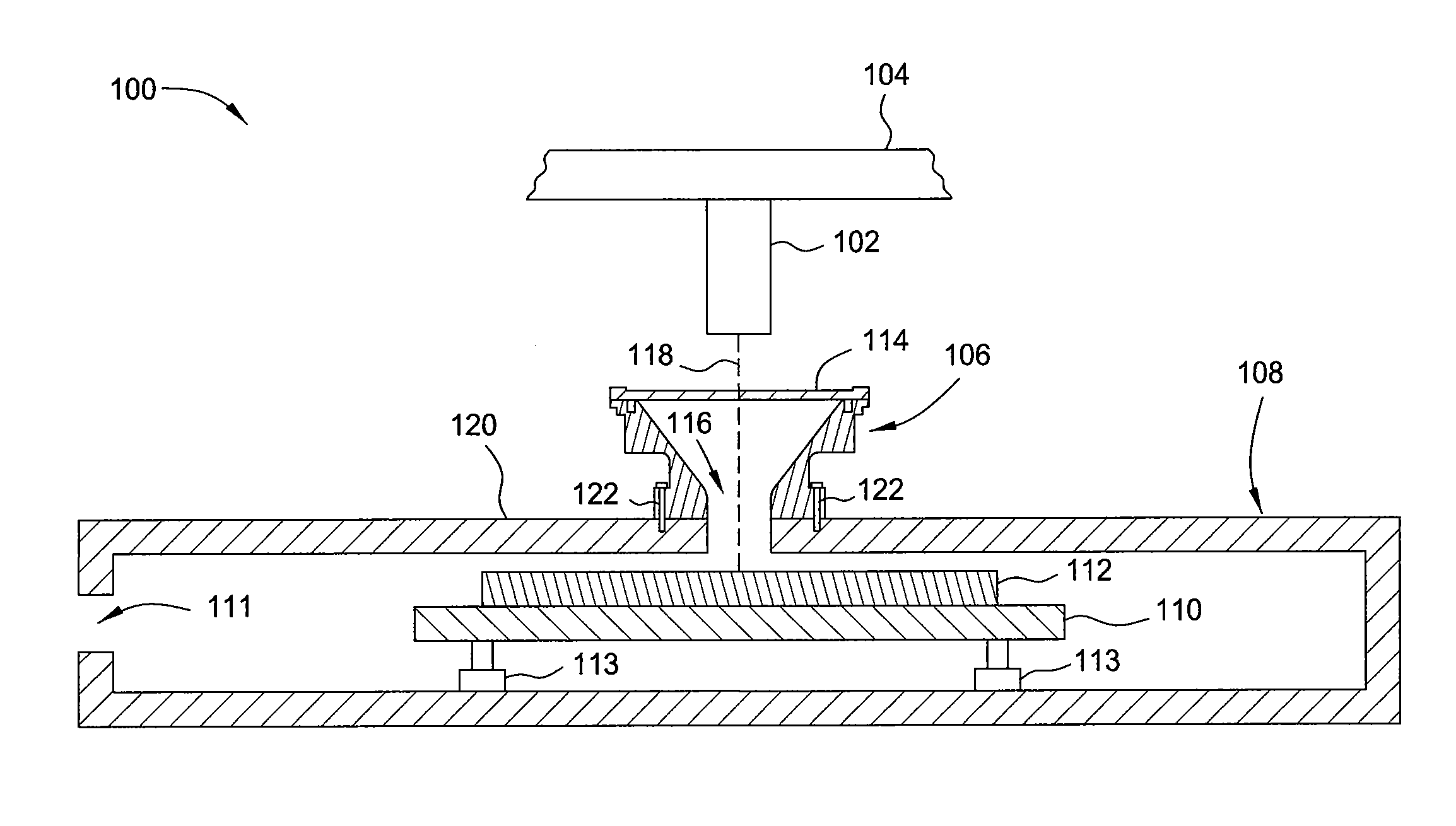

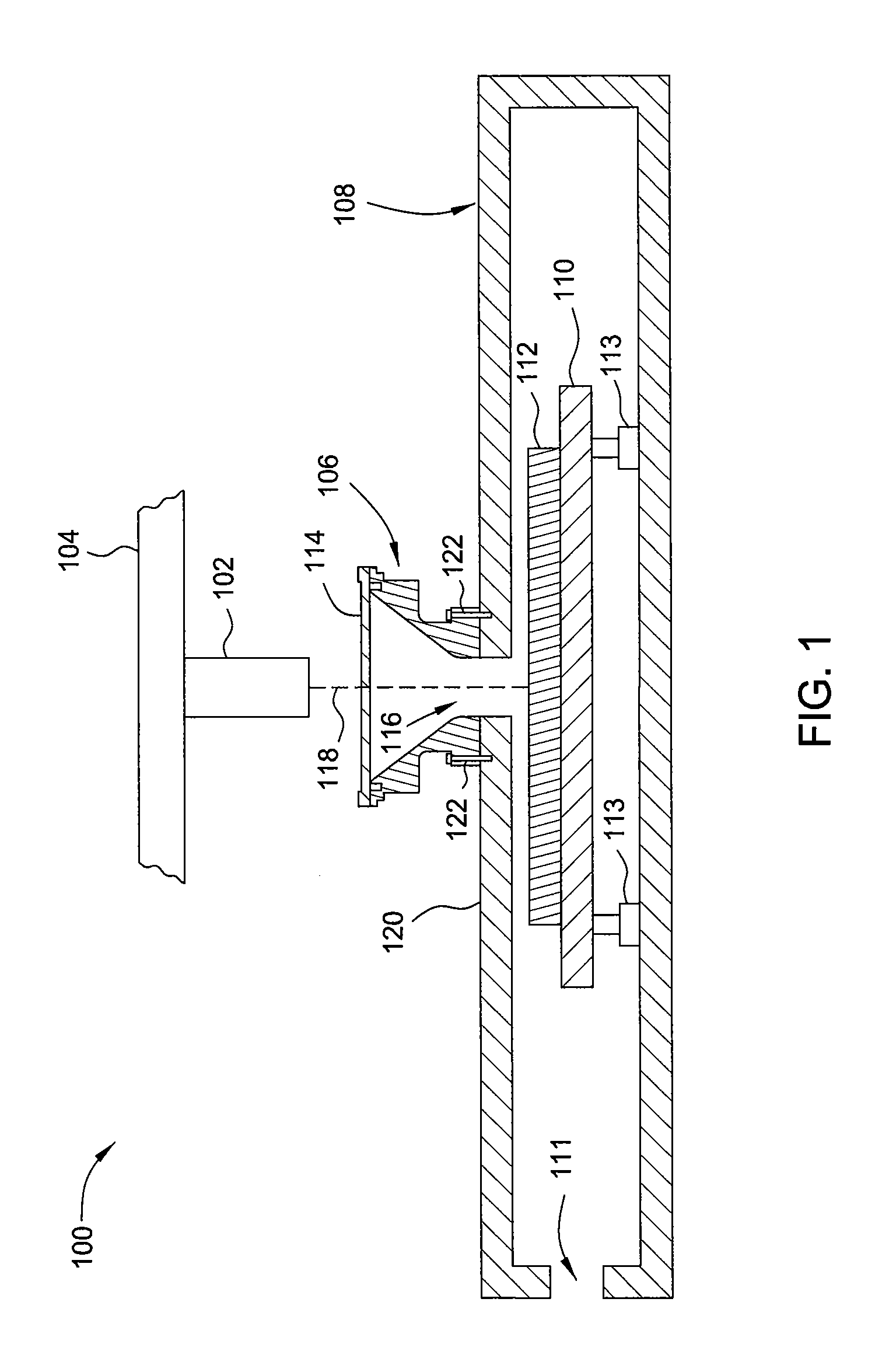

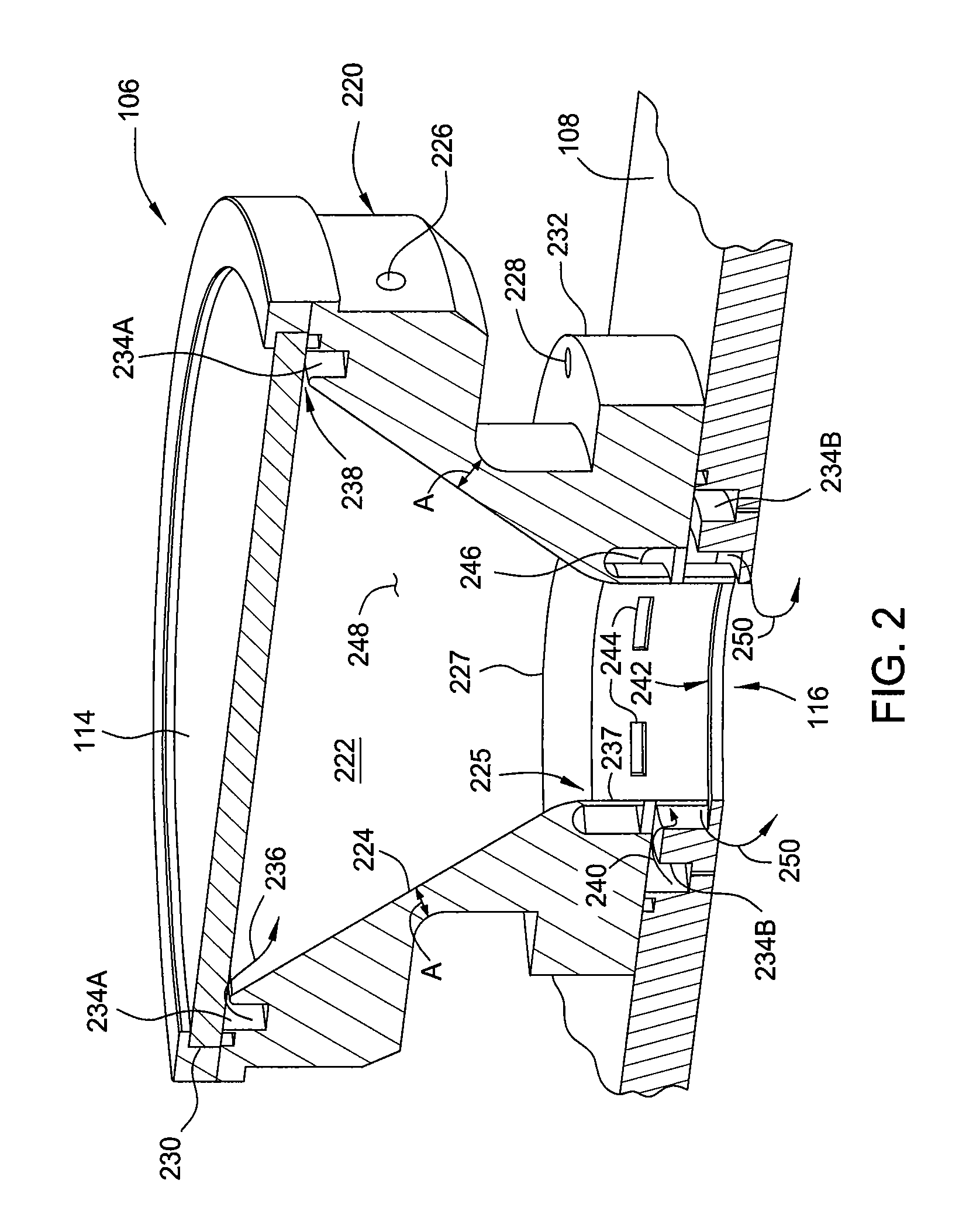

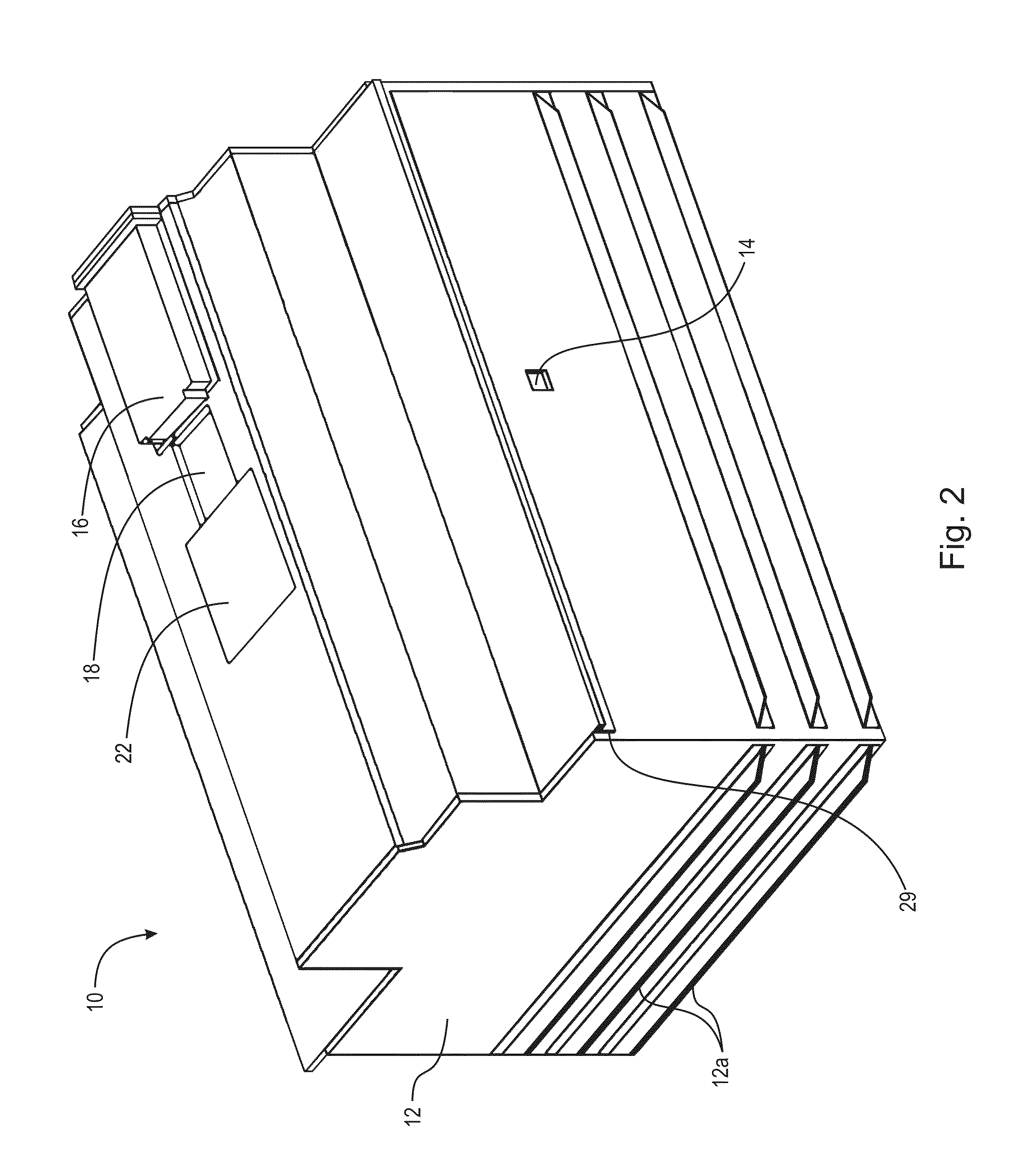

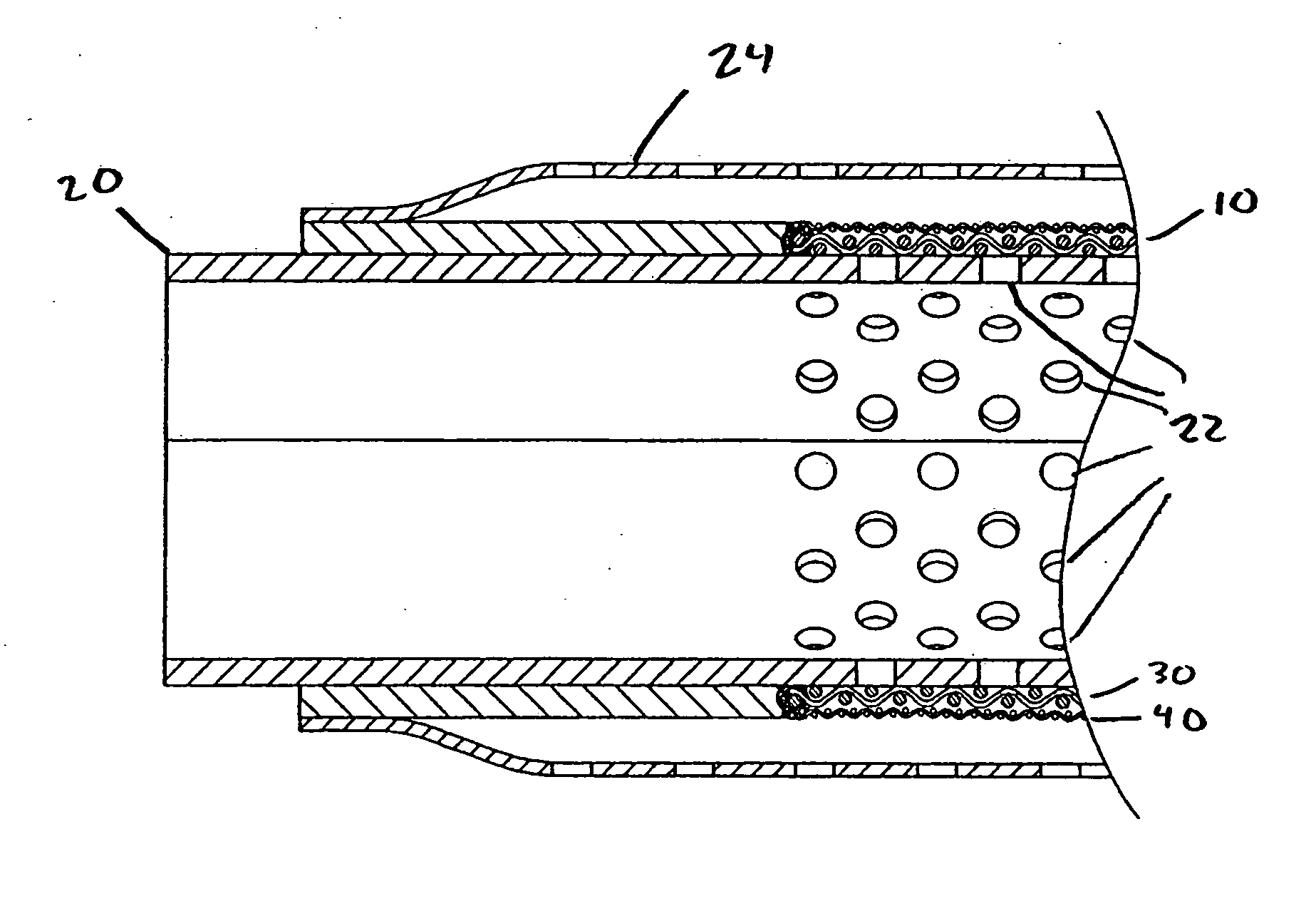

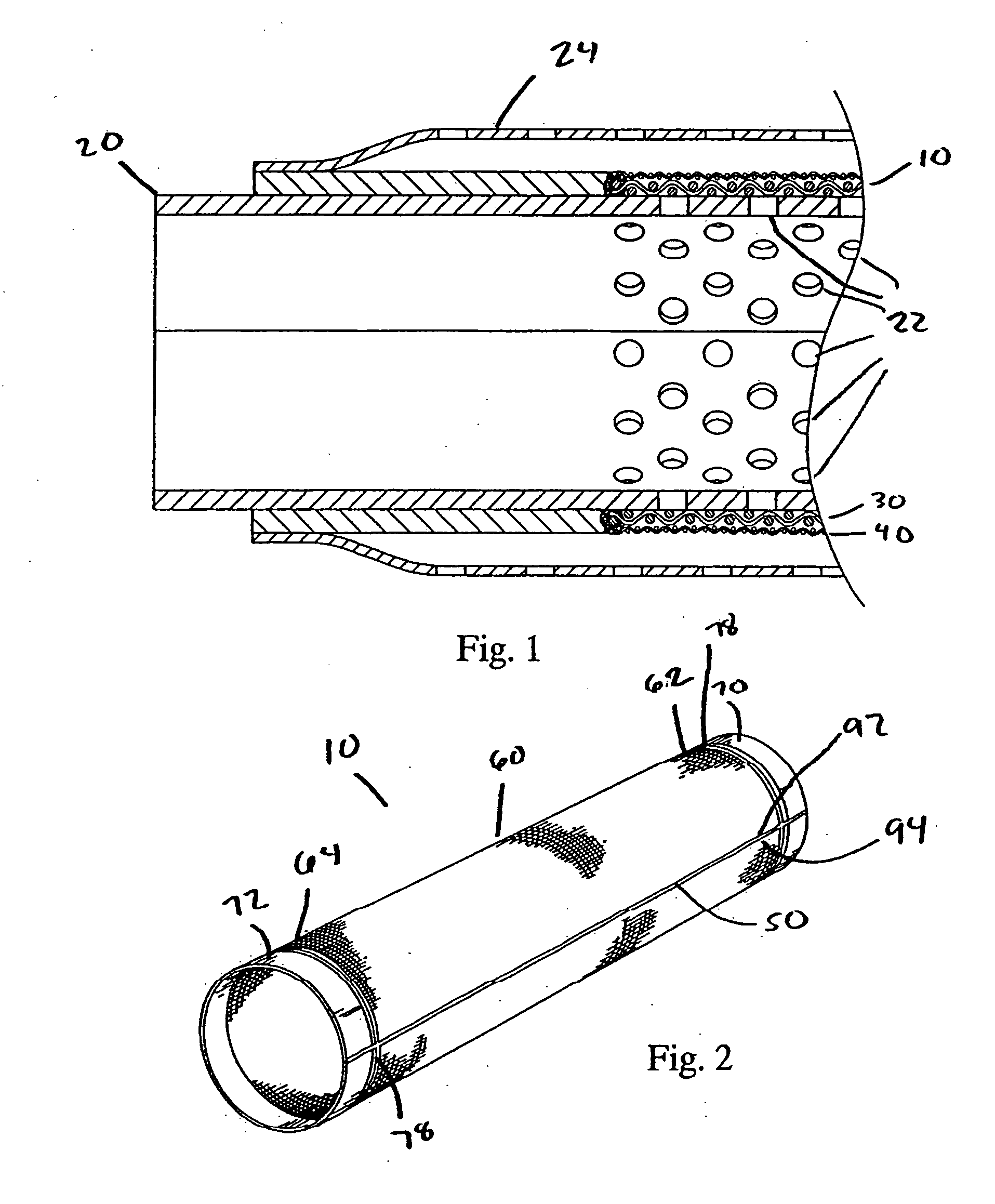

Particle control screen with depth filtration

ActiveUS20070256834A1Avoid accumulationIncreases particles-holding capacity of filterFluid removalDrinking water installationFiltrationComputational physics

A particle control screen includes a support layer. A first filter layer is disposed around the support layer. A second filter layer is disposed around the first filter layer. A third filter layer is disposed around the second filter layer. Each of the filter layers has a pore size. The pore size of the third filter layer is greater than the pore size of the second filter layer. The pore size of the second filter layer is greater than the pore size of the first filter layer.

Owner:PUROLATOR FACET INC

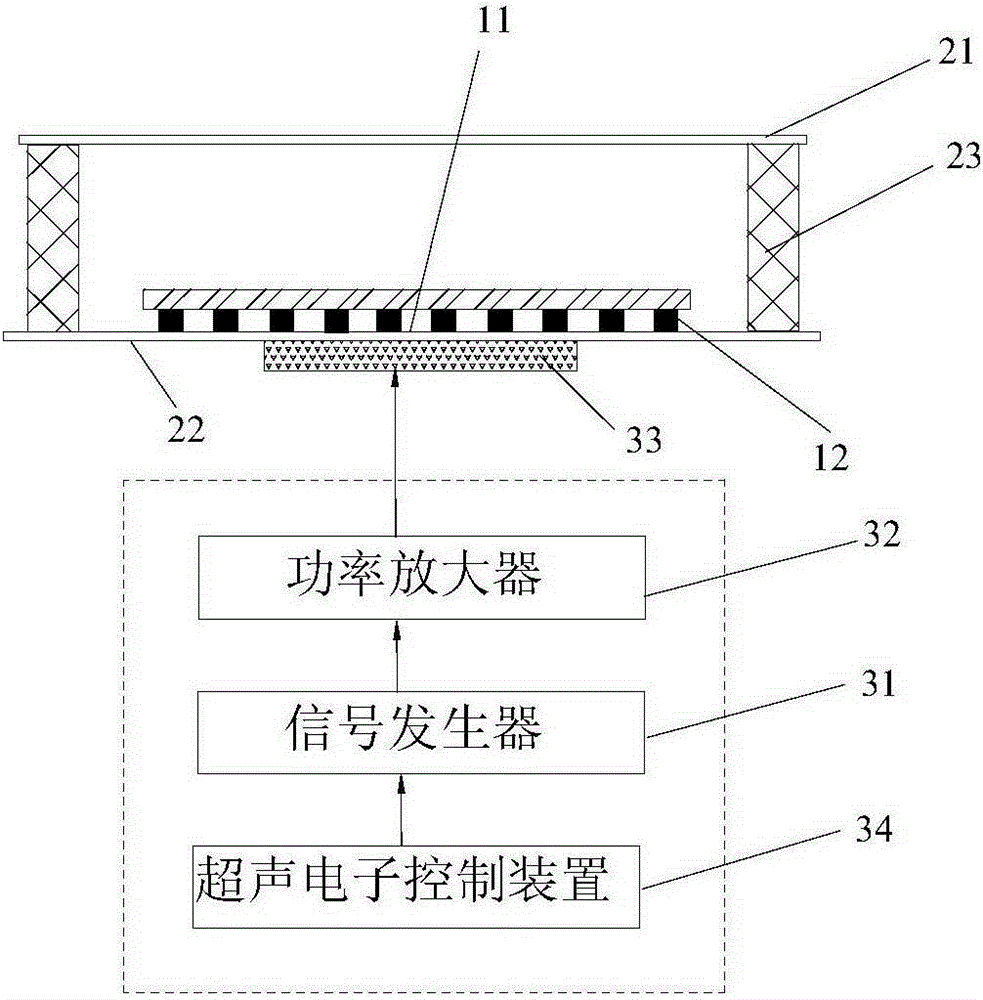

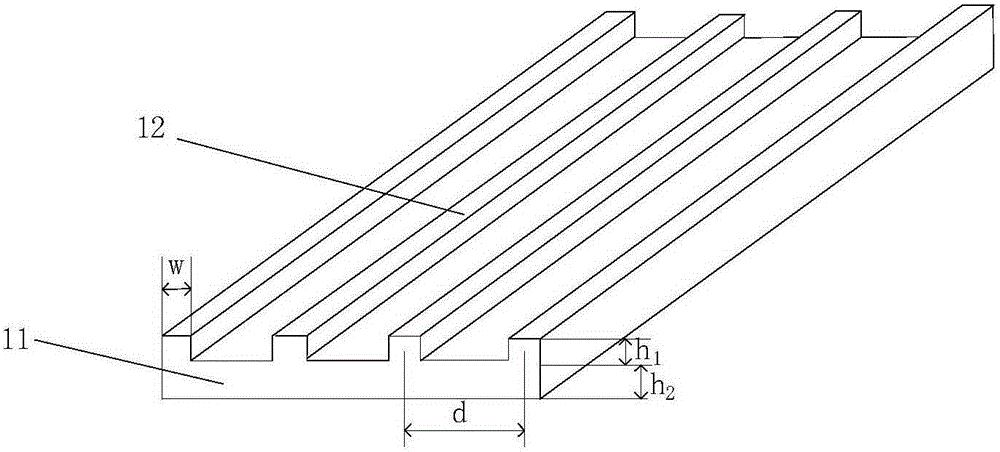

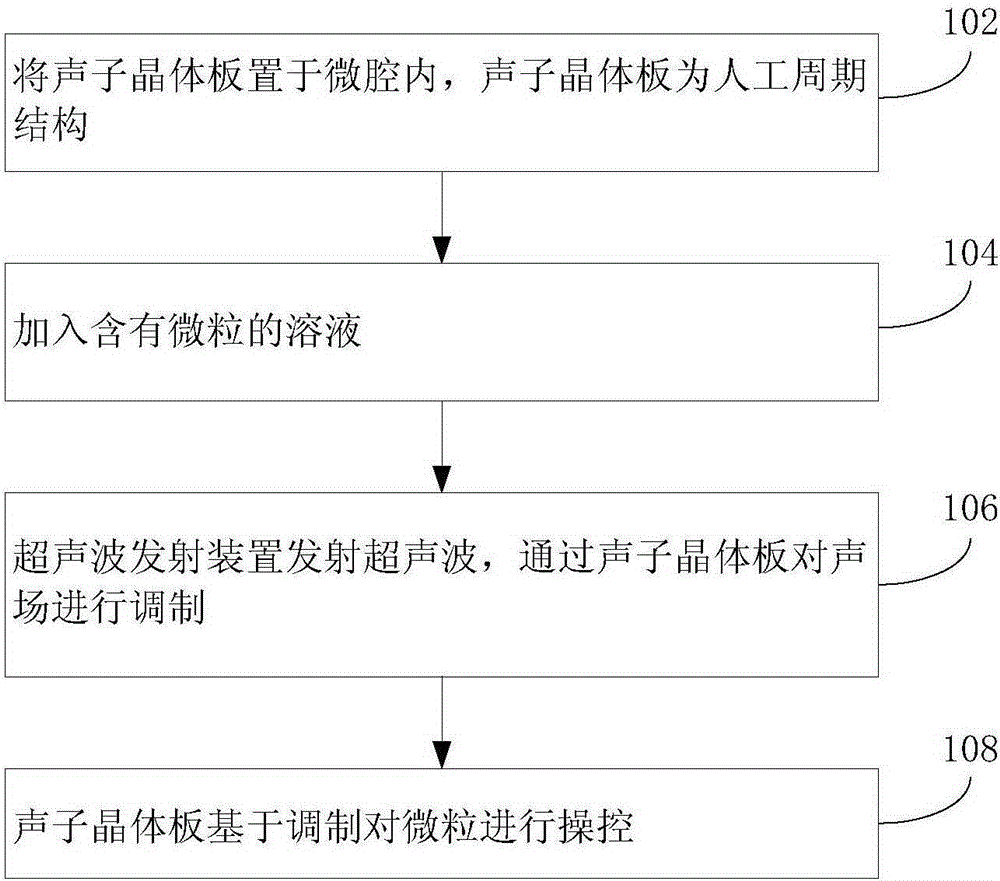

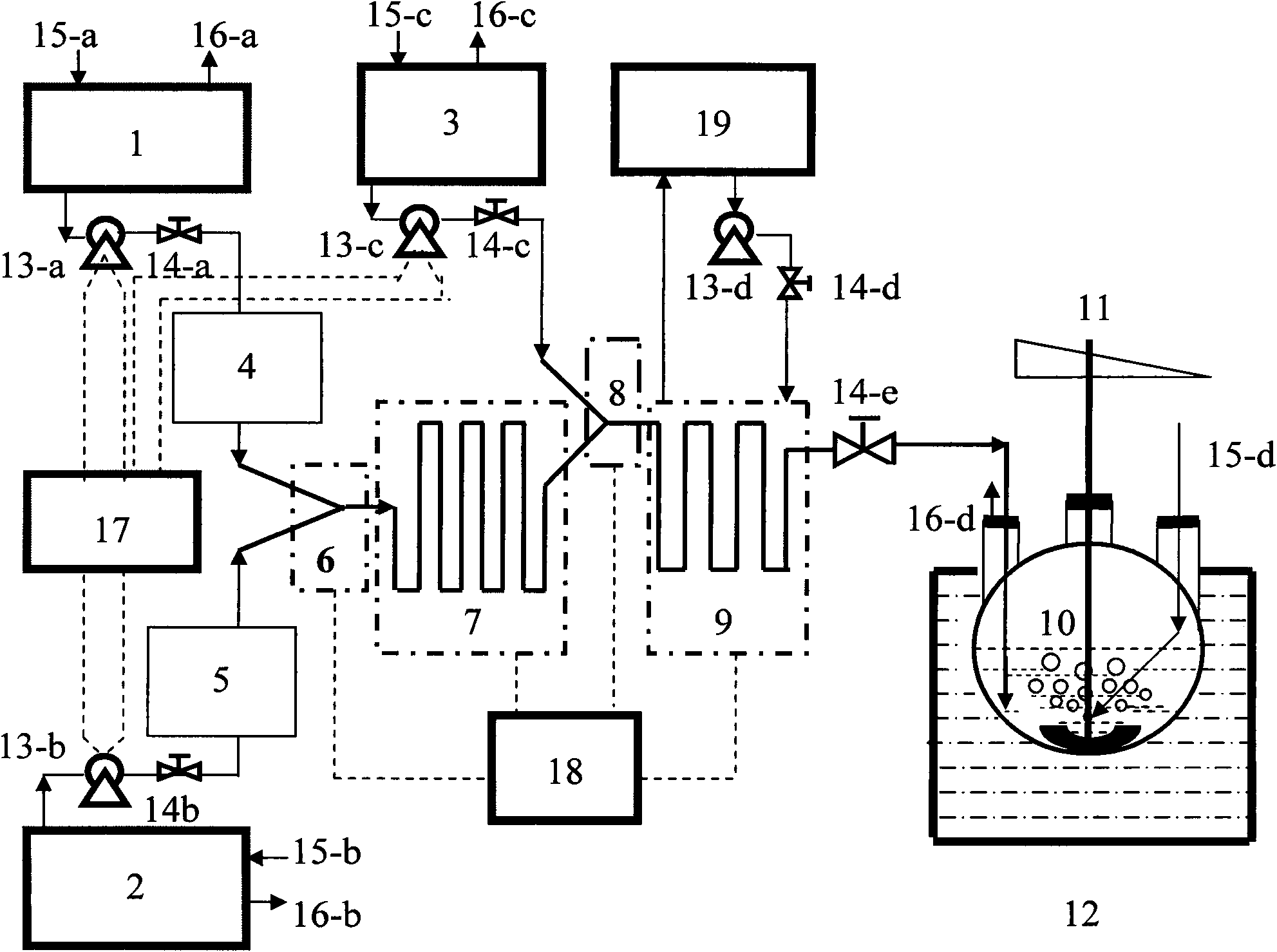

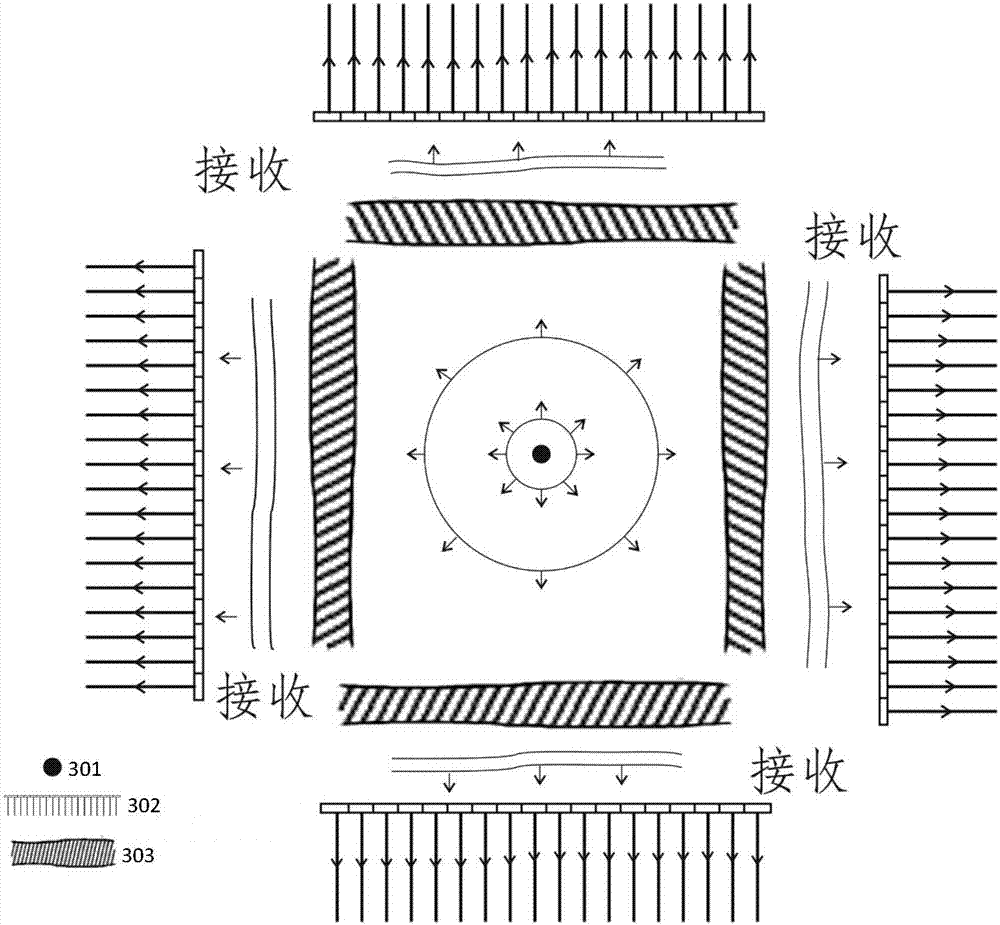

Artificial structural acoustic field based micro-fluid system and particle control method

ActiveCN105214742AFlexible design of transport routesShipping route changesLaboratory glasswaresEnergy based chemical/physical/physico-chemical processesPhotonic crystalFluid system

The invention discloses an artificial structural acoustic field based micro-fluid system which comprises a micro-cavity and an ultrasonic transmitting device. The micro-cavity is used for containing a particle-containing solution, and the ultrasonic transmitting device is used for transmitting ultrasonic waves. The artificial structural acoustic field based micro-fluid system is characterized by further comprising a photonic crystal slab arranged in the micro-cavity, the photonic crystal slab is of an artificial periodic structure and is used for modulating an acoustic field to control particles. The invention further discloses a particle control method for an artificial structural acoustic field based micro-fluid. In the preferred embodiment of the invention, due to the fact that the micro-fluid system comprises the micro-cavity, the ultrasonic transmitting device and the photonic crystal slab, the ultrasonic transmitting device is used for transmitting the ultrasonic waves and the photonic crystal slab is of the artificial periodic structure and is used for modulating the acoustic field to control particles, a new medicine delivery means is provided, and technical support is provided for research and development of drugs.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

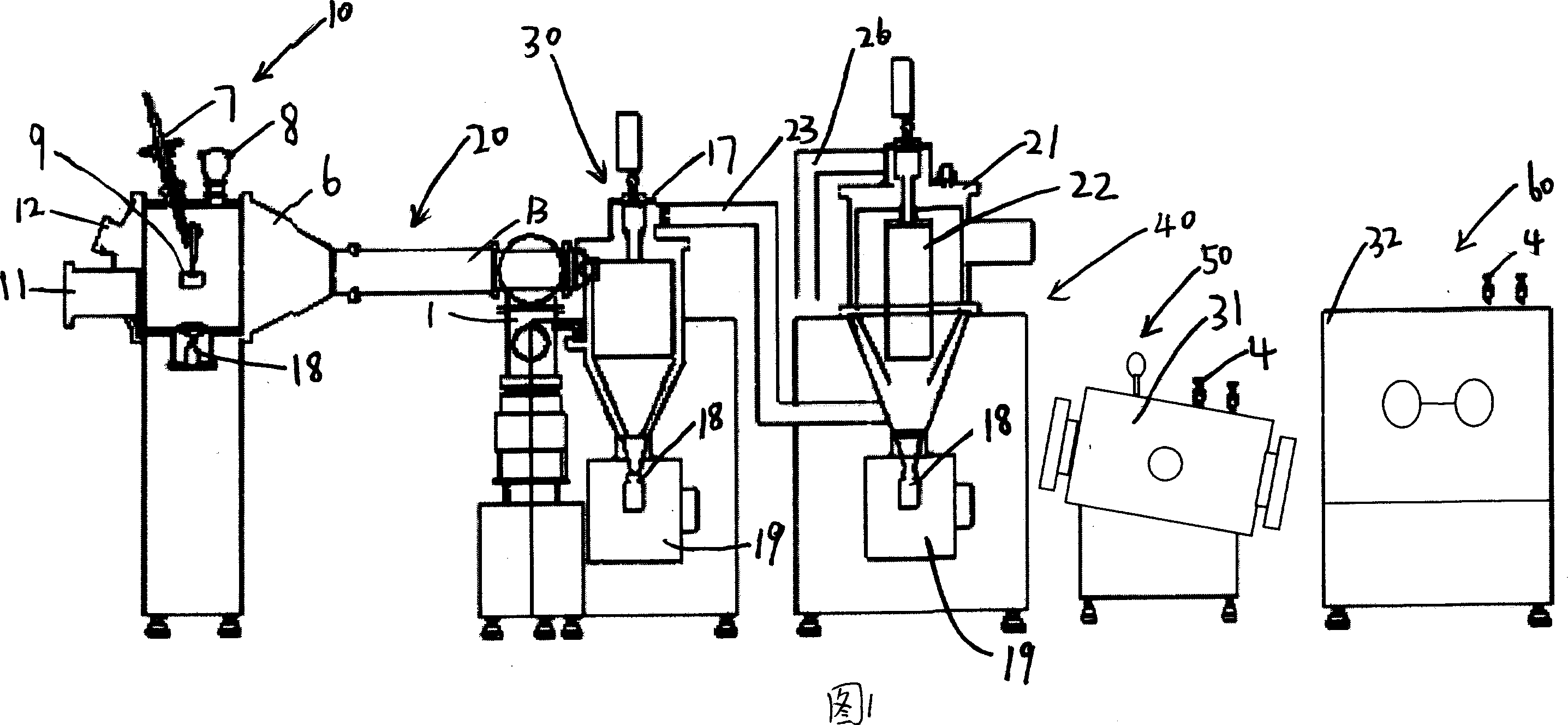

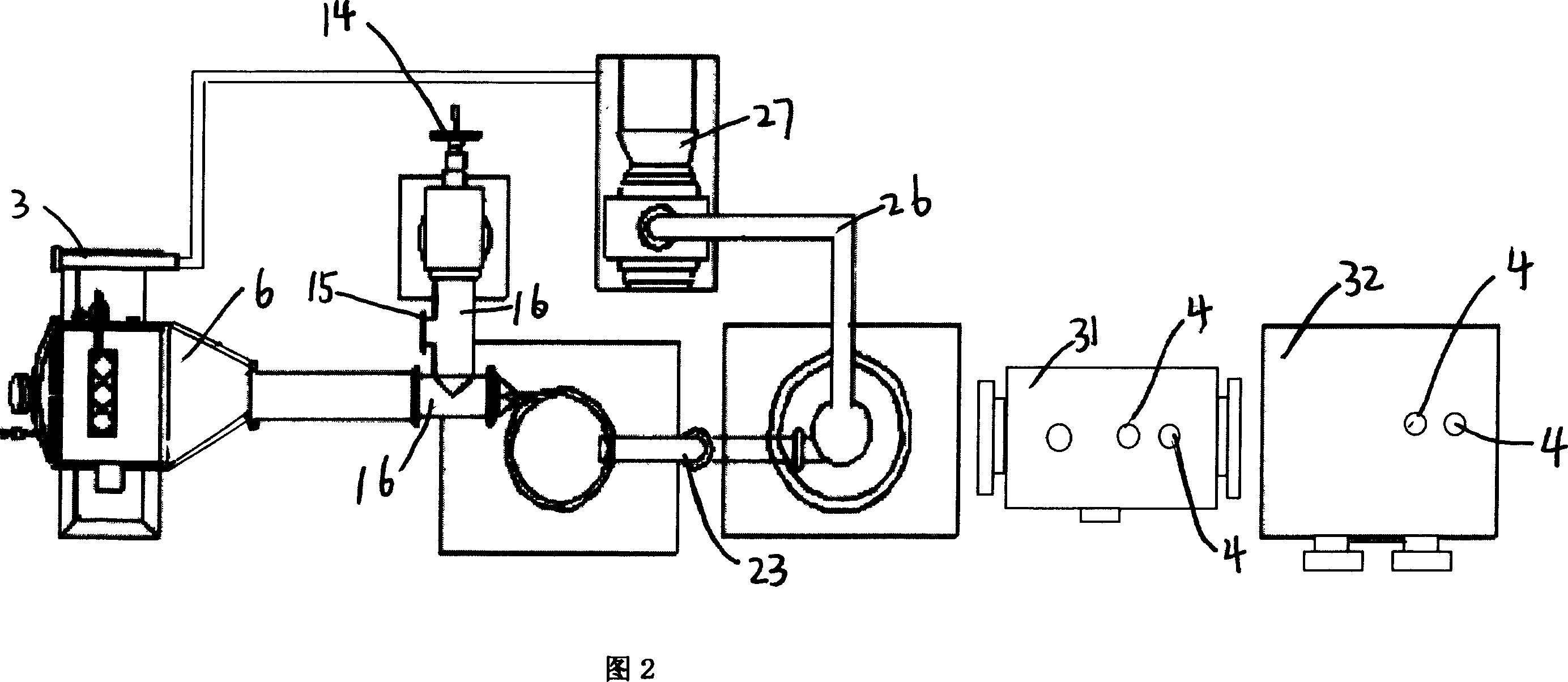

Continuous production apparatus for nano metal powder

The invention discloses a nanometer metal powder continuous producing device, comprising a vacuum measuring aerating system, a plasma / sensitive heating evaporating powder preparing system, a particle controlling system, a nanometer metal powder cyclone grading collecting system, a nanometer powder catching collecting system, a gas cooling circulating system, a water cooling circulating system, an electric controlling detecting system, a metal nanometer powder inactivating system and a powder vacuum packing storing system. The invention has high vacuum and three-gun structure, uses plasma constant-weight packing storing device, and plasma / electromagnetic sensitive evaporation or the like to realize continuous production of nanometer metal powder, change gas component and flux or the like.

Owner:MIYOU GROUP

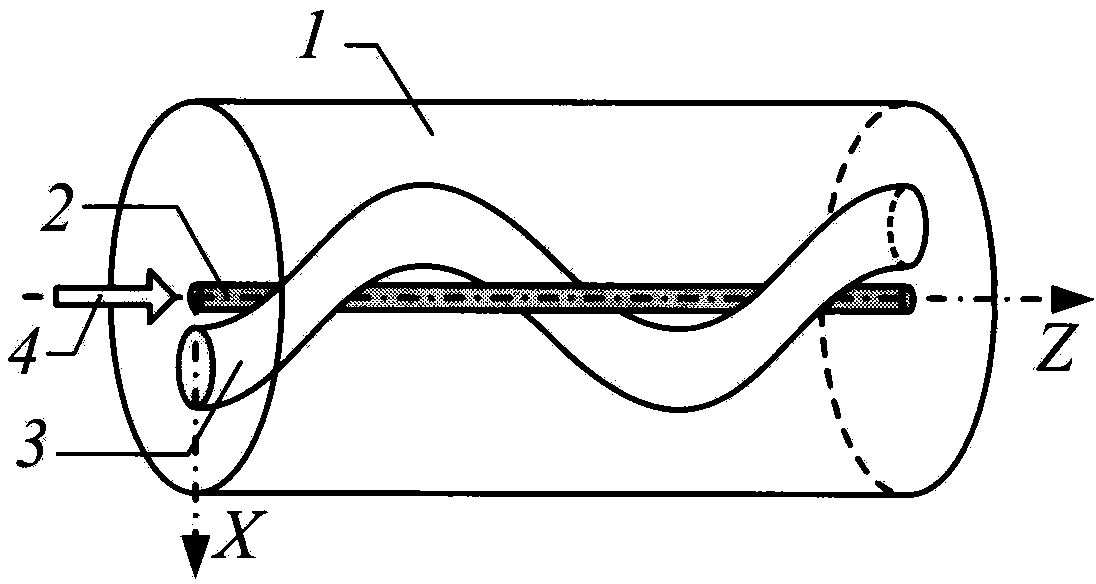

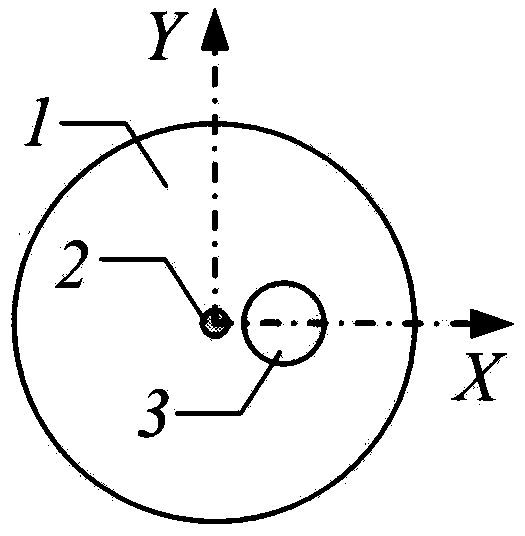

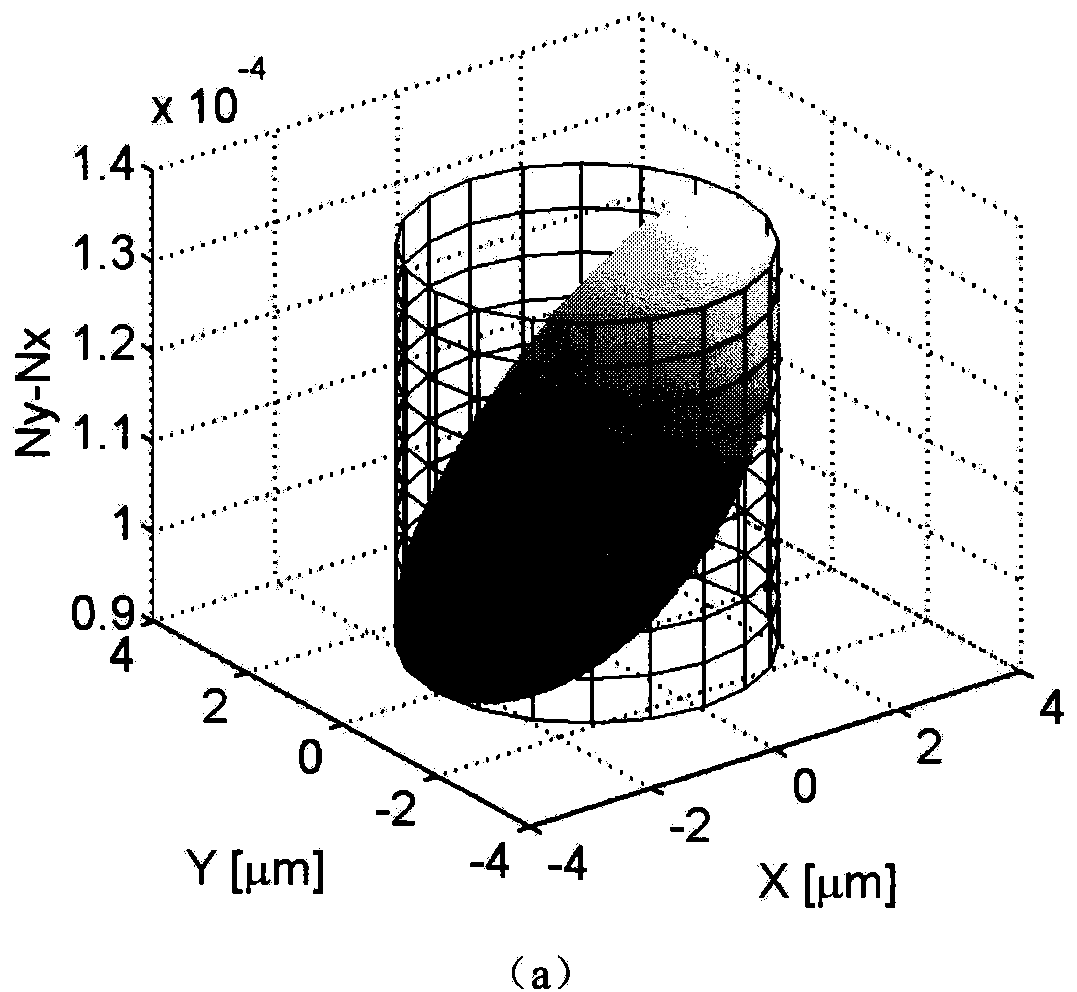

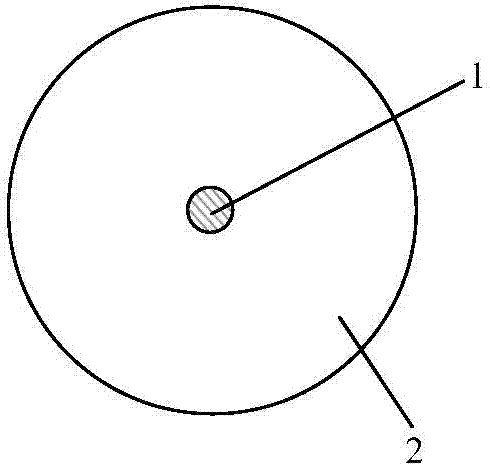

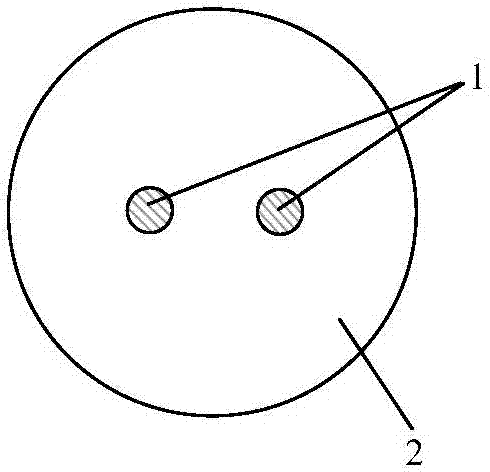

Asymmetric birefringence vortex fiber and manufacturing method of asymmetric birefringence vortex fiber

ActiveCN103969737AEasy to makeEasy to controlGlass making apparatusCladded optical fibreFiberNon symmetric

The invention discloses an asymmetric birefringence vortex fiber and a manufacturing method of the asymmetric birefringence vortex fiber. The asymmetric birefringence vortex fiber is formed by drawing an optical fiber perform with a single stress area or dual stress areas in a rotary mode, and therefore the asymmetric birefringence vortex fiber has a single spiral stress area or dual spiral stress areas; in addition, due to asymmetric distribution of the stress areas or different materials of the stress areas, spirally-distributed asymmetric stress birefringence is generated in a fiber core of the asymmetric birefringence vortex fiber, a radial phase difference of transmission light waves is accordingly formed, the light waves transmitted in the asymmetric birefringence vortex fiber can accordingly obtain the orbital annular momentum, vortex phase transmission is generated, and a similar vortex light transmission mode is achieved. The asymmetric birefringence vortex fiber overall has the advantages of being tiny in structure, flexible in operation, stable in system, high in interference resistant capacity and the like, and can be used for vortex beam generation, particle control, sensing application and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

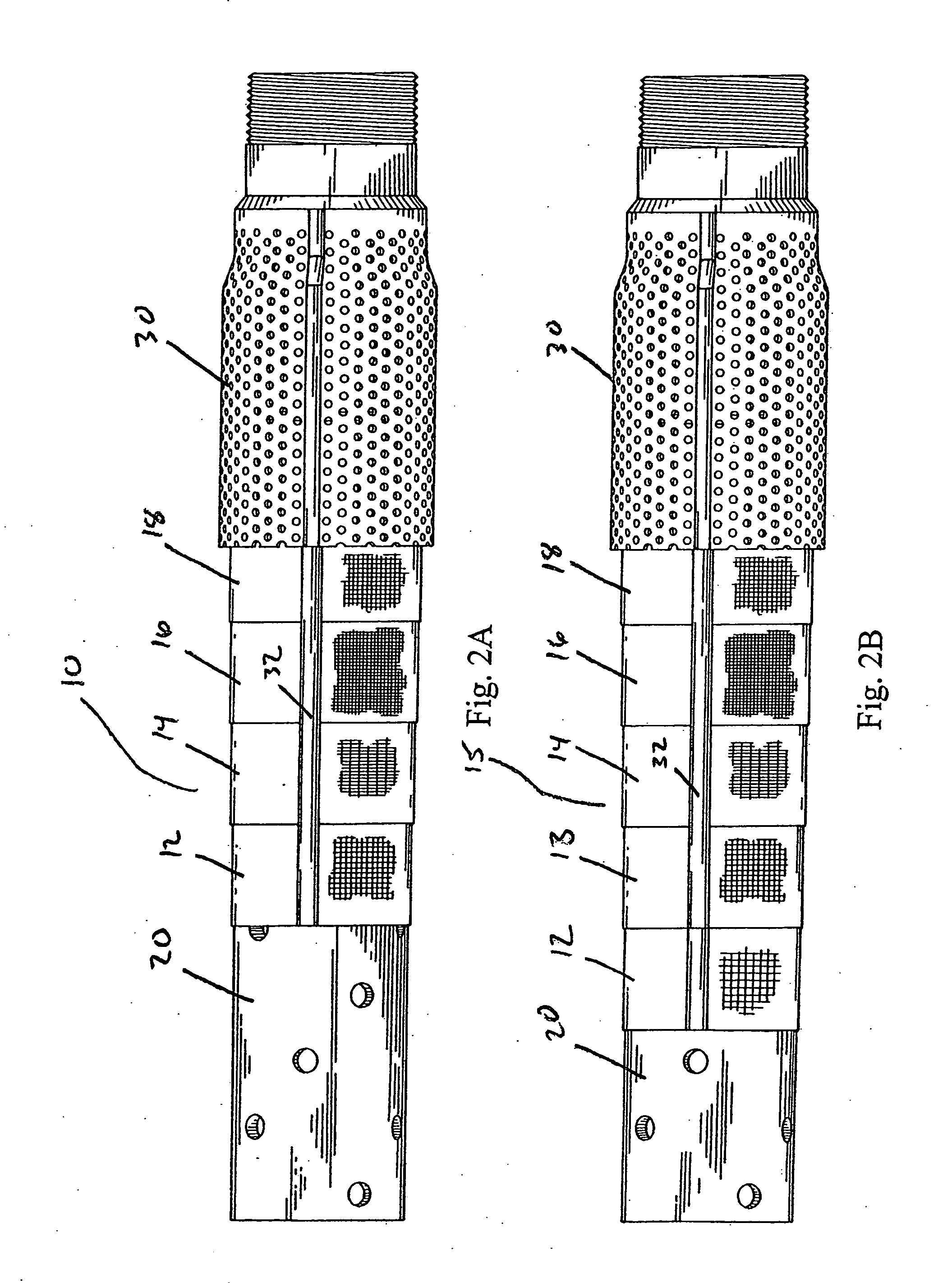

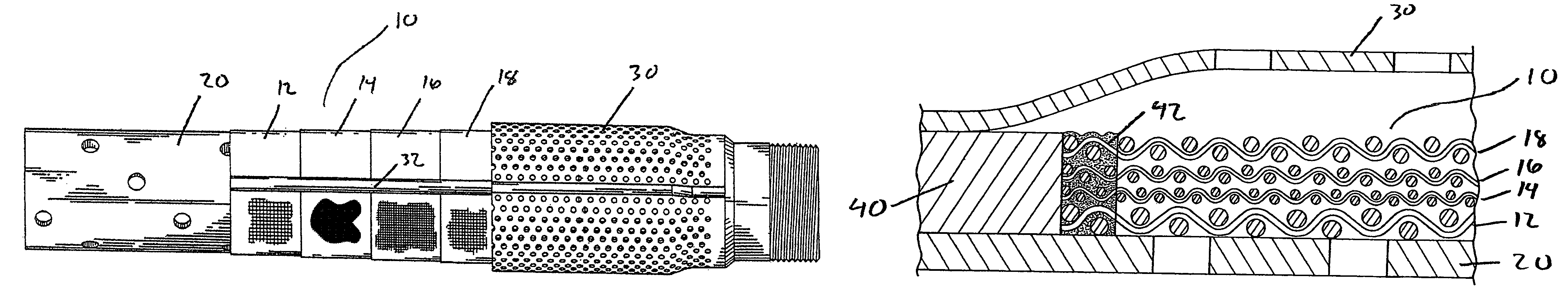

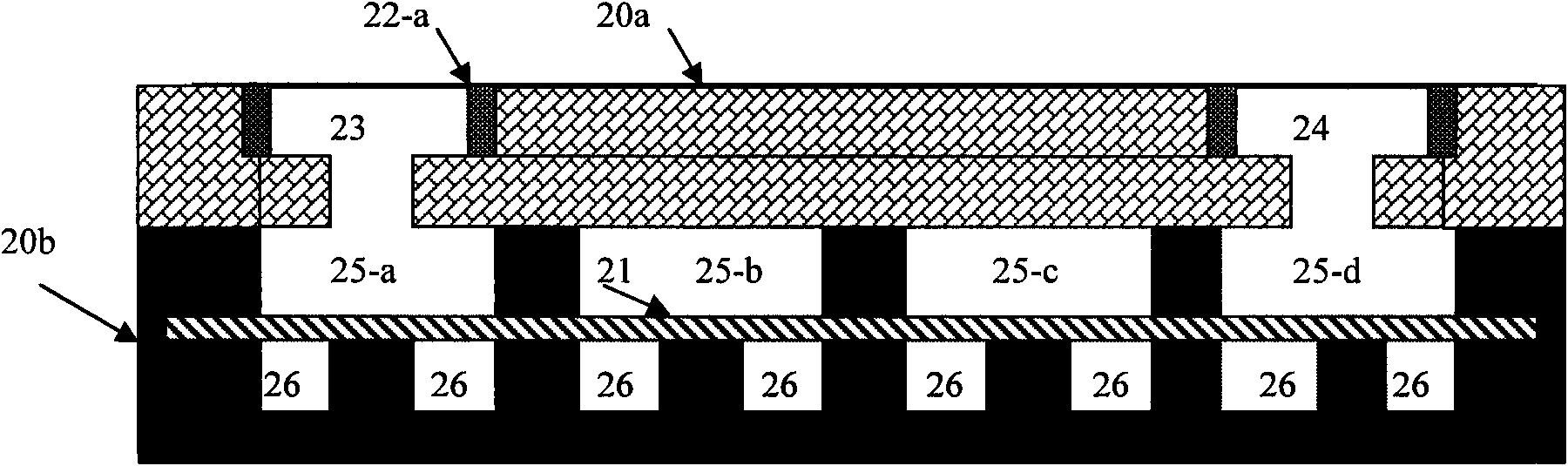

Particle control screen with depth filtration

ActiveUS7497257B2Avoid accumulationIncreases particles-holding capacity of filterFluid removalDrinking water installationFiltrationComputational physics

A particle control screen includes a support layer. A first filter layer is disposed around the support layer. A second filter layer is disposed around the first filter layer. A third filter layer is disposed around the second filter layer. Each of the filter layers has a pore size. The pore size of the third filter layer is greater than the pore size of the second filter layer. The pore size of the second filter layer is greater than the pore size of the first filter layer.

Owner:PUROLATOR FACET INC

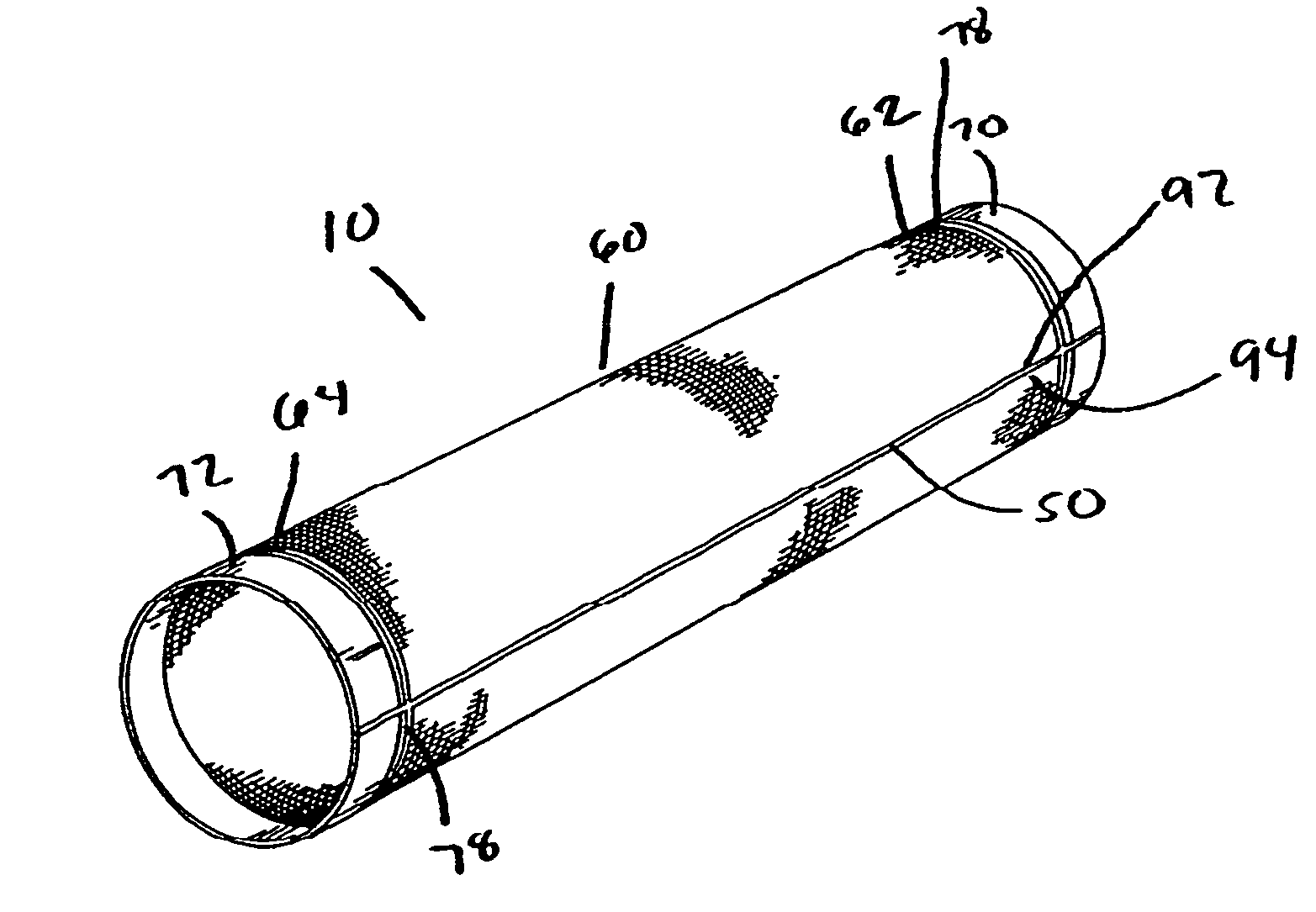

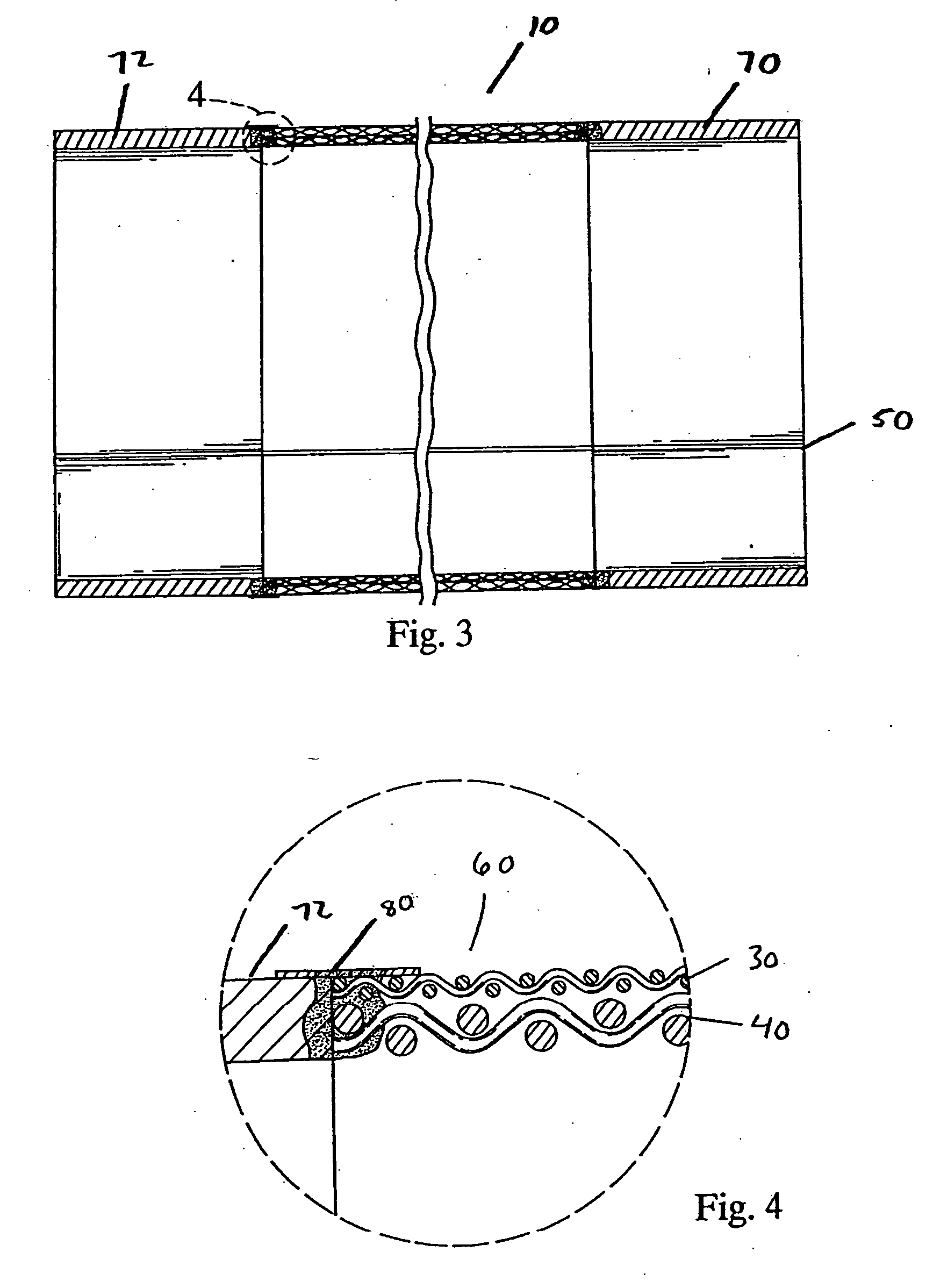

Unsintered mesh sand control screen

A particle control screen assembly for a perforated pipe used in a well. The particle control screen assembly includes a screen with a first end and a second end. The screen includes a first and a second unsintered woven mesh layer, each layer having a first longitudinal edge and a second longitudinal edge. The cylindrical screen also includes openings sized to prevent passage of particulate material and a longitudinal metal weld adjacent the first and second longitudinal edges of the first and second unsintered woven mesh layers. The longitudinal metal weld secures the edges of the unsintered woven mesh layers together. The particle control screen assembly also includes a weld-compatible metal structure adjacent the first end of the cylindrical screen. A circumferential metal weld between the cylindrical screen and the metal structure bonds a portion of the metal structure and a portion of the cylindrical screen.

Owner:PUROLATOR FACET INC

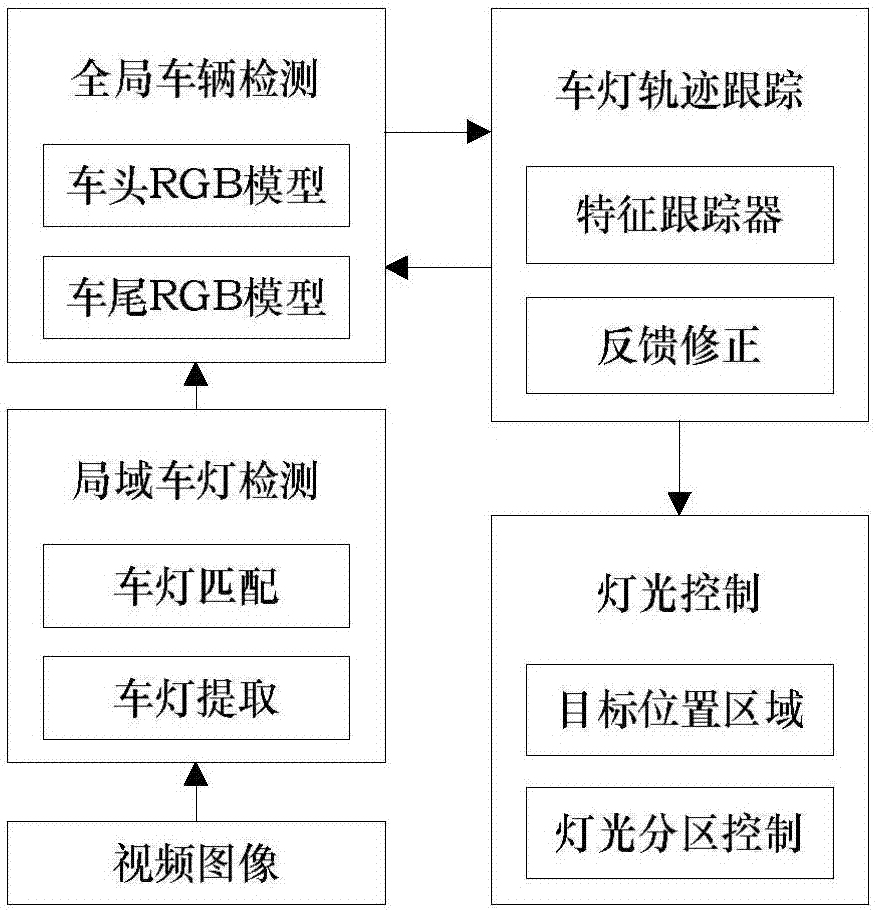

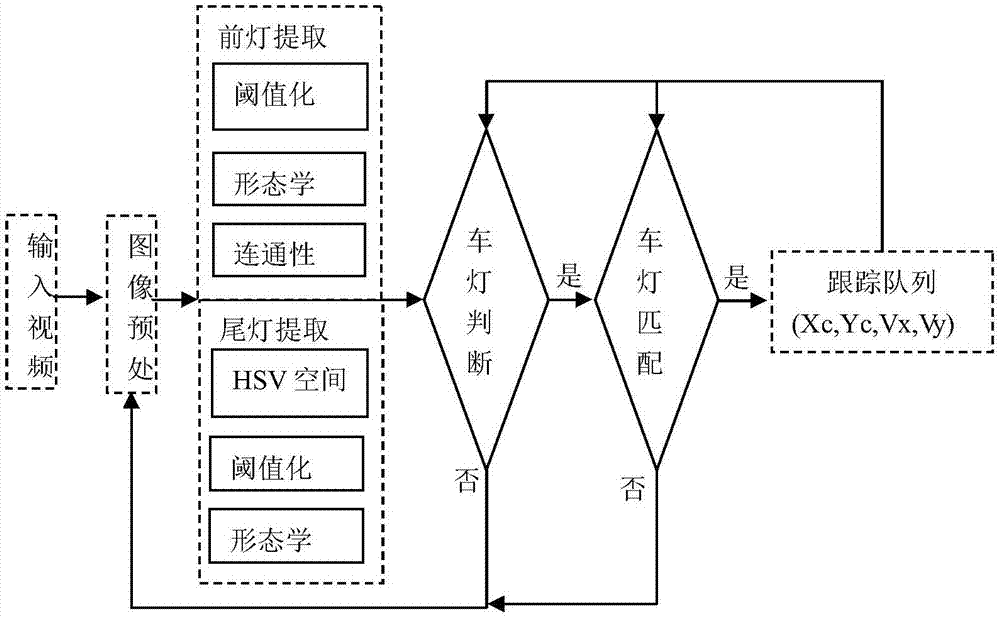

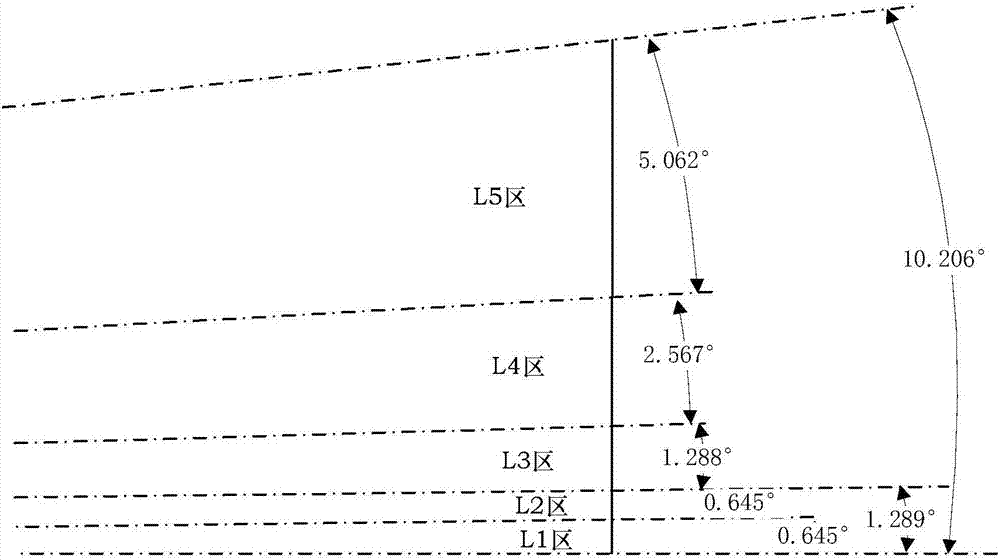

Method for tracking and identifying headlight and taillight of automobile under visual perception

ActiveCN106934808AEnsure safetyGuaranteed comfortImage enhancementImage analysisImage ViewVideo image

The invention discloses a method for tracking and identifying a headlight and a taillight of an automobile under visual perception. The method comprises the steps of video image acquisition, local space automotive light detection, global space automobile detection, automotive light track real-time tracking, and matrix type LED particle control. On the basis of intelligent image recognition and tracking technologies, a camera is used for collecting and storing an automotive head target and an automotive tail target in front of an automobile; with a target detection and tracking technology and a feedback correction model, orientation, speed, and position motion parameter detection of the automobile by a vehicle in front of the automobile can be realized; and with an image view and an LED illumination area mapping model, adaptive controlling of single or grouped light brightness in a matrix type LED headlamp is realized by using a visual image sensing parameter as a control input. Therefore, stable multi-target vehicle tracking can be realized on the condition of complex light and the headlight of the automobile can be adjusted in real time based on a tracking result, so that the method can be applied to a headlight intelligent control service in auxiliary automobile driving.

Owner:JIANGSU WENGUANG VEHICLE ACCESSORIES

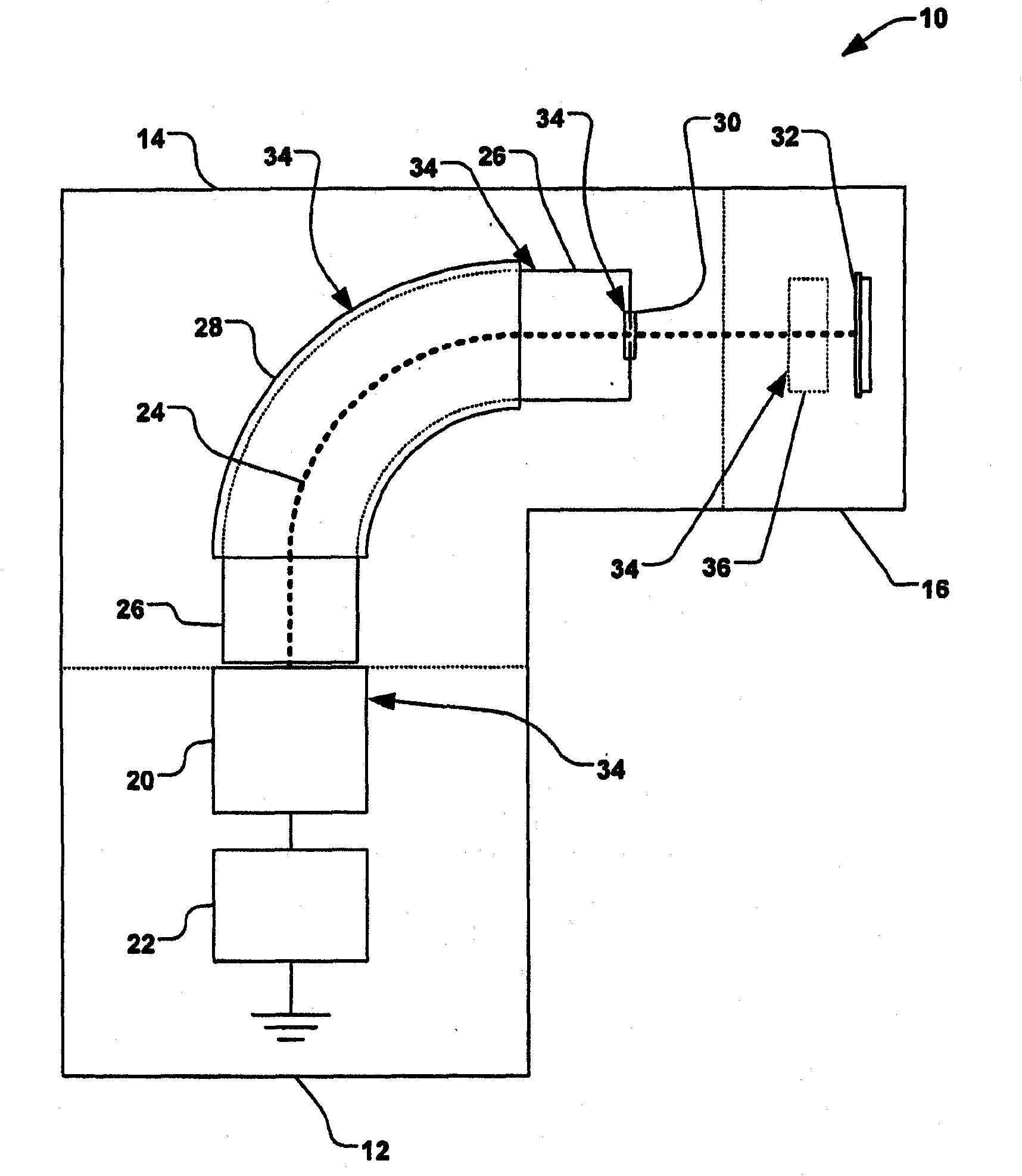

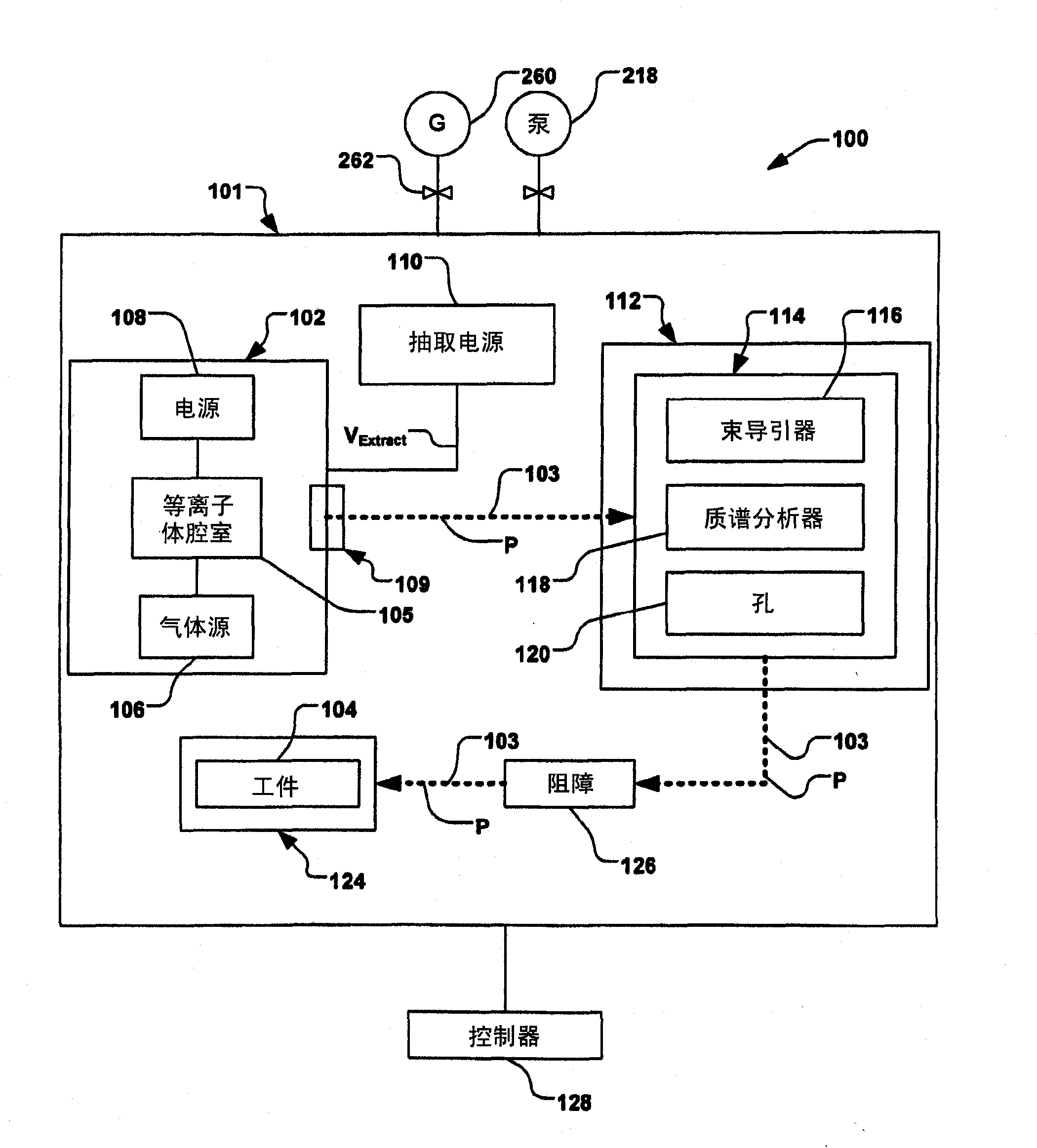

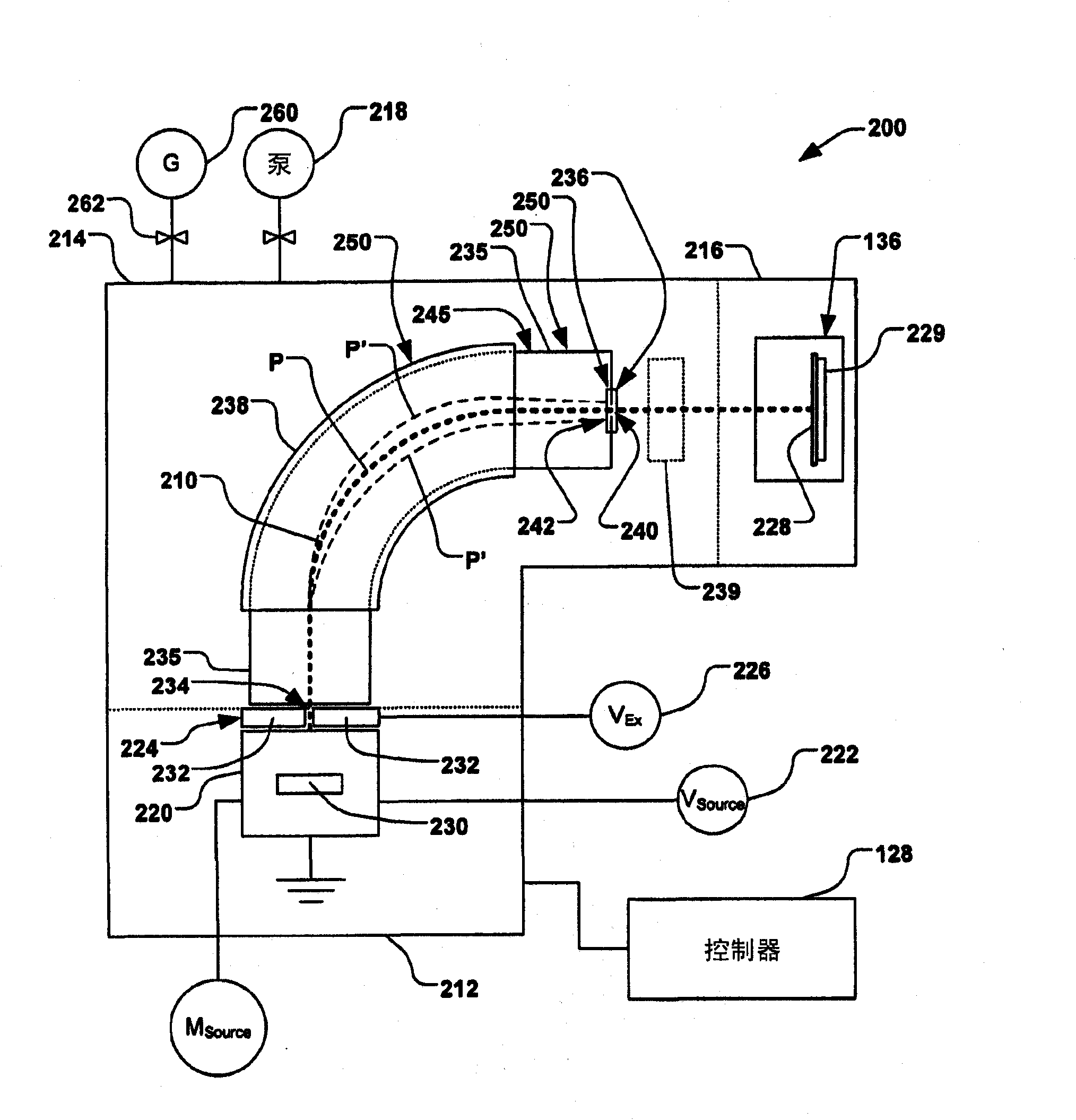

Control of particles on semiconductor wafers when implanting boron hydrides

InactiveCN102047376AElectric discharge tubesSemiconductor/solid-state device manufacturingPhysical chemistryIon beam

A method for reducing particle contamination during implantation of ions comprises providing an implantation system (200) for implanting ions into a workpiece (228) via an ion beam (210), wherein one or more components are under selective vacuum and have one or more contaminants in a first state disposed thereon. A gas is introduced to the implantation system (at 200), wherein the gas generally reacts with at least a portion of the one or more contaminants, therein transforming the at least a portion of the one or more contaminants into a second state. The at least a portion of the one or more contaminants in the second state remain disposed on the one or more components, and wherein the at least a portion of the second state of the one or more contaminants generally does not produce particle contamination on the one or more workpieces.

Owner:AXCELIS TECHNOLOGIES

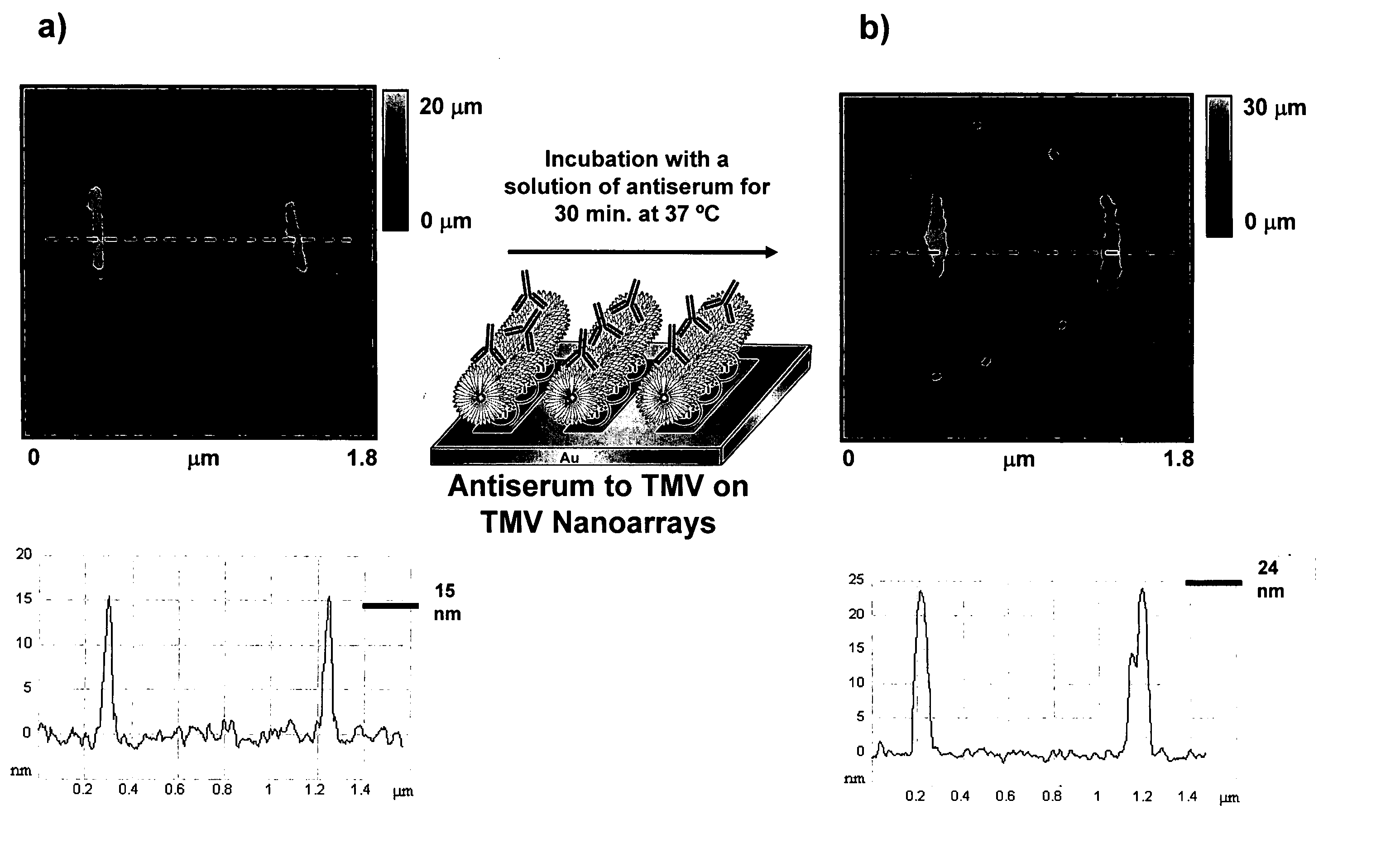

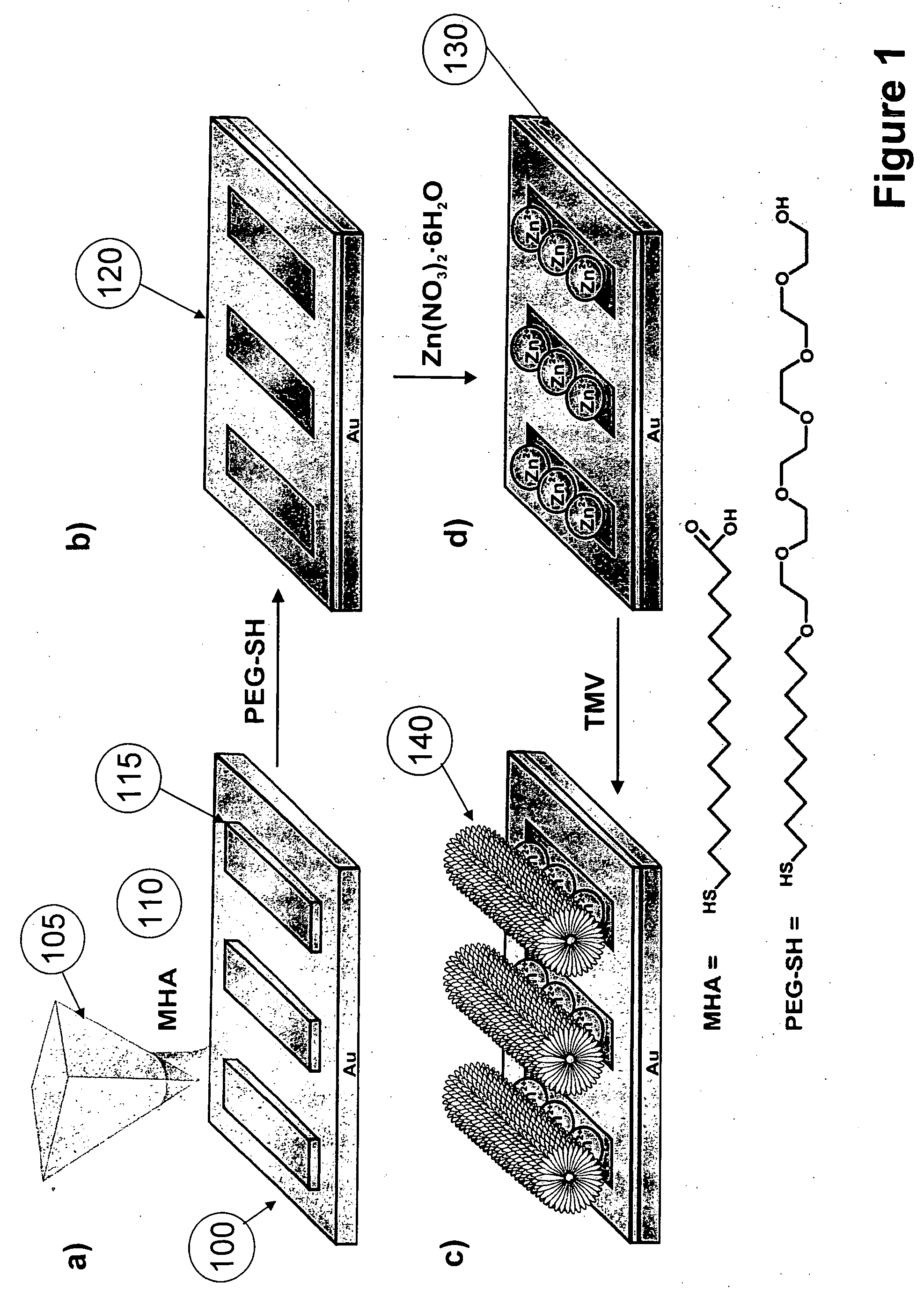

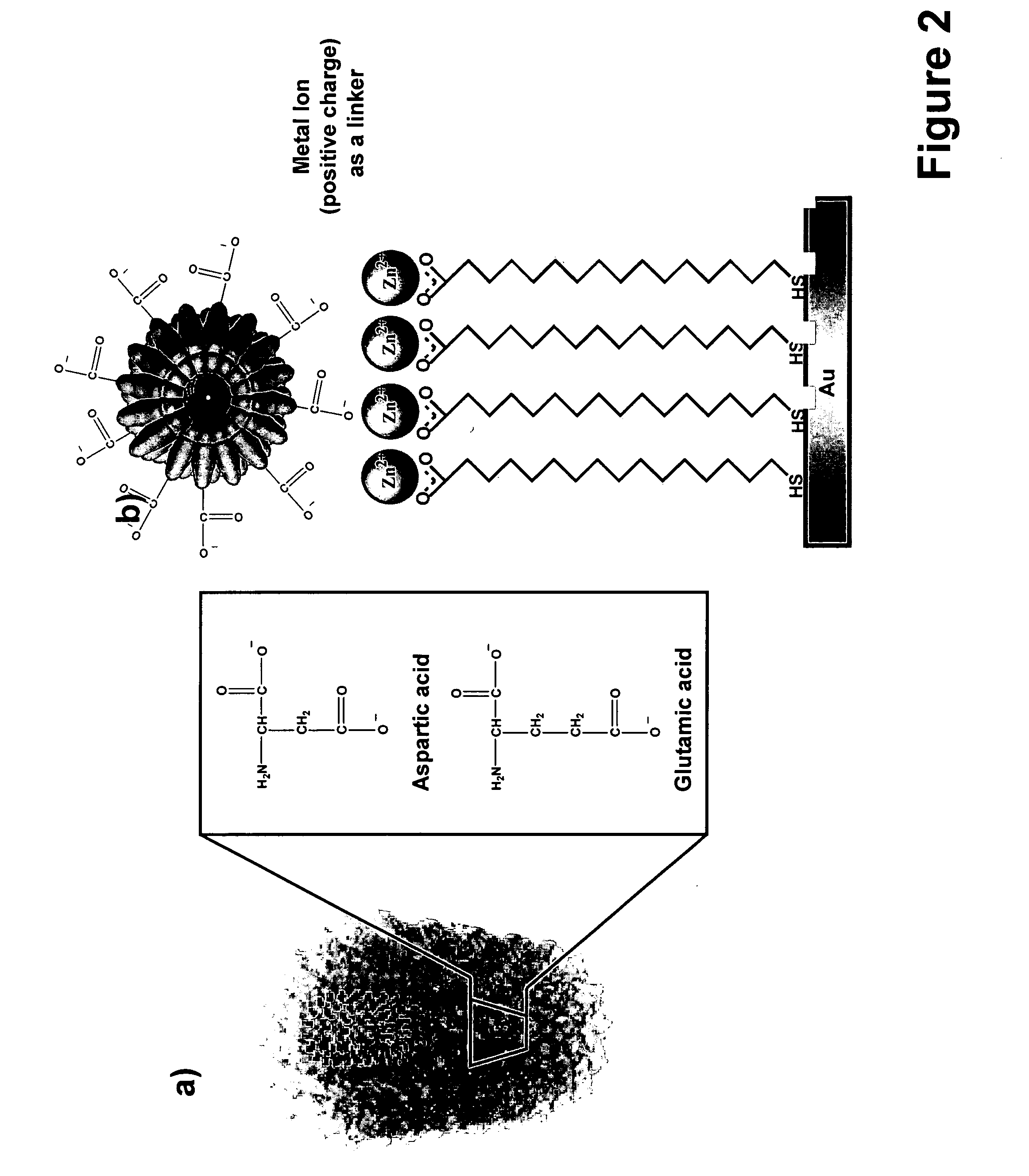

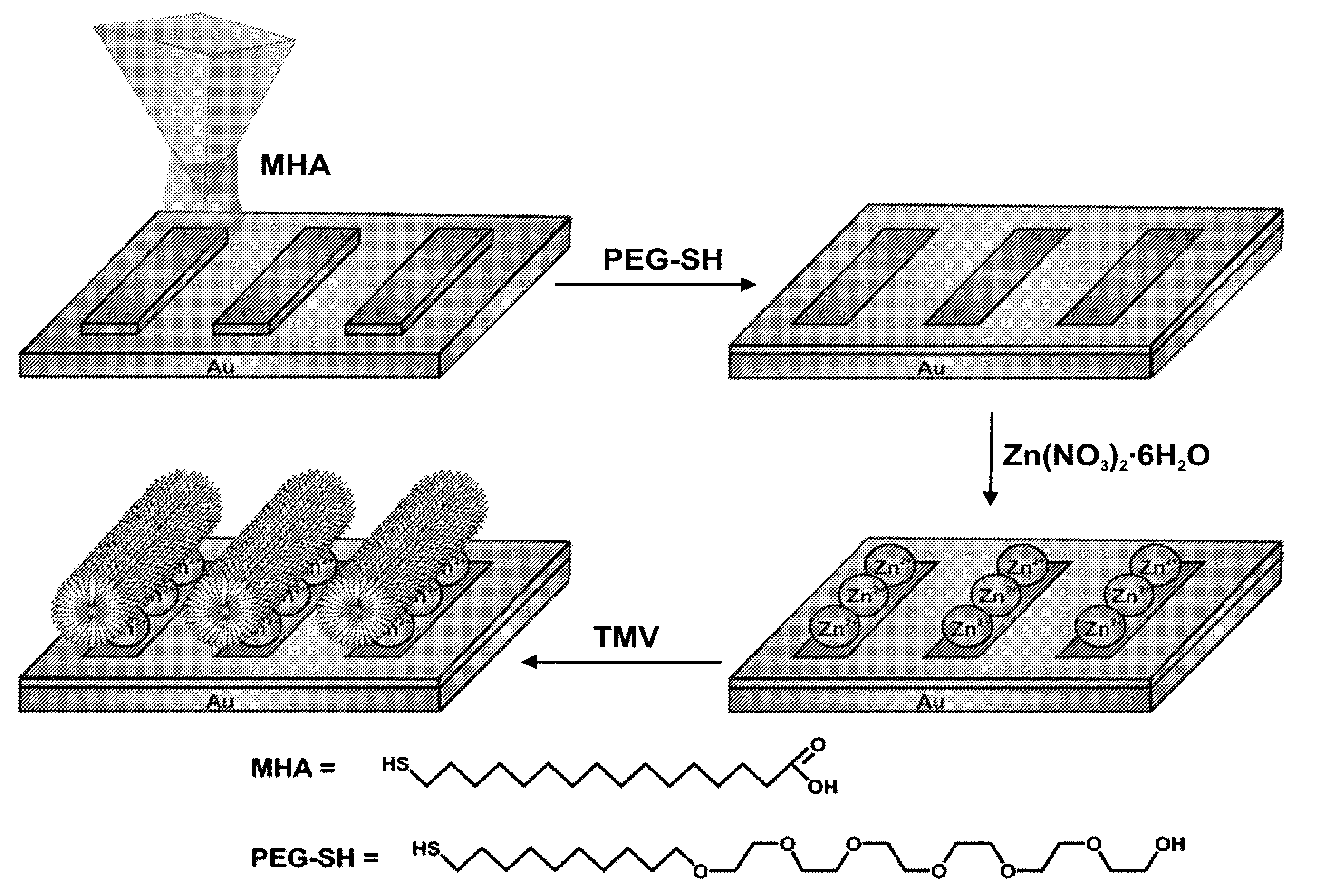

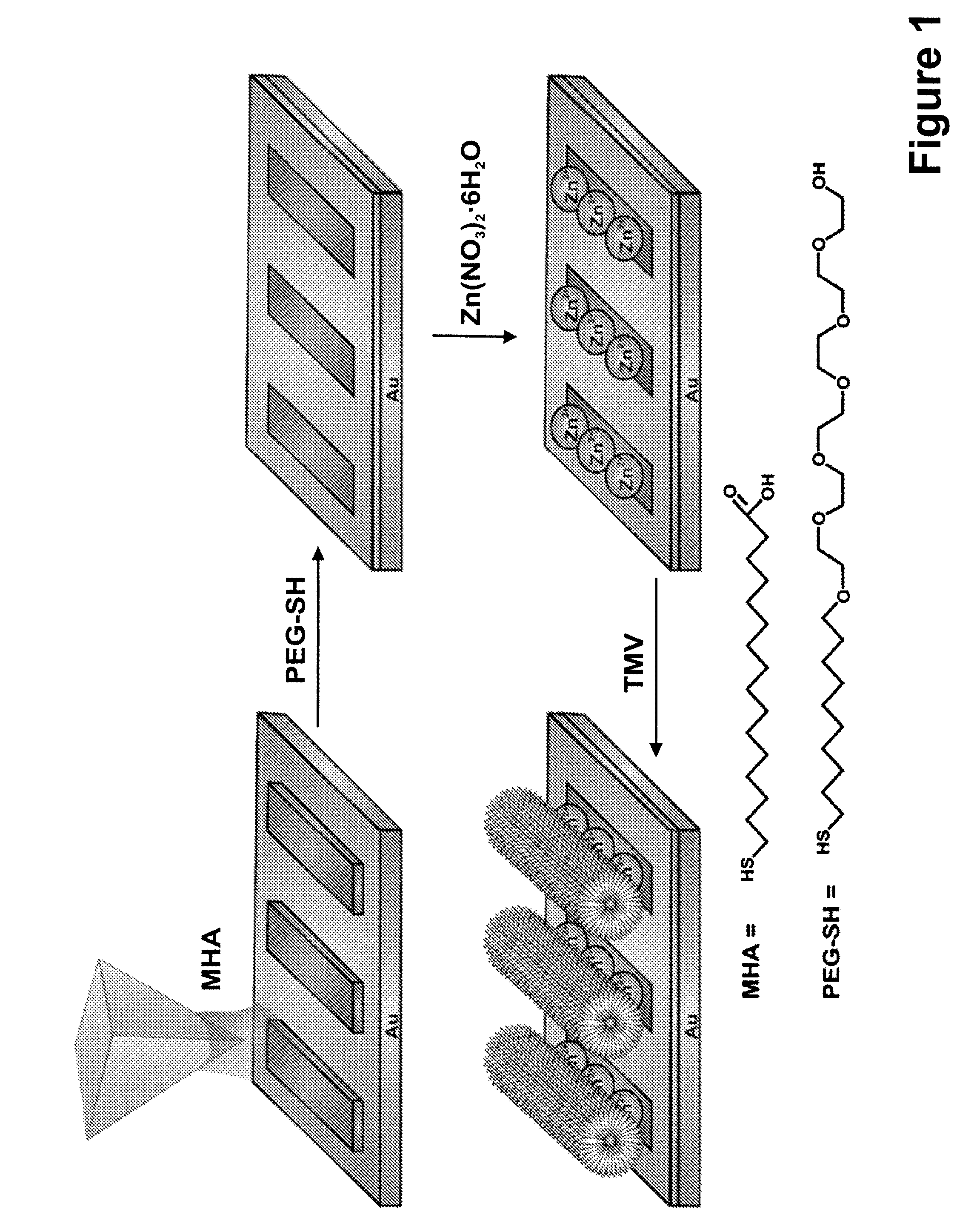

Nanoarrays of single virus particles, methods and instrumentation for the fabrication and use thereof

ActiveUS20070129321A1Increase the scope of applicationBiocideMaterial nanotechnologyDip-pen nanolithographyMolecular electronics

A novel coordination chemistry or metal ion binding approach to controlling the site-isolation and orientation of virus particles, such as TMV, on a nanoarray template generated by lithography including Dip Pen Nanolithography. By using the surface chemistry that is inherent in many viruses, metal-ion based or inorganic coordination chemistry was used to immobilize individual virus particles without the need for their genetic modification. Single particle control will enable a wide variety of studies involving viruses that are not possible with microarrays because of the size mismatch between the architecture of the virus and the features that make up such arrays. These include: single particle, single cell infectivity studies, the exploration of such structures as templates in materials synthesis and molecular electronics, and studies aimed at understanding how surface presentation can influence their bioactivity. This is a pioneering example of such control at the single-particle level, and therefore, commercial use of nanoarrays in biological systems.

Owner:NORTHWESTERN UNIV

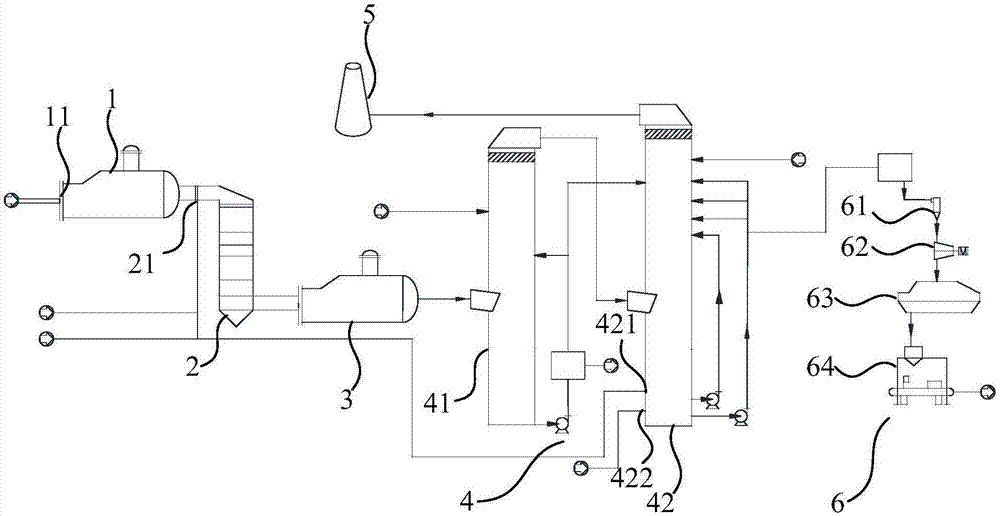

Method and device for denitration, desulfurization and dust removal of FCC tail gas through ammonia process

ActiveCN107213785ARealize collaborative controlNo secondary pollutionGas treatmentCatalytic crackingHandling systemPollution

The invention discloses a device and method for denitration, desulfurization and dust removal of an FCC tail gas through an ammonia process. The device comprises a first-stage waste heat recovery system, a denitration system, a dust removal and desulfurization system, a tail gas exhaust system and an ammonium sulfate aftertreatment system, wherein the dust removal and desulfurization system comprises a dust removal tower and an absorption tower which are separately arranged; the tower top and the tower bottom of the absorption tower are connected with the tail gas exhaust system and the ammonium sulfate aftertreatment system; and the absorption tower is sequentially divided into an oxidation segment, an absorption segment and a fine particle control segment from bottom to top. The method for denitration, desulfurization and dust removal of the FCC tail gas through the ammonia process is carried out by adopting the device. According to the method, no wastewater is discharged, secondary pollution is avoided, cooperative control of multiple pollutants is achieved, sulfur dioxide is recovered to obtain an ammonium sulfate finished product, the investment and operation cost can be reduced and long-period stable operation can be achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Nanoarrays of single virus particles, methods and instrumentation for the fabrication and use thereof

ActiveUS7569340B2Immobilised enzymesMaterial nanotechnologyDip-pen nanolithographyMolecular electronics

A nanoarray template utilizing coordination chemistry or metal ion binding to control the site-isolation and orientation of virus particles is provided. The nanoarray template is generated by lithography including Dip Pen Nanolithography. The surface chemistry that is inherent in many viruses, metal-ion based or inorganic coordination chemistry is used to immobilize individual virus particles without the need for their genetic modification. Single particle control enables a wide variety of studies involving viruses that are not possible with microarrays, including single particle, single cell infectivity studies, exploration of such structures as templates in materials synthesis and molecular electronics, and studies aimed at understanding how surface presentation influences their bioactivity. This is an example of such control at the single-particle level, and therefore, commercial use of nanoarrays in biological systems.

Owner:NORTHWESTERN UNIV

Particle control in laser processing systems

ActiveUS20130087547A1Reduce pollutionElectric heating for furnacesLaser beam welding apparatusLaser processingOxygen

Owner:APPLIED MATERIALS INC

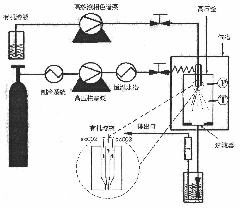

Microfluid reactor based nano-particle preparation and particle controlled preparation process

InactiveCN101618308AImprove stabilityLattice defect minimizationChemical/physical/physico-chemical processesLattice defectsMicrofluidics

The invention discloses a microfluid reactor based nano-particle preparation and a particle controlled preparation process. The particle controlled preparation process is characterized in that technological parameters of particles in different generation steps are regulated and controlled in a nanoliter or smaller scale by a microfluid control technology, particles quickly mix and react to form cores on line, evenly grow up and are quenched to stop growing at low temperature so as to regulate and control the size, the shape, the crystal structure and the surface performance of the particles on line, and the hierarchical structure of the particles can be regulated and controlled. The method effectively inhibits widened size distribution and crystal lattice defect caused by Ostwald ripening and directional binding during nano-particle formation. Compared with a tank stirred reactor which is unable to respectively control the technological parameters of nano-particles in different generation steps, the microfluid reactor can increase the stability of the crystal structure and the physical performance of the particles, and the structure and the performance at least can be stabilized above three months to one year according to the types of the particles. The nano-particle output of the process can reach above 300ml / hour, and the process is an environment-friendly type nano-material continuous scale production process.

Owner:宋玉军

Particle control near reticle and optics using showerhead

ActiveUS20140085618A1Free from pollutionMaterial analysis by optical meansPhotomechanical exposure apparatusProjection opticsEngineering

A method and an apparatus to protect a reticle against particles and chemicals in an actinic EUV reticle inspection tool are presented. The method and apparatus utilizes a pair of porous metal diffusers in the form of showerheads to provide a continual flow of clean gas. The main showerhead bathes the reticle surface to be inspected in smoothly flowing, low pressure gas, isolating it from particles coming from surrounding volumes. The secondary showerhead faces away from the reticle and toward the EUV illumination and projection optics, supplying them with purge gas while at the same time creating a buffer zone that is kept free of any particle contamination originating from those optics.

Owner:KLA TENCOR TECH CORP +1

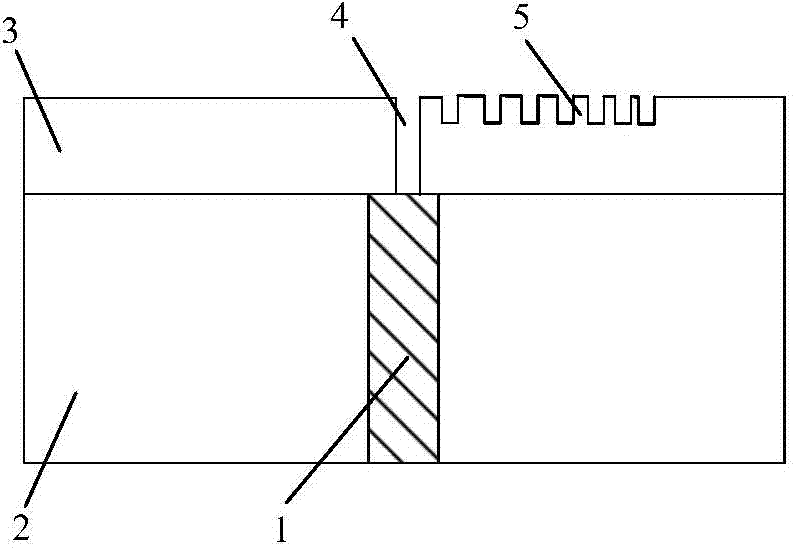

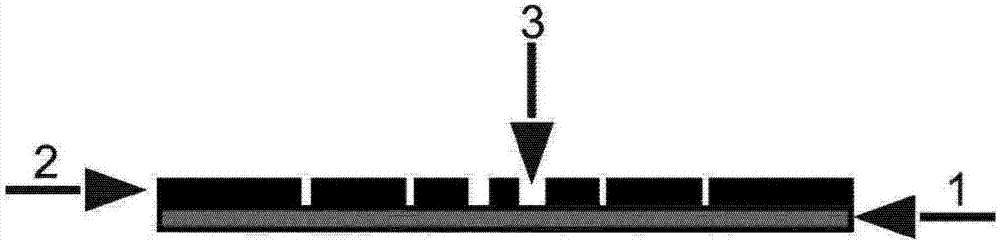

Optical fiber on-line surface plasmon Airy light beam generator

The invention belongs to the technical field of optics, and particularly relates to an optical fiber on-line surface plasmon Airy light beam generator used for optical micro capturing. The optical fiber on-line surface plasmon Airy light beam generator is formed in the mode that a metal film is plated on the end surface of an optical fiber and then a single slit and an array microgroove structure are formed in the surface of the metal film in an inscribing mode, the thickness of the metal film is 100-300 nanometers, the single slit is formed in the central axis of a fiber core, the depth of the single slit is the same as the thickness of the metal film, and the width of the single slit is 50-200 nanometers. The depth of the array microgroove structure is 20-90 nanometers, and the width of the array microgroove structure is 100-400 nanometers. The Airy light beam generator is small in size and high in integration level, can achieve all-fiber integration easily, can be interconnected with the existing optical fiber technology and is of great significance in particle control of micro-optics.

Owner:HARBIN ENG UNIV

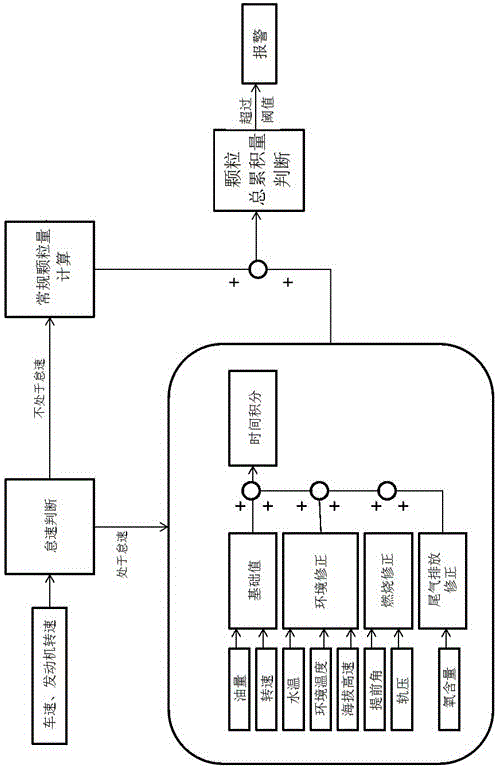

Method for controlling tail gas particle catcher in idling state of vehicle

ActiveCN105298601AEmission reductionIncrease the function of overload reminderInternal combustion piston enginesExhaust apparatusDriver/operatorEngineering

Provided is a method for controlling a tail gas particle catcher in the idling state of a vehicle. After an engine rotating speed threshold value, a vehicle speed threshold value and a particle amount threshold value are set, a controller records the initial particle amount of the tail gas particle catcher when the vehicle is in the idling condition; the idling particle accumulating amount in the idling condition is calculated; the total particle accumulating amount is calculated, judgment is carried out, and after the total particle accumulating amount exceeds the particle amount threshold value, the controller reminds a driver that the particle amount of the tail gas particle catcher exceeds the standard; and the total particle accumulating amount equals the sum of the initial particle amount and the idling particle accumulating amount. According to the method, the idling standard of the vehicle is set, the idling particle control mode is started when the vehicle is in the idling state, and an overload reminding function of the tail gas particle catcher is added, so that the problem that polluting emission is increased due to the fact that the driver is still not reminded to carry out effective regeneration after the tail gas particle catcher is overloaded and even blocked when the vehicle is in the idling condition for a long time is solved.

Owner:SAIC MOTOR

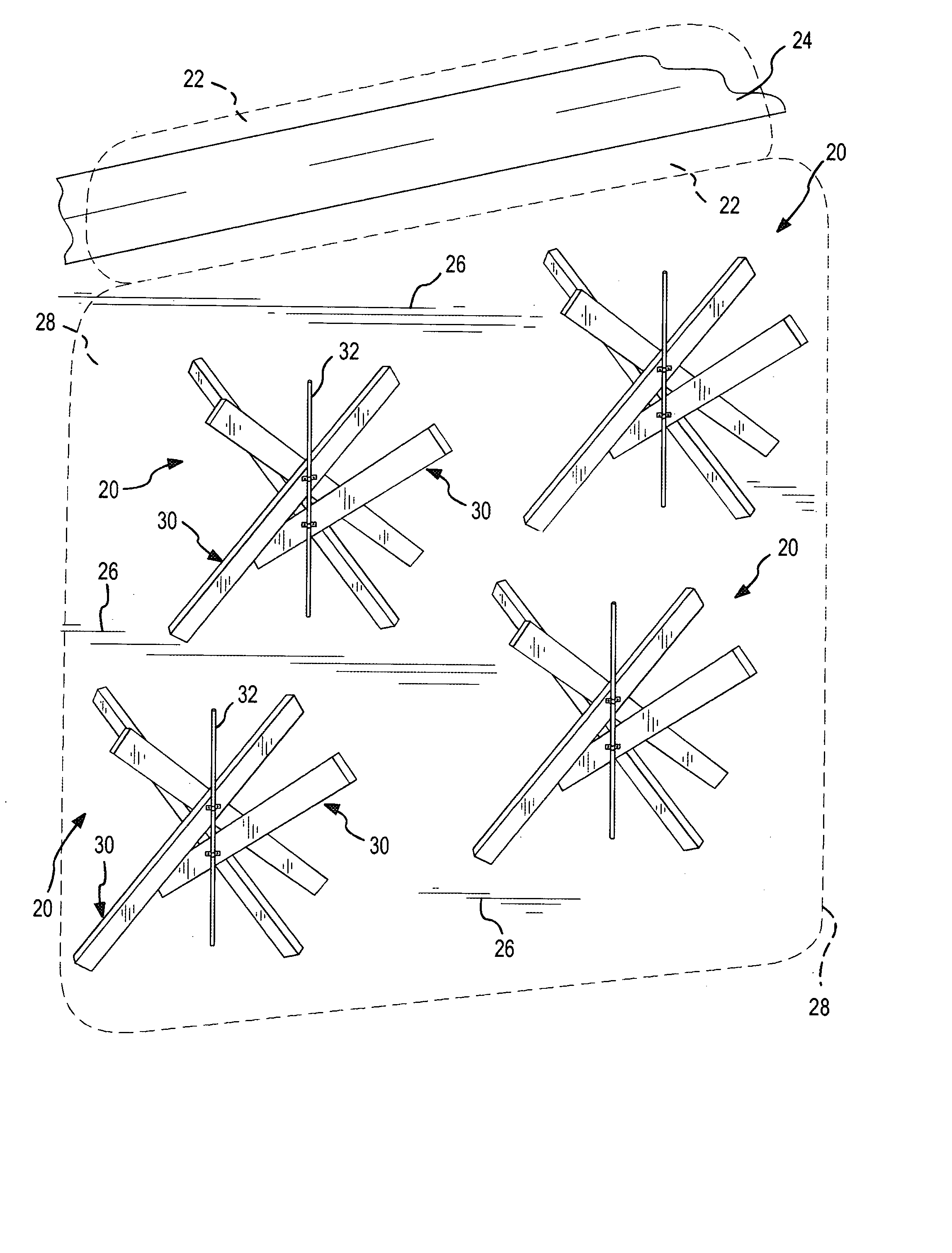

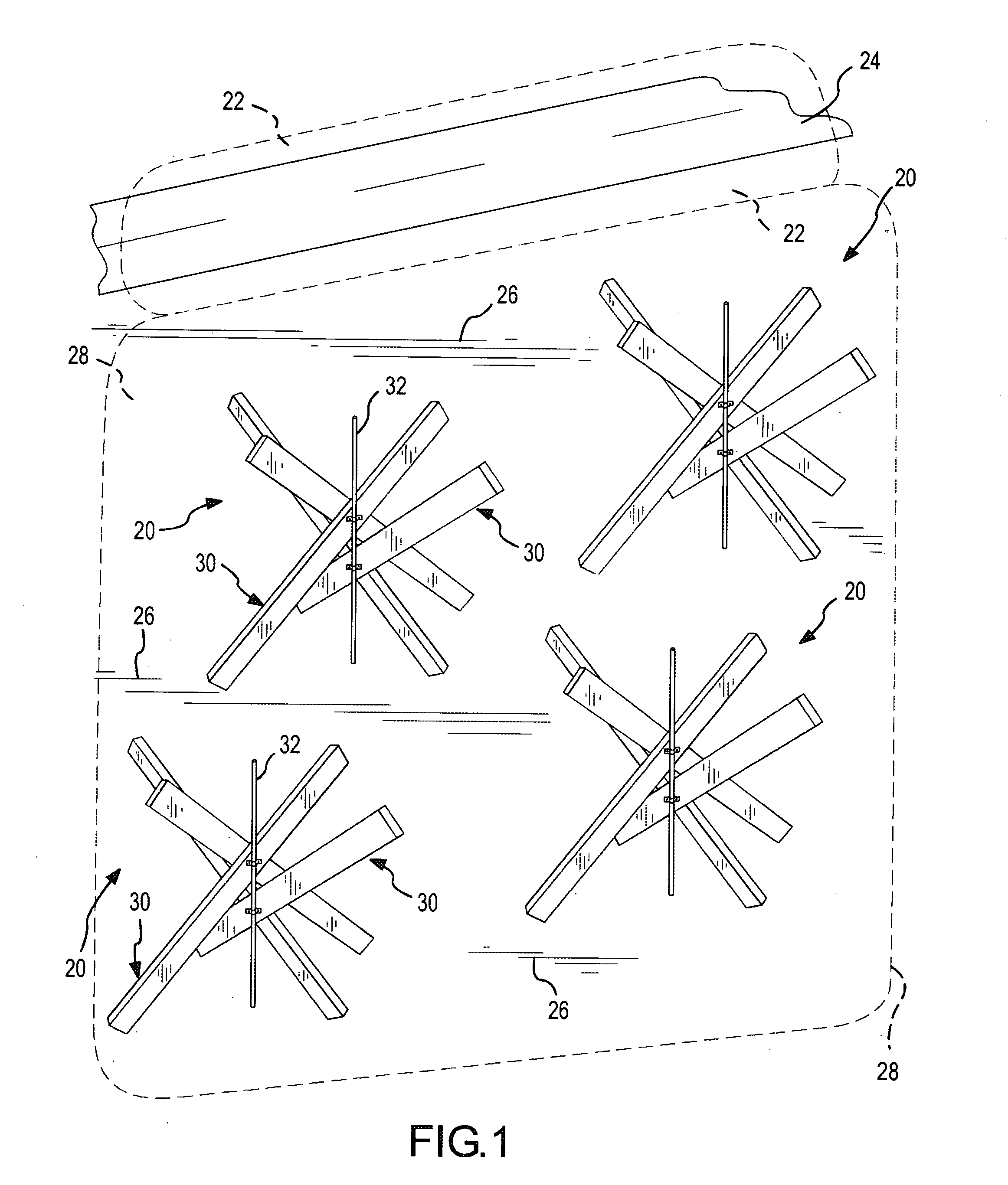

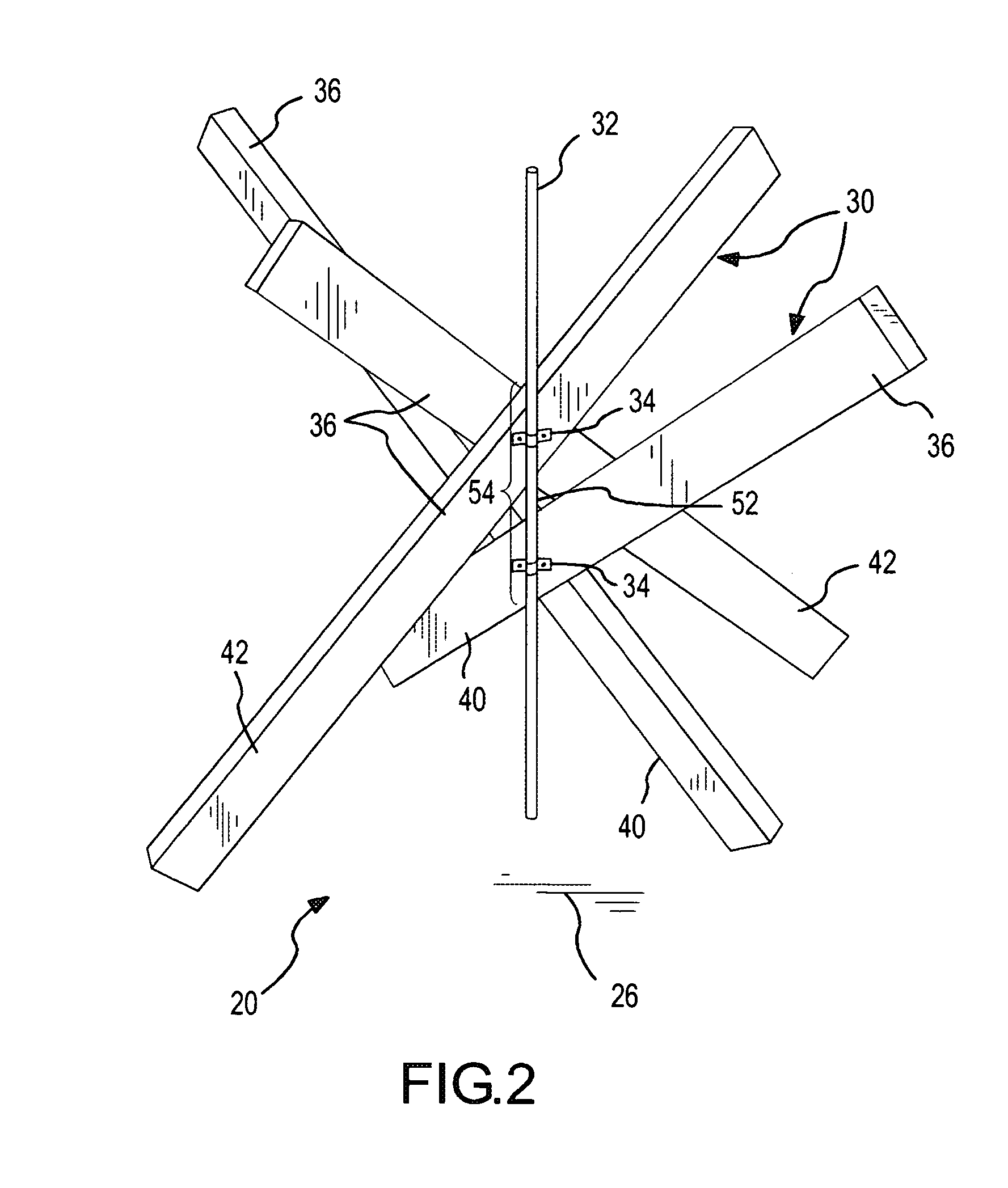

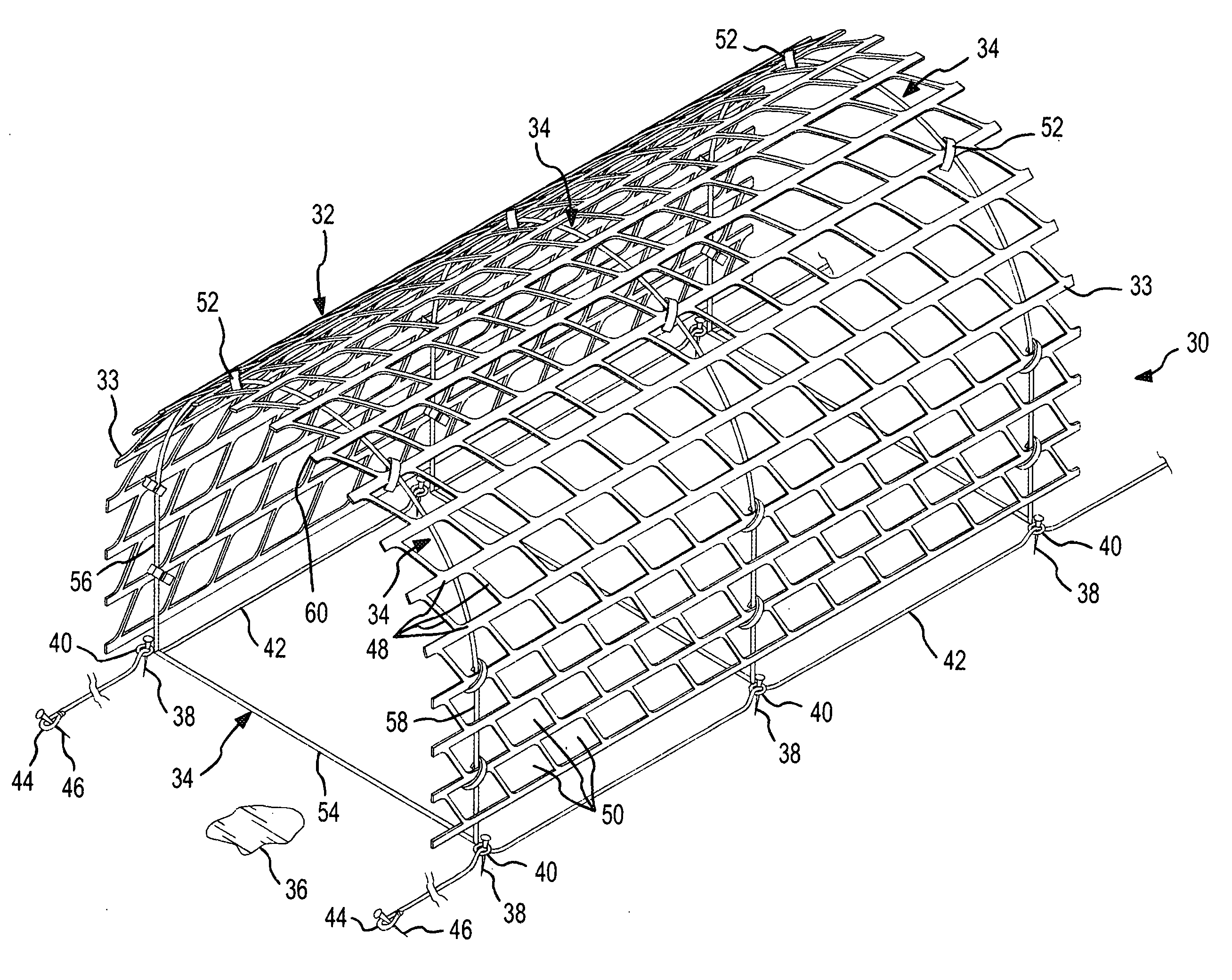

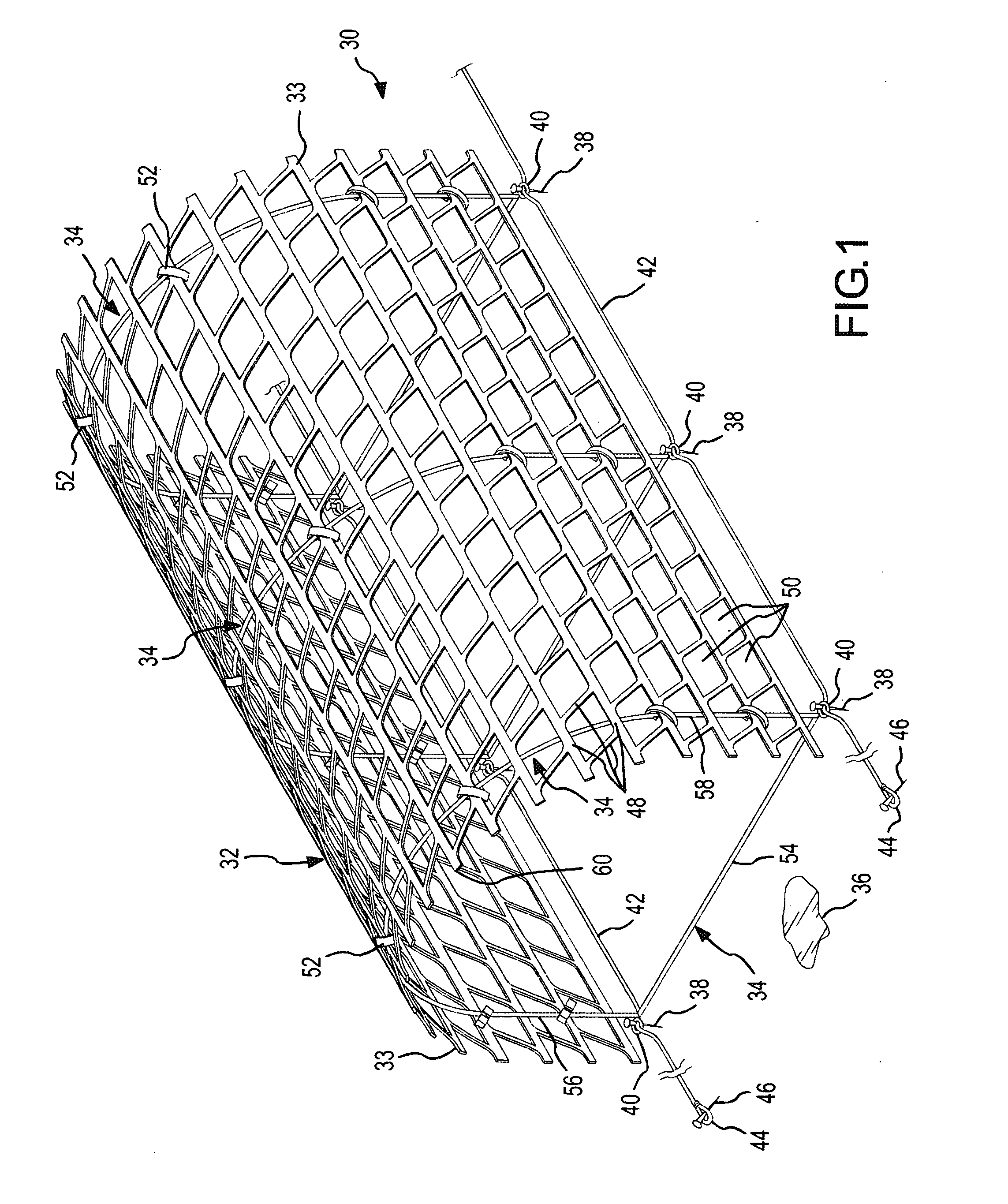

Tetrapod control device and method for stabilizing, depositing and retaining windblown particles

InactiveUS7097385B2Easy to repositionObstruction in may takeBreakwatersQuaysEngineeringEarth surface

A three-dimensional multi-pod windblown particle control device is used to control the deposition, accumulation and retention of windblown particles. The multi-pod device is formed by connecting beams to create legs which intersect one another at a crossing area. The ends of some of the legs contact the earth surface to support the device while the ends of the other legs extend in three dimensions to interact with the wind. The device may be formed by substantially identical X-shaped frame structures which intersect and connect with one another. The optimal spacing for using the devices in an array is within a range of approximately 0.5–1.5 of a transverse dimension across the surface area occupied by each particle control device.

Owner:TABLER RONALD D

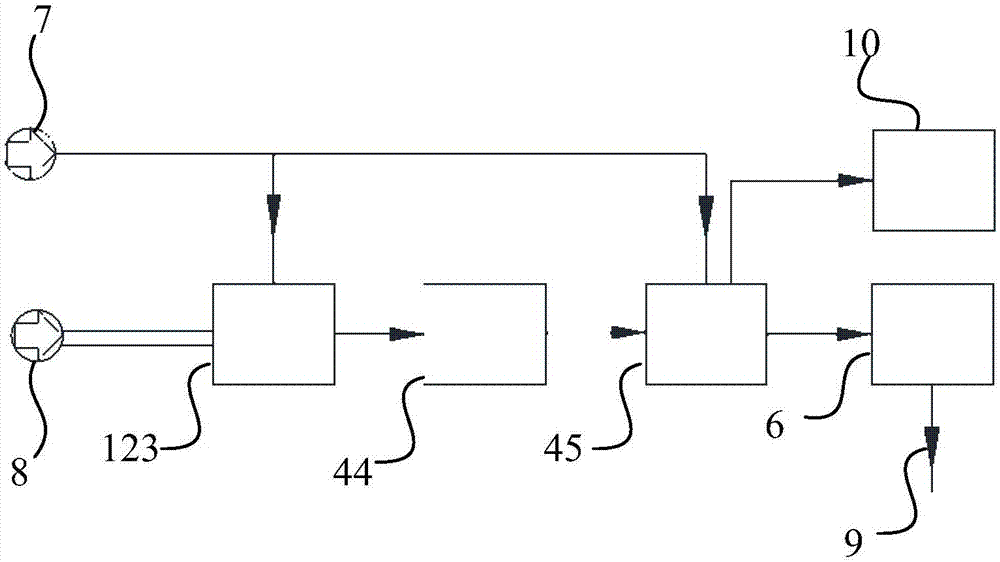

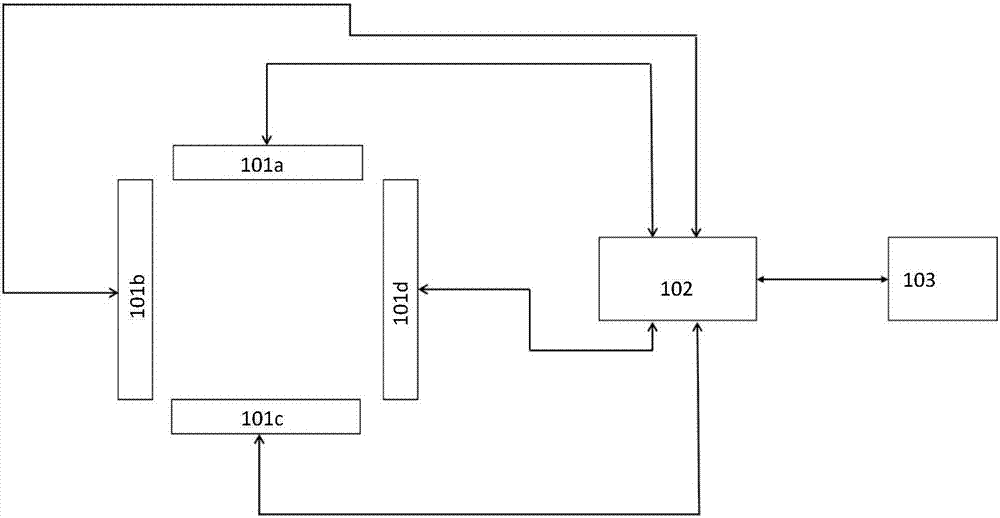

Particle control system and method based on time reversal technology

ActiveCN107050630AEasy to controlAdaptive focus implementationUltrasonic/sonic/infrasonic diagnosticsMedical devicesParticle controlPhysics

The invention relates to the technical field of acoustic control, in particular to a particle control system and a method based on a time reversal technology. The system and the method aim at achieving any path control for a particle in a nonuniform medium. Therefore, the particle control system based on the time reversal technology is characterized by comprising an array probe, a signal reception and transmission control device and an upper computer, wherein the array probe is in communication connection with the signal reception and transmission control device; and the signal reception and transmission control device is in communication connection with the upper computer. Therefore, the system can be applied in the fields of in-vivo fixed-point administration, reproductive medicine and the like and have a higher practical value. The invention further provides the particle control method using the time reversal technology.

Owner:SHENZHEN INST OF ADVANCED TECH

Unsintered mesh sand control screen

A particle control screen assembly for a perforated pipe used in a well. The particle control screen assembly includes a screen with a first end and a second end. The screen includes a first and a second unsintered woven mesh layer, each layer having a first longitudinal edge and a second longitudinal edge. The cylindrical screen also includes openings sized to prevent passage of particulate material and a longitudinal metal weld adjacent the first and second longitudinal edges of the first and second unsintered woven mesh layers. The longitudinal metal weld secures the edges of the unsintered woven mesh layers together. The particle control screen assembly also includes a weld-compatible metal structure adjacent the first end of the cylindrical screen. A circumferential metal weld between the cylindrical screen and the metal structure bonds a portion of the metal structure and a portion of the cylindrical screen.

Owner:PUROLATOR FACET INC

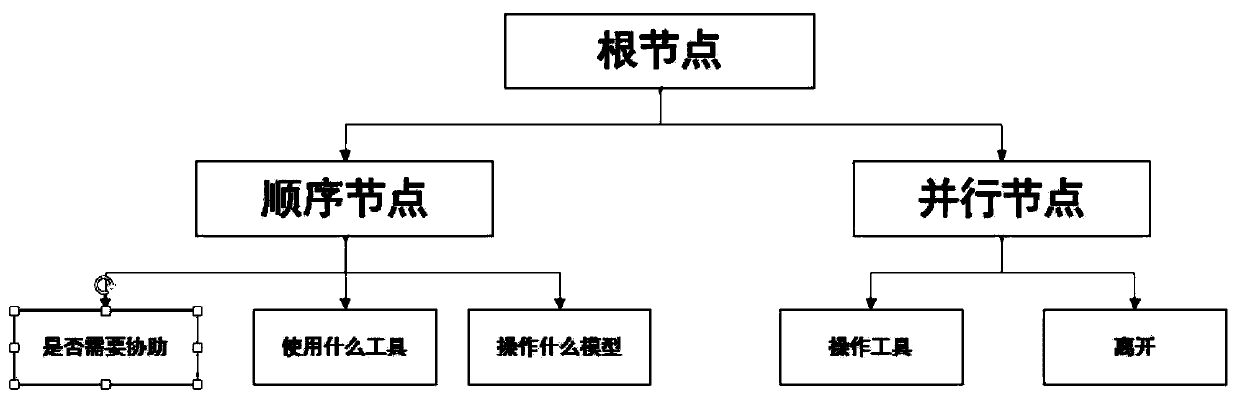

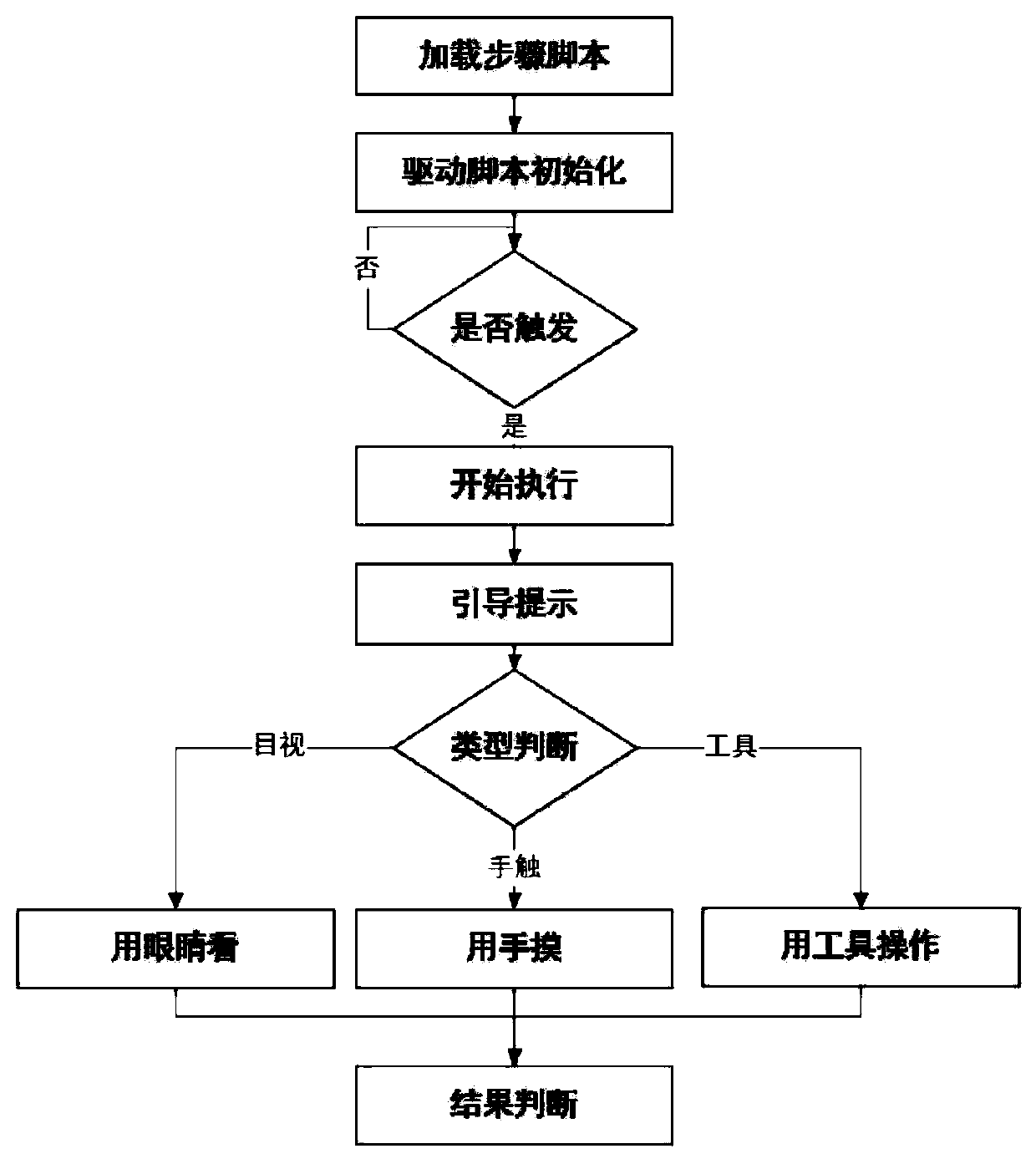

Rail transmit vehicle overhauling simulation training system based on virtual scene

ActiveCN110428688AQuick analysisRealize automatic executionCosmonautic condition simulationsSimulatorsBogieSky

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE +1

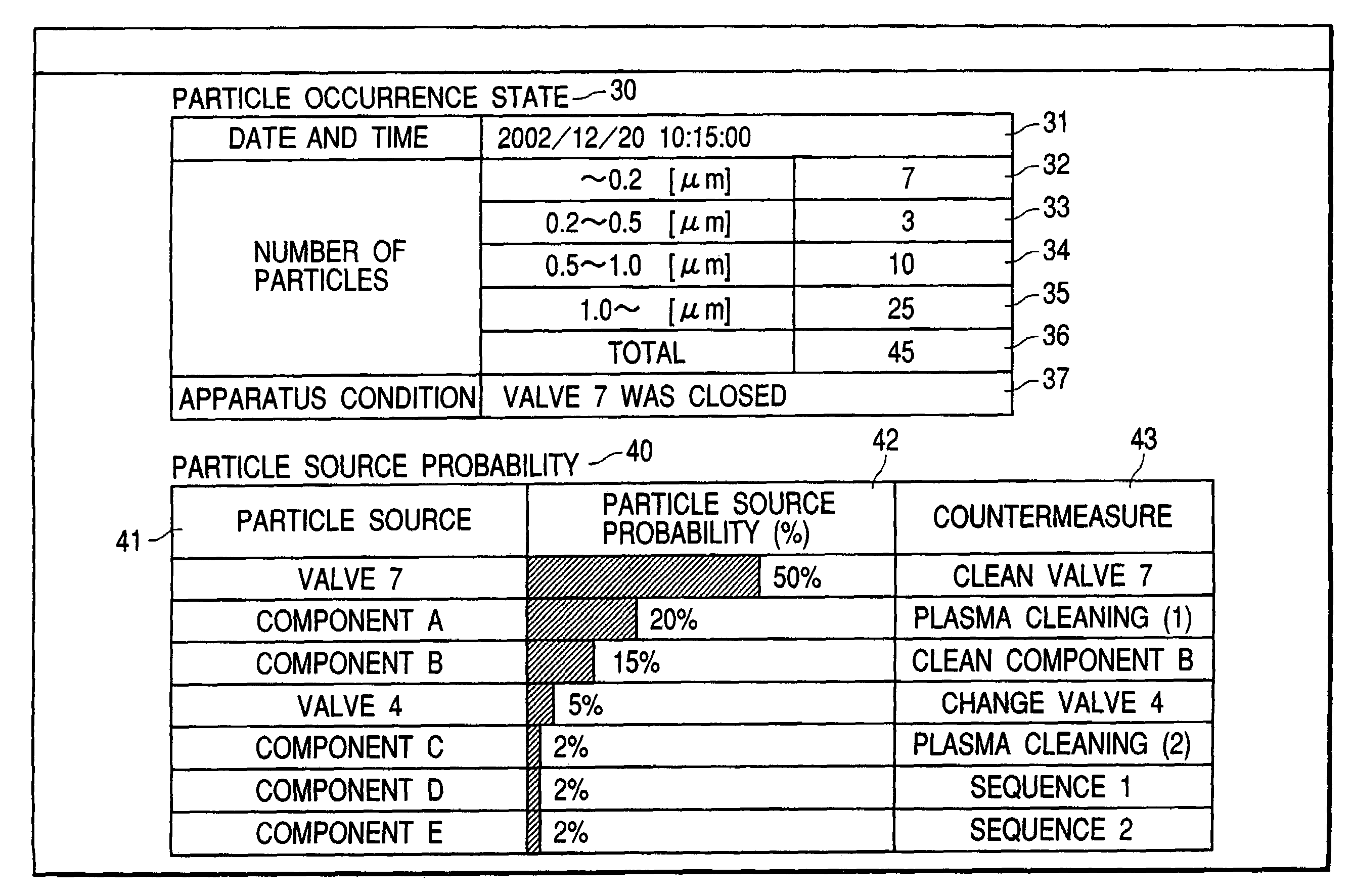

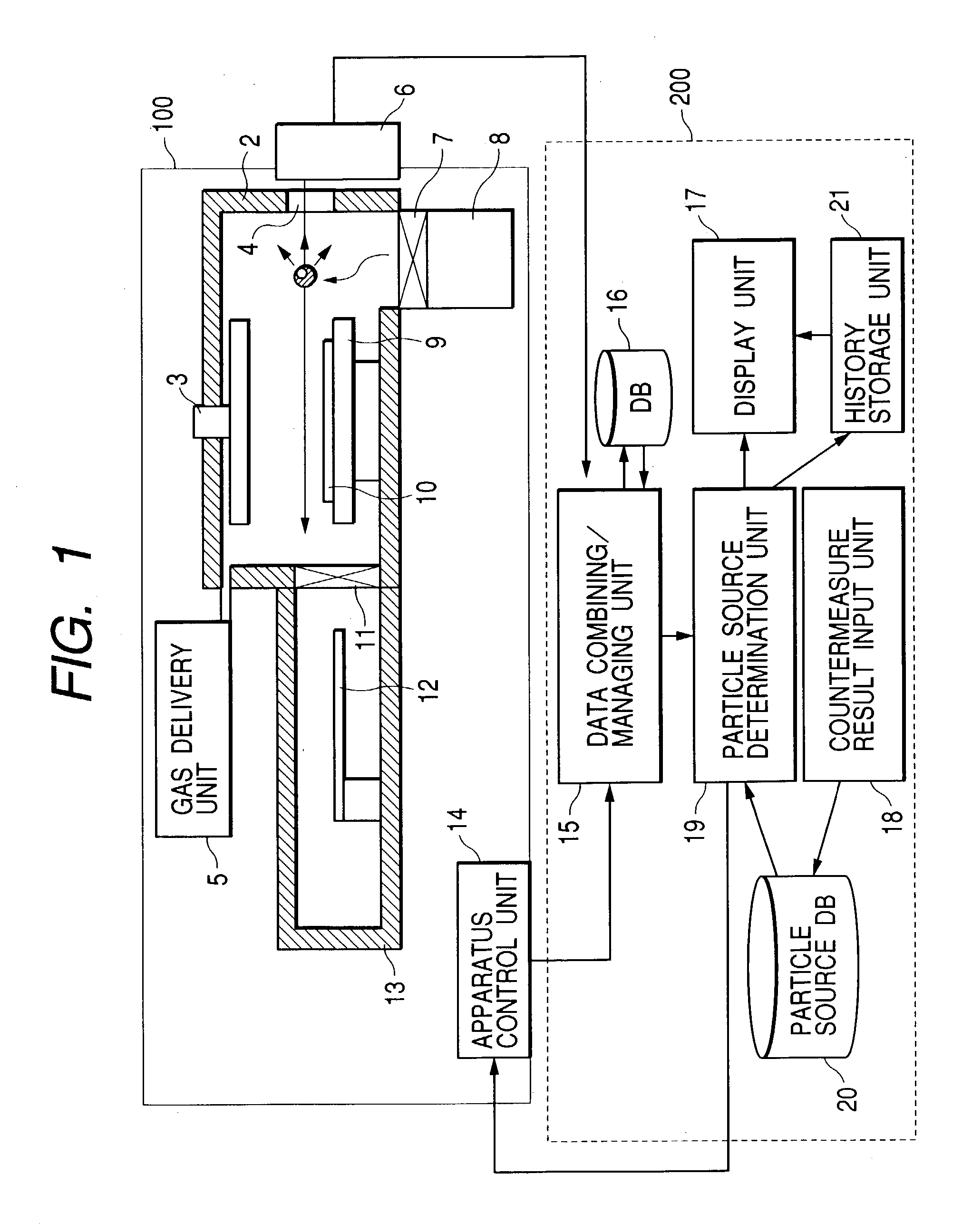

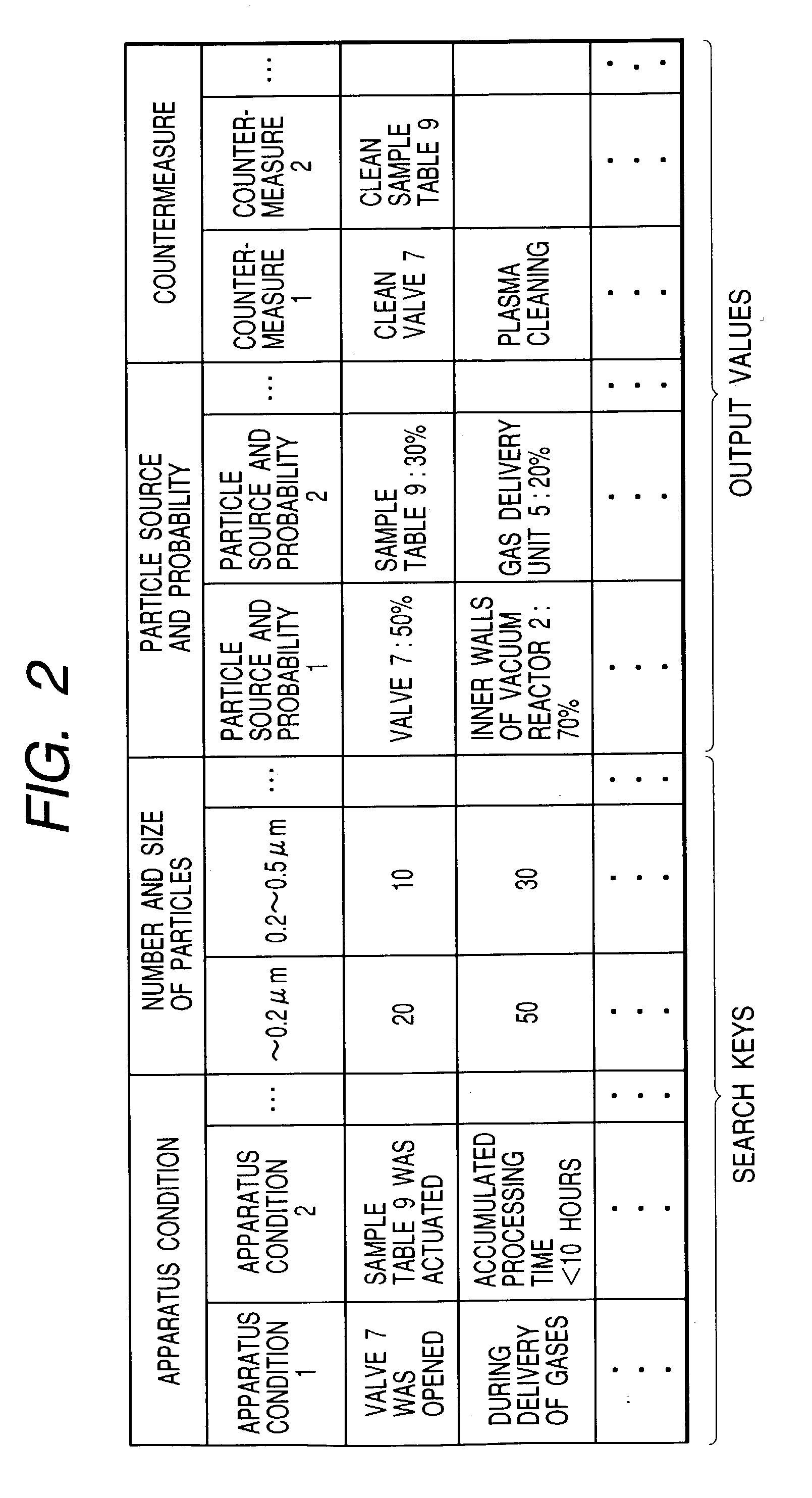

Particle control device and particle control method for vacuum processing apparatus

InactiveUS7166480B2Increased probability of occurrenceIncrease probabilityElectric discharge tubesVacuum evaporation coatingProduct gasAtomic physics

A particle control device and a particle control method are capable of controlling the occurrences of particles in a vacuum reactor. The particle control device is used in a vacuum processing apparatus having a vacuum reactor, a gas delivery unit for supplying processing gases to the vacuum reactor, and a sample table for supporting a sample in the vacuum reactor, wherein the apparatus subjects the sample to vacuum processing. The particle control device detects particles floating inside the vacuum reactor; generates apparatus condition data indicating a condition of the vacuum processing apparatus; and determines a component which is high in a particle occurrence probability based on detected particle data and apparatus condition data, thereby enabling display of the component selected as the particle source.

Owner:HITACHI HIGH-TECH CORP

Preparation method and application of carbonized rice hull powder particle control and flooding agent

ActiveCN106566500AAdvantages of preparation methodDoes not affect viscosityDrilling compositionEnvironmental resistanceCarbonization

The invention provides a preparation method and application of a carbonized rice hull powder particle control and flooding agent. The preparation method comprises the following steps: (1) weighing a certain amount of rice hull and putting the rice hull into a carbonization tank; (2) putting the carbonization tank into a constant-temperature curing box, adjusting heating temperature to 200-270 DEG C, and carrying out carbonization treatment on the rice hull at the constant temperature for 2-3 h; and (3) taking out the carbonized rice hull, cooling the rice hull and finally crushing and screening so as to obtain the carbonized rice hull powder particle control and flooding agent. According to the preparation method of the carbonized rice hull powder particle control and flooding agent, rice hull is commercially available in quantity, and the carbonization processing is simple and easy to operate. The preparation method belongs to refuse reclamation and is low-cost. In comparison with other control and flooding agents, the prepared carbonized rice hull powder particle control and flooding agent is nontoxic and harmless and is green and environment-friendly. After the carbonized rice hull powder particle control and flooding agent is blended with an aqueous solution of partially hydrolyzed polyacrylamide polymers according to a certain mass ratio, the profile control plugging rate of deep-bed formation large-pores can reach 90% and above.

Owner:DAGANG OIL FIELD GRP +1

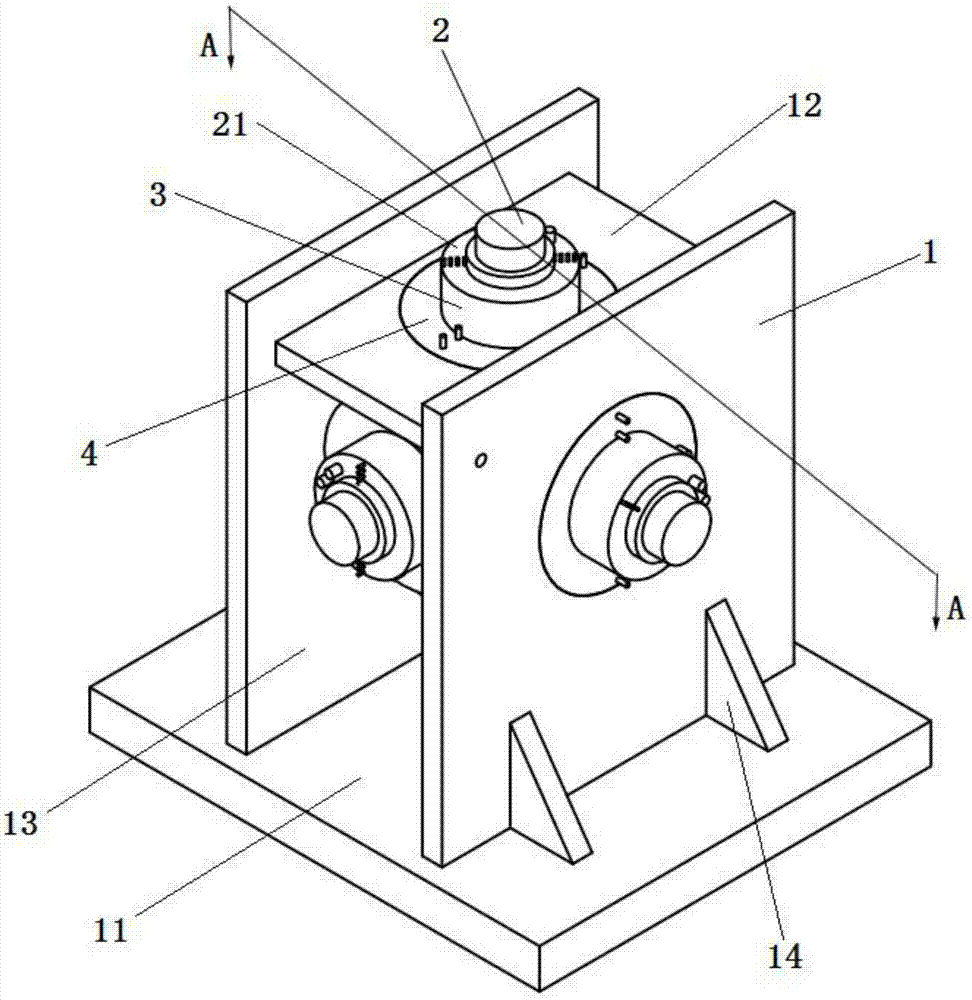

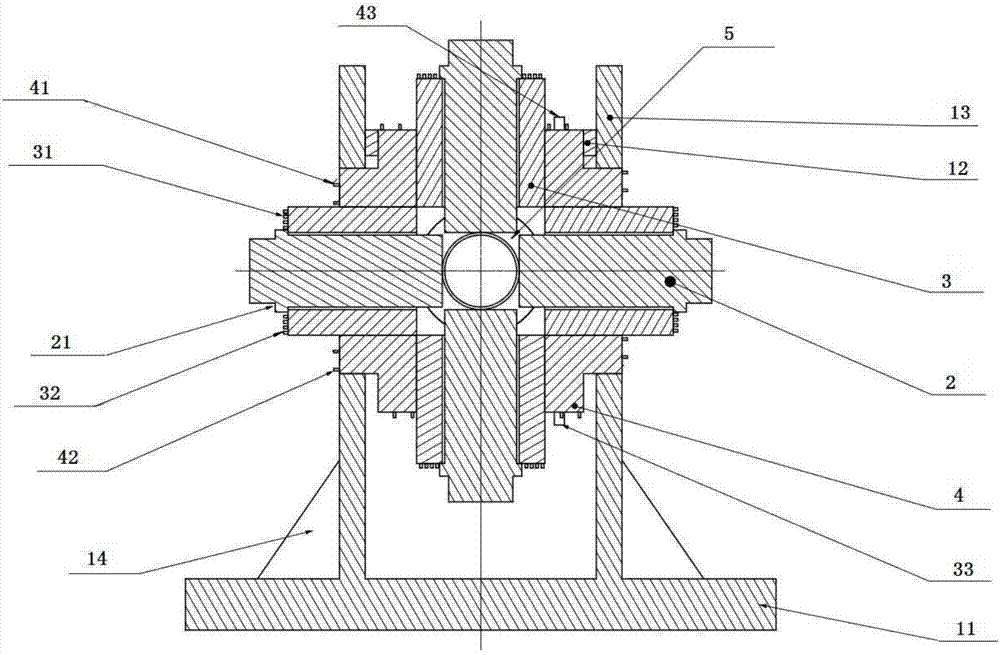

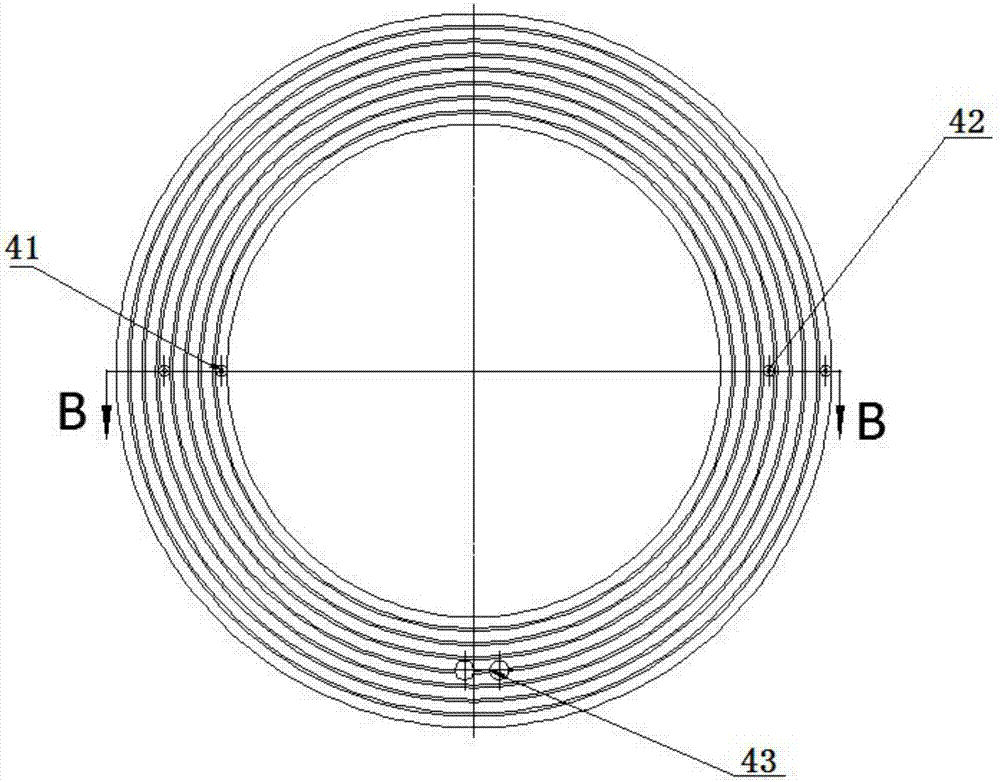

Magnetic particle control device based on three-dimensional magnetic field

ActiveCN107491097ARealize in-depth controlControl using feedbackMagnetite NanoparticlesPulse magnetic field

The present invention provides a magnetic particle control device based on a three-dimensional magnetic field. The device comprises a support frame, an insulating working chamber and six magnetic conductive rods. The support frame comprises a rectangular frame structure, each side of the rectangular frame structure is provided with a fixed hole. The insulating working chamber is arranged in the rectangular frame structure. One end of each of the six magnetic conductive rods abuts against the insulating working chamber. The six magnetic conductive rods are sleeved by pulse coils which are sleeved by polarization coils, the polarization coils are clamped in the fixed holes. The pulse coils are provided with wiring terminals, and the polarization coils are provided with wiring conductive columns which are connected to the anode and cathode of a power supply through conductive wires. According to the device, a three-dimensional timing maintaining constant orientation magnetic field and a pulse magnetic field can be combined so as to realize the deep aggregation of magnetic nanoparticles in the insulating working chamber.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

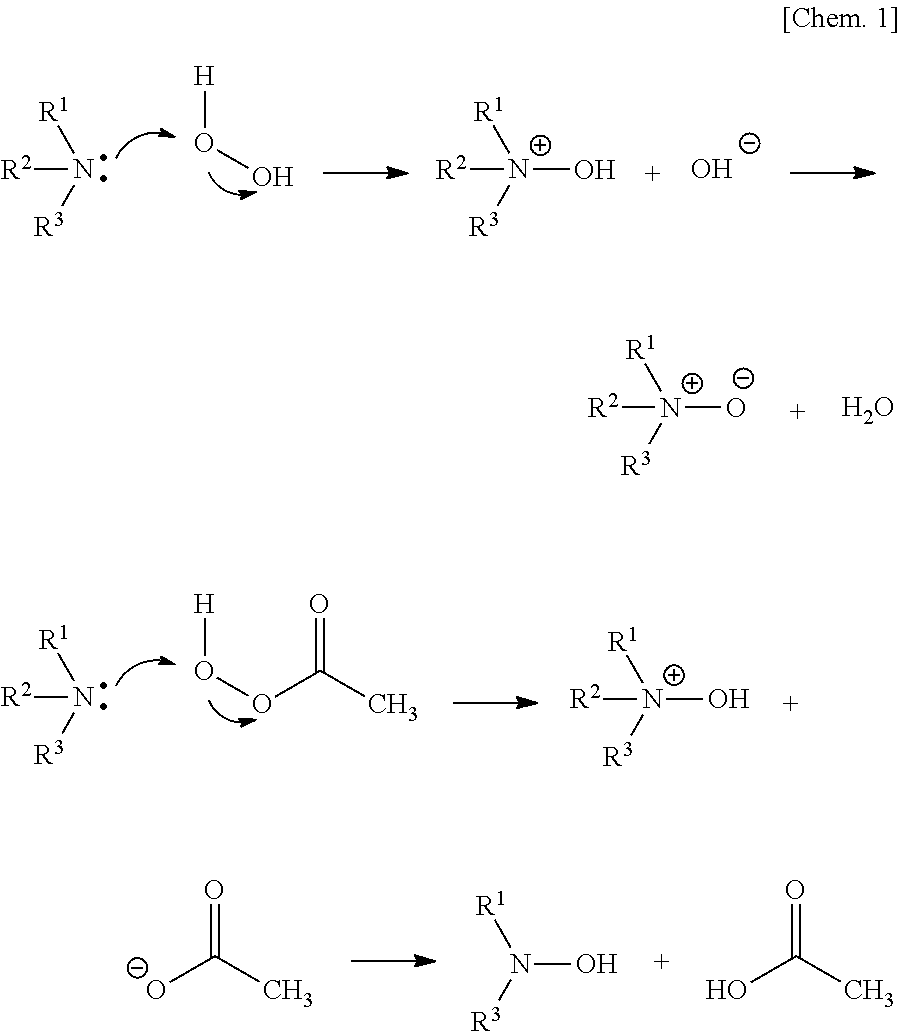

Metal nanoparticle composite body, metal colloidal solution, and methods for producing these

ActiveUS20150203700A1Good low-temperature firing propertyGood low temperatureMaterial nanotechnologyTransportation and packagingDispersion stabilityNanometre

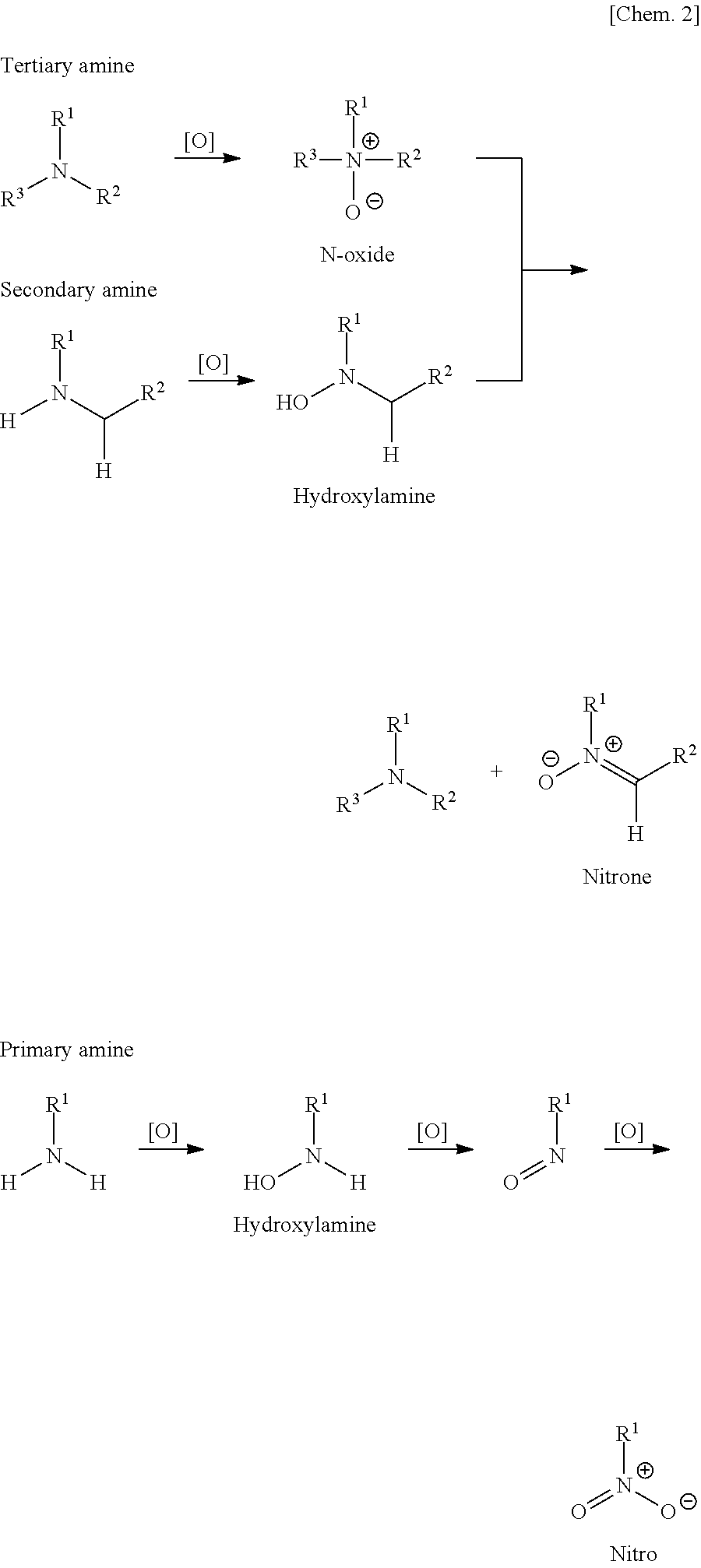

Provided are metal nanoparticle composite body whose multiple properties, such as a good metal nanoparticle control property, high dispersion stability, a good low-temperature firing property, and ease of purifying and separating metal nanoparticles, are intentionally added and controlled so that practical electrical conductivity can be exhibited, a metal colloidal solution in which the metal nanoparticle composite body is dispersed, and methods for producing these. A metal nanoparticle composite body includes a nitrogen-containing compound (A) and a metal nanoparticle (B), in which the nitrogen-containing compound (A) contains an oxidized nitrogen atom. A metal colloidal solution is obtained by dispersing the metal nanoparticle composite body in a medium. A method for producing a metal colloidal solution is characterized in that metal ions are reduced in a medium in the presence of a nitrogen-containing compound (A) containing an oxidized nitrogen atom so as to form metal nanoparticles (B).

Owner:DAINIPPON INK & CHEM INC

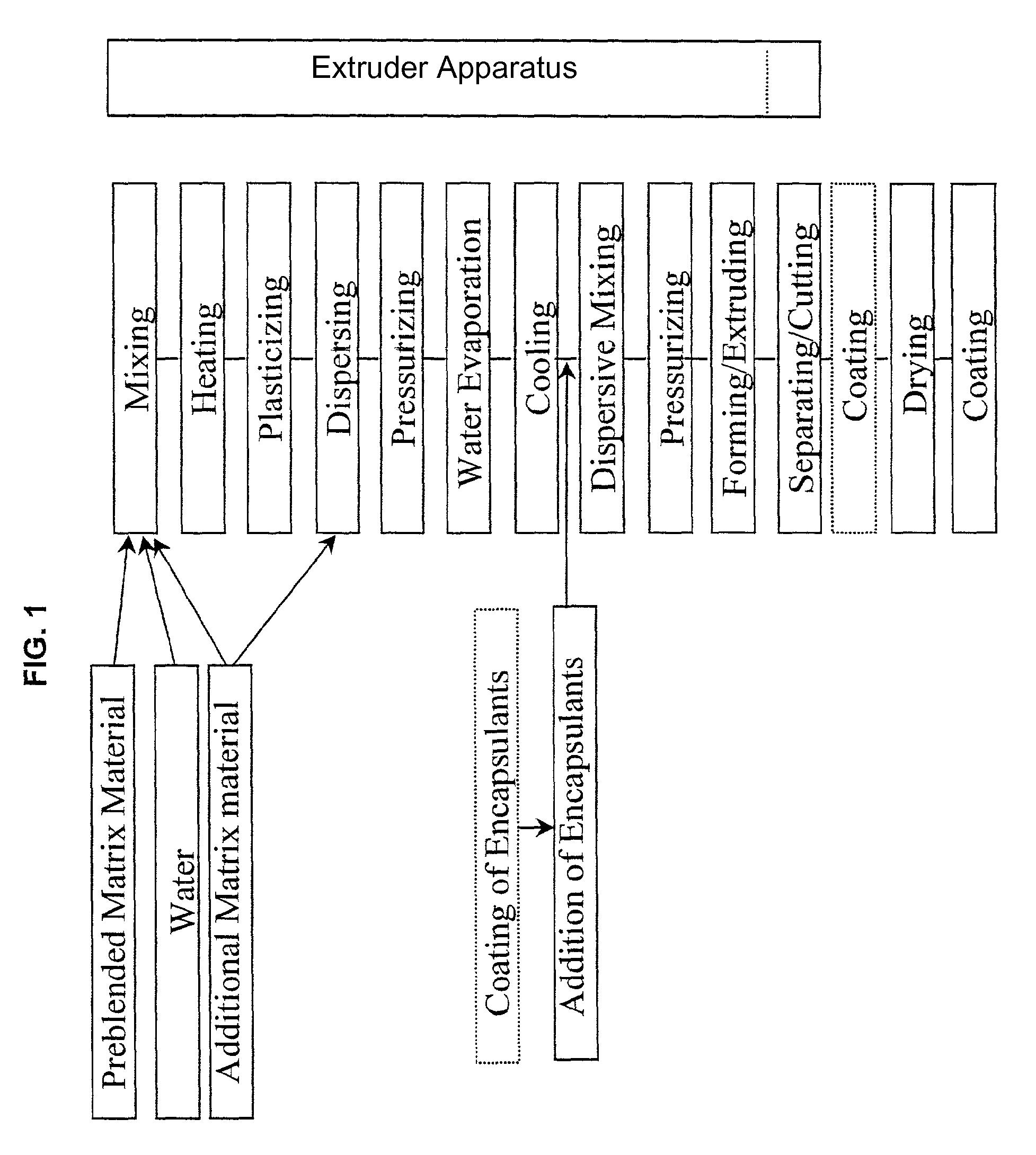

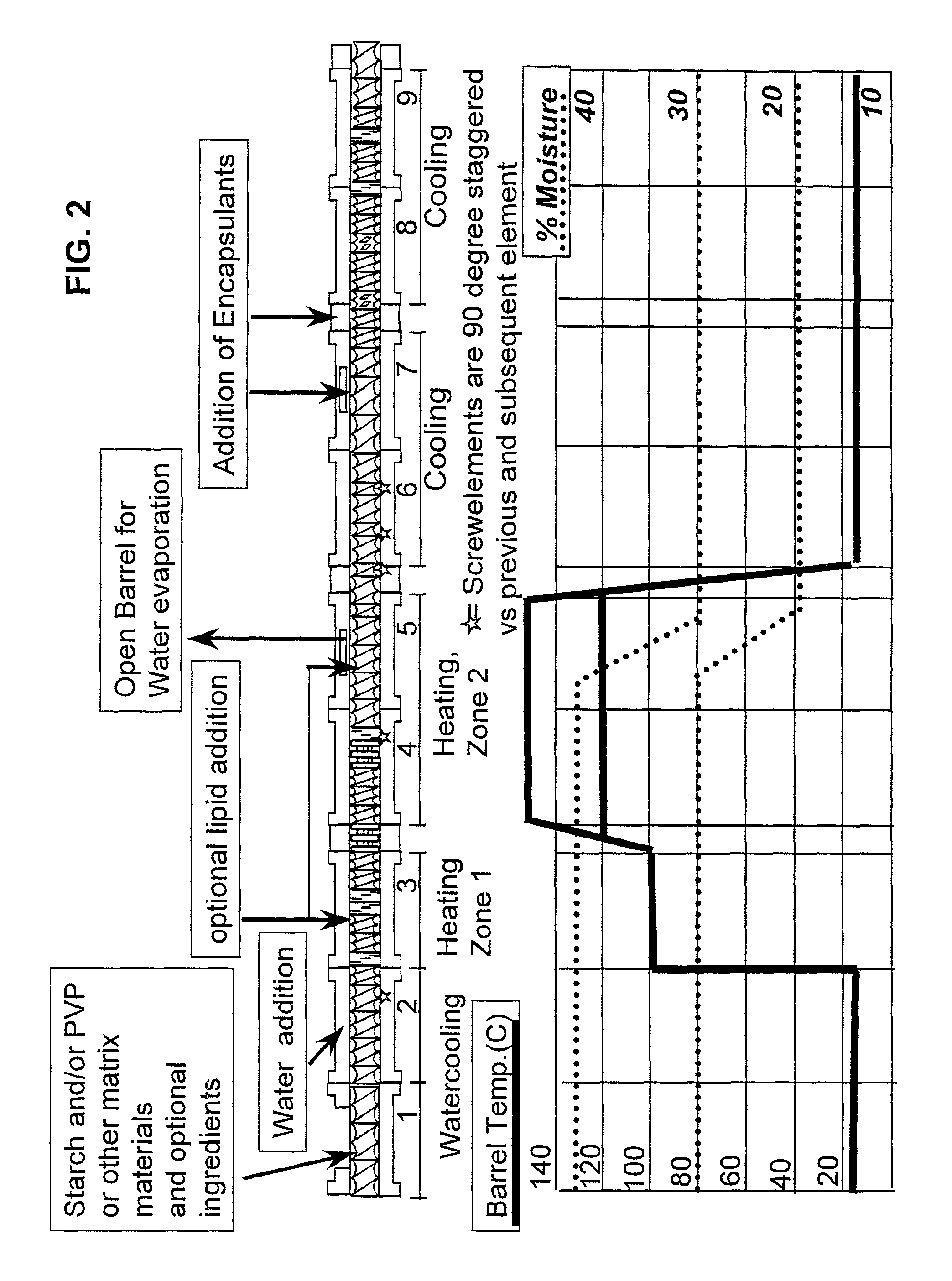

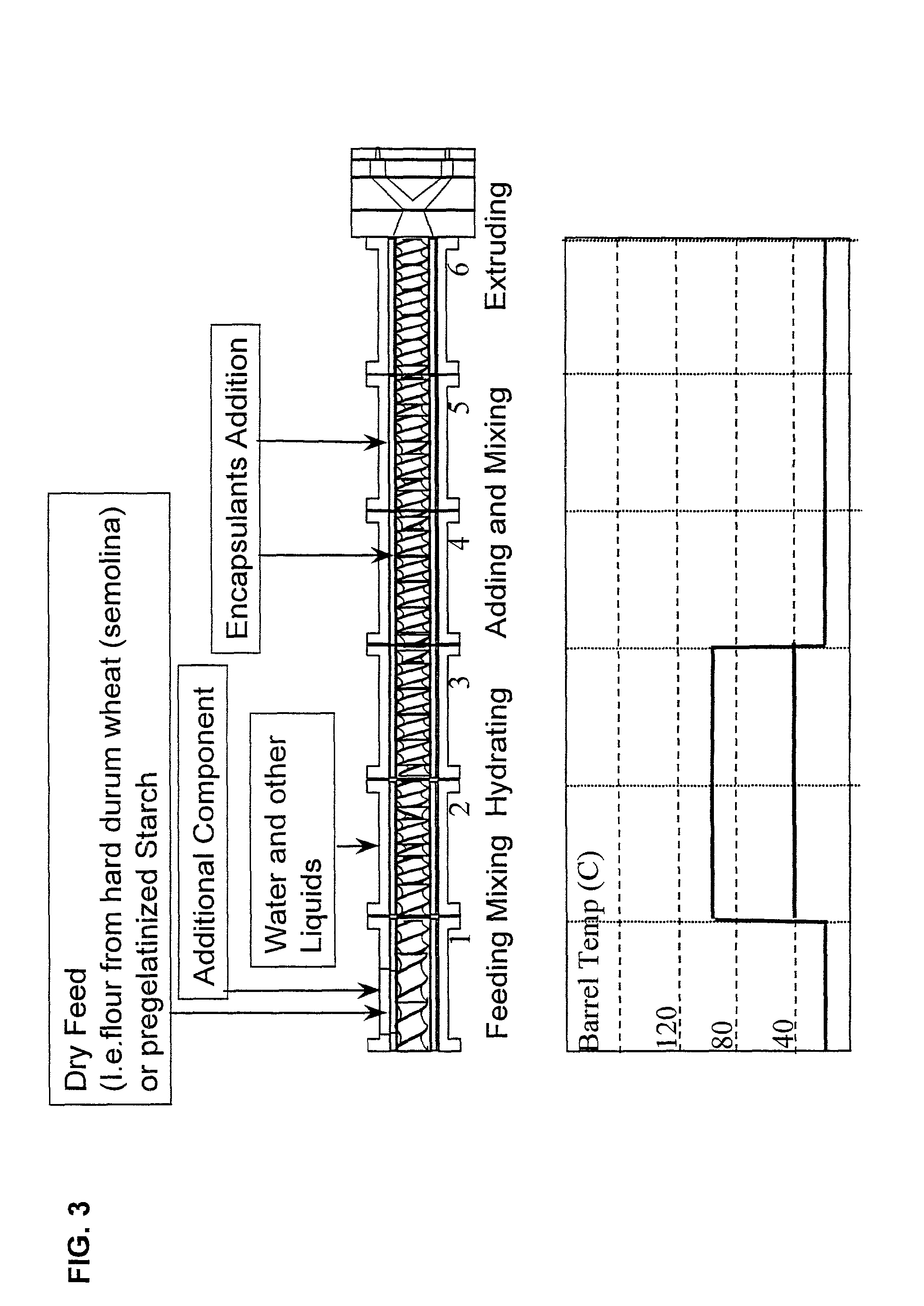

Embedding and encapsulation of sensitive components into a matrix to obtain discrete controlled release particles

InactiveUS8828432B2Avoid substantial destruction of and volatilizationFacilitate substantial gelatinization of starchBiocidePill deliveryRelease timeHeat sensitive

Controlled release, discrete, solid particles which contain an encapsulated and / or embedded component such as a heat sensitive or readily oxidizable pharmaceutically, biologically, or nutritionally active component are continuously produced without substantial destruction of the matrix material or encapsulant. A release-rate controlling component is incorporated into the matrix to control the rate of release of the encapsulant from the particles. The additional component may be a hydrophobic component or a high water binding capacity component for extending the release time. The plasticizable matrix material, such as starch, is admixed with at least one plasticizer, such as water, and at least one release-rate controlling component under low shear mixing conditions to plasticize the plasticizable material without substantially destroying the at least one plasticizable material and to obtain a substantially homogeneous plasticized mass. The plasticizer content is substantially reduced and the temperature of the plasticized mass are substantially reduced prior to admixing the plasticized mass with the encapsulant to avoid substantial destruction of the encapsulant and to obtain a formable, extrudable mixture. The mixture is extruded through a die without substantial or essentially no expansion and cut into discrete, relatively dense particles. Release properties may also be controlled by precoating the encapsulant and / or coating the extrudate particles with a film-forming component.

Owner:GENERAL MILLS INC

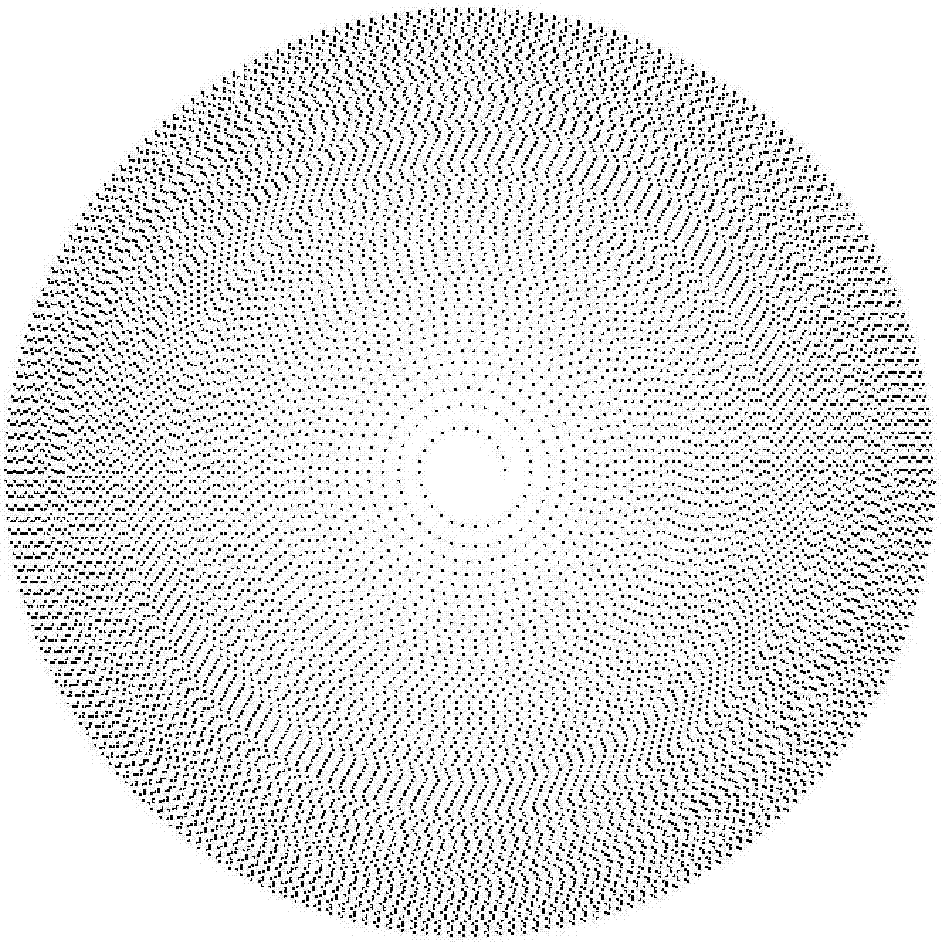

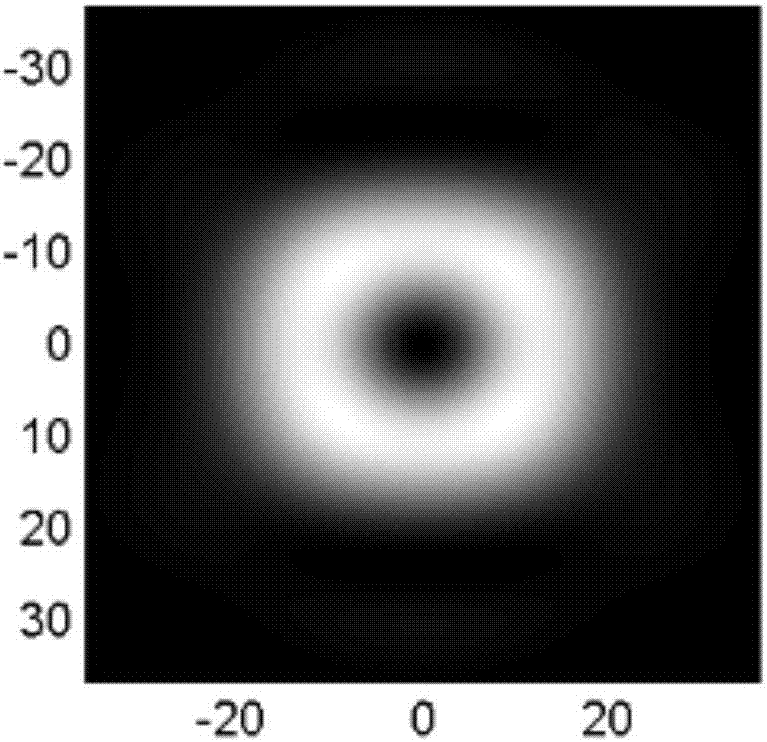

Method for producing oval vortex light of amplitude modulator

The invention relates to a method for producing oval vortex light of an amplitude modulator. The method is characterized in that a novel amplitude-type photon screen is generated through imitated spiral lines and is used for appointing production of oval vortex light on a plane. The novel amplitude-type photon screen comprises a transparent medium substrate, a light-proof metal film and a spiral screen hole structure and is characterized in that the imitated spiral lines are introduced to a traditional wave zone plate structure, small holes are arranged along the spiral lines to form the amplitude-type spiral photon screen, additional optical elements are not needed, and vortex light beams can be produced. The amplitude-type photon screen related in the method is easy to process and copy and can be applied to the fields of light communication, super-resolution imaging, laser precision machining, particle control, data storage, remote sensing and the like and is applicable in wave bands ranging from X rays to terahertz.

Owner:上海霖迈实业有限公司

Controlled-release recombinant human bone morphogenic protein-2 poly-L-lactic acid microspheres and preparation method thereof

InactiveCN101822645AResidue reductionMild preparation conditionsPeptide/protein ingredientsSkeletal disorderMicrosphereAdditive ingredient

The invention discloses controlled-release recombinant human bone morphogenic protein-2 poly-L-lactic acid microspheres and a preparation method thereof, which relate to a medicament carrier and preparation thereof. The component of a microsphere substrate is poly-L-lactic acid (PLLA); the wrapped medicament is recombinant human bone morphogenic protein-2 (rhBMP-2); and the released rhBMP-2 active protein is integral in structure and exists in a form of a homologous dipolymer. The preparation method comprises the following steps: mixing rhBMP-2 organic solution and PLLA organic solution to obtain mixed solution; precipitating microsphere crystals from the mixed solution after the mixed solution passes through a supercritical fluid CO2 solvent extraction; and after obtaining the microspheres, stopping pumping the mixed solution, keeping a pressure and a temperature in a high pressure autoclave unchanged, and continuously introducing CO2 to elute the microsphere crystals to remove residual organic solution. The method of the invention is simple in process, short in period, easy in organic solution removal, high in biological safety, short in burst releasing period and long in obtained microsphere particle controlled-release period, and easier in the storage of the physiological activity of the rhBMP-2.

Owner:SICHUAN UNIV

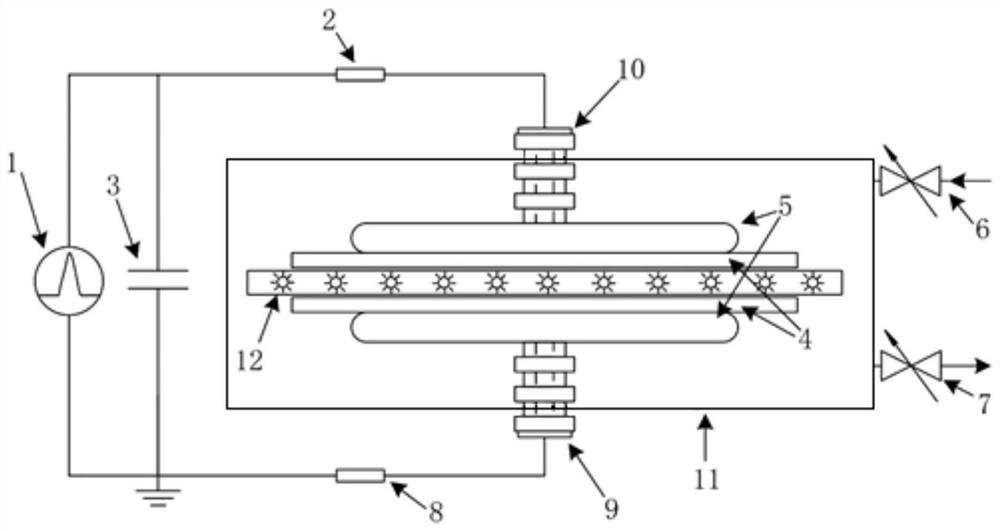

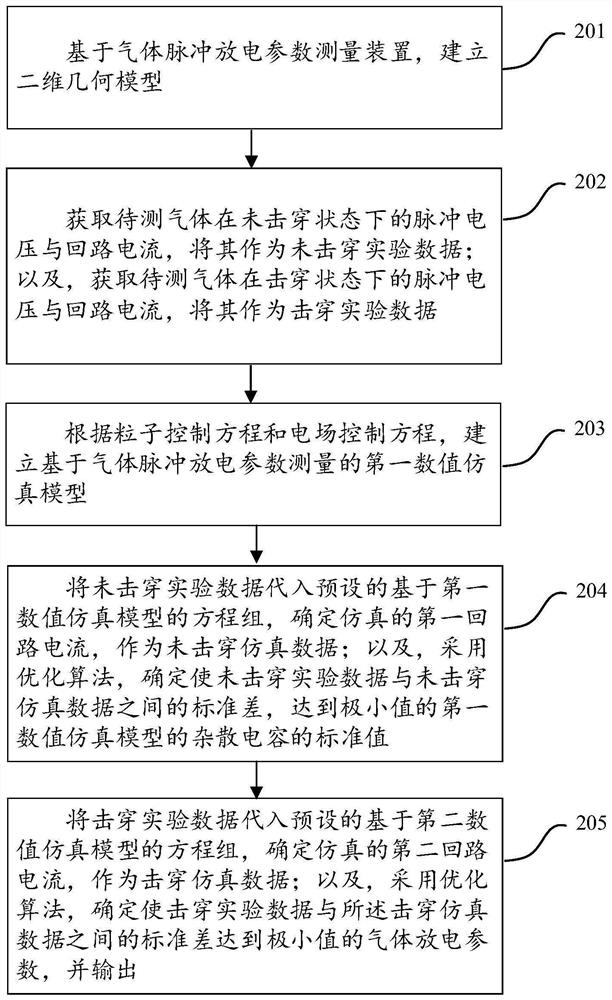

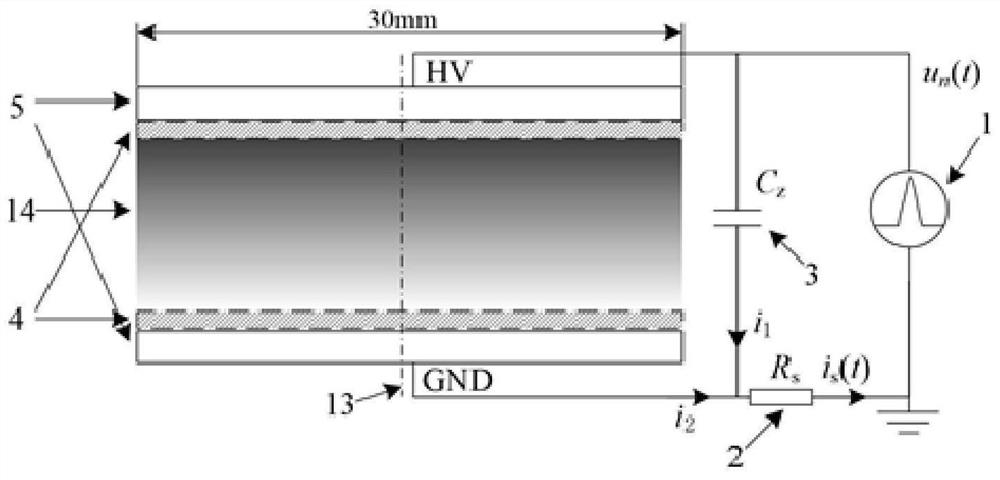

Gas pulse discharge parameter measuring method and device

ActiveCN111880051ARealize measurementFill in the measurement gapsTesting dielectric strengthCapacitanceEngineering

The invention discloses a method and a device for measuring gas pulse discharge parameters, and the method and device are used for realizing accurate measurement of the gas pulse discharge parametersunder an atmospheric pressure condition. According to the invention, the method comprises the steps: adopting a gas pulse discharge parameter measuring device to respectively obtain a pulse voltage and a loop current of gas to be measured in a non-breakdown state and a breakdown state; establishing a numerical simulation model according to the particle control equation and the electric field control equation; according to the numerical simulation model and a preset equation set, adjusting and optimizing the stray capacitance parameter value of the numerical simulation model through the non-breakdown experiment data; according to the optimized numerical simulation model, obtaining the simulated loop current, and then determining gas discharge parameters such as a soup ionization coefficient, an electron adhesion coefficient, a secondary electron emission coefficient, a photoionization coefficient and the like which enable the breakdown experiment data and the breakdown simulation data to take minimum values by adopting a direction acceleration optimization method, and calculating the standard deviation between the breakdown experiment data and the breakdown simulation data.

Owner:XI AN JIAOTONG UNIV

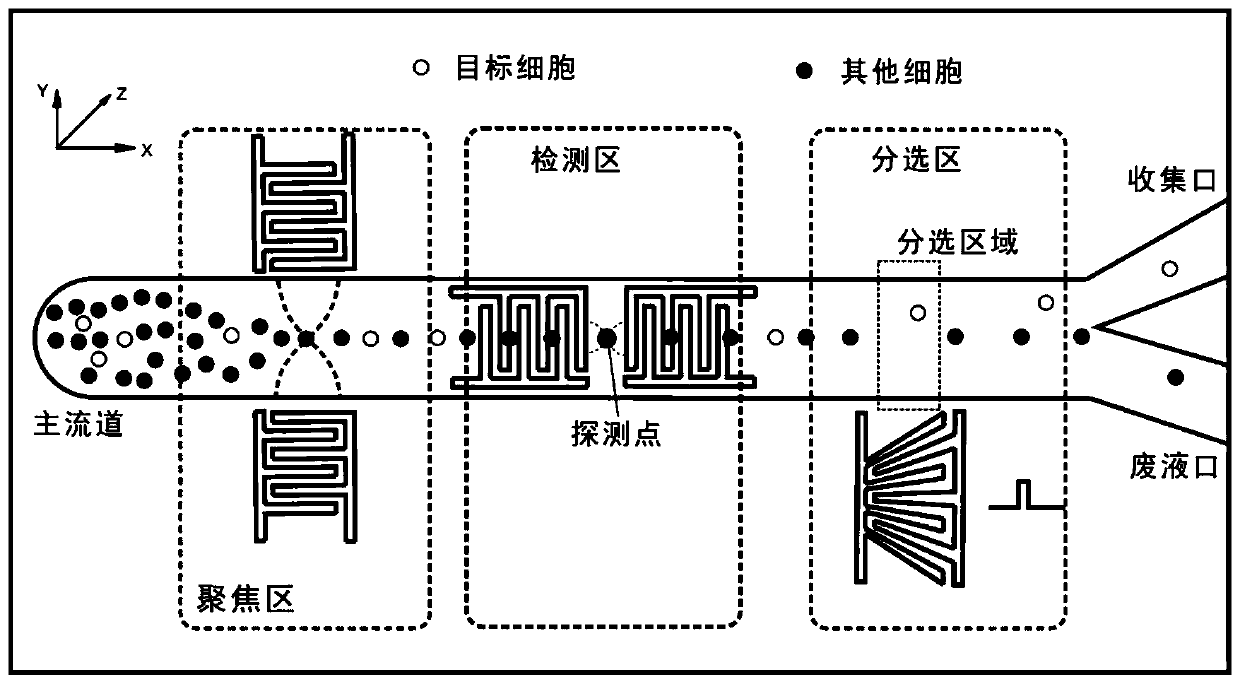

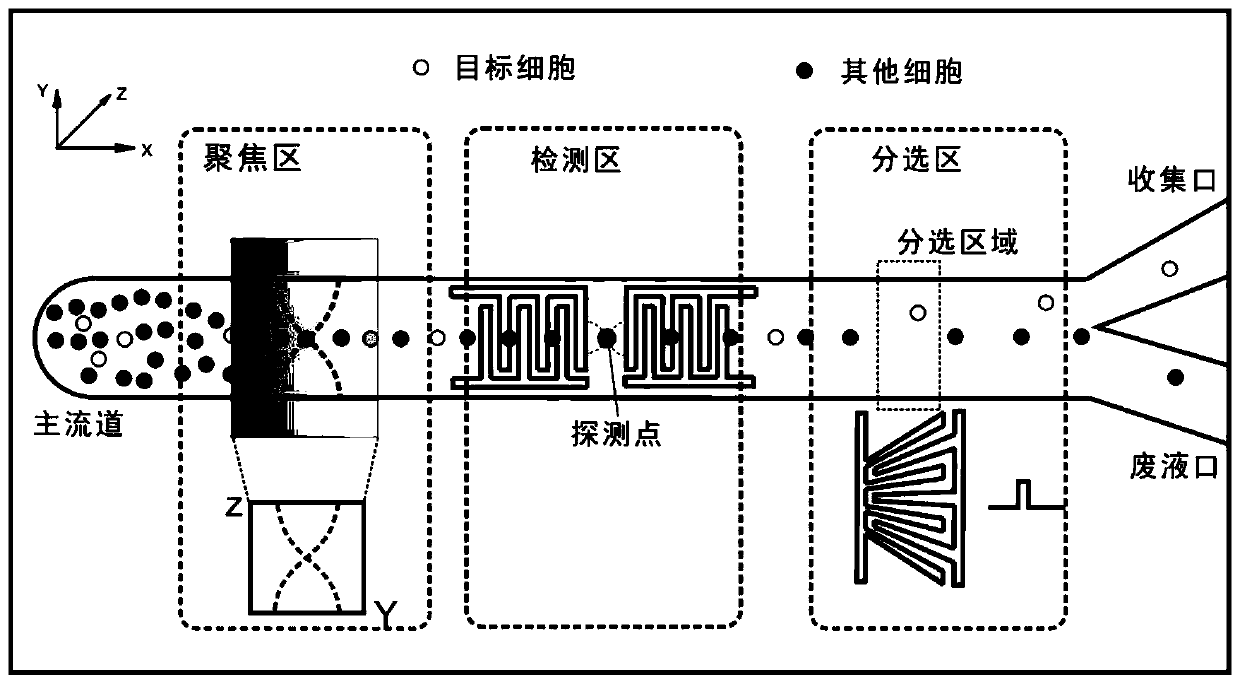

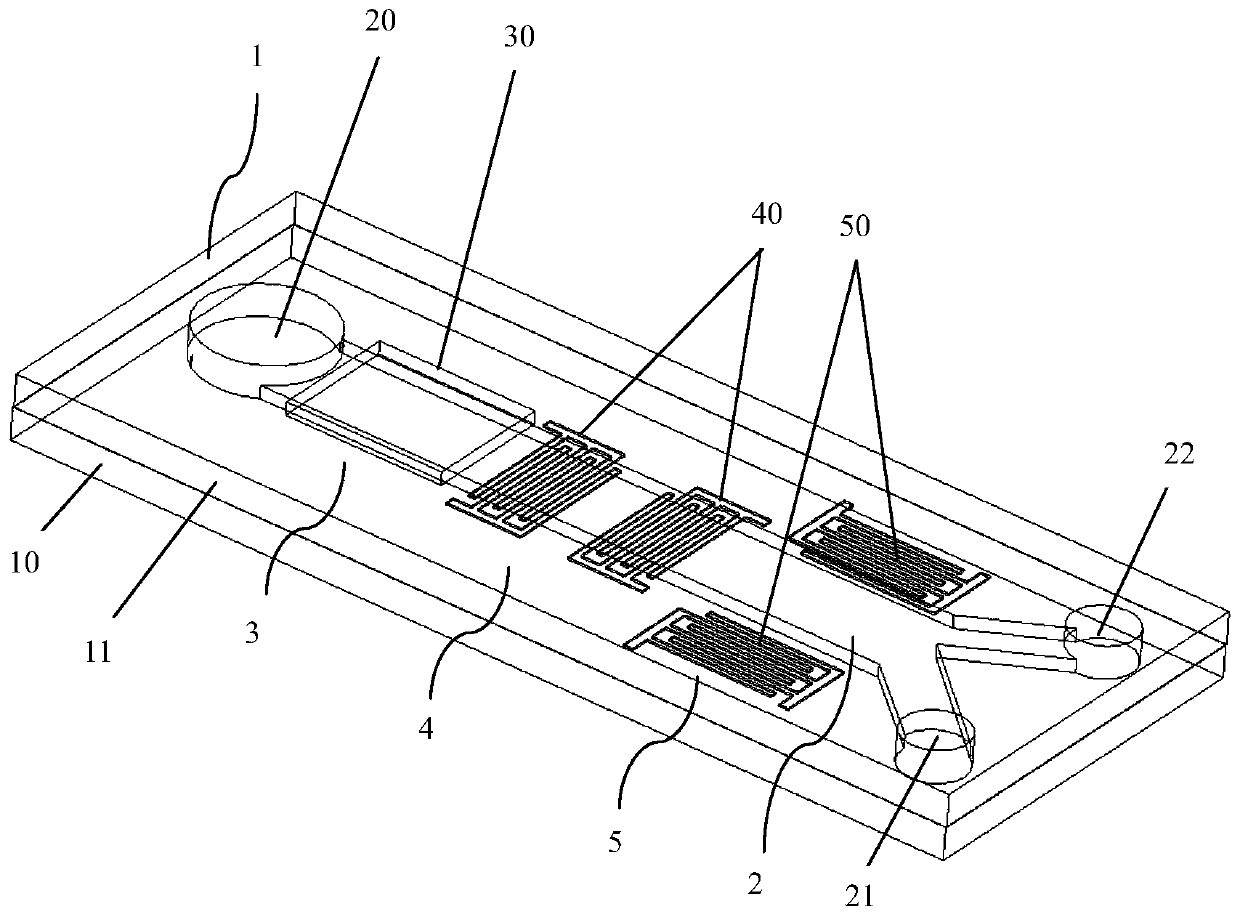

Micro-fluidic chip used for particle control

The invention relates to a micro-fluidic chip which comprises a chip body and a flow channel structure arranged in the chip body, and a main flow channel of the flow channel structure is sequentiallyprovided with a focusing area, a detection area and a sorting area in the particle flowing direction, wherein the focusing area is used for realizing focusing of particles in the main flow channel ina three-dimensional space, the detection area is used for clamping and detecting target particles, and the sorting area is used for realizing sorting of the target particles and non-target particles.According to the invention, single particles in the continuous flow micro-channel can be fixed at a certain position, time is provided for detection, and the detection of the particles is facilitated;acoustic waves are adopted to push particles in fluid to move, and mechanical force acts on the particles, so that the activity of the particles is not affected; the particles are controlled by adopting sound waves, the sample flux is high, the flow velocity is reduced, and the improvement of the subsequent detection sensitivity is facilitated; the flow channel is simple in structure, the numberof the flow ports is small, and bubble discharging and fluid environment stability maintaining are facilitated.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

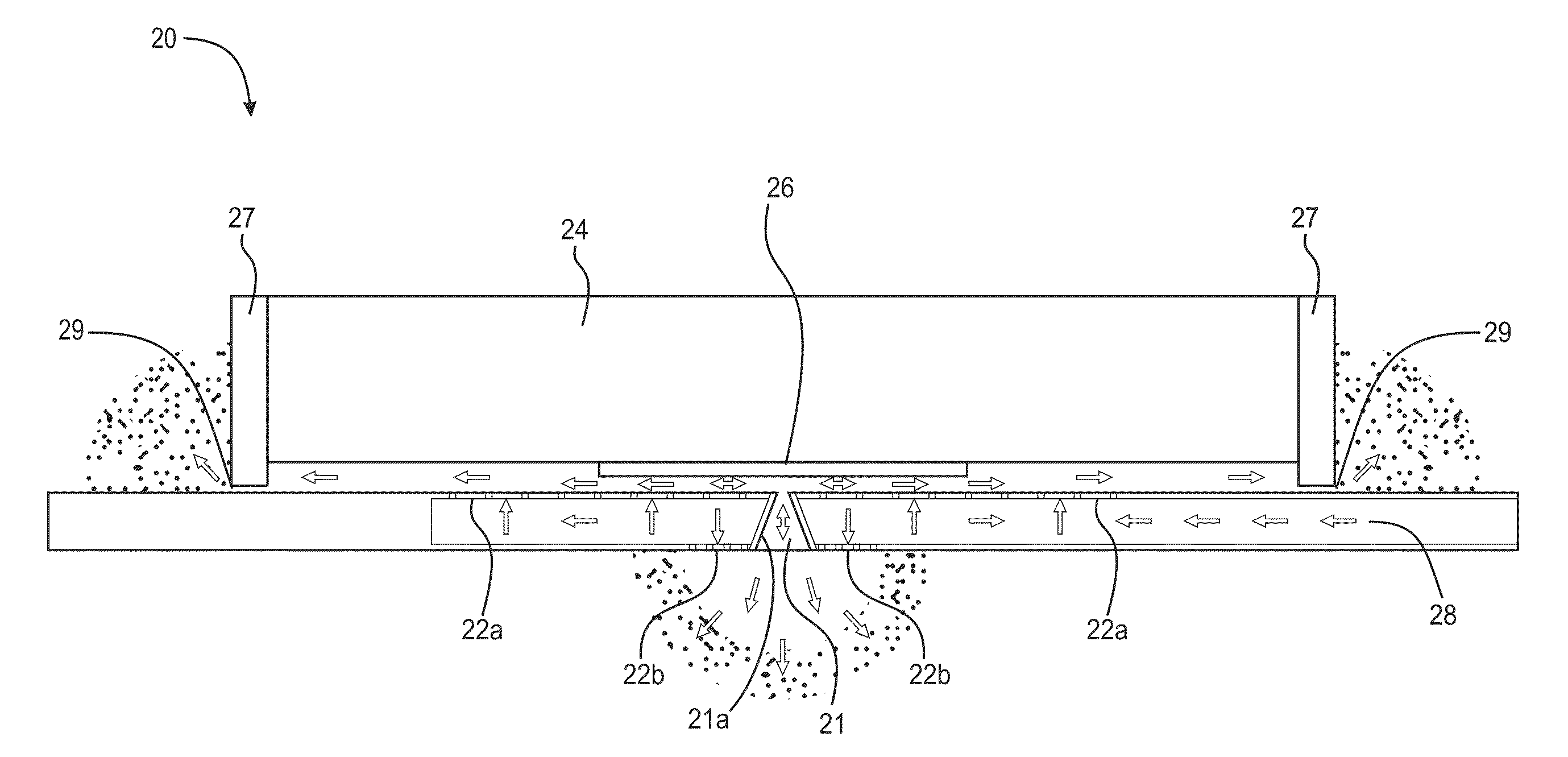

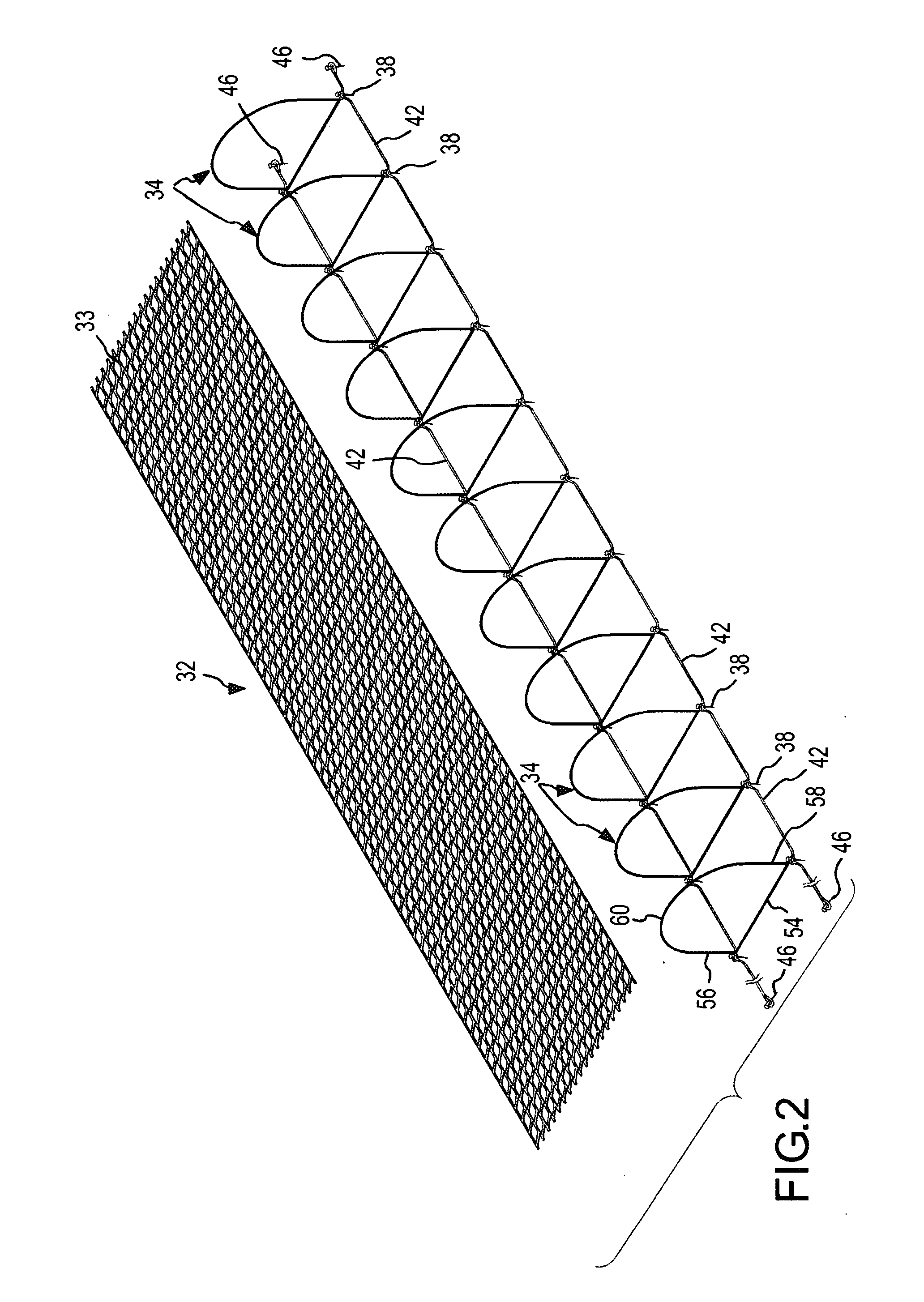

Apparatus and method for efficiently fabricating, dismantling and storing a porous tubular windblown particle control device

InactiveUS20060002772A1Quickly and efficiently erect and dismantleStored efficiently without consuming a large amount of storage spaceProtective constructionExcavationsEngineeringEarth surface

A windblown particle control device which, when attached to the surface of the earth assumes a generally tubular cross-sectional shape, stabilizes particle cover and controls deposition and retention of windblown particles. A sheet of netting material is curved in an arched configuration. Webs of the sheet are linked together to define apertures through the sheet. The apertures create aerodynamic effects in the wind which stabilize, deposit and retain the particles on the earth surface. A kit of components, which includes the netting sheet and a plurality of frame structures to support and maintain the netting sheet in the arched configuration may be employed to assemble the control device for use.

Owner:TABLER RONALD D

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com