Patents

Literature

1644 results about "PEG-terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

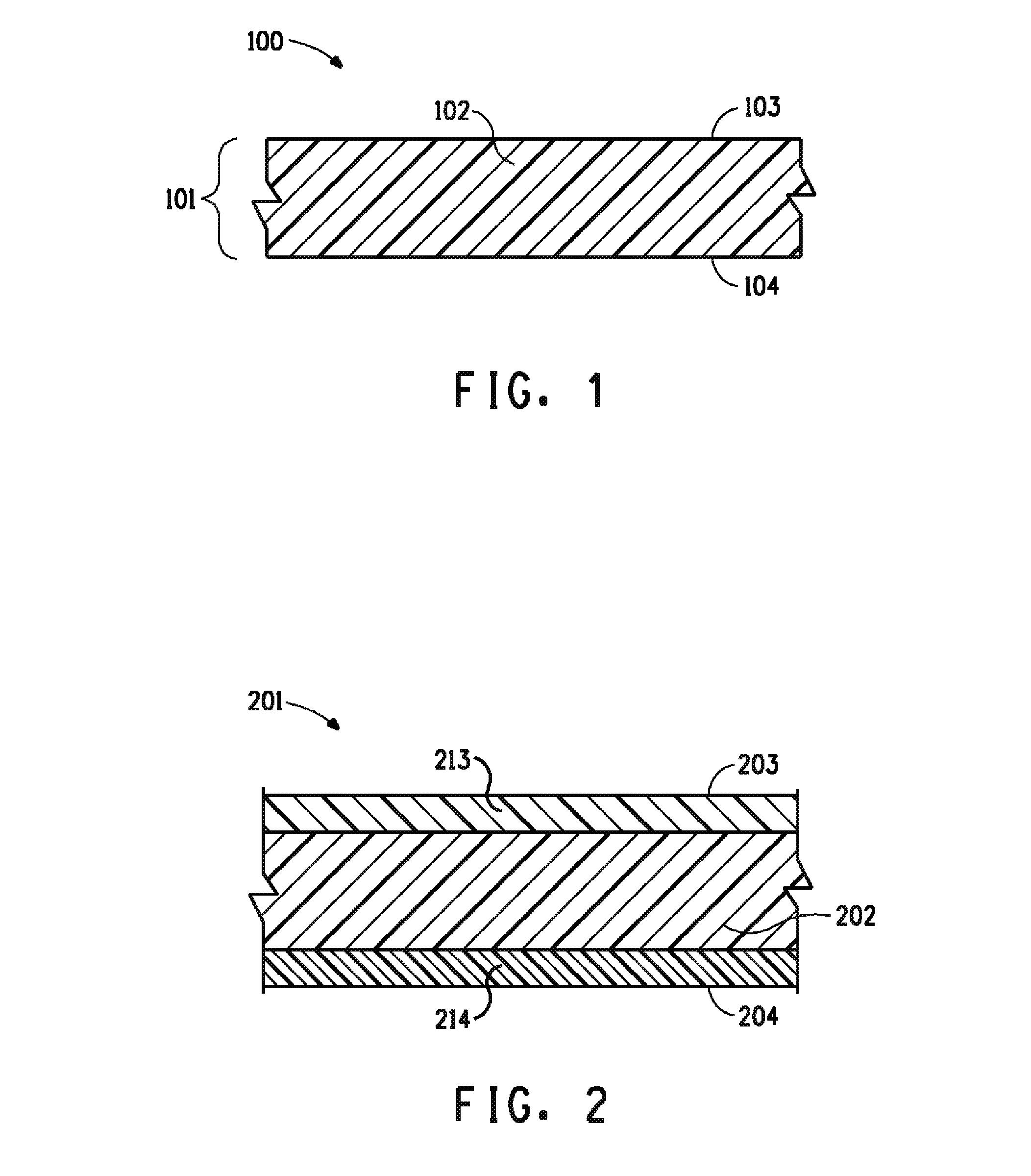

Flexible high-temperature ultrabarrier

InactiveUS7018713B2Final product manufactureSynthetic resin layered productsPolyethylene terephthalateOrganic light emitting device

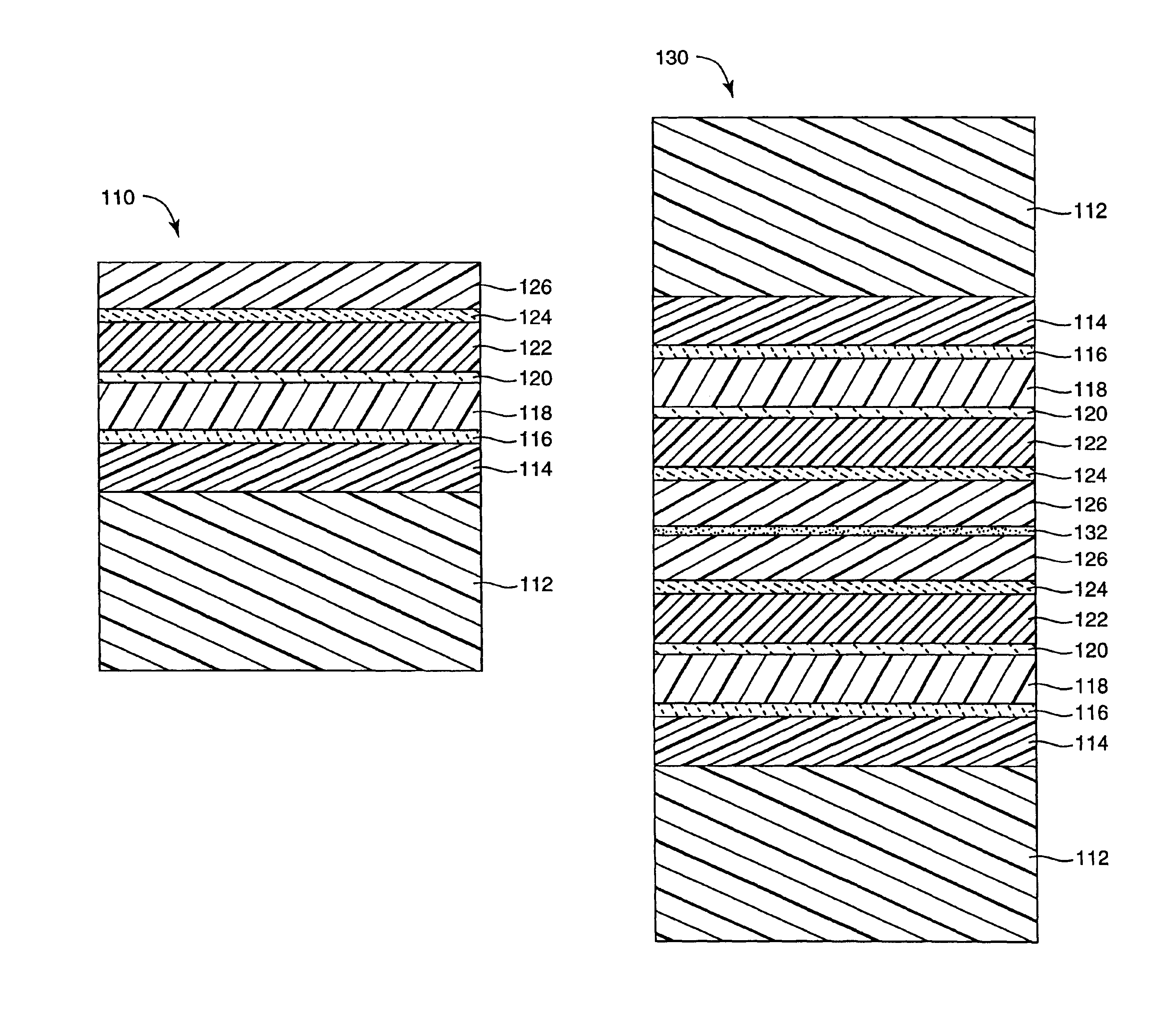

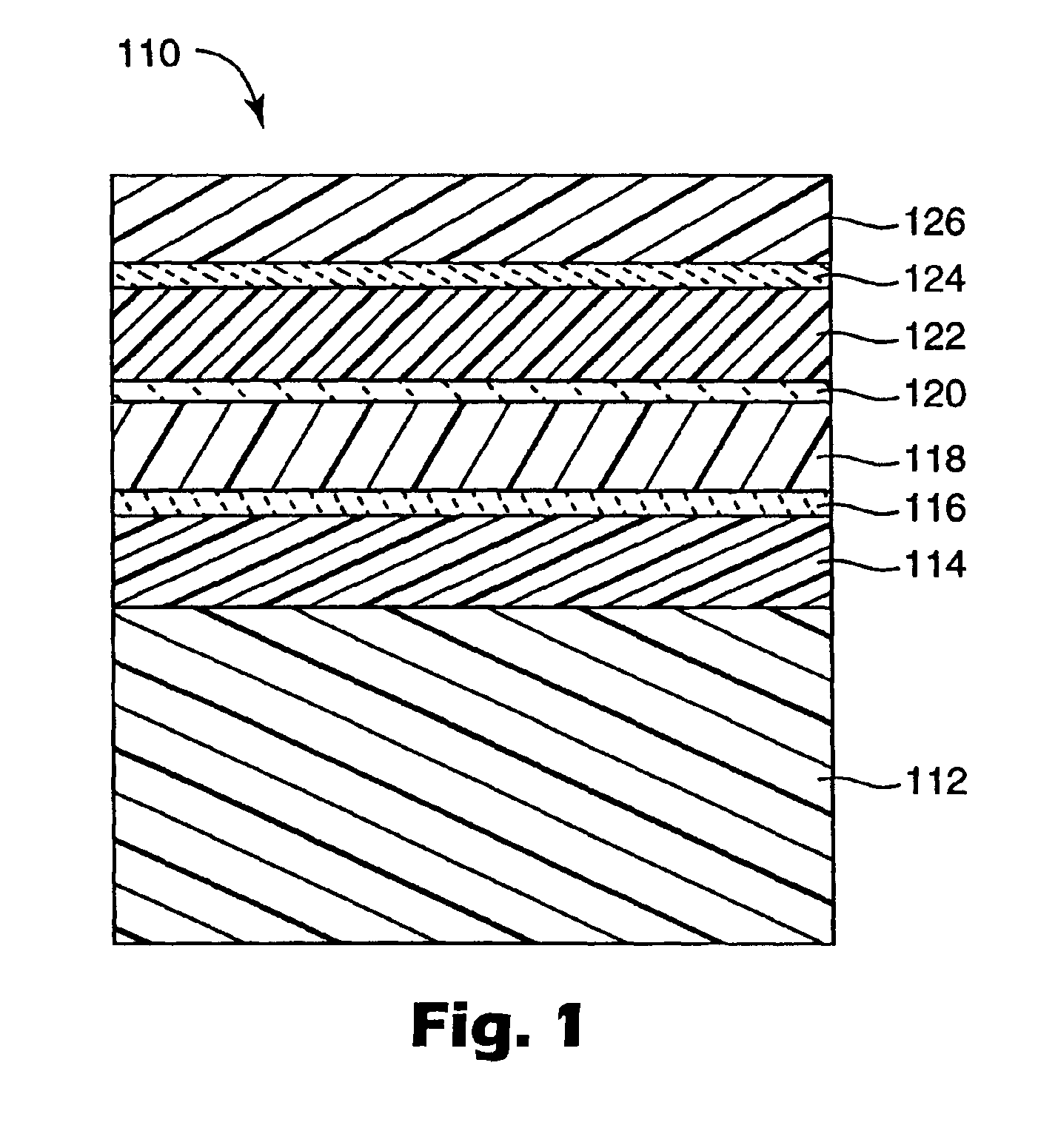

A flexible barrier assembly having a flexible visible light-transmissive substrate having a Tg greater than or equal to that of heat-stabilized polyethylene terephthalate (“HSPET”) overcoated with a first polymer layer having a Tg greater than or equal to that of HSPET and further overcoated with at least two visible light-transmissive inorganic barrier layers separated by at least one second polymer layer having a Tg greater than or equal to that of HSPET can be used to mount, cover, encapsulate or form moisture- and oxygen-sensitive articles such as organic light emitting devices and light valves.

Owner:3M INNOVATIVE PROPERTIES CO

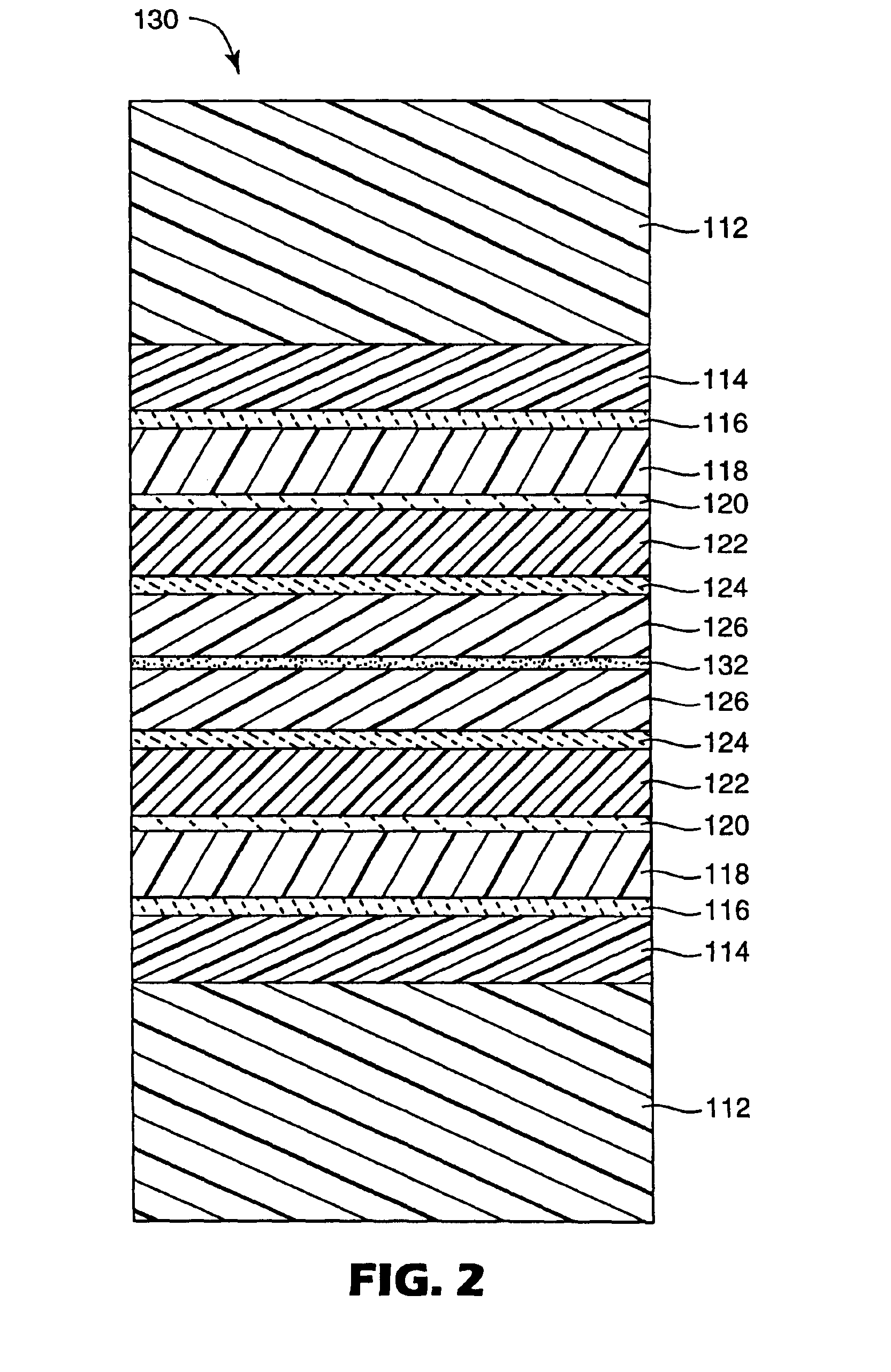

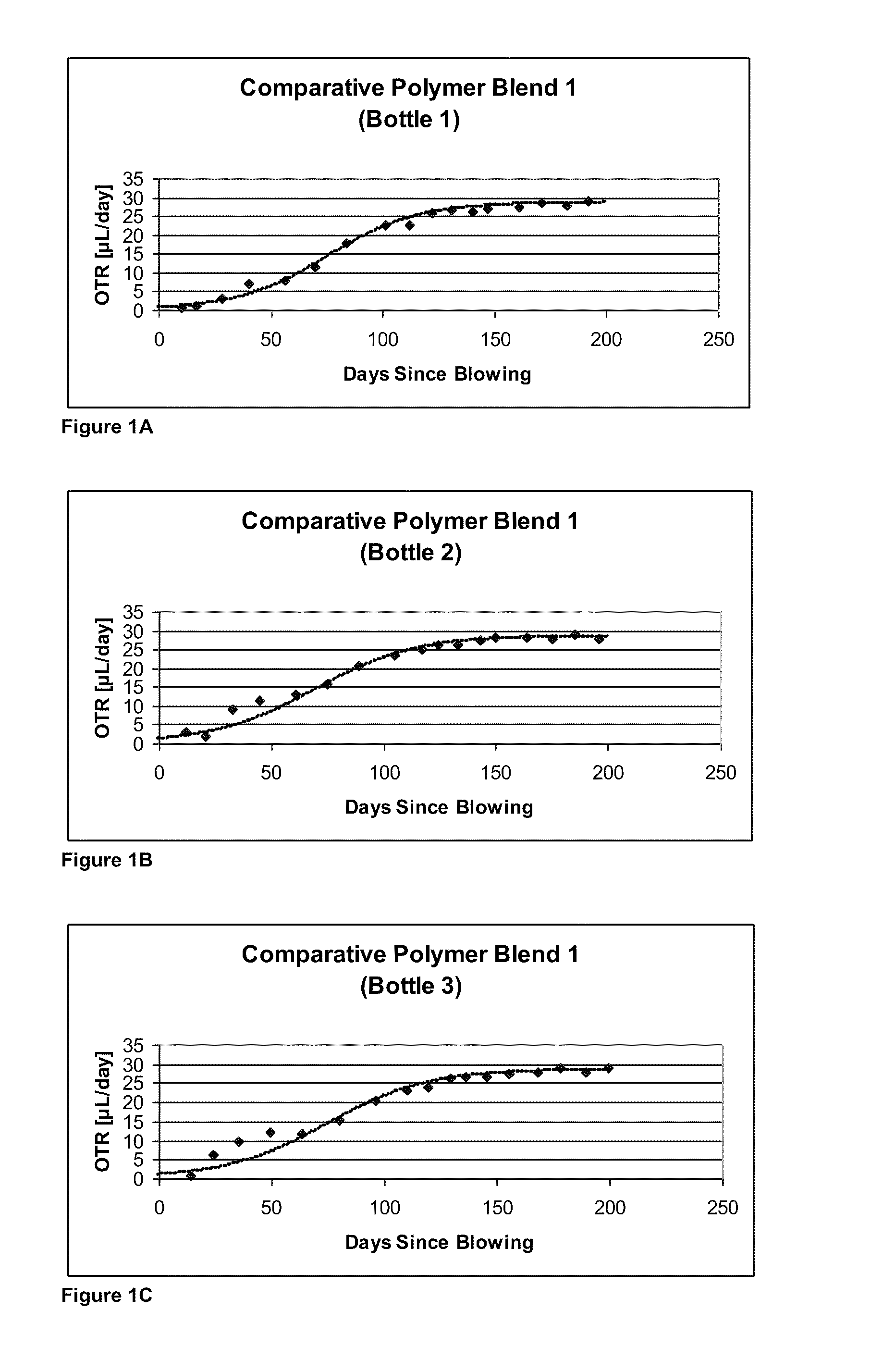

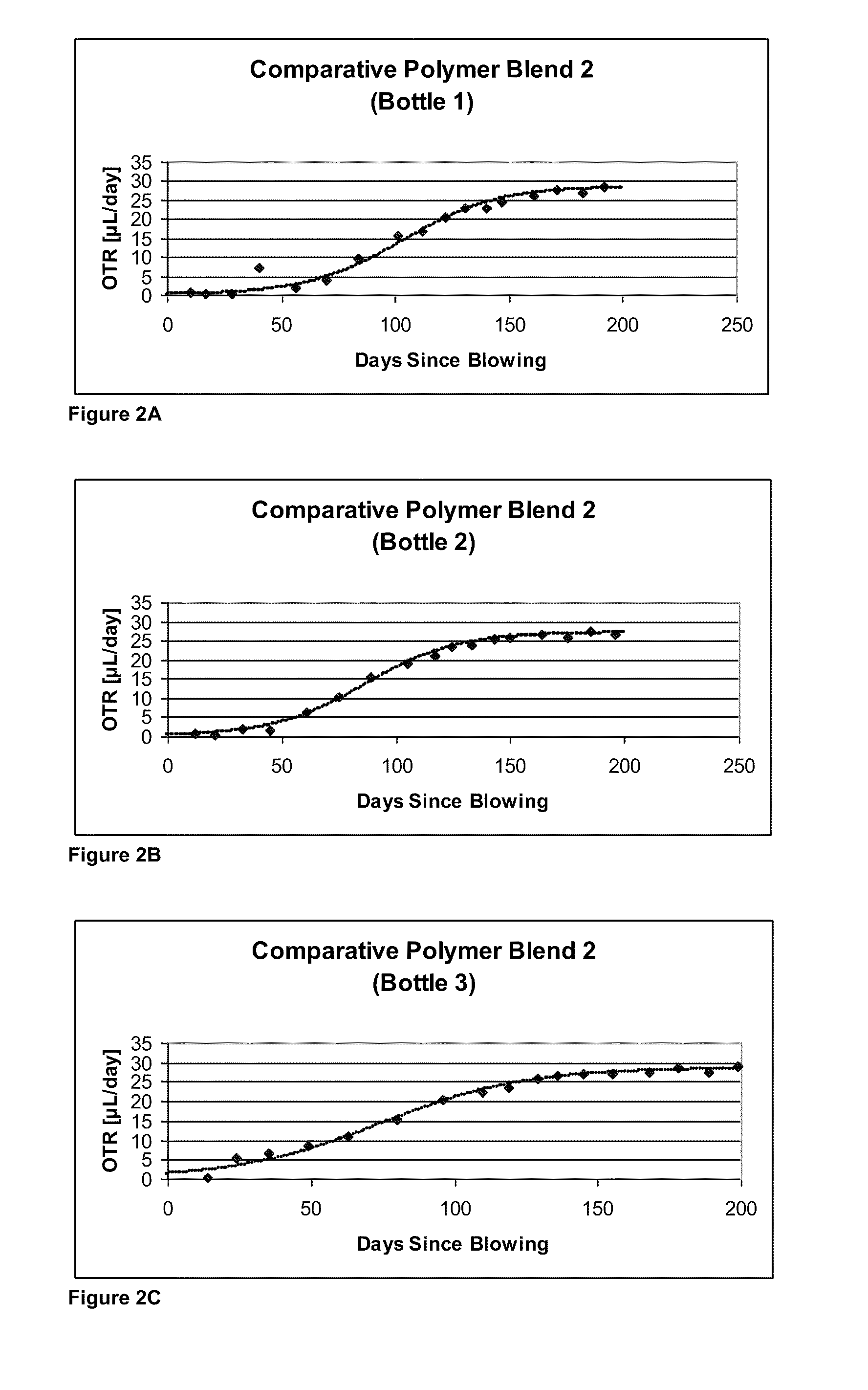

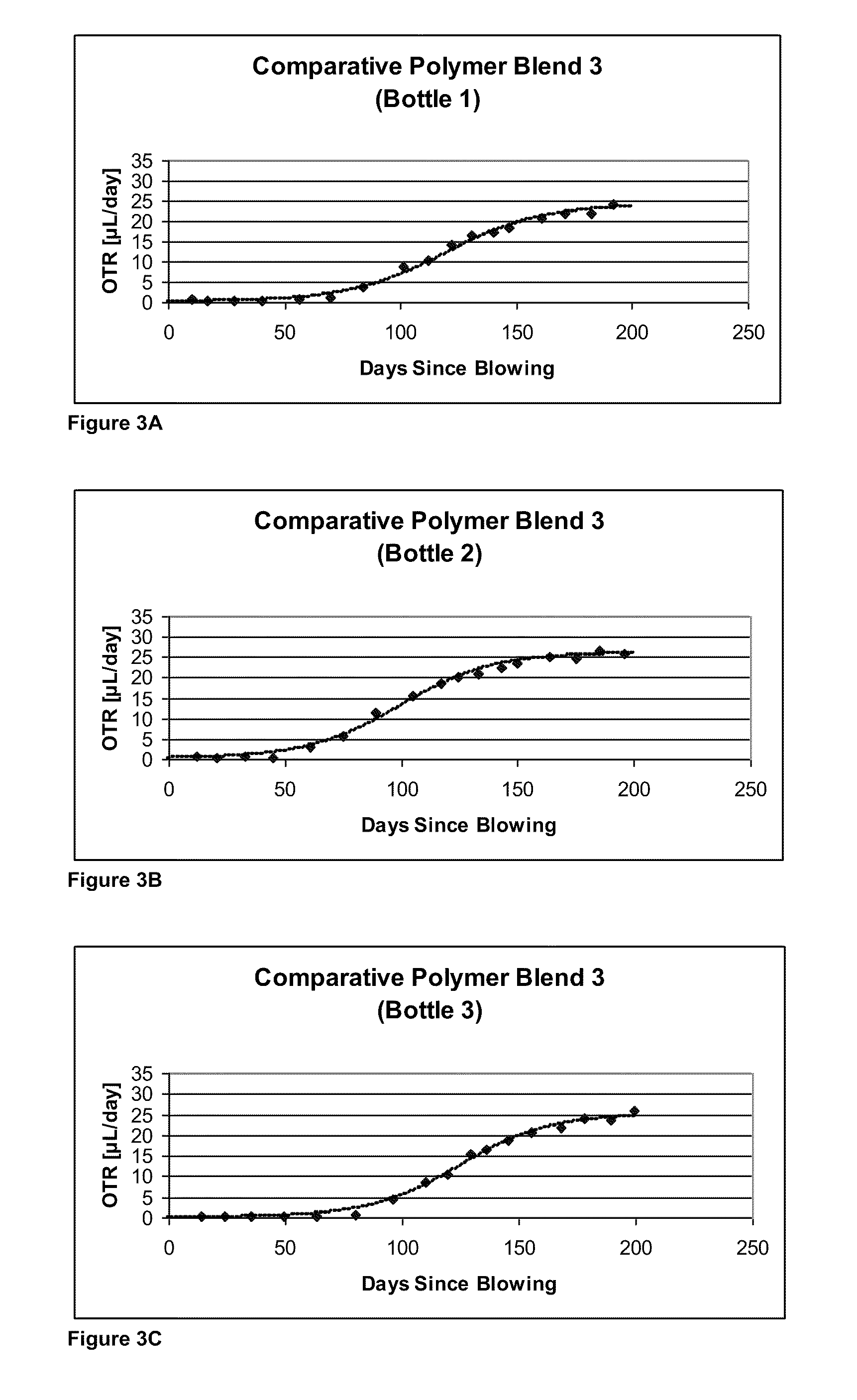

Oxygen-scavenging polymer blends suitable for use in packaging

InactiveUS20110045222A1Group 4/14 element organic compoundsSynthetic resin layered productsPolyethylene terephthalate glycolPolyethylene terephthalate

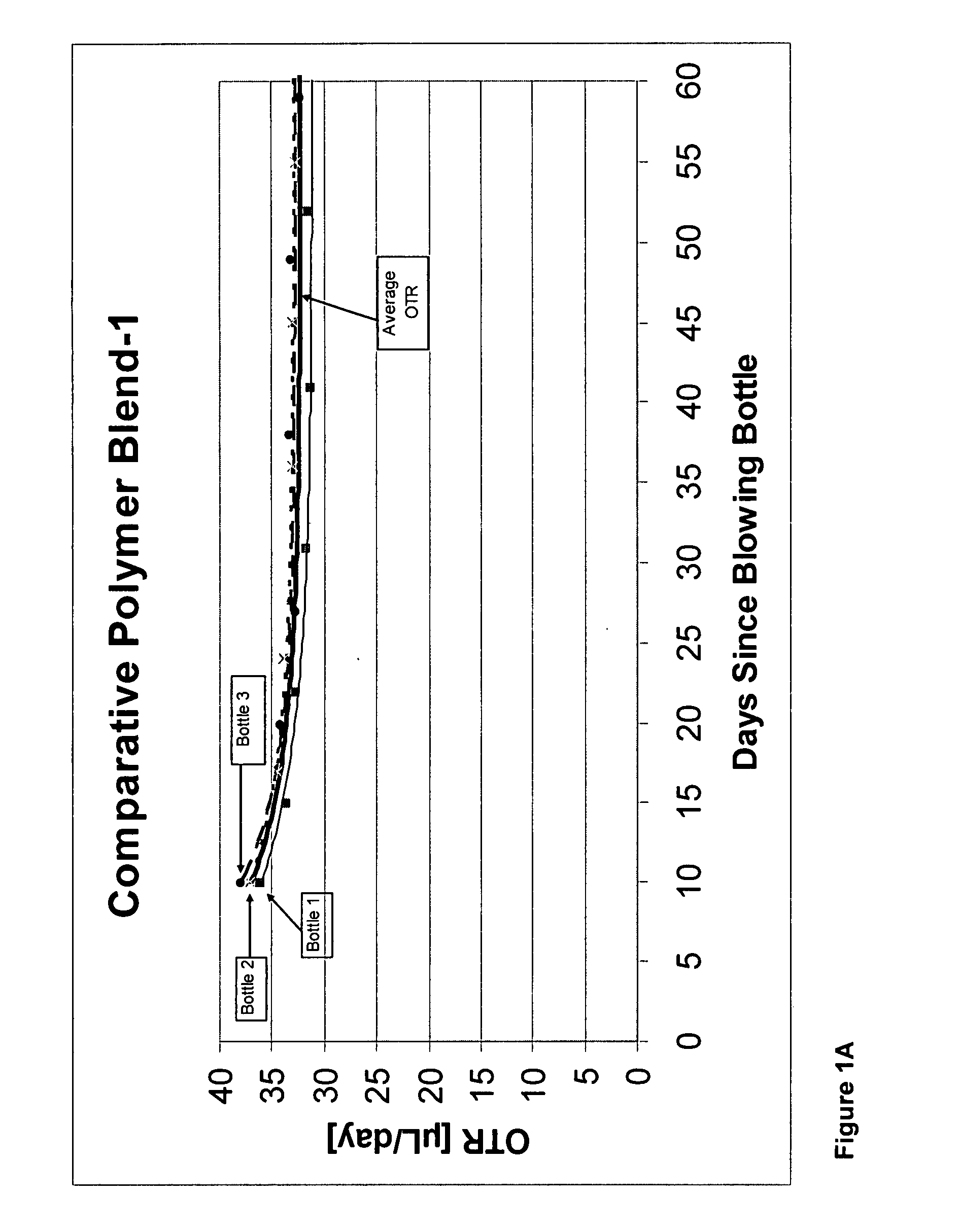

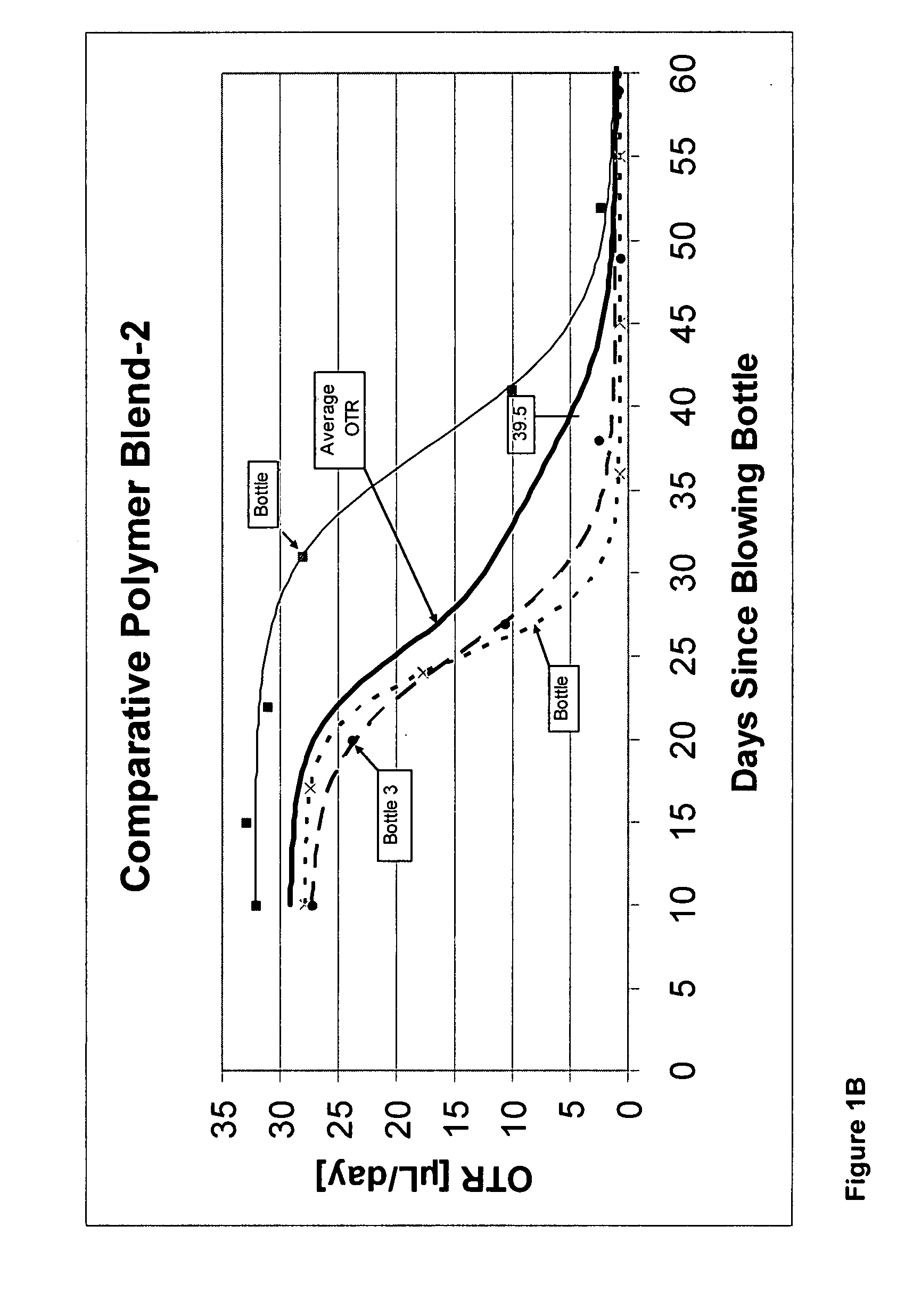

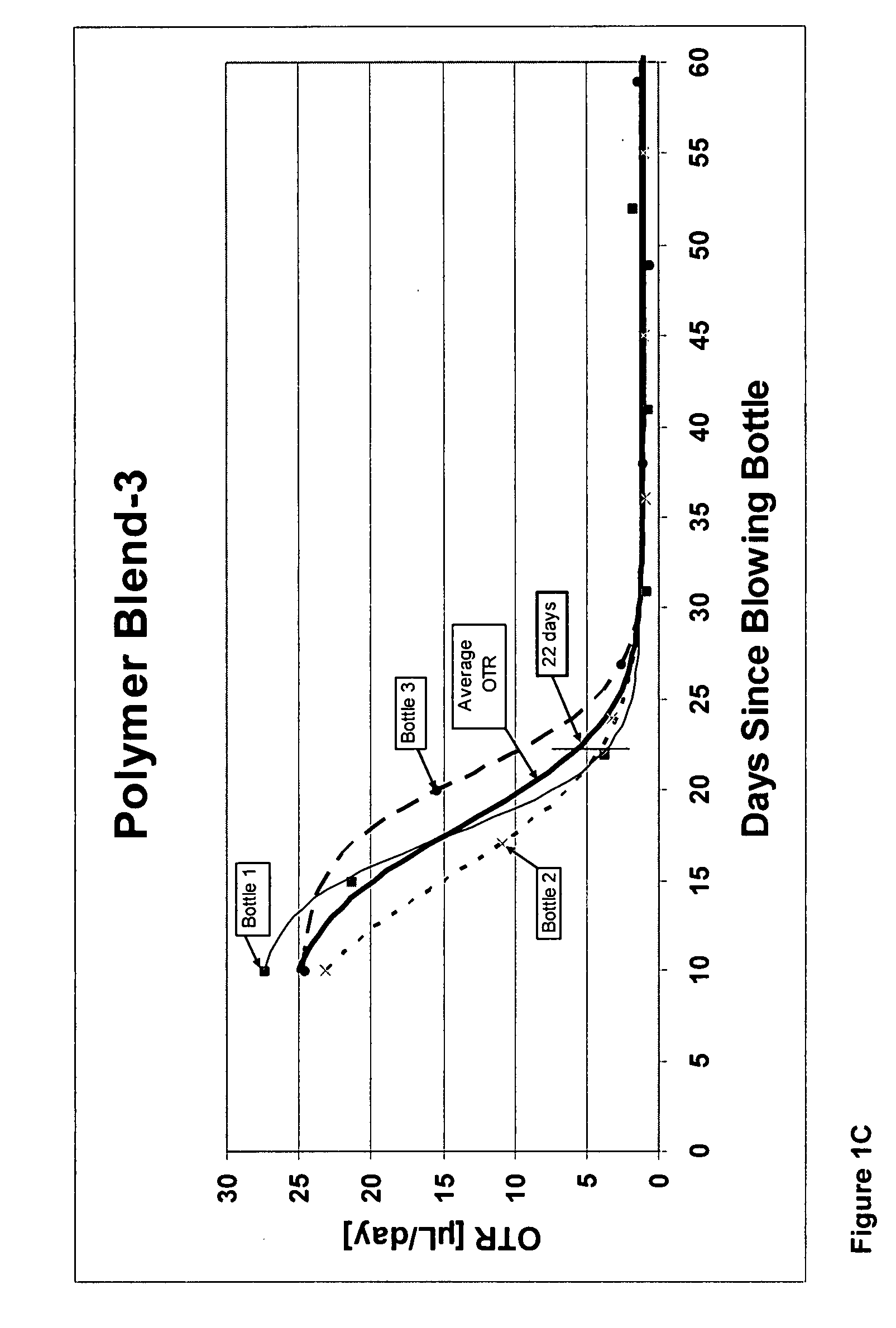

Polymer blends are disclosed that comprise one or more unsaturated olefinic homopolymers or copolymers having at least one functionality capable of entering into condensation reactions; one or more polyamide homopolymers or copolymers; one or more polyethylene terephthalate homopolymers or copolymers obtained using a catalyst system comprising antimony atoms; and one or more transition metal atoms. The inventive blends are useful for packaging, and exhibit improved oxygen-scavenging activity and lower haze compared with blends made using polyethylene terephthalate polymers prepared with antimony catalyst and either the olefinic or the polyamide homopolymers or copolymers, individually.

Owner:EASTMAN CHEM CO

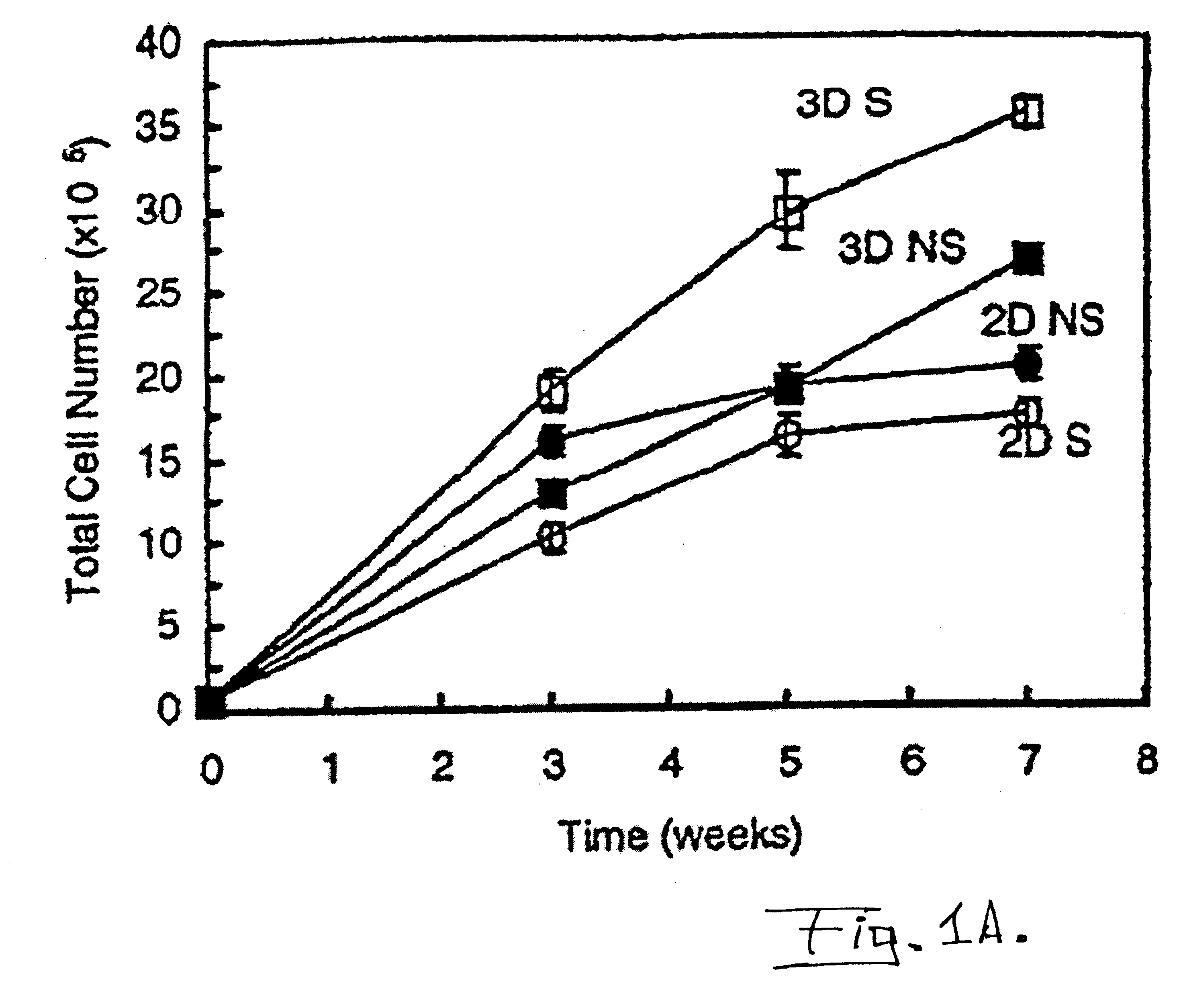

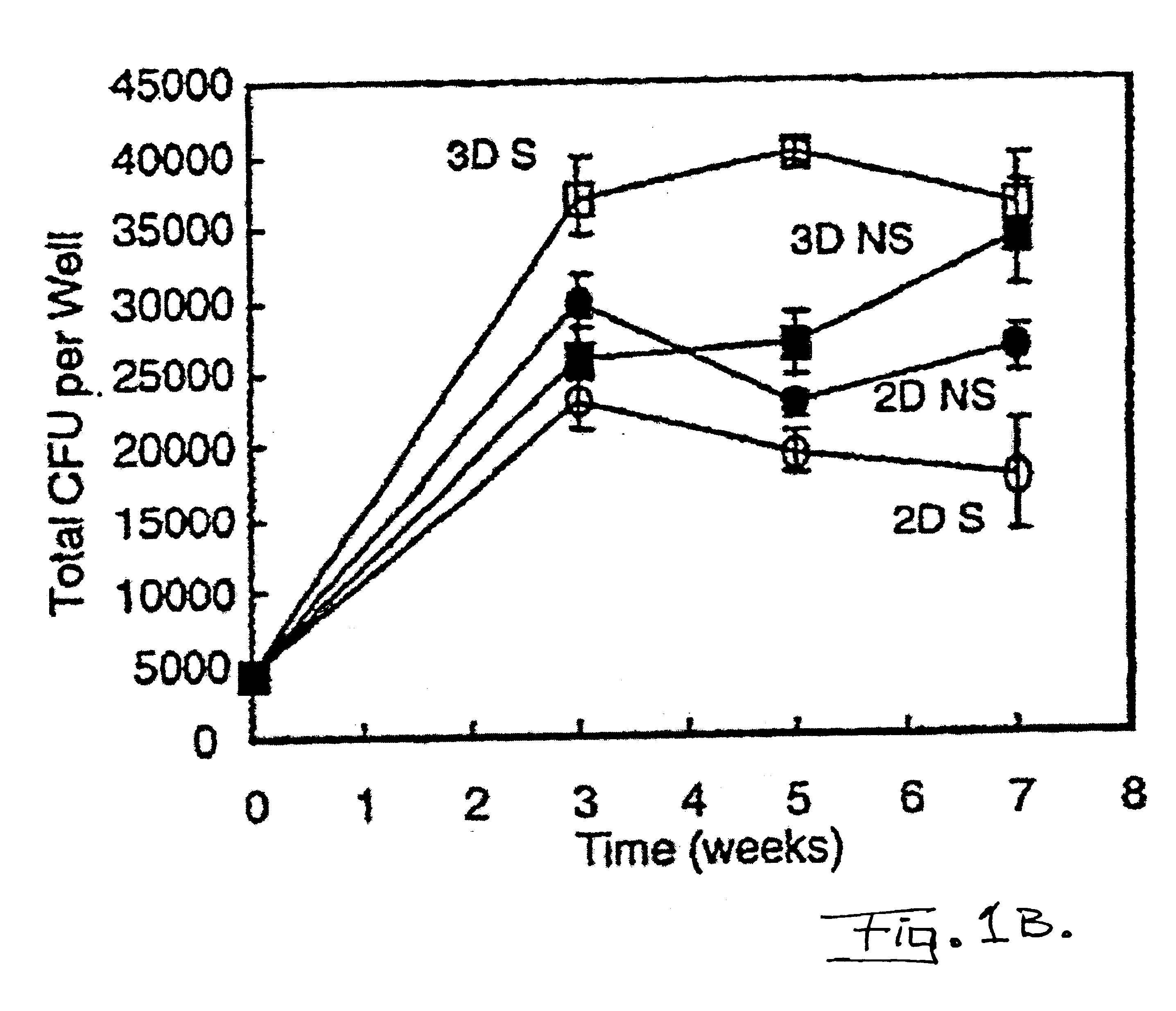

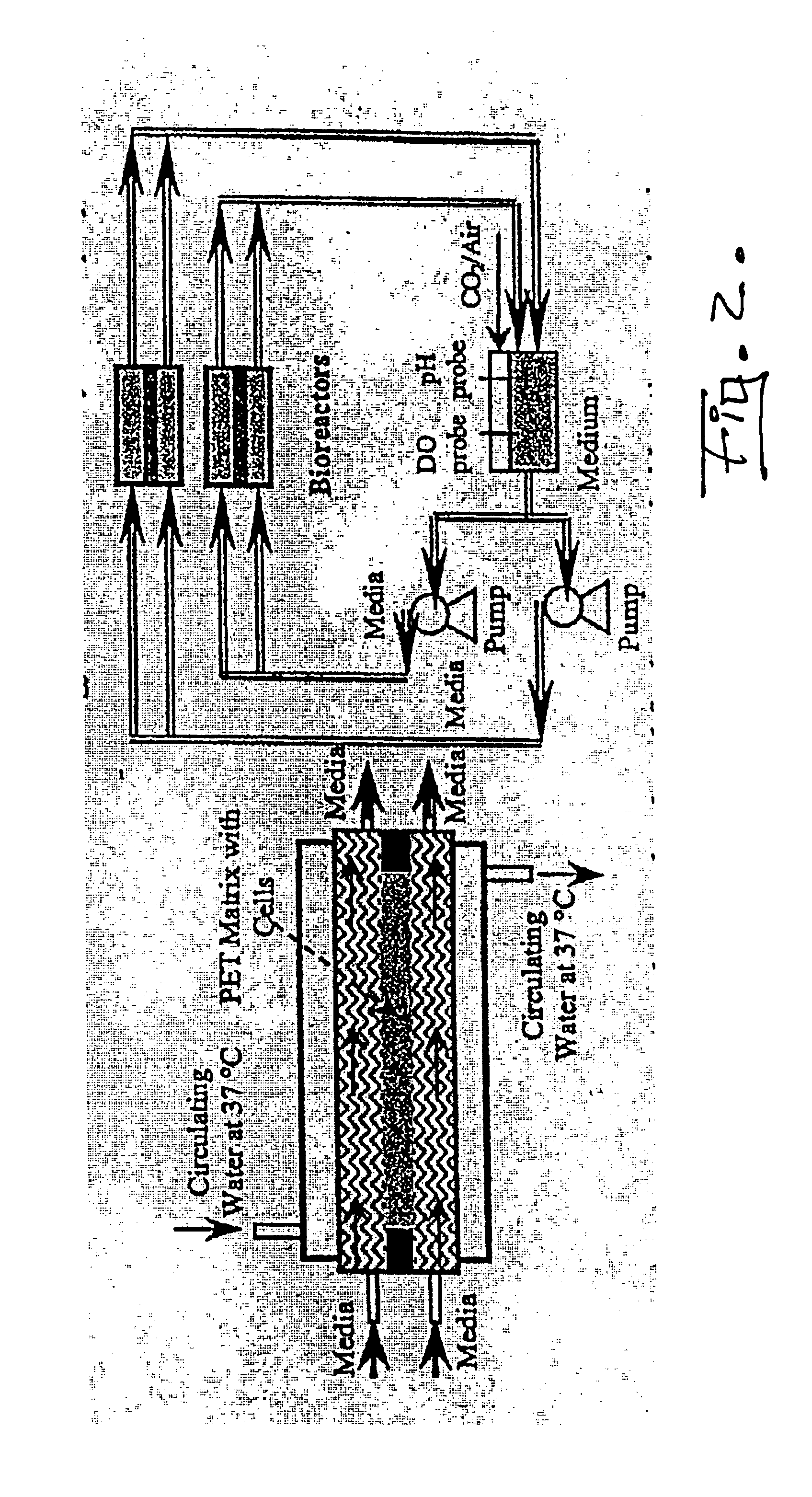

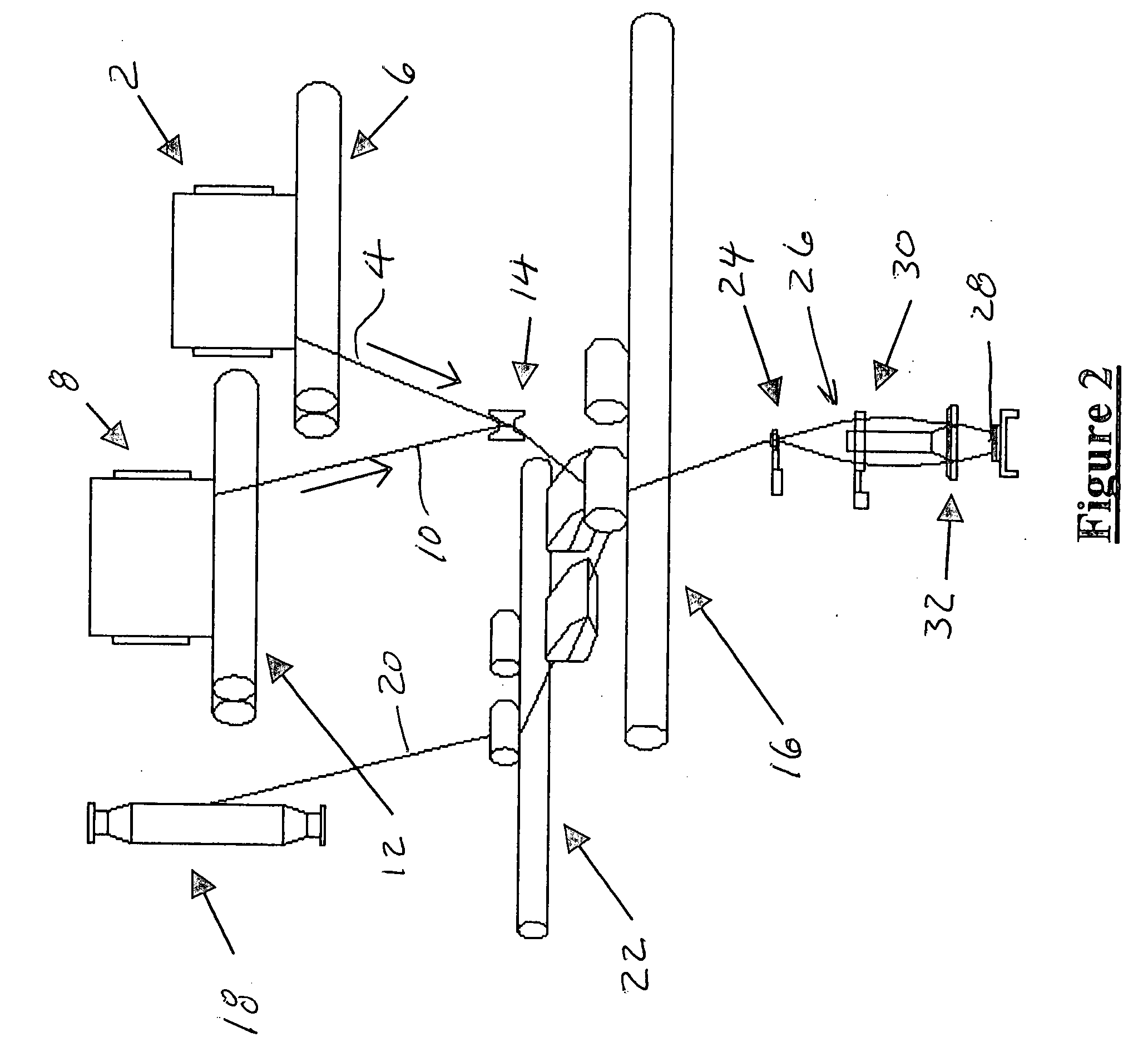

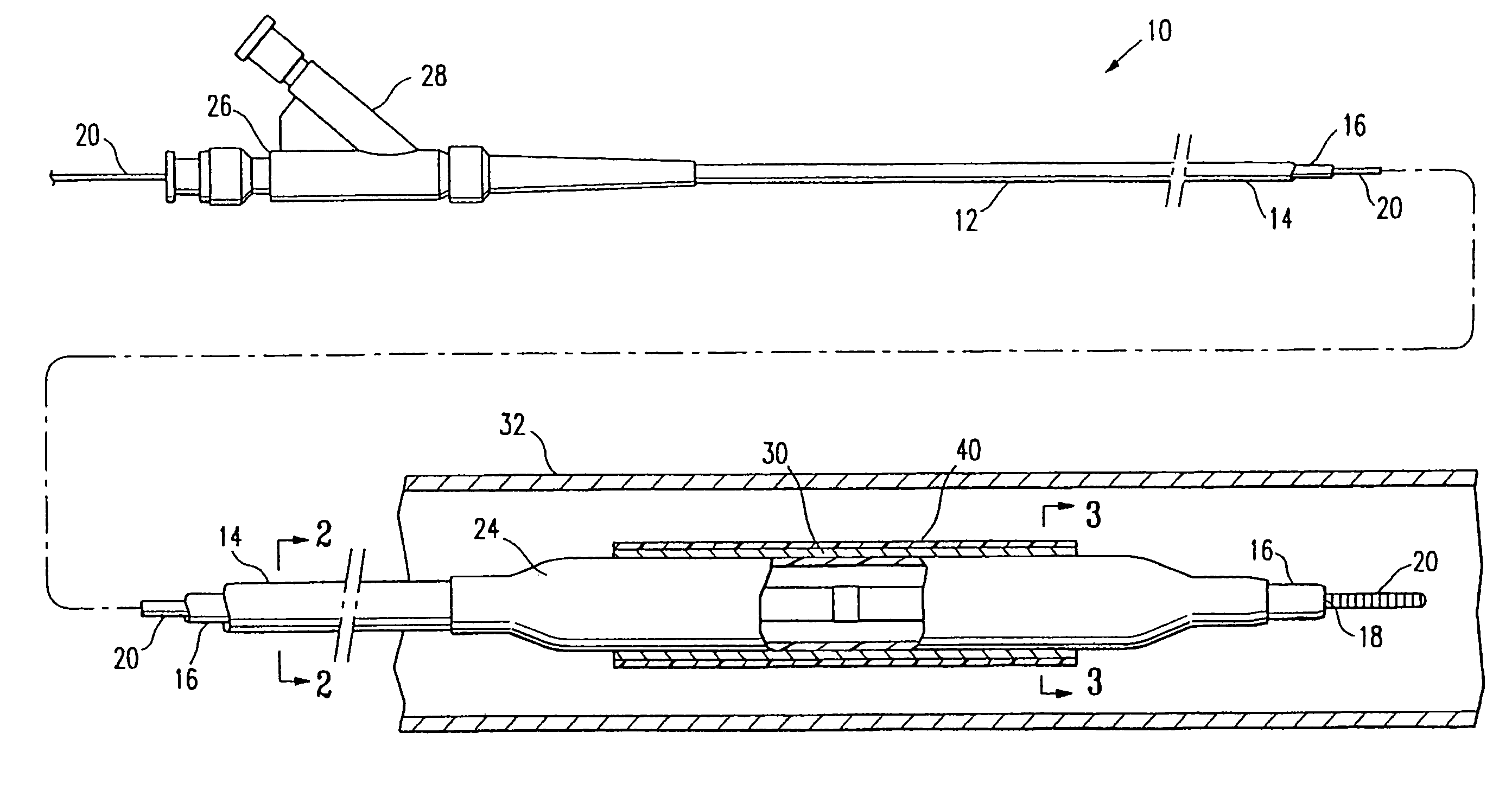

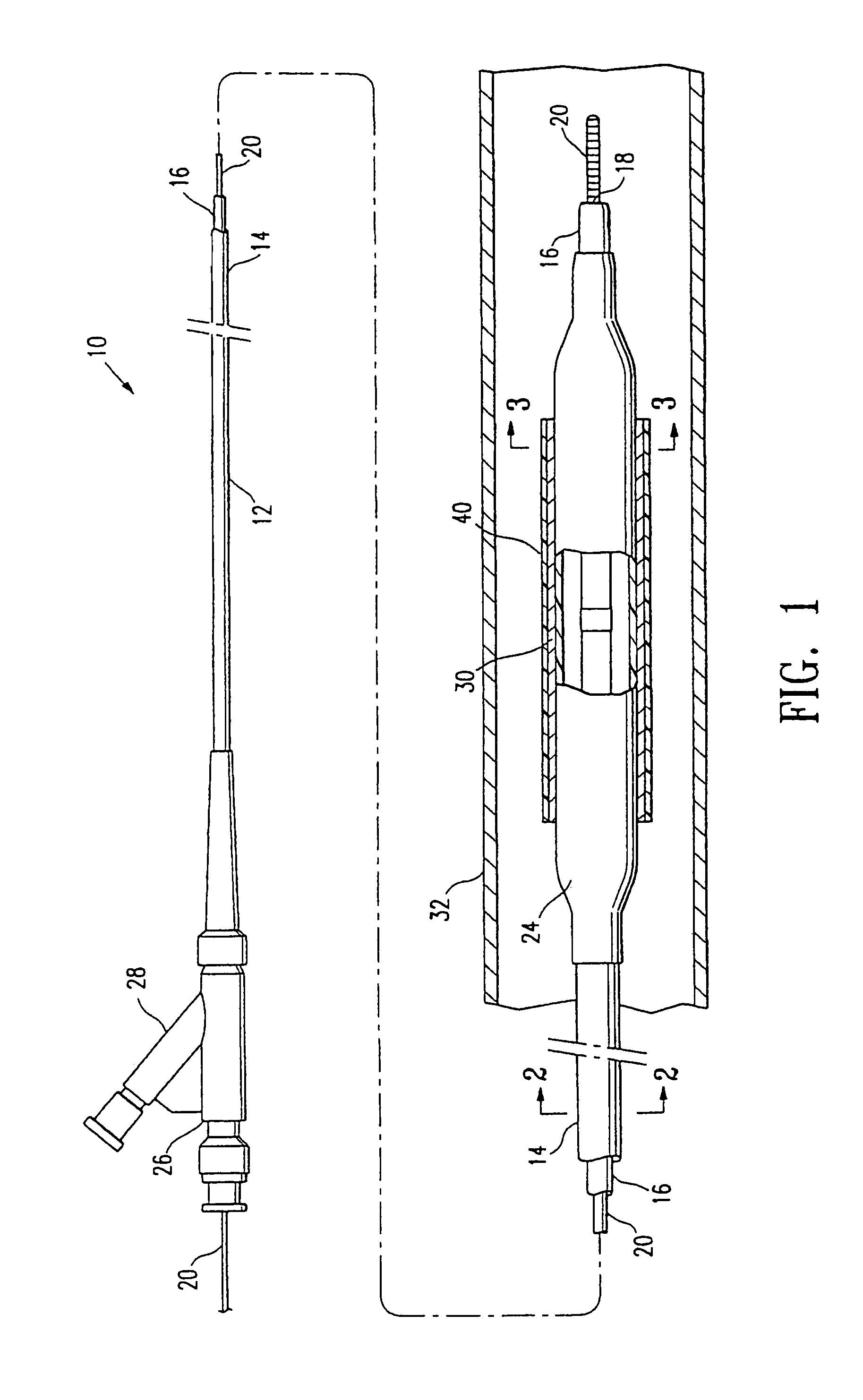

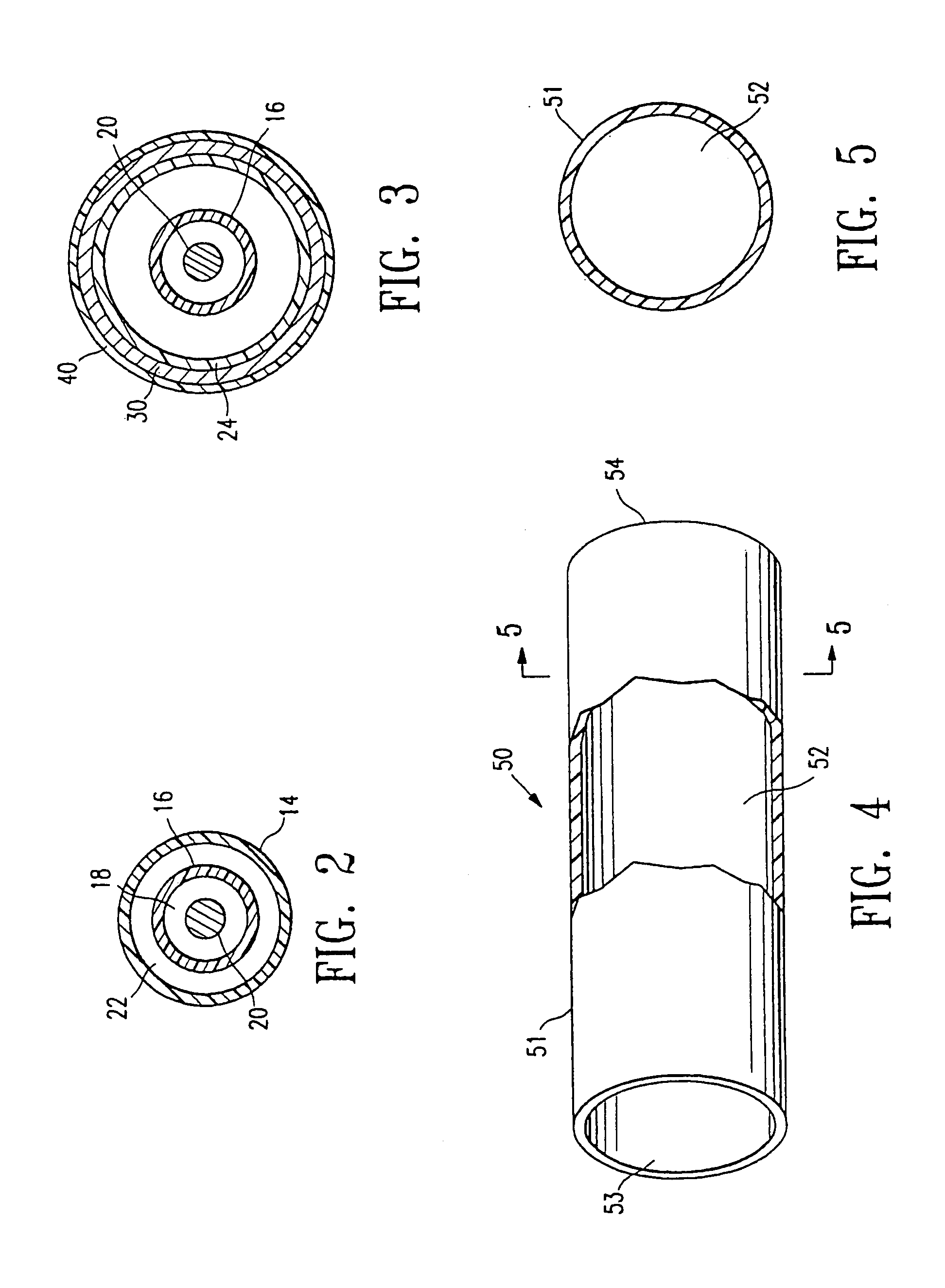

Modular cell culture bioreactor and associated methods

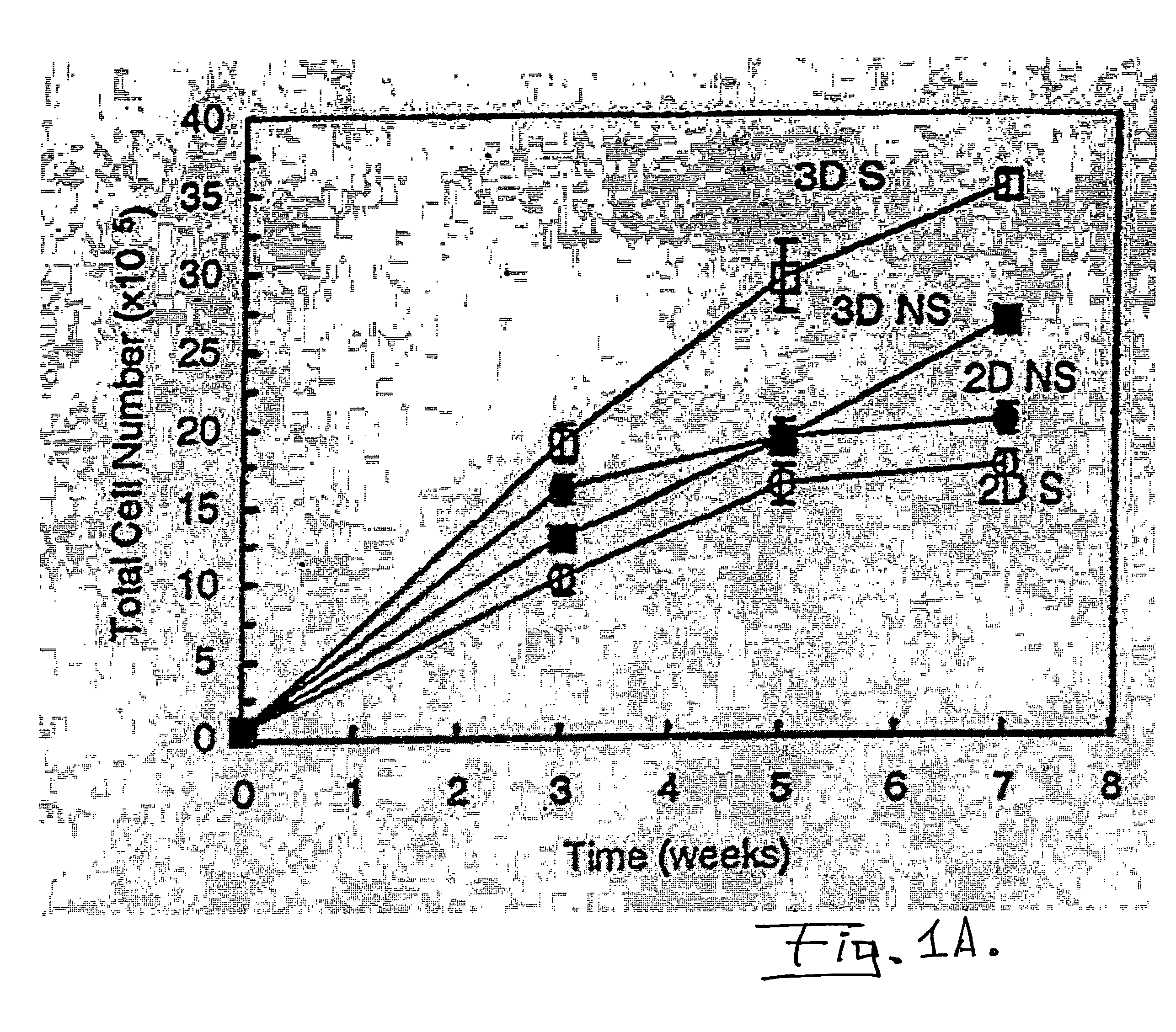

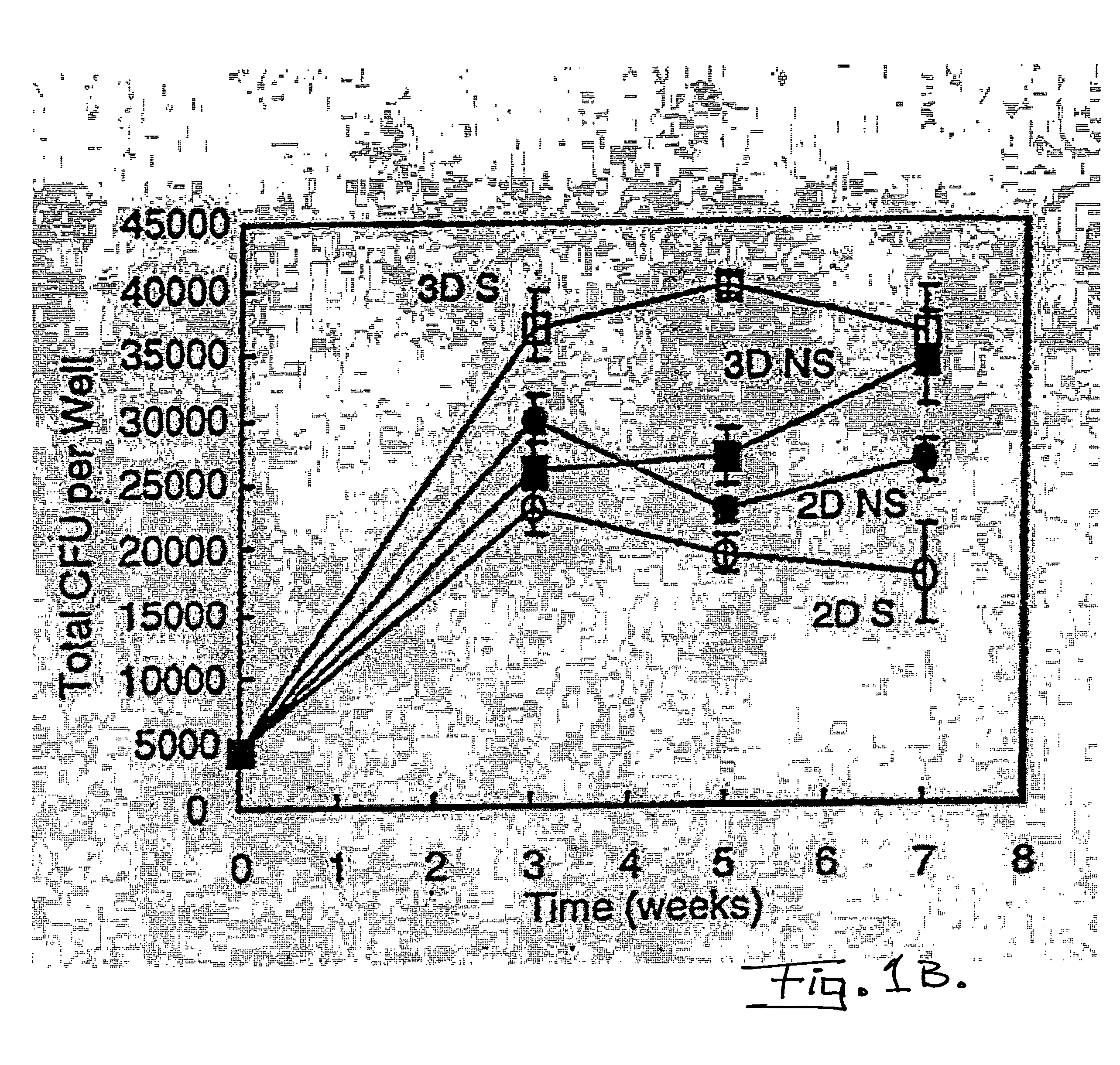

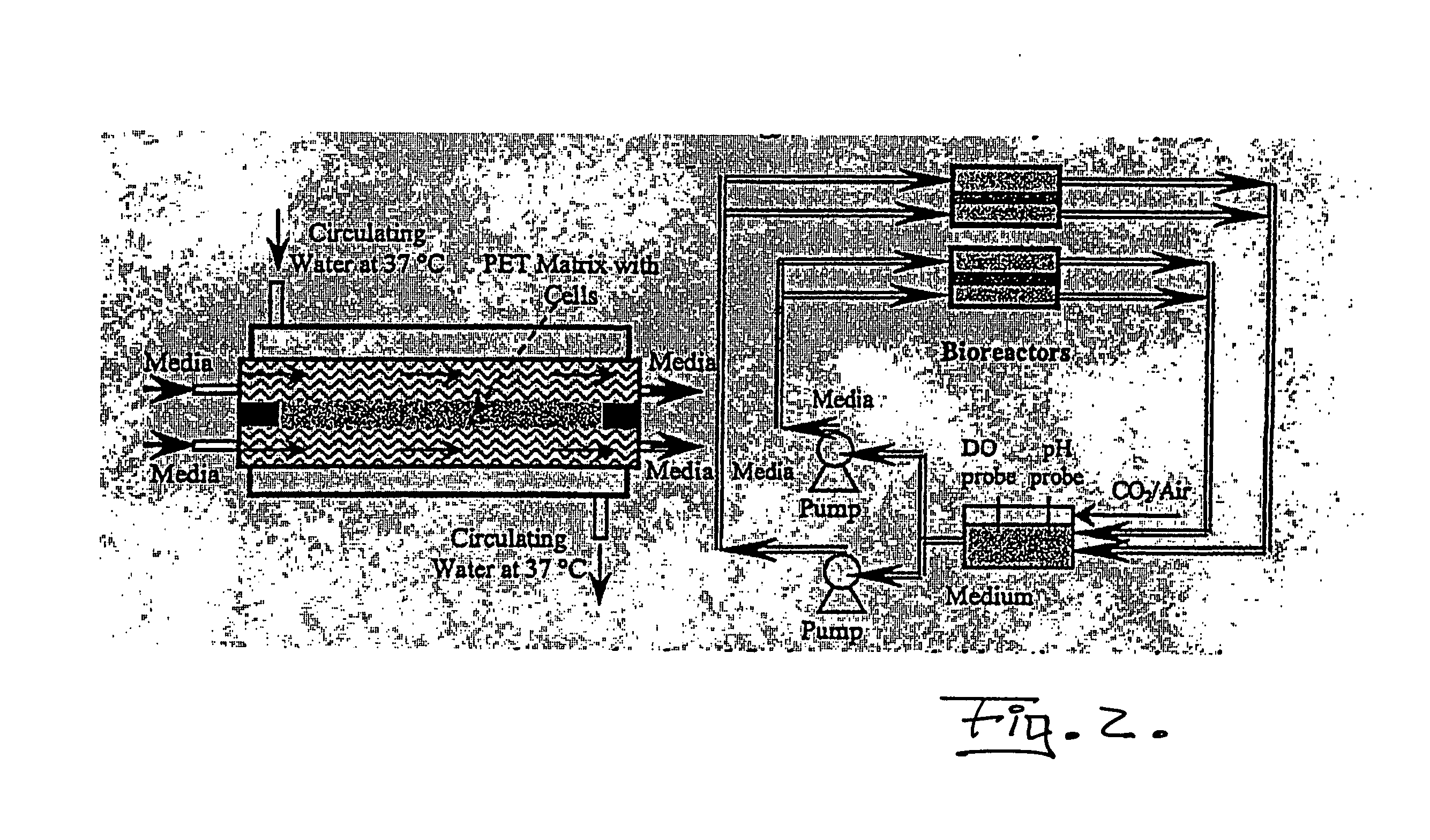

InactiveUS6875605B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPolyethylene terephthalate3D cell culture

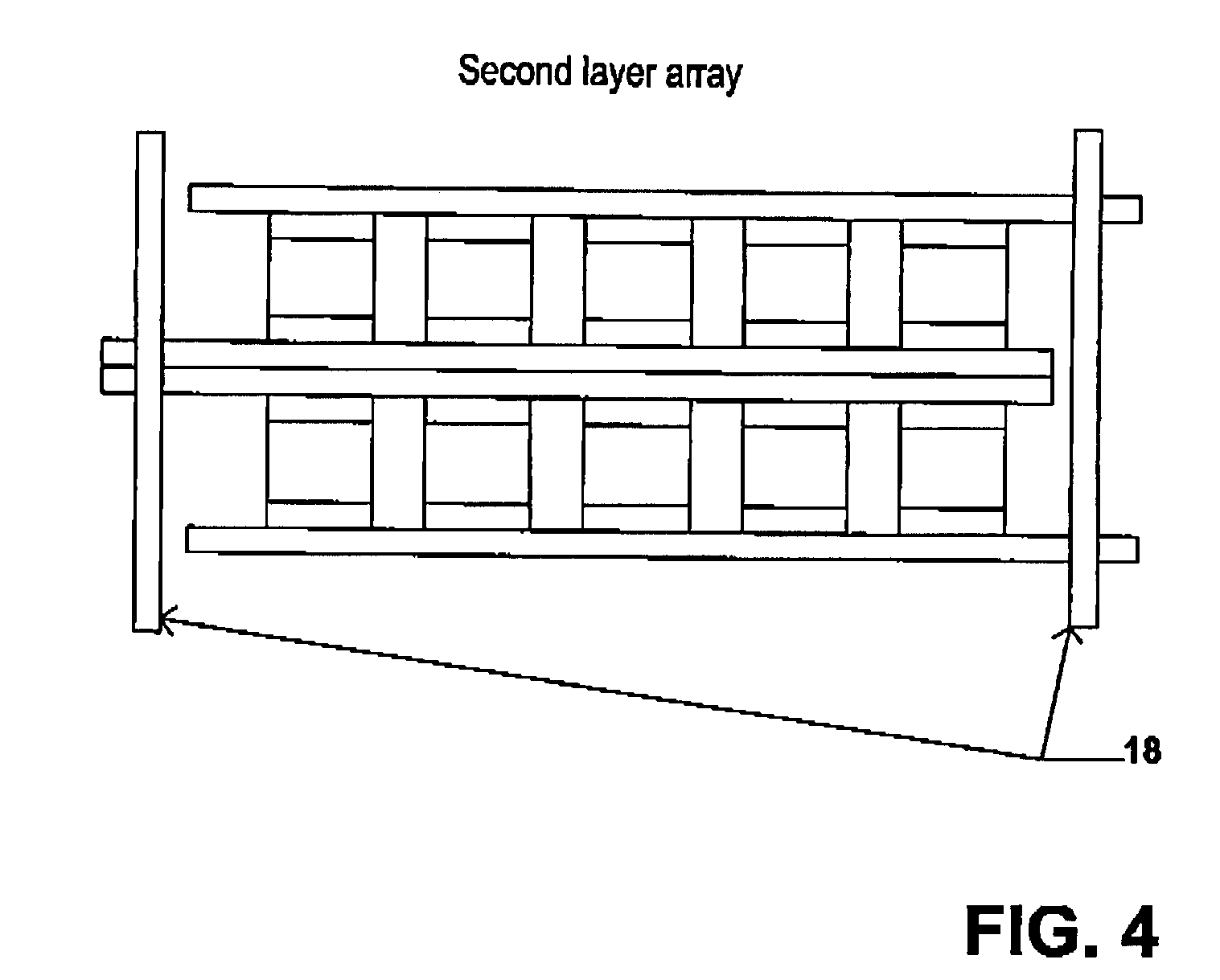

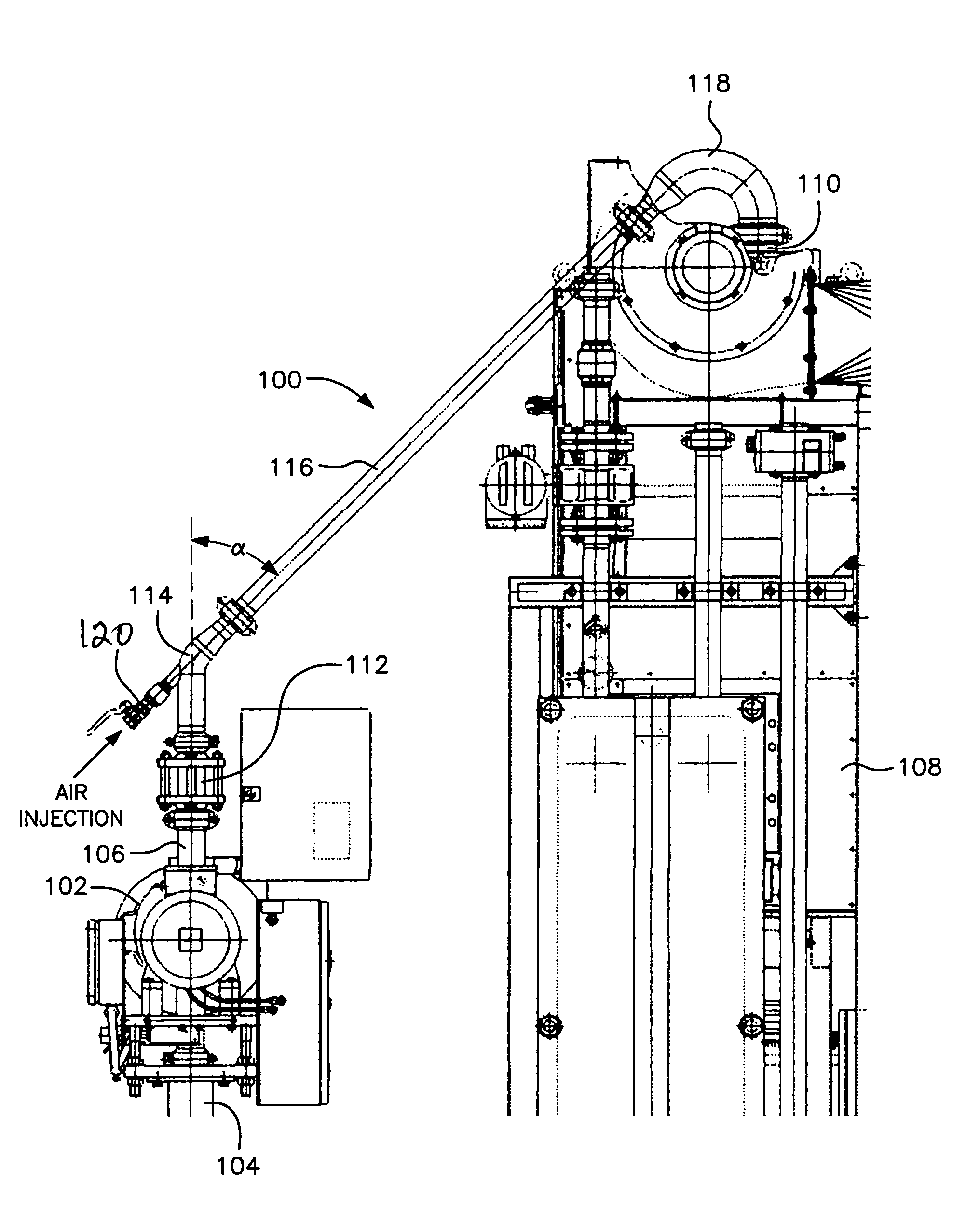

An apparatus and method for a modular cell culture bioreactor comprises a plurality of chambers for cell culture; at least one reservoir containing a cell support medium; a plurality of conduits fluidly connecting the at least one reservoir with the plurality of chambers; and at least one pump fluidly connected through the plurality of conduits with the at least one reservoir and with the plurality of chambers to pump cell support medium therethrough; wherein each individual chamber of the plurality of chambers includes at least one three-dimensional matrix comprising polyethylene terephthalate, a plurality of channels carrying the cell support medium and having the matrix positioned in fluid communication therebetween, and at least two openings into each the channel, wherein a first the opening is in fluid connection with the pump and a second the opening is in fluid connection with the reservoir.

Owner:FLORIDA STATE UNIV RES FOUND INC

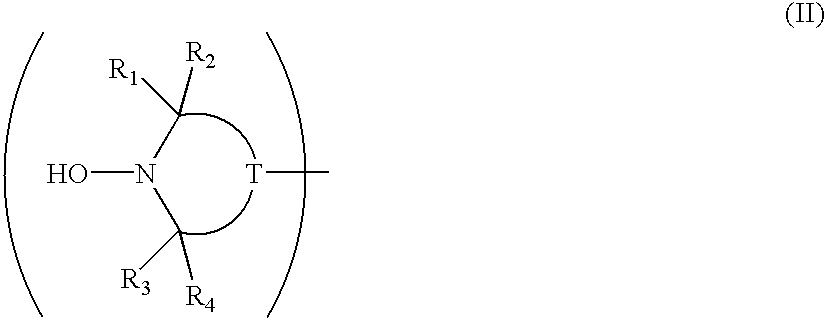

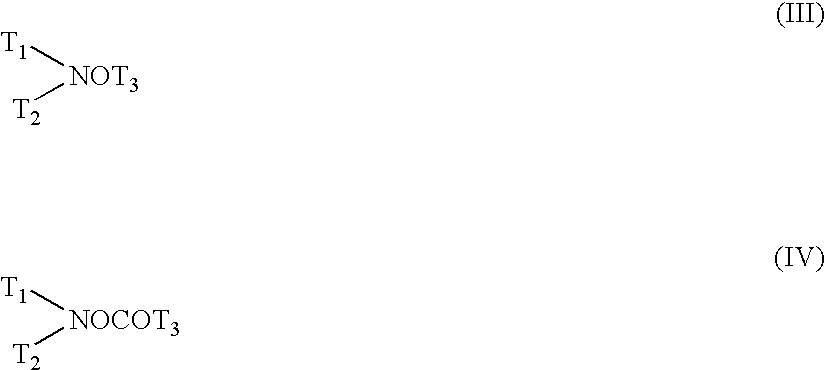

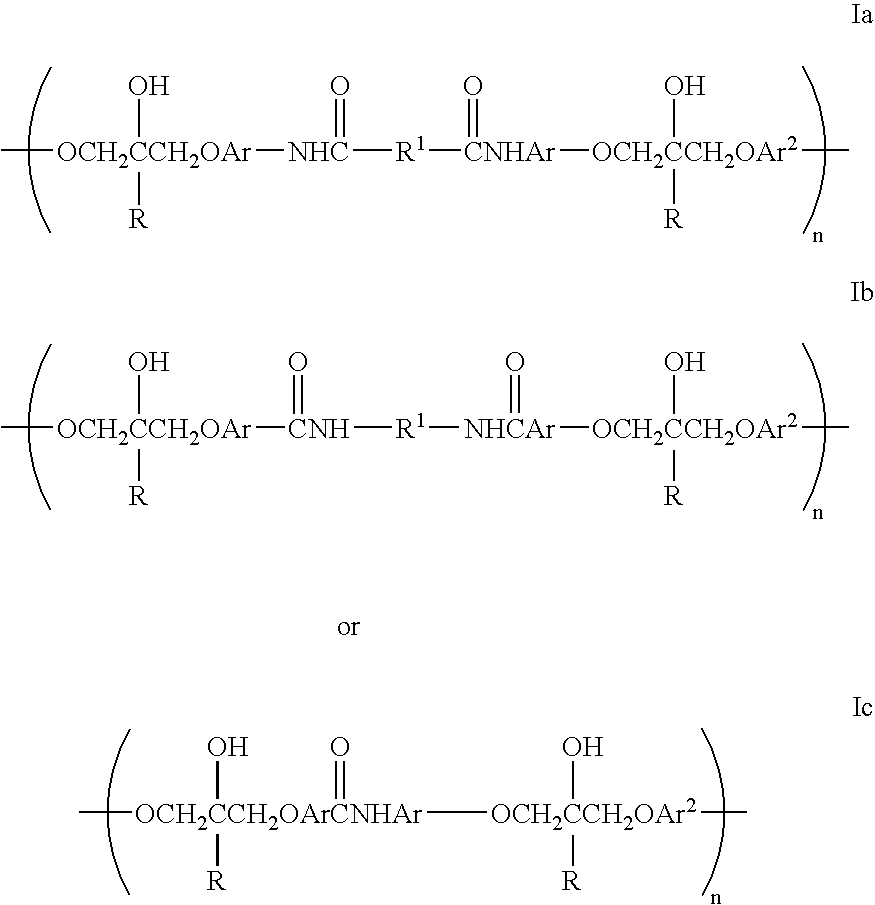

Polyester and polyamide compositions of low residual aldehyde content

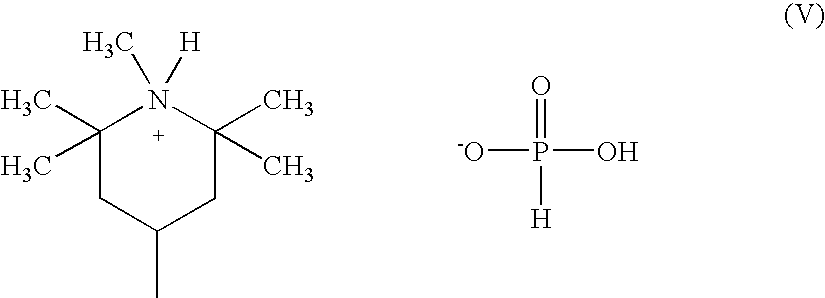

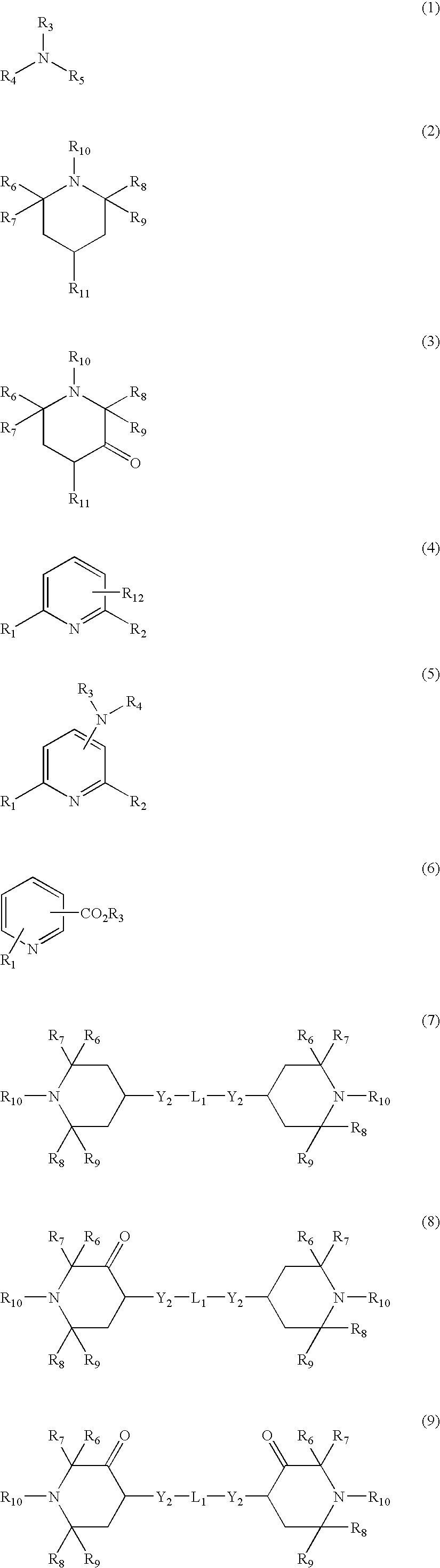

A mixture of a polyester, such as poly(ethylene terephthalate) PET, or a polyamide, and a suitable stabilizer selected from the group consisting of hydroxylamine stabilizers, substituted hydroxylamine stabilizers, nitrone stabilizers and amine oxide stabilizers, when extrusion compounded exhibits a lower residual acetaldehyde content than does polyester or polyamide alone when similarly treated. The invention pertains to any polyester or polyamide used in the manufacture of molded articles, fibers or films, for instance bottles or containers which are used to store consumer materials, for example food, beverages and water.

Owner:CIBA SPECIALTY CHEM CORP

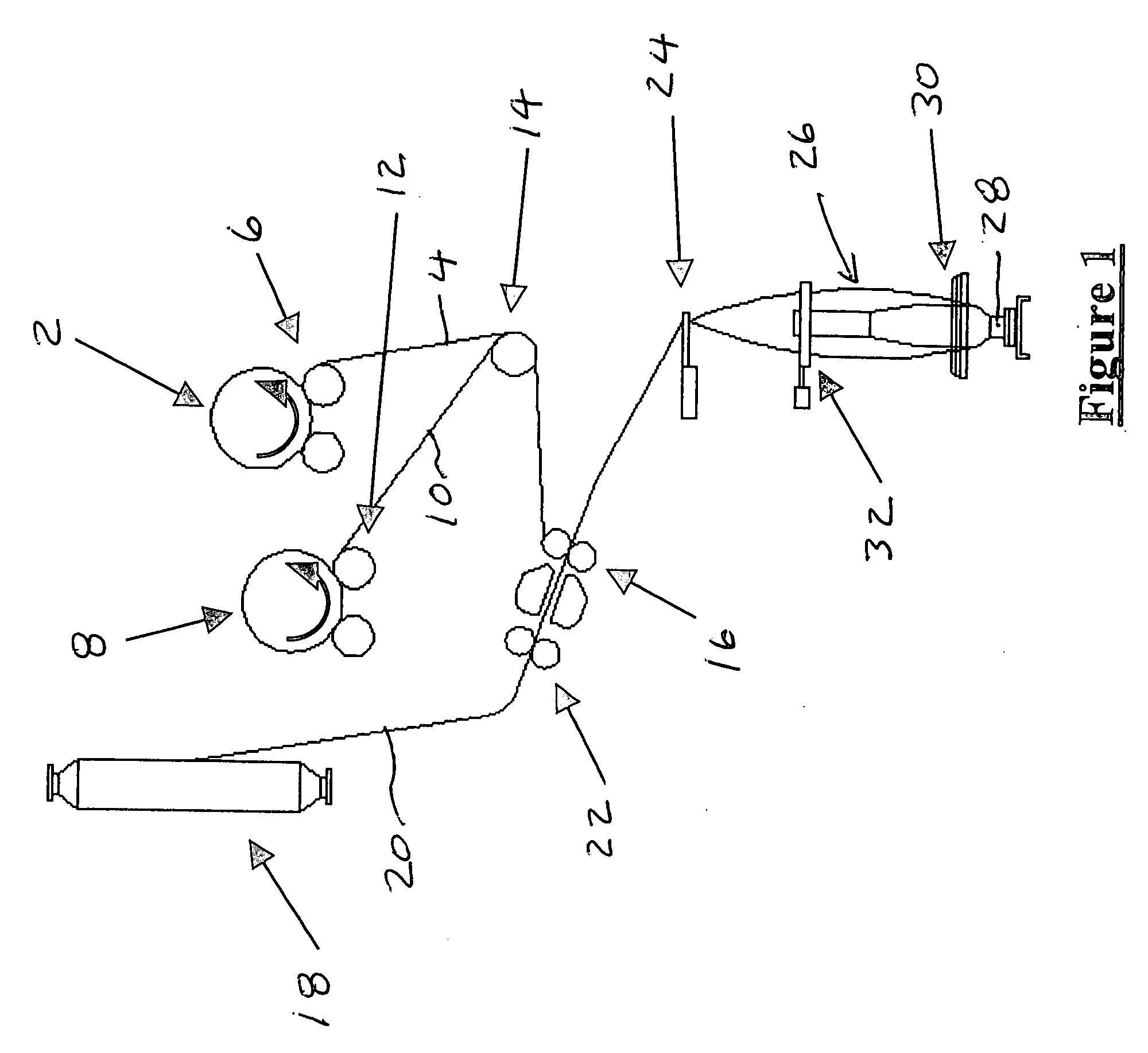

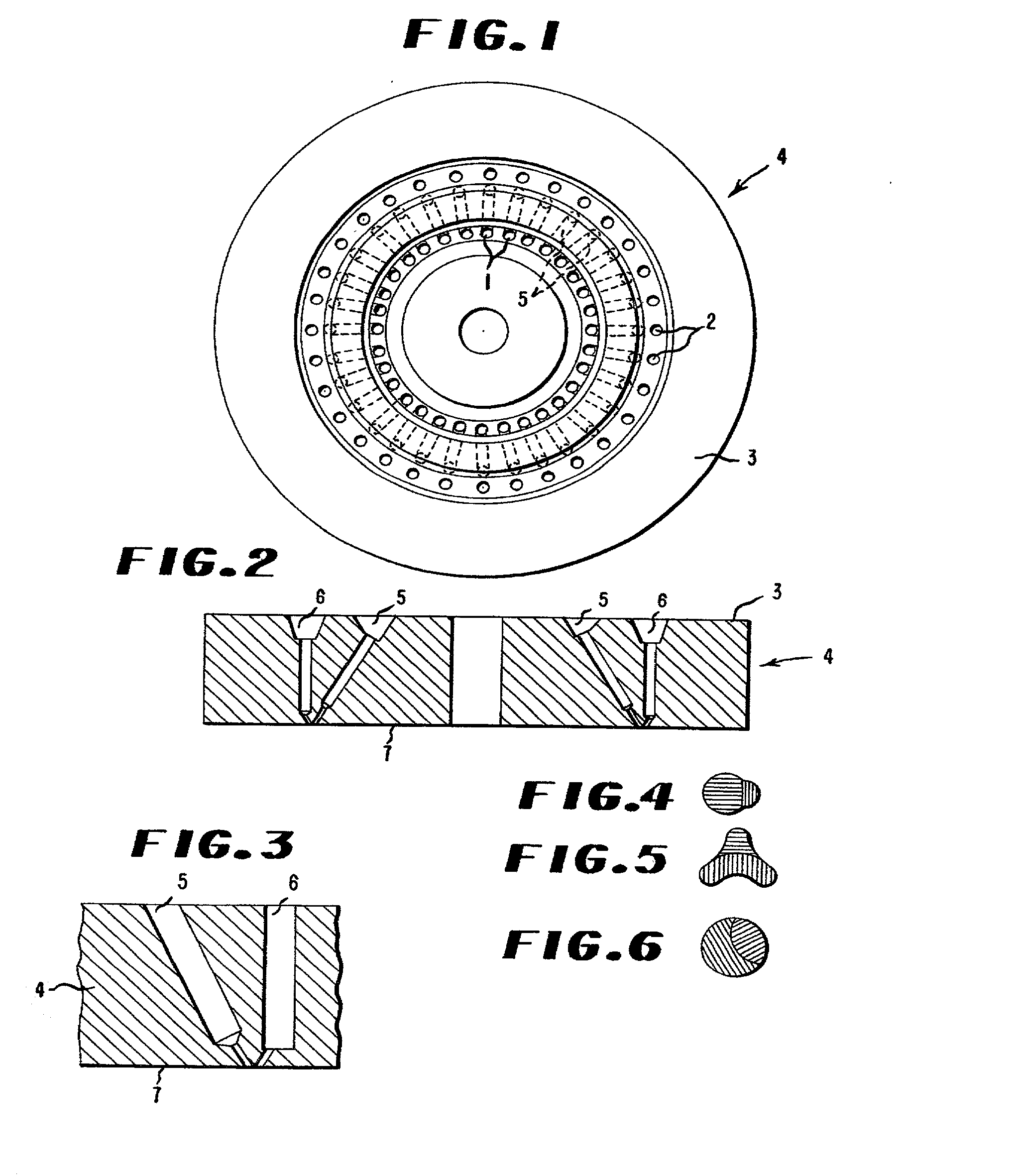

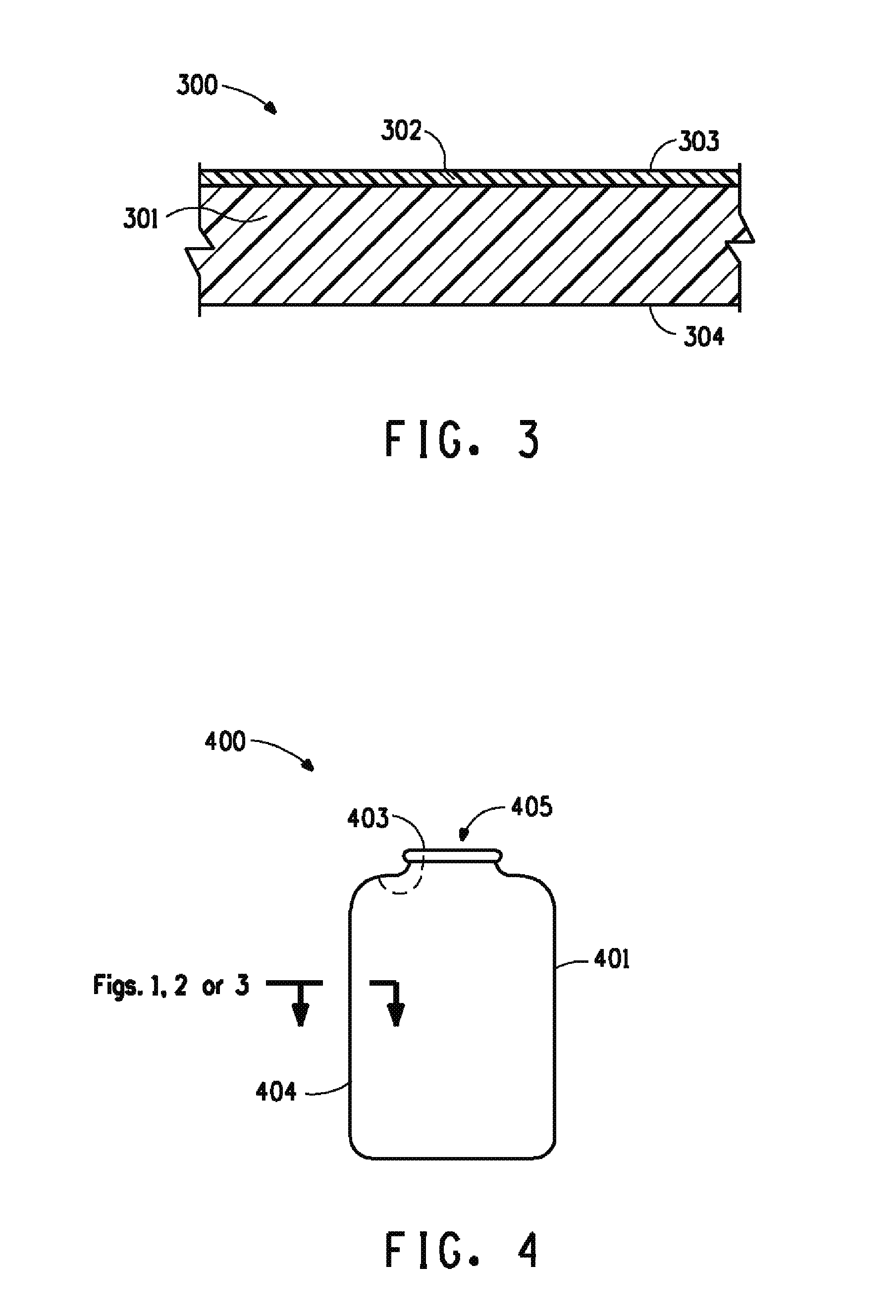

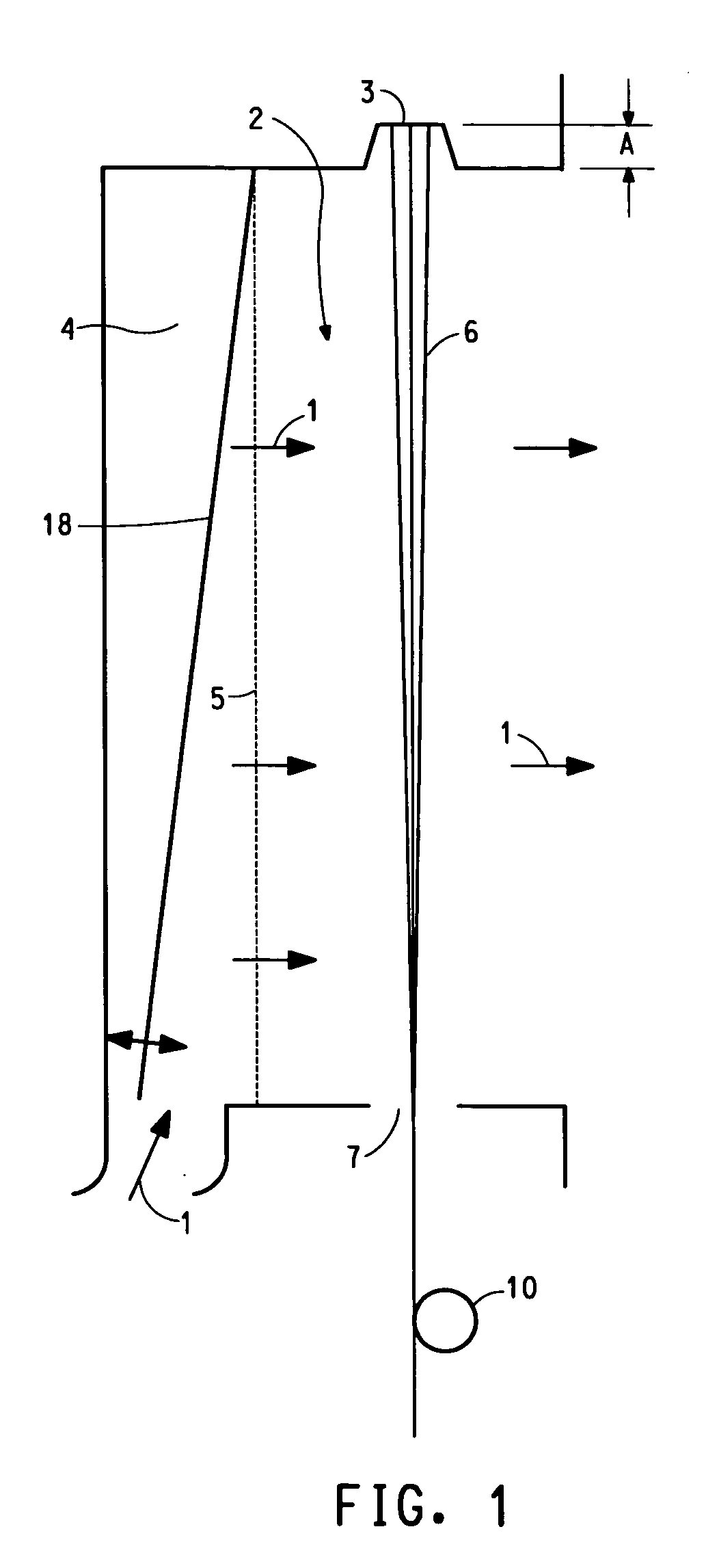

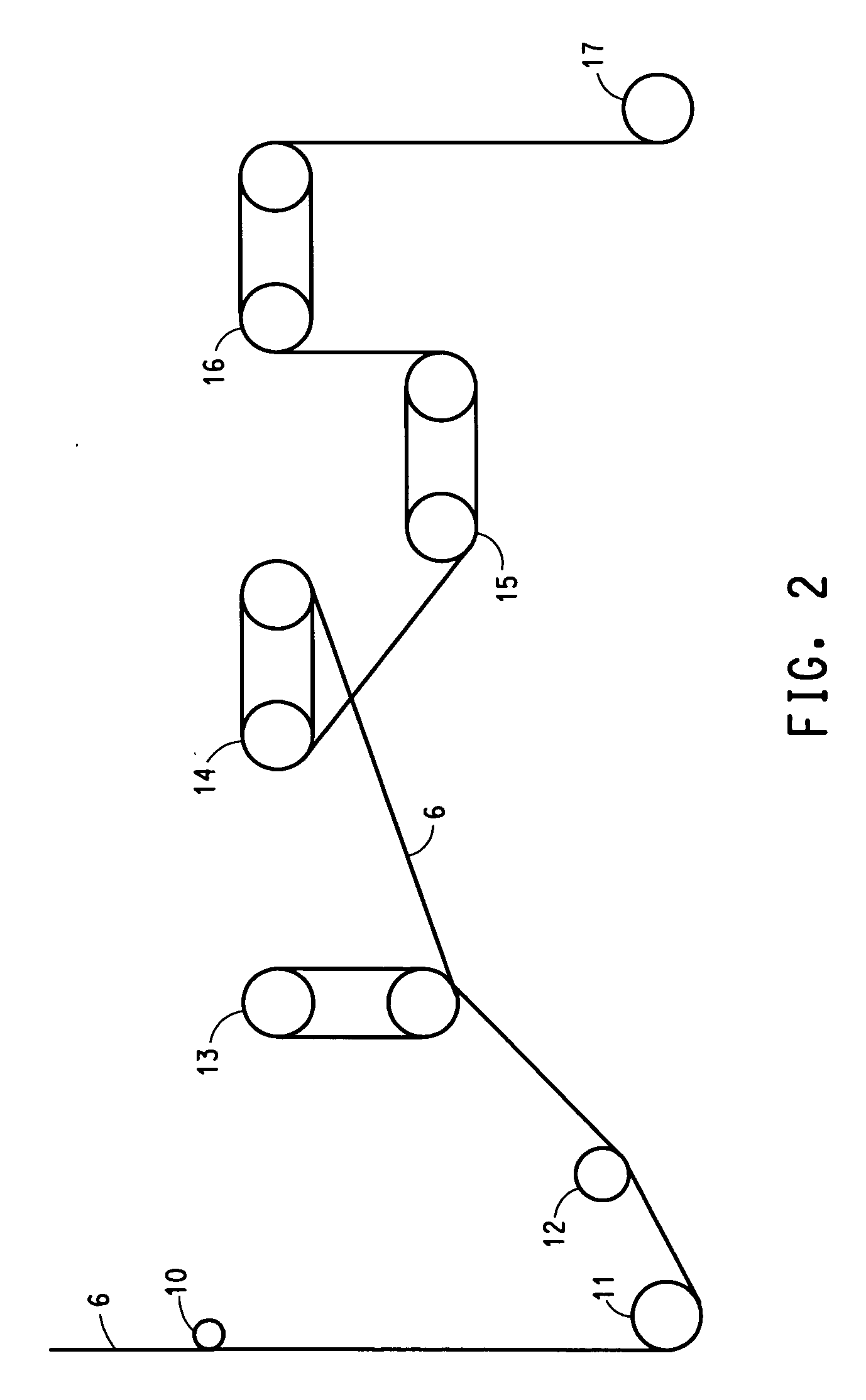

Dip, spray, and flow coating process for forming coated articles

InactiveUS20040071885A1Easy to useSynthetic resin layered productsPretreated surfacesPolyethylene terephthalateMaterials science

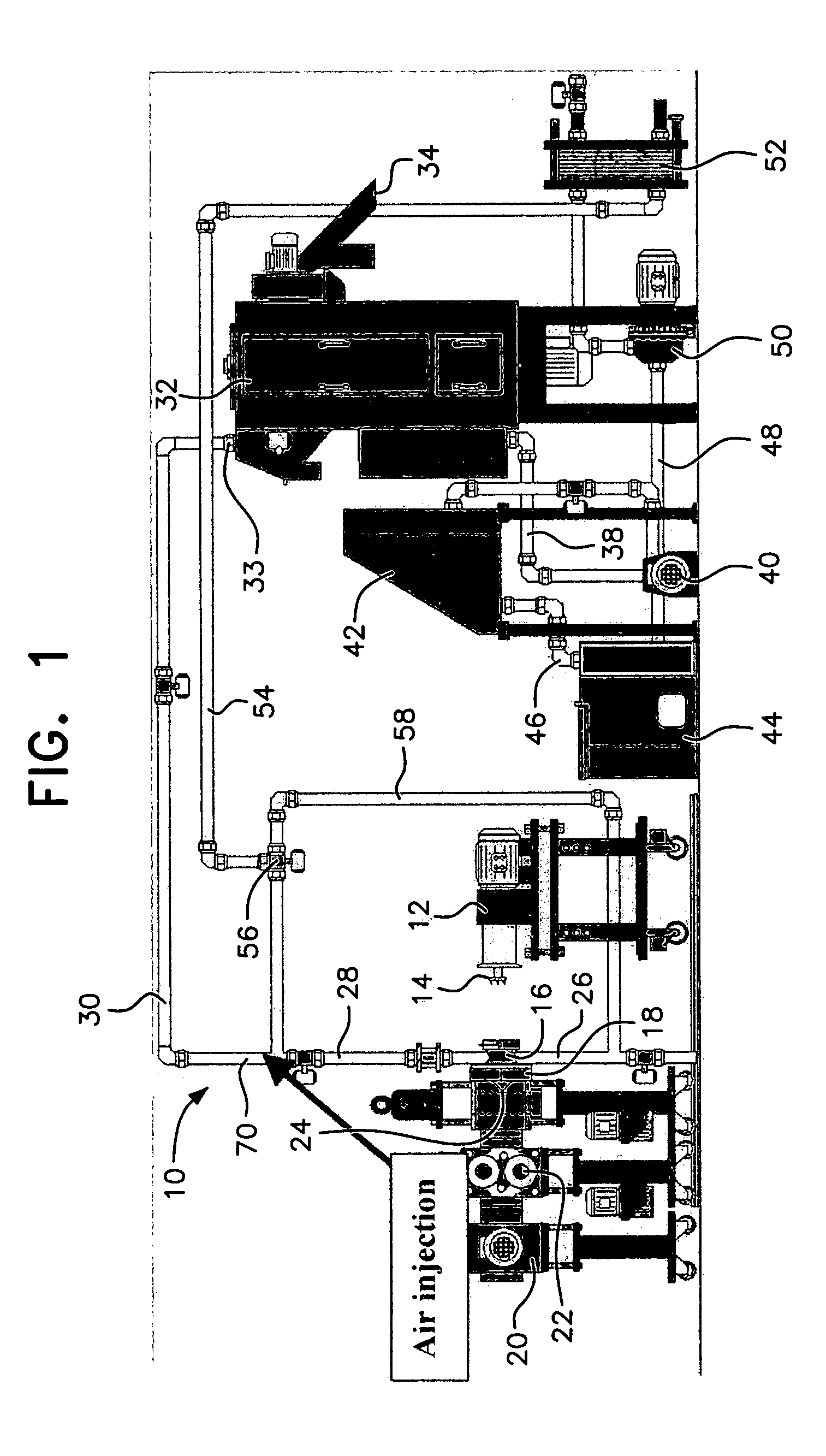

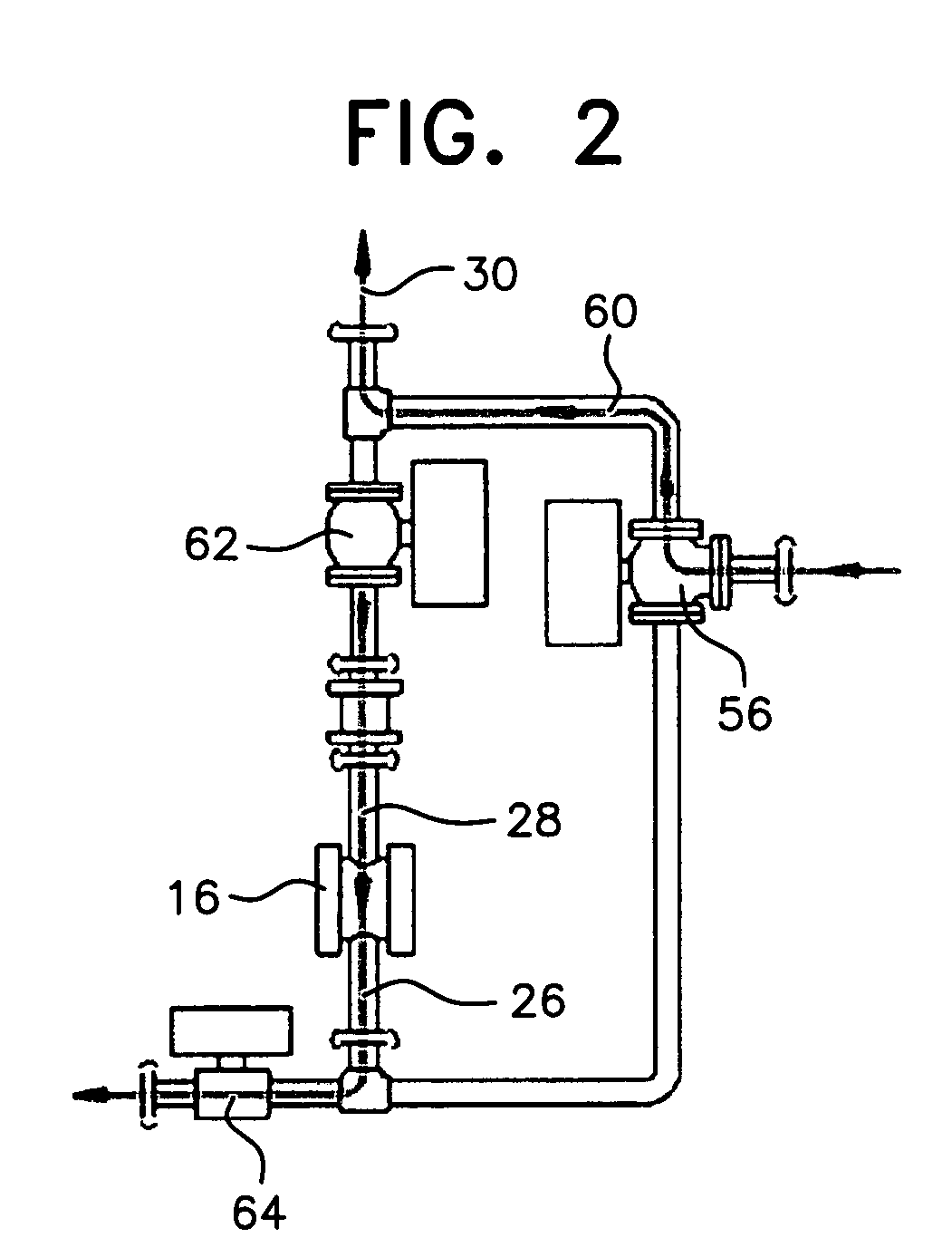

This invention relates to methods and apparatus for making coated articles with one or more layers by dip, spray or flow coating. In one aspect, this invention relates to an apparatus and method for making coated containers, preferably comprising polyethylene terephthalate, from coated preforms. In preferred embodiments, the apparatus and method permit the coated container or preform to be made in an energy-efficient manner that reduces the danger of coating damage and thus increases the efficacy of the final container.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

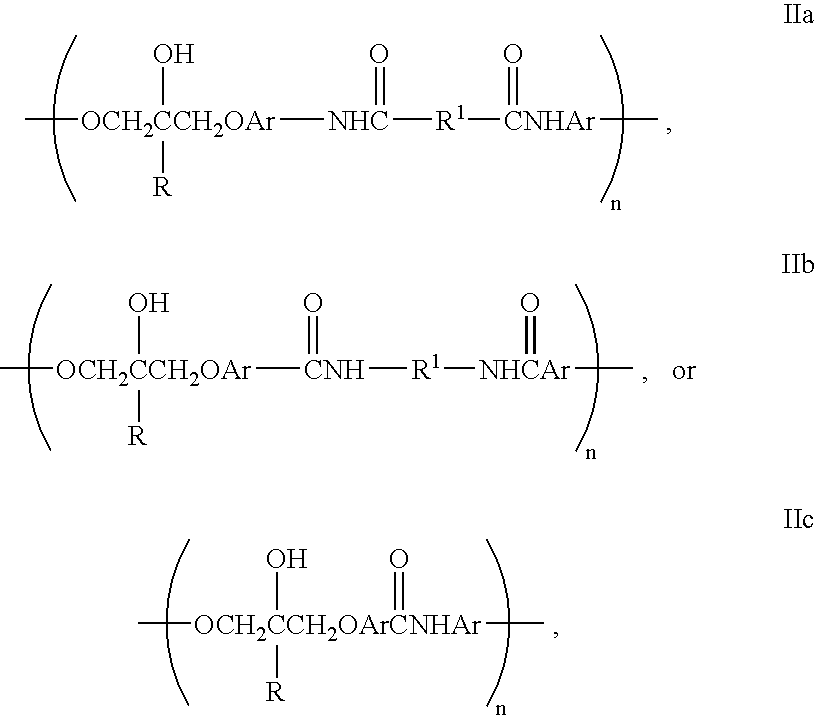

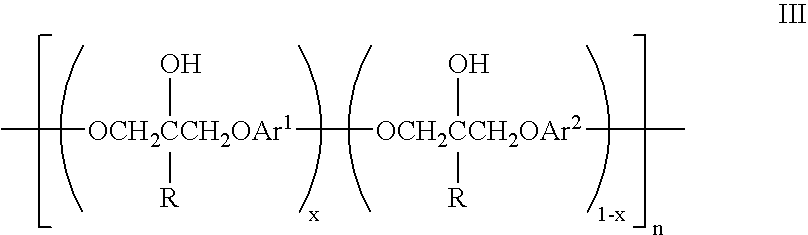

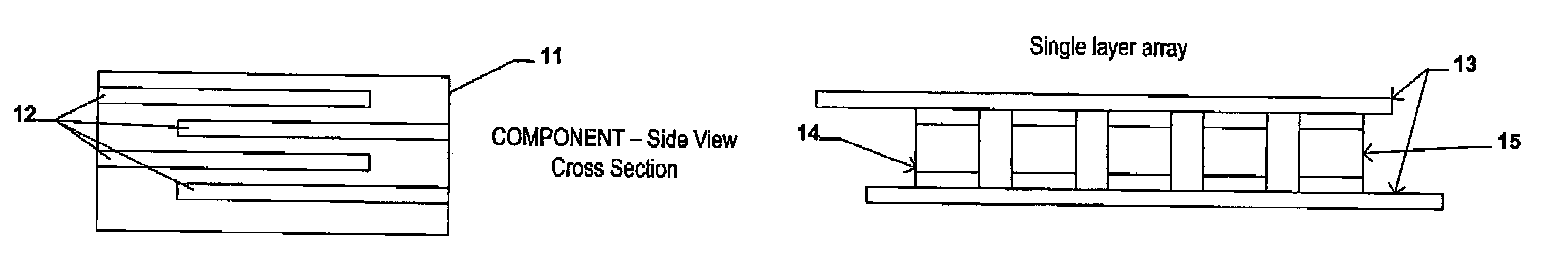

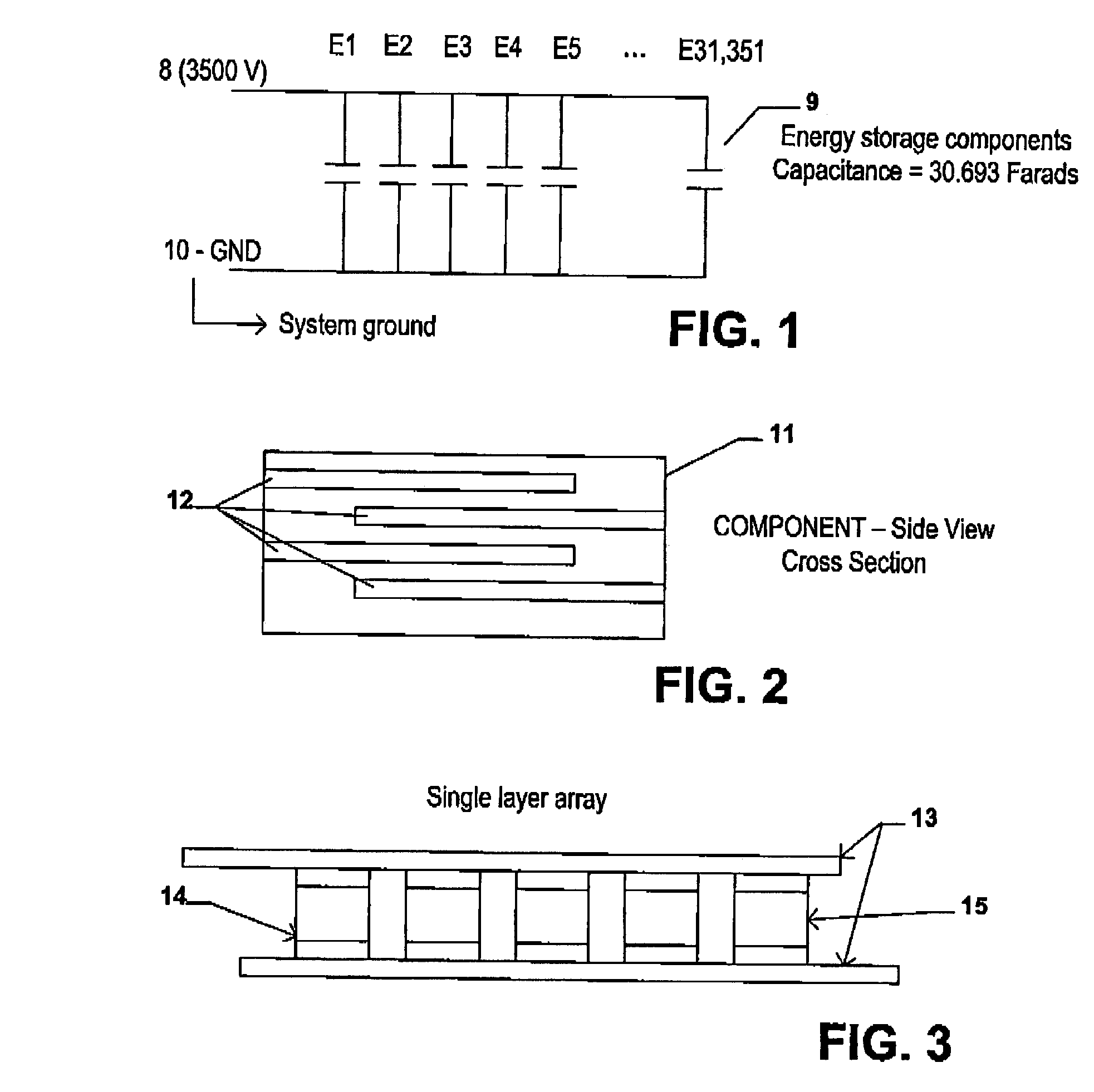

Utilization of poly(ethylene terephthalate) plastic and composition-modified barium titanate powders in a matrix that allows polarization and the use of integrated-circuit technologies for the production of lightweight ultrahigh electrical energy storage units (EESU)

InactiveUS7466536B1Low costLower sintering temperatureCell electrodesFixed capacitor dielectricManufacturing technologyBarium titanate

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is single coated with aluminum oxide and then immersed in a matrix of poly(ethylene terephthalate) (PET) plastic for use in screen-printing systems. The ink that is used to process the powders via screen-printing is based on a nitrocellulose resin that provide a binder burnout, sintering, and hot isostatic pressing temperatures that are allowed by the PET plastic. These lower temperatures that are in the range of 40° C. to 150° C. also allows aluminum powder to be used for the electrode material. The components of the EESU are manufactured with the use of conventional ceramic and plastic fabrication techniques which include screen printing alternating multilayers of aluminum electrodes and high-permittivity composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The 31,351 components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store at least 52.22 kW·h of electrical energy. The total weight of an EESU with this amount of electrical energy storage is 281.56 pounds including the box, connectors, and associated hardware.

Owner:EESTOR

Method and apparatus for making crystalline PET pellets

InactiveUS7157032B2Reduce dwell timeImprove heating conditionsMouldsDrying solid materials without heatPolyethylene terephthalateSlurry

Owner:GALA INDUSTRIES INC

Core spun yarn and woven stretch fabric

InactiveUS20080318485A1Increase draftContinuous wound-up machinesWoven fabricsPolyethylene terephthalateEthylene

A core spun yarn comprising a bi-component polyester filament and an elastomeric fiber. The polyester filament has a denier from about 20 to about 150 and the elastomeric fiber has a denier from 20 to 140. The polyester filament is about 2 weight percent to about 60 weight percent, based on total weight of the yarn and the elastomeric fiber is from about 1 percent to about 40 percent, based on total weight of the yarn. The elastomeric fiber may have higher draft than the bi-component polyester fiber. The polyester filament comprises poly (trimethylene terephthalate) and at least one polymer selected from the group consisting of poly (ethylene terephthalate) and poly (tetramethylene terephthalate) and said elastomeric fiber is spandex. The yarn may include a sheath of at least one staple fiber. The disclosure also includes a fabric of the bi-component polyester filament and an elastomeric fiber.

Owner:CENT TEXTILES HK

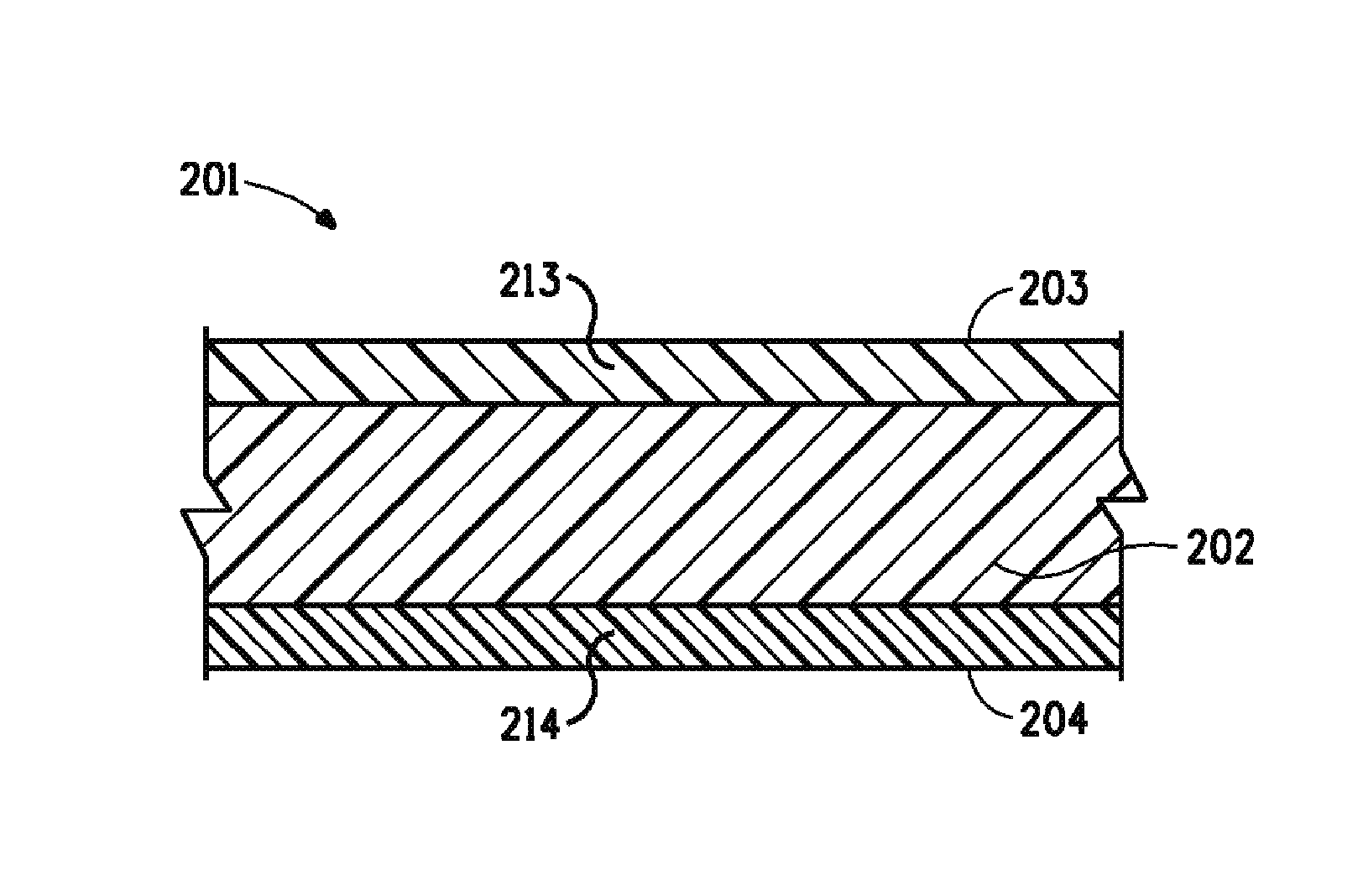

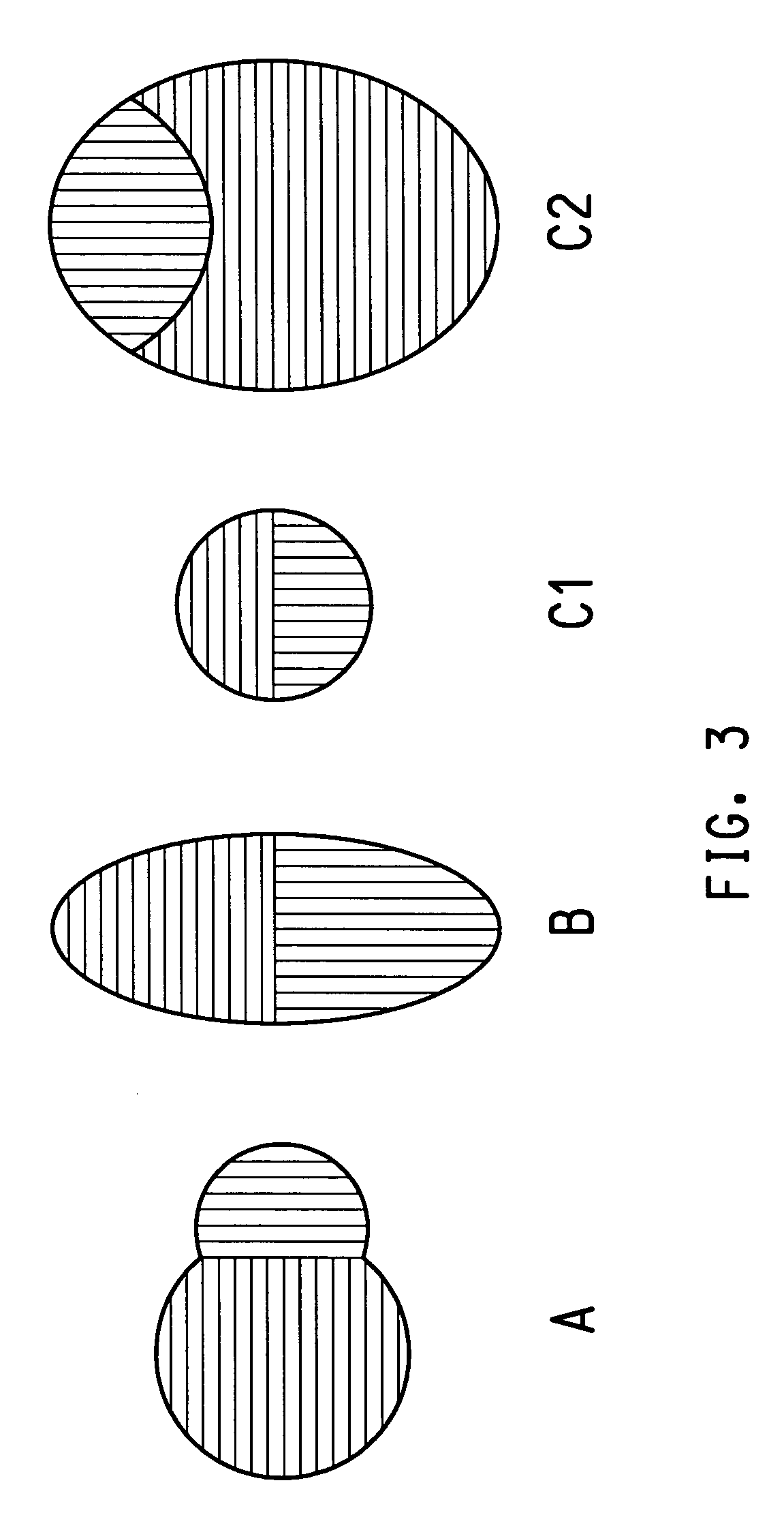

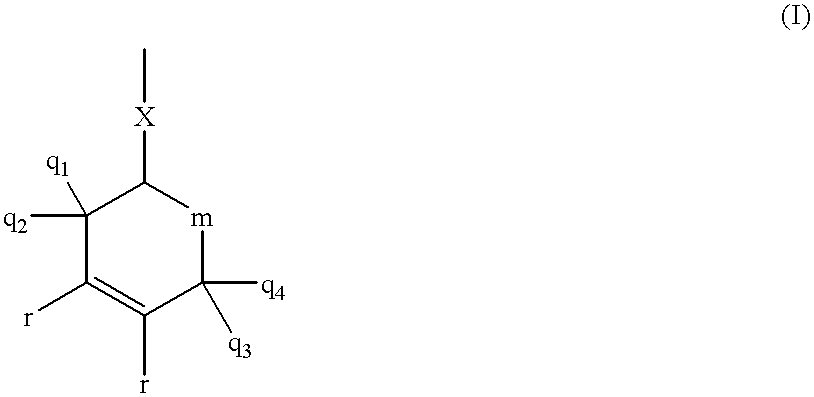

Bicomponent fiber and yarn comprising such fiber

The invention provides a bicomponent staple fiber comprising poly(ethylene terephthalate) and poly(trimethylene terephthalate) wherein the bicomponent fiber has a substantially oval cross-section shape having an aspect ratio A:B of about 2:1 to about 5:1 wherein A is a fiber cross-section major axis length and B is a fiber cross-section minor axis length, a polymer interface substantially perpendicular to the major axis, a cross-section configuration selected from the group consisting of side-by-side and eccentric sheath-core, a tenacity at 10% elongation of about 1.1 cN / dtex to about 3.5 cN / dtex, a free-fiber length retention of about 40% to about 85%, and a tow crimp development value of about 30 to 55%, and a spun yarn comprising the bicomponent staple fiber.

Owner:THE LYCRA CO LLC

Phosphorus-contained flame-retarding nano-class ethanediol polyterephthalate/laminated silicate composition and its preparing process and application

InactiveCN1396206AImprove mechanical propertiesMeet practical requirementsFiberDimethyl terephthalate

A P-contained flame-retarding ethanediol polyterephthalate / laminar silicate composition is prepared from dimethyl terephthalate (or terephthalic acid), ethanediol, laminar silicate, P-contained flame retardant, intercalator, dispersing medium and catalyst. Its advantages are high mechanical properties and refractory nature, and simple preparing process.

Owner:SICHUAN UNIV

Aluminum containing polyester polymers having low acetaldehyde generation rates

ActiveUS20070066791A1Organic-compounds/hydrides/coordination-complexes catalystsCeramic shaping apparatusPolyesterPolymer science

A polyester polymer composition containing polyester polymers such as polymers having repeating ethylene terephthalate units, aluminum atoms in an amount of at least 3 ppm based on the weight of the polymer, the polyester polymers having an It.V. of at least 0.72 dL / g obtained through a melt phase polymerization and a residual acetaldehyde level of 10 ppm or less. Also provided are polyester polymer compositions containing polyester polymers and: (i) aluminum atoms (ii) alkaline earth metal atoms or alkali metal atoms or alkali compound residues, and (iii) a catalyst deactivator such as a phosphorus compound. The phosphorus compound is added to the polyester melt either late in the polycondensation or upon remelting a solid polyester polymer. The polyester polymer exhibits good L* brightness, clarity, and low levels of acetaldehyde generated upon melting.

Owner:ALPEK POLYESTER SA DE CV

Weft-stretch woven fabric with high recovery

A woven fabric comprising warp fibers and a weft is provided. The weft may be of pick-and-pick or co-insertion constructions. The weft includes a spun staple yarn and a polyester bicomponent filament. The polyester bicomponent filament includes poly(ethylene terephthalate) and poly(trimethylene terephthalate), and has an after heat-set crimp contraction value of from about 10% to about 80%. A process for making such a fabric is also provided.

Owner:THE LYCRA CO LLC

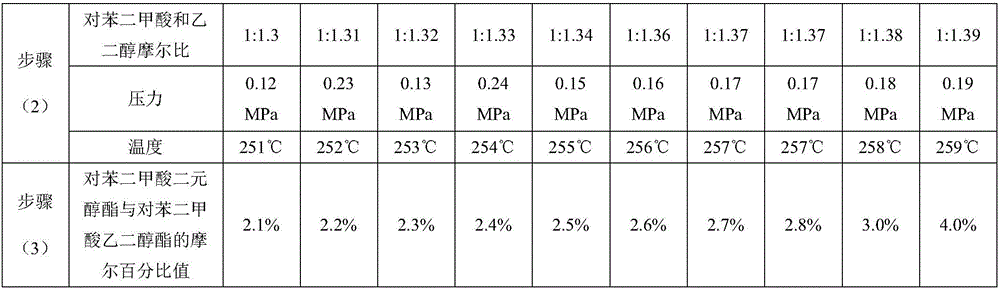

Polyester fibres and preparation method thereof

ActiveCN106367835AImprove dyeing effectEasy to processSpinnerette packsMonocomponent copolyesters artificial filamentSlurryLow vacuum

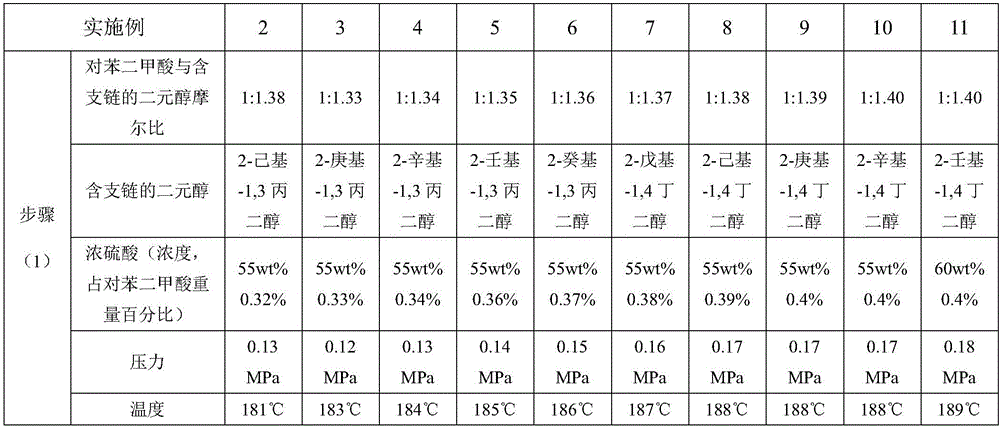

The invention relates to polyester fibres and a preparation method thereof. The raw material of the polyester fibres is modified polyester which consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The preparation method of the polyester fibres comprises the following steps: performing esterification reaction on terephthalic acid and branched chain-containing dihydric alcohol under the catalysis of concentrated sulphuric acid to obtain terephthalic acid dihydric alcohol ester; then, preparing the terephthalic acid and the ethylene glycol into slurry, and performing the esterification reaction on the slurry to obtain the terephthalic acid ethylene glycol ester; finally, stirring and mixing the terephthalic acid dihydric alcohol ester and the terephthalic acid ethylene glycol ester, and performing condensation polymerization in a low vacuum stage and a high vacuum stage under the action of a catalyst and a stabilizing agent to obtain modified polyester; metering, extruding, cooling, oiling, stretching, heat-setting and winding the polyester to prepare the polyester fibres. The increasing amplitude of the spatial gaps of the polyester fibres is much higher than that of branched chain-free polyester fibres at the same temperature, which is beneficial to the degree of micro particles, such as a dye, that enter the polyester; the dyeing rate is improved.

Owner:JIANGSU HENGLI CHEM FIBER

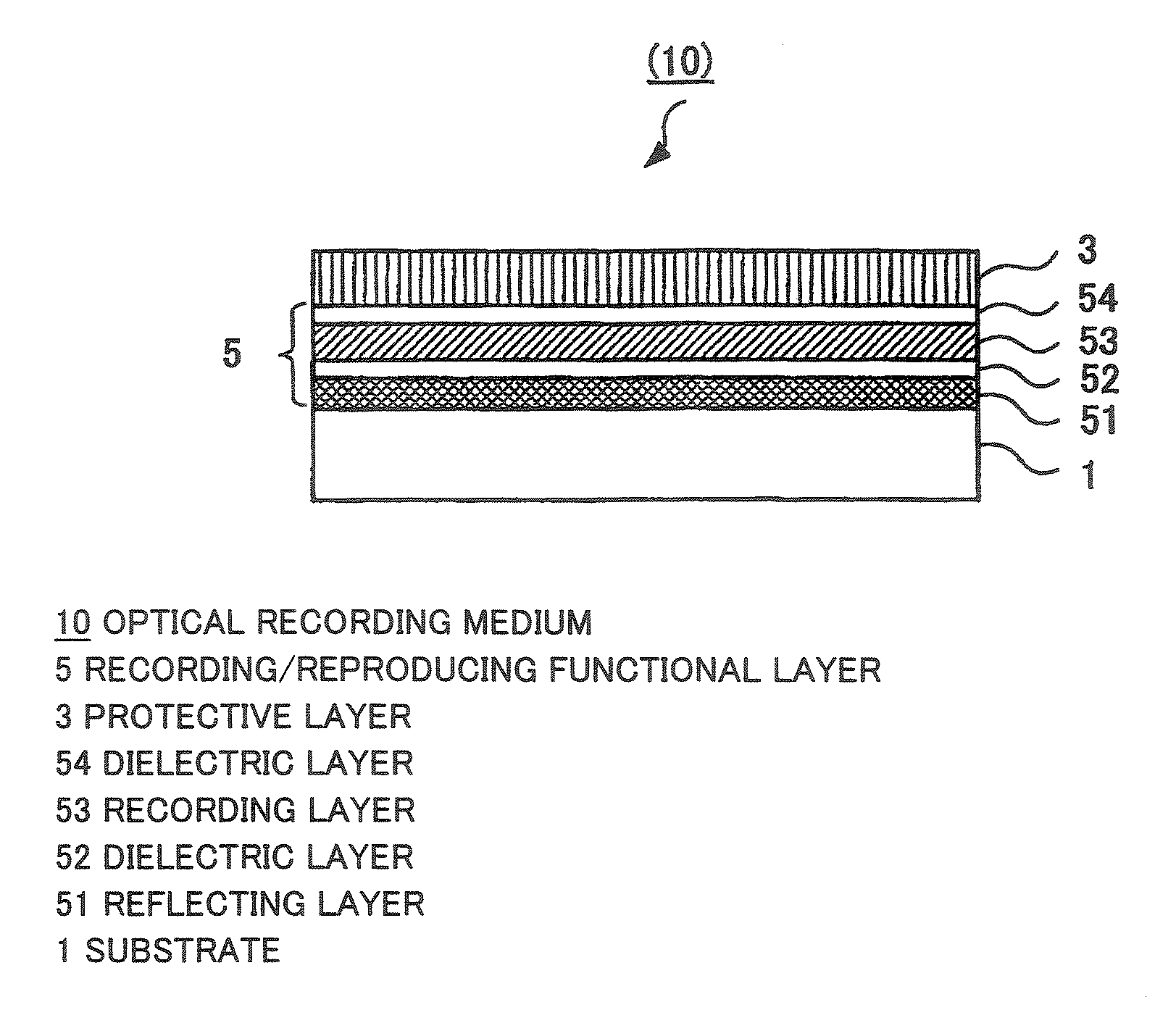

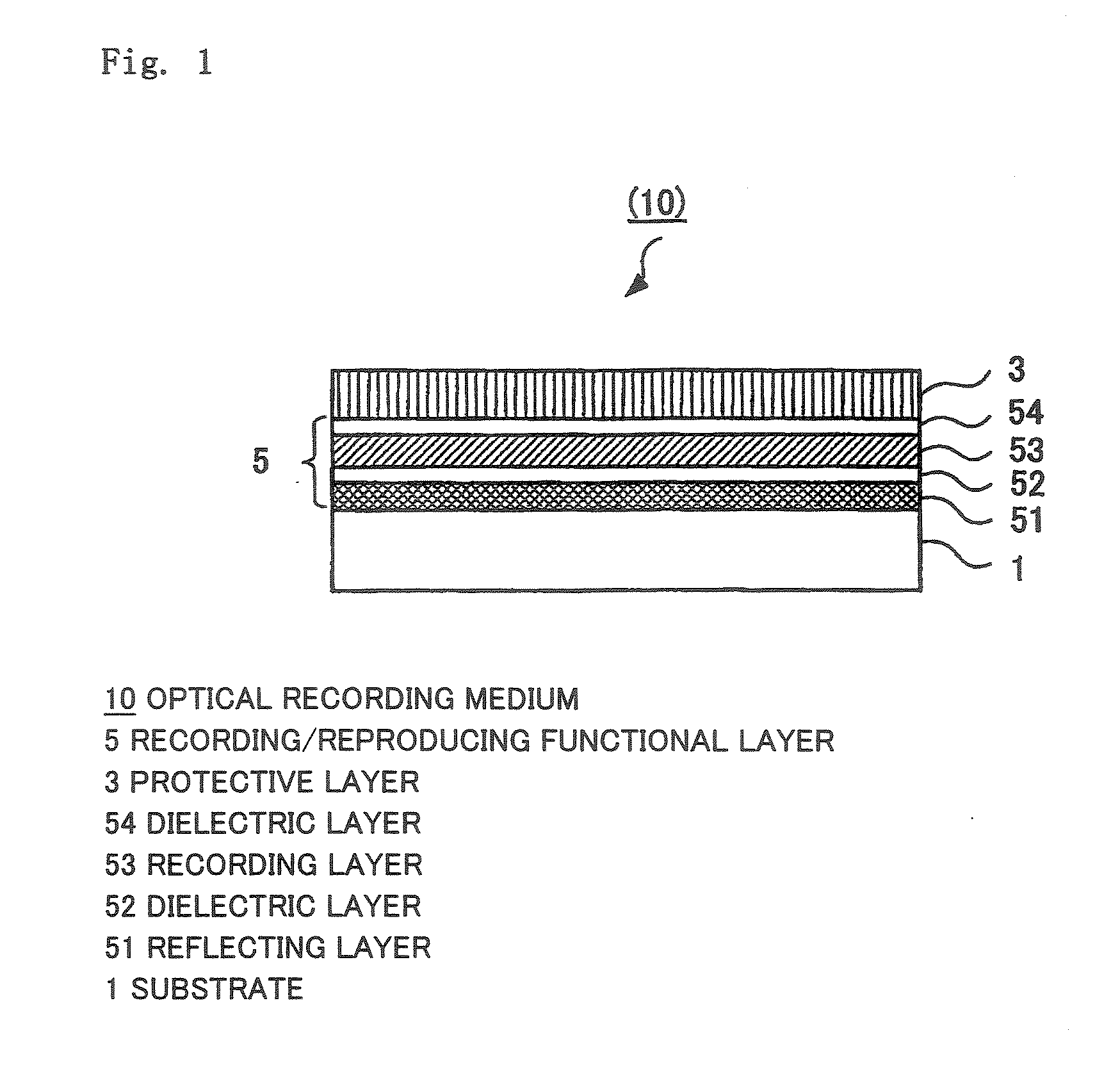

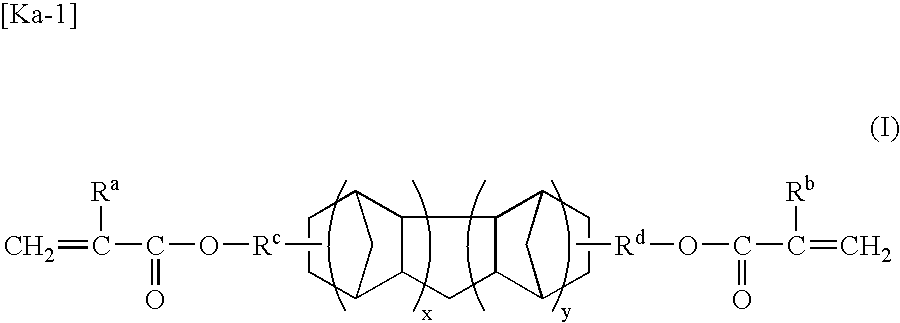

Radiation Curable Composition and Curing Product Thereof, and Laminate Including the Same

InactiveUS20080102262A1High mechanical strengthHigh transparencySynthetic resin layered productsRecord information storageOptical transmittanceHardness

A radiation-curable composition capable of giving a cured product which has excellent transparency, mechanical strength and an excellent balance between surface hardness and resistance to deformation by heat / humidity; the cured product; and a multilayer structure which has a layer of the cured product and is suitable for use as an optical recording medium, etc, are provided A radiation-curable composition which comprises a monomer having a radiation-curable group and gives a cured product having the following properties: (1) when the cured product has a thickness of 100±5 μm, the cured product has a light transmittance at a wavelength of 550 nm of 80% or higher; (2) a multilayer structure where a layer of the cured product having a thickness of 100±5 μm is formed on a poly(ethylene terephthalate) film having a thickness of 100±5 μm, has a surface hardness of HB or higher; and (3) when a multilayer structure where the cured product having a thickness of 100±5 μm is formed on a disk made of a polycarbonate having a diameter of 130 mm and a thickness of 1.2±0.2 mm, is placed in an environment of 80° C. and 85% RH for 100 hours, then an absolute value |a| of an amount of warpage, a (mm), on the circumference of the multilayer structure is 0.5 mm or less.

Owner:MITSUBISHI CHEM CORP

Parallel composite elastic fiber and manufacture method thereof

ActiveCN101851812ALow costElastic Elongation GuaranteedFilament/thread formingConjugated synthetic polymer artificial filamentsExtensibilityPolytetramethylene terephthalate

The invention discloses parallel composite elastic fiber and a manufacture method thereof. The parallel composite elastic fiber is obtained through false twisting process after parallel composite spinning of valox and polyethylene glycol terephthalate according to a weight ratio of 70 / 30 to 30 / 70, wherein the inherent viscosity of the valox is between 0.45 to 0.60 dl / g, and the difference of the inherent viscosity of the valox and the inherent viscosity of the polyethylene glycol terephthalate is between 0.40 and 1.05 dl / g. The elastic extensibility of the elastic fiber of the invention is between 130 and 220 percent, and the elastic recovery rate is higher than 85 percent.

Owner:TORAY IND INC

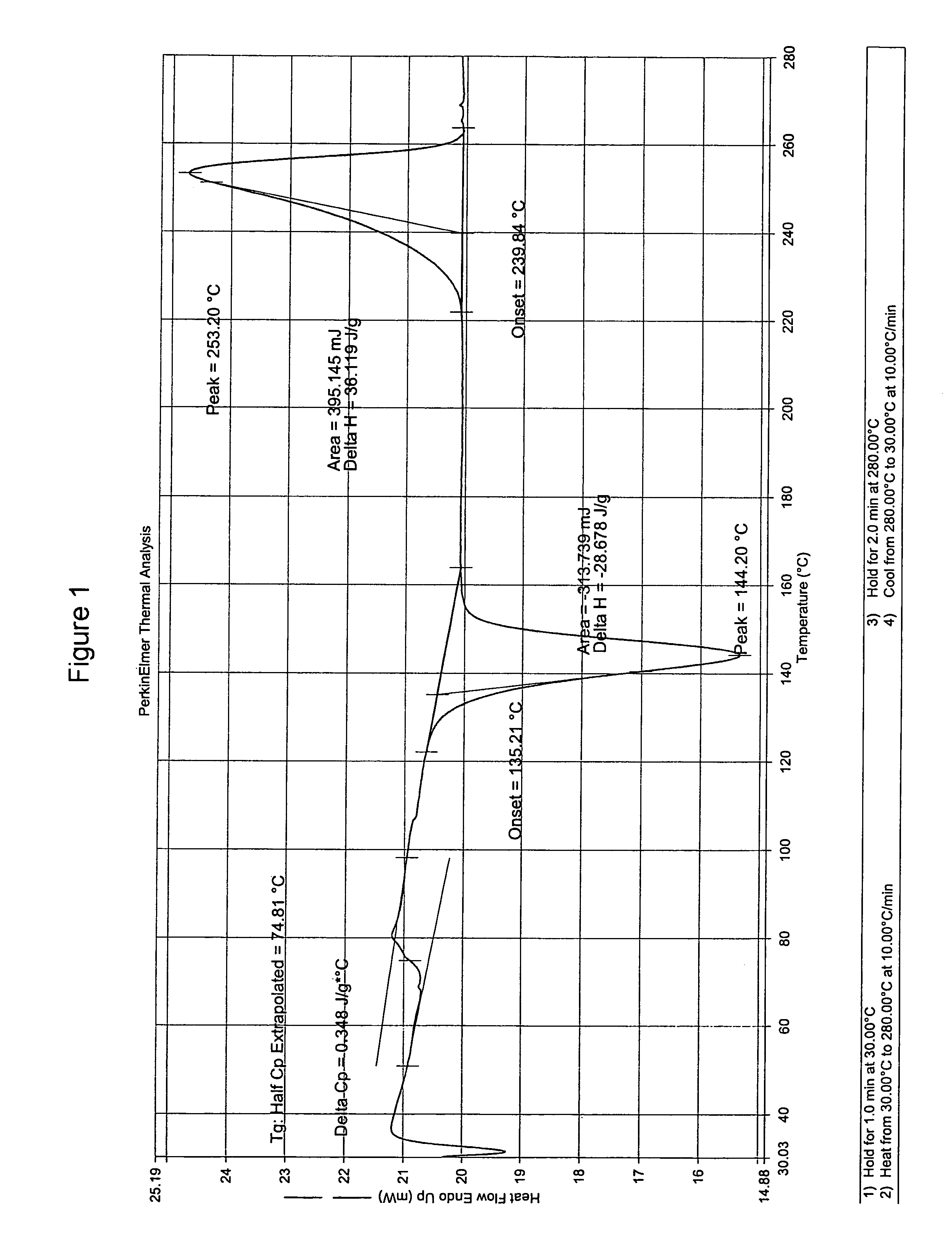

Polyester preforms useful for enhanced heat-set bottles

ActiveUS7094863B2Acceptable dimensional stabilityImproved reheating profileSynthetic resin layered productsThin material handlingPolyesterPolyethylene terephthalate

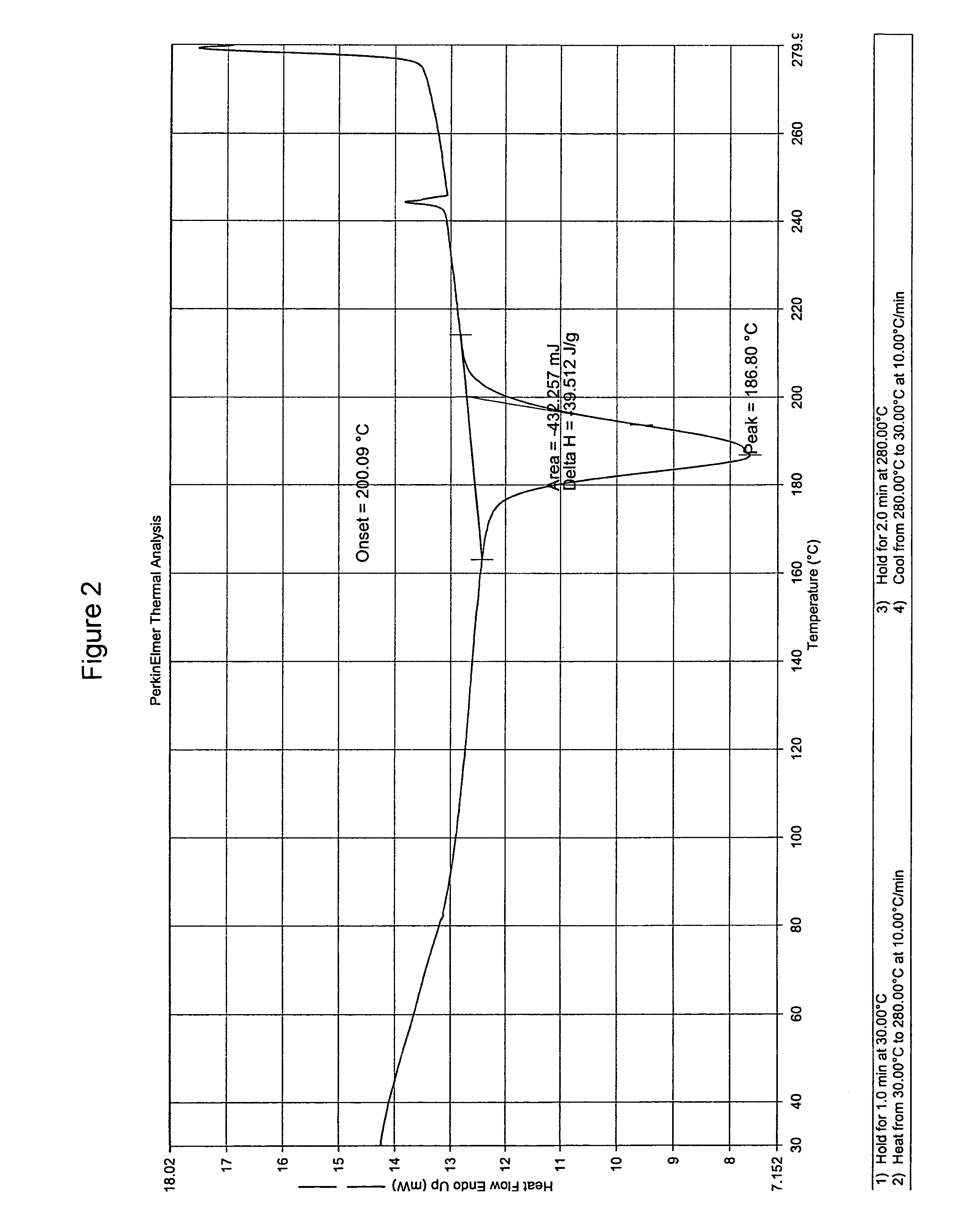

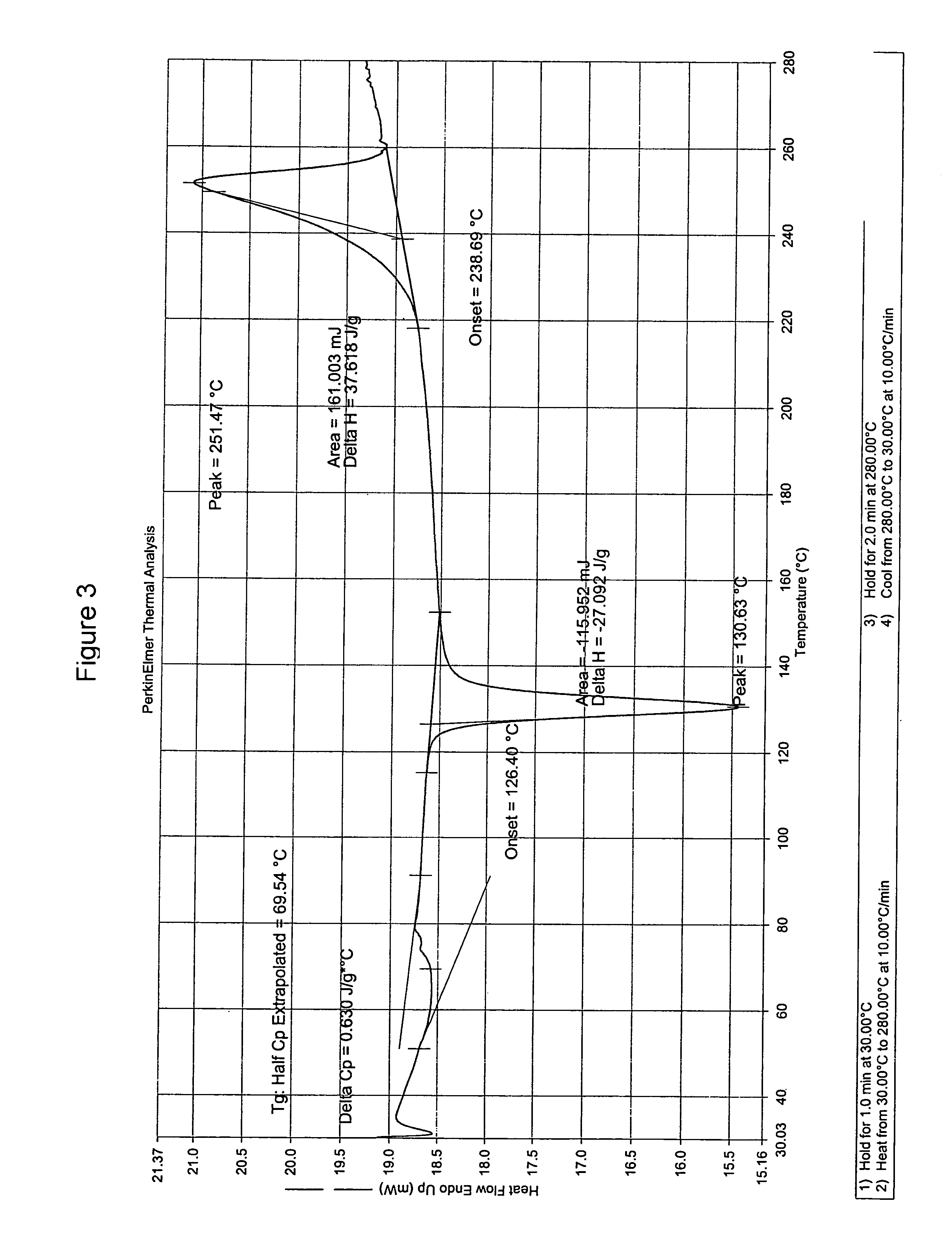

The present invention relates to slow-crystallizing polyethylene terephthalate resins that possess a significantly higher heating crystallization exotherm peak temperature (TCH) as compared with those of conventional antimony-catalyzed polyethylene terephthalate resins. The polyethylene terephthalate preforms of the present invention, which possess improved reheating profiles, are especially useful for making polyester bottles that have exceptional clarity and that retain acceptable dimensional stability upon being hot-filled with product at temperatures between about 195° F. and 205° F.

Owner:DAK AMERICAS MISSISSIPPI INC

Oxygen-scavenging polymer blends suitable for use in packaging

InactiveUS20080255280A1Group 4/14 element organic compoundsConductive materialPolymer scienceAlkaline earth metal

Polymer blends suitable for packaging are disclosed that include a transition metal; one or more polyamide homopolymers or copolymers; and one or more polyethylene terephthalate homopolymers or copolymers obtained by a melt phase polymerization using a catalyst system comprising aluminum atoms in an amount, for example, from about 3 ppm to about 60 ppm and one or more alkaline earth metal atoms, alkali metal atoms, or alkali compound residues in an amount, for example, from about 1 ppm to about 25 ppm, in each case based on the weight of the one or more polyethylene terephthalate homopolymers or copolymers The polymer blends disclosed exhibit improved oxygen-scavenging activity compared with blends made using polymers prepared with conventional catalyst systems.

Owner:EASTMAN CHEM CO

Methods and materials for depolymerizing polyesters

Provided is a method of depolymerizing polyesters from post-consumer products, such as beverage bottles, to produce a high purity reaction product. For the depolymerization reaction, the polyesters are reacted with an alcohol having 2 to 5 carbons and an amine organocatalyst at a temperature of about 150° C. to about 250° C. In one application, the use an organocatalyst with a boiling point significantly lower than the boiling point of the reactant alcohol allows for the ready recycling of the amine organocatalyst. In another application, performing the depolymerization reaction under pressure at a temperature above that of the alcohol allows for accelerated depolymerization rates and the recovery of the organocatalyst with no further heat input. In a further application, glycolytic depolymerization of poly(ethylene terephthalate) (PET) from post-consumer beverage bottles produces a pure reaction product of bis(2-hydroxyethyl)terephthalate (BHET), which may in turn be used to produce high purity beverage bottle grade PET, in a closed loop process with minimal output and waste.

Owner:IBM CORP

Medical device formed of polyester copolymer

InactiveUS6949112B1Improve performanceHigh flexibility and trackabilityStentsBalloon catheterPolyesterPercutaneous angioplasty

A medical device or component thereof, and particularly intracorporeal devices for therapeutic or diagnostic uses, formed at least in part of a copolymer having a hard block and a polylactone soft block. In a presently preferred embodiment, the hard block of the copolymer is a polyester, and more specifically, the copolymer comprises a di-block copolymer of poly(ethylene terephthalate) and polycaprolactone. The copolymer is suitable for forming a variety of medical devices or medical device components, and is preferably used to form a catheter balloon, such as a balloon for an angioplasty or stent delivery catheter. However, a variety of medical devices or medical device components can be formed of the copolymer, including stent covers, vascular grafts, and shaft components.

Owner:ADVANCED CARDIOVASCUAR SYST

Weft-stretch woven fabric with high recovery

The invention provides a woven fabric comprising warp fibers and a weft wherein the weft is selected from the group consisting of pick-and-pick and co-insertion constructions; the weft comprises a spun staple yarn and a polyester bicomponent filament wherein said polyester bicomponent filament comprises poly(ethylene terephthalate) and poly(trimethylene terephthalate); and the polyester bicomponent filament has an after heat-set crimp contraction value of from about 10% to about 80%. The invention further provides a process for making such fabric.

Owner:THE LYCRA CO LLC

Polyesters and articles made therefrom

InactiveUS20140205786A1Excellent gas barrier performanceBottlesDomestic containersPolyesterPolyethylene terephthalate glycol

Disclosed herein are polyesters and articles made therefrom. The article comprising a substrate comprising a first surface and a second surface, the second surface in contact with an outside environment, wherein the substrate comprises a polymer comprising poly(trimethylene furandicarboxylate) (PTF), and wherein the polymer provides an improvement in gas barrier properties of the substrate as compared to a substrate comprising nascent polyethylene terephthalate) (PET).

Owner:EI DU PONT DE NEMOURS & CO

Modular cell culture bioreactor

InactiveUS7122371B1Bioreactor/fermenter combinationsBiological substance pretreatmentsPolyethylene terephthalate3D cell culture

An apparatus and method for a modular cell culture bioreactor comprises a plurality of chambers for cell culture; at least one reservoir containing a cell support medium; a plurality of conduits fluidly connecting the at least one reservoir with the plurality of chambers; and at least one pump fluidly connected through the plurality of conduits with the at least one reservoir and with the plurality of chambers to pump cell support medium therethrough; wherein each individual chamber of the plurality of chambers includes at least one three-dimensional matrix comprising polyethylene terephthalate, a plurality of channels carrying the cell support medium and having the matrix positioned in fluid communication therebetween, and at least two openings into each the channel, wherein a first the opening is in fluid connection with the pump and a second the opening is in fluid connection with the reservoir.

Owner:FLORIDA STATE UNIV RES FOUND INC

Growth factor slow-release type double-layered artificial skin

ActiveCN101716376AImprove waterproof performanceImprove breathabilitySkin implantsMicrospherePolyethylene glycol

The invention relates to a growth factor slow-release type double-layered artificial skin which is used for repairing injured skin with related growth factor slow-release functions and a preparation method thereof. The artificial skin is divided into two layers of an epidermal layer and an enderonic layer, wherein the epidermal layer is constituted by a micropore double-layered thin film with the functions of water proofing, ventilation and enderonic protection; the materials of the upper layer which contacts with air is polyurethane, or silicon rubber, or polyethylene glycol, or ethylene terephthalate and other medical materials; the lower layer which contacts with the dermis is a natural biological macromolecule thin film which is constructed by silk fibroin and chitosan; the enderonic layer of the artificial skin is constituted by collagen, polysaccharide and microspheres carrying growth factors related to skin regeneration and repairing; the microspheres have good slow-release function, and the slow-release period is equal to or slightly longer than the degradation period of the collagen and polysaccharide and can be matched with the skin regeneration and repairing period; and the thickness of the artificial skin is in a range of 0.5-1.5mm and can be regulated according to requirements.

Owner:SHENZHEN QIKANG MEDICAL DEVICES

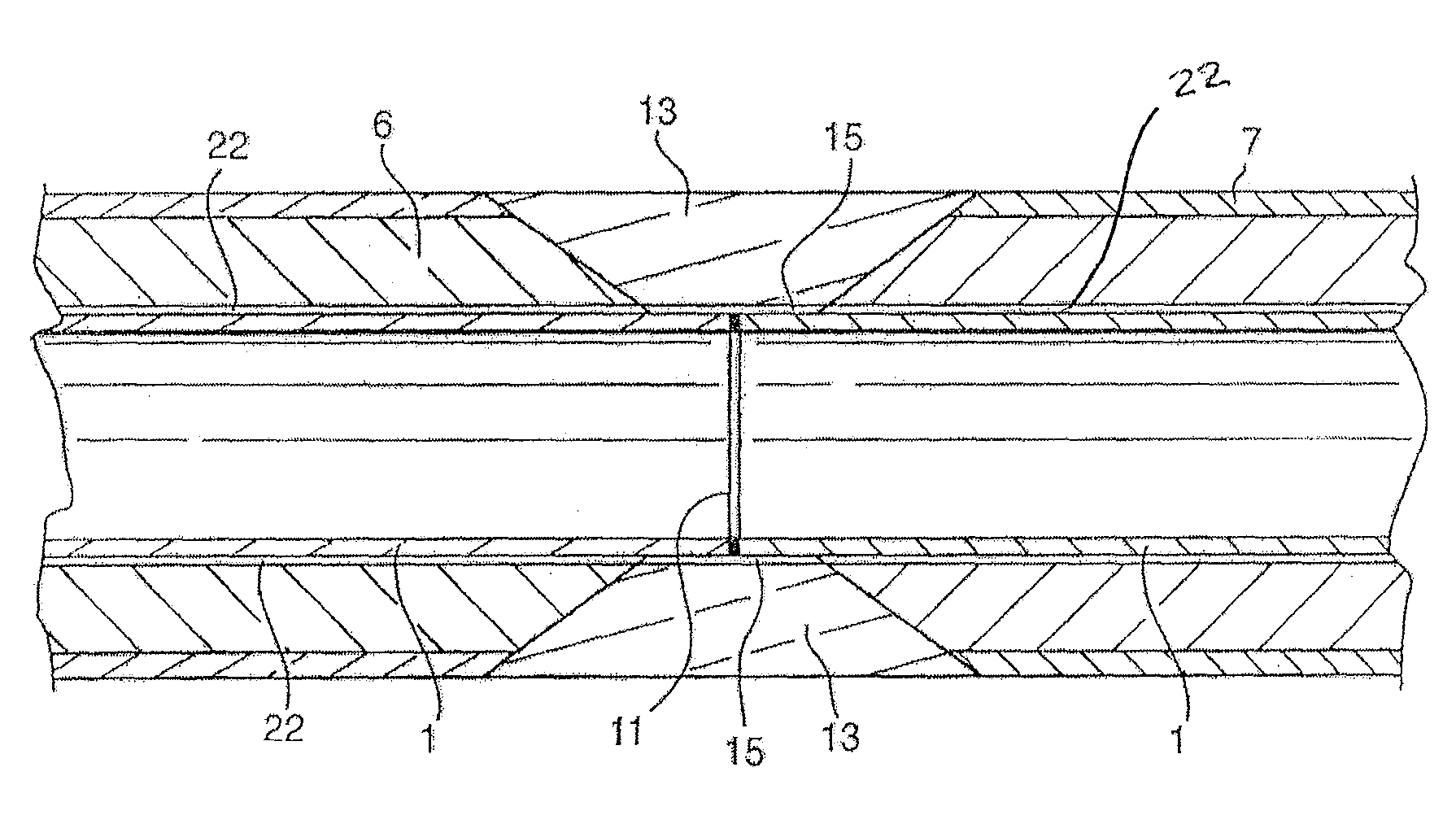

Multi-layer barrier film structure

InactiveUS20050089682A1Raise the barrierImprove barrier propertiesBottlesSynthetic resin layered productsPolyolefinPolyethylene terephthalate

A laminate film comprising a polyetheramine resin-containing layer on a first polyolefin resin-containing layer or a first polyethylene terephthalate resin-containing layer is disclosed. The laminate film could further have additional layers such as a second polyolefin resin-containing layer, a second polyethylene terephthalate resin-containing layer, a metal layer or combinations thereof.

Owner:TORAY PLASTICS AMERICA

Cation dye normal pressure deep dyeing estercopolymer and its preparing method

The present invention is one kind of copolyester capable of being deeply dyed with cationic dye at normal pressure and its preparation process. The copolyester may be blended with common PET to obtain fiber capable of being deeply dyed with cationic dye at normal pressure. The copolyester has main repeated units of glycol phthalate and has acid components including polybasic carboxylic acid in 5-10 wt%, sulfo isophthalate in 5-18 wt% and polyalkylene diol or alphatic binary acid or its derivative in 4-10 wt%. The copolyester is prepared through semi-continuous process, including continuous esterification and intermittent polymerization. The copolyester is one kind of modified cationic dyeable polyester and may be blended into composite fiber with improved air permeation, hydroscopicity and dyeing property and suitable for various kinds of fabric.

Owner:洛阳高新技术开发区南峰聚酯有限公司

3gt/4gt biocomponent fiber and preparation thereof

Owner:EI DU PONT DE NEMOURS & CO

Sustainable packaging for consumer products

ActiveUS8083064B2Package recyclingContainer decorationsPolymer sciencePolyethylene terephthalate glycol

Disclosed herein is a sustainable article substantially free of virgin petroleum-based compounds that includes a container, a cap, and a label, each made from renewable and / or recycled materials. The article has a shelf life of at least two years, and is itself entirely recyclable. The container can include polyethylene, polyethylene terephthalate, or polypropylene. The cap can include polypropylene or polyethylene. The label can include polyethylene, polyethylene terephthalate, polypropylene, or paper.

Owner:THE PROCTER & GAMBLE COMPANY

Compatible blend systems of oxygen barrier polymers and oxygen scavenging polymers

InactiveUS7186464B2Improve compatibilityGood compatibilitySynthetic resin layered productsConductive materialCross-linkPolyethylene terephthalate

Herein is disclosed an oxygen barrier composition comprising an oxygen barrier polymer and an oxygen scavenging polymer. The composition can be in the form of a physical blend or a cross-linked blend, and can further comprise a compatibilizer, a transesterification catalyst, or both. Preferably, the oxygen barrier polymer is poly(ethylene / vinyl alcohol) (EVOH), polyethylene terephthalate (PET), or polyamide other than MXD6. Preferably, the oxygen scavenging polymer comprises an ethylenic backbone and a pendant cyclic olefinic group, or the oxygen scavenging polymer is a polyamide derived at least in part from a xylene diamine-based monomer.The oxygen barrier composition can be formed into an oxygen barrier layer of a packaging article. Such layers and articles, and methods for making same, are also disclosed.

Owner:CRYOVAC ILLC

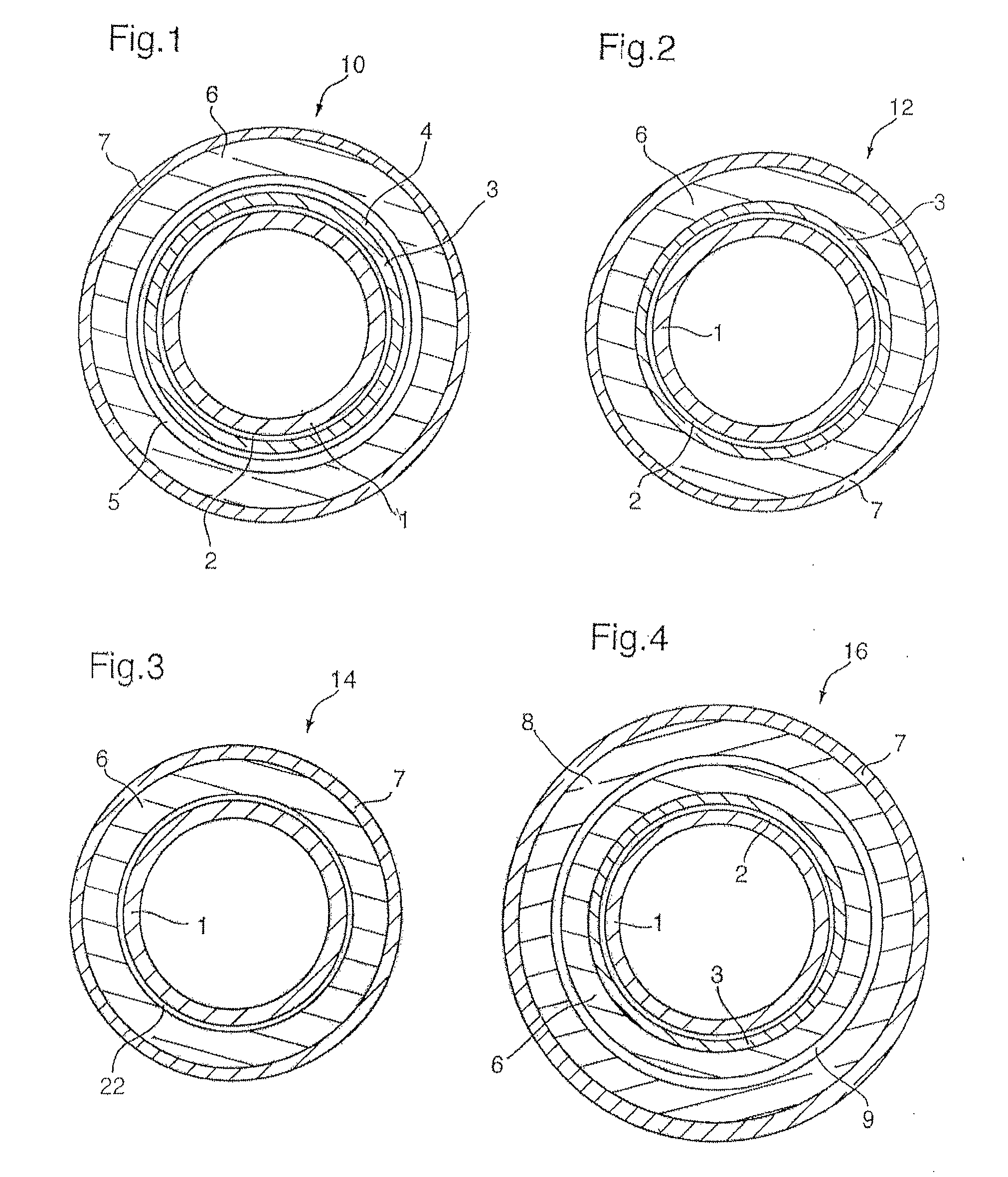

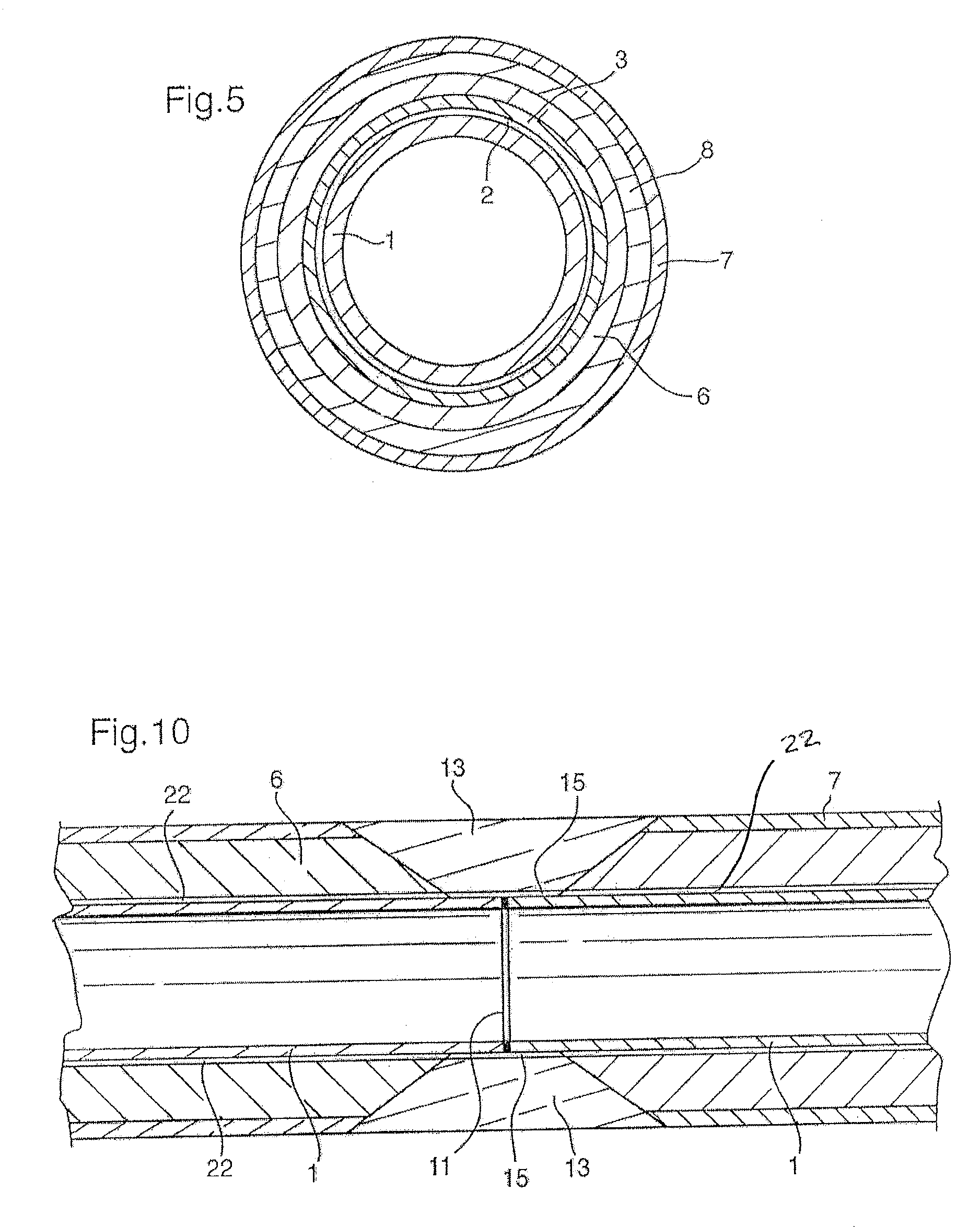

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

Compositions and methods for storing aqueous chlorine dioxide solutions

InactiveUS6284152B1Little and no diffusional lossLoss and degradationCosmetic preparationsBiocideDiffusionChlorine dioxide

The present invention is directed to both physical and chemical means for maintaining continuous high levels of chlorine dioxide in aqueous solutions for extended periods, with minimum loss through degradation in the solution and dissipation through the walls of the containing vessel within which the solution is stored. The ClO2 may be maintained even in the absence of very high levels of chlorite, from which supplemental, offsetting levels of ClO2 may be generated. The present invention relates to the discovery that certain types of plastic and glass containers have the ability to maintain relatively constant levels of ClO2 in their contained solutions over extended periods, particularly in aqueous compositions comprising chlorite / ClO2 ratios sufficient for a stabilizing complex of the two, presumably Cl204-, to suppress the ClO2 loss. Of particular value is certain high-density polyethylene terephthalate (PETE) plastic bottling and plastic containers which have been initially exposed to a fluorinating environment. Specifically, in the latter regard, it has been discovered that certain plastic containers which ordinarily are incapable of maintaining aqueous ClO2 levels can be treated with fluorine gas to transform their surfaces so as to effectively suppress ClO2 diffusion therethrough.

Owner:PROFRESH PROPERTIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com