Patents

Literature

44 results about "Polyhexanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyhexanide (polyhexamethylene biguanide, PHMB) is a polymer used as a disinfectant and antiseptic. In dermatological use, it is spelled polihexanide (INN) and sold under names such as Lavasept, Serasept, Prontosan and Omnicide. PHMB has been shown to be effective against Pseudomonas aeruginosa, Staphylococcus aureus (also the methicillin-resistant type, MRSA), Escherichia coli, Candida albicans (yeast), Aspergillus brasiliensis (mold), vancomycin-resistant enterococci, and Klebsiella pneumoniae (carbapenem-resistant enterobacteriaceae).

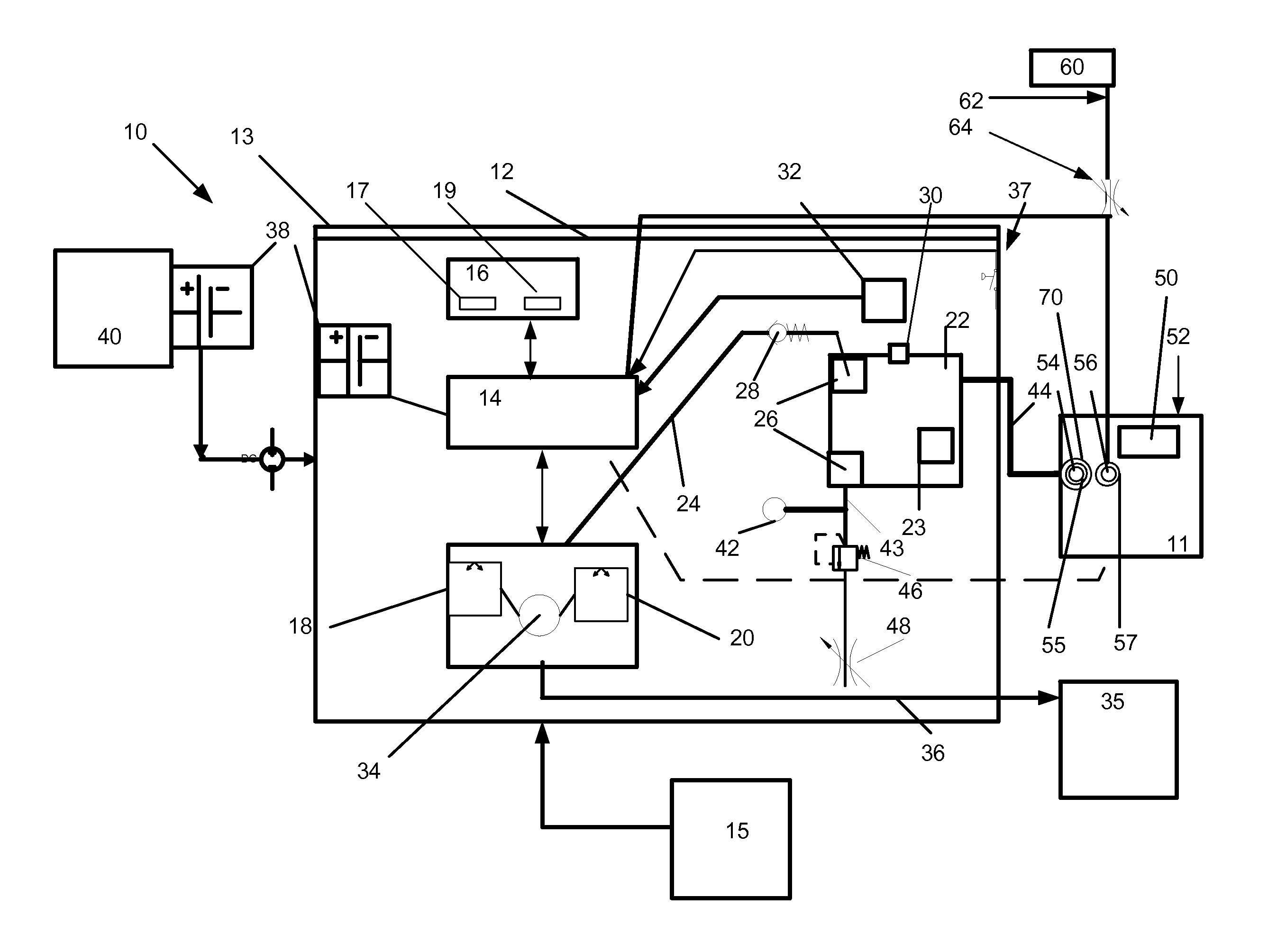

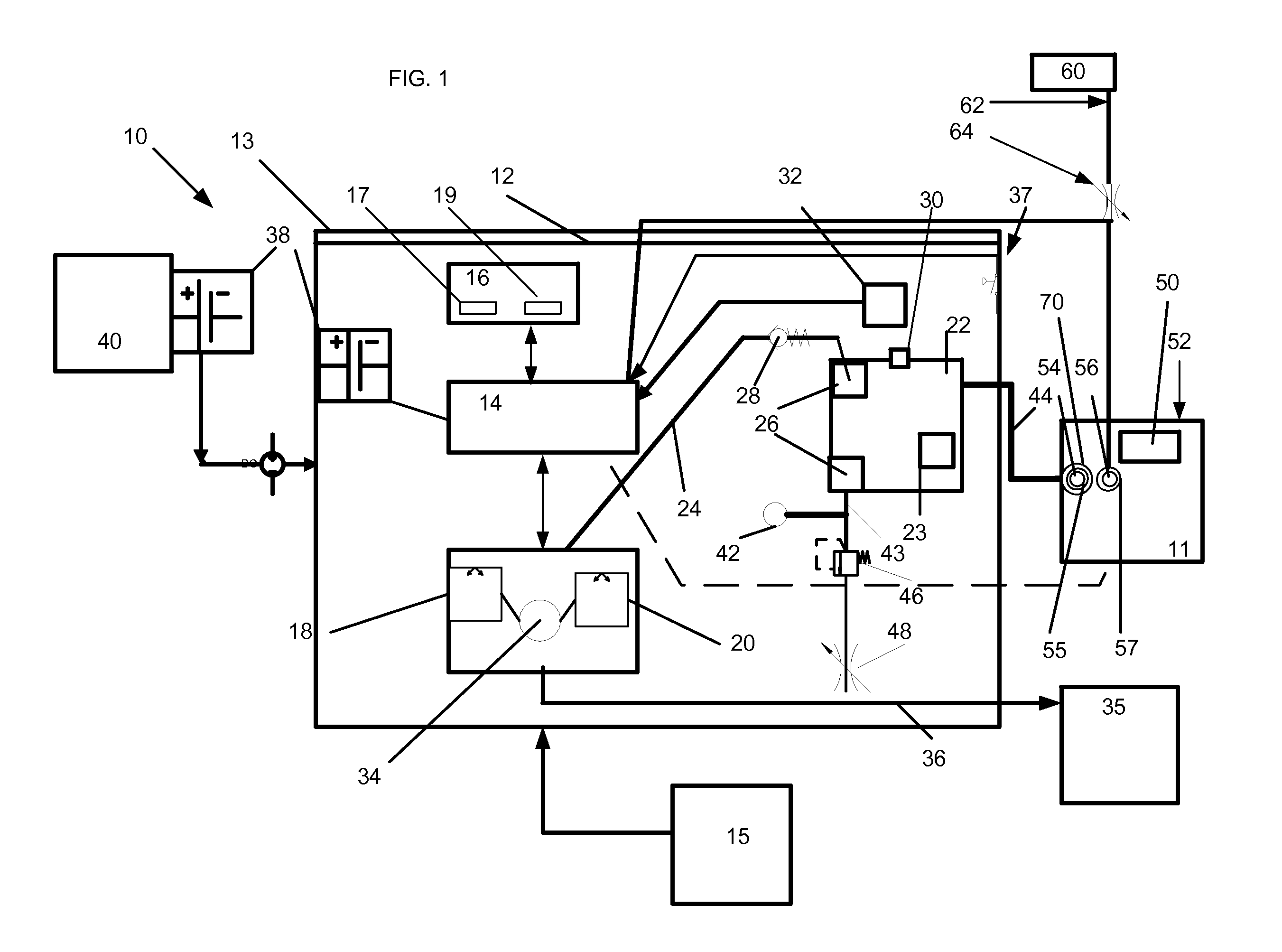

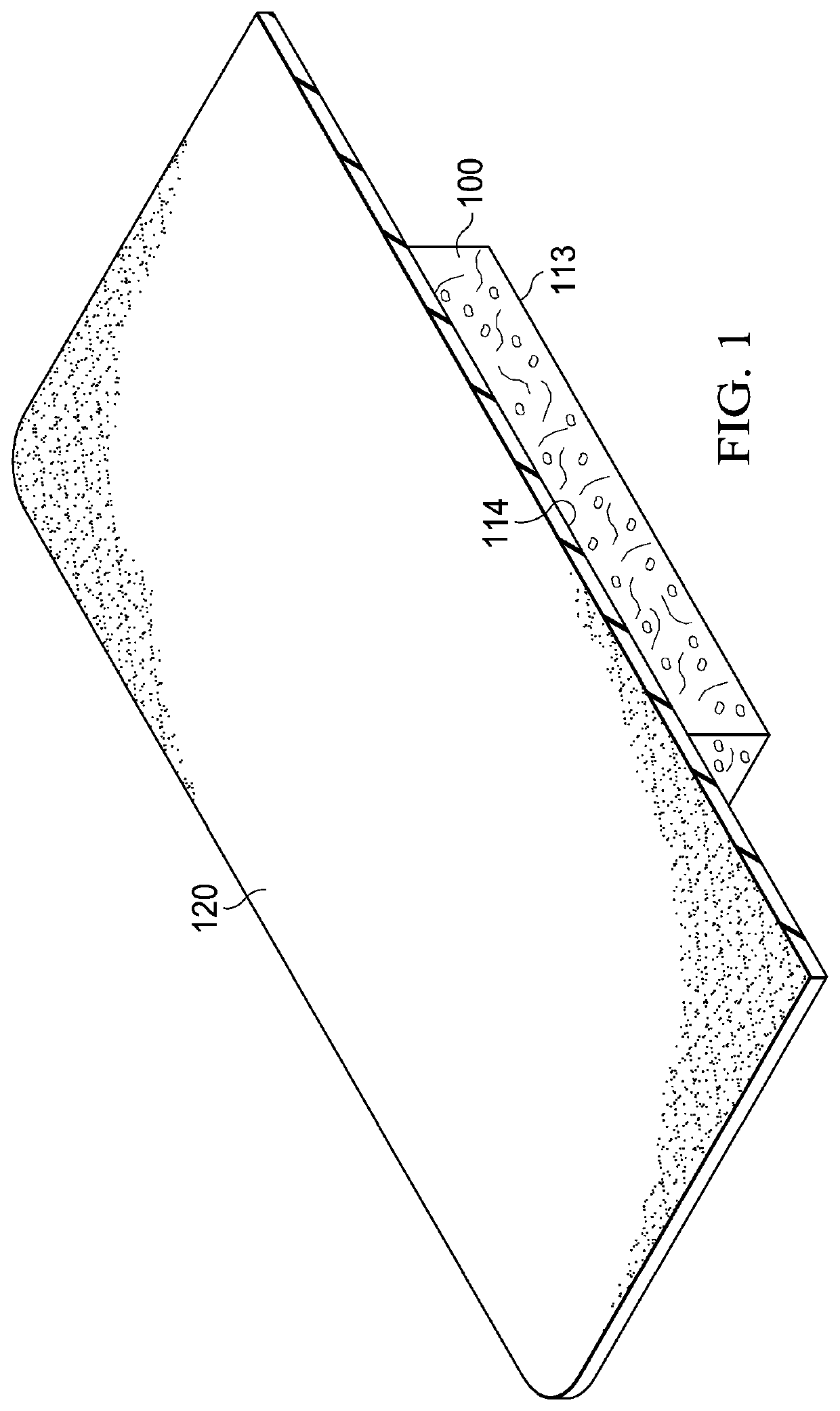

Irrigation Device and Method Using Same

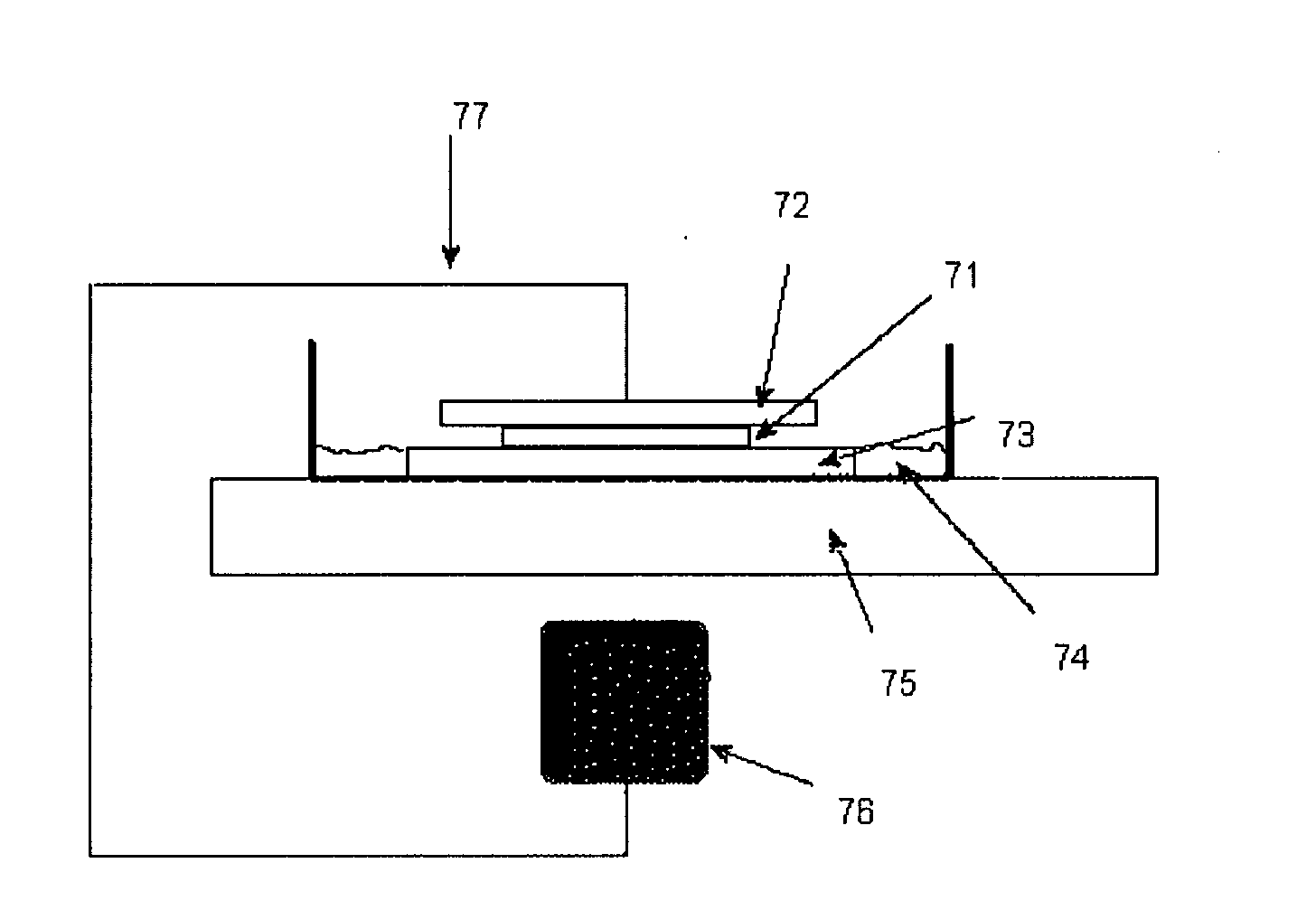

InactiveUS20110015587A1Promote wound healingEasy treatmentMedical devicesMedical applicatorsWound healingDakins Solution

A disposable therapeutic device for the promotion of wound healing providing fluid irrigation and vacuum drainage of a wound includes a housing containing a controller and fluid moving device in a waterproof manner, a fluid mover capable of raising, compressing, or transferring fluid, a controller equipped to restrict fluid moving device in accordance with a predetermined treatment plan or duration, a chargeable power source removably connected to the housing, an optional therapeutic member of a compressible dressing or inflatable cuff to provide hemostasis, an identification member for regulating the operation of the device in accordance with a predetermined treatment plan, a disposable container, a pressure sensor and a control display panel. The fluid includes, but is not limited to, Lactoferrin, Xylitol, Dakins Solution, Polyhexanide and Hypochlorous Acid.

Owner:VOGEL RICHARD C MR

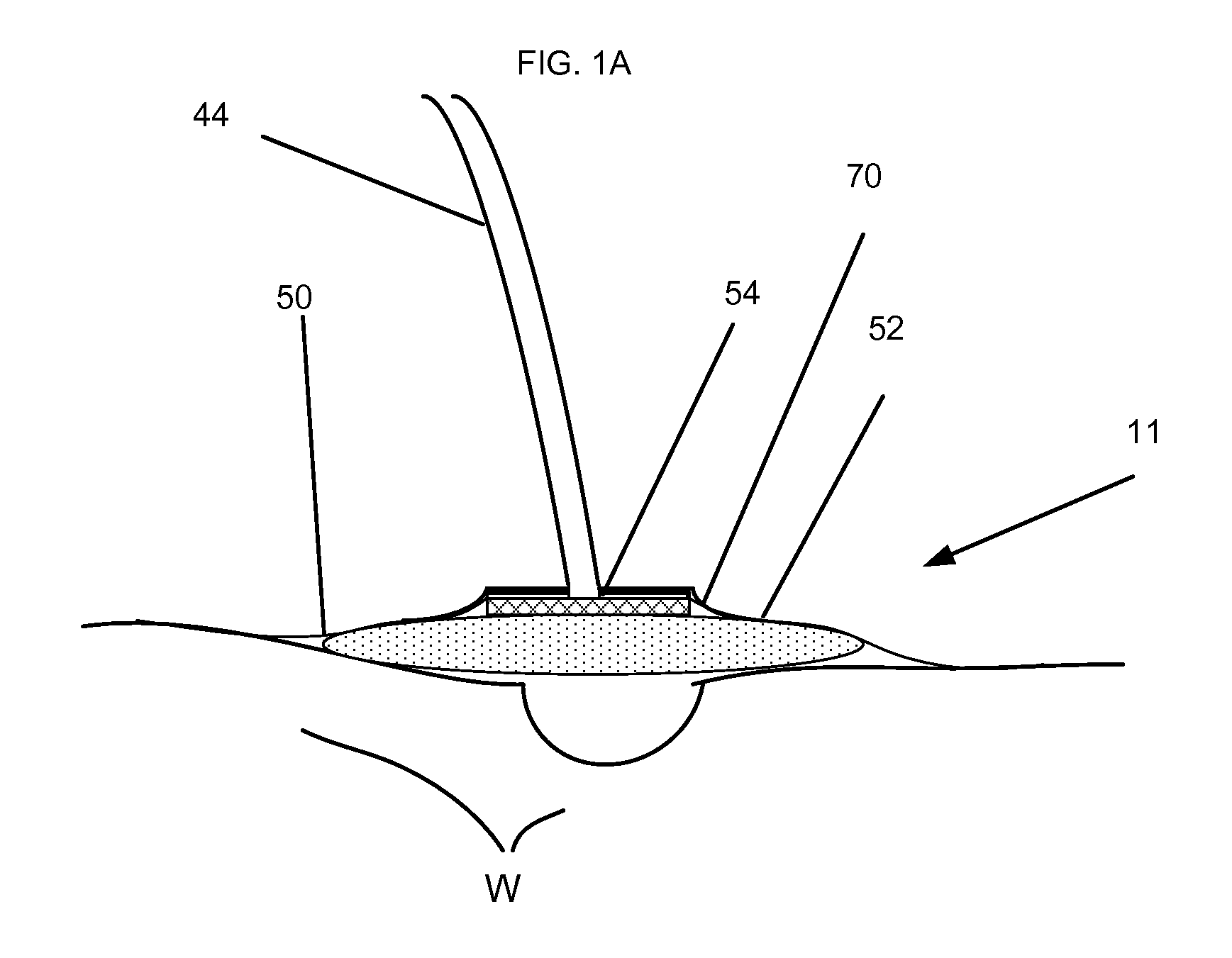

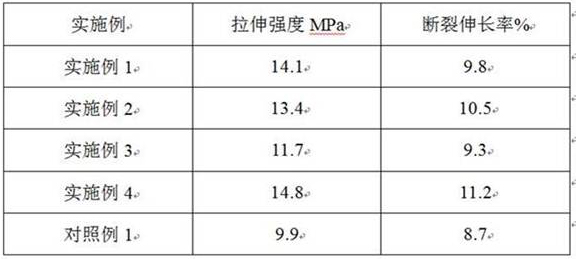

Polylactic acid composition and polylactic acid product

InactiveCN102618003AGood comprehensive mechanical propertiesImprove blow molding processabilityPlasticizerPolylactic acid

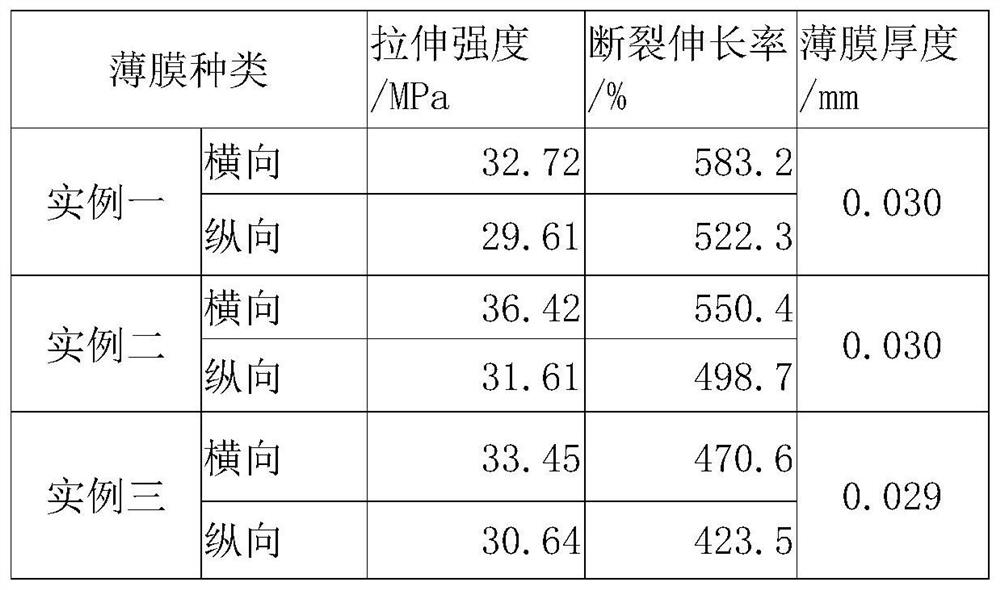

The invention provides a polylactic acid composition and a polylactic acid product. The polylactic acid composition comprises the following components by weight percent: 50 to 80 percent of polylactic acid, 0 to 35 percent of adipic acid-polybutylene terephthalate, 0 to 35 percent of poly(butylene succinate), 0.05 to 0.5 percent of peroxide, 0.05 to 0.5 percent of chain extendor and 3 to 15 percent of plasticizer, wherein the content of the adipic acid-polybutylene terephthalate and the content of the poly(butylene succinate) are not 0 percent. The mechanical properties such as melt strength, elongation at break, tenacity and anti-tear strength of the polylactic acid composition provided by the invention are improved, so that the polylactic acid composition with better comprehensive mechanical properties can be obtained, and the polylactic acid composition has more stable processability and better film forming stability.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Ternary copoly ester capable of biological degradation and its preparation method

A biodegradable three-element copolymer with high mechanical and thermal performance is prepared from the raw material used for synthesizing butanediol polysuccinate, the raw material used for synthesizing ethanediol polysuccinate, hexanediol polysuccinate, etc, and the raw materialused for synthesizing ethanediol polyterephthalate, etc through atactic copolymerizing.

Owner:SICHUAN UNIV

High-toughness, wear-resistant, self-lubricating polyamide material and preparation thereof

The invention discloses a polyamide material with high tenacity, wear-resisting capacity and self-lubricating property and a method for preparing the same. The compositions by weight percentage of the polyamide material are: 65 to 80 percent of polyhexamethylene adipamide, 15 to 23 percent of wear-resistant agent, 0 to 0.5 percent of lubricating agent, 0 to 3 percent of coupling agent, 0 to 0.5 percent of antioxidant, and 5 to 10 percent of toughener. The method improves wear-resisting property and self-lubricating property of the product mainly through auxiliary materials, thereby enlarging the application range of polyamide modified engineering plastics. The product of the invention has the advantages of good toughness, high impact strength, good surface glossiness, excellent chemical resistance and good dimension stability; a part of wear-resisting agent is added in the polyamide material, so the wear-resisting property of the material can be greatly improved; because the application range of the polyamide material is enlarged, wear-resisting requirements of partial transmission parts, shuttle wear parts and anti-sand-scraping parts can be met; and the polyamide material can be widely used for transmission components of an engine, an outer housing of a roller, an outer housing of an engine, a mechanical socket connector and transmission accessories, and can be used in positions which are often contacted and abraded in other transmission devices.

Owner:SHENZHEN KEJU NEW MATERIAL

Medical nonwoven composite material and preparation method thereof

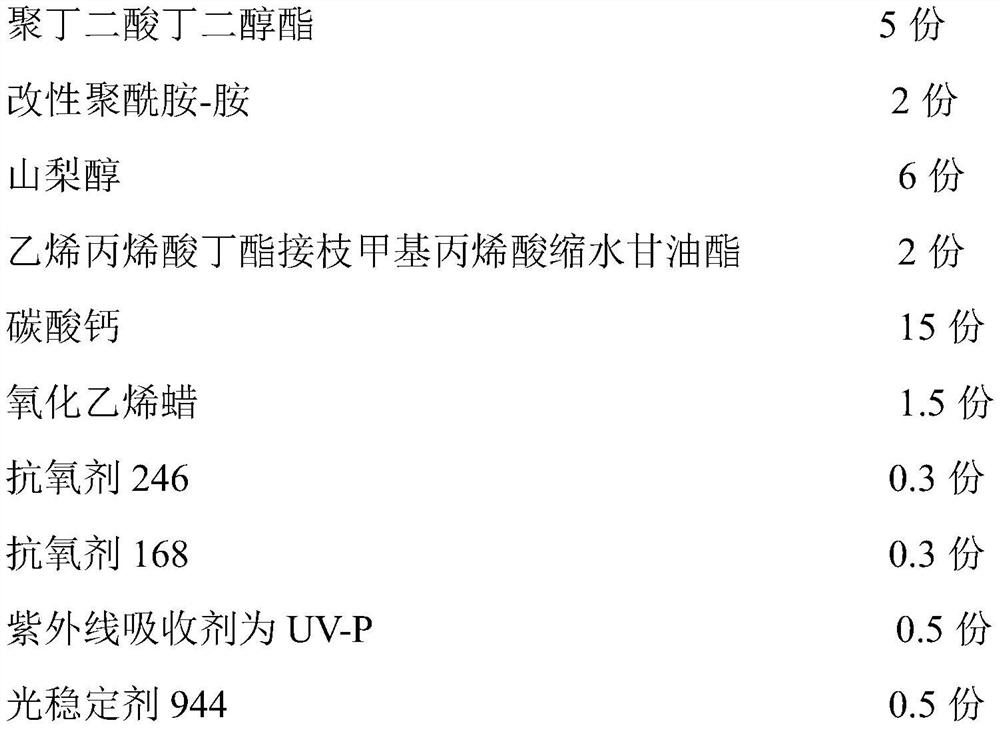

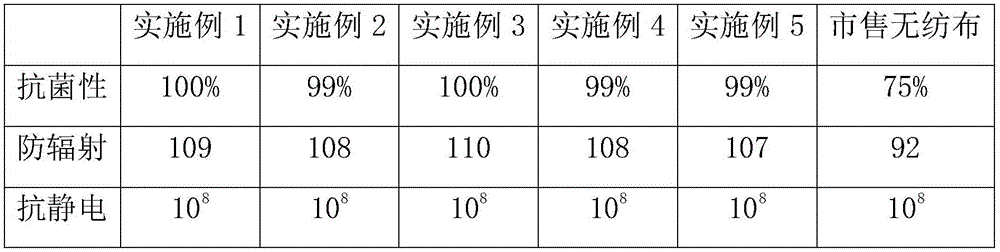

ActiveCN105568562ASolve all aspects of medical needsGood broad-spectrum antibacterial effectElectroconductive/antistatic filament manufactureArtificial thread manufacturing machinesAntistatic agentRespirator

The invention provides a preparation method of a medical nonwoven composite material. The preparation method comprises the following specific steps: (1) respectively weighing 30-50 parts by weight of poly(adipate-co-butylene terephthalate), 20-30 parts by weight of polylactic acid and 30-40 parts by weight of polypropylene, and fully mixing to obtain a mixture A; (2) blending the mixture obtained in the step (1) with 1-4 parts by weight of an antistatic agent and 0.5-2 parts by weight of an antibacterial agent, and extruding and pelletizing by a double-screw extruder to obtain a blend; (3) drying the blend obtained in the step (2) in vacuum, and heating, fusing, extruding, stretching, cooling and self-adhering the dried blend by the screw extruder to obtain a non-woven; and (4) spraying an anti-radiation layer to one side of the non-woven obtained in the step (3), and finally, drying and shaping in a drying oven. The medical nonwoven composite material has antibacterial property as well as anti-radiation and antistatic performance, and is mainly applied to manufacture of medical masks.

Owner:CHTC JIAHUA NONWOVEN CO LTD

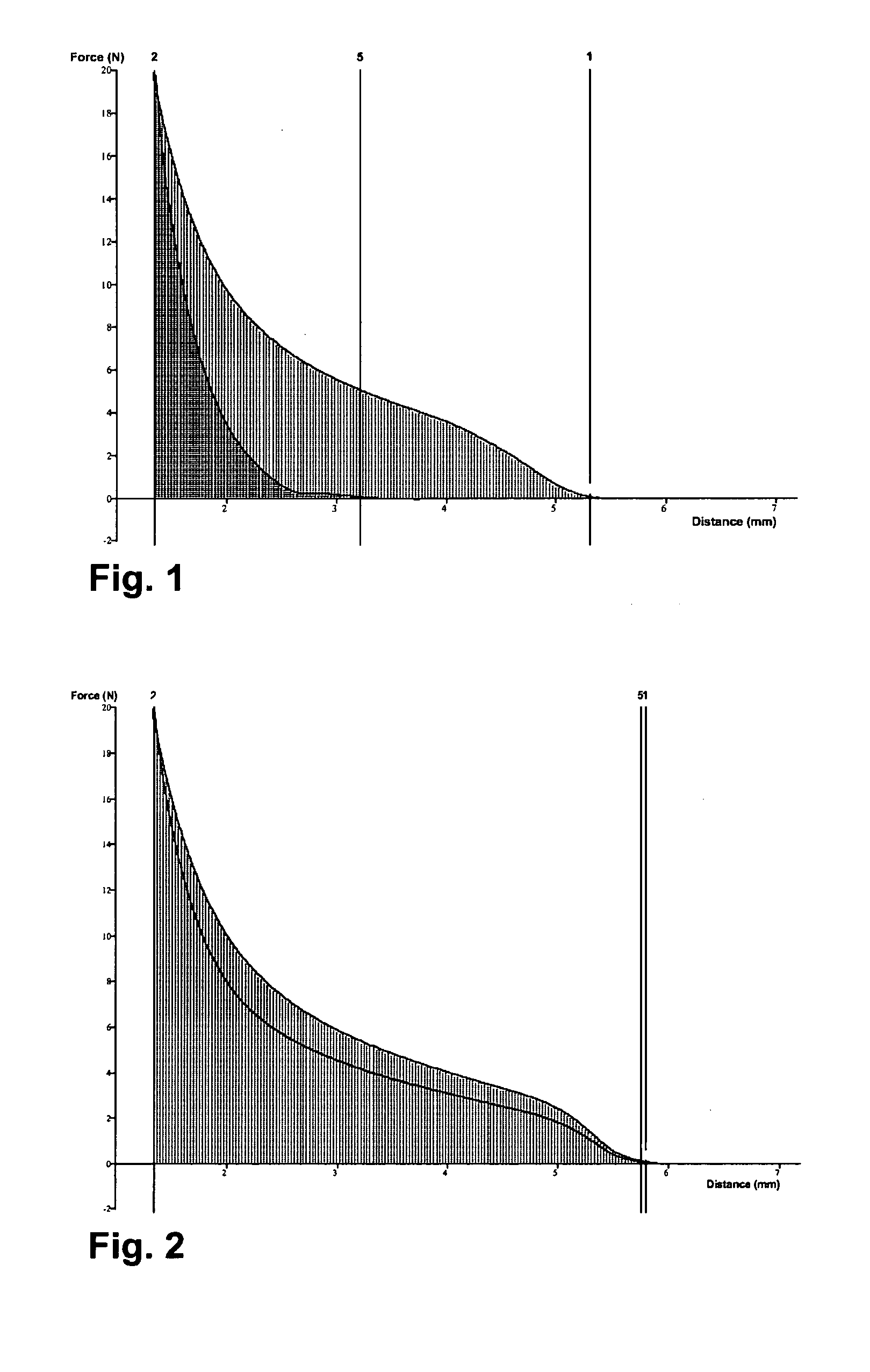

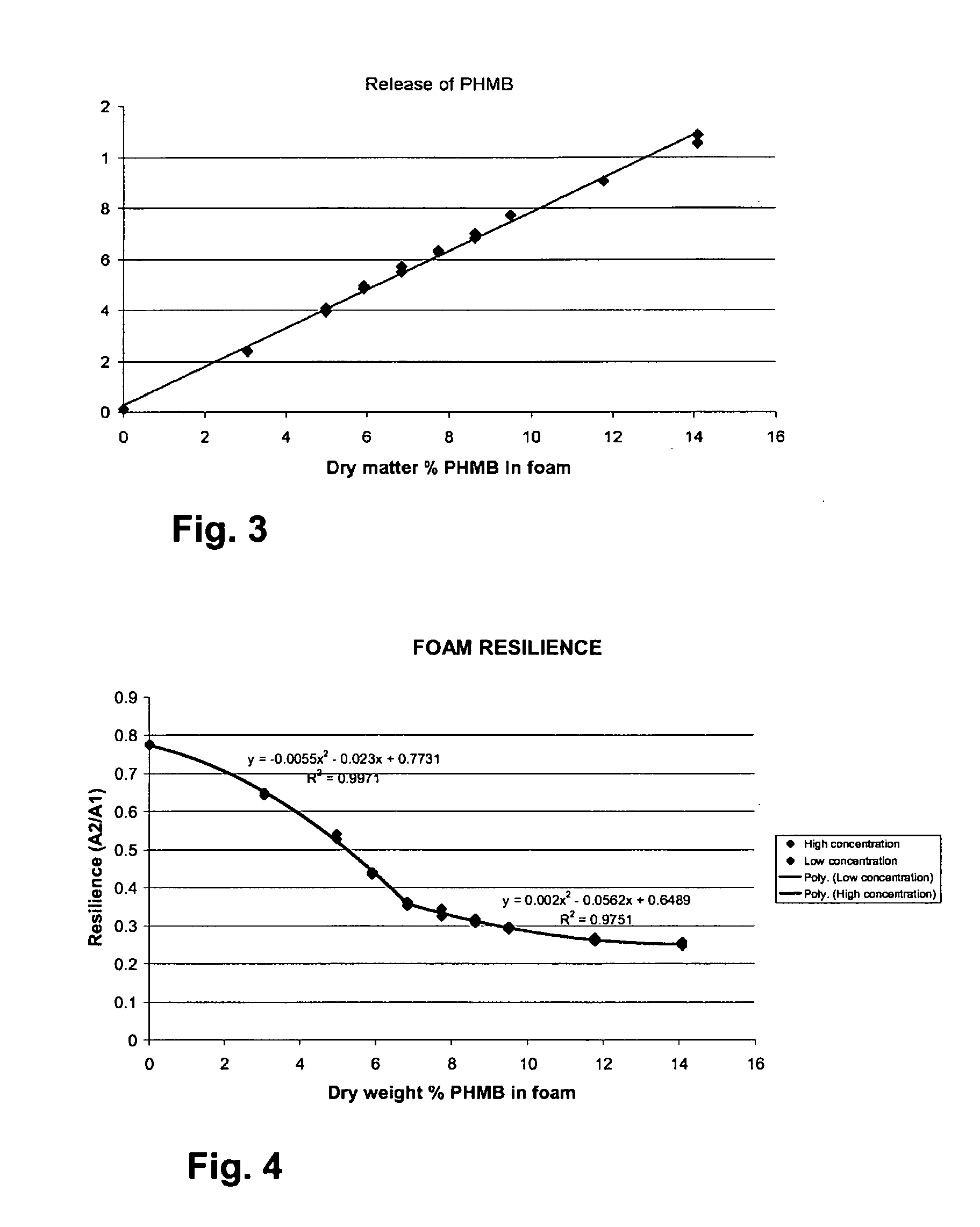

Medical dressing comprising an antimicrobial agent

A medical dressing comprising absorbent polyurethane foam wherein the foam comprises an antimicrobial agent, which can be released from the foam by the action of water. The antimicrobial agent is also used as a control of the resilience of the foam. The antimicrobial agent can be poly(hexamethylene biguanide)hydrochloride, also named PHMB or polyhexanide.

Owner:COLOPLAST AS

Biodegradable material and preparation method thereof

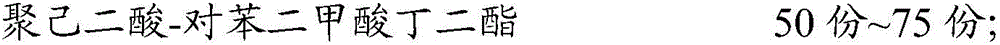

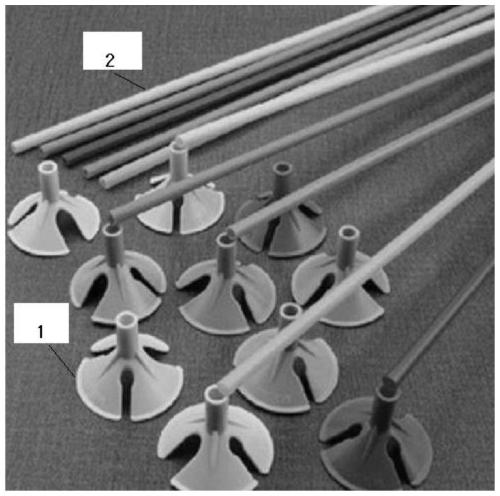

The invention relates to a biodegradable material and a preparation method thereof. The biodegradable material comprises, by weight, 50-75 parts of poly(butyleneadipate-co-terephthalate), 25-50 parts of polypropylene carbonate, 2-8 parts of inorganic filler, 1-5 parts of plasticizers and 0.5-1 part of nucleating agents, wherein the inorganic filler is selected from at least one of montmorillonite, talcum powder, mica and nano-Al2O3. The biodegradable material is capable of blocking off water vapor effectively.

Owner:SHENZHEN PRINCE NEW MATERIALS CO LTD

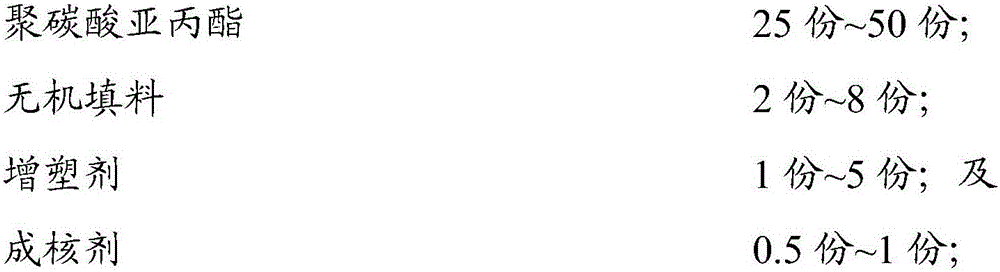

Full-biodegradable balloon bottom support and preparation method thereof

The invention provides a full-biodegradable balloon bottom support and a preparation method. The bottom support is prepared through extrusion and injection molding from the following materials: 70-90parts by mass of polylactic acid, 5-30 parts by mass of a toughening agent, 0-20 parts by mass of a filler, 0.1-2 parts by mass of a lubricant, and 0.1-1 part by mass of a compatibilizer, wherein thetoughening agent is selected from one or more of poly(butyleneadipate-co-terephthalate), polycaprolactone, polyhydroxyalkanoate, polypropylene carbonate, an acrylate degradable polymer and a maleic anhydride grafted degradable polymer, and the compatilizer is selected from one or more of a silane coupling agent, an aluminate substance and a titanate substance. The bottom support component not onlymeets the use requirements of the balloon bottom support, but also can realize complete biodegradation. Meanwhile, the process is simple, the cost is low, and the market competitiveness of the product is stronger.

Owner:海南明宸新材料有限公司 +1

Full-biodegradable mulching film with controllable degradation period and preparation method thereof

InactiveCN112280258AImprove air tightnessImprove moisture conservation effectClimate change adaptationPlant protective coveringsPolymer scienceButanedioic acid

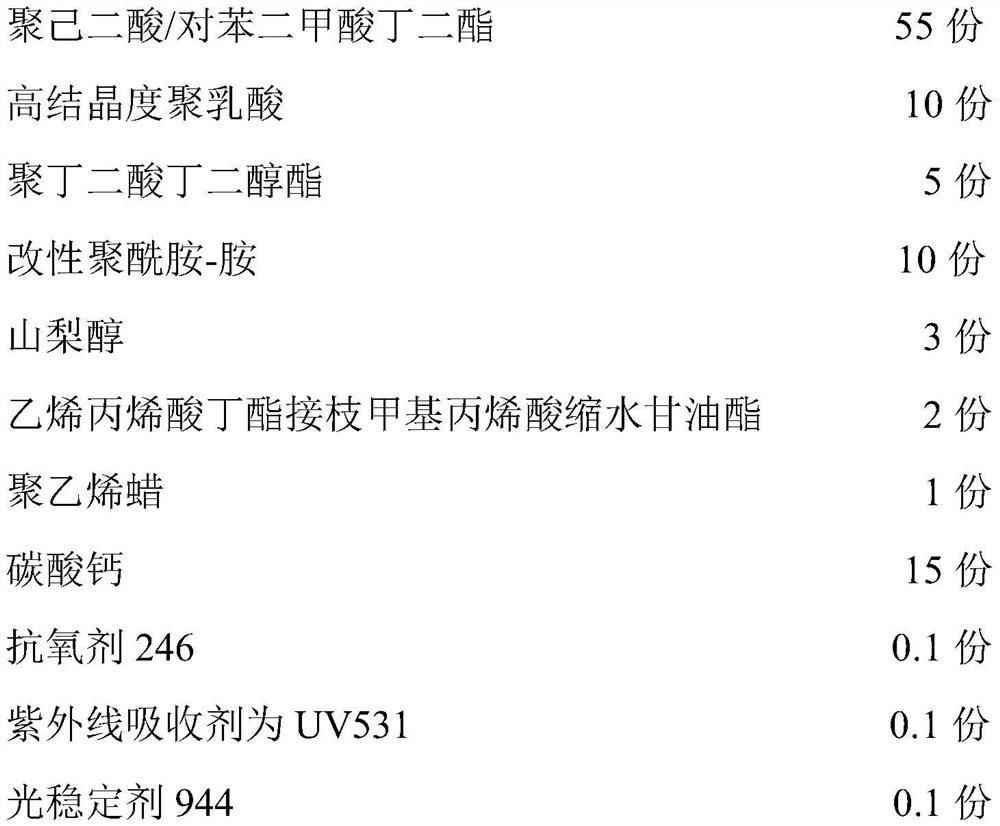

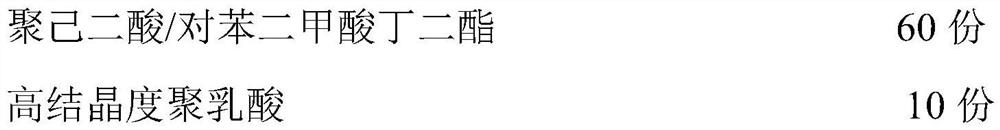

The invention discloses a full-biodegradable mulching film with a controllable degradation period and a preparation method thereof. Raw materials for preparing the mulching film comprise the followingcomponents in parts by weight: 40-60 parts of polyadipic acid / butylene terephthalate, 5-20 parts of high-crystallinity polylactic acid, 5-15 parts of polybutylene succinate, 2-10 parts of modified polyamidoamine, 2-6 parts of aliphatic polyol, 5-20 parts of inorganic filler, 1-5 parts of compatilizer, 1-2.5 parts of dispersing agent, 0.1-2 part of antioxidant, 0.1-5 part of ultraviolet light absorber, 0.1-3 part of a light stabilizer, and 0-0.5 part of an auxiliary agent. By selecting high-crystallinity polylactic acid with good air tightness, the air tightness of the mulching film can be effectively improved, degradation of the mulching film can be accelerated by adding modified polyamidoamine into a polymer, and degradation of the mulching film can be accelerated by adjusting the typesand the use amounts of the antioxidant, the ultraviolet light absorber and the light stabilizer as well as the dispersing agent and the auxiliary agent. The degradation time of the full-biodegradablemulching film can be regulated and controlled, and the growth requirements of different altitudes, different regions and different crops can be met.

Owner:LANZHOU XINYINHUAN RUBBER & PLASTIC PROD CO LTD

Antibacterial flame-retardant nonwoven composite and preparation method thereof

InactiveCN106042504ASolve all aspects of medical needsImprove antibacterial propertiesSynthetic resin layered productsArtificial filament heat treatmentChemistryActivated carbon

The invention provides an antibacterial flame-retardant nonwoven composite, comprising a first nonwoven layer, a base material layer and a second nonwoven layer sequentially from top to bottom; a first antibacterial layer and an anti-radiation layer are disposed sequentially between the first nonwoven layer and the base material layer, and a second antibacterial layer and a flame-retardant antistatic layer are disposed sequentially between the second nonwoven layer and the base material layer; the first antibacterial layer is a porous nano activated carbon silver-supported antibacterial agent coating 15-50 nm in particle size, and the second antibacterial layer is a bio-polypeptide antibacterial agent layer; the first and second nonwoven layers are made from polyadipic acid / butylene terephthalate, polypropylene and polycaprolactam through melt-blowing; the medical nonwoven composite prepared herein is antibacterial, anti-radiation, flame-retardant and antistatic and is mainly used in the field of medical use.

Owner:毛文明

Degradable antibacterial material for medical treatment and public health and preparation method thereof

InactiveCN113025016AImprove antibacterial propertiesHas antibacterial propertiesTriclosanAntimicrobial action

The invention relates to the technical field of preparation of high polymer materials, and particularly discloses a degradable antibacterial material for medical treatment and public health and a preparation method thereof. The degradable antibacterial material for medical treatment and public health comprises the following raw material components in parts by weight: 50-80 parts of polylactic acid, 30-50 parts of poly(butylene adipate / terephthalate), 30-50 parts of starch, 0.5-2 parts of an antibacterial agent, 1-3 parts of antibacterial essential oil, 1-3 parts of a lubricant, and 1-10 parts of a dispersant. The invention provides the degradable antibacterial material for medical treatment and public health and with a brand new composition; the antibacterial agent triclosan and the antibacterial essential oil are added into the material, so that the material can play an antibacterial role in medical use and can be automatically degraded when being discarded.

Owner:广州暨明科技有限公司

Fully-biodegradable air bubble film and preparation process thereof

InactiveCN111114077AGood compatibilityPrevent extrusionFlexible coversWrappersPolymer sciencePolybutylene

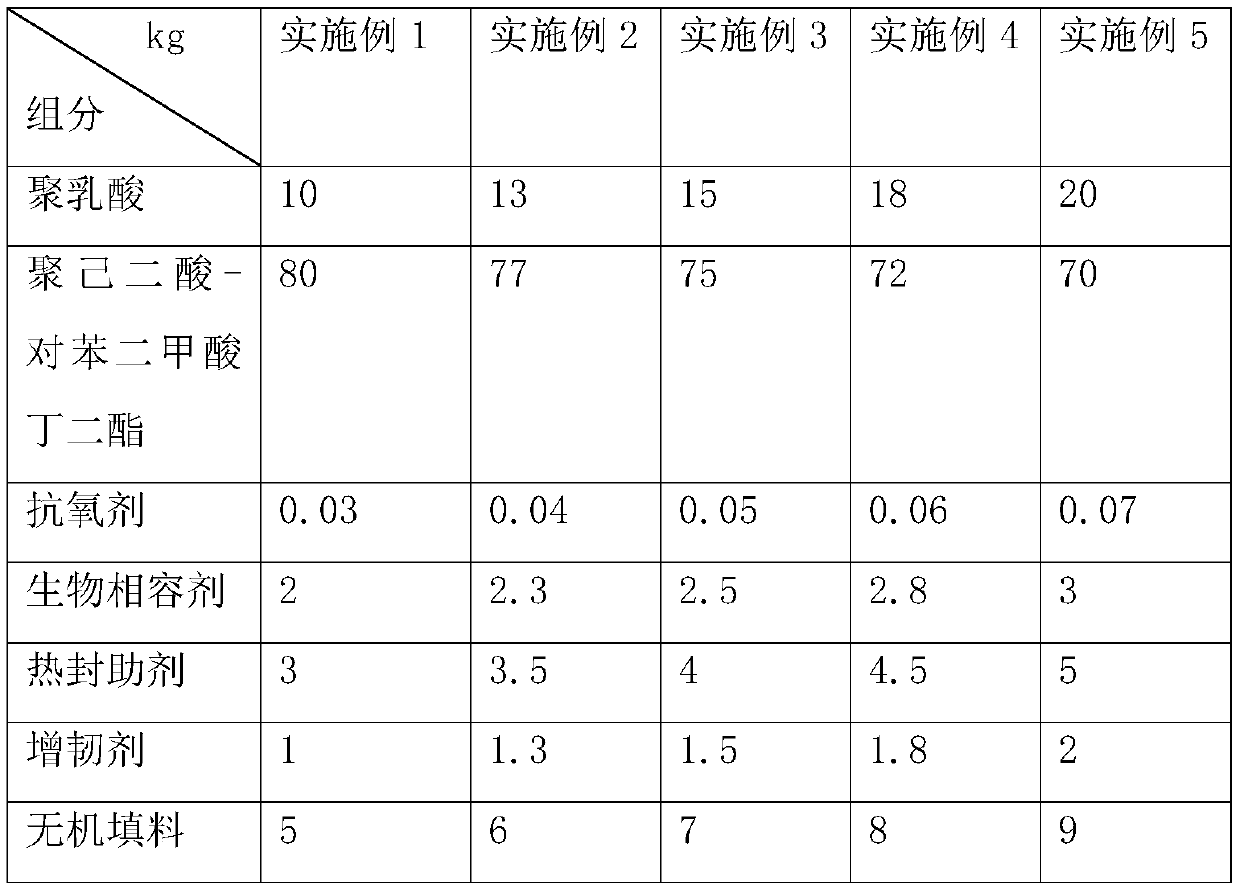

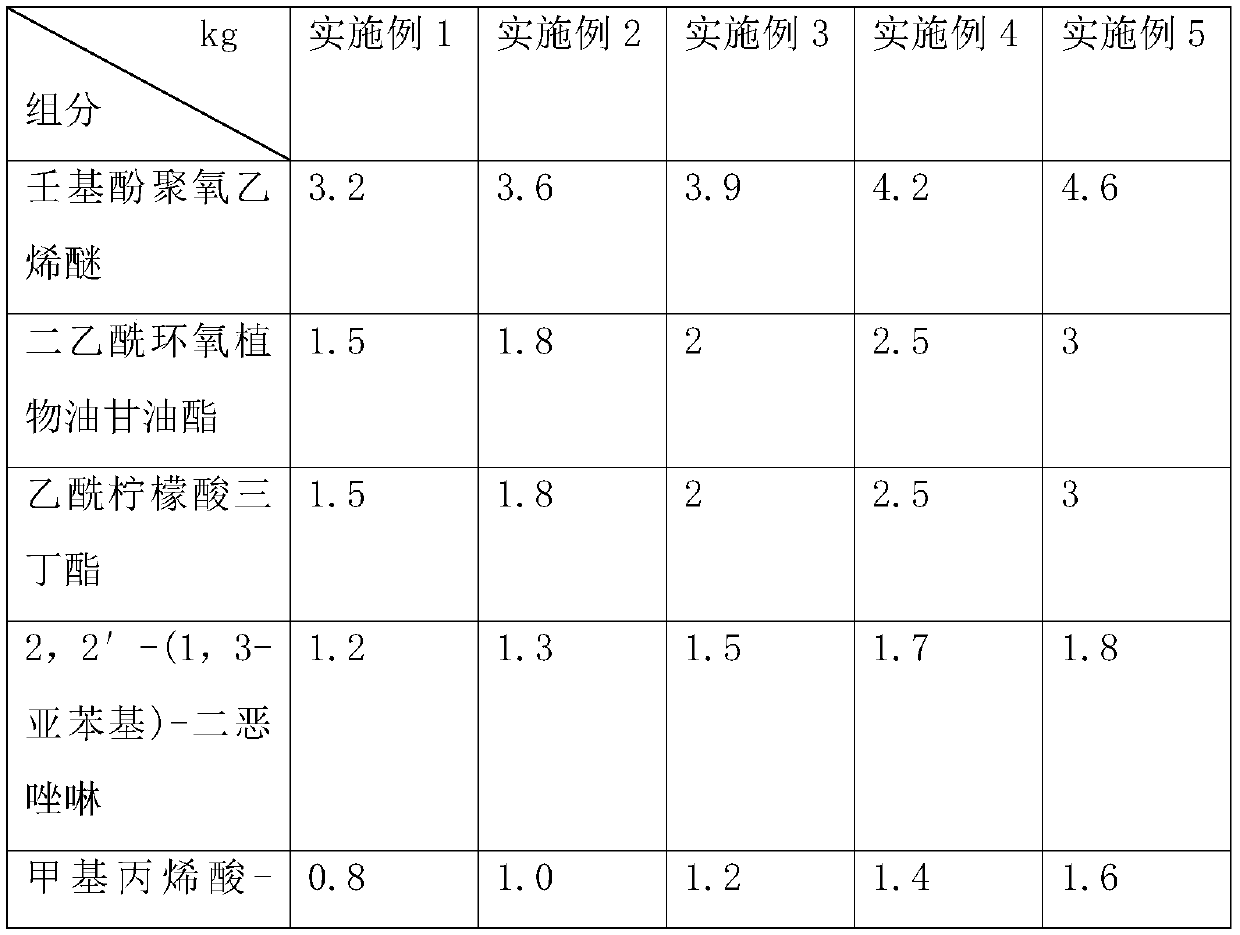

The invention discloses a fully-biodegradable air bubble film and a preparation process thereof. The fully-biodegradable air bubble film comprises a surface layer, an air bubble layer and an inner layer which are compounded in sequence; the surface layer, the bubble layer and the inner layer are prepared from, by weight, 10 to 20 parts of polylactic acid, 70 to 80 parts of polybutylene adipate-terephthalate, 0.03 to 0.07 part of an antioxidant, 2 to 3 parts of a biocompatilizer, 3 to 5 parts of a heat sealing auxiliary agent, 1 to 2 parts of a toughening agent and 5 to 9 parts of an inorganicfiller; and the heat sealing auxiliary agent is prepared from nonylphenol polyoxyethylene ether, diacetyl epoxy vegetable oleic acid glyceride, acetyl tributyl citrate, 2,2'-(1,3-phenylene)-dioxazoline and 2,2,2-trifluoroethyl methacrylate. The fully-biodegradable air bubble film has the advantages of being high in degradation speed, excellent in mechanical property, high in heat sealing strength,good in heat preservation property and buffer shock resistance and capable of insulating sound and reducing noise.

Owner:周锐

Enhanced fully biodegradable material and preparation method thereof

The invention relates to an enhanced fully biodegradable material and a preparation method thereof. The enhanced fully biodegradable material is prepared from the following raw materials in parts by weight: 61-69.5 parts of polyhexamethylene terephthalate, 27-30 polylactic acid, 0.5-1 part of a carbon nano tube and 2-8 parts of a coupling reagent. According to the fully biodegradable material, through adding a proper amount of the carbon nano tube, a prepared fully biodegradable material has excellent mechanical properties, and is good in film-forming property; a prepared film has high tensile strength and high elongation rate; compared with a film prepared from a common fully biodegradable material, the tensile strength and the elongation rate of the film prepared from the fully biodegradable material provided by the invention can be improved by over 50%. In addition, the fully biodegradable material can be quickly degraded into carbon dioxide, water, humus and the like, and does not cause pollution to the environment.

Owner:LANZHOU XINYINHUAN RUBBER & PLASTIC PROD CO LTD

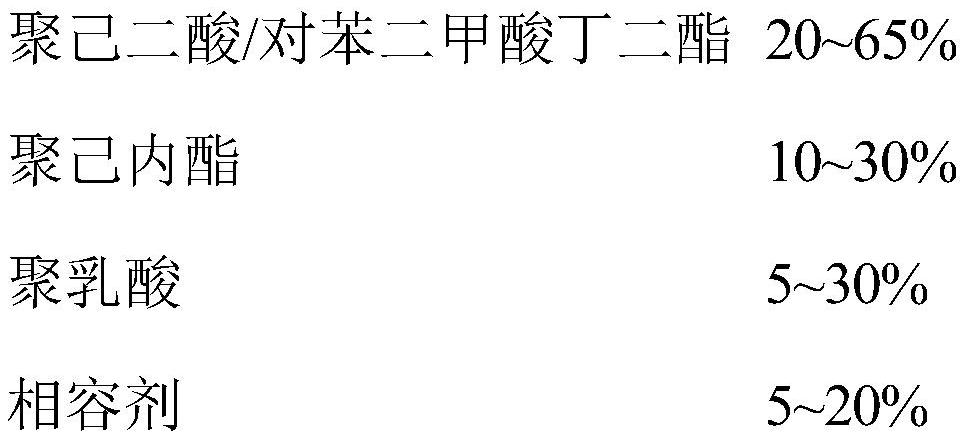

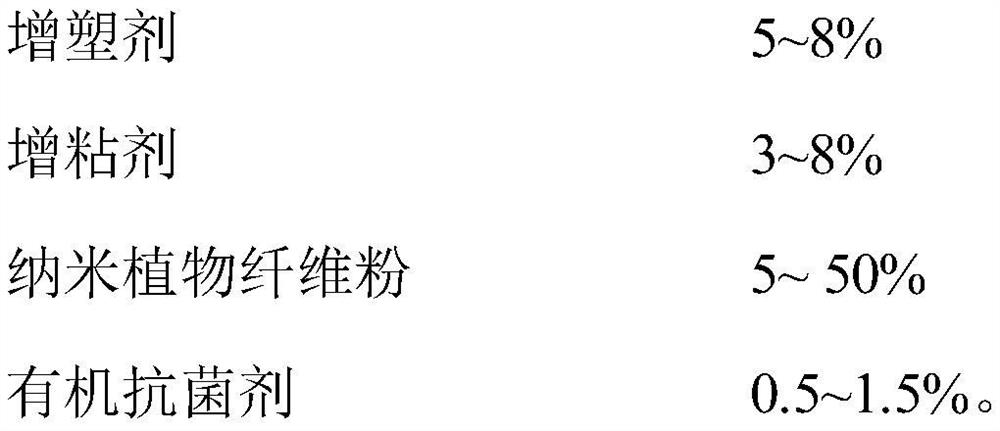

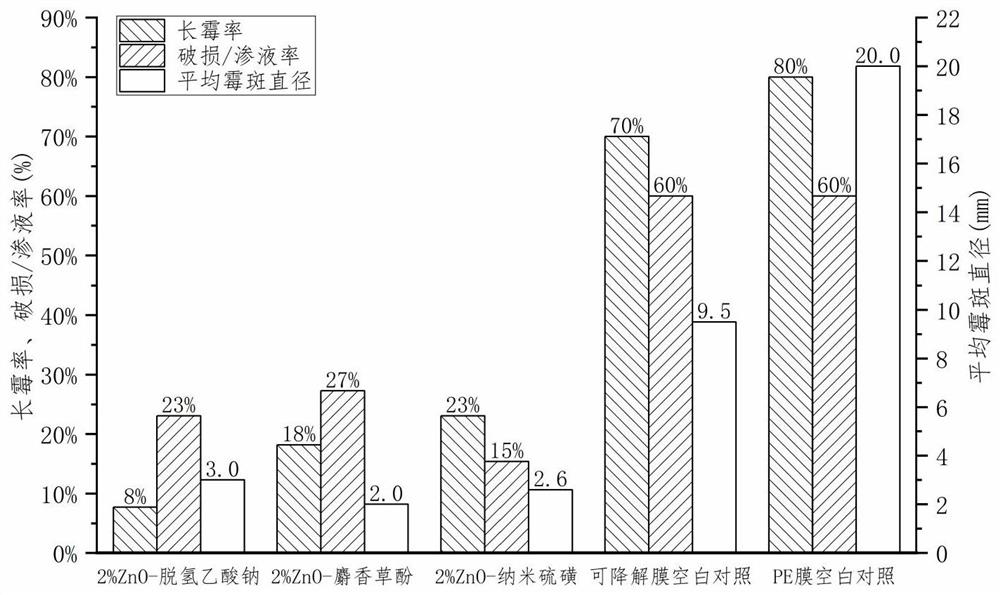

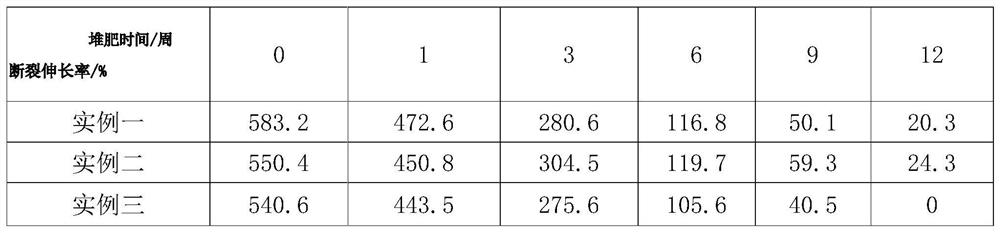

Antibacterial biodegradable composite material as well as preparation method and application thereof

InactiveCN112442261AInhibition of reproductionKeep yourself cleanFlexible coversWrappersVegetable fibersAdipic acid

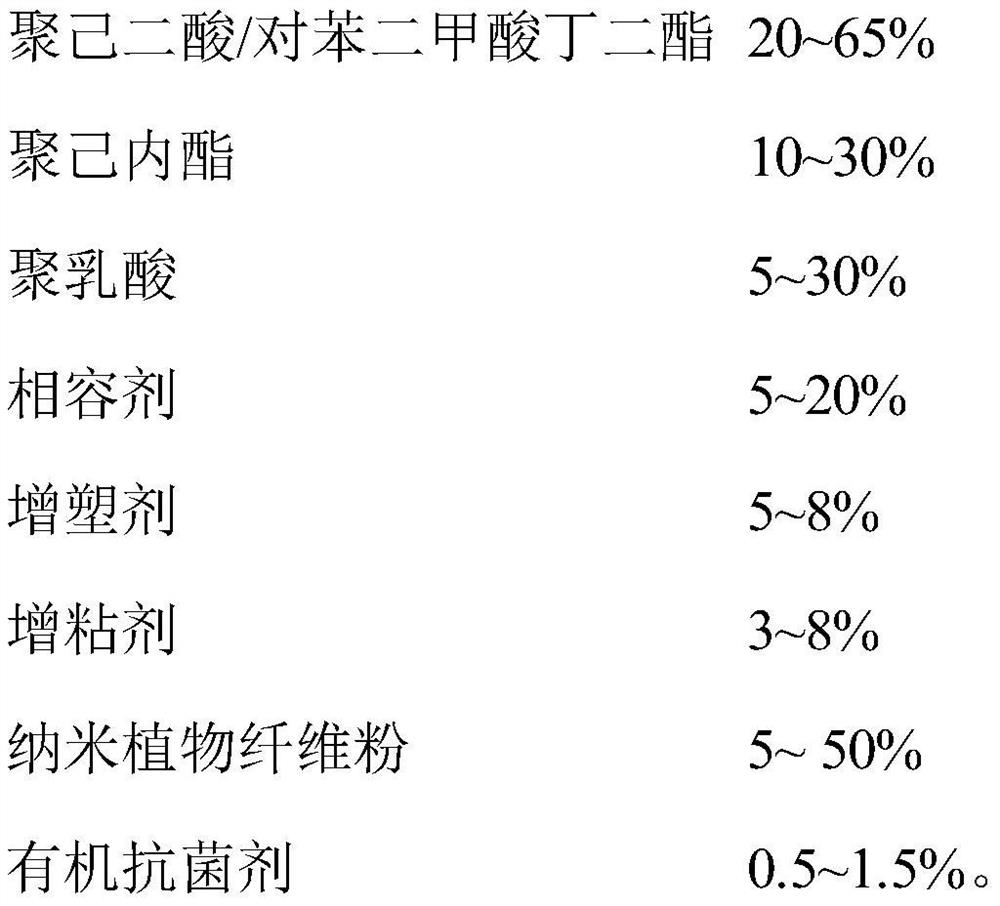

The invention discloses a biodegradable composite material as well as a preparation method and application thereof. The composite material is prepared by mixing the following raw materials in percentage by weight: 20-65% of polyadipic acid / butylene terephthalate, 10-30% of polycaprolactone, 5-30% of polylactic acid, 5-20% of compatilizer, 5-8% of plasticizer, 3-8% of tackifier, 5-50% of nano plantfiber powder and 0.5-1.5% of organic antibacterial agent. By means of the synergistic effect of the degradable plastic, the nano plant fiber powder and the organic antibacterial agent, the biodegradable plastic can be subjected to antibacterial modification, and therefore, the product is endowed with antibacterial and bactericidal effects, so that the product has the effects of inhibiting microbial reproduction and keeping the surface of the material clean; and the product has the effect of prolonging thefood fresh-keeping period when being used for food packaging; the degradable material canalso be used for packaging medical products; and the application range of the degradable material is expanded.

Owner:李小文

Low-surface energy polyamide 66 engineering plastic and preparation method thereof

The invention provides a low-surface energy polyamide 66 engineering plastic and a preparation method thereof. The preparation method comprises the following steps: mixing and extruding 30-90 parts of polyhexamethylene adipamide, 0-40 parts of filling modifier, 10-30 parts of red phosphorus flame retardant, 1-5 parts of zinc borate, 1-5 parts of zinc oxide and 1-5 parts of silicone master batch to prepare the plastic. The silicone master batch is introduced into a PA66 system, the surface energy of the PA66 material can be well reduced, the tin adhesion resistance of the material is improved, and an application of the PA66 material in aspects of electronic electric appliance engineering plastic products is widened. Meanwhile, the production cost is relatively low, and the market requirements can be met.

Owner:HEFEI GENIUS NEW MATERIALS

Completely biodegradable material

The invention discloses a completely biodegradable material, and relates to the technical field of high polymer materials. The completely biodegradable material is prepared from, by weight, 55-65 parts of poly-adipic acid / butylene terephthalate, 35-40 parts of polylactic acid, 2-5 parts of polycaprolactone, 0-2 parts of a lubricating agent, 1-4 parts of an antioxidant, 2-5 parts of an auxiliary and 1-4 parts of packing. According to the completely biodegradable material, a formula of a biodegradable material is optimized, a plastic product made of the material obtained by taking the poly-adipic acid / butylene terephthalate as the main raw materials and cooperating with the appropriate polylactic, polycaprolactone and the other auxiliary materials is excellent in comprehensive mechanical performance, the strength is high, the toughness is good, tensile break is not prone to occurrence, the ductility is high, processing is easy, waste materials can be recycled, no polluting emission occurs in the production process, the final product can be completely decomposed into organic matter under the microorganism action, and a nutrient supplementation effect on soil is achieved.

Owner:JILIN YIYANGSHENG BIOLOGICAL ENVIRONMENTAL PROTECTION TECH CO LTD

Oral delivery system

ActiveUS9820918B2Easy to useEfficient deliveryAntibacterial agentsCosmetic preparationsOral medicationOral treatment

The present invention provides a delivery system for the treatment and / or prevention of infectious pathological changes, including compositions comprising polyhexanide, various pharmaceutical formulations, and processes for using these formulations in oral treatment modalities.

Owner:ARNOLD CHRISTIAN

Water-blocking enhanced degradable antibacterial film as well as preparation method and application thereof

InactiveCN113667168AImprove antibacterial propertiesImprove water resistanceFlexible coversWrappersPolymer sciencePolyvinyl alcohol

The invention discloses a water-blocking enhanced degradable antibacterial film and a preparation method and application thereof. The preparation method includes the steps that: a composite antibacterial agent, an antioxidant and a base material are mixed through a blending method; and granulation is conducted through an LTE16-40 double-screw extruder, a film is prepared through a tape casting method, so that a degradable antibacterial packaging film is obtained; a layer of polyvinyl alcohol (PVA) modified by nano SiO2, stearic acid and glutaraldehyde coats the obtained degradable antibacterial packaging film to obtain the water-resistant barrier degradable antibacterial packaging film. According to the method, the base material comprises 20-40 parts of polylactic acid (PLA) and 60-80 parts of poly (butylene adipate / terephthalate) (PBAT).

Owner:JIANGNAN UNIV

Environment-friendly bio-based high-toughness material for 3D-printed garage kit and preparation method of environment-friendly bio-based high-toughness material

ActiveCN111944119AImprove toughnessHigh strengthAdditive manufacturing apparatus(Hydroxyethyl)methacrylateToluene diisocyanate

The invention provides an environment-friendly bio-based high-toughness material for a 3D-printed garage kit and a preparation method of the environment-friendly bio-based high-toughness material. Theenvironment-friendly bio-based high-toughness material comprises the following components in parts by weight: 30-50 parts of castor oil, 10-30 parts of polyhexamethylene adipate polyol, 15-35 parts of toluene diisocynate, 5-10 parts of hydroxyethyl methacrylate, and 10-20 parts of an active diluent. According to the environment-friendly bio-based high-toughness material for the 3D-printed garagekit, bio-based castor oil is adopted as a raw material, so the prepared high-toughness material is biodegradable, environmentally-friendly and free of pollution; the castor oil and polyhexamethylene adipate polyol are matched for use, so the hardness of the material is guaranteed, the flexibility of the material is improved, and a product prepared from the material is not easy to damage; and the high-toughness material is simple in formula and structure, and the product is good in stability and enhances the use feeling of customers.

Owner:上海奔佑新材料科技有限公司

Ternary copoly ester capable of biological degradation and its preparation method

A biodegradable three-element copolymer with high mechanical and thermal performance is prepared from the raw material used for synthesizing butanediol polysuccinate, the raw material used for synthesizing ethanediol polysuccinate, hexanediol polysuccinate, etc, and the raw materialused for synthesizing ethanediol polyterephthalate, etc through atactic copolymerizing.

Owner:SICHUAN UNIV

Oral delivery system

ActiveUS20150297468A1Easy to useCounteract delayed effectAntibacterial agentsCosmetic preparationsDiagnostic Radiology ModalityOral treatment

The present invention provides a delivery system for the treatment and / or prevention of infectious pathological changes, including compositions comprising polyhexanide, various pharmaceutical formulations, and processes for using these formulations in oral treatment modalities.

Owner:ARNOLD CHRISTIAN

Anaerobic fermentation co-extrusion degradation bag and preparation method thereof

PendingCN113561590AImprove toughnessGood heat sealingSynthetic resin layered productsMicroorganismPolymer science

The invention discloses an anaerobic fermentation co-extrusion degradation bag and a preparation method thereof, the degradation bag comprises an outer layer, a middle layer and an inner layer, the outer layer and the inner layer are prepared by mixing three raw materials of poly (p-butyl adipate) (PBAT), polylactic acid (PLA) and thermoplastic starch resin, the middle layer is prepared from a modified PVA raw material, and the inner layer is prepared from a modified PVA raw material. The outer layer and the inner layer are prepared from the following raw materials in parts by mass: 50 to 60 parts of poly (butylene adipate-co-terephthalate), 20 to 30 parts of polylactic acid and 10 to 30 parts of thermoplastic starch resin. The inner layer and the outer layer are decomposed under the environment of light, heat, microorganisms and the like, when the outer layer is damaged, if the middle layer meets water molecules, the middle layer can be dissolved by water, the degradation rate is increased, fermentative degradation can be carried out within a week, biogas is generated, and the method is friendly to nature and microorganisms. According to the method, water in the natural world is used as a carrier for degradation, the degradation threshold is lower, the speed is higher, environmental protection and saving are achieved, and meanwhile the degradation bag has good toughness and heat sealability.

Owner:GUANGZHOU TONGYUAN PLASTIC PROD CO LTD

Biodegradable material as well as raw material composition, preparation method and application thereof

InactiveCN111849129ALow costImprove mechanical propertiesInsect catchers and killersPolymer scienceBenzoyl peroxide

The invention discloses a biodegradable material as well as a raw material composition, a preparation method and application thereof. The raw material composition of the biodegradable material comprises the following components in parts by weight: 100 parts of poly (butylene adipate-co-terephthalate), 12.5-100 parts of polylactic acid, 12.5-125 parts of hemicellulose and 2.5-37.5 parts of an auxiliary agent, wherein the auxiliary agent comprises the following components in parts by weight: 0.625-5 parts of a crosslinking agent, 1.25-20 parts of a plasticizer and 0.625-7.5 parts of a lubricant,and the crosslinking agent is one or more of dicumyl peroxide, benzoyl peroxide and 2, 5-dimethyl-2, 5-di-tert-butyl hexane peroxide. The biodegradable material and the biodegradable product preparedby the invention can be completely degraded by microorganisms in the nature and do not pollute the environment; the hemicellulose is added into the biodegradable resin, so that the cost is reduced, and the mechanical property of the product is improved; and the application of the hemicellulose is expanded.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

Disposable degradable PPC modified medical material as well as preparation method and application thereof

PendingCN114752203ARemain fully degradableImprove mechanical propertiesButanedioic acidSuccinic acid

The invention discloses a disposable degradable PPC (polypropylene carbonate) modified medical material. The medical carbon dioxide composite material comprises the following components in parts by weight: 20-70 parts of a medical carbon dioxide copolymer, 10-30 parts of polylactic acid, 40-50 parts of poly adipic acid / terephthalic acid succinic acid, 5-10 parts of an antibacterial modifier, 1-5 parts of a flame retardant, 1-5 parts of an anti-aging agent, 2-8 parts of a tackifier, 3-5 parts of a plasticizer and 1-3 parts of an end-capping reagent, the invention also discloses a preparation method and application of the medical material, and the disposable degradable PPC modified medical material disclosed by the invention has wide application prospects in the aspect of manufacturing disposable medical consumables, including degradable disposable throat swabs, samplers, disposable syringes, disposable infusion apparatuses, blood transfusion apparatuses, blood bags, urethral catheters, drainage tubes and the like. And disposable surgical instruments such as a needle holder, tweezers, a surgical knife handle and some special fixing devices in an operation.

Owner:吉林华碳科技发展有限公司

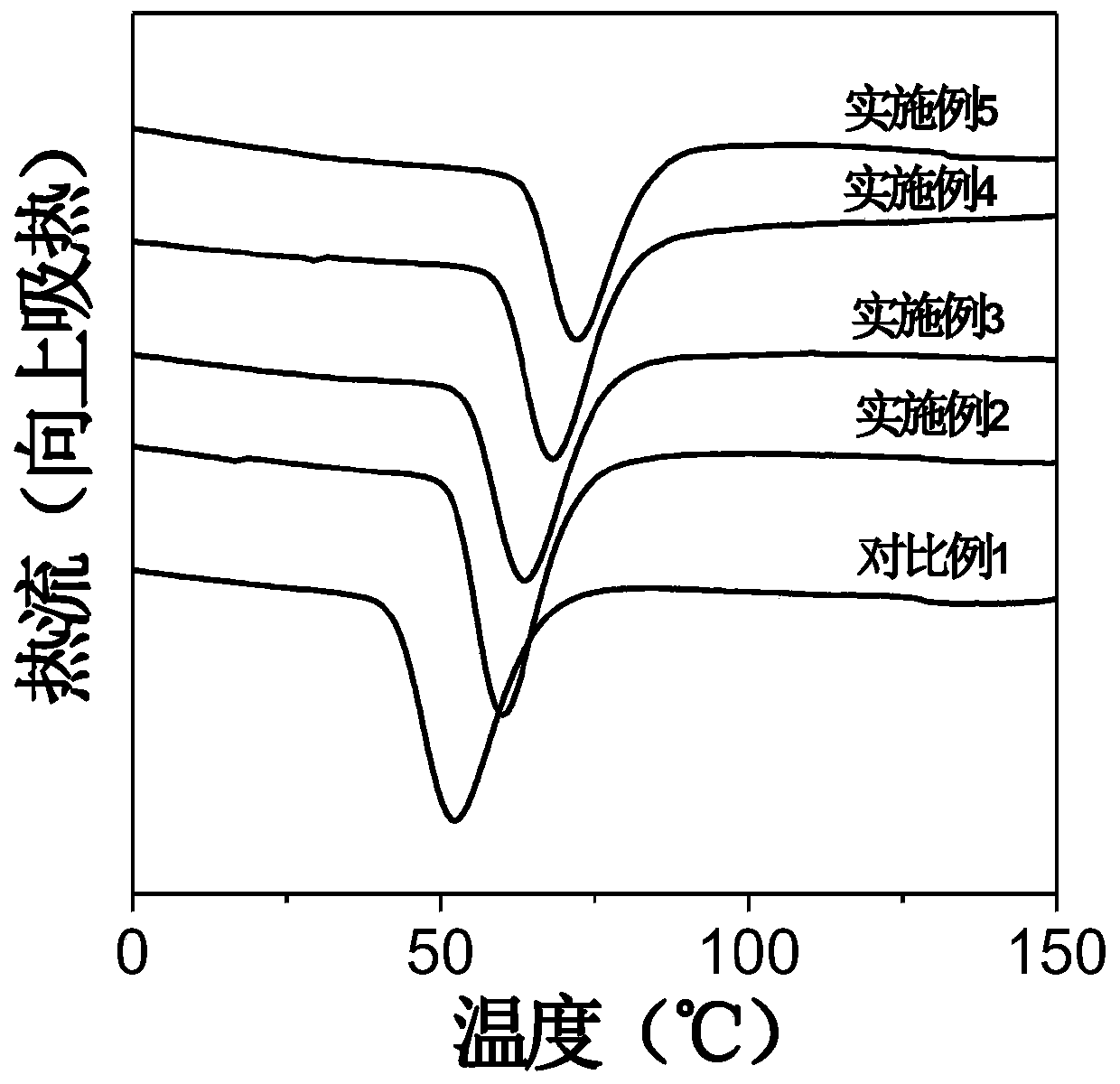

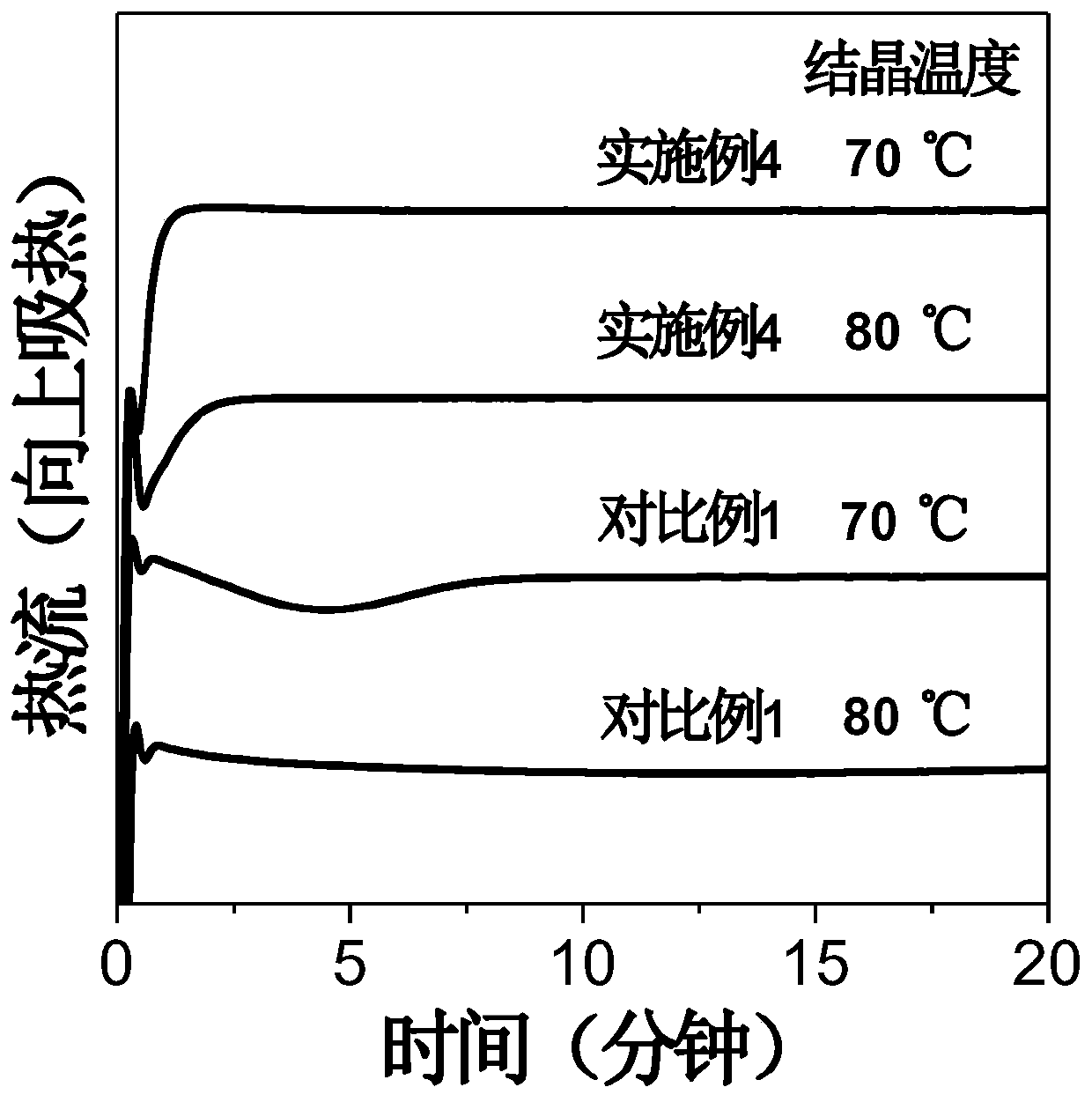

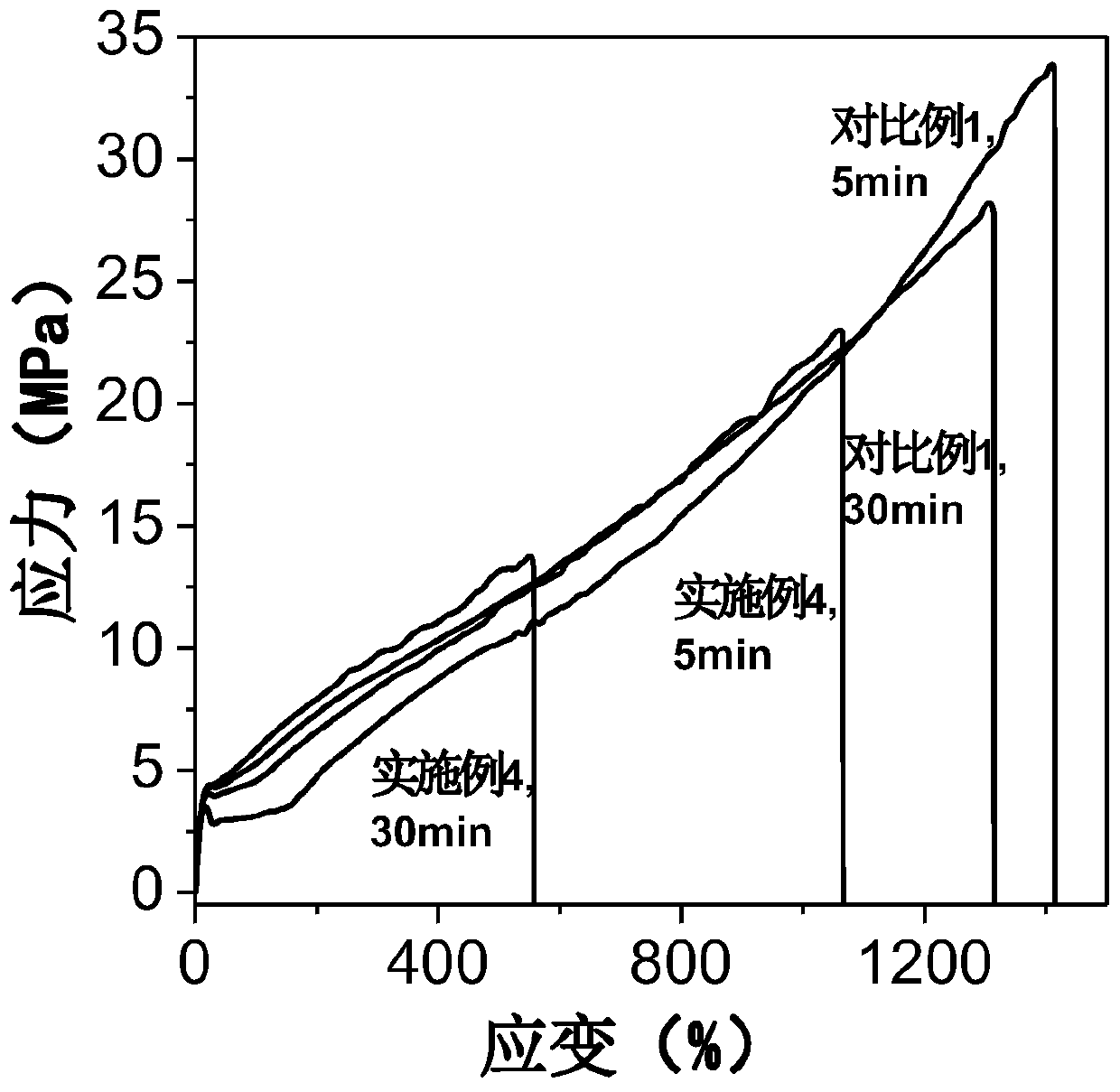

A kind of rapidly crystallized pbat material and preparation method thereof

The invention relates to a modification technology of a biodegradable polymer material, and aims at providing a rapidly crystallized polybutylene adipate terephthalate (PBAT) material and a preparation method thereof. The material is a mixture consisting of polybutylene adipate terephthalate and a nucleating agent, wherein the mass percentage content of the nucleating agent in the mixture is 0.05-5%, the nucleating agent is a complex of melamine and cyanuric acid, and the molar ratio of the melamine to the cyanuric acid is 1:1. According to the invention, the melamine / trimer cyanamide complexis adopted as a nucleating agent to promote the crystallization of the PBAT, so that the crystallization speed and the mechanical property of the PBAT are greatly improved. The nucleating agent has low usage amount and good dispersity in the PBAT, and can effectively improve the crystallization velocity of the PBAT. According to the invention, the crystallization temperature of the PBAT can be improved, the crystallization speed can be improved, and then a PBAT film does not adhere to equipment during processing, so that the processing efficiency of the PBAT film is improved and the processingcost is reduced. The preparation process is simple, the production cost is low, the pollution is small, and large-scale industrial production is easy.

Owner:ZHEJIANG UNIV

Water treatment reactor

InactiveCN112354529AGood removal effectHigh activityOther chemical processesWater contaminantsWire rodPhysical chemistry

The invention discloses a water treatment reactor, which is prepared by the following steps: drying polylactic acid and chitosan in a drying oven for 6-10 hours, cooling, taking out, mixing with polyadipic acid and dibutyl terephthalate, adding into a double-screw extruder, carrying out melt extrusion in the double-screw extruder, and carrying out traction granulation to obtain blended particles,wherein the temperature of the double-screw extruder is 135-160 DEG C, and the rotating speed is 160-240 rpm / min, then adding the blended particles into the single-screw wire extruder, then adding themodified graphene oxide, setting the temperature of the single-screw wire extruder at a certain temperature, then putting the extruded linear material into a mold, pressing the mold at a high temperature for a period of time, cooling and stripping from the mold. The water treatment reactor prepared in the invention has good tensile and impact performances, also has excellent chromium ion removalability, and can remove chromium ions through multiple cycles.

Owner:何雅贵

Preparation method of polylactic acid/polyadipate-butylene terephthalate blend

ActiveCN109467898BImprove microstructureImprove impact toughnessBulk chemical productionPolymer scienceNanoparticle

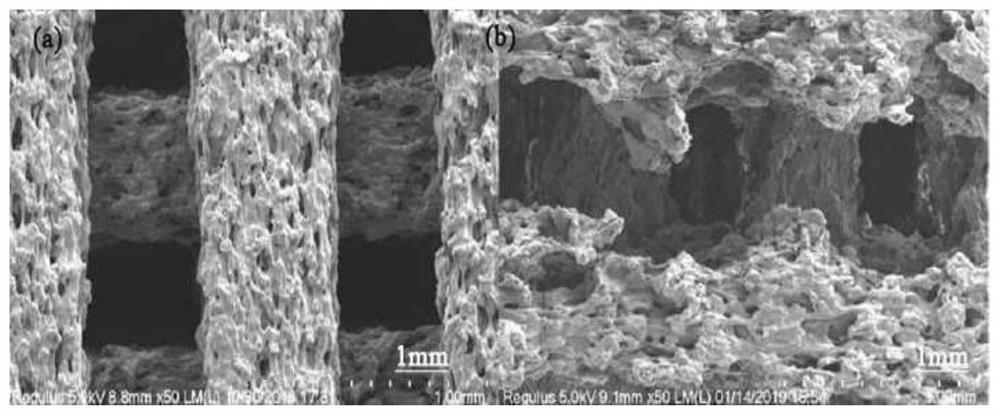

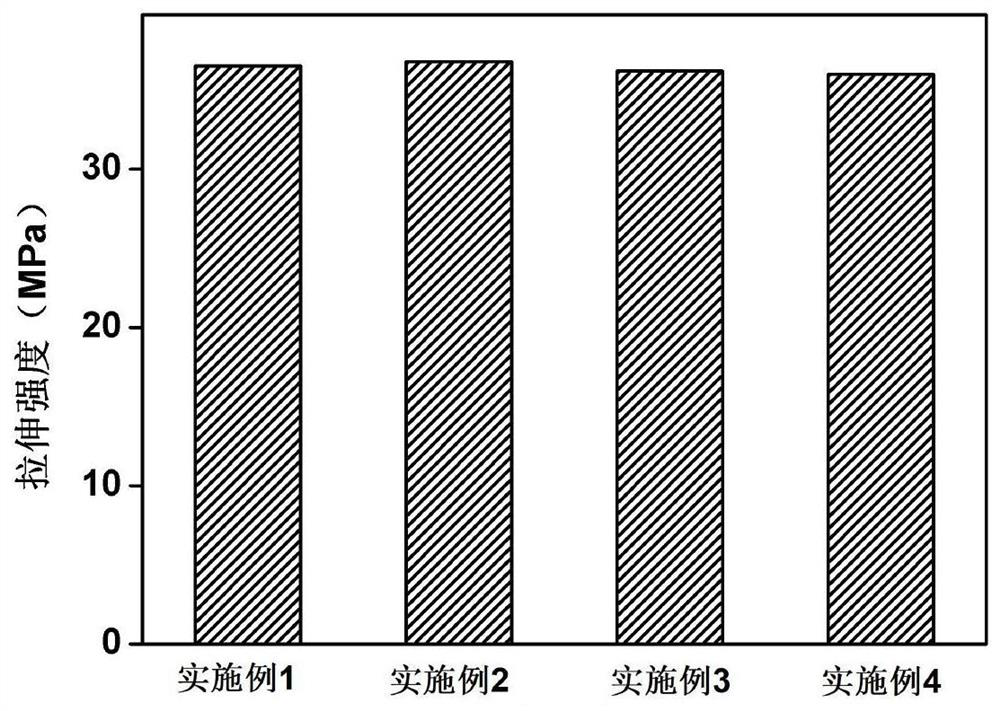

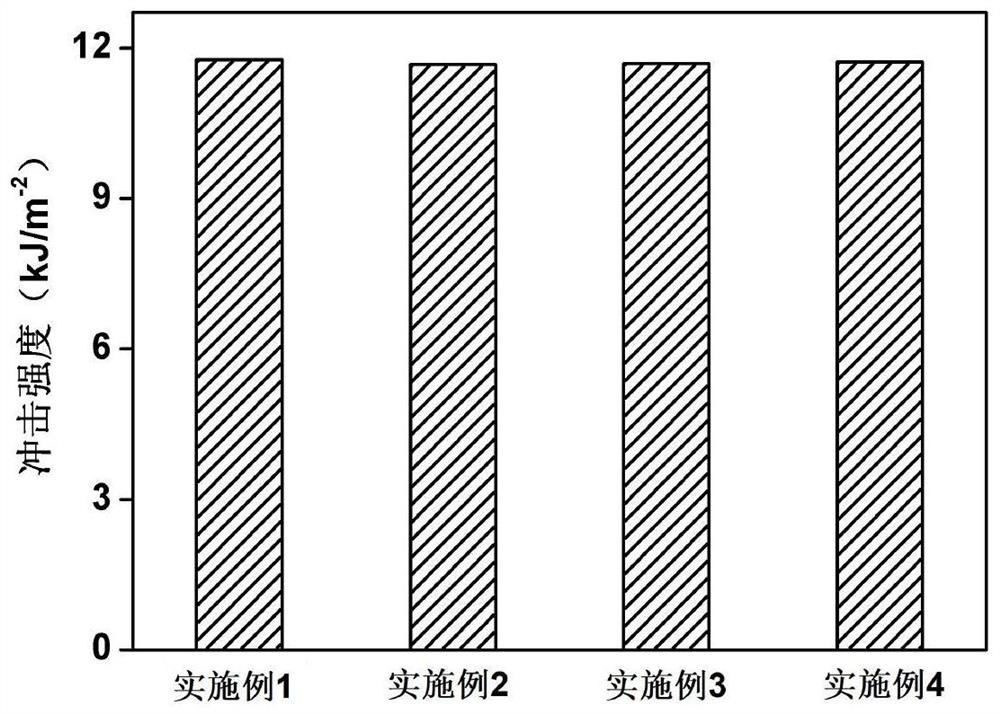

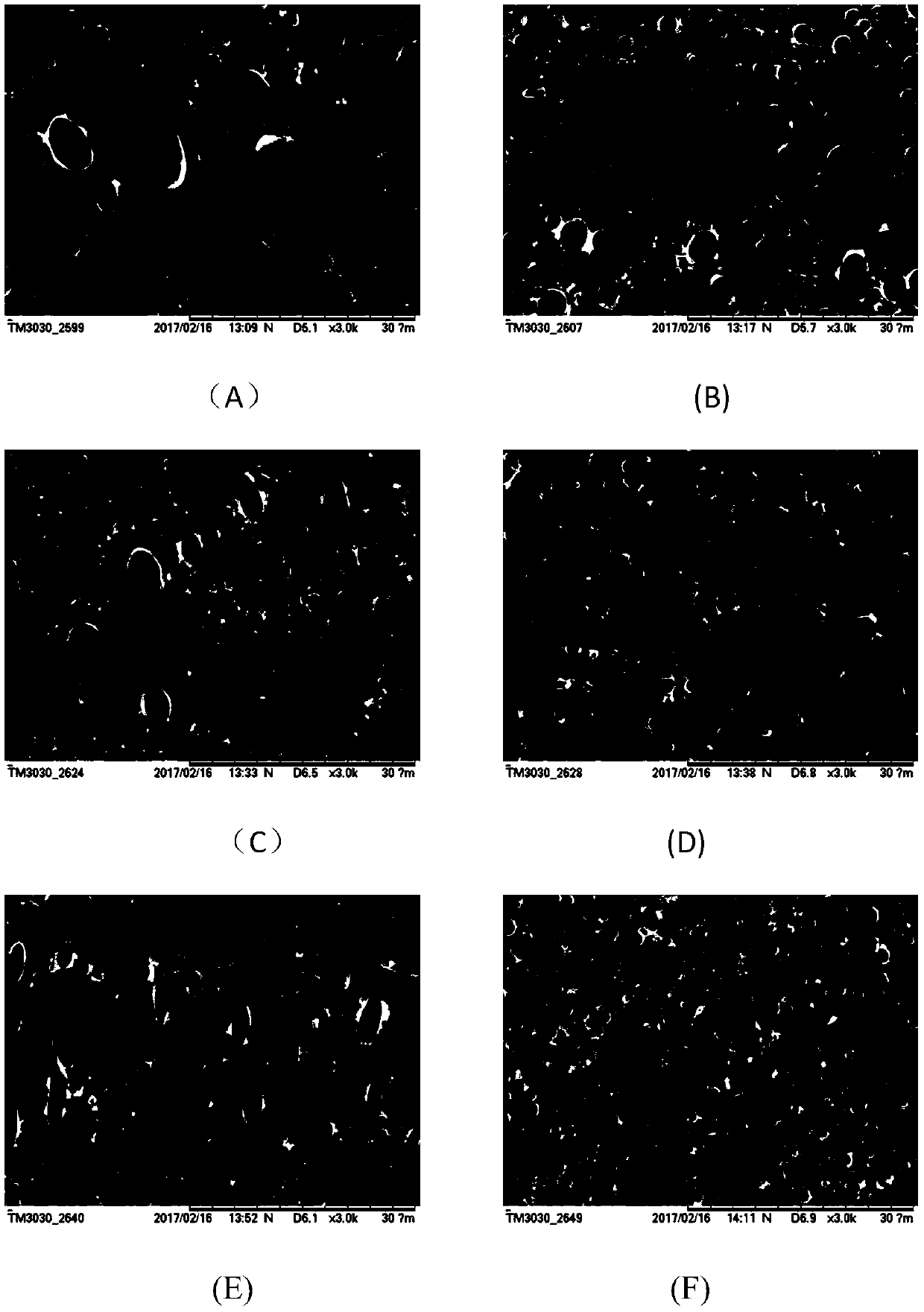

The invention relates to a preparation method of polylactic acid / polyadipic acid-polybutylece terephthalate blend, and belongs to the field of high molecular polymer blending modification. In the method, the injection of a supercritical carbon dioxide fluid can generate synergistic capacity increasing and toughening effects on the PLA / PBAT blend with a chain extender ADR or ADR and organic montmorillonite (OMMT) beside reducing the viscosity of a processed melt, so as to further refine a PBAT dispersion phase and enhance the adhesion of a PLA / PBAT interface layer. Finally, a set of PLA / PBAT modified blends with high toughness is obtained, and the maximum notched impact strength is 36.23 kJ / m2. Under the plasticization of the supercritical carbon dioxide fluid, the selective distribution ofOMMT nanoparticles in the PBAT and PLA interface layers and in-situ generated PLA-ADR-PBAT block macromolecules can stabilize the interface of PBAT dispersion phase; and the synergistic effect enables the dispersion phase to be better refined during the blending process, thereby improving the impact toughness of the blend.

Owner:HAINAN UNIVERSITY

A kind of composite modified starch-based environmental protection material, preparation method and application

Owner:北京禾易和科技有限公司

Drug-resistant fully biodegradable mulch composition and preparation method thereof

The invention discloses a drug resistance full-biodegradation mulching film composition. The drug resistance full-biodegradation mulching film composition is prepared from the following components inparts by weight: 100 parts of polylactic acid, 50 to 70 parts of polydiethylene / butylene terephthalate (PBAT), 5 to 10 parts of pentaerythritol, 0.1 to 0.5 part of ammonium persulfate, 0.1 to 1 partof an antioxidant, 0.5 to 3 parts of an anti-ultraviolet assistant, and 2 to 10 parts of a drug resistance intensifier. Under the initiation effect of ammonium persulfate, polylactic acid and PBAT aresubjected to cross-linking reaction during extrusion, the molecular weight of a produced composition is increased, the strength is improved, degradation is slow, and the drug resistance is enhanced.

Owner:山东天野生物降解新材料科技有限公司

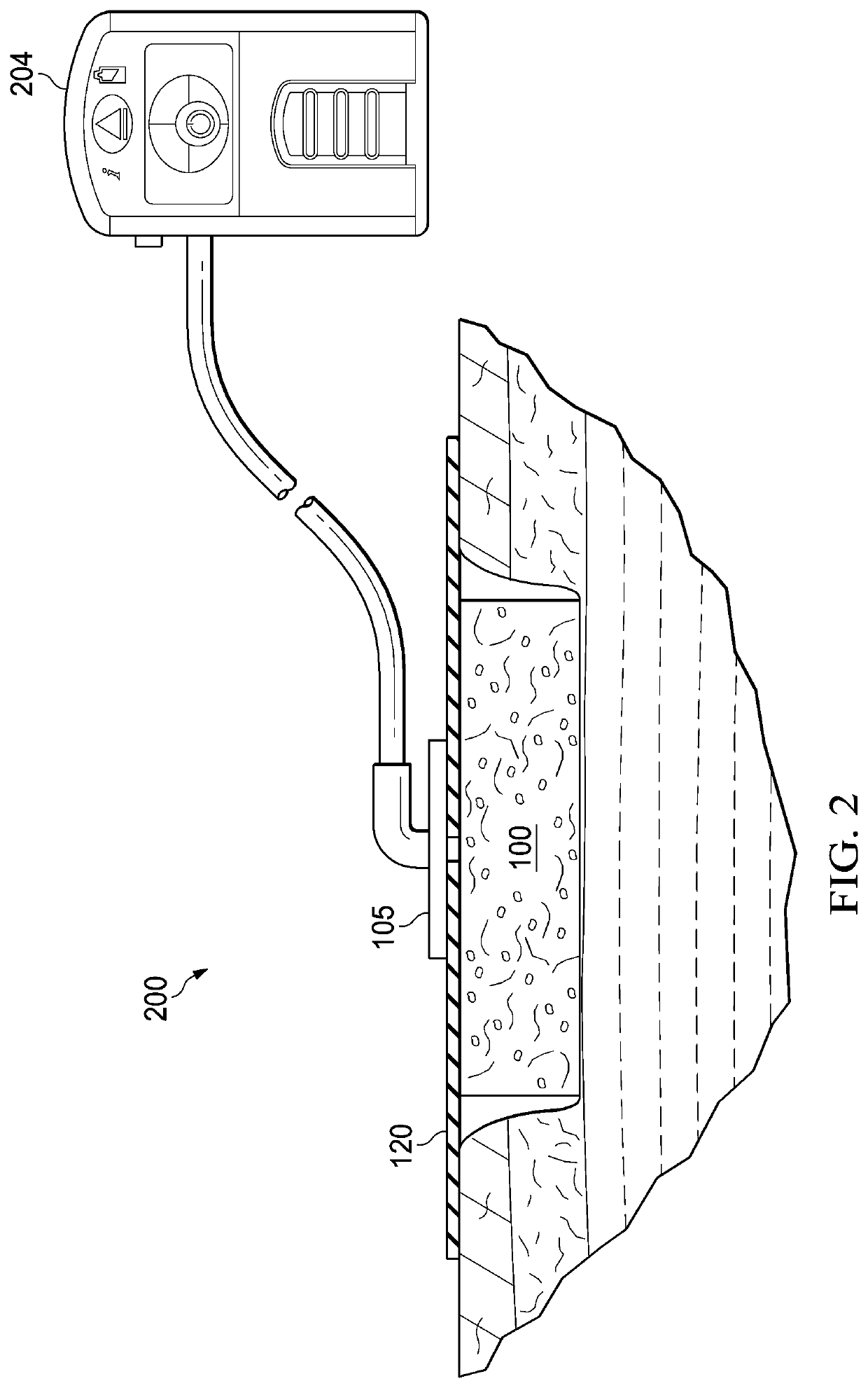

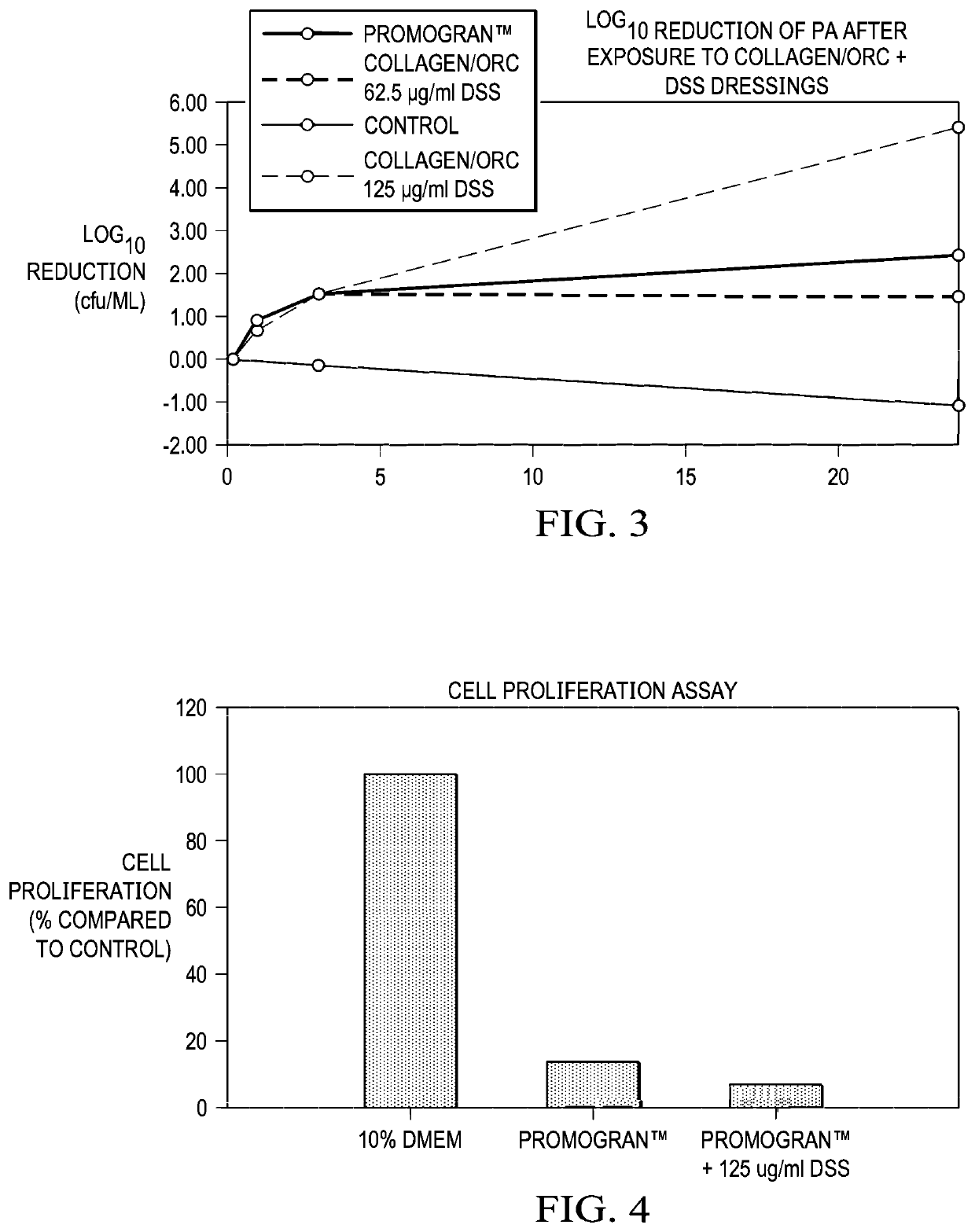

Antimicrobial composition, dressing, dressing components, and method

An antimicrobial composition may comprise a surfactant. The antimicrobial composition may include about 30 μg / ml to about 1,000 μg / ml of the surfactant, by volume of the antimicrobial composition. The surfactant may comprise a docusate salt such as docusate sodium. The antimicrobial composition may comprise an antimicrobial agent. The antimicrobial composition may include from about 0.01% to about 10% of the antimicrobial agent, by weight of the antimicrobial composition. The antimicrobial agent may comprise polyhexanide (PHMB). In some embodiments, the antimicrobial composition may comprise a matrix-forming material. The antimicrobial composition may include at least 90% of the matrix-forming material, by weight of the antimicrobial composition. The matrix-forming material may comprise collagen, oxidized regenerated cellulose, alginate, carboxymethylcellulose, or combinations thereof.

Owner:SYSTAGENIX WOUND MANAGEMENT (US) INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com