Fully-biodegradable air bubble film and preparation process thereof

A bubble film, all-biological technology, used in biological packaging, sustainable manufacturing/processing, flat products, etc., can solve the problem of large differences in solubility and melting temperature, reduction in heat sealing strength and impact resistance, shrinkage of heat sealing parts, Wrinkling and other problems, to achieve the effect of shortening crystallization time, improving degradation speed, and increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

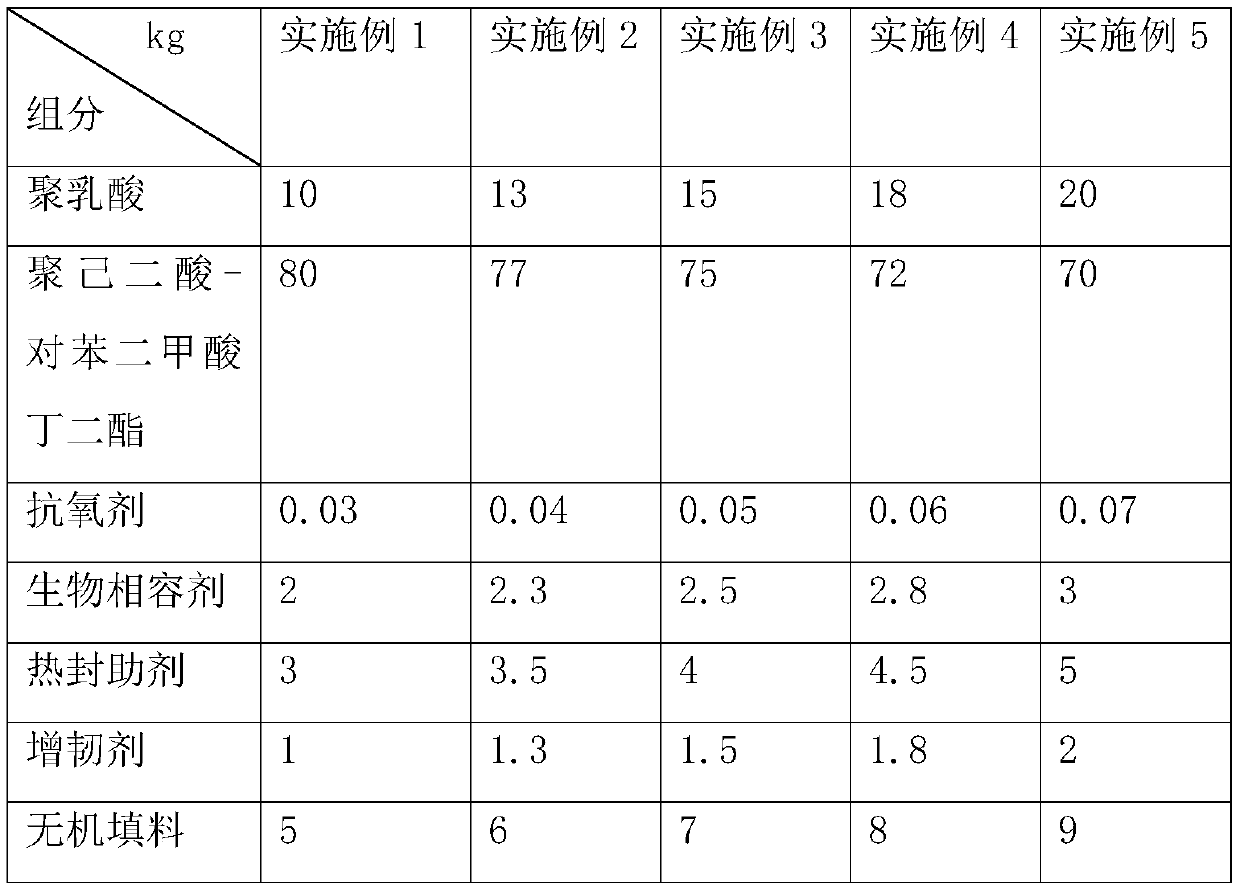

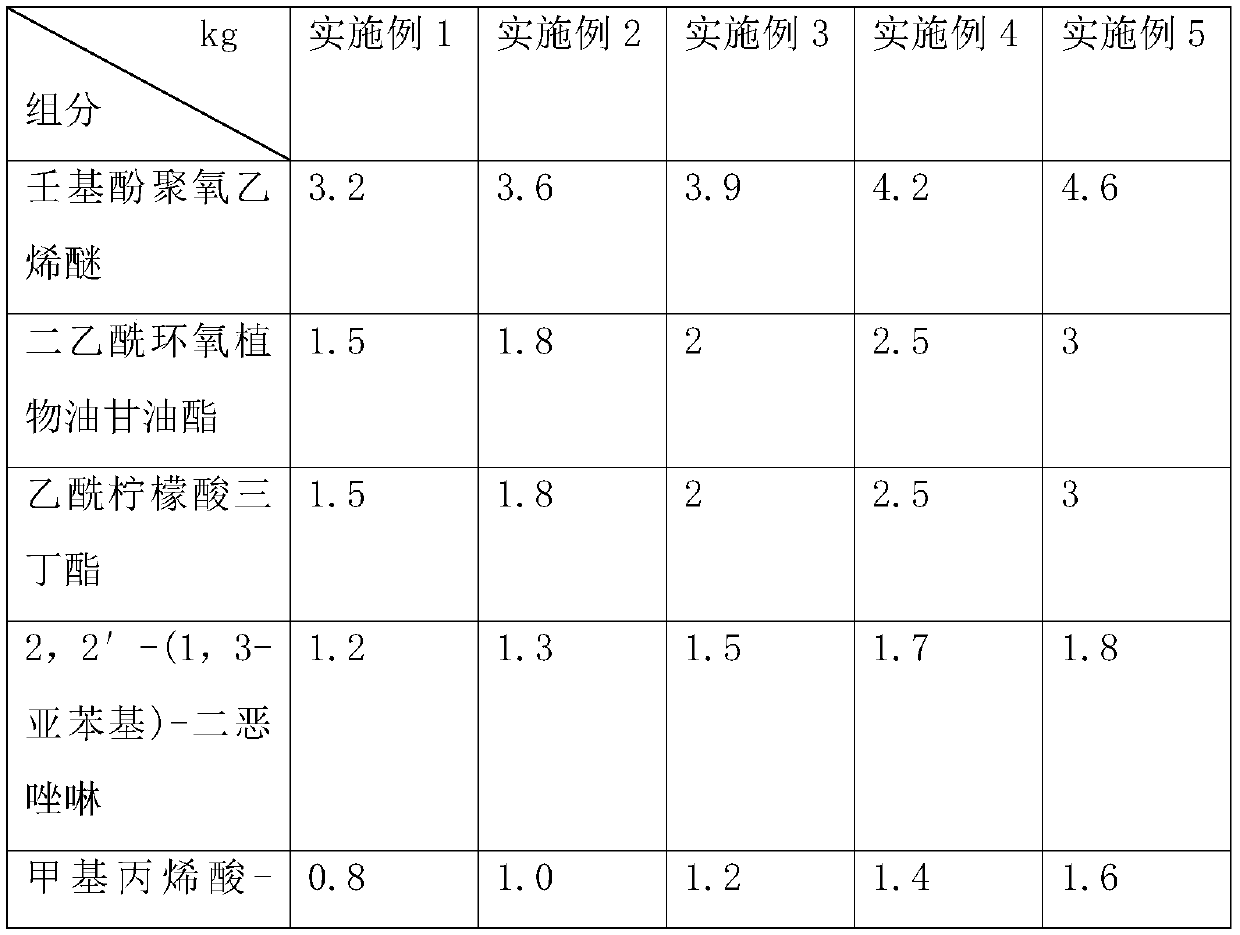

Method used

Image

Examples

preparation example 1-3

[0046] In the preparation example 1-3, the titanate coupling agent is selected from the titanate coupling agent sold by Dongguan Lvwei Plastic Products Co., Ltd., and the model is NDZ-201. The nano-calcium carbonate is selected from the processing of Baifeng Mineral Products in Lingshou County. The article number sold by the factory is 14 nano-calcium carbonate, and the nano-silica is selected from the nano-silica of A200 sold by Quzhou Edhan Chemical Co., Ltd.

preparation example 1

[0047] Preparation Example 1: (1) Rotate lactic acid aqueous solution with a mass fraction of 88% at 65°C and an absolute pressure of 1000Pa for 2 hours, then mix it with stannous chloride and p-toluenesulfonic acid at 100°C under vacuum conditions, and then heat up React at 145°C for 2 hours, add pentaerythritol, then raise the temperature to 170°C for 2 hours, the mass ratio of polylactic acid, stannous chloride and p-toluenesulfonic acid is 1:0.005:0.005, and the mass ratio of lactic acid to pentaerythritol is 1:0.4 ;

[0048] (2) Add toluene to the resultant of step (1), heat up to 90°C, add acrylic acid, p-toluenesulfonic acid and hydroquinone, heat up to 120°C for 5 hours, vacuumize, and wash with acetone to obtain a semi-finished product Polylactic acid, the mass ratio of lactic acid and toluene is 1:2.5, the mass ratio of lactic acid, p-toluenesulfonic acid and hydroquinone is 3:0.01:0.003, the mass ratio of acrylic acid and pentaerythritol is 3:1;

[0049] (3) 2.3kg ...

preparation example 2

[0050] Preparation Example 2: (1) Rotate lactic acid aqueous solution with a mass fraction of 88% at 65°C and an absolute pressure of 1000Pa for 2 hours, then mix it with stannous chloride and p-toluenesulfonic acid at 110°C under vacuum conditions, and then heat up React at 150°C for 1.5h, add pentaerythritol, then raise the temperature to 175°C and react for 1.5h, the mass ratio of polylactic acid, stannous chloride and p-toluenesulfonic acid is 1:0.008:0.008, and the mass ratio of lactic acid to pentaerythritol is 1 :0.45;

[0051] (2) Add toluene to the resultant of step (1), heat up to 95°C, add acrylic acid, p-toluenesulfonic acid and hydroquinone, heat up to 135°C for 4 hours, vacuumize and wash with acetone to obtain a semi-finished product Polylactic acid, the mass ratio of lactic acid and toluene is 1:2.8, the mass ratio of lactic acid, p-toluenesulfonic acid and hydroquinone is 3:0.02:0.004, the mass ratio of acrylic acid and pentaerythritol is 4:1;

[0052] (3) 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com