Patents

Literature

154results about How to "Short degradation cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making fermenting bed for ecological pig breeding by using composite strain culture

InactiveCN101565684AShort degradation cycleStrong bacterial activityFungiBacteriaMicroorganismStart time

The invention discloses a method for making a fermenting bed for ecological pig breeding by using composite strain culture, in particular relates to a method for making the fermenting bed by using a plurality of microorganisms. The invention comprises the steps of preparing the culture and making the fermenting bed. In the invention, the culture is mainly prepared by microzyme, lactobacillus, actinomycetes, photosynthetic bacterium and mycelial fungus according to proportion. The culture after being activated is stirred uniformly with organic padding pro rata, piled, fermented, prepared into the fermenting bed, and then can be used for breeding live pigs. The method solves the problems of long fermenting starting time of the organic padding, unstable microbial inoculum, strict requirements on the fermenting conditions and materials as well as short service life in the existing ecological pig breeding method. The method uses the composite strain culture to build ecological colony house; the fermenting starting time of the organic padding is short, which can be 1 to 2 days in summer and 3 to 5 days in winter; the strain activity is strong; the decomposing process can be finished in 1 to 3 days; the effect lasts for long; and the fermenting bed can be continuously used for 5 to 8 years. Moreover, the method is green and environmental friendly.

Owner:千智伟

Technique for preparing biogas by high-temperature anaerobic zymosis method using animal manure as raw material

InactiveCN101358209AQuality assuranceImprove filtration efficiencyBio-organic fraction processingClimate change adaptationSludgeAnimal feces

The present invention relates to a technique which utilizes animal and poultry feces as material to prepare biogas underground by anaerobic fermentation, which belongs to the technical field of environment-friendly energy. The technique utilizes the cheap animal and poultry feces as material, in which liquid dung or active sludge perennially accumulated in a farm is added when fermentation is started; high temperature can ensure good growth, thus increasing fermentation efficiency; by a high temperature of 58 DEG C plus or minus 1 DEG C and 8 to 30 grades of anaerobic fermentation, the degradation period of feces and sludge can be shortened; harmful bacteria can be thoroughly sterilized in order to ensure harmlessness; moreover, the post-fermentation biogas residue and biogas slurry can be used as high-quality organic manure; and the produced residual heat can be used for fermentation heat supply or factory heat preservation and heating.

Owner:张永军

Hemostatic material in medical use

InactiveCN1727013AGood biocompatibilityImprove ductilitySurgical adhesivesPharmaceutical containersLactideTriol

A medical styptic material able to be fully absorbed and degradated is composed of the basic material prepared by fusion polycondensation reaction of low-molecular poly-DL-lactic acid or poly-L-lactic acid or polyethanol-acid copolymer / mixture, and the auxiliary which may be polyether diol, polyether triol, high-molecular polylactic acid, high-molecular glycolide-lactide copolymer, high-molecular caprolactone-lactide copolymer, or high-molecular caprolactone-glycolide copolymer through fusion and mixing.

Owner:HUIZHOU HUAYANG MEDICAL EQUIP

Biodegradable environment protection tableware and its processing method

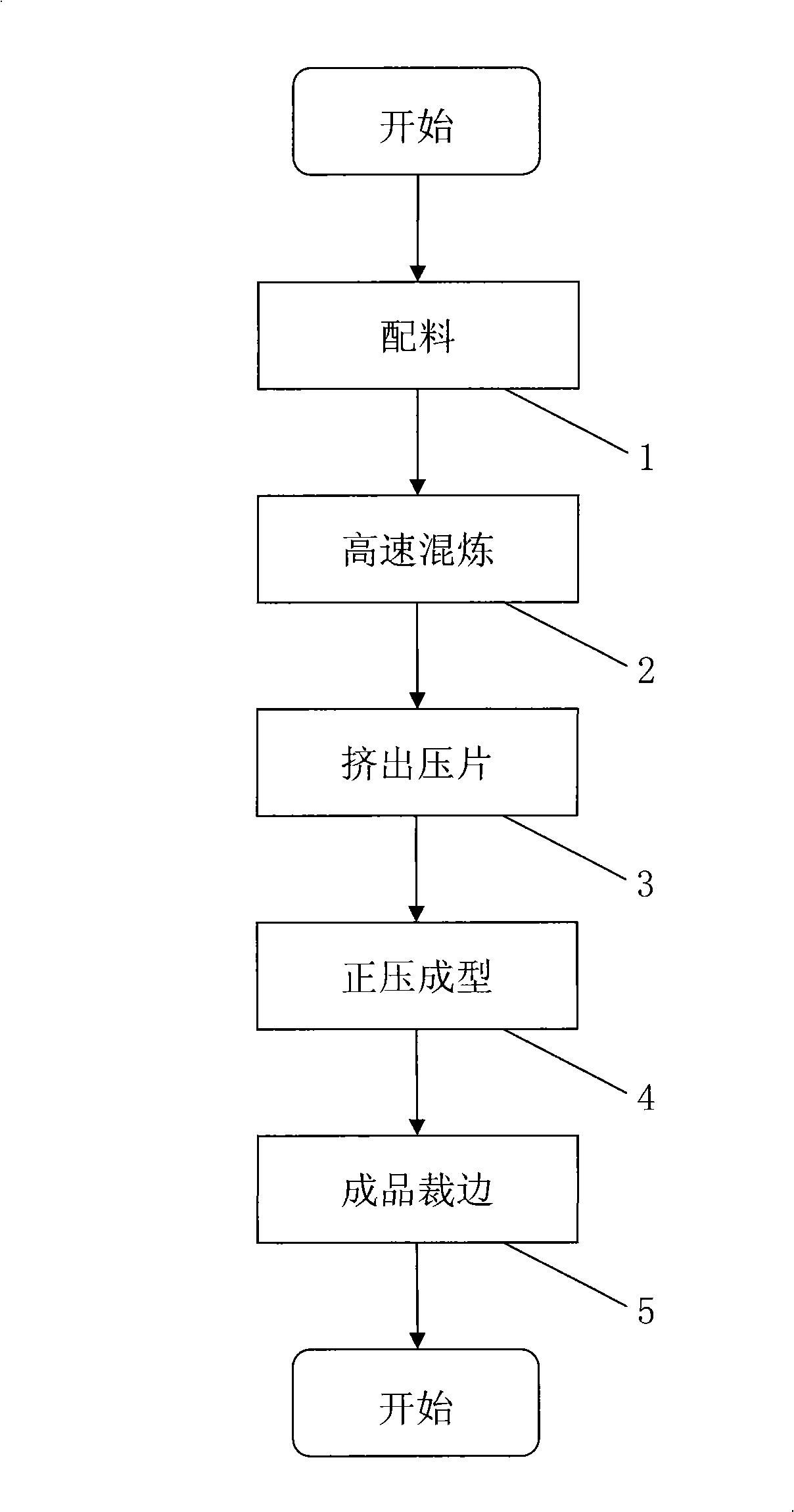

ActiveCN101293975AHigh mechanical strengthEasy to useTable equipmentsLow-density polyethylenePositive pressure

The invention discloses a biodegradable tableware which contains the following components in weight percentage: 30-60% of starch, 2.5-7% of low-density polyethylene, 20-42% of polyethylene, 1-3% of polyethylene wax, 1-2% of glyceryl monostearate, 3-5% of ethylene-vinyl acetate copolymer, 1-3% of titanium white powder, 2-6% of light calcium carbonate, 1-3% of talc powder, 0.2-0.5% of Al-Ti composite coupler, 0.01-0.02% of modifier, 0.1-0.2% of anti-oxygen agent and 0.04-0.06 of antioxidant. The invention also discloses a method for processing the biodegradable tableware. The method comprises the steps of proportioning, mixing and melting at high speed, extruding and tabletting, molding under positive pressure, trimming and finishing, etc. The invention modifies the formulation and the corresponding production process, so that the biodegradable tableware is not fragile and has high mechanical strength. The biodegradable tableware has water-proof and oil-proof functions without needing inner coating, and can be degraded completely in a short degradation period.

Owner:HUZHOU GLOBAL XINYIFENG ENVIRONMENTAL PROTECTION TECH

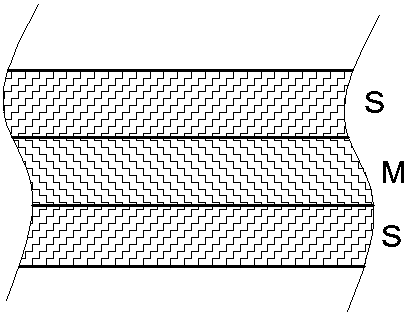

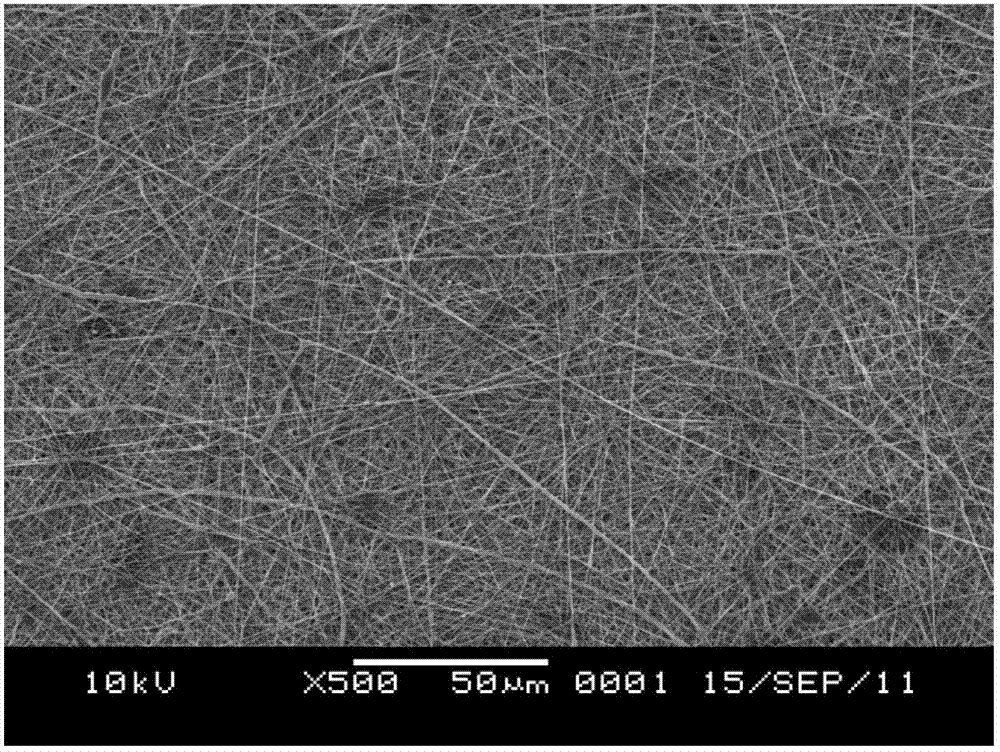

Spunbonded pulp non-woven fabric

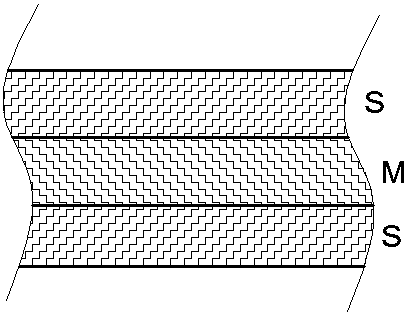

The invention discloses a spunbonded pulp non-woven fabric. The spunbonded pulp non-woven fabric comprises three layer structures which are bonded together by hot pressing; the first layer and the third layer are spunbond non-woven material layer, and the second layer as an intermediate layer is cellulose fiber layer; the spunbonded non-woven material layer of the first layer is melt-blown non-woven fabric, spunbonded non-woven fabric or melt-blown spunbonded composite non-woven fabric, and the melt-blown spunbonded composite non-woven fabric is an SMS or an MSM or an MS or an SM; the second layer, the cellulose fiber layer, is a mixture of cellulose fiber pulp and hot melt fiber. The cellulose fiber pulp is compounded with the melt-blown non-woven material through the hot melt fiber, comparing with the cellulose fiber is firstly prepared, the cellulose fiber is compounded with the melt-blown non-woven material through spunlace process, the loss of the wood pulp short fiber is avoided,and the process is simpler, the production is more convenient, the cost is lower, while the same hydrophilic and oleophilic property is ensured, the competitiveness of the product can be greatly improved, and the produced non-woven fabric is used for manufacturing the wiping cloth.

Owner:郑州豫力新材料科技有限公司

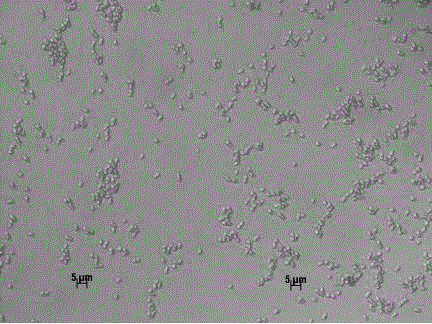

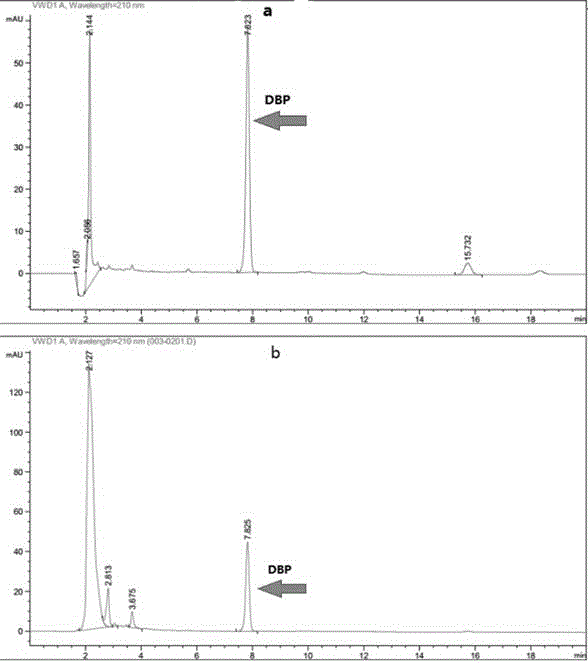

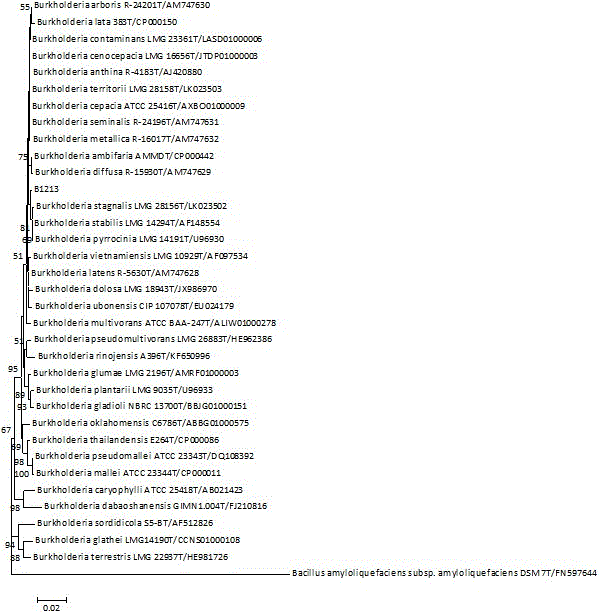

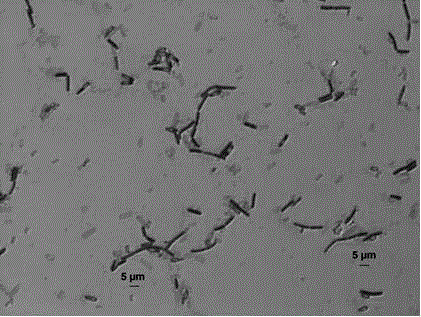

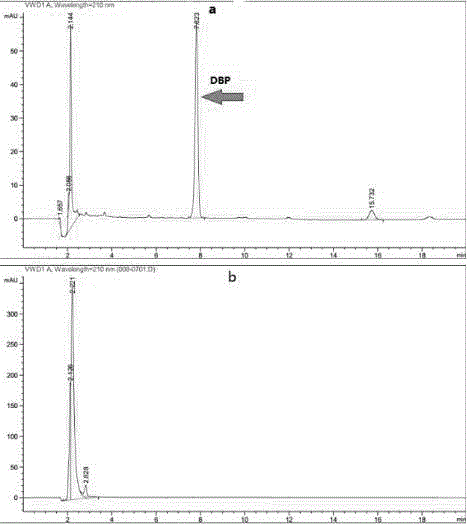

Burkholderia pyrrocinia and application thereof

ActiveCN106244508AImprove degradation rateShort degradation cycleBacteriaMicroorganism based processesBacteroidesPyrrole

The invention relates to burkholderia pyrrocinia and application thereof, which belong to the field of environmental microorganism application. The burkholderia pyrrocinia B1213 provided by the invention has the preservation No. CGMCC No.12806, is preserved on July 21, 2016, belongs to a bacilliform gram-negative bacterium, and cannot form gemma. The burkholderia pyrrocinia B1213 provided by the invention can degrade dibutyl phthalate (DBP); the degradation rate of the DBP can reach up to 45.5 to 75.35 percent. A method for adopting the burkholderia pyrrocinia B1213 provided by the invention to degrade the DBP is characterized in that in the presence of a yeast extract, the burkholderia pyrrocinia B1213 is contacted with DBP. Compared with a method for adopting bacteria and fungus to degrade the DBP, the method for degrading the DBP provided by the invention is novel in strain source, high in degradation rate, short in degradation period, and simple to operate.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

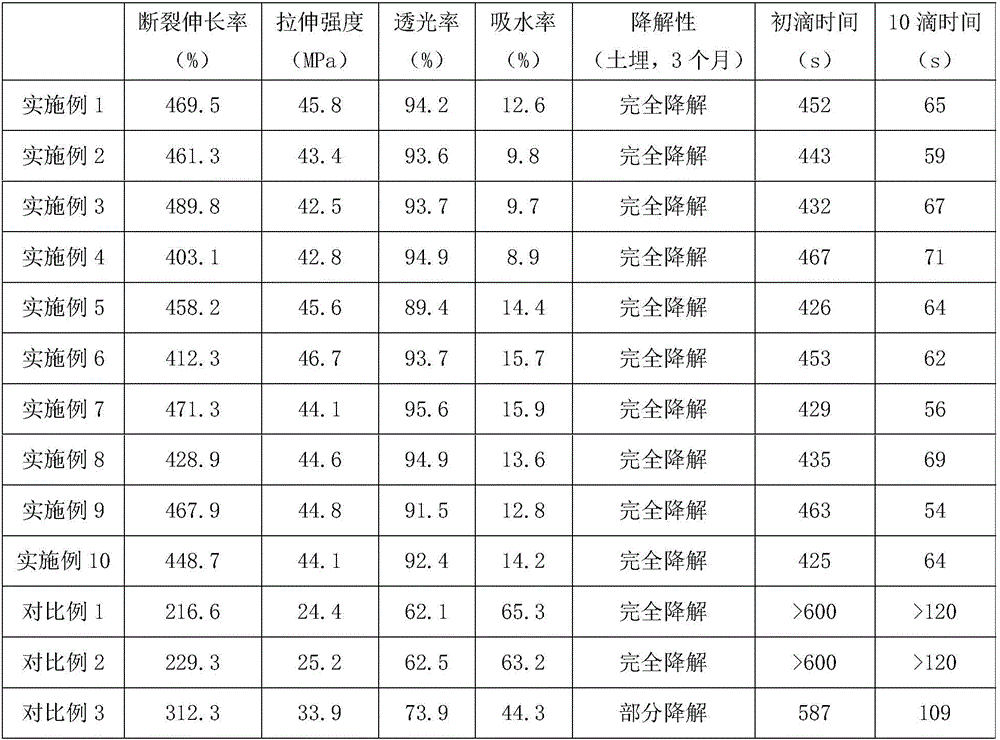

Thermoplastic starch-polyvinyl alcohol fogging-resistance film and preparation method thereof

The invention relates to a thermoplastic starch-polyvinyl alcohol fogging-resistance film which is prepared from the following raw materials in parts by weight: 60 to 70 parts of thermoplastic starch, 40 to 60 parts of polyvinyl alcohol, 25 to 40 parts of compound plasticizer, 5 to 15 parts of cross-linking agent, 5 to 10 parts of antifogging agent, 0.5 to 1 part of titanium dioxide and 1 to 2 parts of other additives; the compound plasticizer is combination of glycerinum, diethanol amine and citric acid, wherein the weight ratio of the lycerinum to the diethanol amine to the citric acid is 1:1:1 to 2:2:1. The thermoplastic starch-polyvinyl alcohol fogging-resistance film provided by the invention has a good antifogging effect, high transparency and excellent water resistance and mechanical property, can be completely biodegraded, can be produced by using a traditional plastics processing equipment, and is simple and easy to process and easy to popularize, and the degradation period is short.

Owner:QINGDAO UNIV OF SCI & TECH +1

Method for degrading landscaping garbage to produce organic fertilizer by utilizing high-efficiency mixed bacteria

InactiveCN101987794AChange physical stateChange molecular structureClimate change adaptationOrganic fertilisersDecompositionLandscaping

The invention relates to a method for degrading landscaping garbage to produce an organic fertilizer by utilizing high-efficiency mixed bacteria, which comprises the steps: (1) organic matters of the landscaping garbage are sterilized after being crushed; (2) nutrition substrates, lignin and cellulose degradation bacteria are added to the solid phase; (3) the mixture is irradiated for 20 minutes every other 8 hours by adopting low-frequency ultrasonic wave until the fourth to seventh day of the fermentation cultivation after the fermentation cultivation for 24 to 26h; and (4) the sterilization processing is carried out to obtain the finished product organic fertilizer after the thoroughly decomposition for 1 to 3 days. The method has the advantages of simple required equipment, simple andconvenient process, and safety disposal realization of the landscaping garbage. Meanwhile, the method produces the organic fertilizer capable of promoting the growth of crops, solves the difficultiesof difficult degradation and difficult recycle of the current landscaping garbage, and has extremely profound social significance and economic value.

Owner:NANKAI UNIV +1

Degradation bacterium for oil-base drilling cuttings, and preparation method and application method thereof

ActiveCN104312936AIncreased degradation rateShort degradation cycleBacteriaWater contaminantsBioremediationKocuria kristinae

The invention discloses a degradation bacterium for oil-base drilling cuttings, and a preparation method and an application method thereof, and belongs to the technical field of microbiological processing of oil-containing solid wastes. The degradation bacterium for oil-base drilling cuttings is composed of multiple microorganisms, and is prepared by performing fermentation culturing on three degradation single bacteria which are obtained by performing enriching, separation, purification and screening on bacteria in petroleum polluted soil. The degradation bacterium for oil-base drilling cuttings comprises pPseudomonas aeruginosa, kocuria kristinae and acinetobacter calcoaceticus, is used for degradation of petroleum composition in oil-base drilling cuttings, and has the substantial advantages of high oil removal efficiency and short processing period. When oil-base drilling cutting with the initial oil content less than 5% is processed by using the degradation bacterium for 5-30 d, the oil content can be reduced to 1% or less, and the oil removal rate can reach 80% or more. The degradation bacterium also has good application prospect when being applied to biological restoration of oil-containing soil and oil-containing sludge.

Owner:CHINA PETROCHEMICAL CORP +1

Microbial preparation, preparation and use thereof

InactiveCN101280272APromote digestion and absorptionIncrease appetiteFungiBacteriaMicroorganismMicrobial agent

The invention relates to microbial agent and the preparation method and usage thereof, which belongs to the preparation method and the usage of bacteria agent. The microbial agent solves the problems that the fermentation time of the organic wad material is long, the fermentation process is complicated, the bacteria quantity is not easy to be controlled and determined, and the bacteria is easy contaminated by other bacteria in the prior ecological pig raising method. The microbial agent is made through mixing lactic acid bacteria, microzyme, photosynthetic bacteria, actinomyceto and filamentous fungi. The microbial agent adopts that the lactic acid bacteria, the microzyme, the photosynthetic bacteria, the actinomyceto and the filamentous fungi are mixed, wherein the lactic acid bacteria, the microzyme, the photosynthetic bacteria, the actinomyceto and the filamentous fungi are cultured through first-stage slant culture, second-stage liquid seed culture and third-stage liquid fermentation culture. The degradation process can be completed in seven to ten days by the microbial agent provided by the invention, the maximum temperature in the process can reach 60 to 65 DEG C, the bacteria quantity is fixed, the method is simple, and the microbial agent has no environmental pollution.

Owner:孙波 +1

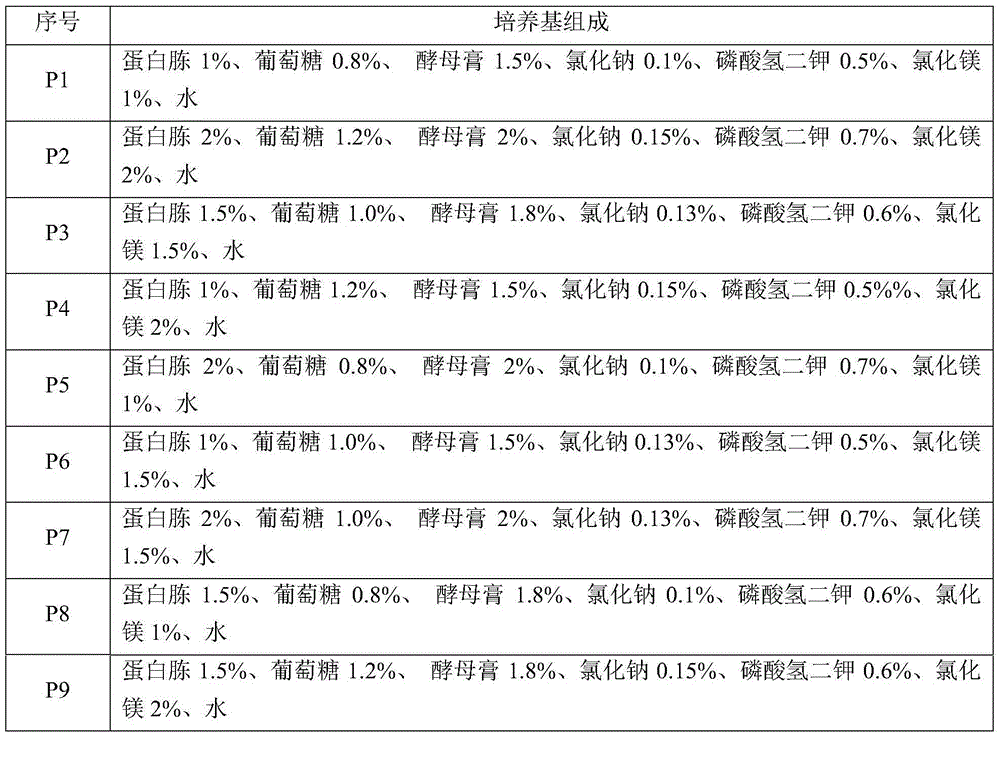

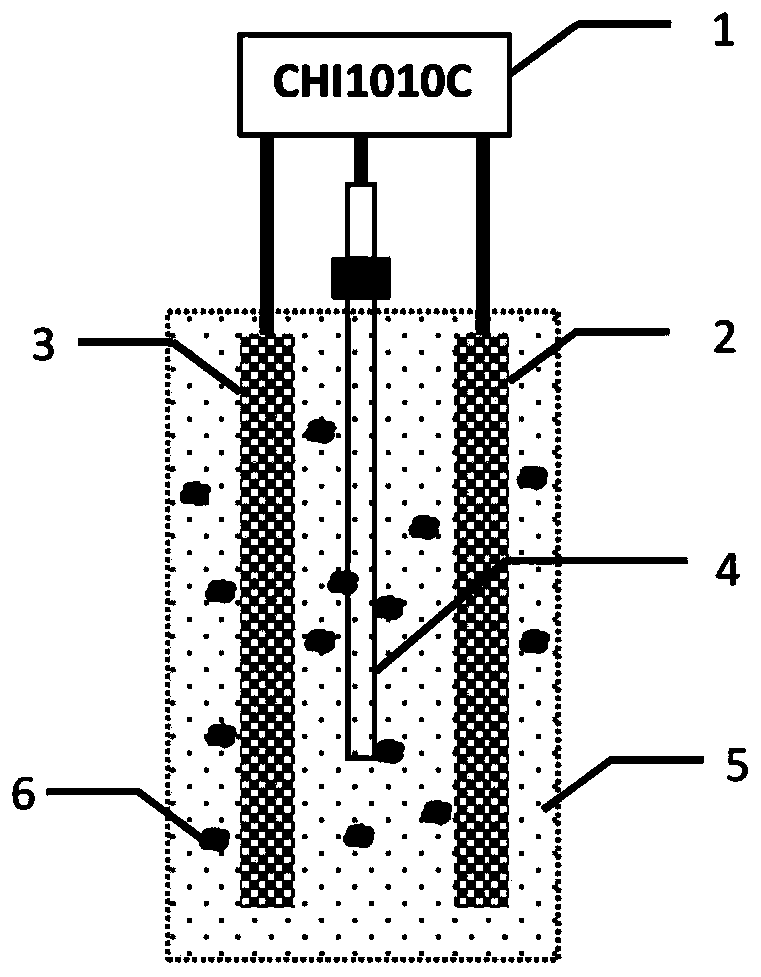

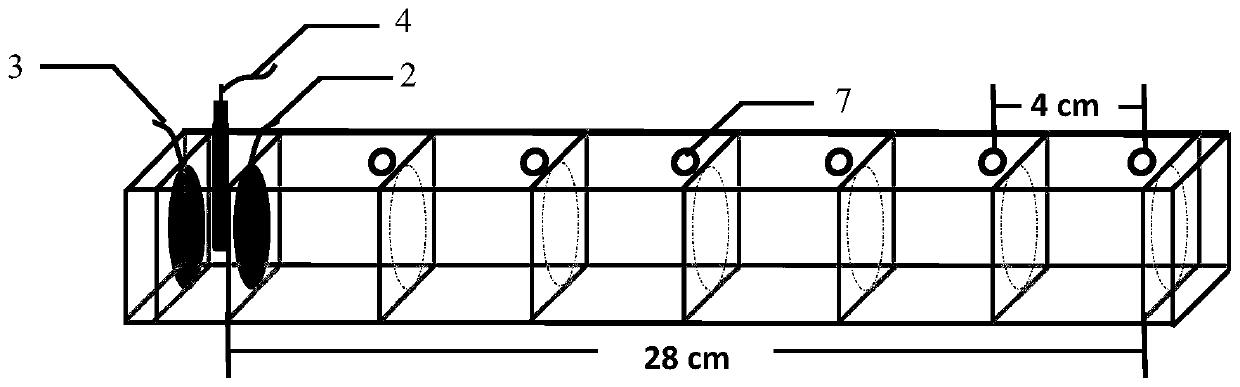

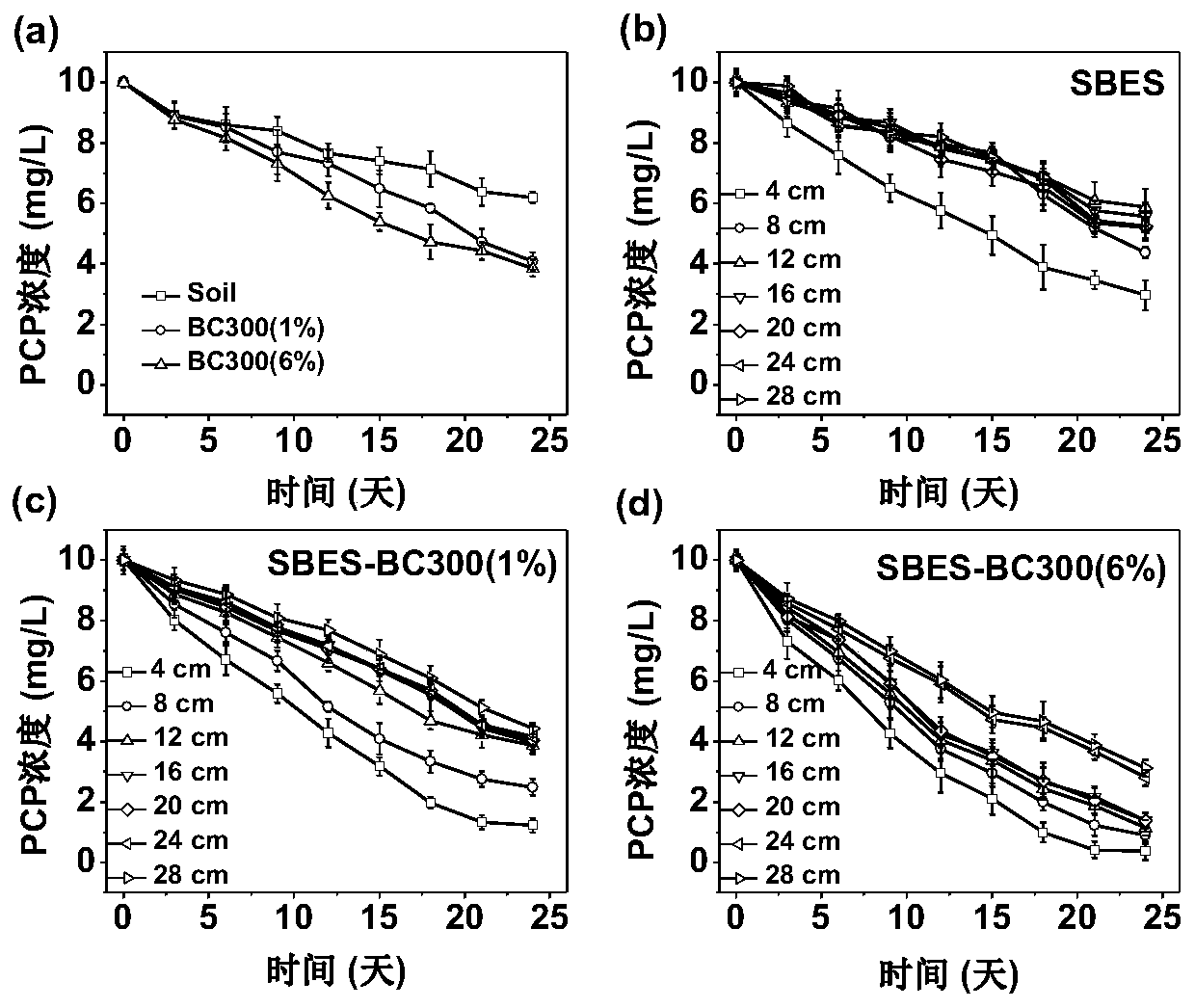

Biochar-bioelectrochemistry coupled soil remediation system and method

InactiveCN111167848AShort degradation cycleIncrease the effective degradation radiusContaminated soil reclamationAuxiliary electrodeEdaphic

The invention discloses a biochar-bioelectrochemistry coupled soil remediation system and method. The soil remediation system comprises a bioelectrochemical reactor and biochar which is to be mixed with to-be-remediated soil. The bioelectrochemical reactor comprises a reaction container used for containing the to-be-remediated soil, electrodes used for being inserted into the to-be-remediated soiland an electrochemical workstation, wherein the electrodes comprise a working electrode, an auxiliary electrode and a reference electrode, and the working electrode, the auxiliary electrode and the reference electrode are electrically connected with the electrochemical workstation. The biochar-bioelectrochemistry coupled soil remediation system provided by the invention is suitable for in-situ remediation of soil, capable of reducing the environmental risk of secondary pollution caused by a physicochemical remediation method, shortening the degradation period of pollutants and increasing theeffective degradation radius of soil pollutant degradation, low in equipment cost, low in energy consumption and capable of being widely applied to in-situ remediation of persistent organic contaminated soil.

Owner:GUANGDONG UNIV OF TECH

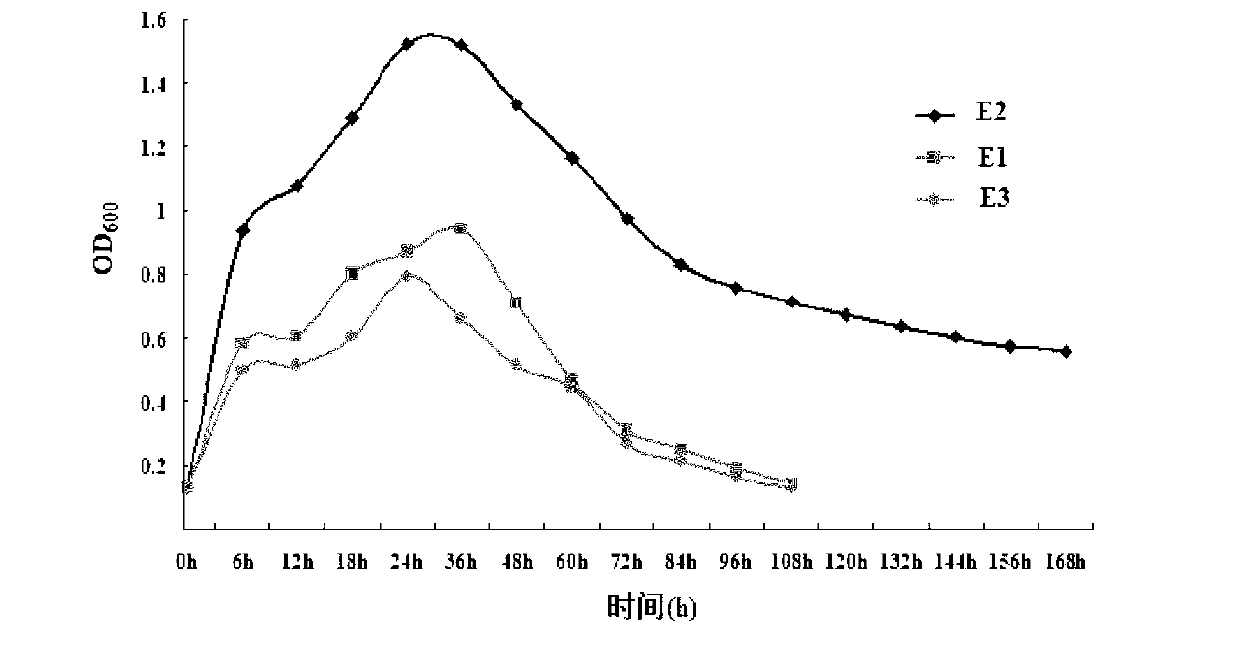

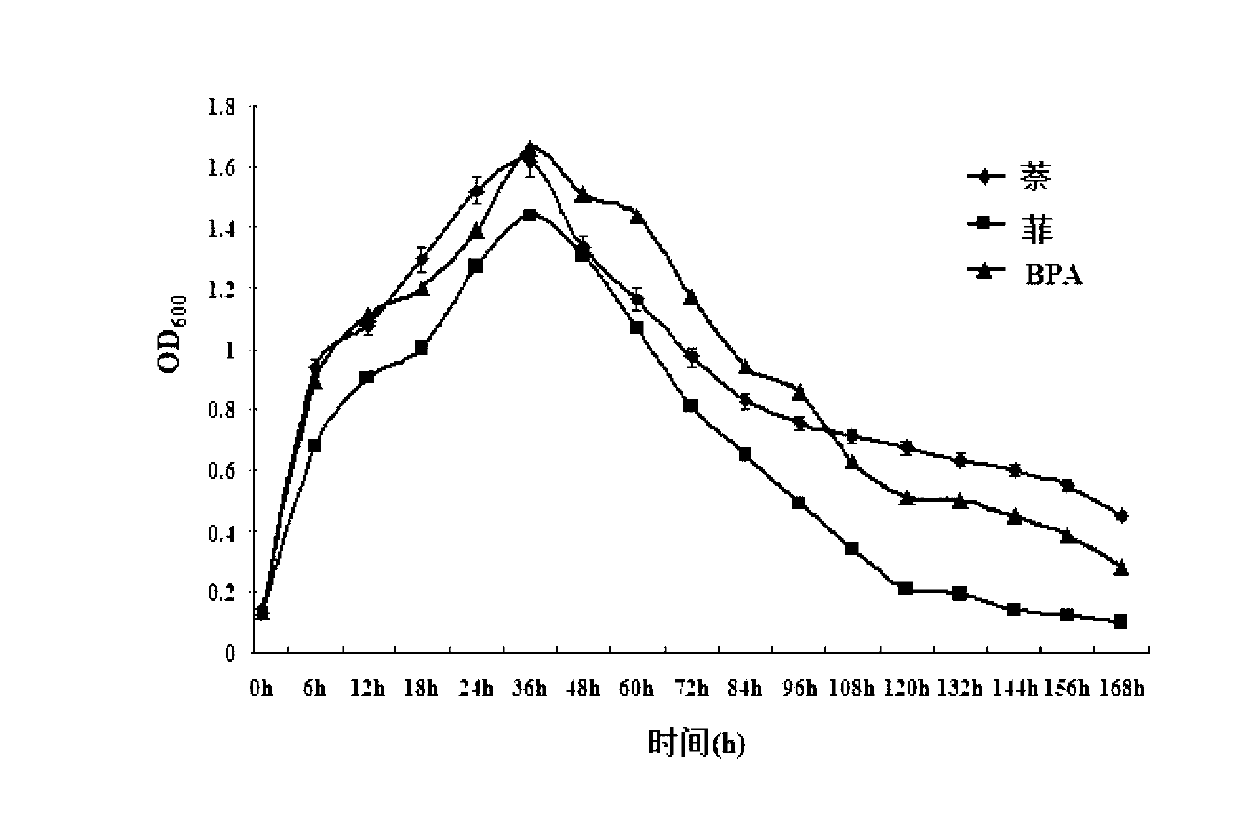

Pseudomonas fluorescens capable of degrading estrogen substances and preparation method and application thereof

Pseudomonas fluorescens capable of degrading estrogen substances is named as SJTE-2, and a preservation number is CGMCC No.6587. The pseudomonas fluorescens can use natural estrogen or environmental estrogen as the only carbon source to grow and can degrade estrogen substance oestrone, 17-Beta-estradiol, estriol and polycyclic aromatic hydrocarbon substance naphthalene, luxuriant, bisphenol A, and can be used for decomposing and removing an estrogen substance and a polycyclic aromatic hydrocarbon substance in an environment. Under the culture condition that the estrogen or the polycyclic aromatic hydrocarbon is used as the only carbon source, a bacterial strain SJTE-2 can degrade oestrone, 17-beta-estradiol and estriol within 24 hours, wherein the initial concentration of the oestrone, 17-beta-estradiol and estriol is 1 mg / L, and degradation rate of naphthalene, luxuriant and bisphenol A is over 90%, wherein the concentration of the naphthalene, luxuriant and bisphenol A is 50 mg / L. The bacterial strain can degrade oestrone, 17-beta-estradiol and estriol for more than 90% in 7 days, wherein the initial concentration of oestrone, 17-beta-estradiol and estriol is 50 mg / L, and degradation rate of naphthalene, luxuriant and bisphenol A is larger than 80%, wherein the concentration of naphthalene, luxuriant and bisphenol A is 500 mg / L.

Owner:SHANGHAI JIAO TONG UNIV

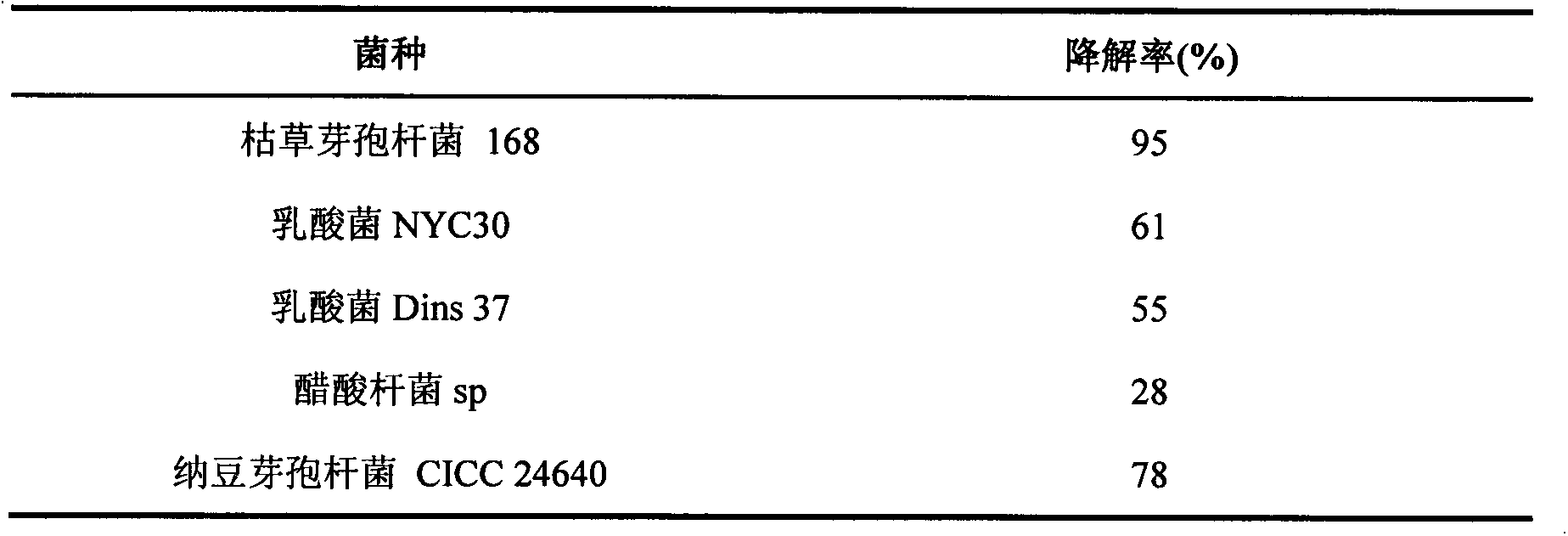

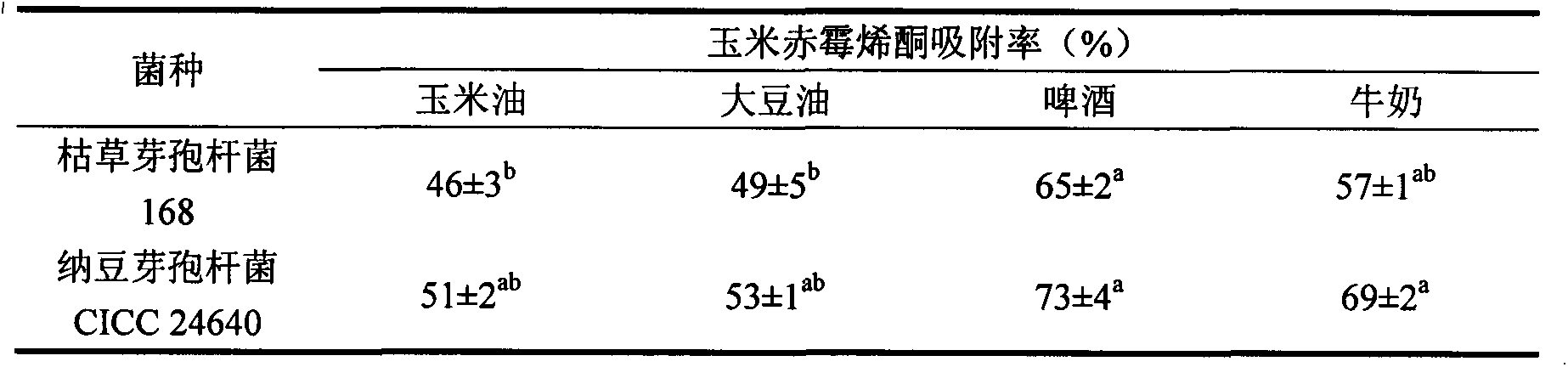

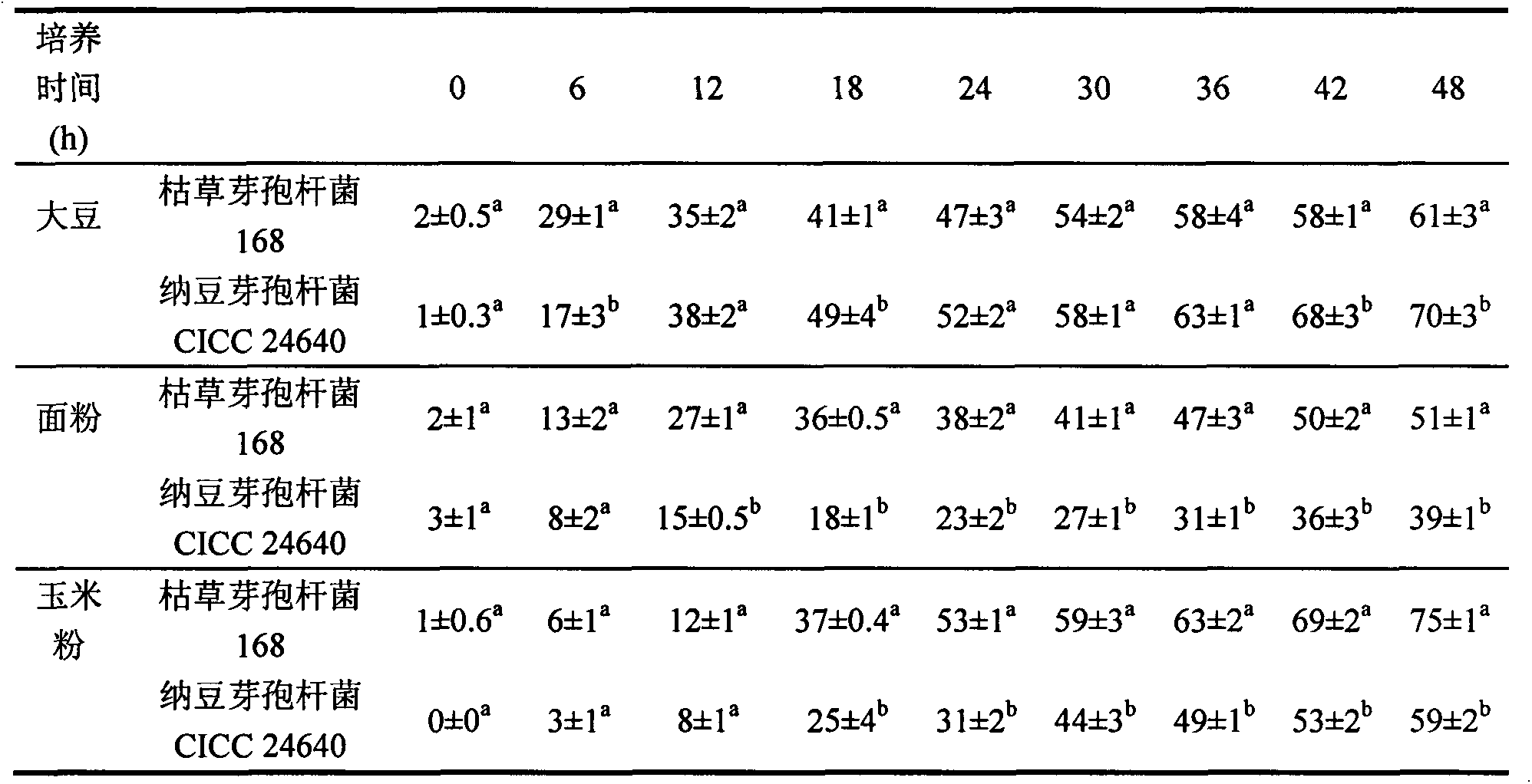

Application of food-grade microorganism in degradation of zearalenone

The invention relates to application of a food-grade microorganism in degradation of zearalenone. Probiotics is any one or more of bacillus subtilis 168, lactic acid bacteria NYC30, lactic acid bacteria Dins 37, acetobacter aceti sp and bacillus natto CICC24640; further, the probiotics is preferably the bacillus subtilis 168 and bacillus natto CICC24640. The application has the advantages that the food-grade probiotics strain is adopted and used for degrading fungaltoxin zearalenone, so that the degradation period is short, the degradation efficiency is high, the product is safe, obvious advantages are brought for the safety of foods for people and livestock, and a new way is provided for the degradation of zearalenone.

Owner:JIANGNAN UNIV

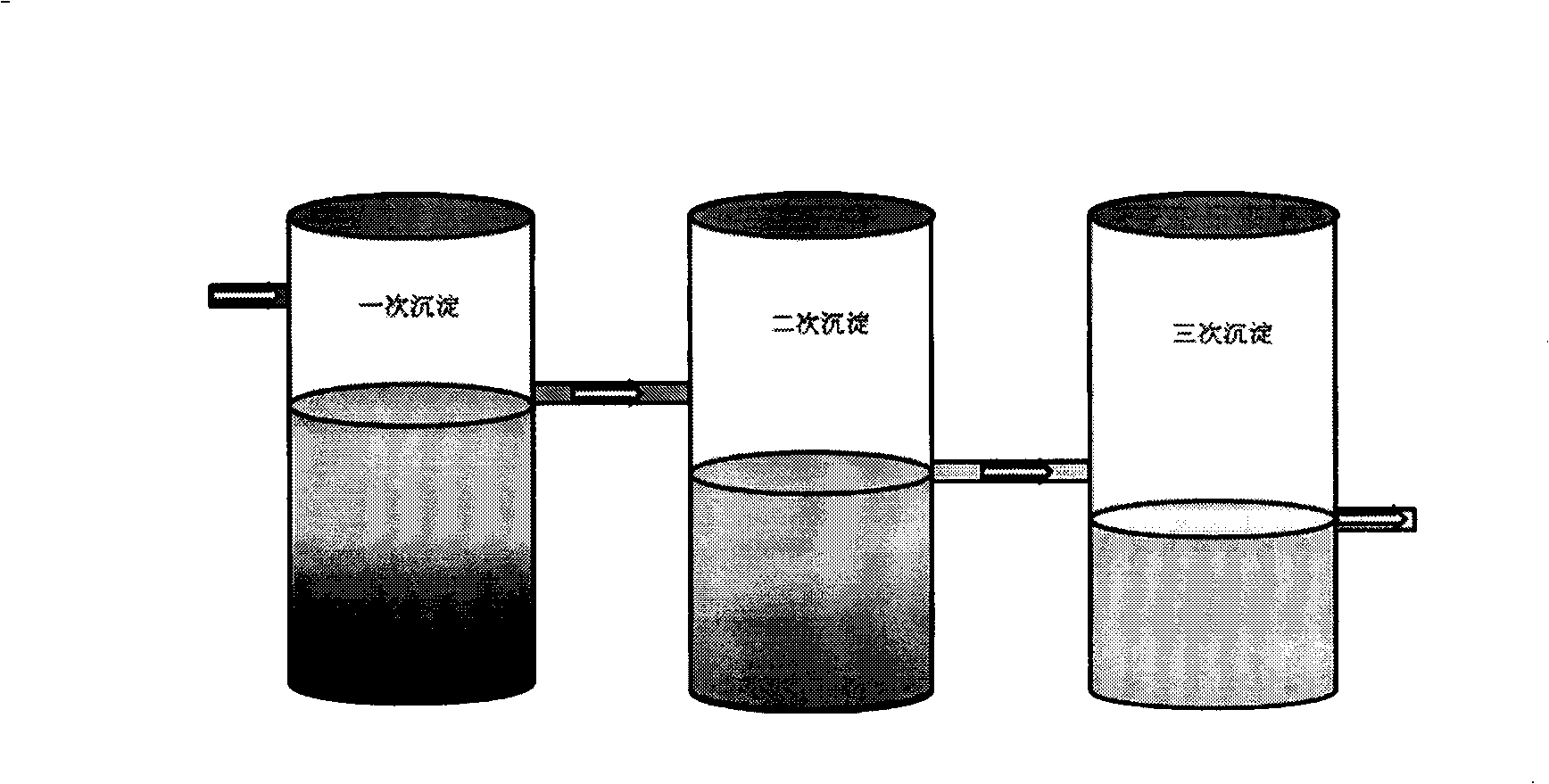

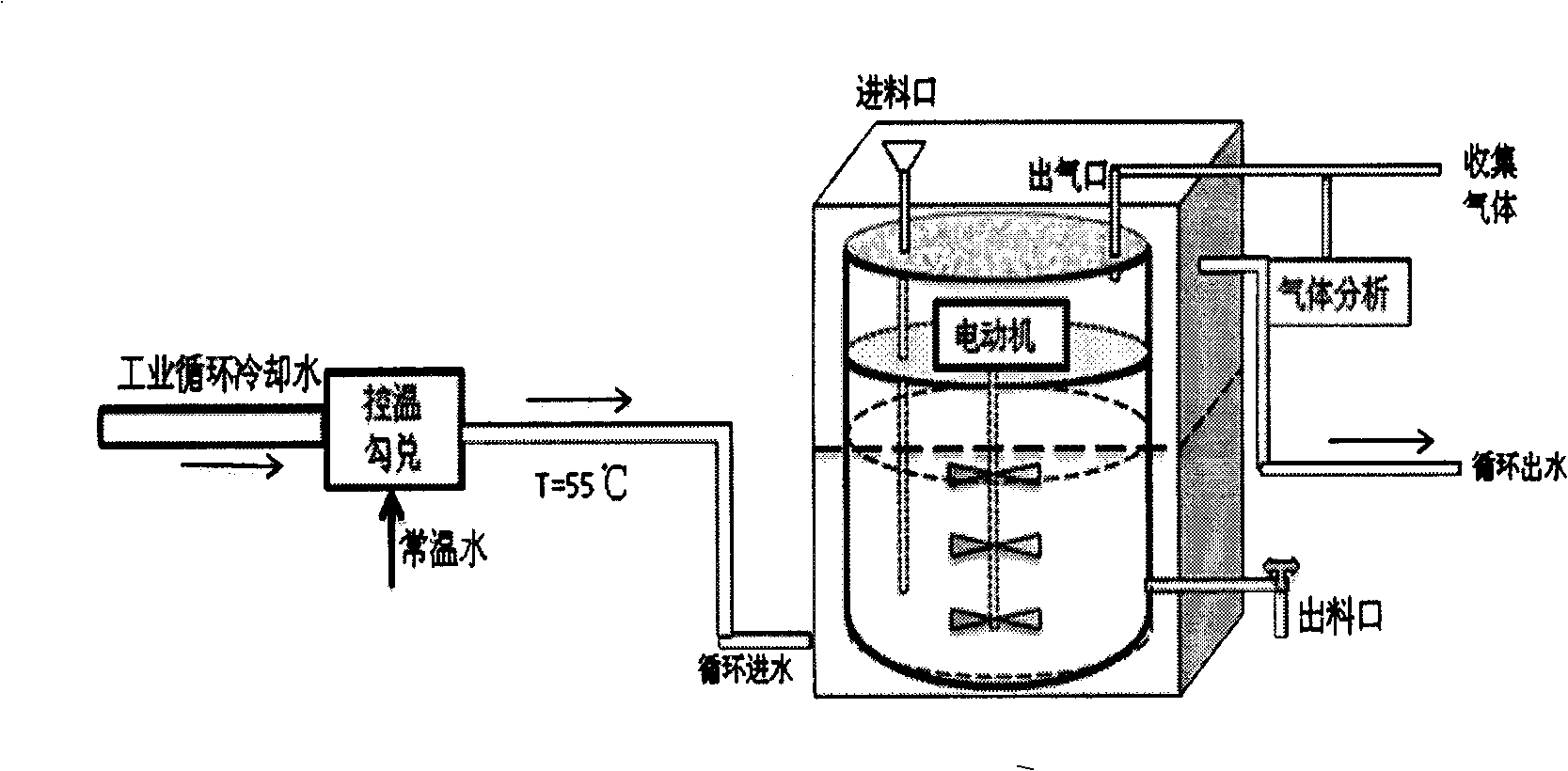

Anaerobic fermentation technical method of septic tank sediments by assist of industrial waste heat

InactiveCN101538109AEmission reductionImprove gas production efficiencyBiocideBio-organic fraction processingMarshEngineering

The invention provides an anaerobic fermentation technical method of septic tank sediments under the assist of industrial waste heat, belonging to the technical field of an environment-friendly energy. The invention is characterized in that the method comprises the following steps of: taking septic tank sediments as a raw material under the condition that the temperature provided by the industrial waste heat is 55 DEG C; adding liquid dung which is adjusted to ensure that pH=7.2-7.4 and Ts=8%-10% into an anaerobic fermentation pot; stirring and fermenting the mixture; when enriched strains meet the condition that fermentation pot operates at the full load, normally generating gas; stopping stirring before fermentation gas generation reaches an inflection point at each time; extracting 2 / 3 fermenting fluid to produce fertilizer, fermenting the remaining 1 / 3 fermenting fluid to generate marsh gas; rinsing, desulfurizing, drying and storing the marsh gas in a canning way after the marsh gas enters into a marsh gas collecting tower. The invention can advance gas generating time, lift gas-generating efficiency, shorten degradation period, achieve a recycling effect since marsh residues and marsh liquid can be made into fertilizer and biotic pesticide with high quality, and simultaneously reduce sewage discharge to achieve a minimizing effect.

Owner:UNIV OF SCI & TECH BEIJING

Absorbable medical suture line with good mechanical performance

ActiveCN105079869AImprove mechanical propertiesHigh strengthSuture equipmentsLactidePolyethylene glycol

The invention discloses an absorbable medical suture line with good mechanical performance. The absorbable medical suture line comprises, by weight, 100-120 parts of modified polylactic acid, 20-40 parts of polyglycollide, 4-6 parts of sorbitol, 3-5 parts of methyl methacrylate and 5-6 parts of cassia oil. The preparation method of the modified polylactic acid includes: in ice-bath, adding chitosan into perchloric acid, well mixing, dripping sorbic acid chloride, stirring, cooling, preserving heat and purifying to obtain modified chitosan; taking polyethylene glycol, feeding inert gas, heating, preserving heat until the polyethylene glycol melt, adding stannous chloride and lactide, well mixing, heating, preserving heat and stirring, and purifying to obtain intermediate material; dissolving the modified chitosan in mixed solvent, adding triethylamine, well mixing, heating, refluxing, adding the intermediate material, well mixing, continuing refluxing, purifying and drying to obtain the modified polylactic acid.

Owner:安徽省康宁医疗用品有限公司

Degradable hollow fiber membrane and application thereof

InactiveCN102580578APorosity adjustableAperture adjustableSemi-permeable membranesFiberHollow fibre membrane

The invention relates to a degradable hollow fiber membrane and application thereof. The degradable hollow fiber membrane comprises polybutylene carbonate (PBC) as a completely biodegradable material, wherein the PBC has a molecular weight is 0.01-0.25 million. The degradable hollow fiber membrane is applied to tissue engineering as an artificial blood vessel repair material and a catheter stent material. A preparation method of the degradable hollow fiber membrane is simple, and can be used for preparing degradable hollow fiber membranes with different internal diameters, wall thicknesses, lengths and porosity in batches; and the degradable hollow fiber membrane has better mechanical property, is suitable for cell growth, has shorter degradation period, and also has better application prospect in the field of biological application.

Owner:DONGHUA UNIV

Starch-based degradable environment-friendly plastic and preparation method thereof

The invention discloses starch-based degradable environment-friendly plastic and a preparation method thereof, and the starch-based degradable environment-friendly plastic is prepared from the following raw materials in parts by weight: 1.2-1.5 parts of polylactic resin, 0.5-0.7 part of polyvinyl chloride, 0.3-0.4 part of a plasticizer, 0.2-0.4 part of plant fibers, 0.6-0.8 part of guar gum, 0.3-0.6 part of a lubricant, 0.5-0.6 part of a coupling agent, 0.1-0.3 part of plant starch, 0.4-0.6 part of a plasticizer and 0.2-0.5 parts of a stabilizer, wherein the polyvinyl chloride is prepared by adopting a suspension polymerization method, one or more of a suspension stabilizer, gelatin, polyvinyl alcohol, methyl cellulose and hydroxyethyl cellulose are added during preparation, preferably, 0.5 g of a sample needs to be taken and dissolved in 80mL of water after the guar gum is prepared, and the solution must be kept in a flowing state, so that gel cannot be formed, 8 mL of a hydrochloricacid solution is added, and one drop of the sample mixed solution is dropwise added to the turmeric test paper to show brown red. The whole process is safe, non-toxic and environment-friendly, the obtained plastic is high in tensile strength and has high practical value and good application prospects, and the problem of environmental pollution is effectively solved.

Owner:辽阳市晨阳编织制品有限公司

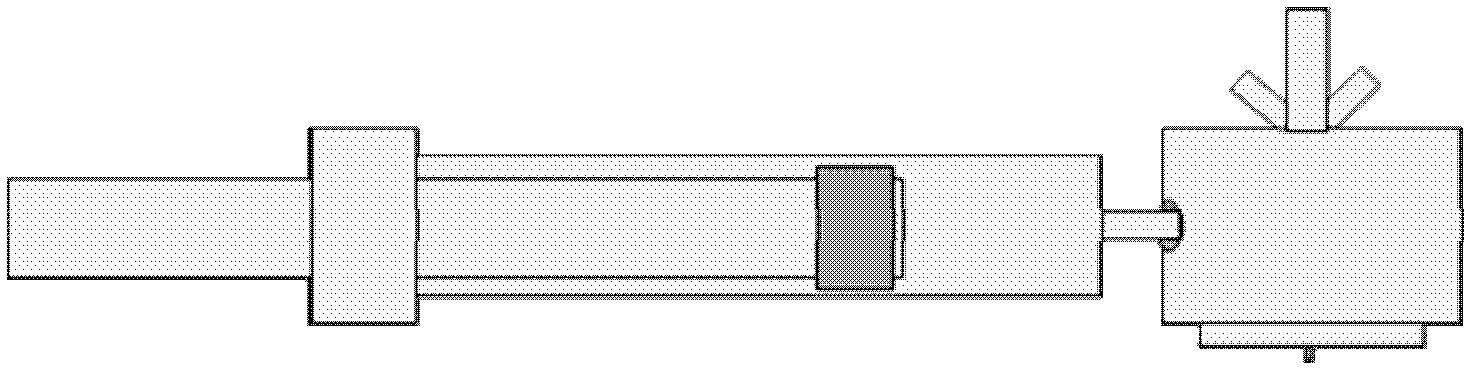

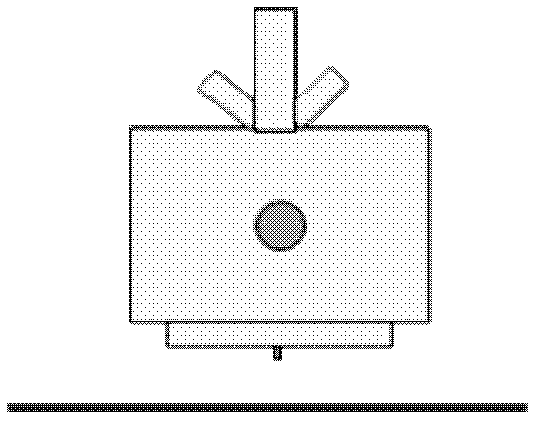

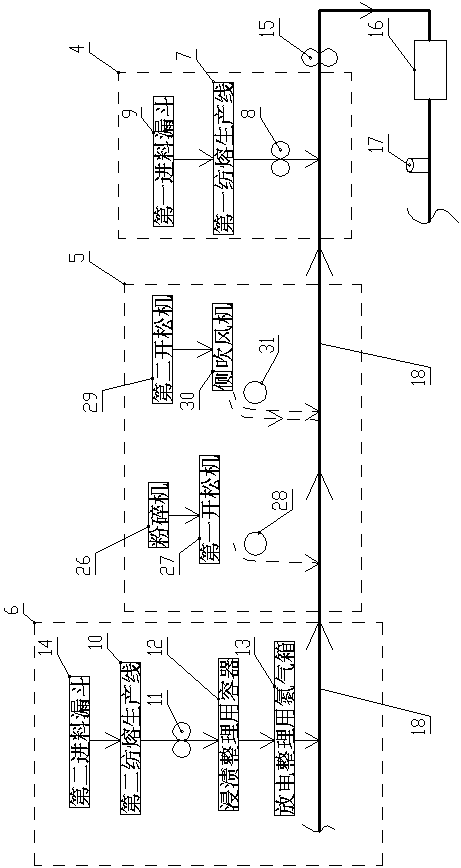

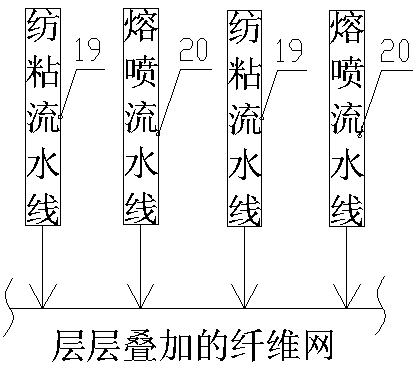

Production line of spunbond pulp-based nonwoven fabric and production technology thereof

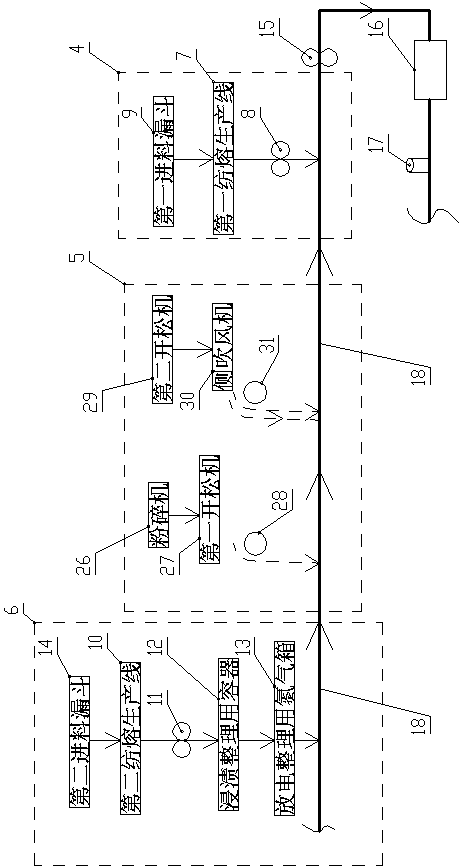

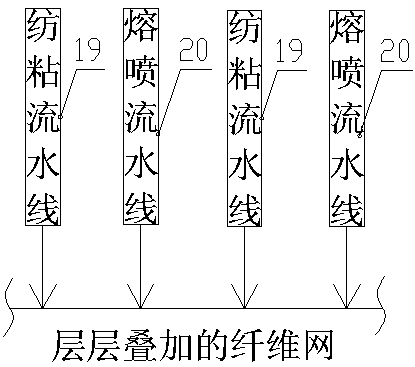

PendingCN108754877AAvoid pollutionAvoid wastingArtificial thread manufacturing machinesUltrasonic/sonic fibre treatmentProduction lineCellulose fiber

The invention discloses a production line of spunbond pulp-based nonwoven fabric and a production technology thereof. The production line comprises a third layer assembly line, a second layer assemblyline and a first layer assembly line in an upstream-and-downstream direction, wherein the first layer assembly line comprises a first spunbond production line and a first hot press; the second layerassembly line comprises a cellulose fiber pulp subline and a hot-melt fiber subline; the third layer assembly line comprises a second spunbond production line, a second hot press, a dip finishing container and a discharge finishing nitrogen tank; a third hot press is arranged in the downstream direction of the first layer assembly line; a hot air drying oven is arranged in the downstream directionof the third hot press; a fiber mesh conveying device for conveying a fiber mesh is arranged among the third layer assembly line, the second layer assembly line, the first layer assembly line, the third hot press and the hot air drying oven. The invention further discloses the production technology of the production line. Pollution and waste in the production process of cellulose fiber and in a spunlacing technology can be avoided, and a product has good lipophilicity and hydrophilicity.

Owner:郑州豫力新材料科技有限公司

Biological agent used for straw composting

InactiveCN107298633AGood synergyEfficient degradation abilityCalcareous fertilisersBio-organic fraction processingPlant hormoneMetabolite

The invention provides a biological agent used for straw composting. The biological agent comprises a composting agent and a compost agent, wherein the composting agent is prepared from a composite bacteria liquid and carriers in a weight ratio of 2 to 3; the compost agent is prepared from a cake powder, lime and urea in a weight ratio of 7-8 to 4-5 to 3-4. According to the biological agent provided by the invention, the materials is thoroughly composted in the straw treatment process, and a large quantity of functional microorganisms and various metabolites such as plant hormones and antibiotics are generated, so that the growth and the development of crops are stimulated, the soil nutrient is improved, the soil structure is improved, the utilization rate of chemical fertilizers is improved, and the biological agent is simple and convenient in operation and beneficial for production.

Owner:章勤

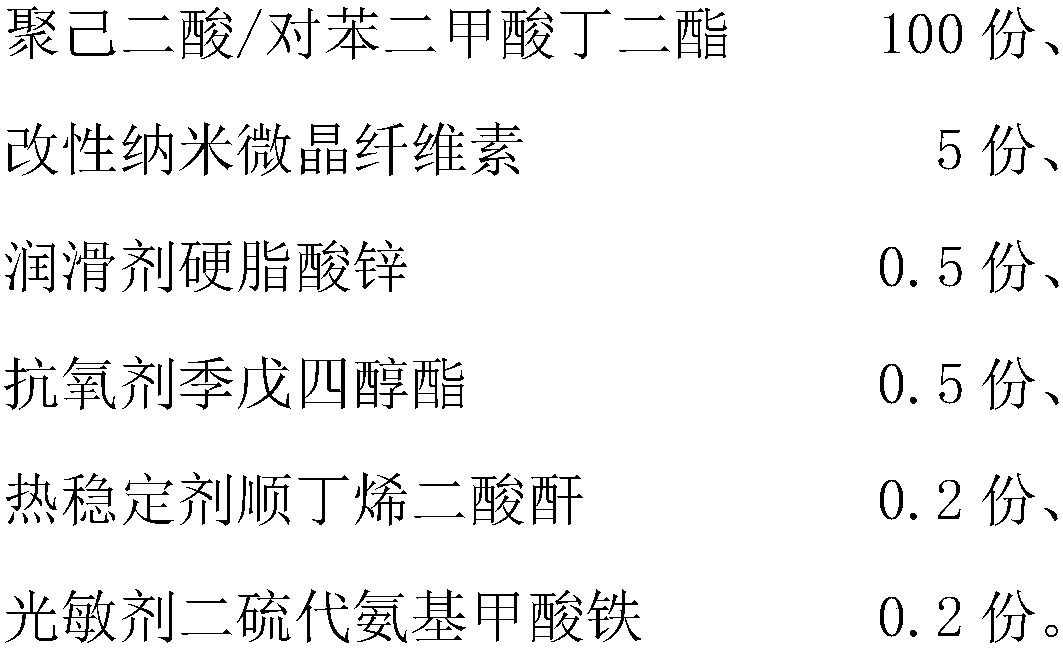

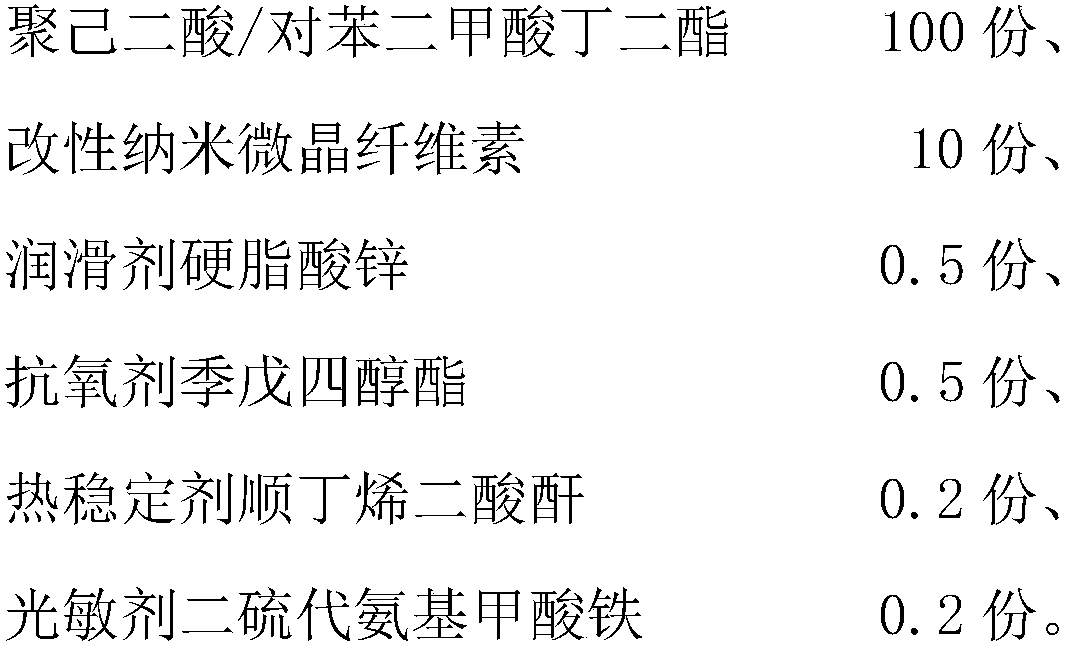

Polyadipic acid/butylene terephthalate composite material containing modified nanometer microcrystalline cellulose, and preparation method thereof

InactiveCN109666269AMeet modification needsShort degradation cyclePolyethylene terephthalateRoom temperature

The invention discloses a polyadipic acid / butylene terephthalate composite material containing modified nanometer microcrystalline cellulose, wherein the material comprises, by mass, 100 parts of polyadipic acid / butylene terephthalate, and 1-20 parts of modified nanometer microcrystalline cellulose, and is prepared sequentially through high speed blending and extrusion granulation, wherein the preparation method of the modified nanometer microcrystalline cellulose comprises: mixing nanometer microcrystalline cellulose and anhydrous ethanol, ultrasonically dispersing to obtain a nanometer microcrystalline cellulose suspension liquid, dissolving a coupling agent in absolute ethanol to form a coupling agent solution, mixing the nanometer microcrystalline cellulose suspension liquid and the coupling agent solution, refluxing for 2-4 h at a temperature of 75-85 DEG C, cooling to a room temperature, carrying out centrifugal separation, and drying to obtain the modified nanometer microcrystalline cellulose. According to the present invention, by organically modifying the nanometer microcrystalline cellulose, the interface resistance can be effectively reduced, the compatibility with the matrix material can be improved, and the modification requirements polyadipic acid / butylene terephthalate can be met.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

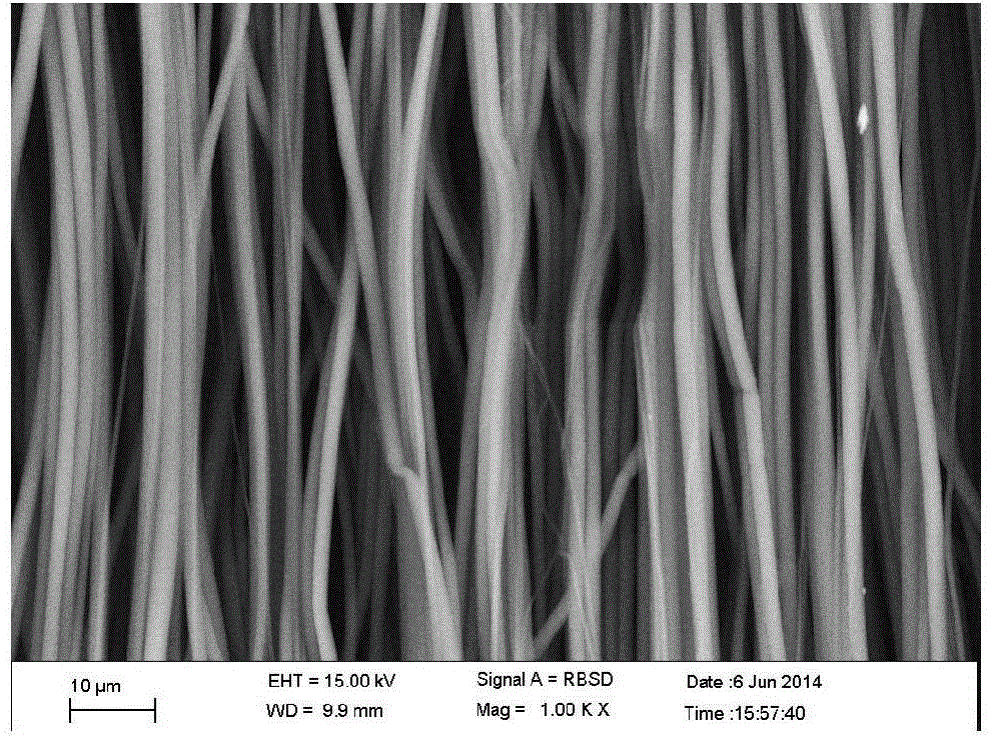

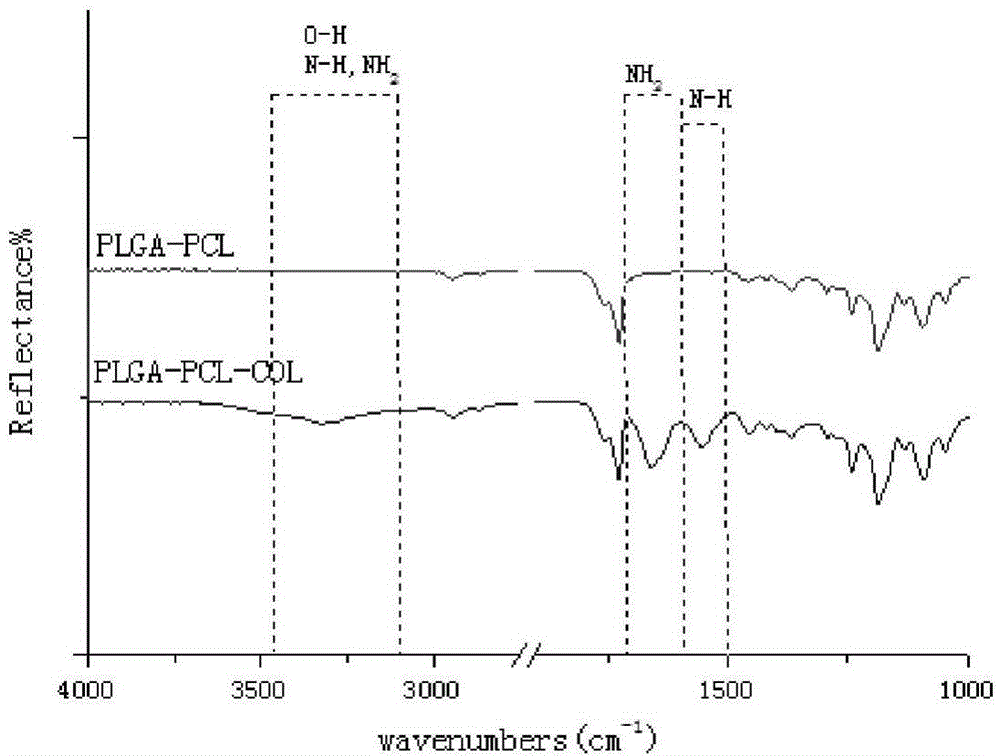

Preparation method for degradable polylactic acid-glycolic acid/polycaprolactone/I-type collagen electrospun fiber membrane material

InactiveCN104831476AHigh mechanical strengthEasy to operateConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

The invention discloses a preparation method for degradable polylactic acid-glycolic acid / polycaprolactone / I-type collagen electrospun fiber membrane material. The preparation steps comprise that 1) polylactic acid-glycolic acid and polycaprolactone are cut into pieces to be added to a solvent to form a uniform solution, an I-type collagen solution is added, and the solution is fully mixed through stirring so that a spinning solution is obtained; and 2) the electrospun fiber membrane material is prepared by the spinning solution through a directional electrospinning method. The electrospun fiber membrane material is great in fiber direction uniformity, great in mechanical strength and adjustable and controllable in fiber diameter and has biological activity, and the prepared material is short in degradation period. The preparation method is easy to operate and low in cost.

Owner:RES INST OF SOUTHEAST UNIV IN SUZHOU

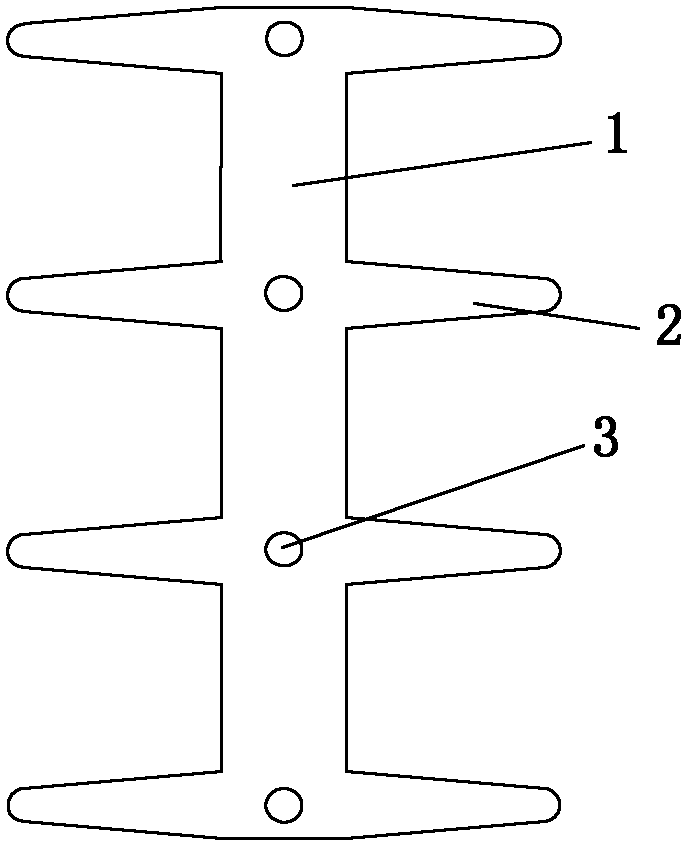

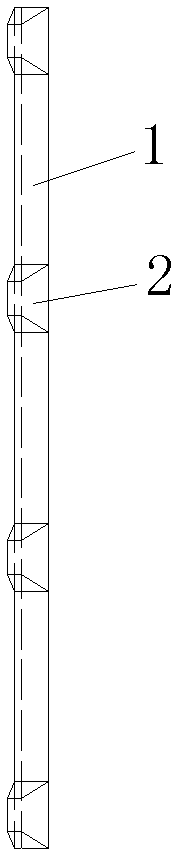

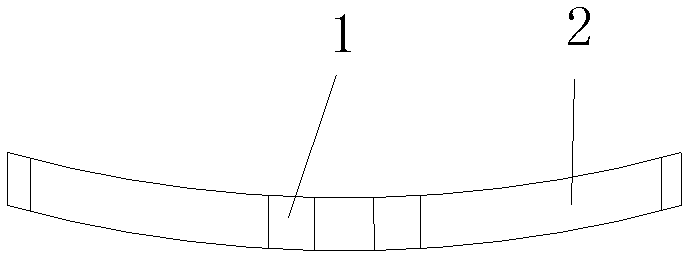

Degradable rib fixator

InactiveCN102499742AAdjustable sizeSimple and fast operationInternal osteosythesisHuman bodySurgical operation

A degradable rib fixator relates to a medical instrument, is adjustable in size, degradable in the human body, free of damage to bone mass, free of secondary surgery, simple in forming process, convenient in surgical operation and safe and reliable, and is provided with a center ridge plate and lateral fixing claws. A plurality of cylindrical holes are arranged at the center of the center ridge plate, and the lateral fixing claws are distributed on the left side and the right side of the center ridge plate. The tip end faces of the lateral fixing claws are circular preferably, and cross parts of the lateral fixing claws are arc-shaped. The center ridge plate and the lateral fixing claws are integrated by injection molding and are made of biomedical high-polymer poly-L-lactic acid with fine biological compatibility and degradable in the human body.

Owner:175TH HOSPITAL OF PEOPLES LIBERATION ARMY

Production method of environment-friendly tableware

The invention discloses a production method of environment-friendly tableware. The environment-friendly tableware comprises the following components in percentage by weight: 6-17% of carbon dust powder, 4-16% of corn straws, and 78-85% of mung bean starch. The preparation method comprises the following steps of: mixing carbon dust powder, corn straws, and mung bean starch; adding proper amount of water to the components for uniformly mixing the components; feeding the uniform mixture to a mould to carry out high-temperature steam forming by a pipeline; feeding the formed tableware to a disinfection processor by a conveying belt to carry out sterilization processing; and transmitting the disinfected tableware to a filming machine by a conveying belt to carry out film covering. The production method has the characteristics that the environment-friendly tableware is not easy to break, the normal use is ensured, an effect of preventing oil and water can be reached without an inner coating, and a full degradation of the environment-friendly tableware can be really realized. Moreover, the environment-friendly tableware has a short degradation period, water resistance and oil resistance and is easy to clean, and in particular the environment-friendly tableware has the advantages of high degradation rate, no white pollution and the like.

Owner:CHANGZHOU UNIV

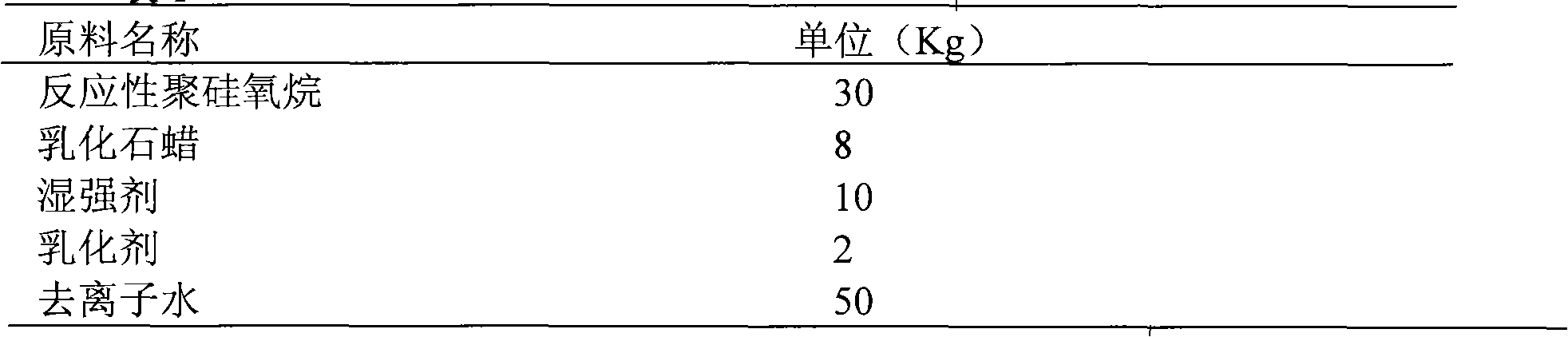

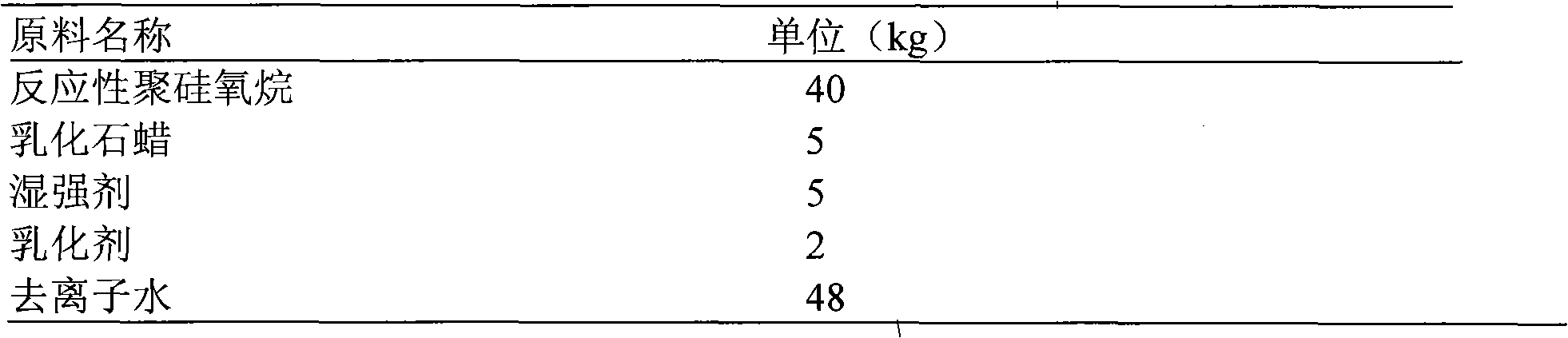

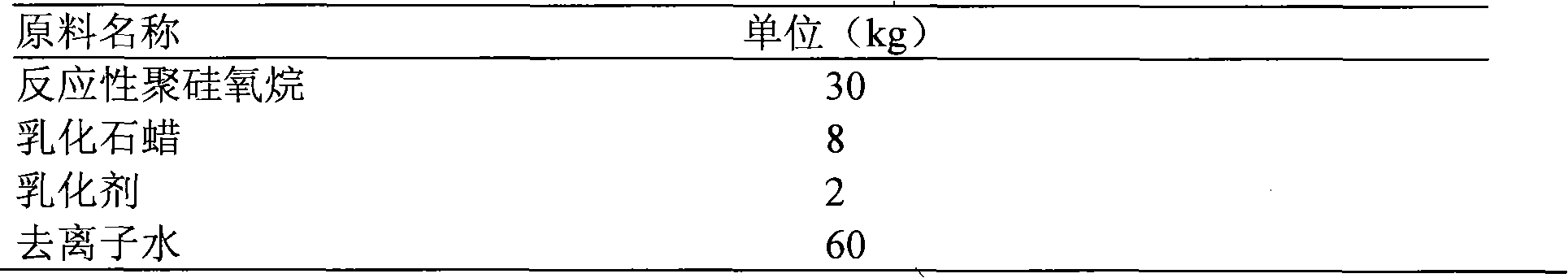

Water-proof agent for fruit cultivating bag paper and preparation method and application thereof

ActiveCN102086612AImproved or improved water resistanceImprove or enhance breathabilityNon-fibrous pulp additionEmulsionEngineering

The invention discloses a water-proof agent for fruit cultivating bag paper and a preparation method and application thereof. The water-proof agent for the fruit cultivating bag paper comprises the following components: reactive polysiloxane, an emulsifier and deionized water. One or both of a wet strength agent and emulsion paraffin can be added into the components so as to enhance the wrinkle resistance of paper sheets. The invention also discloses the application of the water-proof agent for the fruit cultivating bag paper in enhancing of the waterproofness of raw fruit cultivating bag paper. The water-proof agent is applied by the following steps of: diluting the water-proof agent for the fruit cultivating bag paper with water; soaking the raw fruit cultivating bag paper; and drying. The performances such as water resistance, waterproofness, air permeability, wrinkle resistance and the like of the raw fruit cultivating bag paper treated by the water-proof agent for the fruit cultivating bag paper are remarkably improved or enhanced. The water-proof agent has a short degradation period, and meets requirements for fruit cultivating period and environmental protection.

Owner:SHANGHAI VENUS PACKAGE MATERIALS

Degradable electric power packing film

The invention discloses a degradable electric power packing film, belongs to the field of a packing material for covering an electric appliance and a power transmission device, and is used for solving the weaknesses in the prior art that the electric power packing film cannot be degraded. The degradable electric power packing film comprises the following components in parts by weight: 15 to 40 parts of polyvinyl alcohol, 40 to 60 parts of amination starch, 20 to 40 parts of polypropylene, 2 to 8 parts of plasticizer, 1 to 5 parts of complexing agent and 1 to 2 parts of lubricating agent. The prepared packing film can be degraded in a natural environment and is relatively short in degradation period and relatively small in pressure on the environment.

Owner:国网山东沂水县供电公司 +1

Method for wholly and directly returning corn straw into field

InactiveCN107226760AEasy to prepareEasy wayExcrement fertilisersBiological combination treatmentDecompositionBiotechnology

The invention provides a method for wholly and directly returning corn straw into field. The method comprises the following steps: (1) collecting straw after corns are harvested and smashing the straw; (2) digging a cellar in harvested corn field; (3) putting the straw treated in the step (1) into the cellar and adding a biological agent to ferment under normal temperature to obtain a fermented product; (4) adding livestock excrement and plant ash according a weight ratio of the fermented product to the livestock excrement to the plant ash as 10 to 3 to 1, evenly mixing, covering with standby soil and fermenting for 10d to obtain a straw fermented organic fertilizer which is used for being returned to field. The method disclosed by the invention effectively solves the problems of tight crop rotation caused by wholly and directly returning the straw to field between double cropping, difficulty in cuttage sowing of next-stubble crops, nitrogen battle between seedlings and straw decomposition, yellowing, seedling weakness and the like; the straw can be returned to field directly; the method can be widely applied to returning crop straw to field.

Owner:朱玲芳

Method for returning straws into field through stack retting by using microbial preparation

InactiveCN107285925AGood synergyEfficient degradation abilityCalcareous fertilisersBio-organic fraction processingOrganic fertilizerBiology

The invention provides a method for returning straws into a field through stack retting by using a microbial preparation. The method comprises the following steps: conveying the straws into the nearby field; digging channels in the periphery of the field and carrying out ridging by a distance which is 30 cm or above; flattening a stack bottom, wherein the width of a straw stack is 1.5-2.0 meters, and the height of the straw stack is 1.5-1.8 meters; adding a dilute microbial inoculum which accounts for 20-30% of the weight of the straws to obtain a matured product; adding a compost preparation under the condition that the ratio of the matured product to the compost preparation is 3: 2; and after the matured product and the compost preparation are mixed uniformly, tightly sealing the mixture by using mud or black plastic agricultural films, and fermenting for 10 days to obtain straw fermented organic fertilizers. The straws can be directly returned into the field.

Owner:章勤

Preparation method of degradable polycarbonate butanediol ester electrospinning fiber films

InactiveCN102787448AFast degradationShort degradation cycleFilament/thread formingNon-woven fabricsPolymer scienceElectrospinning

The invention relates to a preparation method of degradable polycarbonate butanediol ester electrospinning fiber membranes. The preparation method comprises the following steps that (1) polycarbonate butanediol ester is sheared into pieces to be added into solvents, modification components are added, the polycarbonate butanediol ester is dissolved through stirring, and in addition, the modification components are fully and uniformly dispersed; and (2) spinning liquid is obtained and is subjected to electrostatic spinning to obtain electrospinning fiber membrane materials. The electrospinning fiber membrane materials have the advantages that the mechanical strength is good, the fiber diameter is adjustable and controllable, the degradation period of the prepared materials is short, and the purpose is wide. The preparation method provided by the invention has the advantages that the operation is simple, and the cost is low.

Owner:DONGHUA UNIV

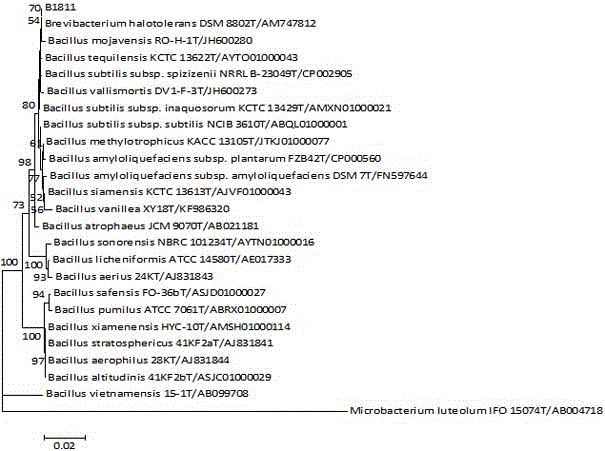

Bacillus mojavensis and application thereof

ActiveCN106635872AImprove degradation rateShort degradation cycleBacteriaMicroorganism based processesBacteroidesMicroorganism

The invention relates to bacillus mojavensis and application thereof and belongs to the field of environmental microorganism application. The bacillus mojavensis B1811 is preserved at the general microbiology center of China Committee for Culture Collection of Microorganisms(CGMCC), the preservation number is CGMCCNo.12805, the preservation date is on July 21, 2016. The bacillus mojavensis can be used for degrading dibutyl phthalate. The degradation rate of the dibutyl phthalate can be as high as 99.7%. A method for degrading the dibutyl phthalate by using the bacillus mojavensis B1811 is adopted. In the presence of a yeast extract, the bacillus mojavensis B1811 is in contact with the dibutyl phthalate. Compared with methods for degrading the dibutyl phthalate by using bacteria and fungi, the method for degrading the dibutyl phthalate has a new conception in strain source, has high dibutyl phthalate degradation rate and is short in degradation period and simple to operate.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Composite biochemical agent and application thereof in straw turnover

InactiveCN107445694AGood synergyEfficient degradation abilityCalcareous fertilisersFungiPlant hormoneMicroorganism

The invention provides a composite biochemical agent. The composite biochemical agent comprises a straw decaying agent and a composting fermentation agent, wherein the composting fermentation agent is prepared from urea, lime and excrements of livestock according to a weight ratio of (4-5.5) to (7-10) to (10-15); the straw decaying agent is prepared from compound bacteria liquid and a carrier according to a weight ratio of 1 to 4. According to the composite biochemical agent disclose by the invention, the materials are completely composted in the straw treatment process, and lots of functional microbes and multiple metabolites such as plant hormones, antibiotics and the like are produced, so that growth and development of the crops are stimulated, the soil nutrient is improved, the soil structure is improved, the chemical fertilizer utilization ratio is improved, the operation is easy and convenient, and the production is facilitated.

Owner:张雅琪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com