Patents

Literature

104 results about "Continuous scale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

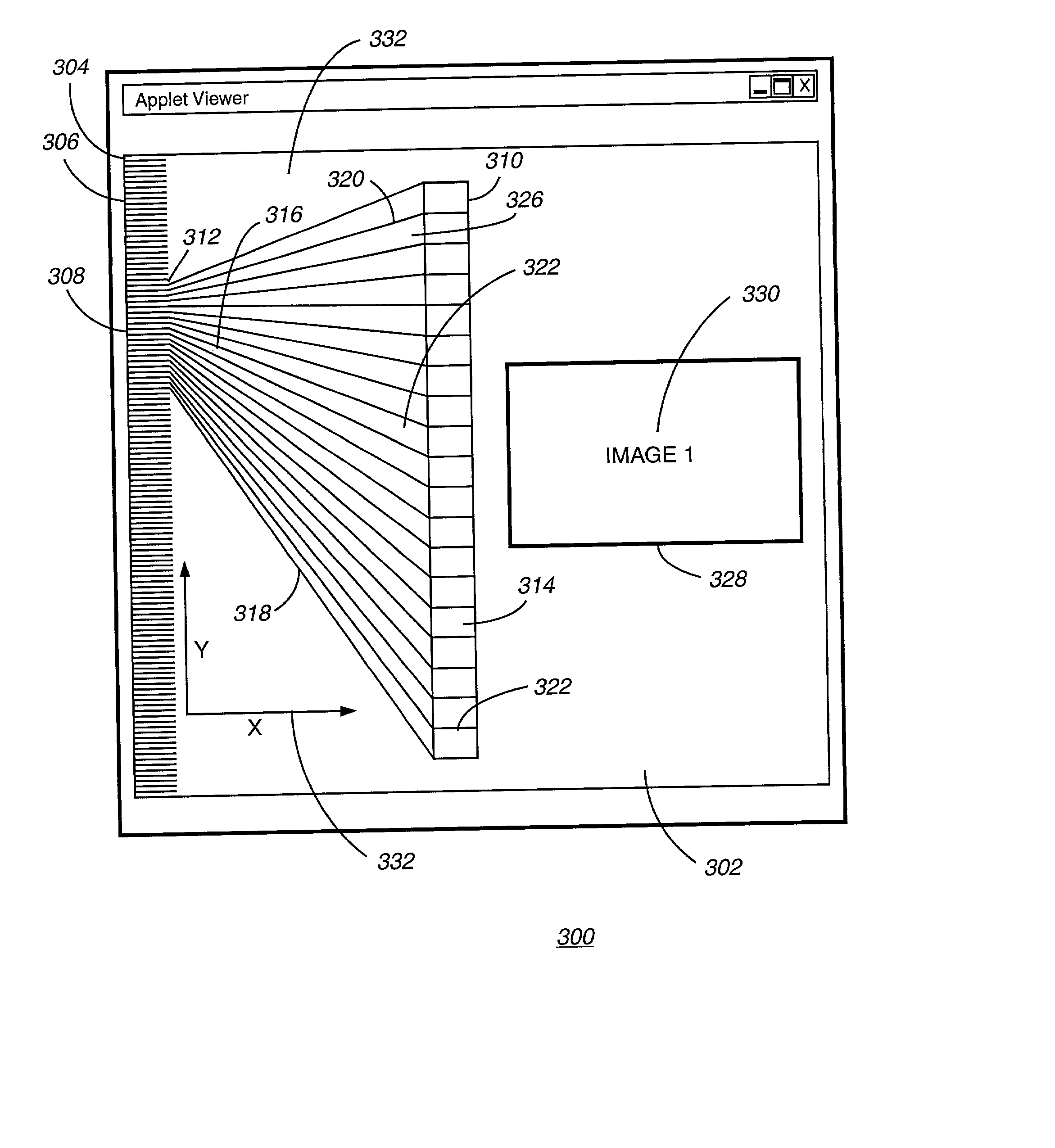

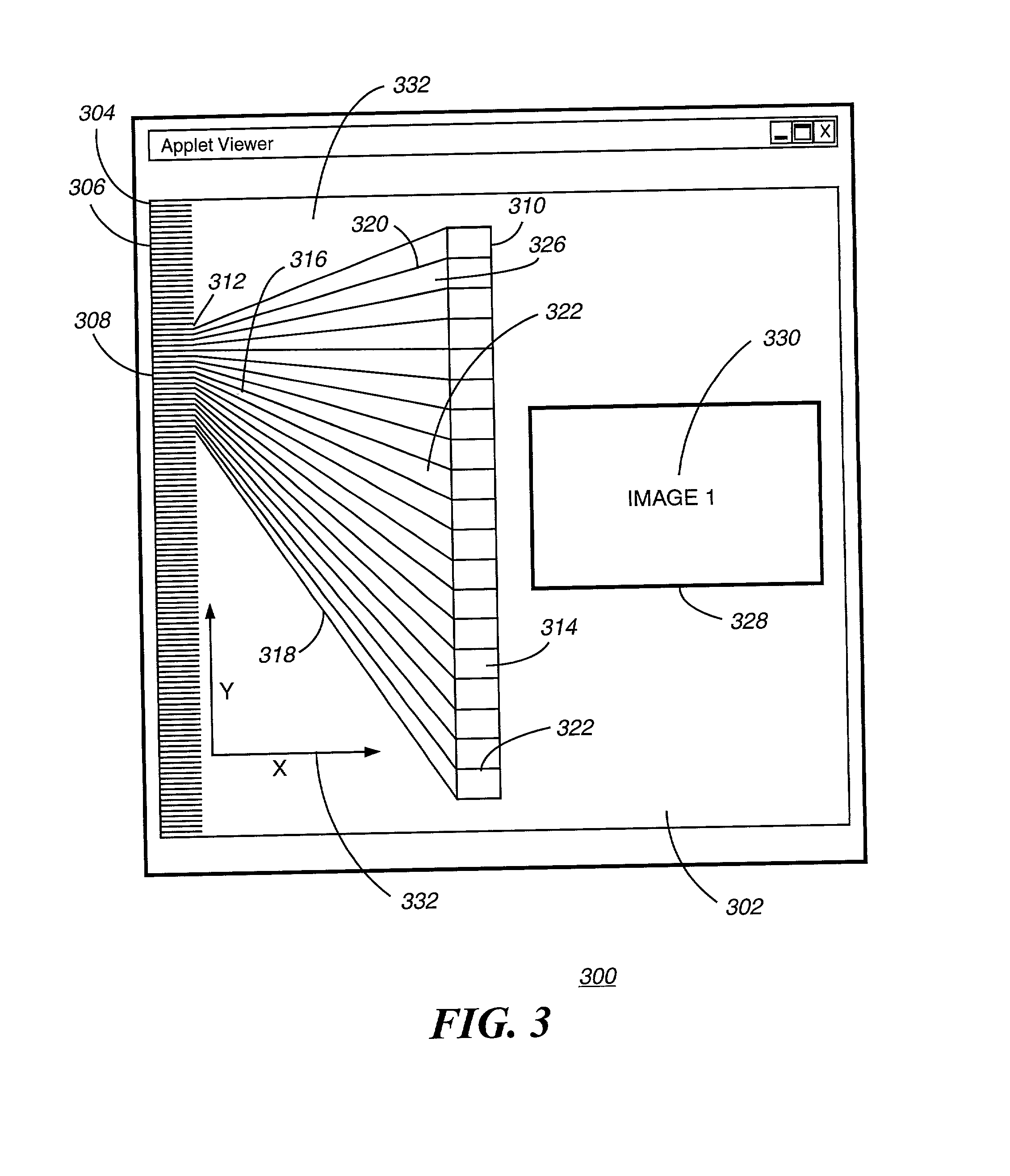

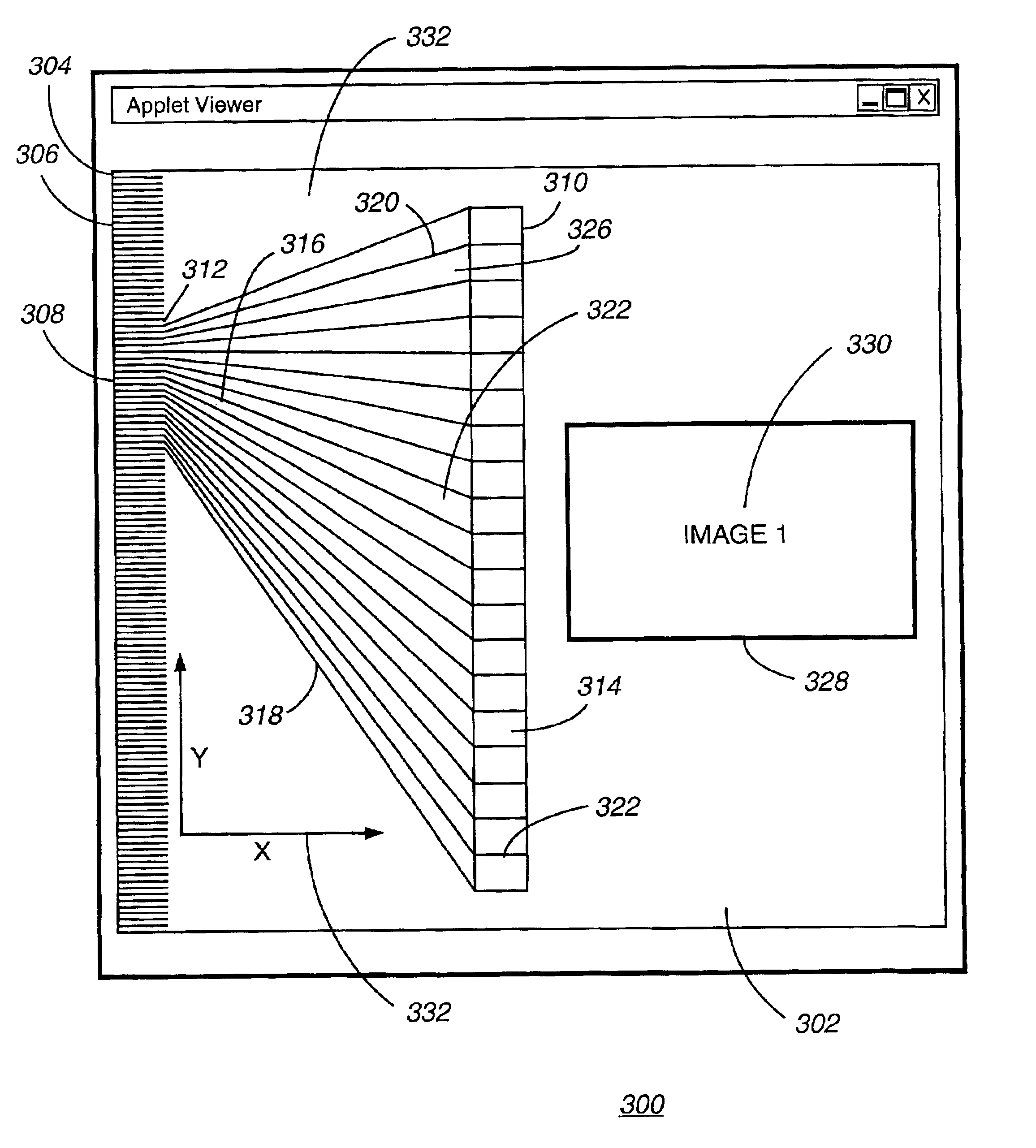

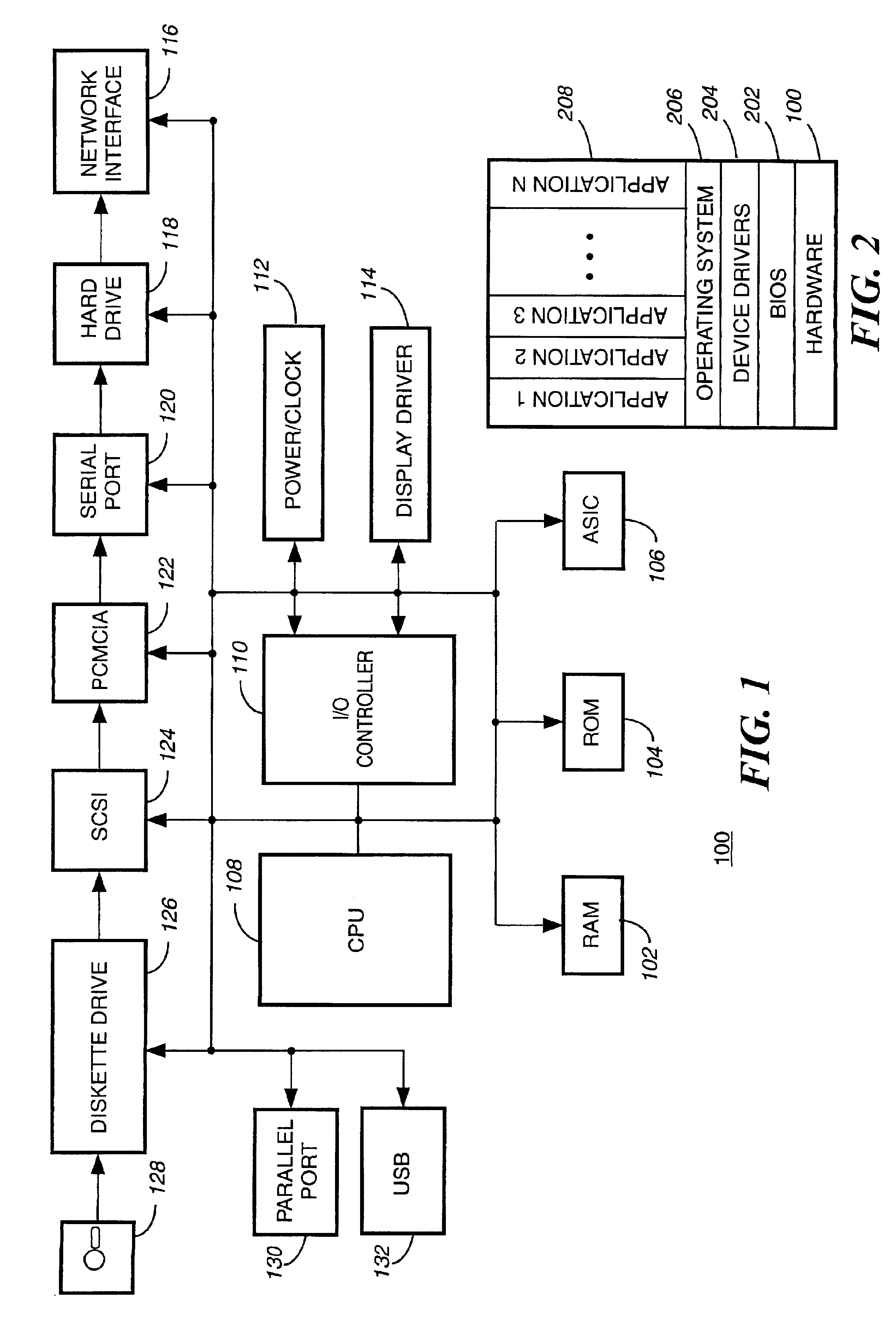

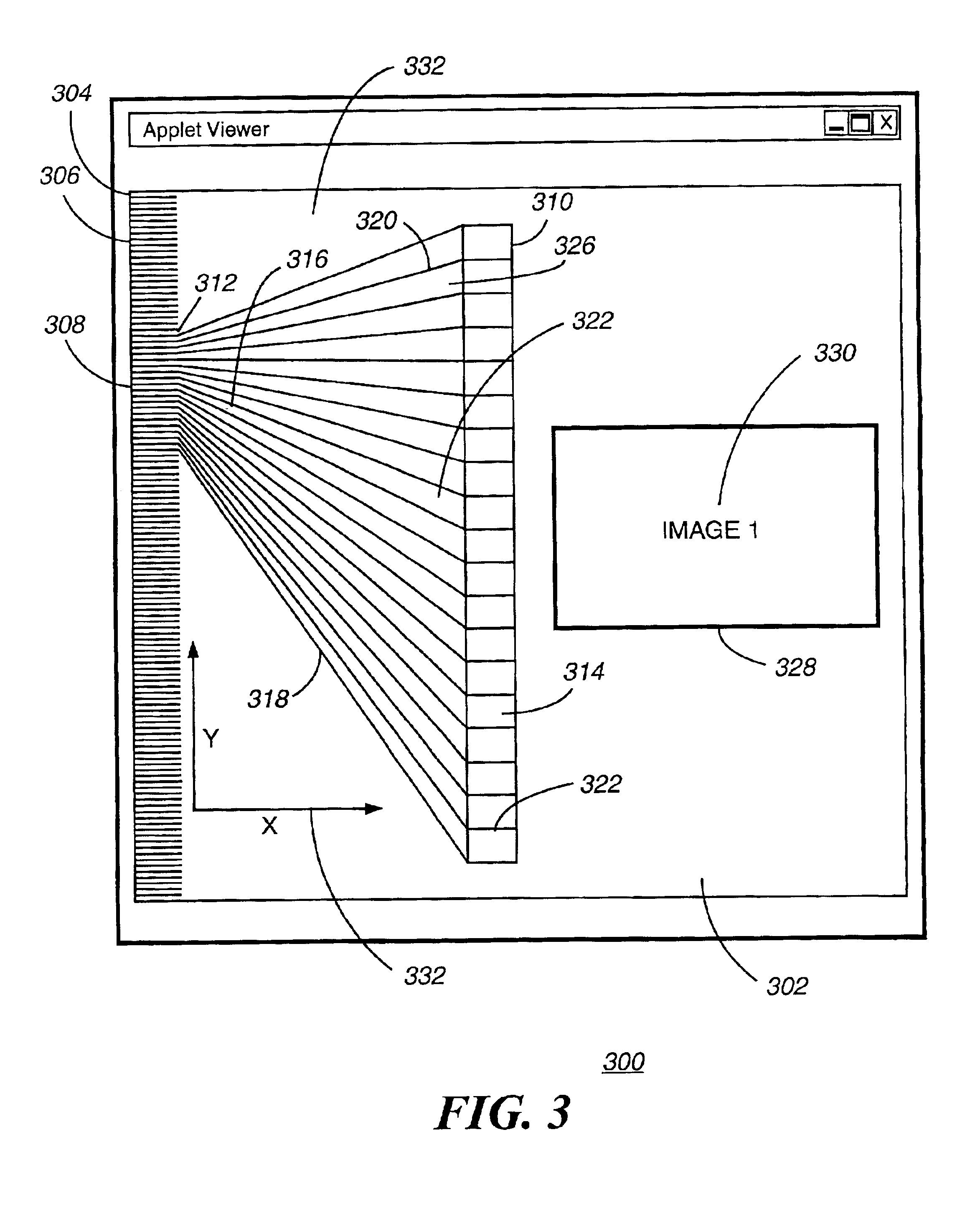

Method and apparatus for variable density scroll area

InactiveUS20020109728A1Data processing applicationsInput/output processes for data processingData setScrolling

A method and system to provide a user additional positional context for the information they are browsing and allows for rapid browsing through large data sets thereby providing a more usable interface. Two embodiments are described in the following sections. In the first, the 2-D scroll area is a continuous area. In this continuous embodiment the user can change the scroll resolution on a continuous scale. The second embodiment uses a set of discrete vertical scrolling bars. These scrolling bars work in concert to fine tune the scrolling access to the data.

Owner:IBM CORP

Method and apparatus for variable density scroll area

A method and system to provide a user additional positional context for the information they are browsing and allows for rapid browsing through large data sets thereby providing a more usable interface. Two embodiments are described in the following sections. In the first, the 2-D scroll area is a continuous area. In this continuous embodiment the user can change the scroll resolution on a continuous scale. The second embodiment uses a set of discrete vertical scrolling bars. These scrolling bars work in concert to fine tune the scrolling access to the data.

Owner:IBM CORP

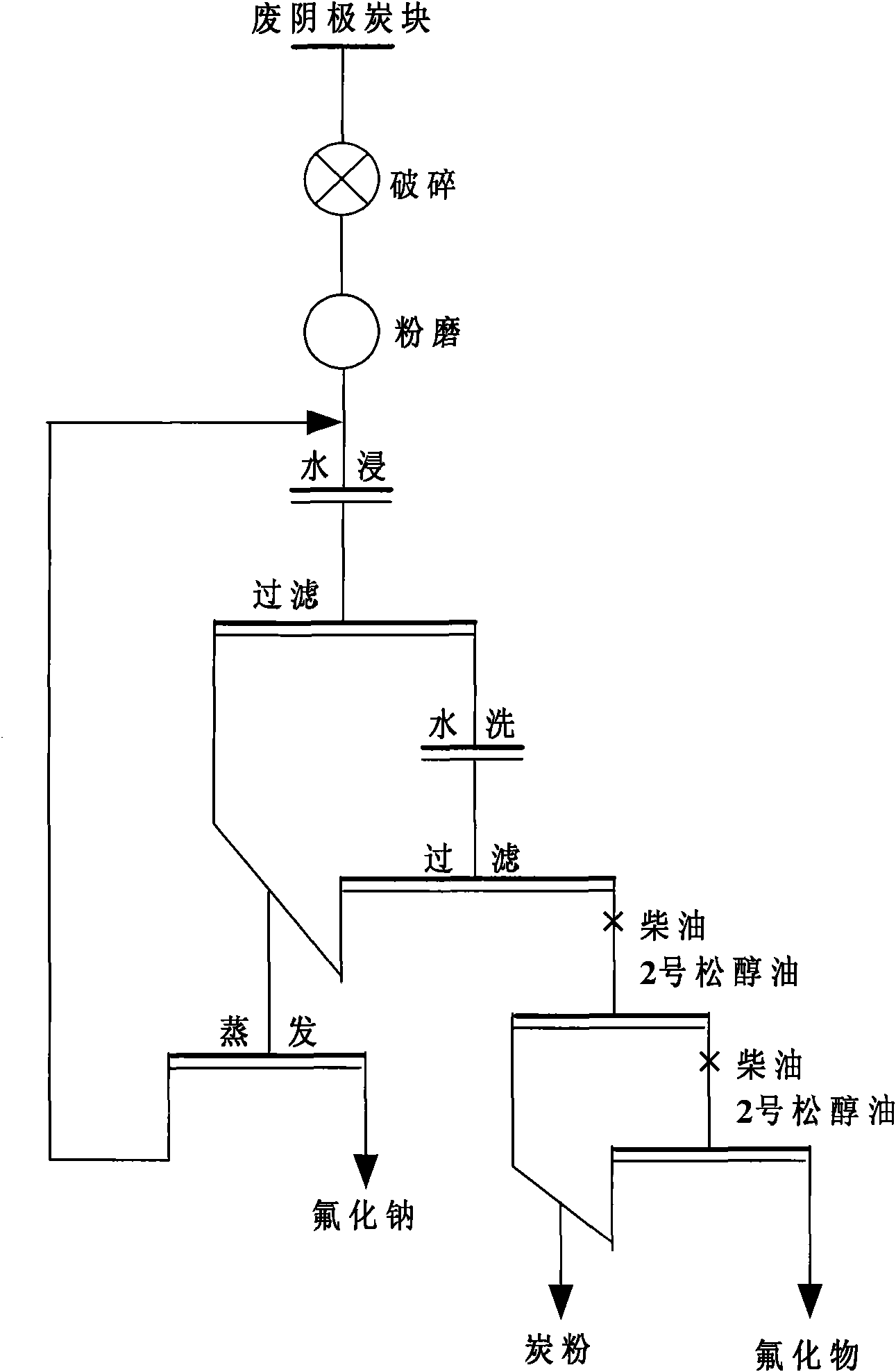

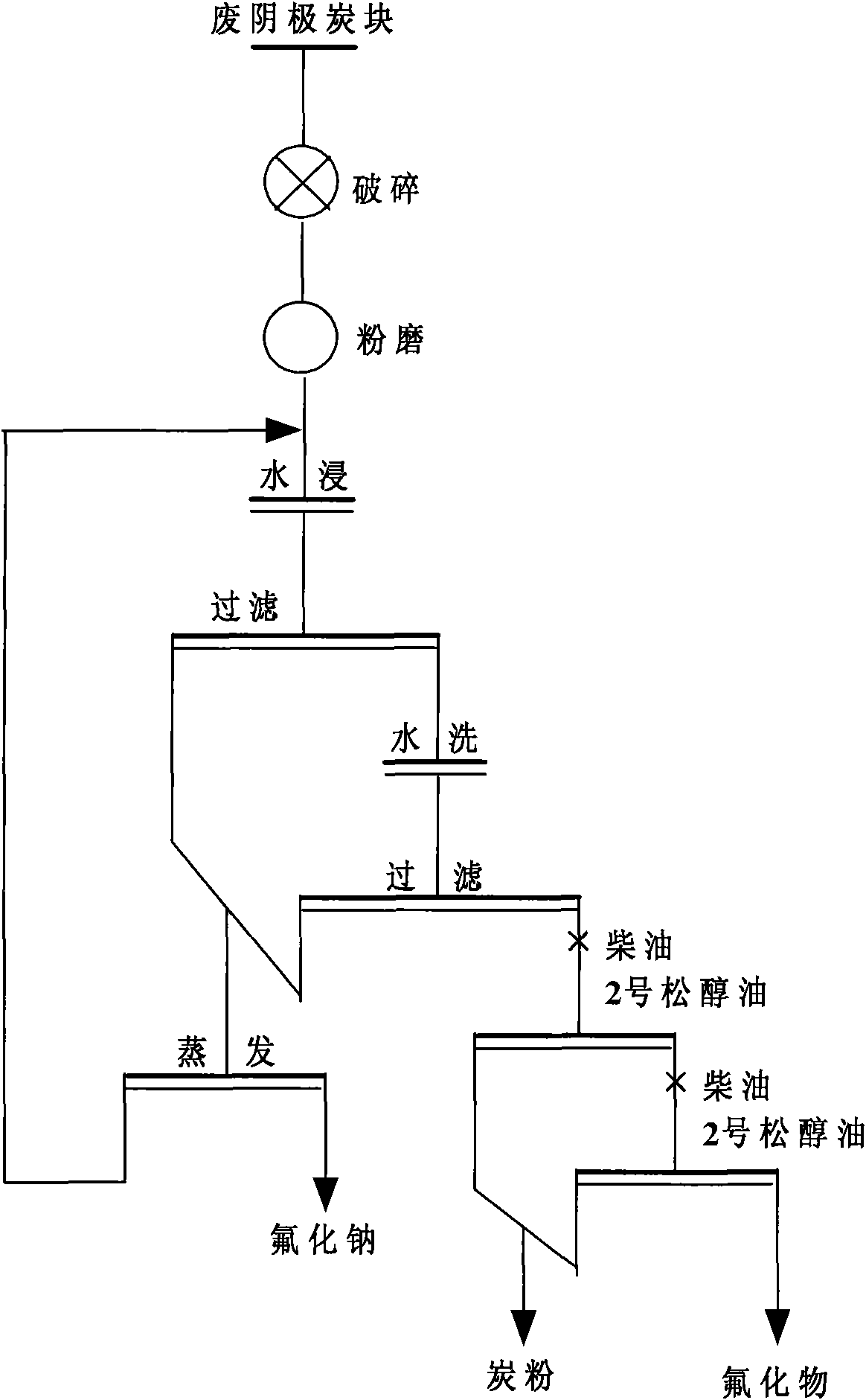

Method for recovering carbon from waste cathode carbon blocks of electrolytic aluminum

The invention discloses a method for recovering carbon from waste cathode carbon blocks of electrolytic aluminum. The method mainly comprises the following steps of: crushing, grinding, leaching in water, floating, and the like. The method has the advantages that the carbon content of recovered powdered carbon reaches higher than 70 percent, and the carbon recovery rate reaches higher than 98 percent, thus the recovered powdered carbon can be used for preparing carbon materials for aluminum electrolysis, aluminum oxide desulfurizing agents, and the like; and the method has simple process, low production cost, no secondary pollution, stable and reliable product quality and high yield, can realize continuous scale production and is beneficial to environmental protection.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

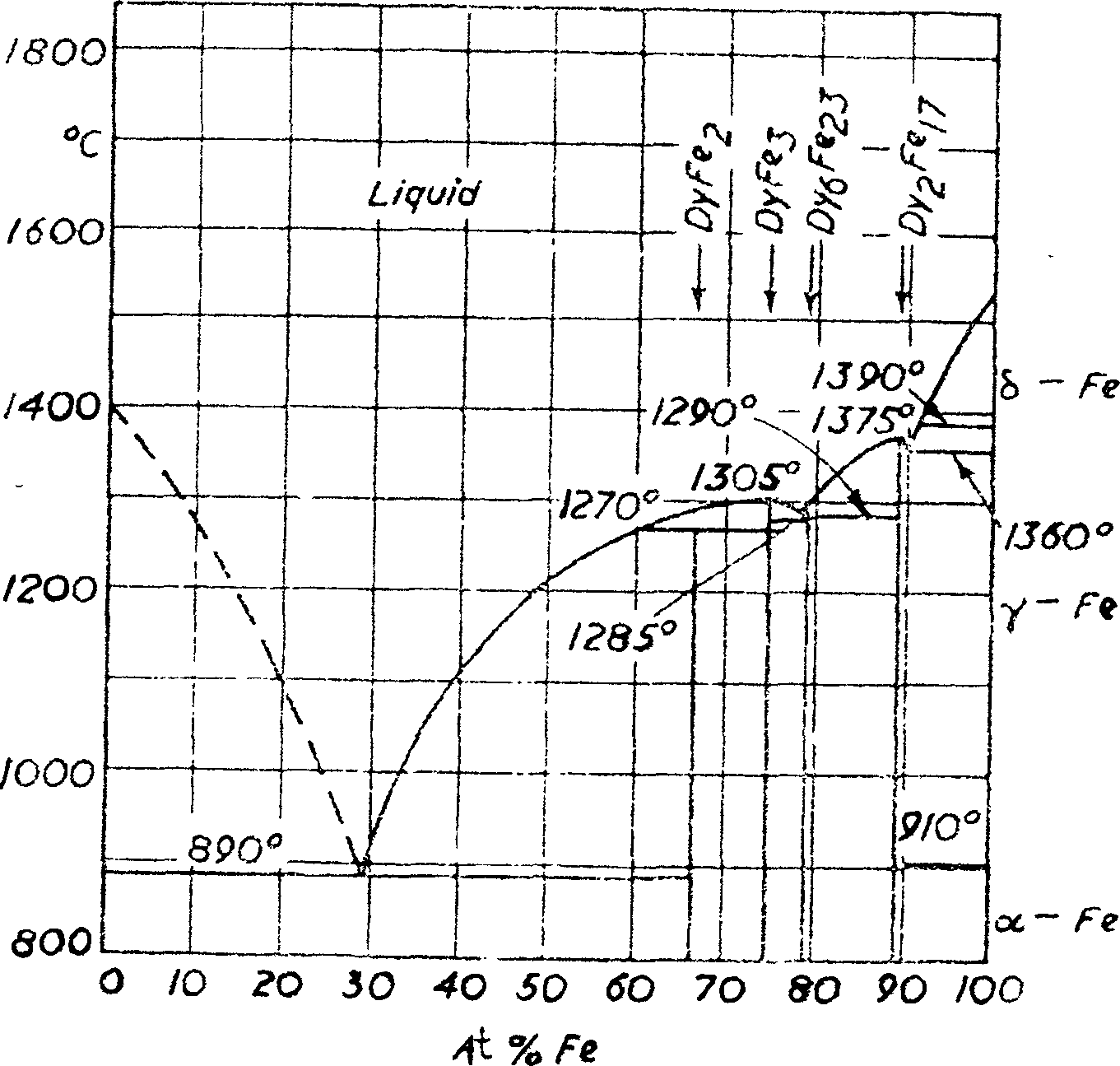

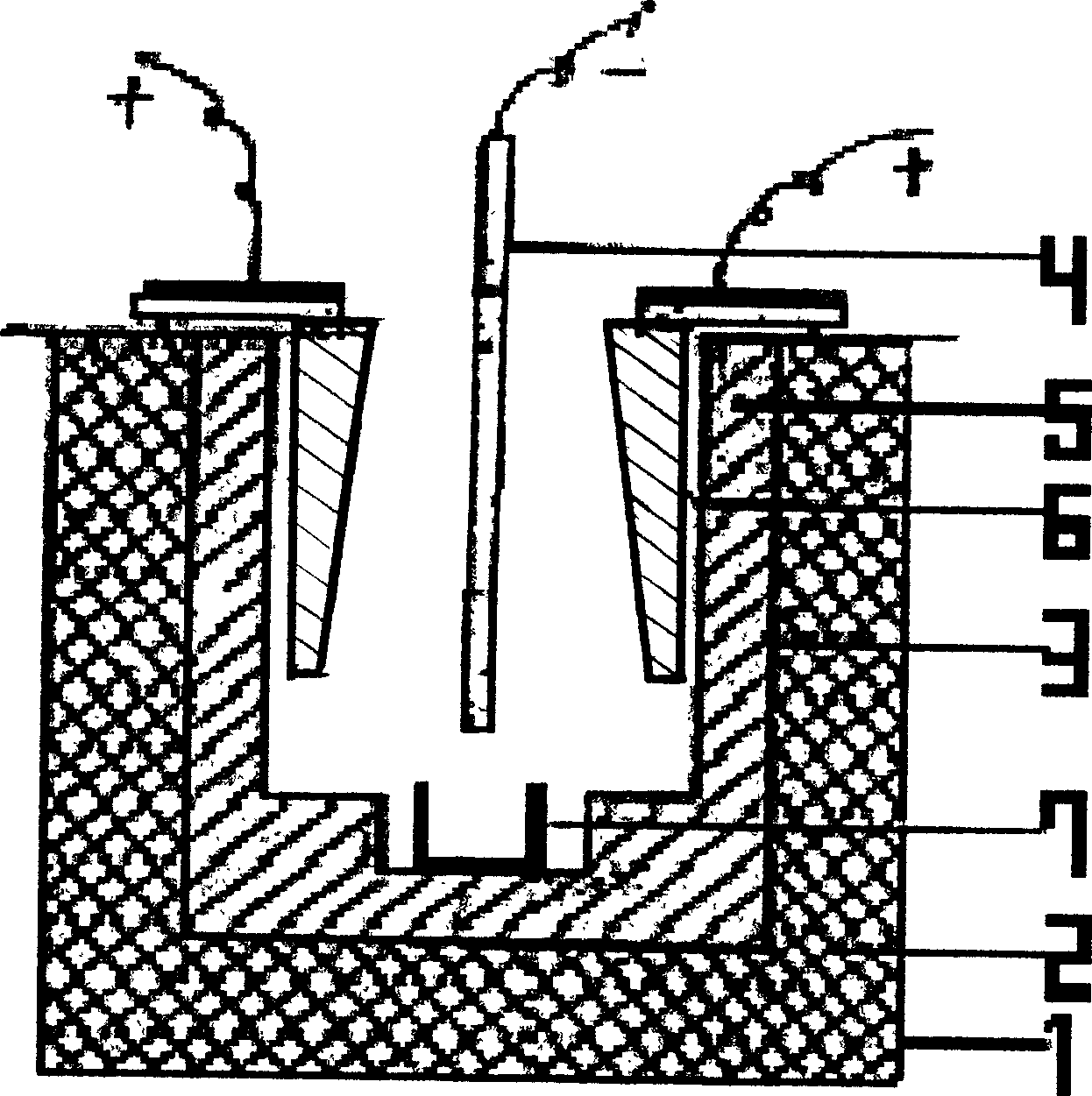

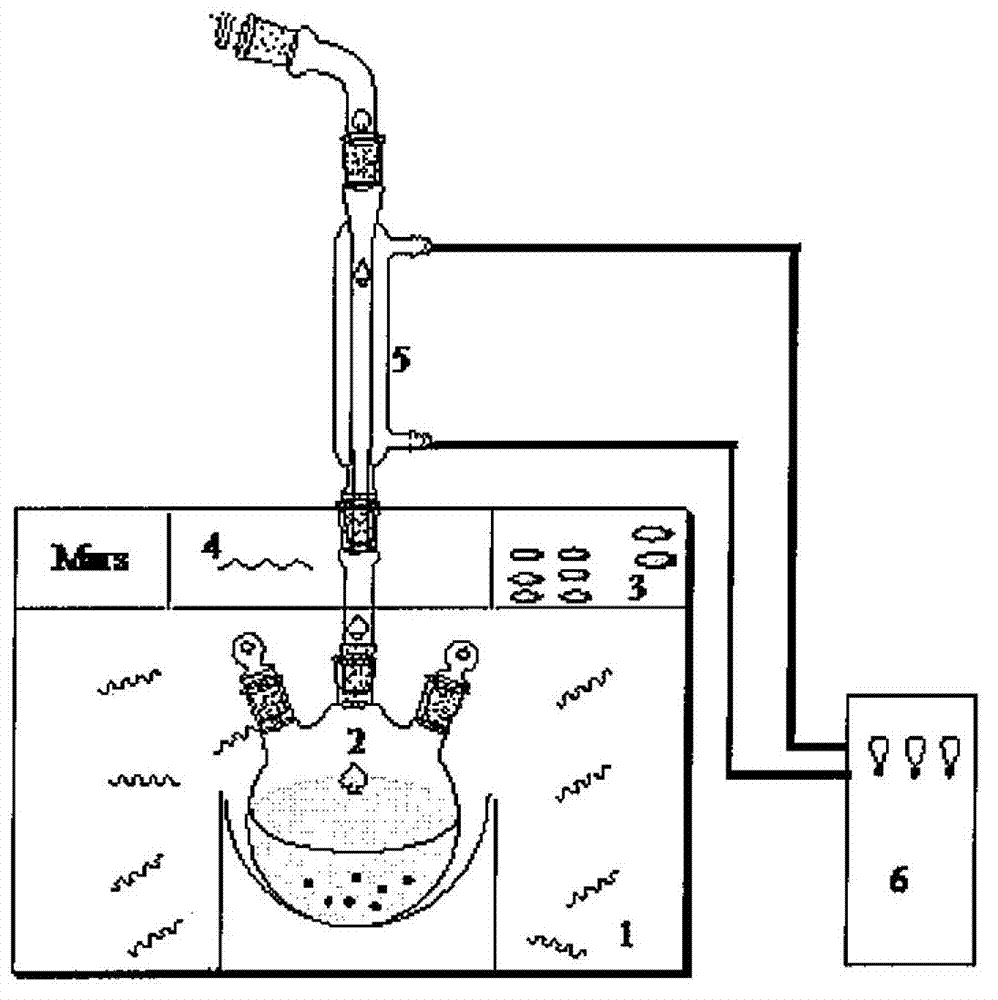

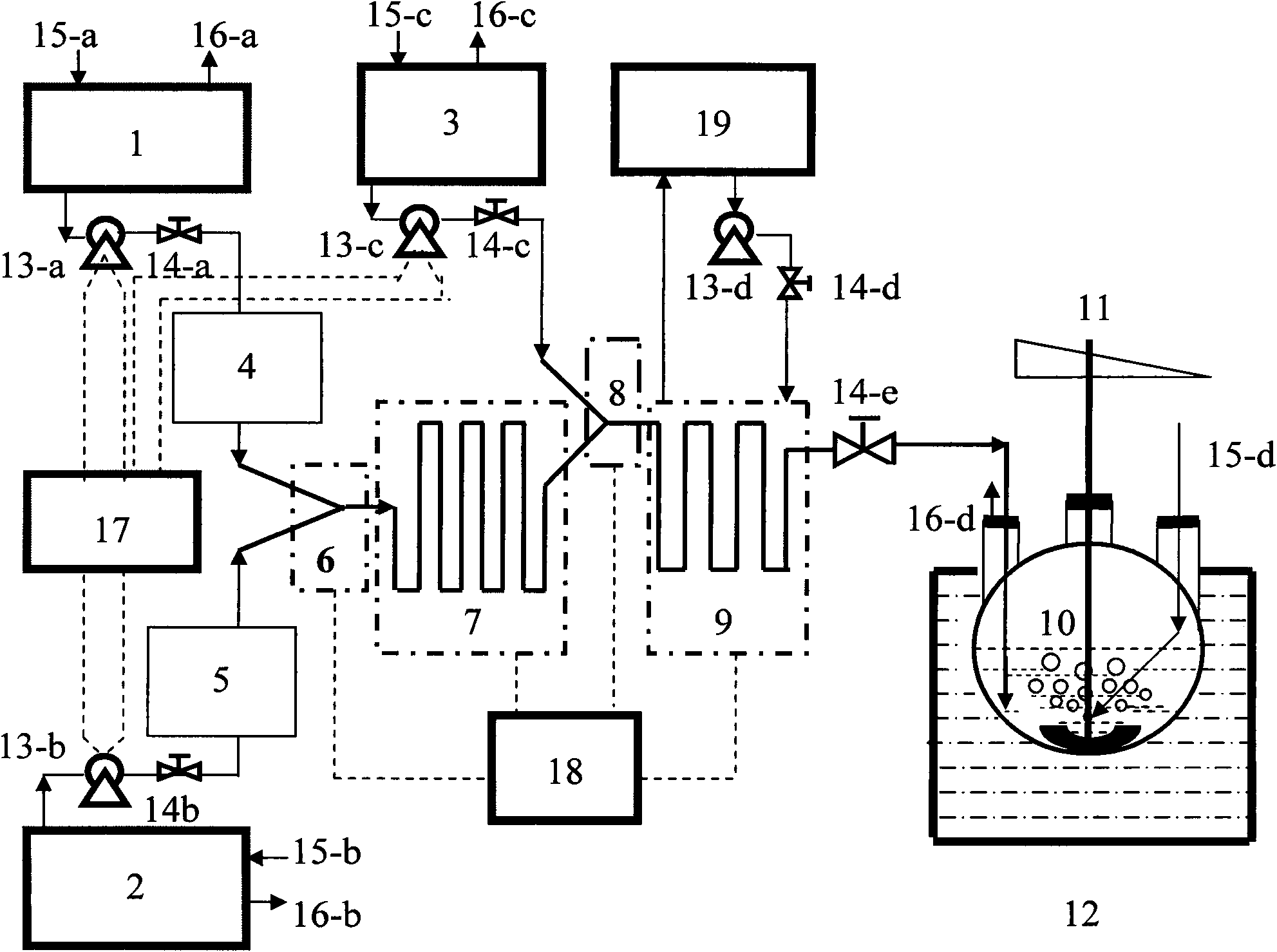

Process and apparatus for producing Dy-Fe alloy by molten salt electrolysis method

The invention relates the dysprosium-iron alloy technology with fused salt electrolysis process and device, belonging to rare-earth products preparing field. The method comprises the following steps: at high temperature, dysprosium oxide melting at fluoride, dysprosium oxide beginning ionizing; at the condition of 95V / M direct current field, separating out Dy3+ on the surface of iron cathode, deacidizing Dy3+ to Dy, and alloying Dy and Fe to form Dy-Fe. O2- is oxygenated to O2 on the surface of graphite cathode, and it reacts with carbite to form CO2. The melting point of dysprosium-iron (20úÑFe) is 1046Deg.C, and the melting point of Dy is 1407Deg.C, so the electrolyzation is carried out at 1050Deg.C. The invention has the advantages of low investment, low cost, simple technology, continuous production and low impurity content.

Owner:包头市稀土应用技术研究所

High Mn Austenitic Stainless Steel

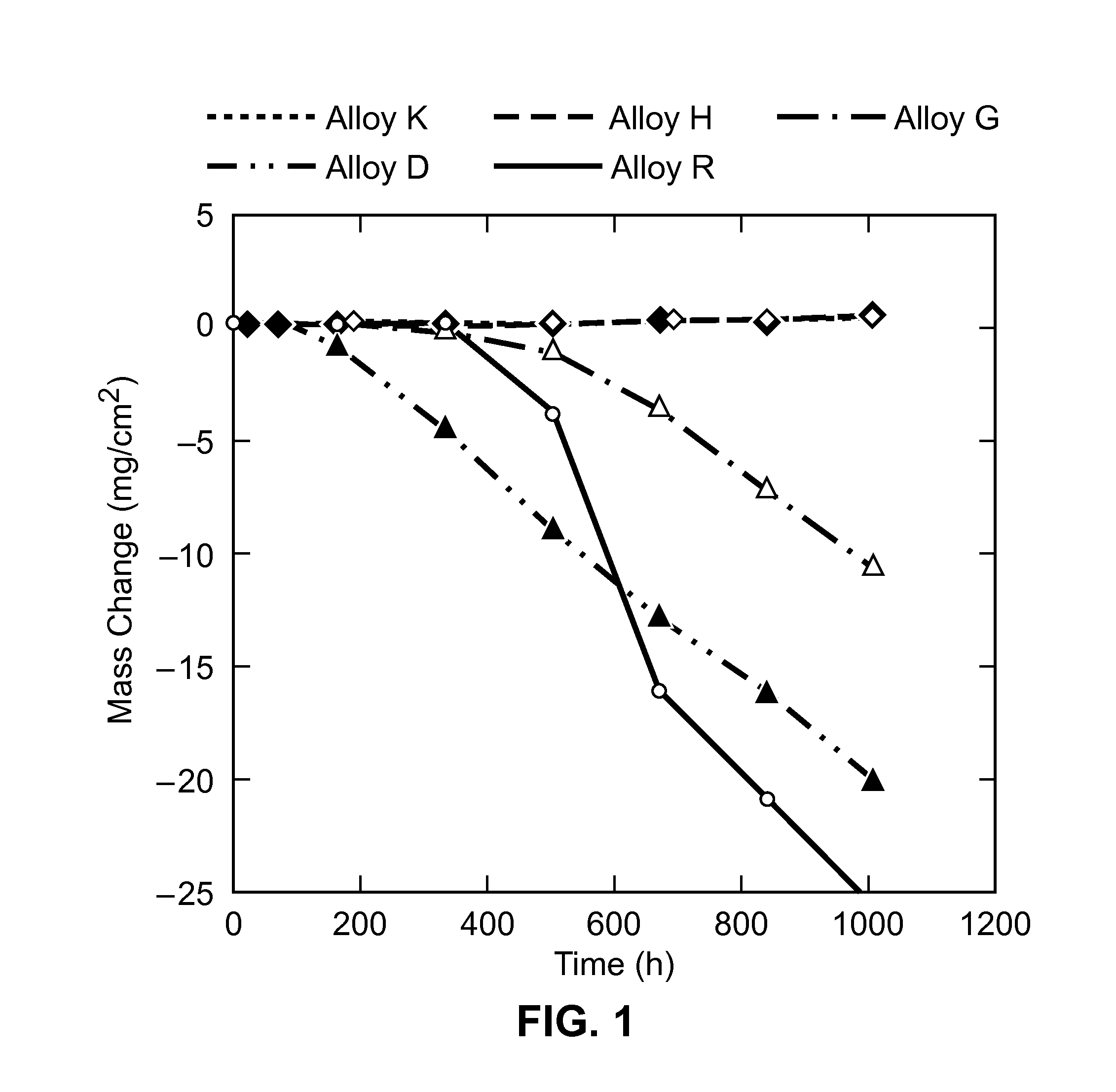

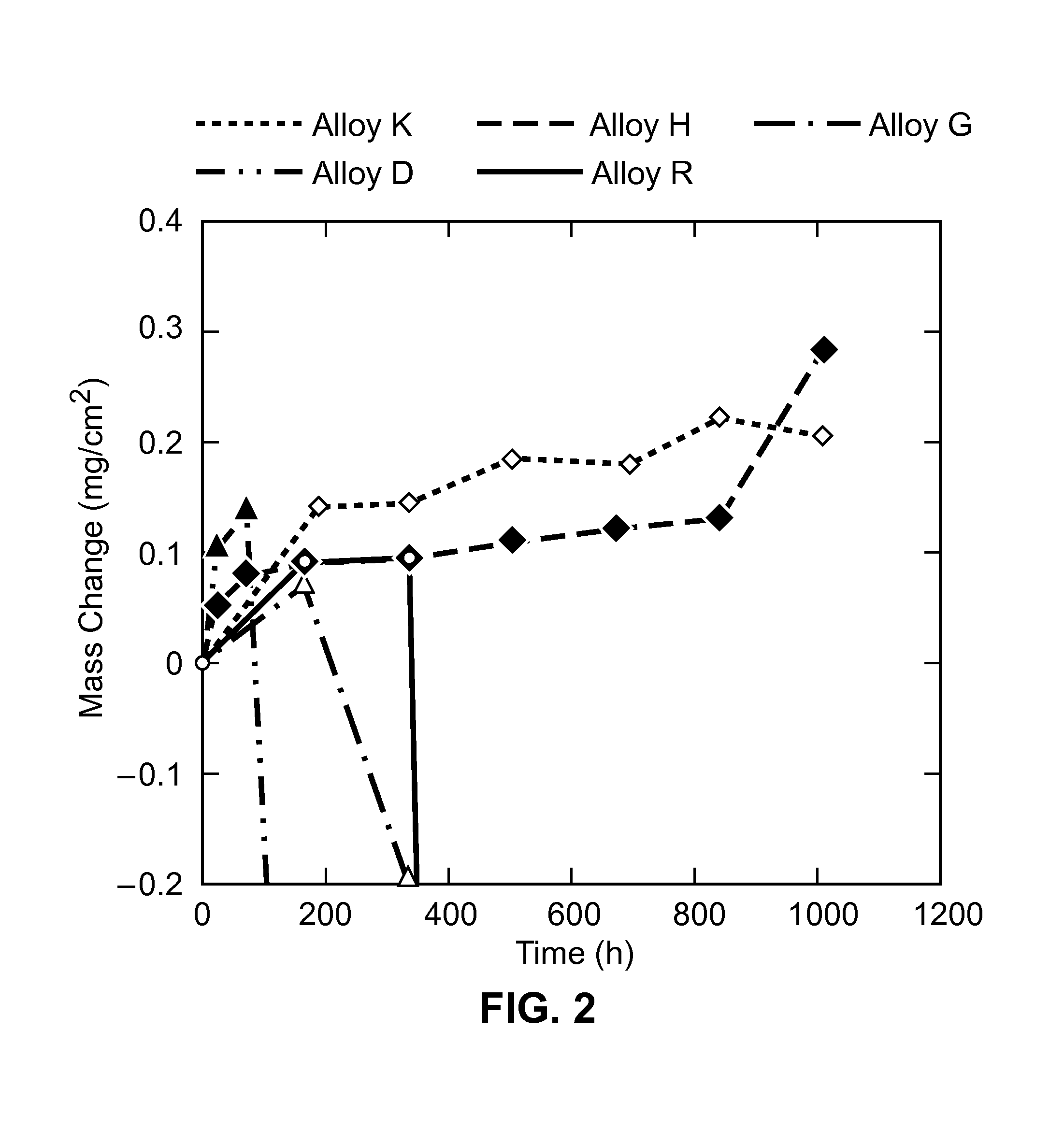

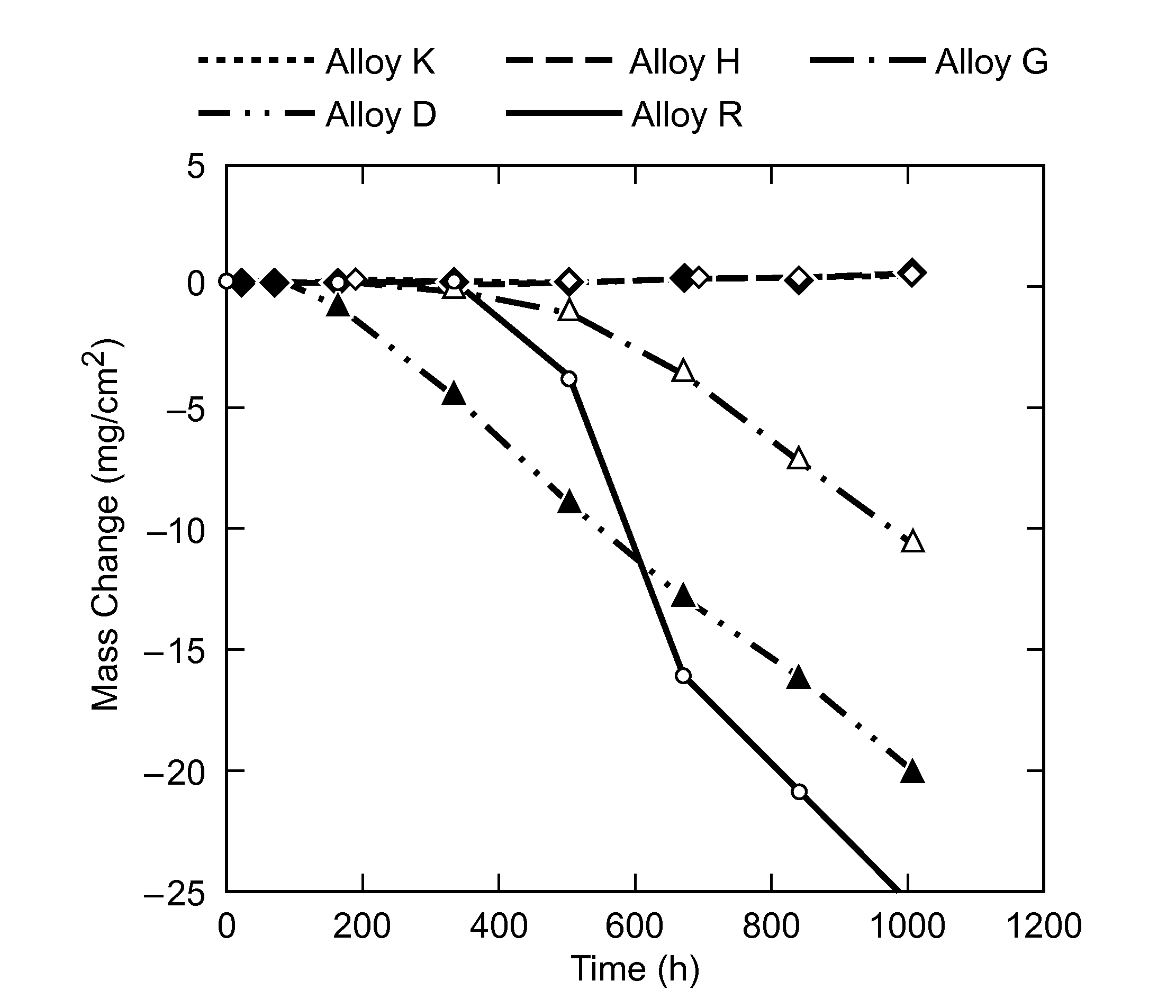

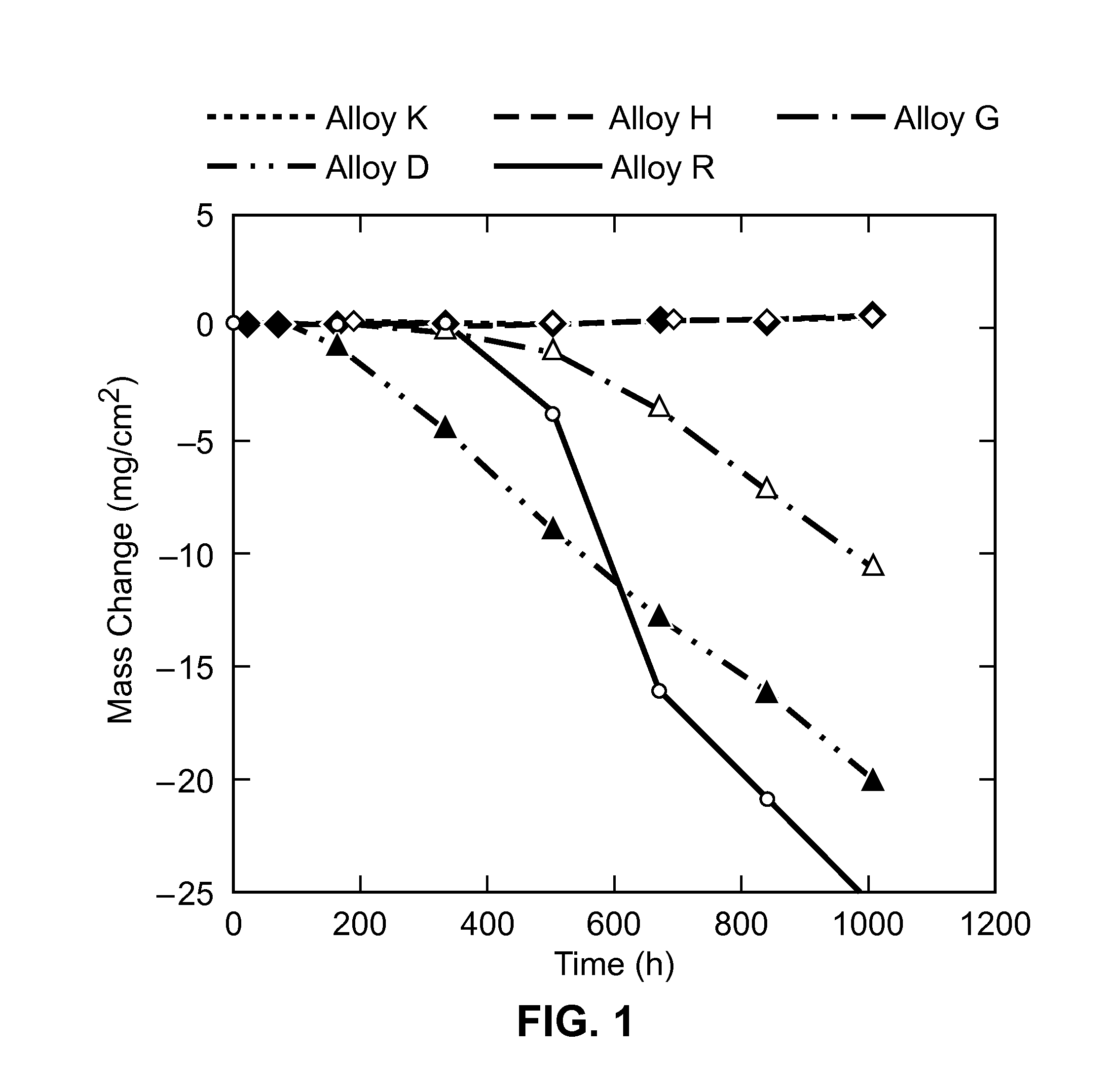

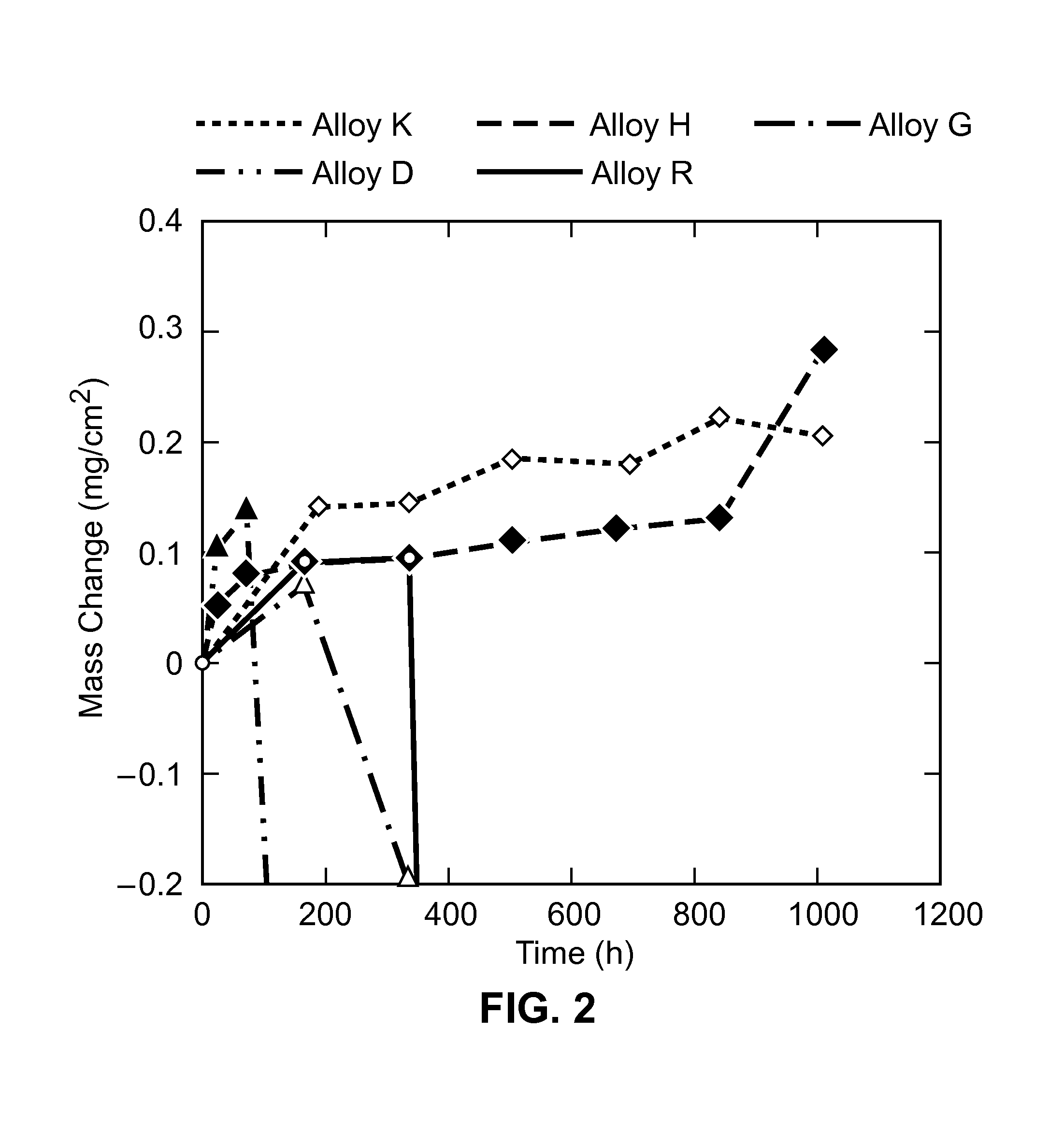

An austenitic stainless steel alloy includes, in weight percent: >4 to 15 Mn; 8 to 15 Ni; 14 to 16 Cr; 2.4 to 3 Al; 0.4 to 1 total of at least one of Nb and Ta; 0.05 to 0.2 C; 0.01 to 0.02 B; no more than 0.3 of combined Ti+V; up to 3 Mo; up to 3 Co; up to 1W; up to 3 Cu; up to 1 Si; up to 0.05 P; up to 1 total of at least one of Y, La, Ce, Hf, and Zr; less than 0.05 N; and base Fe, wherein the weight percent Fe is greater than the weight percent Ni, and wherein the alloy forms an external continuous scale including alumina, nanometer scale sized particles distributed throughout the microstructure, the particles including at least one of NbC and TaC, and a stable essentially single phase FCC austenitic matrix microstructure that is essentially delta-ferrite-free and essentially BCC-phase-free.

Owner:UT BATTELLE LLC

Method for rapid synthesis of aluminum orthophosphate salt polyalcohol

InactiveCN101172596AProduction Method AdvantagesShort synthesis timePhosphorus compoundsMicrowave ovenPhosphoric acid

The invention discloses a method for rapidly synthesizing aluminum phosphate salt polymeric compound. The method is characterized in that the mixture of phosphoric acid and aluminum hydroxide reacts and the mixture is synthesized under microwave condition. The method comprises the following steps: the phosphoric acid and the aluminum hydroxide are added with water to be mixed and stirred uniformly according to mol ratio; the mixture after being stirred uniformly is put into a microwave oven, and the defrosting and heating mode is selected to radiate the mixture; 750 W is selected to heat the mixture; white aluminum tripolyphosphate powder is gotten through hydrating, drying and grinding. The aluminum tripolyphosphate powder product is put into the microwave oven again to be radiated with 900 W power, and aluminum metaphosphate powder is gotten. The method integrates the reaction and polymerization of the prior art, reduces the composition time, saves the energy and the equipment, and improves the production efficiency. Because of the penetrating action of the microwave, the composition is not limited by the material quantity, and the synthetic ratio of the aluminum tripolyphosphate and the aluminum metaphosphate is improved. Related equipment can be adopted during the industrial production to realize continuous scale production.

Owner:GUANGXI UNIV FOR NATITIES

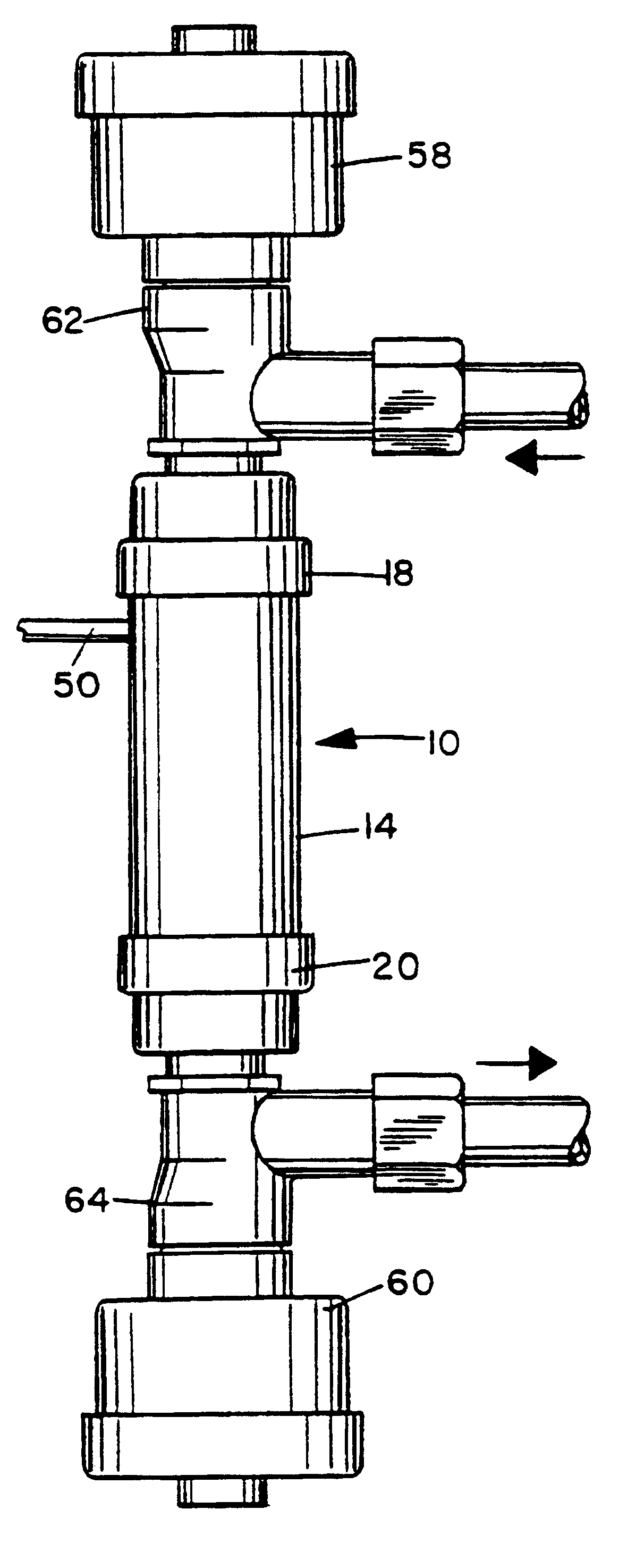

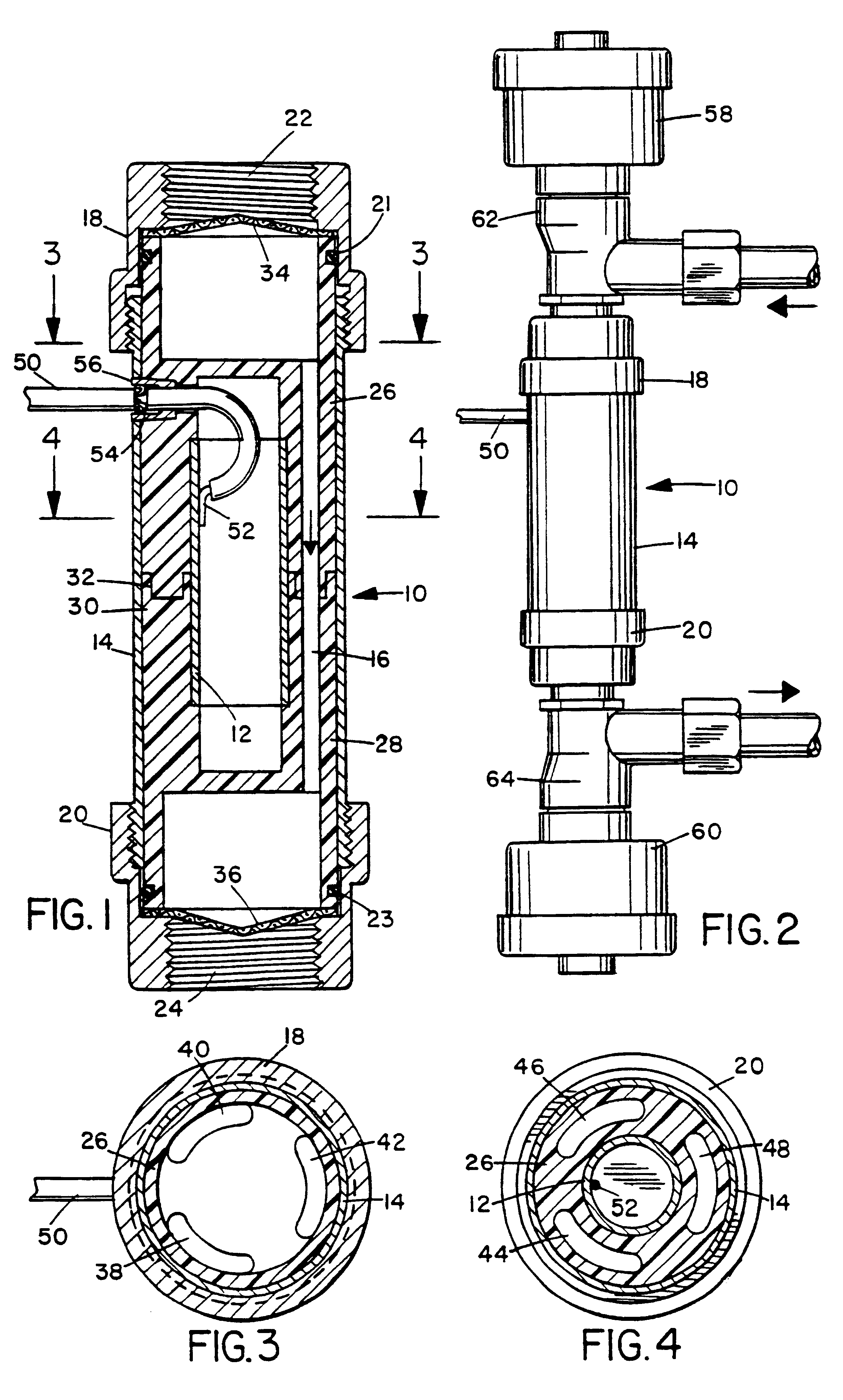

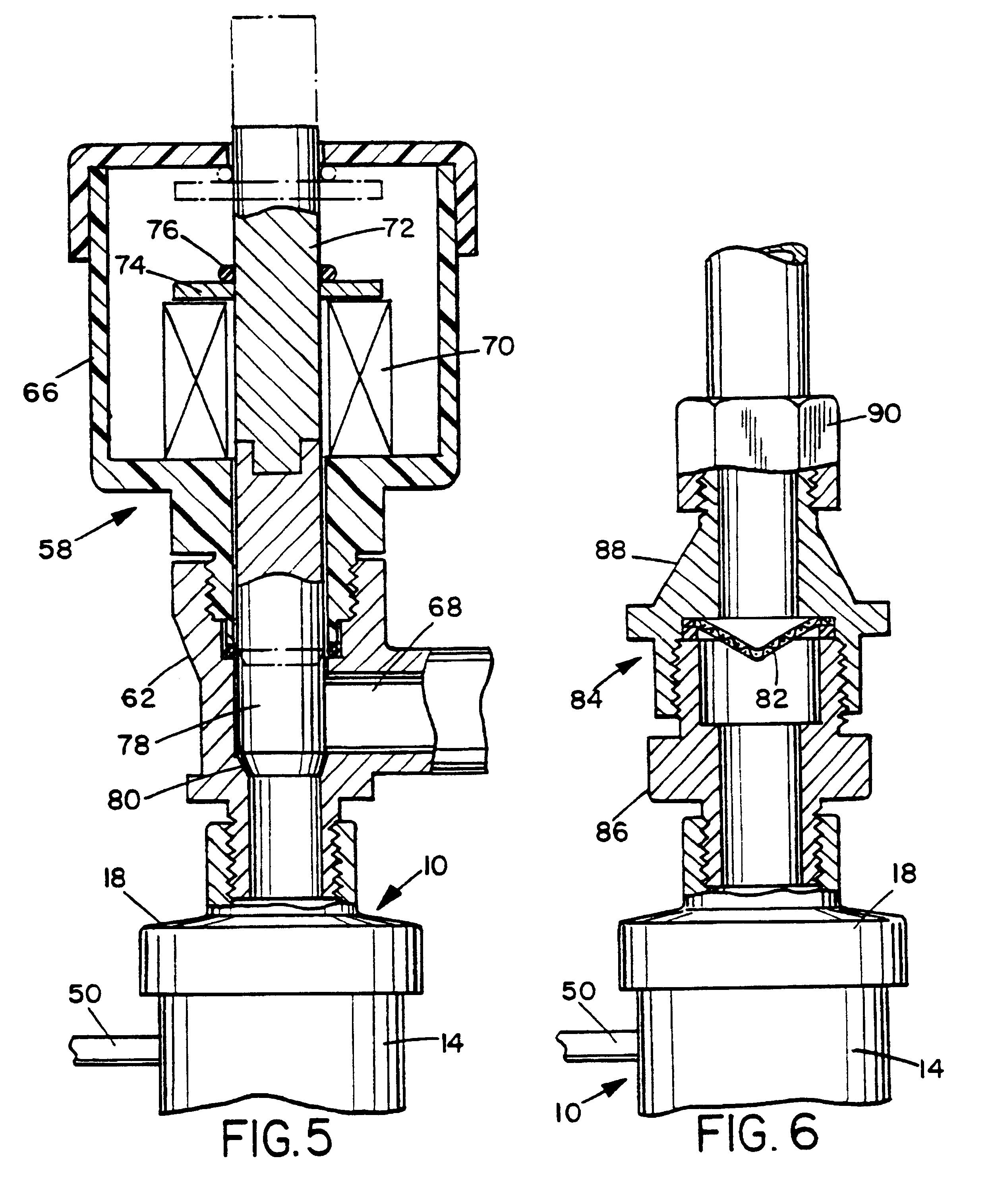

Volume charge density measuring system

InactiveUS6586950B1Minimize chargeImprove linearityResistance/reactance/impedenceVoltage/current isolationCapacitanceElectrical conductor

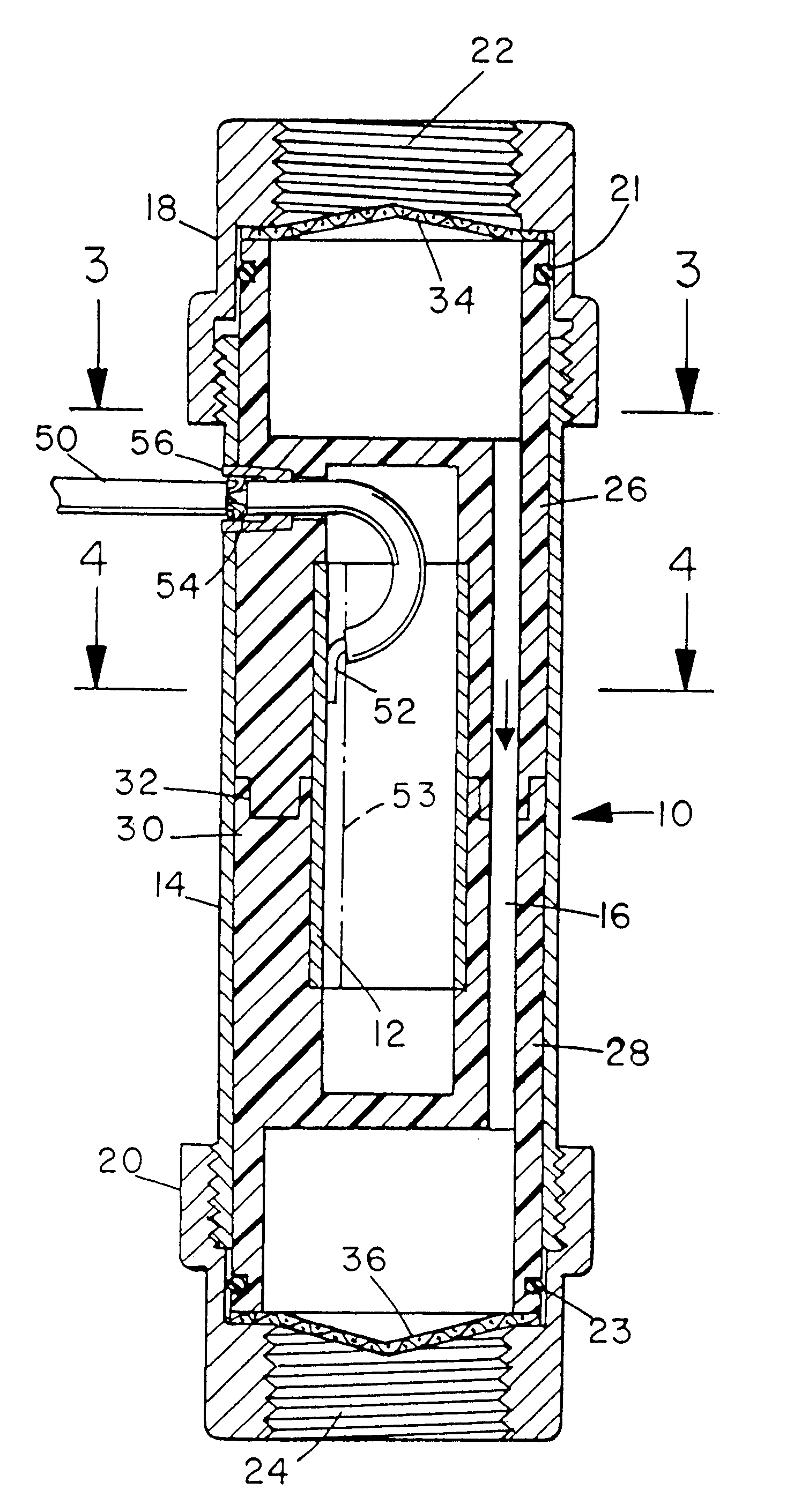

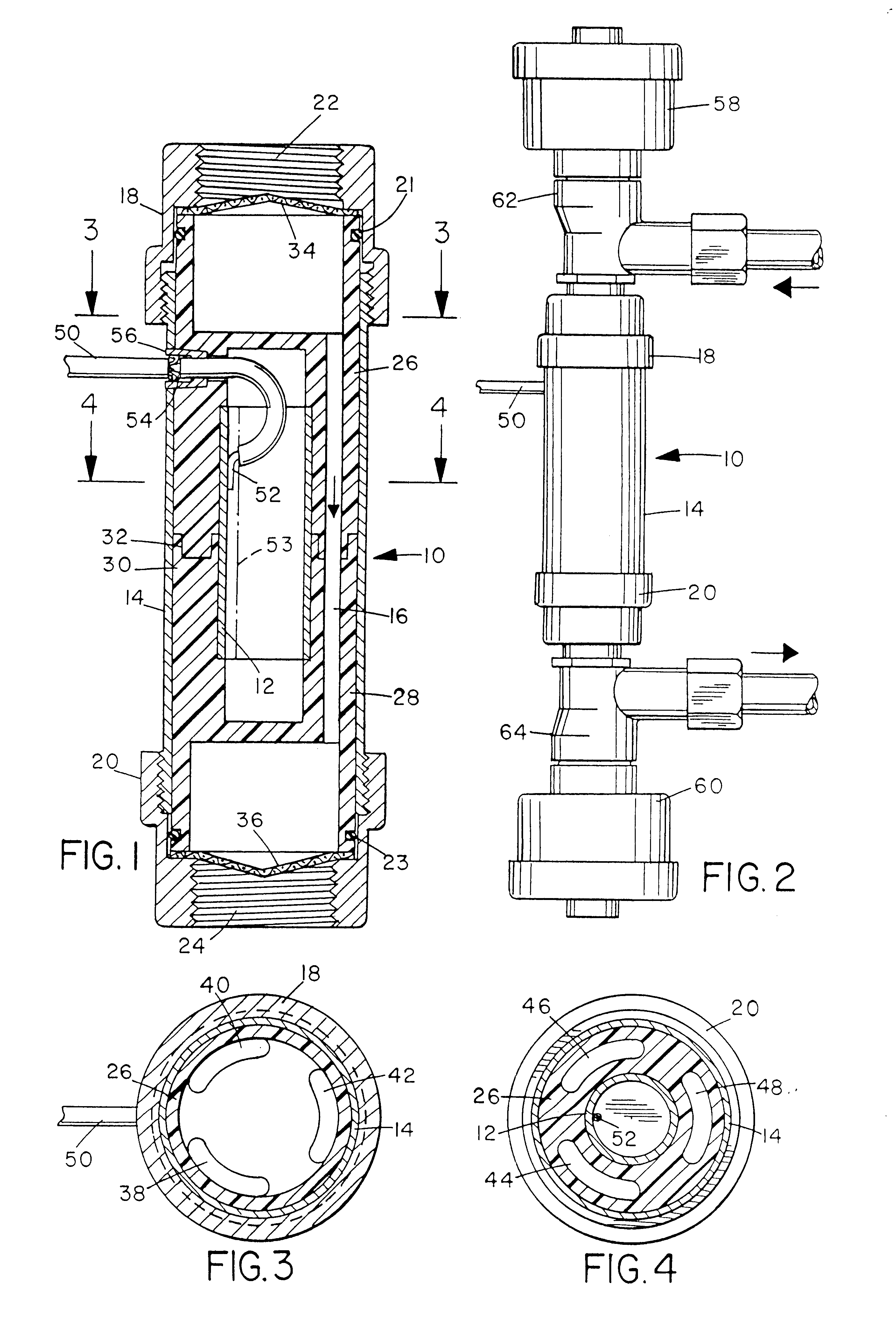

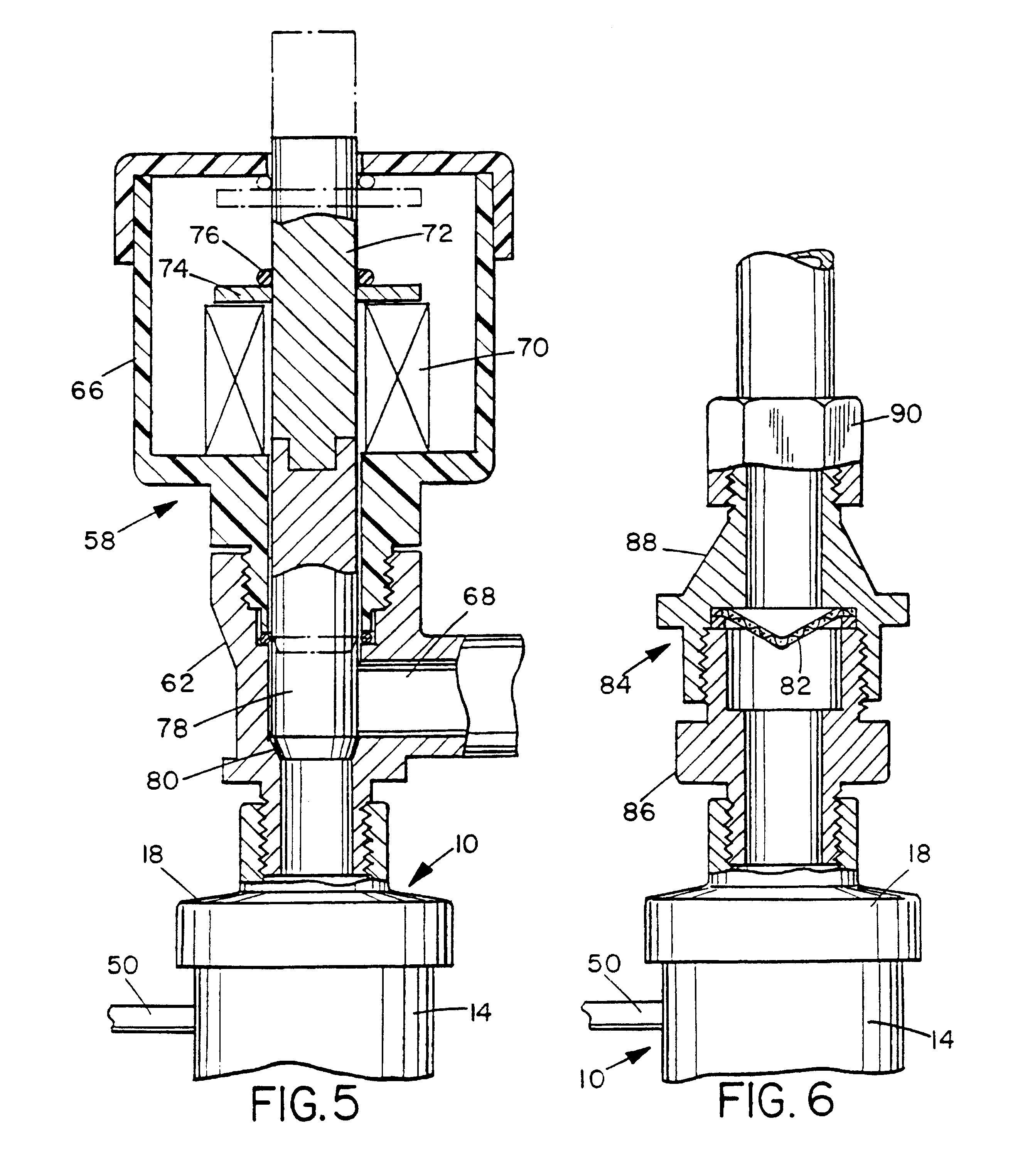

A capacitive sensor is shielded against external electric fields to maximize measurement accuracy. The sensor may include two coaxial, tubular conductors with a chamber between them into which a material sample to be measured is introduced. A measurement circuit connected to the sensor may include a reference oscillator that oscillates at a constant frequency and a test oscillator that oscillates at a frequency responsive to sensor capacitance. The circuit may display a value responsive to the difference between the test and reference frequencies. The circuit may also reverse the polarity of the signal applied to the sensor to minimize charge buildup, a phase-locked loop frequency measuring circuit, a temperature compensating circuit, and a non-linearity compensating circuit. The indicating circuit that displays a representation of the measured capacitance may display a continuous-scale or proportional representation or may display a binary or "go-nogo" representation. An alternative sensor of the system includes coaxial, finned inner and outer conductors that intermesh to maximize capacitive surface area. Another alternative sensor includes two parallel, plate-like conductors. The sensor system may be used to measure volume charge density of a fluid or parameters responsive to changes in volume charge density, such as flow velocity.

Owner:JOFRACH L L C

Volume charge density measuring system

InactiveUS6586949B1Eliminate the effects ofMinimizes shrinkageResistance/reactance/impedenceMaterial capacitanceElectrical conductorDisplay device

A capacitive sensor includes one or more chambers through which a material can flow. Two conductors are located to partially surround the flow chamber so that the material flows between the conductors. Where more than one chamber is used, additional conductors are provided. A measurement circuit connected to the conductors provides an output corresponding to a difference between test and reference frequencies. A display indicates the measured capacitance as a continuous-scale, proportional representation or a binary representation. The sensor system can measure volume charge density of a fluid or parameters responsive to changes in volume charge density, such as flow velocity.

Owner:JOFRACH L L C

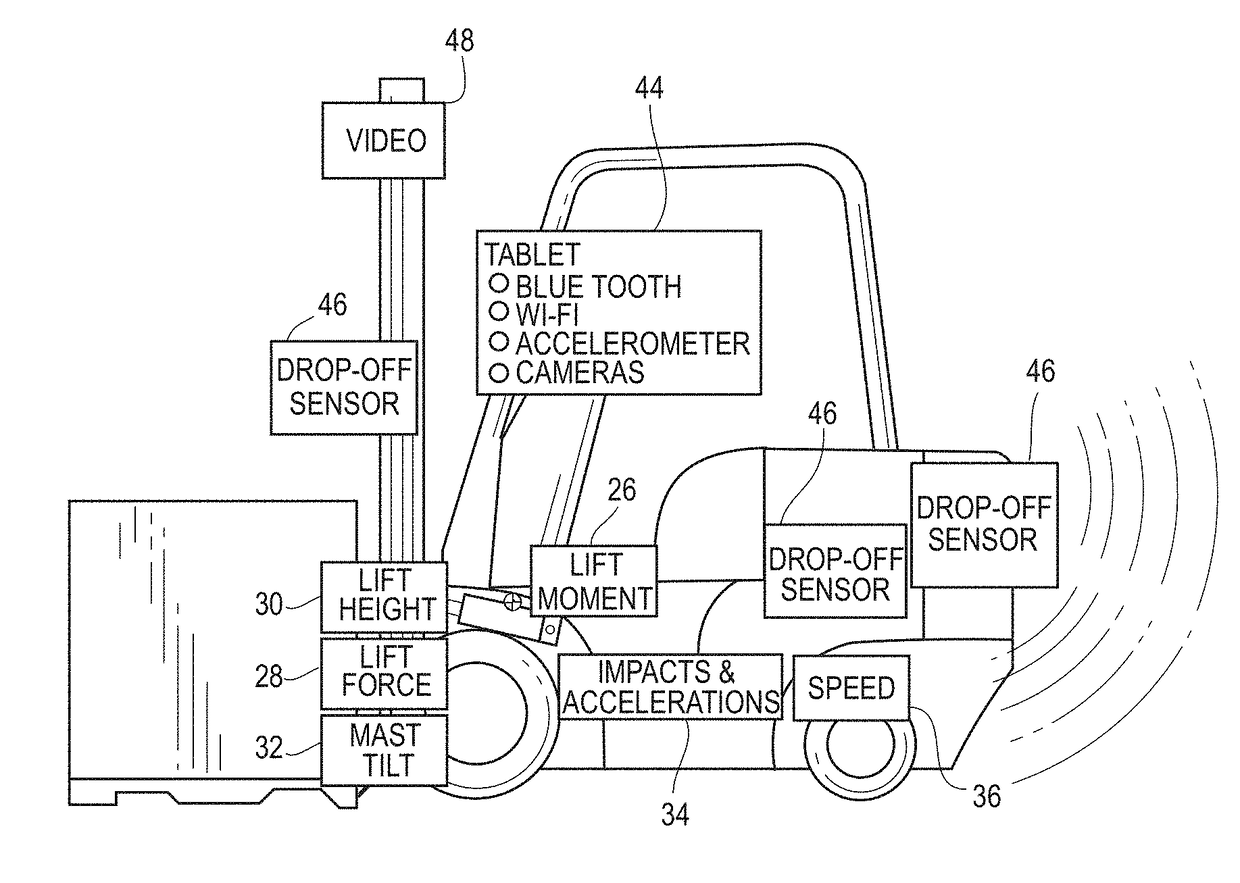

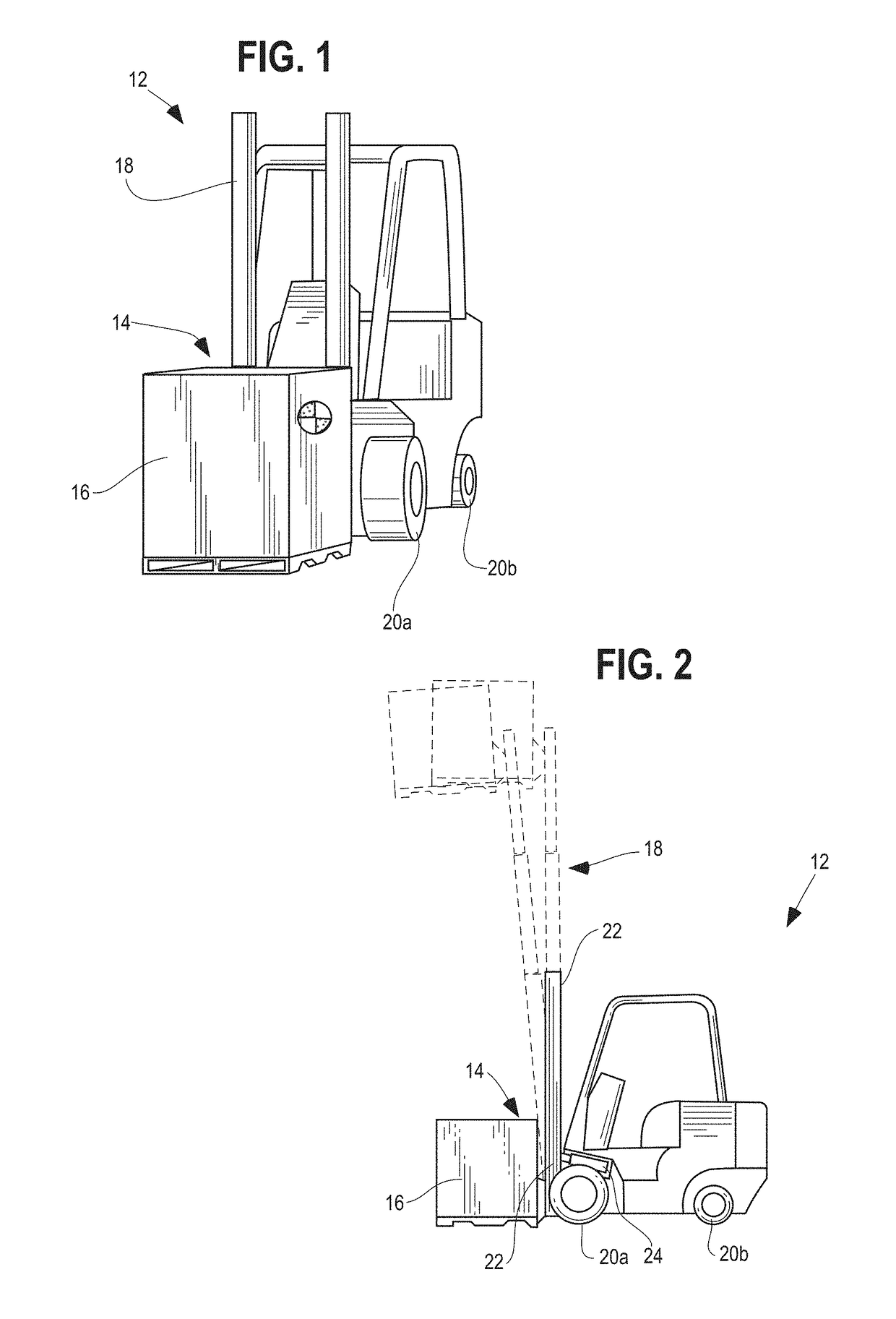

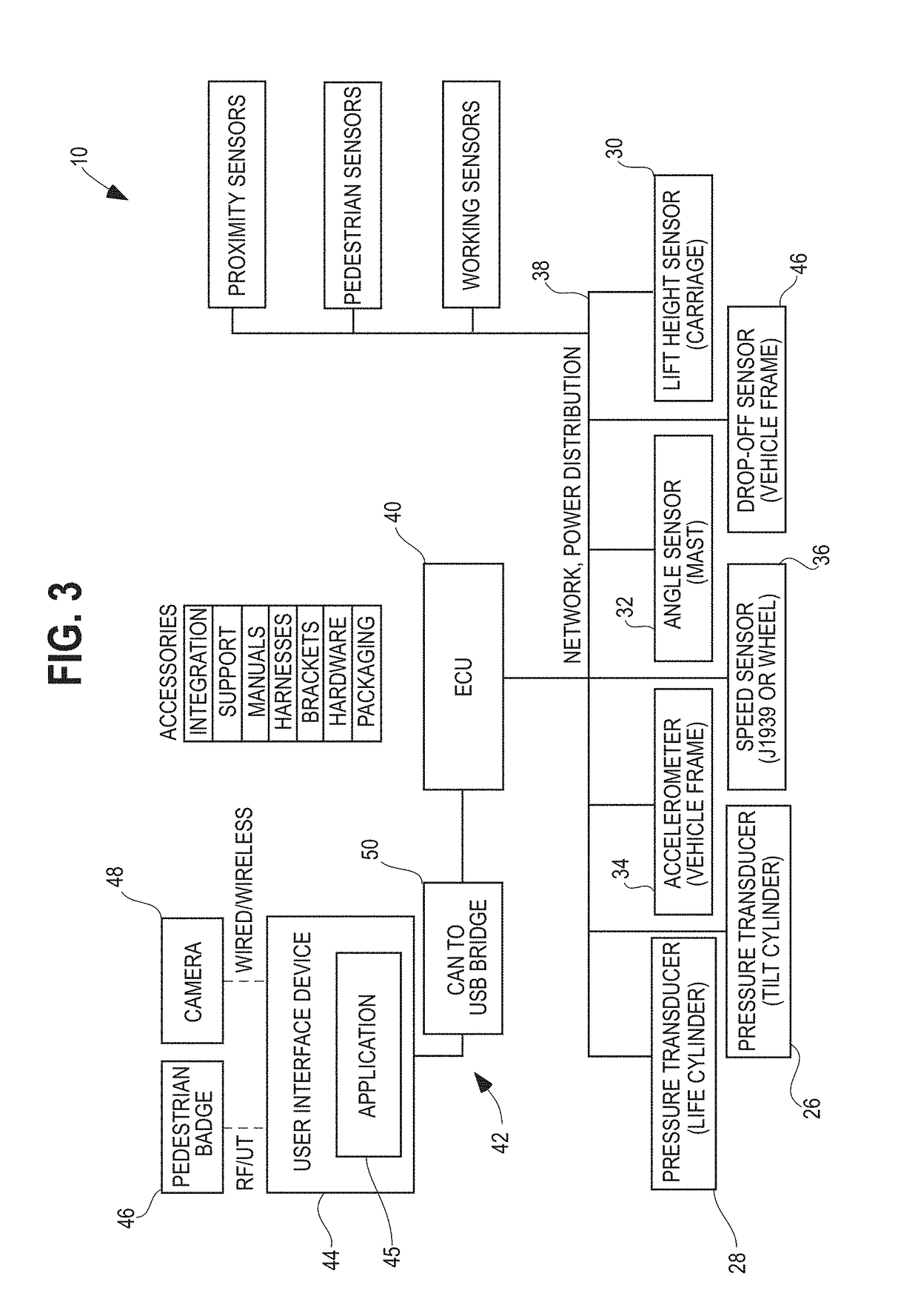

System and method for dynamically controlling the stability of an industrial vehicle

ActiveUS20180229988A1Avoid instabilityPrevent tippingSafety devices for lifting equipmentsSoil-shifting machines/dredgersDynamic dataTime dynamics

A system and method for monitoring the dynamic load moment and stabilization of a lifting vehicle is provided. The system is adapted for monitoring the stability of the vehicle on a real-time basis, and displaying the real-time dynamic load moment of the vehicle / cargo combination on a continuous scale on a user interface. The system may also include an object detection device oriented for determining the presence or absence of a floor surface within a specified distance from the vehicle in order to detect drop-offs in the floor surface surrounding the vehicle and alert the operator of same. A method for calibrating the system is also provided. The calibration method can include a series of lift and acceleration steps for collecting static and dynamic data in order to determine one or more coefficients associated with the vehicle.

Owner:ARROW ACQUISITION

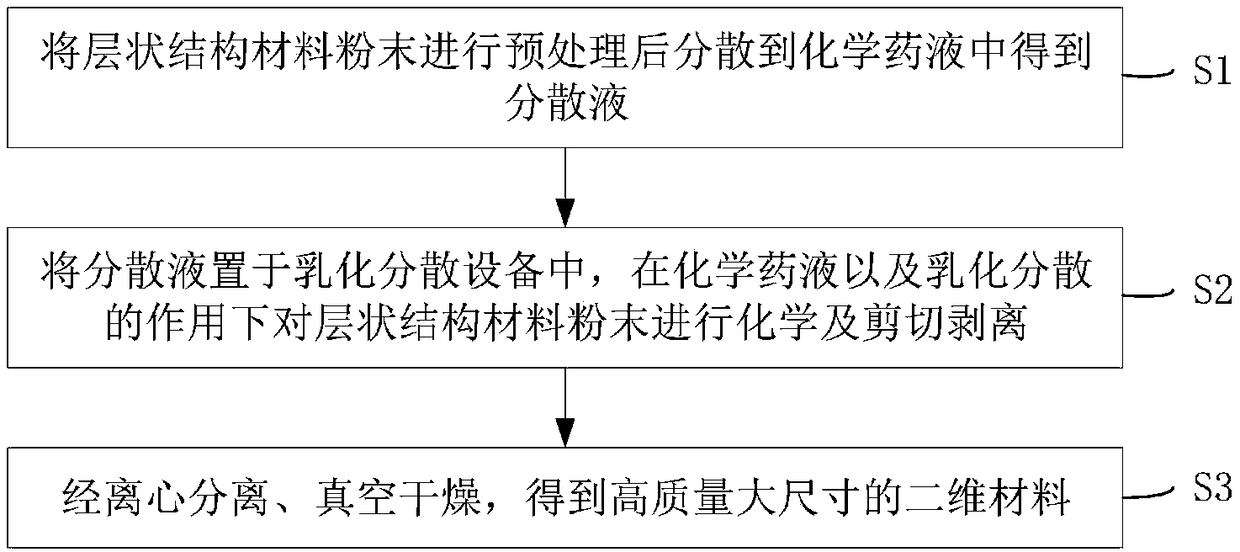

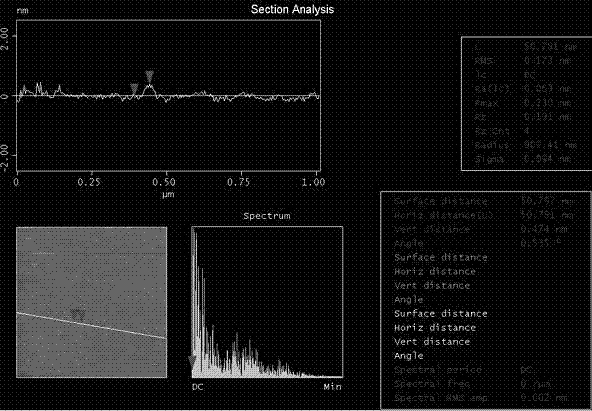

High-quality and large-size two-dimensional material and preparation method thereof

ActiveCN108793140AIncrease tangential speedImprove stripping efficiencyNitrogen compoundsTitanium carbidePre treatmentLarge size

The invention discloses a high-quality and large-size two-dimensional material and a preparation method thereof. The preparation method of the high-quality and large-size two-dimensional material comprises the following steps: S1, after pre-treating lamellar structure material powder, dispersing in chemical drug liquid, so as to obtain a dispersion solution; S2, putting the dispersion solution into emulsifying and dispersing equipment, and carrying out chemical and shearing peeling on the lamellar structure material powder under the action of the chemical drug liquid and emulsification and dispersion; S3, carrying out centrifugal separation and vacuum drying to obtain the high-quality and large-size two-dimensional material. The high-quality and large-size two-dimensional material and thepreparation method thereof, provided by the invention, have the advantages of simplicity and rapidness, high peeling efficiency and capability of realizing continuous scale production.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

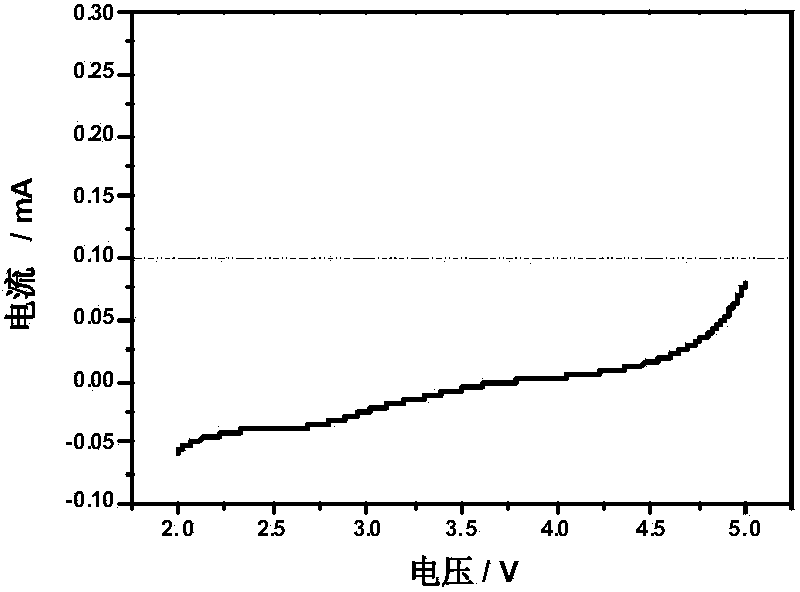

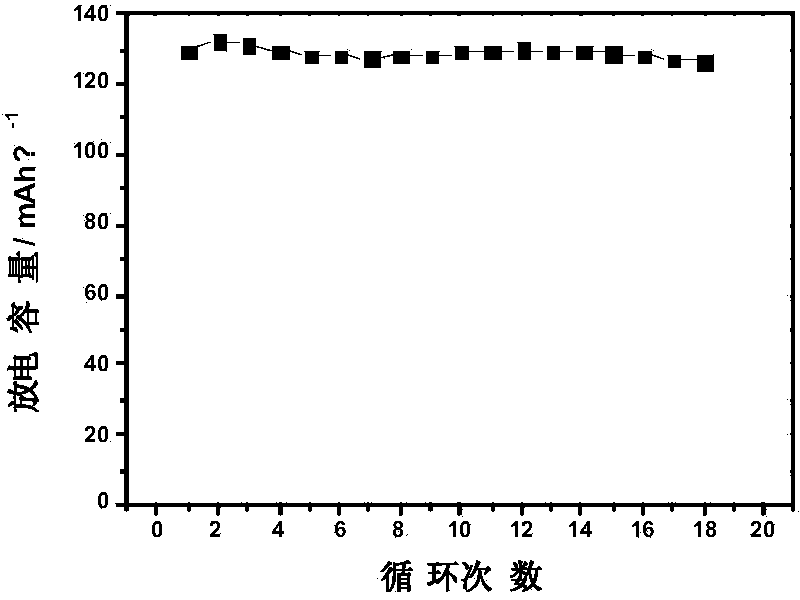

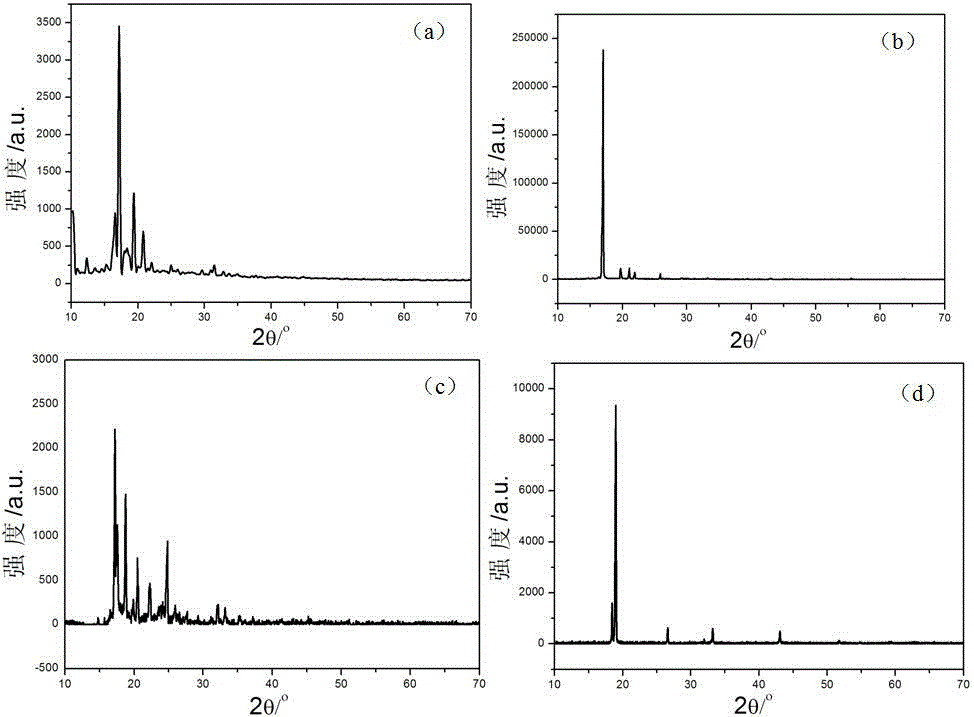

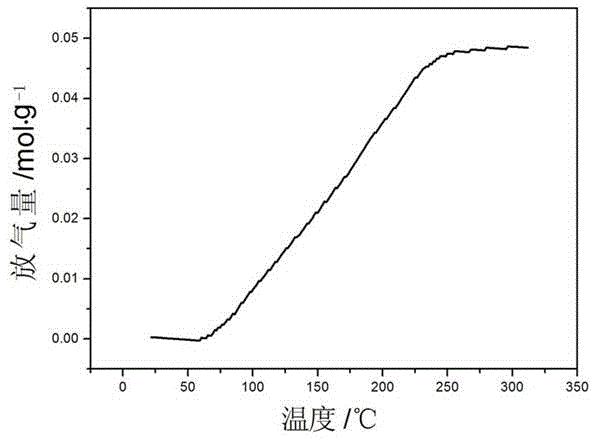

Preparation method and application of polyvinyl acetal-based gel polymer electrolyte

ActiveCN104319420AIn situ synthesisRealize comprehensive applicationFinal product manufactureElectrolyte accumulators manufacturePolymer dissolutionPolymer science

The invention discloses a preparation method and an application of a polyvinyl acetal-based gel polymer electrolyte. According to the preparation method, the polyvinyl acetal polymers with the structures shown as the general formulae (1), (2), (3) and (4) are dissolved in an organic solvent system; and a reactive diluent and a photoinitiator are added into the liquid electrolyte in a certain ratio and are uniformly mixed to obtain a precursor solution; a lithium ion battery diaphragm is fully swelled and infiltrated by the precursor solution, and then is irradiated under the ultraviolet rays with the wavelength in the range of 200 to 365 nm; chemical cross linking happens to the obtained a diaphragm-supported gel polymer electrolyte, wherein R1 and R2 express a full acetal compound or a hemiacetal compound of aliphatic hydrocarbons or aromatic hydrocarbons with 1 to 13 hydrogen atoms or carbon atoms. The preparation method is easy to operate, and is suitable for continuous scale production of gel polymer electrolyte and in-situ film-forming production of polymer lithium ion batteries; moreover, the prepared gel polymer electrolyte has high ionic conductivity and a wide electrochemical stability window; the matching cycling performance with an electrode material is high; the liquid leakage pollution of the liquid electrolyte battery is avoided; the safety performance is high.

Owner:UNIV OF SCI & TECH BEIJING

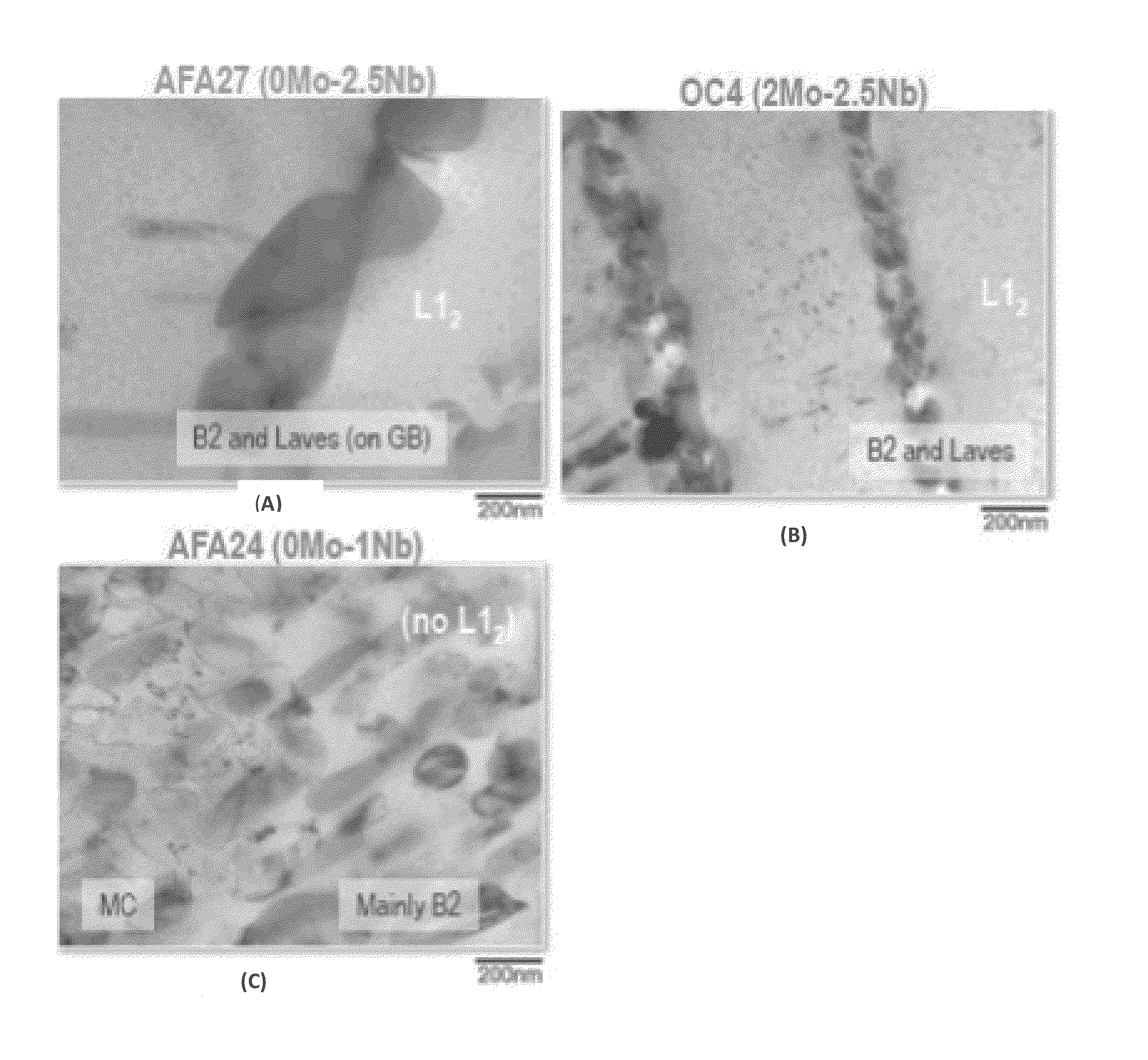

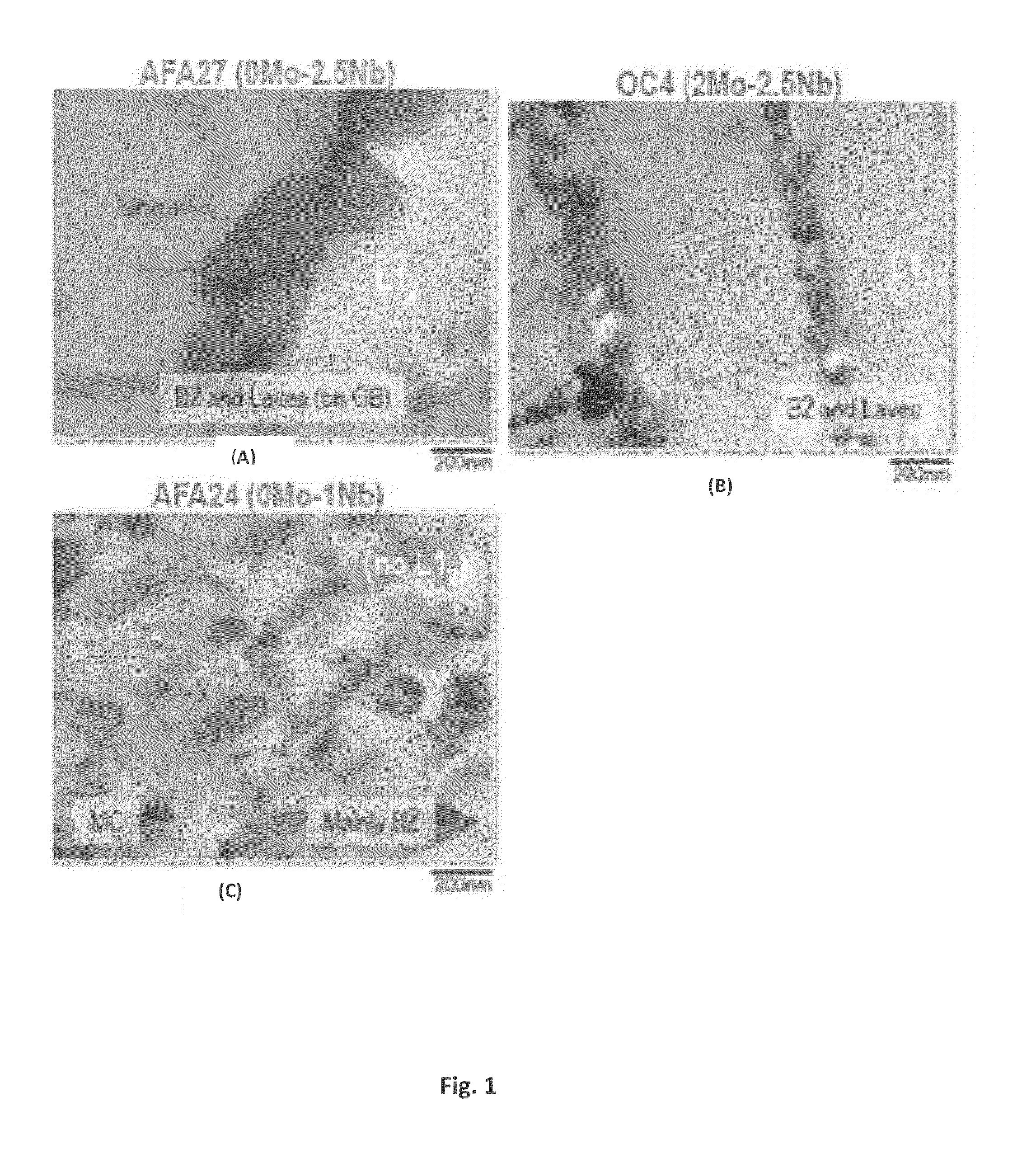

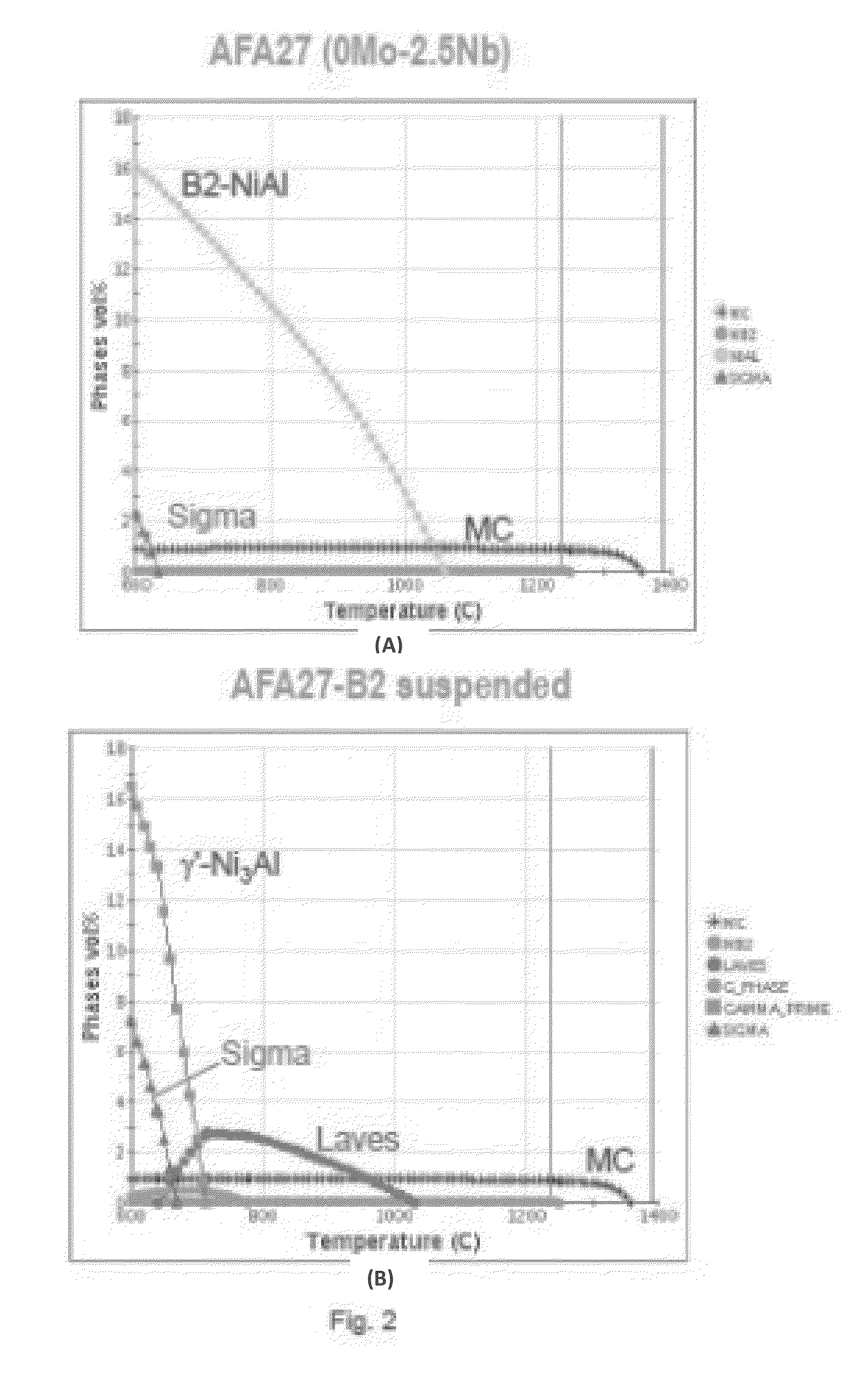

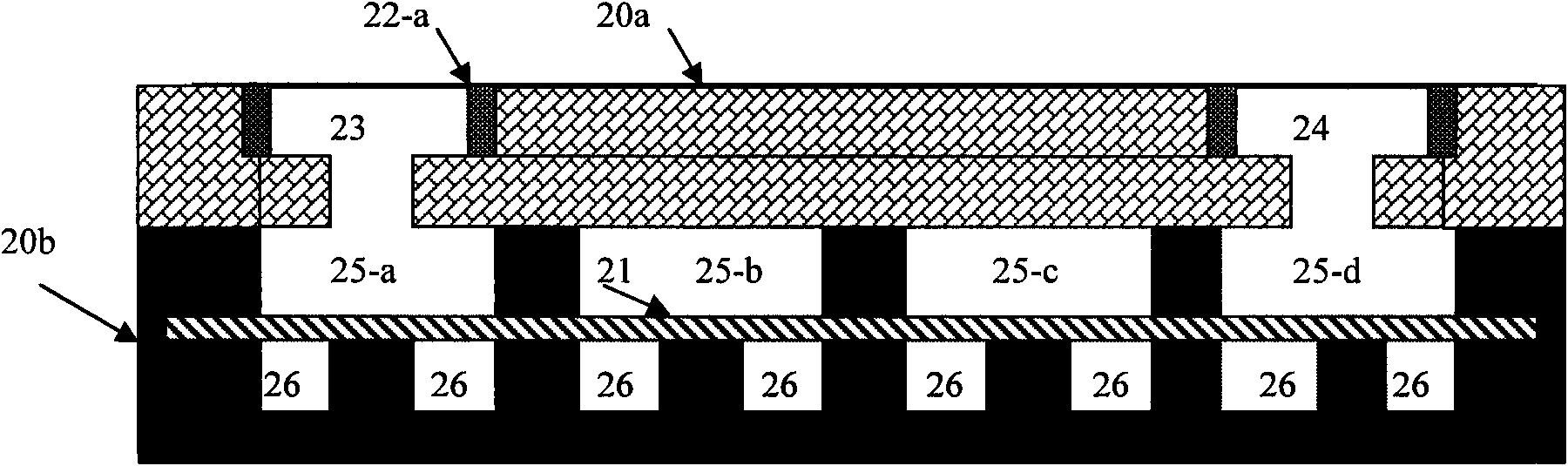

Alumina Forming Iron Base Superalloy

An austenitic stainless steel alloy, consists essentially of, in weight percent 2.5 to 4 Al; 25 to 35 Ni; 12 to 19 Cr; at least 1, up to 4 total of at least one element selected from the group consisting of Nb and Ta; 0.5 to 3 Ti; less than 0.5 V; 0.1 to 1 of at least on element selected from the group consisting of Zr and Hf; 0.03 to 0.2 C; 0.005 to 0.1 B; and base Fe. The weight percent Fe is greater than the weight percent Ni. The alloy forms an external continuous scale including alumina, and contains coherent precipitates of γ′—Ni3Al, and a stable essentially single phase FCC austenitic matrix microstructure. The austenitic matrix is essentially delta-ferrite-free and essentially BCC-phase-free.

Owner:UT BATTELLE LLC

Method for preventing banana pulp from browning

InactiveCN104305161AEfficient productionContinuous productionFood preparationEnzymeProtective Agents

The invention discloses a method for preventing banana pulp from browning. During deep banana processing, bananas can be oxidized to cause browning very easily, and further the loss of color, fragrance and taste is caused. Therefore, preventing browning during the banana processing is very important. The method provided by the invention achieves the purposes of enzyme deactivation and browning prevention through the procedures of batch charging, enzyme deactivating, pulping, filtering, sterilizing and bulking. The entire banana pulp processing process is performed in a sealed state, the banana pulp is not in contact with air, on one aspect, browning reaction cannot be easily caused under an anaerobic condition, on the other aspect, enzymatic browning inactivation is achieved, and the browning reaction is stopped fundamentally. During the processing, the bananas quickly enter into a coil heat exchanger under the pushing of a screw pump to be heated to reach a temperature of 100 to 120 DEG C, and the temperature is kept for 5 to 6 minutes, therefore, a color-protecting effect is played. The method provided by the invention can achieve high efficiency and continuous scale production under a state of not adding any protective agents.

Owner:合浦果香园食品有限公司

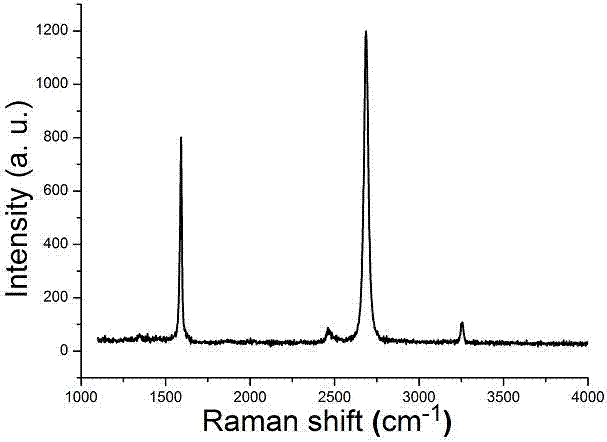

Method of continuously preparing high-quality graphene in a large scale

The invention relates to a method of continuously preparing high-quality graphene in a large scale. The method comprises the following steps of: (1) uniformly mixing a carbon source and a surface isolation synergistic stabilizer according to a proportion, so as to obtain a mixture; (2) dispersing the mixture in a liquid medium, then grinding and stripping in a ball mill, and obtaining a graphene dispersion liquid after 0.5-5 hours; and (3) drying the graphene dispersion liquid so as to obtain graphene powder. The method is simple, is low in cost, can prepare non-aggregated graphene, can realize industrial continuous production, and has a broad application prospect in the electricity field.

Owner:拜永孝

Method for preparing zinc-nickel alloy powder and application thereof

InactiveCN101648273AHigh strengthImprove corrosion resistanceMetallic material coating processesHigh energySlurry

Owner:WUHAN UNIV OF TECH

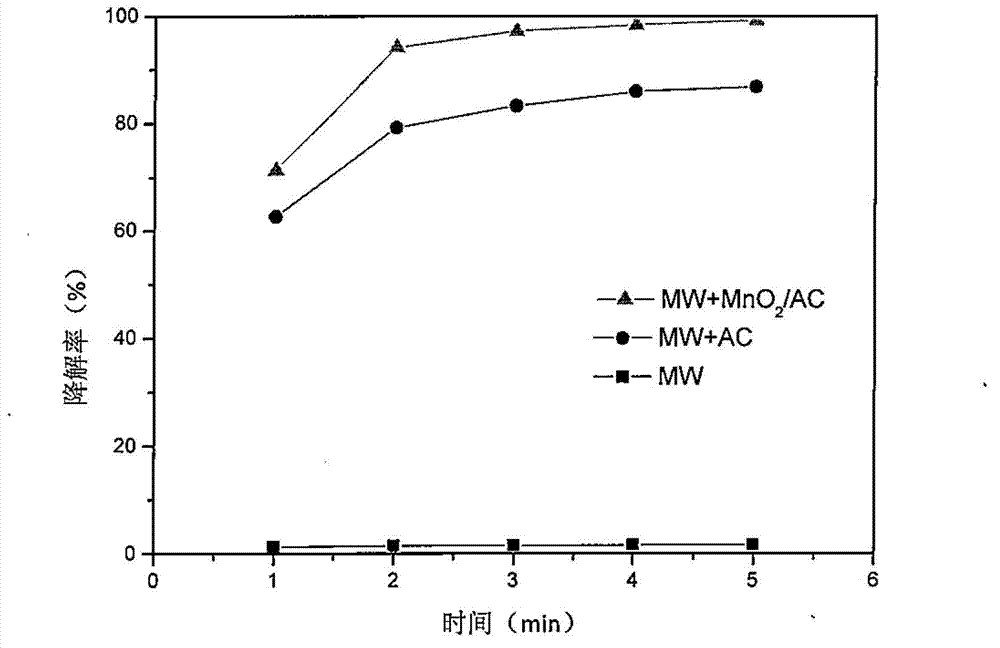

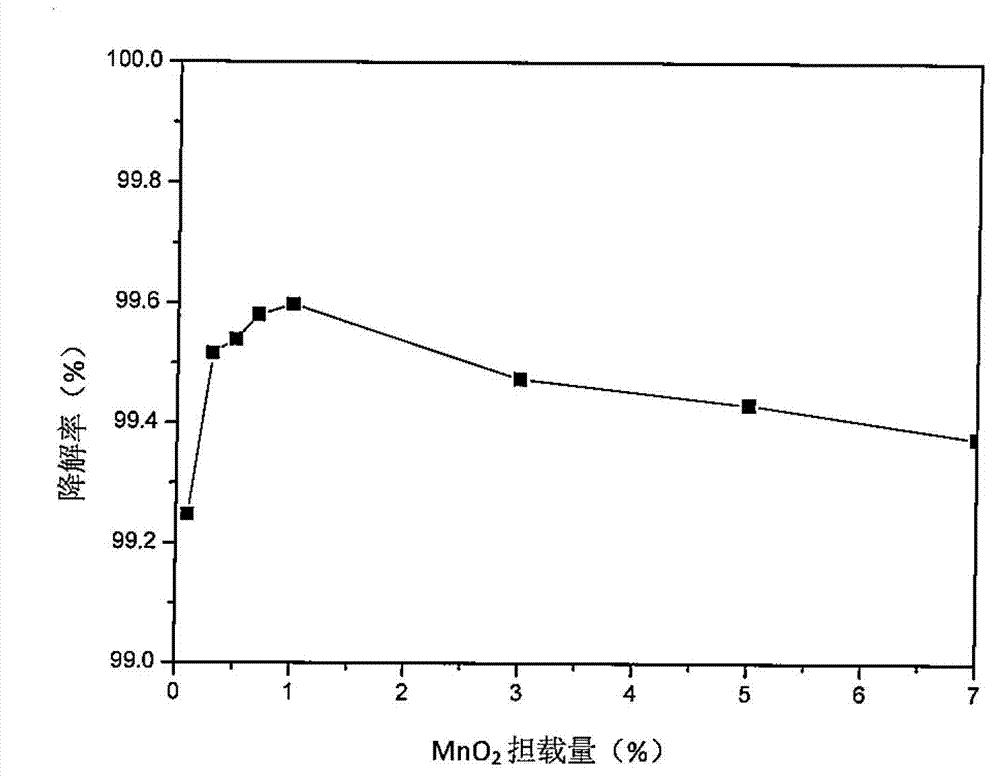

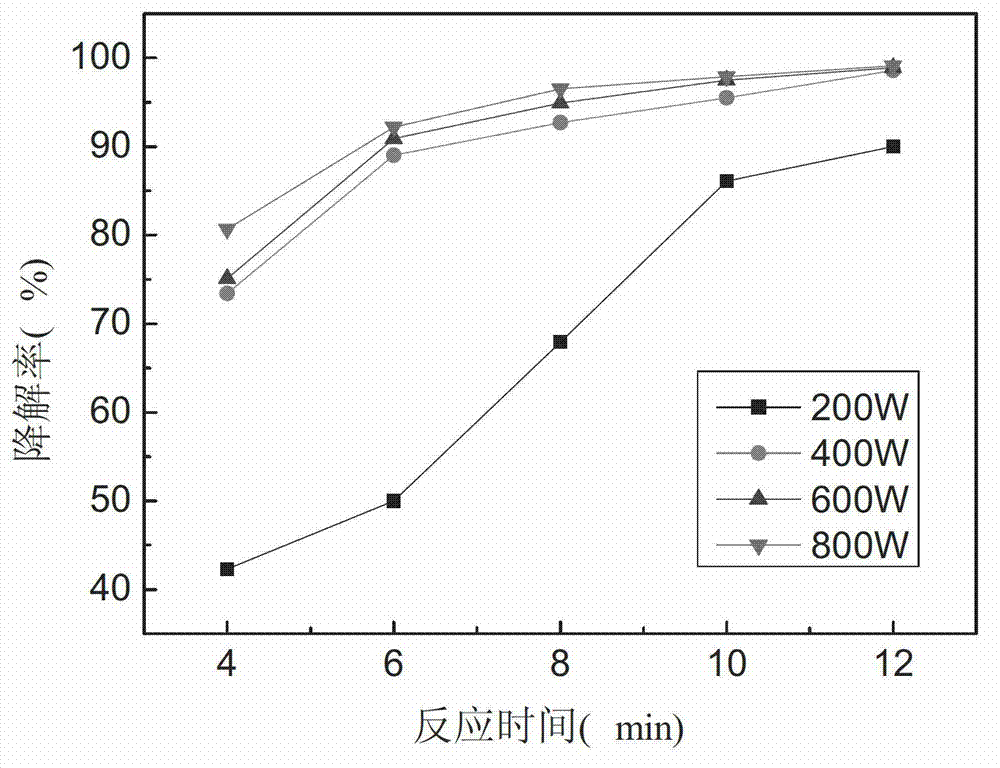

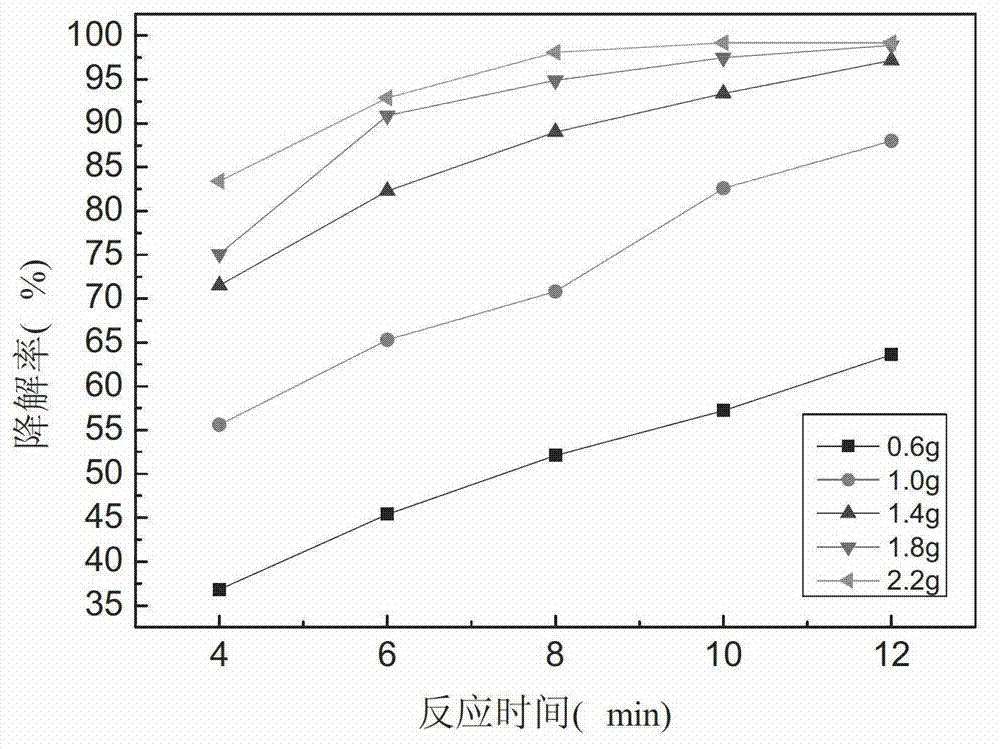

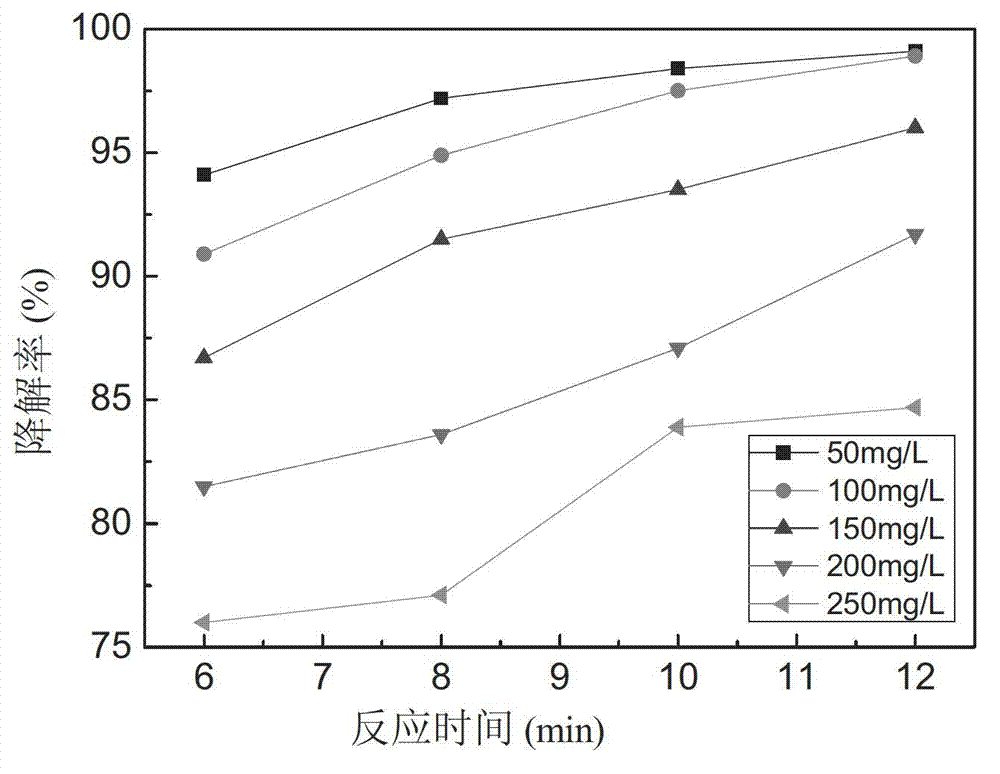

Method for catalyzing and degrading phenolic wastewater through microwaves

InactiveCN103159282AImprove degradation efficiencyReduced photocatalytic efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationChemical industryCatalytic oxidation

The invention relates to method for catalyzing and degrading phenolic wastewater through microwaves. The method includes (1) preparing microwave catalysts, namely transition metallic oxide is loaded on activated carbon, (2) forming solid and liquid mixture, namely a certain amount of the microwave catalysts prepared in the step (1) is added in phenolic wastewater, (3) and carrying out microwave irradiation, namely the solid and liquid mixture is subjected to a microwave catalytic oxidation reaction to degrade phenolic organic matters under the microwave irradiation. According to the method, degradation efficiency is greatly reduced, processing time is greatly shortened, operation is simple and practical, investment and operation cost is low, occupation area is small, degradation is complete, concentration range of the degradable organic wastewater is wide, scale processing can be carried out in a continuous mode, industrialized production is easy to achieve, secondary pollution does not exist, and the method is suitable for processing organic wastewater in printing and dyeing industry, papermaking industry, chemical industry, pharmacy industry and the like.

Owner:XIANGTAN UNIV

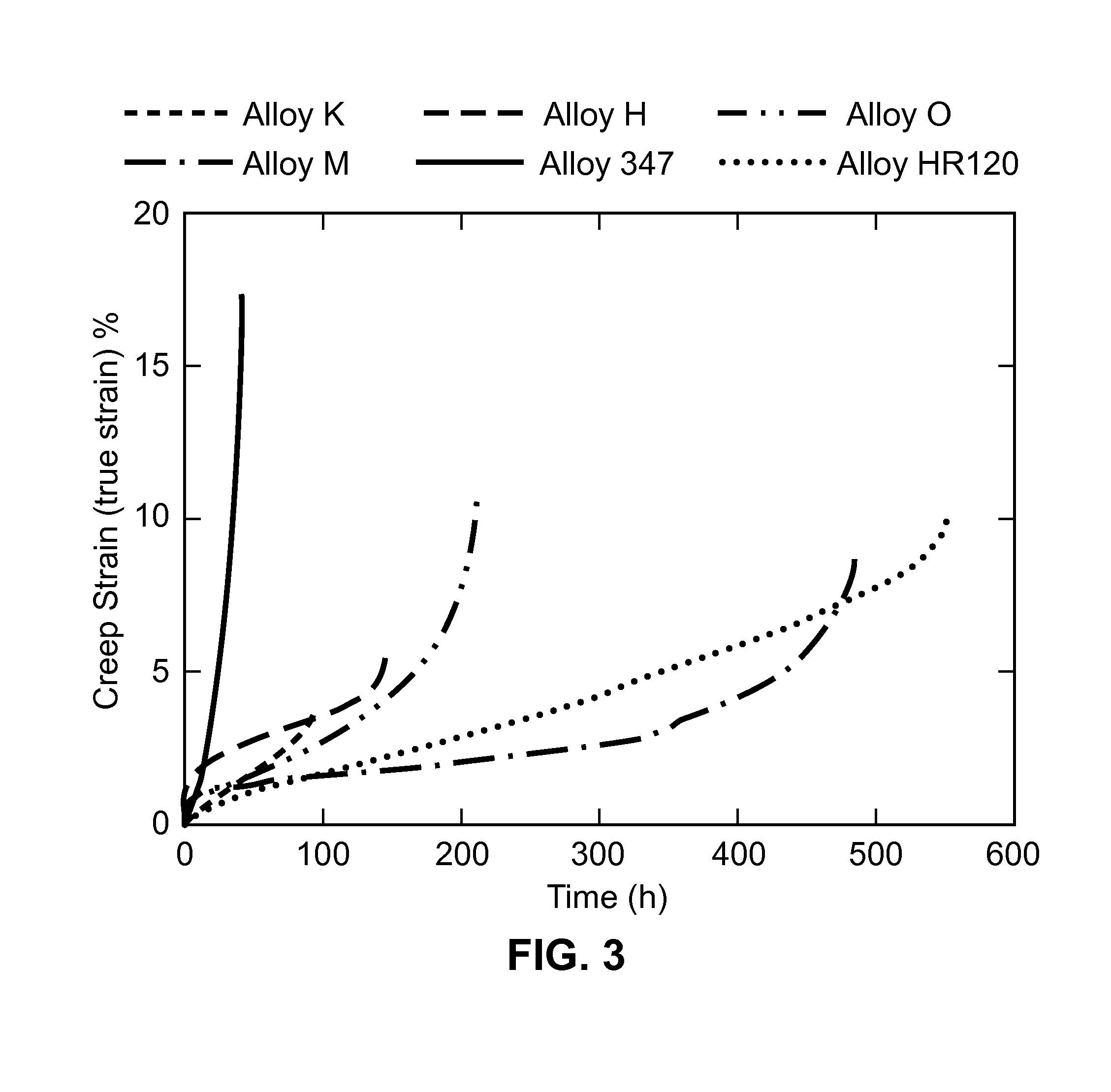

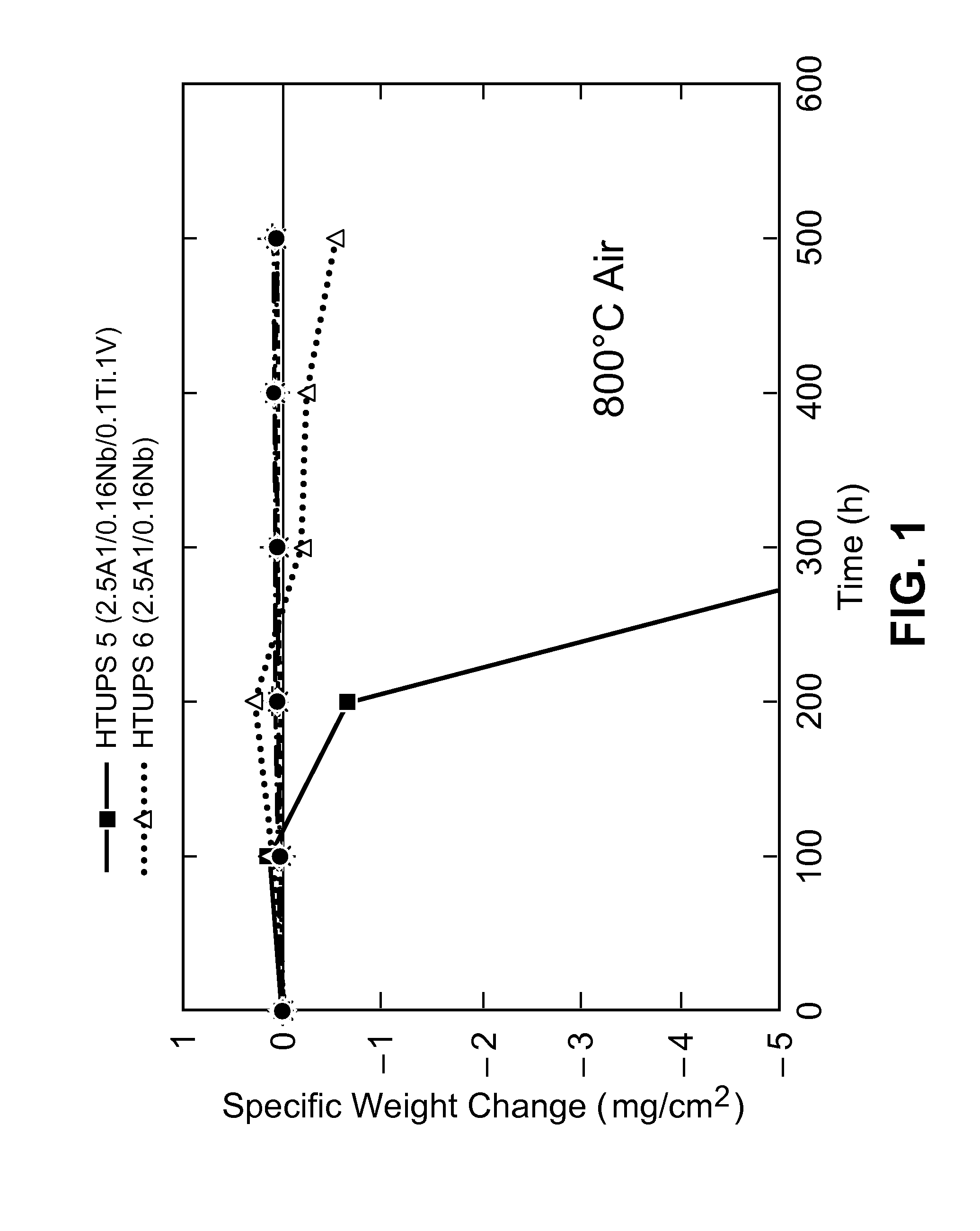

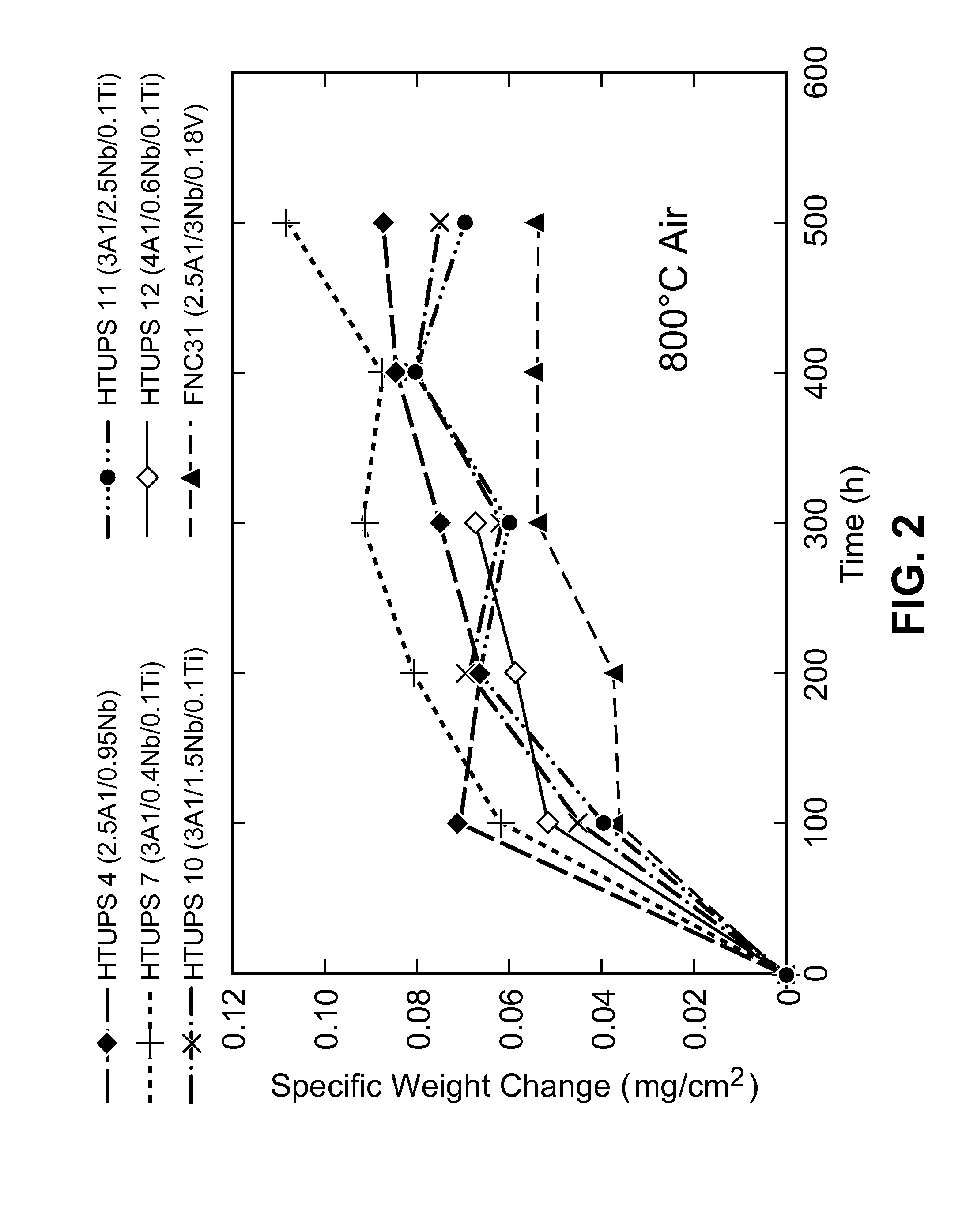

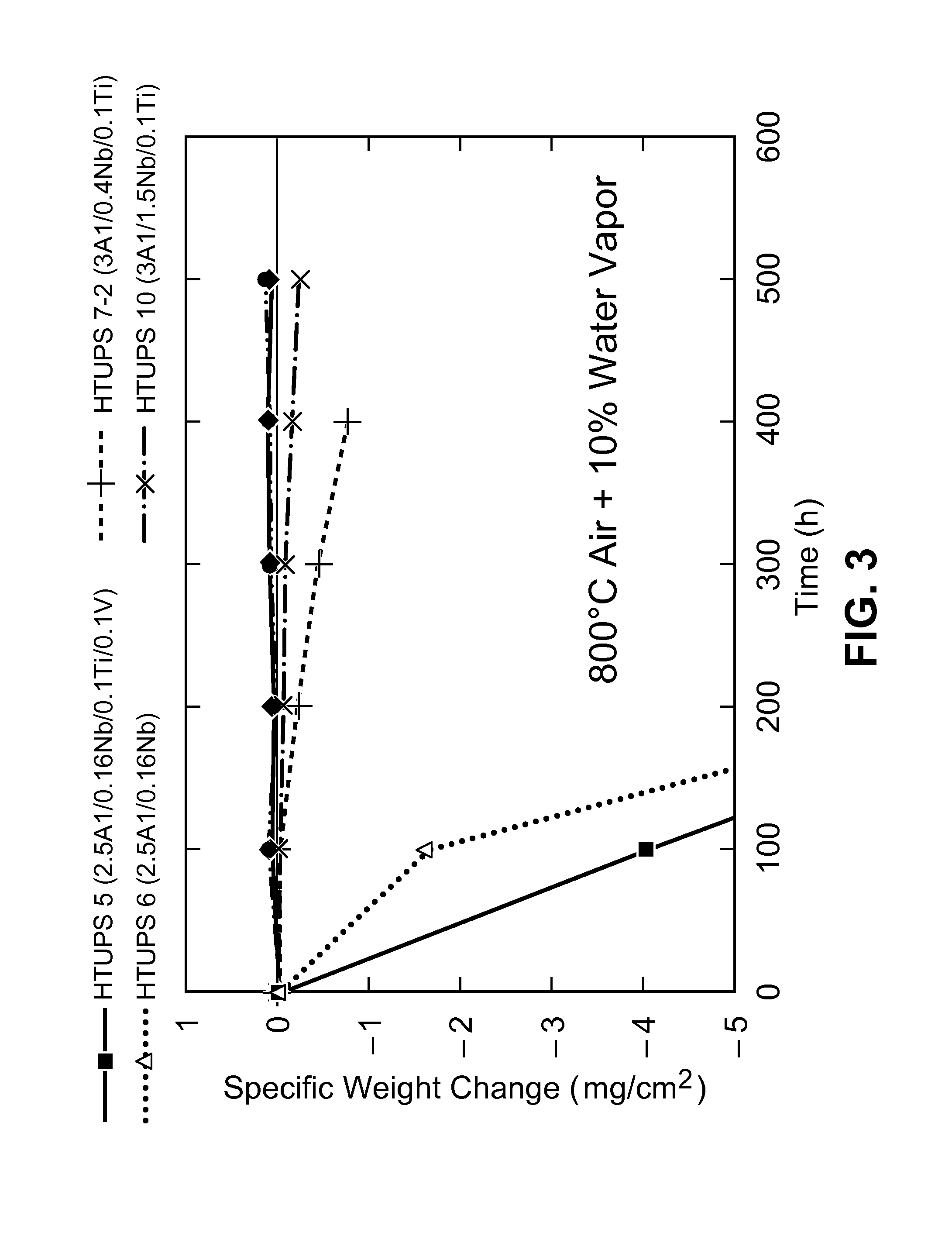

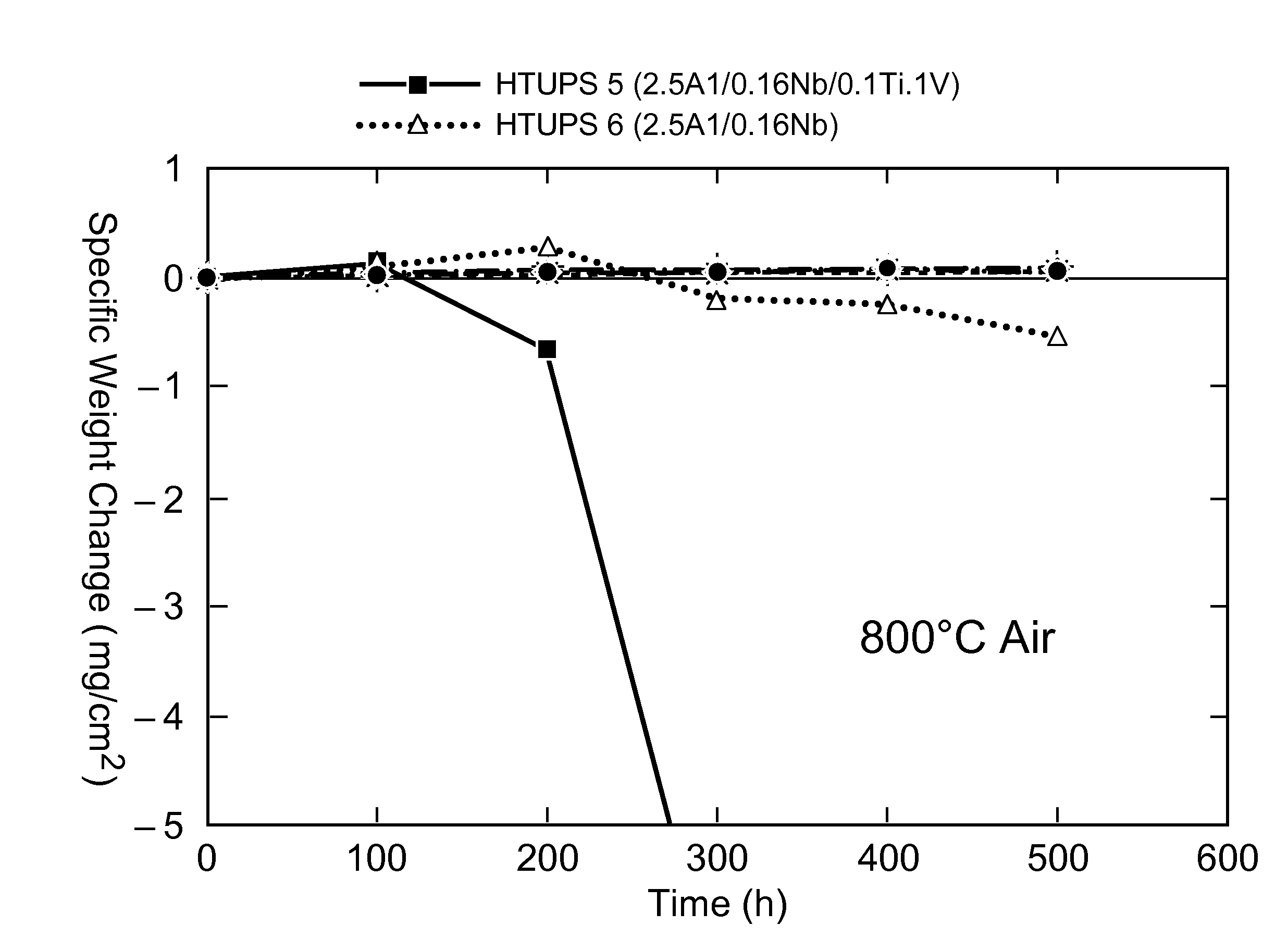

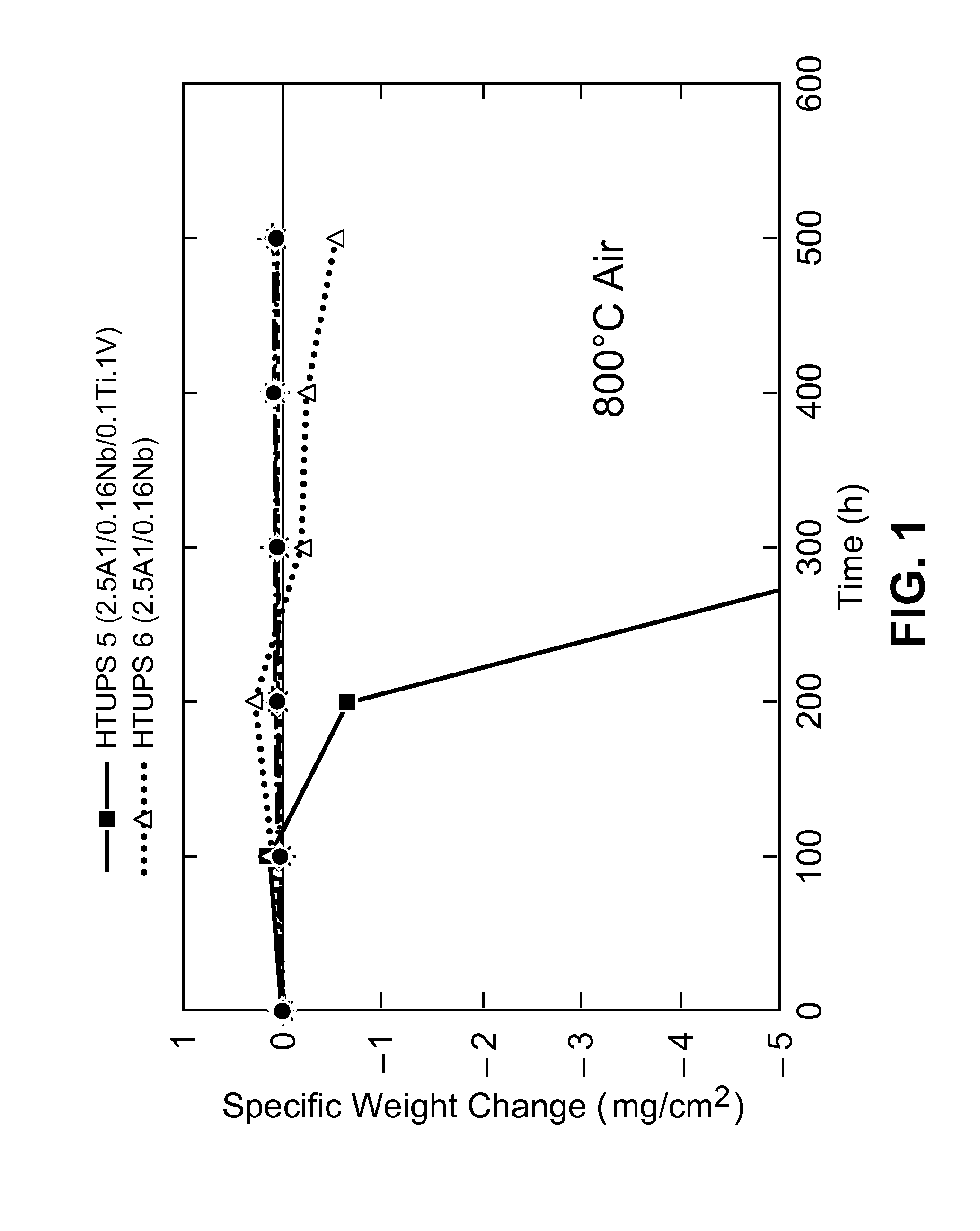

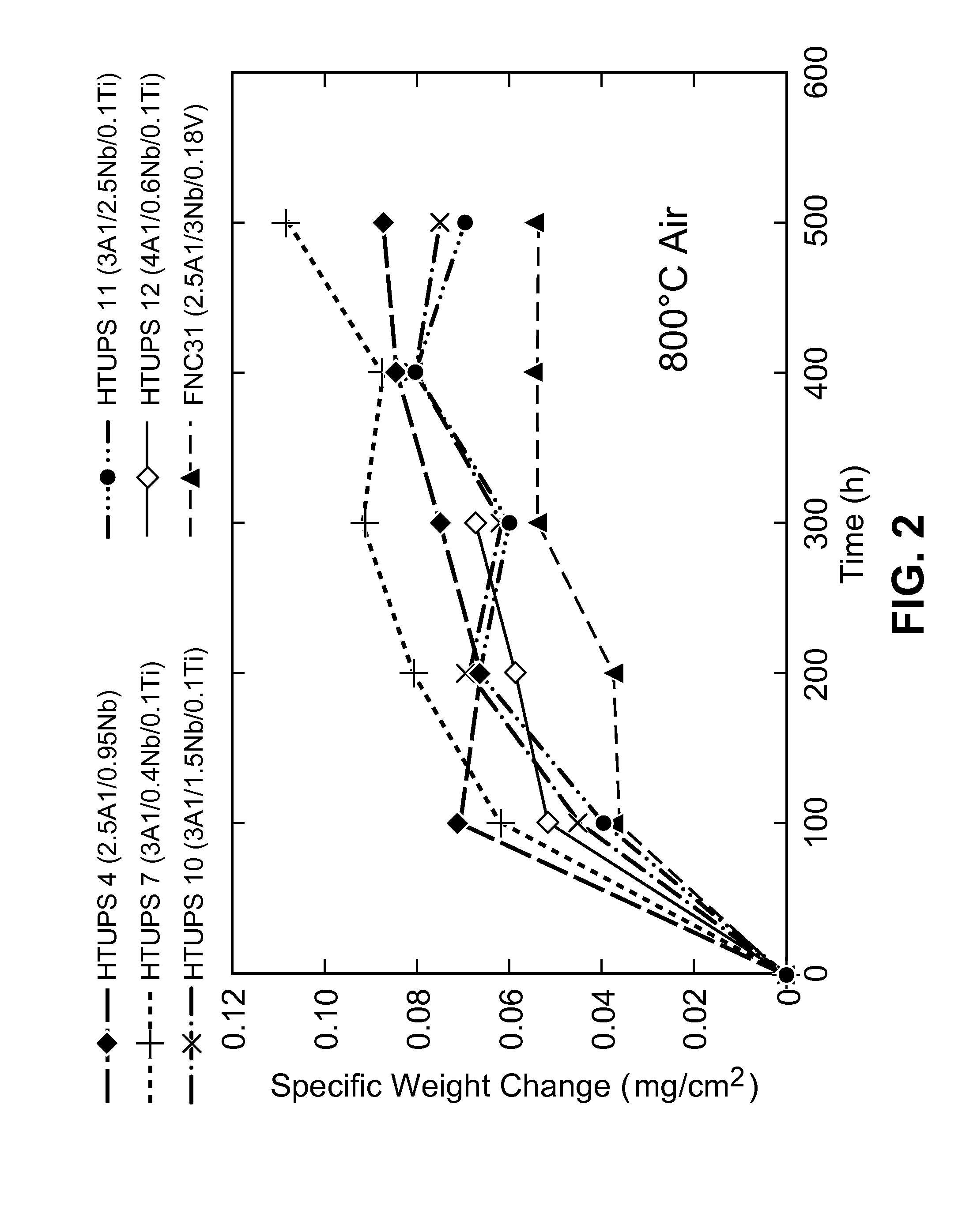

High Nb, Ta, and Al Creep- and Oxidation-Resistant Austenitic Stainless Steels

An austenitic stainless steel HTUPS alloy includes, in weight percent: 15 to 30 Ni; 10 to 15 Cr; 2 to 5 Al; 0.6 to 5 total of at least one of Nb and Ta; no more than 0.3 of combined Ti+V; up to 3 Mo; up to 3 Co; up to 1 W; up to 0.5 Cu; up to 4 Mn; up to 1 Si; 0.05 to 0.15 C; up to 0.15 B; up to 0.05 P; up to 1 total of at least one of Y, La, Ce, Hf, and Zr; less than 0.05 N; and base Fe, wherein the weight percent Fe is greater than the weight percent Ni wherein said alloy forms an external continuous scale comprising alumina, nanometer scale sized particles distributed throughout the microstructure, said particles comprising at least one composition selected from the group consisting of NbC and TaC, and a stable essentially single phase fcc austenitic matrix microstructure, said austenitic matrix being essentially delta-ferrite-free and essentially BCC-phase-free.

Owner:UT BATTELLE LLC

Microfluid reactor based nano-particle preparation and particle controlled preparation process

InactiveCN101618308AImprove stabilityLattice defect minimizationChemical/physical/physico-chemical processesLattice defectsMicrofluidics

The invention discloses a microfluid reactor based nano-particle preparation and a particle controlled preparation process. The particle controlled preparation process is characterized in that technological parameters of particles in different generation steps are regulated and controlled in a nanoliter or smaller scale by a microfluid control technology, particles quickly mix and react to form cores on line, evenly grow up and are quenched to stop growing at low temperature so as to regulate and control the size, the shape, the crystal structure and the surface performance of the particles on line, and the hierarchical structure of the particles can be regulated and controlled. The method effectively inhibits widened size distribution and crystal lattice defect caused by Ostwald ripening and directional binding during nano-particle formation. Compared with a tank stirred reactor which is unable to respectively control the technological parameters of nano-particles in different generation steps, the microfluid reactor can increase the stability of the crystal structure and the physical performance of the particles, and the structure and the performance at least can be stabilized above three months to one year according to the types of the particles. The nano-particle output of the process can reach above 300ml / hour, and the process is an environment-friendly type nano-material continuous scale production process.

Owner:宋玉军

Microwave catalyst for degrading organic wastewater and catalytic oxidation degradation method thereof

InactiveCN103084216AImprove degradation efficiencyReduced photocatalytic efficiencyMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical industryWastewater

The invention discloses a microwave catalyst for degrading organic wastewater and a catalytic oxidation degradation method thereof. The catalyst is of a porous structure and can be used for absorbing microwave, wherein in the adsorption of microwave, oxygen or air is introduced into the catalyst in the presence of water molecules so as to generate a large quantity of OH free radicals under microwave irradiation. By adopting the technical scheme, the microwave catalyst greatly improves the degradation efficiency, greatly shortens the processing time, is easy and feasible to operate, low in investment and operation costs, small in occupying area, complete in degradation, wide in concentration range of degrading the organic wastewater, easy for industrial production and suitable for treatment of organic wastewater in the industries of printing and dyeing, paper making, chemical industry, pharmacy and the like, and can perform continuous scale treatment; and moreover, the secondary pollution is avoided.

Owner:XIANGTAN UNIV

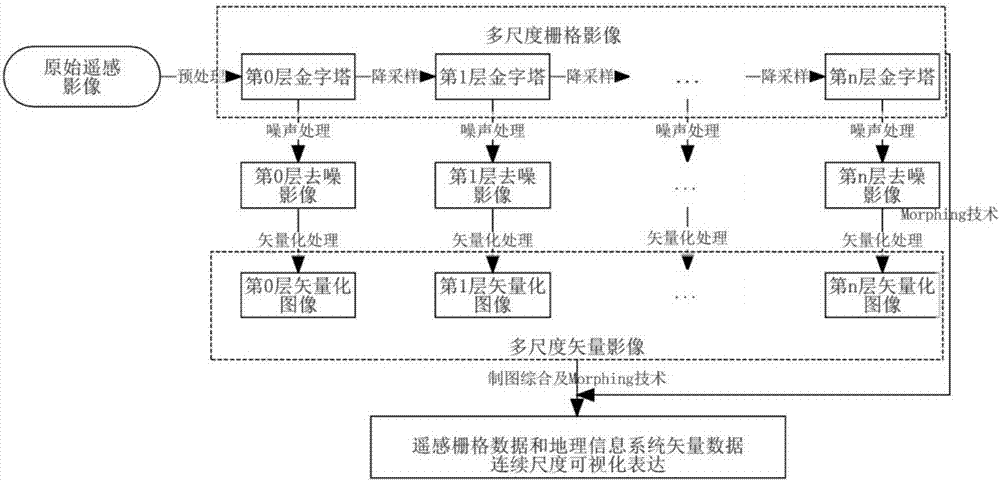

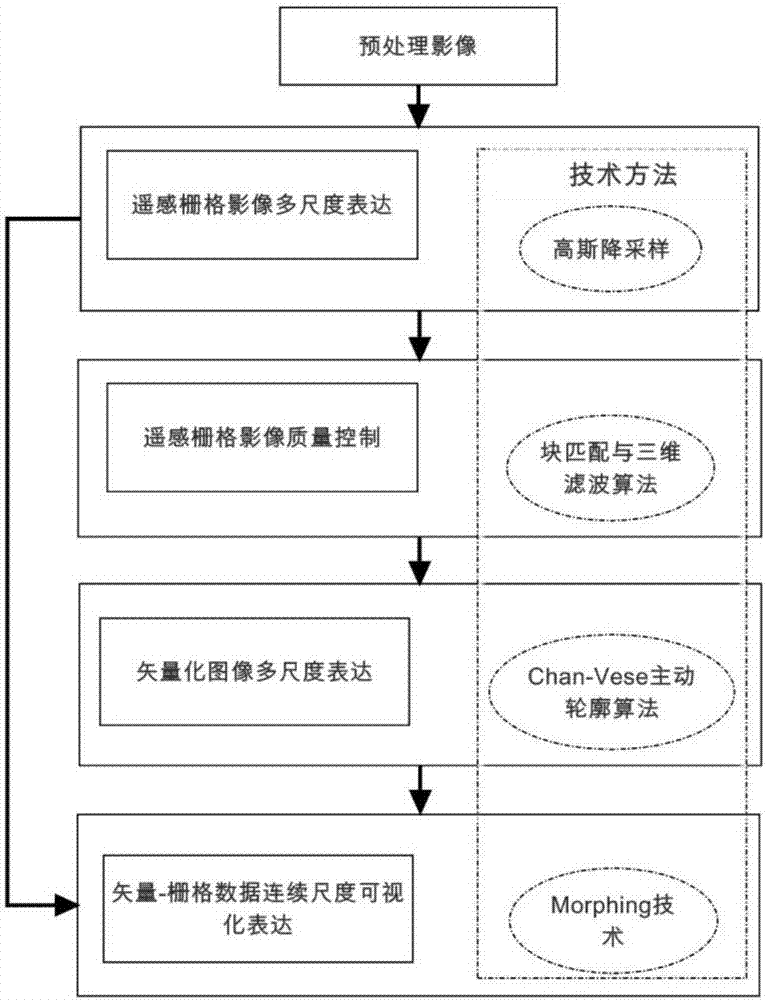

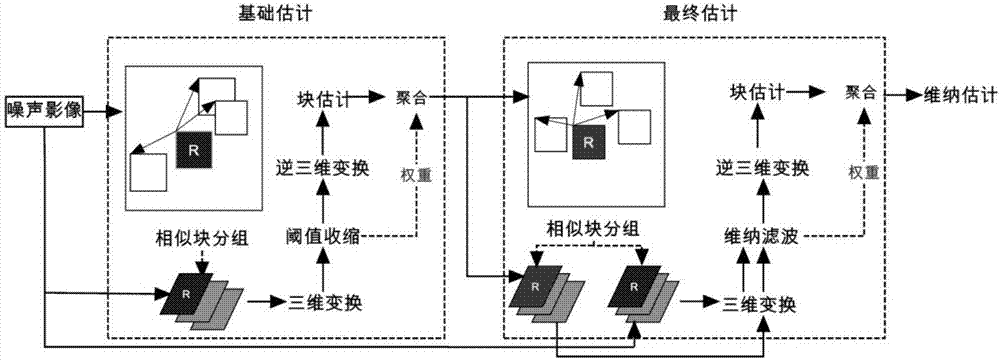

Grid-vector data conversion and continuous scale representation method based on image pyramid

ActiveCN107341837AAutomatic vectorization implementationEasy to handleImage enhancementImage analysisCartographic generalizationComputer science

The invention discloses a grid-vector data conversion and continuous scale representation method based on an image pyramid. The method comprises the following steps of firstly, carrying out preprocessing on a remote sensing image and carrying out multiscale visual representation on the preprocessed image to obtain a multiscale grid remote sensing image; secondly, carrying out noise processing on the multiscale grid remote sensing image obtained in the step 2 and carrying out automatic vectorization operation on the multiscale grid remote sensing image after noise processing; and lastly, carrying out simplification treatment on the image after automatic vectorization operation in order to obtain continuous scale representation of a vector image after simplification treatment. According to the method, the present matured remote sensing image processing technology and cartographic generalization are comprehensively and organically fused, and the automation of grid-vector data conversion of the remote sensing image data and the continuous scale representation of the remote sensing grid data and the map vector data are realized, so that the efficiency and the effect of geographical spatial data processing are greatly improved.

Owner:HUAZHONG NORMAL UNIV

Method for continuously preparing graphene by utilizing ultrasonic wave

The invention provides a method for continuously preparing graphene by utilizing ultrasonic wave. The method is characterized by comprising the following steps: immerging a physical foaming agent into a graphitic layer under high pressure; cracking the graphitic layer by the foaming agent under a heating condition; and ultrasonically cavitating and stripping in a continuous ultrasonic device, thereby realizing the continuous ultrasonic stripping preparation for graphene. Different from the traditional method that the ultrasonic wave is used to damage the graphitic interlayer structure under a liquid phase condition, continuous scaled production is unavailable, and efficiency is low, the method is suitable for large-scale continuous production; the yield of the graphene is increased; the preparation capacity is promoted; the production cost is obviously lowered; the preparation process is nontoxic and harmless; the operation is safe; the process is simple; the after-treatment is simple and easy; and the method is safe and environment-friendly.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

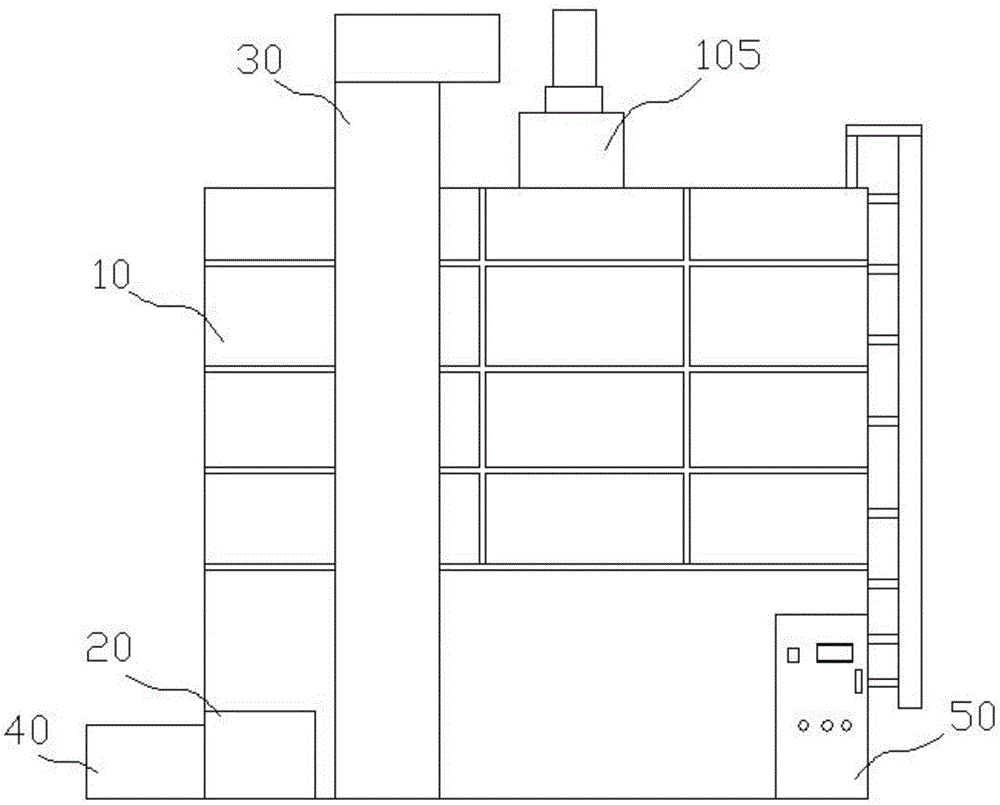

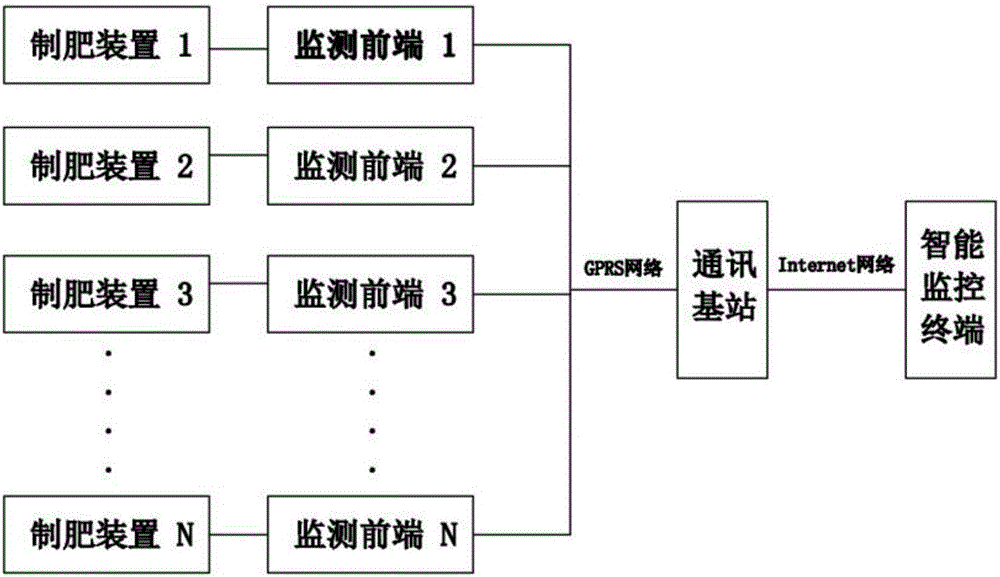

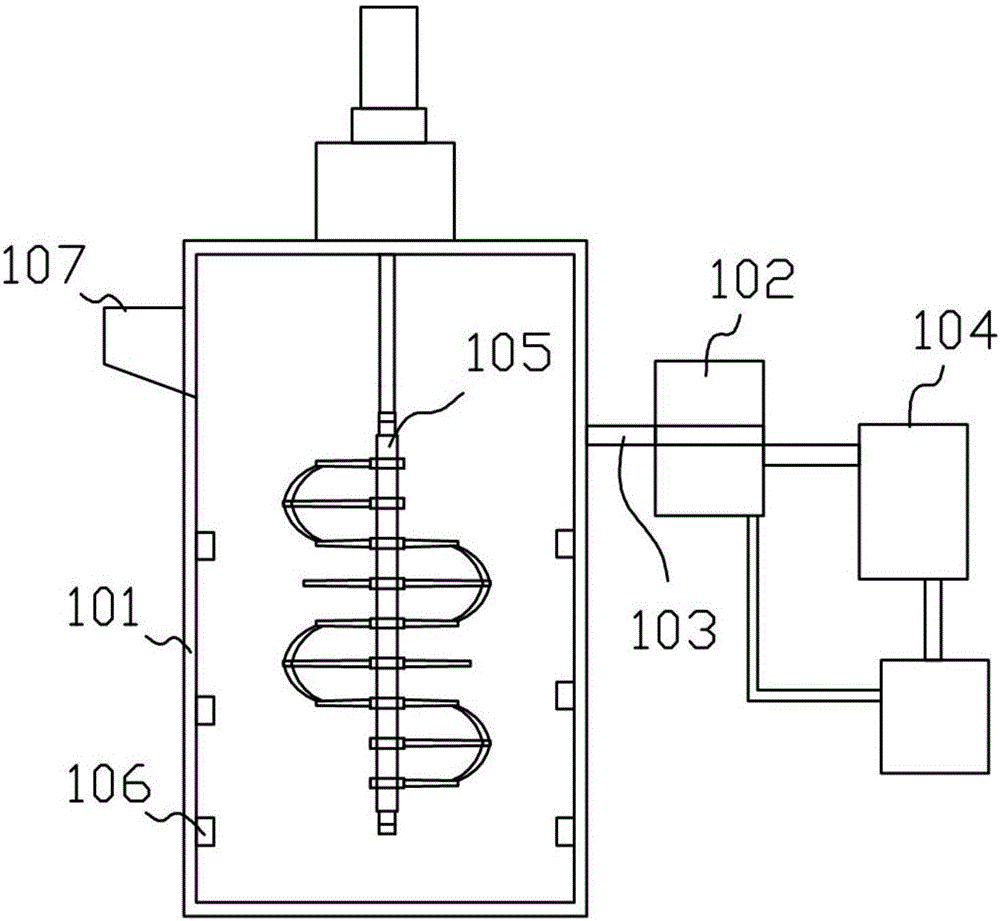

Special fermenting device for high-value development of multifunctional fertilizer by utilizing straws

ActiveCN106747742ARealize automatic heat exchangeMake up for the lack of slow onsetCalcareous fertilisersBio-organic fraction processingDecompositionEngineering

The invention discloses a special fermenting device for high-value development of a multifunctional fertilizer by utilizing straws. The special fermenting device comprises a double-tower fermenting tank, a crushing mechanism, an automatic feeding mechanism and an automatic discharging mechanism; one end of the automatic feeding mechanism is connected with a material outlet end of the crushing mechanism; the other end of the automatic feeding mechanism is connected with a material inlet section of the double-tower fermenting tank; the automatic discharging mechanism is connected with the bottom of the double-tower fermenting tank; an interlayer is arranged in an outer shell of the double-tower fermenting tank; the interlayer is connected with first heat exchange equipment; a heat exchange pipe is arranged in the first heat exchange equipment; the heat exchange pipeline is loaded with a refrigerant internally; an outlet of the heat exchange pipeline is connected with second heat exchange equipment. The overall equipment is high in automation degree and low in energy consumption, and can realize continuous scale production; the product decomposition period is short; the cost is low; the yield is high; the fertilizer efficiency is high; the technology is mature; the process is environment-friendly.

Owner:ANHUI JULI MACHINERY MFG

High Nb, Ta, and Al creep- and oxidation-resistant austenitic stainless steel

An austenitic stainless steel HTUPS alloy includes, in weight percent: 15 to 30 Ni; 10 to 15 Cr; 2 to 5 Al; 0.6 to 5 total of at least one of Nb and Ta; no more than 0.3 of combined Ti+V; up to 3 Mo; up to 3 Co; up to 1 W; up to 0.5 Cu; up to 4 Mn; up to 1 Si; 0.05 to 0.15 C; up to 0.15 B; up to 0.05 P; up to 1 total of at least one of Y, La, Ce, Hf, and Zr; less than 0.05 N; and base Fe, wherein the weight percent Fe is greater than the weight percent Ni wherein said alloy forms an external continuous scale comprising alumina, nanometer scale sized particles distributed throughout the microstructure, said particles comprising at least one composition selected from the group consisting of NbC and TaC, and a stable essentially single phase fcc austenitic matrix microstructure, said austenitic matrix being essentially delta-ferrite-free and essentially BCC-phase-free.

Owner:UT BATTELLE LLC

High Mn austenitic stainless steel

An austenitic stainless steel alloy includes, in weight percent: >4 to 15 Mn; 8 to 15 Ni; 14 to 16 Cr; 2.4 to 3 Al; 0.4 to 1 total of at least one of Nb and Ta; 0.05 to 0.2 C; 0.01 to 0.02 B; no more than 0.3 of combined Ti+V; up to 3 Mo; up to 3 Co; up to 1W; up to 3 Cu; up to 1 Si; up to 0.05 P; up to 1 total of at least one of Y, La, Ce, Hf, and Zr; less than 0.05 N; and base Fe, wherein the weight percent Fe is greater than the weight percent Ni, and wherein the alloy forms an external continuous scale including alumina, nanometer scale sized particles distributed throughout the microstructure, the particles including at least one of NbC and TaC, and a stable essentially single phase FCC austenitic matrix microstructure that is essentially delta-ferrite-free and essentially BCC-phase-free.

Owner:UT BATTELLE LLC

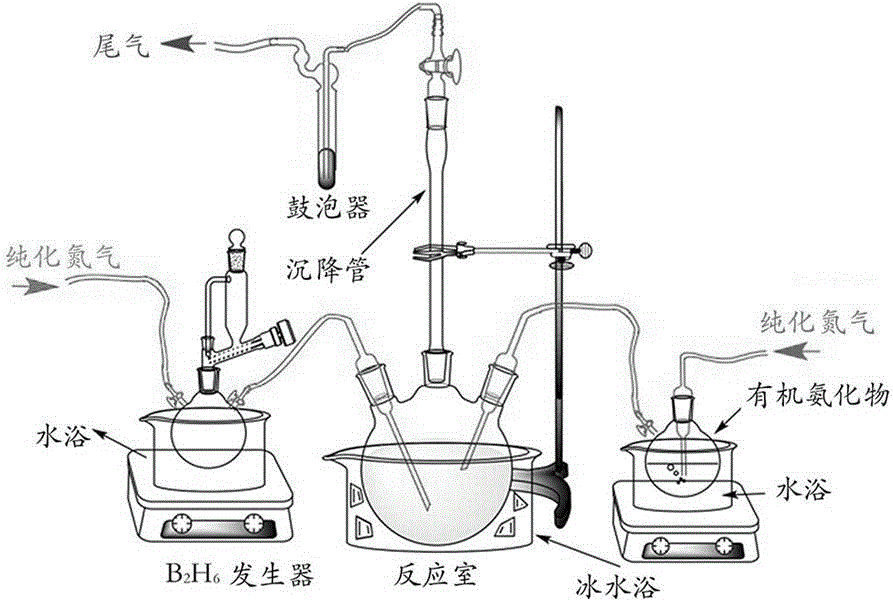

Production method of amine borane complex

InactiveCN104628755AHigh purityAvoid direct manipulationGroup 3/13 element organic compoundsToxic gasMaterials preparation

The invention belongs to the technical field of material preparation, and particularly relates to a production method of an amine borane complex. The production method provided by the invention comprises the following steps: directly reacting borane with inert gas flow of amine, regulating and controlling the proportion of the two components, and carrying out further aftertreatment if necessary to prepare the final product, namely the amine borane complex. No salt impurities are introduced in the reaction process, and no organic solvent is used; such safe reagents as hydroboron are used for producing the borane, and the borane is used once being prepared to avoid the direct operation of the toxic gas borane. The method provided by the invention is simple to operate, high in product purity, low in cost and capable of achieving continuous scale production. Meanwhile, the method is compatible with equipment for producing the amine borane complex in other manners, and the production equipment can be used for producing via the method after simple adjustment.

Owner:FUDAN UNIV

Nano-copper antibacterial plastic masterbatch

The invention discloses a nano-copperantibacterial plastic masterbatch, which is prepared from the following components in parts by mass: 50 to 65 parts of nanometer-sized neodymium oxide, 8 to 15 parts of polypropylene, 1 to 5 parts of nano-copper powder antibacterial agent, 0.1 to 5 parts of coupling agent, 0.1 to 5 parts of dispersing agent, 2 to 8 parts of polypropylene wax, 50 to 65 parts of nanometer titania antibacterial agent, 20 to 40 parts of plastic resin, 20 to 70 parts of carrier resin, 15 to 40 parts of pigment, 15 to 40 parts of filler, 0.5 to 2 parts of antioxygen, and 0.5 to 9 parts of dispersing agent. The antibacterial plastic masterbatch disclosed by the invention has the advantages of simple production process, high universality, good processability, capability of continuous large-scale production and the like; a plastic product obtained through plastic processing methods such as injection molding and extruding has a favorable antibacterial effect; the adding of the antibacterial master batch cannot influence the mechanical performance of the plastic product.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Edible camellia oil cold pressing process

InactiveCN103773592AQuality improvementOutstanding inherent flavorFatty-oils/fats productionEdible oils/fatsOil and greaseAgricultural engineering

The present invention discloses an edible camellia oil cold pressing process, which is performed through simply-configured equipment, has advantages of simple process, good crude oil quality, energy source saving, low running cost, less equipment investment, small occupation area and the like, and achieves continuous scale production. According to the present invention, the low energy consumption microwave conditioning machine is arranged, and the irradiation treatment is performed on microwave tea seeds to overcome the defect of mechanical cell wall breaking, such that greases in cells are completely at the free state so as to improve the oil yield; and nutrients in tea oil can be stored to the maximal degree, the flavor of the tea seed oil is prominent, and the high-quality primary tea oil can be obtained.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

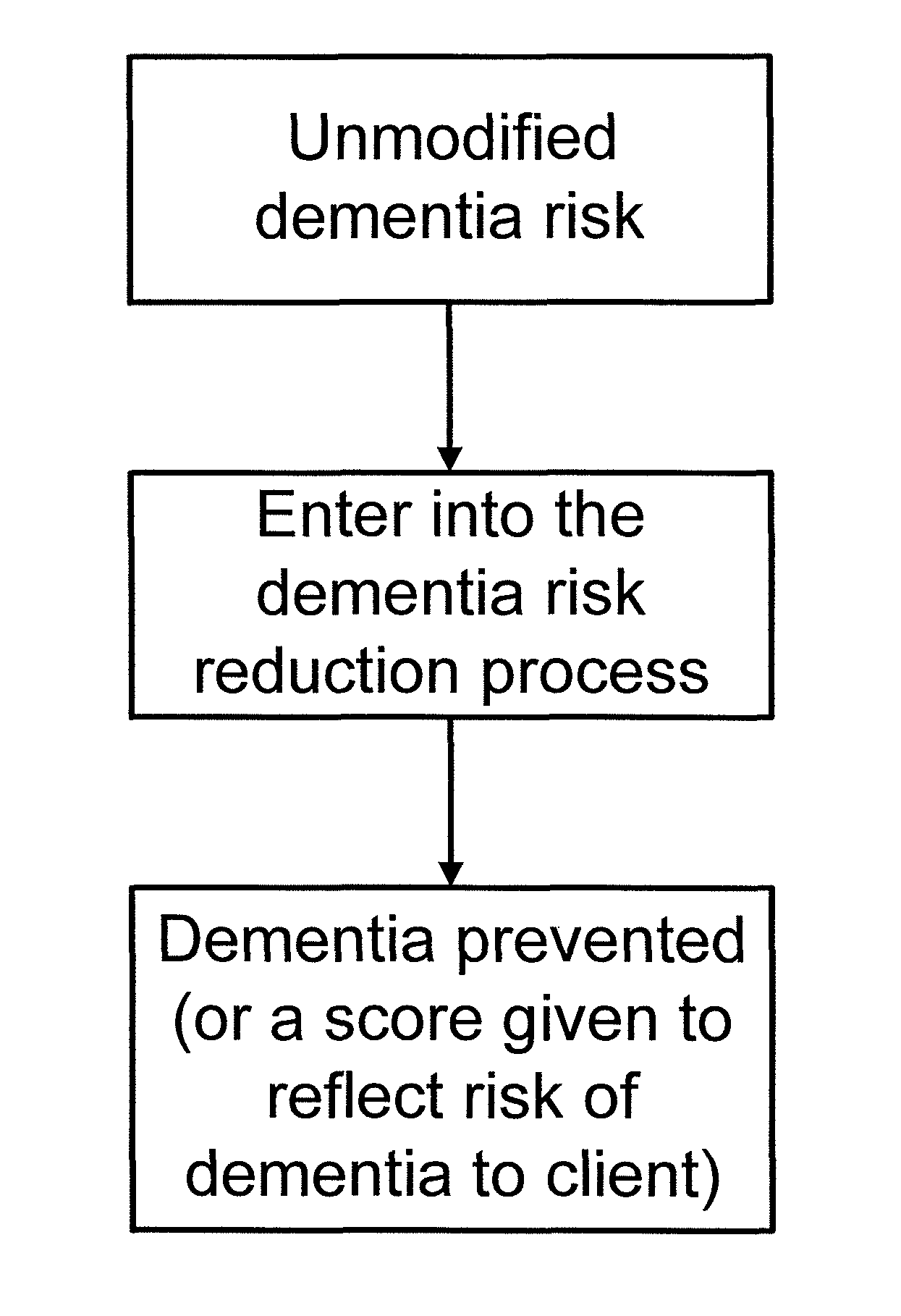

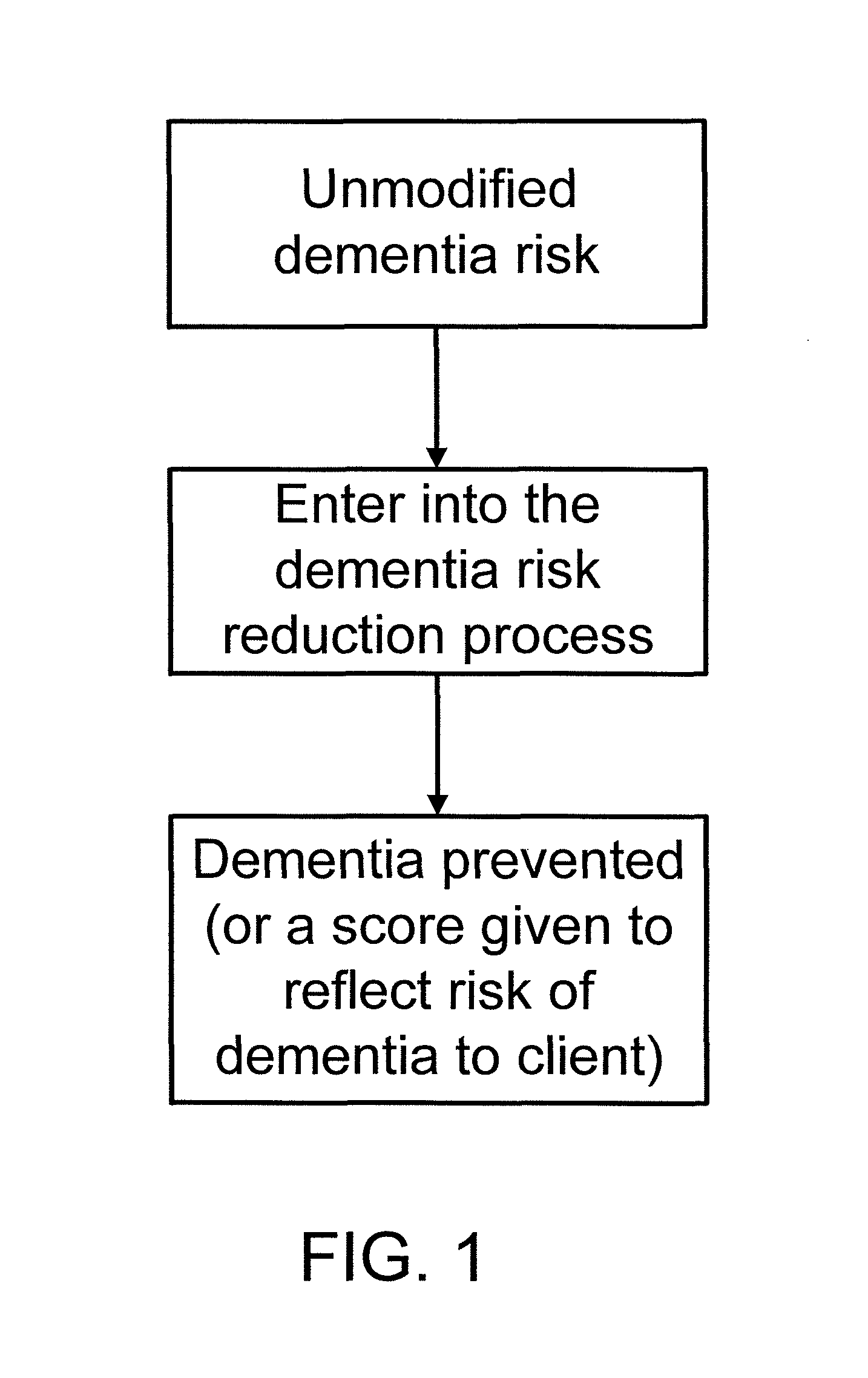

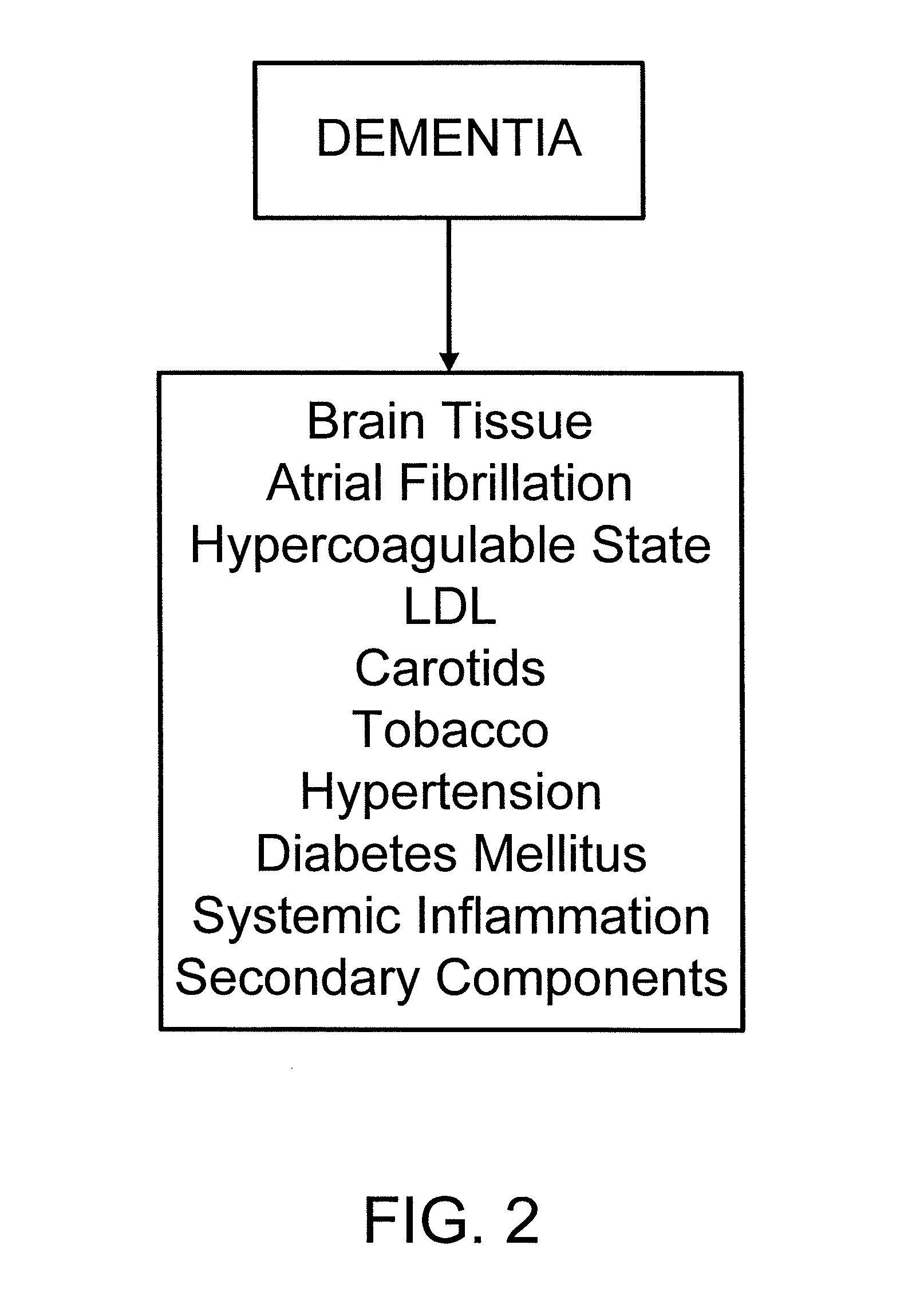

Method for the prevention of dementia and Alzheimer's disease

ActiveUS8708906B1Preventing dementiaHealth-index calculationDiagnostic recording/measuringCvd riskPrevention of dementia

A method for the prevention of dementia is provided including the steps of testing, in a client, for a dementia risk factors (including those related to brain tissue, atrial fibrillation, hypercoaguable state, LDL cholesterol, carotid artery evaluation, tobacco use, hypertension, and inflammation evaluation), determining a score for each of the risk factors tested, wherein each score is based on a continuous scale from a low number to a high number, wherein a low number corresponds to a relatively low likelihood of dementia risk and a high number corresponds to a relatively low likelihood of dementia risk, applying all of the scores obtained to an equation that yields a resulting value proportional to an overall risk of dementia, and providing dementia risk reduction advice to the client to lower the scores for each of the components.

Owner:OREHEK ALLEN J

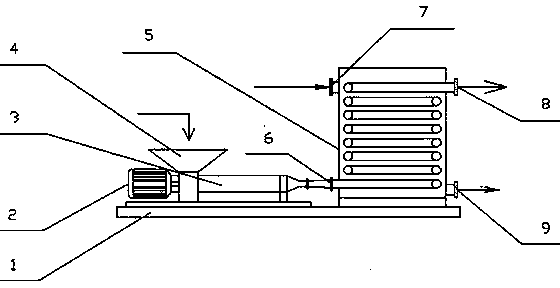

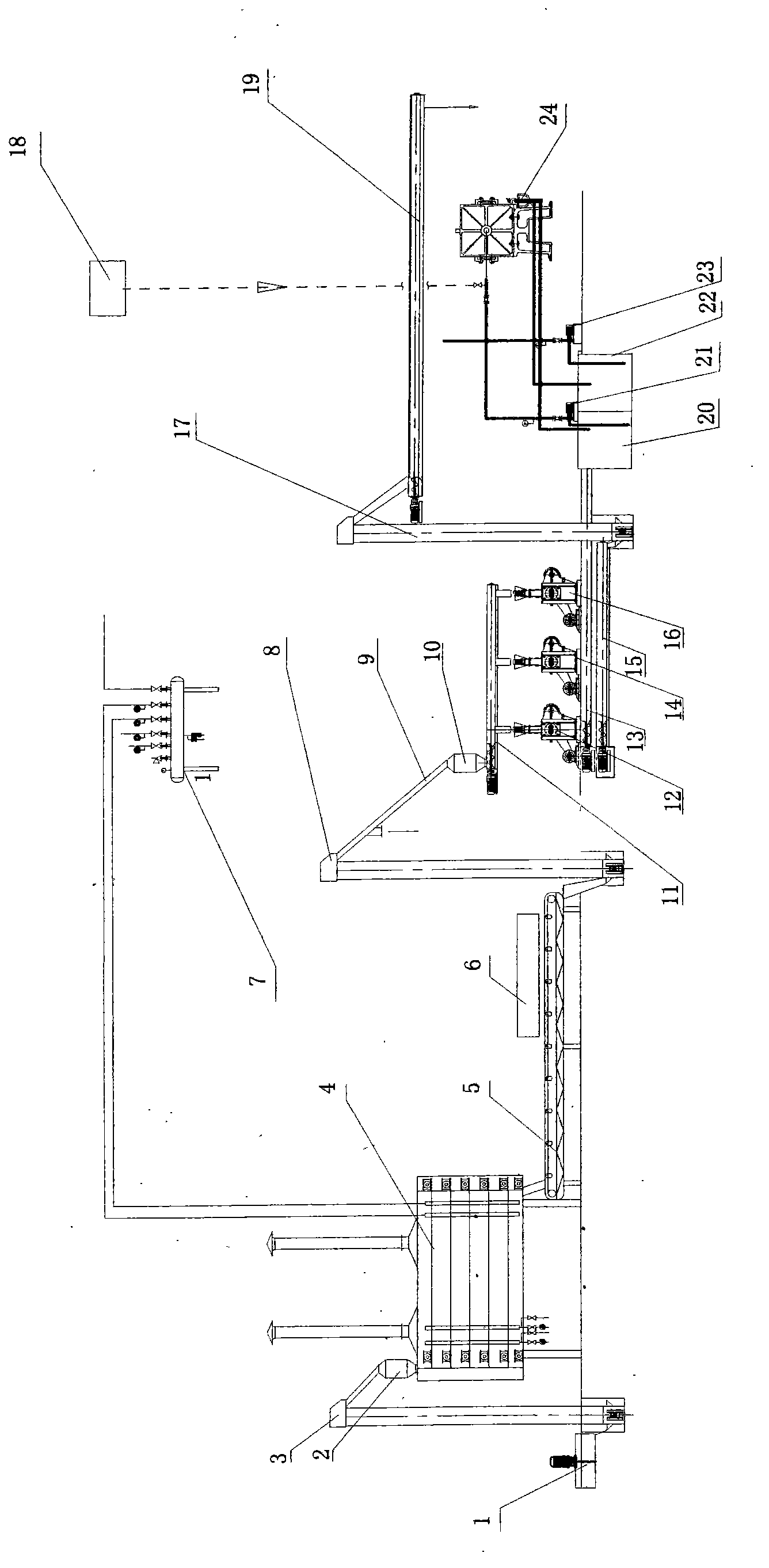

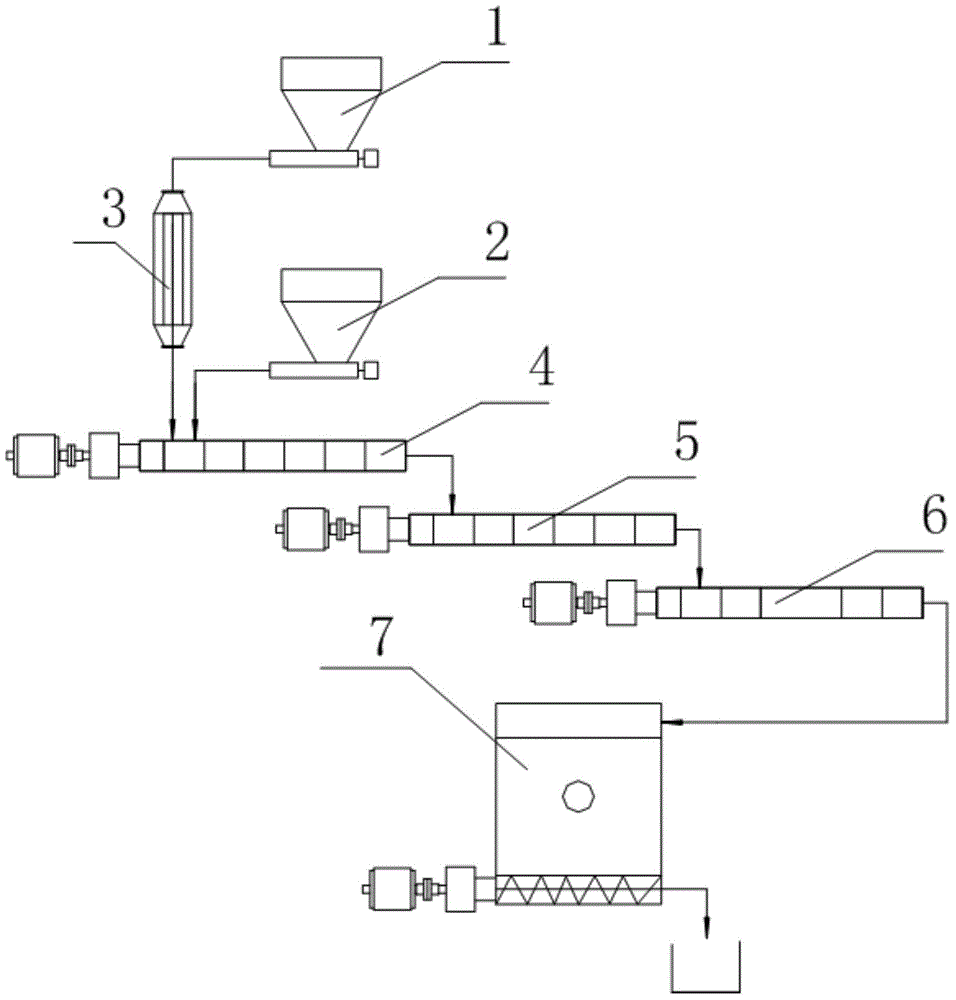

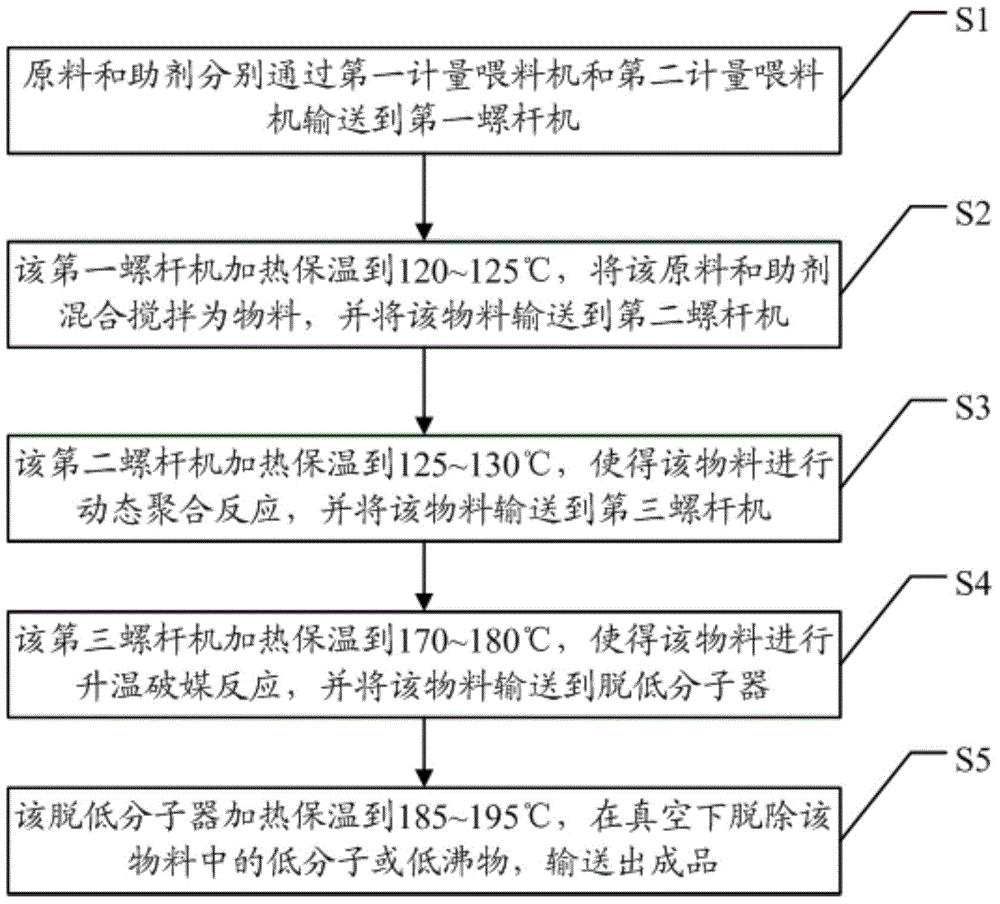

Continuous production method and production line of organic silicon high polymers

InactiveCN104589547ARealize continuous large-scale productionIncrease productivityProduction linePulp and paper industry

The embodiment of the invention discloses a production line of organic silicon high polymers, and the production line is used for solving the technical problems that continuous large-scale production cannot be achieved and the production efficiency is low. The production line of organic silicon high polymers in the embodiment of the invention comprises a first metering and feeding machine, a second metering and feeding machine, a first screw machine, a second screw machine, a third screw machine and a low molecule remover; the discharge openings of the first metering and feeding machine and the second measuring feeding machine are respectively connected with the feed opening of the first screw machine; the first screw machine, the second screw machine, the third screw machine and the low molecule remover are connected in sequence; heating equipment is installed on each of the first screw machine, the second screw machine and the third screw machine; vacuum equipment is installed on the low molecule remover.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

Preparation method of para-aramid and graphene oxide/graphene composite paper

ActiveCN110055807ASimple methodReduce manufacturing costSynthetic cellulose/non-cellulose material pulp/paperInorganic compound additionDispersityPapermaking

The invention relates to a preparation method of para-aramid and graphene oxide / graphene composite paper and belongs to the technical field of high molecular materials. The preparation method includes: utilizing a polymerization one-step process without a surfactant added to prepare para-aramid nanofiber water dispersion liquid, utilizing the characteristic that para aramid nanofiber and grapheneoxide have high dispersity in water to well mix two dispersion liquids proportionally, and utilizing a conventional papermaking method to prepare the para-aramid / graphene oxide composite paper; utilizing a wet process or a dry process to reduce graphene oxide to obtain the para-aramid / graphene composite paper. Compared with the prior art, the preparation method has the advantages that the para-aramid and graphene / graphene oxide composite paper can be produced continuously on a large scale, the obtained composite paper has excellent performance, and the preparation method is friendly in corresponding production environment, low in cost and simple in process..

Owner:TSINGHUA UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com