Thermoplastic starch-polyvinyl alcohol fogging-resistance film and preparation method thereof

A thermoplastic starch and polyvinyl alcohol technology, which is applied in the field of thermoplastic starch-polyvinyl alcohol anti-fog film and its preparation, can solve the problems of water resistance, poor anti-fog performance, uneconomical application, etc., and achieves water resistance and mechanical properties. Excellent performance, excellent anti-fog effect, short degradation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

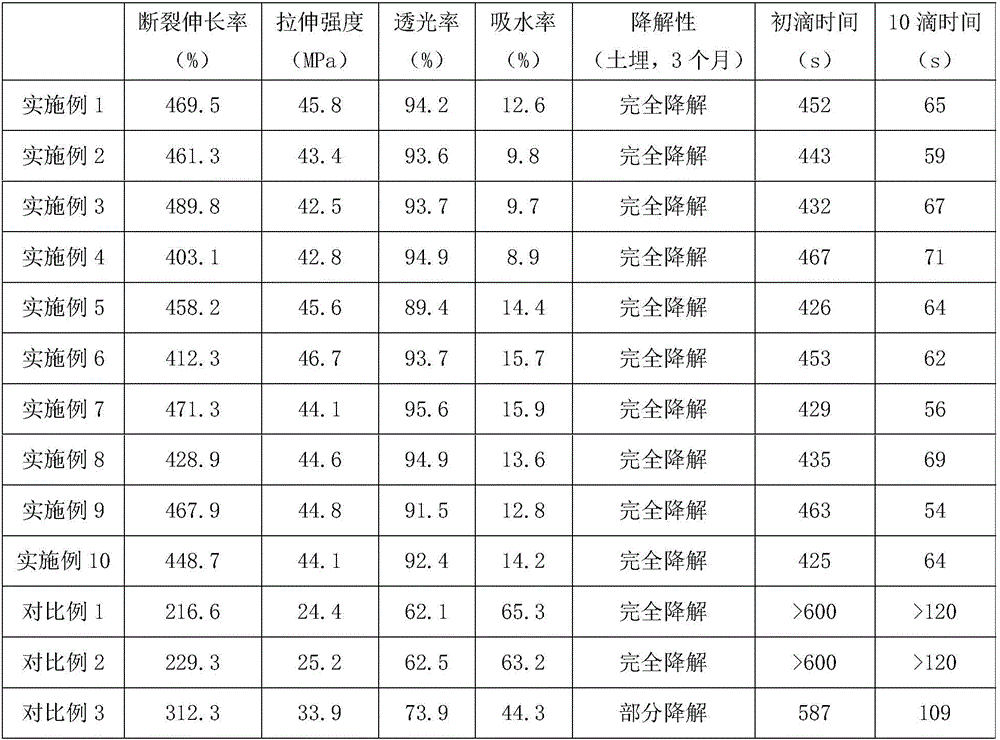

Examples

Embodiment 1

[0036] 60 parts of thermoplastic starch, 40 parts of polyvinyl alcohol, 30 parts of compound plasticizer (glycerin: diethanolamine: citric acid weight ratio = 1:1:1), 5 parts of EAA, 6 parts of triethanolamine laurate, titanium dioxide 1 part, 1 part of 1010 antioxidant.

Embodiment 2

[0038] 65 parts of thermoplastic starch, 45 parts of polyvinyl alcohol, 30 parts of compound plasticizer (glycerin: diethanolamine: citric acid weight ratio = 1:2:1), 5 parts of EAA, 7 parts of triethanolamine laurate, titanium dioxide 0.8 parts, 1 part of 1076 antioxidant.

Embodiment 3

[0040] 70 parts of thermoplastic starch, 50 parts of polyvinyl alcohol, 30 parts of compound plasticizer (glycerin: diethanolamine: citric acid weight ratio = 1:1:2), 5 parts of EAA, 5 parts of triethanolamine laurate, titanium dioxide 0.5 part, 1 part of dispersant barium stearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com