A kind of preparation method of controllable multi-type chromium carbide modified graphite

A chromium carbide, multi-type technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems that restrict the performance of metal-based graphite self-lubricating composite materials, poor wettability between matrix and graphite, and graphite phase extraction. It can solve problems such as peeling and peeling, and achieve the effects of rich functionality and innovation, high production efficiency, and controllable types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The concrete steps of the preparation method of a kind of controllable multi-type chromium carbide modified graphite of the present invention are as follows:

[0030] S1. First use the NaOH solution with a concentration of 15-20wt.% to fully wash the graphite powder, then rinse the graphite powder to neutrality with distilled water, and then evaporate to dryness;

[0031] The temperature of evaporative drying is 80-100° C., and the time is 0.5-1.5 hours.

[0032] The graphite powder is a graphite powder with a particle diameter of 20-40 μm, a particle size of 325-625 mesh, and a purity of 97.5-99.5%, and the shape of the powder is not specifically limited.

[0033] S2, laying the dried graphite powder evenly on the sample stage;

[0034] The thickness of the powder tile is 0.5 ~ 1mm, and the laying area is not more than 30cm 2 .

[0035] S3, performing multi-arc ion plating modification treatment on the laid graphite powder;

[0036] Multi-arc ion plating modificati...

Embodiment 1

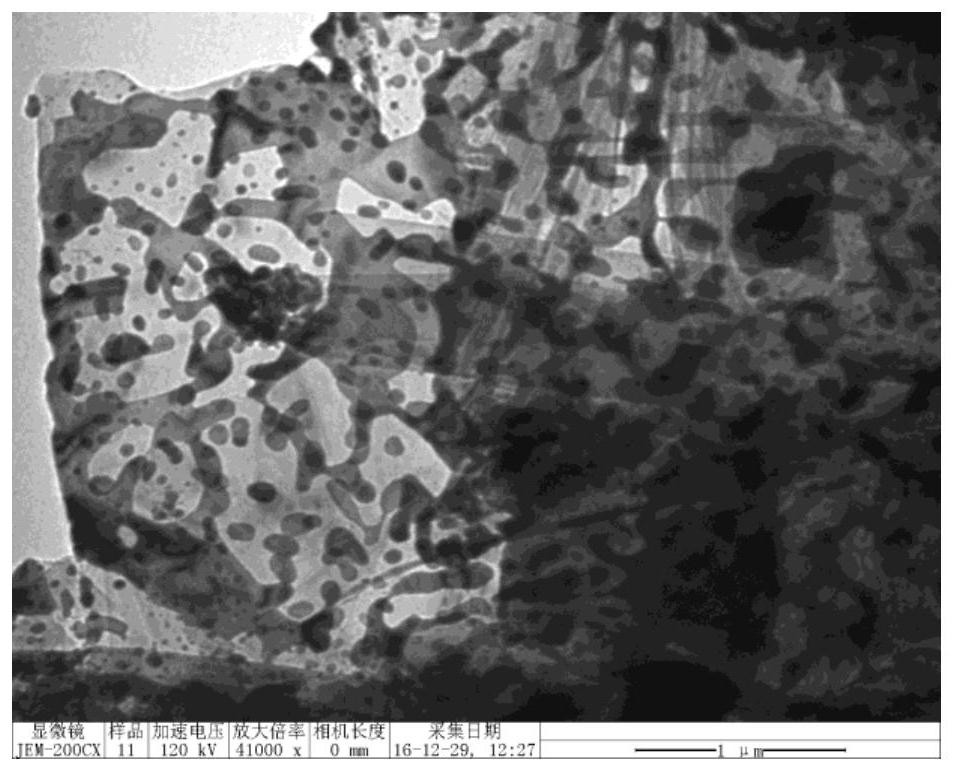

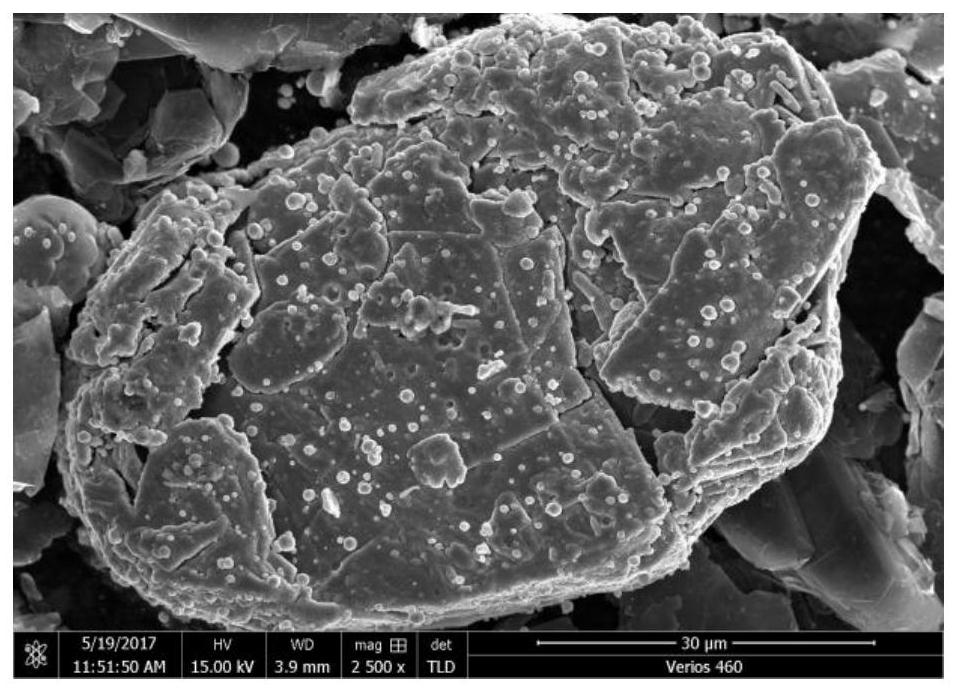

[0044] Diffused H-Cr 7 C 3 Nanoparticles Reinforced Pure Chromium Modified Flake Graphite

[0045] 1) First, fully wash flake graphite powder with a particle size of 40 μm, a particle size of 325 mesh, and a purity of 97.5% with a NaOH solution of a concentration of 15 wt.%. Rinse the flake graphite powder with distilled water to neutrality, and then evaporate to dryness at a drying temperature of 80° C. and a drying time of 1.5 hours.

[0046] 2) Spread the dried flake graphite powder evenly on the sample stage, the thickness of the powder is 0.5mm, and the laying area is 20cm 2 .

[0047] 3) The flake graphite powder that has been laid is subjected to multi-arc ion plating modification treatment. The specific plating parameters are that the plating time is 3 minutes, the plating atmosphere is argon, and the atmosphere pressure is 2×10 -1 Pa, the plating temperature is 240°C, the duty cycle is 50%, the bias voltage is 20V, and the target material is a pure chromium targe...

Embodiment 2

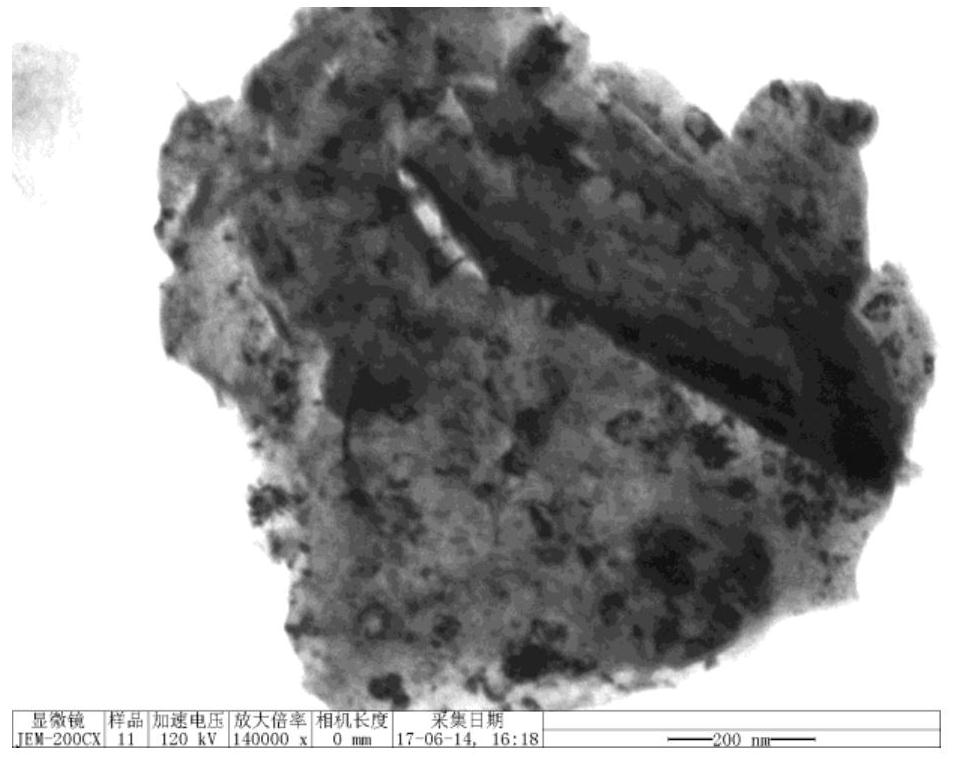

[0051] Diffused Cr 3 C 2 Nanoparticle Reinforced H-Cr 7 C 3 modified graphene

[0052] 1) First, the graphene with a particle size of 20 μm, a particle size of 625 mesh, and a purity of 99% is fully washed with a NaOH solution of a concentration of 18 wt.%. Then the graphene was rinsed with distilled water to neutrality, and then evaporated to dryness at a drying temperature of 100° C. and a drying time of 0.5 hours.

[0053] 2) Place the dried graphene tiles evenly on the sample stage, the thickness of the powder tiles is 0.8mm, and the laying area is 25cm 2 .

[0054] 3) Perform multi-arc ion plating modification treatment on the laid graphene. The specific plating parameters are that the plating time is 1 minute, the plating atmosphere is argon, and the atmosphere pressure is 3×10 -1 Pa, the plating temperature is 260°C, the duty cycle is 70%, the bias voltage is 40V, and the target material is a pure chromium target.

[0055] 4) After the multi-arc ion plating and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com