Spunbonded pulp non-woven fabric

A technology of woven fabrics and non-woven materials, applied in the field of non-woven fabrics, can solve the problems of not being able to avoid cellulose fiber pollution, etc., and achieve the effects of avoiding pollution and resource waste, good mechanical strength, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

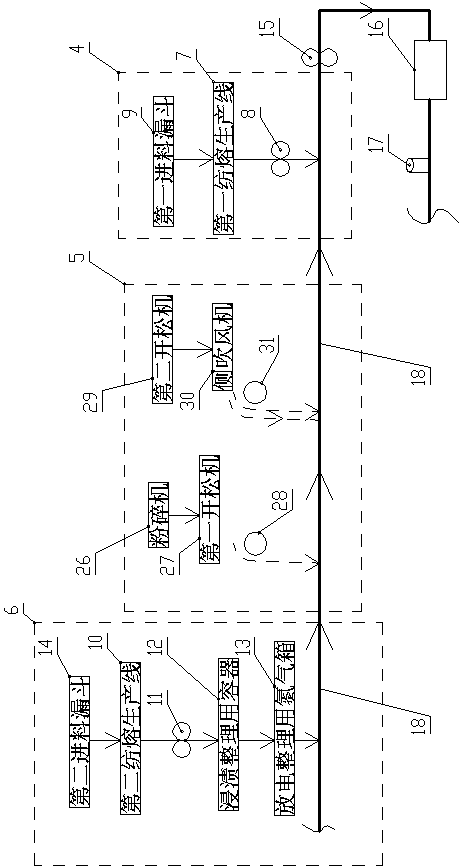

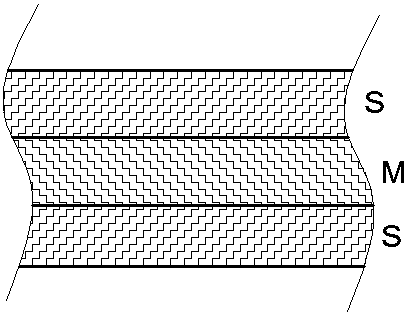

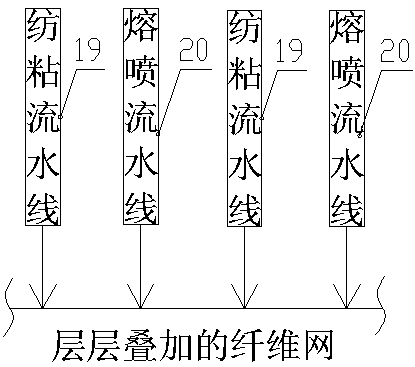

[0030] Such as Figure 1 to Figure 5 As shown, the spunbonded pulp nonwoven fabric of the present invention includes a three-layer structure bonded together by heat and pressure; the first layer 1 and the third layer 3 are both spunbonded nonwoven material layers, as the second layer of the middle layer Layer 2 is a cellulose fiber layer;

[0031] The first layer of spunbond nonwoven material layer is meltblown nonwoven fabric (M), spunbond nonwoven fabric (S) or meltblown spunbond composite nonwoven fabric, and meltblown spunbond composite nonwoven fabric is SMS or MSM or MS or SM;

[0032] The second layer 2, ie, the cellulose fiber layer, is a mixture of cellulose fiber pulp and hot-melt fibers.

[0033] The grammage of the spun-bonded non-woven material layer of the first layer is 8-60 g / m2 (both values 8 and 60 are included) and the thickness is 0.1-1 mm.

[0034] The cellulose fiber pulp is wood pulp short fiber after crushing and opening. In the present invention,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com