Microwave catalyst for degrading organic wastewater and catalytic oxidation degradation method thereof

A technology for microwave catalytic oxidation and organic wastewater, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. Short time and other issues, to achieve the effect of shortened processing time, low investment and operating costs, and complete degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Microwave catalytic reaction: Measure 100mL of 100mg / L methyl orange wastewater into a 500mL Erlenmeyer flask, add 1.8g of the catalyst prepared under the above conditions, and catalyze the reaction under the condition of microwave power of 600W.

[0043] Table 1 Microwave power is the degradation situation within 4-12min under 600W

[0044] time (min)

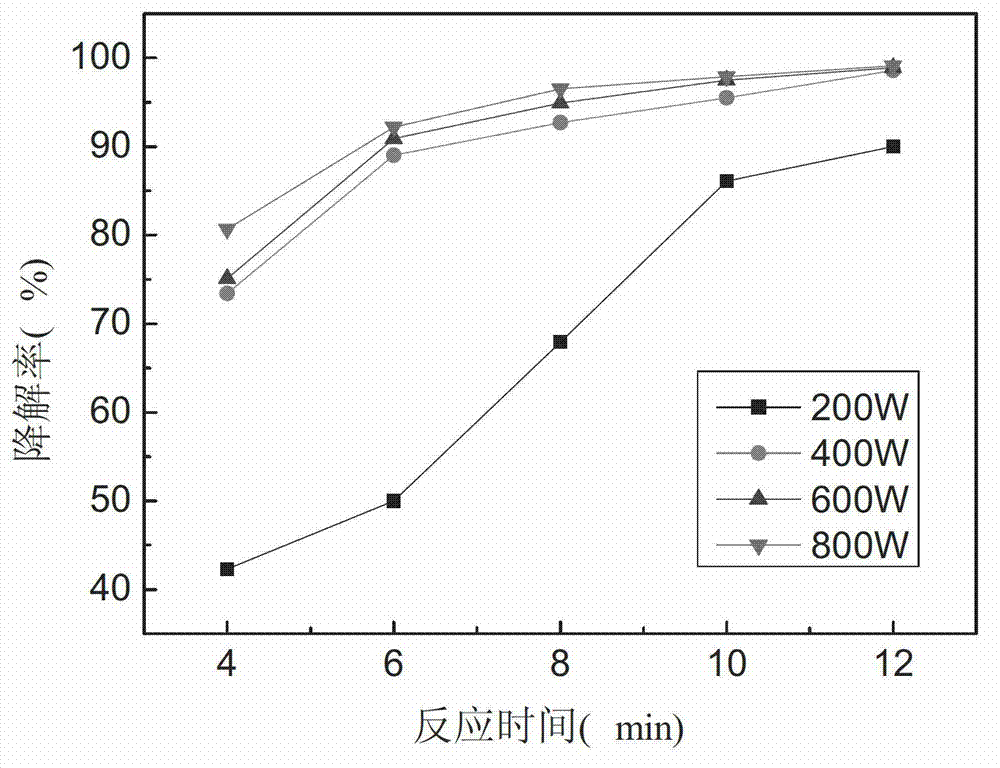

[0045] By adjusting the microwave irradiation power in this test method to be 200W, 400W, and 800W respectively, and treating 100mL of 100mg / L methyl orange wastewater, the initial concentration of methyl orange treated by this test method under different microwave powers is 100mg / L. The removal rate of organic matter in the solution is drawn as a curve, such as figure 1shown. It can be seen from the figure that the greater the microwave power, the greater the degradation rate of organic pollutants in wastewater. When the microwave power is 800W, the degradation rate reaches 99.1% after 12 minutes of microwav...

Embodiment 2

[0046] The impact of embodiment 2 catalyst dosage on methyl orange wastewater degradation rate

[0047] Measure 100mL of 100mg / L methyl orange wastewater into a 500mL Erlenmeyer flask with a microwave power of 600W and a catalyst dosage of 2.2g. The reaction is catalyzed under microwave conditions.

[0048] Table 2 Catalyst dosage is the degradation situation within 4~12min under 2.2g

[0049] time (min)

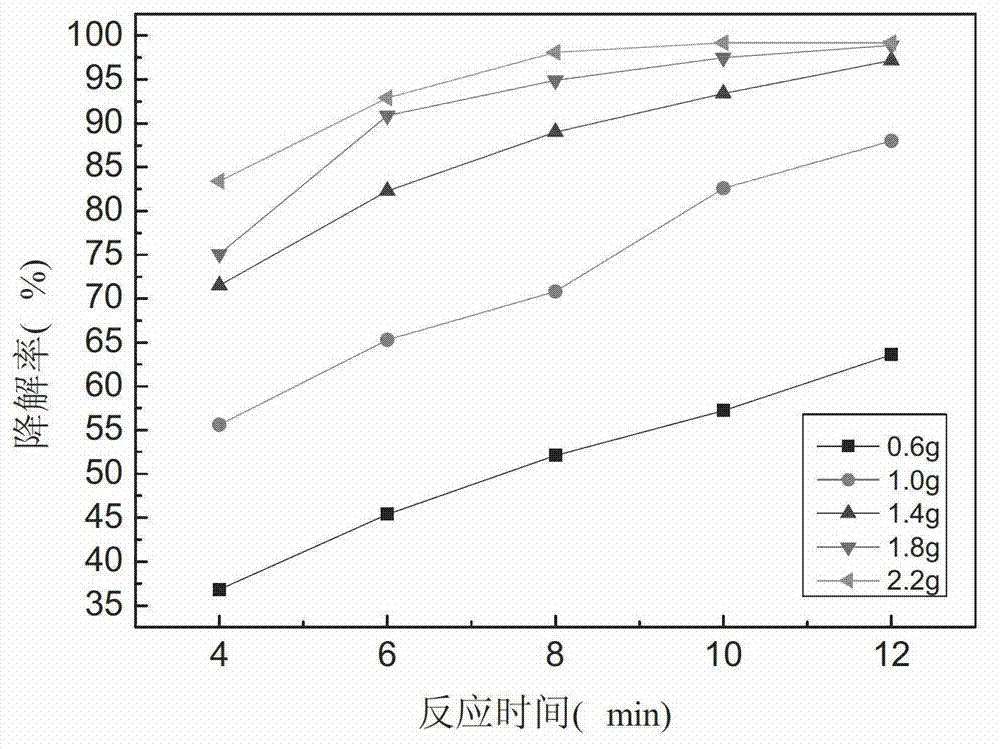

[0050] By adjusting the amount of catalyst in this test method to be 0.6g, 1.0g, 1.4g, 1.8g respectively, the methyl orange wastewater of 100mL100mg / L is processed, and the initial concentration of methyl orange obtained by using this test method under different catalyst amounts is The removal rate of organic matter in the solution of 100mg / L is drawn into a curve, such as figure 2 shown. It can be seen from the figure that the greater the amount of catalyst used, the greater the degradation rate of organic pollutants in wastewater. When the amount of catalyst ...

Embodiment 3

[0051] The impact of the initial concentration of embodiment 3 organic matter on degradation rate

[0052] Measure 100mL of 150mg / L methyl orange wastewater into a 500mL Erlenmeyer flask with a microwave power of 600W and a catalyst dosage of 1.8g. Catalyzed reaction under microwave conditions..

[0053] Table 3 The initial concentration of organic matter is 150mg / L, the degradation situation within 4 ~ 12min

[0054] time (min)

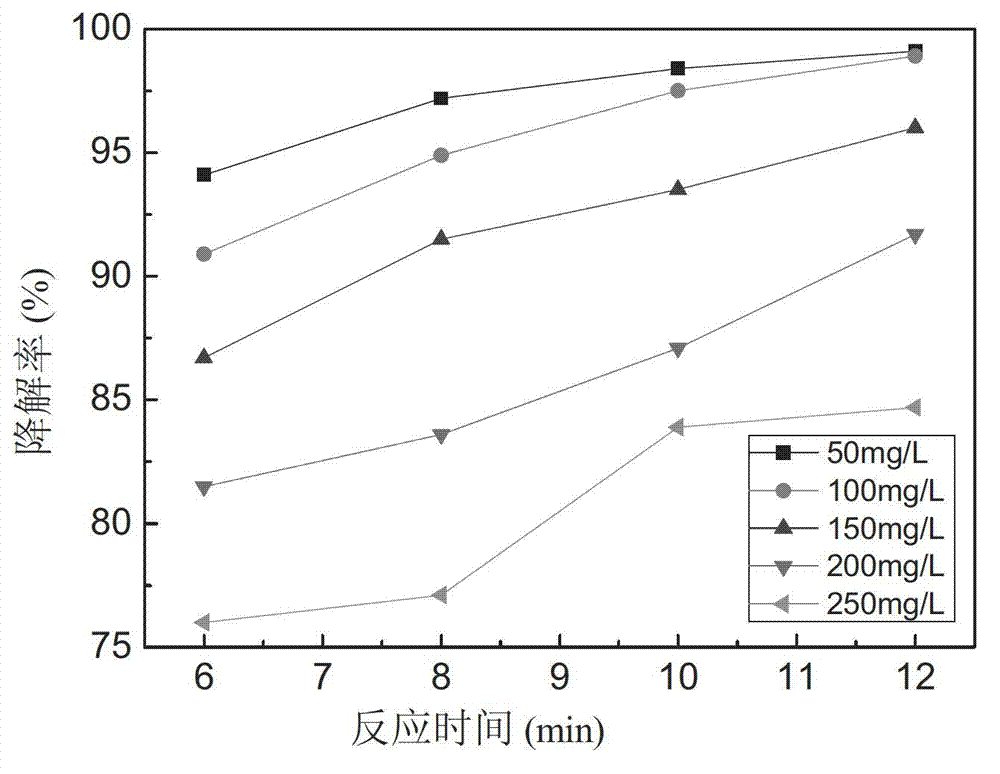

[0055] By adjusting the initial concentration of organic matter in this test method to be 50mg / L, 100mg / L, 200mg / L, and 250mg / L, the removal rate of organic matter treated by this test method under different initial concentrations of organic matter is obtained, and the curve is drawn, such as image 3 shown. It can be seen from the figure that the degradation rate decreases with the increase of the initial concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com