Composite fiber filament for nuclear radiation protection and production method of composite fiber filament

A composite fiber and fiber filament technology, applied in textiles, papermaking, yarn and other directions, can solve the problems of low tensile strength of lead fiber filament and lead-based alloy fiber filament, difficulty in automatic weaving, low product strength, etc., and achieve high yield , Excellent nuclear radiation protection performance, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

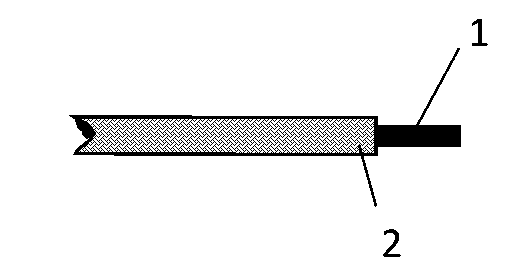

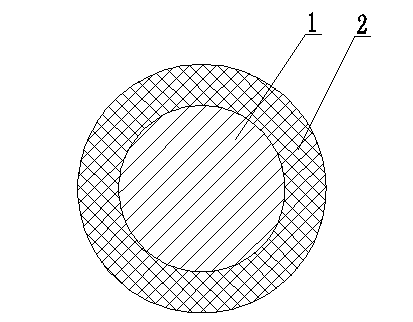

[0018] Example 1: Prepare a lead-based alloy filament with a diameter of 0.5mm and a certain degree of flexibility and tensile strength as the inner core, select 1K carbon fiber as the cladding layer, and perform core-spun braiding on a 16-spindle high-speed braiding machine to obtain lead for nuclear radiation protection. Alloy fiber / carbon fiber composite filament.

[0019] After the composite fiber filaments are tightly woven, their radiation protection performance is tested on a NaI spectrometer, and the radioactive source is Cs-137. After testing, the radiation protection ratio is -6.3%.

Embodiment 2

[0020] Example 2 : The lead-based alloy long fiber wire with a diameter of 0.3mm and the tungsten alloy fiber wire with a diameter of 0.2mm are combined as the inner core, and high-density polyethylene fiber is used as the cladding layer, and core-spun braiding is carried out on a 16-spindle high-speed braiding machine. A lead-based alloy fiber / tungsten alloy fiber / polyethylene fiber composite fiber filament for nuclear radiation protection is obtained. The radiation protection performance test method is as in Example 1. After testing, the radiation protection ratio is -7.4%.

Embodiment 3

[0021] Example 3 : The lead-based alloy long fiber wire with a diameter of 0.3mm is used as the inner core, polyamide fiber is used as the first layer of the coating layer, and polytetrafluoroethylene fiber is used as the second layer, which is carried out twice on a 16-spindle high-speed braiding machine Core-spun braiding to obtain lead-based alloy fiber / polyamide fiber / polytetrafluoroethylene fiber composite fiber filaments for nuclear radiation protection. The radiation protection performance test method is as in Example 1. After testing, the radiation protection ratio is -5.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com