A kind of nano-oxide and soybean protein isolate modified polyadipate/butylene terephthalate composite material and preparation method thereof

A technology of butylene terephthalate and soybean protein isolate, applied in the field of biodegradable polymer composite materials, can solve the problems of low tensile strength and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

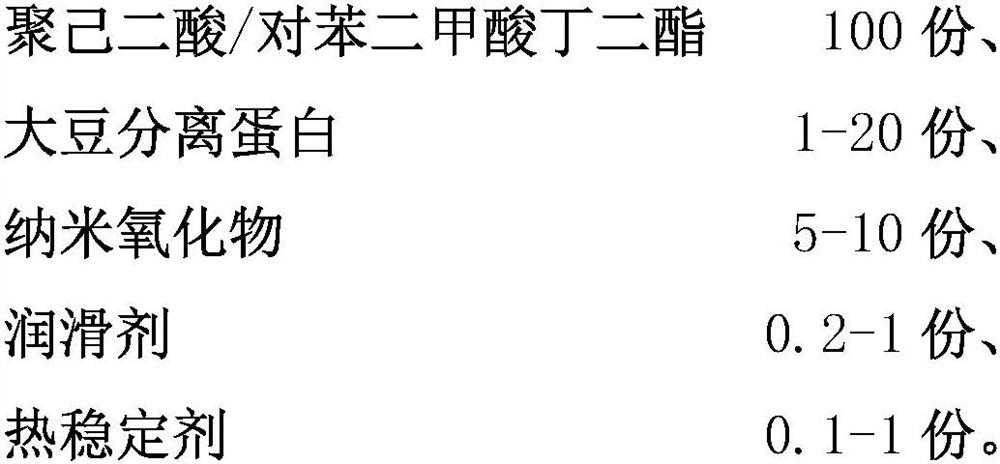

[0024] A modified polyadipate / butylene terephthalate composite material containing nano-oxide and soybean protein isolate, calculated in parts by mass, its composition and content are as follows:

[0025]

[0026] Above-mentioned formula reacts according to the following steps:

[0027] (1) Put a certain amount of soybean protein isolate into a 60°C oven and dry to constant weight, then take a certain amount of pre-dried soybean protein isolate, add epichlorohydrin (45% by mass fraction of soybean protein isolate) ) in a beaker, stirred evenly with a glass rod, and then placed in a mold of a flat vulcanizing machine for curing and molding. The temperature of the flat vulcanizing machine was set at 80°C, the pressure was 30 MPa, and the temperature was kept at a constant temperature for 5 minutes.

[0028] (2) After the pressure holding is completed, open the mold and take out the sample. After it is cooled to room temperature, use a high-speed pulverizer to pulverize the so...

Embodiment 2

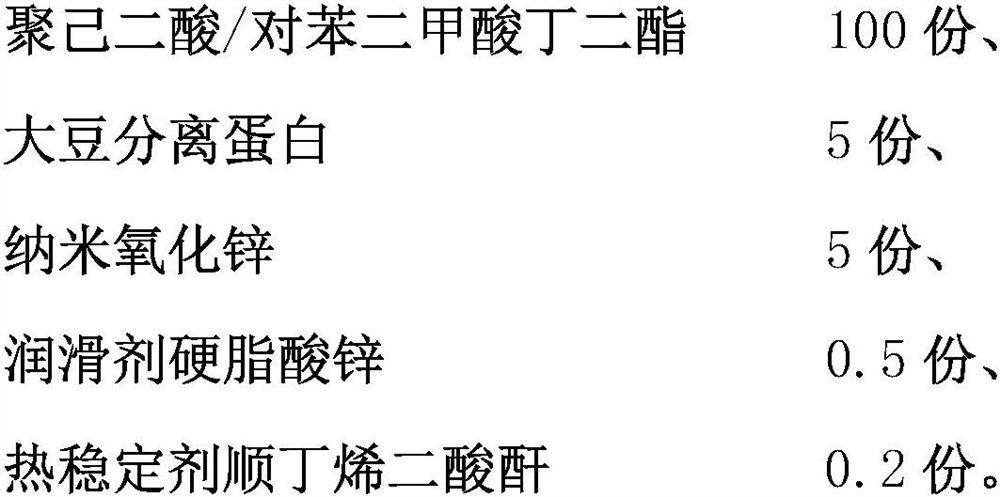

[0033] A modified polyadipate / butylene terephthalate composite material containing nano-oxide and soybean protein isolate, calculated in parts by mass, its composition and content are as follows:

[0034]

[0035] Above-mentioned formula reacts according to the following steps:

[0036] (1) Put a certain amount of soybean protein isolate into a 60°C oven and dry to constant weight, then take a certain amount of pre-dried soybean protein isolate, add epichlorohydrin (45% by mass fraction of soybean protein isolate) ) in a beaker, stirred evenly with a glass rod, and then placed in a mold of a flat vulcanizing machine for curing and molding. The temperature of the flat vulcanizing machine was set at 80°C, the pressure was 30 MPa, and the temperature was kept at a constant temperature for 5 minutes.

[0037] (2) After the pressure holding is completed, open the mold and take out the sample. After it is cooled to room temperature, use a high-speed pulverizer to pulverize the so...

Embodiment 3

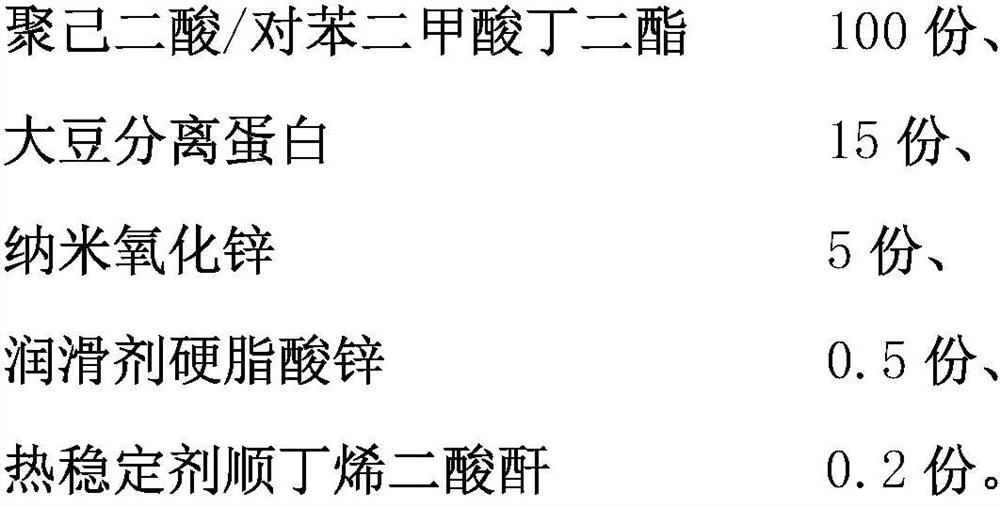

[0042] A modified polyadipate / butylene terephthalate composite material containing nano-oxide and soybean protein isolate, calculated in parts by mass, its composition and content are as follows:

[0043]

[0044] Above-mentioned formula reacts according to the following steps:

[0045] (1) Put a certain amount of soybean protein isolate into a 60°C oven and dry to constant weight, then take a certain amount of pre-dried soybean protein isolate, add epichlorohydrin (45% by mass fraction of soybean protein isolate) ) in a beaker, stirred evenly with a glass rod, and then placed in a mold of a flat vulcanizing machine for curing and molding. The temperature of the flat vulcanizing machine was set at 80°C, the pressure was 30 MPa, and the temperature was kept at a constant temperature for 5 minutes.

[0046] (2) After the pressure holding is completed, open the mold and take out the sample. After it is cooled to room temperature, use a high-speed pulverizer to pulverize the soyb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com