Heat exchange system for reducing ash accumulation and enhancing heat exchange based on corrugated heat exchange fins

A heat-exchange fin and heat-enhancing technology, which is applied in the field of heat-exchange systems based on corrugated heat-exchange fins to slow down fouling and enhance heat exchange, can solve the problems of easy fouling in the leeward area, large eddy currents in the wake area, and large resistance. , to achieve the effect of preventing ash accumulation and bridging, increasing the heat exchange area and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

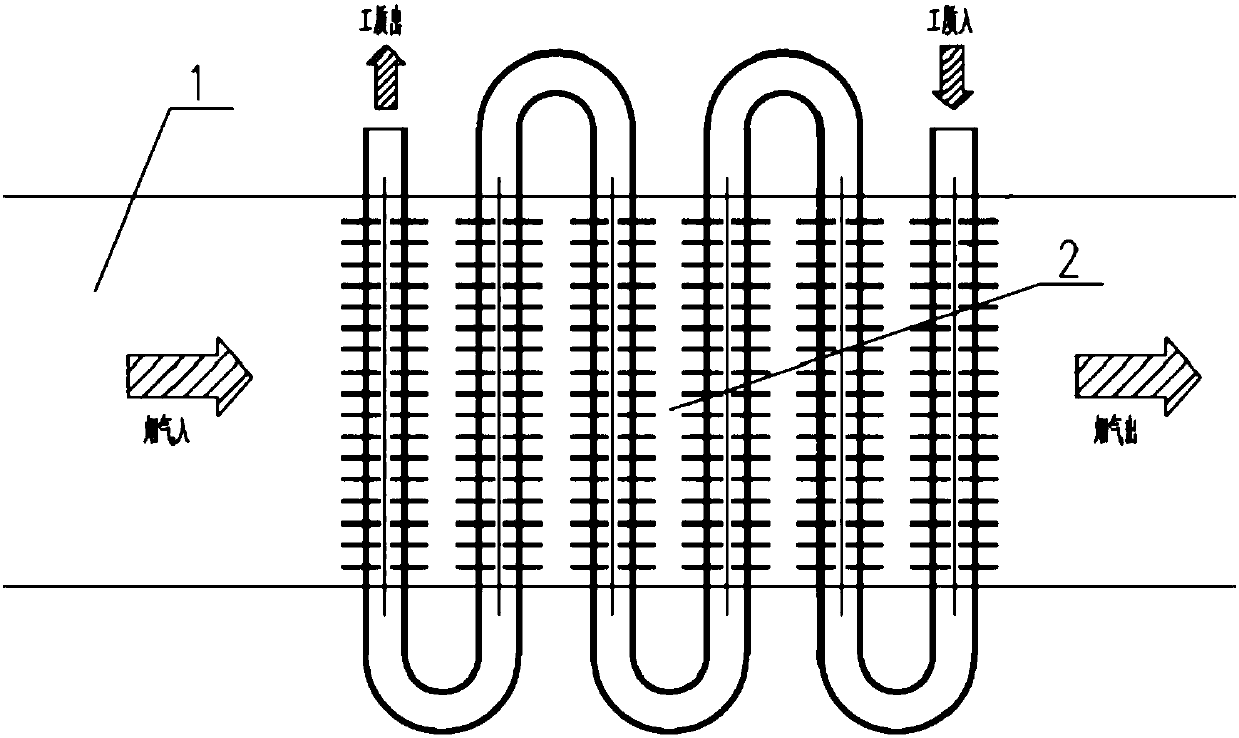

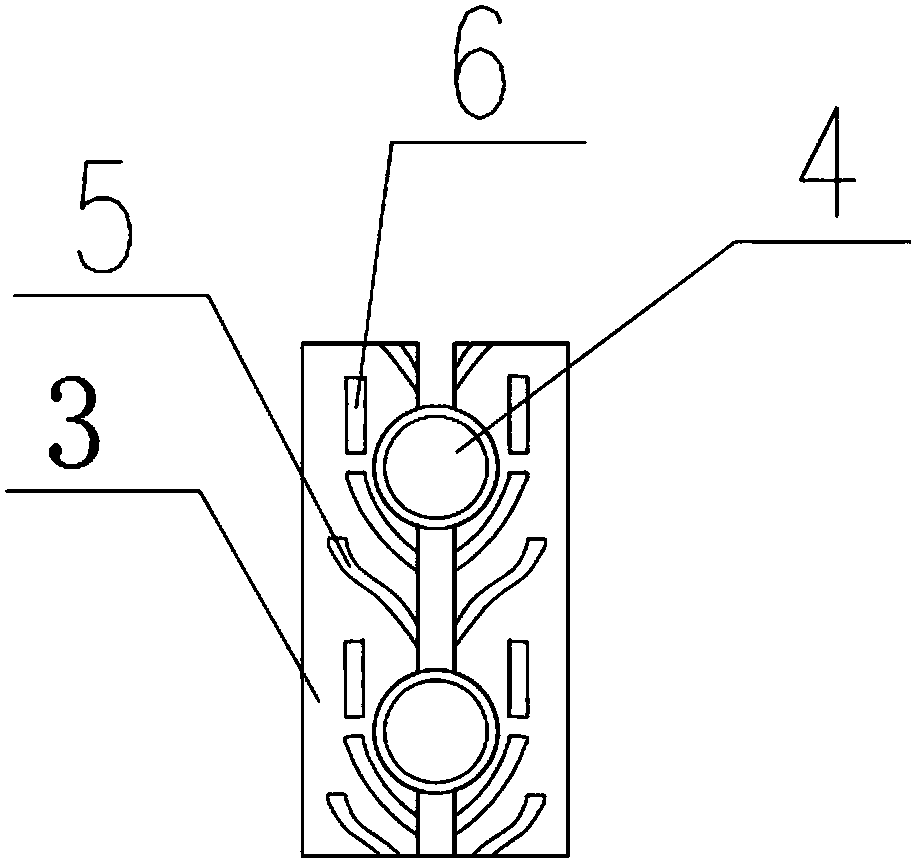

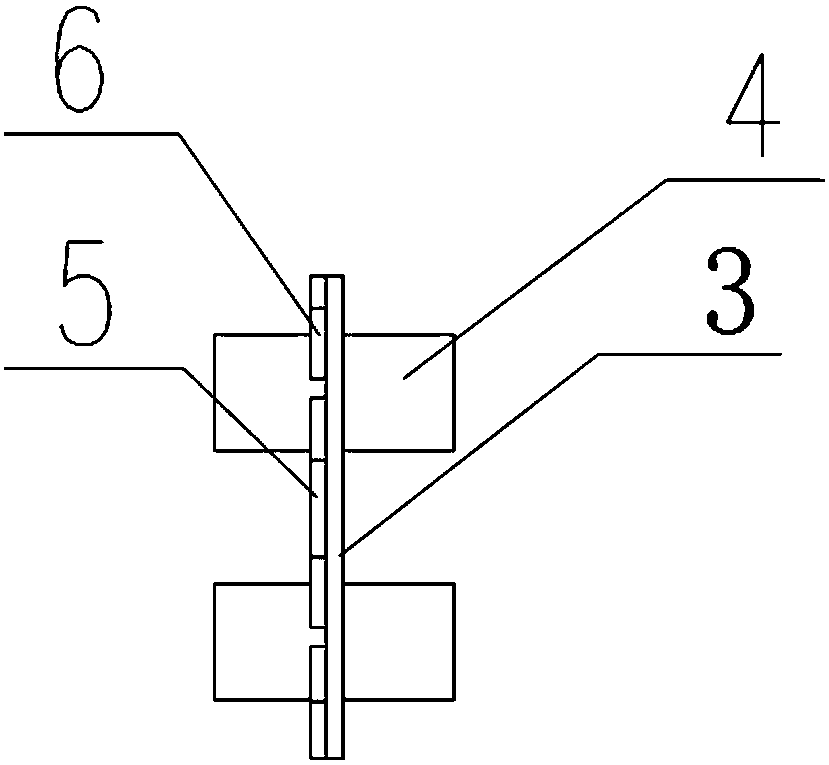

[0023] refer to figure 1 According to the present invention, the heat exchange system based on corrugated heat exchange fins to reduce dust deposition and enhance heat exchange includes a flue 1 and a heat exchanger 2, wherein the heat exchanger 2 includes a number of heat exchange base pipes 4 and a number of heat exchange fins sheet 3, each heat exchange base tube 4 is distributed in a serpentine shape, the working fluid inlet at one end of each heat exchange base tube 4 and the working medium outlet at the other end are located outside the flue 1, and the middle part of each heat exchange base tube 4 is located at In the flue 1, each heat exchanging fin 3 is located in the flue 1, and each heat exchanging fin 3 is sleeved on the outer wall of each heat exchanging base pipe 4, and each heat exchanging fin 3 is provided with a The heat-exchanging corrugations 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com