Cell scratch testing device

A testing device and cell scratching technology, which can be used in measuring devices, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve problems such as difficulty in maintaining consistent force, difficulty in analysis and statistics, messy and unclear edges, etc. Accurate positioning of scratches, high flexibility, and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, schemes and advantages to be solved by the present invention clearer, the present invention will be further described in detail with specific examples below.

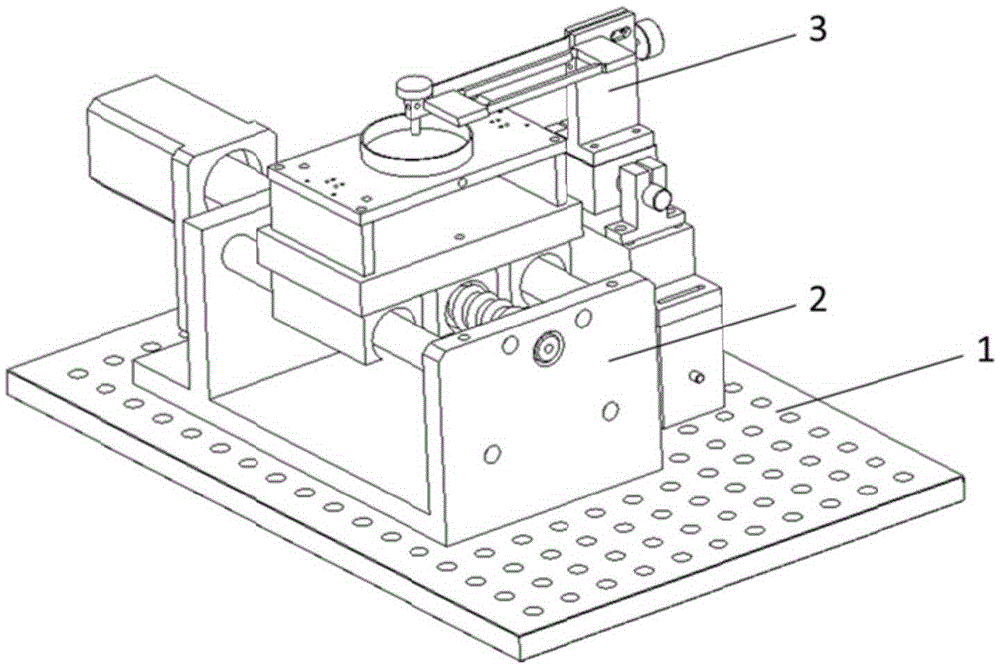

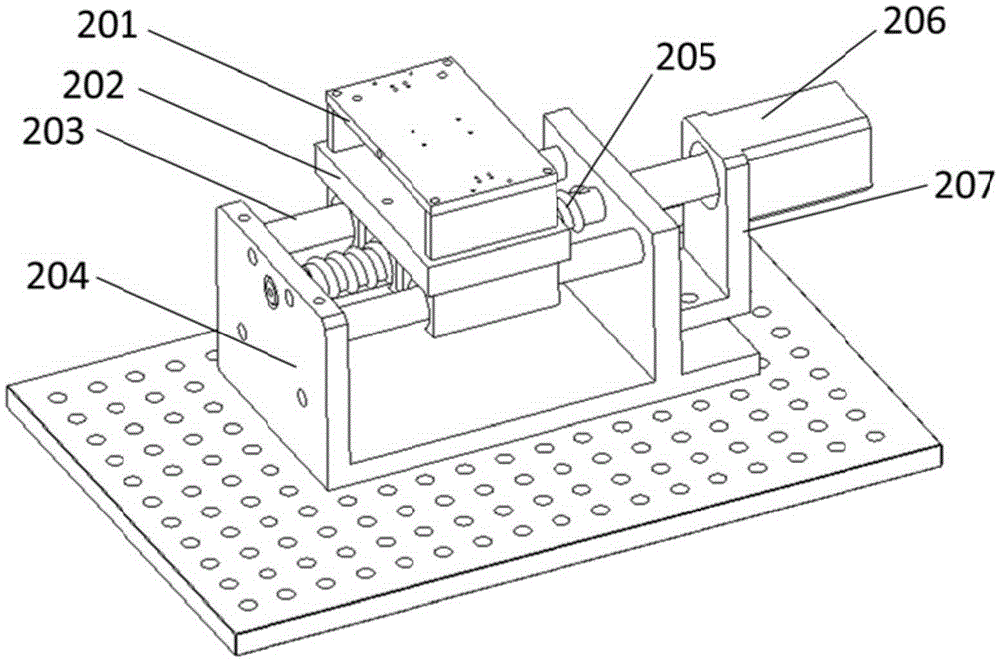

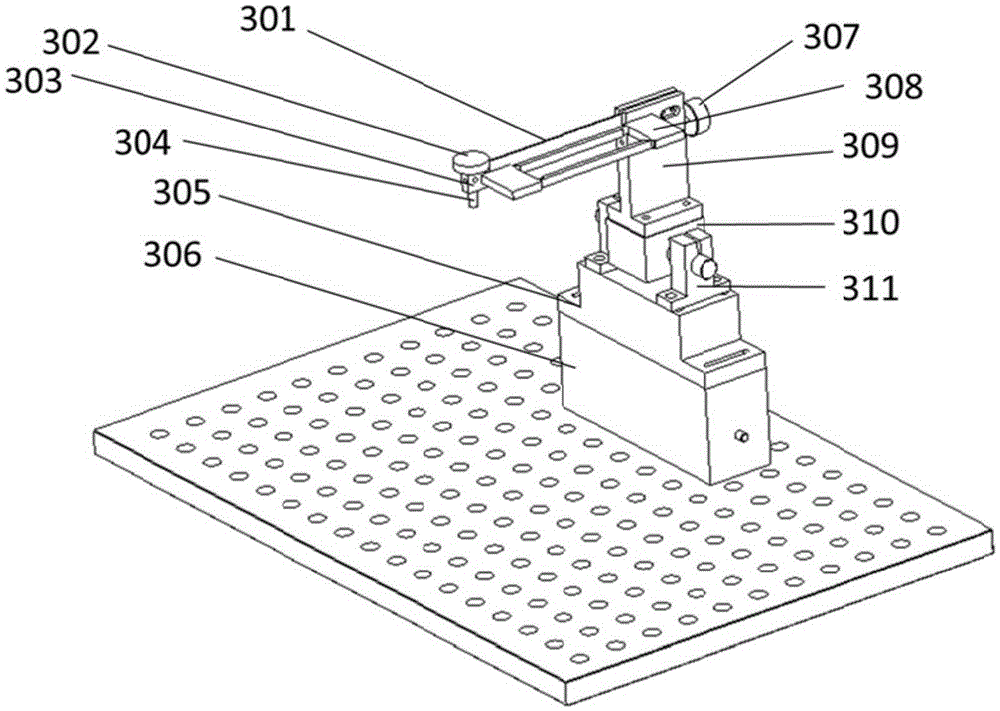

[0022] refer to figure 1 , is an experimental device for cell scratch testing of the present invention, mainly comprising: a honeycomb test platform 1 , a one-dimensional automatic translation platform 2 and a scoring device 3 . The one-dimensional automatic translation platform 2 is set on the honeycomb test platform 1, and the one-dimensional automatic translation platform 2 is fixed with a cell culture dish holding fixture. The present invention uses 3M double-sided adhesive to fix the object to be fixed—the cell culture dish. After the cell culture dish is fixed, adjust the three-dimensional manual translation stage so that the top of the scratch is at the same height as the cell culture dish. By changing the number of weights in the loading tray 302, the force on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com