Patents

Literature

85results about How to "Puncture resistant" patented technology

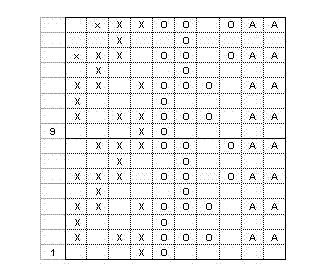

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray polyurea high-performance waterproof paint and preparation method thereof

InactiveCN101818019AFast curingHigh strengthPolyurea/polyurethane coatingsDiluentUltimate tensile strength

The invention relates to a spray polyurea high-performance waterproof paint which is characterized by comprising component A and component B, wherein the component A comprises semi-prepolymer formed by the reaction between 70-35 parts of polyisocyanate and 30-50 parts of polyether glycol, and 0-15 parts of diluent based on parts by weight; the component B comprises 50-70 parts of amine-terminated polyether, 20-40 parts of amine chain extender and 5-10 parts of filler; and the volume ratio between the component A and the component B is 1:1. Compared with the common spray polyurea high-performance waterproof paint, the spray polyurea high-performance waterproof paint has higher tensile strength, elongation at break, tearing strength and other physical properties, and not only is applicable to waterproof projects of common building projects, basic facilities and the like, but also is especially suitable for high-difficulty waterproof projects of large basic facility construction such as a high speed railway, a subway, a tunnel, water conservancy project and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

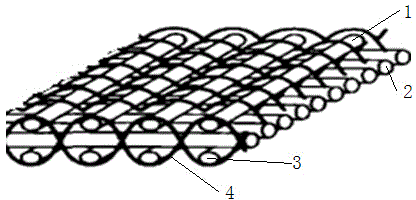

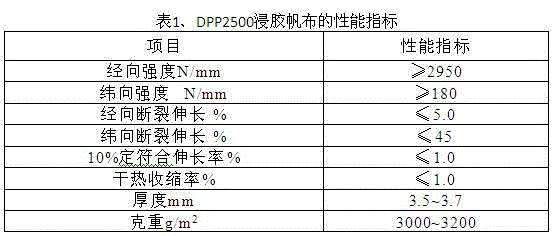

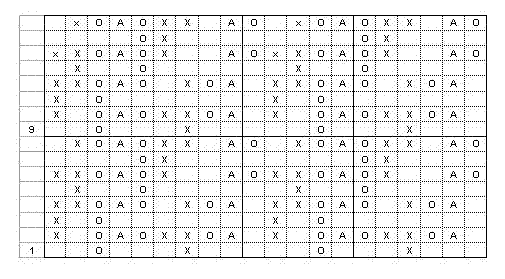

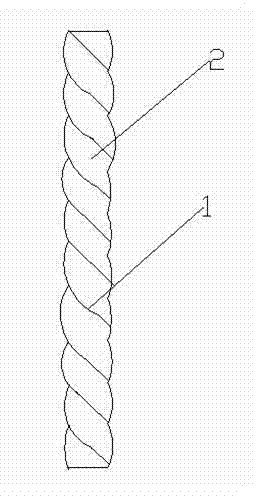

Aramid rubber canvas fabric structure for high-strength conveyor belts and production process of aramid rubber canvas fabric structure

InactiveCN104611819AEasy to weaveGood physical and mechanical propertiesConveyorsMulti-ply fabricsYarnEngineering

The invention discloses an aramid rubber canvas fabric structure for high-strength conveyor belts and a production process of the aramid rubber canvas fabric structure. The aramid rubber canvas fabric structure comprises warps and wefts, aramid materials are adopted in the warps, at least four warps are paved in the belt length direction, nylon industrial yarns are adopted in the wefts which are crisscrossly paved on upper end faces and lower end faces of the warps, the wefts on upper and lower layers are tightly crisscrossly bonded to the warps by adopting bundling yarns, and a canvas fabric structure is obtained after secondary bath gum dipping; the production process includes single-layer canvas knitting, secondary bath gum dipping and reeling. Single-layer structures of the warps adopting the aramid materials and the weft adopting the nylon materials are knitted through bundling yarns, the high-strength conveyor belts with the strength higher than 2500N / mm are produced after secondary bath gum dipping, mechanical physical properties of the conveyor belts are improved, layer reduction and weight reduction of the conveyor belts are realized during the production process, the conveyor belts are adaptively high strengthened, less layered and lightweight, energy consumption is reduced, the production process is further simplified, and production efficiency is higher.

Owner:浙江尤夫科技工业有限公司

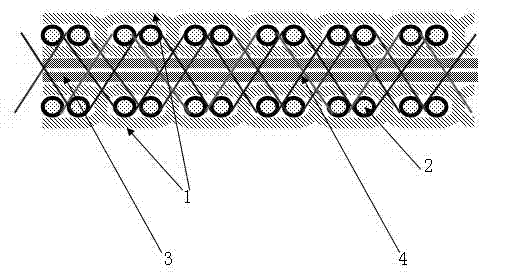

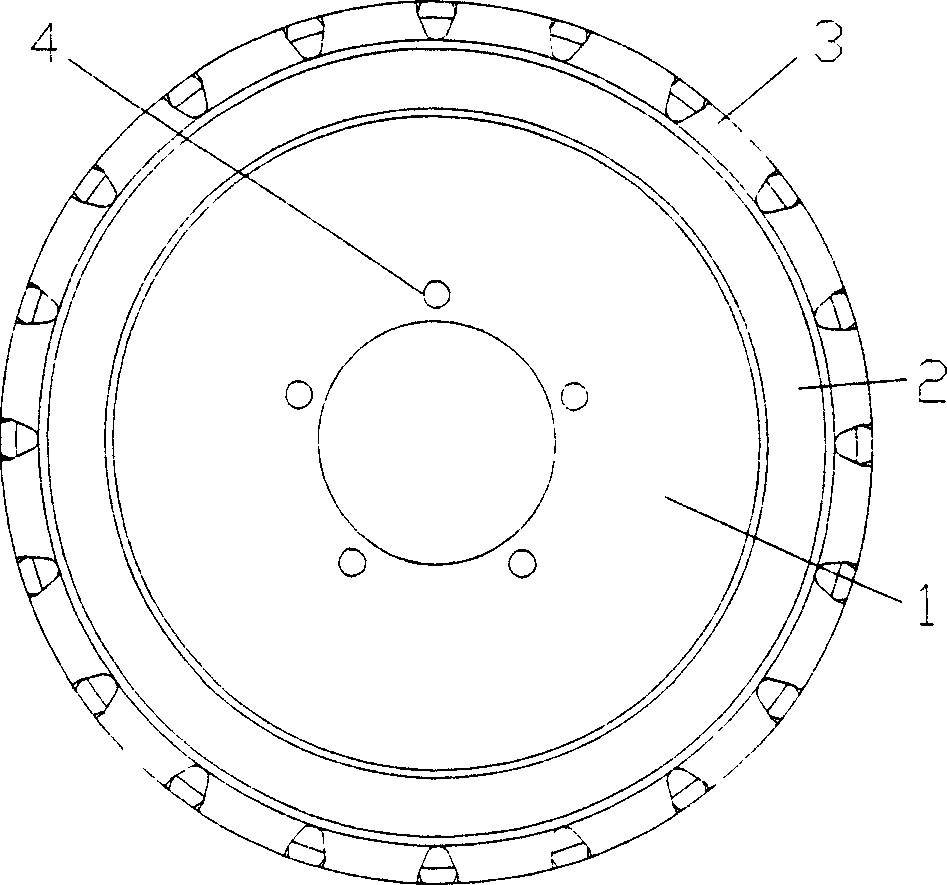

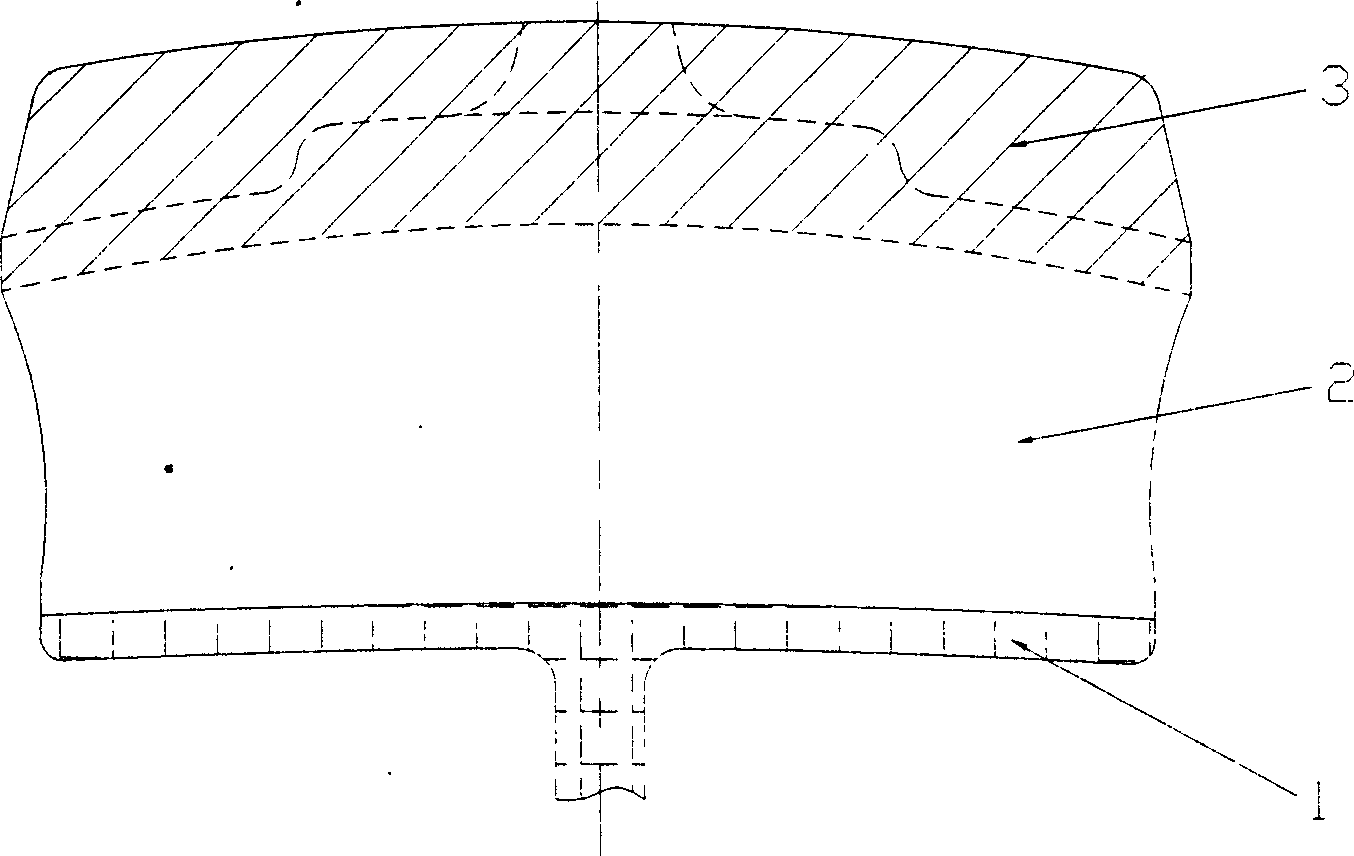

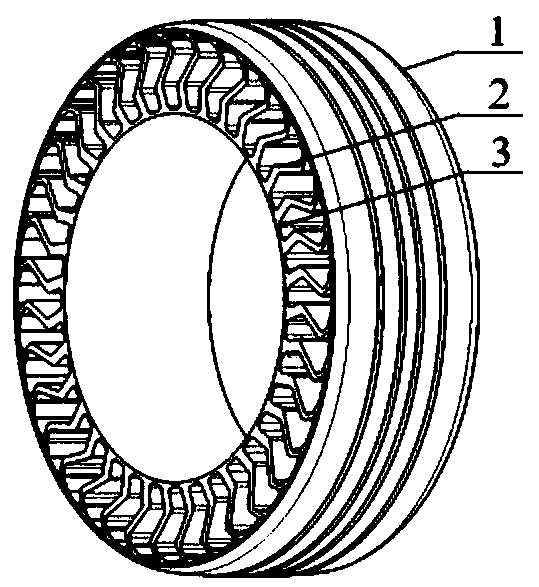

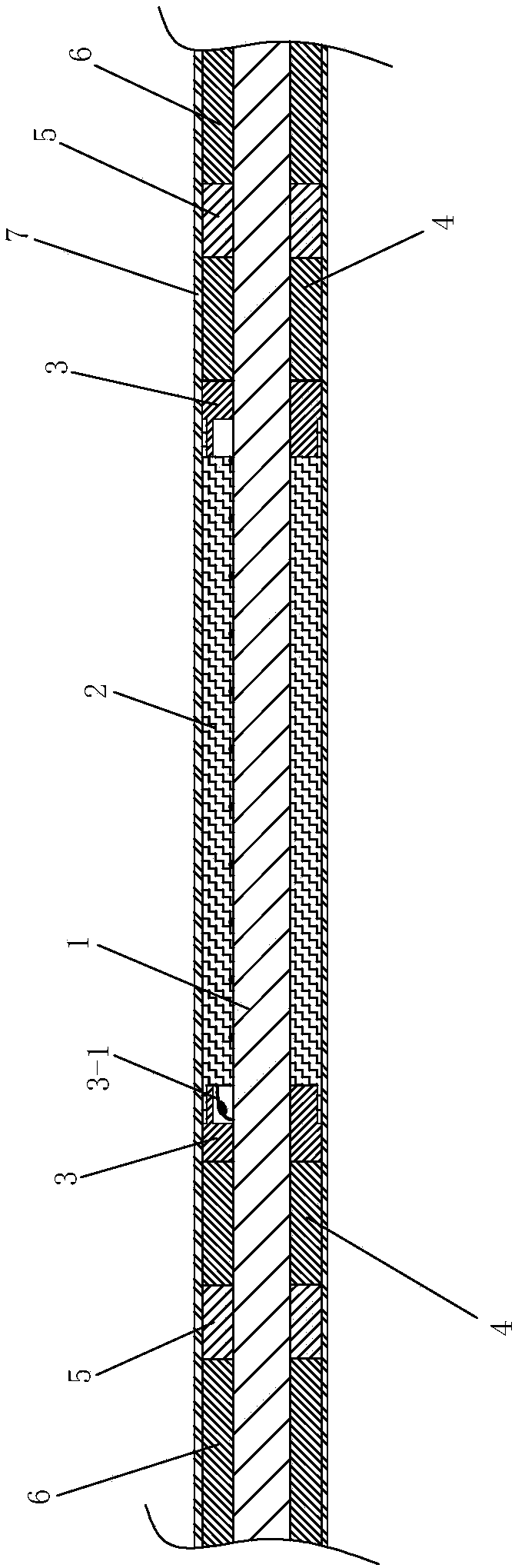

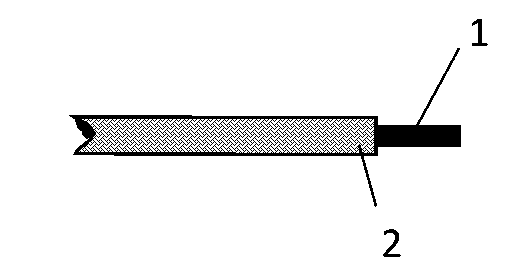

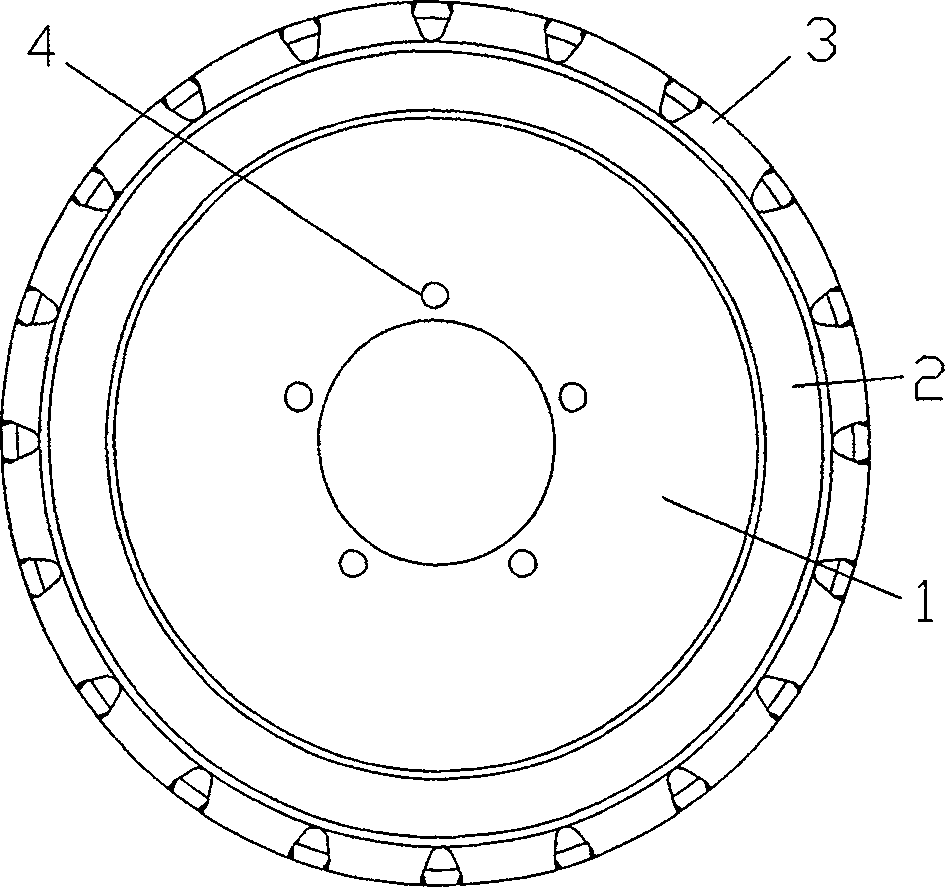

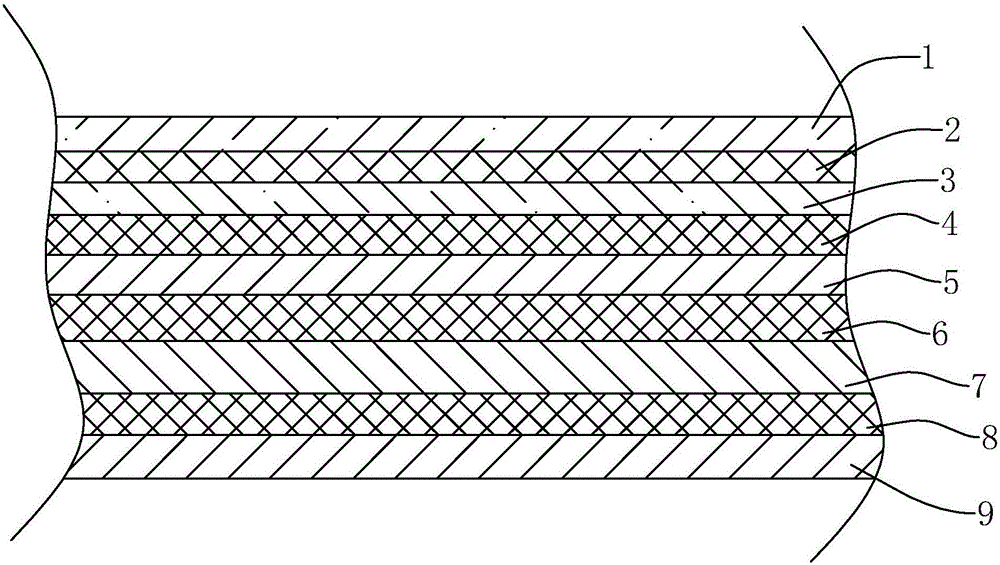

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

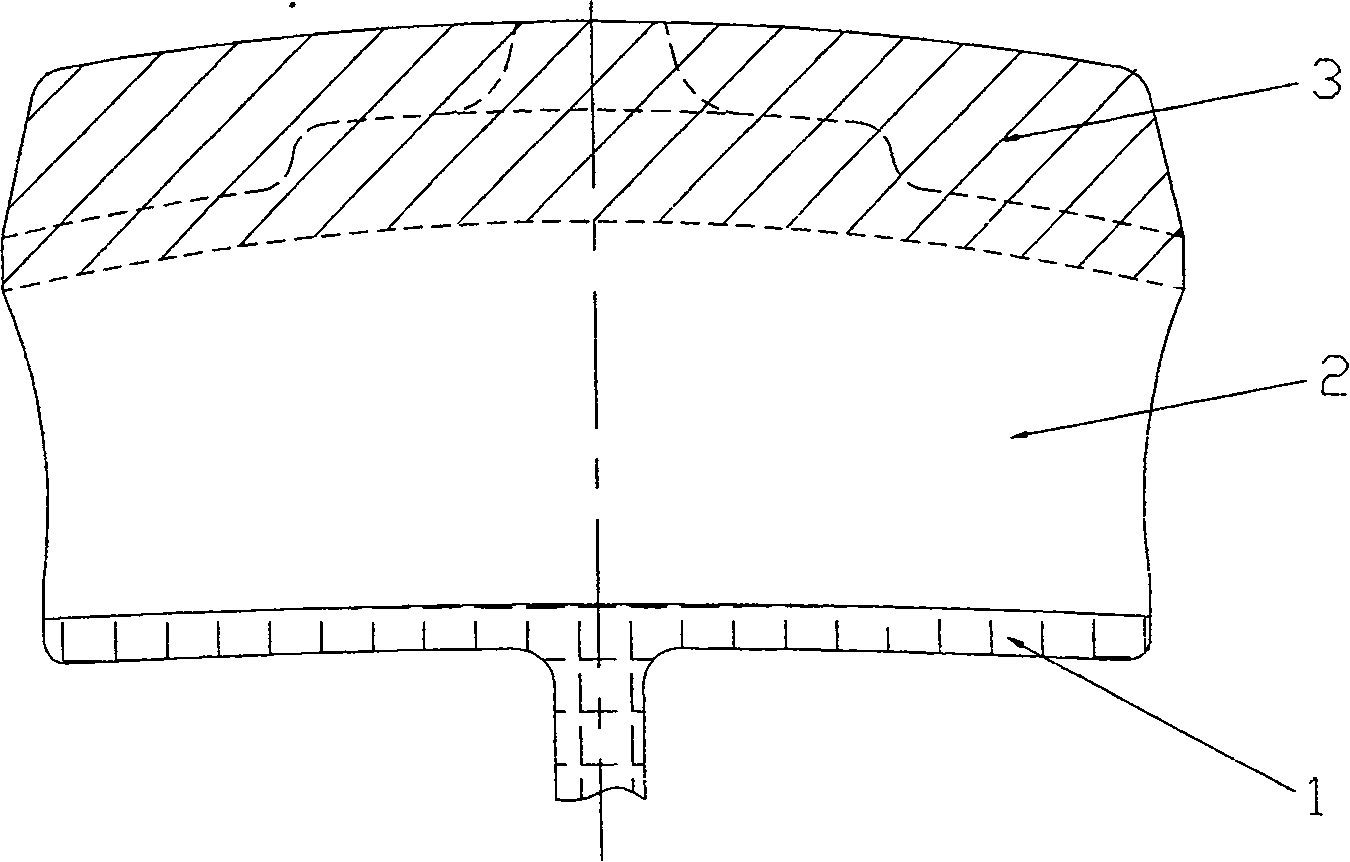

Polyurethane solid tyre and manufacturing method thereof

The invention relates the making method of polyurethane solid tyre used for industry vehicle. The polyurethane solid tyre comprises the metal rim which has supporting and conveying action and the single-lay or double-lay polyurethane which is bonded on metal rim. The single-lay or double-lay polyurethane used in outer layer is oligomer polyatomic alcohol- methyl diphenylene diisocyanate / toluene diisocyanate, and the single-lay or double-lay polyurethane used in inner layer is oligomer polyatomic alcohol-3,3'- dimethyl-4,4'-biphenyl diisocyanate. The carcass has the advantages of long lifetime, non pollution, good heat-sinking capability and not blasting. The cost is low, technology is simple, and it is easy to realize the industrial production.

Owner:SOUTH CHINA UNIV OF TECH

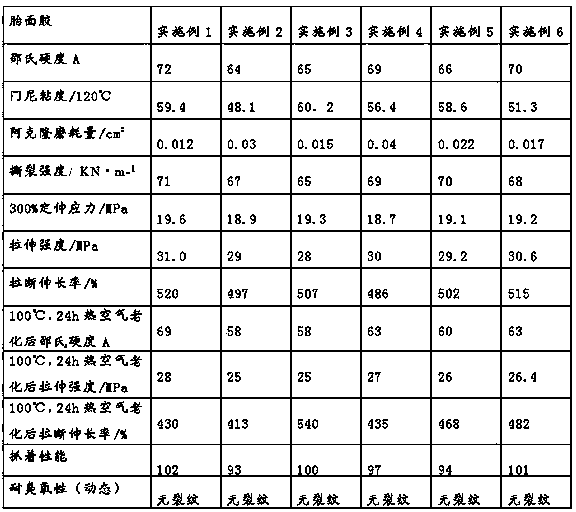

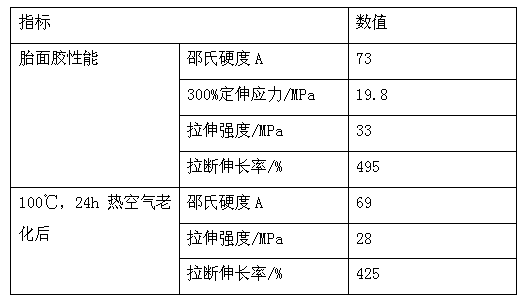

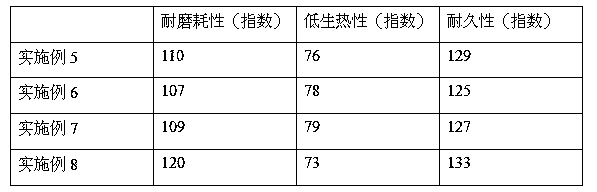

Solution-polymerized styrene-butadiene tread rubber and mixing process thereof

The invention discloses a solution-polymerized styrene-butadiene tread rubber and a mixing process thereof. The tread rubber comprises the components by weight: 40-220 parts of a solution-polymerized styrene-butadiene rubber, 10-60 parts of natural rubber, 5-20 parts of tread rubber powder, 1-4 parts of stearic acid, 1-2 parts of sulphur powder, 20-40 parts of white carbon black, 5-10 parts of carbon black, 2-30 parts of an aromatic hydrocarbon oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of a pine tar oil, 1-4 parts of an accelerant, 0.2-1 part of an anti-reversion agent and 2-5 parts of a bonding agent. A three-stage mixing process is employed. The tread rubber has good anti-aging performance and high wear-resistant property, can prolong service life of an automobile tyre, and has a high safety factor.

Owner:SHANDONG YONGTAI CHEM GROUP

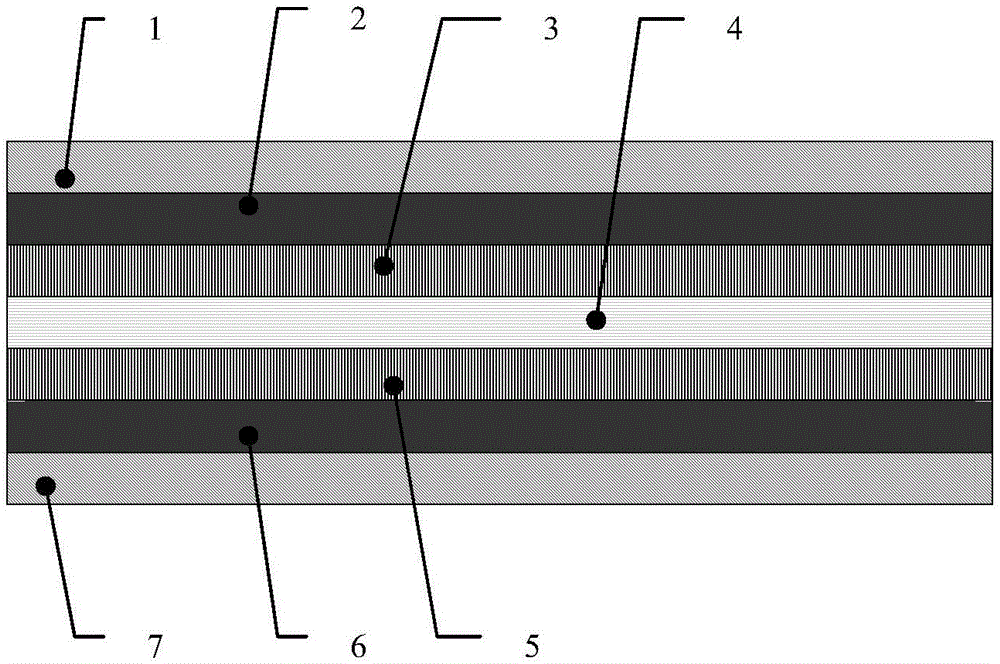

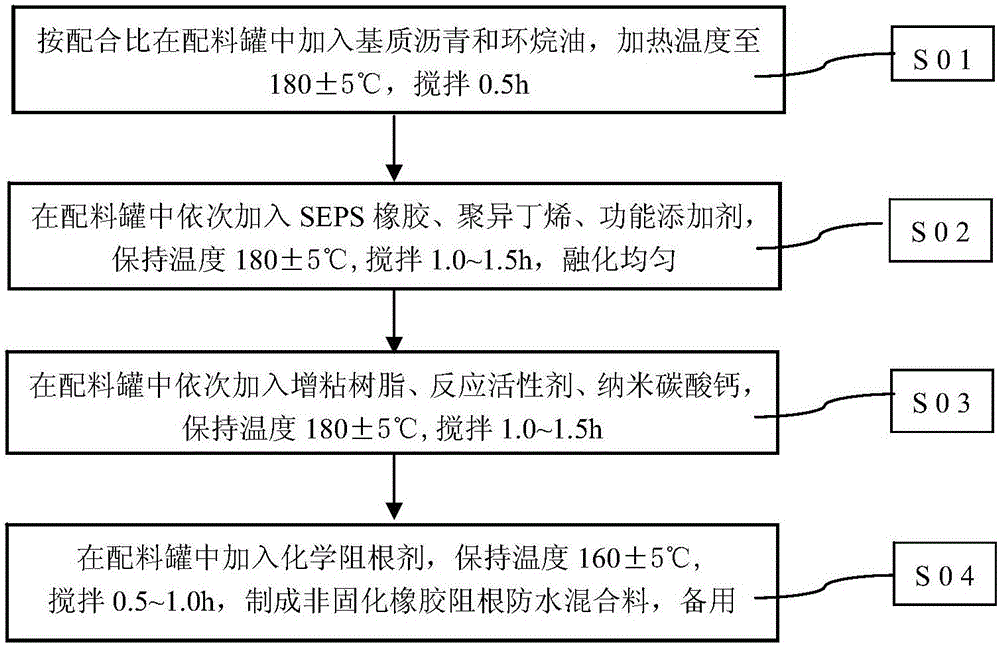

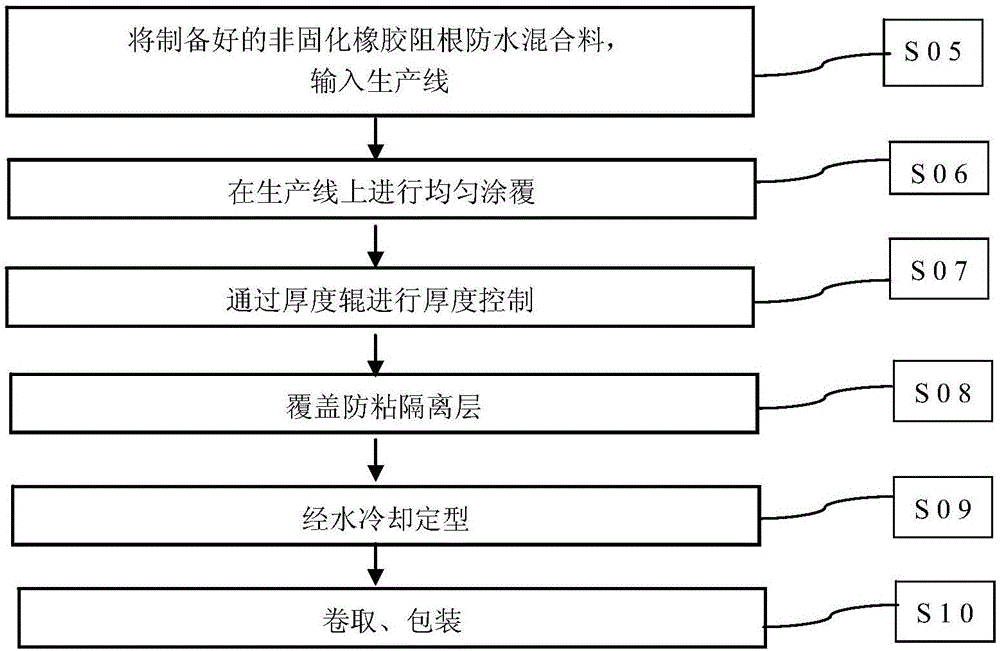

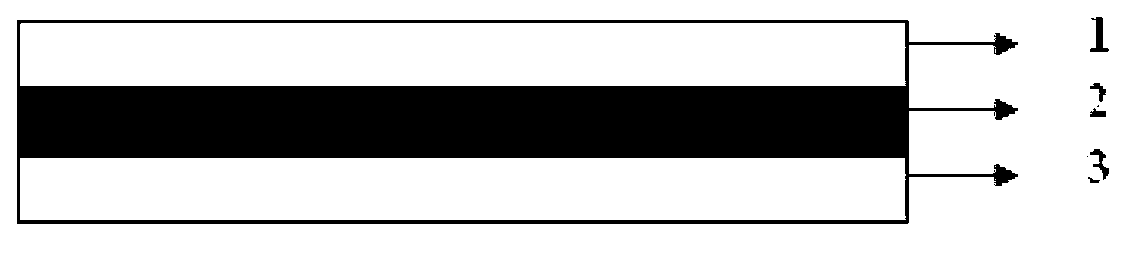

Metal core self-repairing root resisting waterproof coiled material and preparation method thereof

InactiveCN106515142APrevent multiple insuranceSelf-healing hasRoof covering using flexible materialsLaminationPlant rootsActive agent

The invention discloses a metal core self-repairing root resisting waterproof coiled material and a preparation method thereof. The metal core self-repairing root resisting waterproof coiled material comprises a metal core layer; the two sides of the metal core layer are each provided with a macromolecule layer; one side or two sides of each macromolecule layer away from the metal core layer is provided with or are each provided with a non-cured-rubber layer; and the outer surfaces of the non-cured-rubber layers are provided with anti-adhesion isolation layers. Each non-cured-rubber layer is composed of, by mass, 30-50 parts of matrix asphalt, 6-8 parts of naphthenic oil, 12-16 parts of SEPS rubber, 10-15 parts of polyisobutylene, 0.5-0.8 part of modification additives, 5-10 parts of tackifying resin, 0.1-0.5 part of a reaction active agent, 15-25 parts of nanometer calcium carbonate and 0.5-1.0 part of a chemical root resisting agent. The metal core self-repairing root resisting waterproof coiled material integrates sealed waterproofing performance and multiple root resisting, and has the characteristics of self-repairing, puncture resistance, sealing adhesion, ageing resistance and long service life; and meanwhile, the metal core self-repairing root resisting waterproof coiled material has the multiple root resisting function, has a multiple insurance effect on preventing plant root puncture and solves the problem that roots of a roof greening plant puncture a waterproof layer.

Owner:浙江潮源新型建材股份有限公司

Butyl blending emulsion chemical protective glove and preparation method thereof

ActiveCN103965554AKeep airtightCorrosion resistance hasGlovesProtective garmentPolymer scienceVulcanization

The invention discloses a butyl blending emulsion chemical protective glove and a preparation method thereof. The butyl blending emulsion chemical protective glove comprises a glove liner and a macromolecule blending emulsion material outer gumming layer, wherein the macromolecule blending emulsion material outer gumming layer comprises the components of a macromolecule blending alloy material main body, a vulcanizer, a promoter and a vulcanization activator according to the mass ratio of 100 to 0.5-5 to 0-2 to 1-3; the macromolecule blending alloy material main body comprises 60 to 100 percent of butyl rubber and 0 to 40 percent of other high polymer materials; the high polymer materials are PVC, PE, phenolic aldehyde or nitrile rubber. The butyl blending emulsion chemical protective glove overcomes defects in binding power and tear resistance, has excellent performances of chemical corrosion prevention, solvent resistance and oil resistance, has an excellent water resisting property and an electrical insulating property, and also has wear resisting, cut preventing and puncture resisting properties and the like; the preparation process is accomplished through mechanized linkage and flow production; the production is feasible, the technology is reasonable, the cost is reasonable, and the butyl blending emulsion chemical protective glove and the preparation method are applicable to industrialized scale production.

Owner:ZHEJIANG KANG LONG DA SPECIAL PROTECTION TECH CO LTD

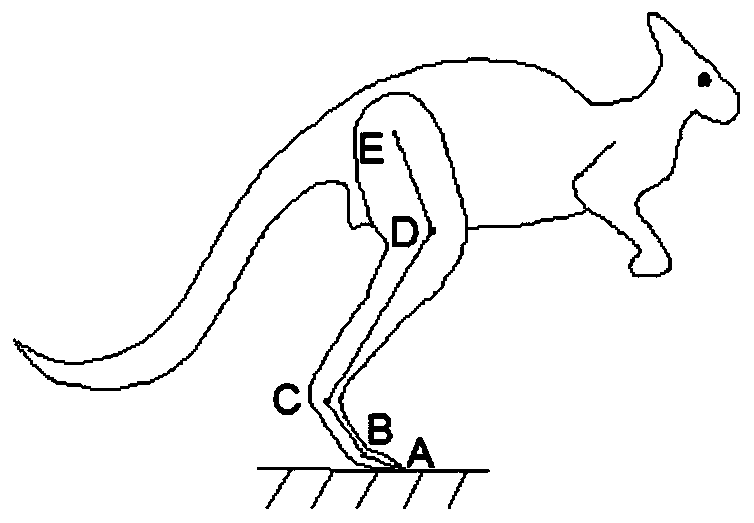

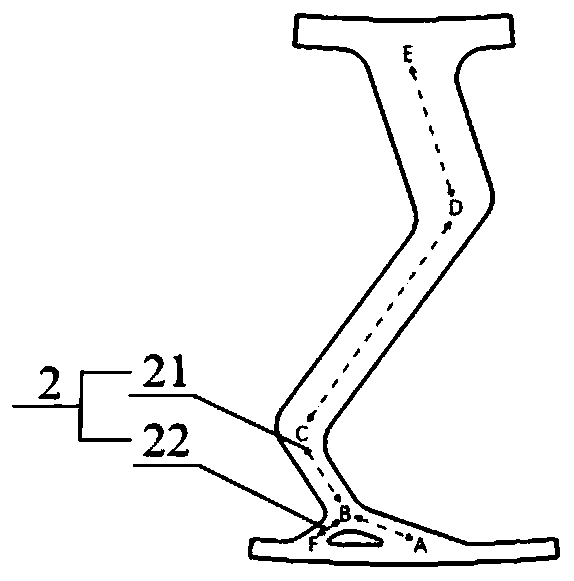

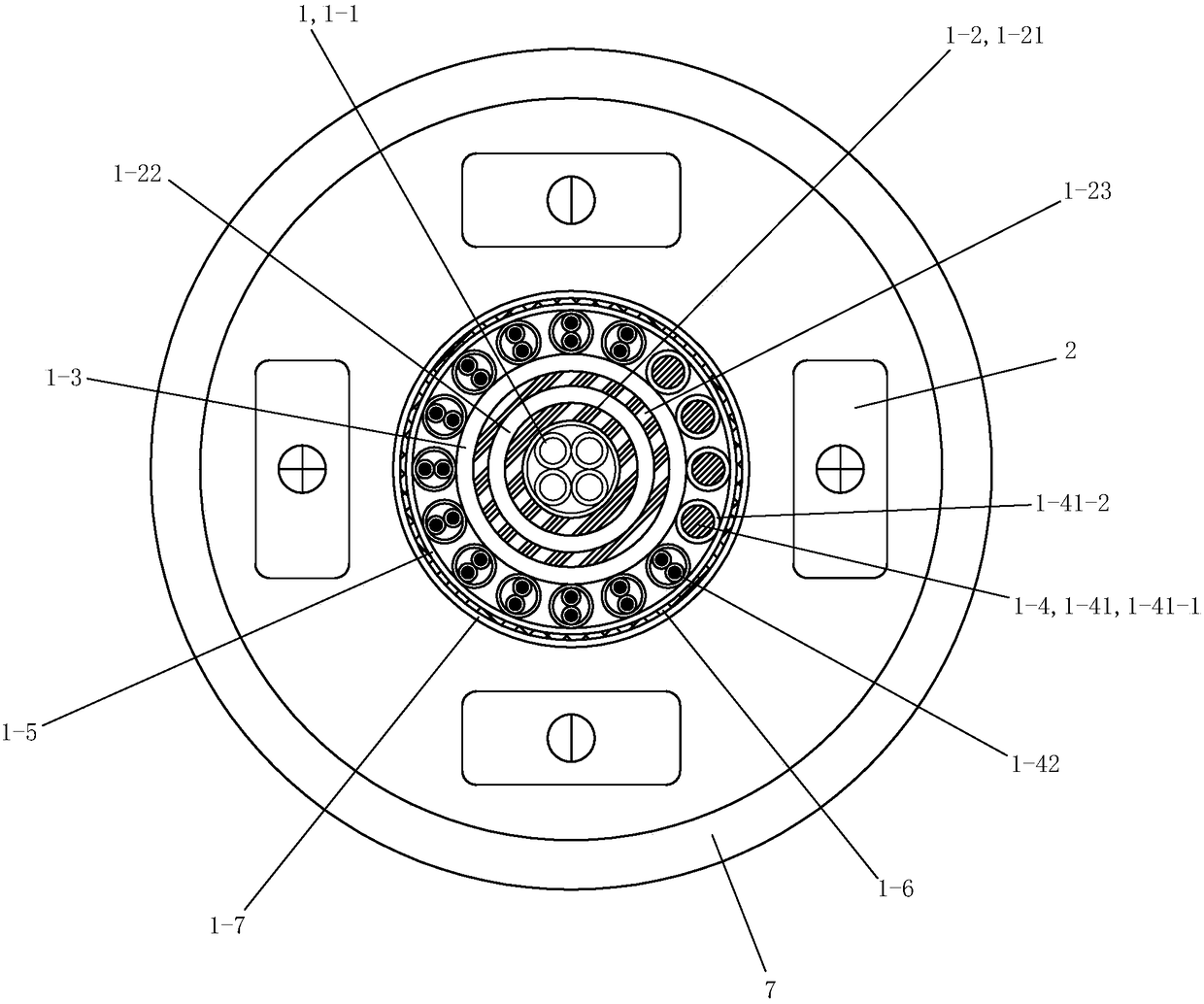

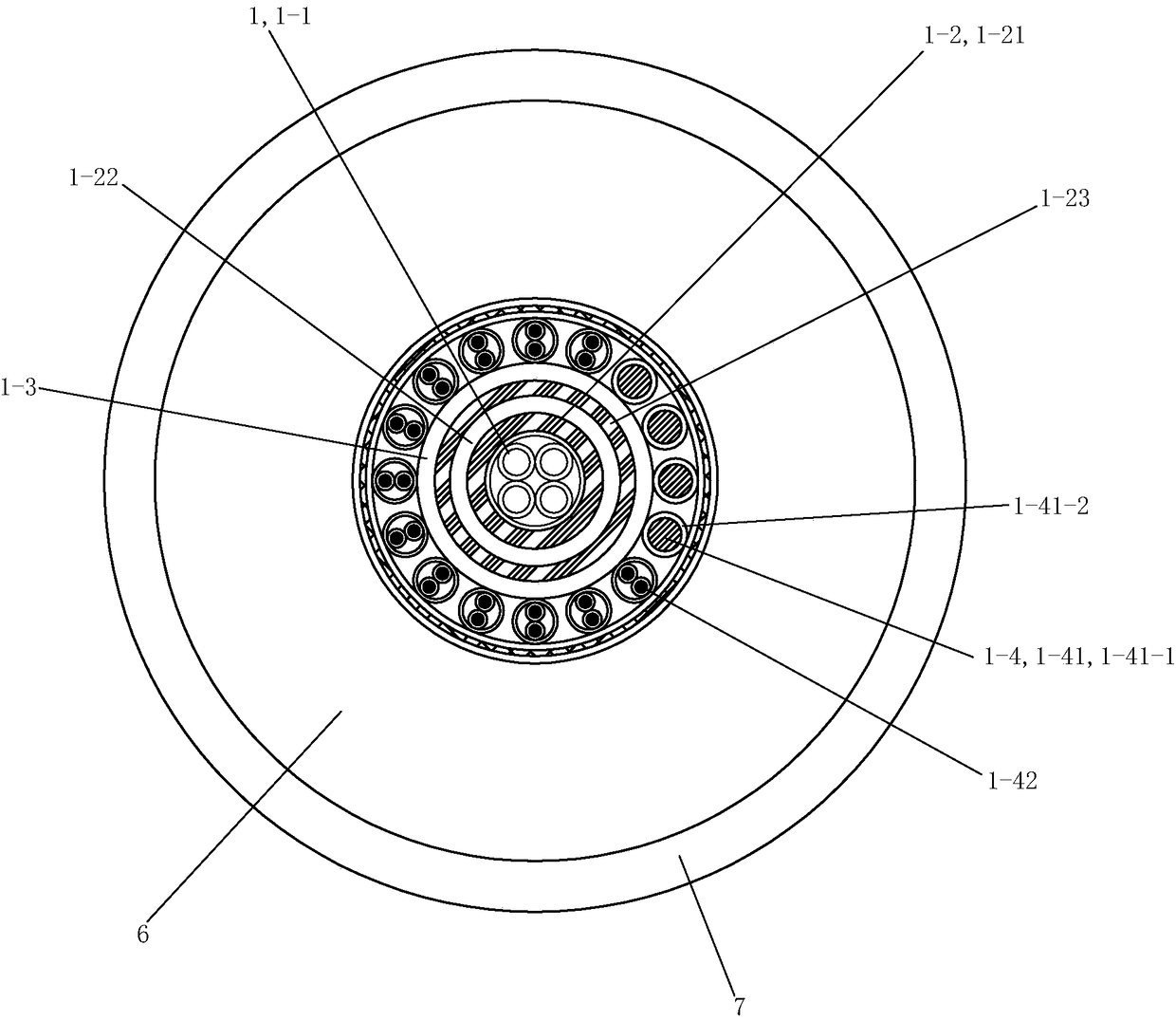

Bionic non-pneumatic tire

PendingCN110682741AHigh strengthImprove carrying capacityNon-inflatable tyresTyre tread bands/patternsControl theoryMechanical engineering

The invention discloses a bionic non-pneumatic tire. The bionic non-pneumatic tire comprises a crown, a bionic spoke plate support body and a spoke plate inner ring, wherein the crown, the bionic spoke plate support body and the spoke plate inner ring are sequentially arranged from outside to inside according to the radial direction of the tire; the crown comprises a tread, a cap ply and belt plies, wherein the tread, the cap ply and the belt plies are sequentially arranged from outside to inside according to the radial direction of the tire; the belt plies comprise a # 1 belt ply and a # 2 belt ply which are sequentially arranged from outside to inside according to the radial direction of the tire; and the bionic spoke plate support body is designed by imitating a kangaroo lower limb structure, and the bionic spoke plate support body comprises a kangaroo lower limb-imitated main spoke plate and a supporting auxiliary spoke plate. According to the bionic non-pneumatic tire, shock absorption, drainage and heat dissipation capability of the non-pneumatic tire are remarkably improved, and the overall mass is remarkably reduced; and the bionic spoke plate support body adopts a high-modulus polyurethane material, and thus high hardness, fatigue resistance, cutting resistance and green and environmental protection performance are achieved.

Owner:SHANDONG UNIV OF TECH

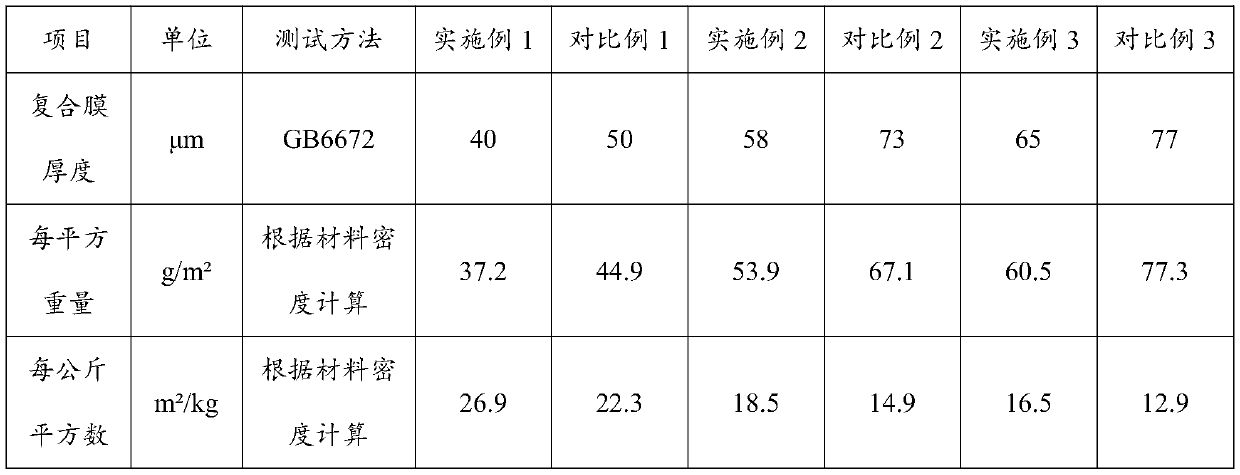

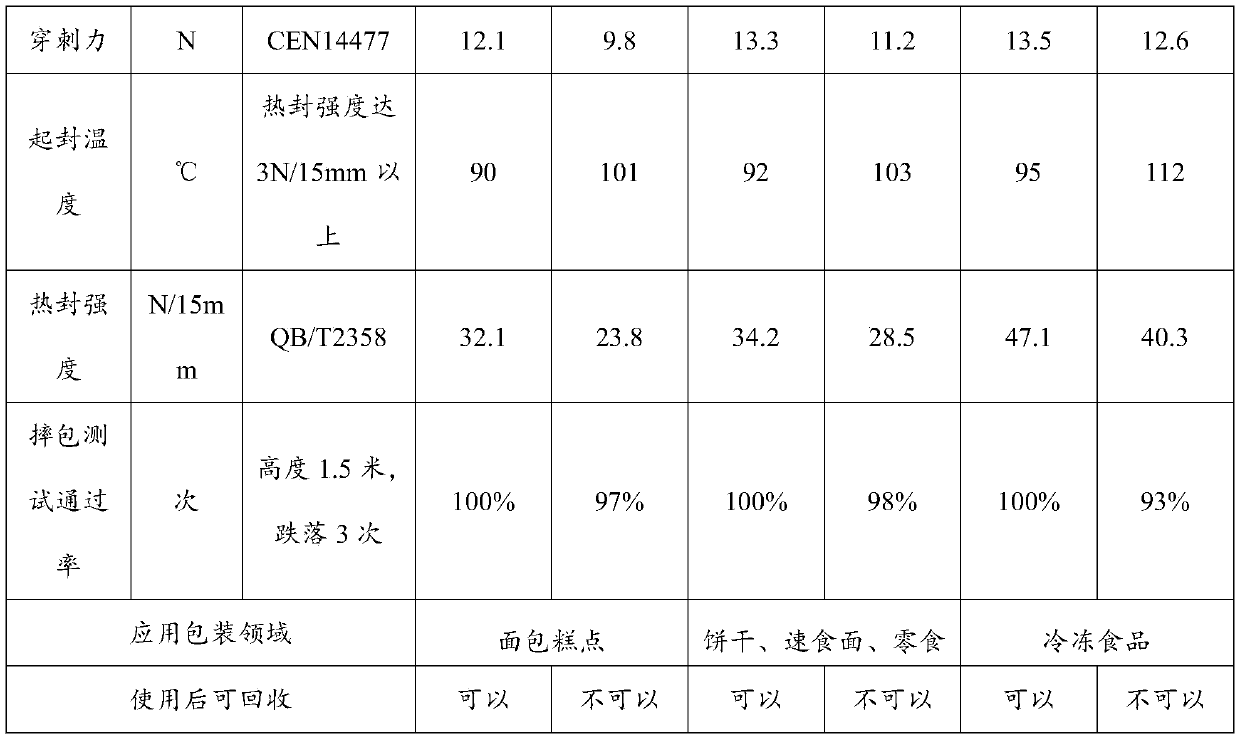

Polyethylene composite film capable of 100% recovery as well as preparation method and application thereof

ActiveCN111531991AGood printabilityGood optical performancePackage recyclingFlexible coversLow-density polyethylenePolymer science

The invention belongs to the technical field of polyethylene materials, and particularly relates to a polyethylene composite film capable of 100% recovery as well as a preparation method and application thereof. The provided polyethylene composite film comprises a composite printing layer, a bonding layer and a composite heat-seal layer which are bonded in sequence, wherein the composite printinglayer is a longitudinally-stretched polyethylene printing film; the direction from the composite printing layer to the composite heat sealing layer is from outside to inside, and the composite printing layer comprises a printing layer outer layer, a printing layer middle layer and a printing layer inner layer in sequence; the bonding layer is a low-density polyethylene film or a solvent-free gluelayer; the composite heat-seal layer is a multi-layer co-extrusion polyethylene heat-seal film and comprises a heat-seal layer outer layer, a heat-seal layer middle layer and a heat-seal layer inner layer in sequence. Experimental results show that the polyethylene composite film capable of 100% recovery can be recycled by 100%, and has the characteristics of small thickness, low density, punctureresistance and low unsealing temperature.

Owner:江门市华龙膜材股份有限公司

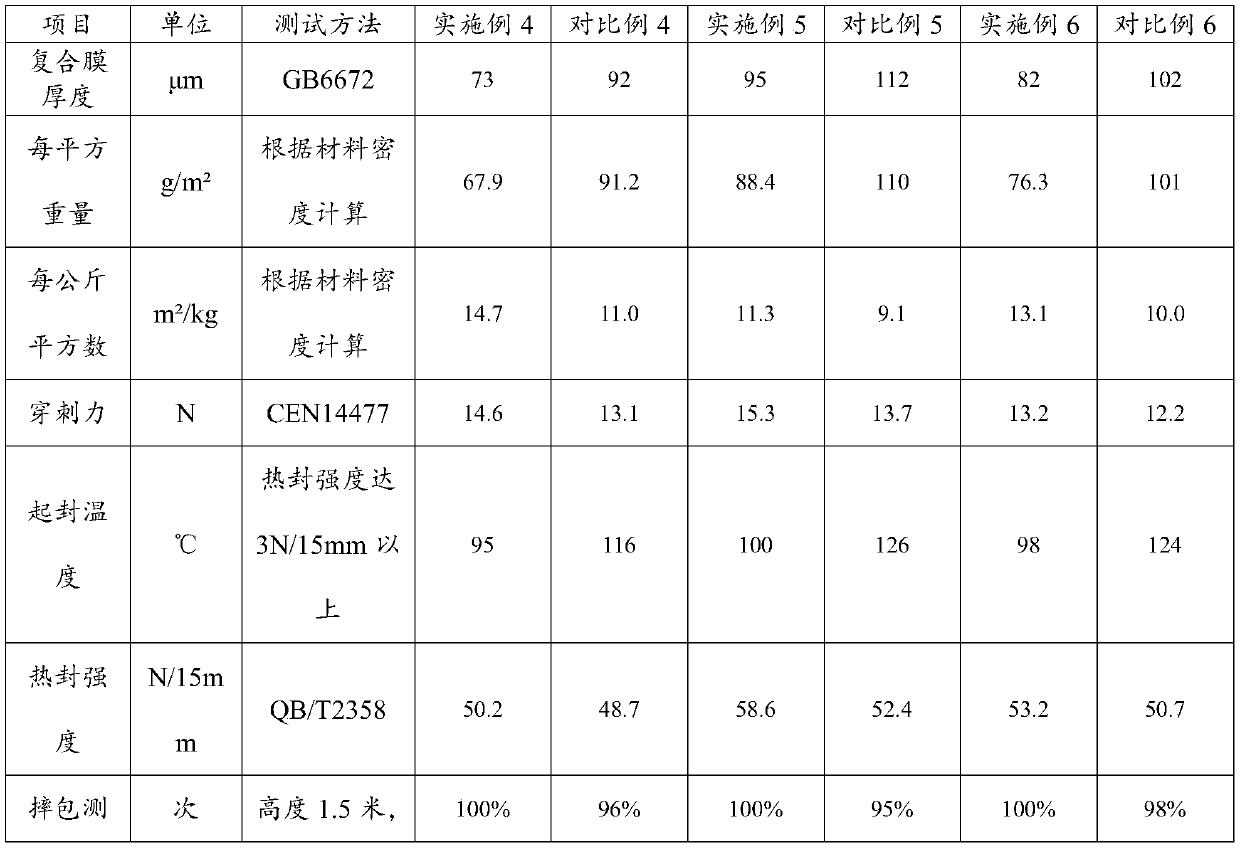

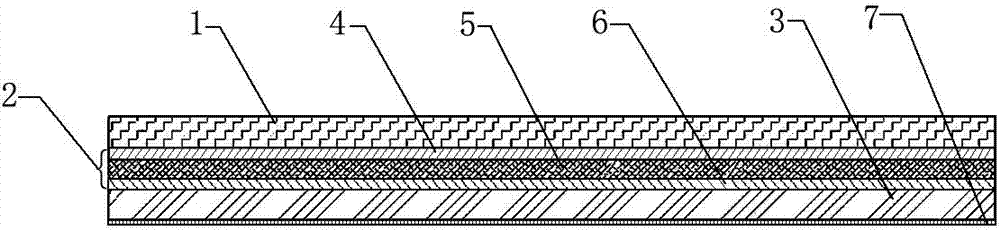

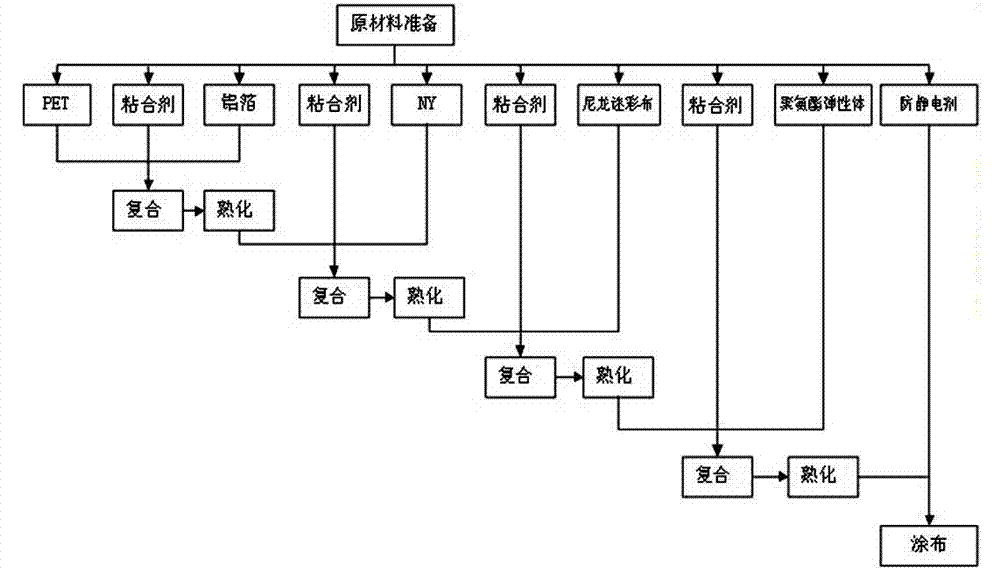

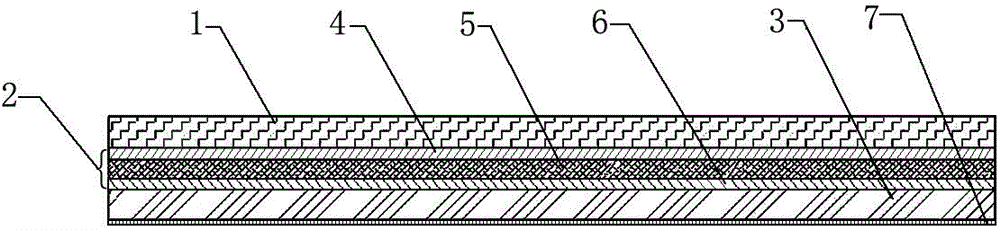

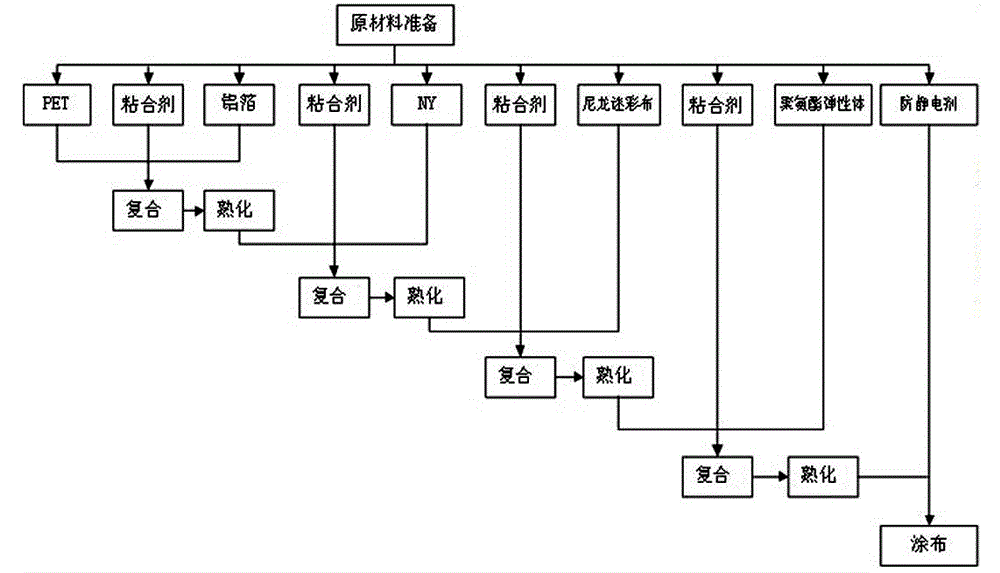

Military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite and preparation method thereof

ActiveCN103029386AImprove mechanical propertiesGood antistatic functionSynthetic resin layered productsLaminationPolyurethane elastomerAntistatic agent

The invention discloses a military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite which sequentially comprises a nylon camouflage cloth camouflage layer, a high-barrier layer taking aluminum foil as a substrate, and a heat sealing layer of a polyurethane elastomer film from the outside in. A preparation method of the composite comprises the steps of A preparing the high-barrier layer, and compositing polyethylene glycol terephthalate film and a polyamide film on the upper and the lower surfaces of the substrate, namely the aluminum foil, B compositing the upper surface of the high-barrier layer with a camouflage layer and curing, C compositing the lower surface of the high-barrier layer with the heat sealing layer of the thermoplastic polyurethane elastomer film and curing, and D coating the internal surface of the heat sealing layer with an antistatic agent, and obtaining the camouflage composite. According to the composite and the method, with the adoption of specific compositing and curing processes, the prepared camouflage composite has puncture-proof, tear-resistant, anti-static and high-barrier functions and the like, a protection envelope prepared by the material can effectively prevent army materials from being damp during long-term field storage and transportation, and the storage and transportation quality of the materials is improved.

Owner:中国人民解放军32181部队

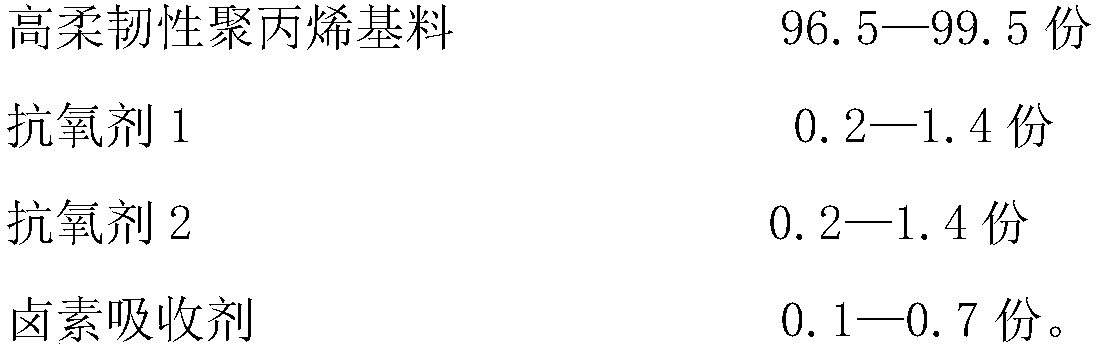

High-toughness polypropylene resin and production method thereof

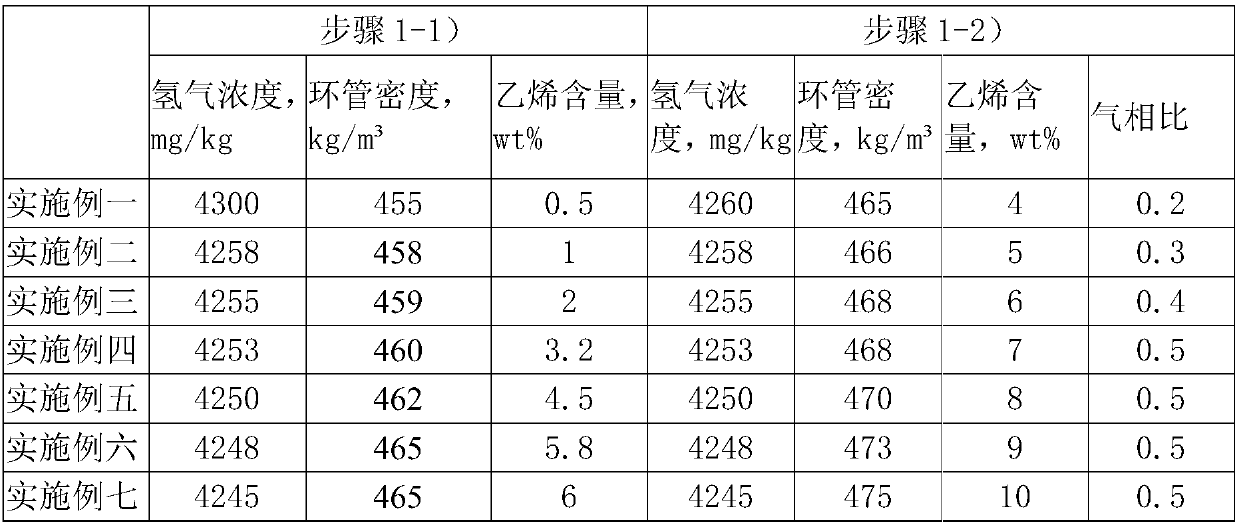

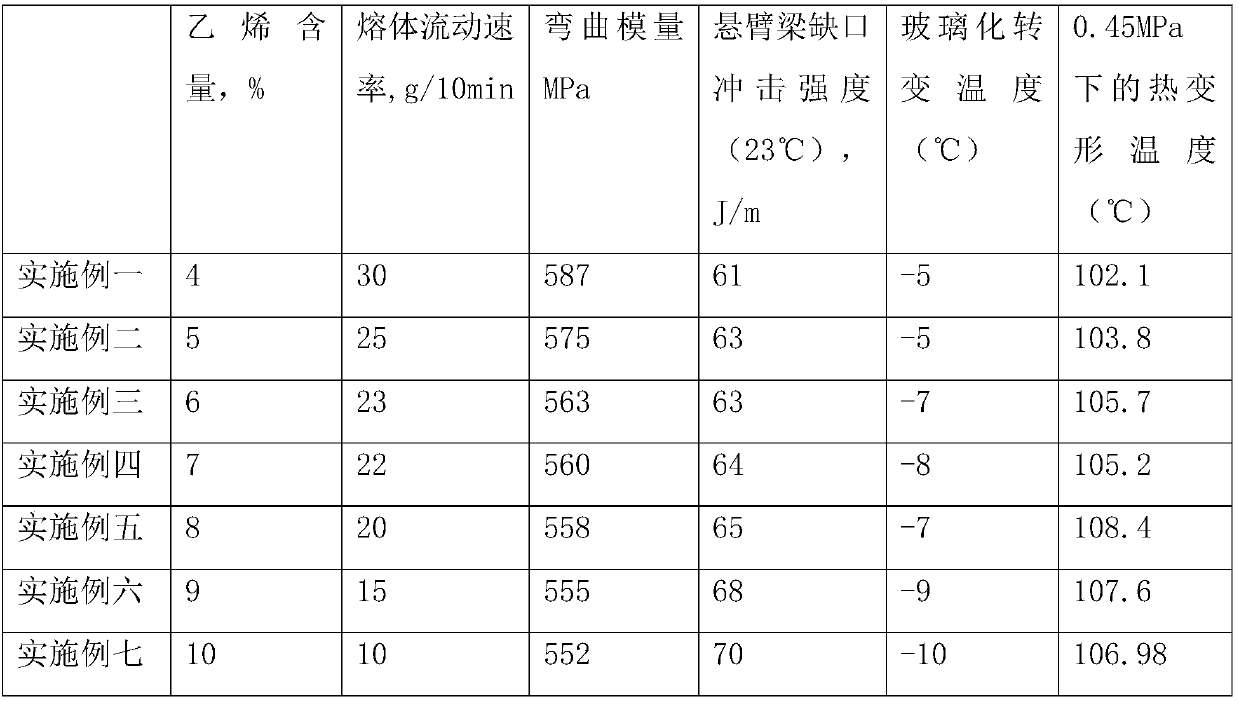

The invention discloses high-toughness polypropylene resin and a production method thereof. The high-toughness polypropylene resin is mainly prepared from high-toughness polypropylene base materials,antioxidants 1, antioxidants 2 and halogen absorbing agents, and the base materials are produced by a two-step compounding method in a Spheripol process. A production method of the base materials particularly includes the steps: taking propylene and hydrogen as raw materials in a first loop reactor, adding a catalyst, an electron donor and a promoter, controlling the concentration of the hydrogento be 4245-4300mg / kg, controlling loop density to be 460kg / m<3>, controlling ethylene content to be 0.5-6wt%, and producing polypropylene random copolymers; performing gas-phase copolymerization reaction on propylene homopolymers and ethylene monomers in the polypropylene random copolymers acquired in the first step in a second loop reactor, controlling the concentration of the hydrogen to be 4245-4260mg / kg, controlling loop density to be 460kg / m<3>, controlling loop density to be 470kg / m<3>, controlling ethylene content to be 4-10wt%, controlling gas phase ratio to be 0.2-0.5, preparing polypropylene powder, and namely, preparing the base materials. The bending modulus is 600MPa or more, the impact strength of a cantilever beam gap is 60J / m (23 DEG C) or more, haze is smaller than 10, andthe polypropylene resin is provided with good-transparency soft impact-resistant polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP

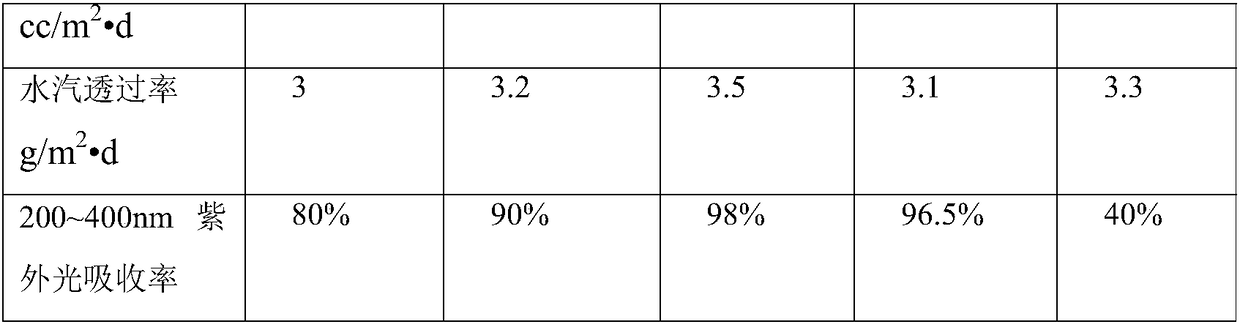

High-barrier multi-layer coextrusion functional packaging film with ultraviolet resistance effect

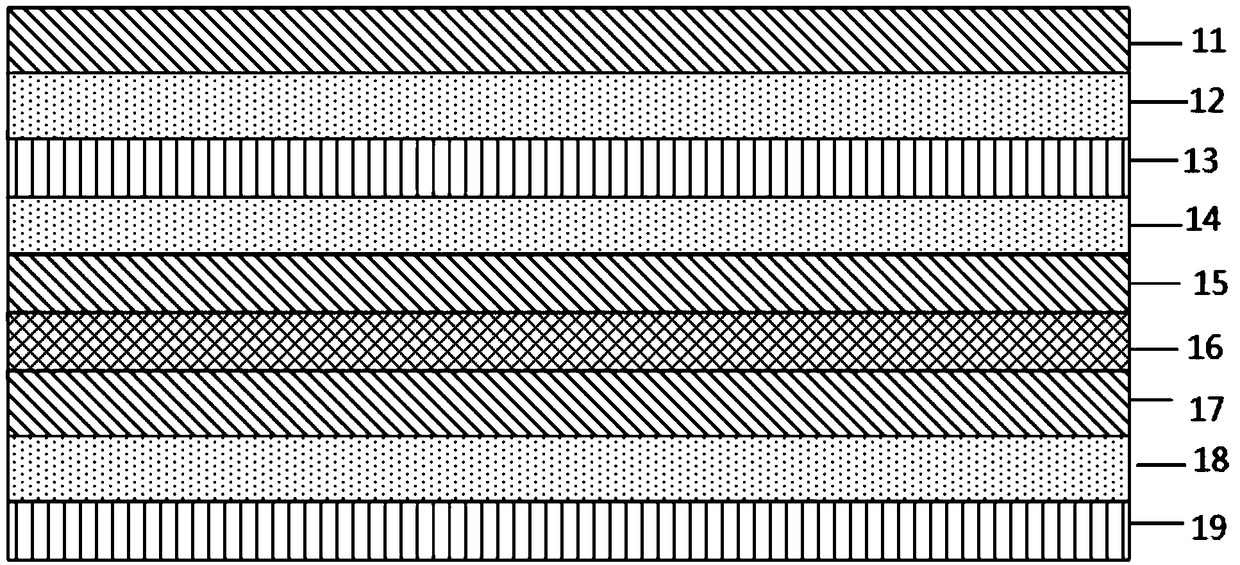

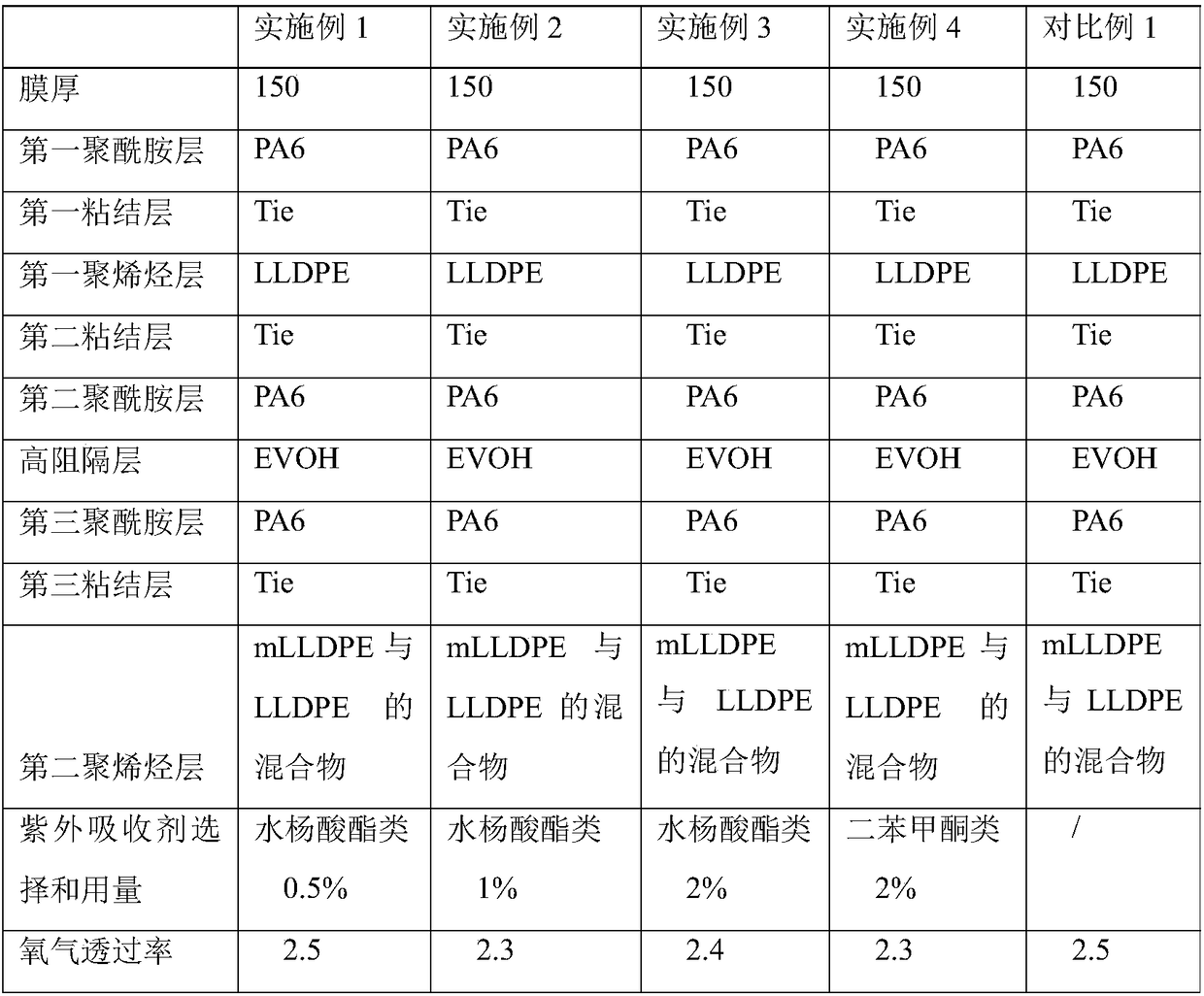

InactiveCN109397778AEffective protectionPuncture resistantFlexible coversWrappersHigh humidityPolyolefin

The invention discloses a high-barrier multi-layer coextrusion functional packaging film with ultraviolet resistance effect. The high-barrier multi-layer coextrusion functional packaging film sequentially comprises a first polyamide layer, a first bonding layer, a first polyolefin layer, a second bonding layer, a second polyamide layer, a high barrier layer, a third polyamide layer, a third bonding layer and a second polyolefin layer from top to bottom sequentially; the high barrier layer is made of the raw material EVOH. The packaging film, which is produced through the multi-layer coextrusion process, has excellent ultraviolet resistance effect, also has good barrier performance, high humidity blocking performance, good puncture resistance and the like, and is applicable to the fields offood packaging, electronic packaging, medical packaging and the like to effectively protect content in packages.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Solid towline with good dragging performance for marine seismic exploration

InactiveCN108447591AMaintain pressure resistanceWith impact resistanceNon-insulated conductorsFloating cablesYarnRubber material

The invention discloses a solid towline with good dragging performance for marine seismic exploration. The solid towline is characterized in that the solid towline comprises a main cable, hydrophones,buoyancy sleeves and an outer sheath. The hydrophones are fixedly arranged on the main cable with an equal interval. The hydrophones are electrically connected to corresponding wire cores in the maincable. Each of the buoyancy sleeves is made of a foamed polyethylene material, and foamed polyethylene is extruded on the main cable. The main cable includes the transmission wire cores, a tensile fiber layer and a conductive wire layer. The tensile fiber layer is formed by weaving aramid yarn and / or polyester yarn outside the transmission wire cores. The conductive wire layer includes a set of power lines and a set of signal lines. The power lines and the signal lines are orderly arranged with an equal interval along the circumferential direction of the main cable outside the tensile fiber layer to form the corresponding wire layer. The buoyancy sleeves are fixedly arranged on the main cable with an equal interval, and each of the buoyancy sleeves is between two adjacent hydrophones. Theouter sheath is made of a thermoplastic polyurethane elastomer rubber material and is extruded outside the hydrophones, positioning ends and the buoyancy sleeves, and the outer sheath is seamlessly bonded to the hydrophones.

Owner:CHANGZHOU MARINE CABLE

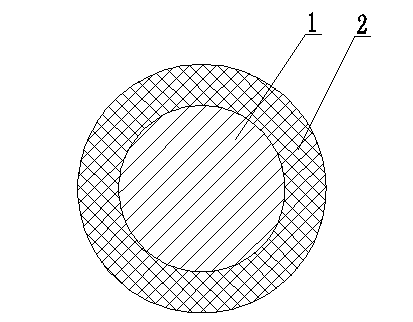

Composite fiber filament for nuclear radiation protection and production method of composite fiber filament

InactiveCN103757778AExcellent nuclear radiation protection performanceFlame retardantYarnMetal fiberNuclear radiation

The invention discloses a composite fiber filament nuclear radiation protection and a production method of composite fiber filament and relates to the technical field of nuclear radiation protection. Core knitting is performed on a knitter, and a material covered during knitting is made of carbon fiber, high density polyethylene fiber, polytetrafluoroethylene fiber, polyphenylene sulfide fiber, polyarmide fiber, polyester fiber or polyimide fiber, a coating material is made from the carbon fiber, the high density polyethylene fiber, the polytetrafluoroethylene fiber, the polyphenylene sulfide fiber, the polyarmide fiber, the polyester fiber or the polyimide fiber, and thereby the composite fiber filament with a nuclear radiation protection function is formed. The composite fiber filament comprises a metal fiber core and at least one outer knitted coating layers which are in net structures. The composite fiber filament is simple and reasonable in technology, high in yield, and beneficial to follow-up weaving for weaving the composite fiber filament into fabric via a weaving technology so as to form clothes with the nuclear radiation protection function.

Owner:扬州锦沃科技有限公司

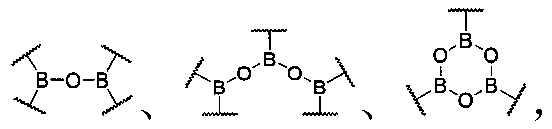

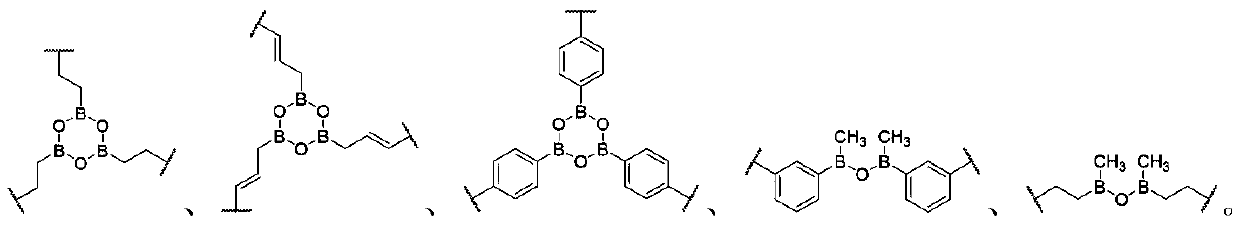

Expanded-flow hybrid dynamic polymer and method for realizing expanded-flow property thereof

ActiveCN111253583AStrong controllabilityRich control meansBulk chemical productionPolymer sciencePolymer chemistry

The invention relates to an expanded-flow hybrid dynamic polymer, which at least contains vitrification swelling property and contains common covalent cross-linking above a gel point and a dynamic unit. The expanded-flow hybrid dynamic polymer has excellent swelling property, the common covalent crosslinking provides good structural stability for the swelling hybrid dynamic polymer, and the dynamic unit has dynamic reversibility, provides synergistic swelling property, molecular level and microscopic self-repairing property and shape memory property for the swelling hybrid dynamic polymer, andimproves the strength, toughness and damage resistance of the material. The expanded-flow hybrid dynamic polymer can be used as an energy absorbing material, a tough material, a shape memory materialand the like, and is widely applied to impact resistance protection, shock absorption, damping, sound absorption, noise elimination, packaging, medical treatment, traffic and the like. The inventionalso relates to a method for realizing the flow expansion property of the hybrid dynamic polymer, and an energy absorption method for absorbing energy by taking the hybrid dynamic polymer with the flow expansion property as t energy absorbing material.

Owner:厦门天策材料科技有限公司

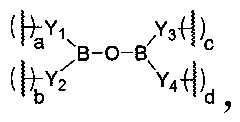

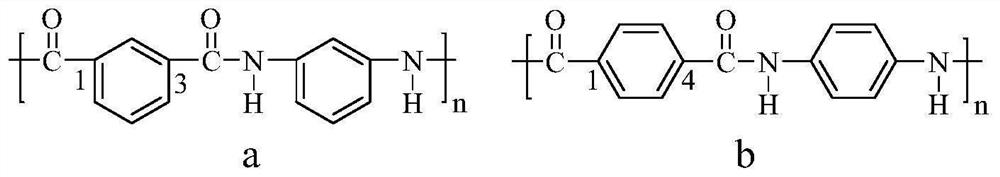

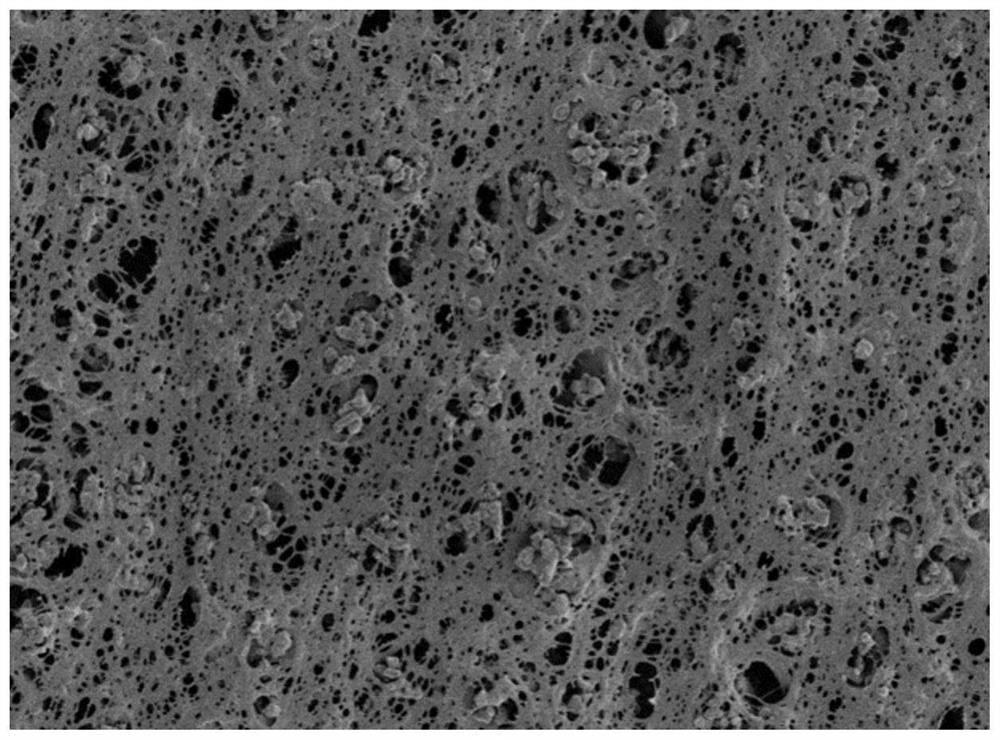

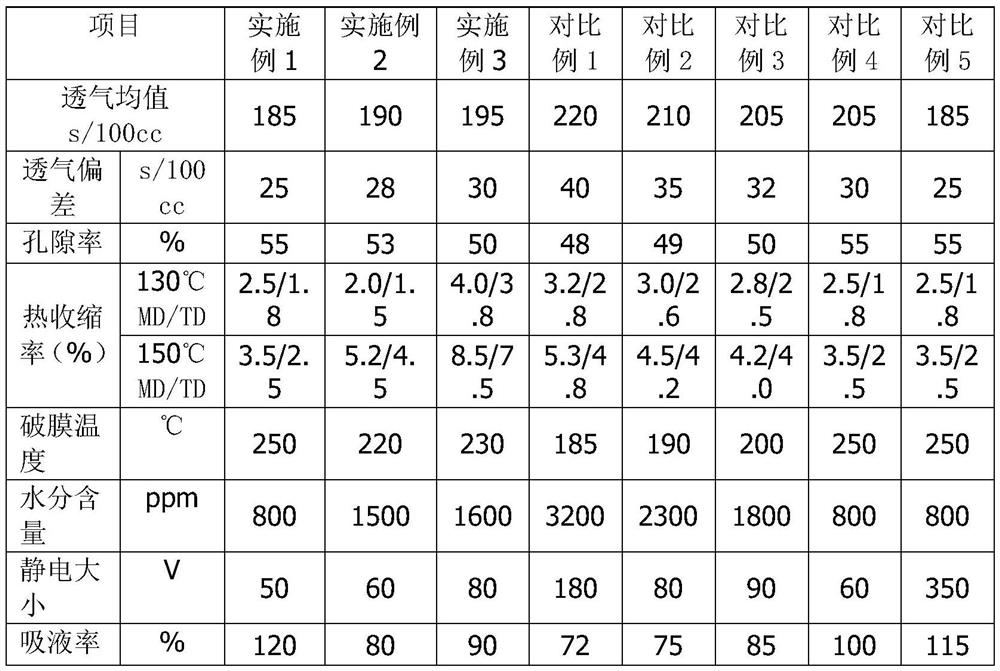

Modified composite heat-resistant lithium ion battery diaphragm and preparation method thereof

InactiveCN112216928AImprove electrochemical performanceImprove mechanical propertiesSecondary cellsNanotechnologyHeat resistanceLithium-ion battery

The invention belongs to the field of high polymer materials, and discloses a preparation method of a modified composite heat-resistant lithium ion battery diaphragm, which comprises the following steps: A, modifying aramid fibers; B, modifying an inorganic nano material; C, mixing the modified aramid fiber slurry and the modified inorganic nano slurry with a solvent in proportion to prepare organic-inorganic mixed modified slurry; and D, coating a base membrane with the organic-inorganic mixed modified slurry, and carrying out moisture solidification, washing, solvent removal and drying to obtain the modified composite heat-resistant lithium ion battery diaphragm. The problems of insufficient heat resistance, high moisture, large static electricity and the like of an existing aramid fibercoating diaphragm are solved.

Owner:长园泽晖新能源材料研究院(珠海)有限公司

Preparation method of mooring rope for anchoring aircraft carrier

The invention discloses a preparation method of a mooring rope for anchoring an aircraft carrier. Ultra-high molecular weight polyethylene fiber filaments are selected and used, the doubled ultra-high molecular weight polyethylene fiber filaments are twisted and heat-set, and heat-set ultra-high molecular weight polyethylene fiber compound yarns are twisted and formed through a rope twisting machine to obtain the high-performance mooring rope for anchoring the aircraft carrier. The preparation process is simple, safe and reliable, and the prepared mooring rope has abrasion resistance, cutting resistance, puncture resistance, light weight and high strength.

Owner:TAIAN ROPE NET PLASTIC

Polyurethane solid tyre and manufacturing method thereof

Owner:SOUTH CHINA UNIV OF TECH

Production of composite waterproof hung-laying curling material of self-adhesive and high-strength rubber

InactiveCN101074354AFast vulcanizationSlow vulcanizationOther chemical processesRubber layered productsPolymer scienceHigh intensity

Production of high-strength self-adhesive hung and spreading coiling material of composite water-proof rubber is carried out by preparing non-vulcanized rubber sheet, synthesizing rubber 100, tack producing agent-polyisobutylene 8-10, improver 1.0-1.6 and hydrophilic agent-sodium oleate 2-5 proportionally, cooking, milling, laying aside for 24 hrs, calendaring or extruding into slices, preparing un-vulcanized rubber sheet, synthesizing rubber 100, activator 2.5-5, vulcanizing agent-S1-5 and improver 2-4 proportionally, milling, laying aside for 24 hrs, cooking at 70-80 degree, forming by calendaring stack or extruder, combining, and passing non-woven fabric sheet, vulcanized rubber sheet and non-vulcanized rubber sheet through vulcanizing drum successively to obtain final product. The products consist of non-woven fabric layer, vulcanized rubber layer and non-vulcanized rubber layer. It has better affinity with concrete, penetration resistance and extendibility and no leakage. It can be used for water proofing layer of underground architecture.

Owner:天津市腾祥科技发展有限公司

Multi-layer structure buffer packaging product comprising waste foamed plastic and preparation as well as application thereof

InactiveCN103287001AConducive to environmental protectionSave resources and energyFlexible coversWrappersPuncture resistancePolystyrene

The invention discloses a multi-layer structure buffer packaging product comprising waste foamed plastic and a preparation and an application of the packaging product, and belongs to the technical field of packaging materials. Waste foamed polystyrene is used as a core layer, paper materials outside the core layers are used as outer layers, and the waste foamed polystyrene core layer and the paper material outer layers are bound together through a binding agent to form a composite product in a paper material / waste foamed polystyrene / paper material structure. The waste foamed polystyrene is cut to needed regular shapes or crushed to particles, then a binding agent solution is applied to the surface of polystyrene, the treated waste foamed polystyrene is placed between the two paper materials, and then waste foamed polystyrene and the paper materials are bound. The product disclosed by the invention can be used as a corrugated board buffer packaging material for the protective package and transportation package of cargoes, and is quite high in pressure resistance, folding resistance and puncture resistance.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Rubber liner plate with layer structure and preparation method of rubber liner plate

InactiveCN104476860AImprove wear resistanceImprove erosion resistanceRubber layered productsRubber materialPolymer science

The invention relates to a wear-resistant and erosion-resistant rubber liner plate with a layer structure and a preparation method of the rubber liner plate and belongs to rubber materials in the field of polymer materials. The rubber liner plate is formed by hot curing adhesion of a rubber substrate and surface wear-resistant rubber, wherein the surface wear-resistant rubber uses aramid fiber glass fiber and chinlon fiber to constitute a framework, special corrosion-resistant rubber is taken as a base material, and silicon carbide micropowder or zirconium carbide micropowder, aluminum oxide micropowder, silicon oxide micropowder and elemental silicon micropowder are added as admixtures for preparation, so that when the rubber liner plate is applied as a lining material, the rubber liner plate integrates not only certain strength, wear resistance, erosion resistance and puncture resistance, but also certain resilience and flexibility; and compared with a conventional metal liner or a liner poured by an inorganic nonmetallic material, the rubber liner plate has the characteristics of light weight and easiness in mounting and replacement.

Owner:平顶山华瑞锦橡耐磨材料有限公司

Environmental degradable express bag film material and preparation method thereof

InactiveCN109320828AReduce pollutionRapid photooxidative degradationLow-density polyethyleneLinear low-density polyethylene

The invention discloses an environmental degradable express bag film material and a preparation method thereof. The degradable express bag film material is prepared from starch, polylactic acid, an adipic acid-terephthalic acid-butanediol ester copolymer, a coupling agent, talcum powder, a degradation accelerant, masterbatch and linear low density polyethylene. 5-10% of the starch, 10-30% of the talcum powder, 0.01-5% of the degradation accelerant, 20-40% of the polylactic acid, 40-60% of the adipic acid-terephthalic acid-butanediol ester copolymer, 0.1-0.5% of vinyl trimethoxysilane and 0-20%of the linear low density polyethylene are mixed at a high speed to prepare a degradation material; in percentage by weight, 8-30% of degradation materials and 65-85% of the linear low density polyethylene and 2-7% of the masterbatch are mixed to prepare the express bag film material and then prepare express bags. The expression bag can be rapidly degraded after used.

Owner:北京国瑞新源投资有限公司

Pneumatic tyre

InactiveCN103467789AWith partial wear resistancePuncture resistantSpecial tyresPneumatic tyre reinforcementsNitrile rubberEngineering

The invention belongs to the field of tyres and particularly relates to a pneumatic tyre. The pneumatic tyre is characterized by comprising following components in parts by weight: natural rubber, butadiene rubber, chlorinated butyl rubber, nitrile rubber, an ethylene-propylene-diene monomer, butadiene styrene rubber, carbon black N110, carbon black N22O, carbon black N326, a coupling agent, high styrene, reinforced resin and a vulcanizing agent. With the adoption of the formula and the components by weight parts, the produced tyre has the advantages of being capable of resisting partial abrasion, keeping the operation stability, preventing cracks of a thin film and effectively reducing the air resistance in the high-speed driving process; the tyre provided by the invention also has the good performances on stabbing resistance, slipping resistance, air resistance, ozone resistance, sunlight aging resistance and the like.

Owner:SHANDONG YONGTAI CHEM GROUP

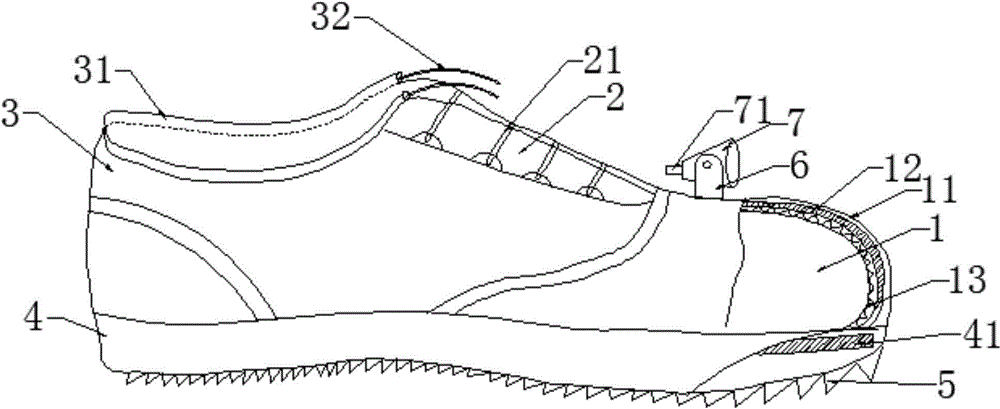

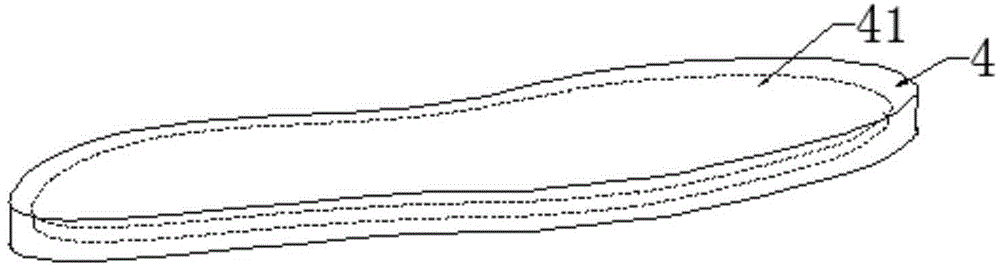

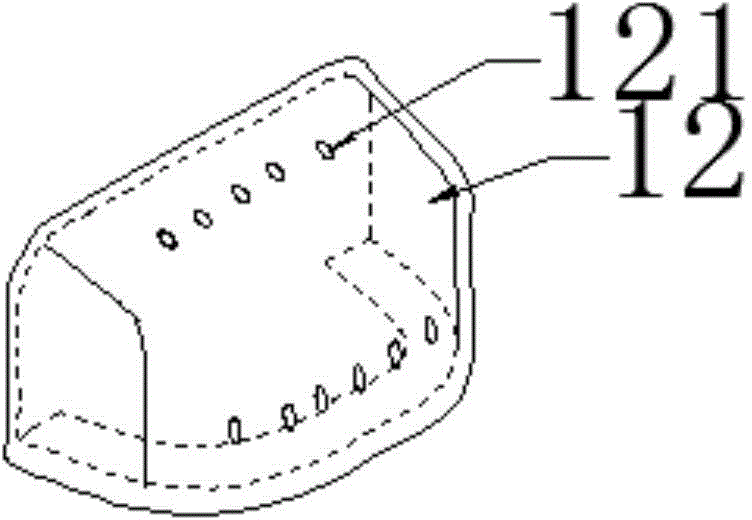

Safety shoes with illuminating lamps

The invention provides a pair of safety shoes with illuminating lamps. Each safety shoe comprises a toe cap, a tongue and a rear upper, wherein the toe cap comprises a vamp, a steel toe cap is coated inside the vamp, a buffer layer is coated inside the steel toe cap, and the toe cap, the tongue and the rear upper are fixedly connected with a shoe sole; a penetration-resistant insole is arranged inside the shoe sole, a skid-resistant layer is arranged beneath the shoe sole, a connecting base is arranged on the toe cap, one illuminating lamp is hinged to the connecting base, and the illuminating lamp is provided with a battery which supplies power to the illuminating lamp and a switch which is used for controlling the illuminating lamp to be powered up. The safety shoes with the illuminating lamps overcome the defects in the prior art, both penetration resistance and smashing resistance can be achieved, and the safety shoes are further provided with illuminating devices.

Owner:TIANJIN YAOSHUN SHOEMAKING

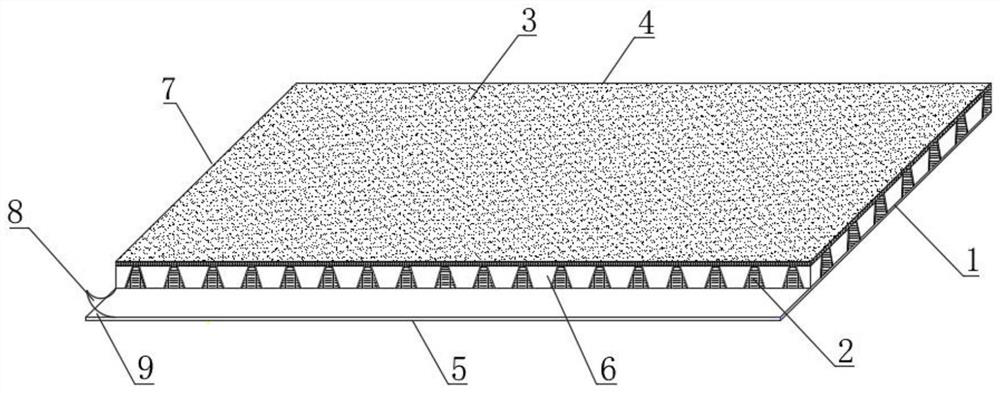

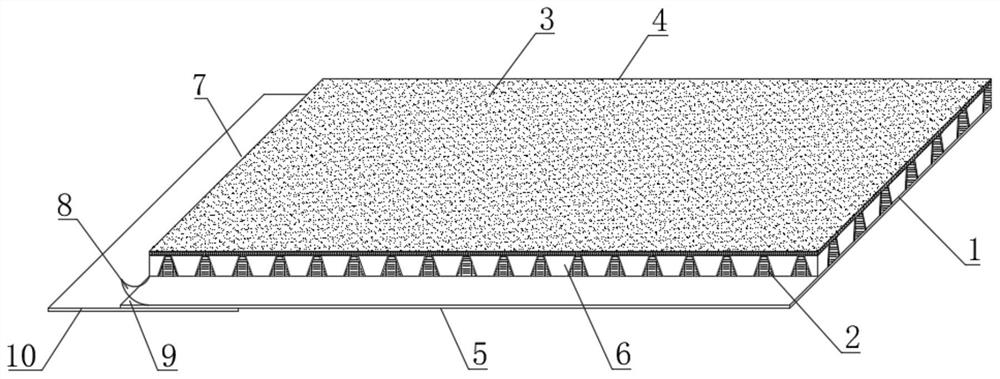

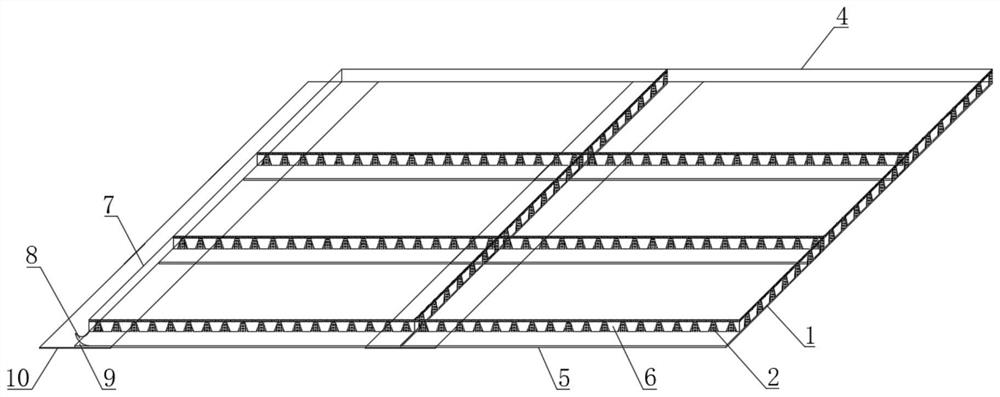

Novel-structure composite waterproof and drainage special-shaped sheet for planted roof and construction process thereof

PendingCN112796468AImprove toughnessTear resistantRoof covering using flexible materialsRoof covering insulationsGeomembraneWater filter

The invention provides a novel-structure composite waterproof and drainage special-shaped sheet for a planted roof and a construction process thereof. The novel-structure composite waterproof and drainage special-shaped sheet for the planted roof comprises a water filtering layer and a waterproof and drainage layer, wherein the waterproof and drainage layer is arranged under the water filtering layer and comprises a waterproof geomembrane; the upper surface, corresponding to the water filtering layer, of the waterproof geomembrane is provided with a plurality of projected casings; spaces among the projected casings form a drainage passage; and at least one edge of the waterproof geomembrane outwards extends out of a lap joint edge. The novel-structure composite waterproof and drainage special-shaped sheet provided by the invention has the advantages that the toughness is good; the tearing resistance and the puncture resistance are realized; the engineering manufacturing cost is reduced; the same-layer drainage design is used, so that the water filtering, the water drainage and the waterproof performance are compounded into a whole; the integration of first drainage and then prevention and waterproof and drainage is really realized; the leakage is thoroughly avoided; and the zero-slope organized drainage is realized.

Owner:青岛门驰建设工程有限公司

Preparation method of synthetic latex gloves

The invention relates to the technical field of glove preparation, particularly a preparation method of synthetic latex gloves. A latex composition is prepared from the following components in parts by weight: 20-40 parts of natural latex, 60-80 parts of acrylonitrile, 0.5-3 parts of sulfur, 0.5-3 parts of zinc diethyl dithiocarbamate, 0.5-3 parts of zinc oxide, 0.5-3 parts of anti-aging agent, 0.5-3 parts of titanium dioxide, 0.2-2 parts of casein, 0.2-2 parts of potassium hydroxide and 1-15 parts of pearl powder. The synthetic latex gloves have the advantages of favorable acid / alkali resistance, excellent puncture resistance, excellent wear resistance, excellent oil resistance and bright color without fading.

Owner:台州市博环橡塑有限公司

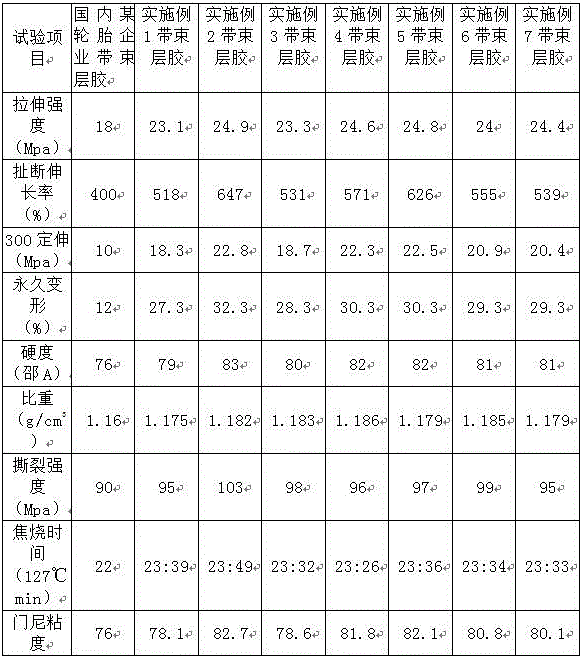

All-steel load-bearing radial tire belt rubber

The invention relates to an all-steel load-bearing radial tire belt rubber which is prepared from the following raw materials in parts by weight: 86-114 parts of natural rubber SMR20, 30-55 parts of carbon black N375, 7-13 parts of white carbon black, 5-11 parts of indirect zinc oxide, 1.3-3.7 parts of anti-aging agent 4020, 1.16-2.6 parts of bonding resin PN760, 0.8-1.6 parts of cobalt salt, 2.5-7.5 parts of adhesive RA65, 0.4-1 part of accelerator NOBS, 0.3-0.9 part of accelerator NS, 3-8 parts of insoluble sulfur OT-20 and 0.09-0.21 part of anti-scorching agent CTP. The scorching time is prolonged by 10%, the phenomenon of waste of rubber is reduced, and the adhesive force between the rubber and steel wires is enhanced by 10% or above. On the premise of ensuring the safety performance of the tire, the average service life of the tire is prolonged from 4-5 months to 7-8 months, and the number of remolds of the tire is doubled.

Owner:WEIFANG YUELONG RUBBER

Military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite and preparation method thereof

ActiveCN103029386BPuncture resistantTear resistantSynthetic resin layered productsLaminationPolyurethane elastomerPolymer science

The invention discloses a military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite which sequentially comprises a nylon camouflage cloth camouflage layer, a high-barrier layer taking aluminum foil as a substrate, and a heat sealing layer of a polyurethane elastomer film from the outside in. A preparation method of the composite comprises the steps of A preparing the high-barrier layer, and compositing polyethylene glycol terephthalate film and a polyamide film on the upper and the lower surfaces of the substrate, namely the aluminum foil, B compositing the upper surface of the high-barrier layer with a camouflage layer and curing, C compositing the lower surface of the high-barrier layer with the heat sealing layer of the thermoplastic polyurethane elastomer film and curing, and D coating the internal surface of the heat sealing layer with an antistatic agent, and obtaining the camouflage composite. According to the composite and the method, with the adoption of specific compositing and curing processes, the prepared camouflage composite has puncture-proof, tear-resistant, anti-static and high-barrier functions and the like, a protection envelope prepared by the material can effectively prevent army materials from being damp during long-term field storage and transportation, and the storage and transportation quality of the materials is improved.

Owner:中国人民解放军32181部队

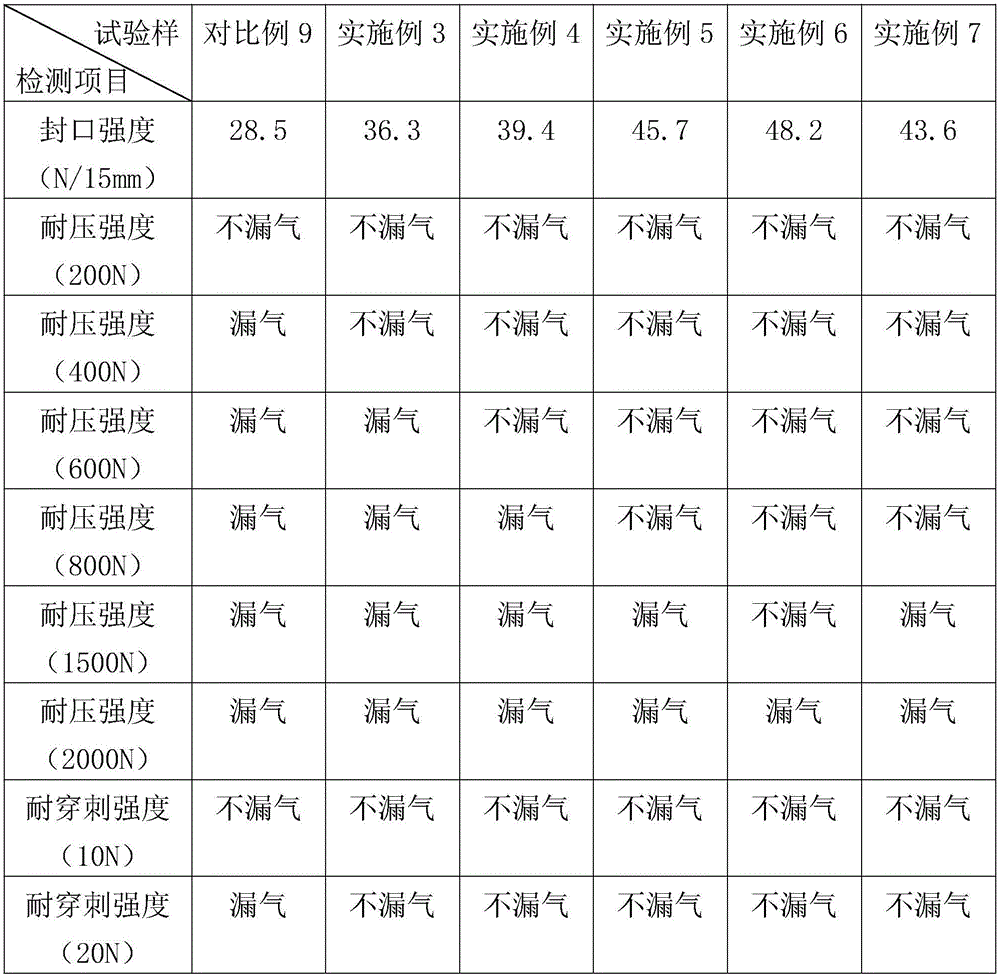

Glass-fiber membrane and glass-fiber vacuum bag

ActiveCN107175861AImprove connection stabilityImprove stabilityFlexible coversWrappersGlass fiberPuncture resistance

The invention discloses a glass-fiber membrane and a glass-fiber vacuum bag. According to the technical scheme, the glass-fiber membrane is characterized by comprising a glass-fiber cloth layer, a flame-retardant adhesive layer, a PET layer, a first adhesive layer, an aluminum-foil layer, a second adhesive layer, a PA layer, a third adhesive layer and an SPE layer which are sequentially connected from bottom to top. The glass-fiber membrane is prepared into the corresponding glass-fiber vacuum bag through a corresponding process, the prepared glass-fiber vacuum bag is good in sealing strength, compression strength and puncture resistance, and the sealing structural strength and usability of the glass-fiber vacuum bag are improved.

Owner:安徽科能新材料环保科技有限公司

Cutting-resistant glove processing technology

InactiveCN110644243ASimple processing technologyImprove cut resistanceWeft knittingGlovesPolyesterYarn

The invention provides a cutting-resistant glove processing technology, and relates to the field of labor protection gloves. The cutting-resistant glove processing technology includes the steps: glovecore preparation; glove core coating. Inner yarns and outer yarns are interwoven to form a glove core, polyethylene fibers with super-high relative molecule weight and bamboo-carbon modified polyester fibers wrap carbon fibers to form the outer yarns, and polyethylene fibers with super-high relative molecule weight and nylon fibers spirally wrap polyurethane filaments to form the inner yarns. A coating method of the glove core particularly includes the step: coating a composite material outside the woven glove core. The cutting-resistant glove processing technology is simple, large-scale automation production can be achieved, a processed cutting-resistant glove has excellent cutting resistance, comfortable and portable to wear and long in service life, hand flexibility is good, and replacing frequency is reduced.

Owner:徐州华通手套有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com