Cushioning body for glass substrate and packing body using the cushioning body

A technology for glass substrates and packaging products, which is applied in the field of buffers, and can solve problems such as easy failures, wear marks on the surface of glass substrates, and L-shaped buffers that are not suitable for automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0091] (Glass base board)

[0092] Mother glass for liquid crystal displays

[0093] Size: 600mm×720mm

[0094] Thickness: 0.7mm

[0095] (Foam)

[0096] Resin material:

[0097] The expansion ratio is 20cm 3 / g of ethylene-propylene random copolymer; average particle size of resin foam particles: 3.6mm

[0098] Fusion ratio: 86%

[0099] Compression elasticity index: 549N / cm 2

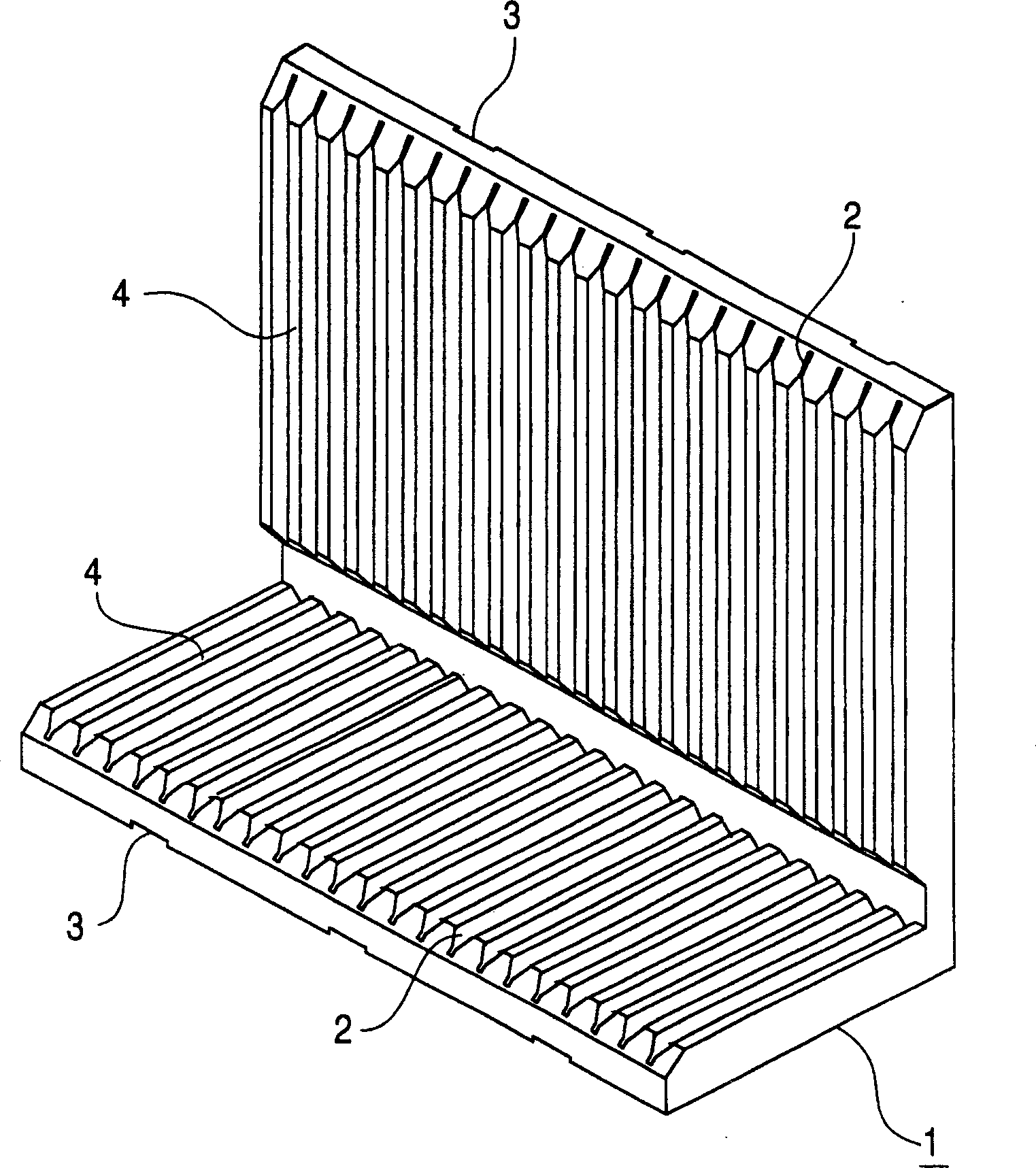

[0100] (buffer)

[0101] Number of glass substrates to be packed: 26

[0102] Dimensions:

[0103] Short side: 250mm

[0104] Long side: 350mm

[0105] Length (at right angles to short side and long side): 300mm

[0106] Maximum thickness: 32mm

[0107] Base plate insertion slot:

[0108] Width: 2.4mm

[0109] Depth: 12mm

[0110] Spacing: 20mm

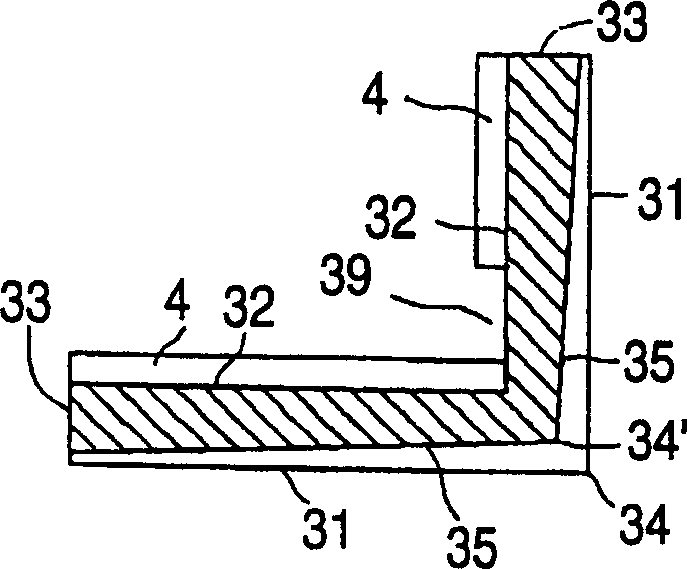

[0111] The shape of the protrusion:

[0112] Has a vertical wall of 6.5mm from the bottom of the substrate insertion groove, and a trapezoidal top with a width of 8mm and a height of 5.5mm in the flat part (shape as shown in Figure 4(c))

...

example 2 and comparative example 1

[0123] (Glass base board)

[0124] Mother glass for liquid crystal displays

[0125] Size: 550mm×650mm

[0126] Thickness: 0.7mm

[0127] (Foam)

[0128] Resin material:

[0129] The expansion ratio is 20cm 3 / g and the resin density is 0.930g / cm 3 XLPE

[0130] Average particle size of resin foam particles: 2.8mm

[0131] Fusion ratio: 98%

[0132] Compression elasticity ratio: 412N / cm 3

[0133] Compression elasticity index: 41.2

[0134] (buffer)

[0135] Number of glass substrates to be packed: 12

[0136] Dimensions:

[0137] Short side: 210mm

[0138] Long side: 310mm

[0139] Length (at right angles to short side and long side): 240mm

[0140] Maximum thickness: 23mm

[0141] Base plate insertion slot:

[0142] Width: 1.5mm

[0143] Depth: 7mm

[0144] Spacing: 20mm

[0145] The shape of the protrusion:

[0146] Has a vertical wall of 3.5 mm from the bottom of the substrate insertion slot, and a herringbone top with a height of 3.5 mm (shape as shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com