Military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite and preparation method thereof

A composite material, high-barrier technology, used in chemical instruments and methods, lamination devices, synthetic resin layered products, etc., can solve the problems of easy puncture of protective materials, poor barrier properties, poor flexibility, etc. Kneading performance, the effect of enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

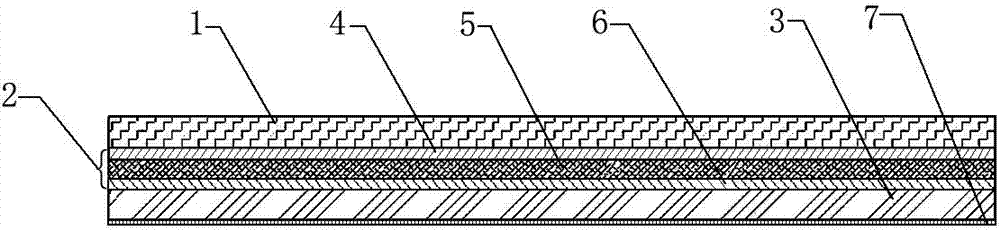

[0031] Such as figure 1 As shown, the camouflage camouflage composite material of the present invention comprises a camouflage layer 1, a high barrier layer 2, a heat seal layer 3 and an antistatic layer 7 from top to bottom, wherein the camouflage layer 1 is a nylon camouflage cloth layer; Down to the bottom are polyethylene terephthalate film 4 with a thickness of 12 μm, aluminum foil 5 with a thickness of 7 μm, and polyamide film 6 with a thickness of 15 μm; the heat-sealing layer 3 is thermoplastic polyurethane with a thickness of 135 μm Elastomeric membrane. Each layer is bonded together with an adhesive, and then heat-compressed by the heating roller of the compound machine to form a composite material. The antistatic layer 7 is a polyurethane antistatic agent coated on the outer surface of the heat-sealing layer 3 .

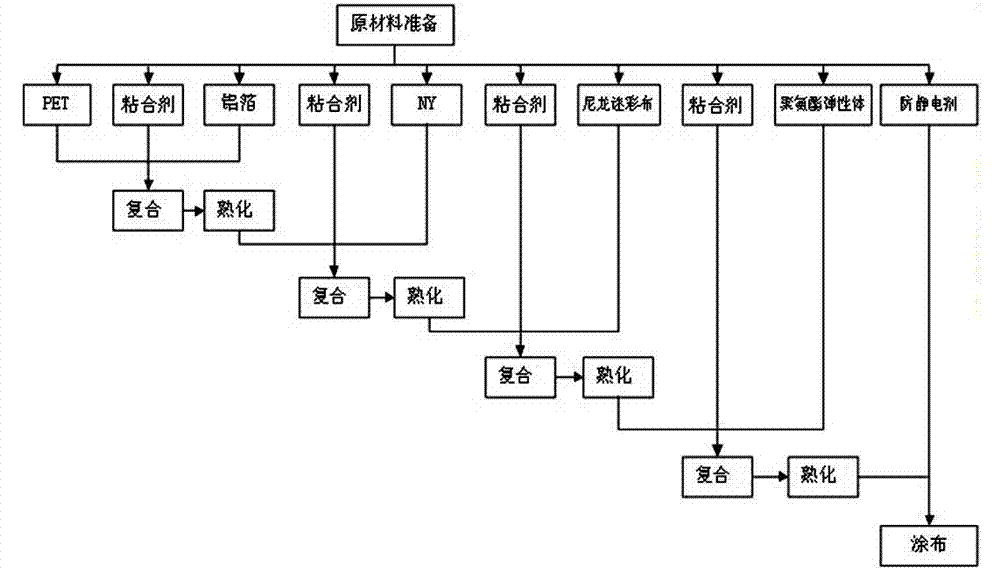

[0032] Such as figure 2 Shown, the preparation technology of camouflage camouflage composite material of the present invention is:

[0033] (1) Coat ...

Embodiment 2

[0038] The camouflage camouflage composite material of the present invention comprises a camouflage layer 1, a high barrier layer 2, a heat seal layer 3 and an antistatic layer 7 from top to bottom, wherein the camouflage layer 1 is a nylon camouflage cloth layer; the high barrier layer 2 is sequential from top to bottom It is a polyethylene terephthalate film 4 with a thickness of 12 μm, an aluminum foil 5 with a thickness of 7 μm, and a polyamide film 6 with a thickness of 15 μm; the heat-sealing layer 3 is a thermoplastic polyurethane elastomer film with a thickness of 140 μm . Each layer is bonded together with an adhesive, and then heat-compressed by the heating roller of the compound machine to form a composite material. The antistatic layer 7 is a polyurethane antistatic agent coated on the outer surface of the heat-sealing layer 3 .

[0039] The preparation technology of camouflage camouflage composite material of the present invention is:

[0040] (1) Coat the surfa...

Embodiment 3

[0045] The camouflage camouflage composite material of the present invention comprises a camouflage layer 1, a high barrier layer 2, a heat-sealing layer 3 and an antistatic layer 7 from top to bottom, wherein the camouflage layer 1 is a nylon camouflage cloth layer, and its lower surface is coated with a thickness of 5 μm Polyurethane elastomer coating; the high barrier layer 2 from top to bottom is a polyethylene terephthalate film 4 with a thickness of 12 μm, an aluminum foil 5 with a thickness of 7 μm, and a polyamide film 6 with a thickness of 15 μm; The heat-sealing layer 3 is a thermoplastic polyurethane elastomer film with a thickness of 130 μm. Each layer is bonded together with an adhesive, and then heat-compressed by the heating roller of the compound machine to form a composite material. The antistatic layer 7 is a polyurethane antistatic agent coated on the outer surface of the heat-sealing layer 3 .

[0046] The preparation technology of camouflage camouflage co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com