Patents

Literature

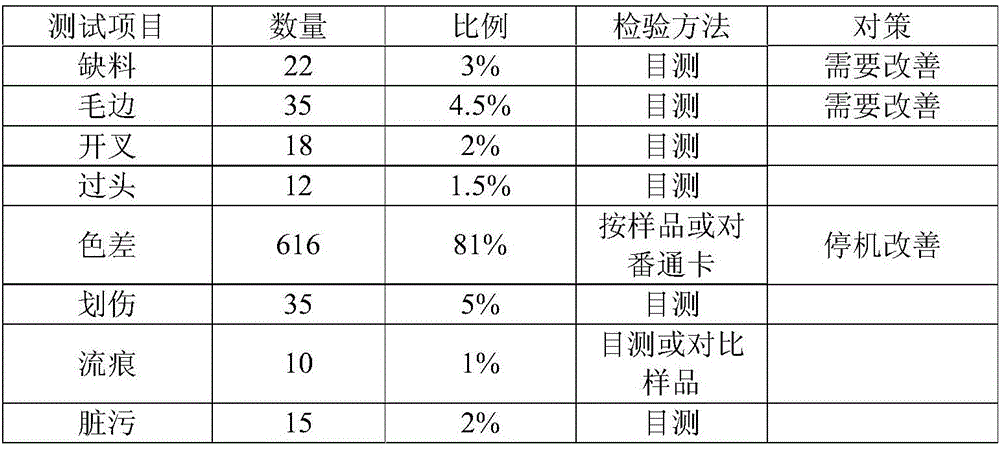

60results about How to "With anti-static effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

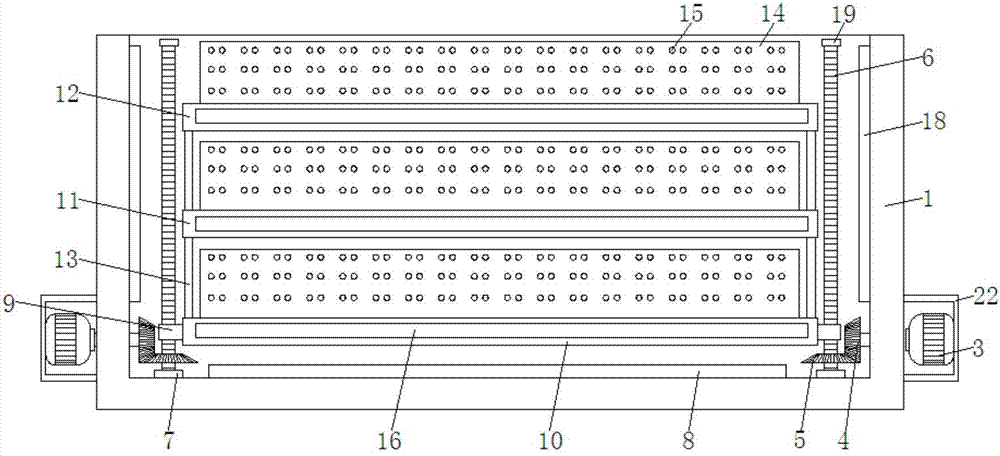

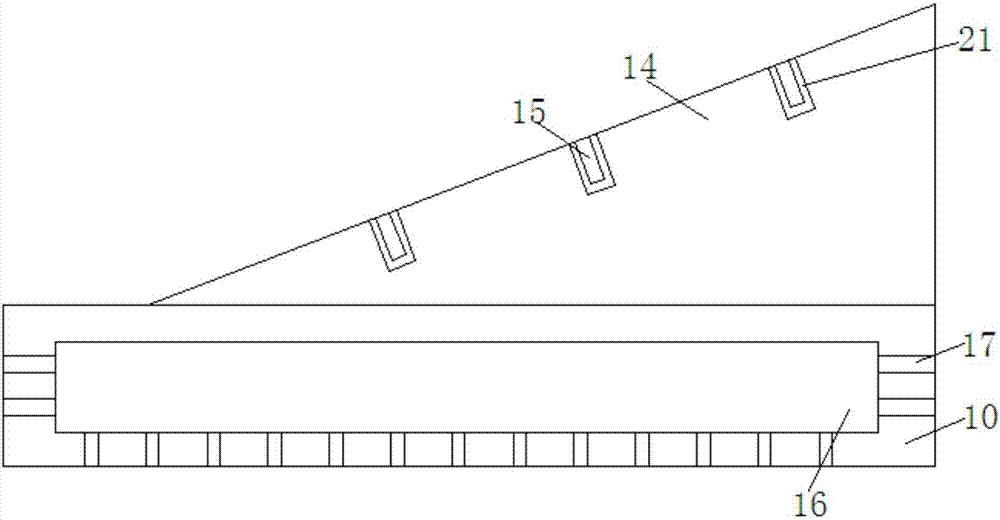

Lifting type storage box for electronic parts and components

InactiveCN107082179AEasy accessEasy to useLinings/internal coatingsDischarging meansDrive motorEngineering

The invention relates to the technical field of electronic components, and discloses a lift-type electronic component storage box, comprising a box body and a box cover, the box cover is closed on the top of the box body, and driving motors are installed on both sides of the box body, The output shaft of the drive motor passes through the side of the box and is fixedly connected with one side of the first bevel gear located in the inner cavity of the box. The bottom of the first bevel gear is meshed with a second bevel gear, and the surface of the second bevel gear and the threaded rod Fixed socket. The elevating electronic component storage box is provided with a driving motor, a threaded rod, a first bearing plate, a supporting rod and a placing plate, and the rotation of the driving motor drives the first bevel gear and the second bevel gear to rotate, so that the threaded rod rotates. Cooperate with the limitation of the two drive motors, so that the first carrier plate, the second carrier plate and the third carrier plate are raised, and at the same time, it cooperates with the limitation of the threaded rod, so as to achieve the effect of convenient access to electronic components, and the use is more convenient .

Owner:长兴恒业达电子股份有限公司

Healthy polyolefine foam material and preparation method thereof

The invention relates to a healthy polyolefine foam material and a preparation method thereof. The healthy polyolefine foam material is prepared from the following original auxiliary materials subjected to mixing, smelting, extrusion, preheating and foaming in parts by weight: 70-100 parts of polyolefine resin, 20-50 parts of anion functional master batch, 15-30 parts of hydrophilic functional master batch, 1-5 parts of a foaming agent, 1-5 parts of a cross-linking agent and 0-5 parts of color master batch. According to the healthy polyolefine foam material provided by the invention, the anion mineral materials and hydrophilic fullerene compounds are added into the formula, so that the foam material has the advantages of air purifying, surface oil contamination resistance, electrostatic prevention and the like; the anion concentration of ambient environment can be effectively increased in virtue of the pyroelectricity and piezoelectricity of the anion mineral material; besides, the hydrophilic groups of the hydrophilic fullerene compounds can form hydrogen bonds with water, so that the contact of pollutants and the polyolefine surface is prevented, accumulated static charges can be leaked quickly, and the antistatic purpose can be further achieved.

Owner:TAISHAN SPORTS IND GRP +1

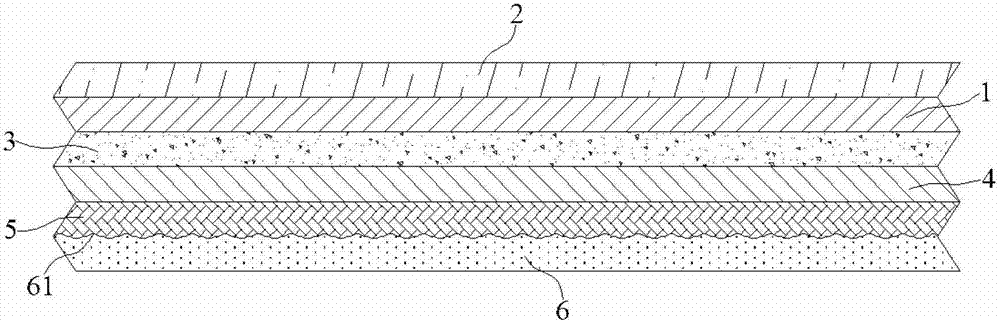

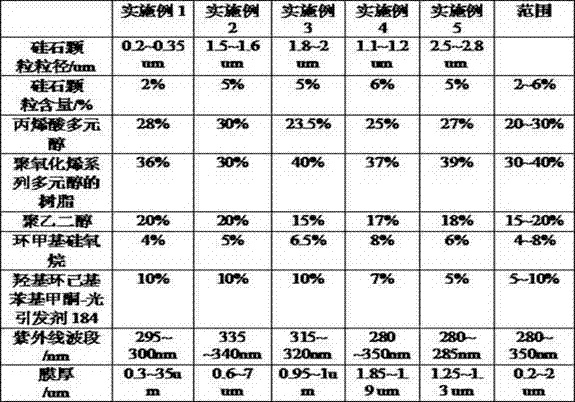

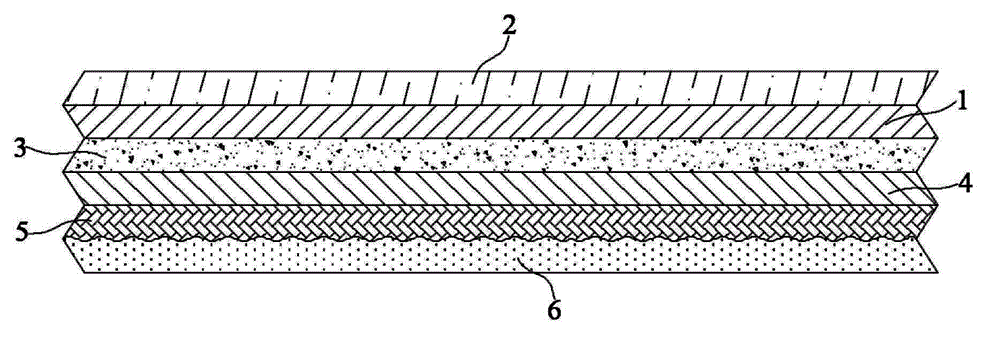

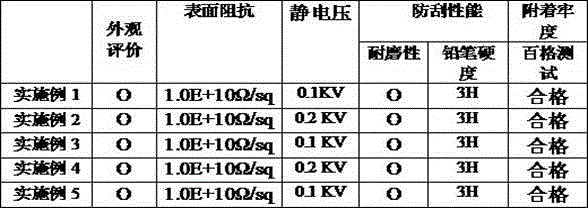

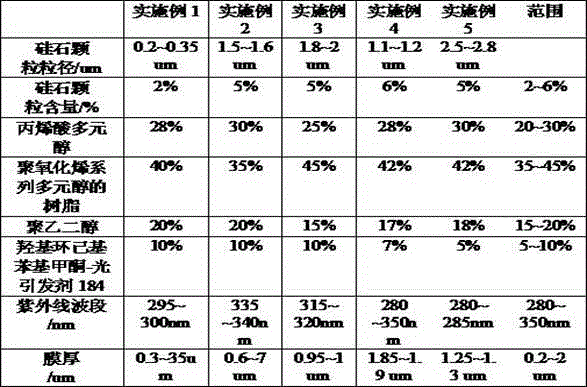

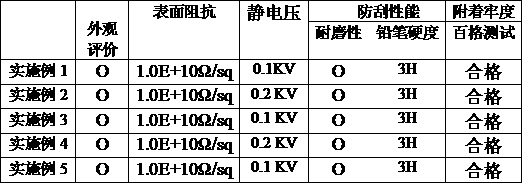

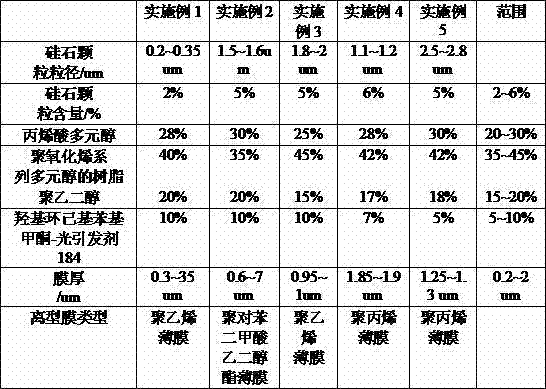

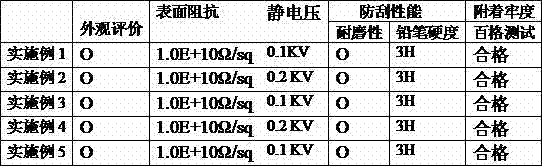

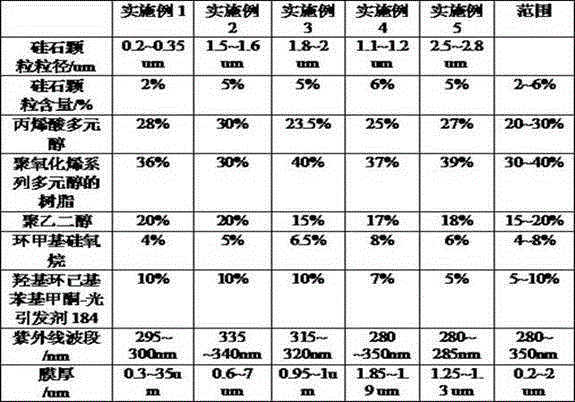

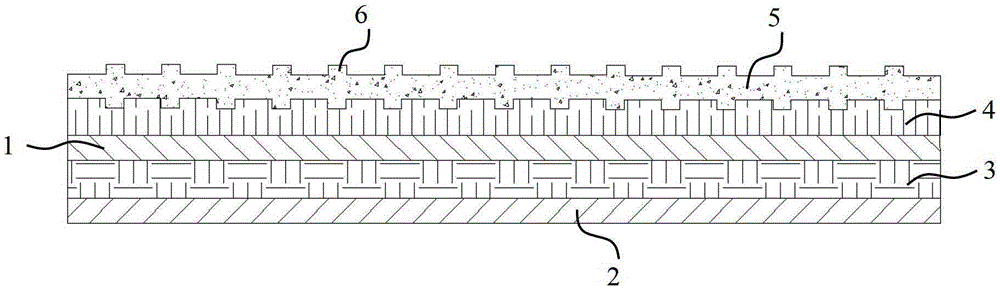

Anti-scuffing matt-surface antistatic release paper

ActiveCN103074819ALow wear resistanceImprove surface antistatic performanceNon-fibrous pulp additionSynthetic resin layered productsElectrostatic coatingPolyethylene glycol

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

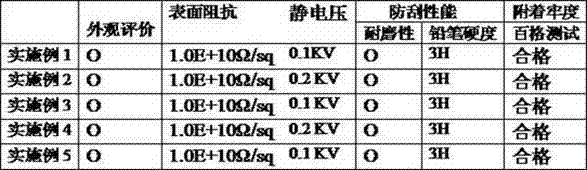

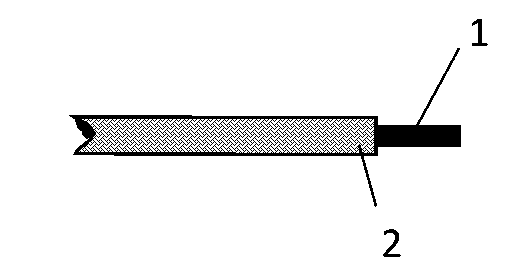

Composite fiber filament for nuclear radiation protection and production method of composite fiber filament

InactiveCN103757778AExcellent nuclear radiation protection performanceFlame retardantYarnMetal fiberNuclear radiation

The invention discloses a composite fiber filament nuclear radiation protection and a production method of composite fiber filament and relates to the technical field of nuclear radiation protection. Core knitting is performed on a knitter, and a material covered during knitting is made of carbon fiber, high density polyethylene fiber, polytetrafluoroethylene fiber, polyphenylene sulfide fiber, polyarmide fiber, polyester fiber or polyimide fiber, a coating material is made from the carbon fiber, the high density polyethylene fiber, the polytetrafluoroethylene fiber, the polyphenylene sulfide fiber, the polyarmide fiber, the polyester fiber or the polyimide fiber, and thereby the composite fiber filament with a nuclear radiation protection function is formed. The composite fiber filament comprises a metal fiber core and at least one outer knitted coating layers which are in net structures. The composite fiber filament is simple and reasonable in technology, high in yield, and beneficial to follow-up weaving for weaving the composite fiber filament into fabric via a weaving technology so as to form clothes with the nuclear radiation protection function.

Owner:扬州锦沃科技有限公司

Preparation method of novel matte anti-static release paper

ActiveCN103061207AImprove surface antistatic performanceLow wear resistanceSpecial paperPaper coatingUltravioletPolyethylene glycol

The invention discloses a preparation method of novel matte anti-static release paper. One surface of release paper body paper is coated with a coating layer through a coating machine, and one surface of a thin film layer is coated with a matte anti-static coating with a thickness of 0.2-2 micrometres. Under the influence of the used ultraviolet rays which are of a wave band of 280-350nm and of an illumination of 1200mW / cm<2>, components, contained in the matte anti-static coating, including 2-6% of silica particles, 20-30% of acrylic polyol with the average molecular weight of 500-2000, 35-45% of resin of polyoxyalkylene polyols with the average molecular weight of 200-2500, 15-20% of polyethylene glycol and 5-10% of 1-1-hydroxy-cyclohexyl phenyl ketone-photoinitiator 184 react to obtain the matte anti-static coating. The thickness of the matte anti-static coating is 4-10 micrometres. The preparation method of the novel matte anti-static release paper not only solves the problems that the binding force between the coating layer and the release agent coating of the release paper is not strong and the release force between the coating layer and the release agent coating of the release paper is not stable, but also promotes the anti-static performance of the surface of the film, and meanwhile promotes the anti-scraping performance.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Antistatic master batches and preparation method and application thereof

The invention relates to antistatic master batches and a preparation method and application thereof. The antistatic master batches are prepared from, by mass, 0.5-6% of an antistatic agent, 89-99% of carrier resin and 0.4-5% of auxiliaries, wherein the carrier resin is polypropylene resin, and the auxiliaries are a lubricant. The antistatic master batches have the good compatibility with resin, the good dispersibility and the good weather resistance. When the antistatic master batches are applied to the injection molding product processing industry, the problem that static electricity is generated due to friction of macromolecule materials is solved, the problem that color aberration is generated due to static electricity of the product is effectively solved, the product is stable in quality, meanwhile, the product has the certain antistatic effect, and the good dust removal effect on the surface of the product is achieved.

Owner:苏州马培德办公用品制造有限公司

Adhesive tape

InactiveCN106905881AImproves bond stabilityFunction increaseMacromolecular adhesive additivesOrganic non-macromolecular adhesiveMethacrylateEpoxy

The invention discloses an adhesive tape, which comprises, from top to bottom, an anti-static coating, a substrate layer, an adhesive layer and a release film layer which are arranged layer by layer. The substrate layer is a PET film layer; the adhesive layer comprises the following materials, by weight part, 20-30% of butyl acrylate, 5-8% of acrylic acid, 10-20% of an epoxy resin, 40-50% of ethyl acetate, 5-15% of a rosin resin, and 5-10% of ethyl methacrylate; and the anti-static coating comprises the following materials, by weight part, 90-95% of glycerol monopalmitate, 2-3% of nanometer silver powder and 3-8% of fluorescent powder. Through the design above, the adhesive tape is good in bonding stability and multiple in functions and has an anti-static effect.

Owner:GUANGDONG YUEHUI TECH CO LTD

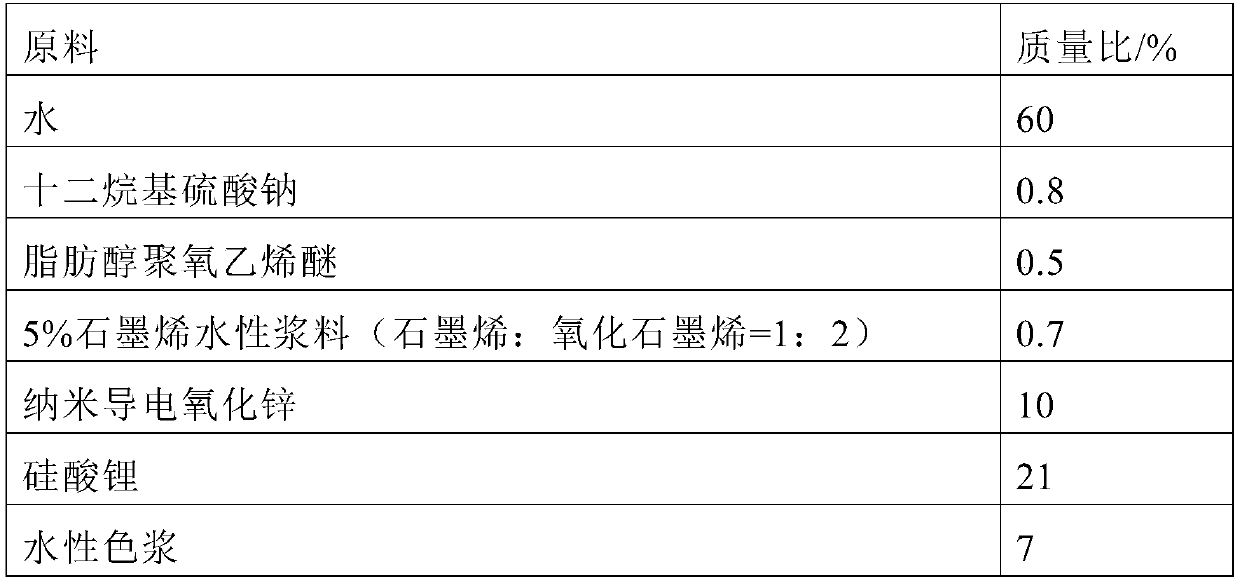

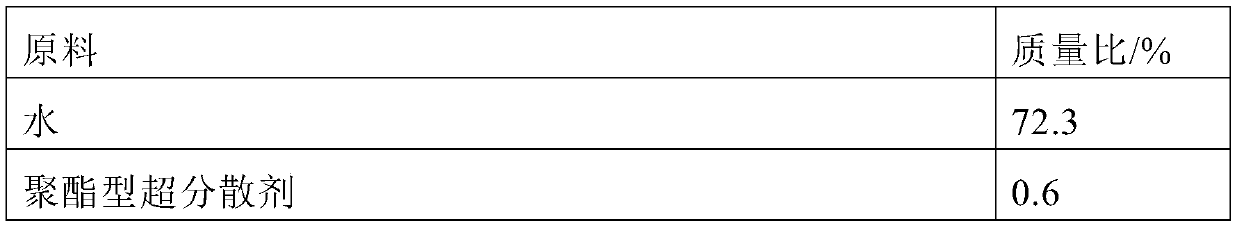

Graphene antistatic lithium-based sealing curing agent for concrete and preparation method of sealing curing agent

The invention relates to a graphene antistatic lithium-based sealing curing agent for concrete and a preparation method of the sealing curing agent. The sealing curing agent is composed of the following components in percentages by mass: 55.5-72.3% of water, 0.6-1% of a dispersing agent, 0.3-1% of a penetrating agent, 0.5-5%of graphene water-based slurry, 3-12% of an electroconductive material, 15-25% of lithium silicate, and 0-10% of water-based color paste. The preparation method comprises the following preparation steps: (1) adding the water into a dispersion cylinder, adding the dispersingagent and the penetrating agent at a low speed, and performing dispersion; (2) adding the graphene water-based slurry and the electroconductive material, and performing grinding in a sand mill; and 3) uniformly stirring the ground components, the lithium silicate and the water-based color paste. According to the method provided by the invention, the product prepared by the method can reduce the use amount of other electroconductive materials correspondingly while ensuring the antistatic effect, and has a durable antistatic effect, high hardness and good water and chemical resistance.

Owner:SHANGHAI INST OF TECH

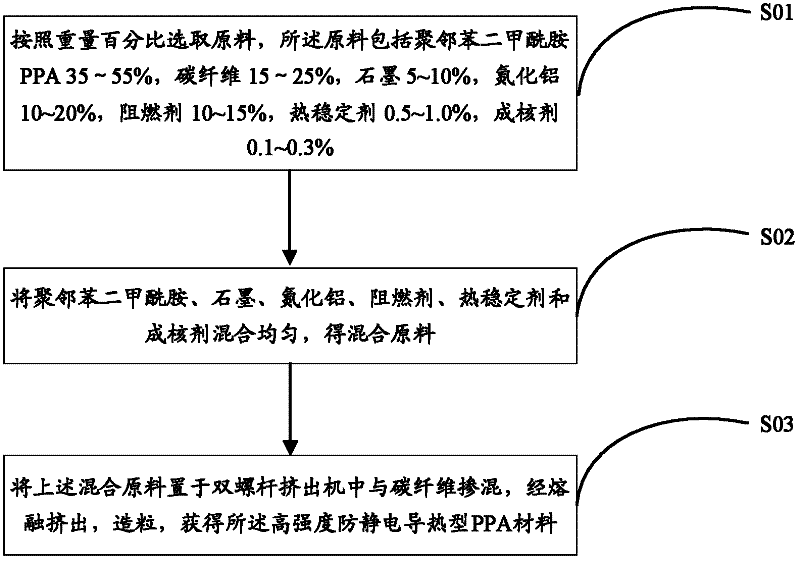

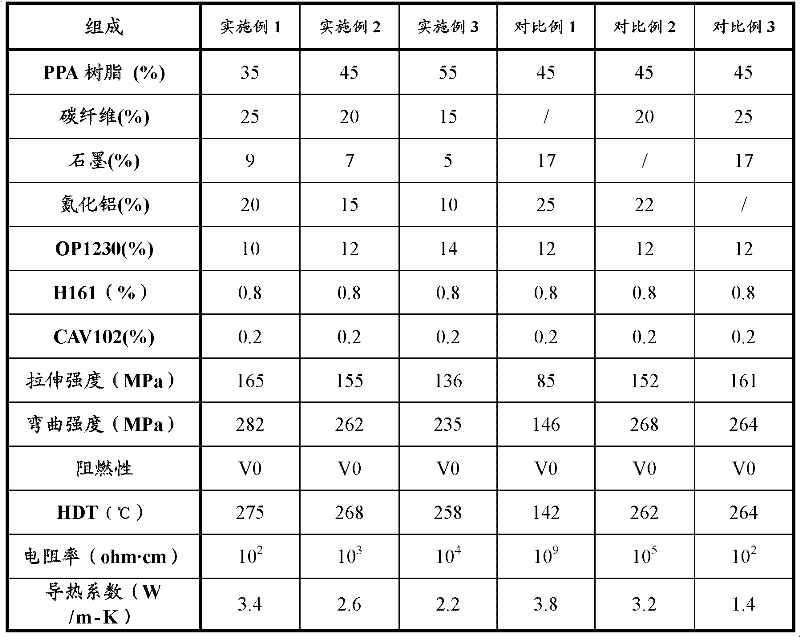

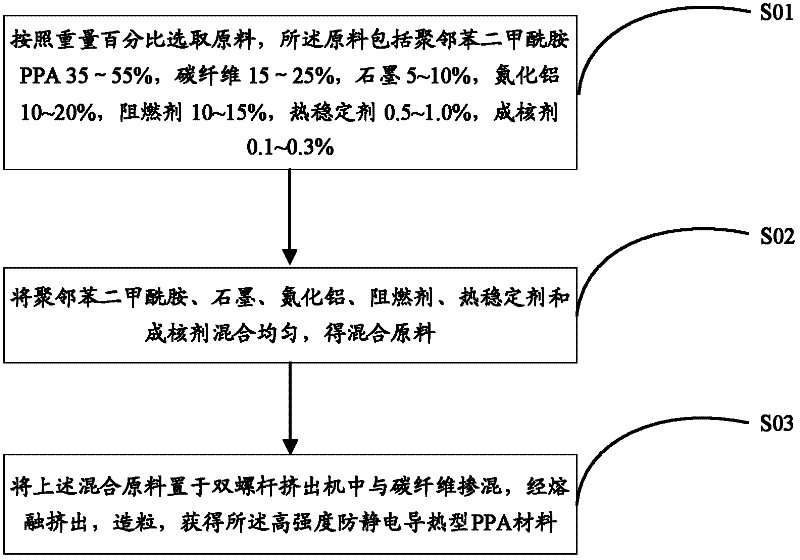

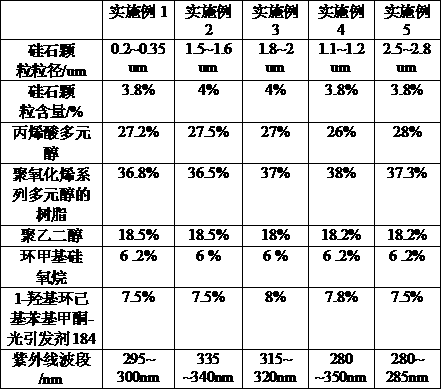

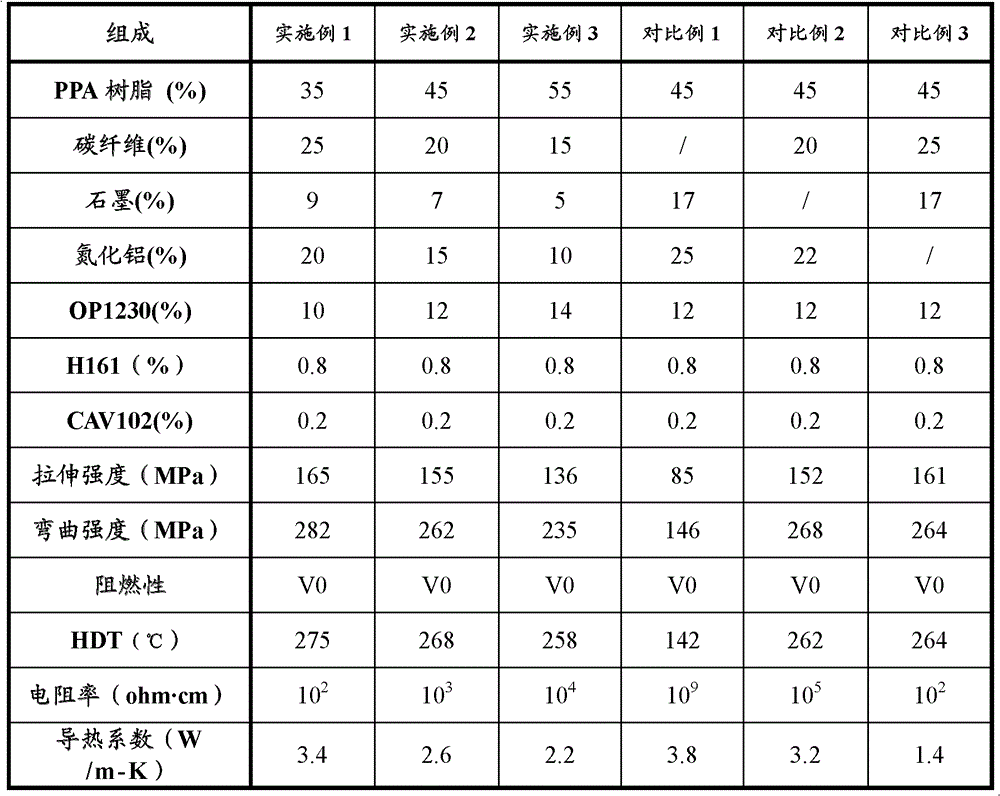

High-strength antistatic heat-conductive PPA (Polyphthalamide) material and preparation method of same

The invention provides a high-strength antistatic heat-conductive PPA (Polyphthalamide) material containing the components in percent by weight as follows: 35-55% of PPA, 15-25% of carbon fiber, 5-10% of graphite, 10-20% of aluminium nitride, 10-15% of fire retardant, 0.5-1.0% of heat stabilizer and 0.1-0.3% of nucleating agent. The invention also provides a preparation method of the high-strength antistatic heat-conductive PPA material. The preparation method includes the steps as follows: selecting the materials in percent by weight as above; mixing the PPA, the graphite, the aluminium nitride, the fire retardant, the heat stabilizer and the nucleating agent to be uniform, thus obtaining a mixed raw material; placing the mixed material in a double-screw extruder and doping the mixed material with the carbon fiber; and then conducting melt extrusion and granulation to obtain the high-strength antistatic heat-conductive PPA material. The product made of the PPA material is high in mechanical strength, excellent in heat resistance and difficult to burn and has an antistatic effect; besides, the product made from the PPA material has a high heat-conducting effect.

Owner:SHENZHEN KEJU NEW MATERIAL

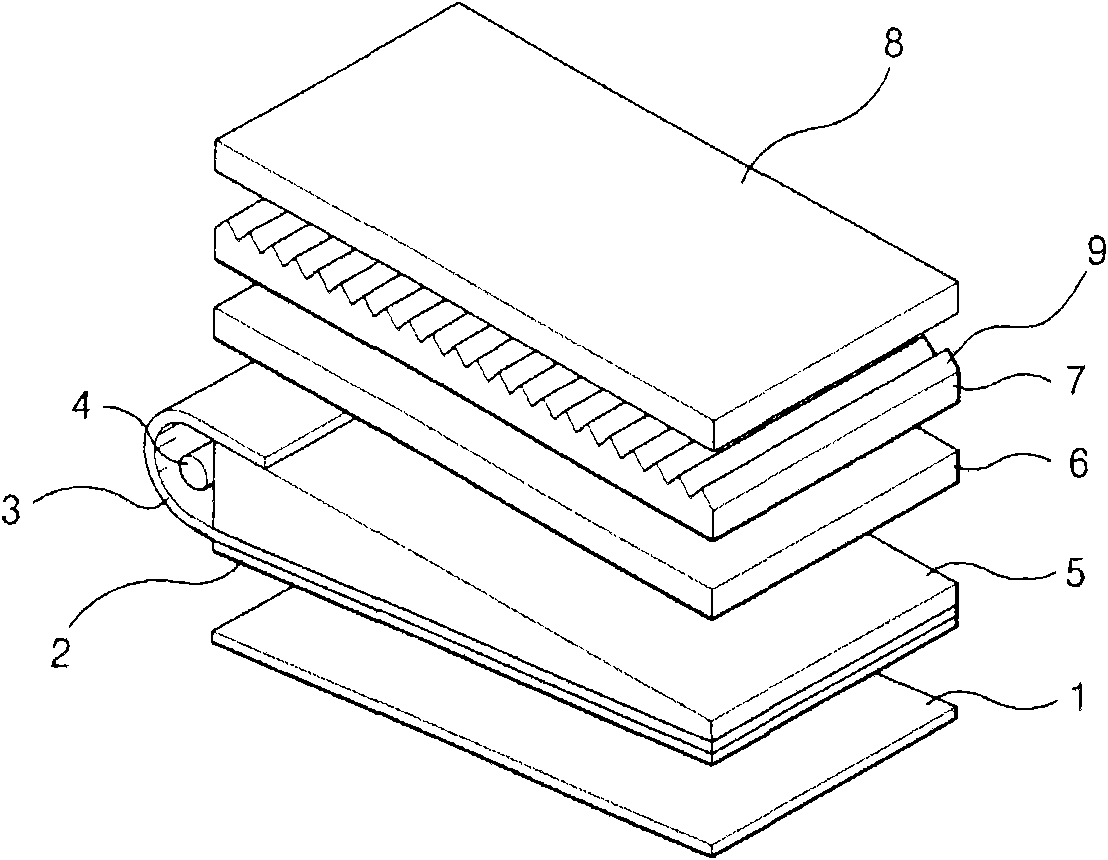

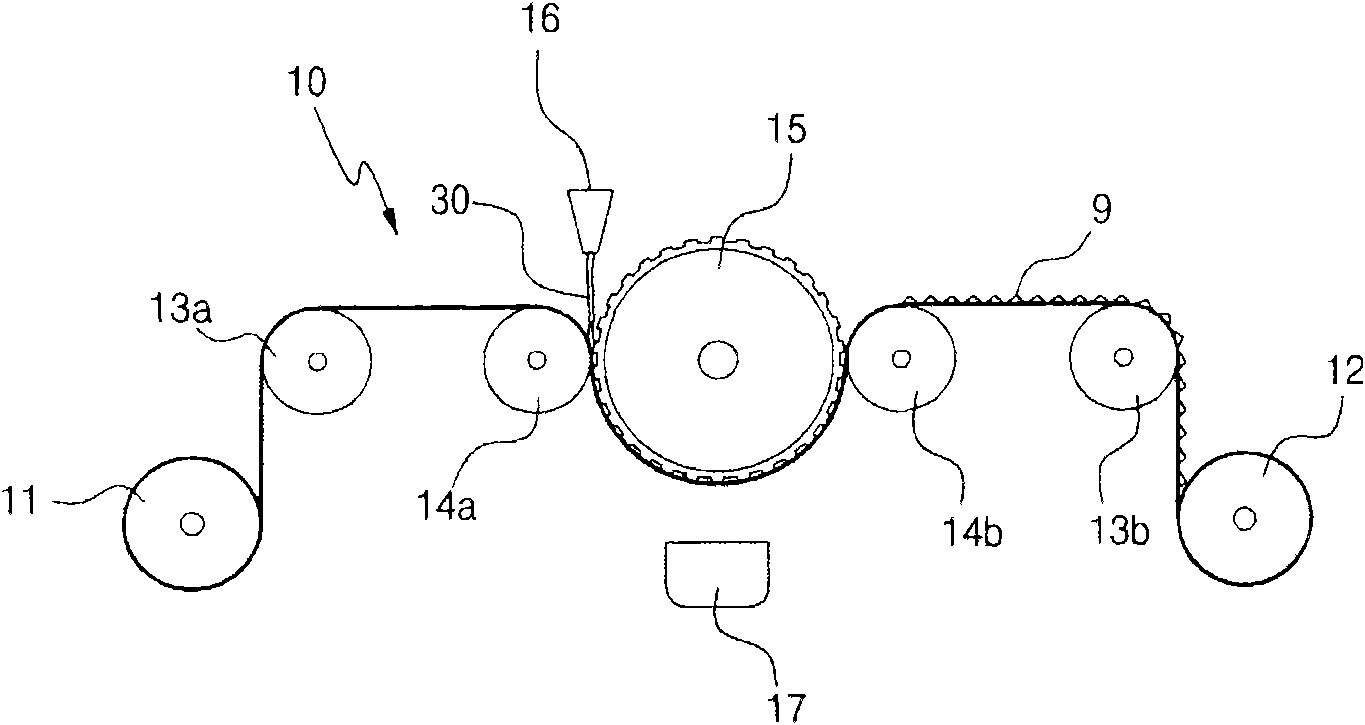

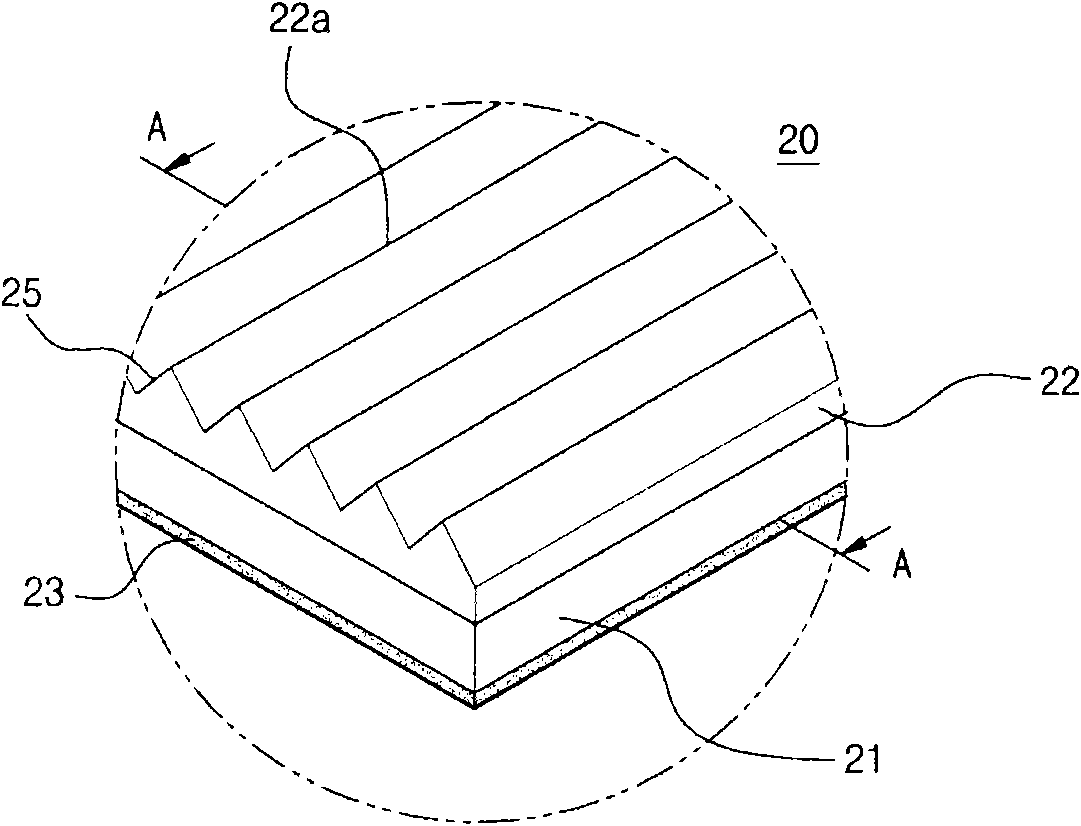

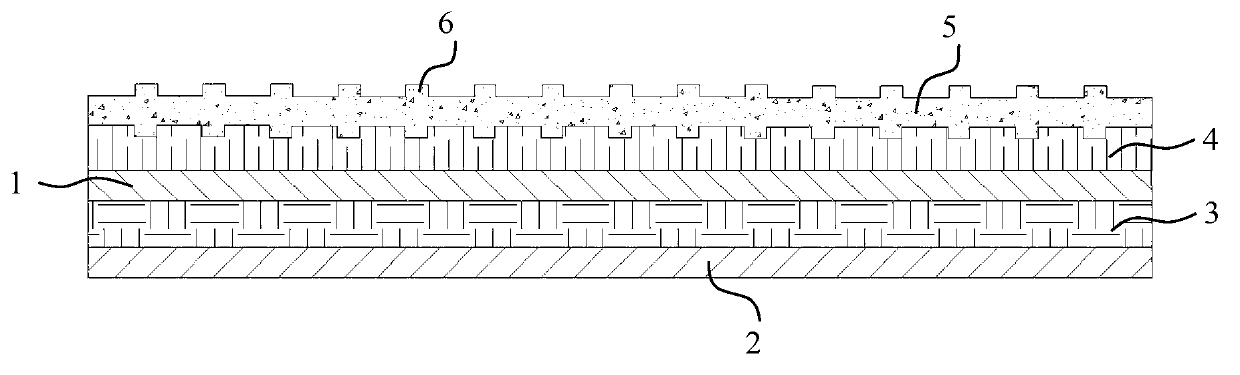

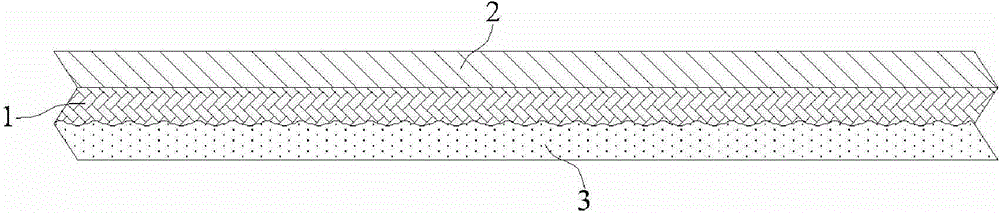

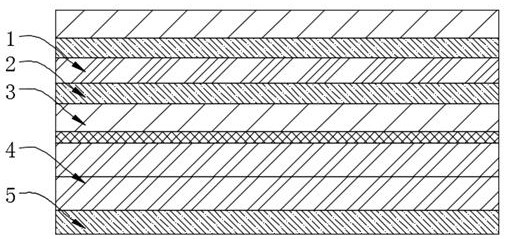

Optical prism sheet for backlight module

ActiveCN101839441AHigh hardnessReduce generationLamination ancillary operationsLaminationLiquid-crystal displayAdhesive

The invention relates to the field of liquid crystal displays, and provides an optical prism sheet for a backlight module. The optical prism sheet comprises a base material layer, a light condensing layer and an anti-scratching layer, wherein the base material layer is made of a light-transmitting material; the light condensing layer is formed on the upper side of the base material layer and comprises a plurality of structured graphs at predetermined intervals; and the anti-scratching layer is on the lower side of the base material layer and forms a thickness of 0.1 to 3mu m by using a nanoparticle-containing ultraviolet curing adhesive. The scratch resistance of the lower side of the prism sheet is improved and the rigidity, distortion resistance and bend resistance of the improved prism sheet for the backlight module are improved by coating the nanoparticle-containing curing adhesive on the lower side of the base material layer with the structured graphs.

Owner:CCS (SHANGHAI) FUNCTIONAL FILMS IND CO LTD

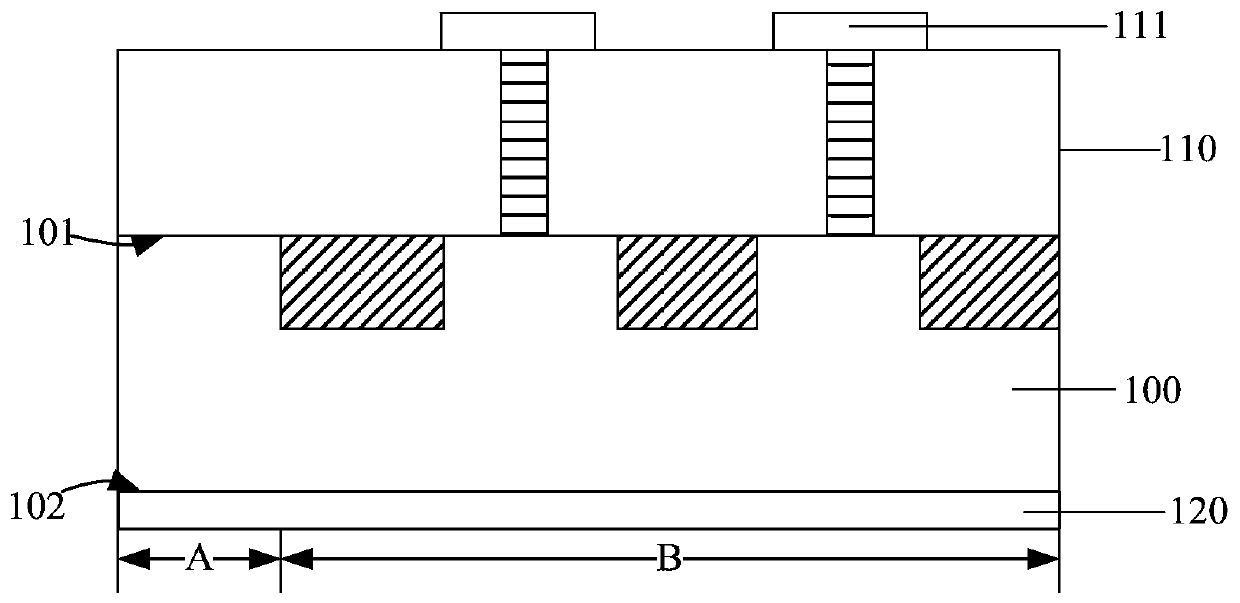

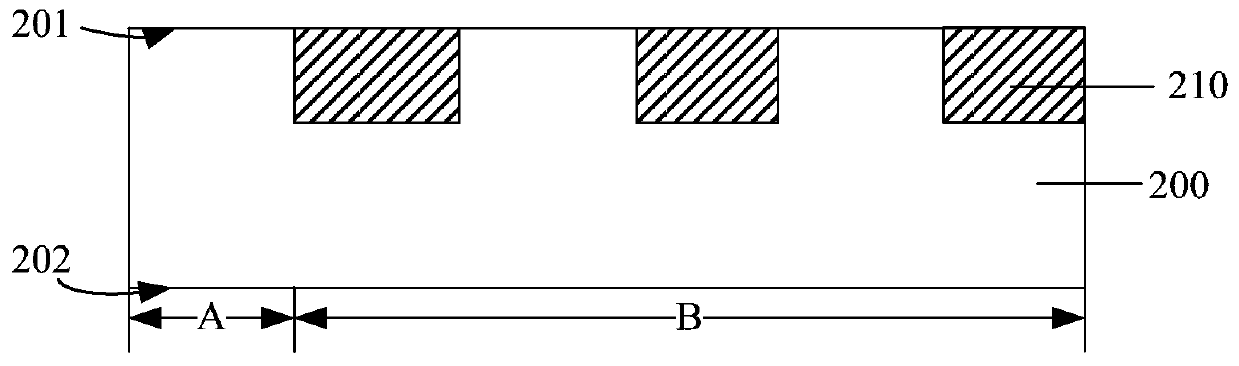

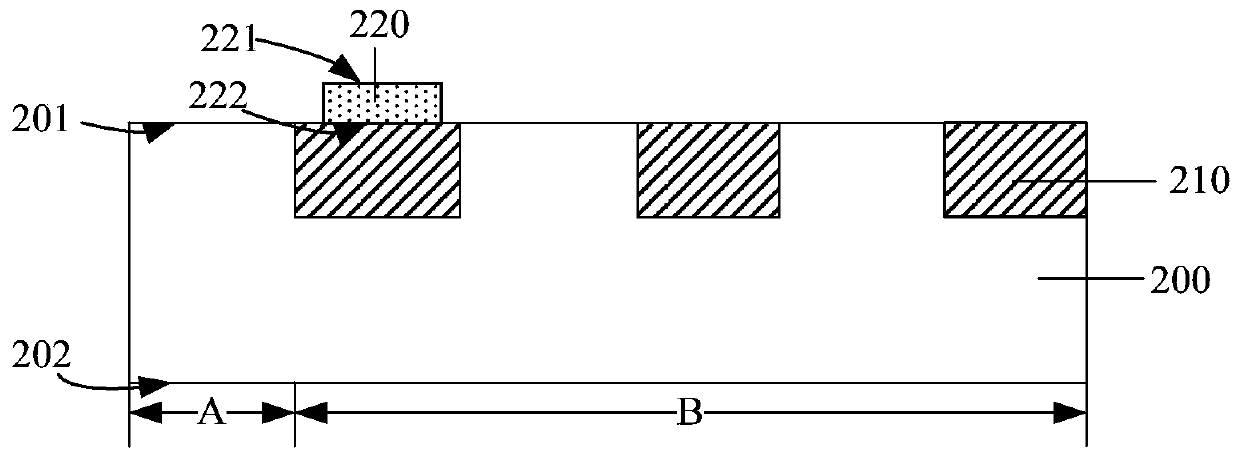

Semiconductor structure and method for forming same

InactiveCN109830464AAvoid damageWith anti-static effectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureEngineering

A semiconductor structure and a method for forming the same are disclosed. The semiconductor structure comprises a first substrate including a plurality of device regions and a plurality of sealing ring regions, wherein each device region is surrounded by the corresponding sealing ring region, and the first substrate includes opposing first and second faces; a first device layer located on the surface of the first face of the plurality of device regions and the plurality of sealing ring regions of the first substrate and including a first conductive layer on the surface of the first face of the sealing ring regions of the first substrate; a first plug located in the sealing ring regions of the first substrate and electrically connected to the first conductive layer, wherein the second faceof the first substrate exposes the first plug; and a second conductive layer on the surface of the second face of the sealing ring regions of the first substrate and connected to the first plug. Thesemiconductor structure has a shielding and antistatic effect.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Oil-free antistatic pearl cotton

The invention relates to oil-free antistatic pearl cotton prepared by foaming the following materials by mass: 75%-85% of high pressure polyethylene, 3%-10% of degreased masterbatch and 3%-10% of antistatic masterbatch; in the making process, butane gas with the mass ratio of 8%-12% is introduced for foaming. The oil-free antistatic pearl cotton prepared from the materials does not appear the phenomenon of infiltration of grease in the late use, and may not pollute parts; by the use of the antistatic masterbatch, the prepared oil-free antistatic pearl cotton has good antistatic effect, may not absorb dust and fine particles, and can ensure the parts are not polluted by dust, the oil-free antistatic pearl cotton can be prepared into foam packing bags by post processing, and the foam packing bags are used to package some electronic products such as TV, mobile phones, LCD panels and the like, ensures that the surface of the electronic product may not stick to grease and dust layer, and ensures the normal operation of electrical components of the electronic products.

Owner:ZHANGJIAGANG SANYING NEW TYPEPACKING MATERIAL CO LTD

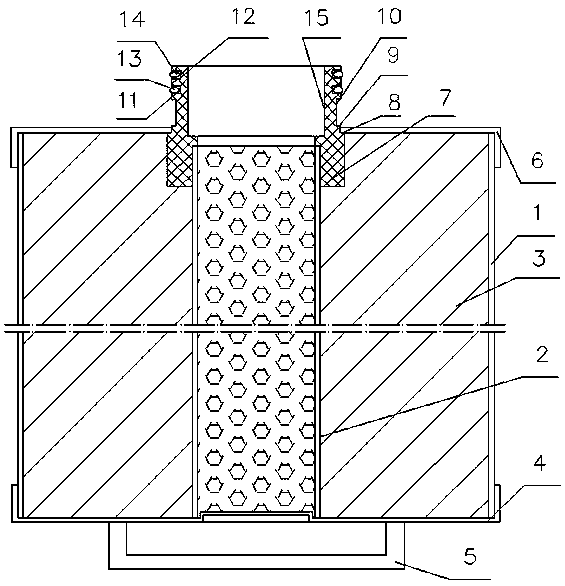

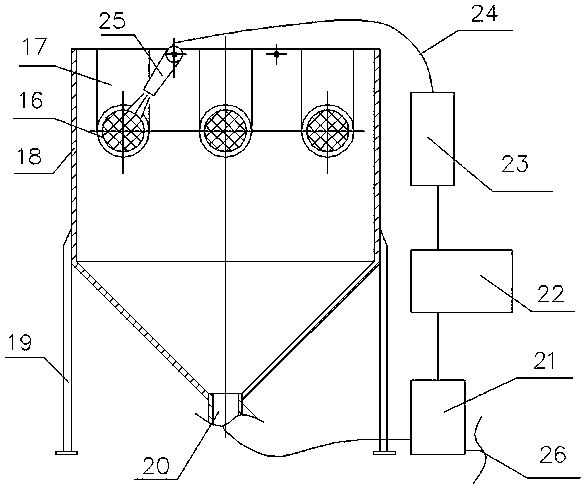

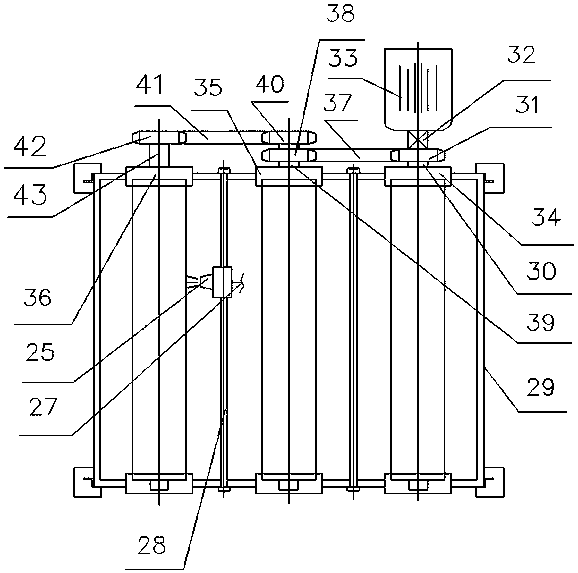

Large-flow recycling filter element and matched cleaning process equipment and operation method

ActiveCN109675371AImprove cleaning rateReduce cleaning costsFilter regenerationProcess equipmentEngineering

The invention discloses a large-flow recycling filter element and matched cleaning process equipment and an operation method. The product comprises an outer support barrel, wherein an inner support barrel is mounted in the outer support barrel, a filter material is contained between the outer support barrel and the inner support barrel, the bottom of the outer support barrel is connected with a lower end cover connected with a support frame, the top of the inner support barrel is connected with a sealing head, the sealing head is connected with an upper end cover, the upper end cover is connected with the outer support barrel, and the outer support barrel, the inner support barrel, the filter material and the sealing head constitute a cleaning filter element. The equipment is used for filter element cleaning.

Owner:大庆净达环保科技有限公司

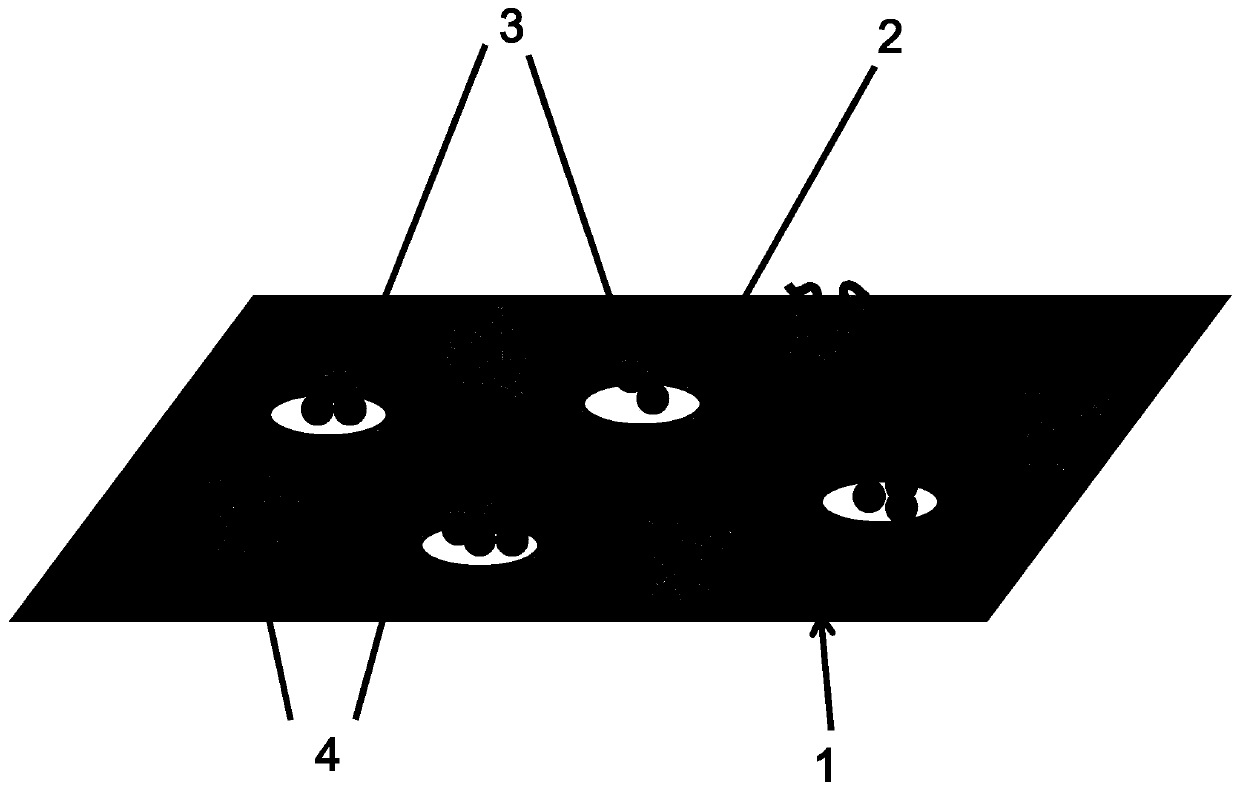

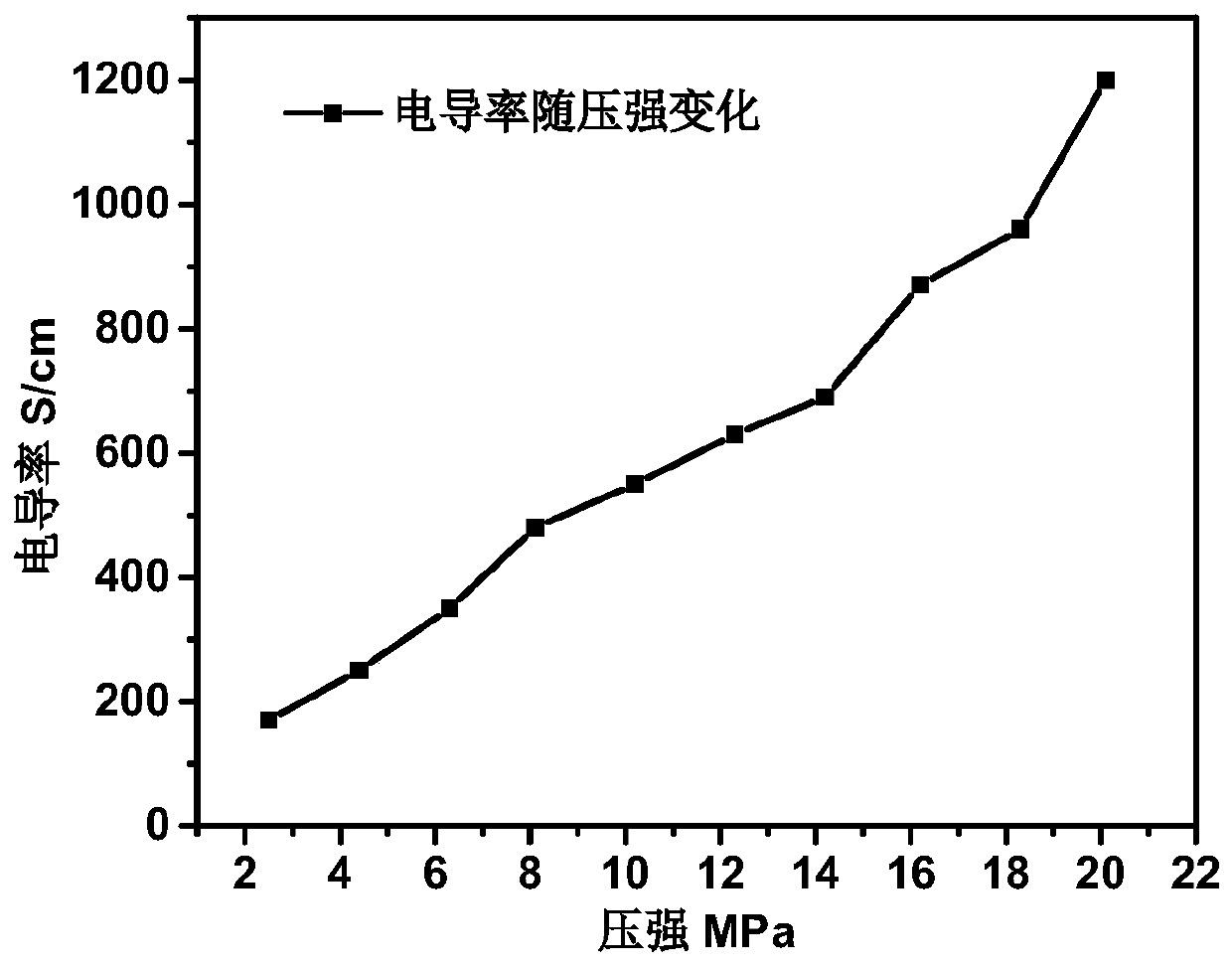

Efficient graphene-based conductive additive and preparation method thereof

The invention discloses an efficient graphene-based conductive additive and a preparation method thereof. Nano carbon black with a specific DBP value is selected and compounded with reduced graphene oxide in a specific ratio, and the nano carbon black with different DBP values is distributed in different regions of the surface of the reduced graphene oxide to form a unique nanocomposite structure,which exhibits excellent electrical conductivity. On one hand, the nano carbon black with the different DBP values repairs in-plane defects of graphene and improves the interfacial conductivity of graphene sheets and other materials, and on the other hand, the coverage of nano carbon black reduces the stacking among the graphene sheets and improves the dispersibility of the conductive additive.

Owner:HANGZHOU GAOXI TECH CO LTD

Anti-static clothing fabric

InactiveCN108162511APromote circulationImprove insulation effectSynthetic resin layered productsClothingsCarboxymethyl celluloseAntistatic agent

The invention discloses an anti-static clothing fabric which is characterized in that the clothing fabric is respectively provided with a first fabric layer, a second fabric layer and a third fabric layer from the inside to the outside, and the first fabric layer is a warm-keeping moisture-guiding layer. The second fabric layer is an antistatic layer, the third fabric layer is an antibacterial andwear-resistant layer; the warm-keeping moisture-guiding layer includes antibacterial moisture-guiding fiber and seaweed carbon fiber; the antistatic layer includes cotton fiber and conductive fiber,and is added with some carboxymethyl cellulose, and the antibacterial and wear-resistant layer includes polyamide fiber, elastic fiber and lignin fiber. The antistatic clothing fabric can play a roleof keeping warm on the basis of antistatic effects, is not easy to damage, increases the antibacterial effect, and protects human health based on the promotion of the overall grade of the clothing fabric.

Owner:HUAINAN FUHUA CLOTHING CO LTD

Far-infrared paint and preparation method thereof

The invention provides a far-infrared coating, which is made from raw materials according to the following weight proportion: 25 to 30 of acrylonitrile, 20 to 30 of methyl acrylate, 10 to 15 of vinyl acetate, 10 to 15 of methyl methacrylate, 10 to 15 of ethyl acrylate, 10 to 20 emulsion particle and 5 to 15 of far-infrared materials. The coating of the invention can generate far-infrared ray, is good for physical health, has antibacterial and antistatic effects with low cost and simple production technique, and is especially suitable for indoor coating.

Owner:张玉明

UV transfer printing process for wall decorative sheet

InactiveCN108177474ADifficult to breedImprove sound insulationDecorative surface effectsPretreated surfacesBenzeneUltraviolet

The invention relates to a UV transfer printing process for a wall decorative sheet. The process comprises the following steps: (1) processing a substrate; (2) carrying out roller painting on the front surface; (3) carrying out transfer printing; and (4) carrying out film covering. No harmful gas such as formaldehyde and benzene are released in the process, so that the process is green and environment-friendly. By adopting a product with inorganic and fluorocarbon coatings, the anti-ultraviolet property of the product in an application of an exterior wall is improved greatly; the product is smooth in surface and is coated with a special antibacterial coating, so that bacteria are unlikely to breed, and the product shows an excellent antibacterial performance; a panel is high in areal density and has a good sound isolating property, and a cavity is formed in a mounting system to achieve a sound absorbing effect; by adopting a special antistatic coating, the surface of the product has the antistatic function; the cold and hot expansion shrinkage coefficient is small, and the size of the panel is scarcely changed as the temperature changes. The process provided by the invention is good in durability, light in weight, easy to clean, energy-saving and environment-friendly, easy to process, waterproof and excellent in drug resistance.

Owner:江苏建院欧野科技有限公司

A kind of healthy polyolefin foam material and preparation method thereof

The invention relates to a healthy polyolefin foam material and a preparation method thereof, which is prepared by mixing, melting and extruding, preheating and foaming the following raw and auxiliary materials in mass ratio: 70-100 parts of polyolefin resin, negative ion functional master 20-50 parts of raw material, 15-30 parts of hydrophilic functional masterbatch, 1-5 parts of foaming agent, 1-5 parts of cross-linking agent, and 0-5 parts of color masterbatch. The health-type polyolefin foam material of the present invention adds negative ion mineral materials and hydrophilic fullerene compounds into the formula, and has the advantages of air purification, surface anti-greasy, anti-static effects and the like. Utilizing the pyroelectricity and piezoelectricity of negative ion mineral materials can effectively increase the concentration of negative ions in the surrounding environment. At the same time, the hydrophilic group of the hydrophilic fullerene compound can form a hydrogen bond with water, which cuts off the connection between the pollutant and the polyolefin surface, and can also quickly leak the accumulated static charge to achieve the purpose of antistatic.

Owner:TAISHAN SPORTS IND GRP +1

Antistatic transparent adhesive tape

InactiveCN103614093AStrong stickinessWith anti-static effectFilm/foil adhesivesPolypropyleneViscosity

The invention discloses an antistatic transparent adhesive tape. The antistatic transparent adhesive tape is obtained by bonding a BOPP film, glue and an adhesive, the BOPP film is made by using a base cloth and a conductive filler, the base cloth is a polypropylene material, the conductive filler is formed by carbon black and talcum powder, the glue is acrylate glue, the adhesive is a white latex, and the glue and the BOPP film are bonded by the adhesive. By adopting the above mode, the obtained adhesive tape has a strong viscosity and has an antistatic efficacy.

Owner:KUNSHAN HANBAO TAPE TECH

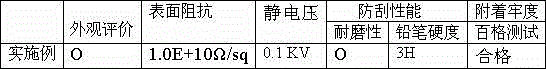

Static electricity resistant anticorrosive paint and preparation method thereof

InactiveCN102344723AMaintain metallic lusterWith anti-static effectAnti-corrosive paintsIodidePolyvinyl alcohol

The invention discloses a static electricity resistant anticorrosive paint and a preparation method thereof. The paint is prepared form the following steps: dissolving polyvinyl butyral in ethanol with stirring to obtain a 5-25wt% polyvinyl butyral solution; adding auxiliaries being 5-28wt% of the polyvinyl butyral into the solution and stirring for 50-80 min; adding corrosion inhibitor being 2-8wt% of the polyvinyl butyral into the prepared solution and stirring to complete dissolve; adding molybdate or iodide being 2-6wt% of the polyvinyl butyral into the prepared solution with stirring and stirring for 50-80 min. The environment-friendly paint of the invention can be applied to non-ferrous metal surface treatment, has good protective and anticorrosive effects and can keep original metal luster; a surface drying speed is fast with a time of 13-18 min; the coating has flattening and light appearance, good adhesion, high hardness, good salt spray resistance and antistatic effect.

Owner:江苏海云花新材料有限公司

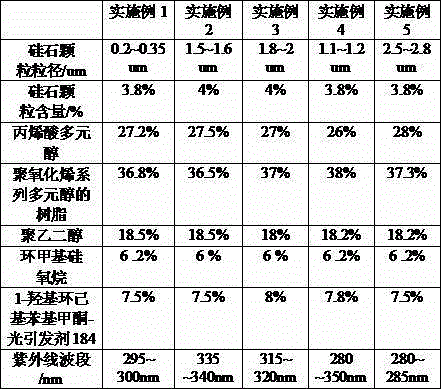

Mist antistatic agent for release liner

ActiveCN103103875AImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionRelease paperPolyethylene glycolEngineering

The invention discloses a mist antistatic agent for a release liner. The release liner comprises a body paper layer with the upper surface and the lower surface laminated with a PE (polyethylene) film and a PET (polyethylene glycol terephthalate) film respectively, the other surface of the PET film on the body paper layer is coated with a mist antistatic coating, the other surface of the mist antistatic coating is coated with a mold release coating, the mist antistatic coating is formed by coating the mist antistatic agent, the mist antistatic agent comprises the following components according to mass percentage: 3.8-4.2% of silica granules, 26-28% of crylic acid polyhydric alcohols with average molecular weight of 500-2000, 36-38% of resin of oxyalkylene polyhydric alcohols, 17.5-18.5% of polyethylene glycol, 5.8-6.2% of cyclic dimethyl siloxane, and 7.5-8.5% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184. According to the mist antistatic agent, the problem of poor binding force and release force of the laminated layer of the release paper and the mold release coating is solved, and the antistatic property and scratch resistance of the film surface are improved.

Owner:斯迪克新型材料(江苏)有限公司

High-strength antistatic heat-conductive PPA (Polyphthalamide) material and preparation method of same

The invention provides a high-strength antistatic heat-conductive PPA (Polyphthalamide) material containing the components in percent by weight as follows: 35-55% of PPA, 15-25% of carbon fiber, 5-10% of graphite, 10-20% of aluminium nitride, 10-15% of fire retardant, 0.5-1.0% of heat stabilizer and 0.1-0.3% of nucleating agent. The invention also provides a preparation method of the high-strength antistatic heat-conductive PPA material. The preparation method includes the steps as follows: selecting the materials in percent by weight as above; mixing the PPA, the graphite, the aluminium nitride, the fire retardant, the heat stabilizer and the nucleating agent to be uniform, thus obtaining a mixed raw material; placing the mixed material in a double-screw extruder and doping the mixed material with the carbon fiber; and then conducting melt extrusion and granulation to obtain the high-strength antistatic heat-conductive PPA material. The product made of the PPA material is high in mechanical strength, excellent in heat resistance and difficult to burn and has an antistatic effect; besides, the product made from the PPA material has a high heat-conducting effect.

Owner:SHENZHEN KEJU NEW MATERIAL

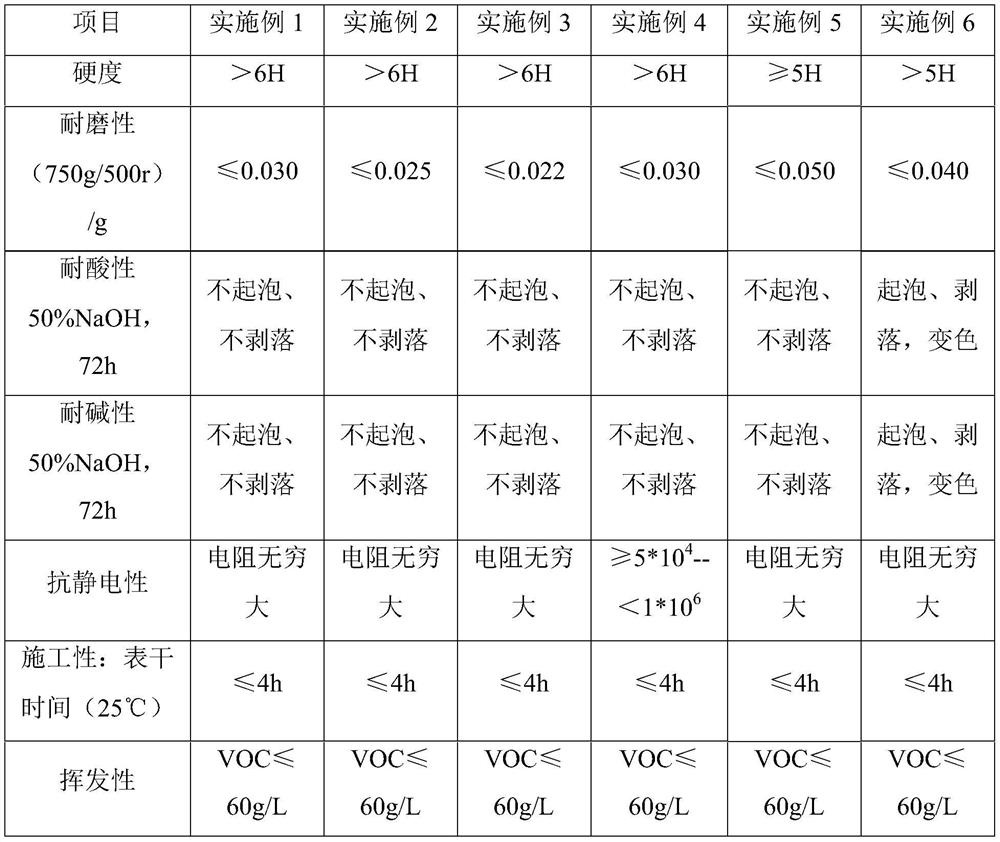

Super-wear-resistant coating for ground decoration and preparation method thereof

PendingCN112898868AGood hardnessExtended service lifeEpoxy resin coatingsElectrically-conductive paintsDefoaming AgentsFirming agent

The invention discloses a super-wear-resistant coating for ground decoration and a preparation method thereof. The super-wear-resistant coating for floor decoration comprises a component A and a component B. The component A comprises epoxy resin, amino resin, alkyl glycidyl ether, filler, a defoaming agent, a flatting agent, a silicon-aluminum compound and optional color paste and conductive powder; and the component B comprises a modified amine curing agent, wherein the coating is prepared from the following components in parts by mass: 30 to 50 parts of epoxy resin, 2 to 4 parts of amino resin, 3 to 5 parts of alkyl glycidyl ether, 15 to 25 parts of filler, 0.2 to 0.8 part of defoaming agent, 0.2 to 0.8 part of flatting agent, 10 to 20 parts of silicon-aluminum compound, 0 to 10 parts of color paste, 0 to 15 parts of conductive powder and 15 to 25 parts of modified amine curing agent. The super-wear-resistant coating for ground decoration has better hardness, wear resistance and chemical resistance, and the service life of a ground decoration material is prolonged.

Owner:沈阳美狮化工有限公司

Conductive glove and preparation process thereof

InactiveCN113498899AWith conductive effectWith anti-static effectGlovesProtective garmentYarnPolymer science

The invention discloses a conductive glove and a preparation process thereof. The glove comprises a glove blank. The palm surface of the glove blank is impregnated with an impregnation layer. The impregnation layer is prepared from, by mass, 70-90 parts of composite latex, 15-30 parts of conductive carbon black, 1.5-2.5 parts of sulfur, 1.5-2.5 parts of zinc oxide, 2-3 parts of an accelerant, 0-2 parts of a degerming additive and 2-3 parts of a reinforcing agent. The glove blank comprises the following components in parts by mass: 50-60 parts of aramid fiber / graphene chinlon covering yarns, 20-30 parts of electro-coppering nylon yarns and 10-20 parts of silk soft spinning soft yarns. The glove prepared in the invention not only has conductive and anti-static functions, but also is comfortable to wear and good in wear resistance, tear strength, tensile strength and aging resistance.

Owner:HONGHAN NANTONG PROTECTION OF SCI &TECH CO LTD

Release film with small release force

InactiveCN104788637AImprove surface antistatic performanceLow wear resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsBinding forcePhenyl ketone

The invention discloses a matte release agent used for mold release material. The matte release agent is arranged between a release film and a mold release agent layer and comprises the following components in percentage by weight: 2%-6% of silica particles, 20%-30% acrylic polyol with average molecular weight of 500-2000, 35%-45% of polyoxyalkylene series polyol resin with molecular weight of 200-2500, 15%-20% of polyethyleneglycol, and 5%-10% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184; wherein the particle diameters of the silica particles have peak values in ranges of 0.1-0.2 um and 1.5-5 um respectively and the average particle diameter is 4 um or less, according to the particles distribution of the silica particles measured by a laser diffraction scattering method. According to the matte release agent provided by the invention, the binding force between a lamination layer of a release paper and the mold release agent is improved, the release force is stable, the anti-static performance of the film surface is improved, and the scratch resistance is simultaneously improved.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Matte release agent used for mold release material

ActiveCN103046432AImprove surface antistatic performanceImprove anti-static performanceCoatingsCoatings without pigmentsSilica particlePolyol

The invention discloses a matte release agent used for mold release material. The matte release agent is arranged between a release film and a mold release agent layer and comprises the following components in percentage by weight: 2%-6% of silica particles, 20%-30% acrylic polyol with average molecular weight of 500-2000, 35%-45% of polyoxyalkylene series polyol resin with molecular weight of 200-2500, 15%-20% of polyethyleneglycol, and 5%-10% of 1-hydroxy cyclohexyl phenyl ketone-photoinitiator 184; wherein the particle diameters of the silica particles have peak values in ranges of 0.1-0.2 um and 1.5-5 um respectively and the average particle diameter is 4 um or less, according to the particles distribution of the silica particles measured by a laser diffraction scattering method. According to the matte release agent provided by the invention, the binding force between a lamination layer of a release paper and the mold release agent is improved, the release force is stable, the anti-static performance of the film surface is improved, and the scratch resistance is simultaneously improved.

Owner:太仓斯迪克新材料科技有限公司

Alga softener and production method thereof

InactiveCN107964794AEnvironmentally friendly and non-toxicWith cleanGrip property fibresEnvironmental resistanceNon toxicity

The invention relates to a daily chemical product, in particular to a softener. A seaweed softening agent, the weight ratio of each component is: seaweed extract: 10-30 parts, polydimethylsiloxane diquaternary ammonium salt: 10-20 parts, sodium alginate: 5-15 parts, polyethylene glycol Alcohol: 5‑15 parts, Serine: 1‑3 parts, Zinc Oxide: 2‑3 parts, Lignin: 2‑5 parts, Boric acid: 0.5‑2 parts, Deionized water: 100 parts. The present invention combines these active substances with traditional softeners to make a seaweed softener with certain cleaning, protection and anti-static effects. A small amount of use can make the fabric clean and sterile, soft and smooth, flat and docile, in addition In addition, it also has the advantages of environmental protection and non-toxicity.

Owner:肖国华

Anti-scratch matte anti-static release paper

ActiveCN103074819BImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionSynthetic resin layered productsSilica particlePolyol

The invention discloses an anti-scuffing matt-surface antistatic release paper. The anti-scuffing matt-surface antistatic release paper comprises a release raw paper and a film layer. The other surface of the film layer is coated with a matt-surface antistatic layer having thickness of 0.2 to 2 micrometers. The other surface of the matt-surface antistatic layer is coated with a silicone oil layer. The surface of the matt-surface antistatic layer contacting with the silicone oil layer is provided with multiple concave and convex points. The matt-surface antistatic layer comprises 2 to 6% of silica particles, 20 to 30% of acrylic polyol having average molecular weight of 500 to 2000, 35 to 45% of polyoxyalkylene polyol having average molecular weight of 200 to 2500, 15 to 20% of polyethylene glycol, 4 to 8% of cyclomethyl siloxane, and 5 to 10% of 1-hydroxycyclohexylphenyl ketone-photoinitiator 184. The anti-scuffing matt-surface antistatic release paper solves the problem that the existing release paper has poor adhesion between a lamination layer and a release agent coating and unstable peel strength, improves antistatic performances of the film surface, and improves scuffing resistance.

Owner:斯迪克新型材料(江苏)有限公司

Oil-proof, stain-resistant and flame-retardant composite fiber fabric

InactiveCN113290951AMildew proofWith anti-static effectBiochemical fibre treatmentLaminationPolymer scienceNonwoven fabric

The invention discloses an oil-proof, stain-resistant and flame-retardant composite fiber fabric which comprises a basic fabric, flame-retardant layers are arranged on the upper surface and the lower surface of the basic fabric, waterproof and antifouling layers are arranged on the repelling sides of the two flame-retardant layers respectively, and non-woven fabric is arranged below the basic fabric; the fabric has mildew-proof and anti-static effects by soaking the fabric in clear water added with the mildew-proof agent and the anti-static agent, and the fabric is smooth in outer layer and has excellent oil and dirt repellency by adding the flame retardant, the fluoride-free waterproof finishing agent and the fluoride-free water repellent agent and bonding the fabric with the non-woven fabric. According to the invention, oily and water-based dirt cannot permeate into fibers, and dust and dirt can be easily shaken off or brushed away, so that the fabric is kept clean for a long time, and the washing frequency is reduced; in addition, when water drips onto the surface of the fabric, small water drops can be formed or directly slip off from the surface of the fabric, so that the fabric is prevented from absorbing water, and the fabric has waterproofness.

Owner:SIMMONS BEDDING&FURNITURE (SUZHOU) LTD

Matte antistatic agent for release film

ActiveCN103103875BImprove surface antistatic performanceLow wear resistanceNon-fibrous pulp additionRelease paperPolyethylene glycolEngineering

Owner:斯迪克新型材料(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com