Patents

Literature

55 results about "Compressive creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

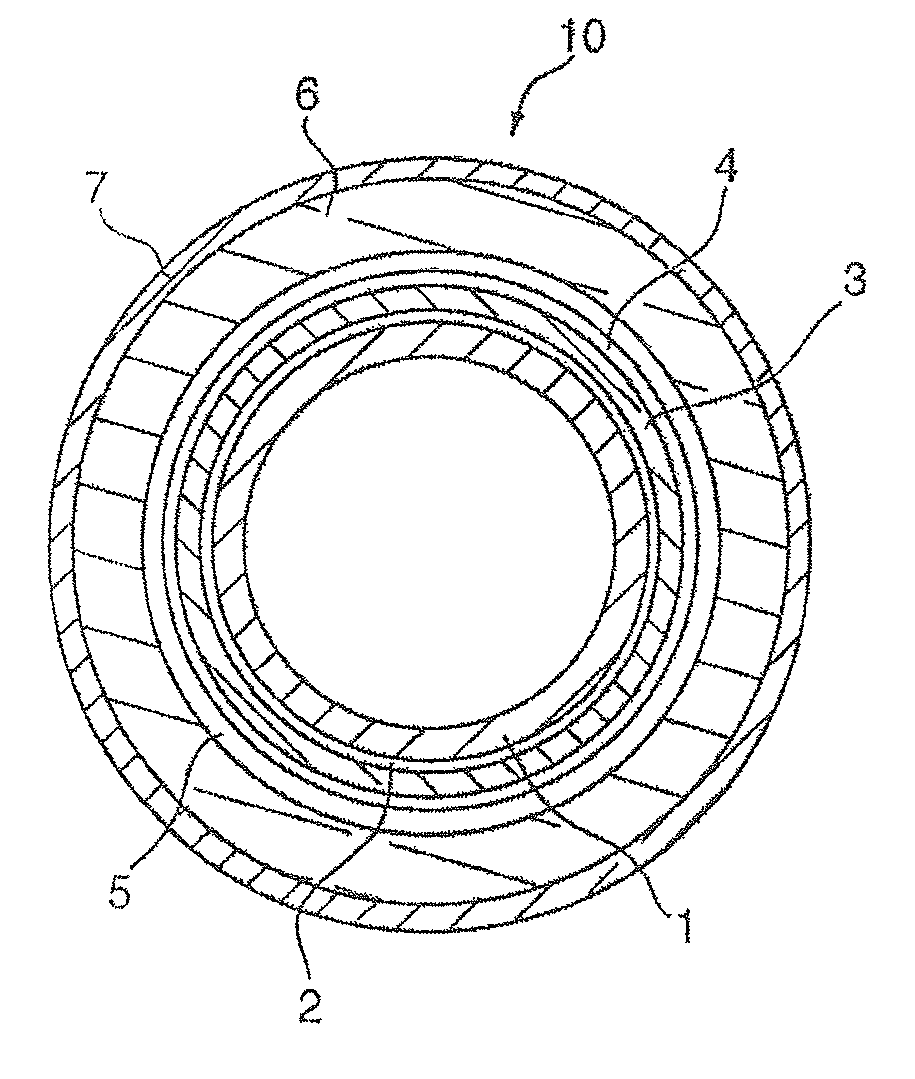

Styrenic insulation for pipe

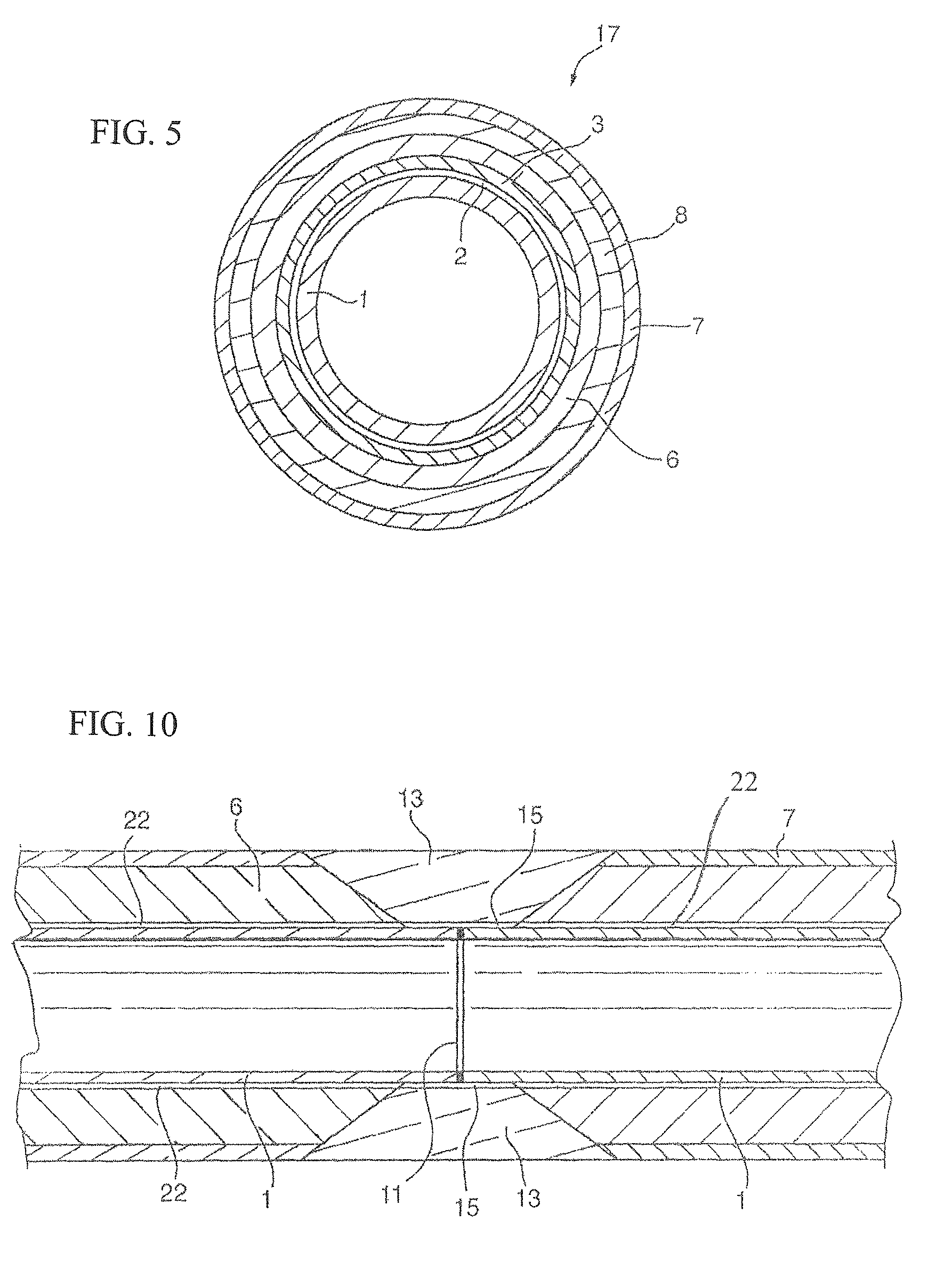

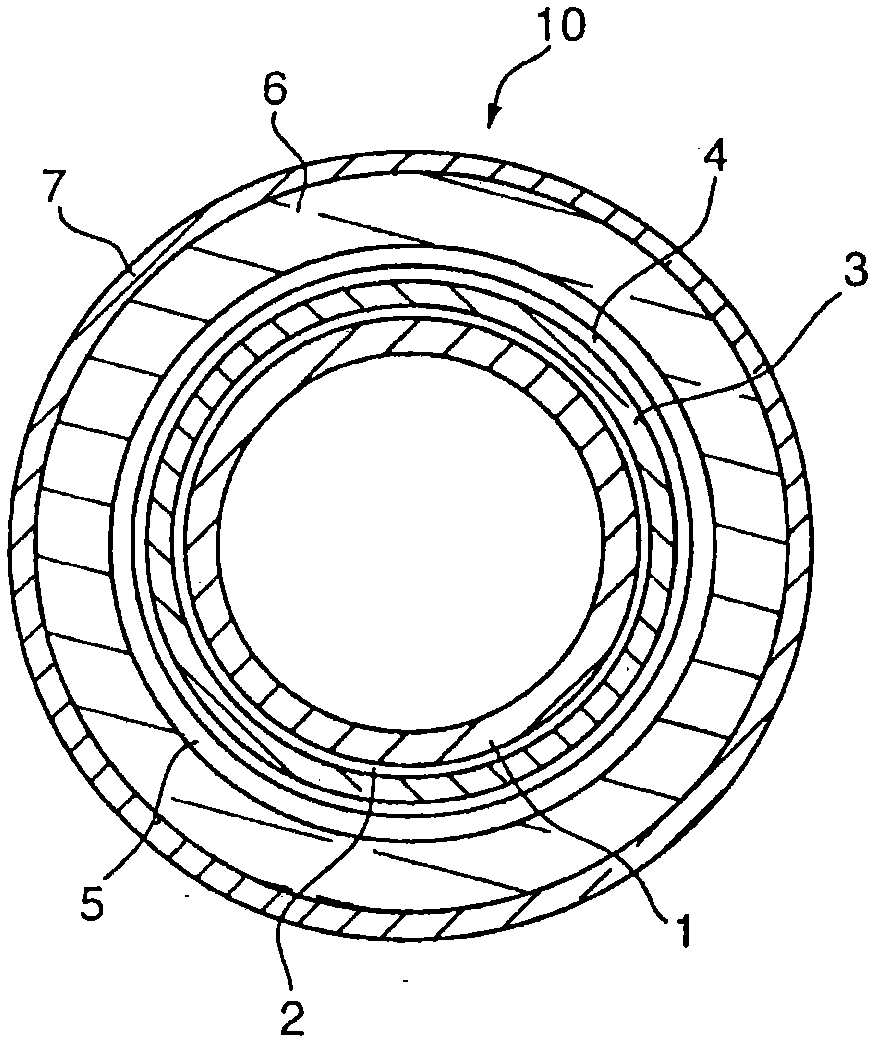

ActiveUS20090159146A1Improve insulation effectReduce coating thicknessThermal insulationCorrosion preventionThermoplasticCompressive creep

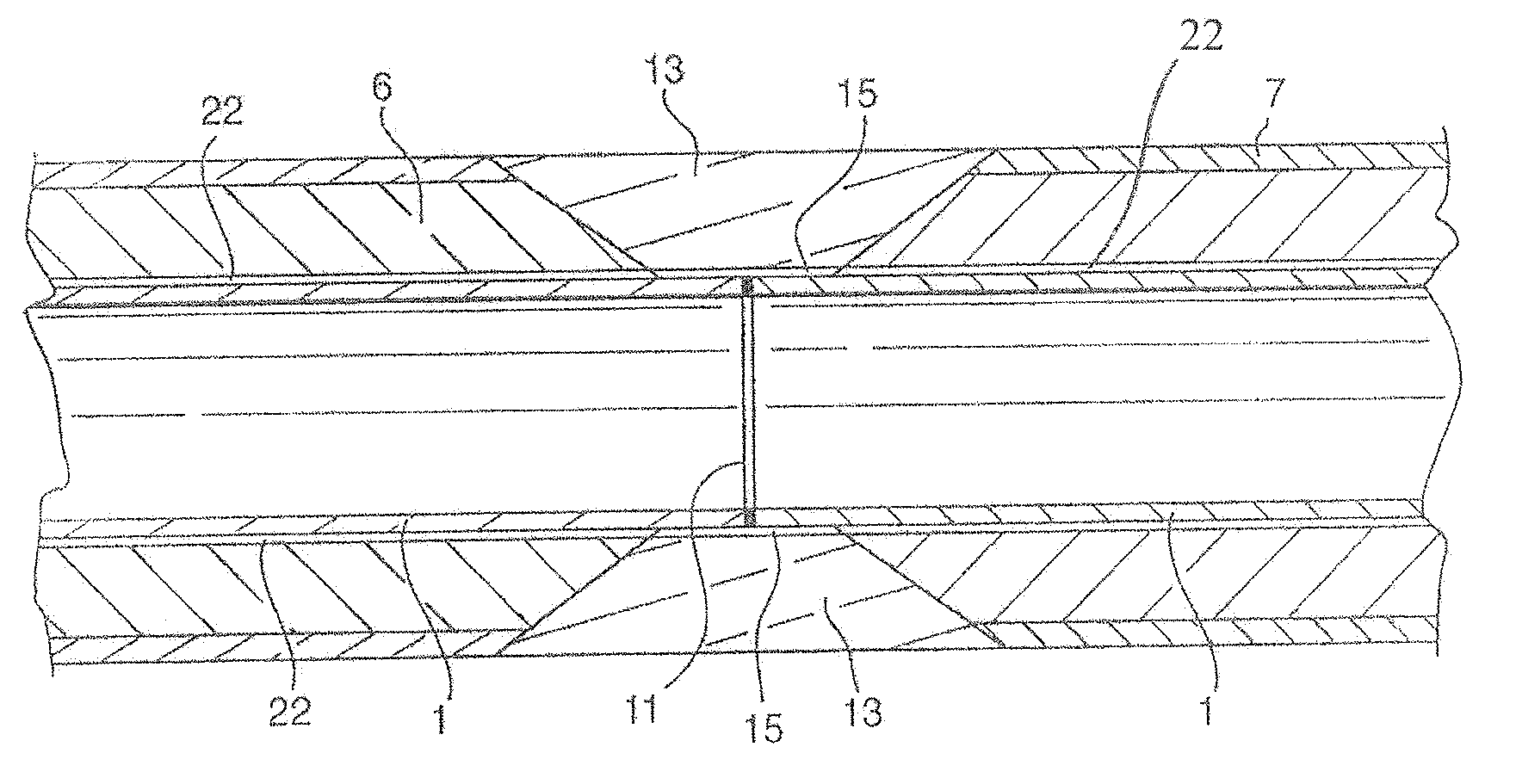

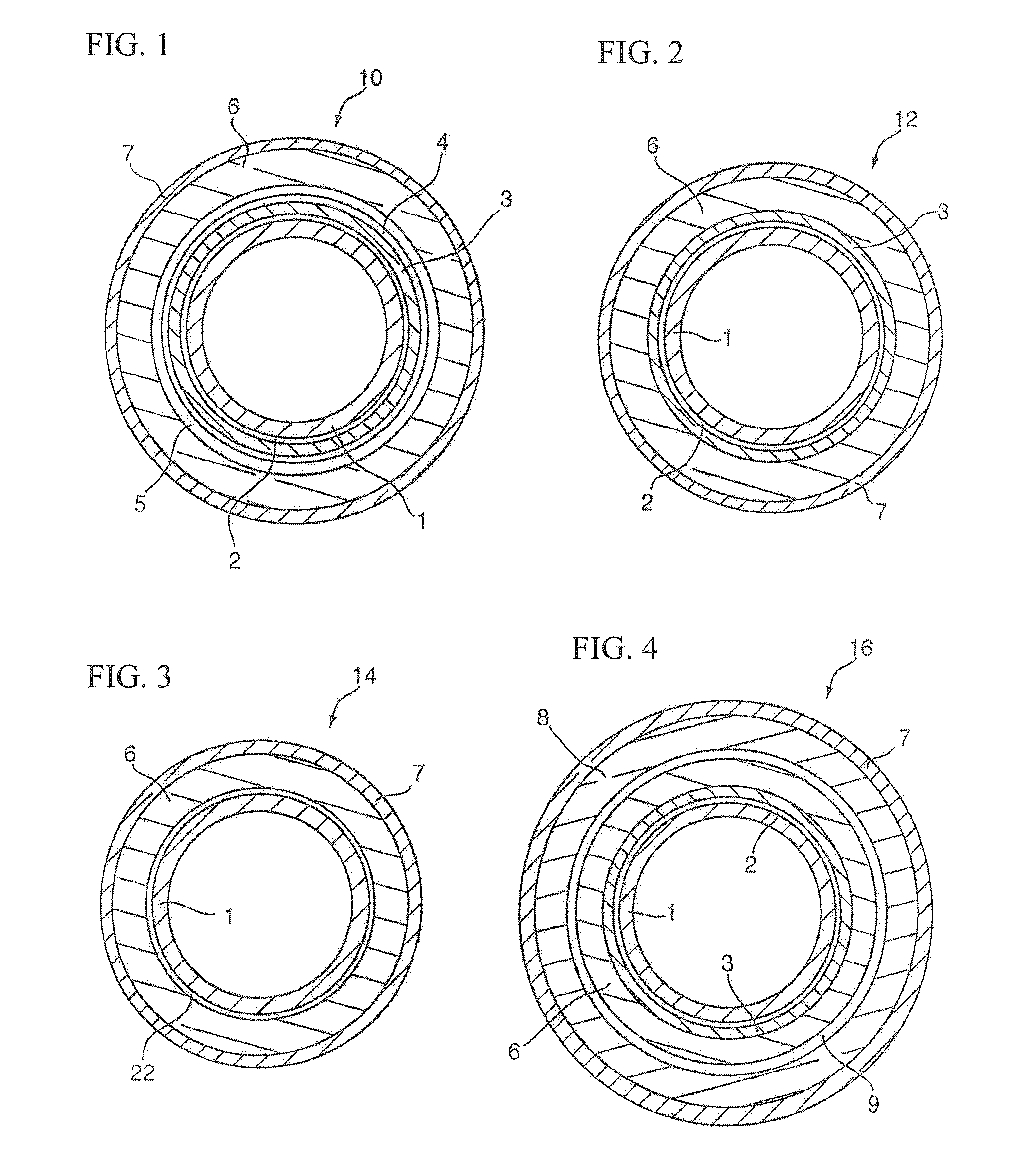

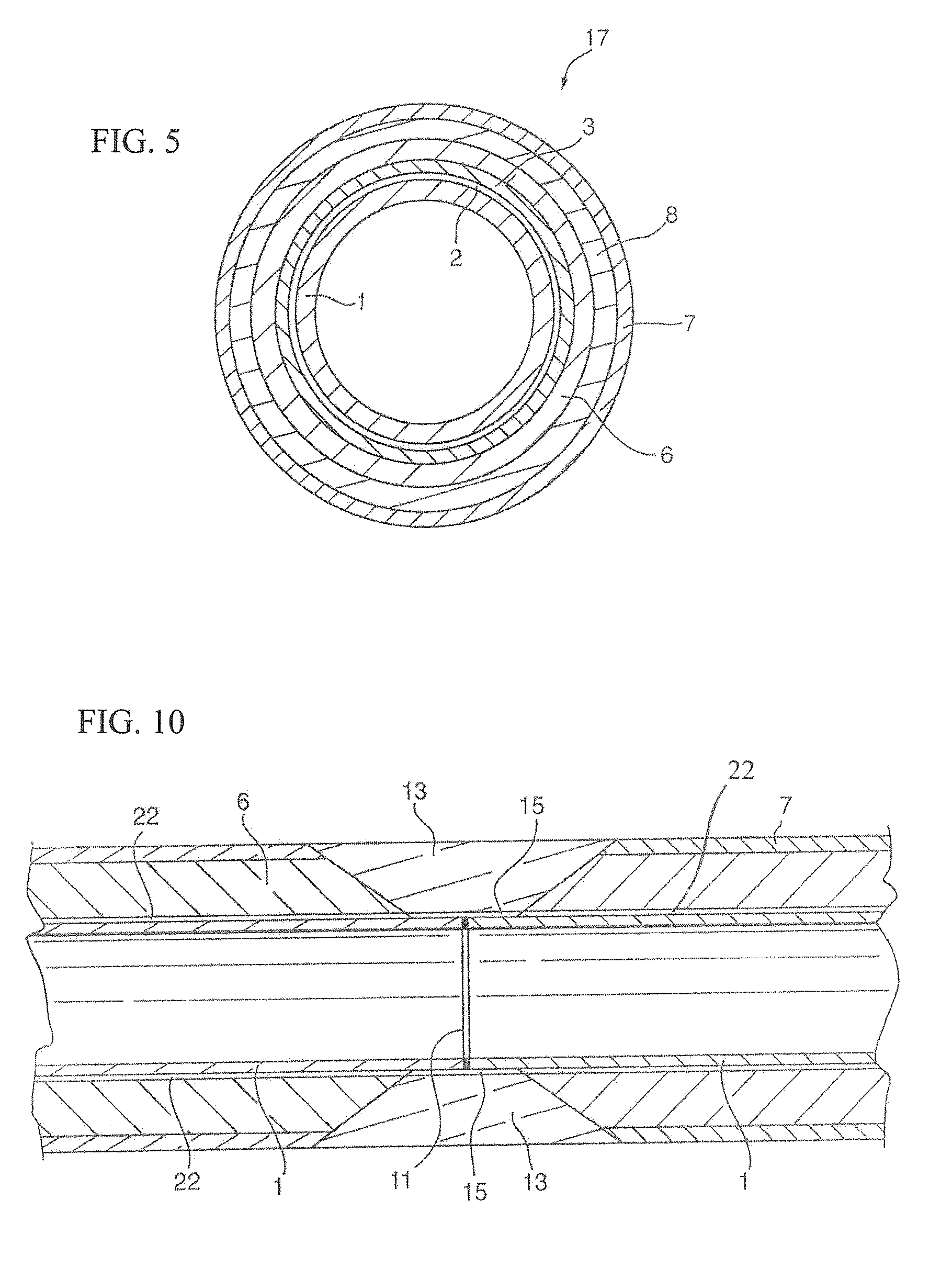

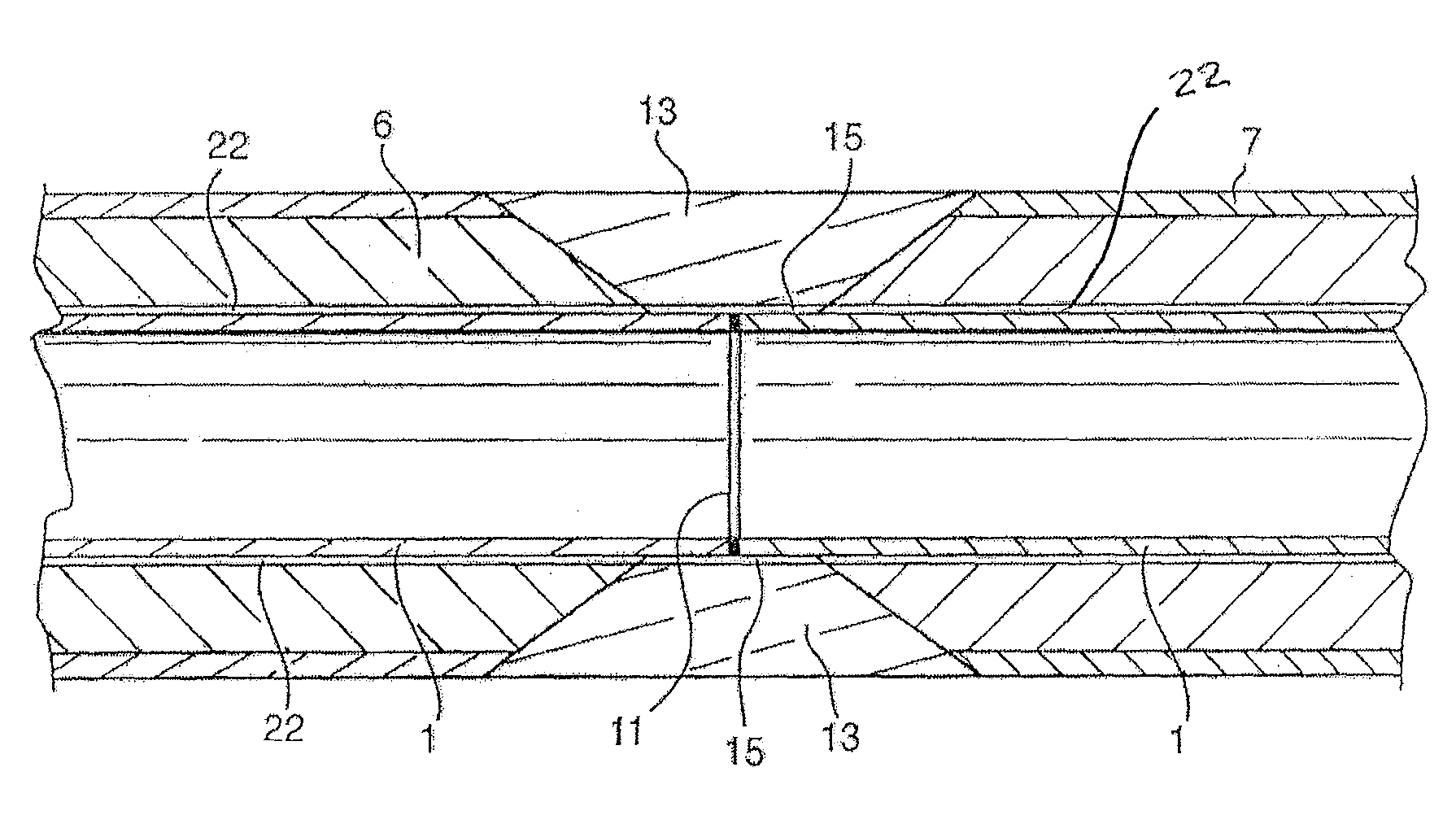

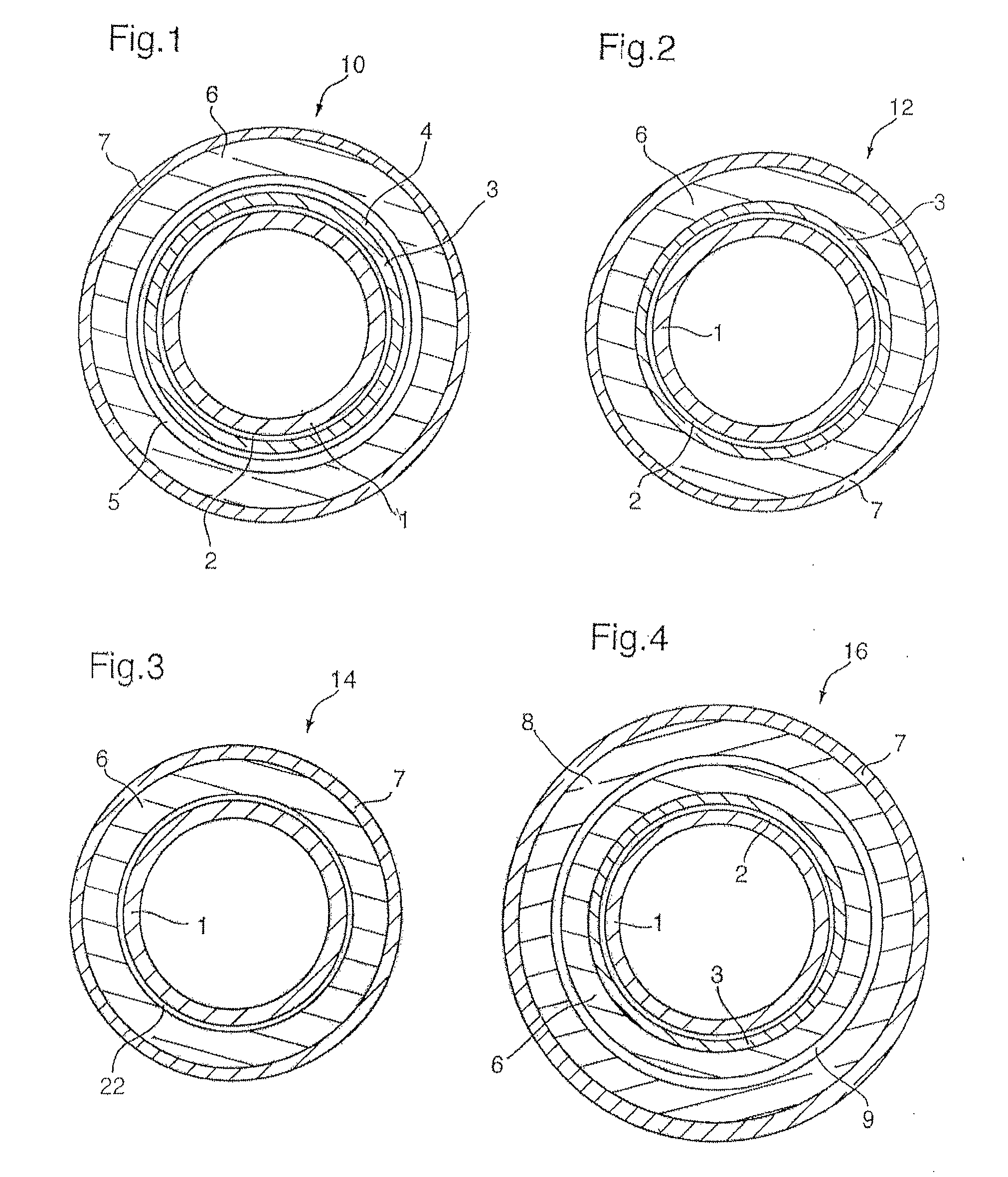

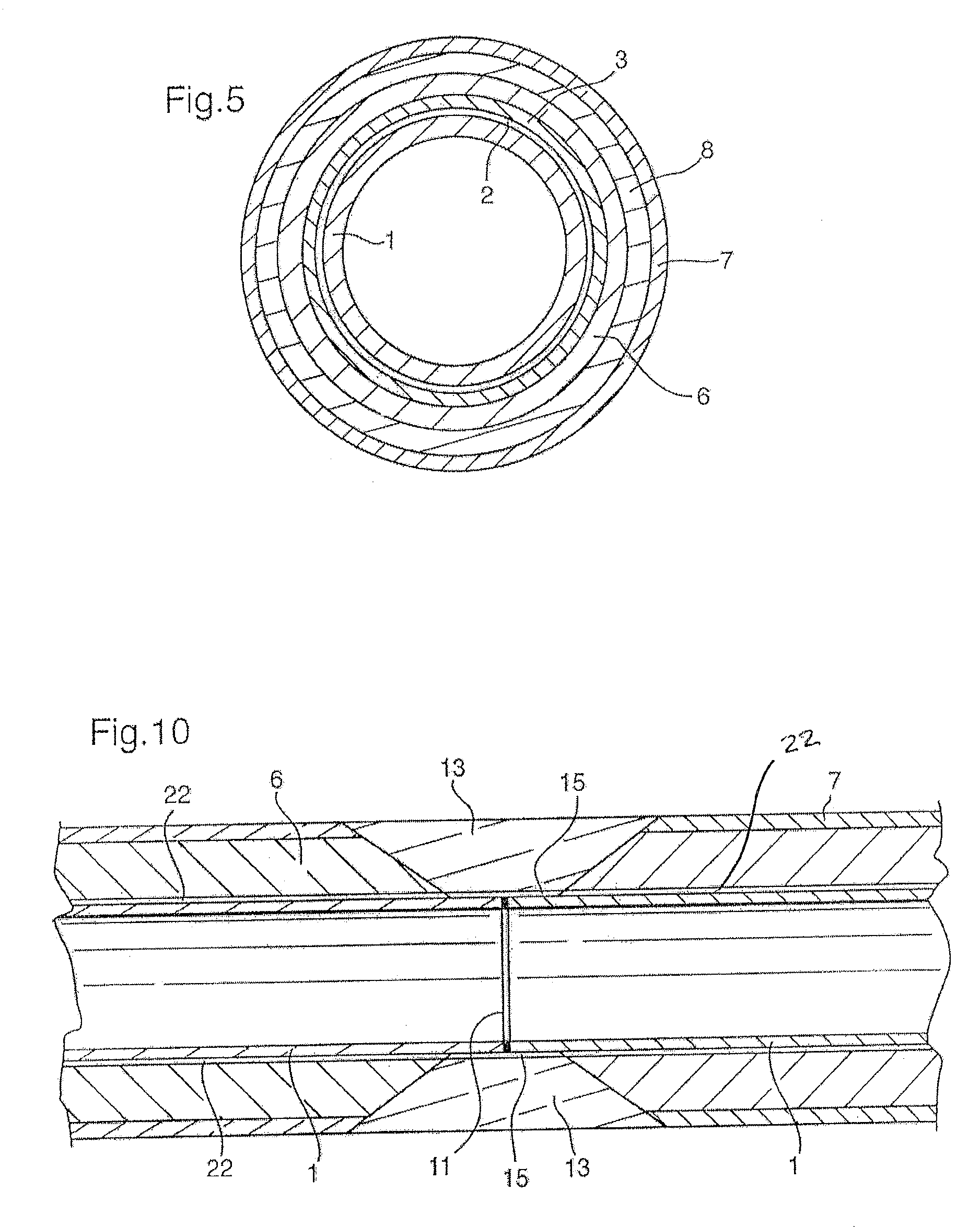

Coatings for protecting and insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of up to 100° C. in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of thermal insulation comprising polystyrene or styrene-based thermoplastic, having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance.

Owner:SHAWCOR LTD

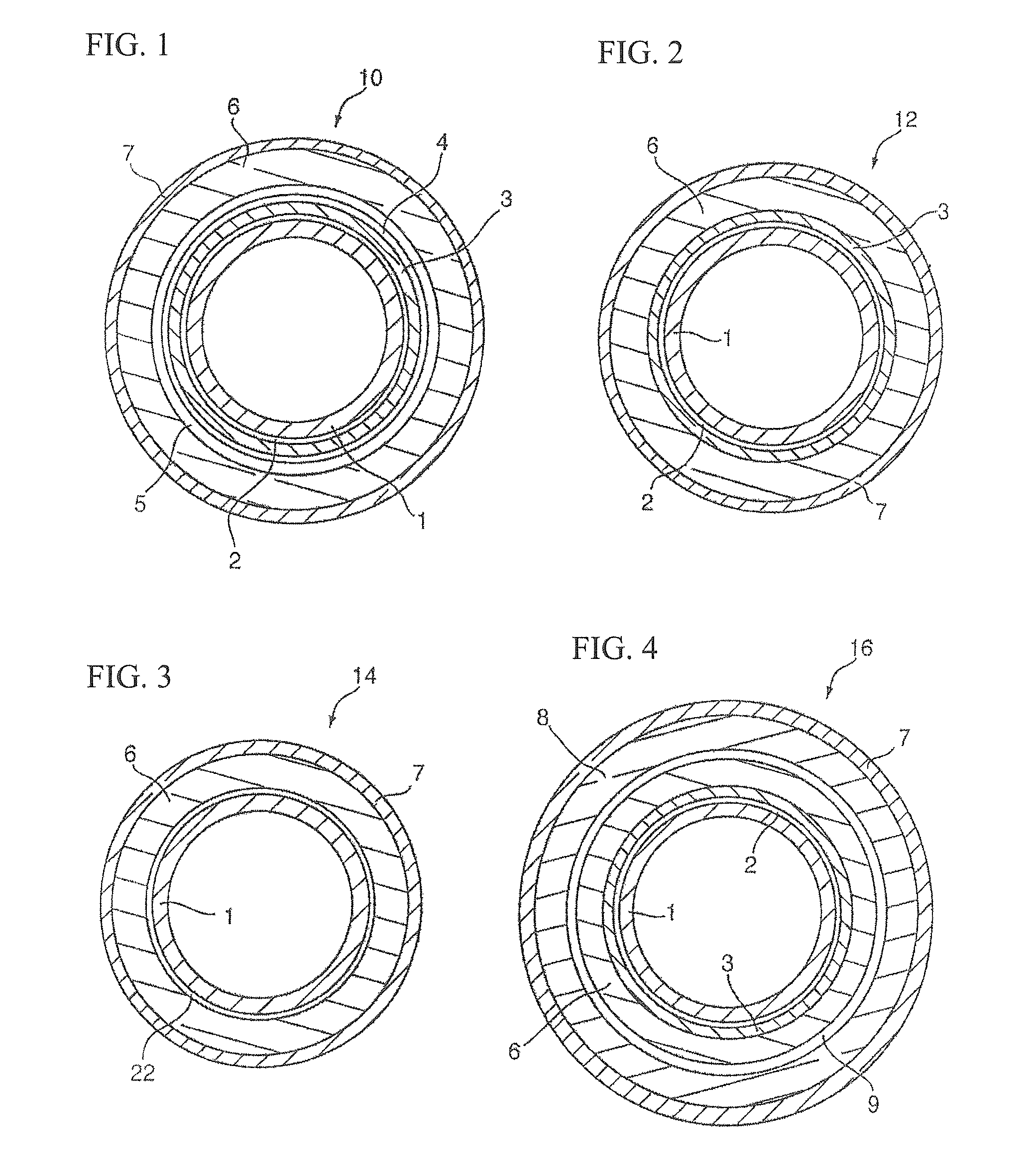

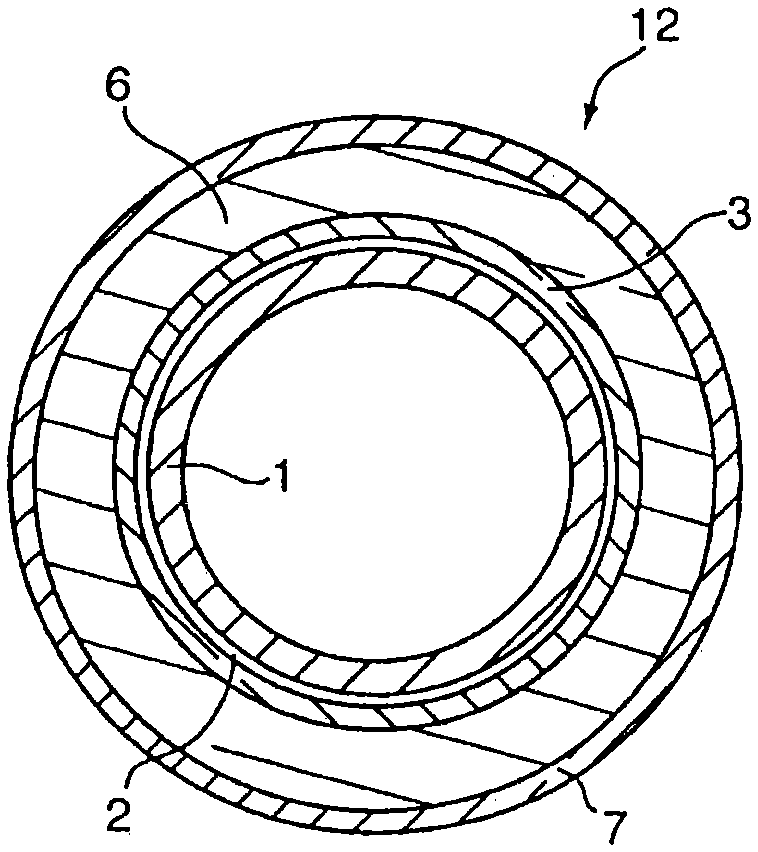

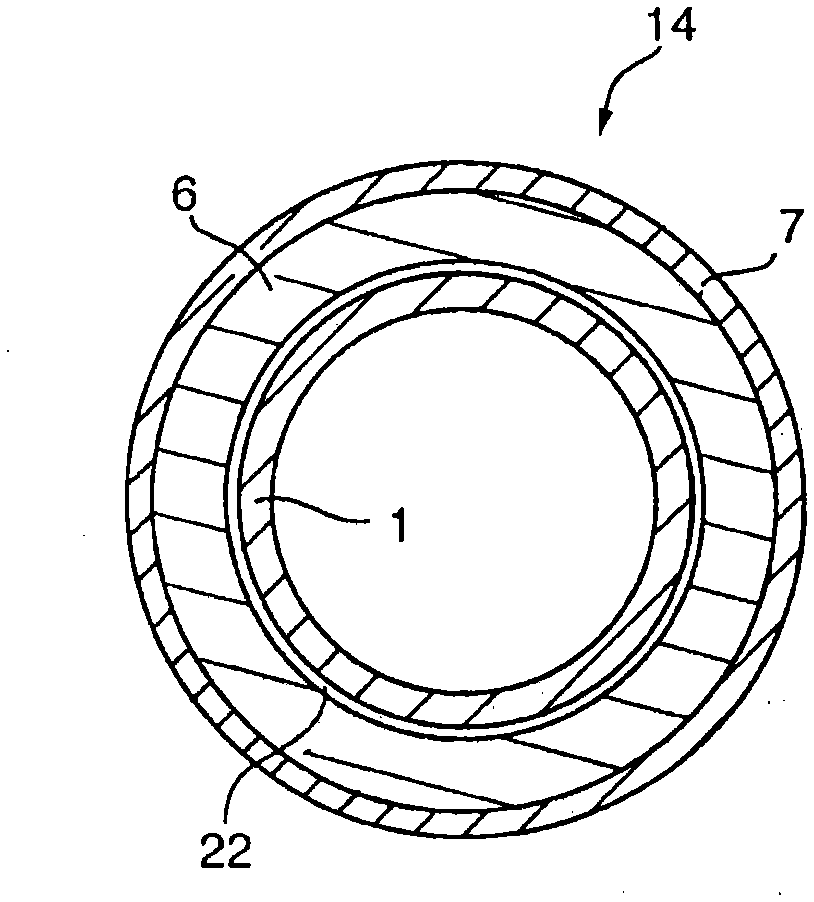

High temperature resistant insulation for pipe

ActiveUS8397765B2Low thermal conductivityImprove thermal stabilityThermal insulationSynthetic resin layered productsElastomerPolyetherimide

A polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130° C. or higher in water depths above 1,000 meters. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

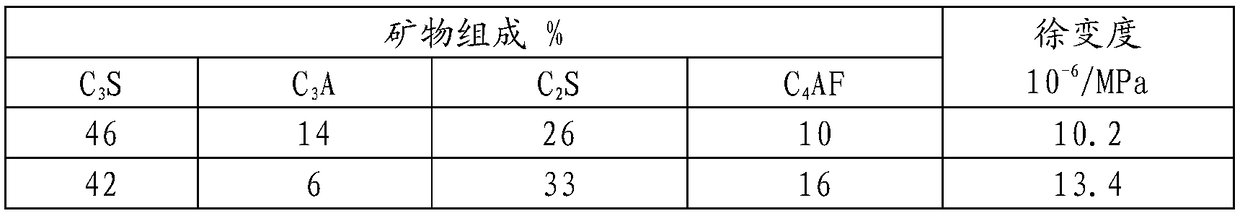

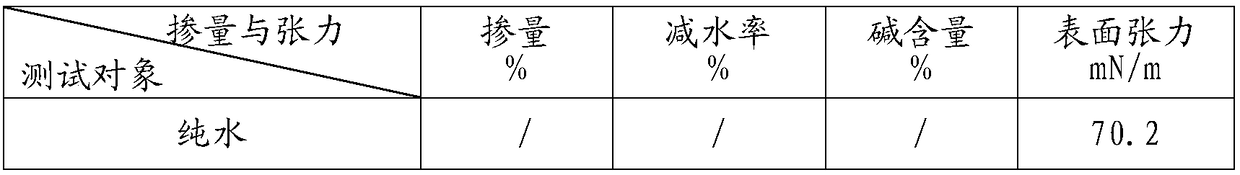

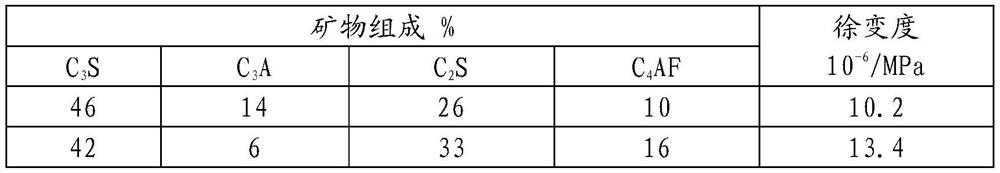

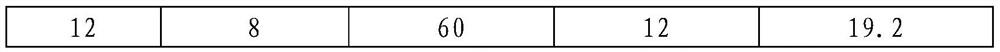

Low-shrinkage low-creep crack-resistant high-performance mass concrete

The invention relates to low-shrinkage low-creep crack-resistant high-performance mass concrete, and belongs to the technical field of concrete. The requirement that the apparent density of the concrete is equal to or more than 2400kg / m<3>, the 28d compressive strength is equal to or more than 70MPa, the 28d tensile strength is equal to or more than 4.7MPa, the 365d dry shrinkage rate is less thanor equal to 519*10<-6>, the 365d compressive creep degree is less than or equal to 28.0*10<->6 / MPa and the 365d compression creep coefficient is less than or equal to 0.72 is met under the conditionthat coal ash is mingled singly. The concrete has the advantages of being free of special stirring process, convenient to stir and capable of changing the stirring charging sequence compared with mixed concrete. The concrete mixture has moderate viscosity, good cohesiveness and small pumping pressure during construction, thereby being easy to pump and pour. The concrete has good crack resistance,low shrinkage, low creep, good volume stability, and can reduce the probability of cracks when used in high-strength stress complex mass concrete construction. By means of single mingling of the coalash in the concrete, the silo configuration of a mixing station can be reduced, stone powder in the mechanism sand can be used reasonably to avoid waste of resources, reduce energy consumption, greatly reduce the cost, and conform to environmentally-friendly development of the concrete. The abstract cannot exceed 300 words, thus deleted.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

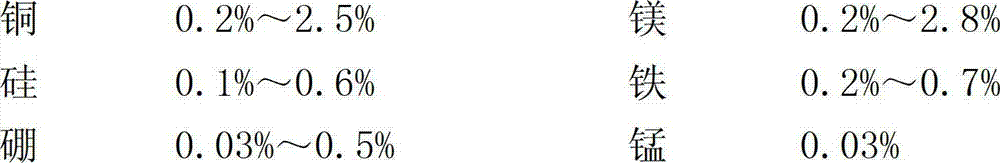

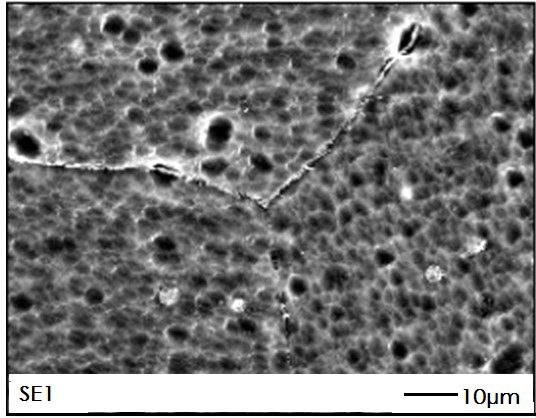

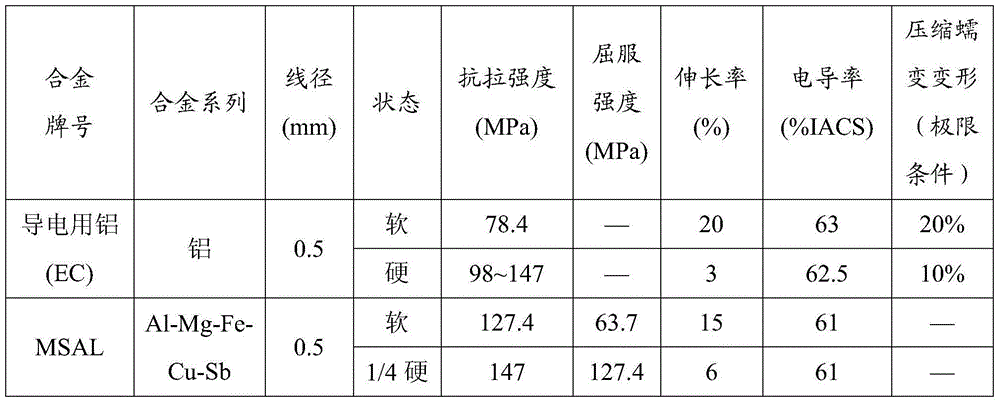

Aluminum-copper-magnesium alloy wire rod and manufacturing technique thereof

The invention relates to an aluminum-copper-magnesium alloy wire rod and a manufacturing technique of the aluminum-copper-magnesium alloy wire rod. The aluminum-copper-magnesium alloy wire rod is formed by the following raw materials in percentage by weight: 0.2-2.5% of copper, 0.2-2.8% of magnesium, 0.1-0.6% of silicon, 0.2-0.7% of iron, 0.03-0.5% of boron, 0.03% of manganese, 0.03% of zinc, 0.03% of chrome, 0.01% of titanium, and 96%-98% of aluminum. The manufacturing technique comprises the following steps: (1), smelting of aluminum alloy, (2), online treatment of aluminum alloy, (3), casting of aluminum alloy, (4), rolling of aluminum alloy wire rod, and (5), carrying out online aging treatment on the rolled aluminum alloy wire rod to obtain the wire rod, wherein the drawing out temperature is not higher than 60 DEG C. The aluminum-copper-magnesium alloy wire rod meets the performance requirements on the raw material aluminum alloy wire rod in copper clad aluminum alloy in the cable industry field, in particular the requirements on the performances in the aspects of tensile strength, percentage elongation and compressive creep, and the like.

Owner:庆毅 +1

Styrenic insulation for pipe

ActiveUS8714206B2Improve insulation effectLow costThermal insulationCorrosion preventionThermoplasticCompressive creep

Owner:SHAWCOR LTD

High teMPERATURE resistant insulating for pipe

The invention provides a polymeric composition for insulating fluid and / or gas transport conduits, such as off-shore oil and gas pipelines operating at temperatures of 130 DEG C or higher in water depths above 1,000 metres. The outer surface of the conduit is provided with at least one layer of solid or foam insulation comprising a high temperature resistant thermoplastic having low thermal conductivity, high thermal softening point, high compressive strength and high compressive creep resistance. The high temperature resistant thermoplastic is selected from one or more members of the group comprising: polycarbonate; polyphenylene oxide; polyphenylene oxide blended with polypropylene, polystyrene or polyamide; polycarbonate blended with polybutylene terephthalate, polyethylene terephthalate, acrylonitrile butadiene styrene, acrylonitrile styrene acrylate, or polyetherimide; polyamides, including polyamide 12 and 612 and elastomers thereof; polymethylpentene and blends thereof; cyclic olefin copolymers and blends thereof; and, partially crosslinked thermoplastic elastomers, also known as thermoplastic vulcanizates or dynamically vulcanized elastomers.

Owner:SHAWCOR LTD

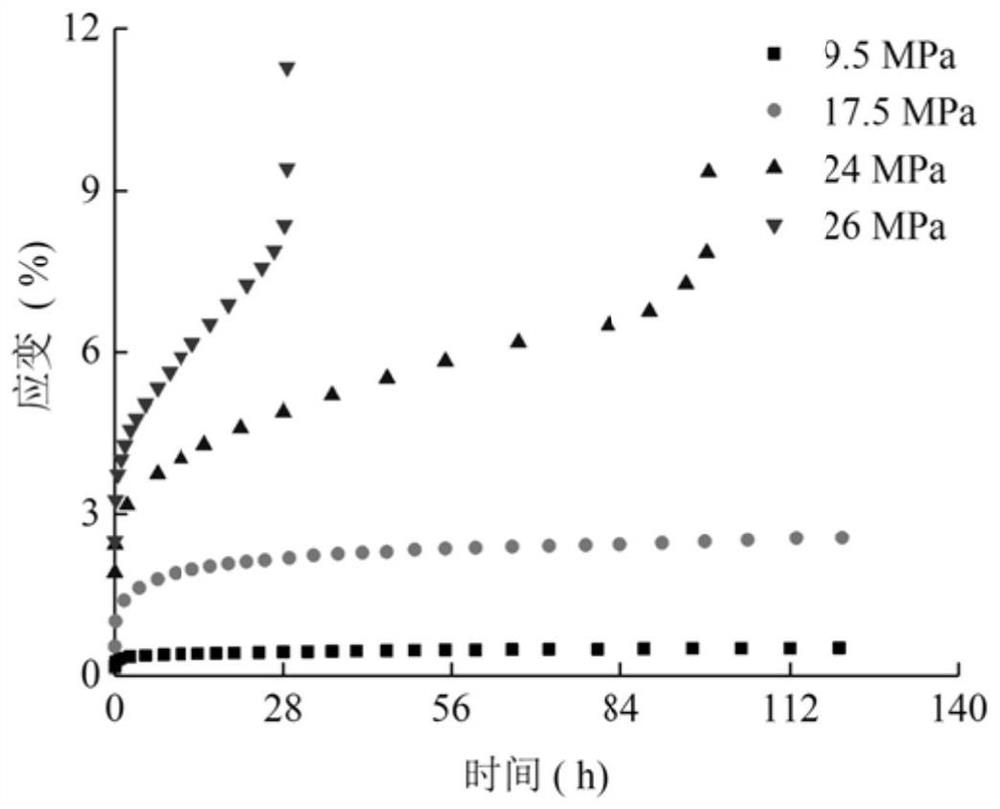

Method for building whole rock uniaxial compression process creep model based on S function

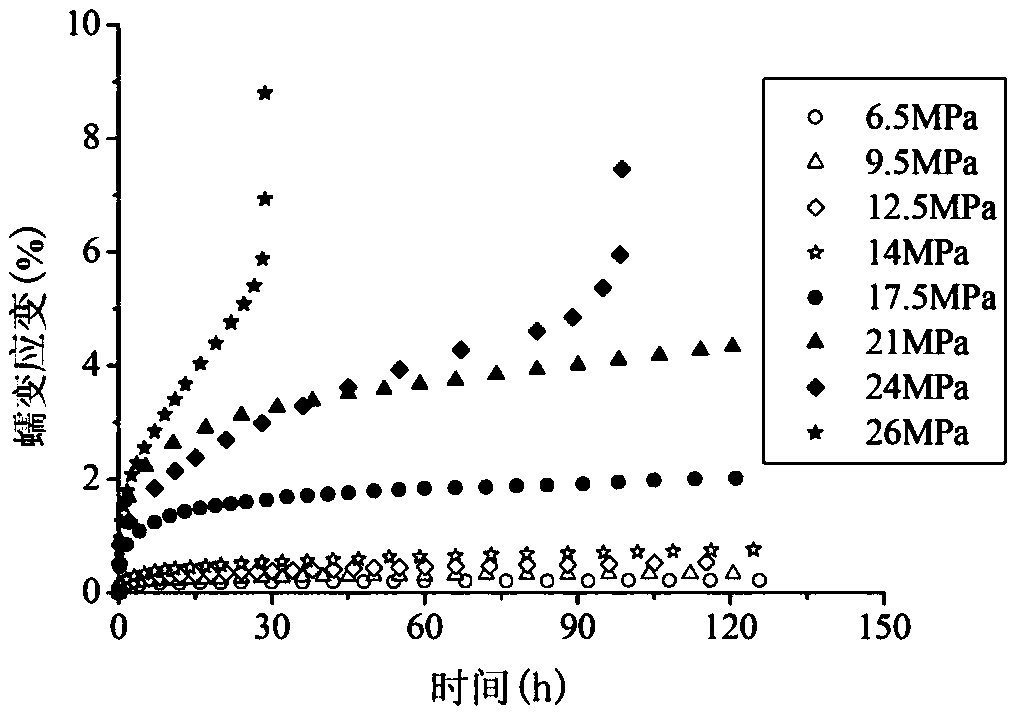

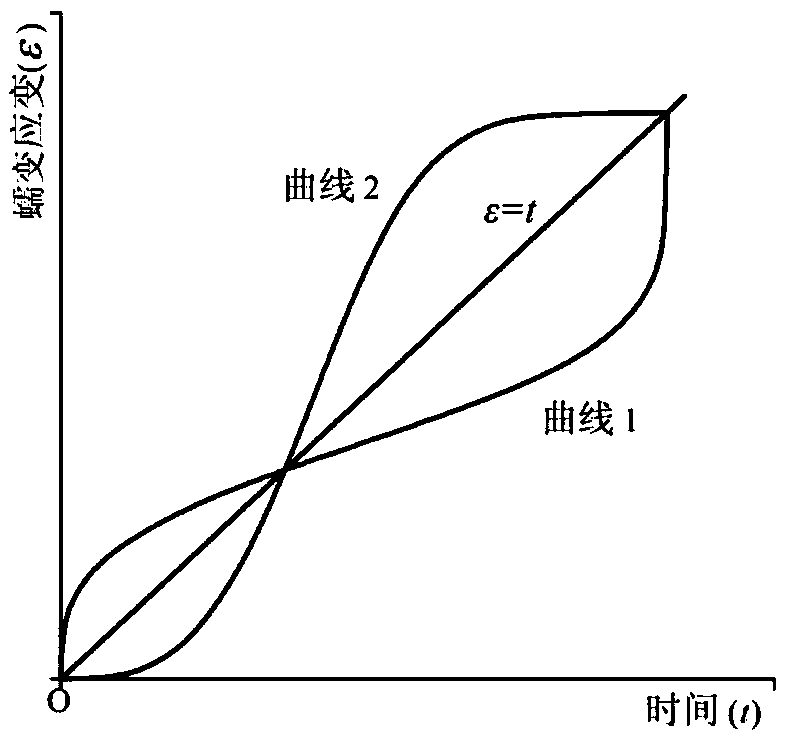

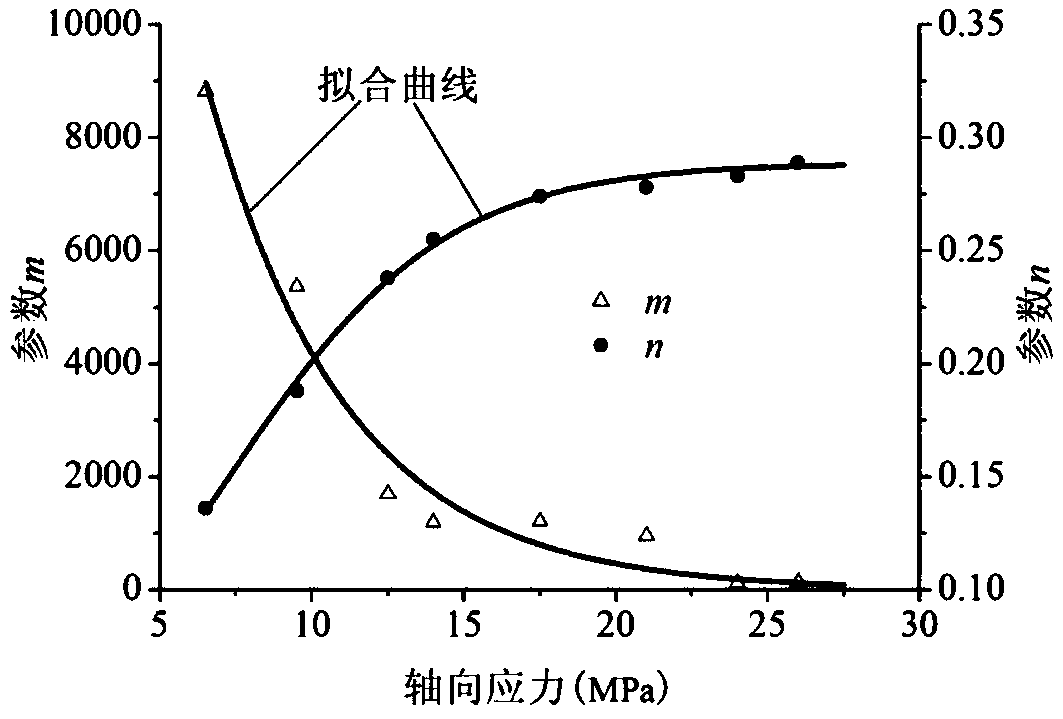

ActiveCN109060549AOvercoming the disadvantages of segmented processingSimple function expressionsMaterial strength using tensile/compressive forcesUniaxial compressionThree stage

The invention discloses a method for building a whole rock uniaxial compression process creep model based on an S function. The method comprises the following steps of 1, carrying out uniaxial compression creep testing on a rock test piece under different axial stresses, thereby obtaining rock creep curves; 2, making a symmetric curve along an angular bisector of a coordinate system for the rock whole-process creep curve with accelerated creep, thereby obtaining an S curve; 3, selecting a Weibull function to describe the S curve; 4, calculating an inverse function for an expression of the Weibull function, and determining a function expression of the whole rock uniaxial compression process creep model; and 5, determining creep model parameters according to a rock uniaxial compression creeptesting result. The creep model built by the method can describe three stages of the whole rock uniaxial compression creep process through the unified function expression, so that the defect that anelement combination model needs to be processed in a segmented manner is overcome; and meanwhile, the model expression is simple in form and convenient to apply.

Owner:西安华清科教产业(集团)有限公司

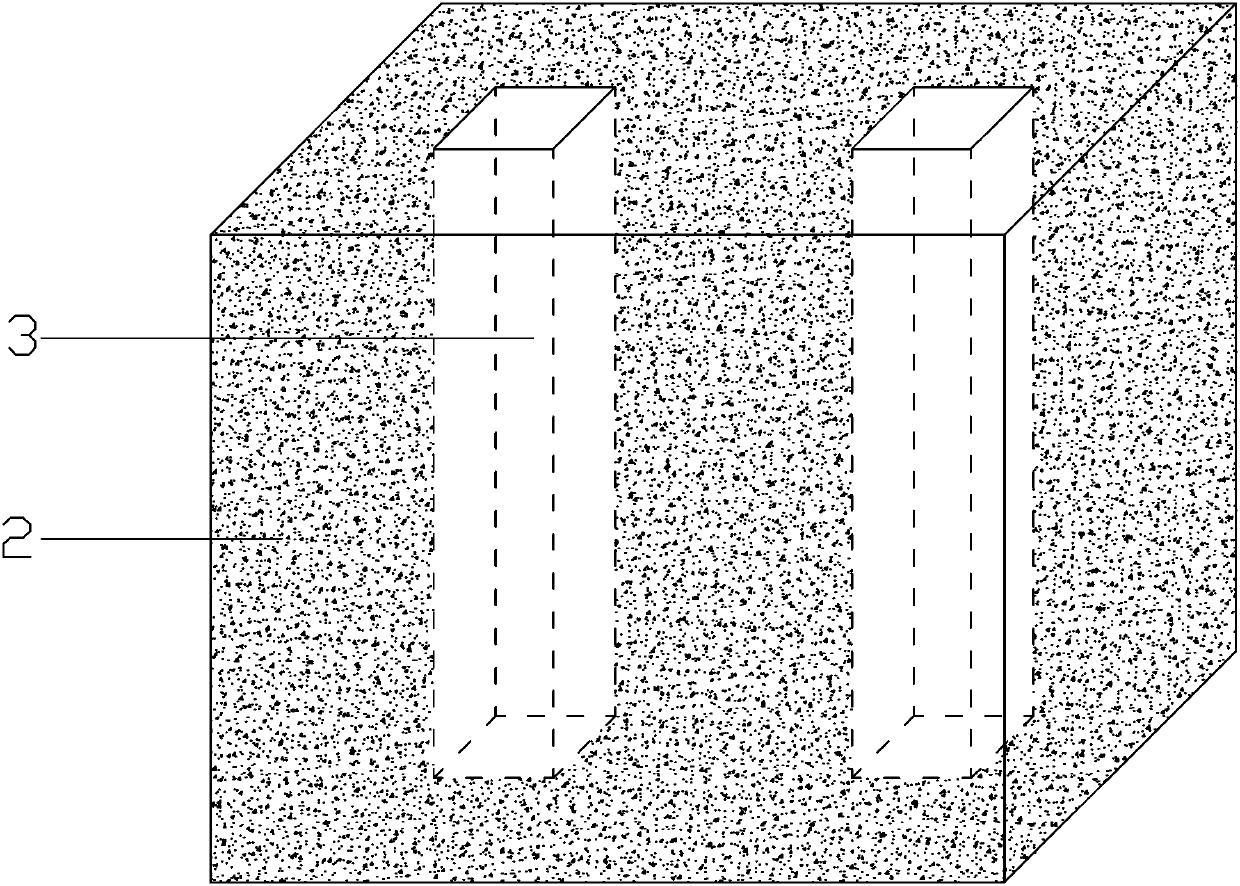

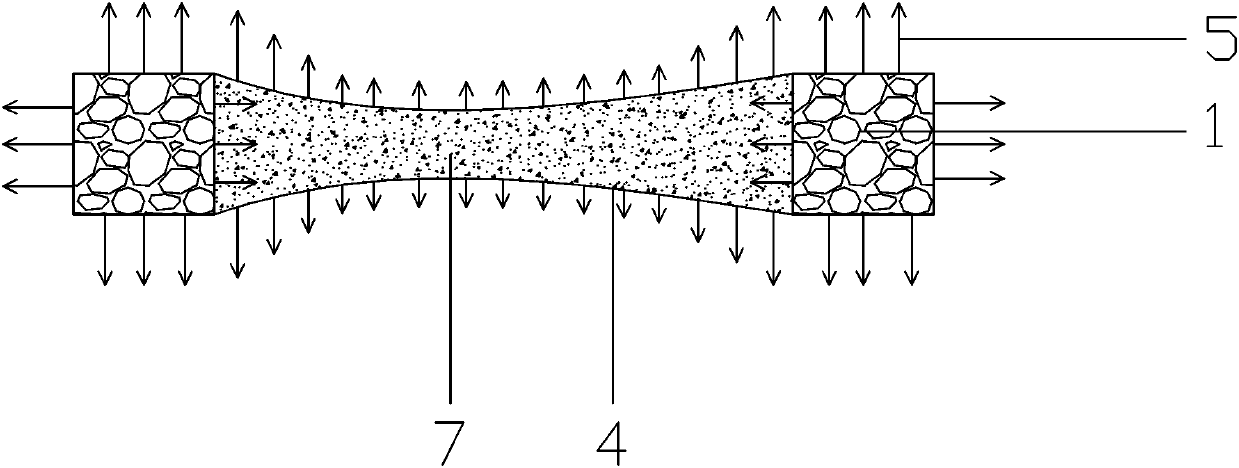

Device and method for testing tensile and compressive creep of inter-hole rock bridges by using expansion agent

ActiveCN110044683AReliable measurement resultsAdjust the size of the forcePreparing sample for investigationMaterial strength using tensile/compressive forcesCompressive creepStructure of the Earth

The invention discloses a device and method for testing tensile and compressive creep of inter-hole rock bridges by using an expansion agent. The device comprises a rock sample for testing, wherein aplurality of small holes are processed inside the rock sample, the expansion agent is filled inside the small holes; a rock bridge is formed between two adjacent small holes, and distributed optical fibers, transparent mesh paper or stress monitoring points for measuring stress on the rock bridges are arranged in different regions of the rock bridges; steel plates are placed on both sides near therock bridges inside the small holes, and two adjacent steel plates are connected by steel bars. The method can monitor and measure various mechanical parameters and timely feedback on the force of the rock sample in real time, is simple in operation, low in cost and simple in structure, can be applied to quantity detection of tensile and compressive molds of rock samples of various shapes and sizes, and has a wide range of engineering practice significance and application prospects.

Owner:CHINA THREE GORGES UNIV

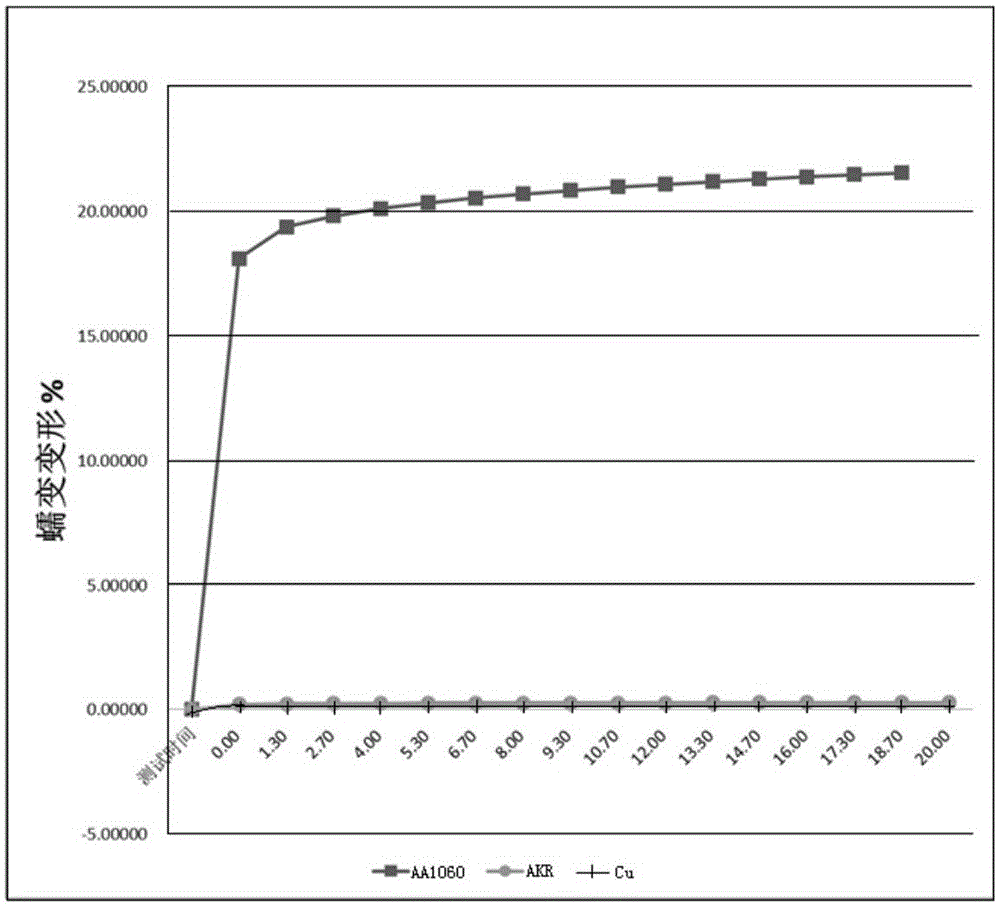

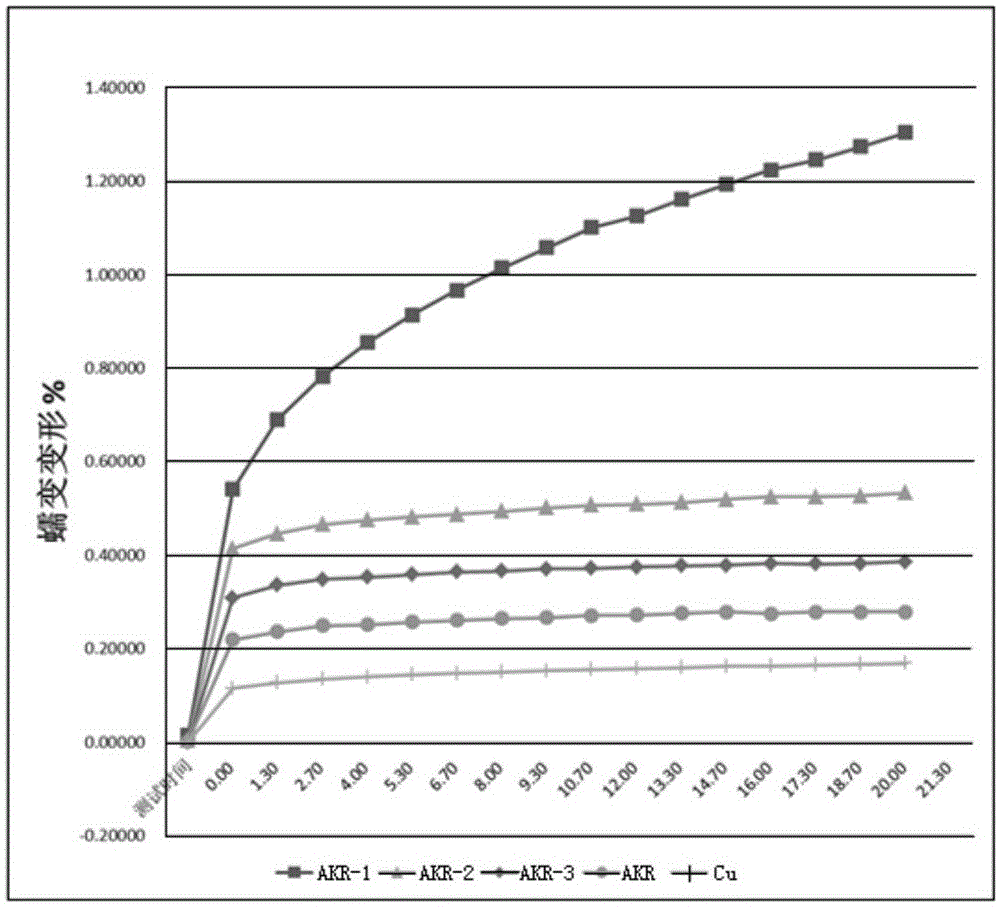

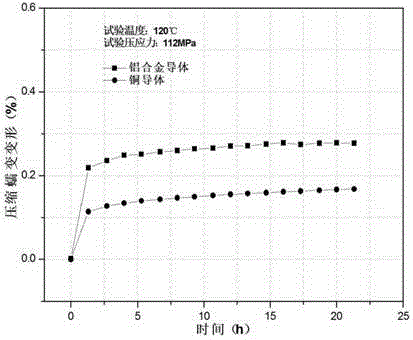

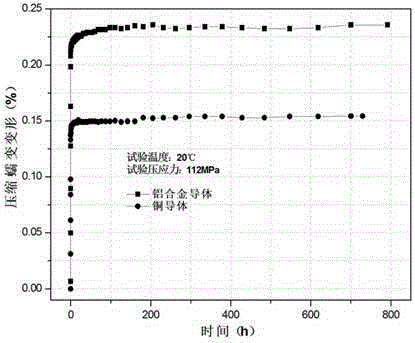

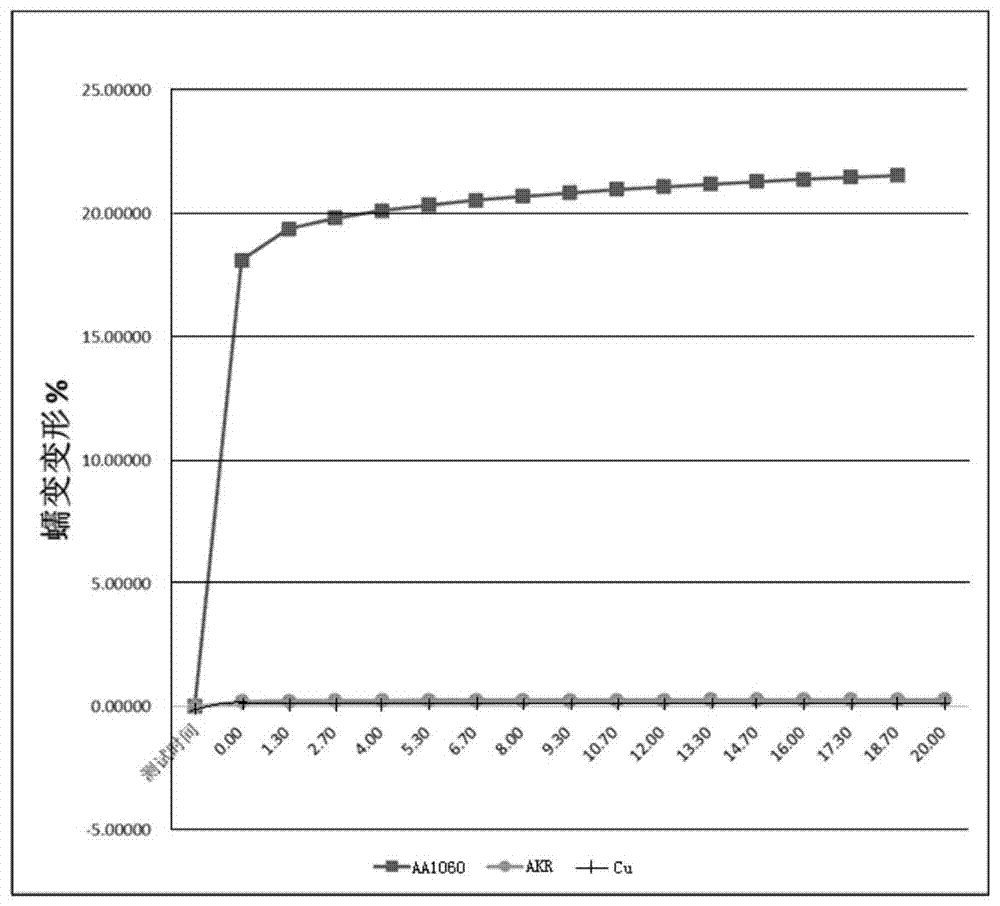

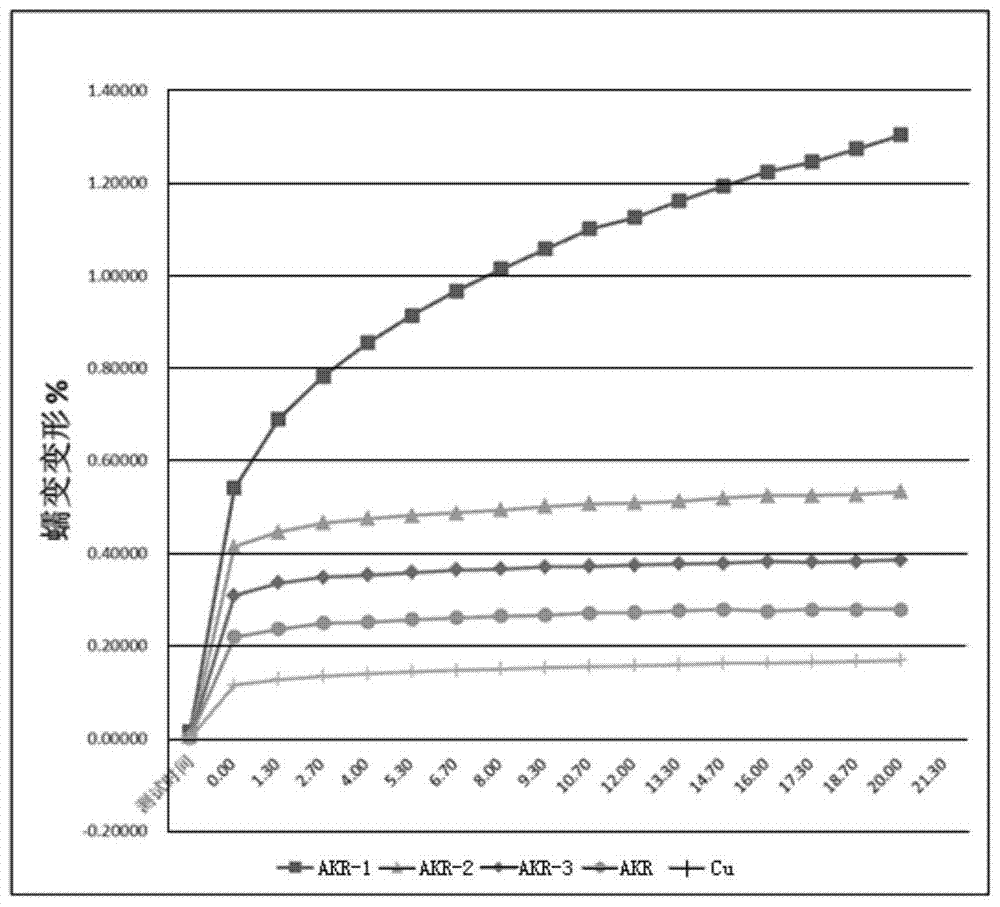

High-conductivity compressive-creep-resistant aluminum alloy and manufacturing method thereof

ActiveCN105132767AHigh tensile strengthHigh yield limitMetal/alloy conductorsCompressive creepRare earth

The invention discloses a high-conductivity compressive-creep-resistant aluminum alloy. The high-conductivity compressive-creep-resistant aluminum alloy comprises the following components in percentage by mass: 0.25%-2.5% of copper, 0.3%-2.8% of magnesium, 0.03%-0.5% of rare earth, 0.3%-1.2% of iron and the balance of aluminum. The invention further discloses a manufacturing method for the high-conductivity compressive-creep-resistant aluminum alloy. The manufacturing method comprises the following steps: (1) pre-treating an alloy raw material; (2) carrying out batching, melting and in-furnace treatment on the alloy raw material; (3) carrying out online refining treatment on a molten aluminum alloy; and (4) casting and forming the alloy. The obtained aluminum alloy material not only has high tensile strength and yield limit, but also has excellent electrical conductivity, and good thermal stability of a resistor at a high temperature; more importantly, at the high temperature, the aluminum alloy material has very excellent compressive creep resistance, is a major breakthrough of replacing copper with aluminum in the electrotechnical industry, greatly solves the defect caused by creep property difference in an aluminum alloy conductor material application process, and meets performance requirements of the aluminum alloy material while applied in the electrotechnical industry.

Owner:深圳阿尔泰克轻合金技术有限公司

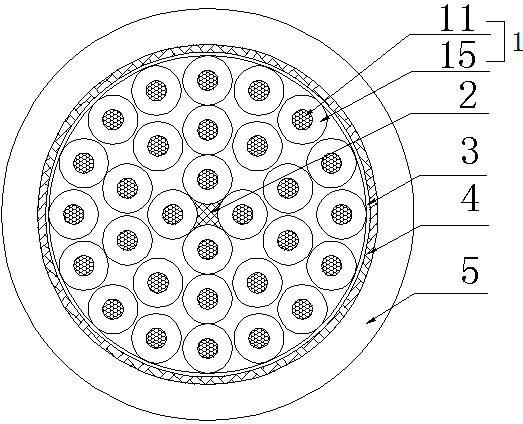

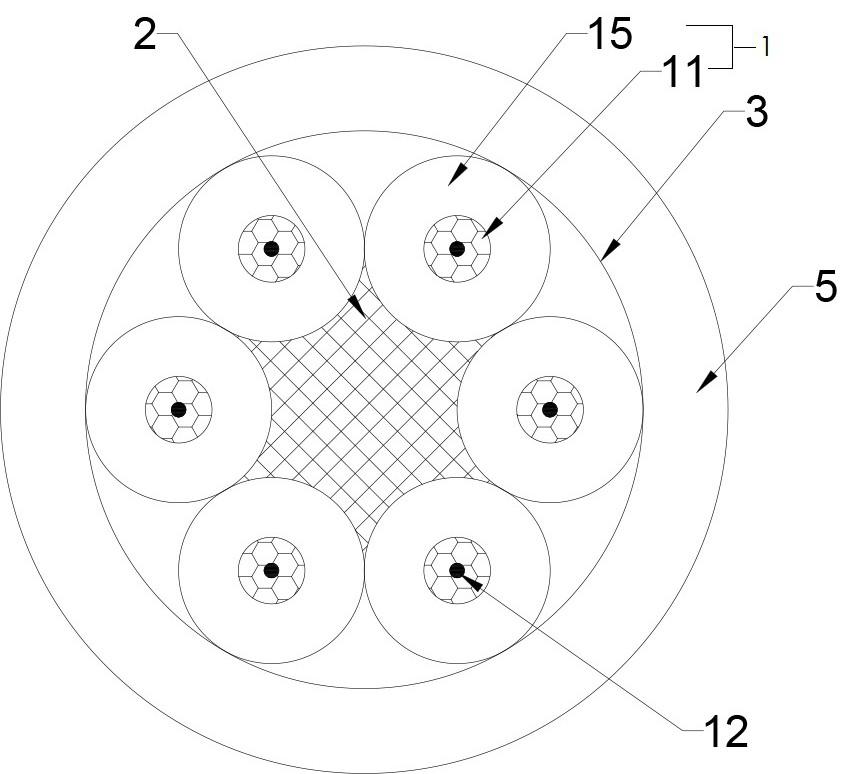

Aluminum alloy conductor flexible cable and preparation method thereof

ActiveCN112259284AHigh strengthAnti-agingClimate change adaptationConductive materialCompressive creepElectro conductivity

The invention discloses an aluminum alloy conductor flexible cable and a preparation method thereof, and belongs to the field of flexible cables. The aluminum alloy conductor flexible cable comprisesone or more cabling sheath layers, a cabling and belting layer and conductor insulating wire cores from outside to inside in sequence, wherein the number of the conductor insulating wire cores is oneor more, cabling fillers are filled between the conductor insulating wire cores, and each conductor insulating wire core sequentially comprises a tensile strand, an aluminum alloy conductor and a wirecore insulating layer from inside to outside. The aluminum alloy conductor flexible cable not only has high conductivity, but further has excellent tensile strength and compressive creep resistance,the possibility of replacing copper with aluminum in the flexible cable is realized, the use cost of the flexible cable is reduced, and the wear resistance and the service life of the cable are improved due to light weight and excellent characteristics.

Owner:TBEA DEYANG CABLE CO LTD

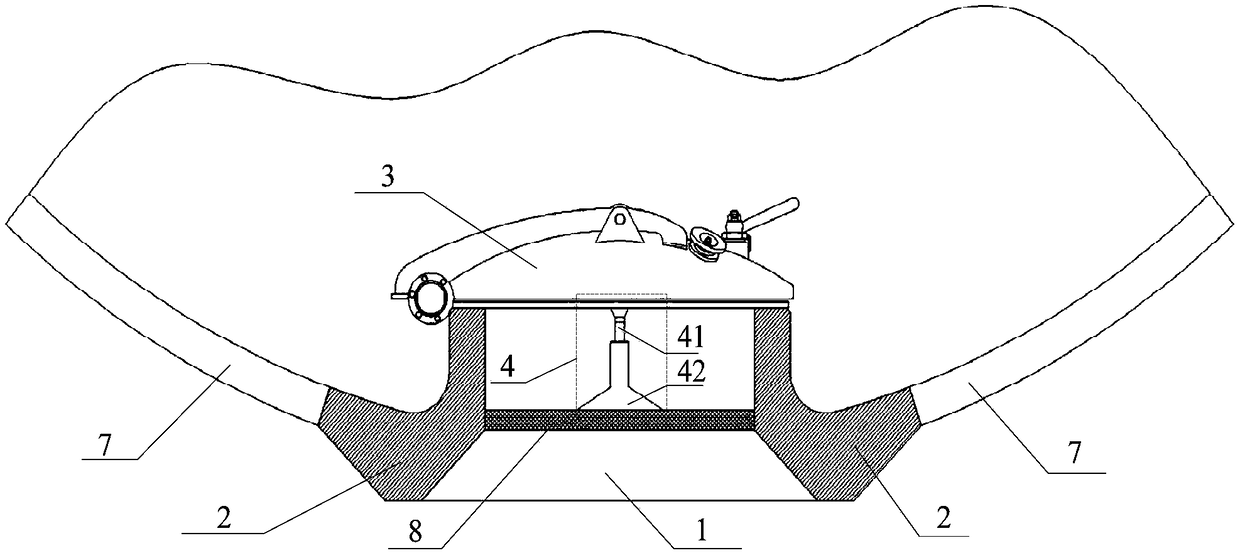

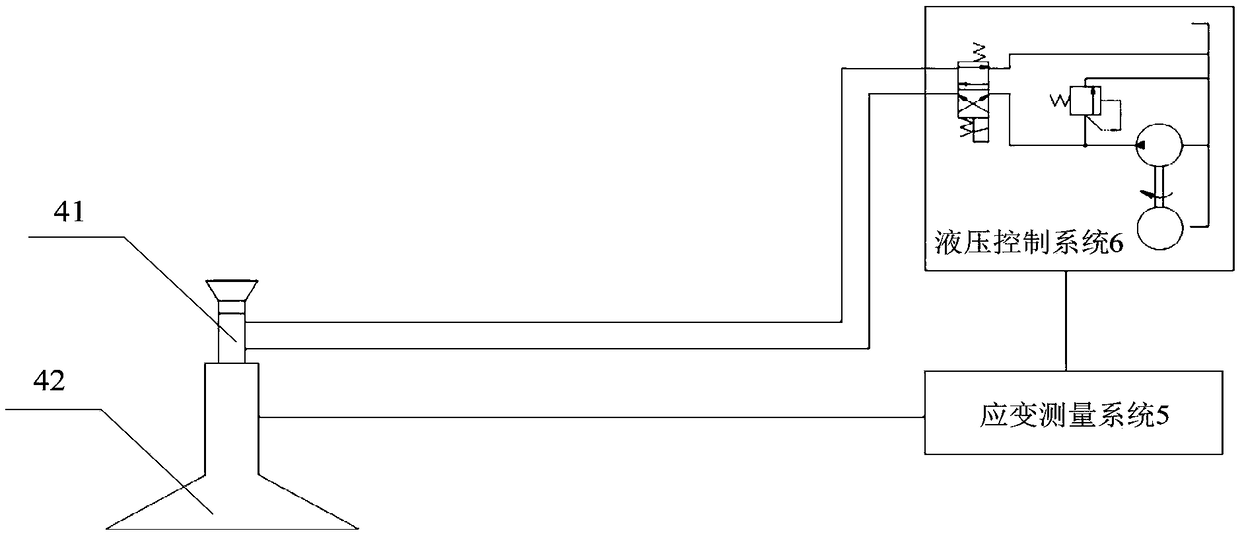

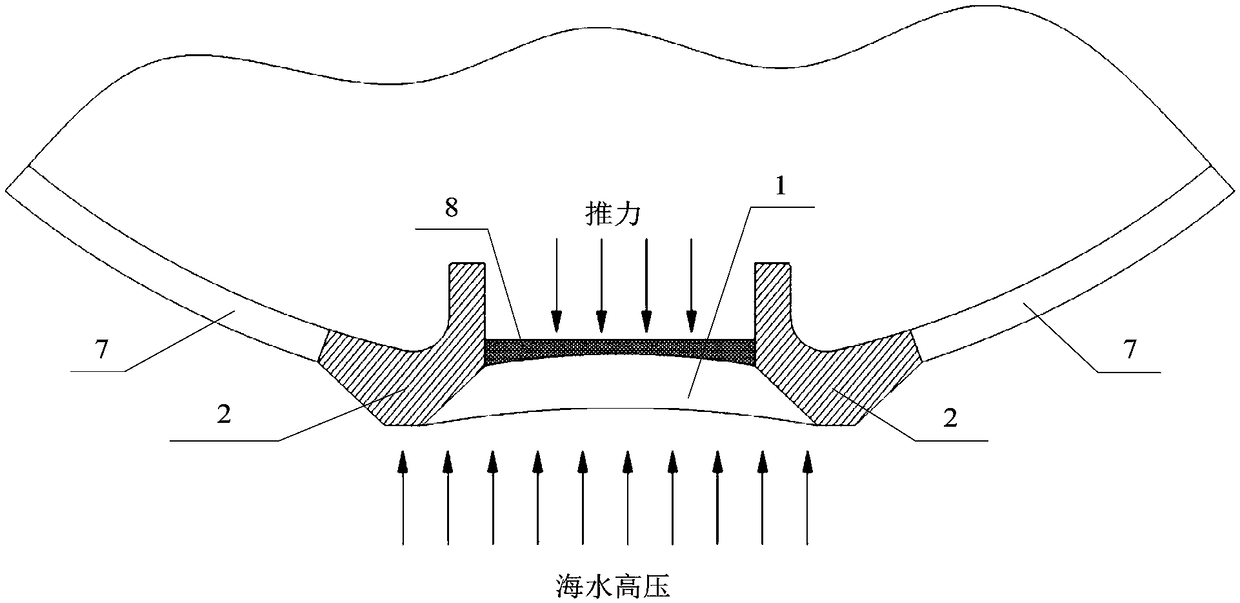

Observation window structure of deep-sea manned submersible with creep mitigation function

ActiveCN109484594ARelieve stressAlleviate large deformationVessel portsUnderwater vesselsCompressive creepElectrical control

The invention discloses an observation window structure of a deep-sea manned submersible with a creep mitigation function, and relates to the field of deep-sea manned submersibles. The observation window structure has the advantages that compared with a conventional observation window structure, a hatch cover and a push rod structure are initiatively introduced, combined with electric control of astrain measurement system and hydraulic control system, the thrust acting on an observation window body is generated when an observation window is idle, the high pressure and large deformation causedby the observation window body can be alleviated under the high pressure state of the external seawater during deep-sea operation, the action time of the observation window body under the high-stressstrain is reduced, and the compressive creep of the observation window can be greatly alleviated; the hatch cover can also effectively protect the observation window body, it is avoided that the observation window body is knocked and worn by sundries in a cabin, and the service life of the observation window is prolonged.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Aluminum alloy conductor material with high compressive creep resistance and low resistivity and preparation method thereof, and cable

InactiveCN104928537AImprove high temperature creep resistanceNot easy to decomposeMetal/alloy conductorsLow voltage circuitsElectrical conductor

The embodiment of the invention provides an aluminum alloy conductor material with high compressive creep resistance and low resistivity, wherein the aluminum alloy conductor material includes the following components by the mass percentage: 0.6%-1.2% of iron, 0.1%-0.3% of copper, 0.01%-0.1% of zirconium, 0.05%-0.12% of yttrium, and aluminum and unavoidable impurities. The aluminum alloy conductor material has both high compressive creep resistance and low resistivity, the resistivity is less than 0.0305 ohm*mm<2> / m, and requirements of aluminum alloy rods for copper-cladded aluminum alloy wires can be met; when applied to a current-carrying cable of a low-voltage circuit, the aluminum alloy conductor material can greatly improve crimping reliability of the aluminum cable, and besides, has a larger current-carrying capacity. The embodiment of the invention also provides a preparation method of the aluminum alloy conductor material with high compressive creep resistance and low resistivity and provides a cable.

Owner:HUAWEI TECH CO LTD +1

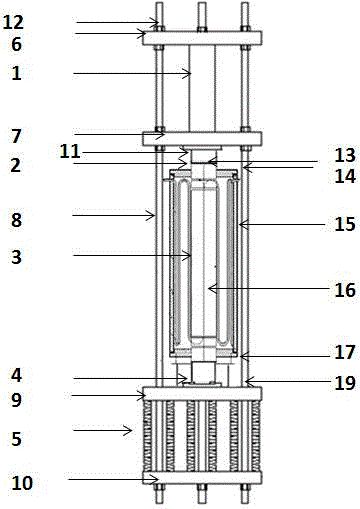

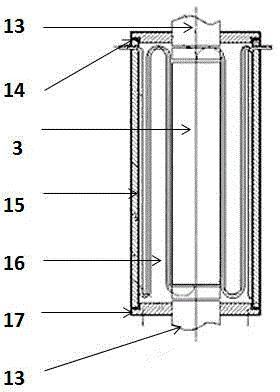

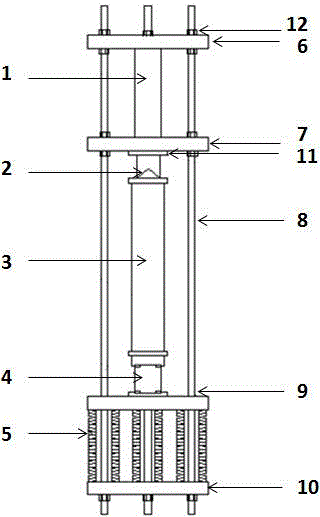

Device for concrete compressive creep test in high-temperature environment

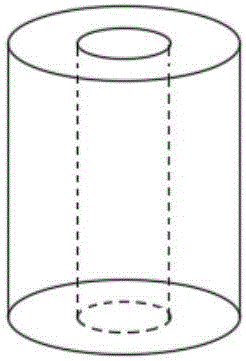

InactiveCN104483204AReduce intensityLow costMaterial strength using tensile/compressive forcesCompressive creepHydraulic engineering

The invention relates to a device for a concrete compressive creep test in a high-temperature environment. The device comprises a traditional creep test device, marble cushion blocks, an upper cover, a baking oven housing, a baking oven heating device, a lower cover, a cover opening hole and a footstand. The baking oven heating device has a cylindrical structure. The middle of the cylindrical structure is provided with a through hole. The through hole structure matches with a concrete test piece. The concrete test piece is placed at the through hole. The top of the baking oven heating device is provided with the upper cover. The bottom of the baking oven heating device is provided with a lower cover. The upper cover and the lower cover produce sealing effects. One of the marble cushion blocks goes through the upper cover and is located between a large cushion plate and an upper pressing plate. The other one of the marble cushion blocks goes through the lower cover and is located between a cushion plate and a force sensor. The device can realize a concrete compressive creep test in a high-temperature environment in the fields of civil engineering, hydraulic engineering and mine engineering. The device is obtained by device addition and reconstruction of the existing compressive creep tester, has a low cost and is convenient for operation.

Owner:TONGJI UNIV

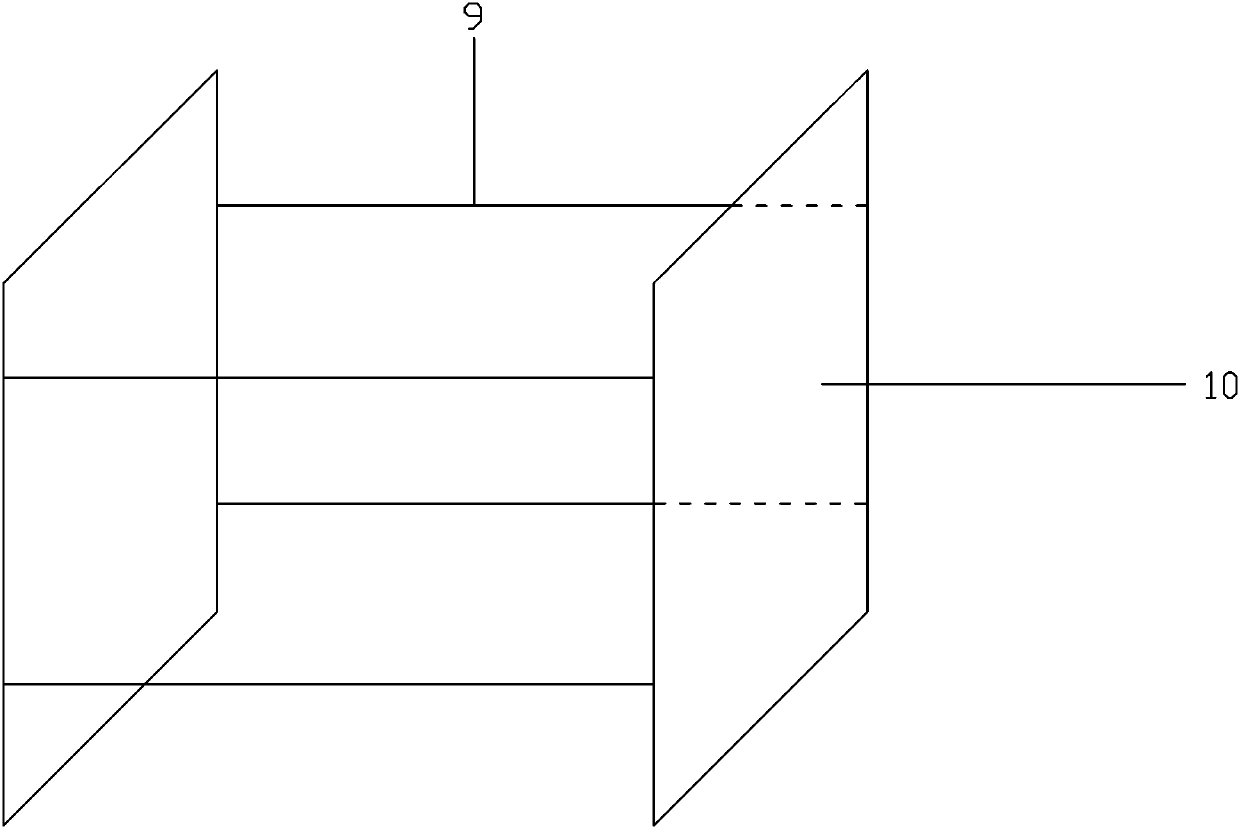

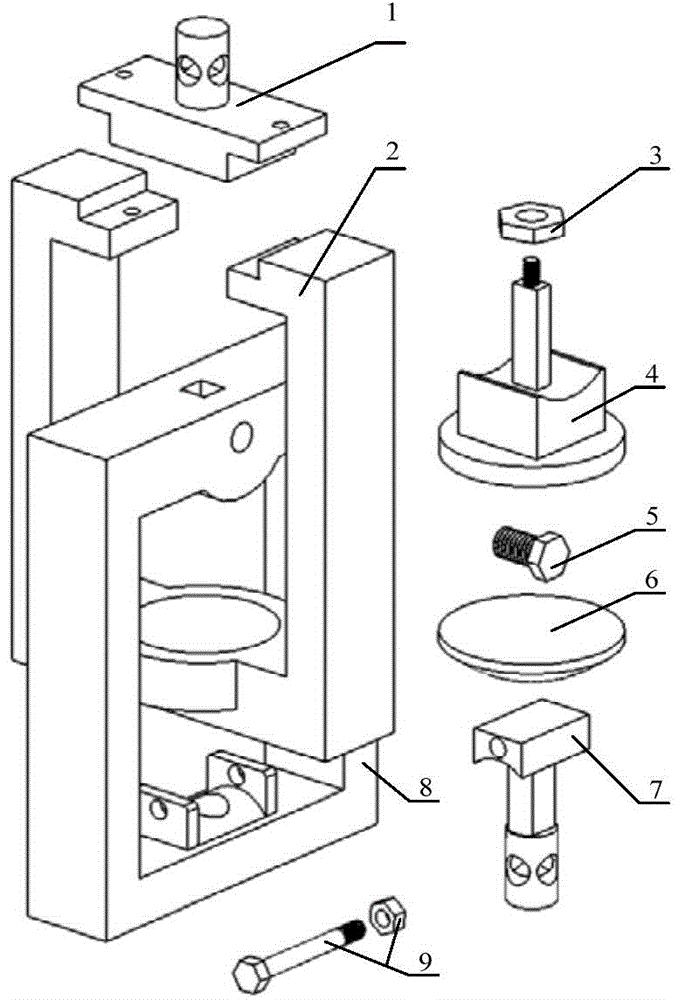

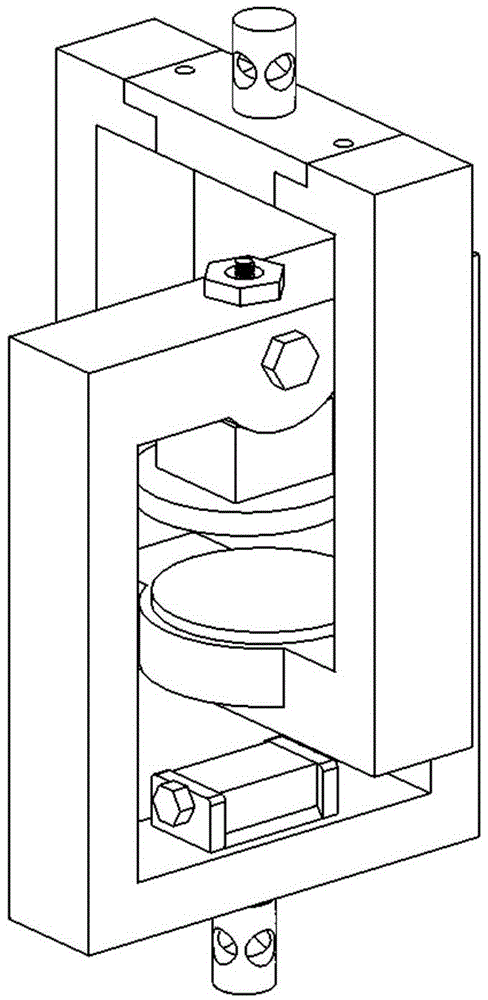

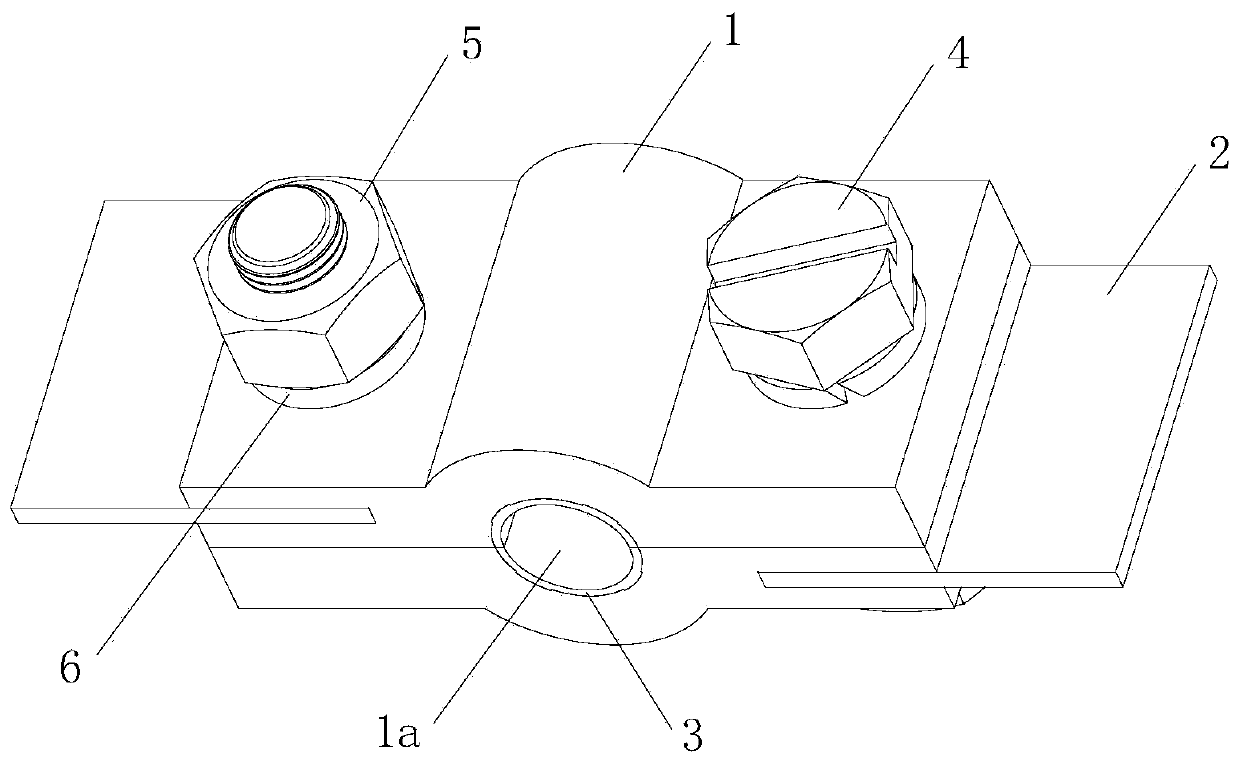

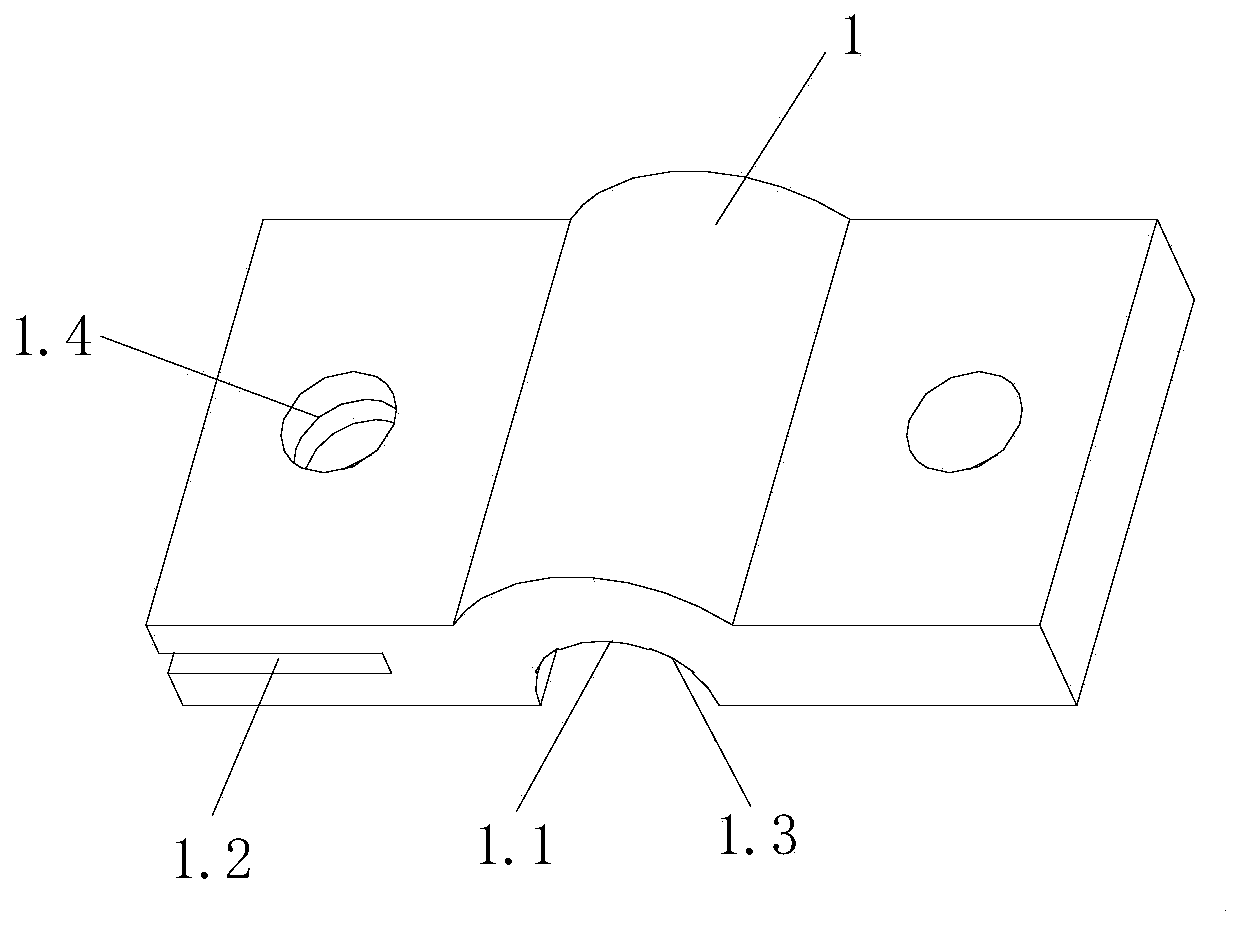

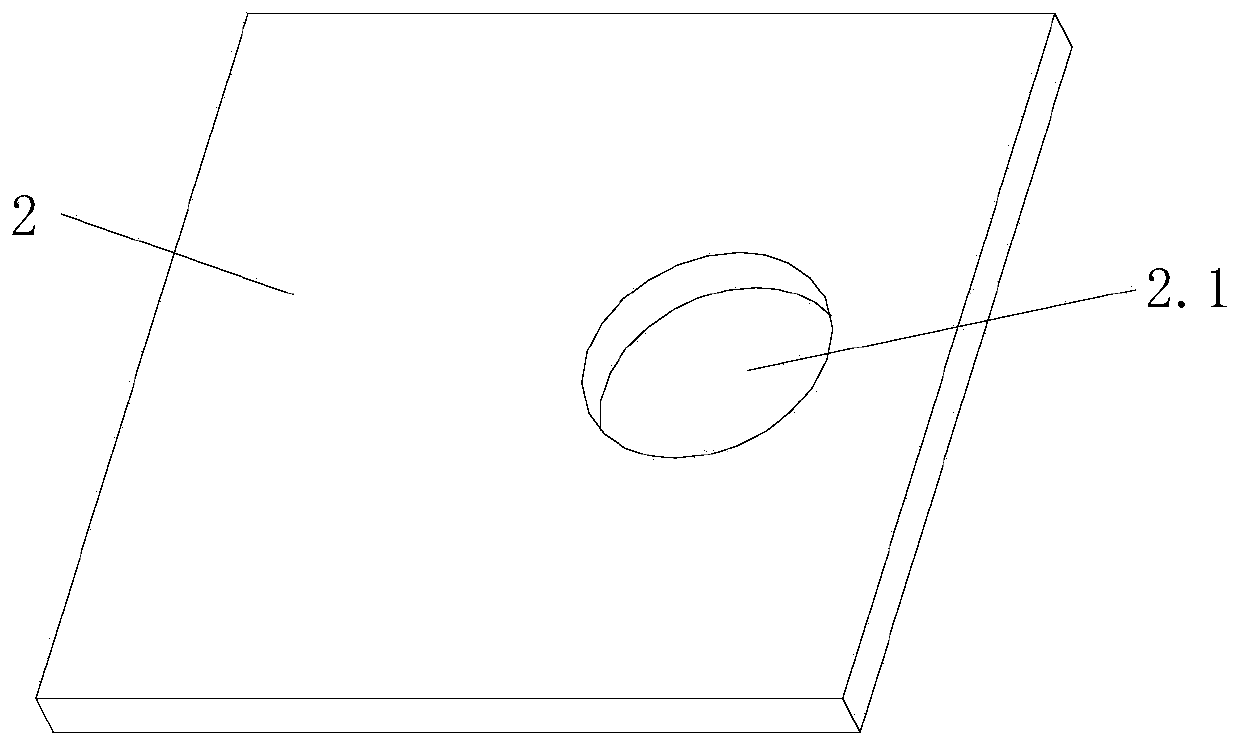

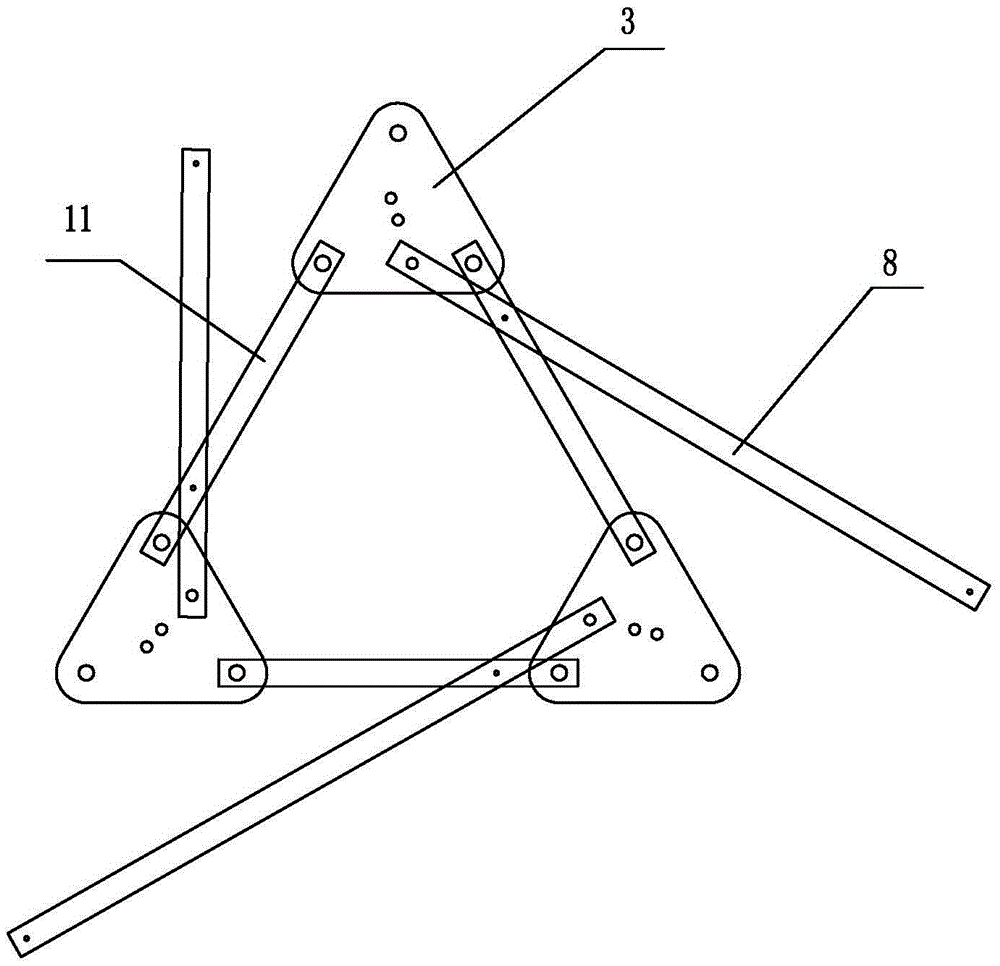

Compression fixture on mechanical tensile creep tester

InactiveCN104634657ASimple structureImprove machining accuracyStrength propertiesCompressive creepEngineering

The invention discloses a compression fixture on a mechanical tensile creep tester. An opening is formed in one end of an upper rectangular ring; stepped surfaces are formed at two ends of the opening; the upper rectangular ring is perpendicularly nested with a lower rectangular ring; a spherical structure which sinks inwards is formed in one end, opposite to the opening, of the upper rectangular ring; a regulating spherical head is configured to be matched with the spherical surface, sinking inwards, of the upper rectangular ring; one surface of the regulating spherical head is matched with the spherical structure on the upper rectangular ring and the other surface of the regulating spherical head is a plane; an upper pressing head is fixedly arranged at one end, opposite to the regulating spherical head, of the lower rectangular ring and is in correspondence with the regulating spherical head; a lower connecting head is fixedly arranged at one end, opposite to the upper pressing head, of the lower rectangular ring; an upper connecting head is arranged at the opening end of the upper rectangular ring; stepped surfaces are formed at both ends of the upper connecting head, and are matched with and fixedly connected to the stepped surfaces on the opening of the upper rectangular ring; and pin holes matched with the tester are formed in the upper connecting head and the lower connecting head. The compression fixture disclosed by the invention can be used for completing compressive creep tests on an existing mechanical tensile creep endurance tester.

Owner:NANJING UNIV OF SCI & TECH

Aluminium alloy conductor material for bus duct and preparation method thereof

The invention discloses an aluminium alloy conductor material for a bus duct and a preparation method thereof and belongs to the technical field of electrical engineering new materials. The aluminiumalloy conductor material for the bus duct comprises the following elements of 0.08-0.28% of Si, 0.17-0.47% of Fe, 0.06-0.25% of Mg, 0.17-0.47% of Ni, 0.03-0.40% of Zn, 0.01-0.05% of B and the balanceof aluminium and inevitable other impurities according to the mass percentage, wherein the mass ratio of Fe and Ni is 0.96-1.03. The aluminium alloy conductor material for the bus duct is adopted to prepare a bus bar with a rectangular section; the tensile strength of the bus bar is higher than 120 MPa, the elongation percentage of the bus bar is higher than 12%, the electric conductivity of the bus bar at 20 degrees centigrade is larger than 60.0% IACS, and the compressive creep resisting performance of the bur bar under a condition with temperature of 100 degrees centigrade and pressure of 45 MPa and under a condition with temperature of 90 degrees centigrade and pressure of 60 MPa is equivalent to that of a soft copper bus TMR. The aluminium alloy conductor material for the bus duct, disclosed by the invention, has the advantages that the bending property and operation safety of the aluminium and aluminium alloy bus bar are enhanced, and the aluminium and aluminium alloy bus bar canreplace a copper bus bar.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

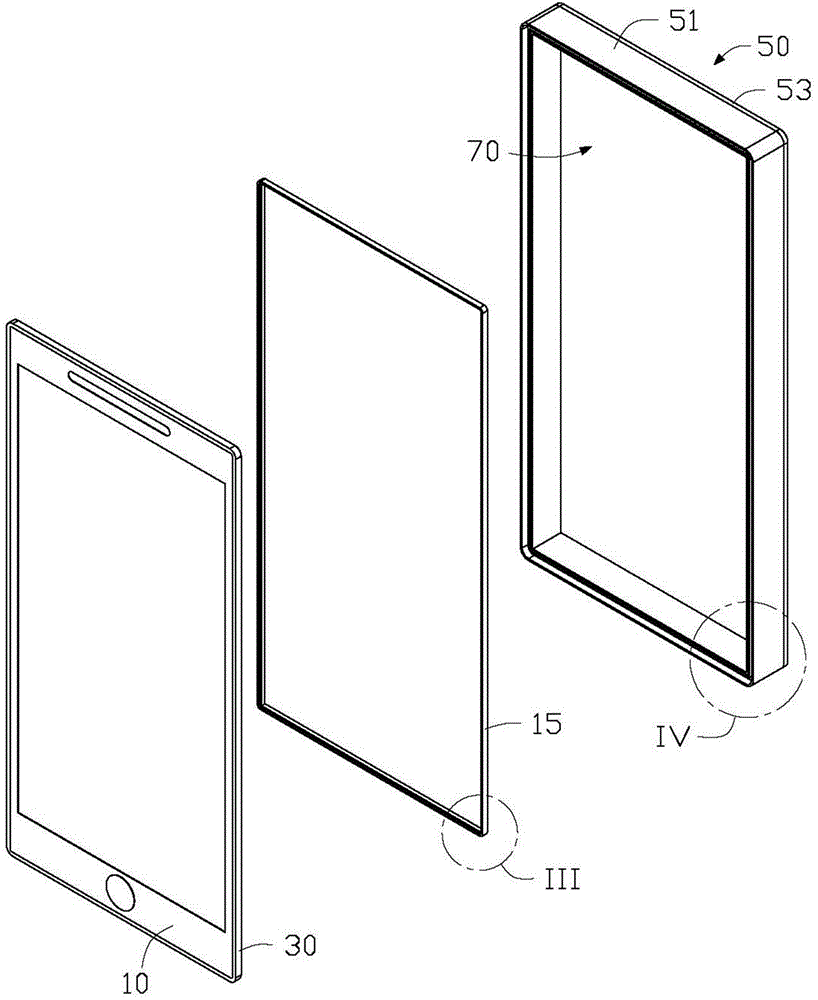

Housing and electronic device provided with housing

InactiveCN105813409AExtended service lifeUnbreakableCasings/cabinets/drawers detailsCompressive creepEngineering

The invention provides a housing. The housing comprises a frame and a rear cover. The frame comprises a first end surface. The rear cover is covered onto the first end surface of the frame. The frame also comprises a frame body and a shockproof layer. The frame body comprises an inner surface. The shockproof layer is formed on the inner surface. The shockproof layer is made of materials having the compressive creep property. The invention also provides an electronic device provided with the housing. According to the technical scheme of the invention, a shockproof ring is formed at the intersection of a window part and a middle frame. The shockproof ring abuts against the middle frame of the housing, so that the window part does not easily break due to collision. The inner surface of the middle frame of the housing is provided with a shockproof layer, so that electronic components inside the electronic device are not easily damaged. Therefore, the service life of the electronic device is effectively prolonged.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

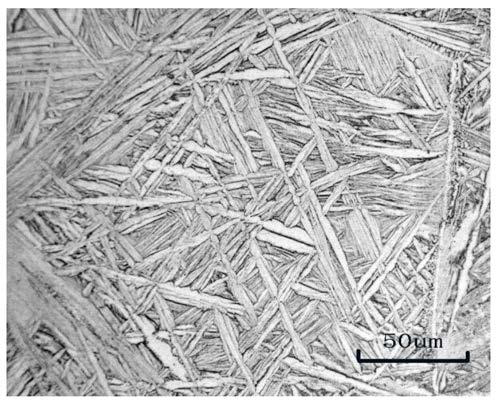

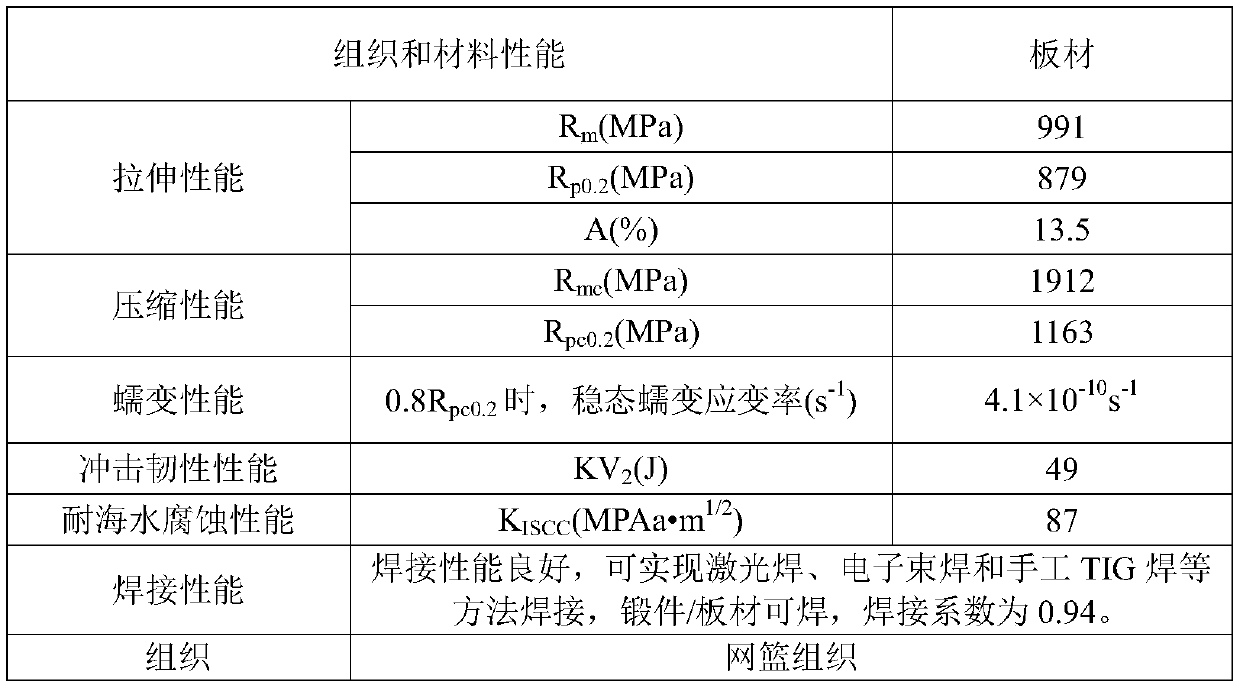

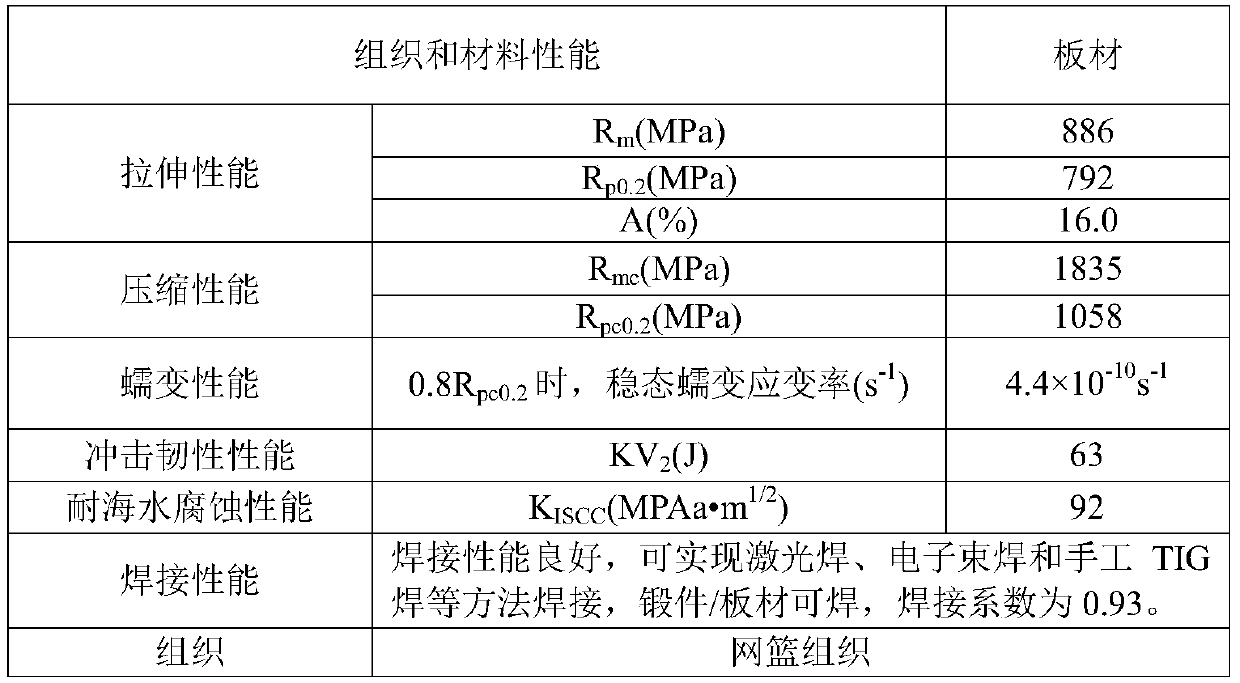

Weldable titanium alloy with creep resistance, high impact toughness and corrosion resistance and preparation method

The invention belongs to the field of titanium alloy materials for deep-sea engineering equipment, and discloses a weldable titanium alloy with creep resistance, high impact toughness and corrosion resistance. The weldable titanium alloy is prepared from the components: 4.0-8.0% of Al, 0.3-4.0% of Mo, 0.5-4.0% of Ta, 0.5-4.0% of Zr, 0.03-0.12% of O and the balance of Ti. A preparation method includes the steps that batching is carried out according to the composition of the titanium alloy, raw materials are melted and subjected to ingot casting, cast ingots are broken down, forged, rolled andheat treated, and titanium alloy plates are obtained. The weldable titanium alloy with the creep resistance, high impact toughness and corrosion resistance has excellent compressive creep performance,plastic toughness, mechanical properties and seawater corrosion resistance, can meet the special service conditions for long-time service under deep-sea high-pressure, can be used for preparing the deep-sea engineering equipment of a deep-sea submersible, a deep-sea mobile work station and a large diving depth submarine and the like, and has a good application prospect and economic benefits in the field of the deep-sea engineering equipment and the like.

Owner:XINXIANG UNIV

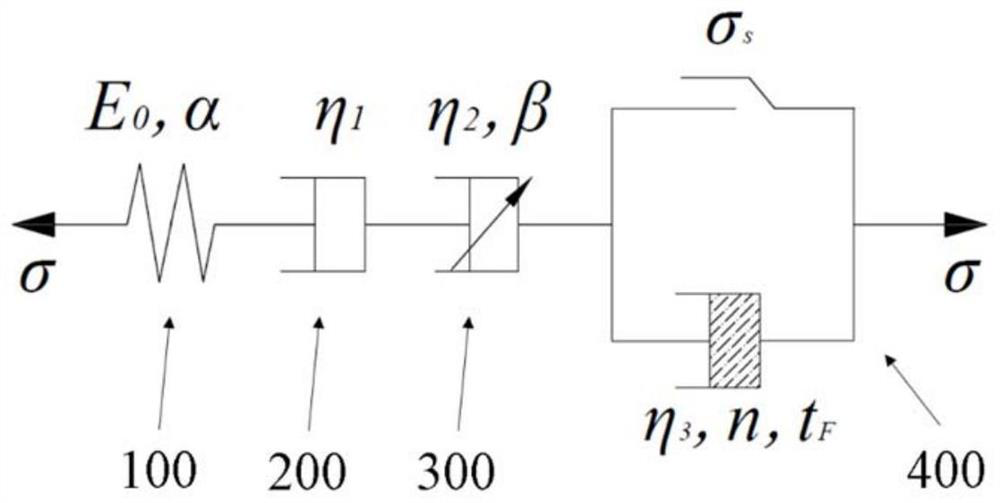

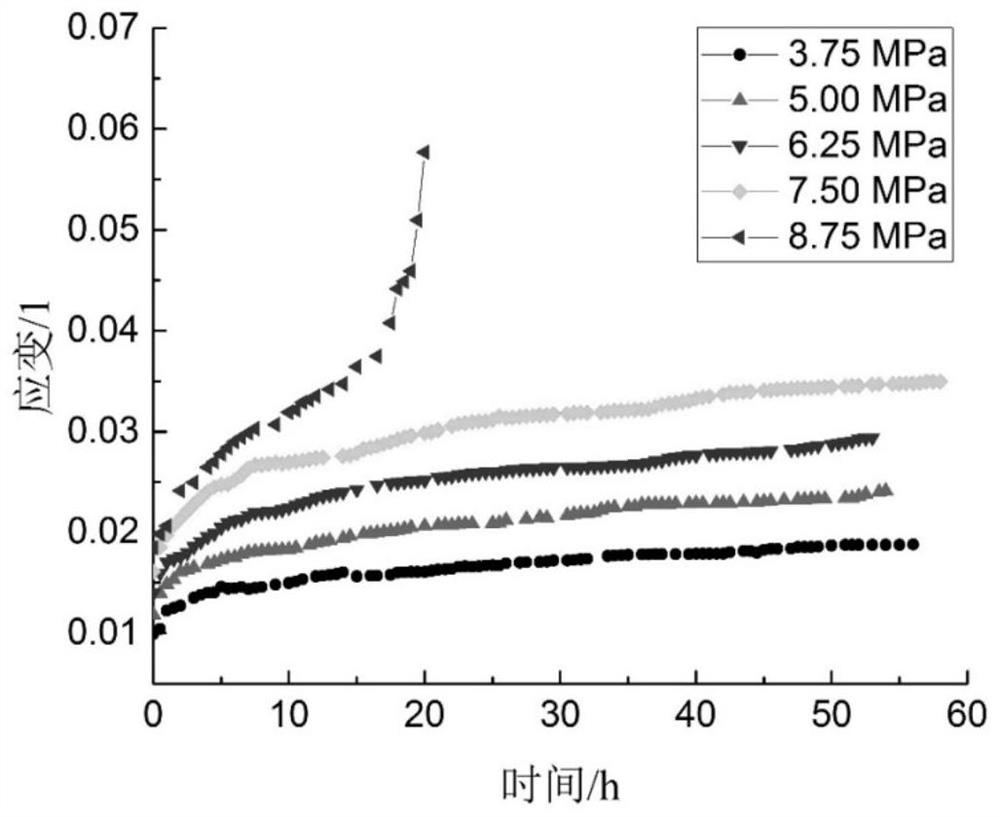

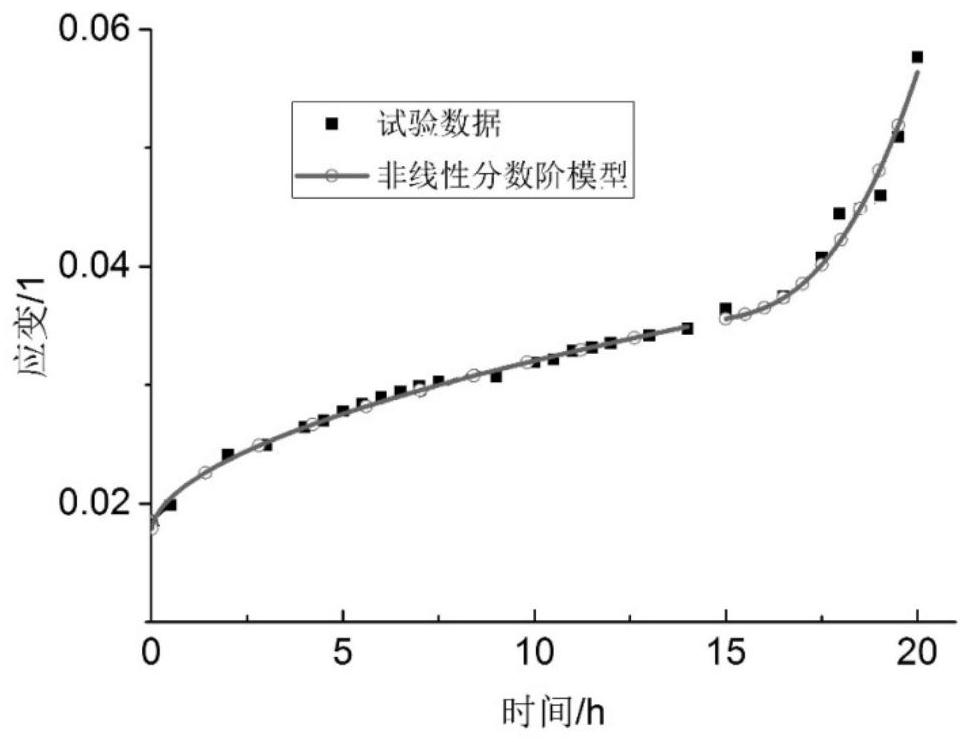

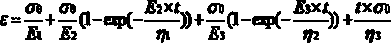

New weak rock mass rheological constitutive model construction and parameter identification method

ActiveCN113297720ALong-term deformation analysis is accurate and efficientAccurate descriptionSustainable transportationMaterial strength using tensile/compressive forcesElastomerRock engineering

The invention provides a new weak rock mass rheological constitutive model construction and parameter identification method, which comprises the following steps: connecting an elastomer, a viscous body, a viscoelastic body and a viscoplastic body in series, and establishing a new weak rock mass rheological constitutive model; carrying out a compression creep test on a weak rock mass sample, obtaining test data, drawing a rheological test curve, and carrying out model parameter identification by adopting a Levenberg-Marquardt method based on the test data and the deformation and failure characteristics of the weak rock mass. According to the method, the full-stage deformation characteristics of gradual deterioration elastic deformation, attenuation creep, stable creep and accelerated creep of the on-site weak rock mass can be described, the creep parameters of the test weak rock mass can be obtained through a parameter identification method, and for the on-site weak rock mass and engineering soft rock with the full-stage creep characteristics, the model can describe rheological characteristics more accurately, and soft rock engineering long-term deformation analysis based on the model is more accurate and effective.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Special-shaped refractory brick refractoriness under load and compressive creep test method

InactiveCN106092696AResponse to actual usabilityPromote safe productionPreparing sample for investigationMaterial strength using tensile/compressive forcesBrickCompressive creep

The invention provides a special-shaped refractory brick refractoriness under load and compressive creep test method. The special-shaped refractory brick refractoriness under load and compressive creep test method comprises the following steps that firstly, according to brick shapes and sizes of special-shaped refractory bricks, samples with sizes approaching to given sizes and similar shapes in a national standard or a smelting standard are prepared; secondly, the actual stress area of the samples is calculated through a seal method; thirdly, loads are exerted on the samples, and the loads are regulated according to the proportion relation between the standard stress area of the samples and the actual stress area of the samples to enable pressure stress acting on the samples to reach standard required demands; fourthly, refractoriness under load or compressive creep tests are carried out according to normal program steps, and test results are recorded. The sample sizes and test parameters can be regulated according to the shapes and the sizes of the special-shaped bricks, the two important high-temperature performance indexes of creep rate and refractoriness under load of lattice bricks can be accurately detected, and the test results can truly and accurately reflect the actual using performance of the lattice bricks.

Owner:武汉钢铁有限公司

Metal material compression creep testing device and measuring method thereof

PendingCN111272557ASolutions for Compression Creep Testing MachinesSolve related standard issuesMaterial strength using tensile/compressive forcesGratingTest sample

The invention discloses a metal material compression creep testing device and a measuring method thereof, and belongs to the technical field of metal material performance testing. The testing device comprises an upper clamp and a lower clamp, the upper clamp comprises an upper plate I, a lower bottom plate I, a stand column I and an upper stretching rod, and the lower clamp comprises an upper plate II, a lower bottom plate II, a stand column II and a lower stretching rod. The boss is arranged on the upper surface of the lower bottom plate I, and a metal material sample is placed on the boss; the two gratings are fixed on the lower bottom plate I through a grating fixer; when the tensile creep testing machine is used for stretching, the upper pull rod and the lower pull rod are driven to relatively move upwards and downwards, so that pressure stress is generated in a test sample, compressive creep deformation is generated, and real-time measurement and recording are carried out throughthe grating ruler sensor. The compression creep performance of the metal material can be tested through an existing tensile creep testing machine, the applicability is good, the cost is saved, and themeasurement precision the same as that of tensile creep is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

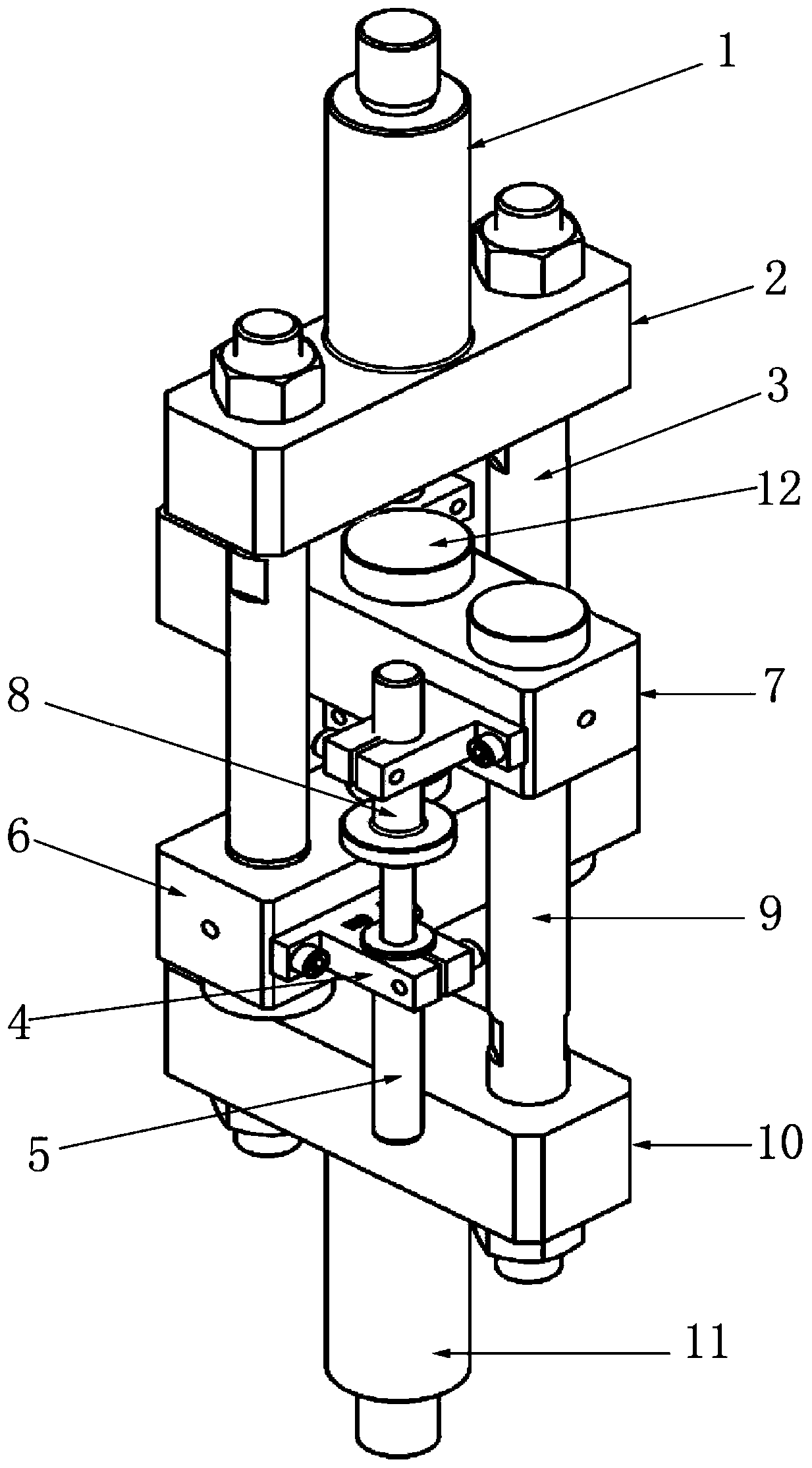

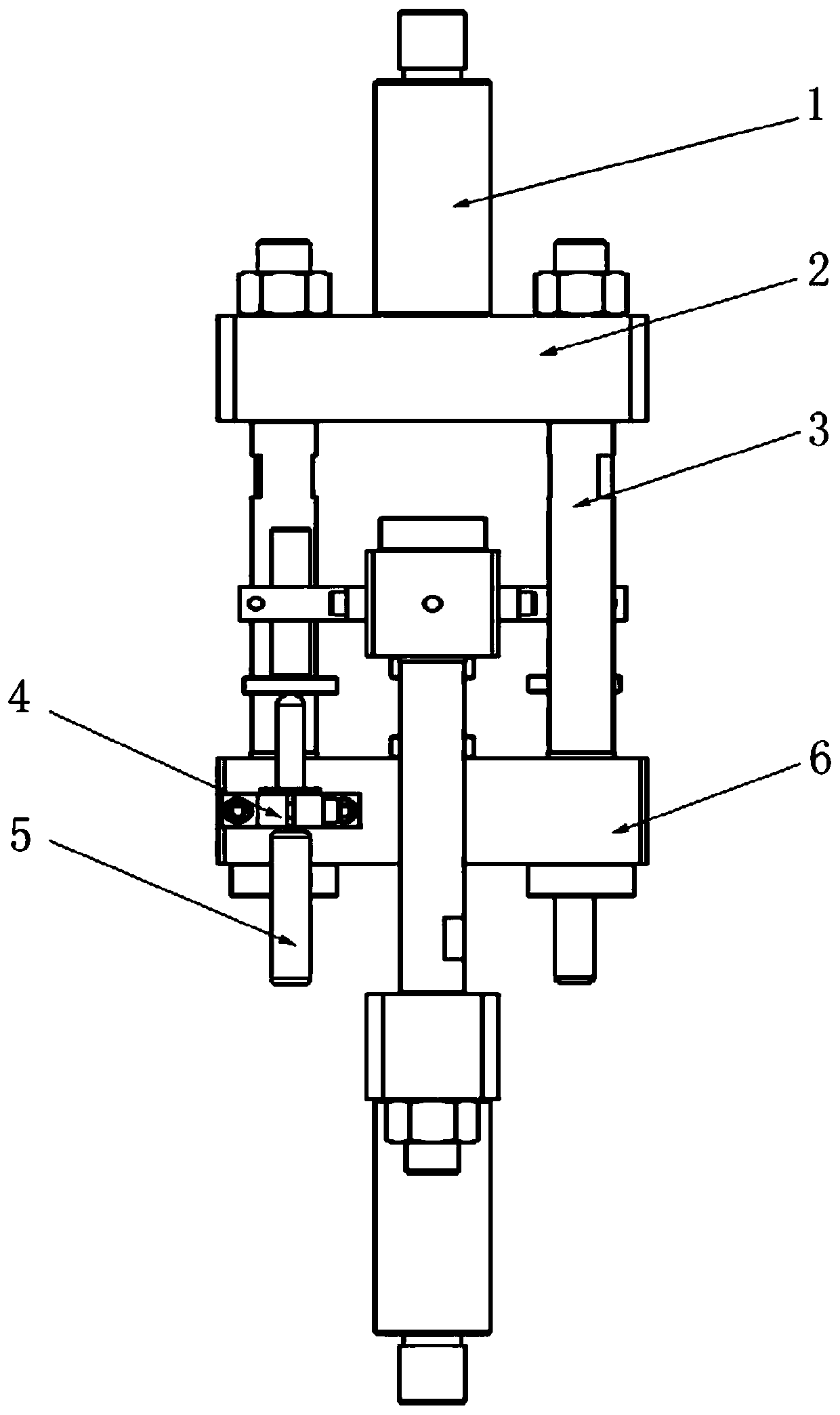

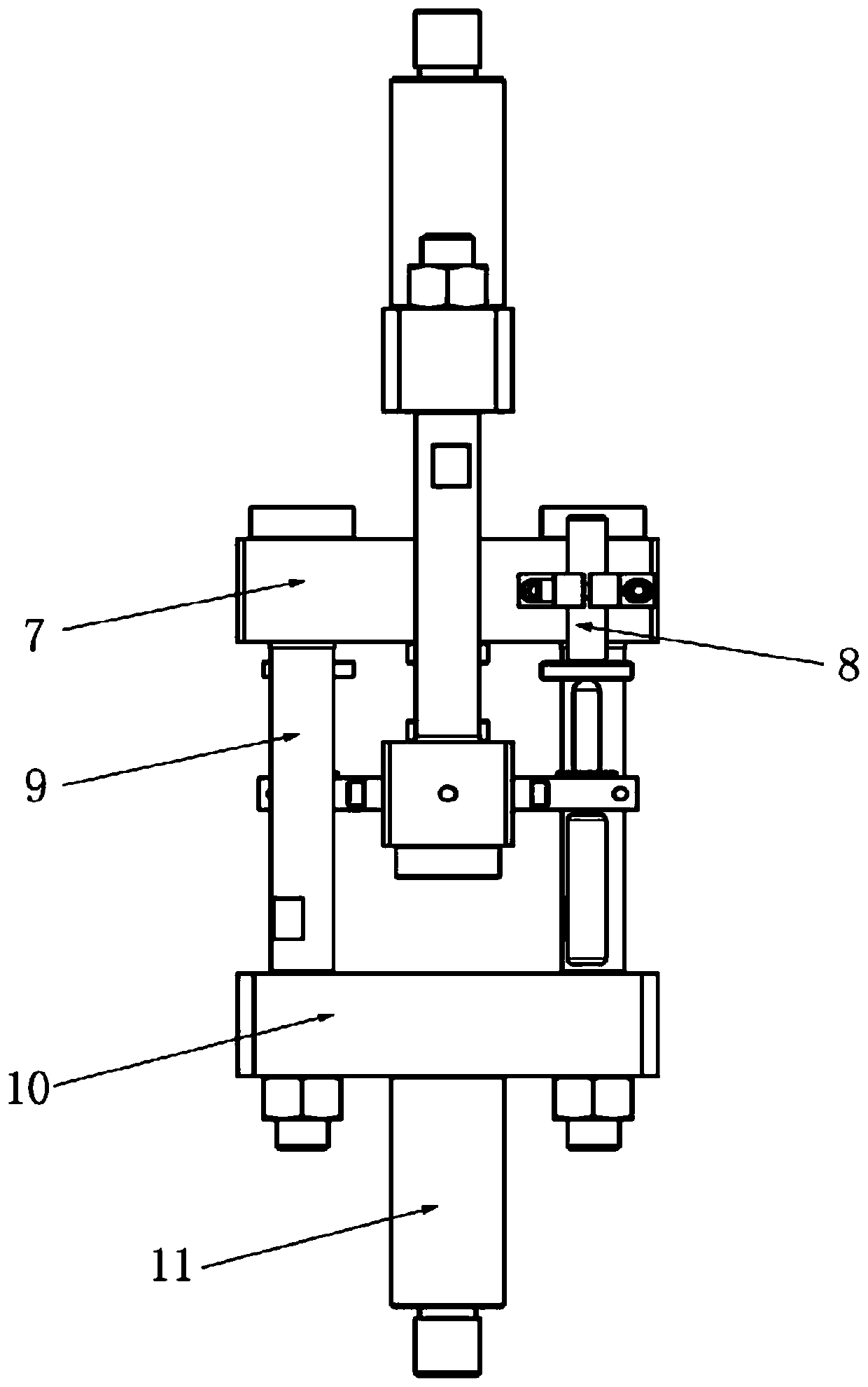

Universal fixture for compression creep aging and stress relaxation aging experiments of round bar-shaped sample

PendingCN111122328ASimple structureEasy to useMaterial strength using tensile/compressive forcesTest sampleCompressive creep

The invention discloses a universal fixture for compression creep aging and stress relaxation aging experiments of a round bar-shaped sample. The fixture comprises a fixture body, a conductive deviceand a plurality of locking devices, the fixture body comprises two clamping parts, each clamping part is provided with an inner groove, and the inner grooves of the two clamping parts define a clamping through hole used for containing a round-rod-shaped sample; the conductive device comprises two conductive blocks which are connected with the two clamping parts respectively; when in use, the clampis clamped in the middle of a test sample to protect the test sample; according to the universal fixture, the compression creep aging / stress relaxation aging experiment with the initial loading stress higher than the yield strength of the material can be accurately tested; meanwhile, a compression experiment can be carried out at high temperature, the reliability of creep aging / stress relaxationaging experiment data is guaranteed, and the sample is not bent after aging is finished. The universal fixture is simple in structure, convenient to use and wide in application range.

Owner:CENT SOUTH UNIV

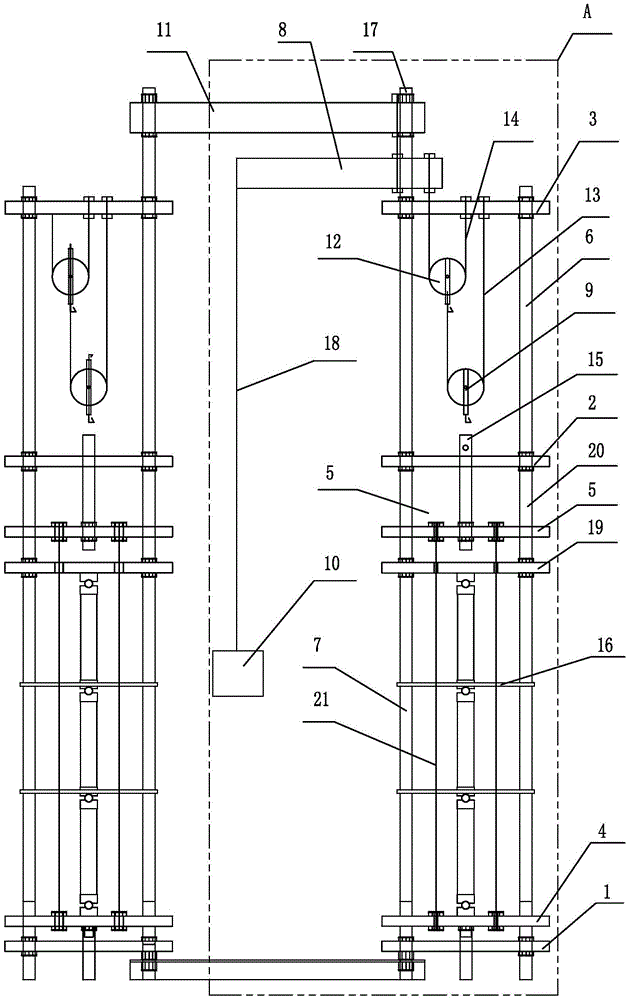

Material compression creep test device

InactiveCN104316411BStable and reliable loading forceAccurate measurementMaterial strength using tensile/compressive forcesCompressive creepSteel bar

The invention provides a material compression creep testing device and relates to a material compression testing device. The material compression creep testing device is used for solving the problem of inaccurate test results due to non-constant loading force and inaccurate test piece deformation measurement of an existing material compression creep device. The material compression creep testing device comprises a plurality of compression loaders; fixed plates are connected by use of upright columns; a first sliding plate slides on the second upright column, while a second sliding plate slides on the third upright column; the first sliding plate is connected with the second sliding plate by use of a steel bar; a piece to be tested is mounted between the fourth fixed plates and the first sliding plate; a first movable pulley is connected with a connecting rod; one end of a first rope is fixed on the third fixed plate, while the other end is connected with a second movable pulley by being wound around the first movable pulley; one end of a second rope is fixed on the third fixed plate, while the other end is fixed on a lever by being wound around the second movable pulley; a heavy carrying basket is connected with the lever by use of a third rope. The material compression creep testing device is constant in loading force and suitable for long lasting of a creep test.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

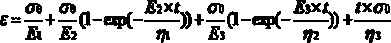

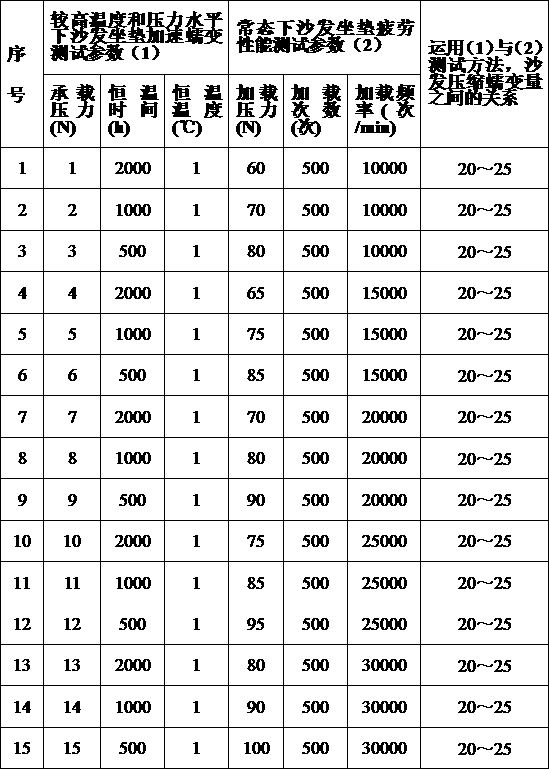

Short-period creep testing method for sofa cushion and equivalence thereof

InactiveCN108956335AEfficiently assess creep performanceEfficiently assess fatigue strengthInvestigating material ductilityMaterial strength using repeated/pulsating forcesCompressive creepRoom temperature

The invention relates to a short-period creep testing method for a sofa cushion, wherein the method comprises the following steps: allowing a wooden bionic loading cushion to completely fall on the upper surface of the sofa cushion with the original thickness of h0 by pressurizing a double-layer steel plate, placing a counter weight on an upper-layer steel plate, heating a whole testing system, and keeping the temperature constant for 1 h after the temperature reaches the highest temperature; and taking out the sofa cushion, placing for 2-3 h at room temperature, measuring the thickness h1 ofthe sofa cushion, to obtain the compressive creep value of the sofa cushion: [delta]h=h0-h1, and predicting the long-term creep behavior at normal temperature and pressure level according to the equivalence. The method has the advantages: 1) the long-term creep behavior at normal temperature and normal pressure level is predicted equivalently by a short-period creep behavior at high temperature and pressure level, the creep performance, fatigue strength and the like of the sofa cushion are effectively predicted by short-period test, and a good guarantee is provided for the mechanical properties of the sofa cushion; and 2) the experimental device is concise, the operation is simple, the experimental efficiency is high and the equivalence is good.

Owner:SHANDONG YIHUA FURNITURE CO LTD

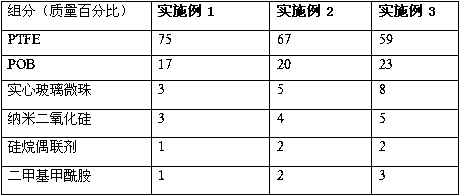

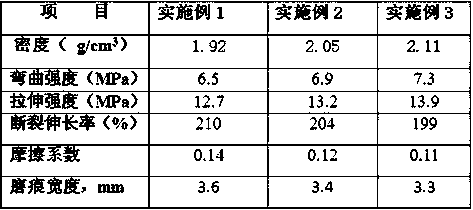

High and low temperature resistant zone sealing strip PTFE resin composite material and preparation method thereof

The invention discloses a high and low temperature resistant zone sealing strip PTFE resin composite material. The composite material comprises, by mass, 17-23% of POB, 3-8% of solid glass beads, 3-5%of nano-silica, 1-2% of a silane coupling agent, 1-3% of dimethyl formamide, and the balance of PTFE. The invention also discloses a preparation method of the composite material. The POB (poly-p-oxybenzoyl) is an insoluble and infusible aromatic high crystallinity polymer, has a decomposition temperature reaching 530 DEG C, can be used at 300 DEG C for a long term, and has the advantages of highhardness, excellent heat stability, excellent ageing corrosion resistance, excellent compressive creep resistance, and good complementation with PTFE in performances. The solid glass beads and the nano-silica effectively improve the wear resistance and the heat resistance of the material, and a high and low temperature resistant zone sealing strip made from the material can be used at -250-90 DEGC for a long term without deformation.

Owner:NANJING COMPTECH COMPOSITES CORP

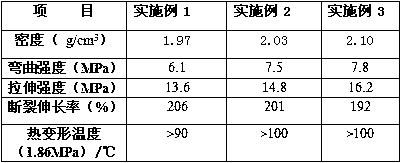

Self-lubricating low temperature zone sealing strip PTFE resin composite material and preparation method thereof

The invention discloses a self-lubricating low temperature zone sealing strip PTFE resin composite material. The composite material comprises, by mass, 15-20% of POB, 5-10% of molybdenum disulfide, 2-4% of nanometer calcium fluoride, 2-4% of graphite fluoride, 1-2% of a silane coupling agent, and the balance of PTFE. The invention also discloses a preparation method of the composite material. ThePOB (poly-p-oxybenzoyl) is an insoluble and infusible aromatic high crystallinity polymer, has a decomposition temperature reaching 530 DEG C, can be used at 300 DEG C for a long term, and has the advantages of high hardness, excellent heat stability, excellent ageing corrosion resistance, excellent compressive creep resistance, and good complementation with PTFE in performances. The molybdenum disulfide, calcium fluoride, graphite fluoride and POB crystals have similar lamellar structures, are excellent lubricating fillers, and cooperate with each other to make a self-lubricating low temperature zone sealing strip have good self-lubricating performance and good mechanical performance in a high temperature zone and a high temperature zone.

Owner:NANJING COMPTECH COMPOSITES CORP

A kind of high conductivity anti-compressive creep aluminum alloy and its manufacturing method

ActiveCN105132767BHigh tensile strengthHigh yield limitMetal/alloy conductorsElectrical conductorCompressive creep

The invention discloses a high-conductivity anti-compression creep aluminum alloy, which comprises the following components in terms of mass percentage: 0.25% to 2.5% of copper, 0.3% to 2.8% of magnesium, 0.03% to 0.5% of rare earth, and 0.3% to 0.3% of iron 1.2%, and the balance is aluminum; also discloses the manufacturing method of high conductivity and anti-compression creep aluminum alloy, including (1) pretreatment of alloy raw materials, (2) alloy batching, melting and furnace treatment, (3) aluminum On-line refining treatment of alloy melt, (4) casting and forming of alloy. The obtained aluminum alloy material not only has high tensile strength and yield limit, but also has excellent electrical conductivity, good thermal stability of resistance at high temperature, and more importantly, the compressive creep resistance of aluminum alloy material at high temperature is also good. It is very excellent, and it is a major breakthrough in the "replacing copper with aluminum" in the electrical industry. It greatly solves the defects caused by the difference in creep performance of aluminum alloy conductor materials in the application process, and meets the performance requirements of aluminum alloy materials in the electrical industry.

Owner:深圳阿尔泰克轻合金技术有限公司

Polyester resin foaming particle and its molding body

A polyester-based resin foamed particle with biodegradability and excellent practicability, characterized in that the base material resin is mainly composed of a polyester-based resin containing at least 35 mol% of aliphatic ester components in the main chain Composition, the apparent density is 0.015-0.09g / cm3, the average weight of each expanded particle is 1mg-less than 5mg, the average bubble film thickness of the expanded particle is 0.2-5μm, and the gel fraction is not less than 5% by weight . The expanded particle molded product obtained by using the expanded polyester resin particles has excellent dimensional stability and appearance, and has a high closed cell ratio, so it is also excellent in mechanical strength such as compression creep and cushioning properties, and is suitable for use as cushioning materials and packaging. Materials, various containers, etc.

Owner:JSP CORP

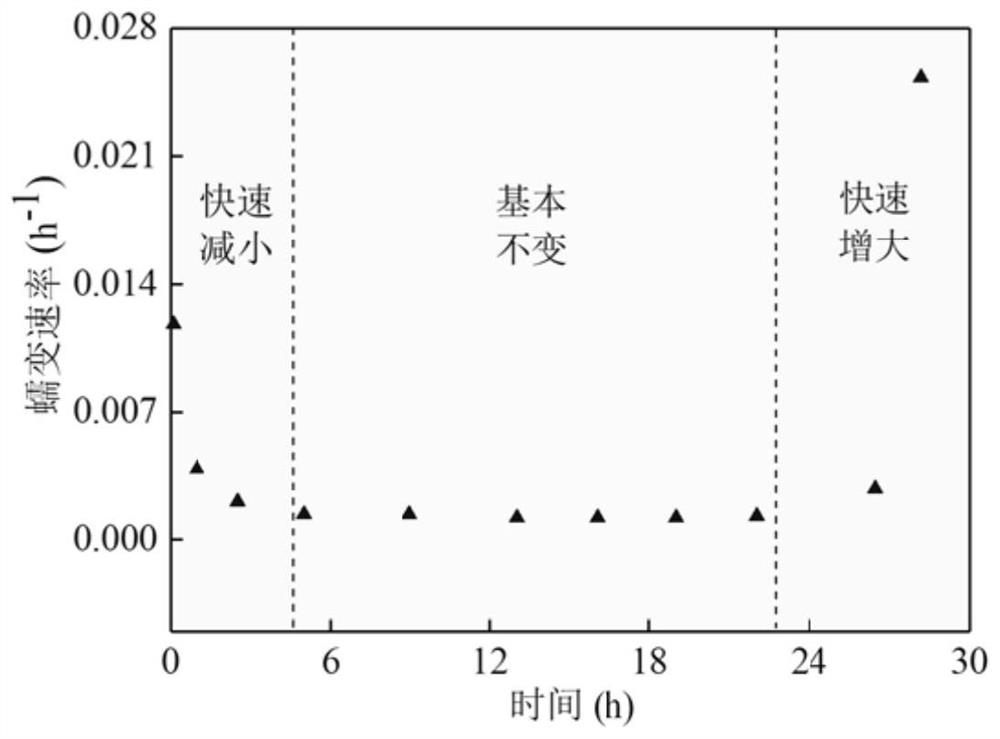

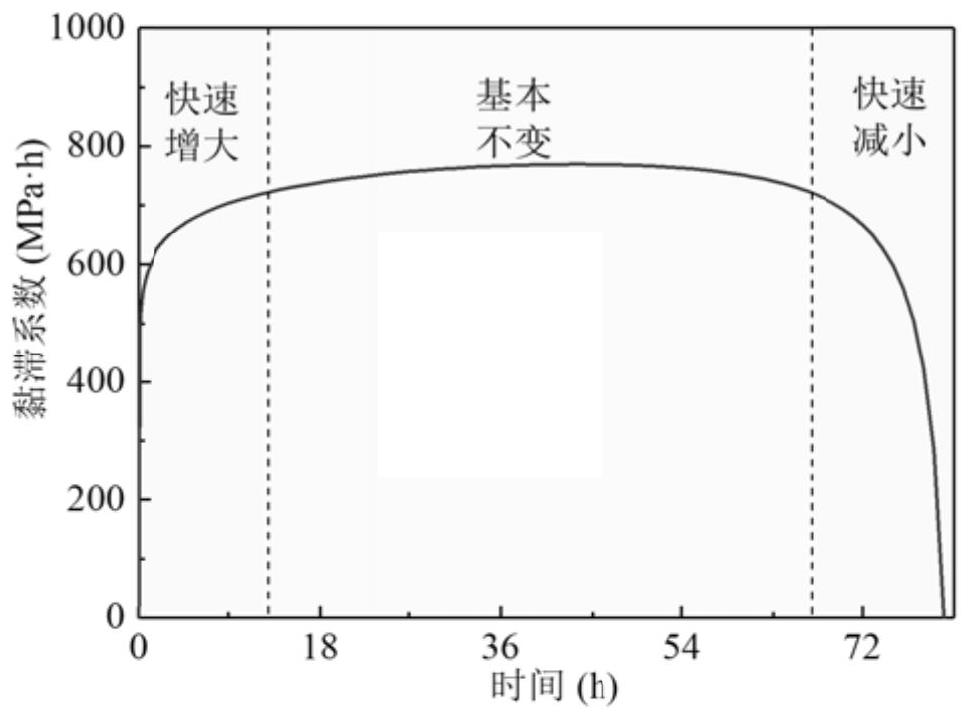

Rock uniaxial compression accelerated creep starting time prediction method

PendingCN114062132AReduce life and property hazardsAccurate predictionMaterial strength using tensile/compressive forcesUniaxial compressionCompressive creep

The invention discloses a rock uniaxial compression accelerated creep starting time prediction method, which comprises the following steps: determining parameters of an improved Maxwell model according to a rock uniaxial compression creep test result; drawing the change rule curve of the viscosity coefficient along with the time and the rock creep curve under the corresponding axial stress in a double-longitudinal-axis coordinate system, determining an attenuation creep end point A, and drawing a vertical line passing through the point A, wherein the vertical line and the change rule curve of the viscosity coefficient along with the time intersect at a point B; and drawing a horizontal line passing through the point B, intersecting the horizontal line and the time-varying rule curve of the viscosity coefficient at a point C, and taking the time corresponding to the point C as the accelerated creep starting time of the rock. According to the method, the starting time of the rock uniaxial compression accelerated creep can be accurately predicted by improving the Maxwell model, accurate prediction of the starting time of the rock accelerated creep is realized, early warning can be performed during rock accelerated creep, and occurrence of harm of surrounding rock collapse to lives and properties of people is greatly reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A low-shrinkage, low-creep, crack-resistant, high-performance mass concrete

The invention relates to a low-shrinkage, low-creep, anti-crack, high-performance, large-volume concrete, which belongs to the technical field of concrete. A concrete apparent density ≥ 2400kg / m was achieved with the addition of fly ash alone 3 , 28d compressive strength ≥ 70MPa, 28d tensile strength ≥ 4.7MPa requirements, 365d dry shrinkage rate ≤ 519×10 ‑6 , 365d compression creep degree ≤ 28.0×10 ‑6 / MPa, 365d pressure creep coefficient ≤0.72. The remarkable feature of the present invention is that there is no special mixing process for mixing concrete with the concrete mixing ratio, the mixing is simple and convenient, and the order of mixing and feeding can be changed. The concrete mixture has moderate viscosity, good cohesion, low pump pressure during construction, easy to pump and pour, good concrete crack resistance, low shrinkage and creep, good volume stability, and is suitable for high-strength stress complex mass concrete construction Reduce the chance of cracks. Concrete mixed with fly ash can reduce the silo configuration of the mixing station and rationally use the stone powder in the machine-made sand, avoid waste of resources, reduce energy consumption, and greatly reduce costs, which is in line with the green development of concrete. The abstract should not exceed 300 words, so it will be deleted.

Owner:CHINA NUCLEAR IND HUAXING CONSTR +1

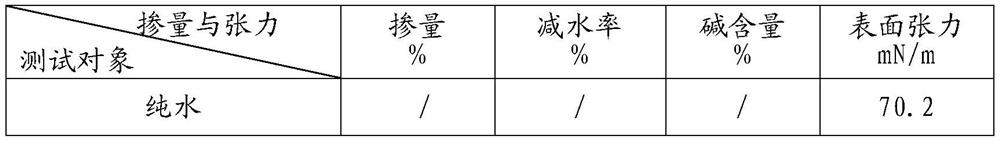

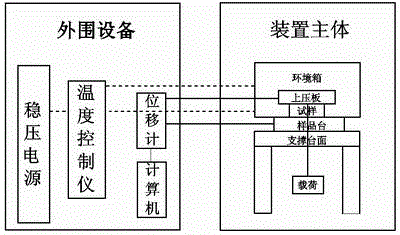

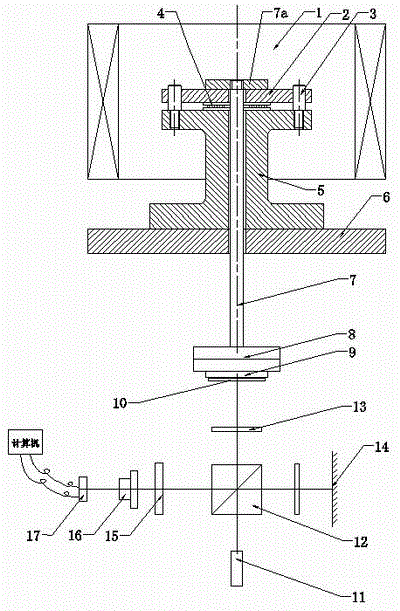

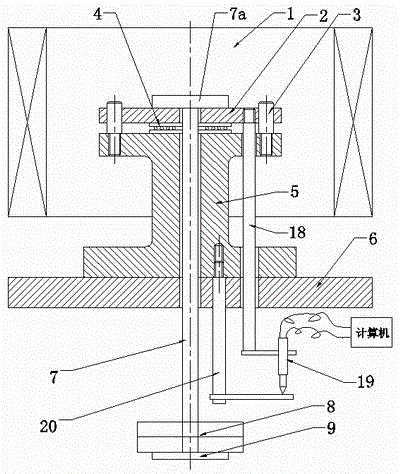

A test device for measuring the compressive creep performance of microelectronic packaging solder joints

ActiveCN103528896BSuitable for testing needsHigh measurement accuracyMaterial strength using tensile/compressive forcesUsing optical meansLinear variable differential transformerCompressive creep

The invention discloses a testing device for determining compression creepage performance of microelectronic packing welding spots, belonging to the field of testing on the mechanical performance of materials. A main body of the testing device comprises an environmental box, a sample stand, a locating mechanism and a loading mechanism, wherein the upper half part of the sample stand is arranged in the environmental box, a load rod of the loading mechanism is fixedly connected with a supporting disc after sequentially penetrating through a supporting table top, the sample stand, a test sample and an upper pressure plate, and a weight tray is arranged at the lower part of the load rod. In testing, the environment box enables the test sample to reach an experimental temperature, the loading mechanism applies pressure stress load to the test sample, and an optical displacement meter mechanism or an LVDT (Linear Variable Differential Transformer) displacement meter mechanism is used for recording the displacement variation of the test sample in testing. The testing device enables the test sample to be located accurately and loaded uniformly, and the experiment accuracy can be improved. The working conditions of the microelectronic packing welding spots under conditions of different temperatures and pressure loads can be simulated through regulating the temperature of the environmental box and the number of loaded weights so as to obtain creepage data under corresponding working conditions, and especially, the testing device can meet testing demands of practical microelectronic products in production.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com