High teMPERATURE resistant insulating for pipe

A heat-insulating, high-temperature technology, applied in the direction of pipeline protection, pipeline protection through heat insulation, pipeline damage/wear prevention, etc., can solve problems such as high transportation and installation costs, difficult foaming process, poor material cost-to-performance ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

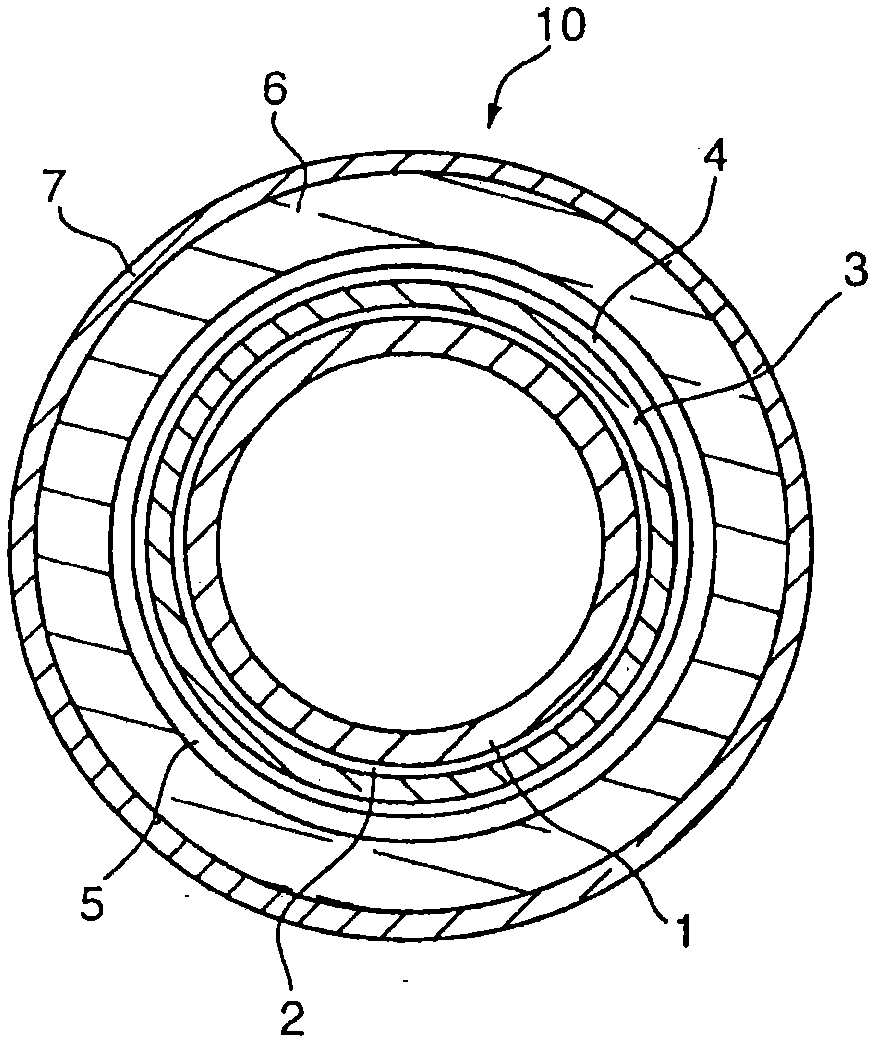

[0163] In this embodiment, corresponding to figure 1 , the steel pipe 1 is provided with the above-mentioned three-layer anti-corrosion coating, the three-layer anti-corrosion coating includes the anti-corrosion layer 2 , the adhesive layer 3 and the outer coating 4 . The steel pipe 1 after surface blasting and cleaning had an outer diameter of 140 mm and a wall thickness of 10 mm. Tube 1 was preheated to 200°C and sprayed with 0.300 + / - 0.100 mm thick layer 2 of fusion bonded high temperature epoxy resin powder (density 1400 + / - 100 g / l) followed by immediate passage at 220°C and 220°C respectively. Extrusion was carried out at a melt temperature of 260°C to form 0.300+ / -0.200mm high temperature modified styrene-maleic anhydride copolymer adhesive layers 3 (density 1.060g / cm) on top of the epoxy resin, respectively. 3 , MFR 0.6g / 10min) and 6.0+ / -1.0mm of solid polyphenylene ether-polystyrene blend overcoat 4 (density 1.060g / cm 3 , the melt flow rate is 8g / 10min). The extru...

Embodiment 2

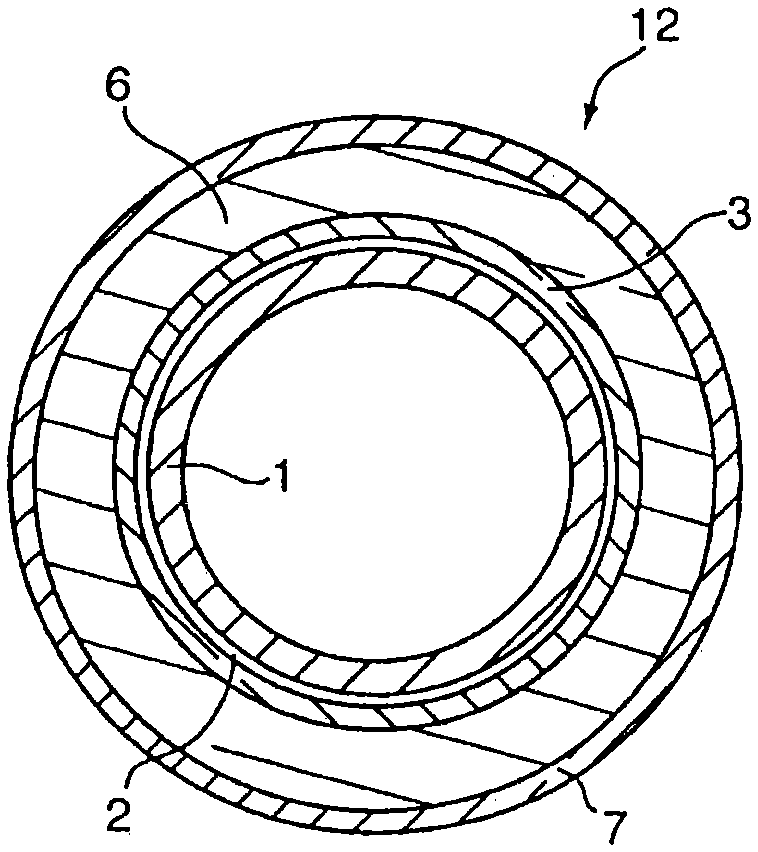

[0165] The anticorrosion pipe produced in Example 1 was subjected to the following processing steps: using an extruder equipped with a sheet die, the outer surface of the anticorrosion pipe was preheated to a temperature of about 220°C, at a temperature of 260°C. The polyphenylene ether-polystyrene blend is wound onto the preheated outer surface at melt temperature to coat the corrosion resistant tube with the same solid polyphenylene ether-polystyrene as outer coating 4 Layer 6 of 20.0+ / -1.0 mm of ethylene blend (degree of foaming = 0%). The properties of the thermally insulated pipes thus produced were tested and the results are shown in Table 3.

Embodiment 3

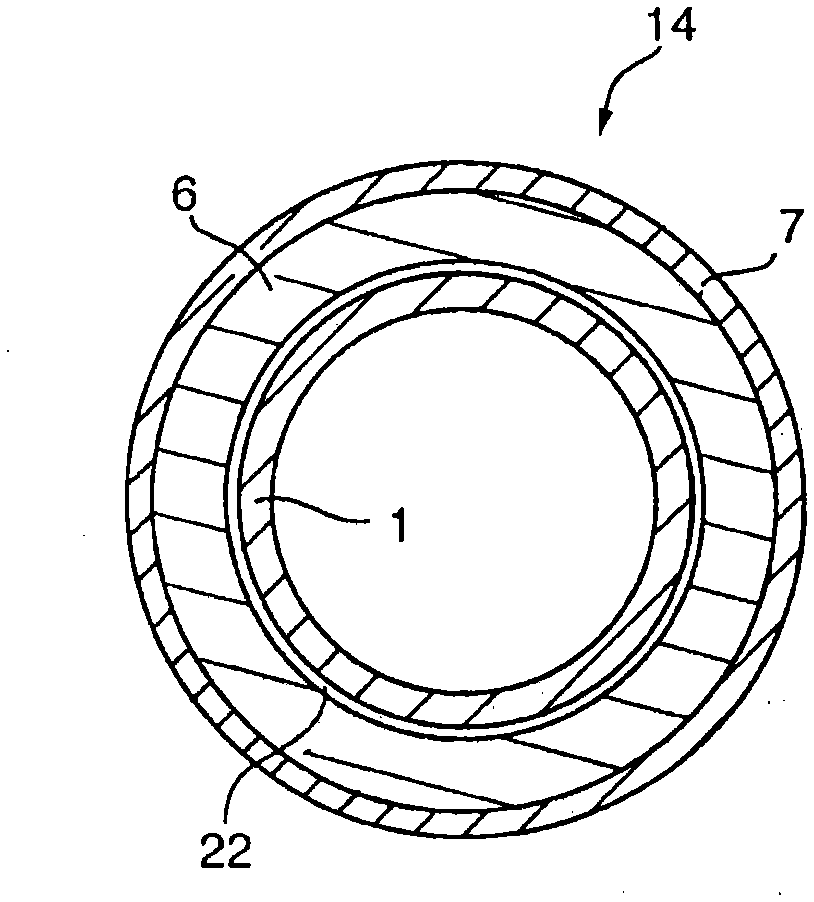

[0167] Using the coating procedure described in Example 2, the anti-corrosion pipe made in Example 1 was further coated with the following layers: foamed to a density of 0.945 g / cm using 0.5 wt% endothermic chemical blowing agent 3 (degree of foaming = 10%) of the 30.0 + / - 1.0 mm layer 6 of the polyphenylene ether-polystyrene blend of Example 1, and the solid high impact polystyrene modified with polyethylene 5.0+ / -1.0mm outer layer 7 (density 1.020g / cm 3 , the melt flow index is 4.0g / 10min.). The properties of the thermally insulated pipes thus produced were tested and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com