Patents

Literature

241results about "Plastic containers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corner protector

InactiveUS20060243636A1Containers to prevent mechanical damagePlastic containersEngineeringMechanical engineering

A corner protector for protecting a corner of merchandise, comprising a first portion contacting a first surface of the merchandise. A second portion is interconnected with the first portion, and contacts a second surface of the merchandise. A third portion is interconnected with the first portion and the second portion, and contacts a third surface of the merchandise, in such a way that a corner of the merchandise at the intersection of the first, second and third surfaces is covered by the corner protector. A first zone of protection is located at the intersection of the second portion and the third portion, the first zone of protection having a corner protrusion defining a hollow recess so as to form an empty space along an edge of the corner of merchandise, whereby an impact on the corner protrusion will have its energy distributed by the corner protrusion to the second and third portions so as to generally prevent contact between said edge of the corner of merchandise and an inner surface of the corner protrusion.

Owner:CAOUTCHOUC & PLASTIQUES FALPACO

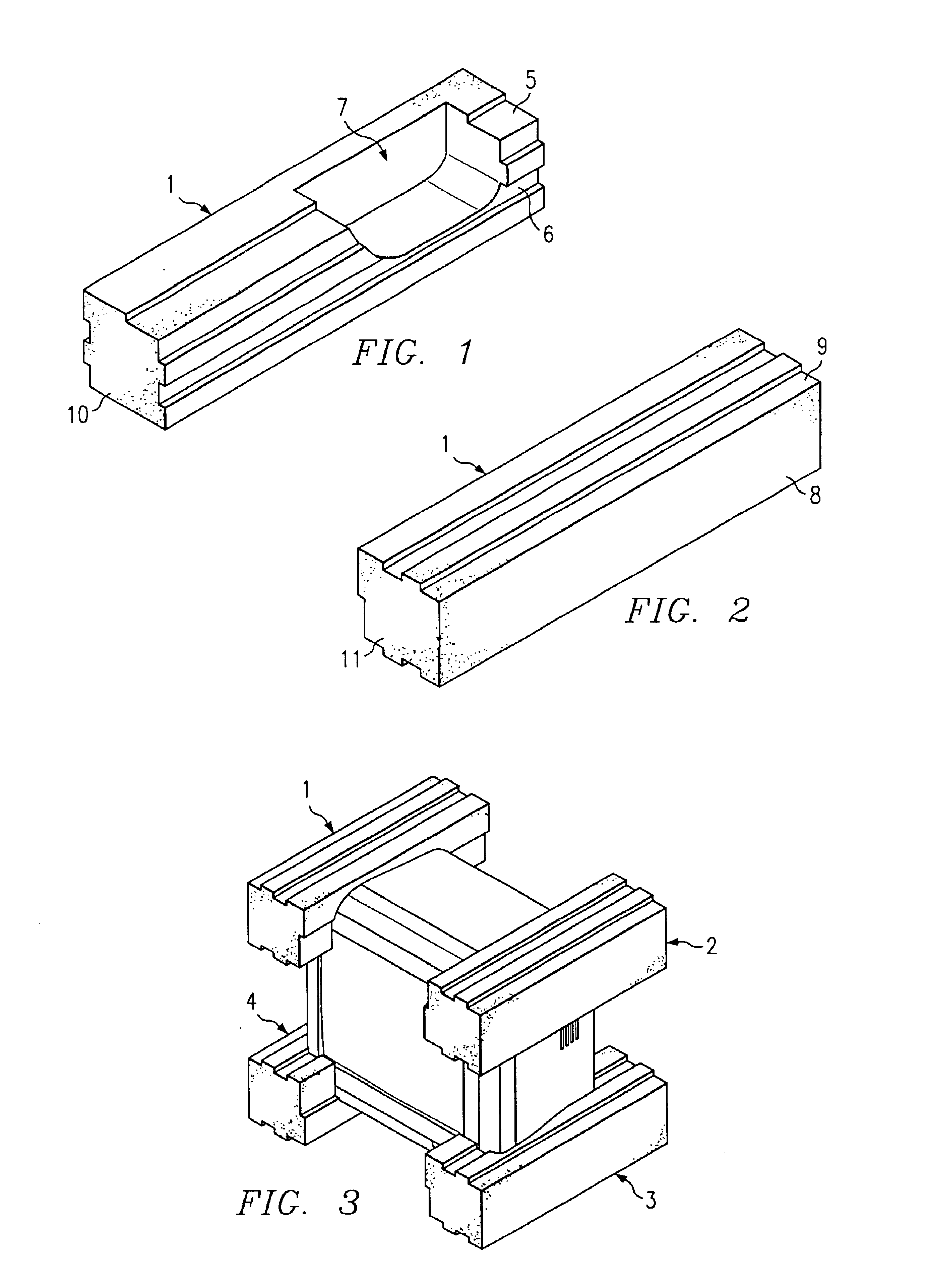

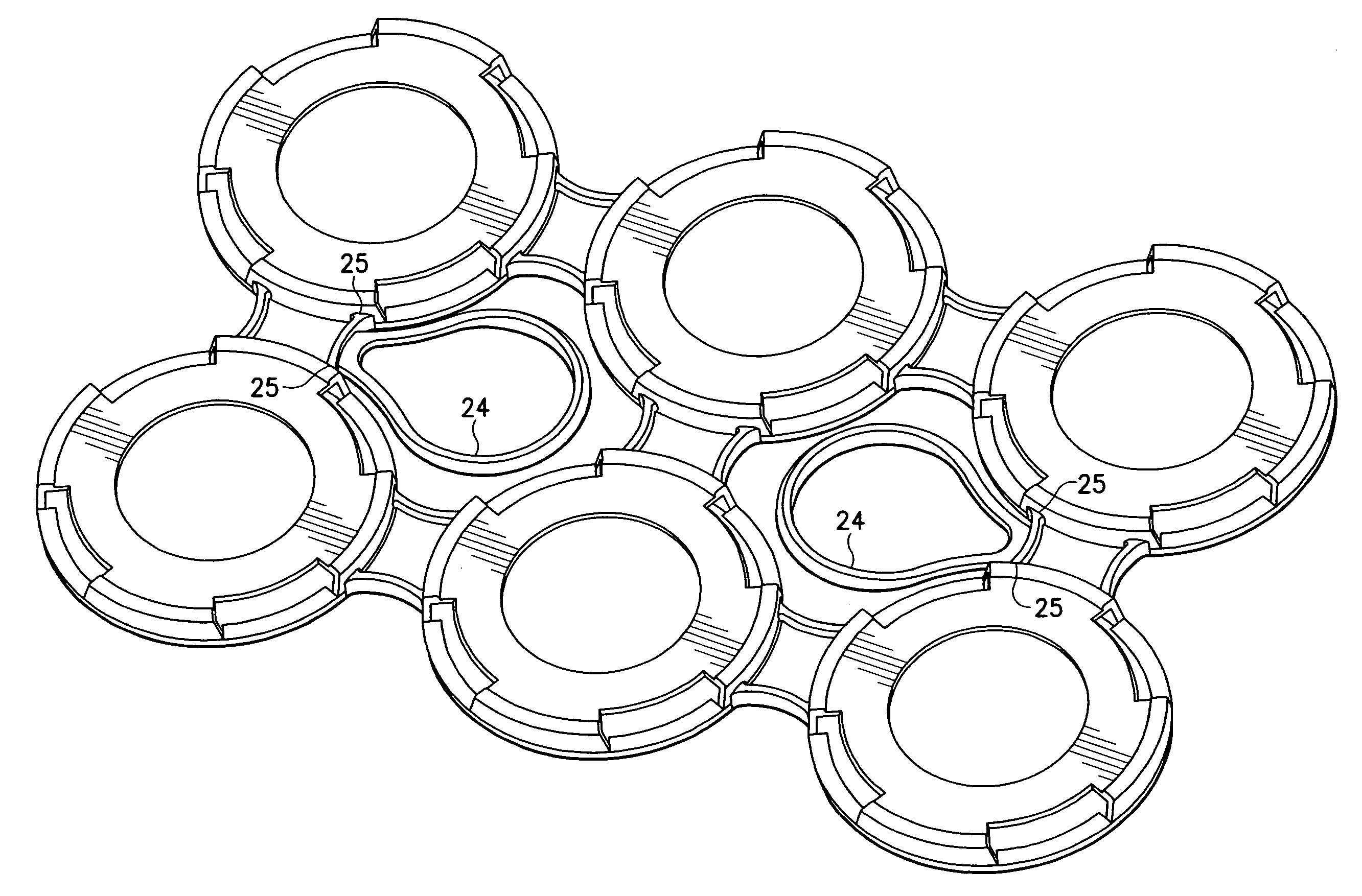

Uniform interlocking foam packing material/building material apparatus and method

InactiveUS6840372B2Reduce productionReduces ecological impactRoof covering using slabs/sheetsRoof covering using tiles/slatesBuilding productElectrical conductor

A foam structure for protecting a product in a package can interlock with another foam structure, concrete or wood to form a structural unit of building material. The foam structure can be made of two nested parts, which can be made of differing materials.A structural unit that can be used as building material can be made from packing material. A foam structure that can be used to pack a product in a package is interlocked with another foam structure, wood or concrete to form the unit of building material. The structural units can be used in construction products or in flotation products. The structural units can be used as part of a wall form and can be attached to the wall or to the other side of the wall form with connectors. The structural units can have conduits. The conduits can pass electrical conductors, air, fluids, ducts or pipes.

Owner:HOAMFOAM ALLIANCE

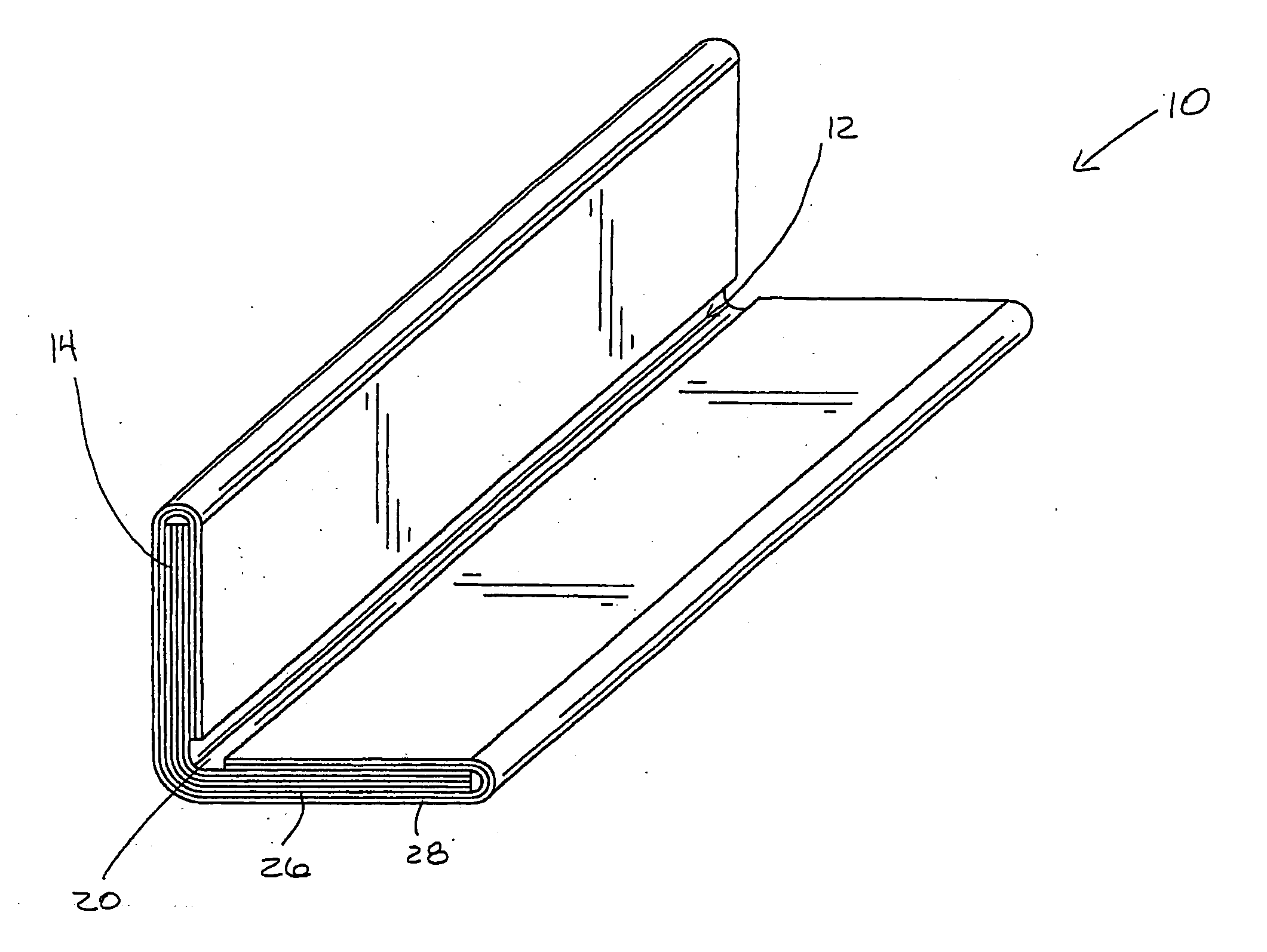

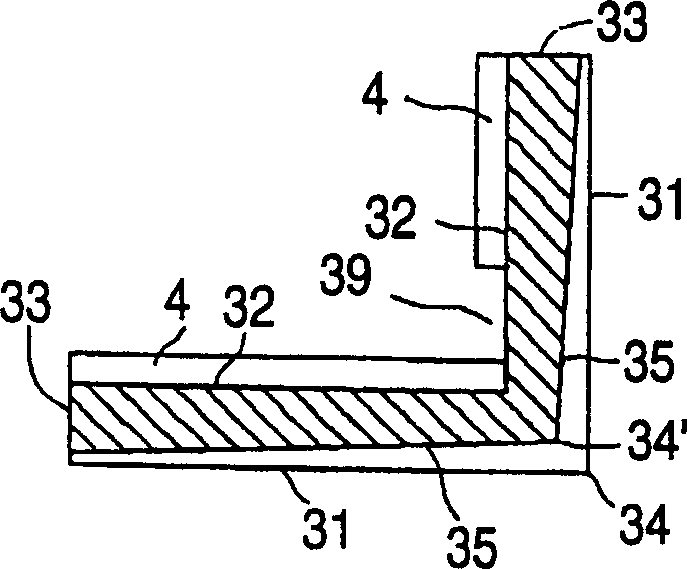

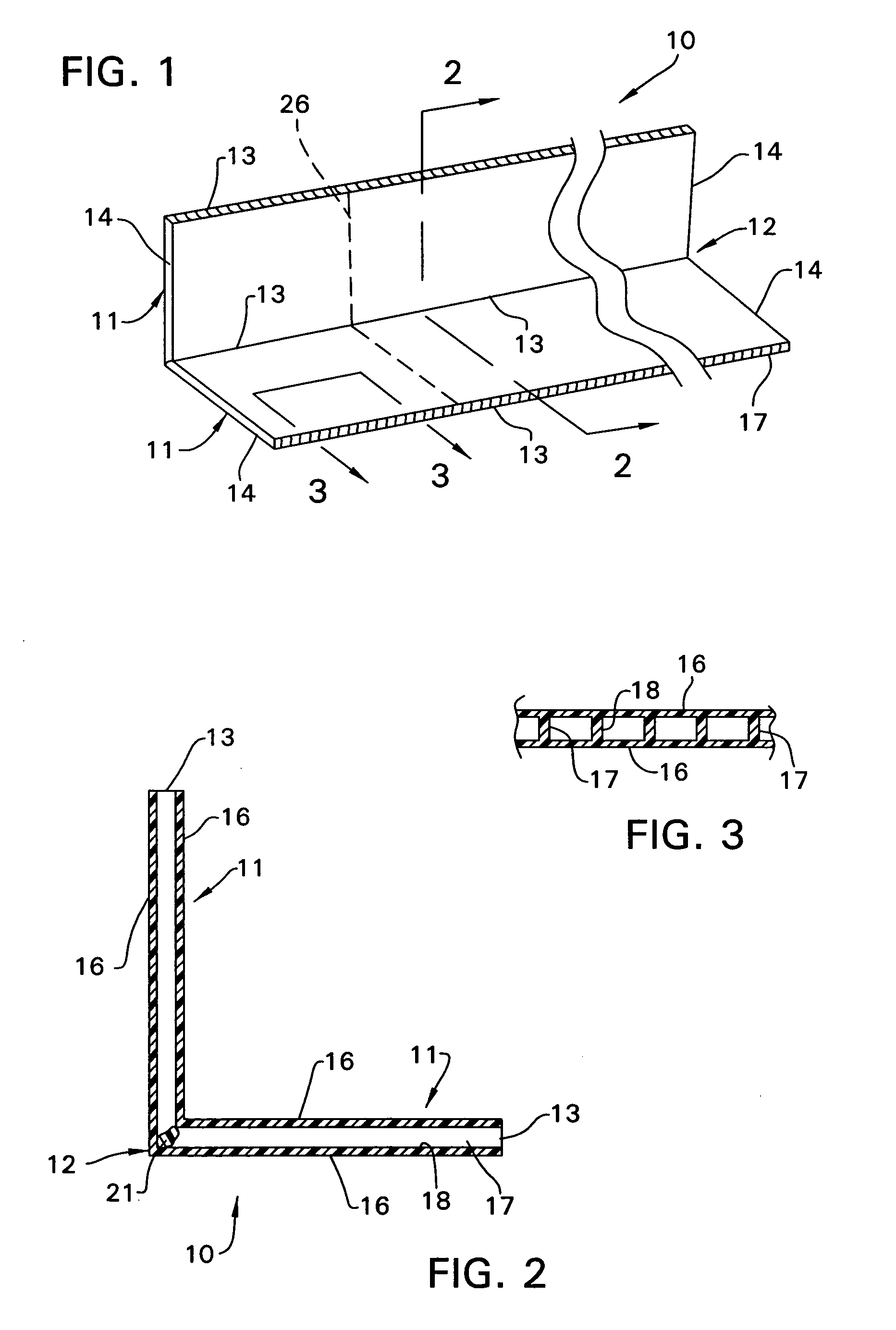

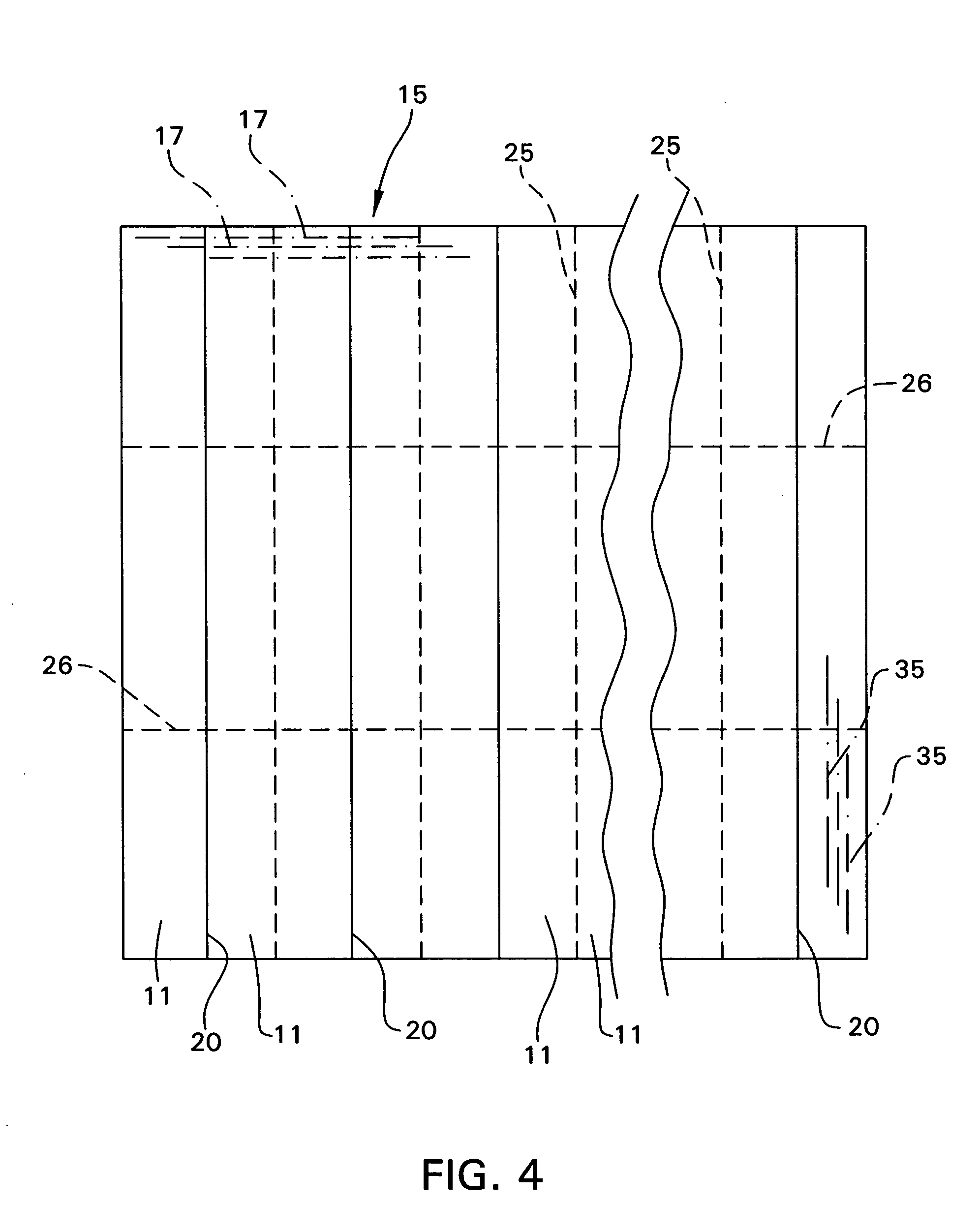

Plastic laminated edge protector

InactiveUS20050087663A1Resists wearPrevents damage and wear and tearStands/trestlesKitchen equipmentCardboardEngineering

An elongated edge protector is for protecting an edge or corner of an article. The edge protector includes a plurality of paperboard plies laminated together and formed into a rigid substantially right angled member. The right angled member has a pair of transversely oriented legs joined at an apex, each of the apex and the legs having inside and outside faces. A layer of plastic laminate is adhered to the outside faces of the legs, and preferably overwraps the edges of the right angled member, such that the laminate is adhered to both inside and outside faces of the legs. In a preferred embodiment, a paper label is laminated to the outside faces of the legs, wherein the layer of plastic laminate is adhered to the paper label.

Owner:GREAT NORTHERN

Combination multiple-canister carrier and lip protection device

Owner:OREGON PRECISION IND INC DBA PAKTECH

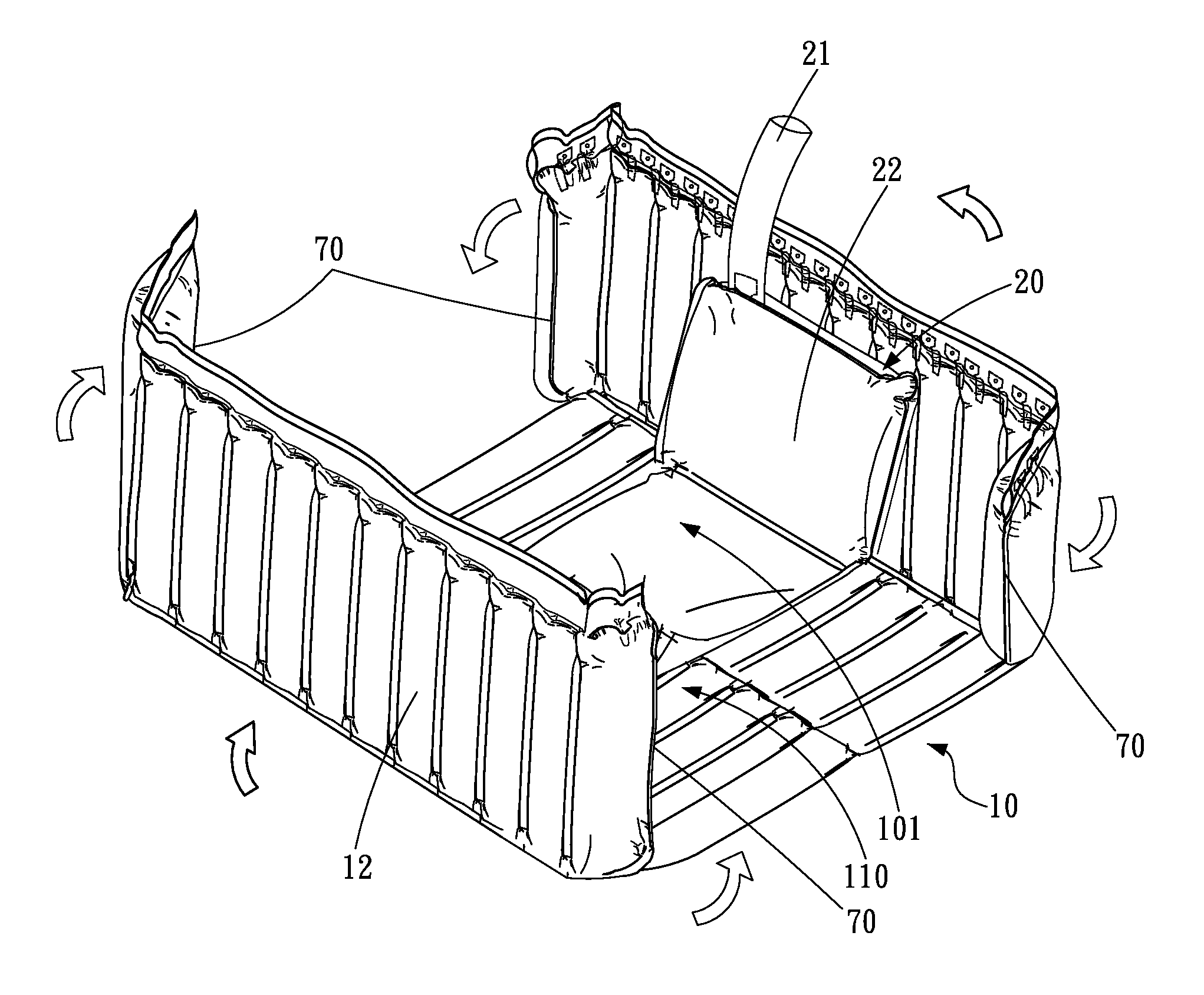

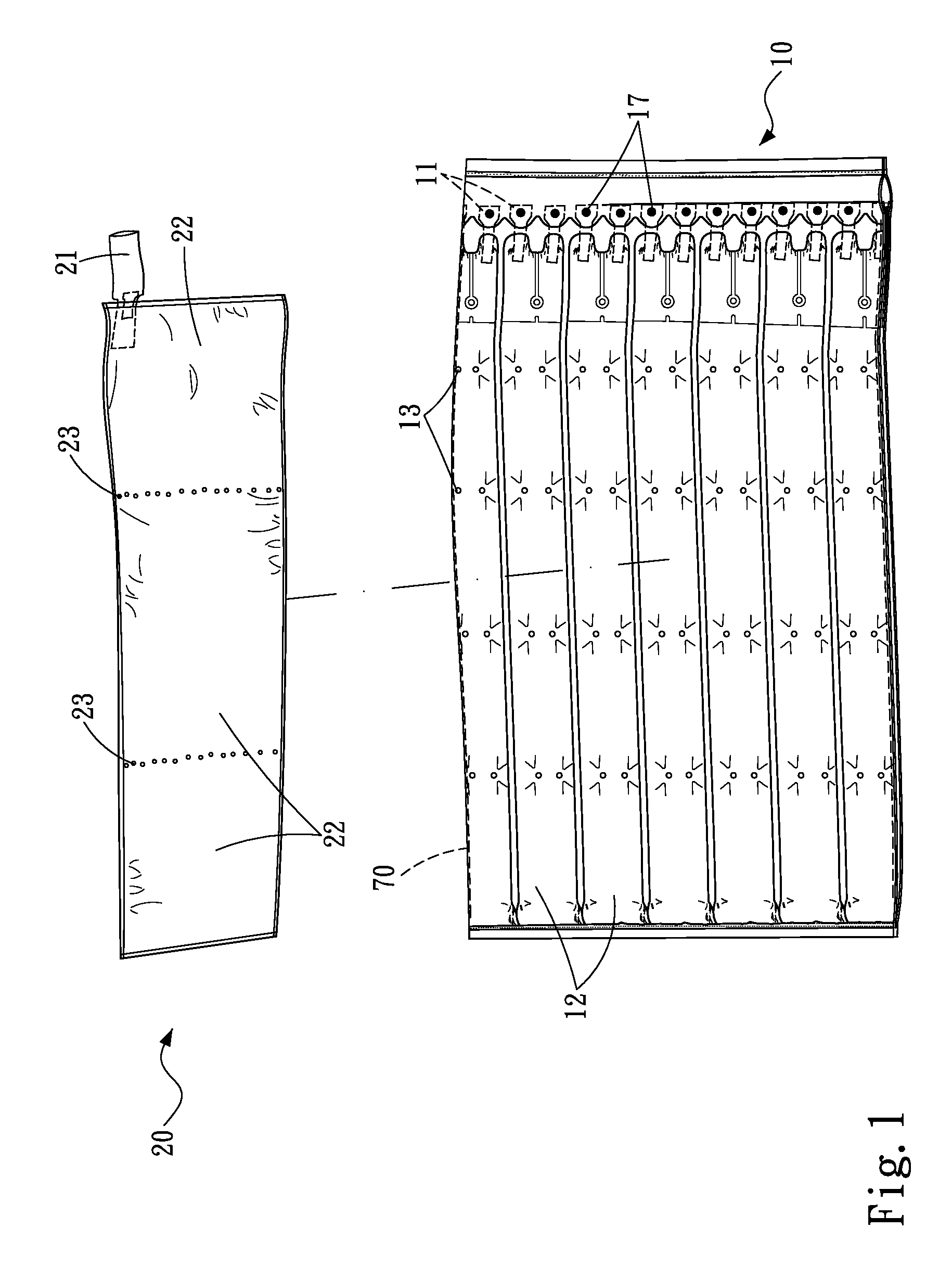

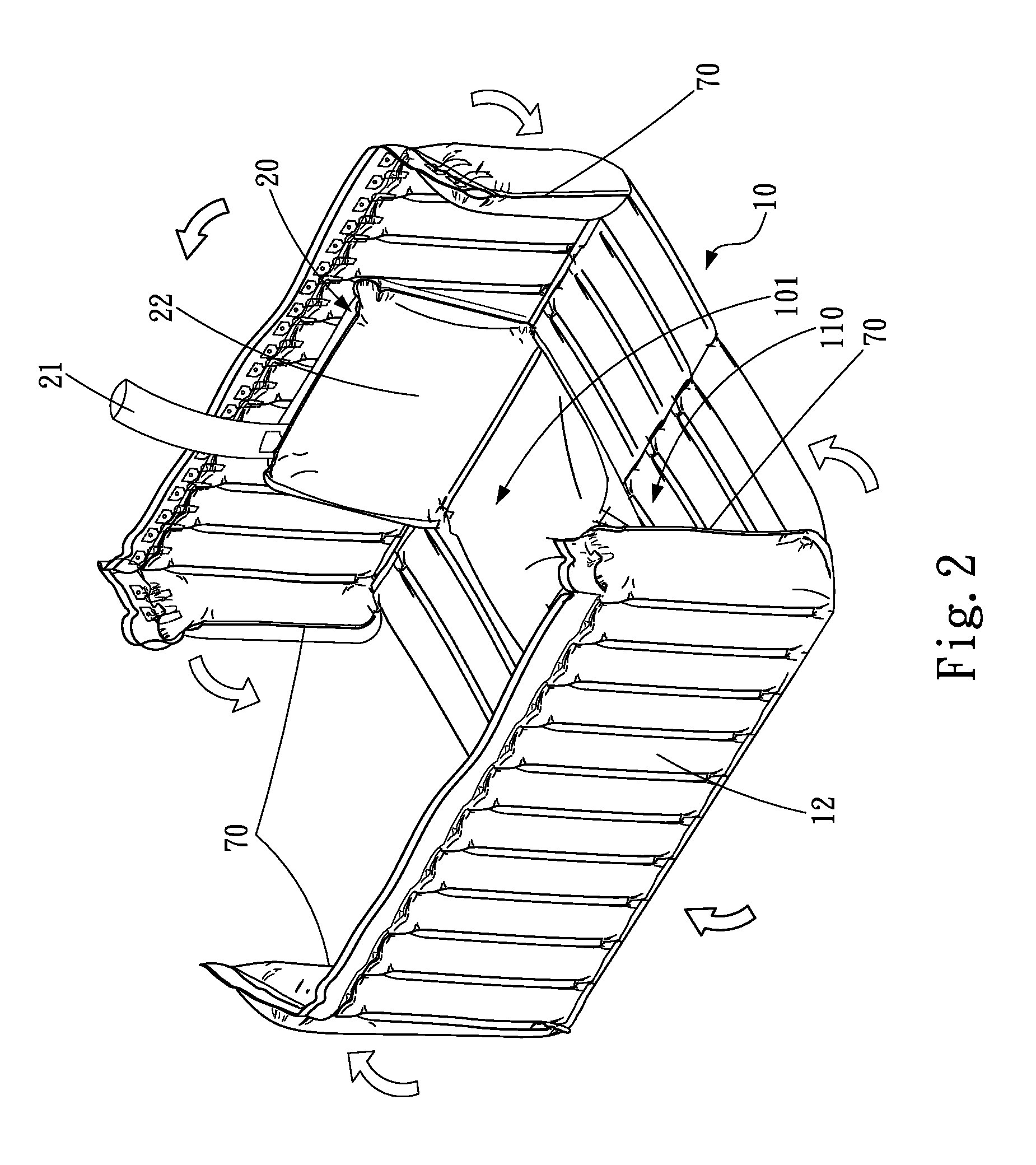

Cushioning air bag with automatically adjustable clamping pressure

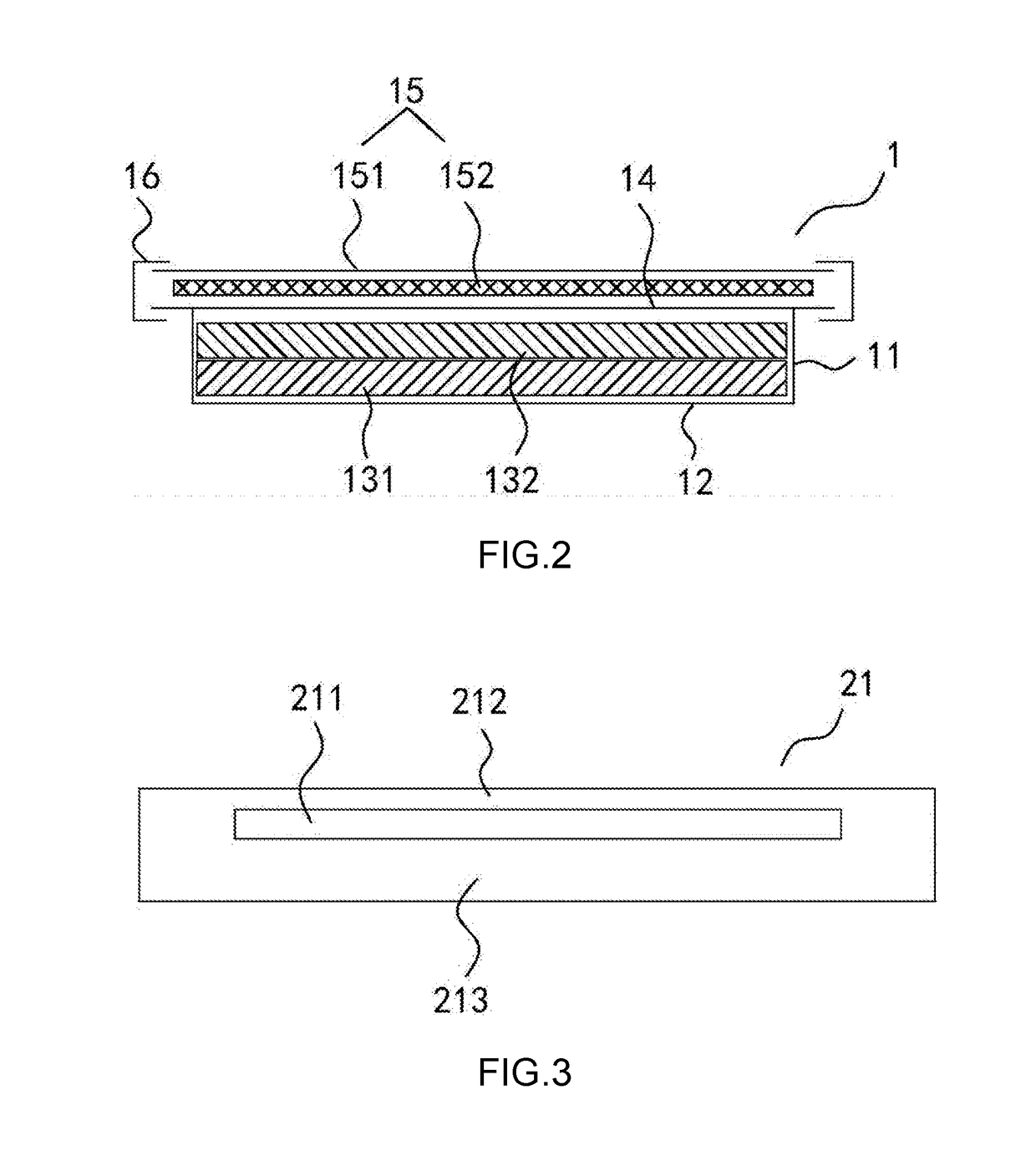

A cushioning air bag with automatically adjustable clamping pressure includes an air cylinder sheet and an adjustable air sac sheet, where the air cylinder sheet includes a first air valve and a plurality of air cylinders, one end of the first air valve is positioned in the plurality of air cylinders, and an adjustable air sac sheet, includes a plurality of cushioning adjustment zones attached to wall surfaces of the plurality of air cylinders, a bag is formed when the air cylinder sheet and adjustable air sac sheet are filled with air, an accepting space is included among the plurality of cushioning zones positioned in the bag, used for clamping a different size of object when the object is received in the accepting space.

Owner:LIAO YAW SHIN

A thermal bag

ActiveUS20180370710A1Improve thermal insulationSimple structureDomestic cooling apparatusLighting and heating apparatusEngineering

Owner:LUO BINGHUA

Edge and corner protector

A protective device that may be used to shield the corner and / or edges of an object from damage during shipping, storage, handling or the like comprises a cap member, first and second outer arms and first and second inner arms. The arms are connected (either directly or indirectly) to the cap member and extend downwardly therefrom. The first and second inner arms are located generally opposite the first and second outer arms, respectively. The first and second inner arms may each include a protrusion that projects toward the first and second outer arms, respectively. Additionally, the first and second outer arms may be positioned so as to define an obtuse angle (e.g., 135 degrees) opposite the vertical plane defined by the downwardly extending first inner arm.

Owner:TENN TEX PLASTICS

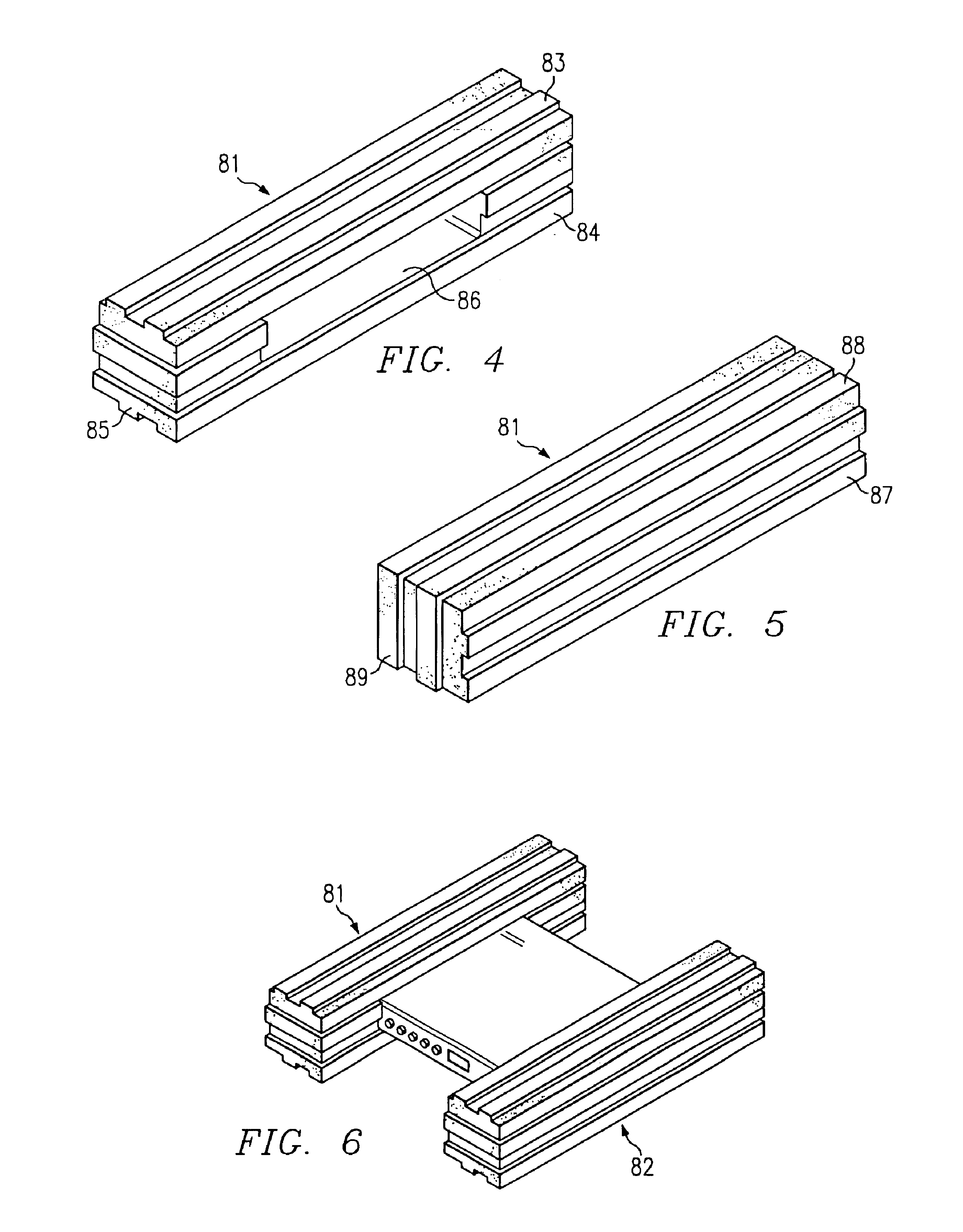

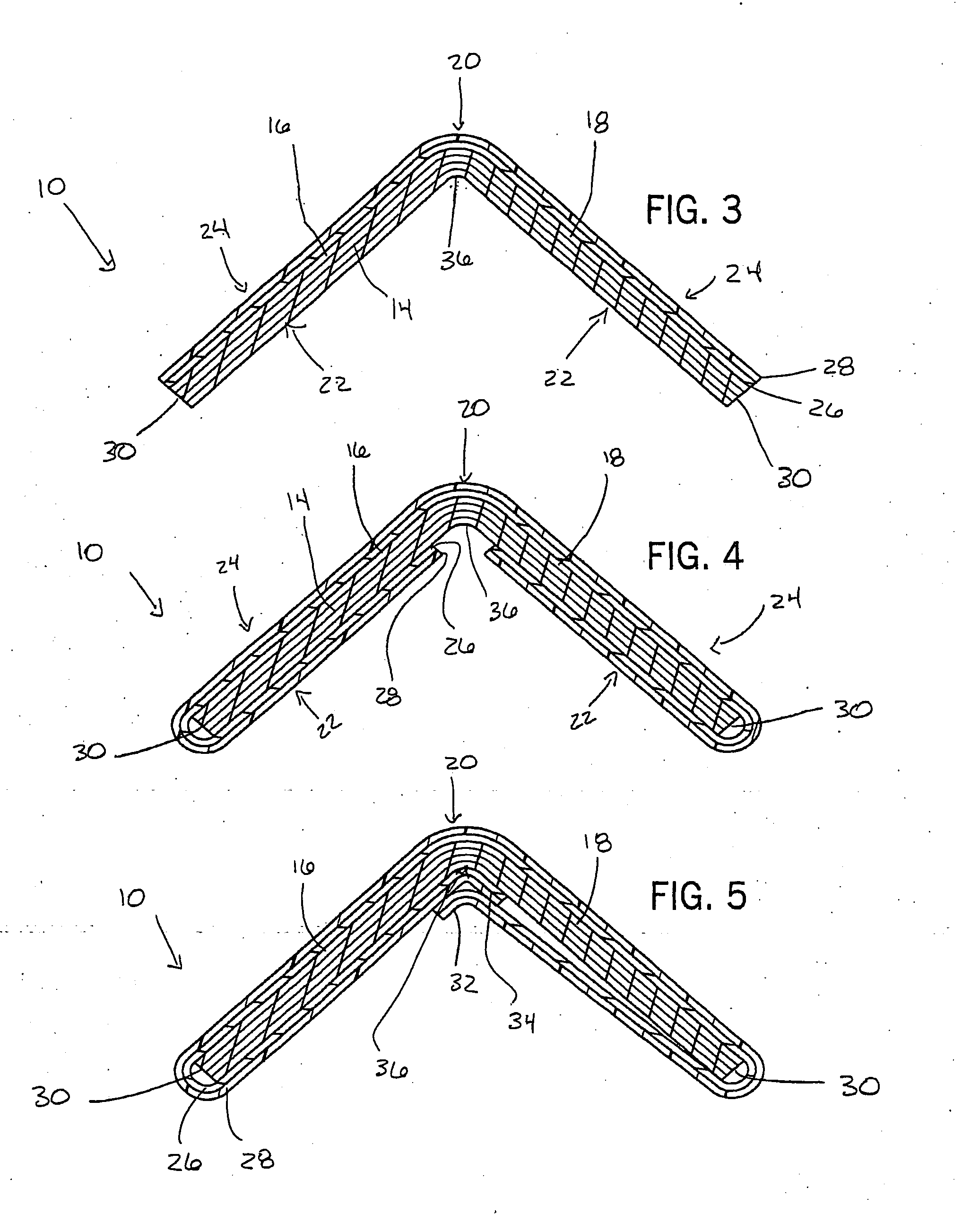

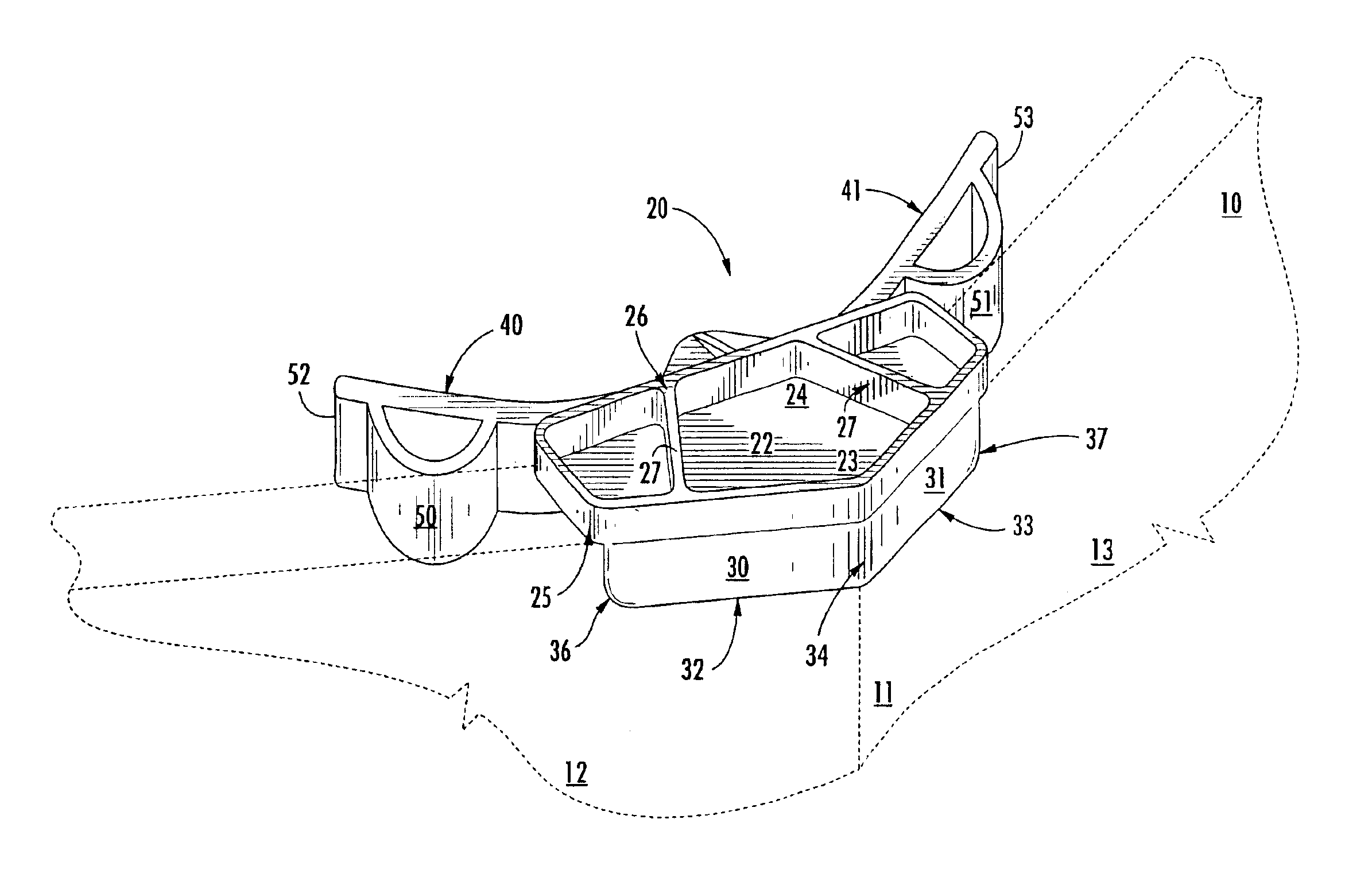

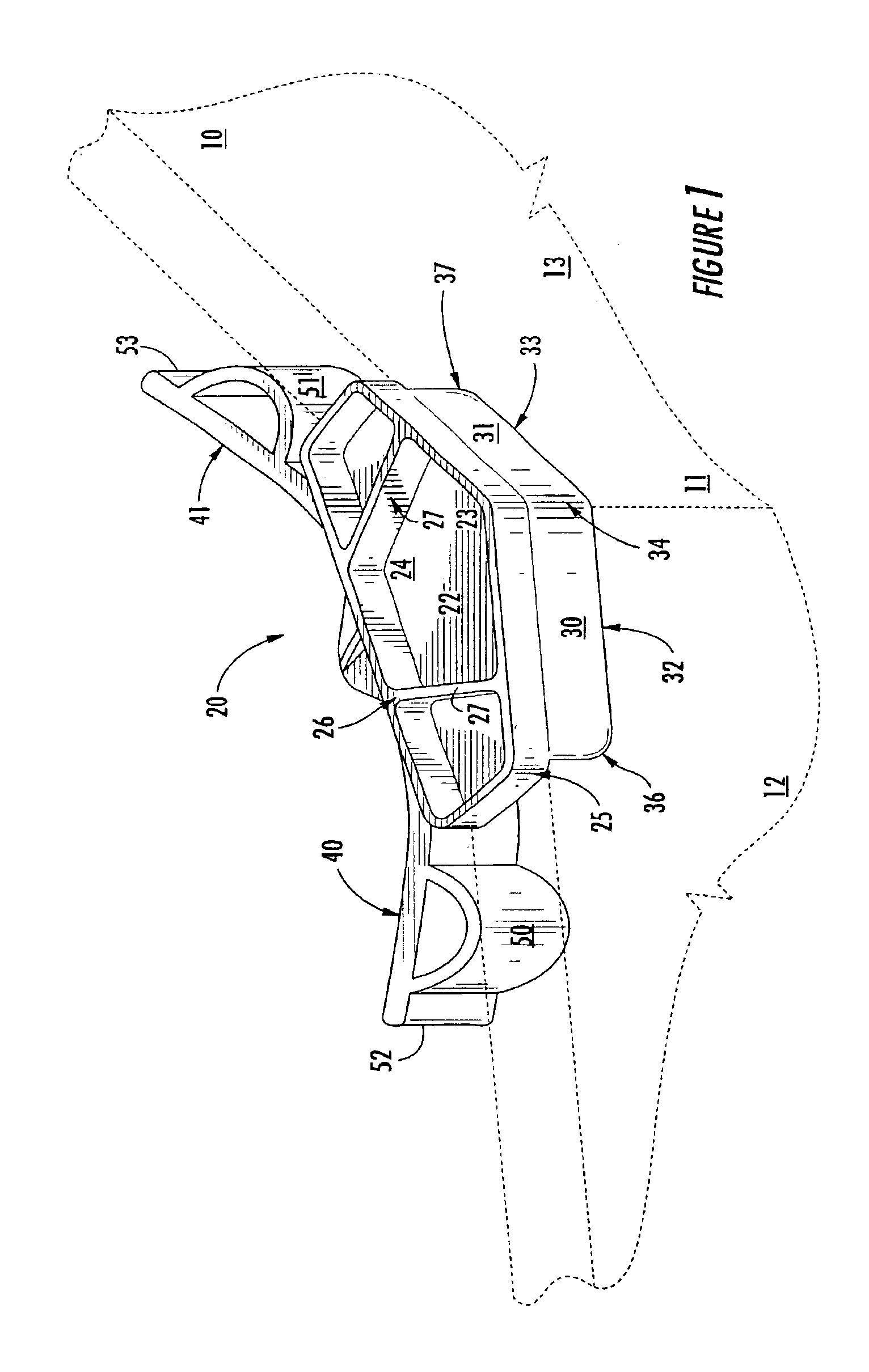

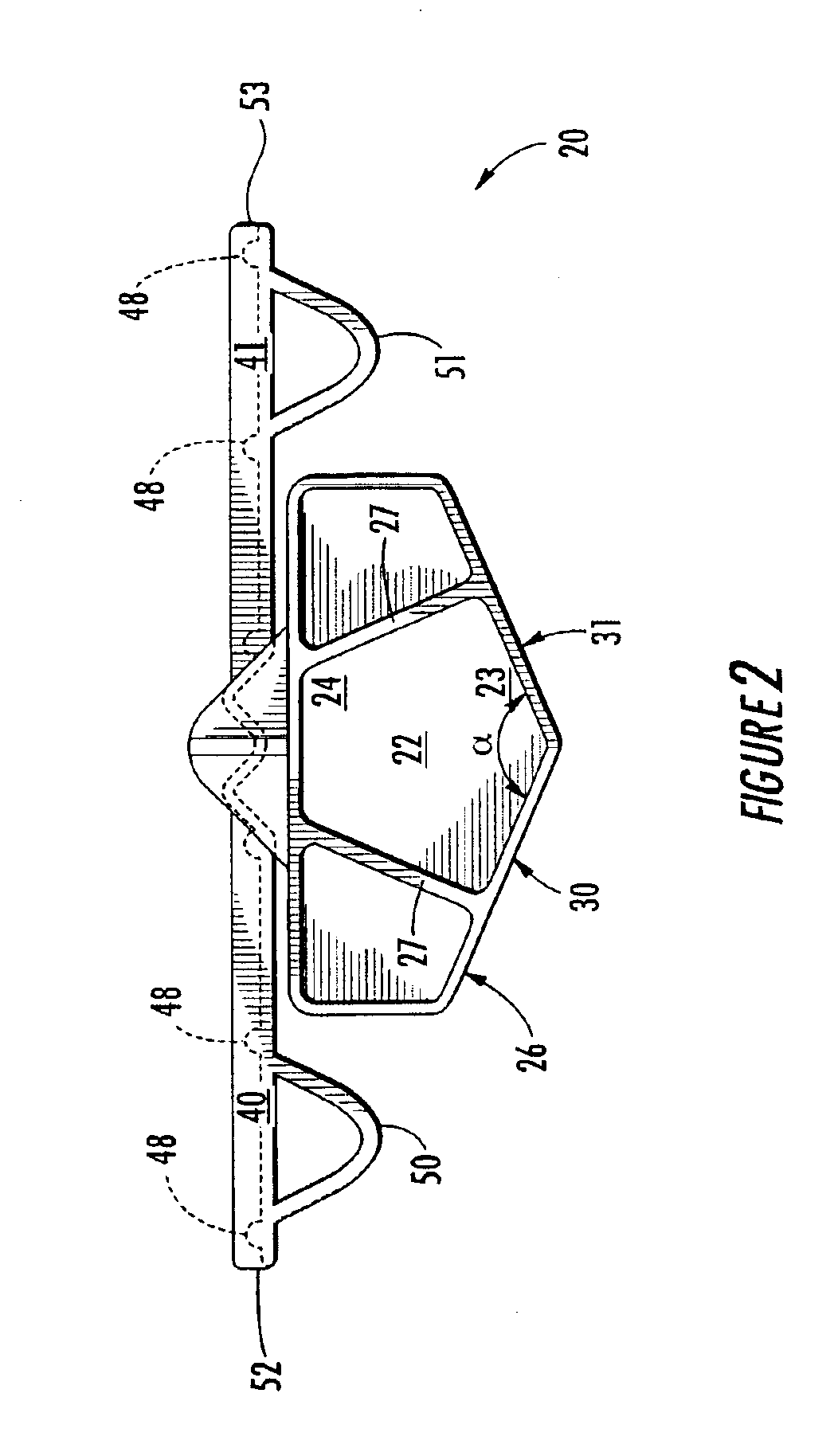

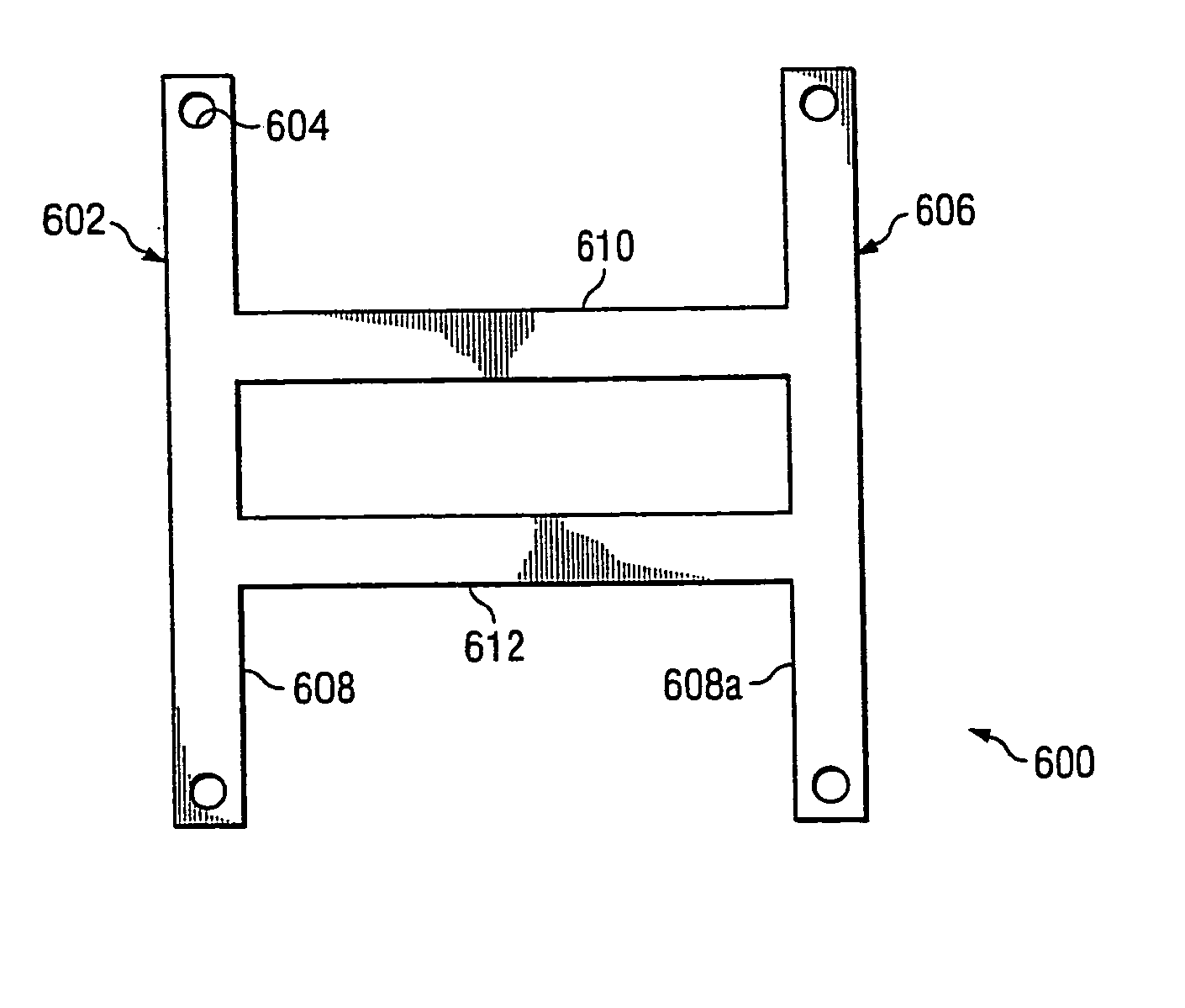

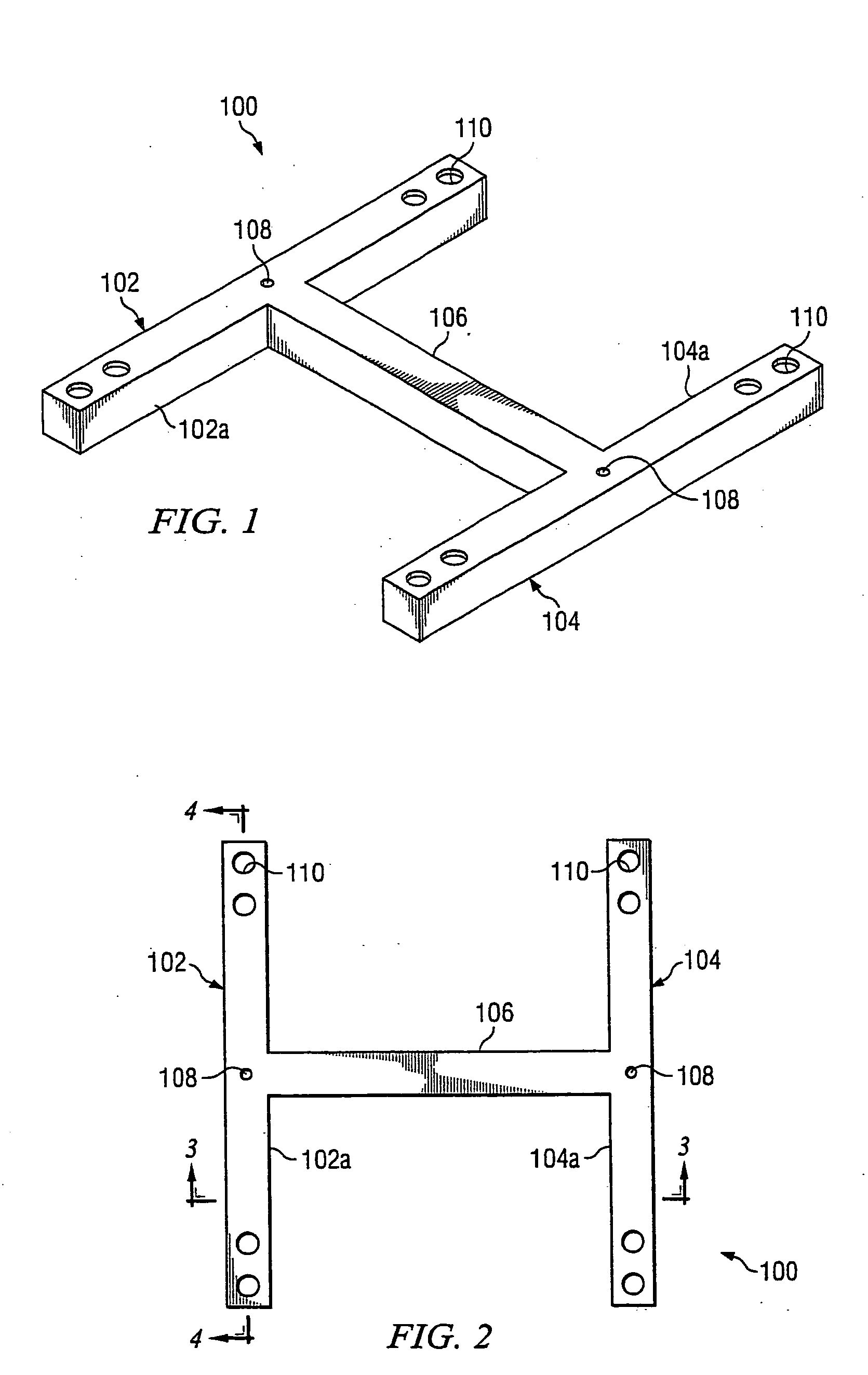

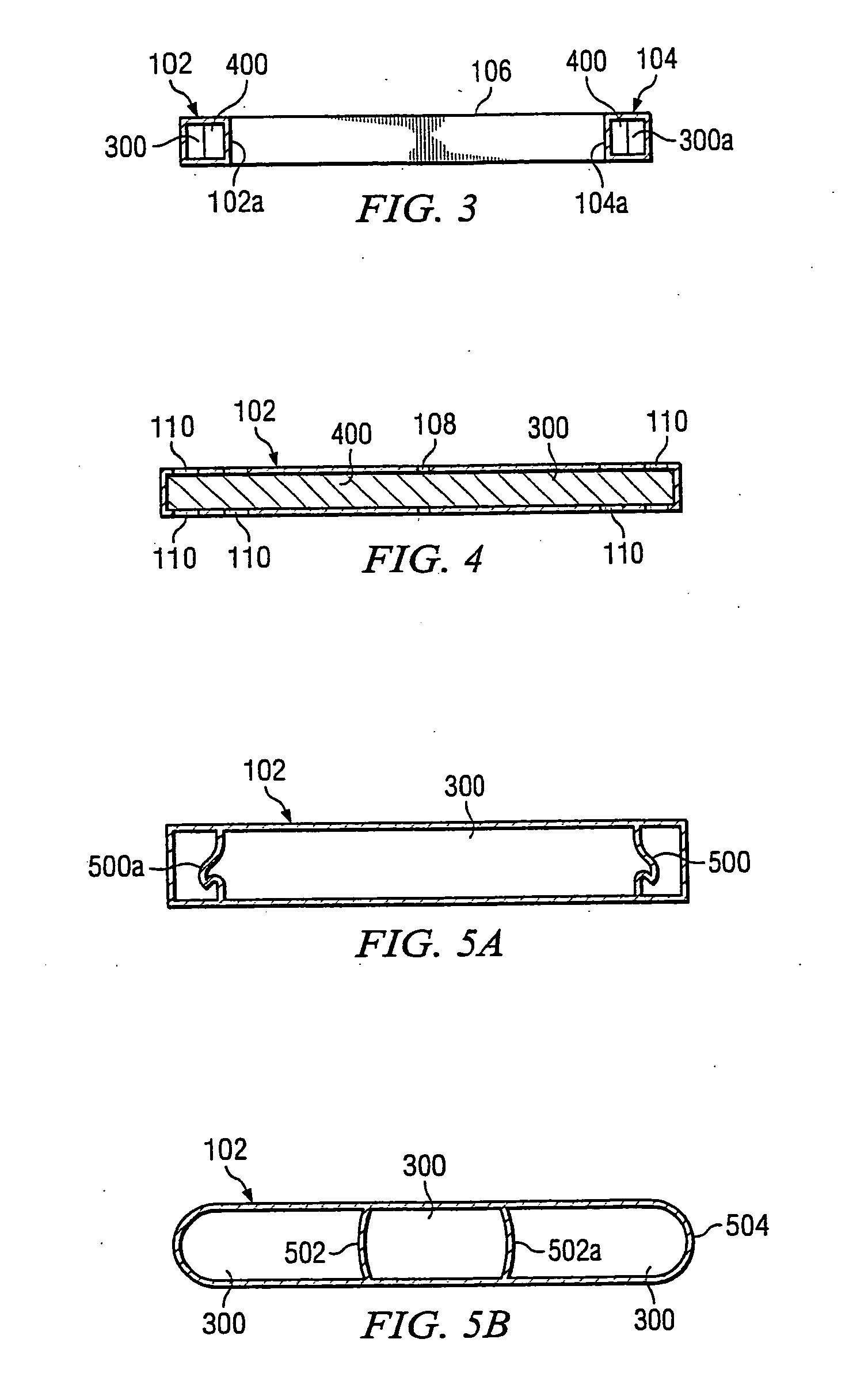

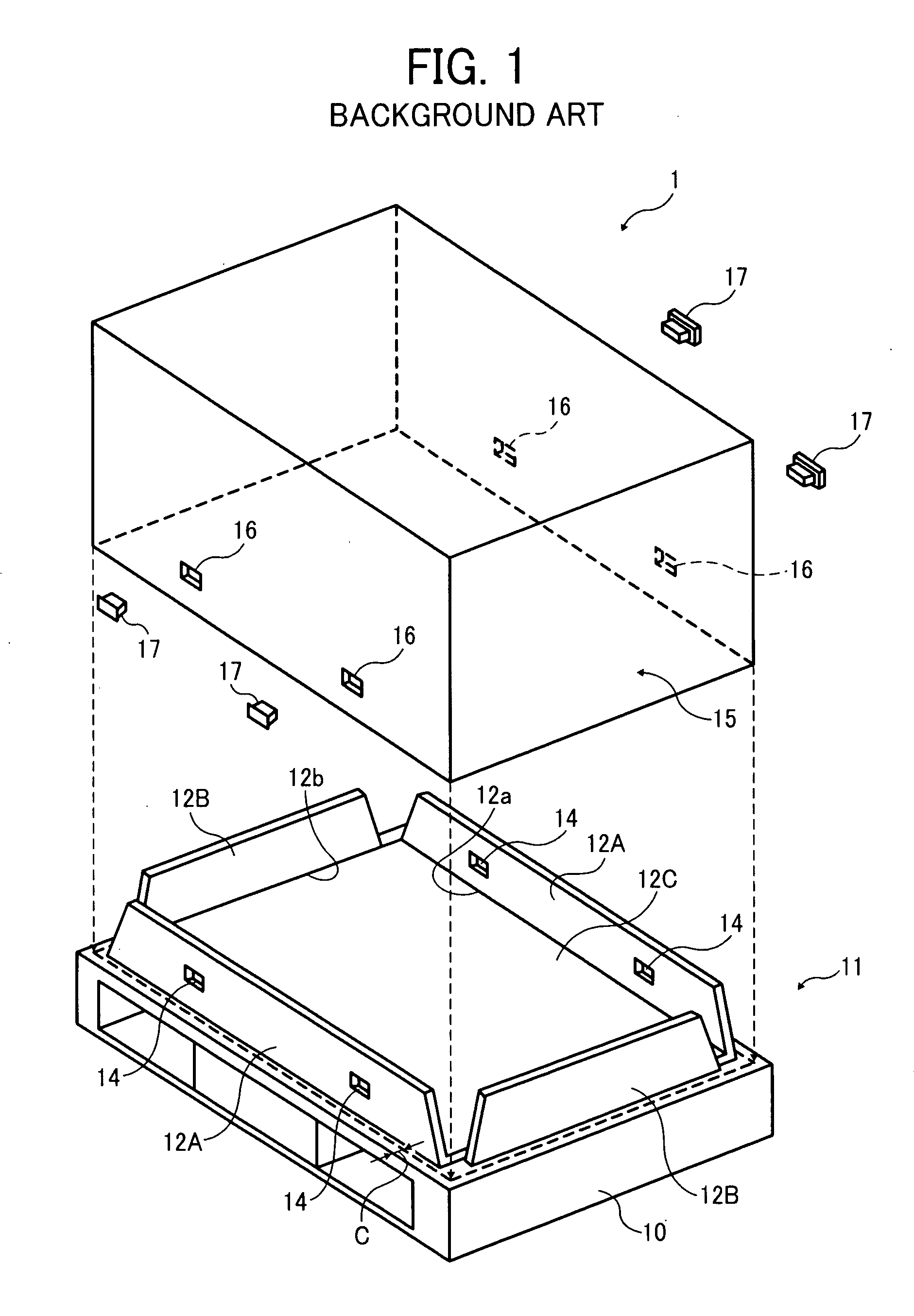

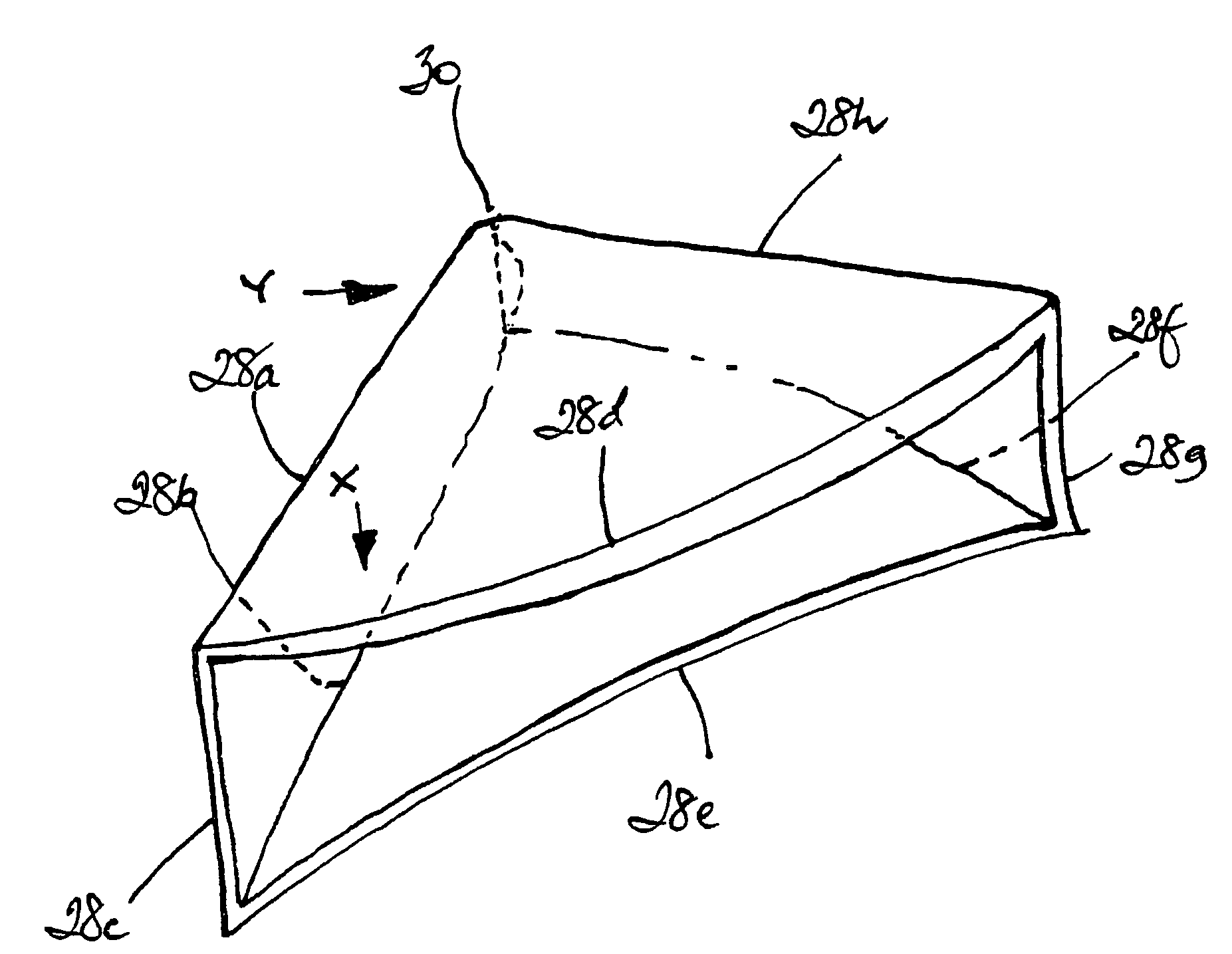

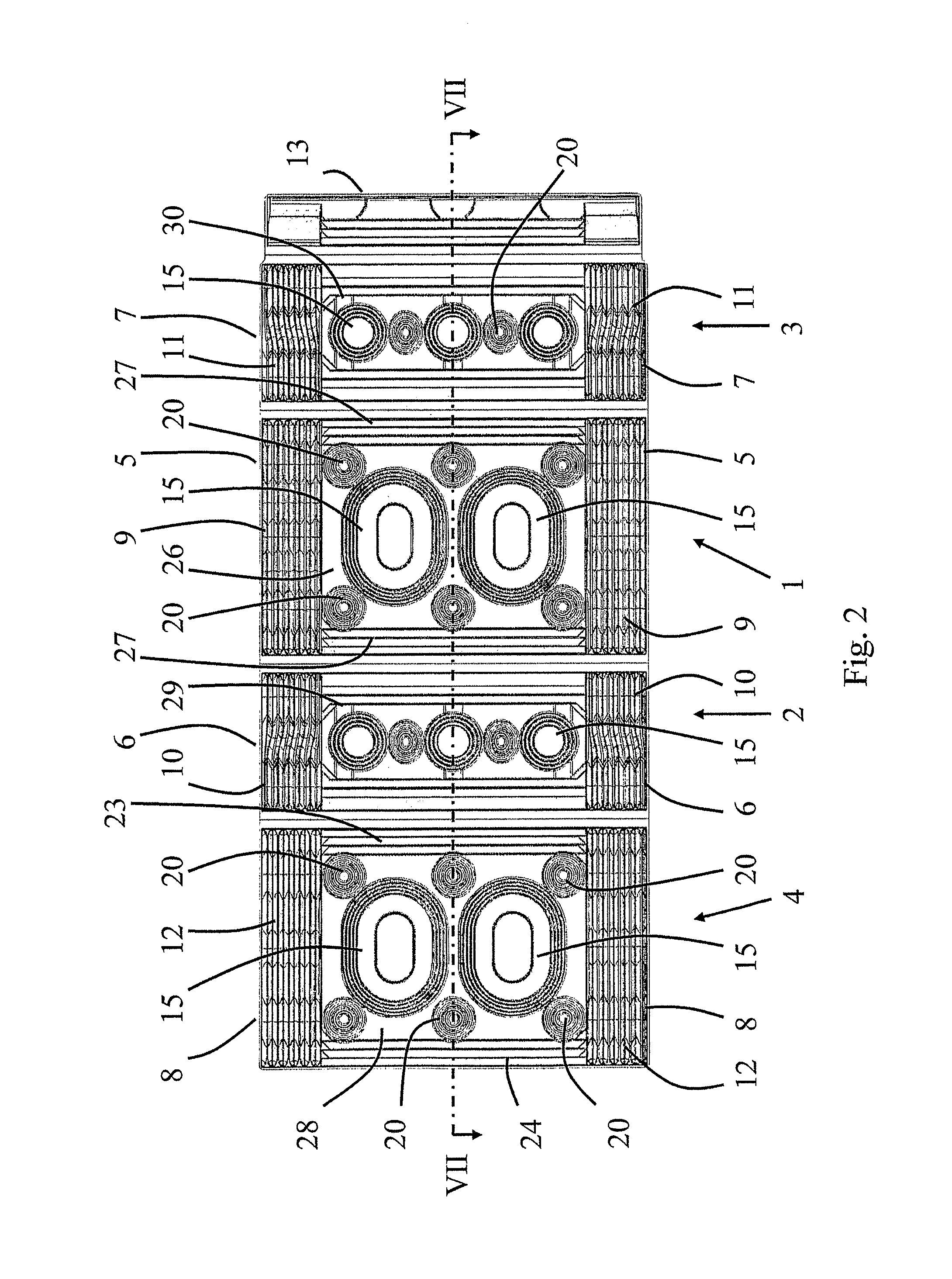

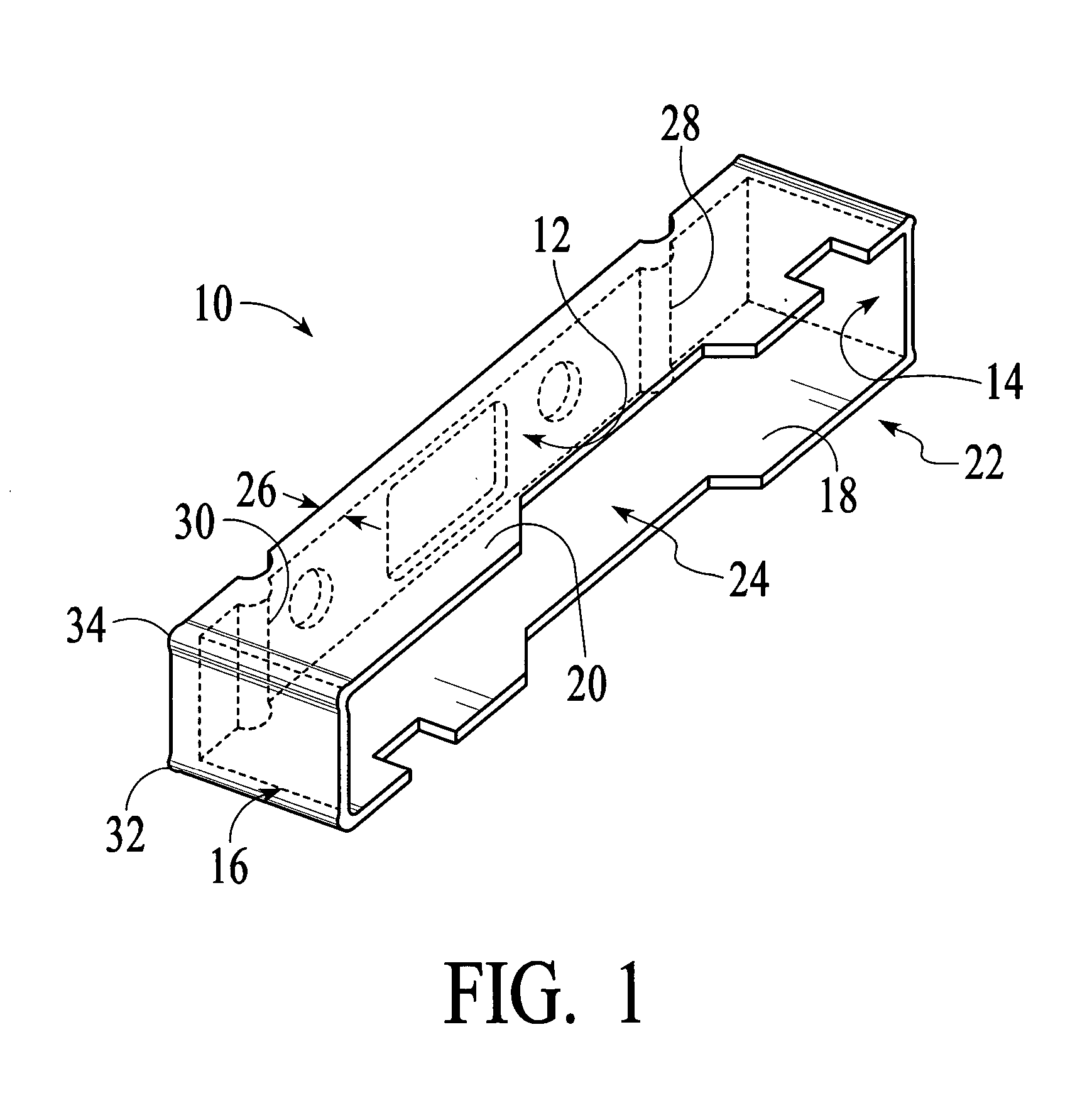

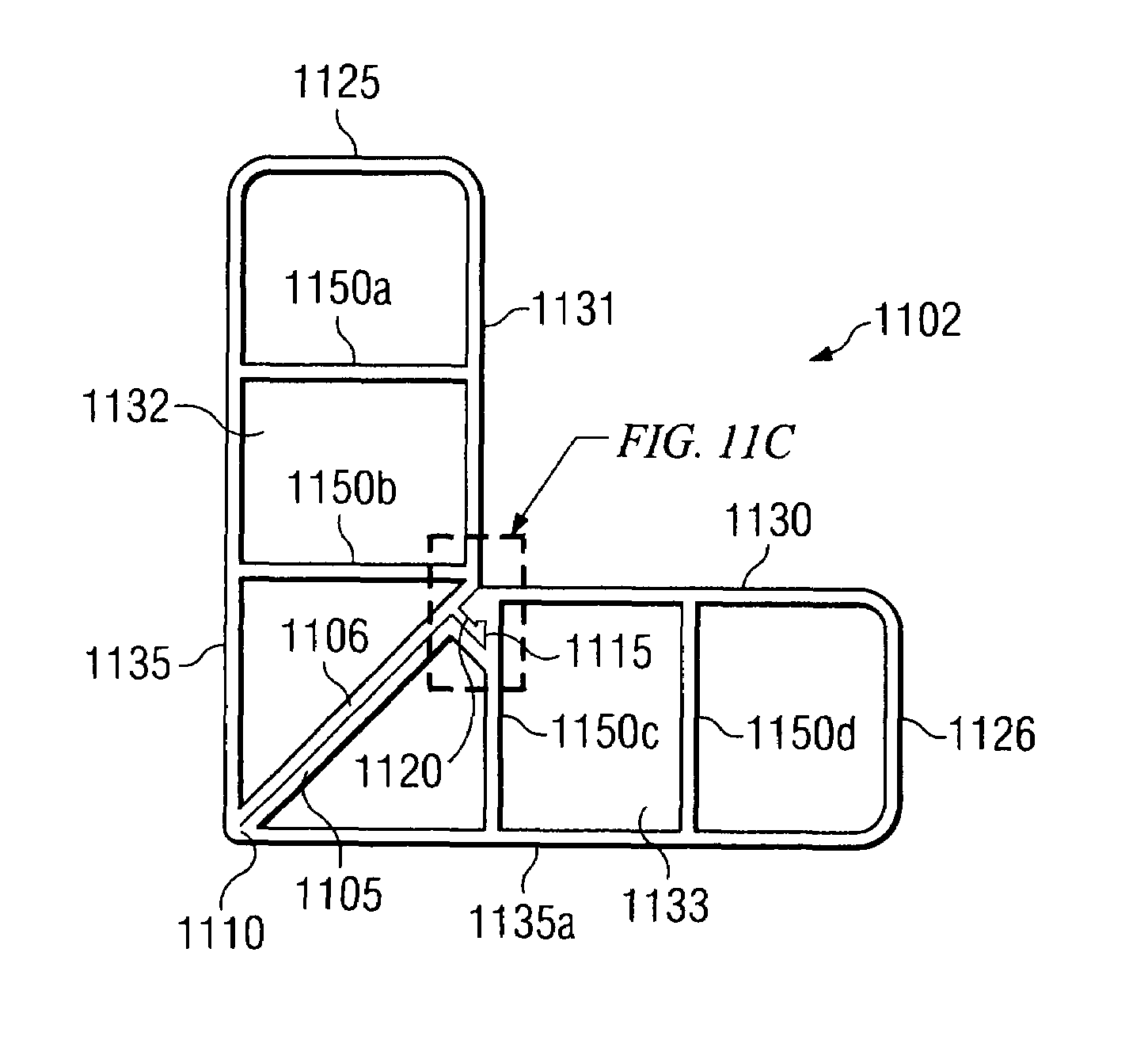

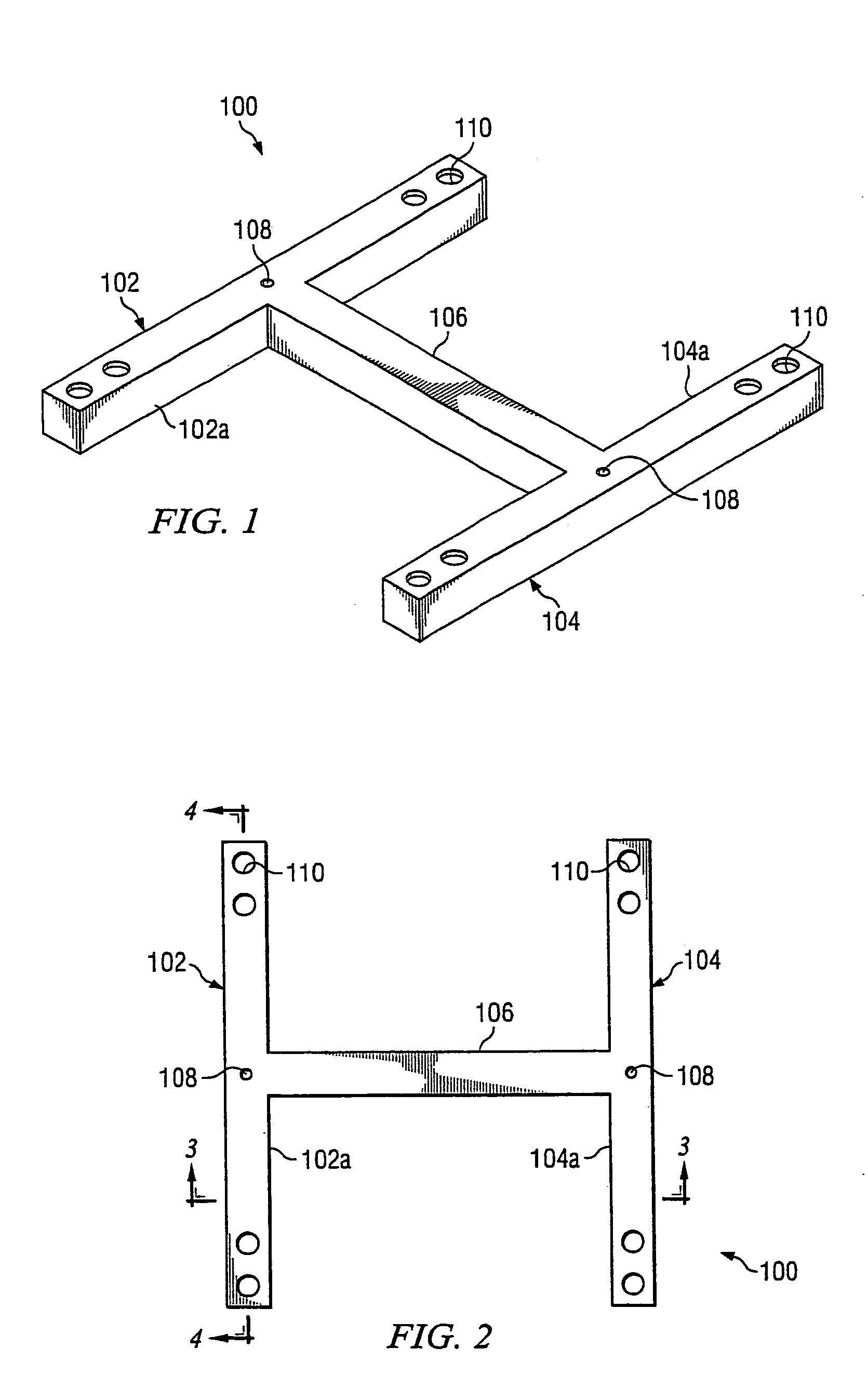

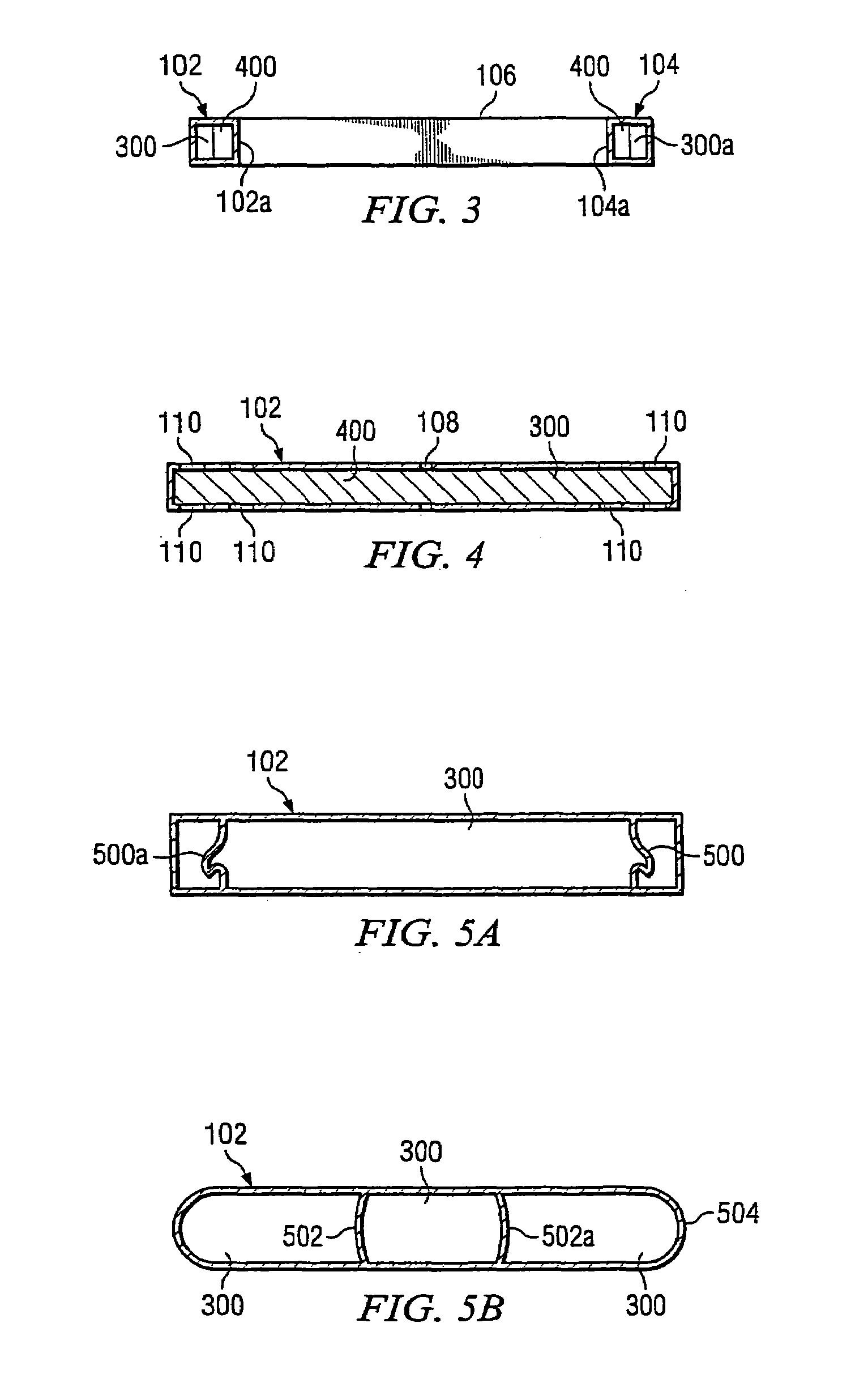

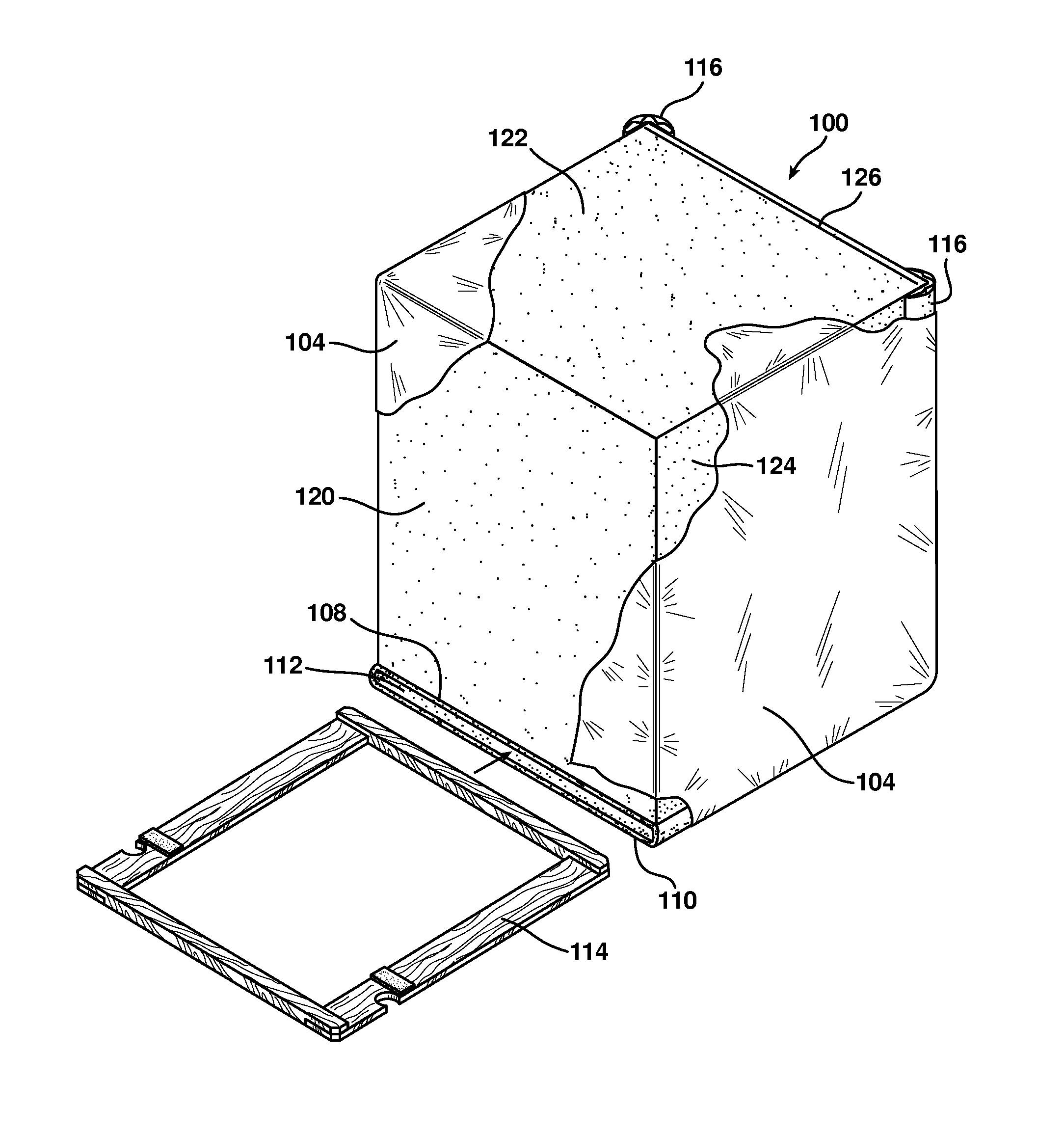

Packaging system, apparatus, and method with articulable corner support members

InactiveUS20050028710A1Easy to storeReduce weightContainers to prevent mechanical damagePlastic containersSynthetic substanceEngineering

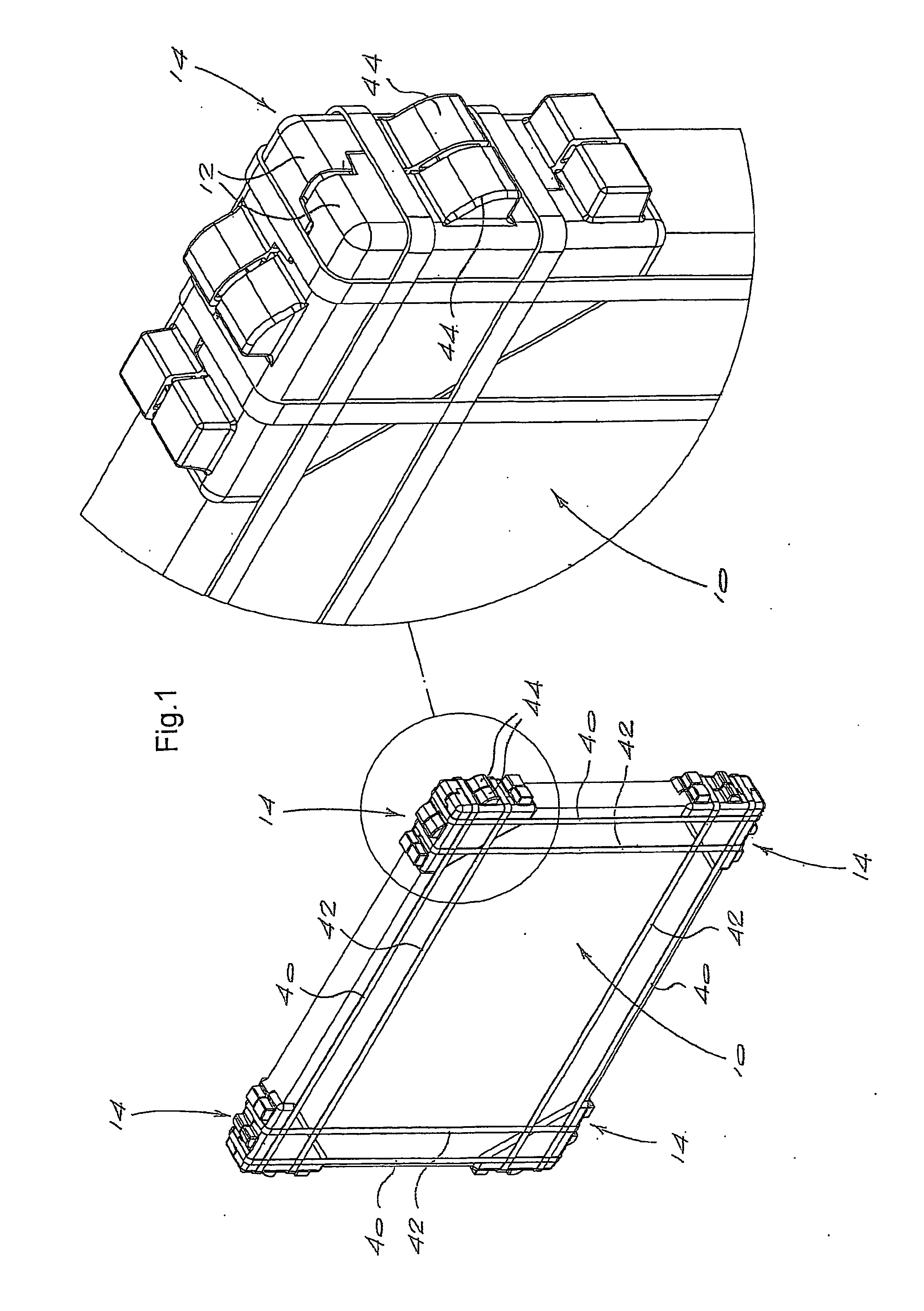

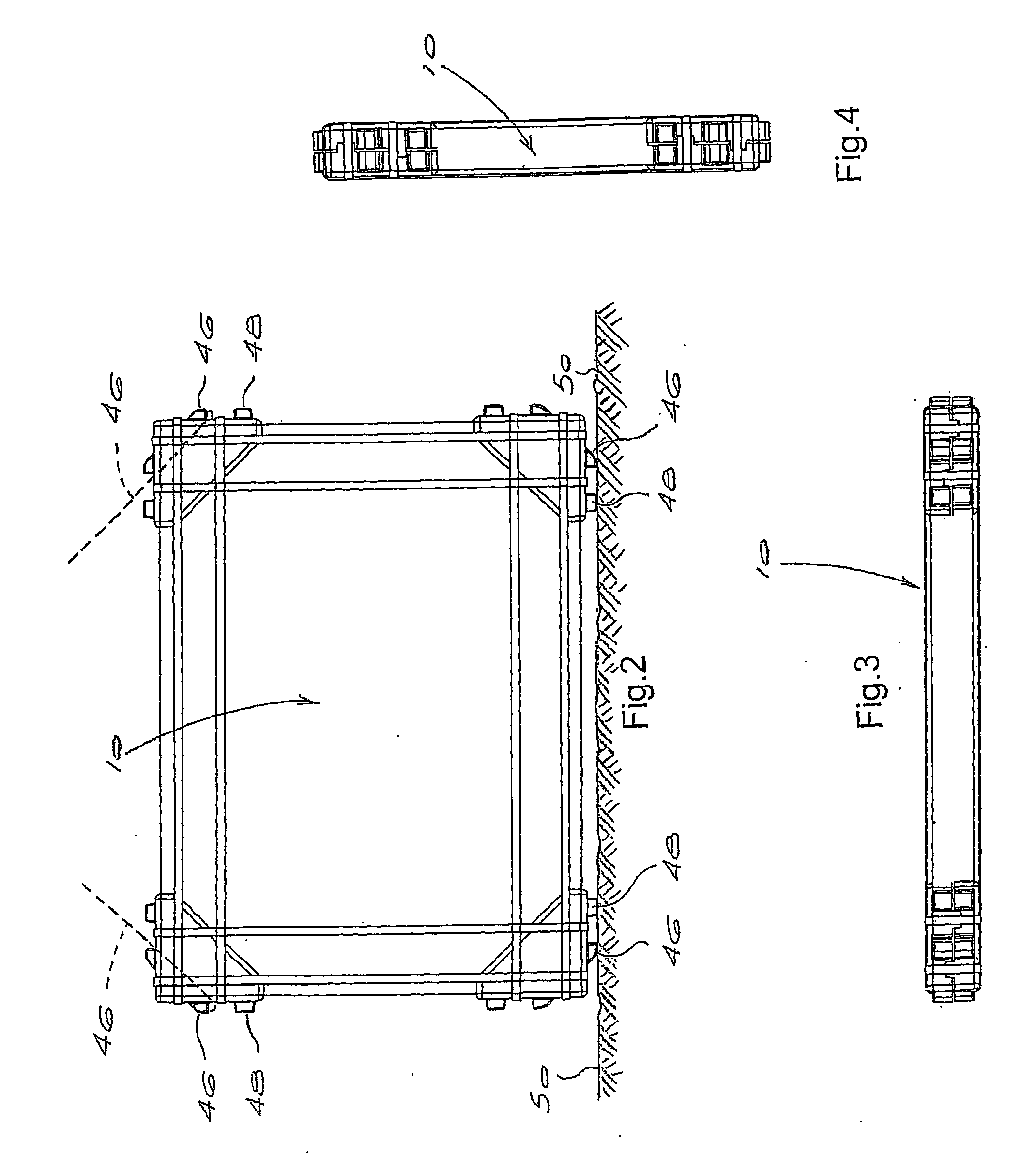

A system for use in the packing of an appliance containing the pallet and corner members is provided. The pallet comprises first and second support members and a connecting cross member, wherein the cross member is substantially perpendicular to the first and second support members. The first and second support members include attachment holes, wherein the attachment holes allow for the attachment of the pallet to the appliance. The first and second support members and the cross member are manufactured from a synthetic substance and are substantially hollow. The system further comprises an available plurality of articulable corner support members, corner junction end caps with tenons, closed cell design elements, and standoffs used to protect, support, separate and / or stabilize the appliance in a container.

Owner:CARPENTER GARY +1

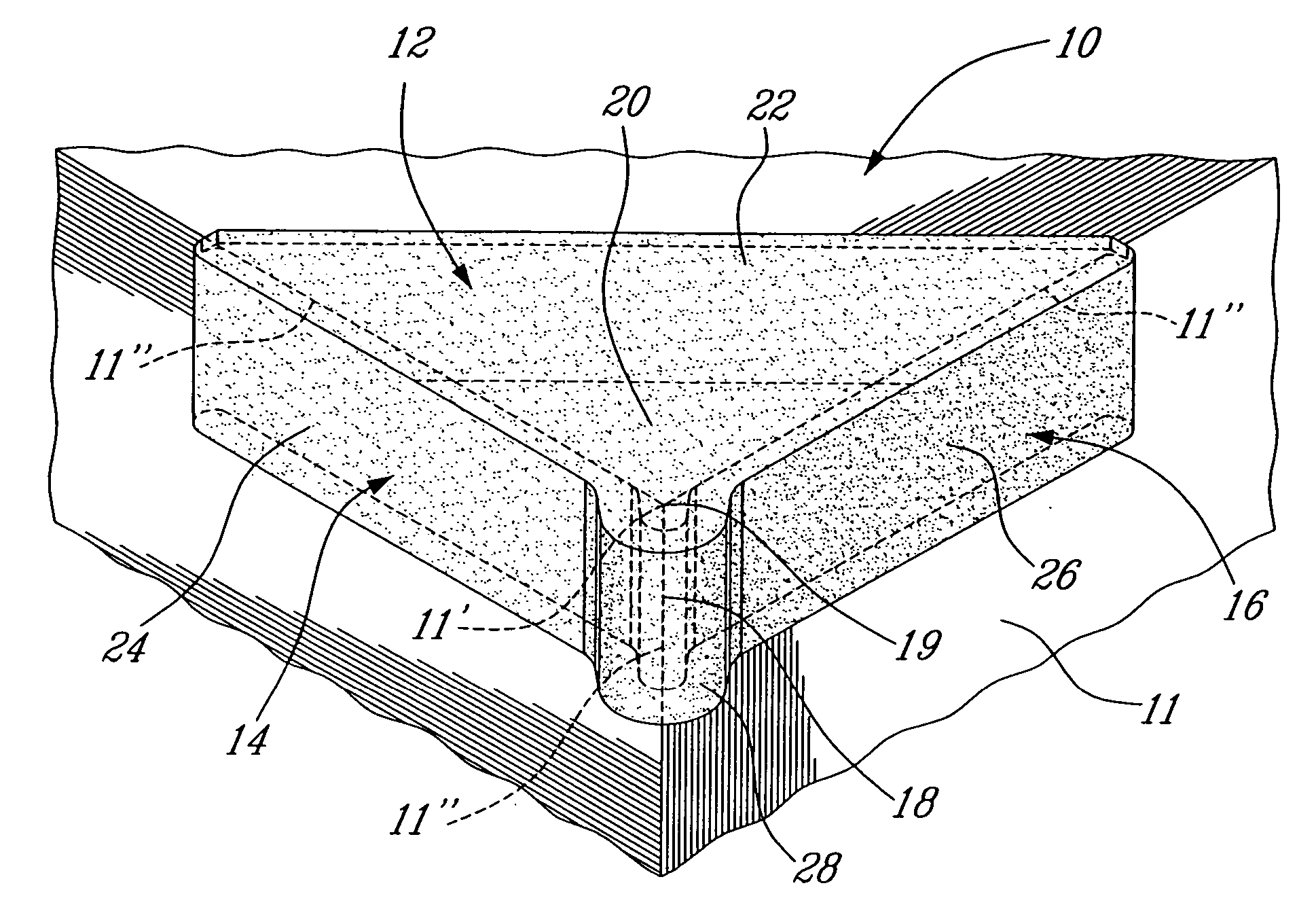

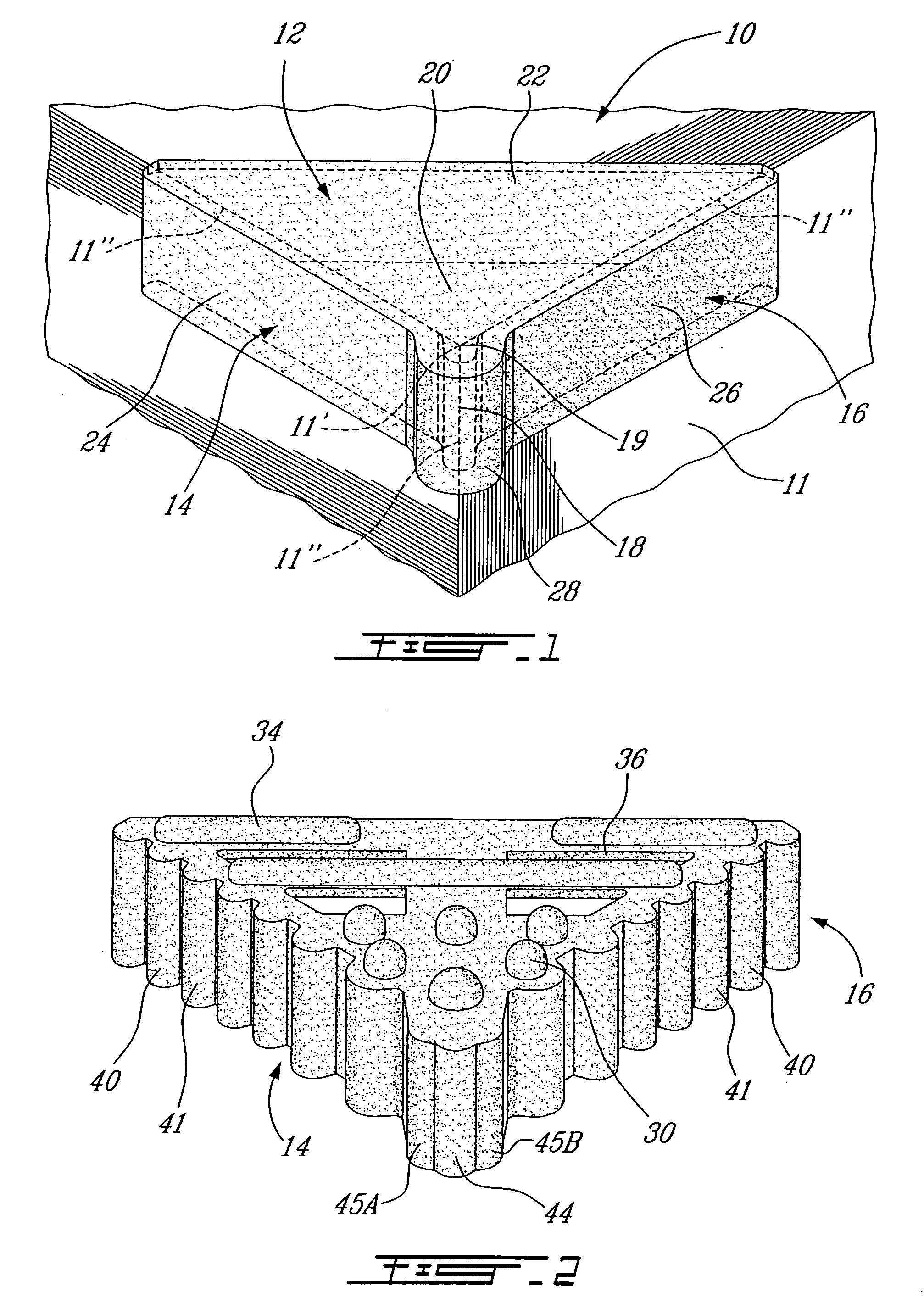

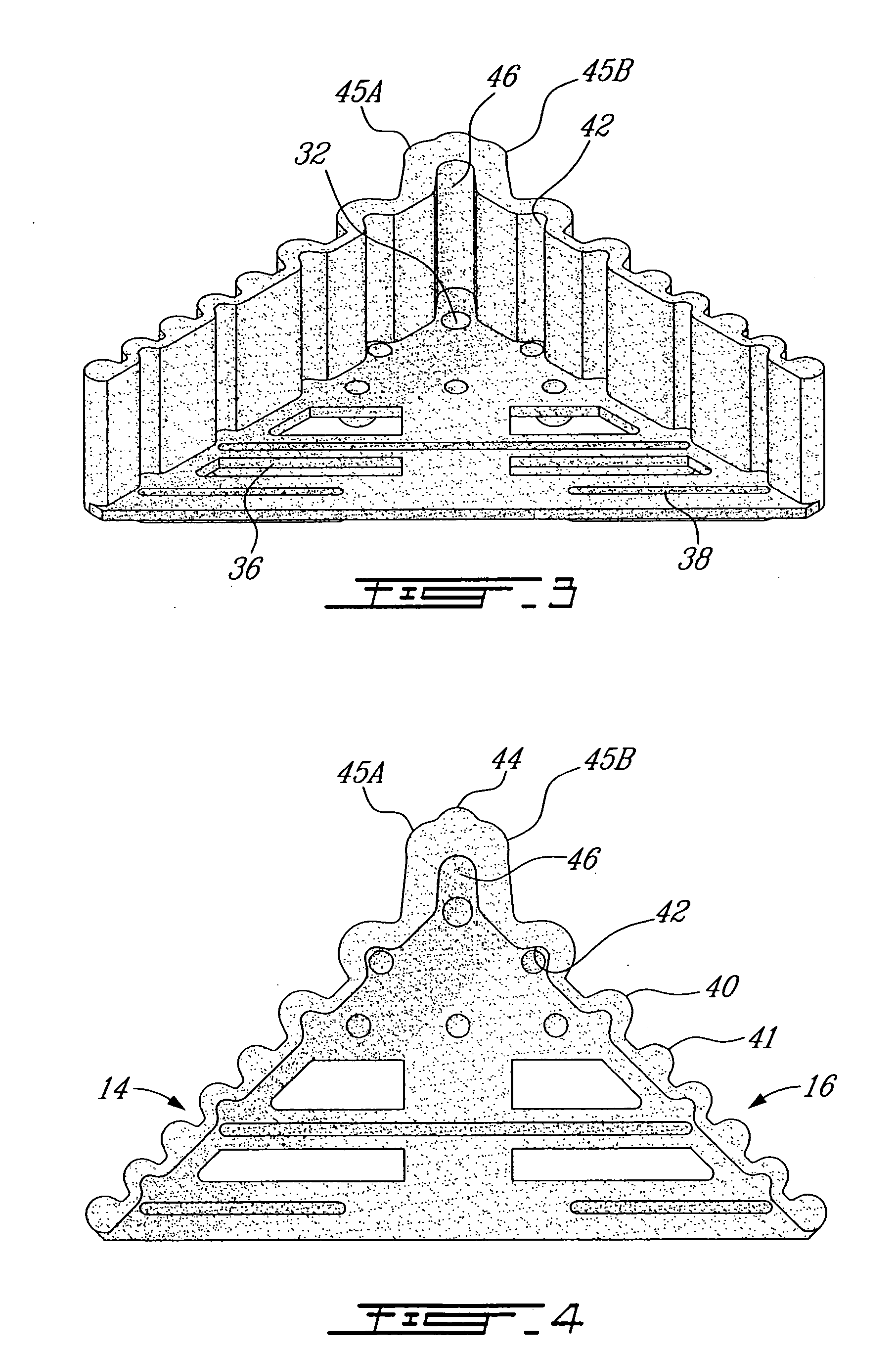

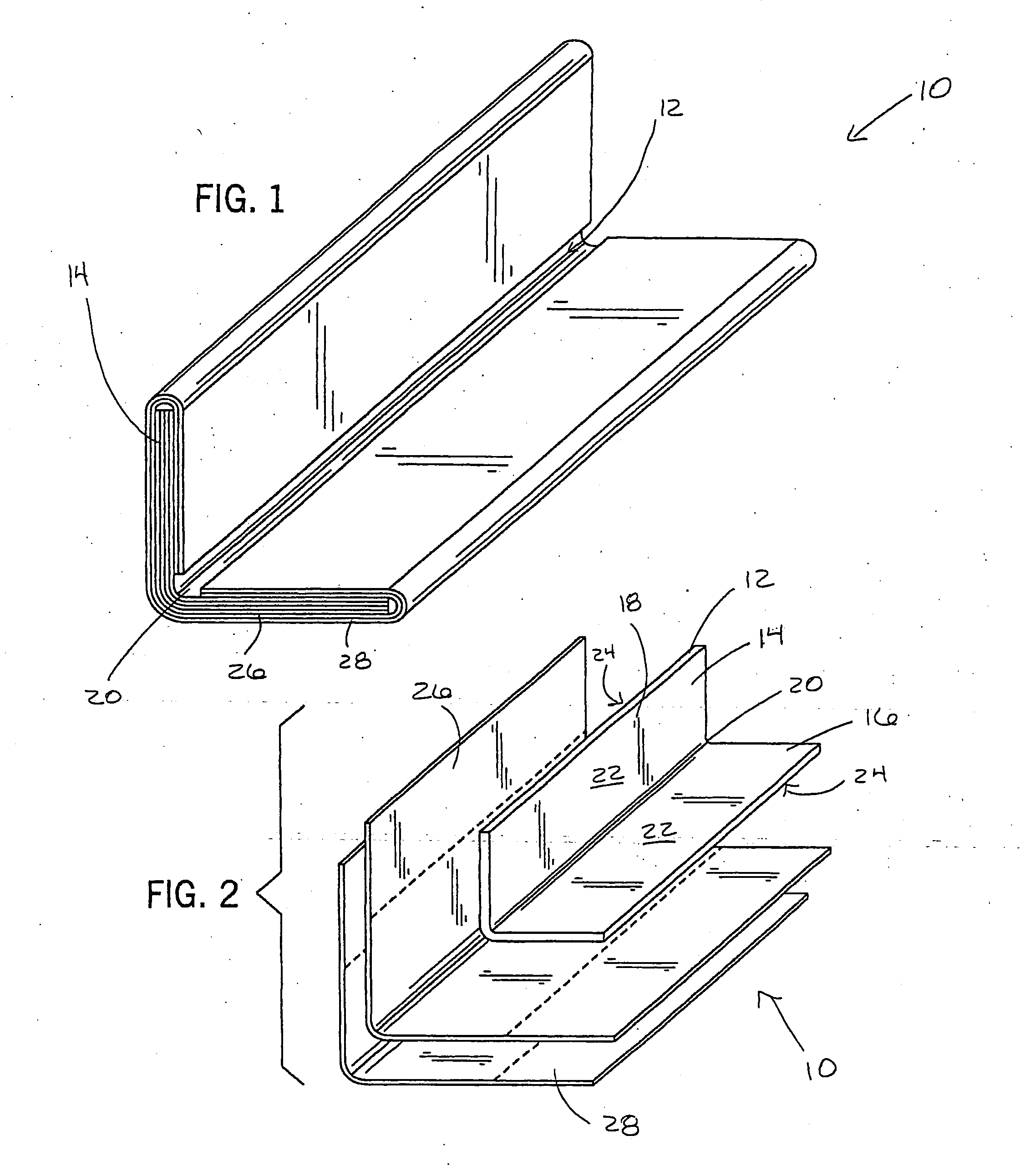

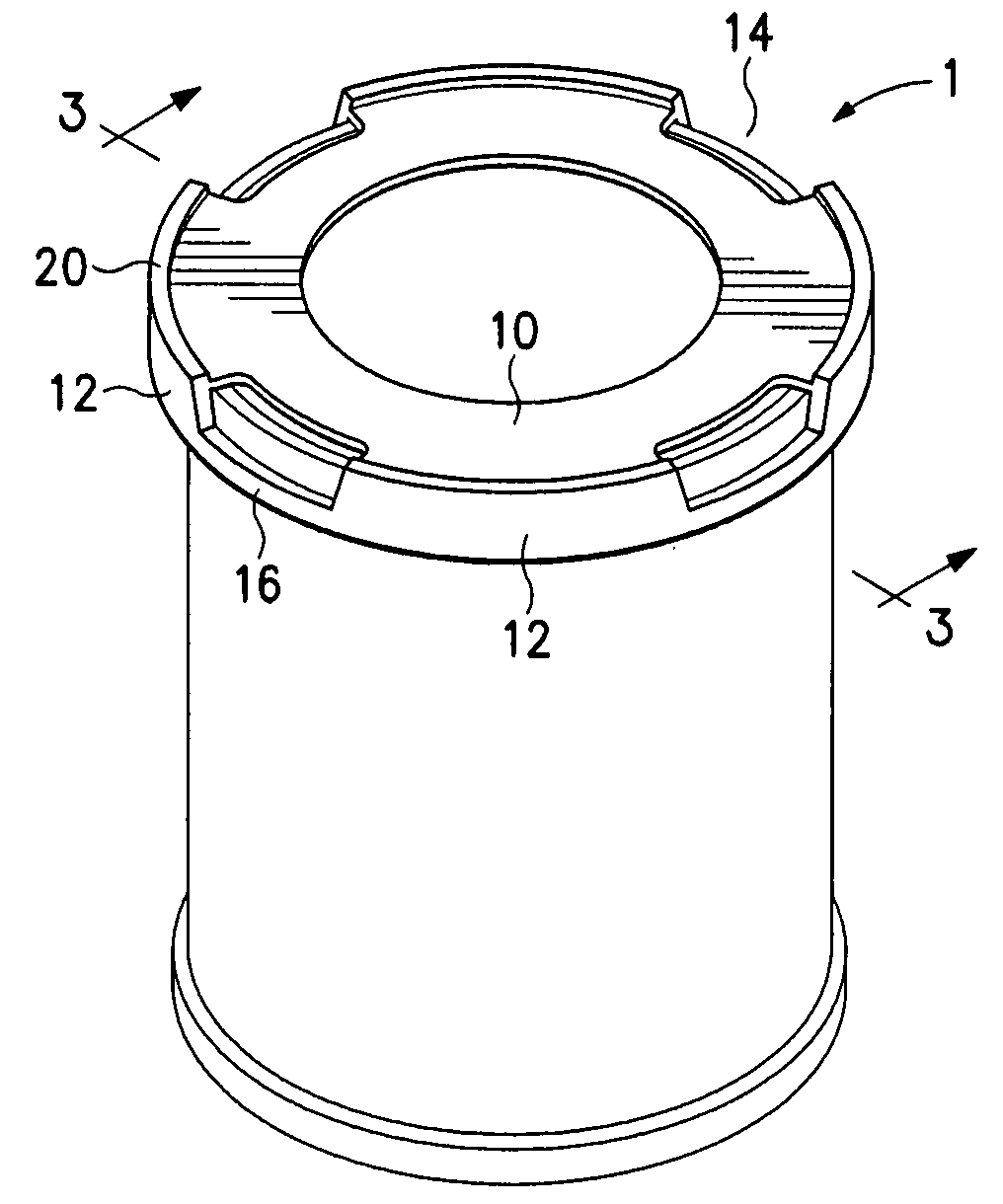

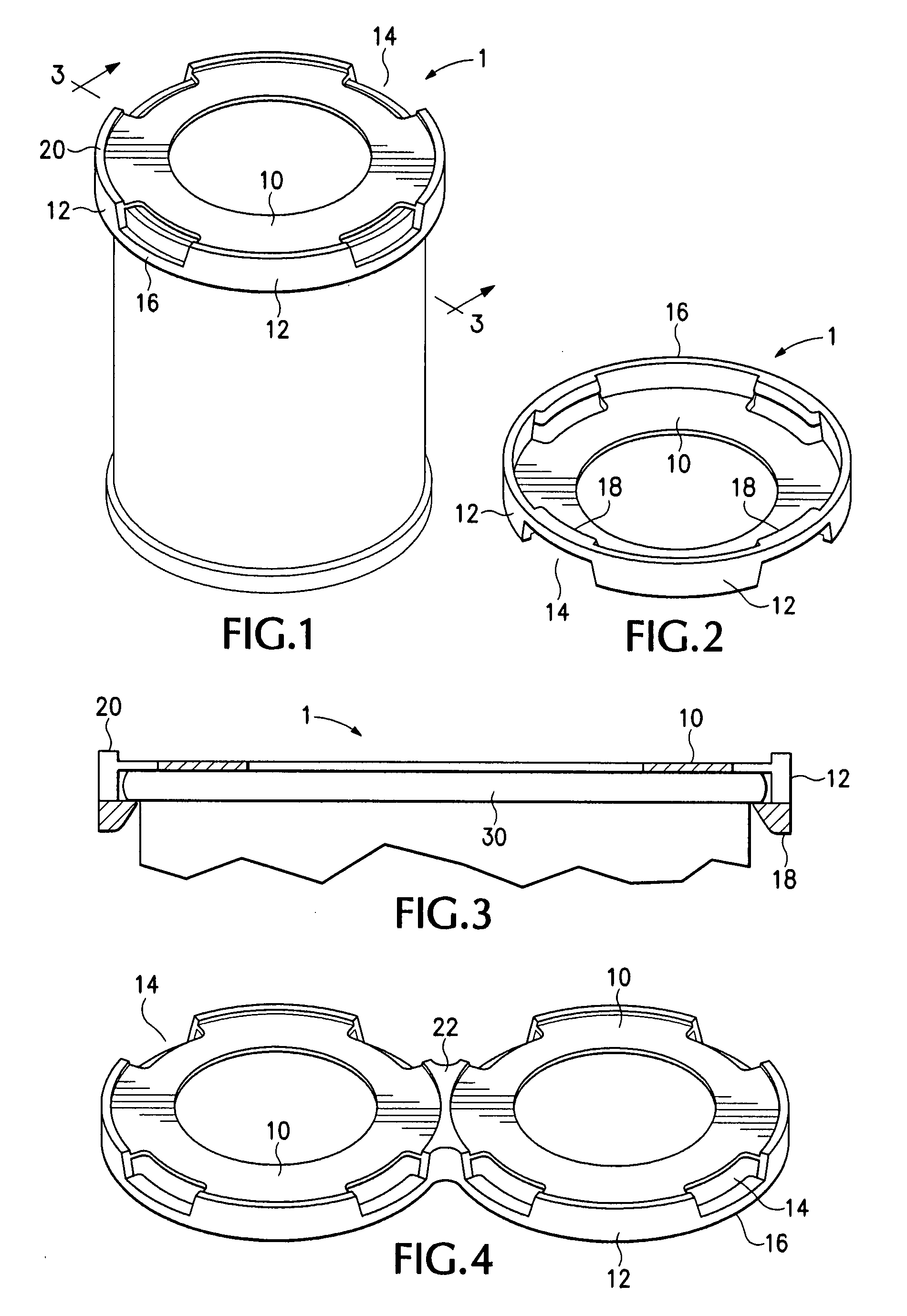

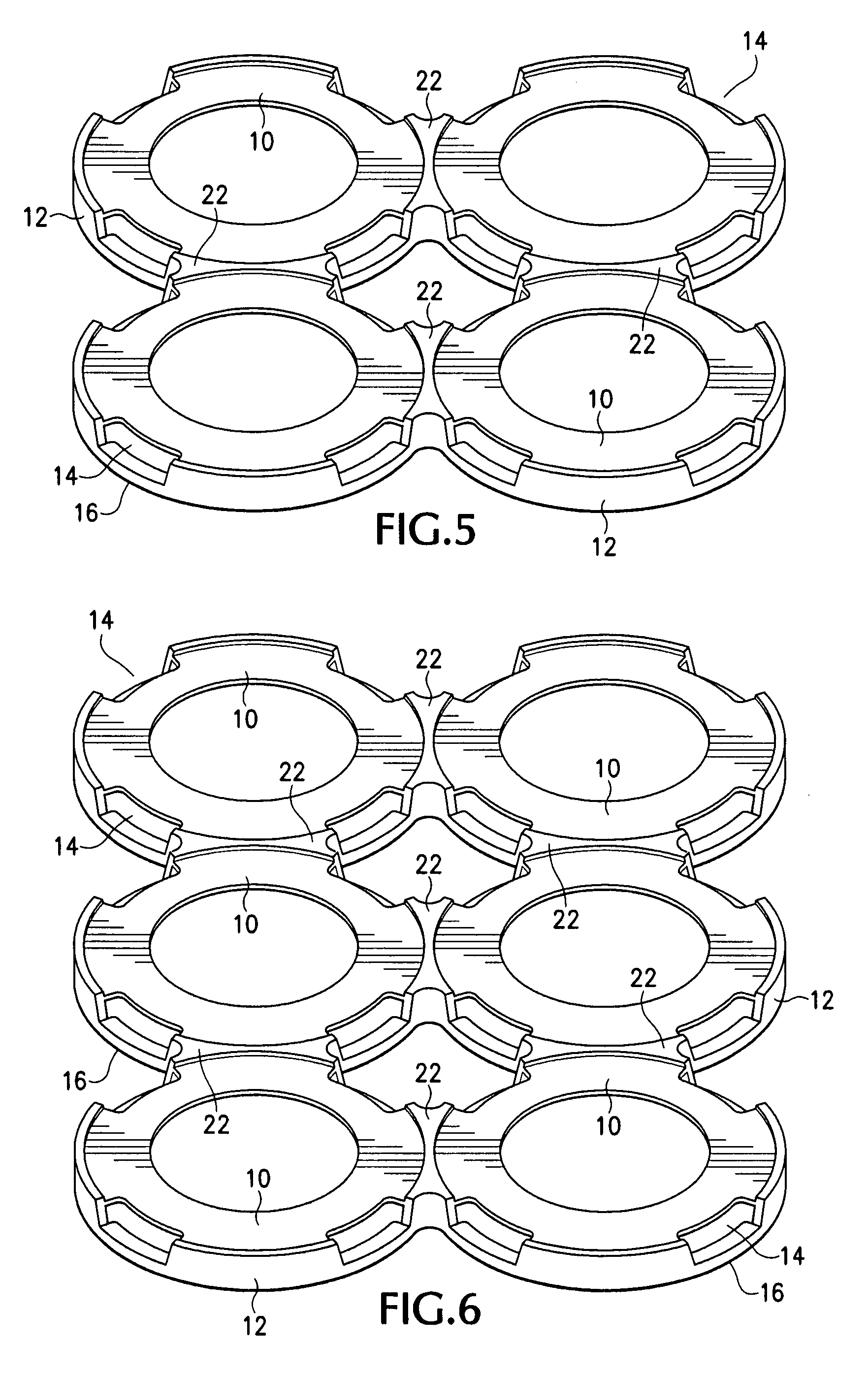

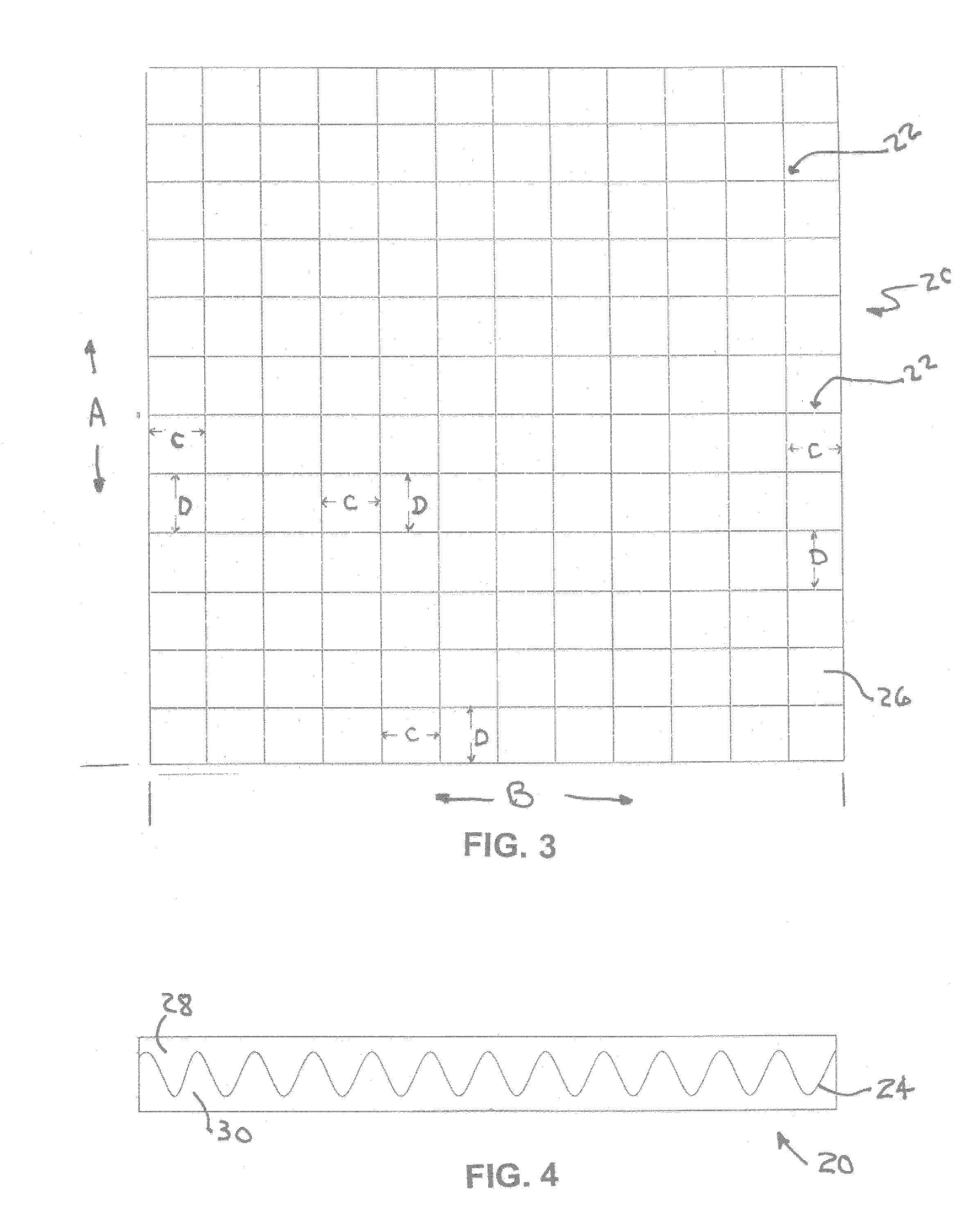

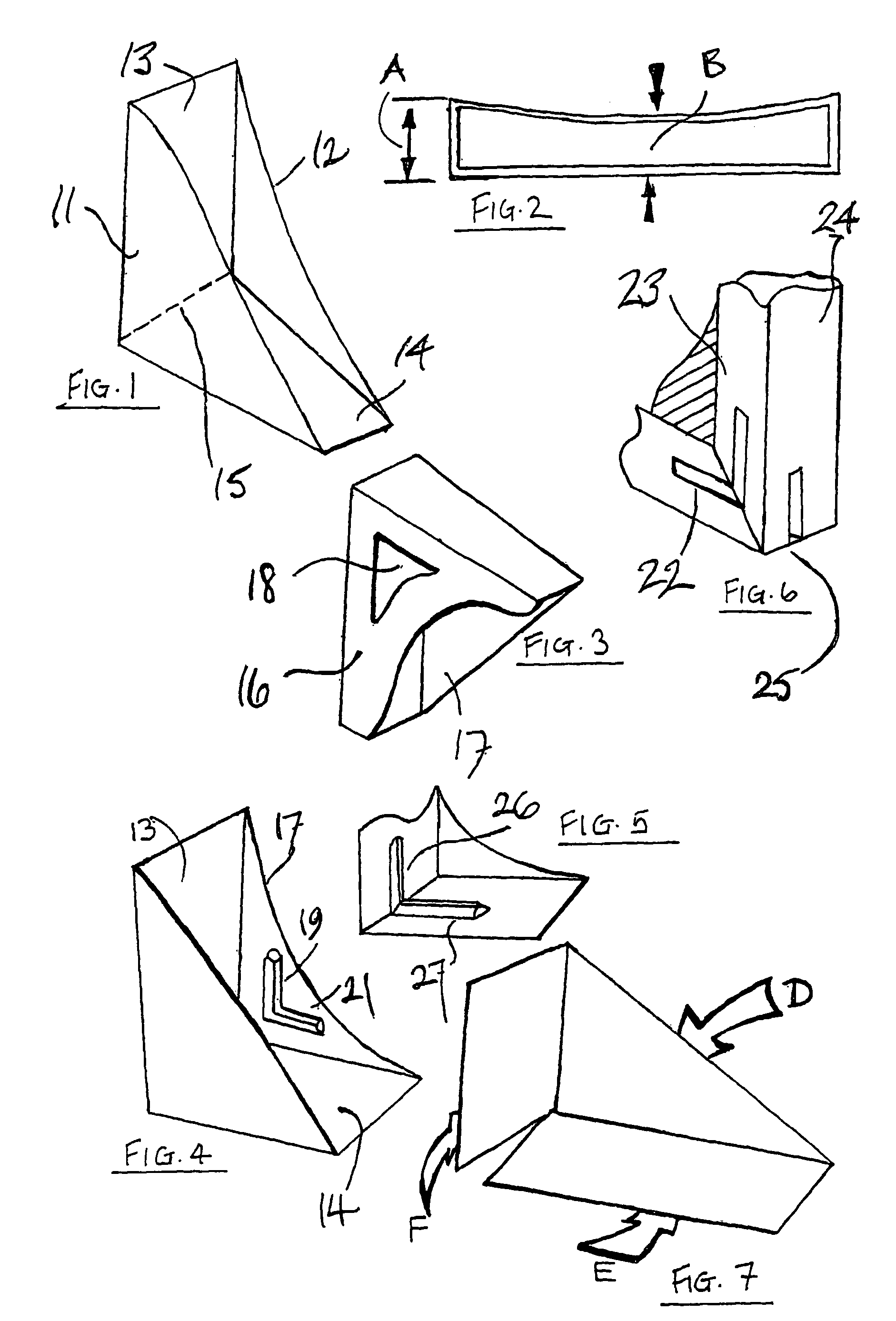

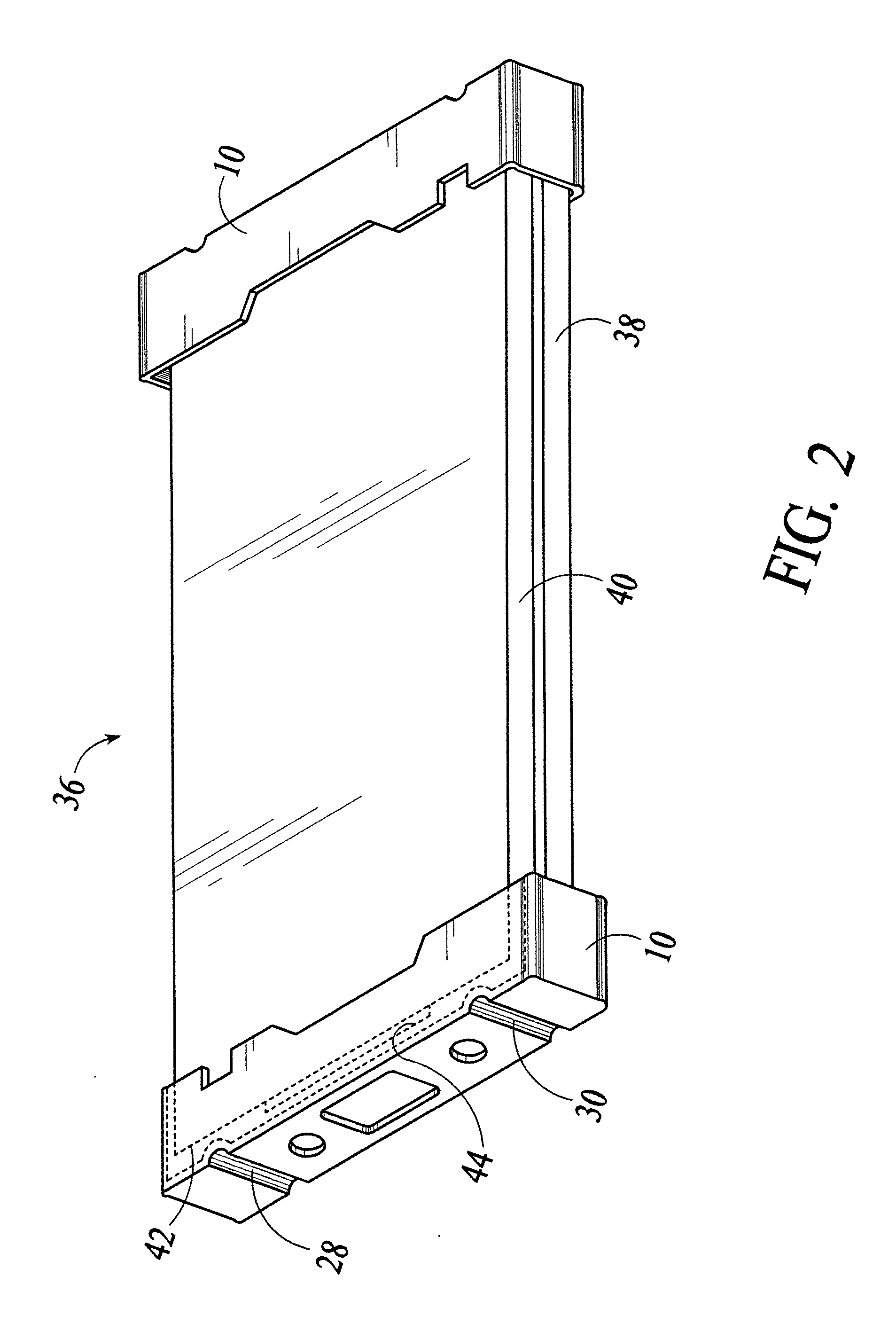

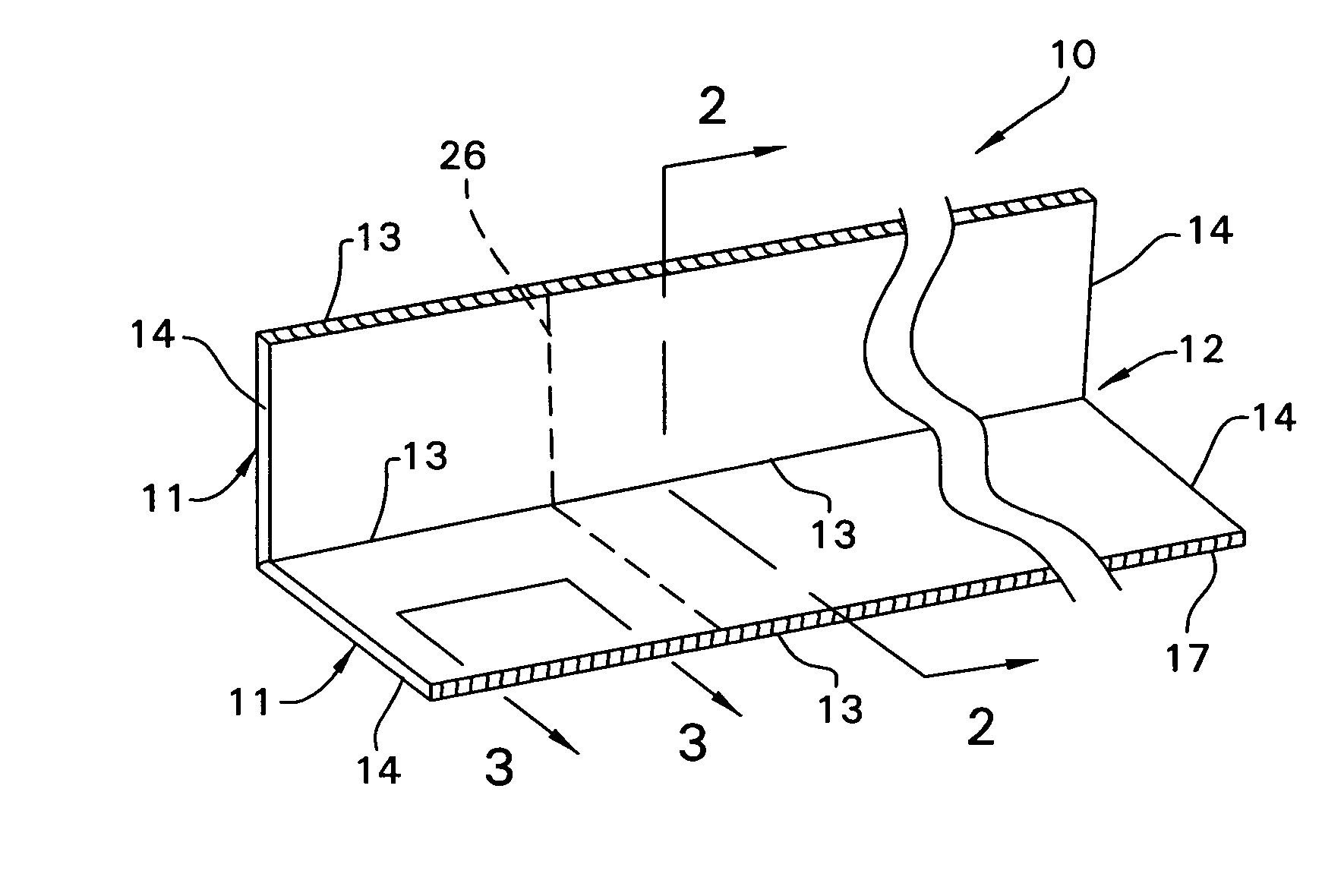

Sheet packaging apparatus

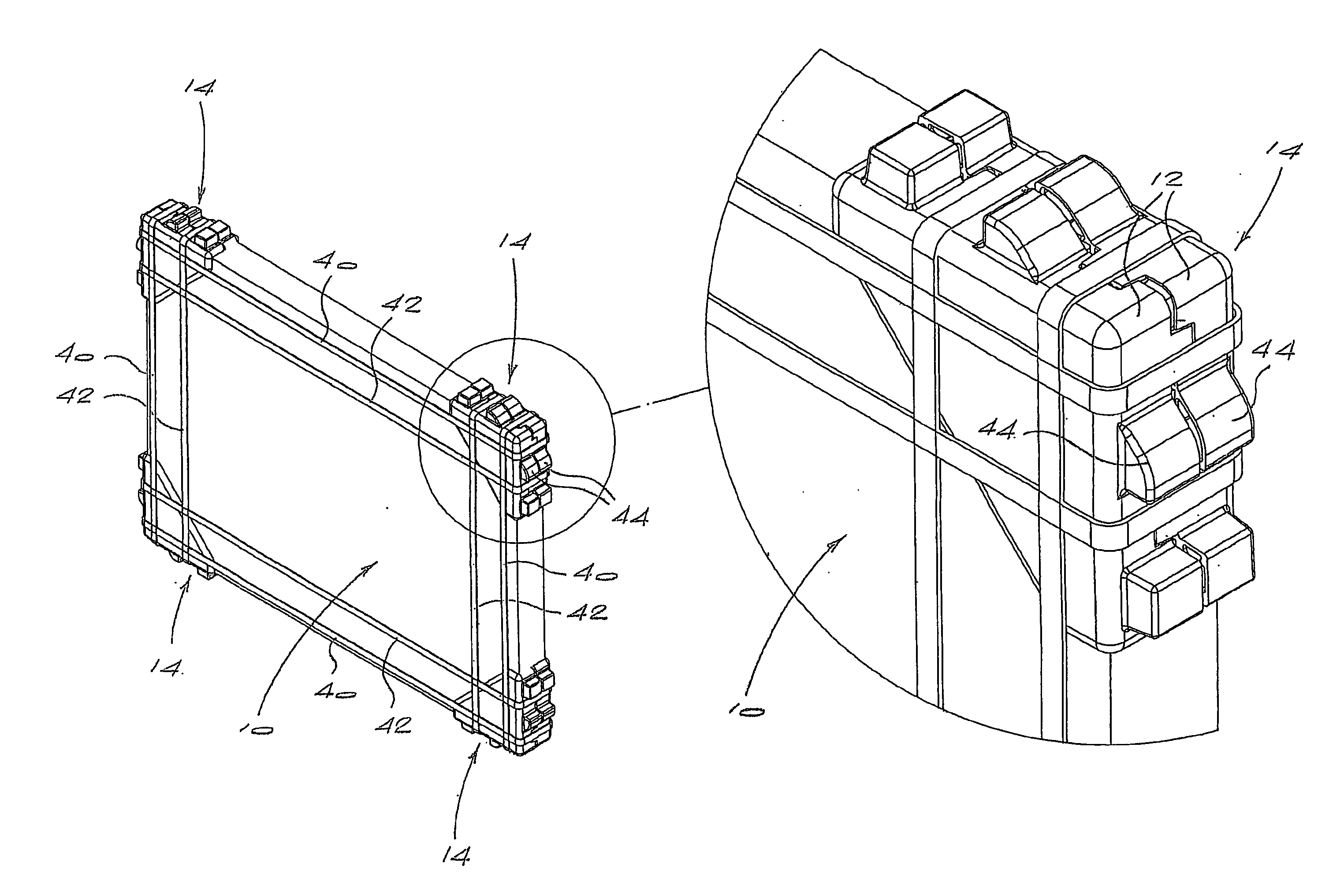

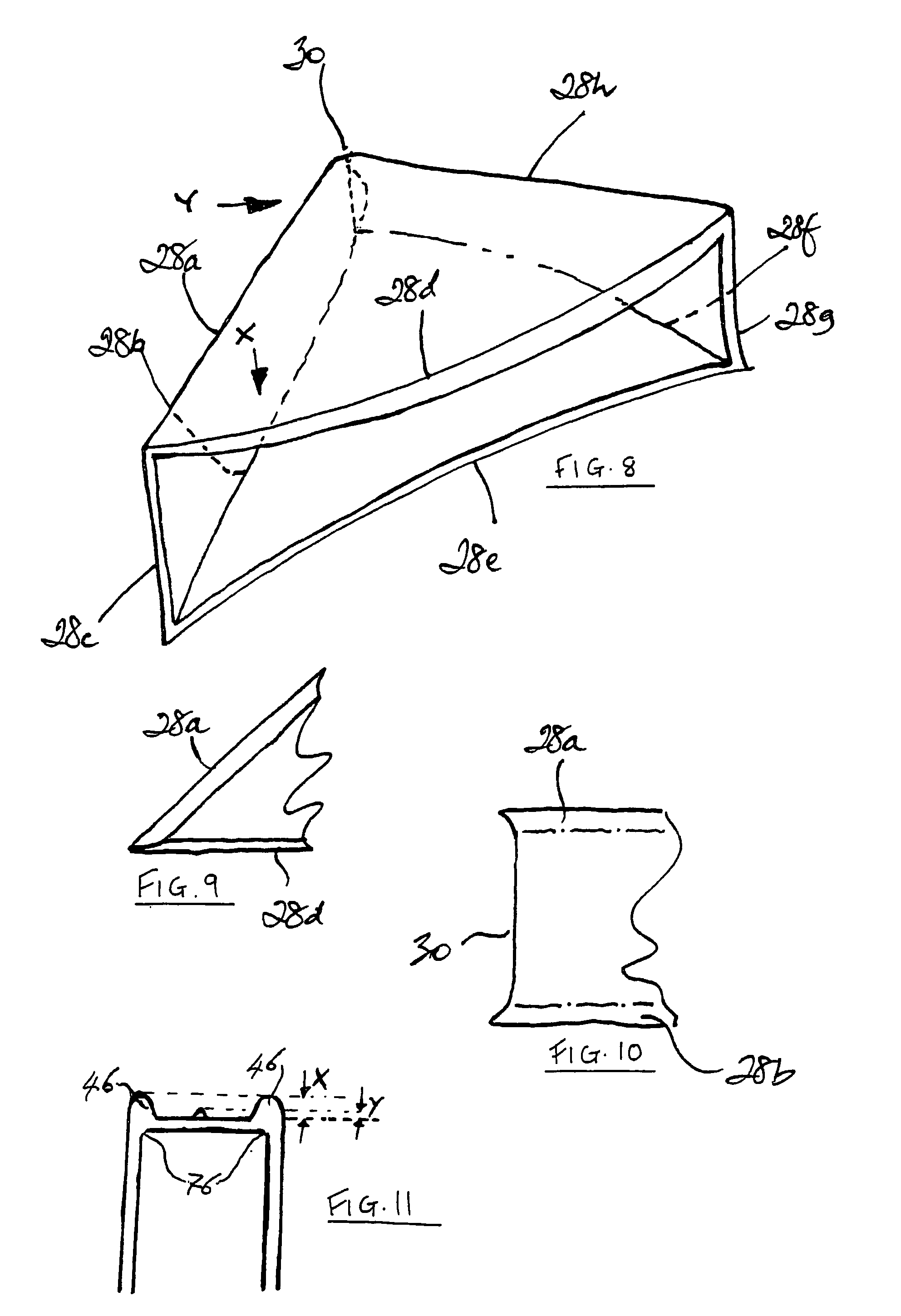

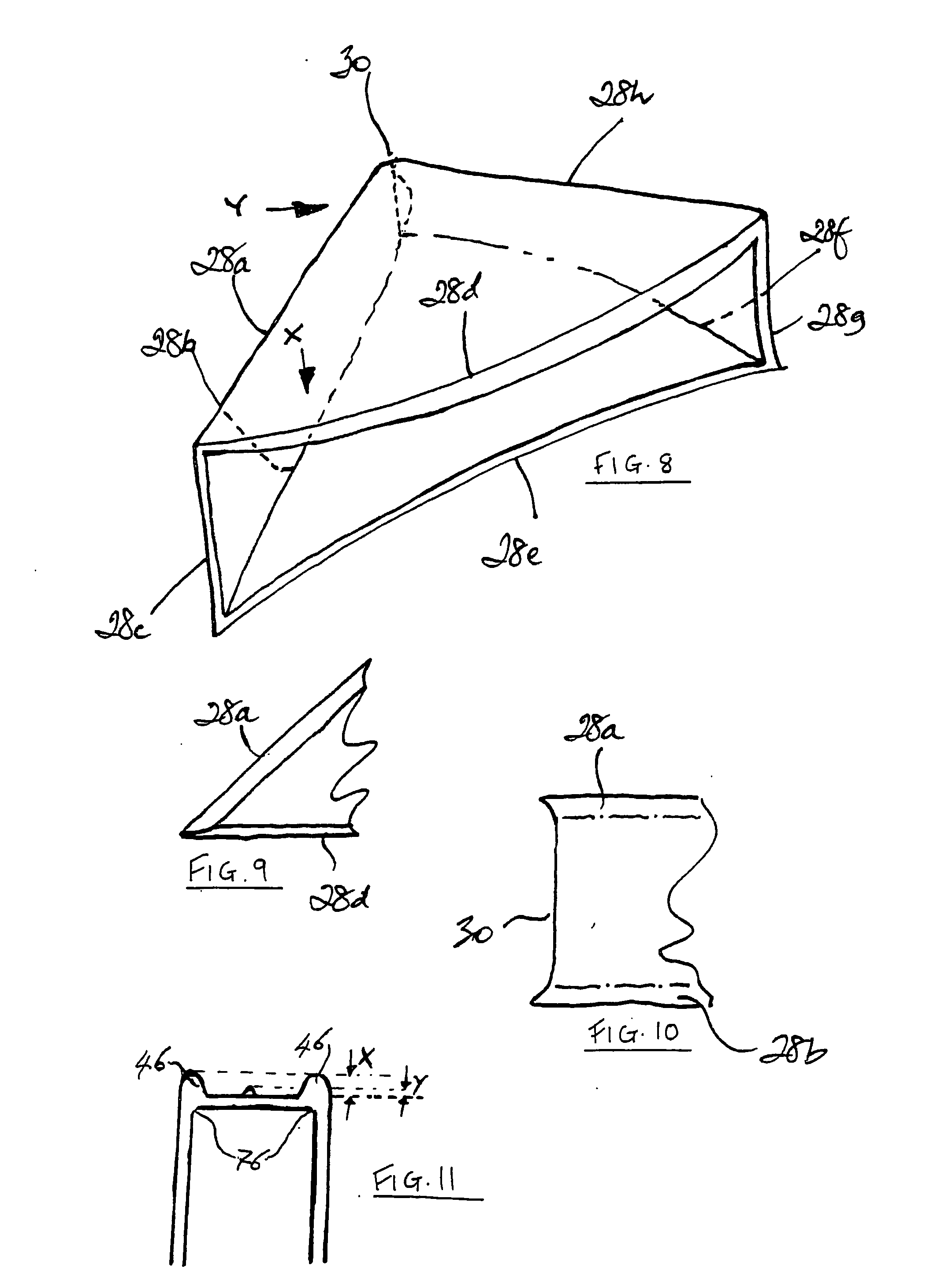

A first aspect of the invention concerns a corner packaging device (14) which can be used in the packaging of a polygonal pack (10) of stacked glass sheets. The device includes two identical packaging members (12) each having a facing element (16) to lie against an outer surface of the pack at a corner and a pair of transverse flanges (22) meeting one another at a corner (24) of the facing element so as in use to lie against adjacent edges of the pack. There is a projection (28) lying generally in the plane of each flange and extending beyond the inner edge (26) of the flange and a recess (30) extending into the flange from that inner edge. With this arrangement, the packaging members can be arranged with their facing elements lying against opposite surfaces of the pack, with their flanges extending towards one another and with the projection of one flange extending over an edge of the pack to be received slidably within the recess of the other flange over a range of different pack thicknesses. Each flange also carries a projecting sling attachment formation (44) beneath which a lifting sling (46) can be engaged for the purposes of lifting the pack at an upright attitude when the devices embrace the corners of the pack and are anchored in position by straps (40, 42) encircling the devices and the pack to hold the pack together. Other aspects of the invention relate to a packaging system incorporating such devices (14) and the individual packaging members (12).

Owner:BURCHELL PAUL CHRISTOPHER

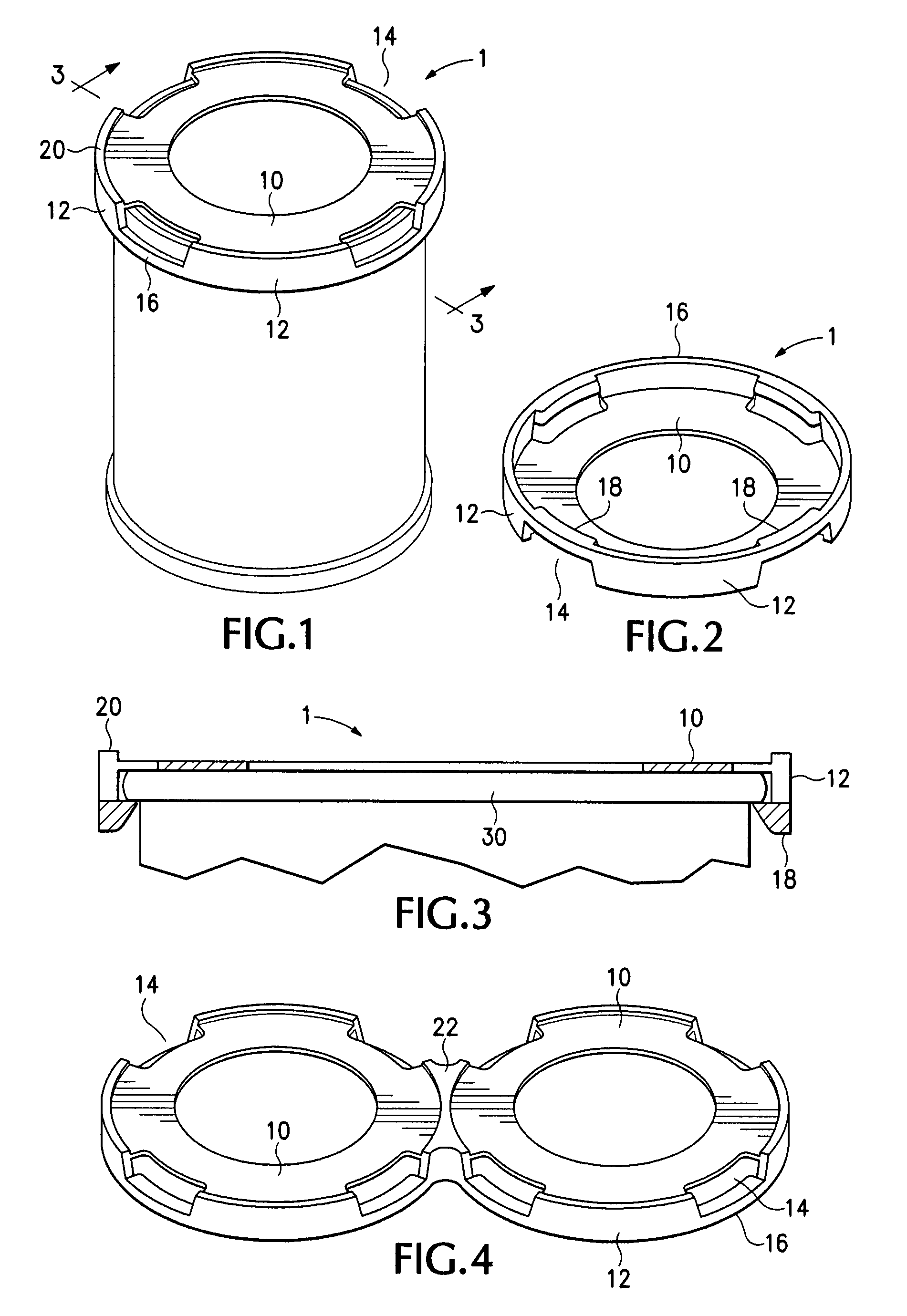

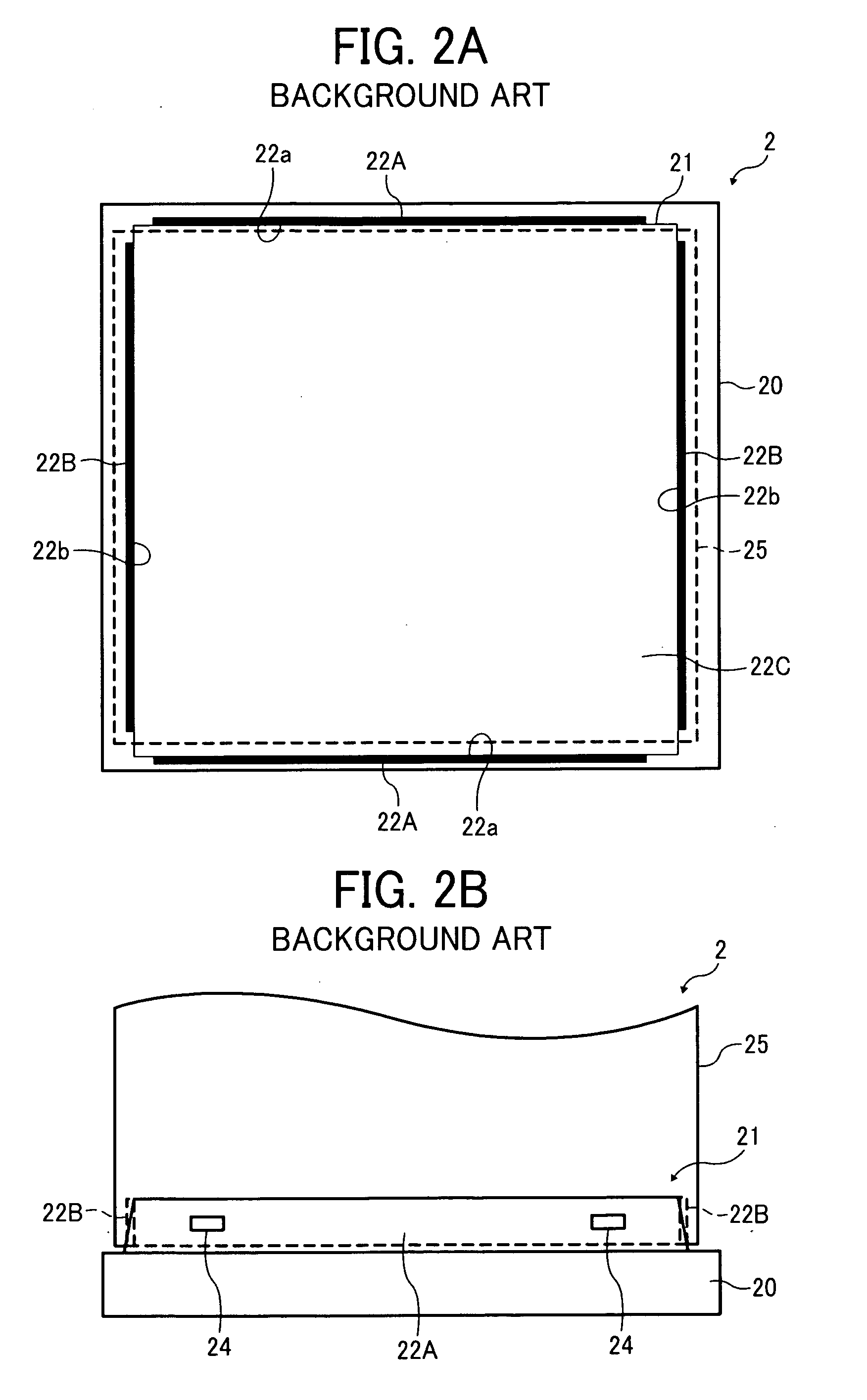

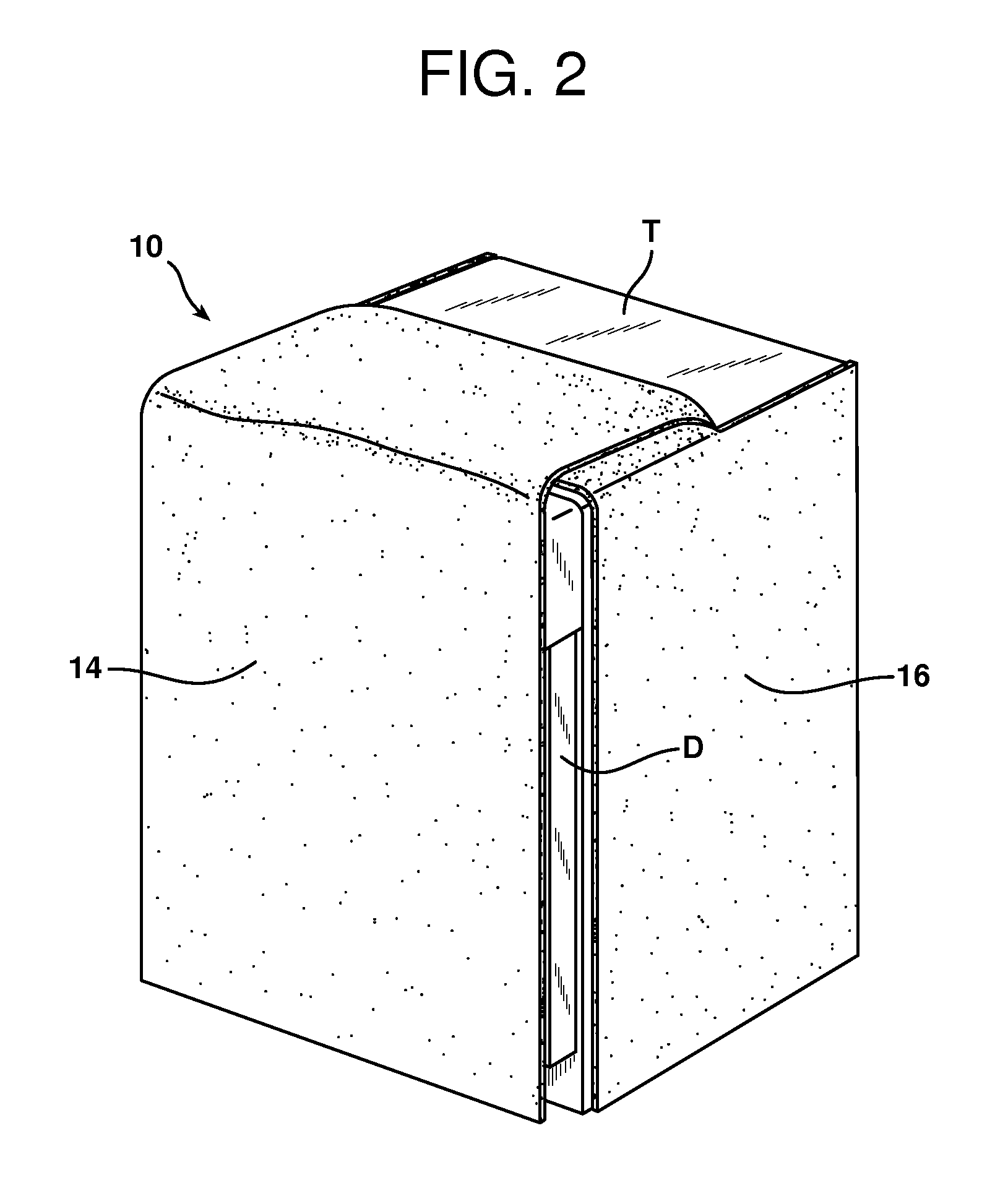

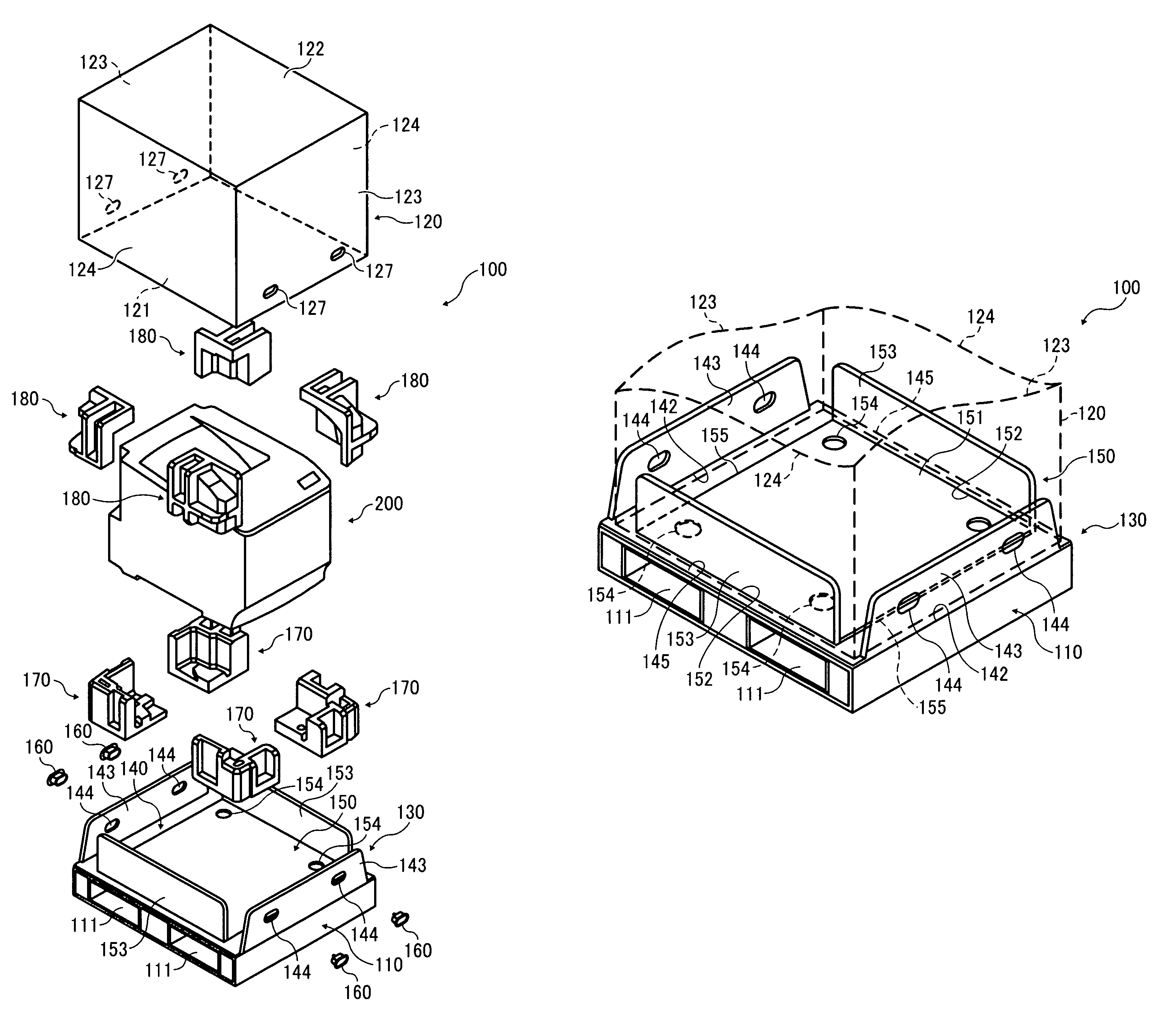

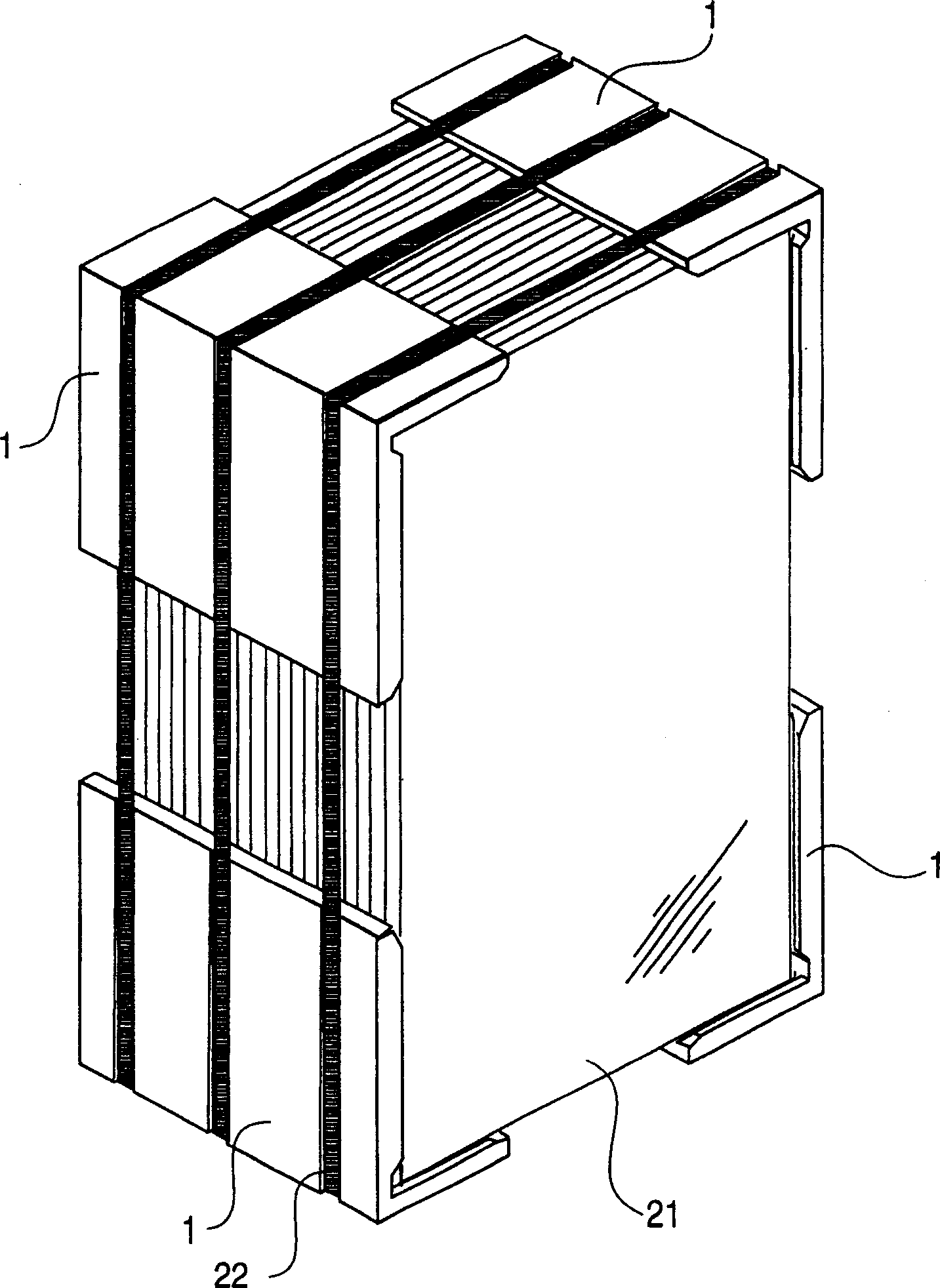

Packaging container

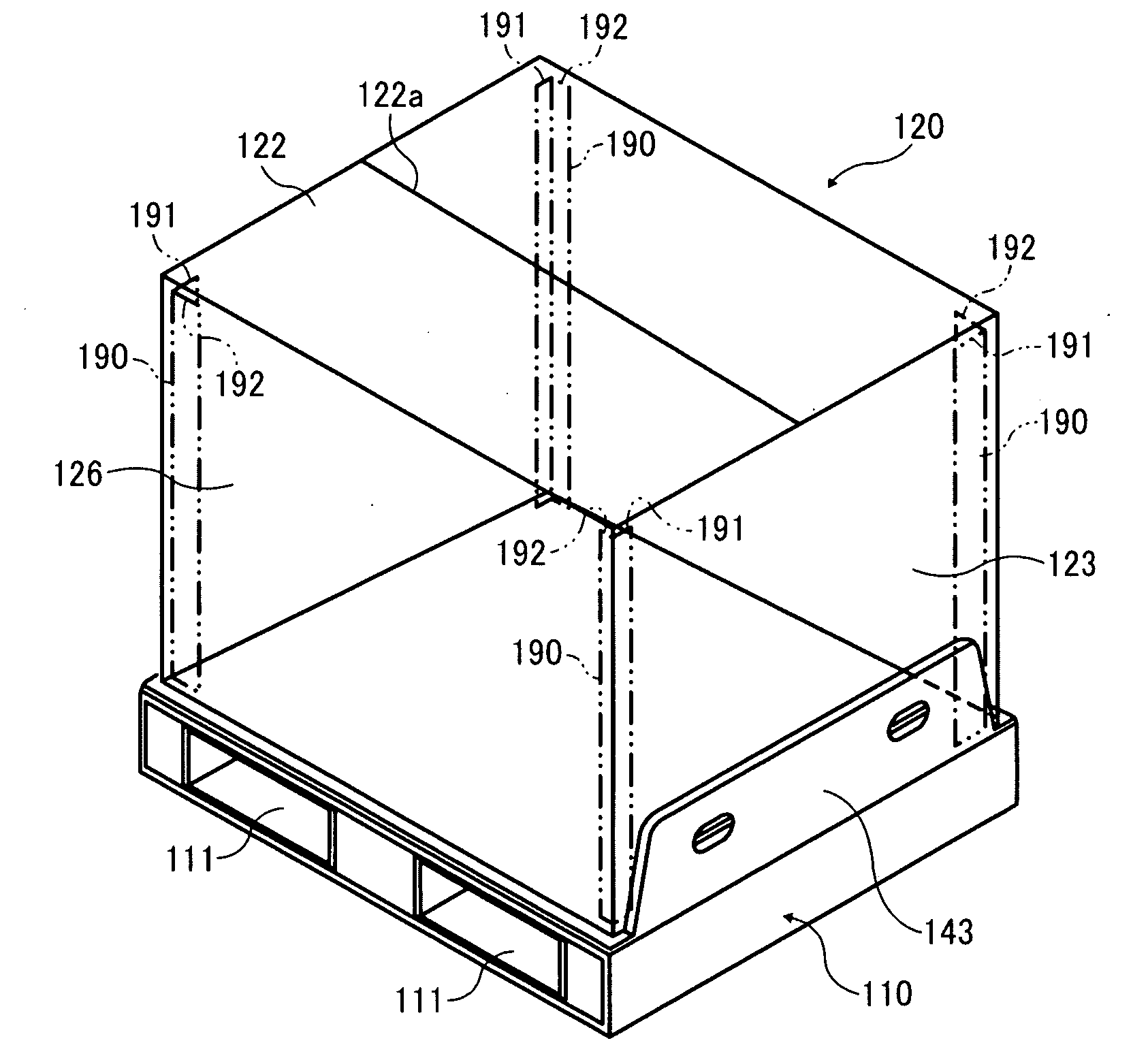

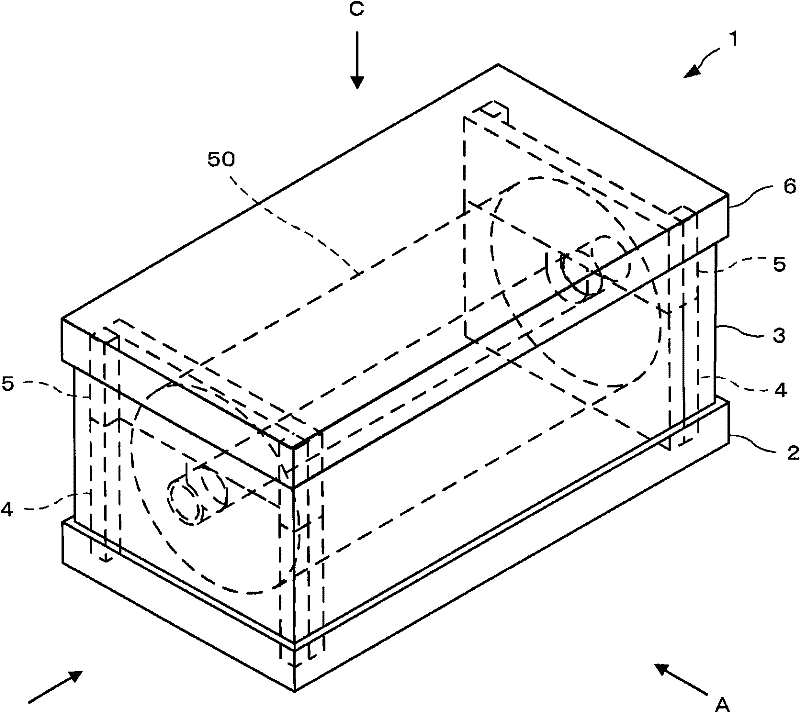

A container includes a pallet, an enclosure base, an enclosure box, and a set of fasteners. The pallet is disposed at a bottom of the container. The enclosure base is placed on the pallet, and includes a lower base sheet and an upper base sheet. The lower base sheet forms a first pair of side flaps. The upper base sheet forms a second pair of side flaps. The enclosure box is placed on the enclosure base, and includes a top wall, a set of four side walls, and an open bottom. The four side walls of the enclosure box rest on the lower base sheet while surrounding the upper base sheet to position the first pair of opposed side flaps outside the enclosure box, and the second pair of opposed side flaps inside the enclosure box. The set of fasteners fastens the enclosure base to the enclosure box.

Owner:RICOH KK

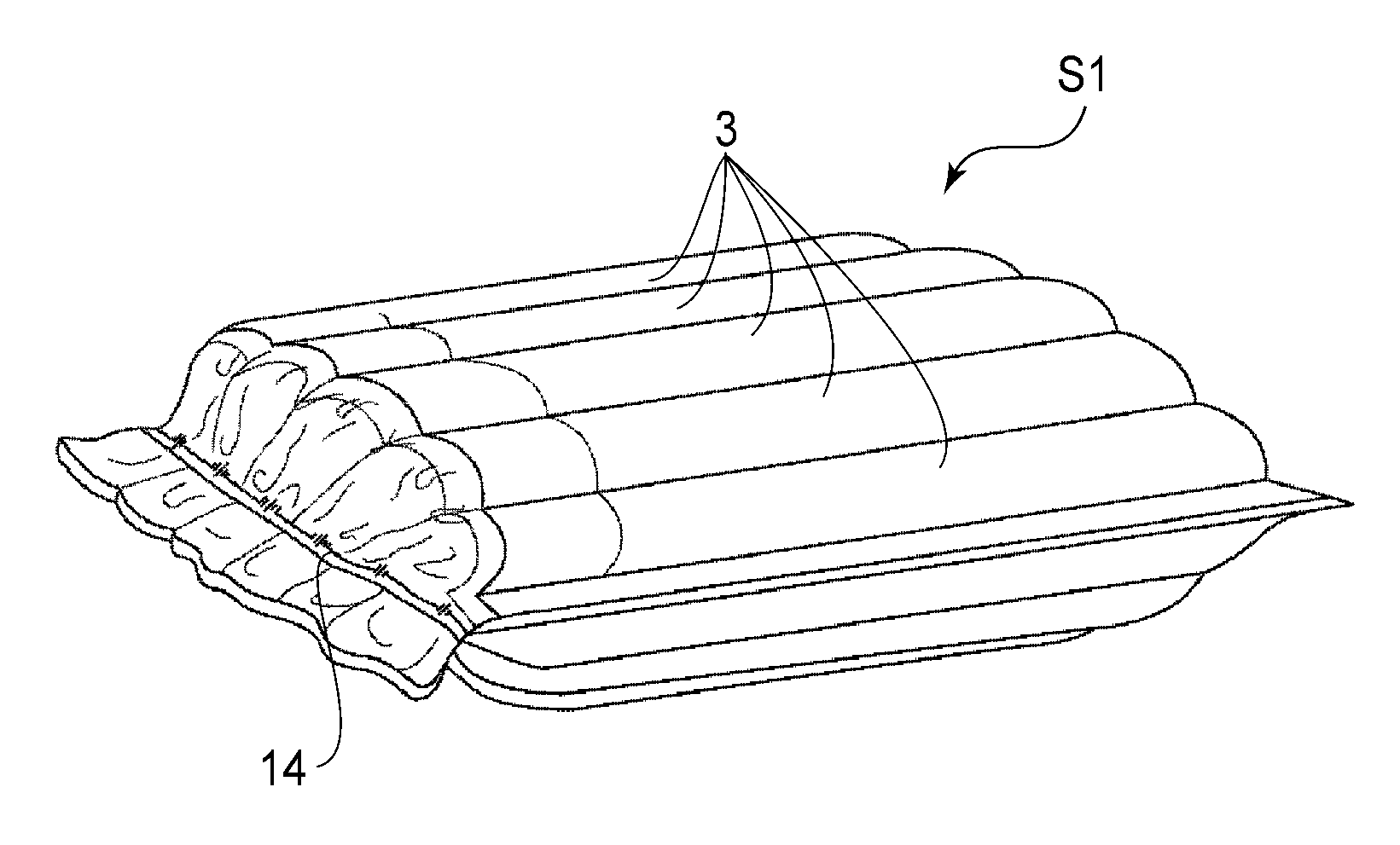

Packing material

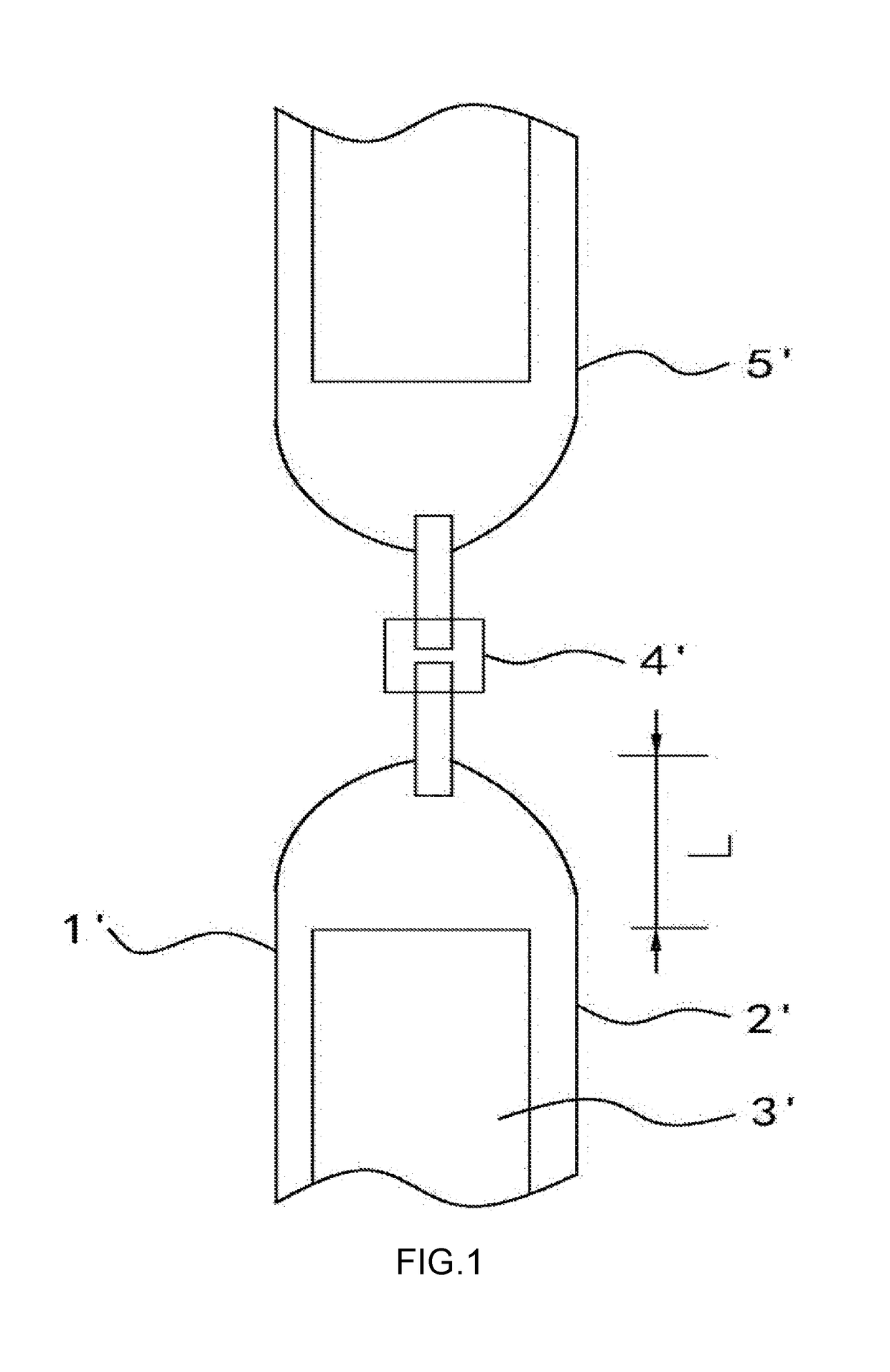

InactiveUS20100072103A1Suitable for processingContainers to prevent mechanical damagePlastic containersEngineeringPack material

A packing member for packing an article, the packing member includes a medium accommodating portion accommodating medium; a non-return valve for passing the medium toward the medium accommodating portion along a longitudinal direction of the medium accommodating portion and for stopping the medium in an opposite direction away from the medium accommodating portion; and a flow path, formed by welding the non-return valve to the medium accommodating portion, for passing the medium, the flow path including a reference flow path portion extending in the longitudinal direction and an expanding flow path portion having a width larger than that of the reference flow path portion.

Owner:CANON KK

Combination multiple-canister carrier and lip protection device

Owner:OREGON PRECISION IND INC DBA PAKTECH

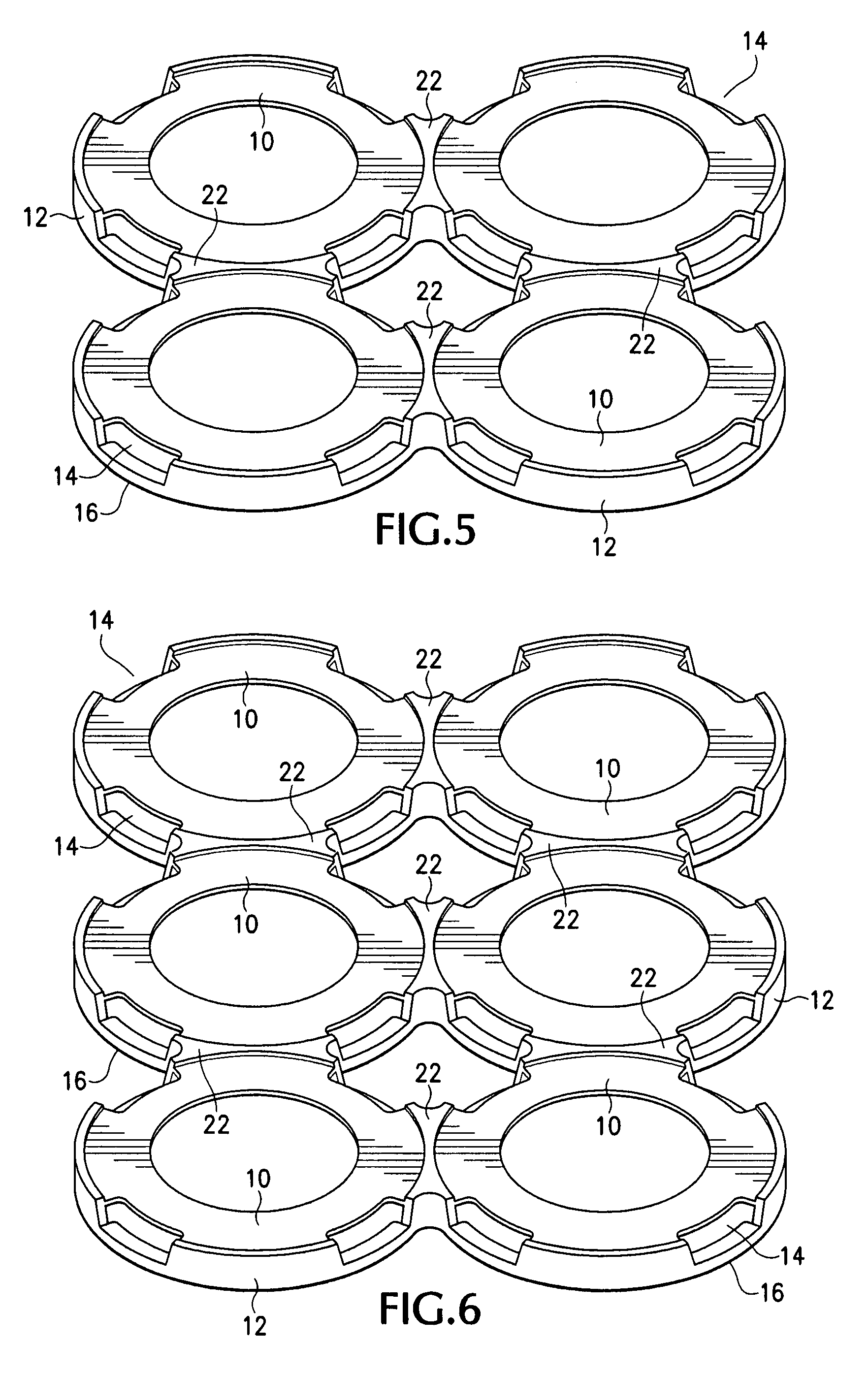

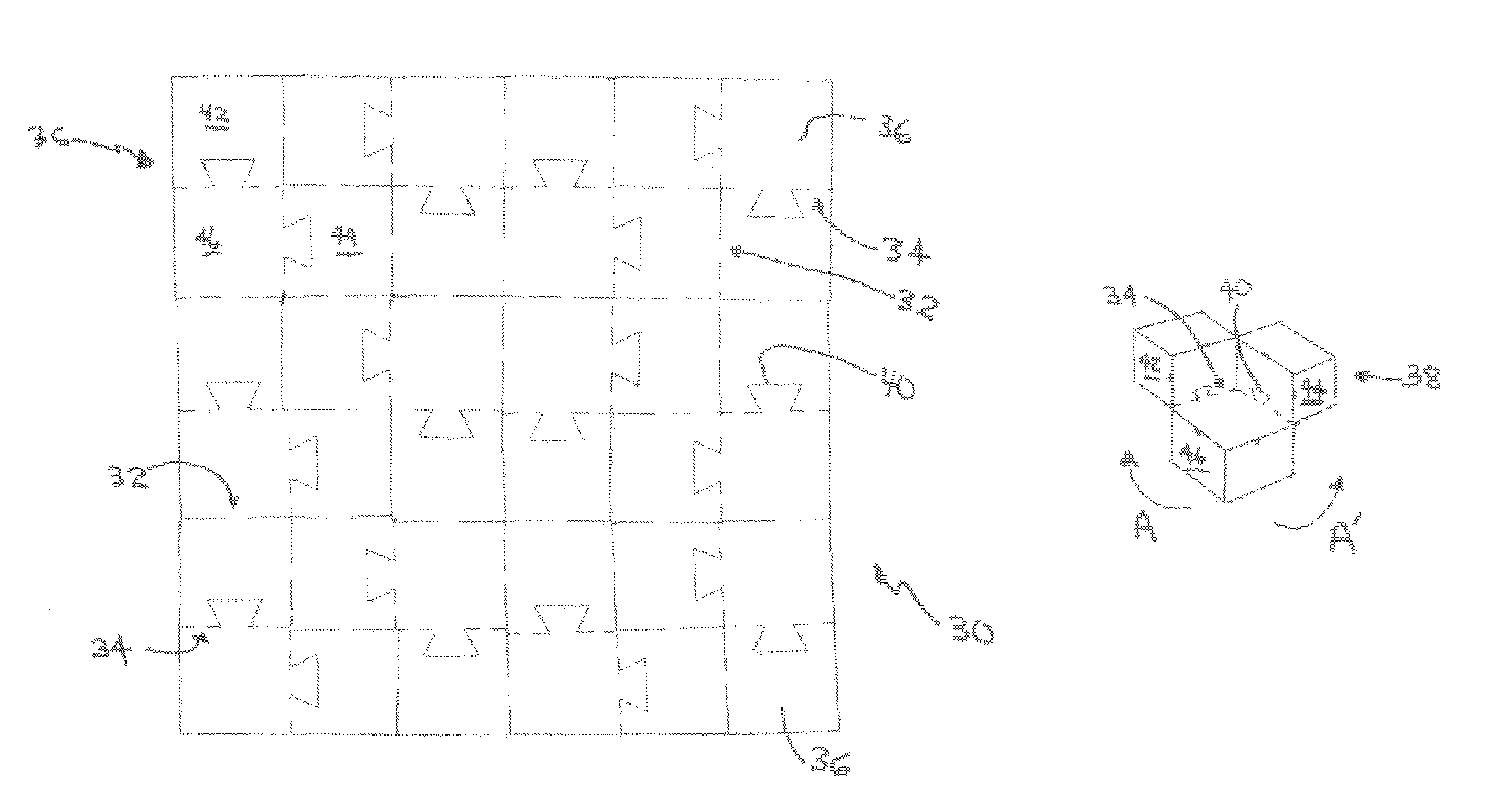

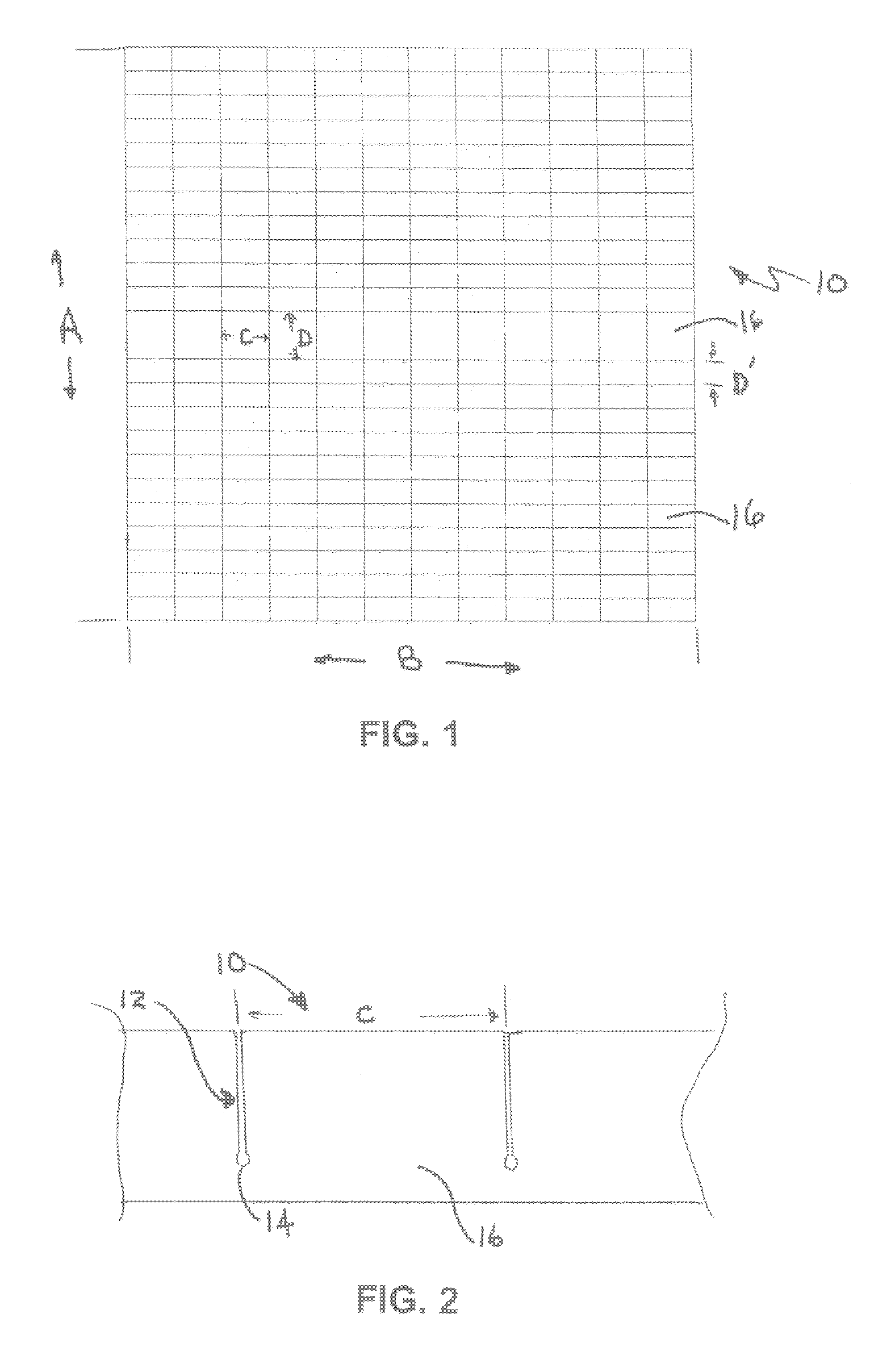

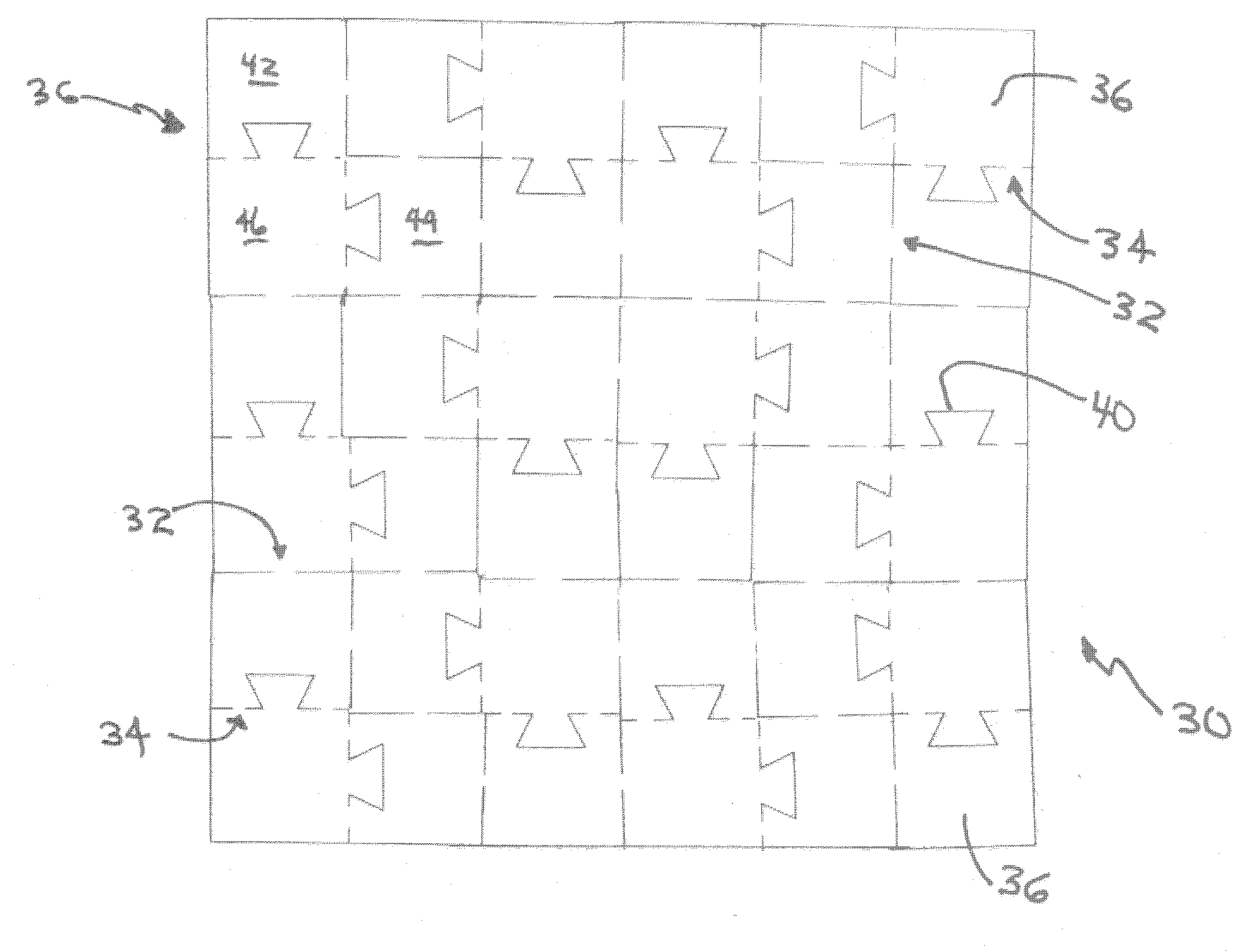

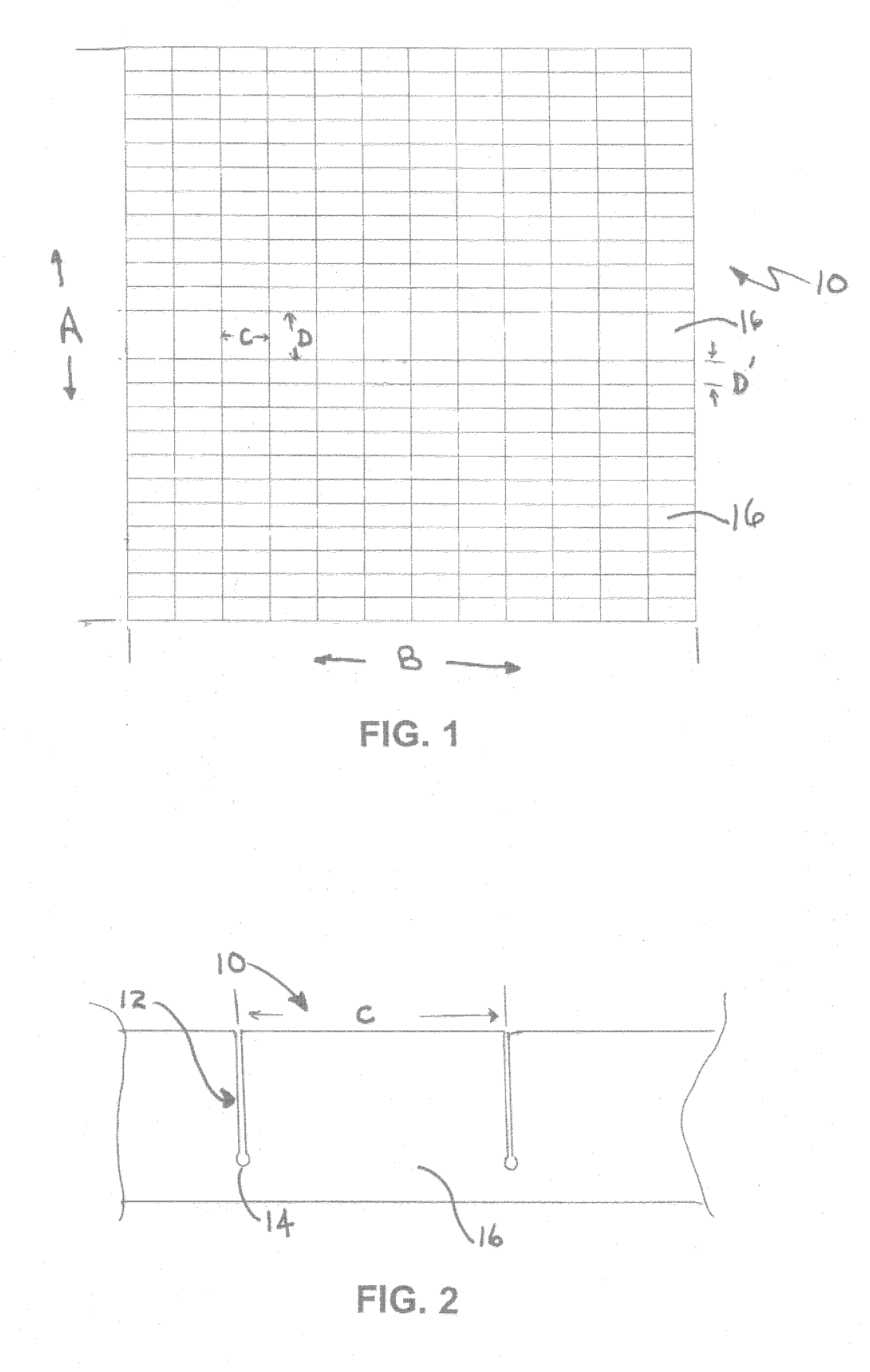

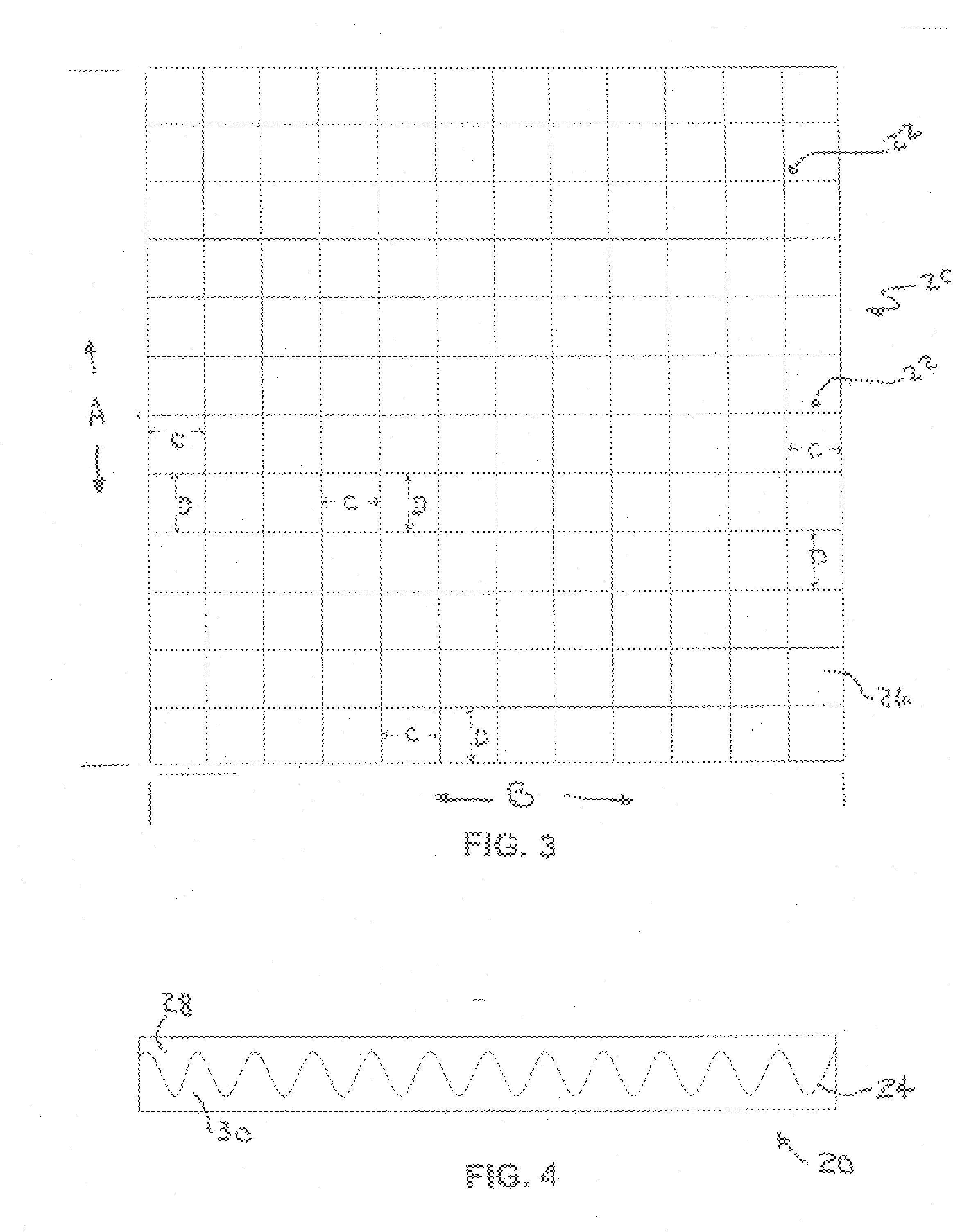

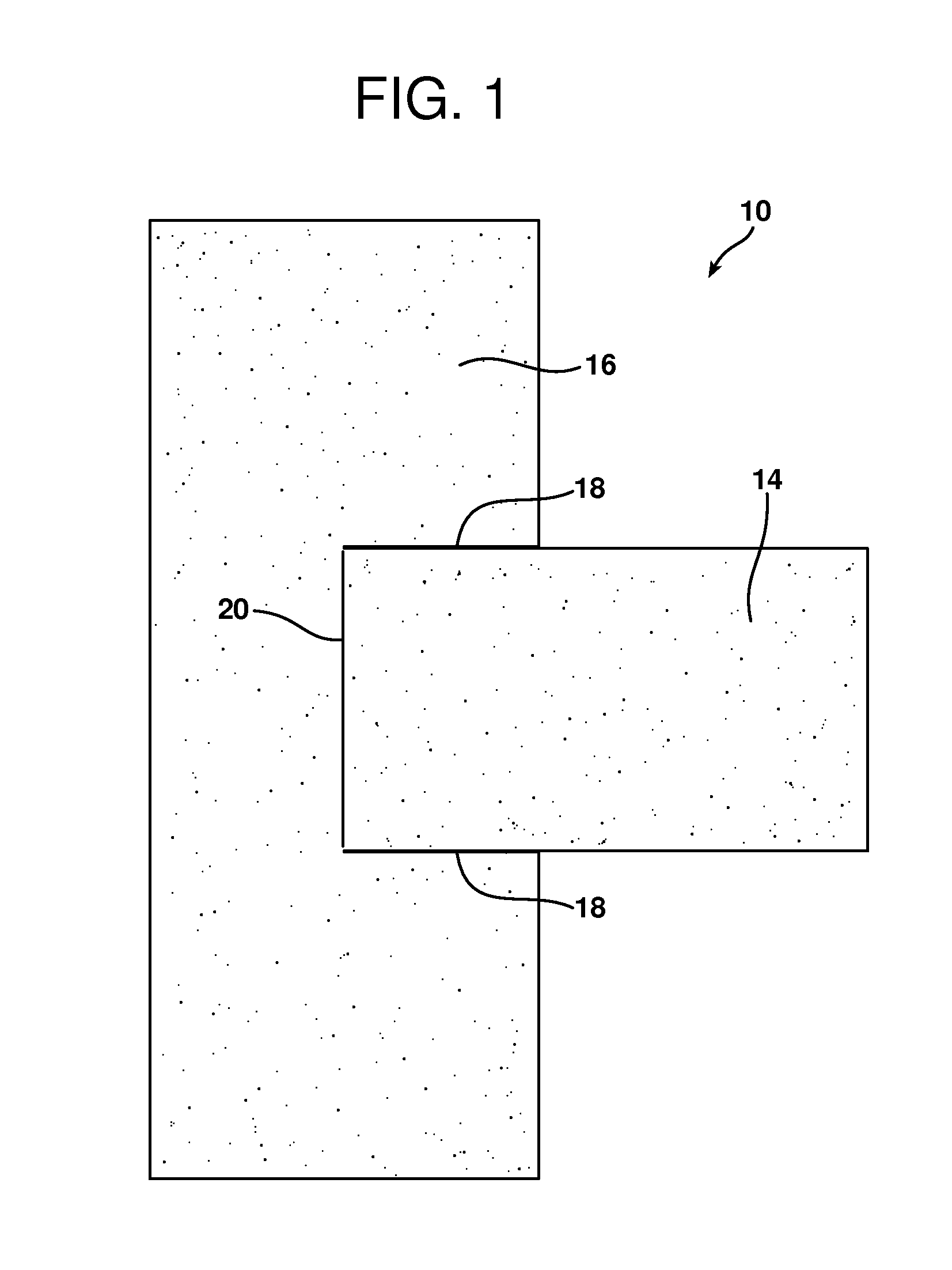

Readily configurable plastic foam packaging

InactiveUS7654391B2Efficient supplyEasy to separateClosuresContainers to prevent mechanical damageBiomedical engineeringVoid space

An efficient means for providing packaging materials comprises foam sheets which have been at least partially cut into regular segments which may be configured by hand into nearly any shape to fit a void space which may surround an article to be packaged in a container. The sheets may be stacked into a cube for ease of transport and storage. The foam sheets may be easily separated into segments by hand by snapping (rigid) or tearing (flexible) the foam into a custom shape which best fits the void space. In one particular embodiment, the segments may comprise a thermoplastic foam which may be configured into corner pads for supporting an article within an outer container.

Owner:LANGER ASSOC INC

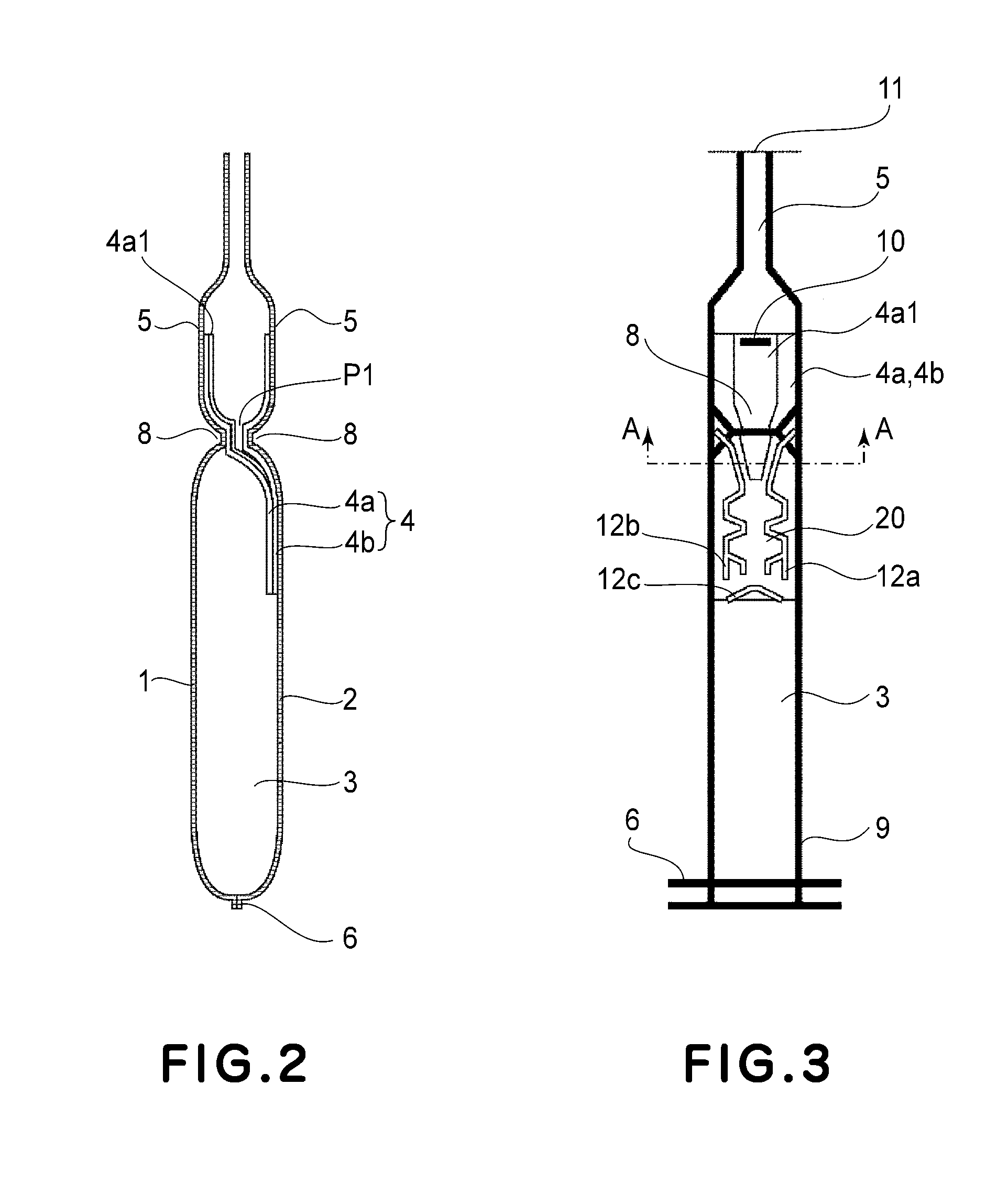

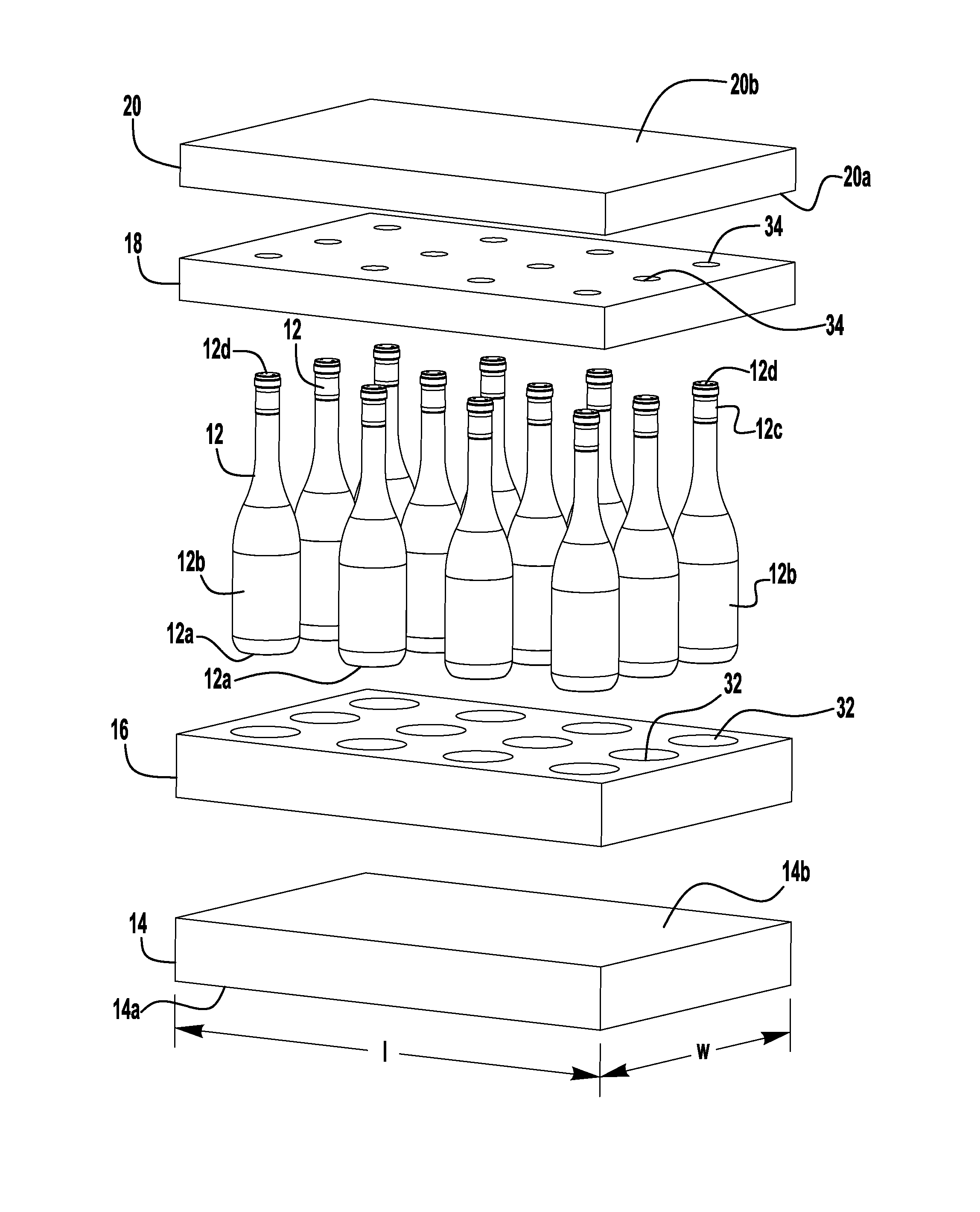

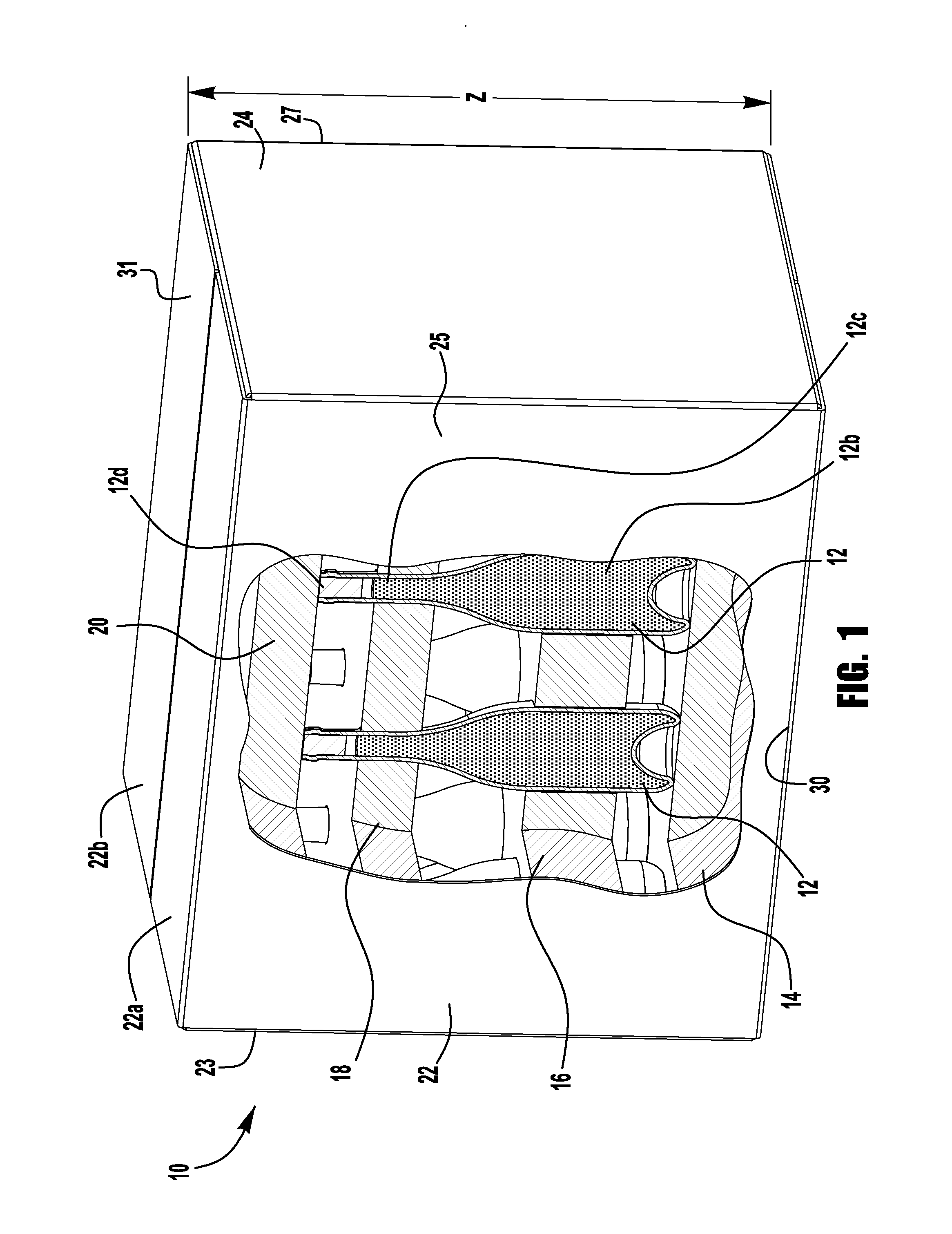

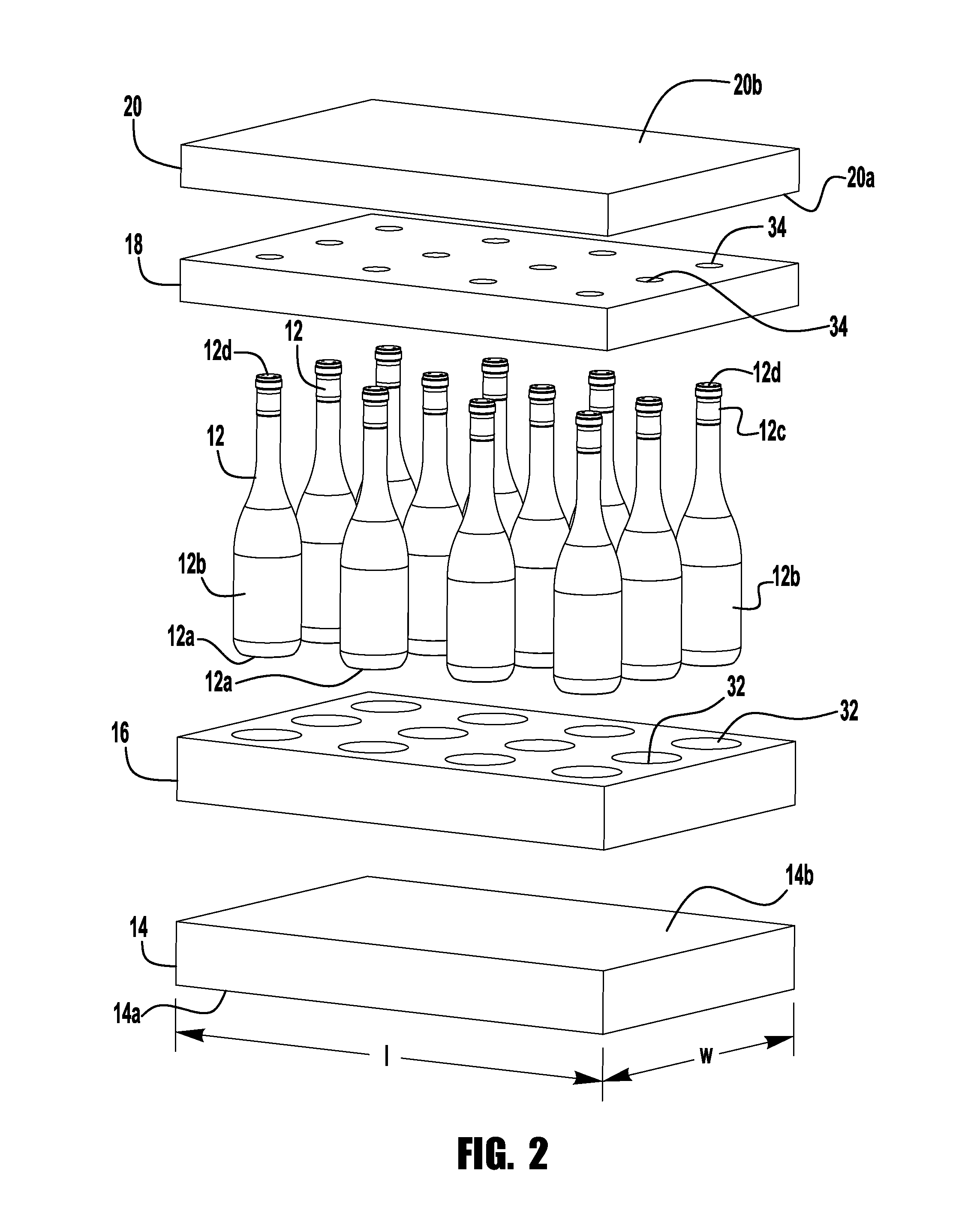

Bottle shipping system

A bottle shipping system and method for packaging bottles that prevents movement of the bottles during transport. The system includes a first foam section is placed on the bottom wall of a carton having a rectangular shaped prism having four side walls, a bottom wall and a top wall to provide a support surface on which the bottles are placed. A second foam section having a first plurality of openings therethrough adapted to receive the body of the bottles is disposed within the carton above the first foam section. A third foam section having a second plurality of openings therethrough adapted to receive the neck of the bottles is disposed between the second foam section and the top wall of the carton. A fourth foam section to provide a buffer surface against which the bottles are pressed is placed against the top wall of the carton.

Owner:DIMAURO PAUL

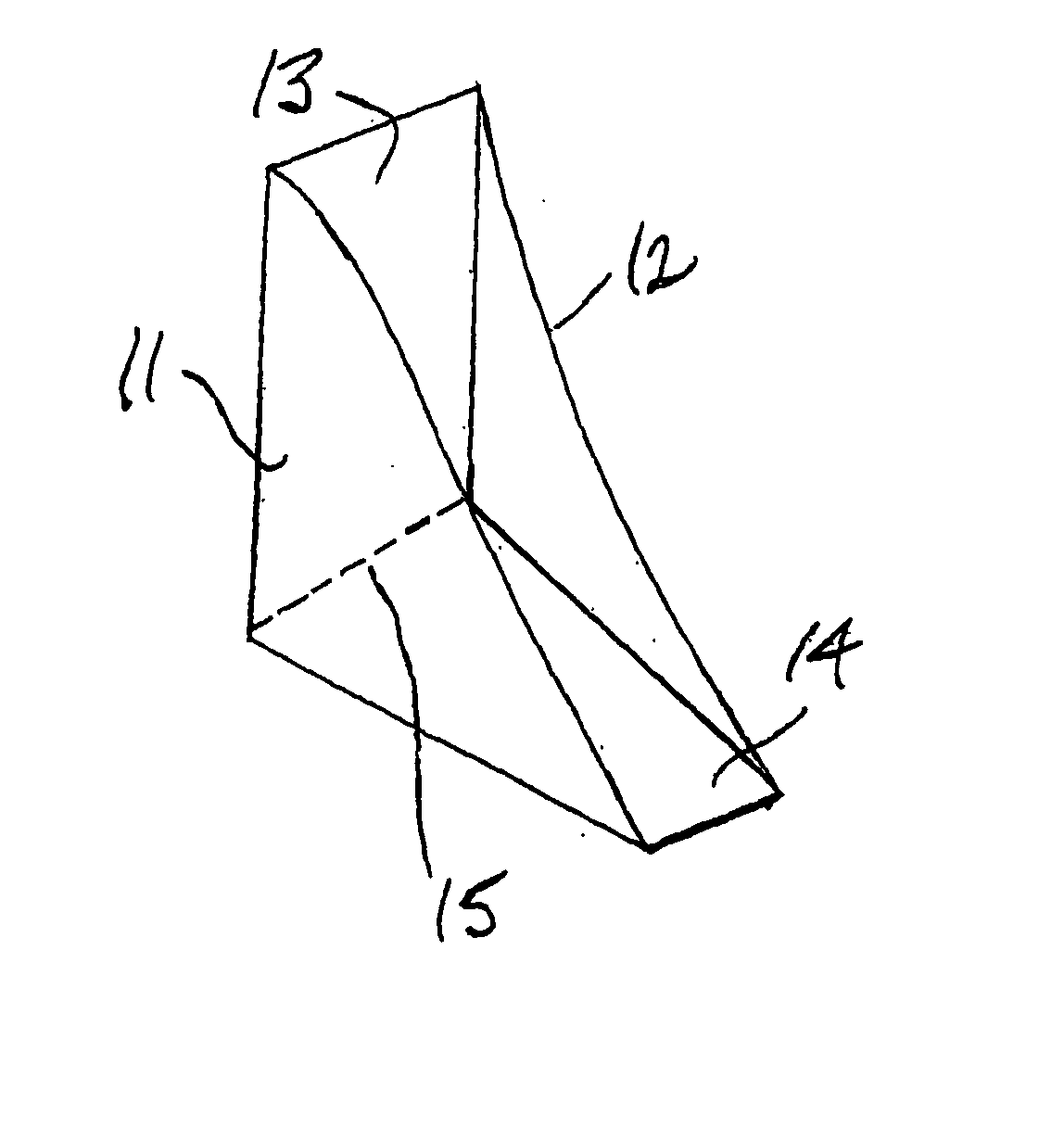

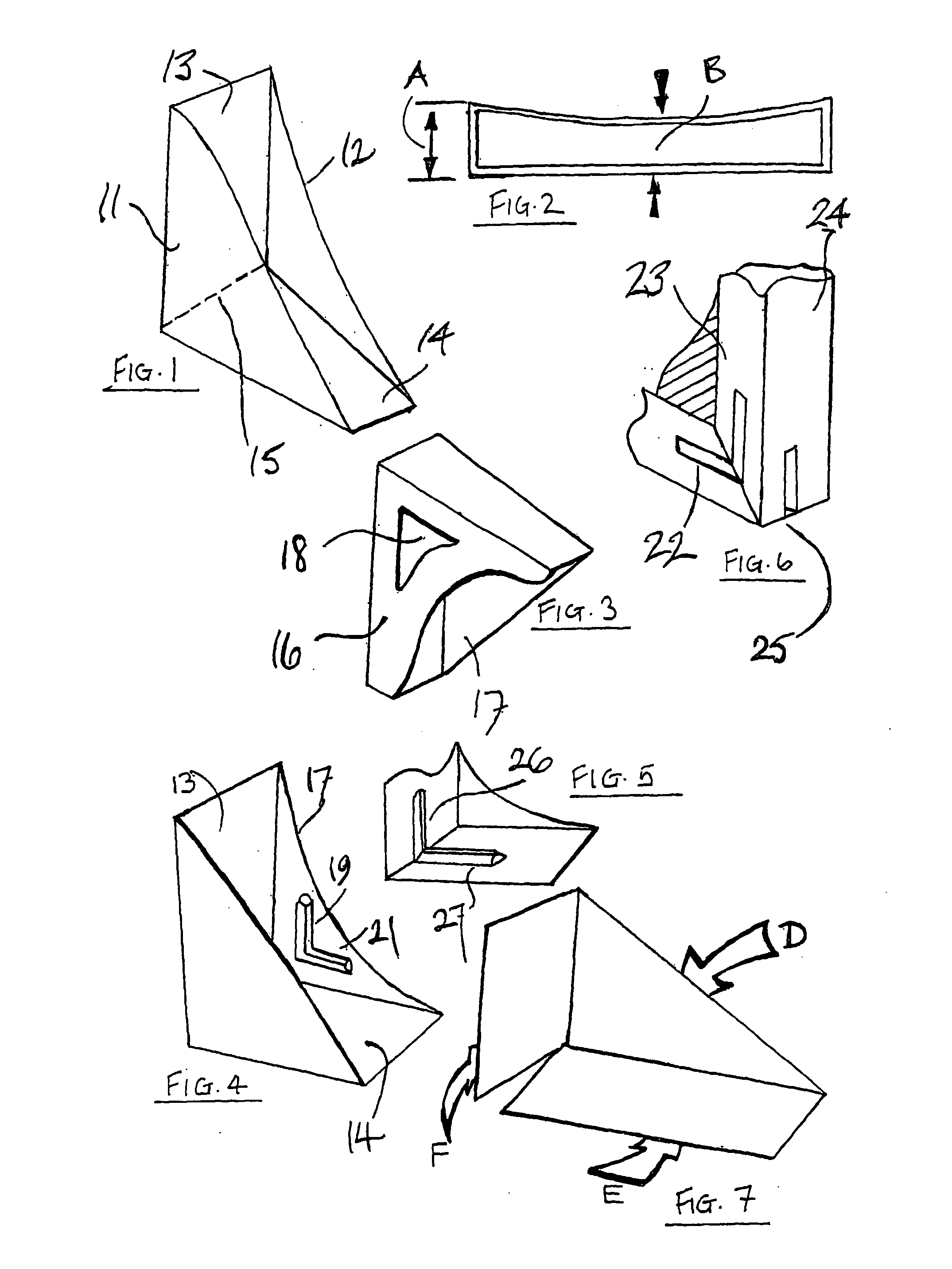

Bowed corner protectors for picture frames

InactiveUS7350646B2Inherent capabilityInherent strengthOther accessoriesStands/trestlesEngineeringCircular segment

A corner protector has a pair of opposite frame embracing faces which are resilient and bowed so that, in use, the corner region of a frame to be protected must force its way into position on between the opposite faces of the protector and will thereafter be frictionally gripped between them until the protector is subsequently released by pulling it off against the frictional resistance. Frame-gripping ribs may be incorporated on the major faces of the protector and in addition the protector may be tapered outwardly from its apex to its open mouth to provide a lead for insertion of the frame. To provide a still greater lead, the open edges of the protector may each be given a slight flange extension, but at opposite ends of the two edges.

Owner:JUPITER MOLDINGS

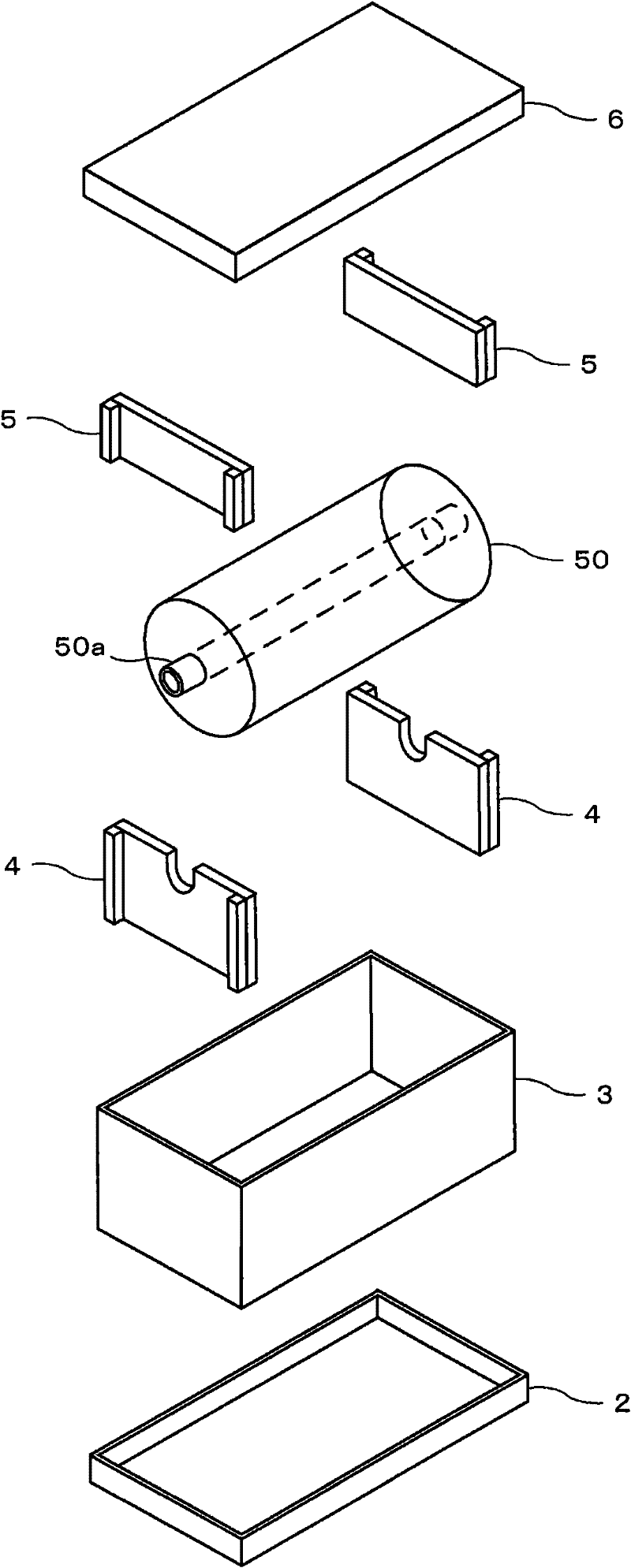

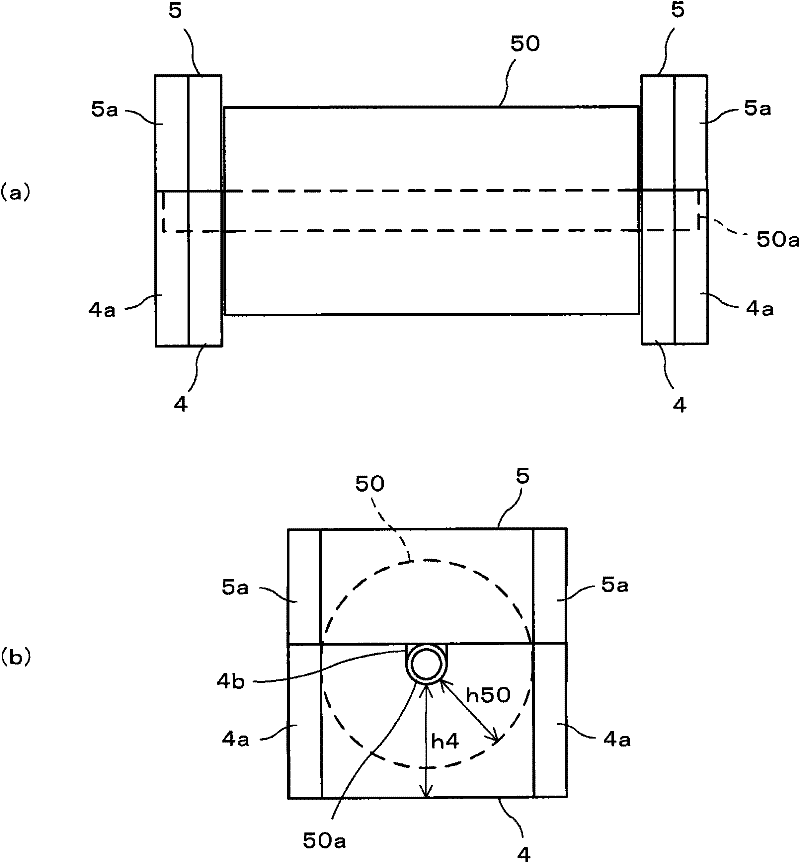

Packing container for roll article

InactiveCN102556524APrevent independent swingStable handlingContainers to prevent mechanical damagePlastic containersEngineeringMechanical engineering

Owner:ASAHI GLASS CO LTD

Readily Configurable Plastic Foam Packaging

InactiveUS20060278555A1Efficient supplyEasy to separateClosuresContainers to prevent mechanical damageBiomedical engineeringVoid space

An efficient means for providing packaging materials comprises foam sheets which have been at least partially cut into regular segments which may be configured by hand into nearly any shape to fit a void space which may surround an article to be packaged in a container. The sheets may be stacked into a cube for ease of transport and storage. The foam sheets may be easily separated into segments by hand by snapping (rigid) or tearing (flexible) the foam into a custom shape which best fits the void space. In one particular embodiment, the segments may comprise a thermoplastic foam which may be configured into corner pads for supporting an article within an outer container.

Owner:LANGER ASSOC INC

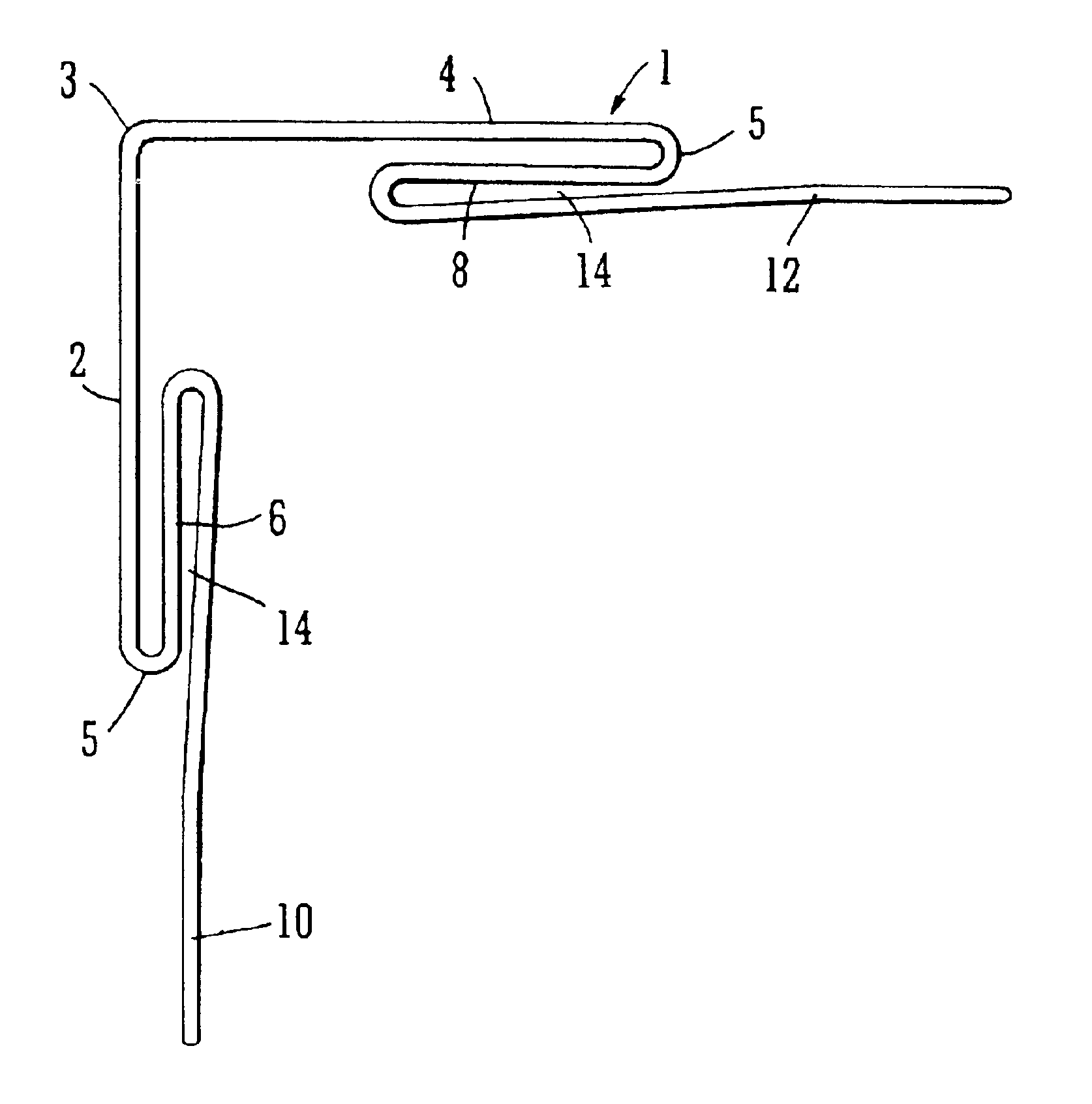

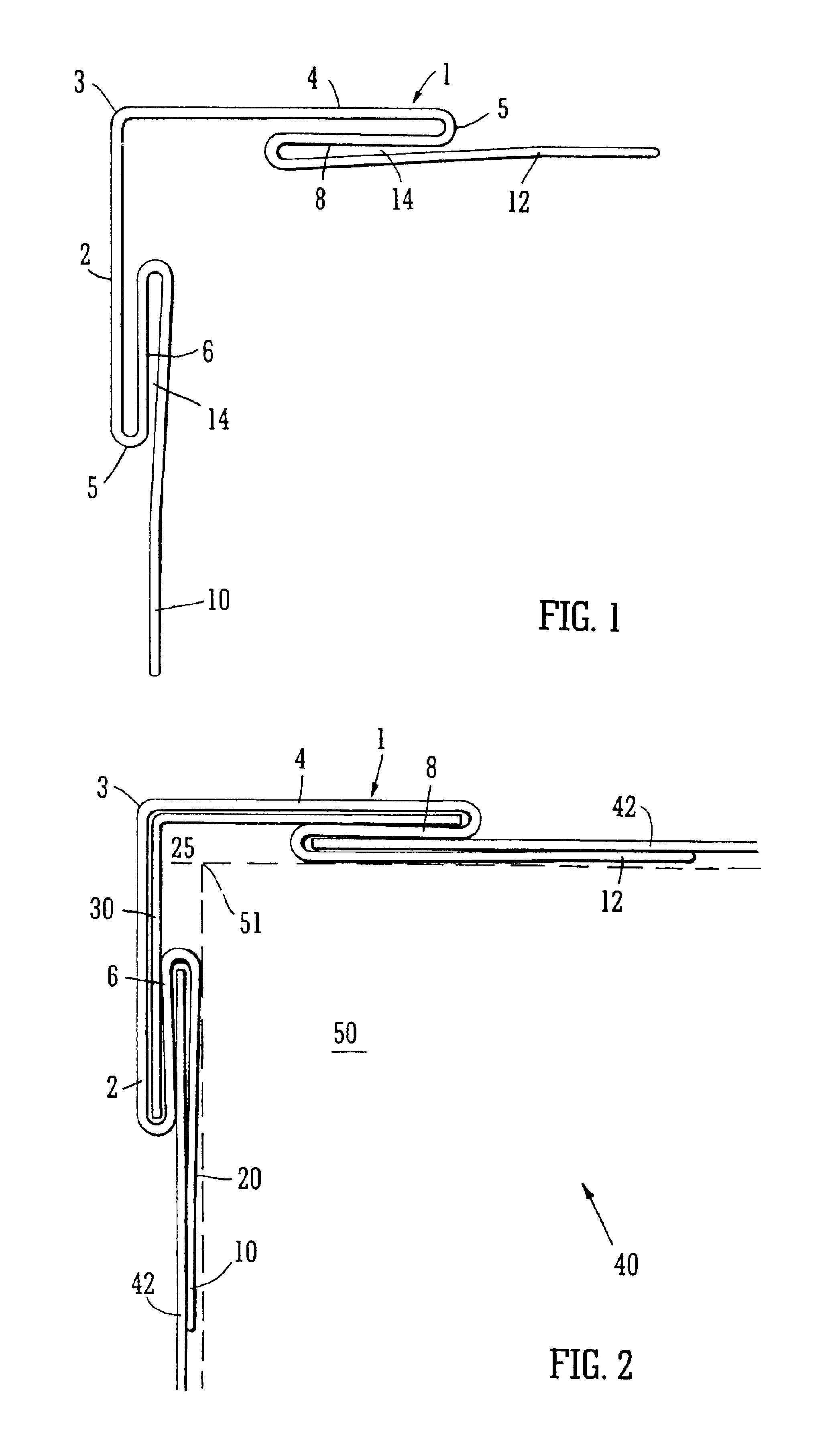

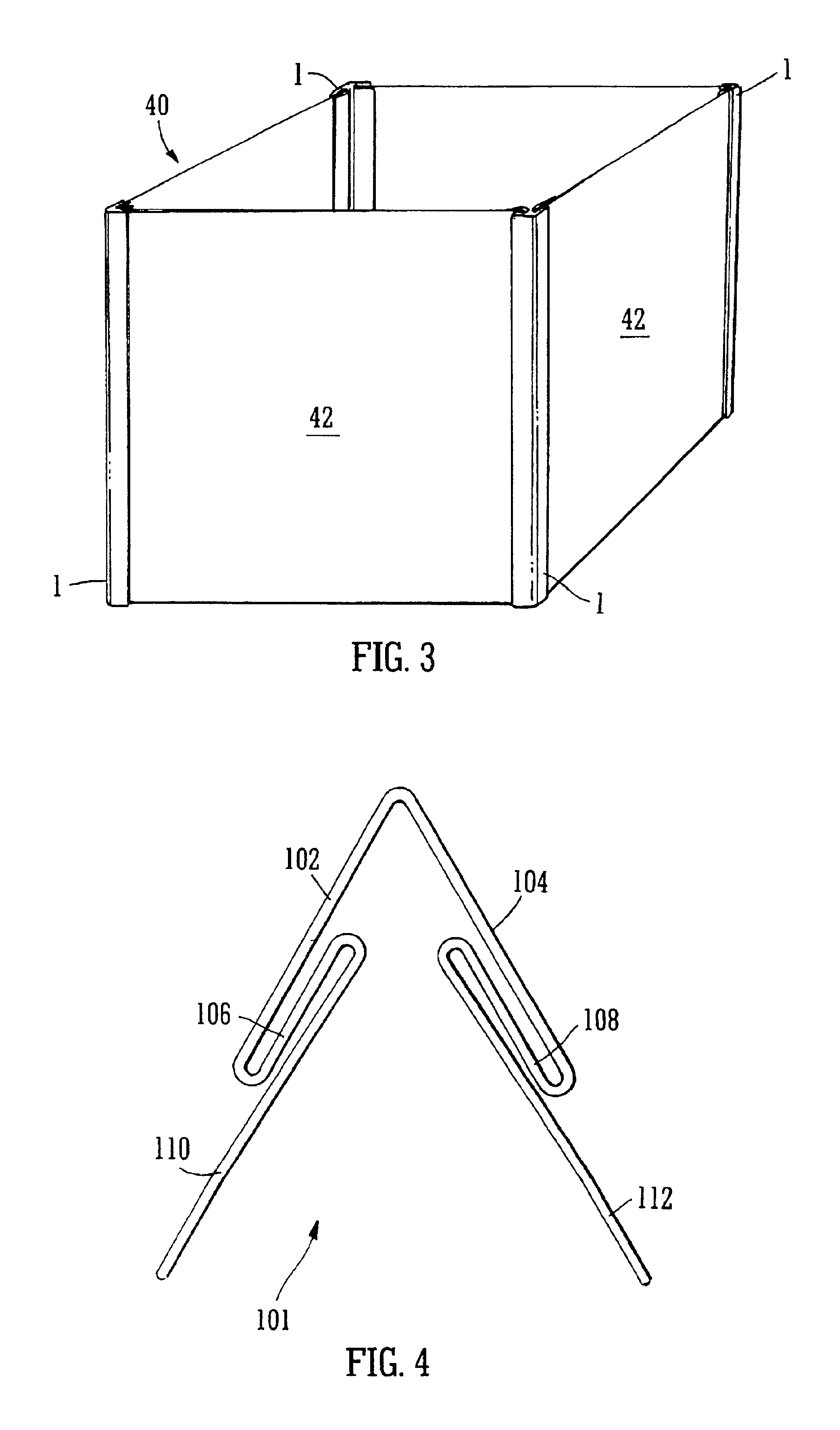

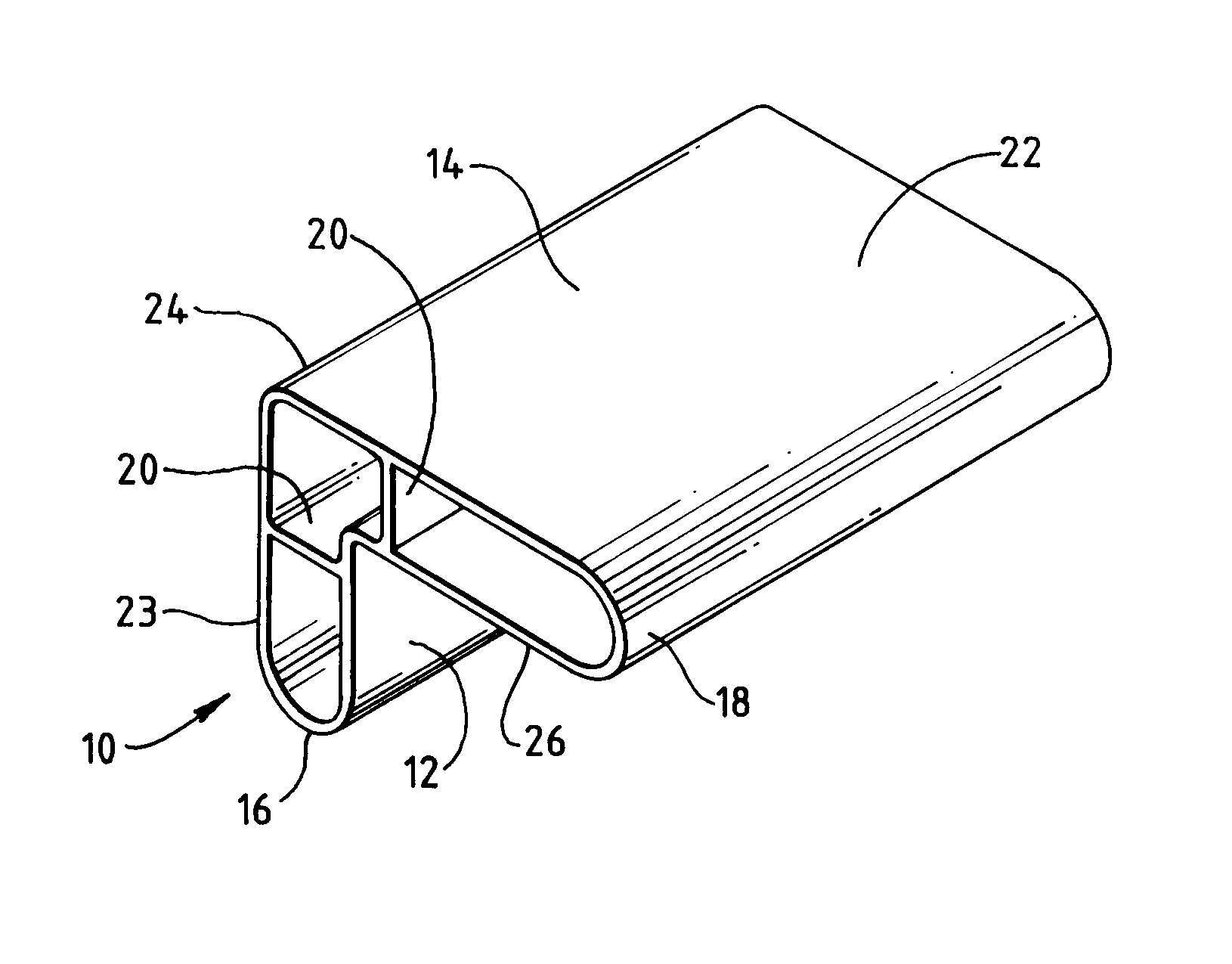

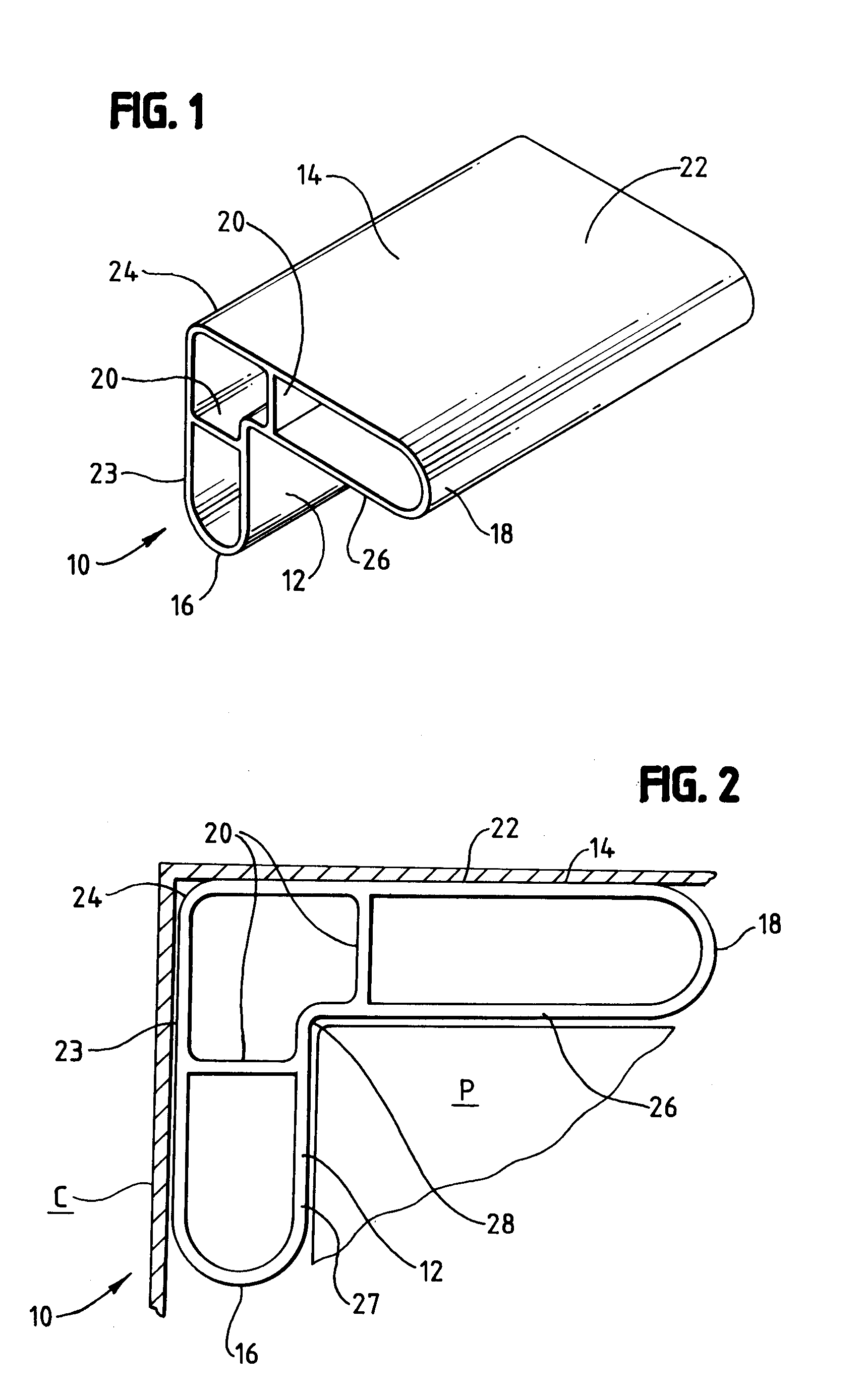

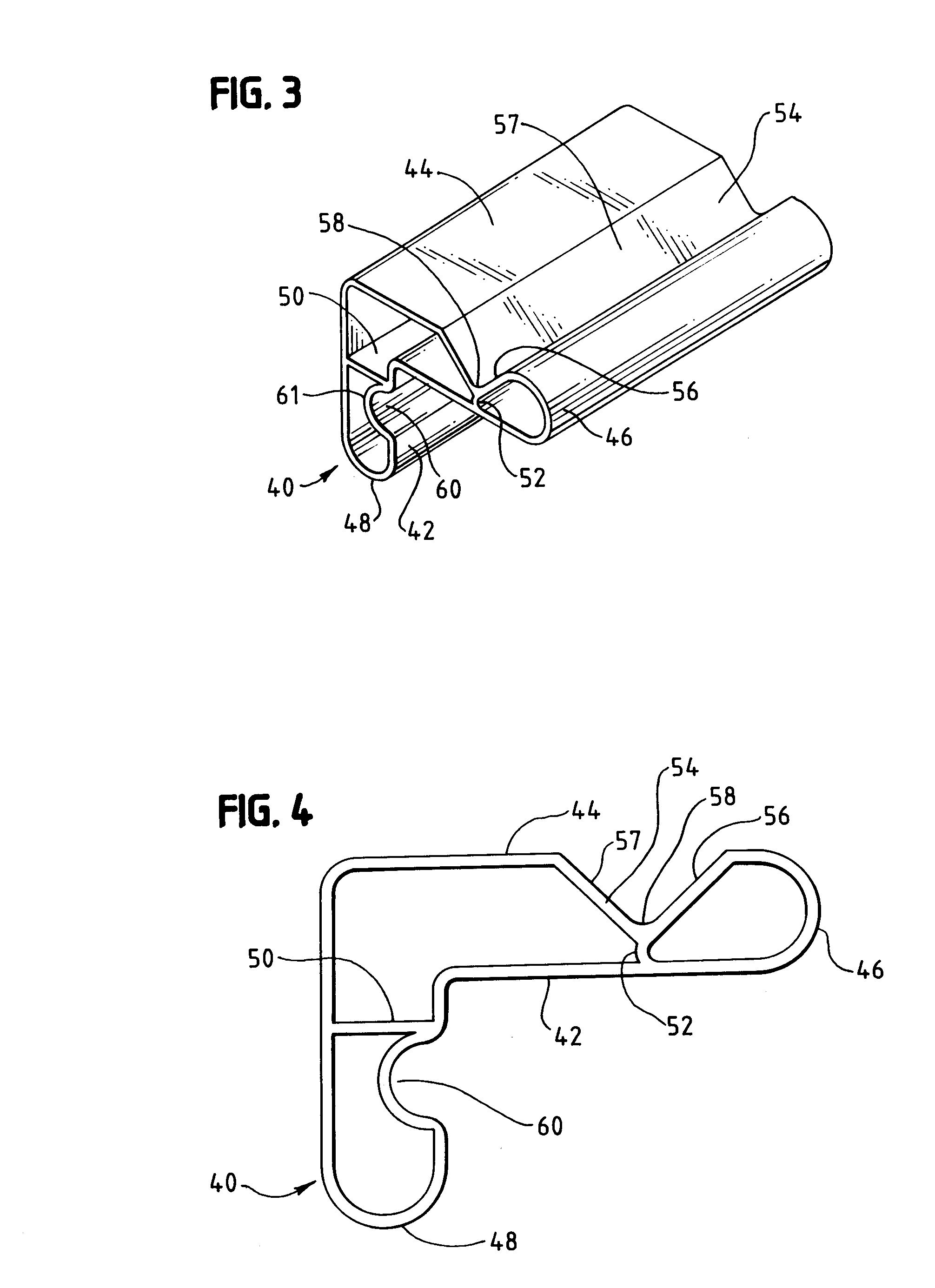

Edge protector

An edge protector (1) for protecting the edge of an article includes a pair of interconnected, non-parallel, first arms (2, 4) which, in use, do not contact any part of the article, and a pair of second arms (10, 12) for contacting or a least being situated adjacent the article in use, one of each of the second arms (10, 12) being connected to one of each of the first arms (2, 4) each first arm (2, 4) and the respective second arm (10, 12) may be arranged in non-parallel relations. Further, the edge protector (1) may be resiliently deformable to absorb the energy of an impact therewith.

Owner:ITW LTD

Shock-protecting packaging

A thermoformed packaging case has four wall-flanges which abut in ridge-within-groove nesting for interlocking and shock-absorbing closure of the case. Each edge has a pattern of ridges and grooves, and nesting of the edges of the flanges is enabled by a lateral shift in its ridge-groove pattern. Articles contained within the case are cushioned from shock by projections which protrude inwardly from inner surfaces of the walls to resiliently bear against the articles. Each buffer has a top surface surrounded by a valley and hump to provide shock-absorbing resilience. Locking of the case involves a flap hinged to a side-wall. To close a top-wall of the case onto the side-wall, projections of the top-wall enter recesses of the side-wall, and by folding the flap over to insert the projections into reverse recesses of the projections. The projections are snapped into recesses to effect triple-locking of the flap.

Owner:PROTECTIVE PACKAGING SYST EUROPE BV

Extruded Corner Post For Vertical and Lateral Protection

Owner:SONOCO DEV INC

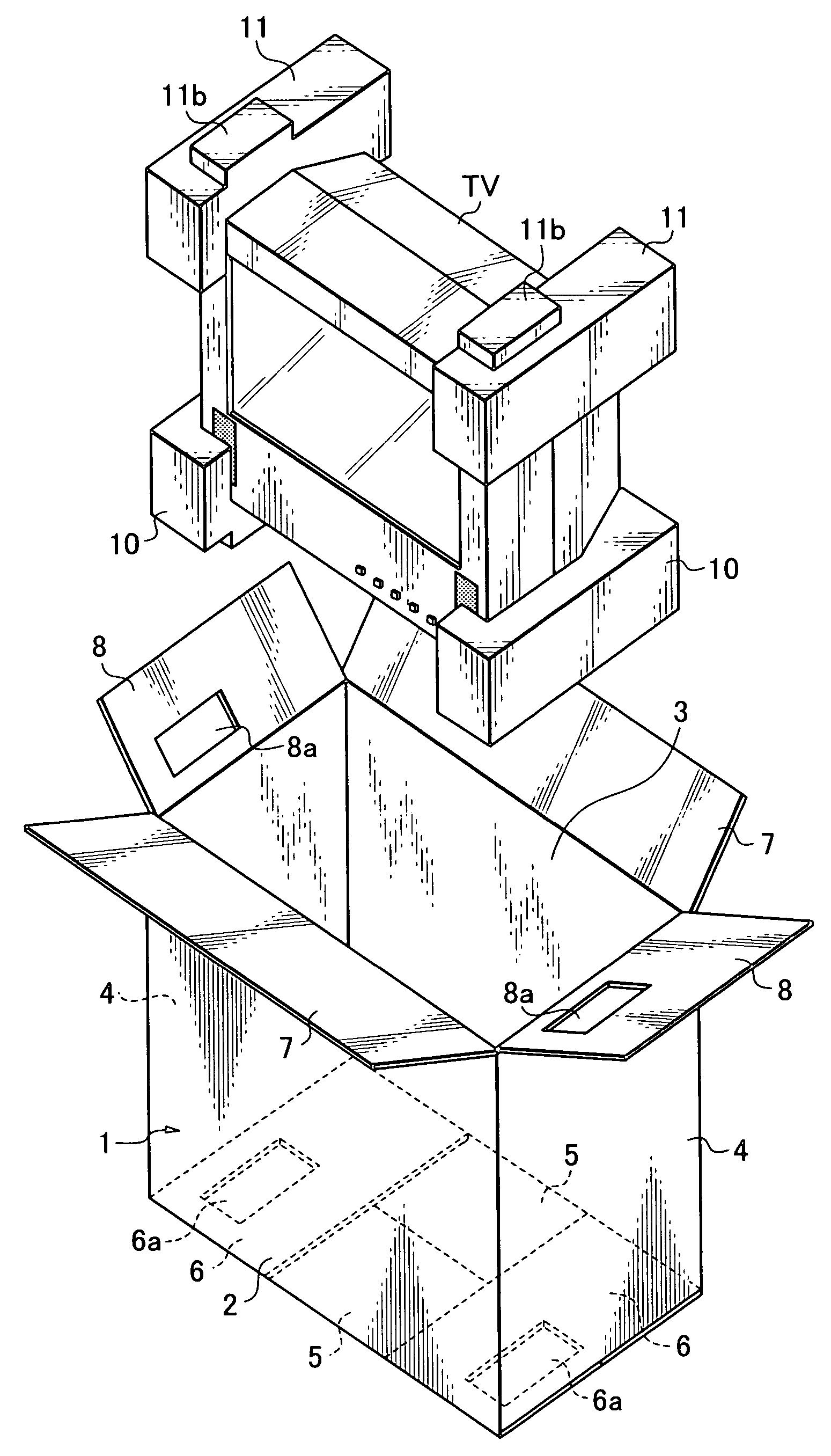

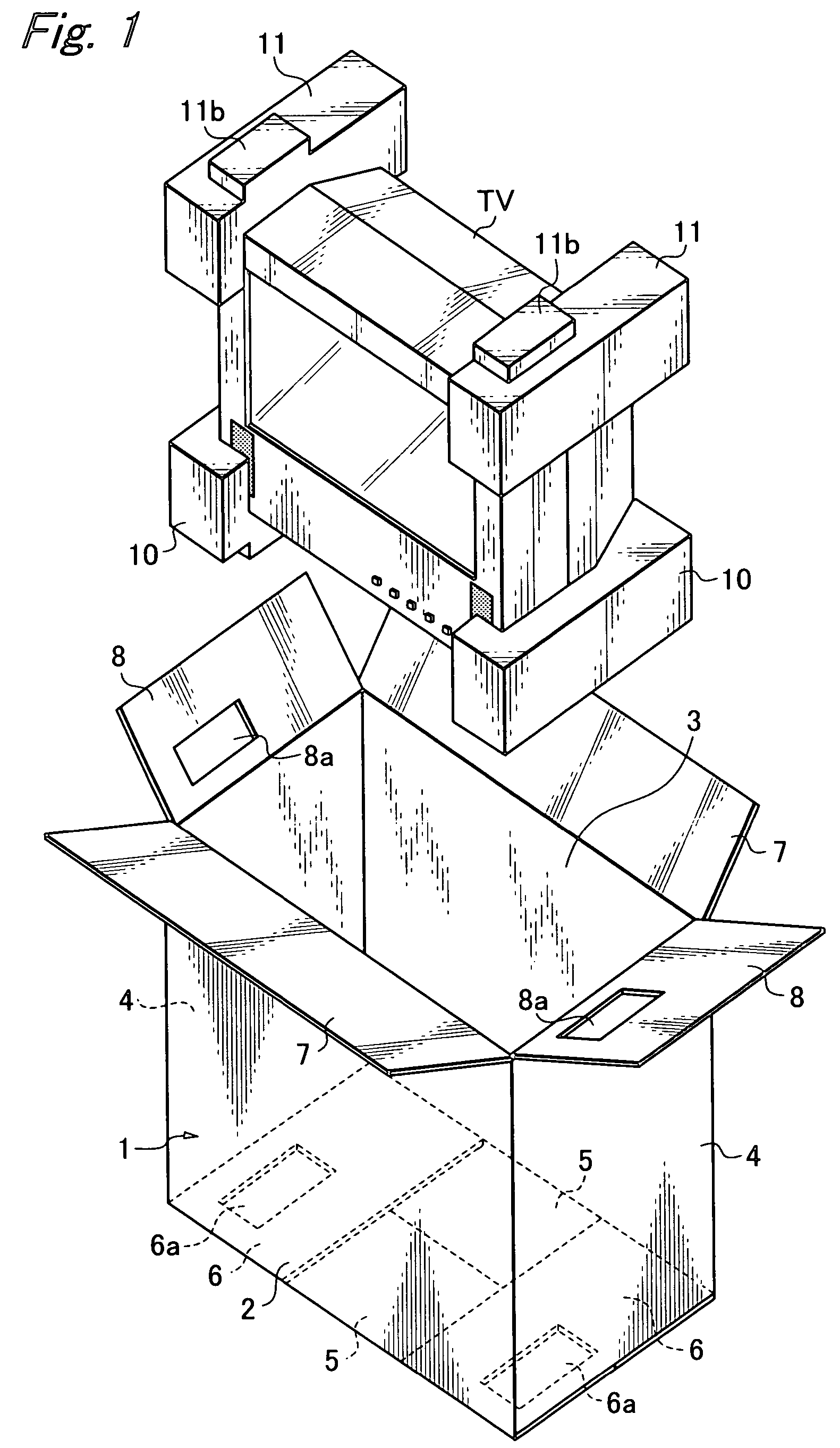

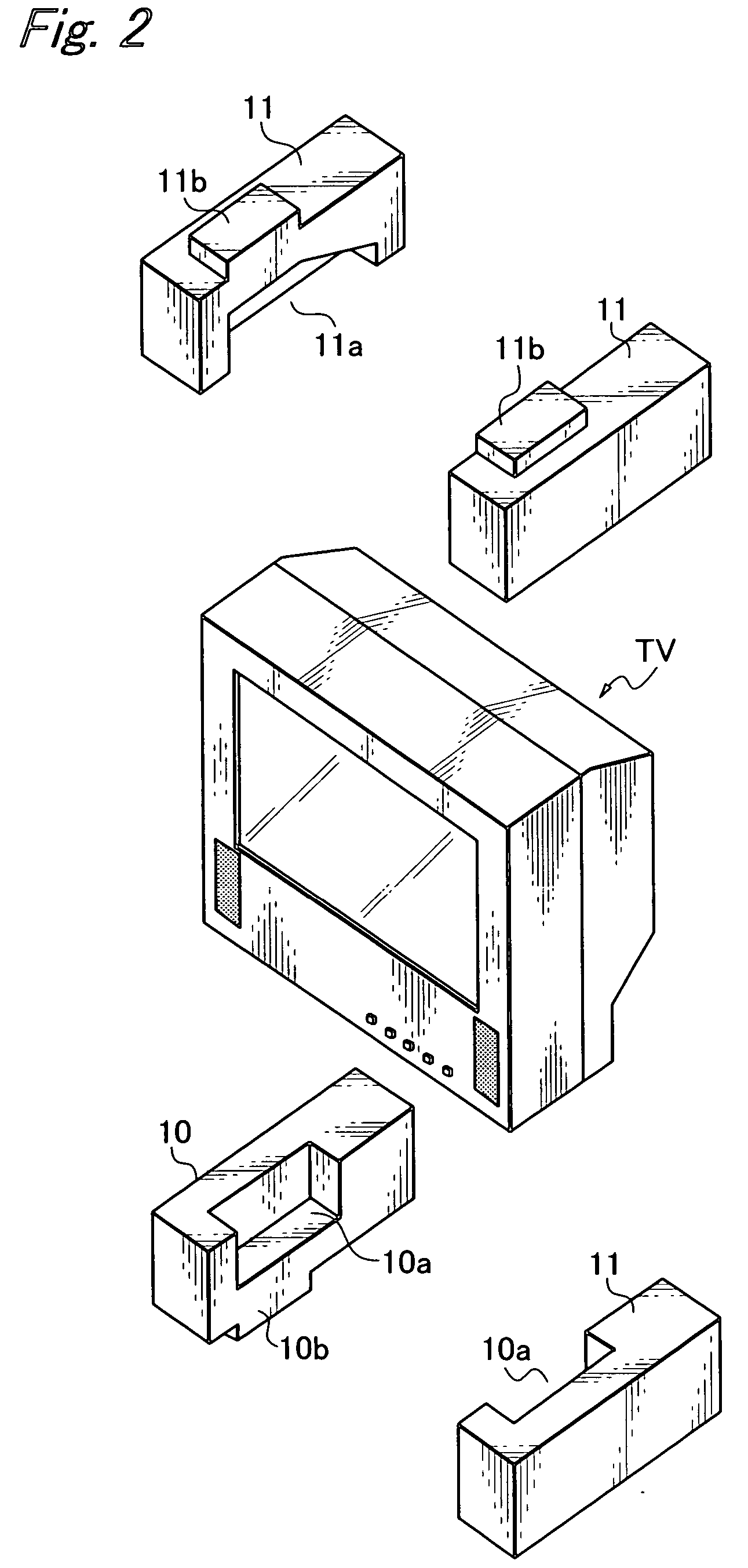

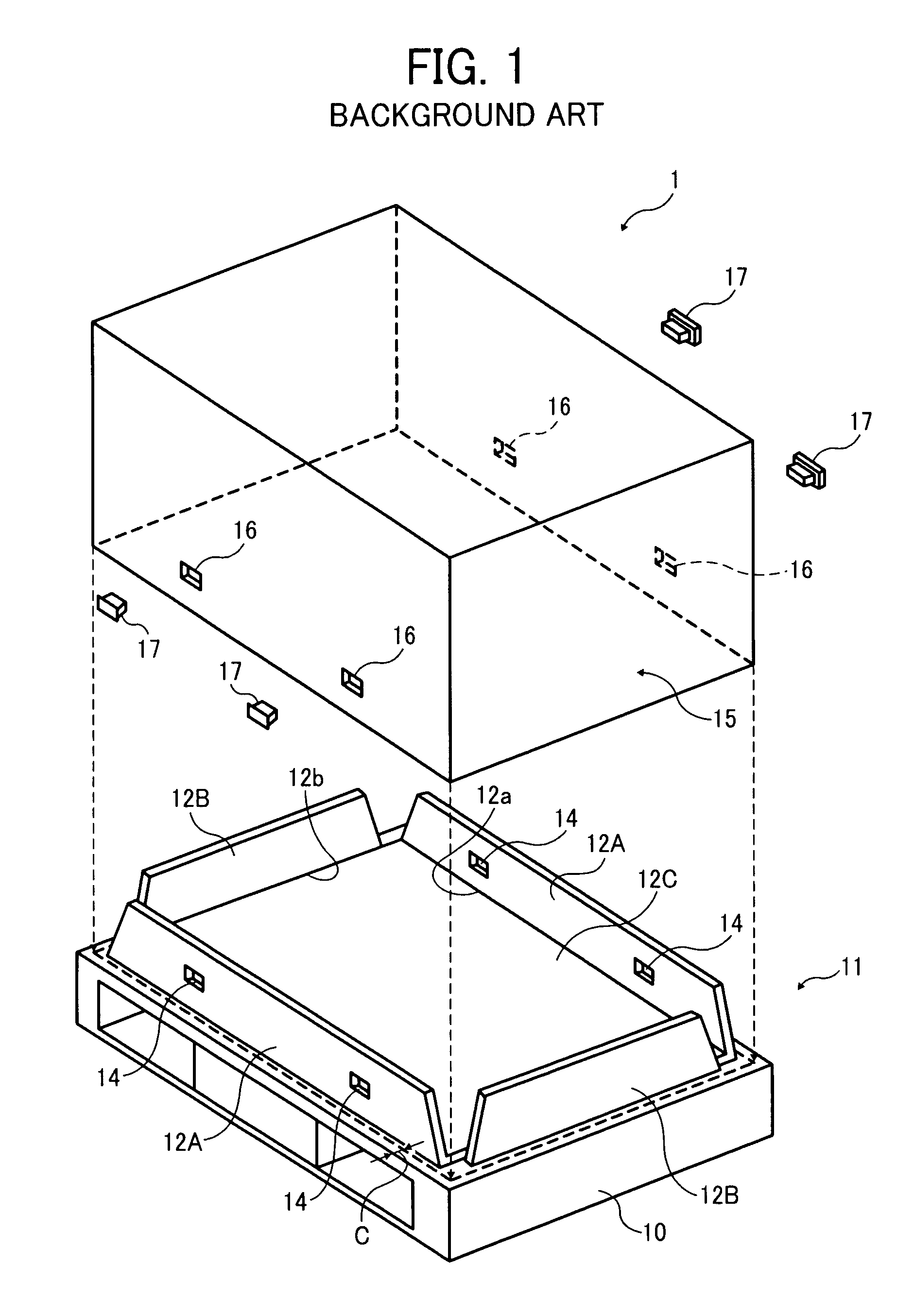

Packaging material provided with cushioning members

InactiveUS20050161366A1Improve package strengthExternal appearance is not spoiledContainers to prevent mechanical damagePaper/cardboard containersCushioningEngineering

To improve cushioning effect for a packaged object without causing cost increase and prevent positional shift of cushioning members without causing lowering of the strength and durability of a packaging box, a packaging material includes a packaging box and cushioning members, a bottom panel and a cover panel of the packaging box being made of inwardly bendable inner flaps and outer flaps respectively, each of the inner flaps being provided with at least a through hole, the cushioning members being provided in inner side surfaces thereof with recesses in which corner portions or side portions of an object to be packaged are fitted, and on outer side surfaces thereof with cushioning projections fitted in the through holes of the inner flaps, the length of the cushioning projections being set larger than the thickness of the inner flaps so as to form a clearance between the inner flaps and cushioning projections when the cushioning members are housed in the packaging box.

Owner:ORION ELECTRIC CO LTD

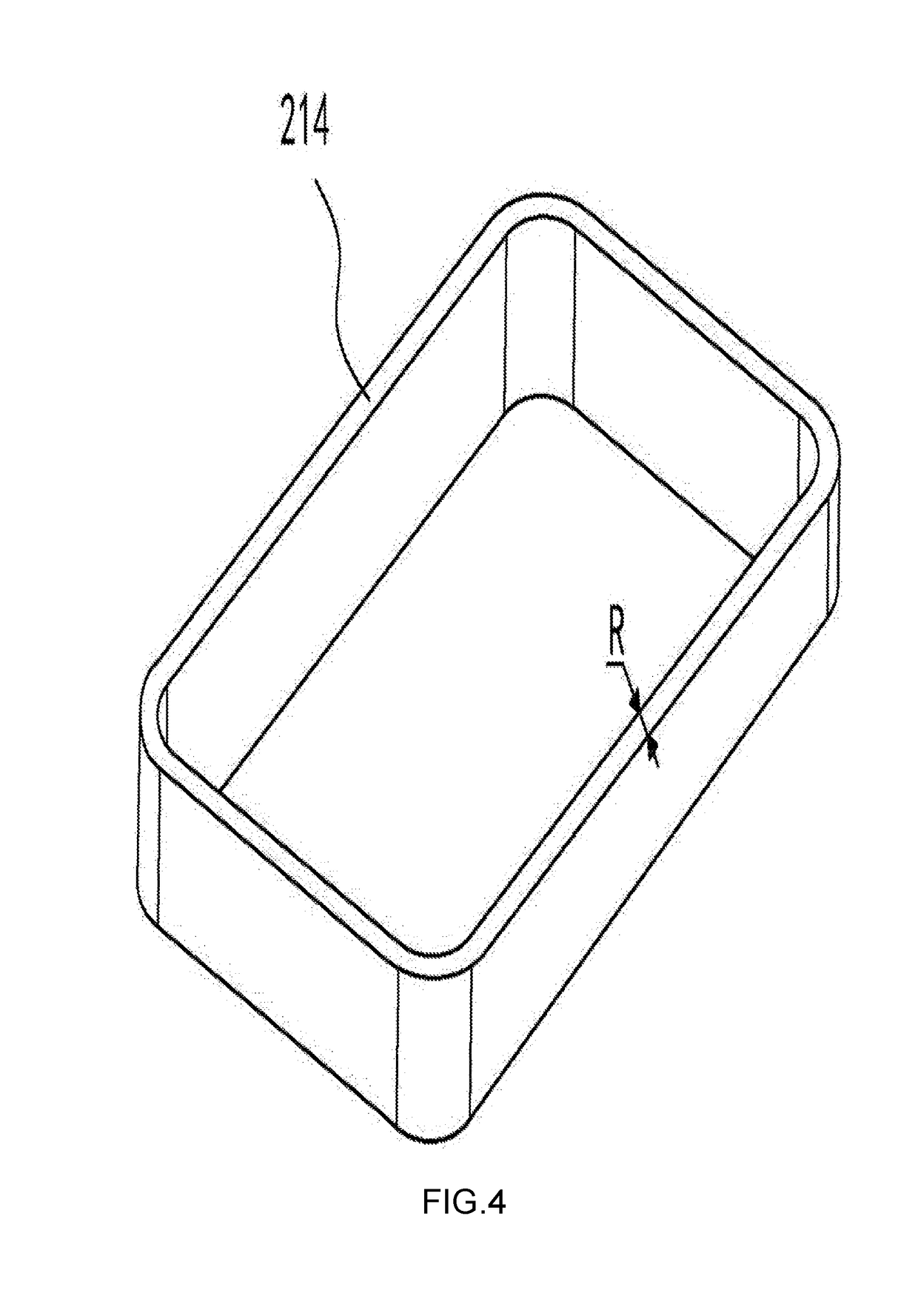

Shock absorbent end cap for trays

In one embodiment of the present invention, an end cap is provided in the form of a box with an open top, having a substantially rectangular base and four substantially rectangular sides, each attached to one of four corresponding edges of the base. The end cap open top has interior length and width dimensions providing clearance for a corresponding width and height respectively of a stack of trays. A depth of the inside of the end cap allows insertion of an end portion of the stack of trays. The end cap is constructed from a shock, absorbent material of thickness and material properties designed to absorb shock for the purpose of protecting the trays and components in the trays. Shock absorbing end caps are placed over both ends of a stack of trays, and the assembly is placed in a dry-pack bag and sealed, and then placed in a cardboard box for transportation.

Owner:PEAK PLASTIC & METAL PRODS INT

Corner protectors

InactiveUS20050150810A1Inherent capabilityInherent strengthContainers to prevent mechanical damagePlastic containersFlangeFrictional resistance

A corner protector has a pair of opposite frame embracing faces which are resilient and bowed so that, in use, the corner region of a frame to be protected must force its way into position on between the opposite faces of the protector and will thereafter be frictionally gripped between them until the protector is subsequently released by pulling it off against the frictional resistance. Frame-gripping ribs may be incorporated on the major faces of the protector and in addition the protector may be tapered outwardly from its apex to its open mouth to provide a lead for insertion of the frame. To provide a still greater lead, the open edges of the protector may each be given a slight flange extension, but at opposite ends of the two edges.

Owner:JUPITER MOLDINGS

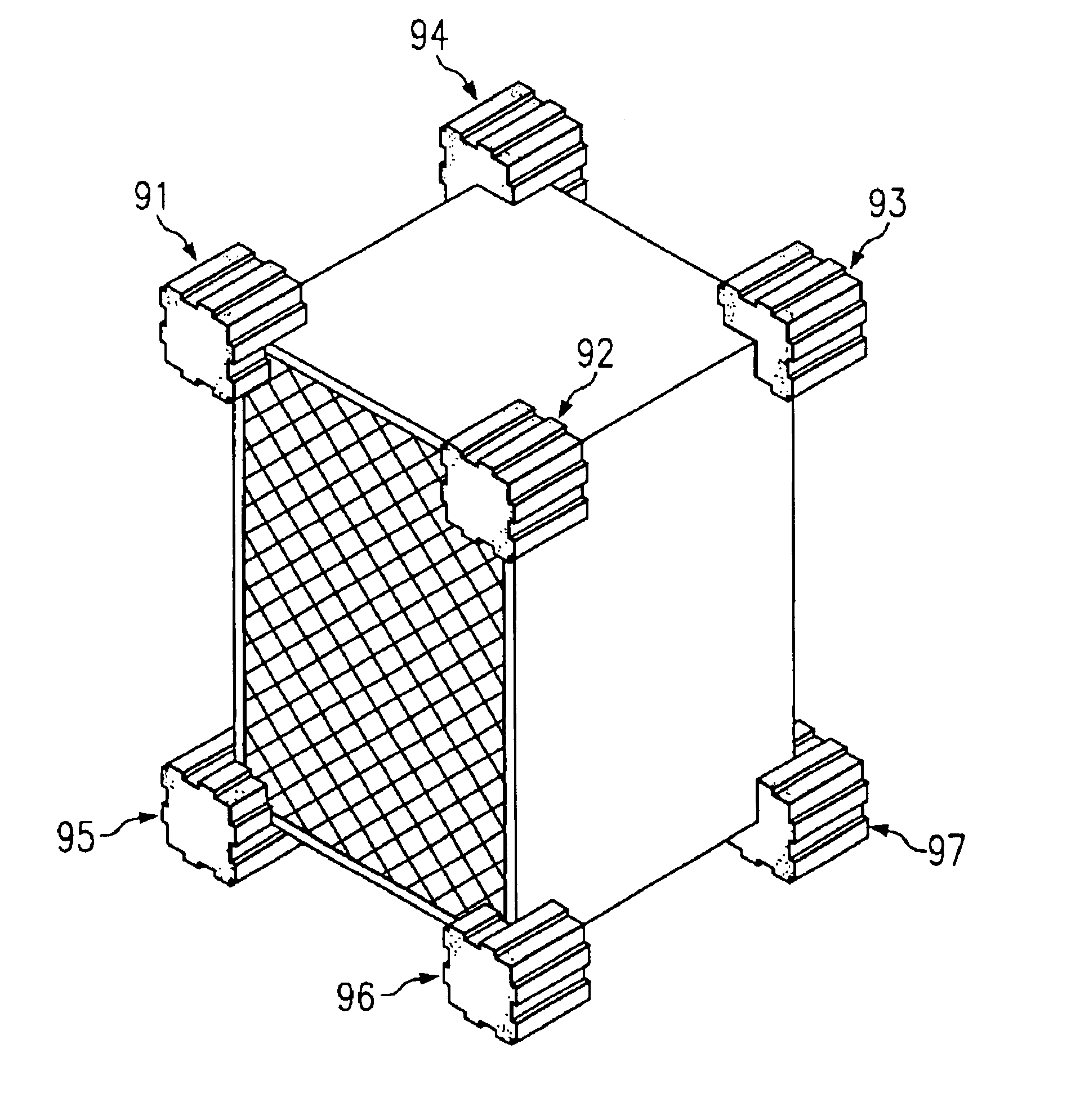

Packaging system, apparatus, and method with articulable corner support members

InactiveUS7325500B2Easy to storeReduce weightContainers to prevent mechanical damagePlastic containersSynthetic substanceBiomedical engineering

A system for use in the packing of an appliance containing the pallet and corner members is provided. The pallet comprises first and second support members and a connecting cross member, wherein the cross member is substantially perpendicular to the first and second support members. The first and second support members include attachment holes, wherein the attachment holes allow for the attachment of the pallet to the appliance. The first and second support members and the cross member are manufactured from a synthetic substance and are substantially hollow. The system further comprises an available plurality of articulable corner support members, corner junction end caps with tenons, closed cell design elements, and standoffs used to protect, support, separate and / or stabilize the appliance in a container.

Owner:CARPENTER GARY +1

Product Packaging that Remains with the Product and Functions as Acoustical and/or Thermal Insulation

InactiveUS20110185682A1Low costReducing shipping wasteWrapper folding/bending apparatusWrappingCardboardThermal insulation

A shipping capsule for an electrical appliance comprises a blanket of insulating material and a layer of stretch wrap. Together these materials function as a durable shipping container eliminating the need for a corrugated cardboard outer carton currently in use. The invention further includes a method of reducing shipping costs and shipping waste associated with shipping an electrical appliance. The method includes the steps of covering at least a portion of the electrical appliance with insulation material that will remain with the electrical appliance after installation and providing a layer of stretch wrap over the insulation material whereby the combination of insulation material and stretch wrap form a shipping capsule.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

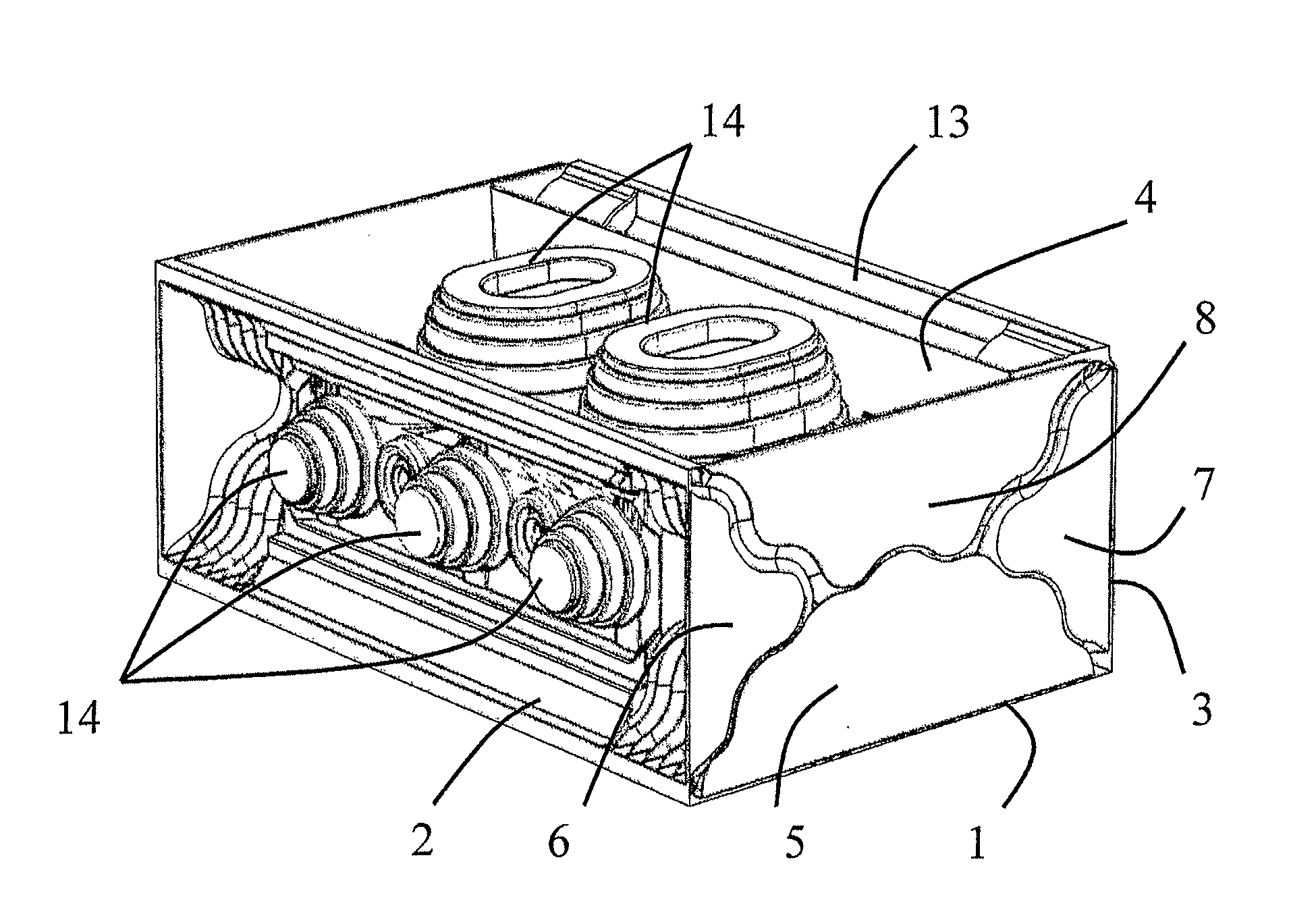

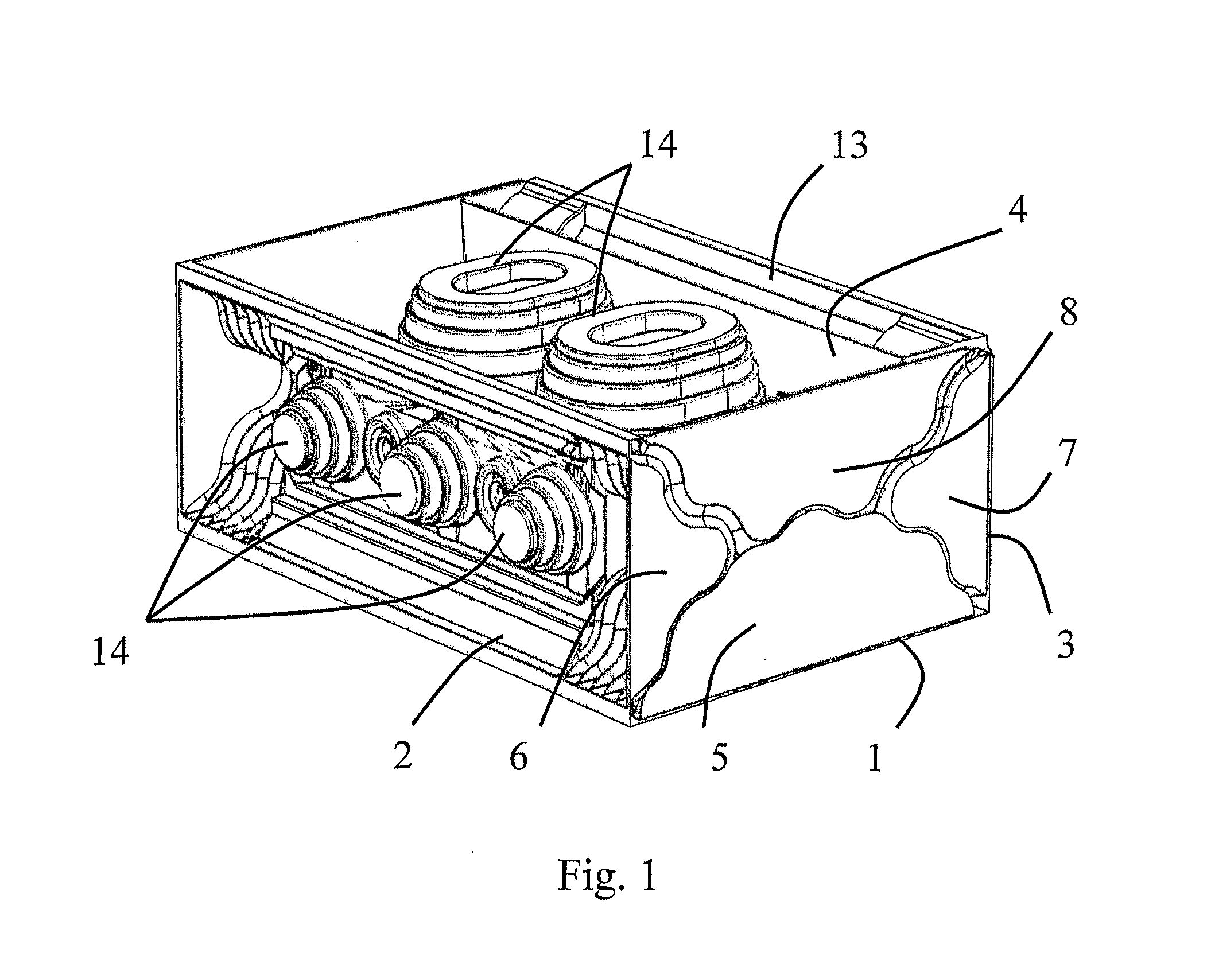

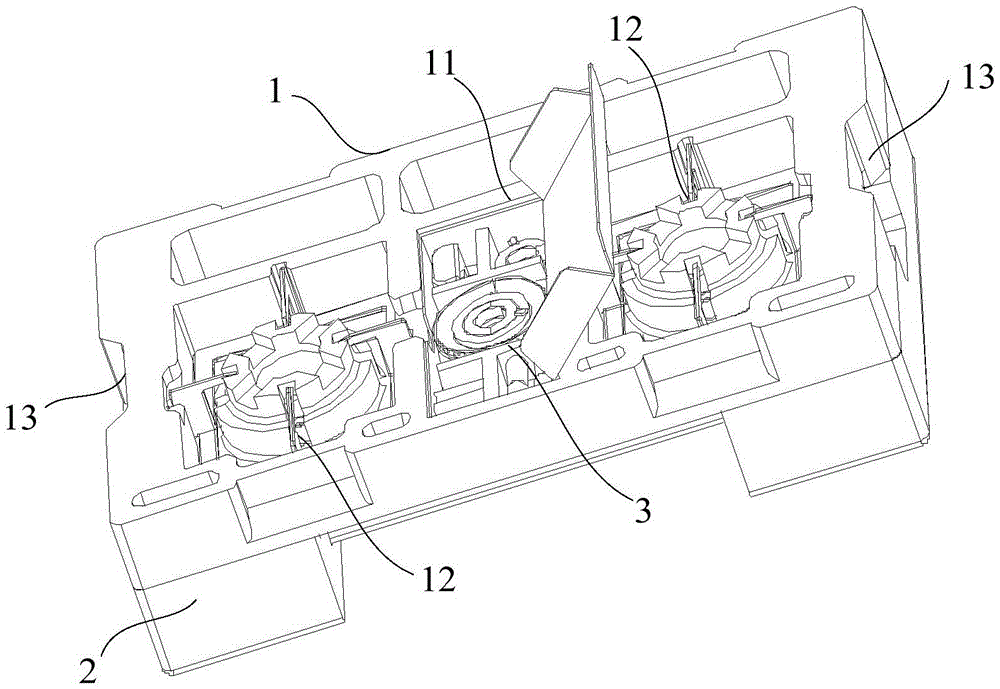

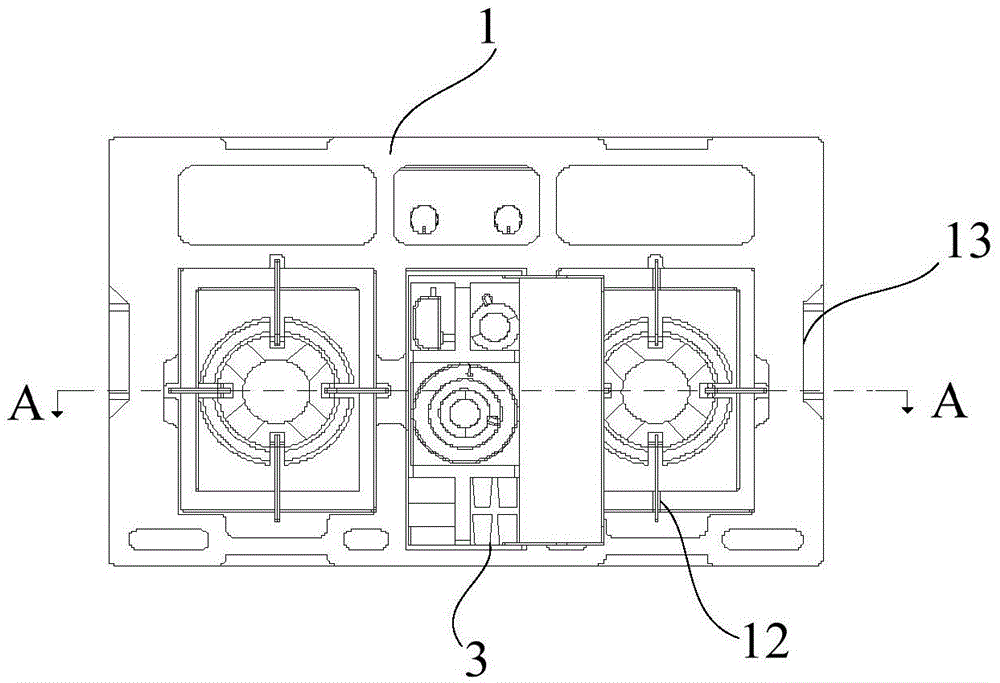

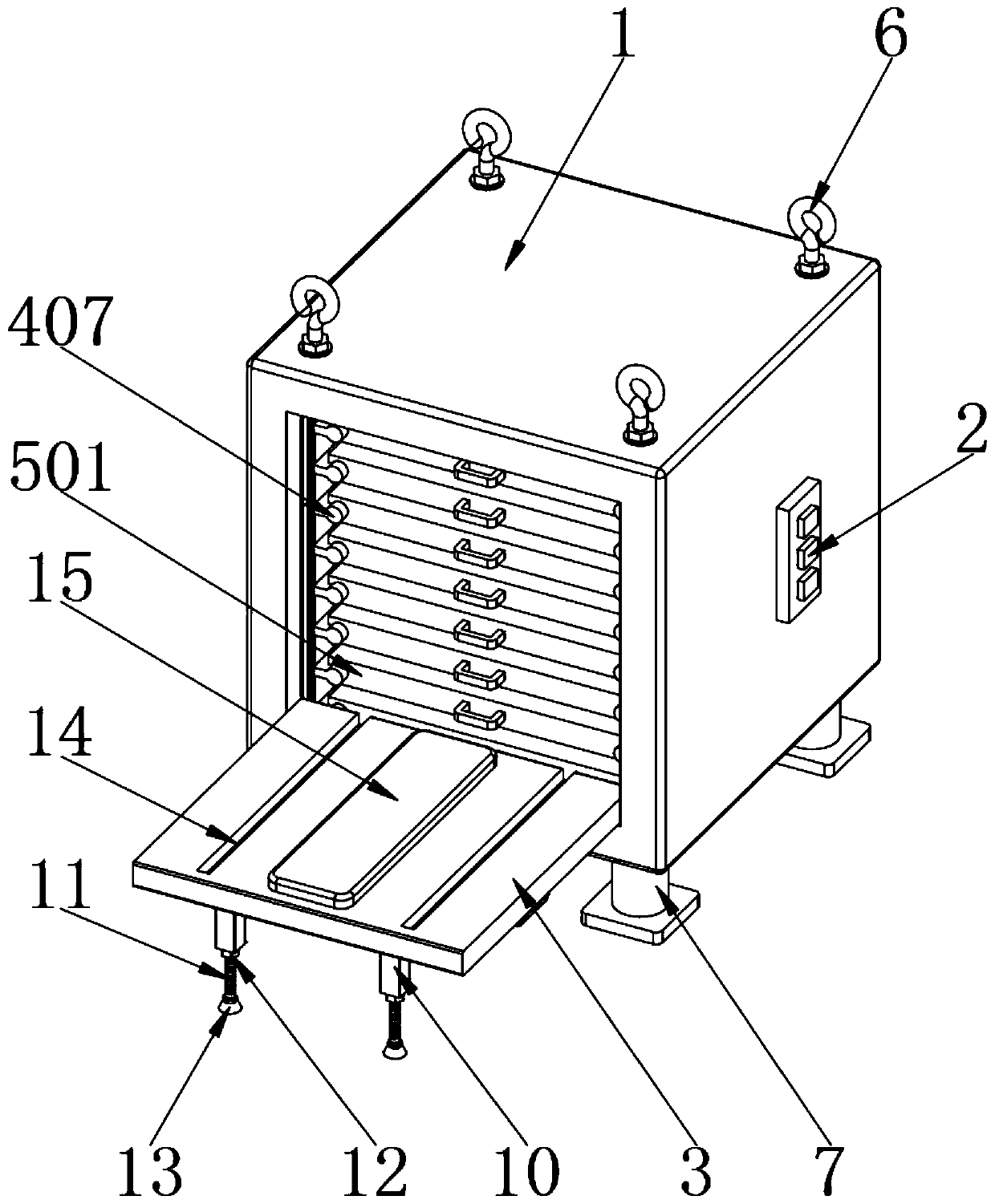

Buffering packing structure and gas stove with buffering packing structure

ActiveCN105540051AImprove stabilityReduce assembly pitchPackaging vehiclesContainers for machinesProcess engineeringGas stoves

The invention discloses a buffering packing structure and a gas stove with the buffering packing structure, and relates to the field of packing of gas stoves. The buffering packing structure comprises a foam base and an upper foam cover, wherein a first accommodating socket is formed in the top of the foam base; the upper foam cover covers the first accommodating socket in the foam base; the upper foam cover and the first accommodating socket define an accommodating space for accommodating the gas stove; a second accommodating socket is also formed in the upper foam cover or the foam base; the buffering packing structure further comprises an accessory box for accommodating gas stove accessories; the accessory box is accommodated in the second accommodating socket. According to the technical scheme, the packing structure of the gas stove is more compact, and the stability of gas stove assembling can be improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

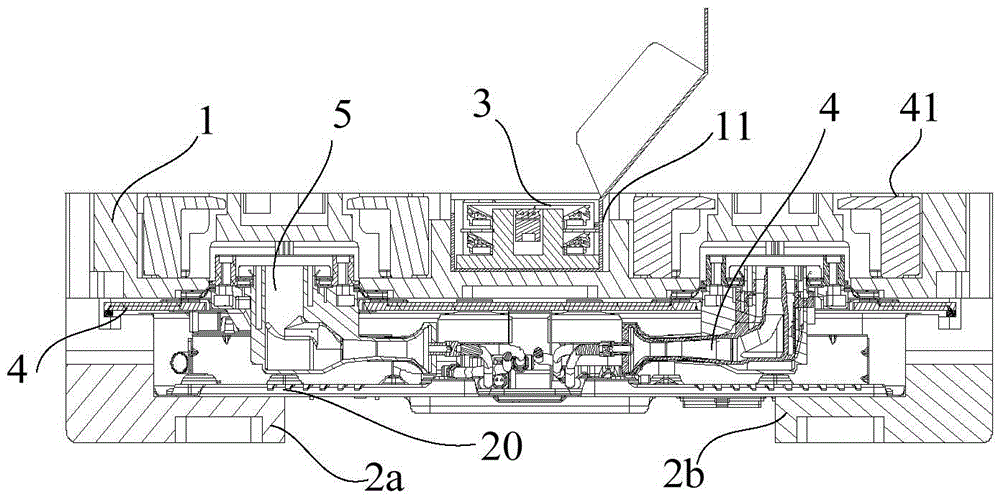

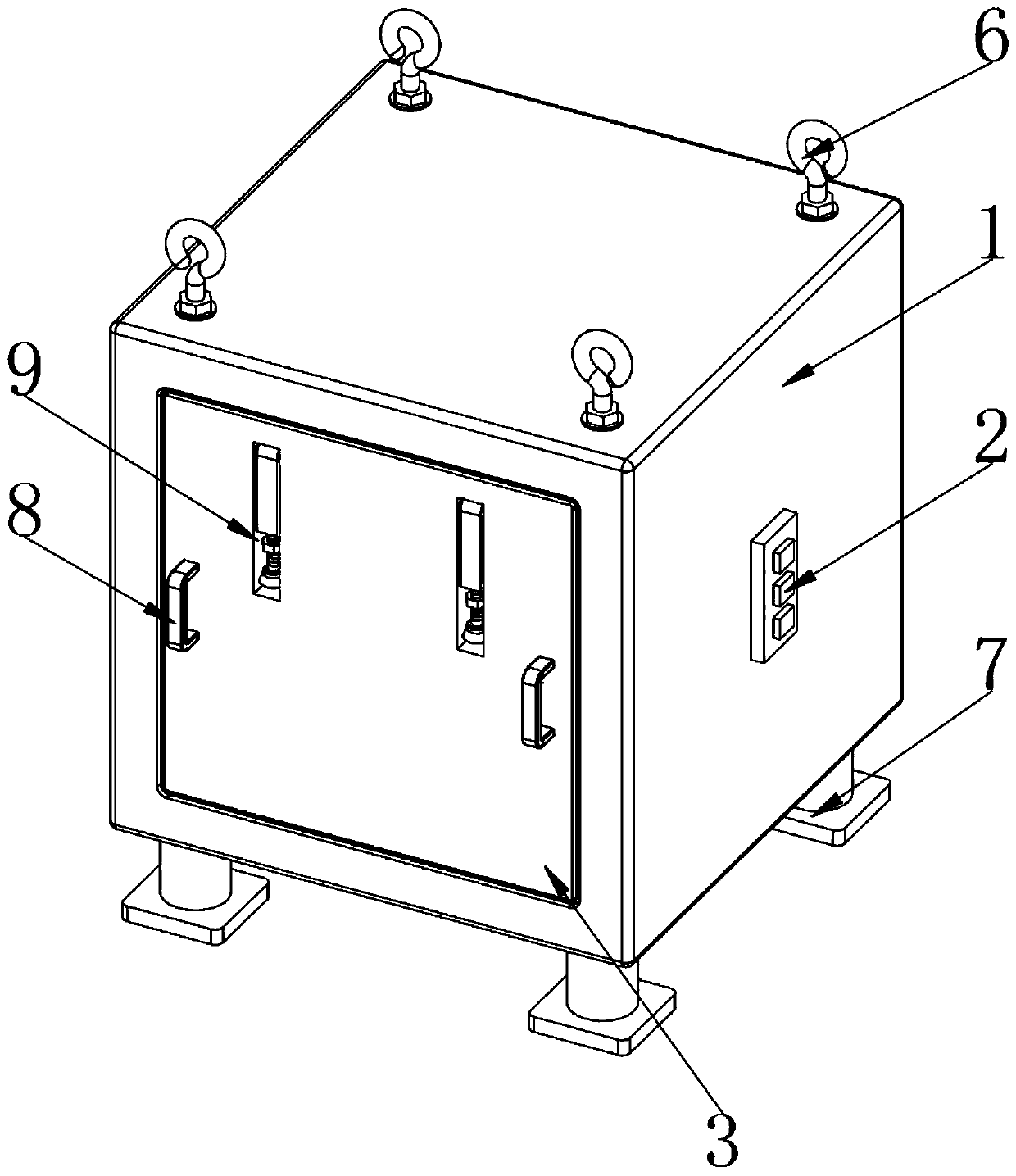

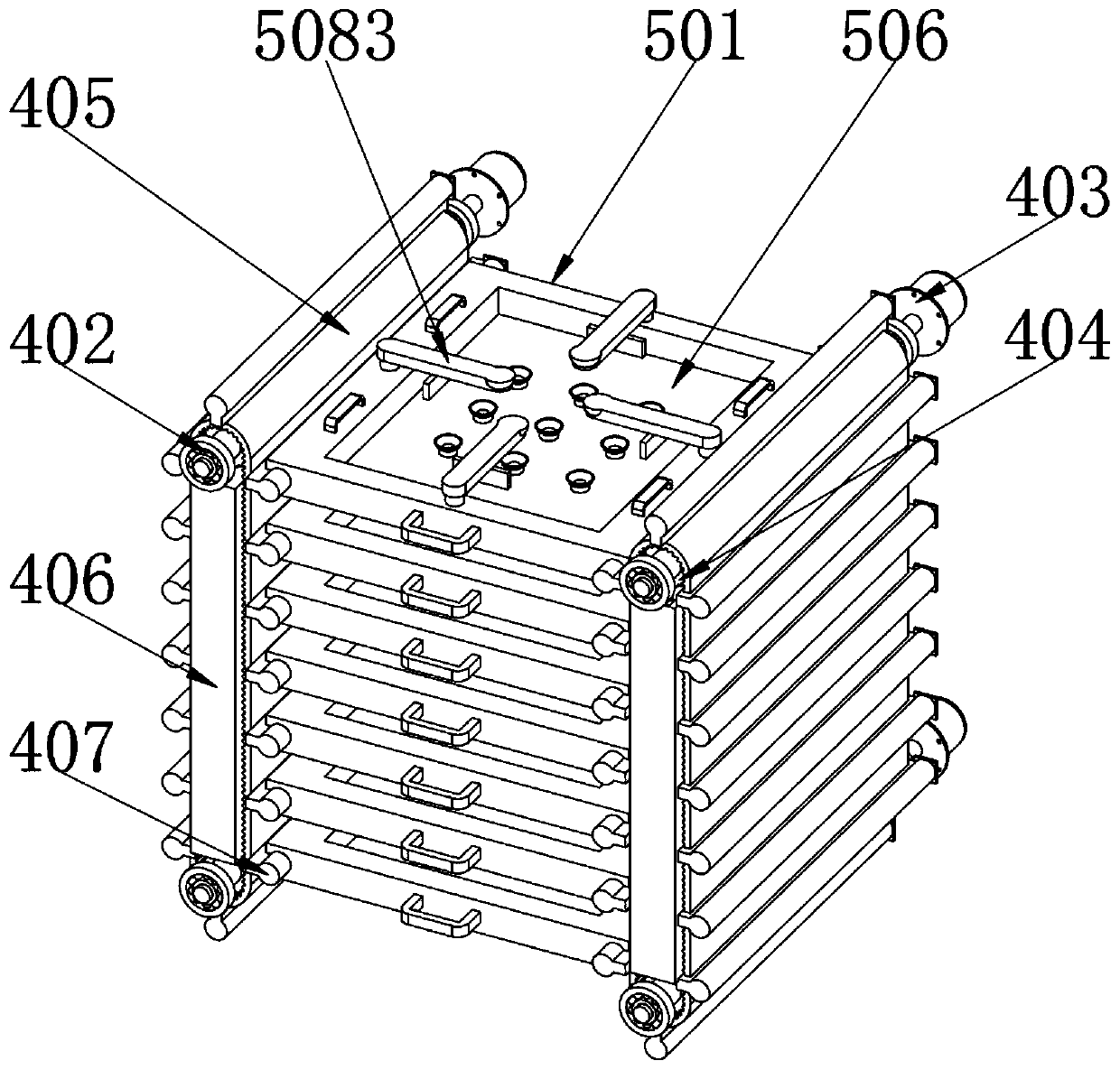

Portable glass loading and transporting device for logistics transportation

ActiveCN110316481APlay a buffer roleAvoid damageDischarging meansContainers to prevent mechanical damageLogistics managementEngineering

The invention discloses a portable glass loading and transporting device for logistics transportation. The device comprises a box body, a box door, transmission components and a loading component, wherein the box door is connected and installed on the front end face of the box body through a hinge; the transmission components are fixedly arranged on two sides in the box body; and a loading component is arranged between the transmission components. The portable glass loading and transporting device for logistics transportation is scientific and reasonable, and is safe and convenient to use. Theportable glass loading and transporting device for logistics transportation is provided with a loading component, the glass is adsorbed by a fixing sucker at the bottom end of a loading groove, and the upper surface of the glass is fixed by a fixing rubber ball by recovering a vertical fixing spring; and a fixing plate fixes the side edge of the glass by utilizing the recovery of a horizontal fixing spring, so that on one hand, a certain buffering effect can be achieved in the glass transportation process, and the glass is prevented from being damaged in the transportation process, and on theother hand, a loading plate can fix glass with different sizes by fixing the horizontal fixing spring, and the application range of the glass transporting device can be effectively improved.

Owner:泰安泰山科技有限公司

Packaging container

A container includes a pallet, an enclosure base, an enclosure box, and a set of fasteners. The pallet is disposed at a bottom of the container. The enclosure base is placed on the pallet, and includes a lower base sheet and an upper base sheet. The lower base sheet forms a first pair of side flaps. The upper base sheet forms a second pair of side flaps. The enclosure box is placed on the enclosure base, and includes a top wall, a set of four side walls, and an open bottom. The four side walls of the enclosure box rest on the lower base sheet while surrounding the upper base sheet to position the first pair of opposed side flaps outside the enclosure box, and the second pair of opposed side flaps inside the enclosure box. The set of fasteners fastens the enclosure base to the enclosure box.

Owner:RICOH KK

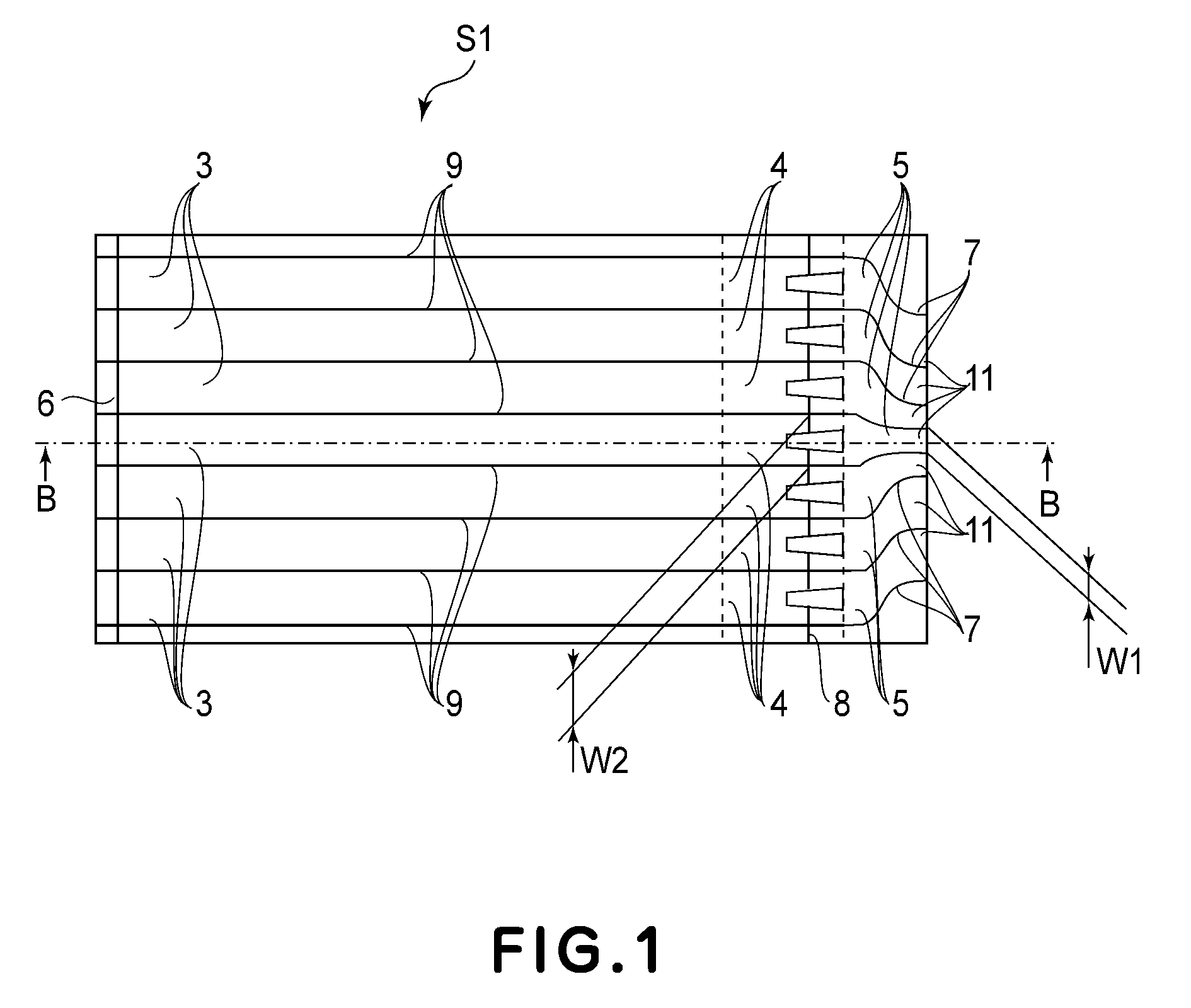

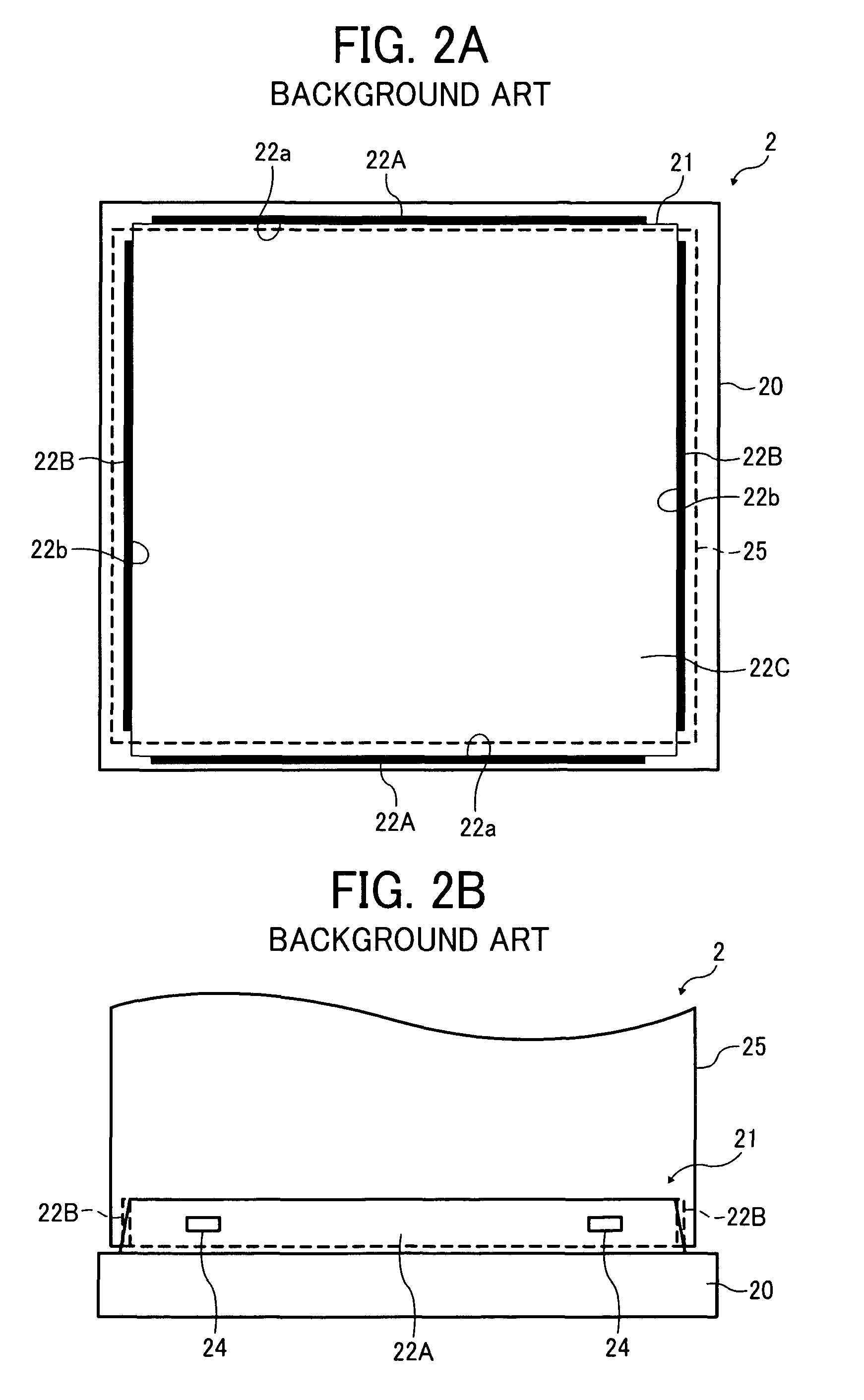

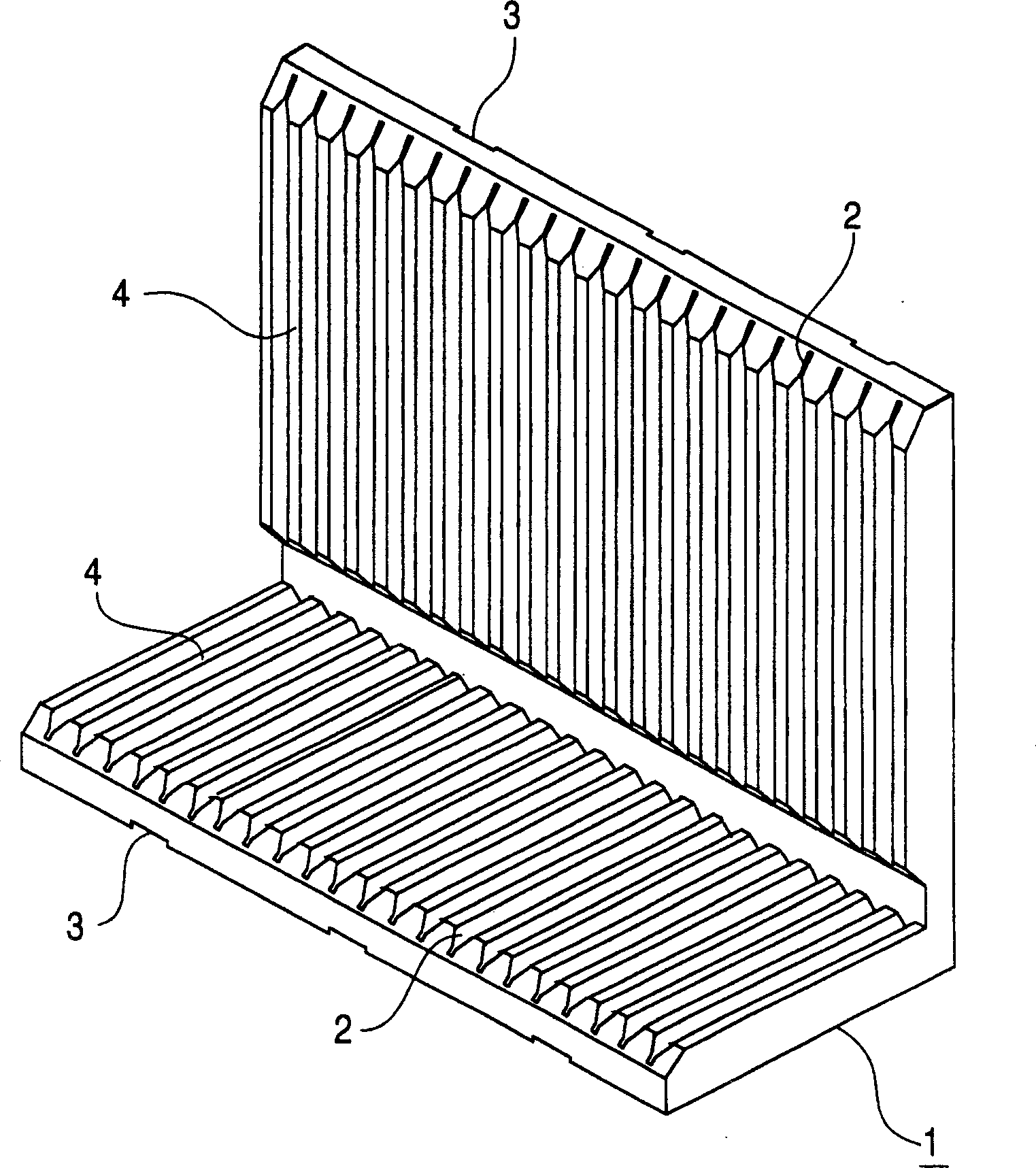

Cushioning body for glass substrate and packing body using the cushioning body

InactiveCN1482985AGood anti-dust effectIncreased durabilityContainers to prevent mechanical damagePlastic containersEngineeringMechanical engineering

A cushioning body for glass substrate having an L-shaped section and the thickness of the L-shaped section at the end part larger than the thickness thereof at the corner part, wherein (1) the thickness of the cushioning body is gradually decreased from the end part to the corner part of the L-shaped section with the bottom part of a fixture guide groove taken as a reference by forming the fixture guide groove so that the depth thereof is gradually increased from the end part to the corner part of the L-shaped section, (2) the cushioning device is formed so that the thickness of the cushioning body itself is gradually decreased from both end parts to the corner part of the L-shaped section without forming the fixture guide groove, and (3) a projected part is formed at both outer end parts of the L-shaped section of the cushioning body, whereby a fixture tightening force is prevented from being concentrated to the corner part when the cushioning body is tightened with a fixture.

Owner:ASAHI KASEI KK

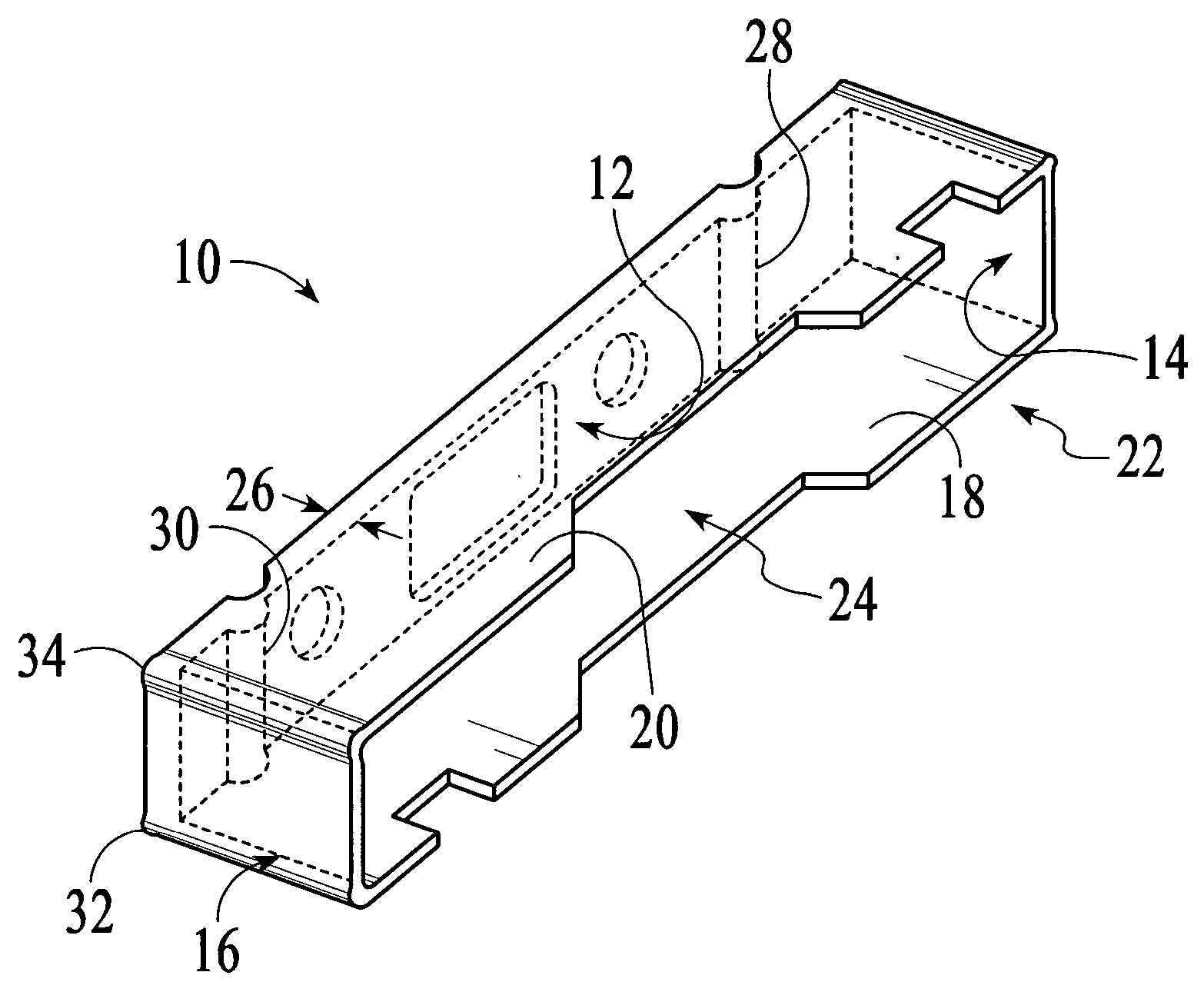

Edge protector and method of making an edge protector

InactiveUS20060081496A1Containers to prevent mechanical damagePlastic containersEngineeringMechanical engineering

A plastic edge protector for protecting corner regions of objects during shipping or transport includes a pair of generally perpendicularly oriented legs or walls, and a reinforced corner region which prevents damage to the object and the protector. The edge protector is formed so as to include a solid interior wall or bead of plastic which extends along the entire longitudinal extent of the edge protector.

Owner:CARTER ASSOCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com