Polyadipic acid/butylene terephthalate composite material containing modified nanometer microcrystalline cellulose, and preparation method thereof

A technology of butylene terephthalate and nano-crystals, which is applied in the field of polymer composite materials, can solve the problems of insufficient tensile strength, application of nano-microcrystalline cellulose to degradable composite materials, and high cost, so as to shorten the degradation cycle, Effect of improving compatibility and reducing interfacial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

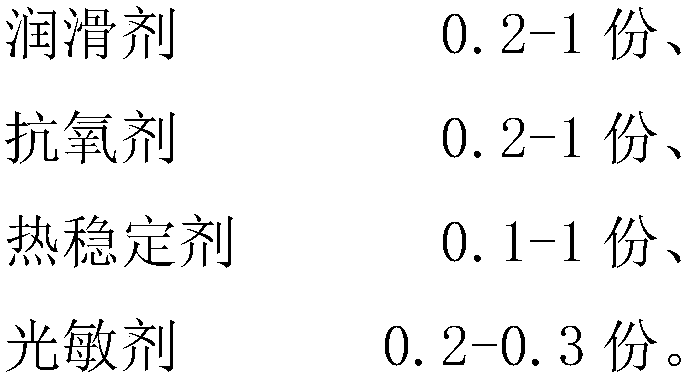

[0029] A modified polyadipate / butylene terephthalate composite material containing nano-microcrystalline cellulose and a preparation method thereof, the composition and content of which are calculated in parts by mass are as follows:

[0030]

[0031] Above-mentioned formula reacts according to the following steps:

[0032] (1) Mix a certain amount of the above-mentioned nano-microcrystalline cellulose with 50ml of absolute ethanol, and disperse it ultrasonically for 10 minutes to obtain a uniformly dispersed suspension; mix γ-aminopropyltriethoxysilane coupling agent (KH550) 0.5% of the mass fraction of crystalline cellulose) was dissolved in 50ml of absolute ethanol; the homogeneous suspension was mixed with the coupling agent solution and refluxed at 80°C for 3-5h; cooled to room temperature, centrifuged, and vacuum oven at 80°C Dry in medium. That is, the coupling agent modified nano-microcrystalline cellulose is obtained;

[0033] (2) Put the above-mentioned modified...

Embodiment 2

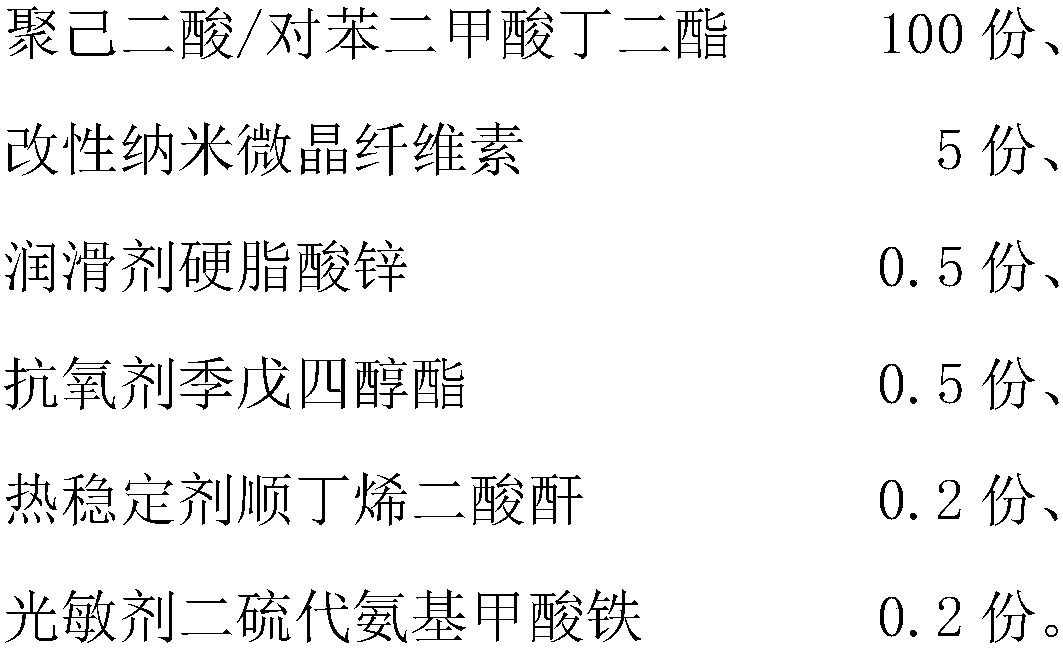

[0037] A modified polyadipate / butylene terephthalate composite material containing nano-microcrystalline cellulose and a preparation method thereof, the composition and content of which are calculated in parts by mass are as follows:

[0038]

[0039] Above-mentioned formula reacts according to the following steps:

[0040] (1) Mix a certain amount of the above-mentioned nano-microcrystalline cellulose with 50ml of absolute ethanol, and disperse it ultrasonically for 10 minutes to obtain a uniformly dispersed suspension; mix γ-aminopropyltriethoxysilane coupling agent (KH550) 0.5% of the mass fraction of crystalline cellulose) was dissolved in 50ml of absolute ethanol; the homogeneous suspension was mixed with the coupling agent solution and refluxed at 80°C for 3-5h; cooled to room temperature, centrifuged, and vacuum oven at 80°C Dry in medium. That is, the coupling agent modified nano-microcrystalline cellulose is obtained;

[0041] (2) Put the above-mentioned modified...

Embodiment 3

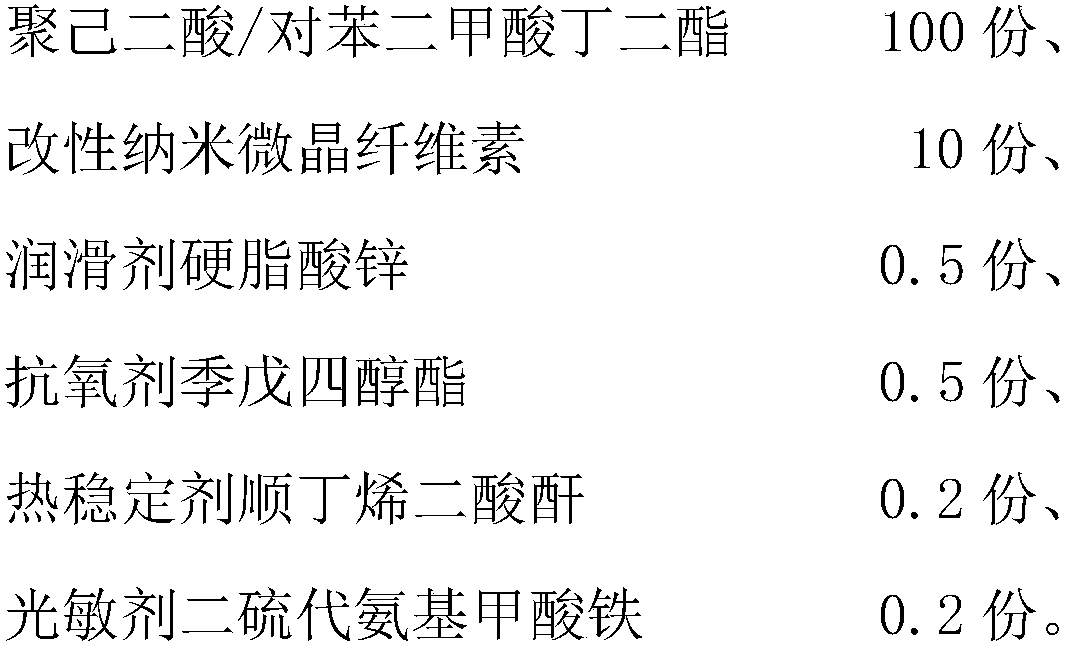

[0045] A modified polyadipate / butylene terephthalate composite material containing nano-microcrystalline cellulose and a preparation method thereof, the composition and content of which are calculated in parts by mass are as follows:

[0046]

[0047] Above-mentioned formula reacts according to the following steps:

[0048] (1) Mix a certain amount of the above-mentioned nano-microcrystalline cellulose with 50ml of absolute ethanol, and disperse it ultrasonically for 10 minutes to obtain a uniformly dispersed suspension; mix γ-aminopropyltriethoxysilane coupling agent (KH550) 0.5% of the mass fraction of crystalline cellulose) was dissolved in 50ml of absolute ethanol; the uniform suspension was mixed with the coupling agent solution and refluxed at 80°C for 3-5h; cooled to room temperature, centrifuged, and placed in a vacuum oven at 80°C drying. That is, the coupling agent modified nano-microcrystalline cellulose is obtained;

[0049] (2) Put the above-mentioned modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com