Patents

Literature

41 results about "Offshore pipelines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vessel for well intervention

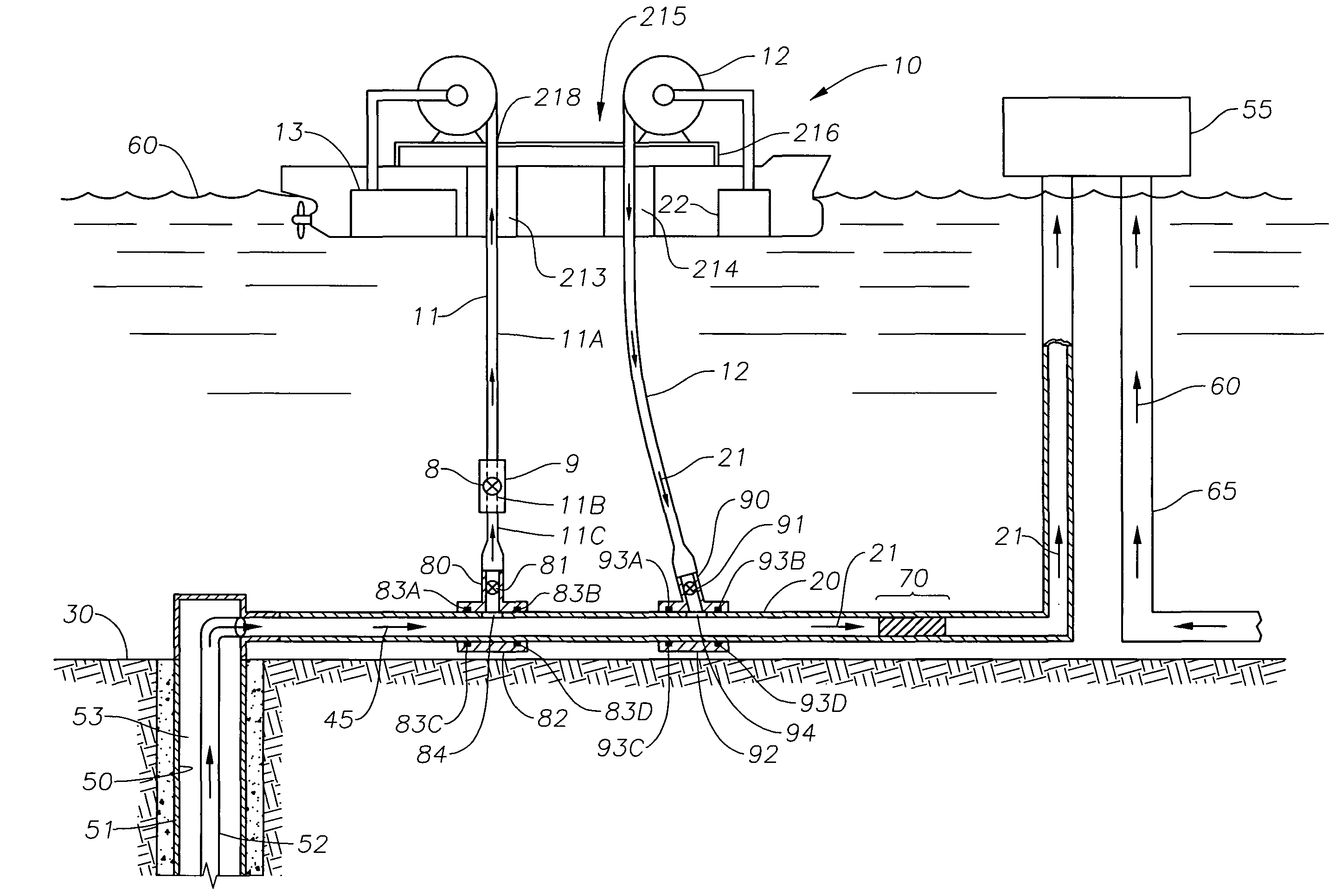

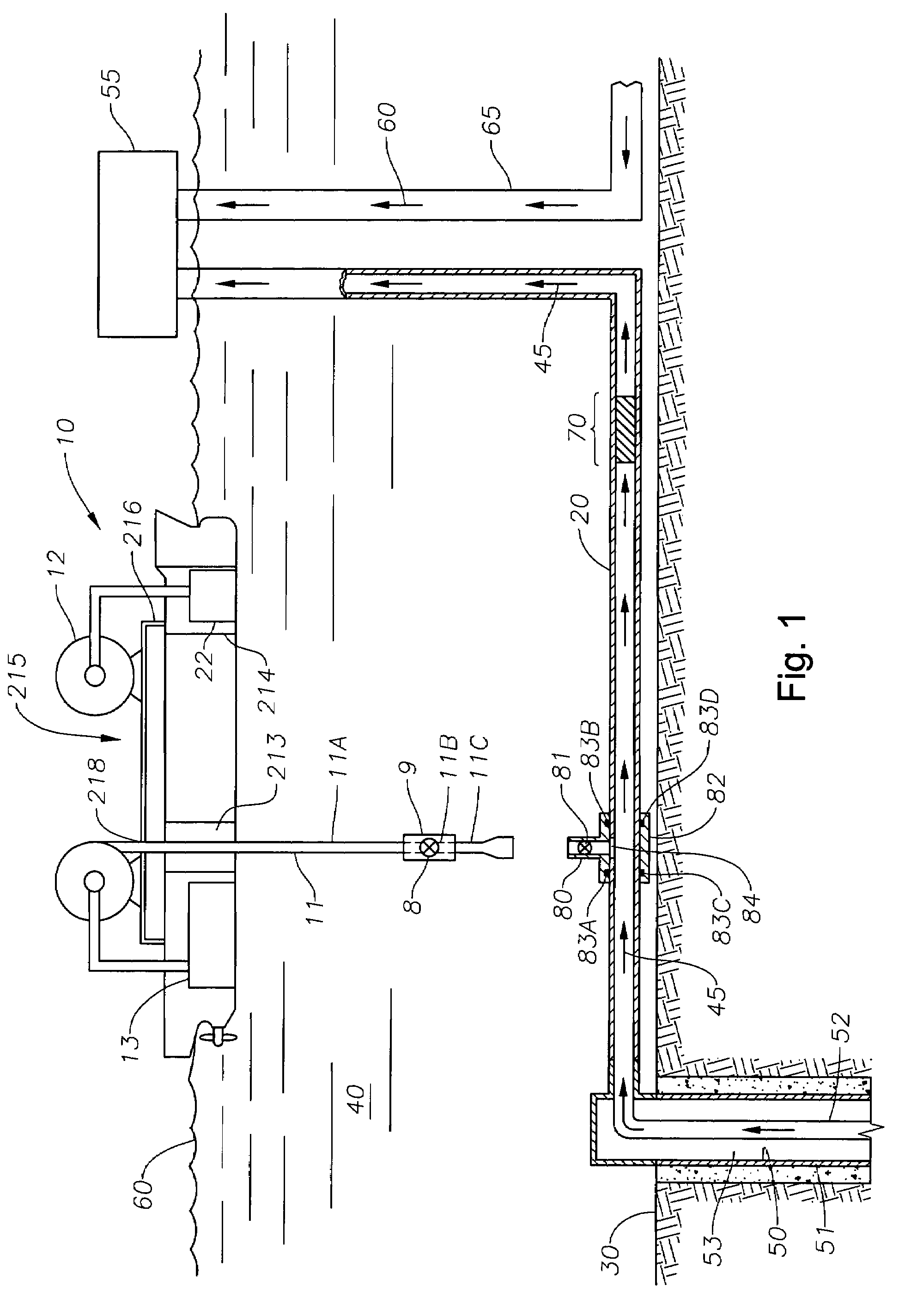

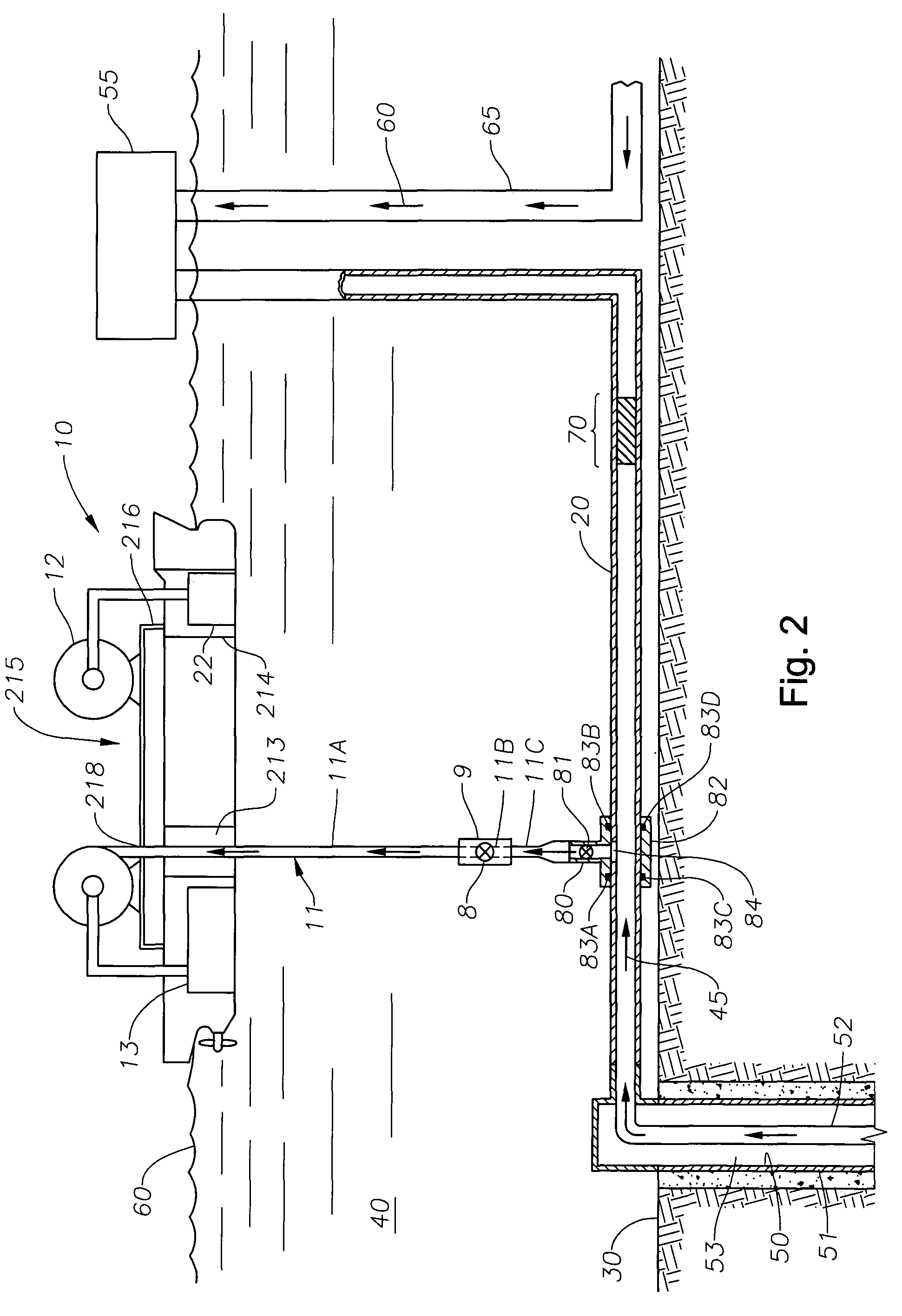

In one aspect, a method and apparatus for intervening in an offshore pipeline while diverting fluid flow to a storage site is provided, so that production through the offshore pipeline may continue while conducting a pipeline intervention operation. An offshore vessel may be used to divert and store fluid flow while intervening in the pipeline. In another aspect, a method and apparatus for drilling a subsea wellbore with an offshore vessel is provided. The method and apparatus involve drilling the wellbore and casing the wellbore with continuous casing lowered from the offshore vessel.

Owner:WEATHERFORD TECH HLDG LLC

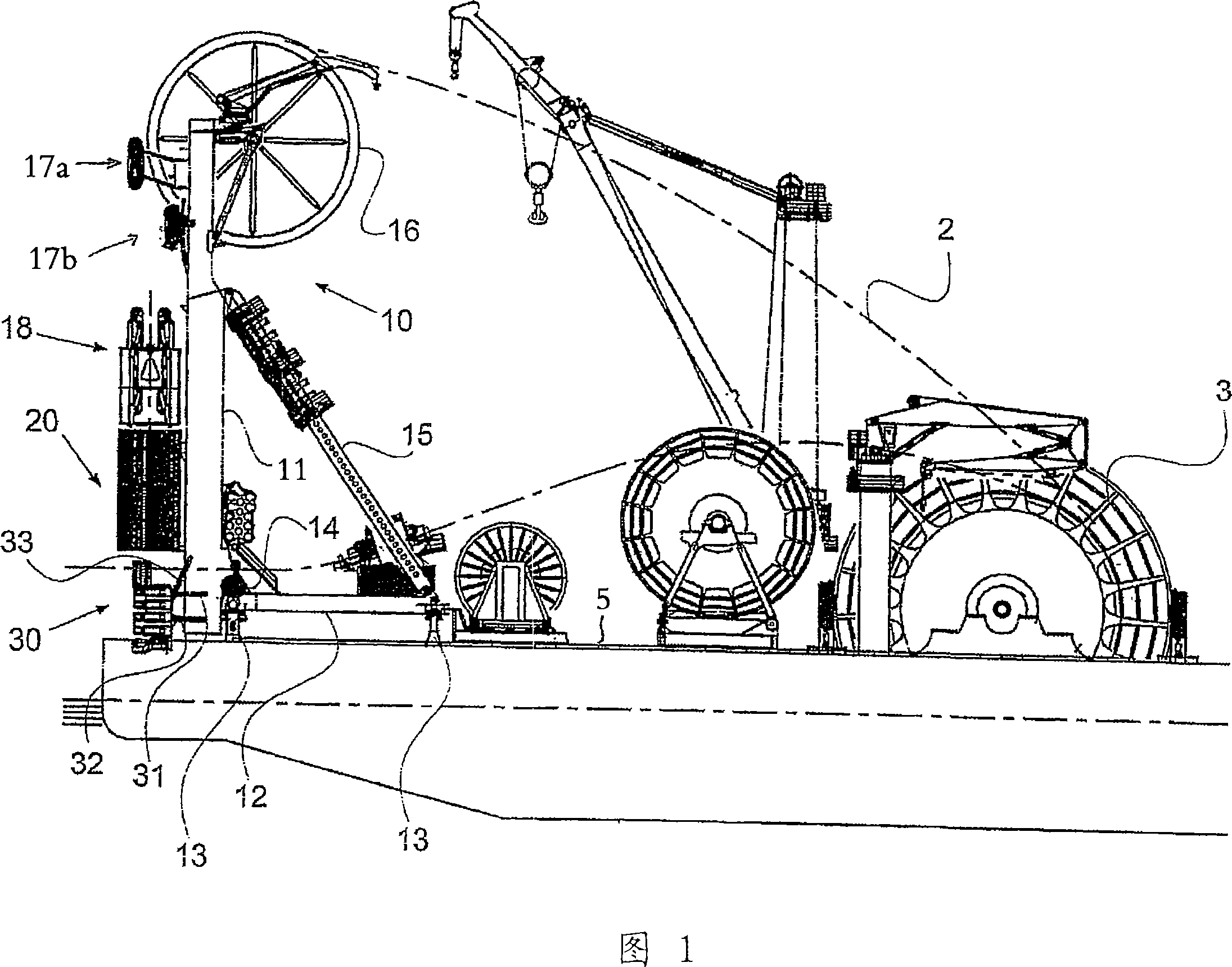

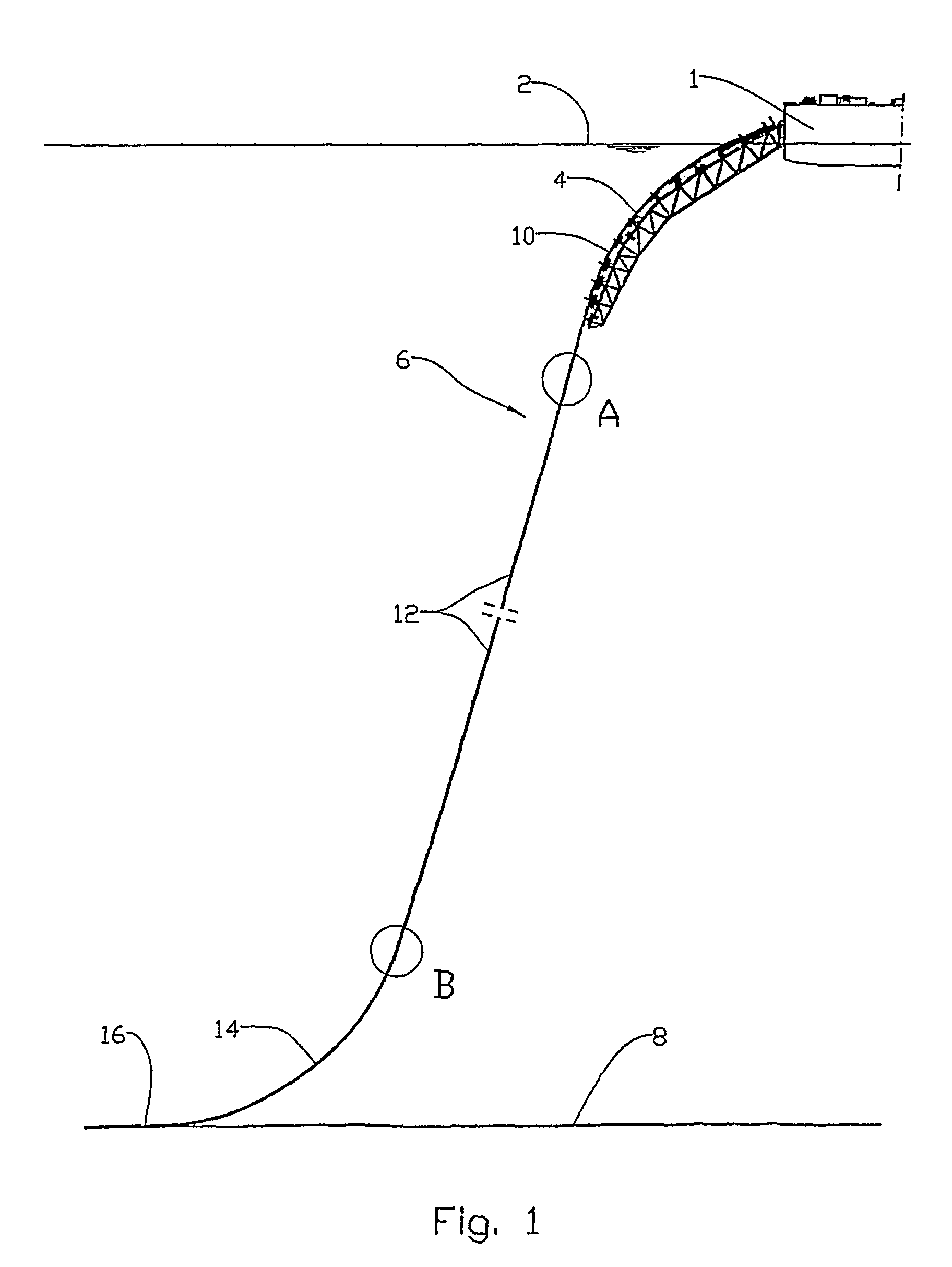

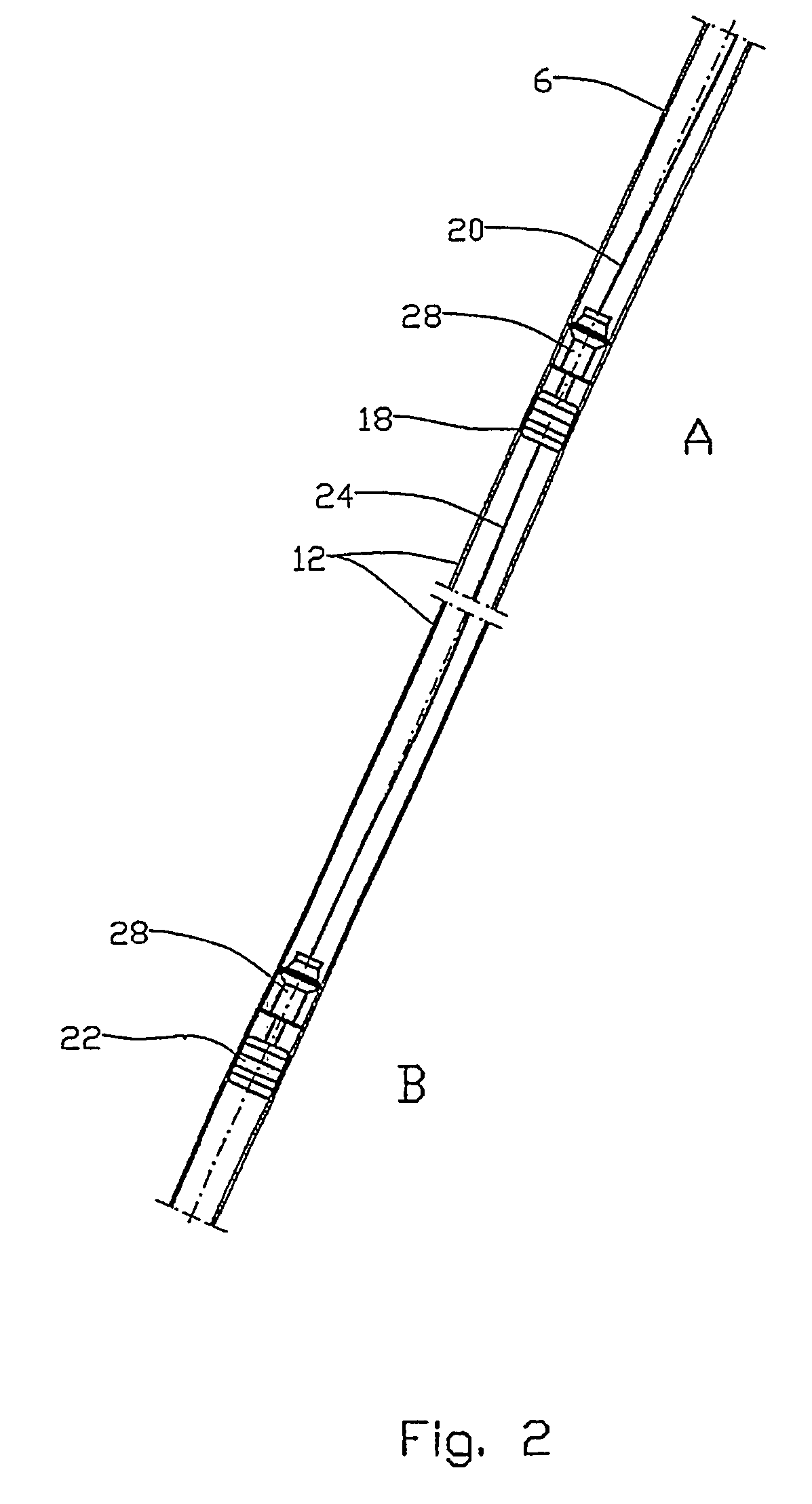

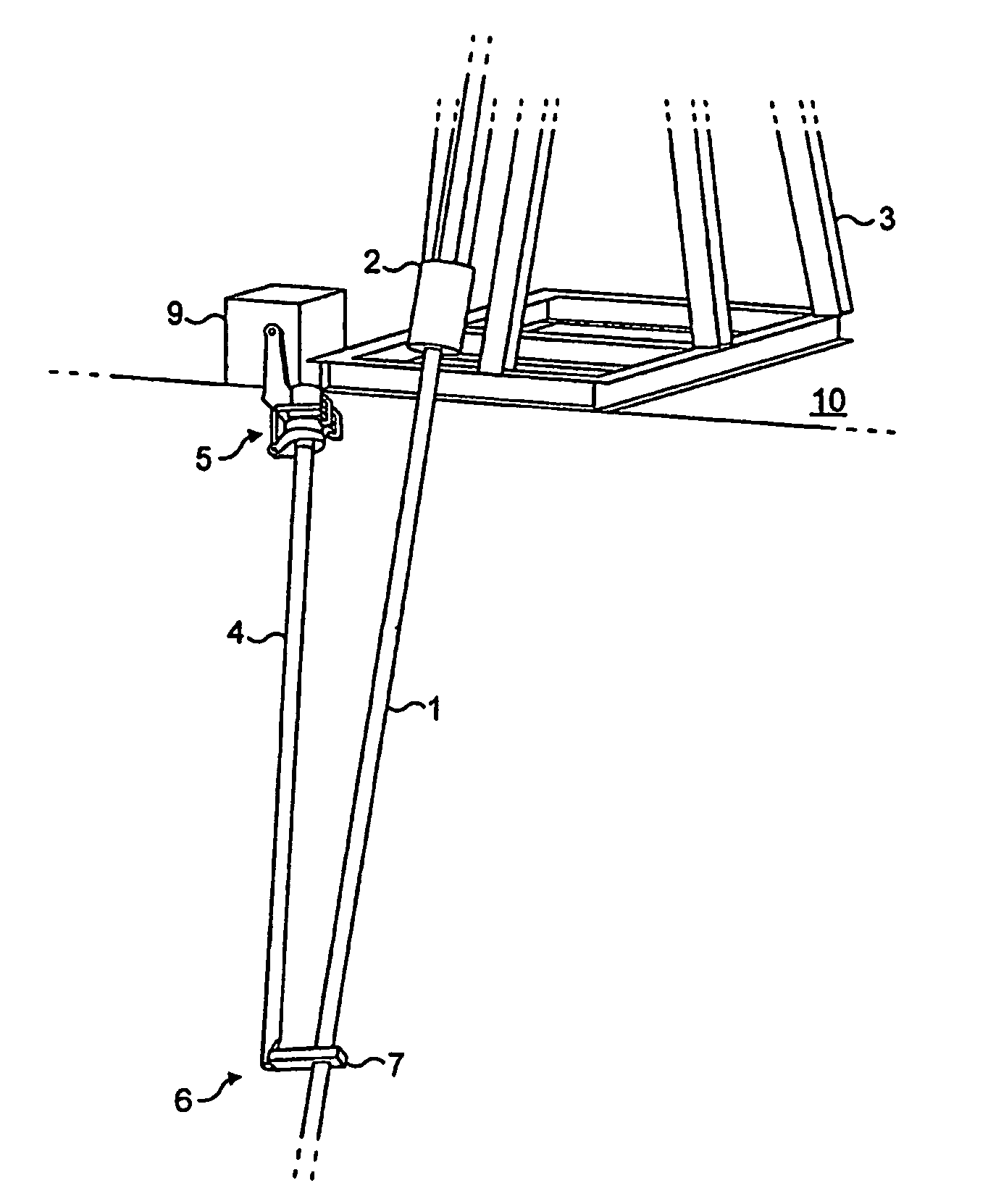

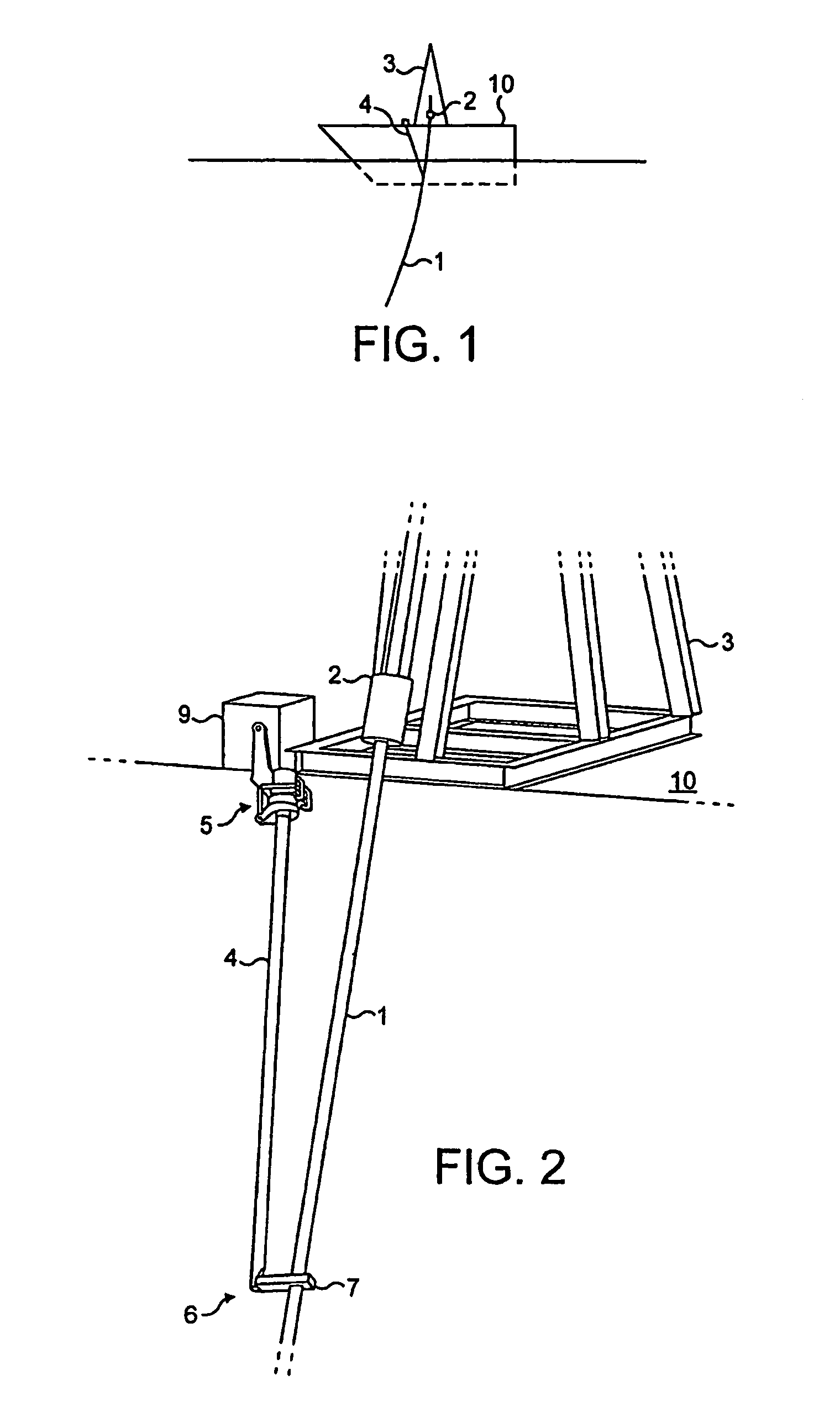

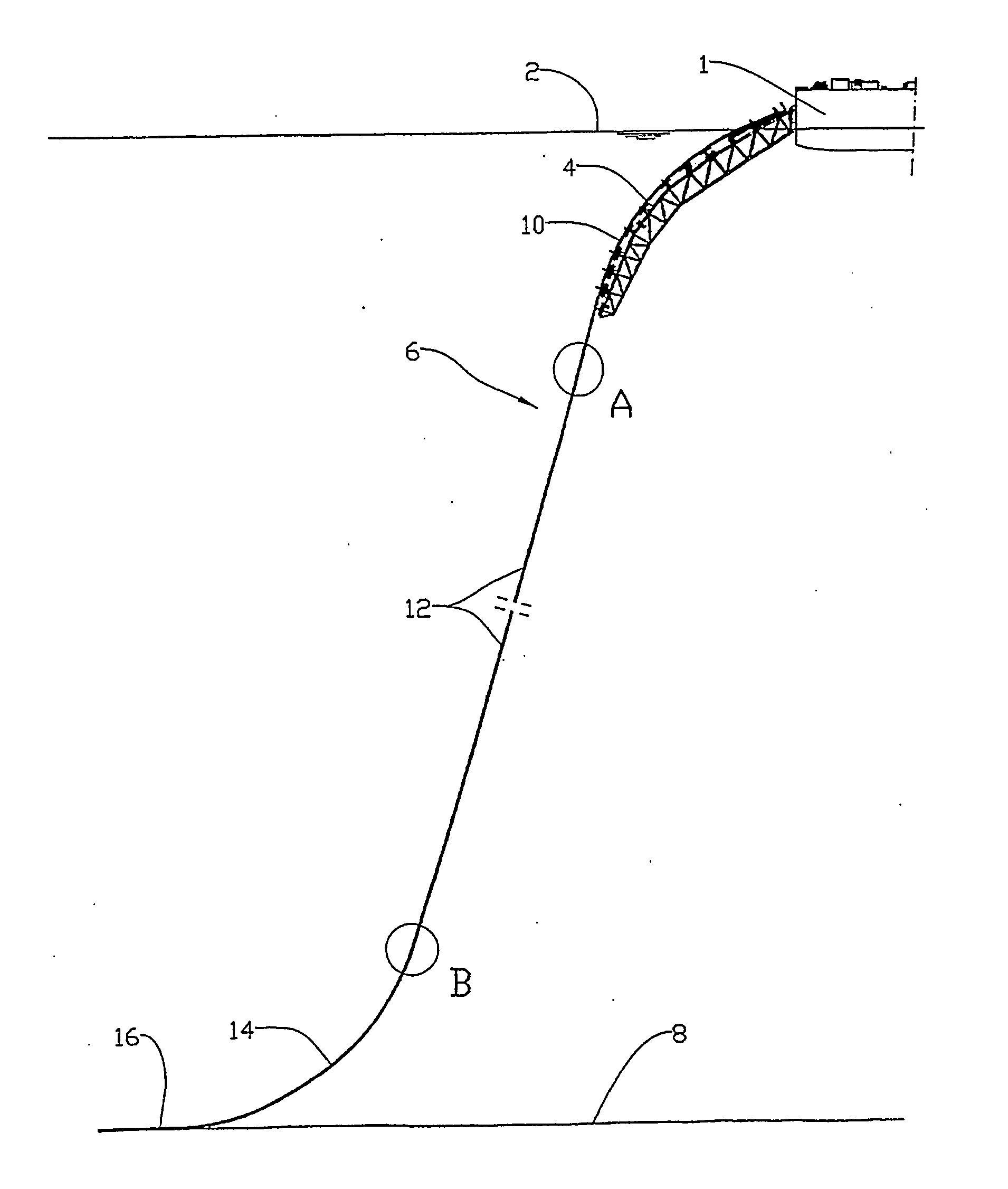

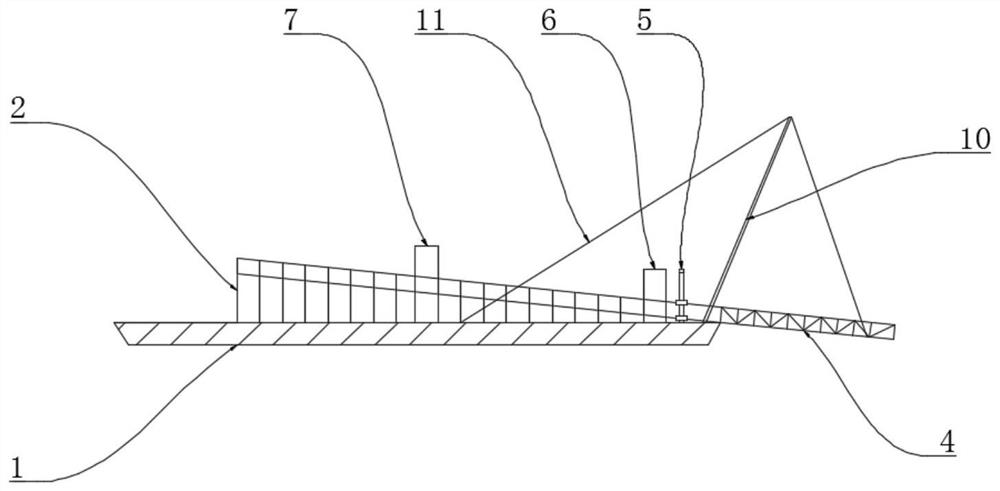

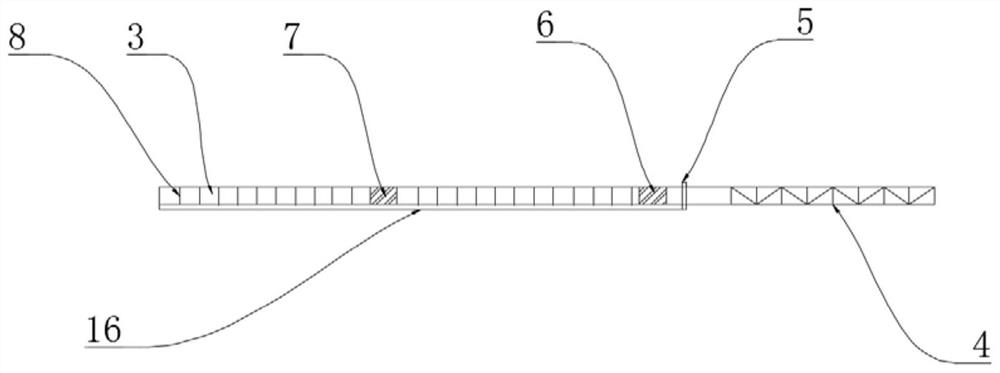

Sea pipe distribution system and method of off-land pipeline with one or more fittings

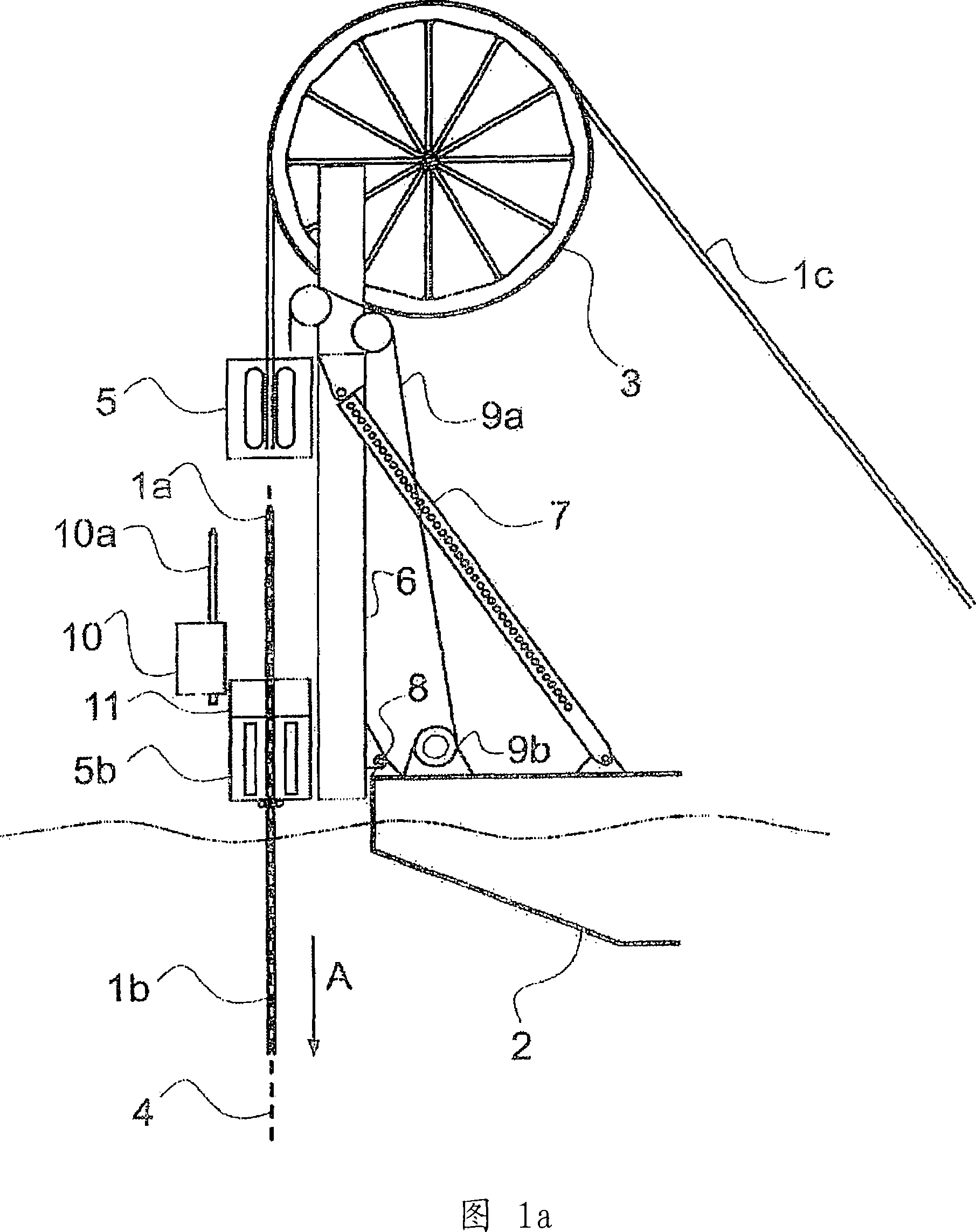

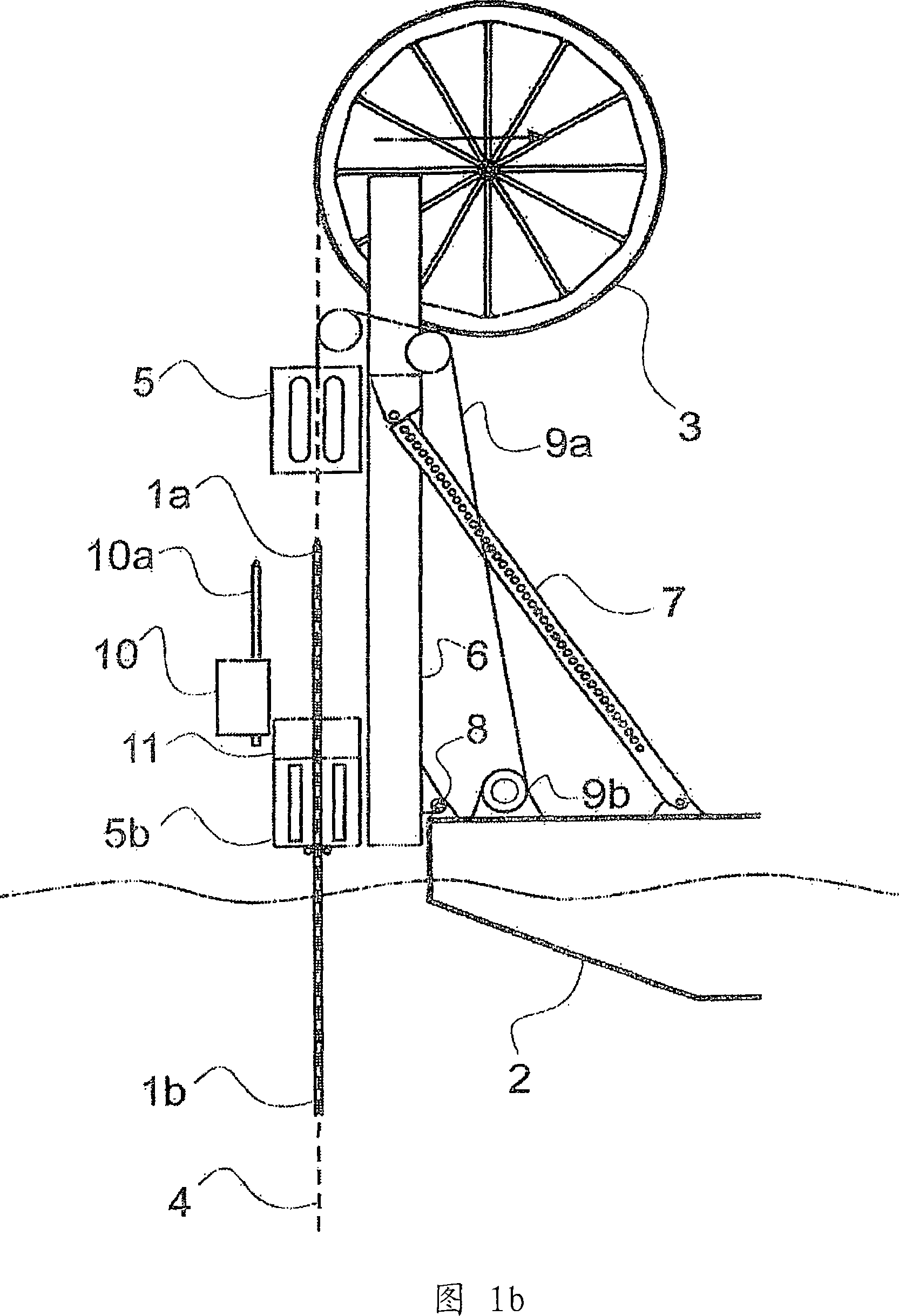

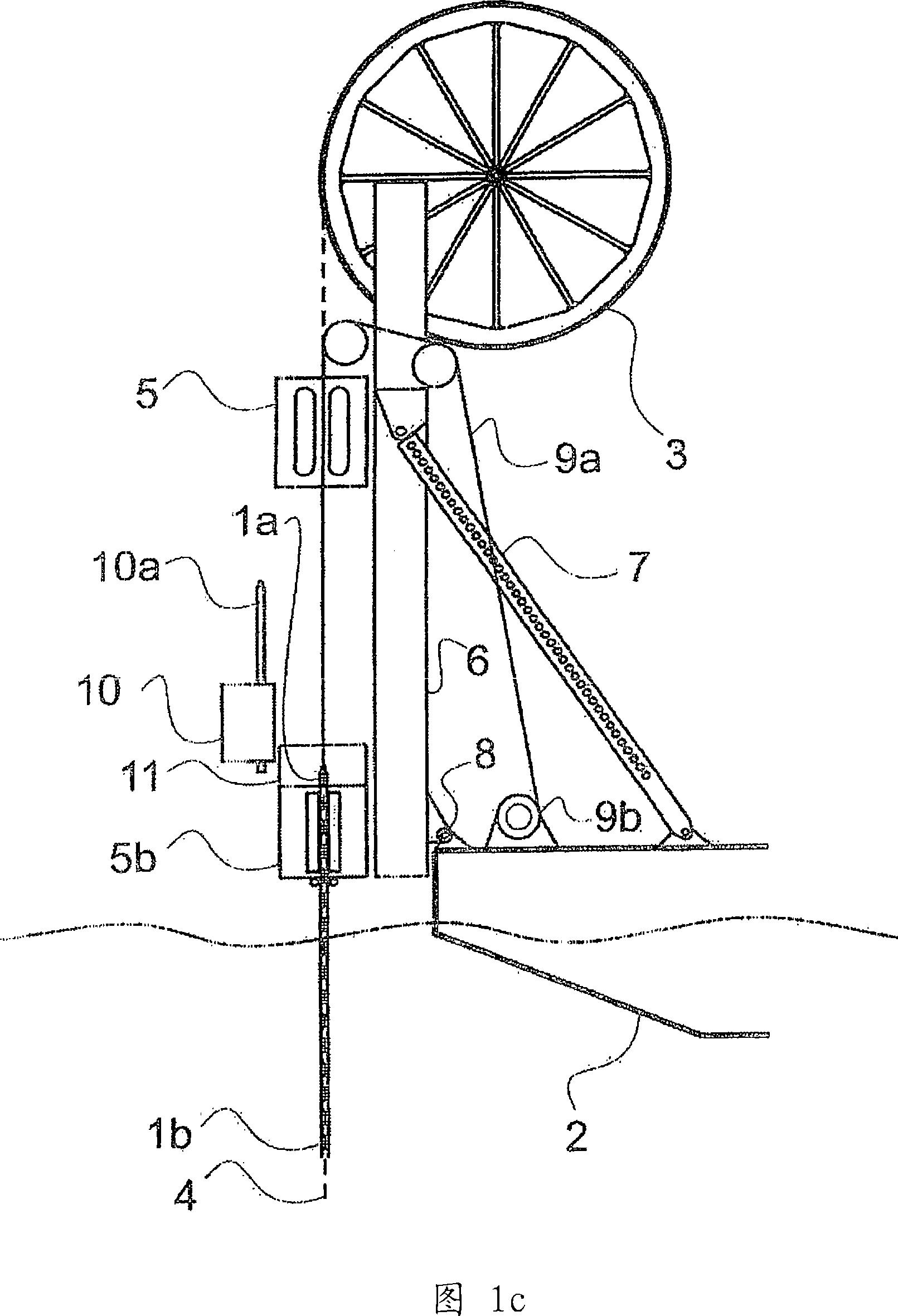

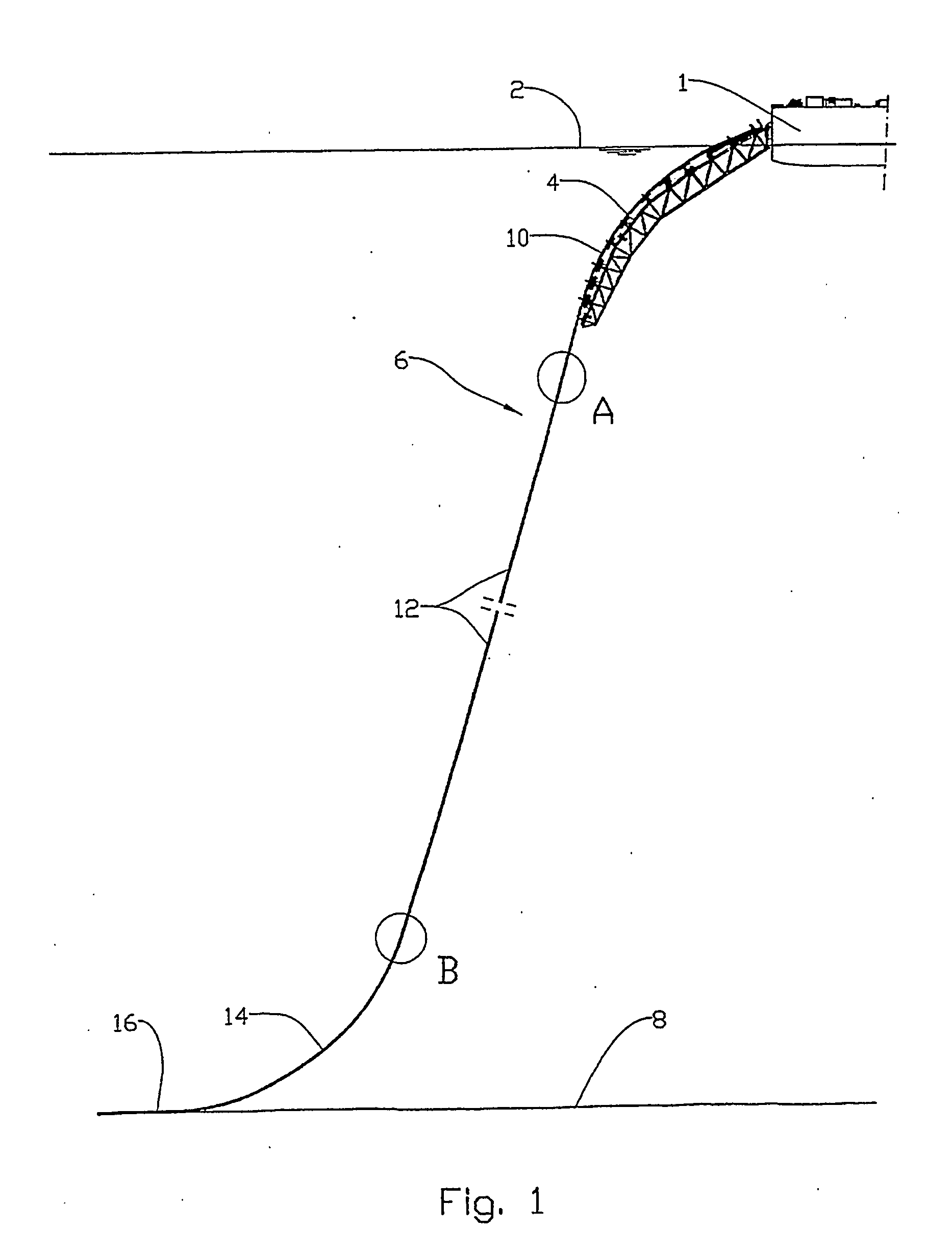

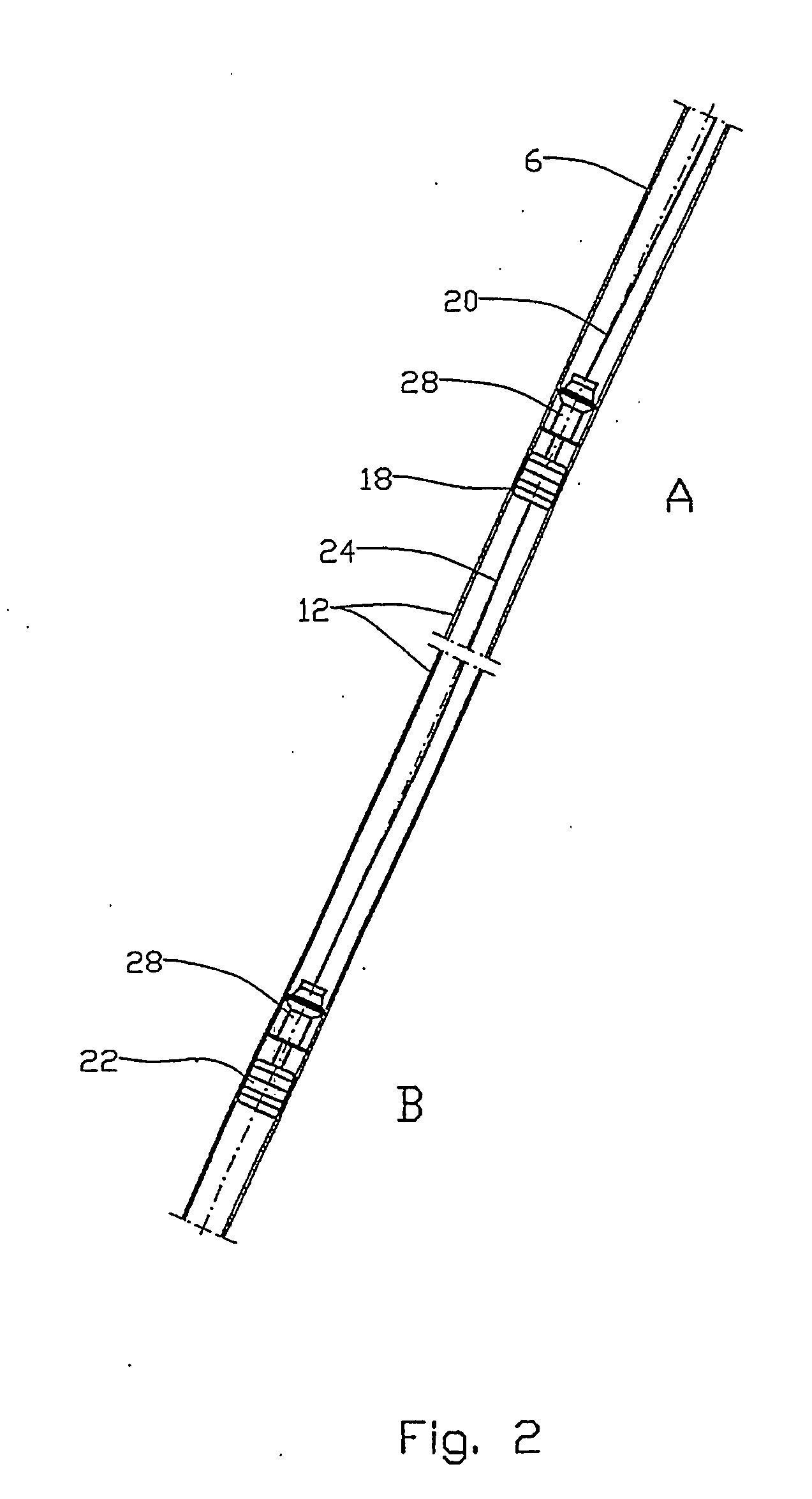

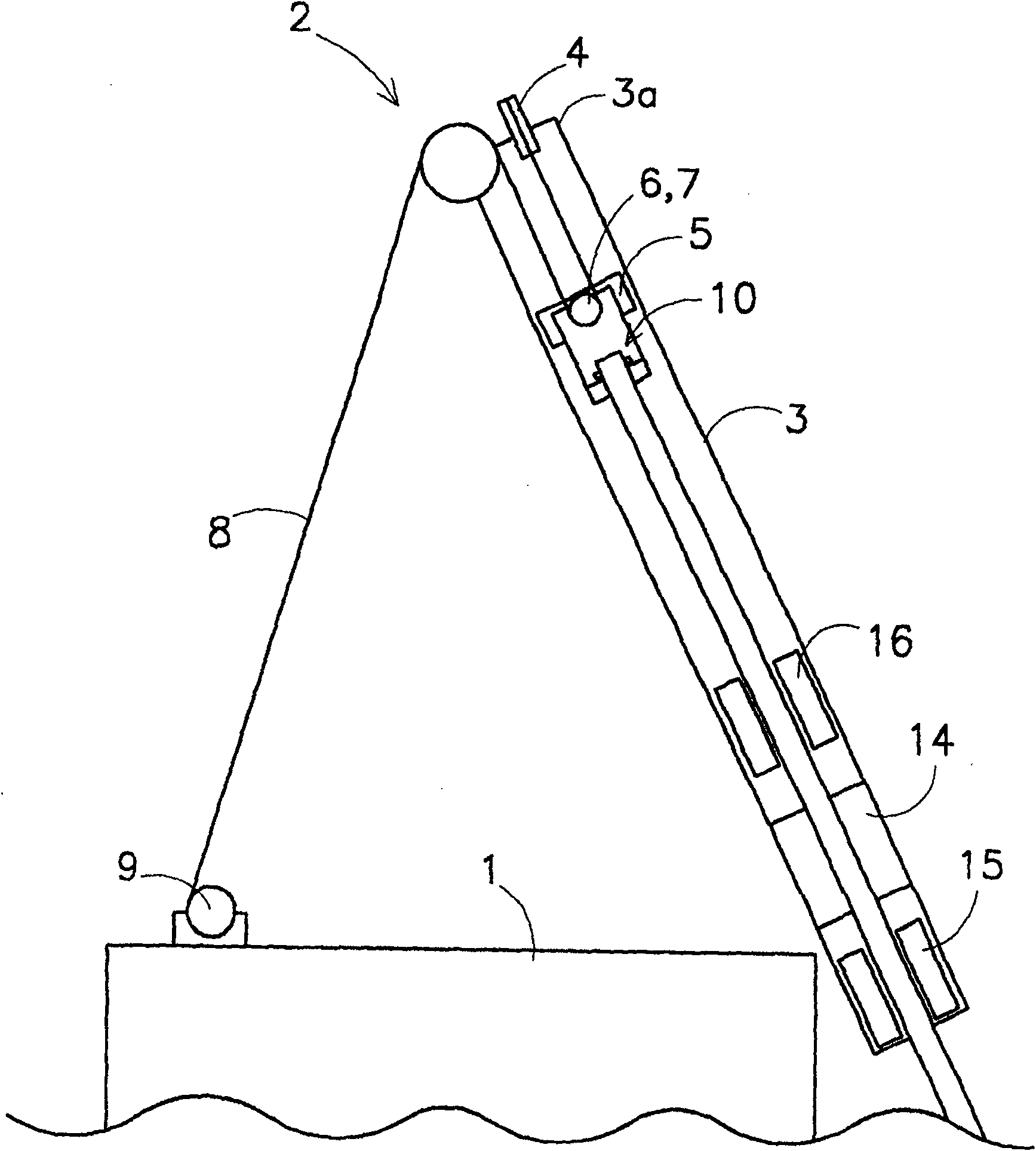

Marine pipelaying method and system for installing an offshore pipeline (1) that includes one or more accessories (10). The method includes the steps of providing a vessel (2), launching the pipeline (1) in a firing line from the vessel (2) in the direction of the seabed, engaging the pipeline (1) with a clamping device (5b) that is connected to the vessel (2) and adapted to support the weight of the previously launched pipeline (1), and moving the accessory (10) into the firing line to a position above the clamping device (5b). Then the accessory (10) is connected to the pipeline (1) above the clamping (5b) device while the pipeline (1) is held by the clamping device (5b) Follow that the accessory (10) and the launched pipeline (1) connected thereto and releasably secured to a controlled load hoisting device (5) and the weight of the accessory (10) and the launched pipeline (1) connected thereto are transferred from the clamping device (5b) to the controlled load hoisting device (5) while the accessory (10) and the launched pipeline (1) connected thereto remain in the firing line. Finally the clamping device (5b) is disengaged from the pipeline (1) and moved away from firing line. Then the accessory (10) and the launched pipeline (1) connected thereto are lowered along the firing line by the controlled load hoisting device (5).

Owner:ITREC BV

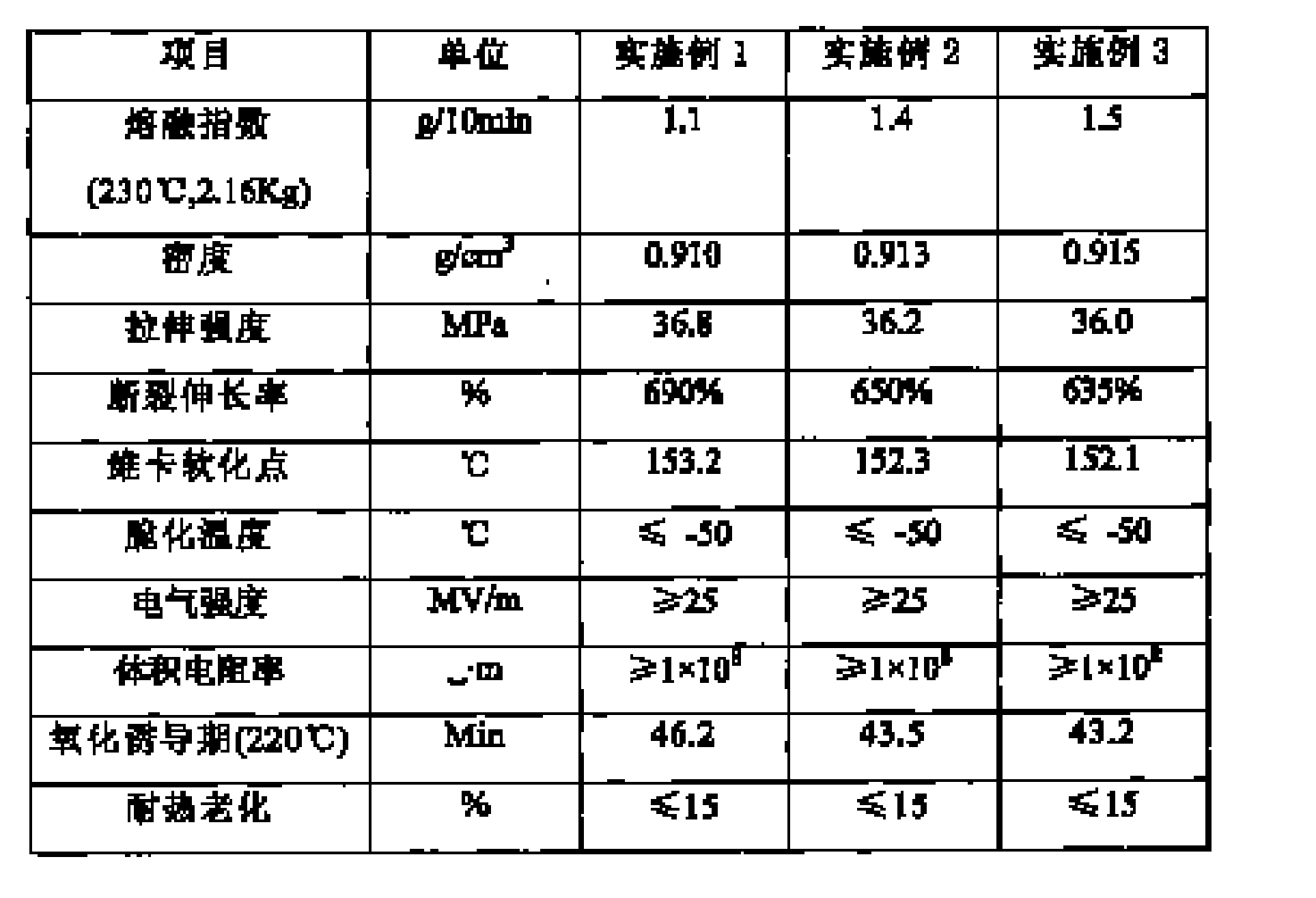

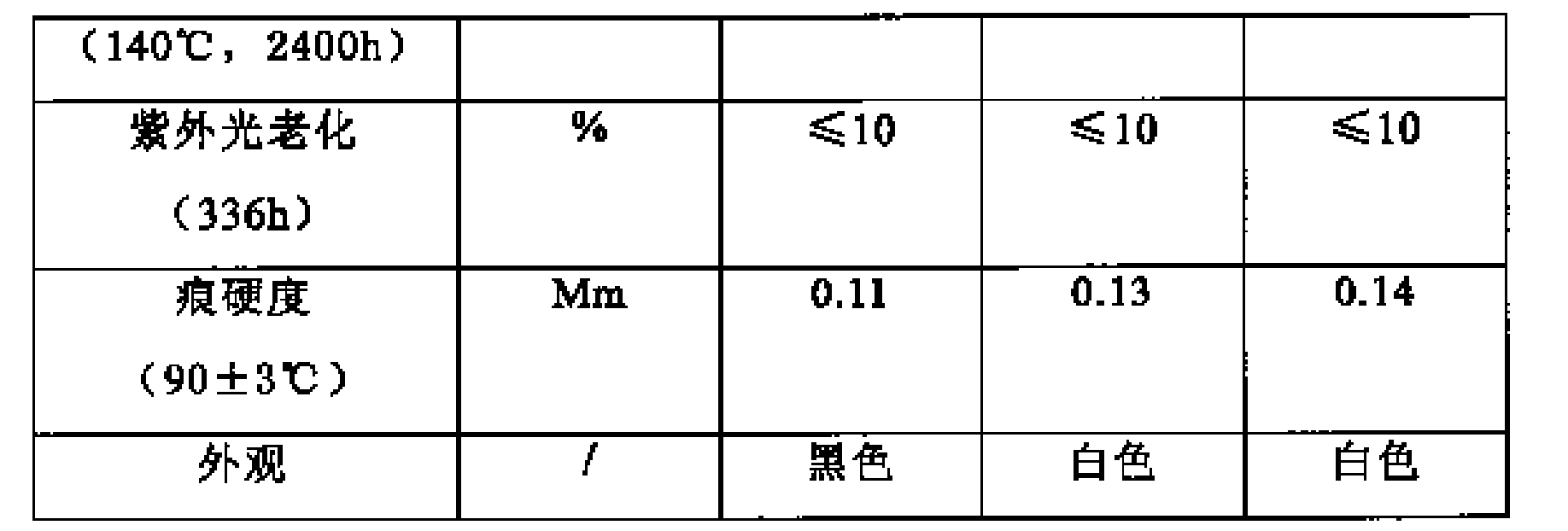

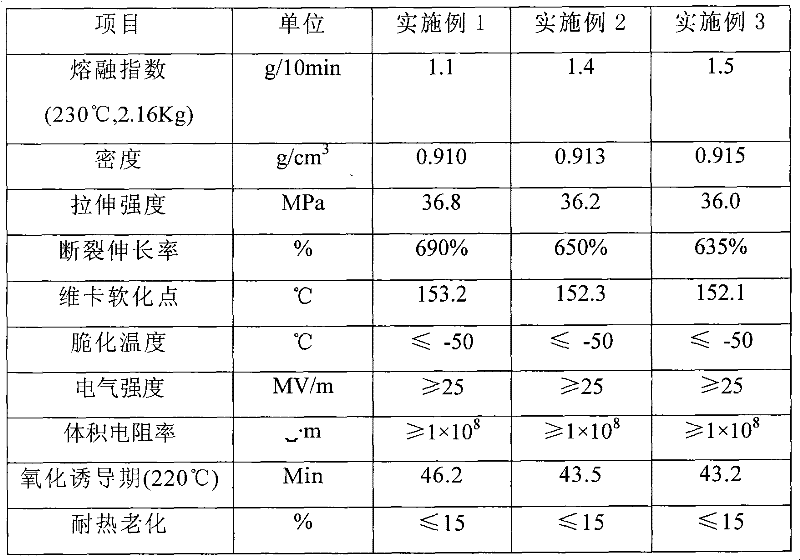

Metallocene polypropylene modified material for corrosion-inhibiting coating of steel pipe and preparation method and application thereof

ActiveCN101519513ACoating processing range is wideImproved environmental stress cracking resistanceAnti-corrosive paintsUltraviolet lightsWorking temperature

The invention discloses a metallocene polypropylene modified material for a corrosion-inhibiting coating of a steel pipe and a preparation method and application thereof. A formula of the material comprises 65 to 95 weight percent of metallocene polypropylene, 3 to 30 weight percent of co-polypropylene, 0.01 to 4 weight percent of thermal oxygen stabilizer, 0.03 to 3 weight percent of ultraviolet absorbent and light stabilizer, 0.02 to 5 weight percent of functional additive, 0.01 to 3 weight percent of inorganic nanometer reinforced material, and 0 to 5 weight percent of black color batch, and the material is prepared by adopting a double screw extruder to carry out plasticizing blending technology for extrusion and pelletization. The metallocene polypropylene modified material has wide casting and coating processing range, has strong adaptability to bottom glue of hot melt adhesives, has outstanding ultraviolet light aging resistance and thermal-oxidative aging resistance, and has excellent shock resistance and surface scratch resistance as well as extremely high environmental stress cracking resistance. The material can be suitable for terrestrial pipelines at continuous working temperature high up to 110 DEG C, and is also suitable for offshore pipelines atcertain special continuous working temperature high up to 140 DEG C at the same time.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

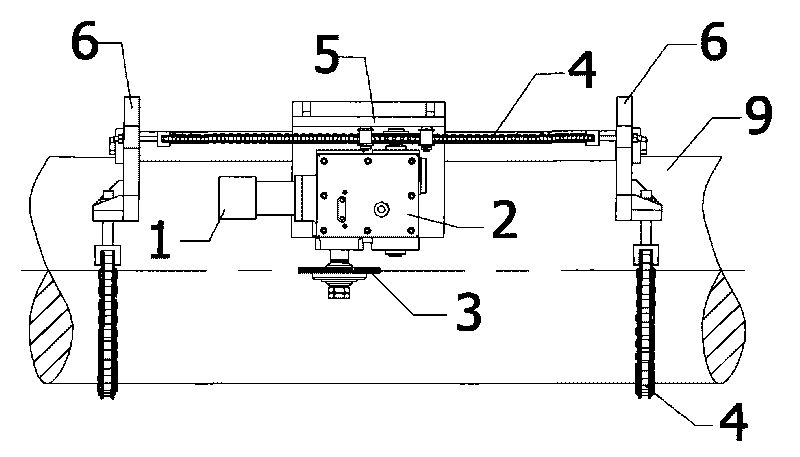

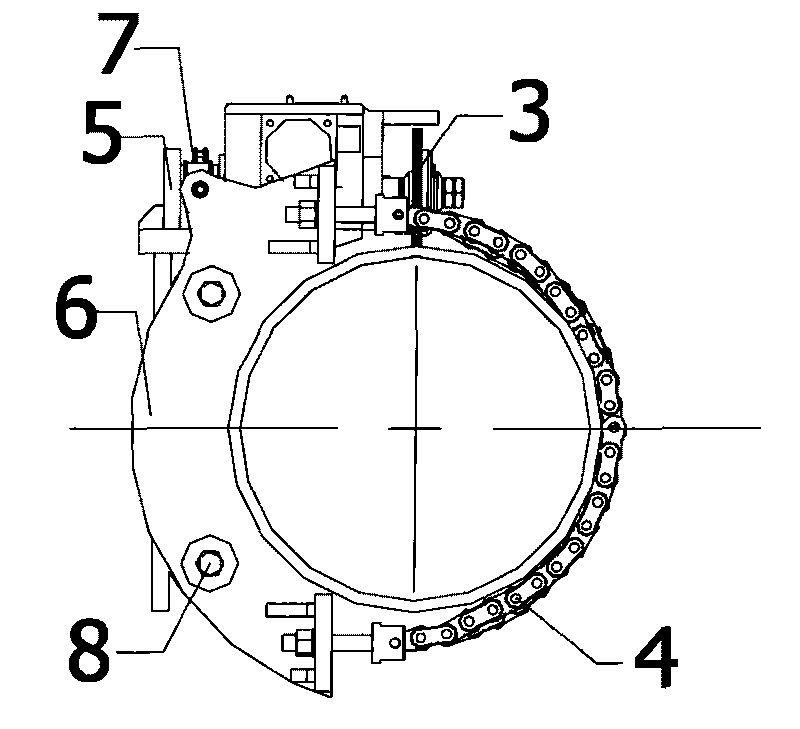

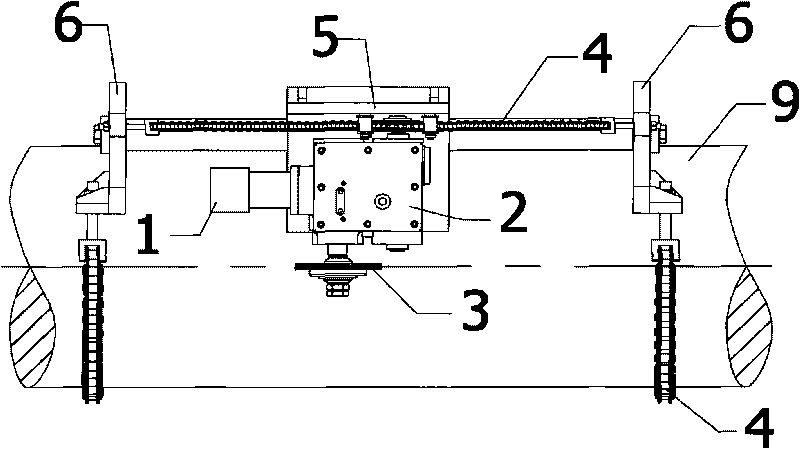

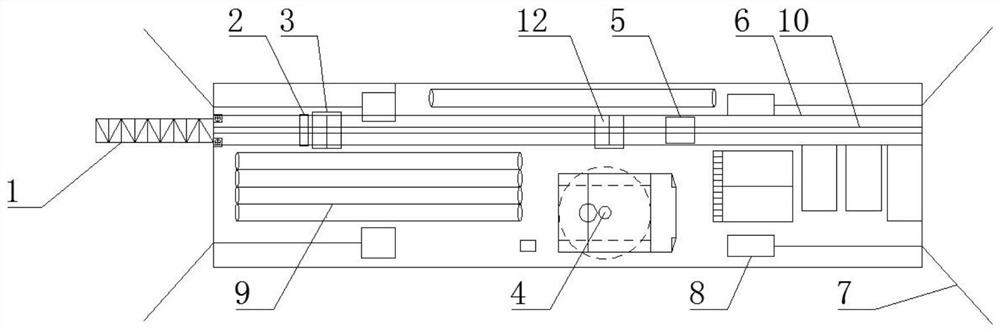

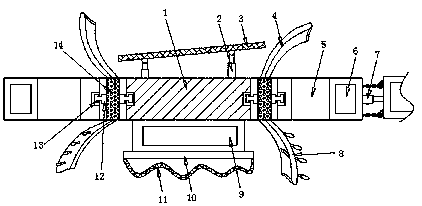

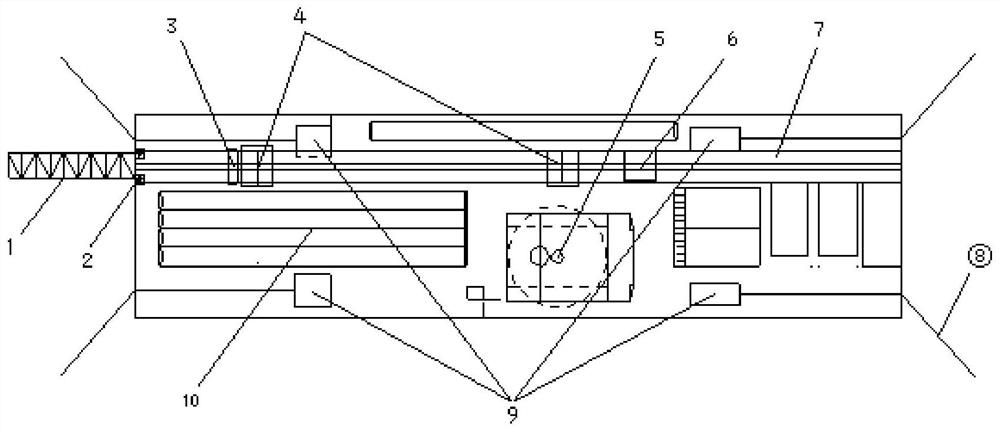

Steel pipe vertical seam cutting machine device

InactiveCN101758284AReduce cleanupEliminate potential safety hazardsTube shearing machinesHydraulic motorMilling cutter

The invention provides a steel pipe vertical seam cutting machine, which consists of a milling cutter 3, a press chain device 5, a speed change gear box 2, a hydraulic motor 1, a guide rail 8, a climbing wheel 7, a chain 4 and an annular plate fixing device 6. The device adopts the mechanical cutting method, eliminates the potential safety hazard for stripping off an outer pipe by oxy arc cutting, omits the cleaning work of an inner pipe, simplifies the construction process, further improves the construction speed of the offshore pipeline leak source restoration, and lowers the construction cost.

Owner:NEPTUNE OFFSHORE ENG DEV

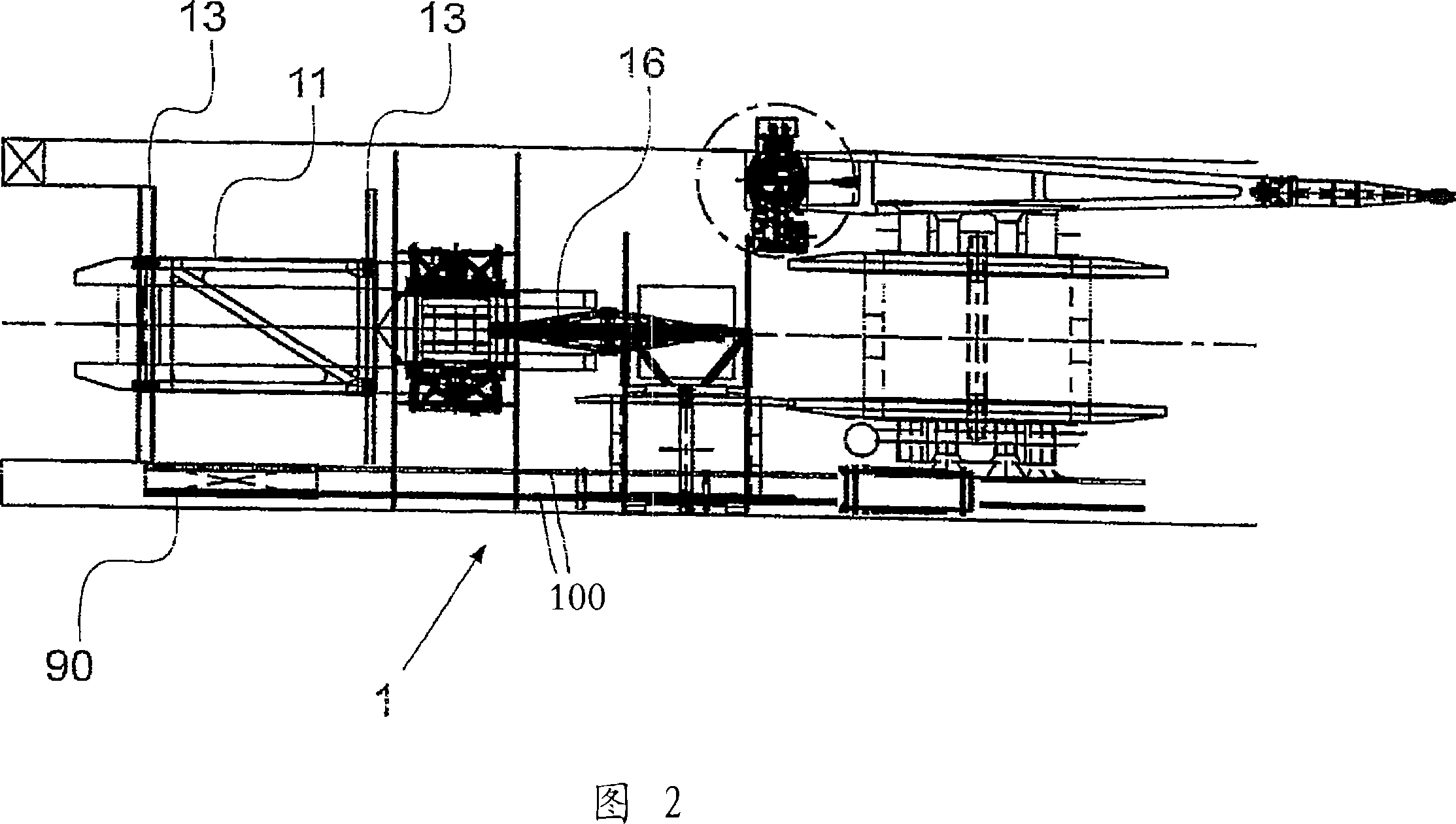

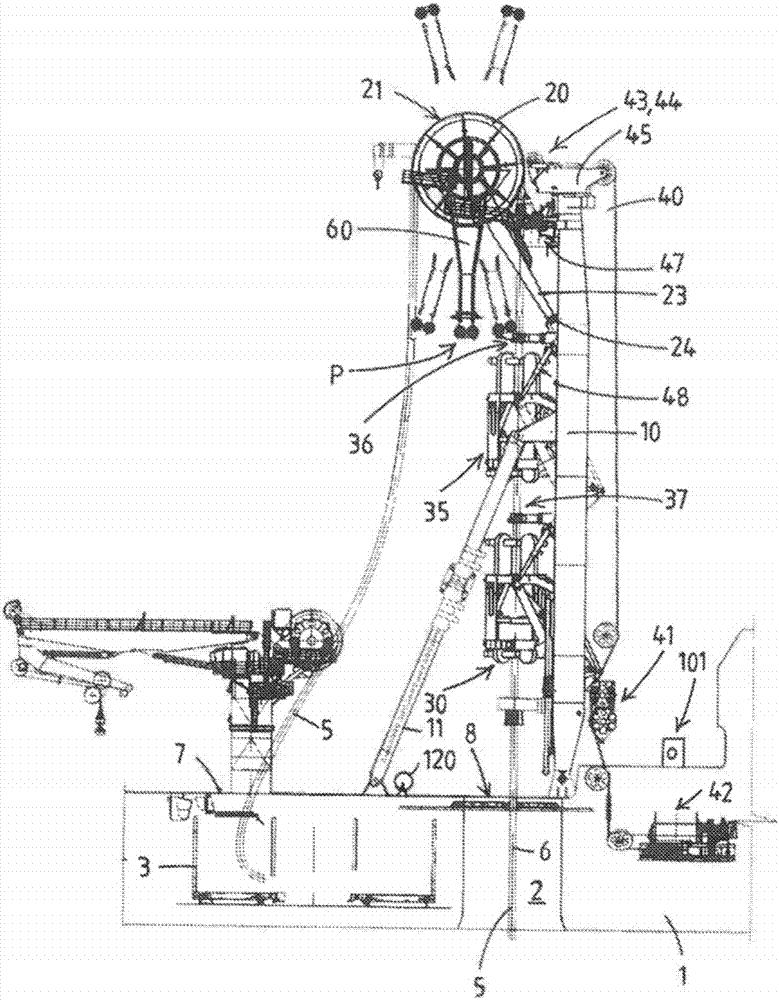

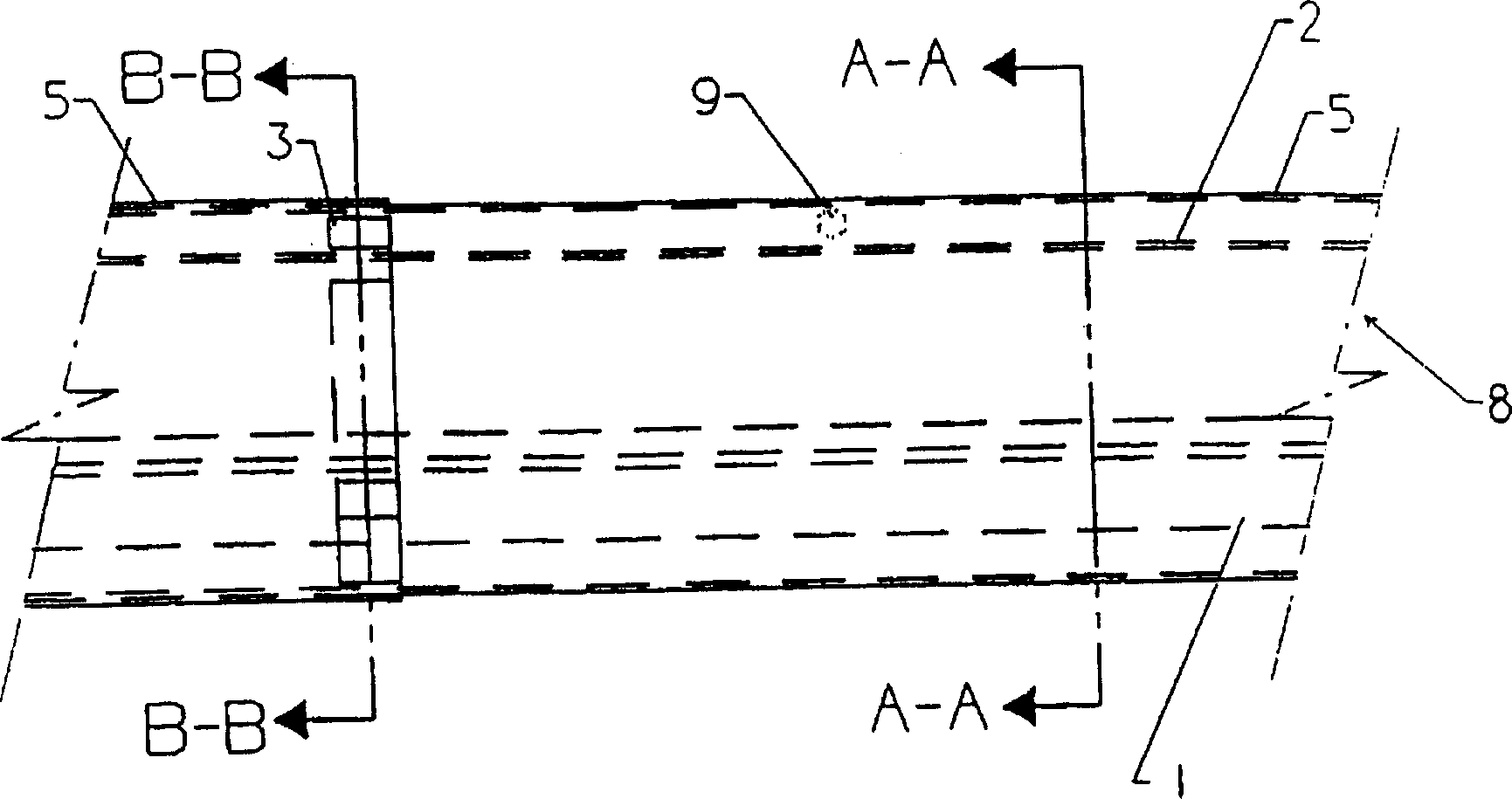

Marine pipelaying system for laying an offshore pipeline

A marine pipelaying system and method for installing an offshore pipeline that includes one or more accessories. The system comprises a vessel (1), a pipeline launch device (10) for launching the pipeline (2) from the vessel (1) in the direction of the seabed, and a clamping device (30) adapted to support the weight of the previously launched pipeline. The system further includes an accessory handling device, which is adapted to receive and support an accessory (40) and allow displacement therof between receiving position, wherein the accessory (40) is received by the handling device and a pipeline connecting position, wherein the accessory (40) can be connected to the pipeline (2).

Owner:ITREC BV

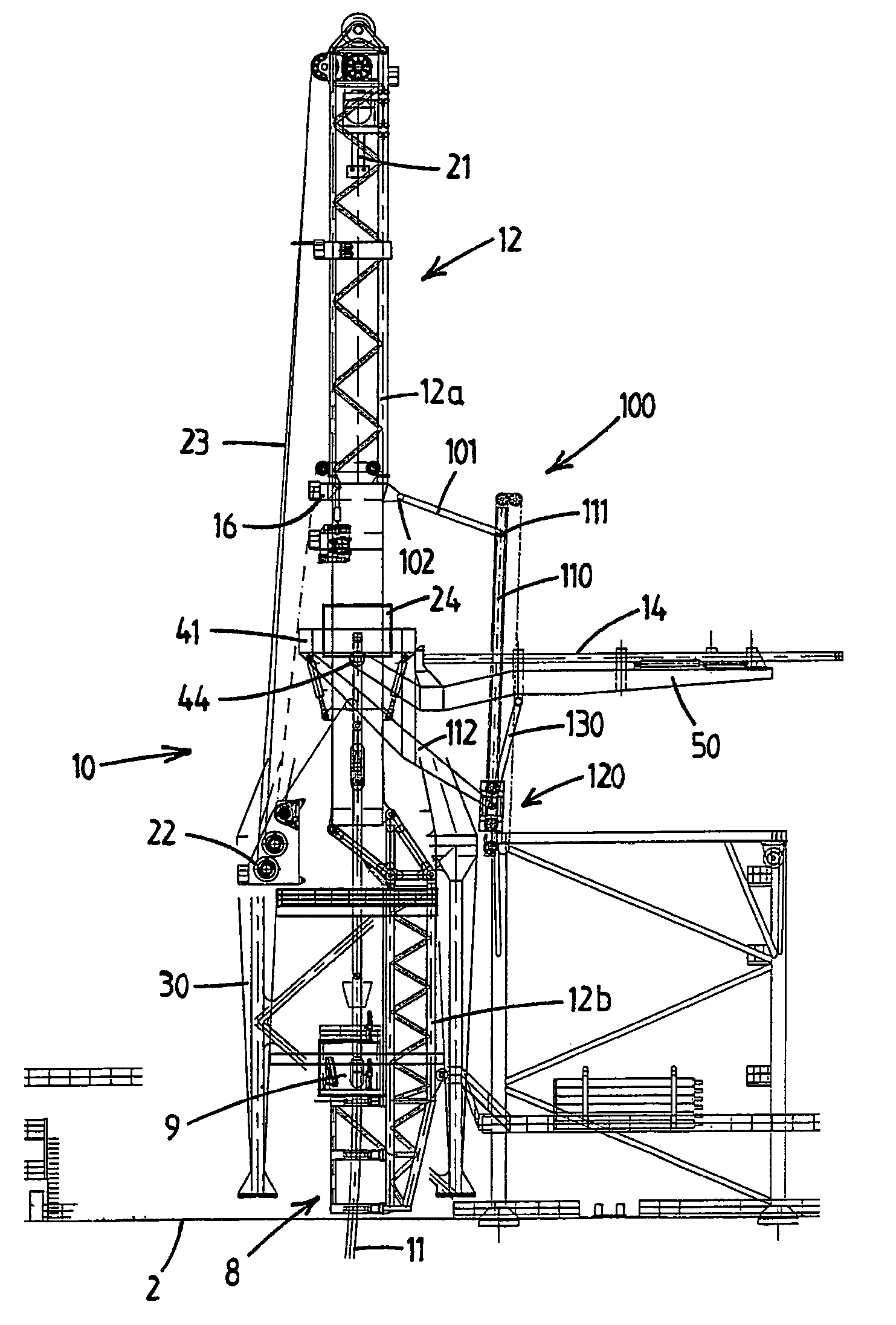

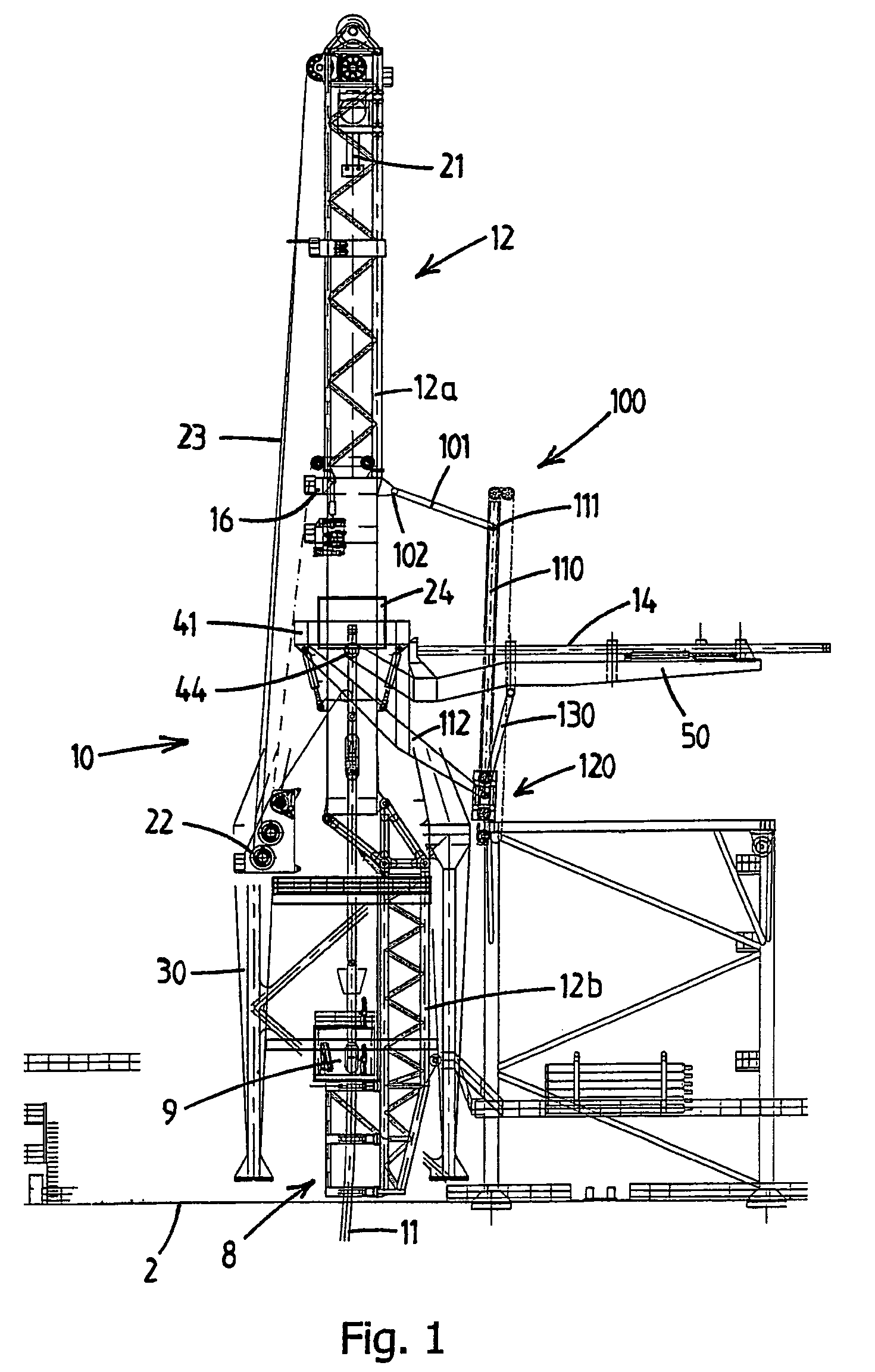

Marine pipe laying system method and hoisting device

ActiveCN1975227AShorten the timeLow costPipe laying and repairPortable liftingOcean bottomEngineering

The invention relates to marine pipe laying. For laying of an offshore pipeline, a system is used having a hoisting device. The hoisting device comprises a tower with a tower top side provided with cable pulleys. Furthermore the hoisting device has a traveling block which is displaceably attached to the tower. The traveling block comprises a first block and a second block, both provided with cable pulleys. The first block is provided with a clamp for holding a pipe section to be connected to the pipeline as well as for lowering the pipeline after the pipe section is connected to the pipeline. The hoisting device has a hoisting cable and a winch , the hoisting cable being guided over the cable pulleys on both the tower top side and the traveling block. The traveling block is moveable with respect to the tower by operation of the hoisting winch. The first block and the second block are adapted to be releasably coupled, in which coupled state they can travel along the tower as a unit and are able to support the weight of the pipeline. The second block can be locked to the tower, such that the first block can travel along the tower while the second block remains stationary with respect to the tower.

Owner:ITREC BV

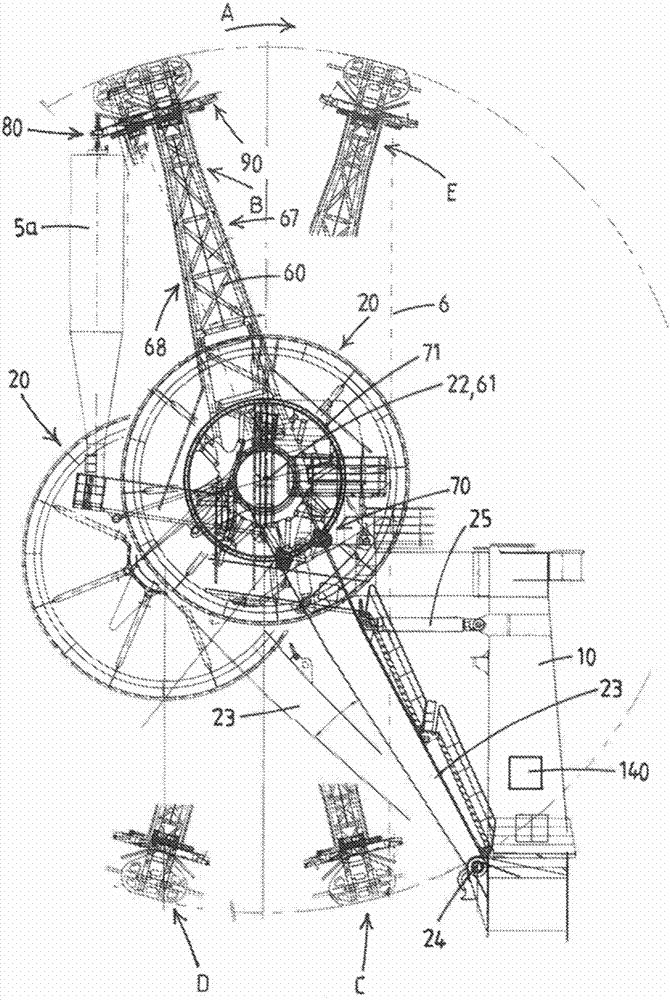

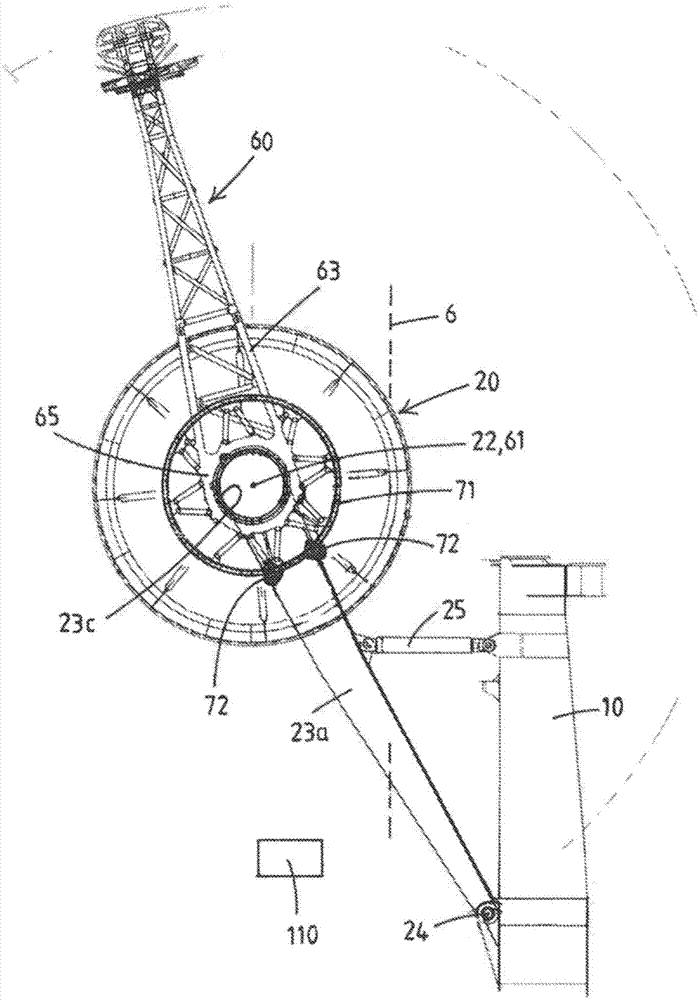

End fitting handling in a marine pipeline installation system

A marine pipeline installation system for laying an offshore pipeline and / or installing a subsea riser. The system comprises a pipeline guide (20) mounted at an elevated position on the launch tower (10) providing an arcuate guide surface (21) in a vertical plane for guiding said pipeline from the storage reel into the firing line. The system further comprises flexible pipeline end fitting transfer mechanism adapted to transfer an end fitting on a flexible pipeline over the pipeline guide. This transfer mechanism comprises a rotatable transfer arm (60) provided with a first retainer (80) for an end fitting adapter (85) to retain, at the trailing side (68) of the transfer arm (60), a first end fitting (5a). And the transfer arm (60) is provided with a second retainer (90) to retain, at the leading side (67) of the transfer arm (60), a second end fitting (5b).

Owner:ITREC BV

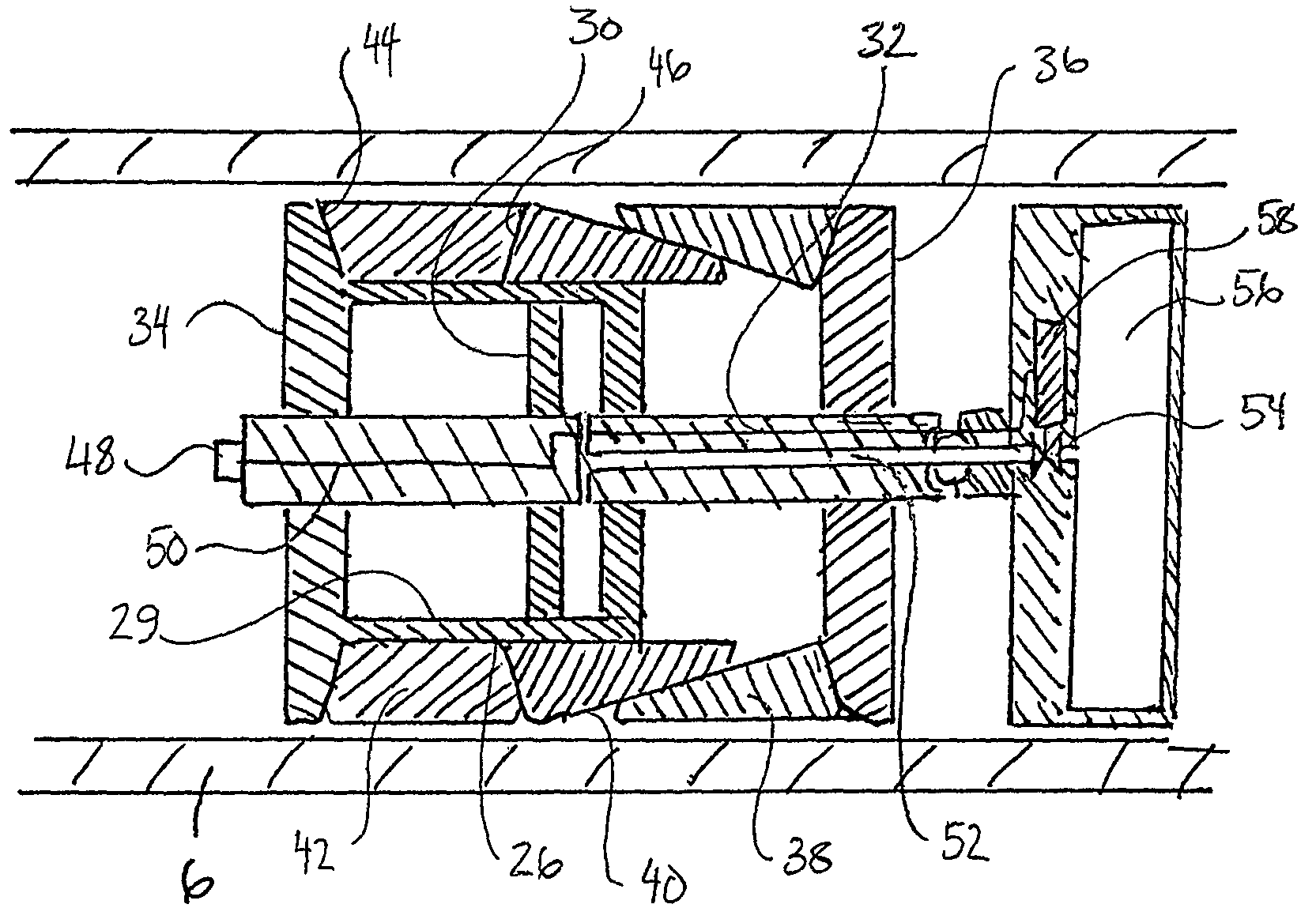

Plugging system for use during an offshore pipeline laying operation

ActiveUS7766046B2Prevent inflowPrevent penetrationPipe laying and repairPipe elementsEngineeringPiston

A plug for use during a pipeline laying operation for sealing off sections of the pipeline in case of water ingress. A sealing and gripping assembly is formed of slip segments around a partially conical shaped surface, the slip segments being moved by a piston / cylinder arrangement. A valve connected to a pressure vessel actuates the piston / cylinder in response to the detection of conductivity of fluid around the plug.

Owner:TDW OFF SHORE SERVICE CO LTD

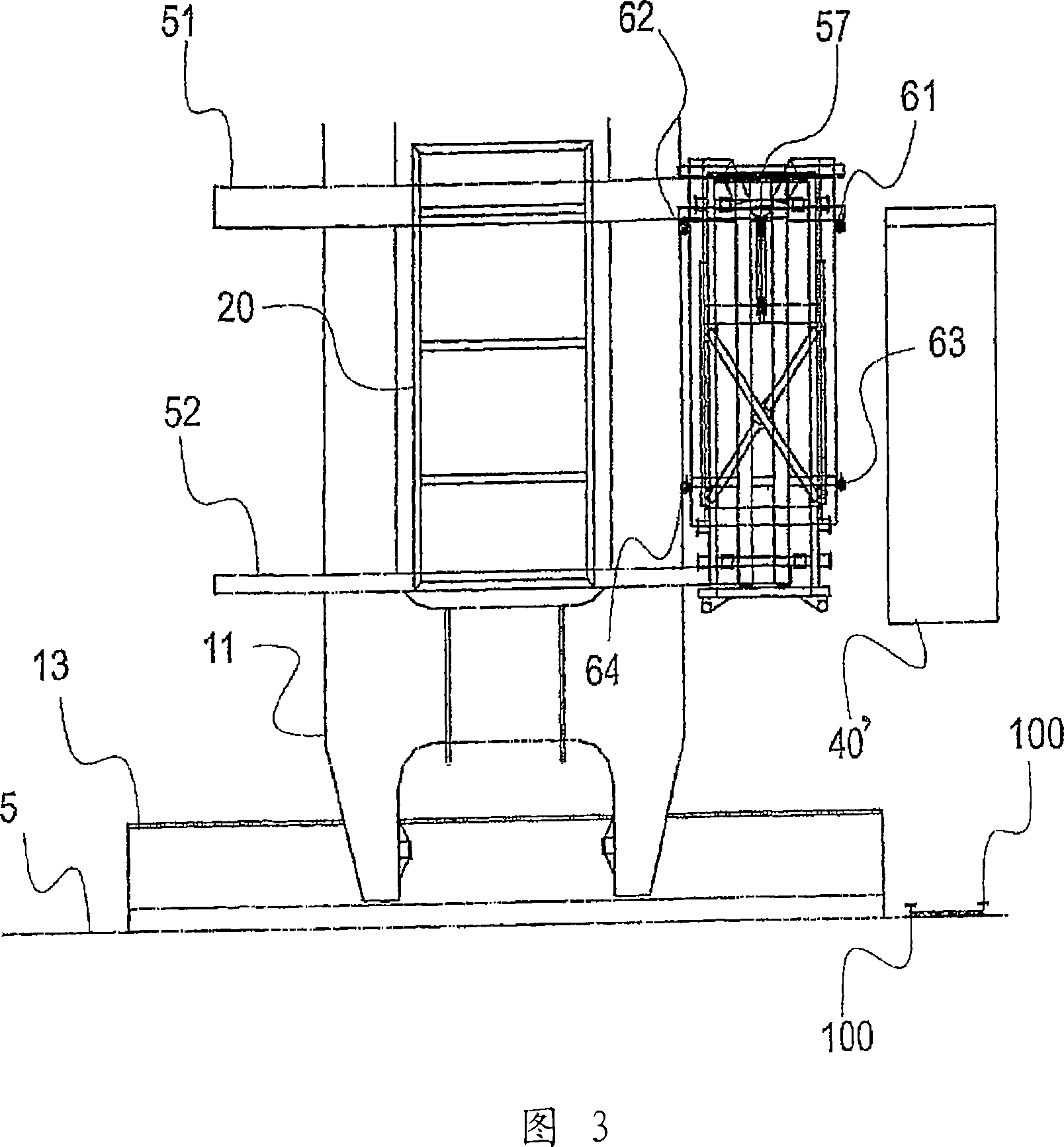

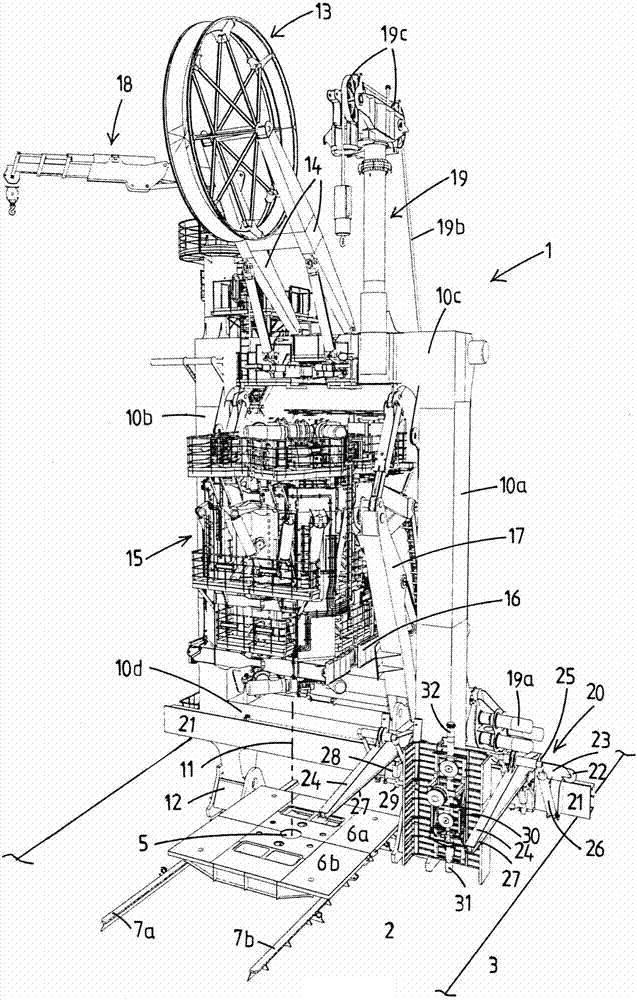

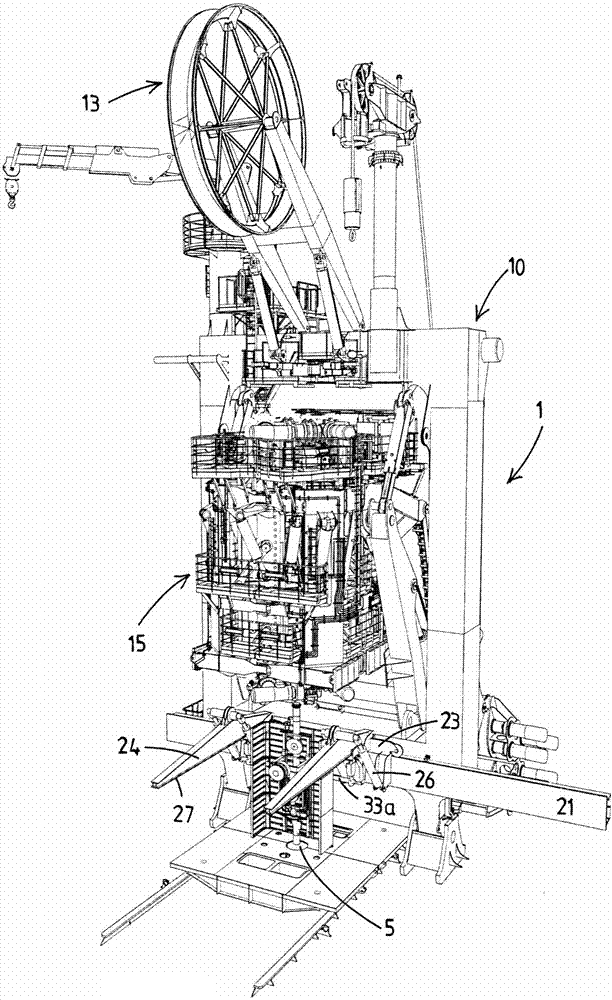

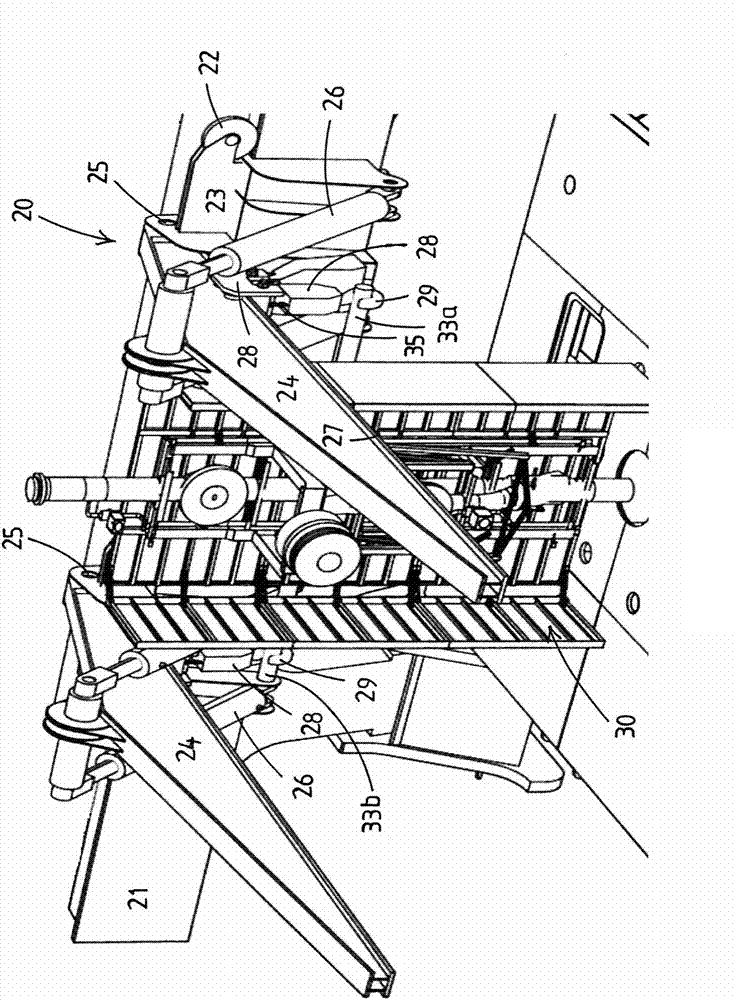

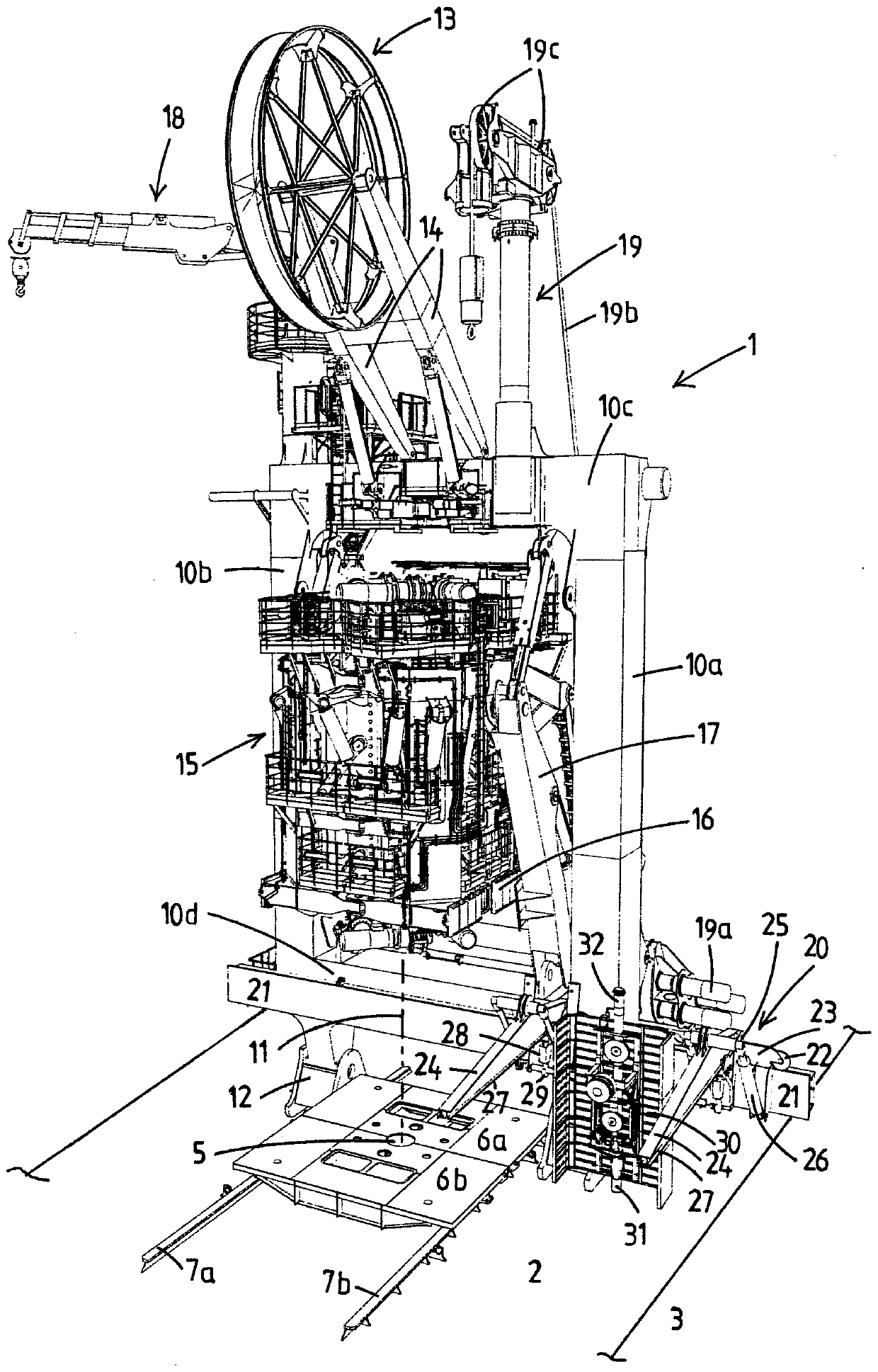

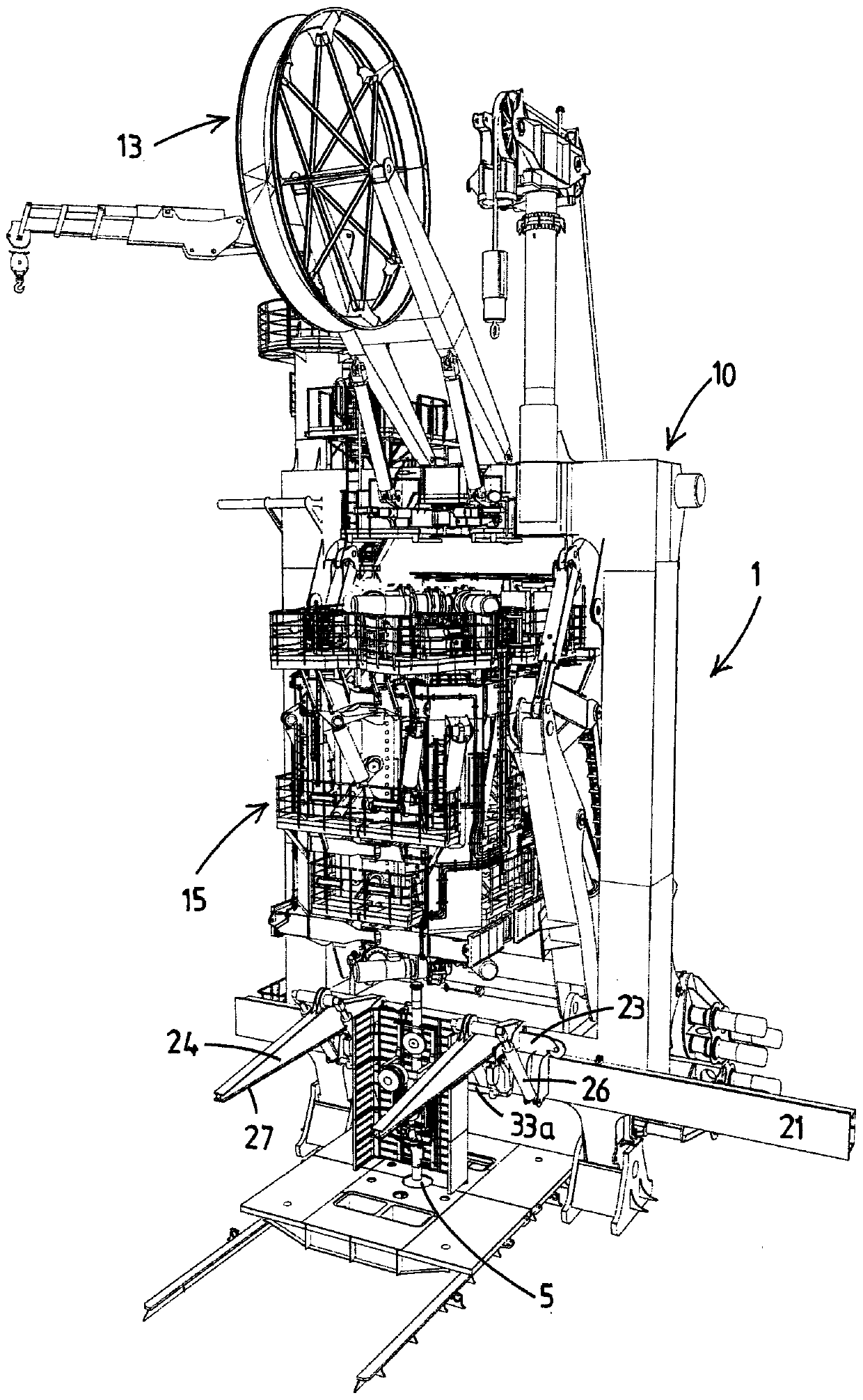

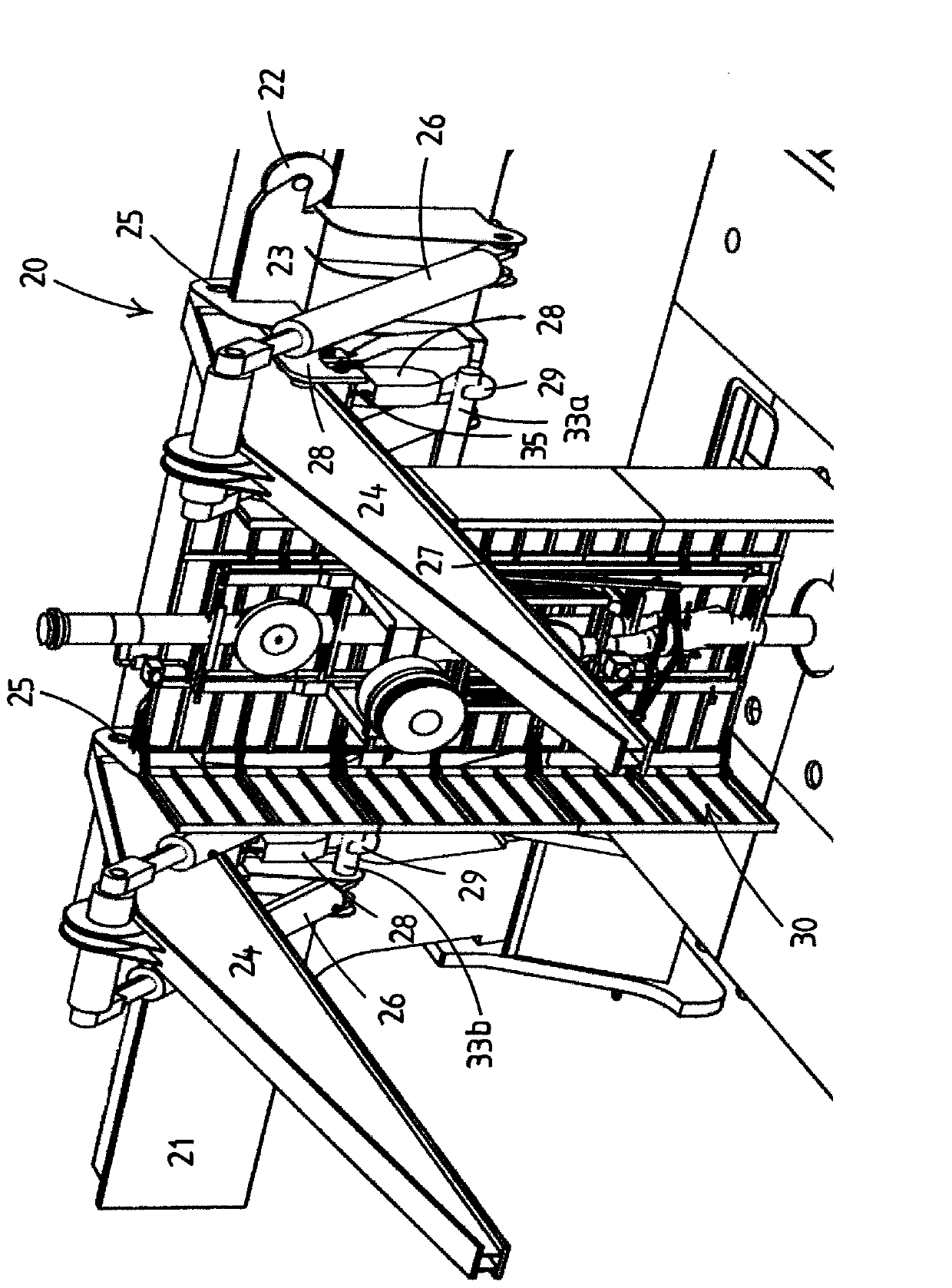

Marine pipelaying system and method for lowering and/ or raising an offshore pipeline and including one or more accessories thereto

The present invention relates to a marine pipelaying system (1) and method for lowering and / or raising an offshore pipeline and including one or more accessories (30) thereto, the system (1) comprising a pipeline launch device (10), a pipeline clamp (6a, 6b), an accessory connecting device and a controlled load hoisting device (19). An accessory handling device (20) is provided comprising an accessory transport track (21) and a cart (23) adapted to engage and support one of the one or more accessories, such that the accessory handling device (20) is adapted to engage said accessory at the engagement position, position said accessory in the pipeline connecting position in the firing line (11) above the pipeline clamp 6a, 6b), wherein the accessory can be connected to the pipeline and support and allow displacement of the accessory between the engagement position and the pipeline connection position.

Owner:ITREC BV

Apparatus and method for use in laying or recovering offshore pipelines or cables

During recovery of an offshore pipeline, to a floating vessel for repair, for example, the pipeline is secured to a hang-off clamp. Due to the motion of the vessel, oscillating bending moments can be caused in the pipeline below the clamp. To reduce these bending moments an auxiliary member is employed which restricts “radial” movement of the pipeline below the clamp. The auxiliary member comprises an elongate element, such as a pipe, whose upper end is fixed to the vessel and whose lower end carries a member connecting it to the pipeline. Axial movement of the pipeline with respect to the connecting member is permitted. The auxiliary member is designed to have predetermined amount of flexibility, this being provided in particular by flexibility of the pipe, and it thus restricts the amount of radial movement of the pipeline which is permitted below the clamp.

Owner:ROCKWATER

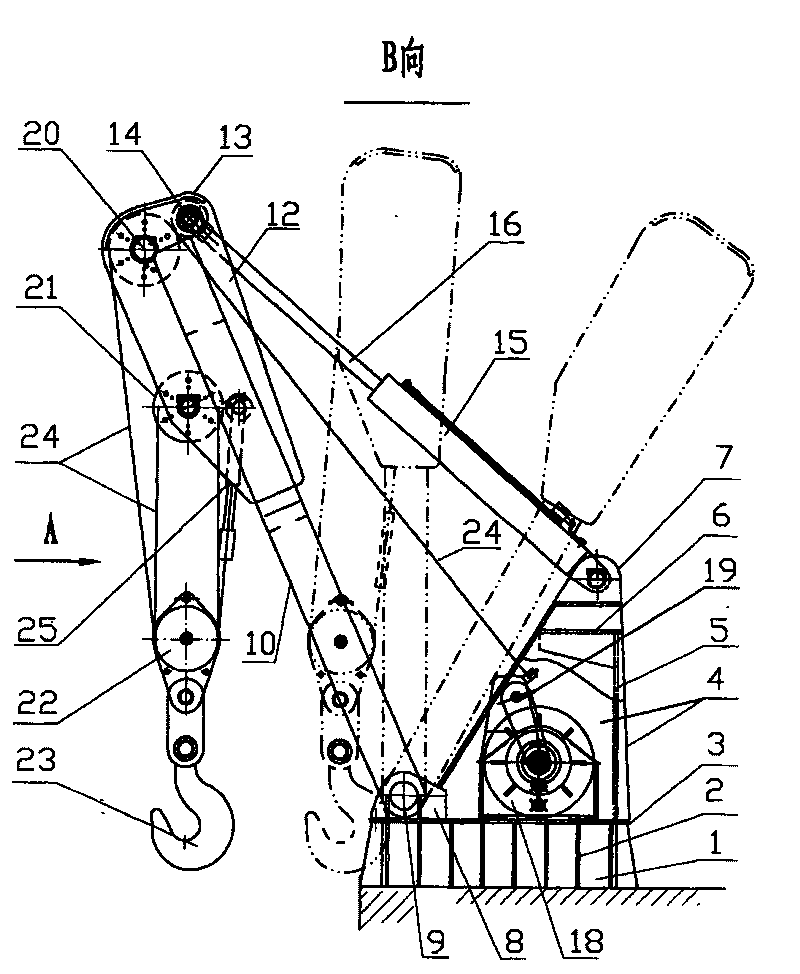

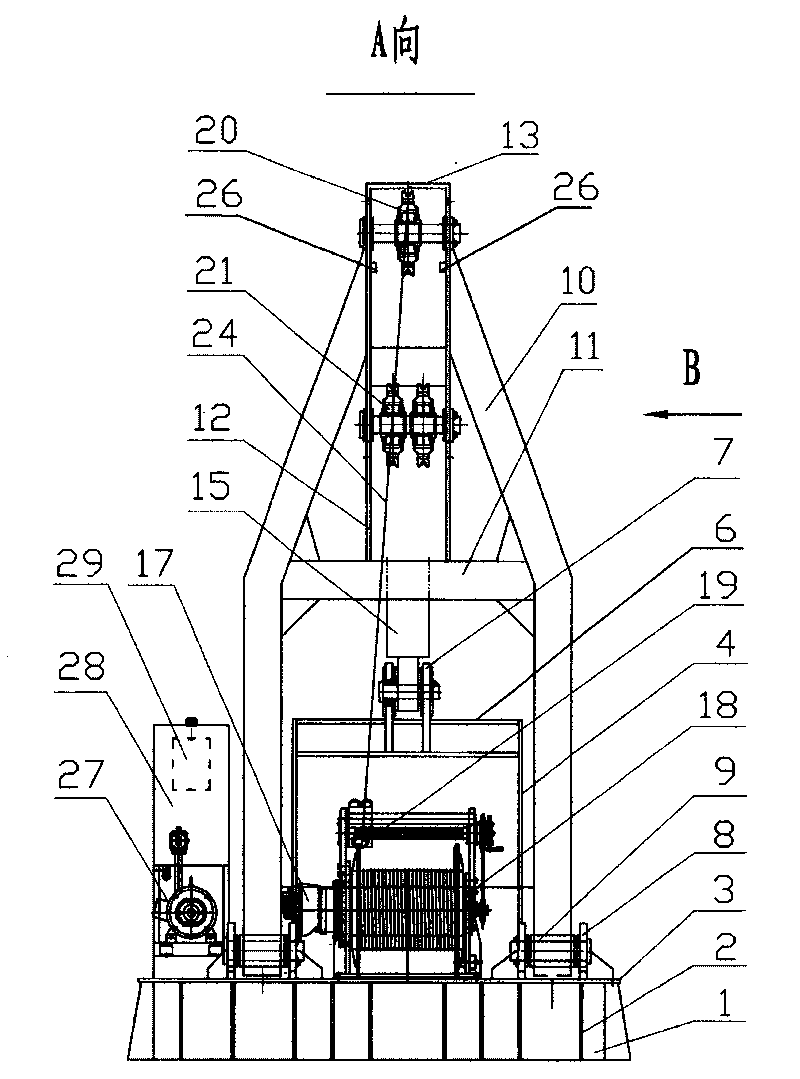

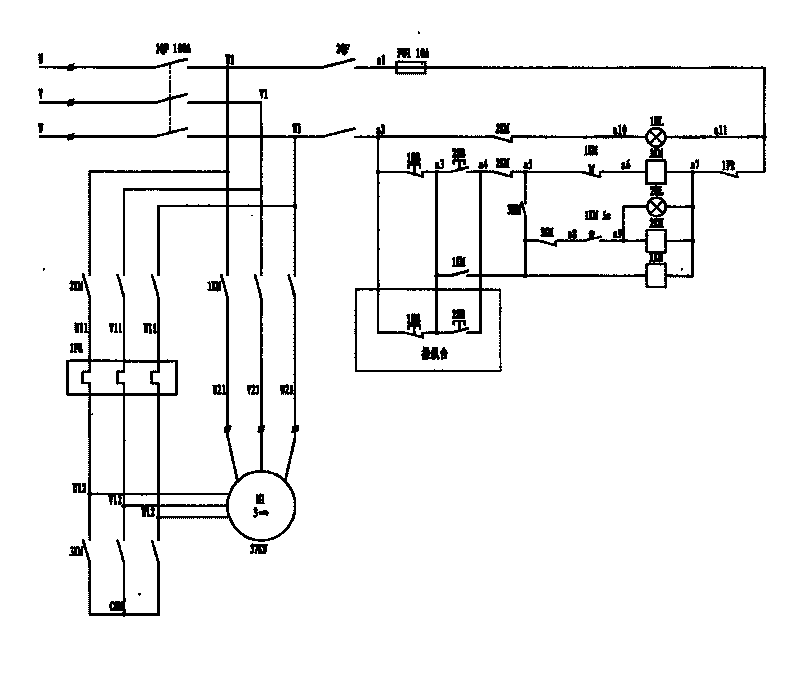

Gunwale hoisting device for pipe-laying ship

InactiveCN101691133ALow powerLarge lifting capacityCargo handling apparatusDavitsFuel tankEngineering

The invention provides a gunwale hoisting device for a pipe-laying ship, belonging to the field of davits of ships. The device mainly comprises a base, a winch bed and a boom. The winch bed is welded on the middle rear part of the base and the boom is installed in front of the base. A swing arm mechanism comprises hydraulic cylinders, a lower hinged support and an upper hinged shaft. The lower hinged support is welded at the top of the winch bed. The hydraulic cylinders are installed on the lower hinged support and the upper hinged shaft. The upper hinged shaft is installed at the top of the boom. A hoisting mechanism comprises a hydraulic winch, a rope-arranging pulley, two fixed pulleys, three movable pulleys, a hook, wire ropes, a weight sensor and length measurement sensors. The hydraulic winch is installed in the winch bed. Each fixed pulley is installed on a dual anchorage plate of the boom. A hydraulic oil tank, a motor and an oil pump are installed on the right of the base. An electric control box is installed above the oil tank. A control circuit is installed in the electric control box. The device mainly has the following advantages: the boom is short and wide, the dead-weight is lighter, the hoisting weight is great, the motor power is smaller and the electricity is saved, the manufacturing cost is 1 / 10 of the import price and the device can complete offshore pipeline aligning and shifting, vertical pipe and hoist boat manufacturing, etc.

Owner:KEWEI INTELLIGENT WELDING INSPECTION DEV DONGYING CITY

Plugging system for use during an offshore pipeline laying operation

ActiveUS20070227604A1Prevent inflowPrevent penetrationPipe laying and repairPipe elementsEngineeringElectrical resistivity and conductivity

A plug for use during a pipeline laying operation for sealing off sections of the pipeline in case of water ingress. A sealing and gripping assembly is formed of slip segments around a partially conical shaped surface, the slip segments being moved by a piston / cylinder arrangement. A valve connected to a pressure vessel actuates the piston / cylinder in response to the detection of conductivity of fluid around the plug.

Owner:TDW OFF SHORE SERVICE CO LTD

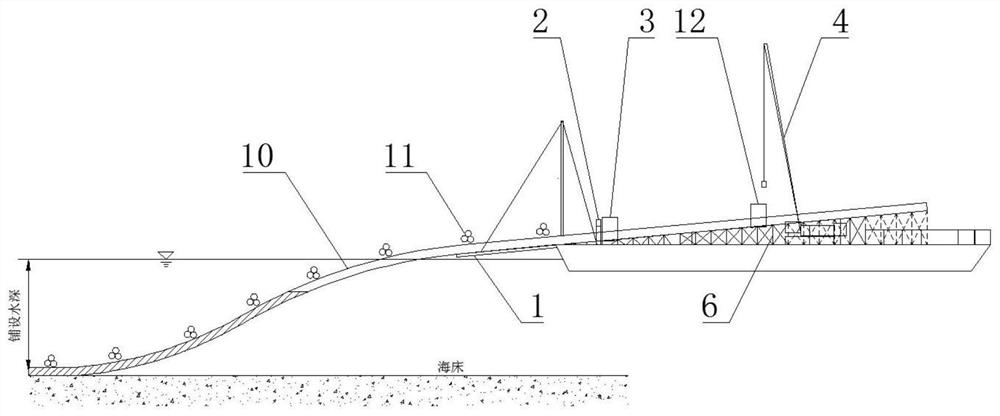

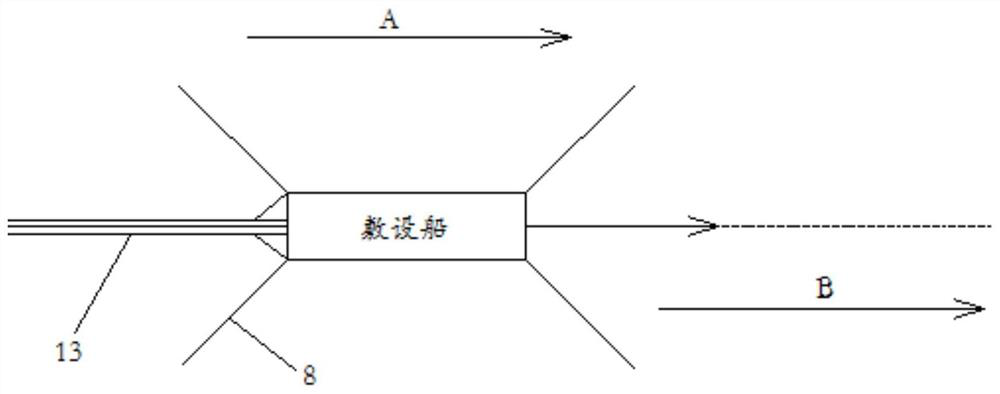

Novel sea area pipeline laying floating assisting method

The invention discloses a novel sea area pipeline laying floating assisting method, and relates to an offshore pipeline laying engineering technology. A pipeline laying ship is accurately positioned to ensure that a pipeline can be laid along a preset pipeline laying axis, seawater is poured into the pipeline, the dead weight of the pipeline is increased, the pipeline automatically slides down to the sea from a stinger, a certain friction force is provided for the pipeline through a clamping device, buckling and wrinkling caused by too high gliding speed of the pipeline are avoided, floating-assisting bodies composed of foam floating bodies are evenly installed on the pipeline, buoyancy is provided when the pipeline sinks, the deformation curve of the pipeline under water is restrained, stress borne by the pipeline is reduced, the protection effect is achieved, a common pipeline laying project does not adopt floating-assisting facilities, and according to the method, economical and efficient floating-assisting facilities are added on the basis of a traditional laying method, so that the stability during pipeline laying is enhanced.

Owner:CCCC THIRD HARBOR ENG

Horizontal continuous measuring method for soil mass parameters of soft soil site

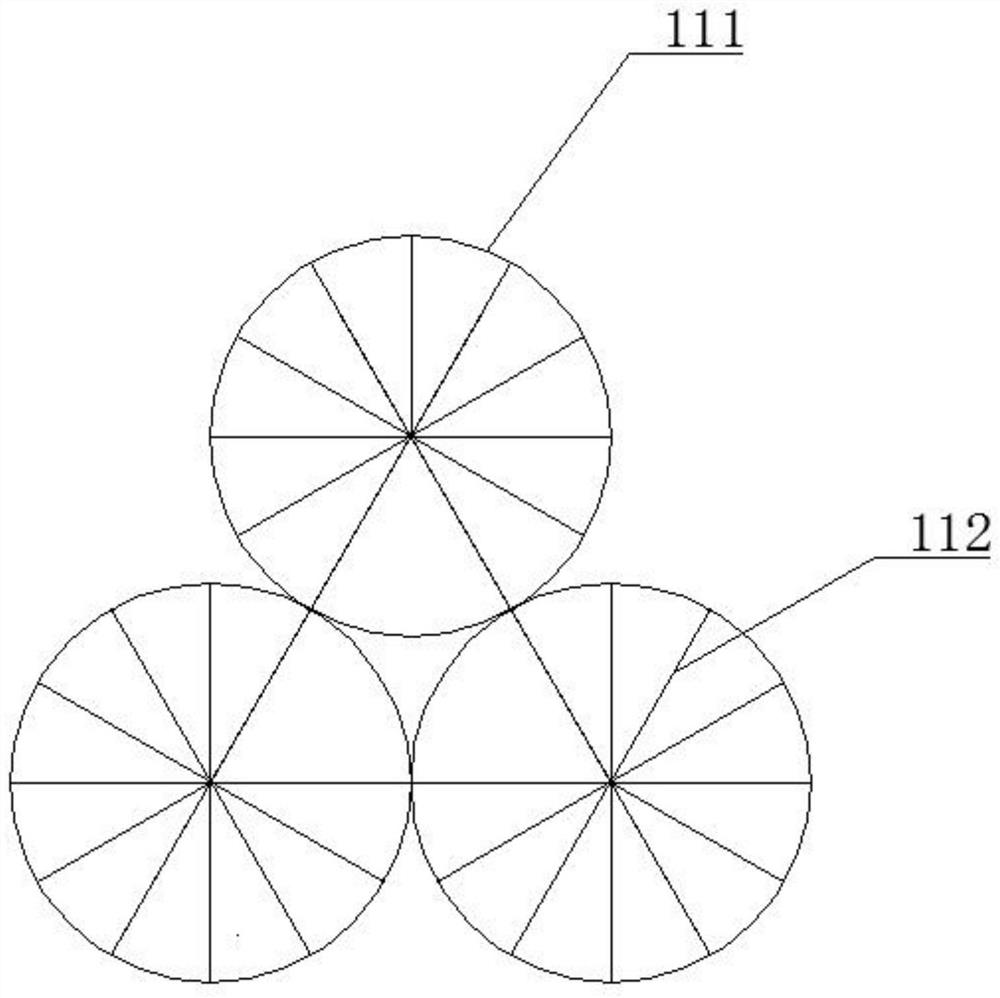

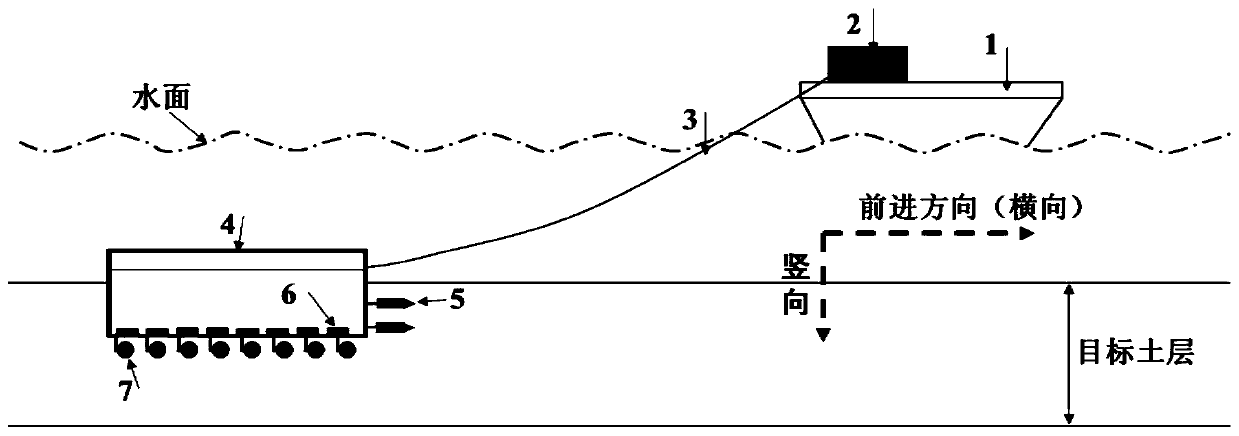

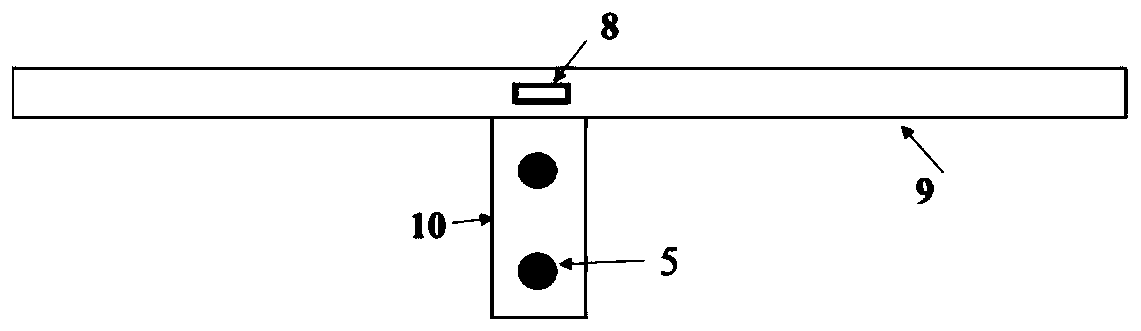

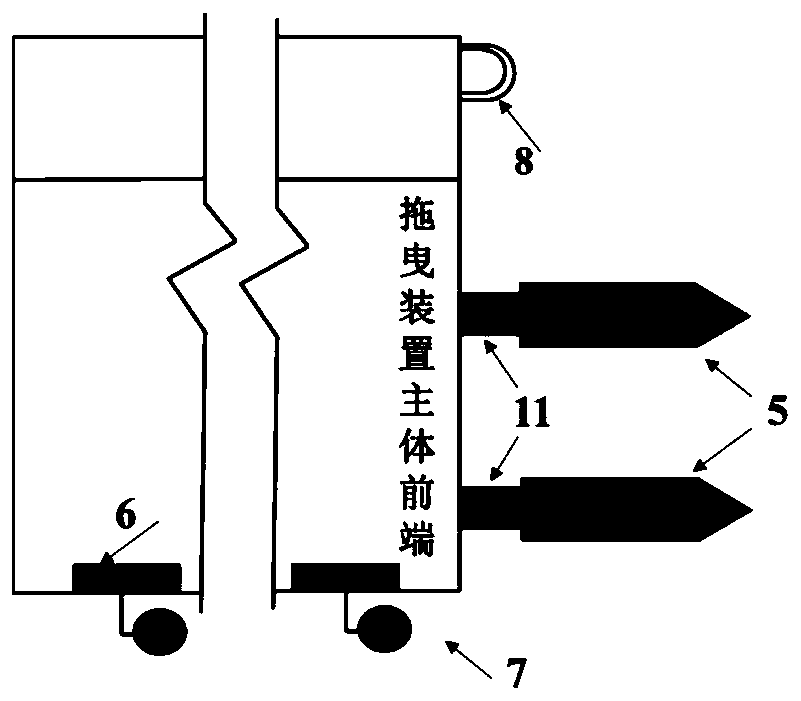

ActiveCN110409399ABreak through the limitation of not being able to obtain the strength parameters of transverse continuous soilImprove engineering safetyTowing/pushing equipmentPipe laying and repairOcean bottomMeasurement device

The invention belongs to the technical field of researches such as rock-soil, geology and environment, and provides a horizontal continuous measuring method for soil mass parameters of a soft soil site. The horizontal continuous measuring method for the soil mass parameters of the soft soil site comprises the following main measuring steps of arranging soil mass strength measuring devices at the front end of a towing device, arranging soil mass strain softening relationship measuring devices at the bottom end of the towing device, and measuring interface friction parameters between a soil massand a structure, wherein the towing device actively or passively walks in a soft soil layer, a part of the towing device in walking is ensured to penetrate into a soil layer to be measured, and the penetration depth of the towing device is controlled through adjusting balance weight above the towing device and a towing angle of the towing device. The method provided by the invention breaks through the limitation that the horizontal continuous soil mass parameters cannot be acquired through a traditional single-point vertical measuring method, and can accomplish the horizontal long-distance continuous field measurement of the parameters such as the soil mass strength, the strain softening, and the interface friction effect between the soil mass and the structure through a one-time towing test; and the measured parameters can be used for guiding design and construction of projects such as breakwater projects, oil and gas offshore pipelines, cables and optical cables.

Owner:DALIAN UNIV OF TECH

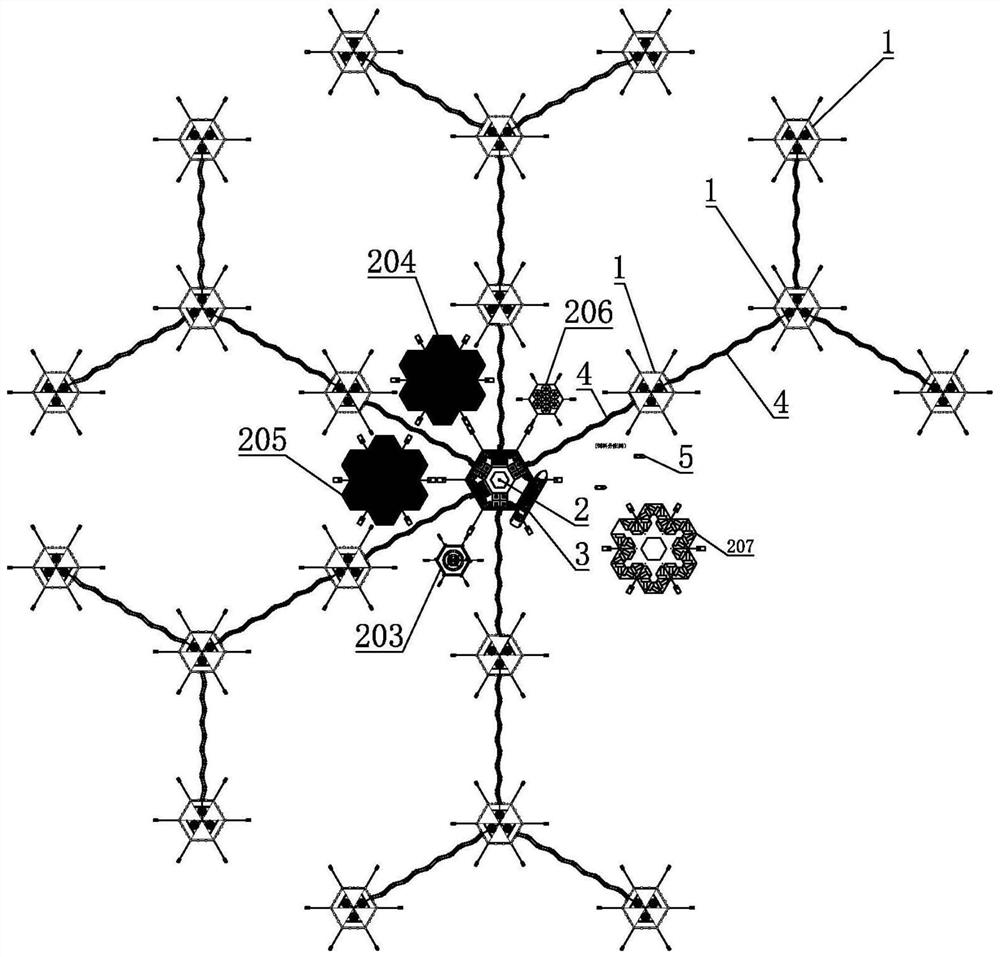

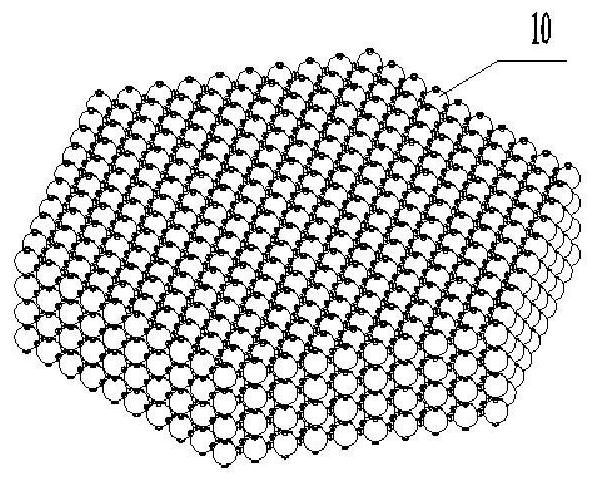

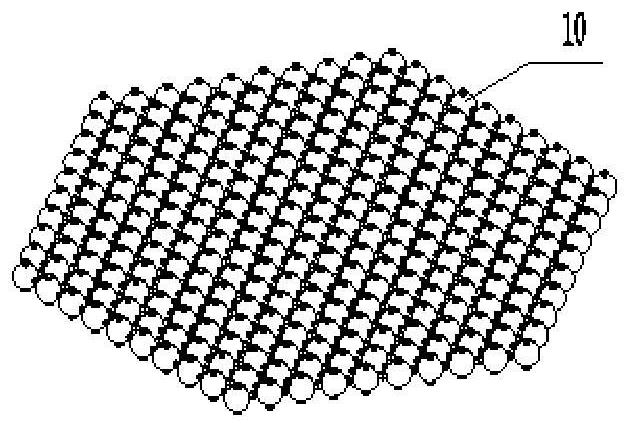

Intelligent new energy floating offshore pipeline truss connection type far reaching sea culture integrated body

ActiveCN111802296AGuaranteed powerQuick emptyClimate change adaptationPisciculture and aquariaMarine engineeringNew energy

The invention discloses an intelligent new energy floating offshore pipeline truss connection type far reaching sea culture integrated body. The intelligent new energy floating offshore pipeline trussconnection type far reaching sea culture integrated body comprises culture net cages, a floating central service platform, a transport ship and a floating offshore pipeline truss; the several culturenet cages are arranged to surround the floating central service platform; a lower buoyancy structure of the floating central service platform is formed by modular stacking of a main buoyancy module;an upper platform structure provides a storage space for platform workload; the net cage framework of the culture net cage is a space truss structure; the difficulties of wind and wave resistance andbenefit offering are solved; the manufacturing and construction difficulty is low; the construction period is short; the transport ship travels between the continental rise and the floating central service platform to transport feeds, energy and equipment; the floating central service platform and the various culture net cages are connected through the floating offshore pipeline truss respectively; platform feeding equipment is arranged on the floating central service platform; and the platform feeding equipment is connected with net cage feeding equipment on the culture net cage needing to befed, so that the feed is fed into the a culture water body space.

Owner:深圳埃吉尔海洋科技有限公司

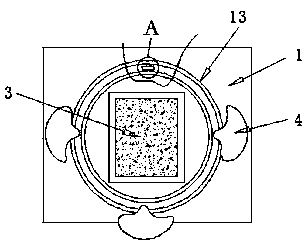

Energy-saving and environment-friendly floating body connection device for offshore pipelines

ActiveCN109229293AImprove compactnessClosely connectedVessel salvagingFloating buildingsSea wavesWater flow

The invention discloses an energy-saving and environment-friendly floating body connection device for offshore pipelines. The device comprises a float, four sliders and a floating body. A manual telescopic rod is fixed on the outer wall of the top of the float body through bolts, At that top end of the manual telescopic rod, a hinge is fix by bolts, At that same time, the hinge is articulate witha solar cell panel, the outer wall of one side of the float body is provided with an annular groove, the inner walls of both side of the annular groove are fixed with slide rails by bolts, the outer walls of the top and the outer walls of the bottom of the four sliding blocks are respectively welded with wind fan blades and rotary fan blades, and the wind fan blades and the rotary fan blades are arc-surface streamlined structures. As that incline groove of the L-shaped mechanism and the arc-shaped fan cooperate with each other, the frictional force between the rotary fan blade and the currentis increased, and the loss of wave energy is reduced. The invention makes the floating body free from the phenomenon of water inflow when the floating body is impacted by the huge sea waves, and doesnot cause the air pressure in the connecting box to change, thus causing the floating body connection to be broken.

Owner:杭州煜贤网络科技有限公司

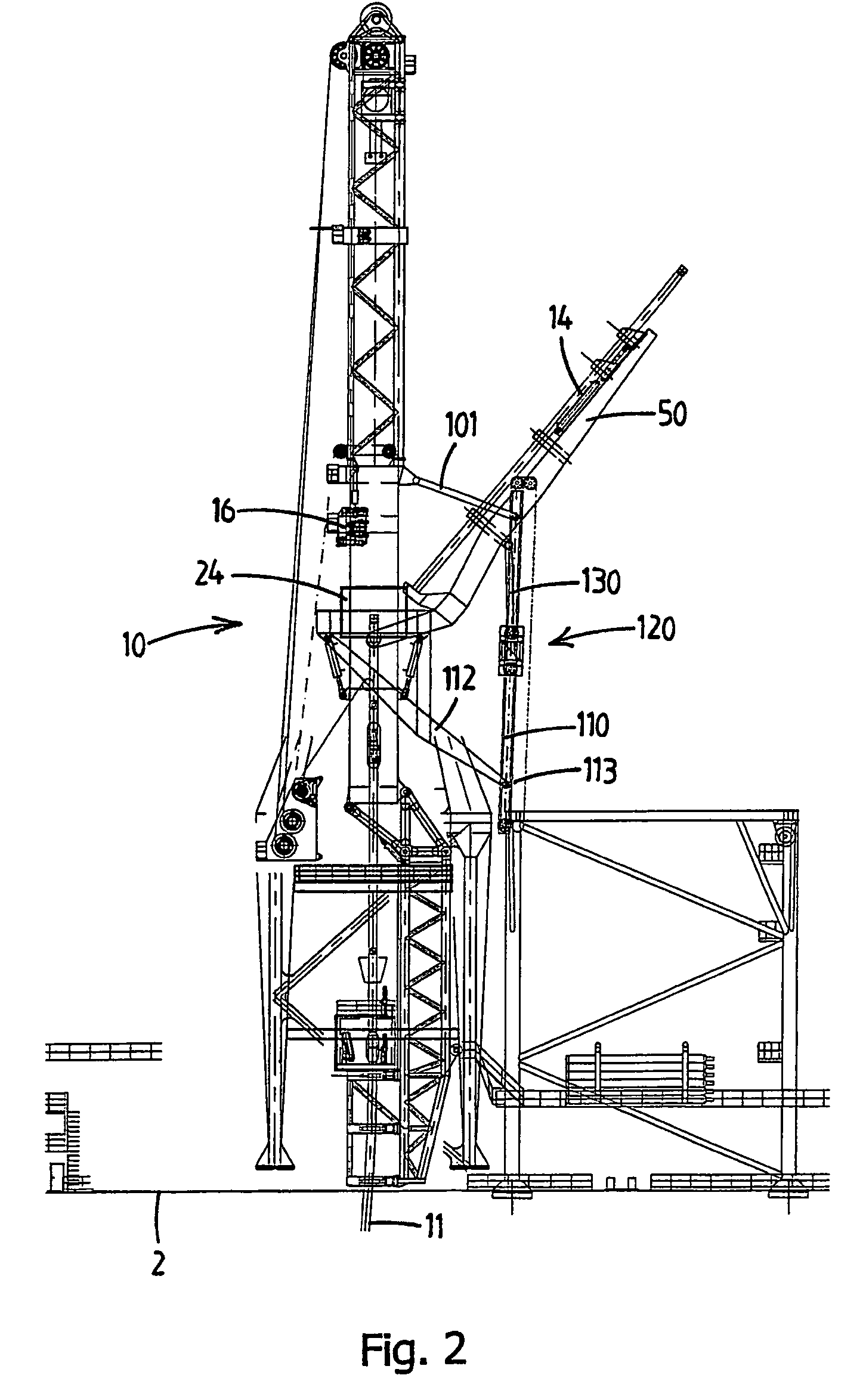

Marine J-lay pipelaying system

ActiveUS7850397B2Efficient processEfficient and reliable loadingPipe laying and repairDrilling rodsMarine engineeringTower

A marine J-lay pipelaying system for use on a vessel for laying an offshore pipeline has a J-lay tower, a pipe connecting station, wherein said pipe section is connected to the previously launched pipeline, and J-lay tower bearing means which allow for the pivoting of the J-lay tower with respect to the vessel.The J-lay tower has a free-pivotal mode wherein the J-lay tower is freely pivotable with respect to the vessel so that the J-lay tower has an orientation independent from sea-state induced vessel motions.A pipe section loader is moveable between a loading position, wherein a new pipe section is received, and a erected position, wherein the new pipe section is aligned with the J-lay tower;The pipe section loader is provided with an automatic synchronizing system which—when the pipe section loader is moved from its loading position to its erected position—causes a synchronised pivotal motion of the pipe section loader with respect to the J-lay tower in its free-pivotal mode—at the latest as the pipe section loader reaches its erected position—, so that the new pipe section is aligned with the J-lay tower is in its free-pivotal mode.

Owner:ITREC BV

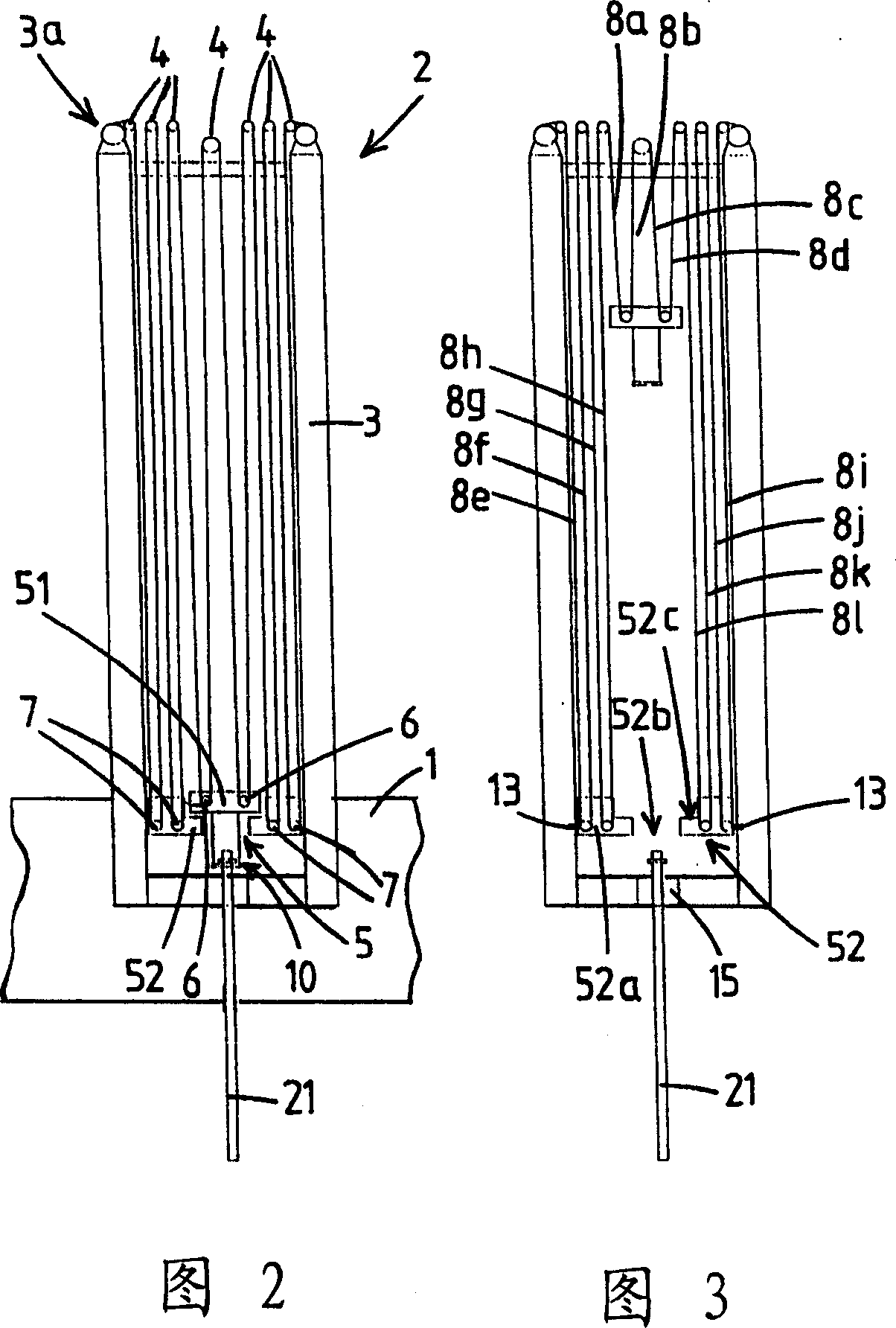

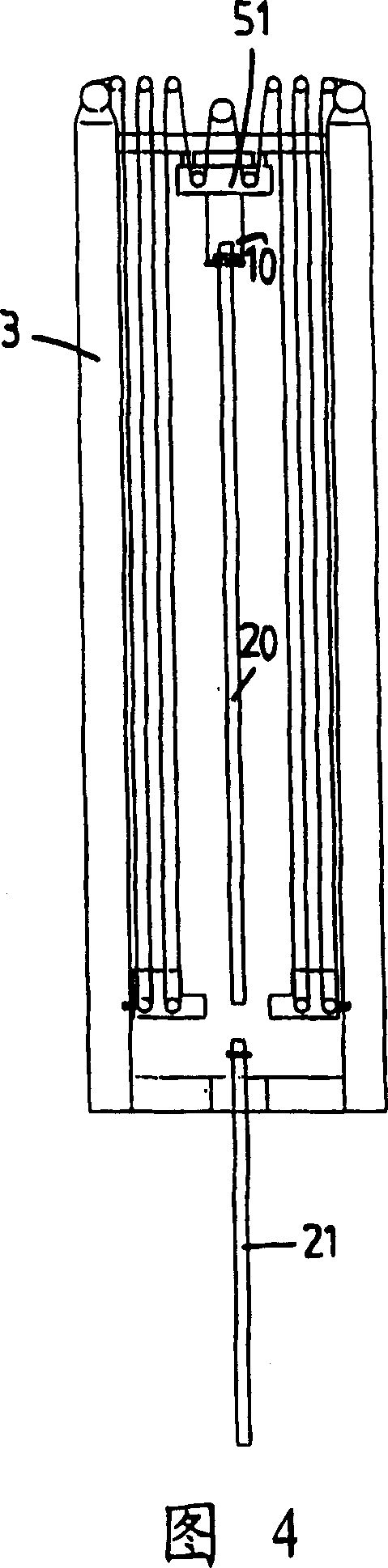

Marine pipe laying system method and hoisting device

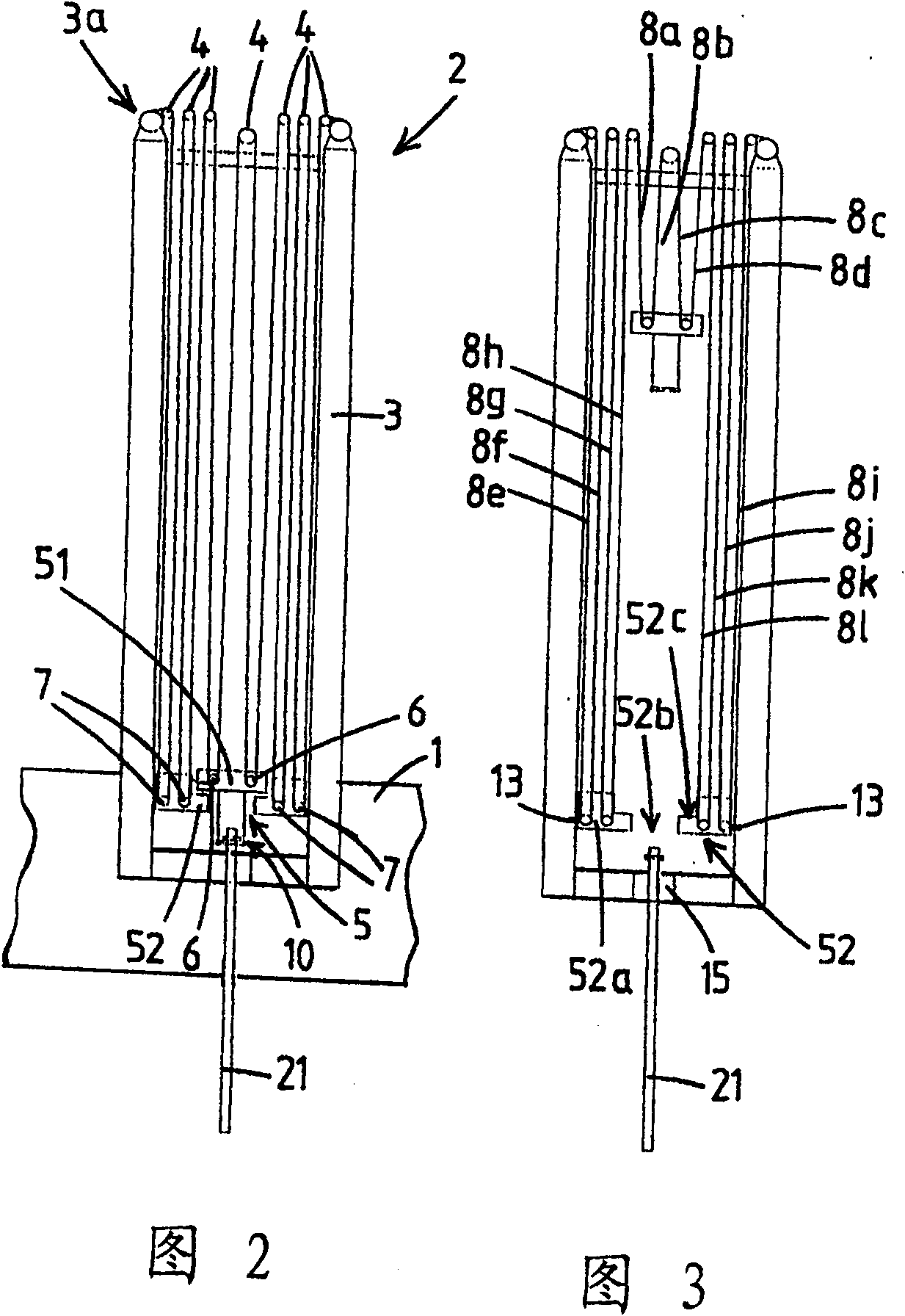

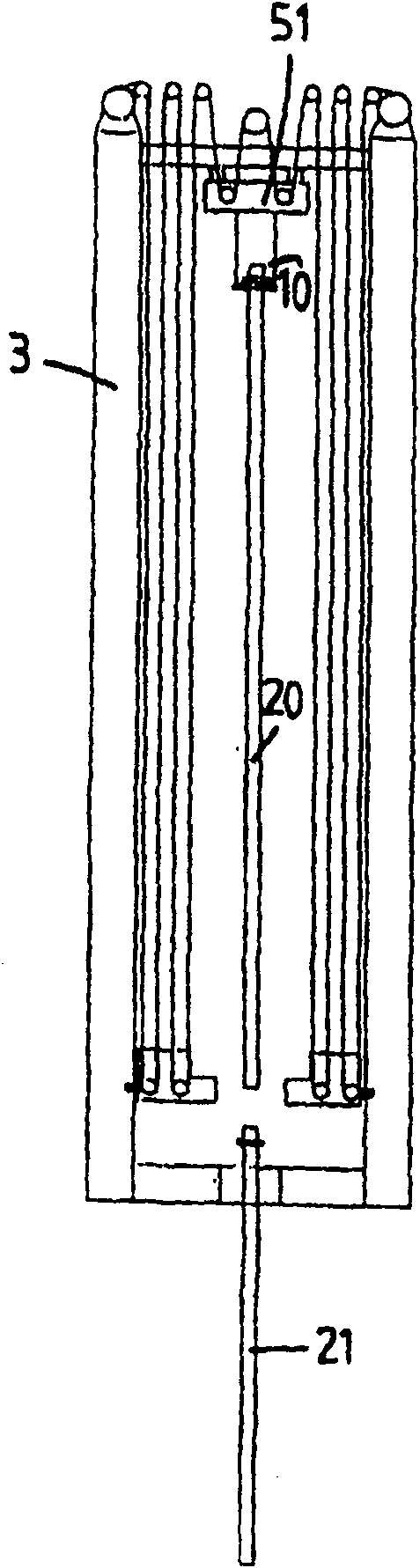

The invention relates to marine pipe laying. For laying of an offshore pipeline, a system is used having a hoisting device (2). The hoisting device (2) comprises a tower (3) with a tower top side (3a) provided with cable pulleys (4). Furthermore the hoisting device (2) has a traveling block (5) which is displaceably attached to the tower (3). The traveling block (5) comprises a first block (51) and a second block (52), both provided with cable pulleys (6,7). The first block (51) is provided with a clamp (10) for holding a pipe section (20) to be connected to the pipeline (21) as well as for lowering the pipeline (21) after the pipe section (20) is connected to the pipeline (21). The hoisting device (2) has a hoisting cable (8) and a winch (9), the hoisting cable (8) being guided over the cable pulleys (4,6,7) on both the tower top side and the traveling block (5). The traveling block (5) is moveable with respect to the tower (3) by operation of the hoisting winch (9). The first block (51) and the second block (52) are adapted to be releasably coupled, in which coupled state they can travel along the tower (3) as a unit and are able to support the weight of the pipeline (21). The second block (52) can be locked to the tower (3), such that the first block (51) can travel along the tower (3) while the second block (52) remains stationary with respect to the tower (3).

Owner:ITREC BV

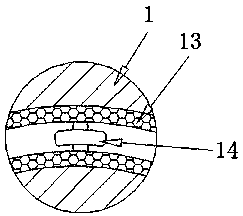

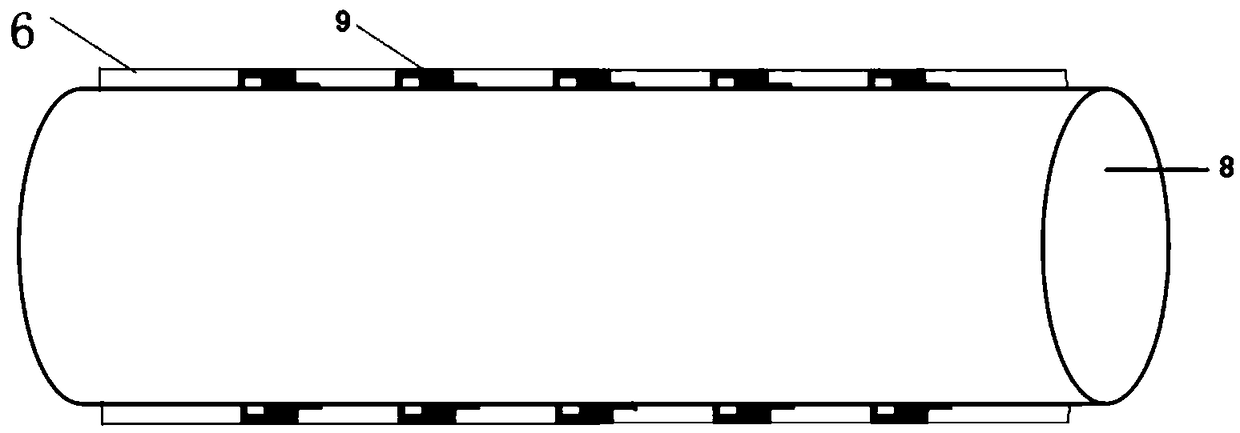

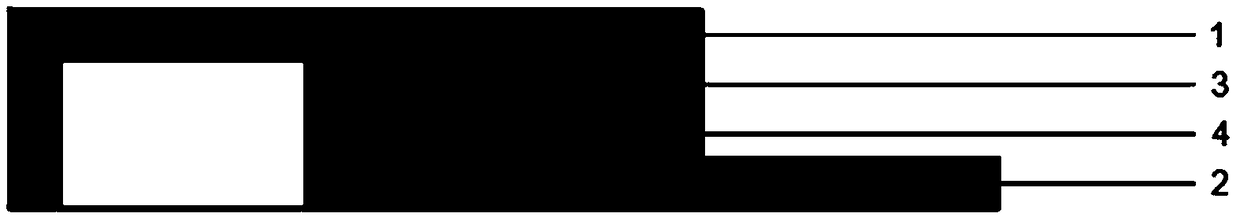

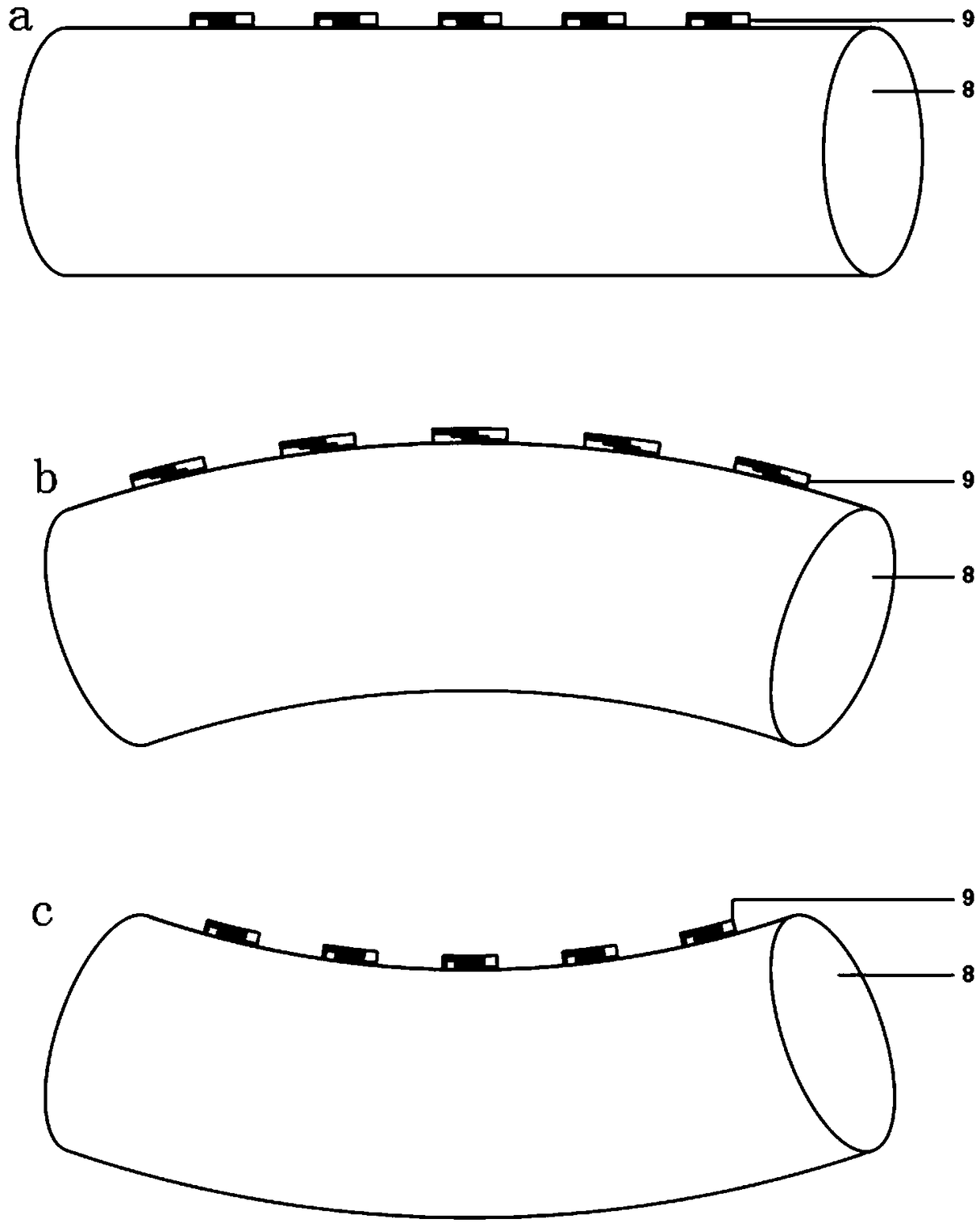

A friction electrostatic power generation device based on the vibration of an offshore riser

PendingCN109039142ATimely storageGuaranteed continuous power supplyFriction generatorsWireless transmissionMechanical energy

The embodiment of the invention discloses a friction electrostatic power generation device based on the vibration of an offshore riser, the device comprises a flexible insulating film coated and fixedon the surface of an offshore riser, a plurality of friction electrostatic generating units are encapsulated in the flexible insulating film, the flexible insulating film and the friction electrostatic generating units inside the flexible insulating film are co-deformed with the offshore riser, and the mechanical energy of the vibration deformation of the offshore riser under the excitation of the ocean current is converted into electric energy. The electric energy generated by the power generation device of the invention can completely provide enough electric energy for the monitoring systemof the offshore pipeline and the monitoring data transmission system, and can also be provided with an electric energy storage device, which can be stored in time when the electric energy is generated surplus, so as to ensure the continuous power supply of the system. The invention directly supports the wireless monitoring of the pipeline in the special environment such as the sea and the wireless transmission of the monitoring data from the technology, which is an important innovation of the underwater structure detection technology.

Owner:SHANTOU UNIV

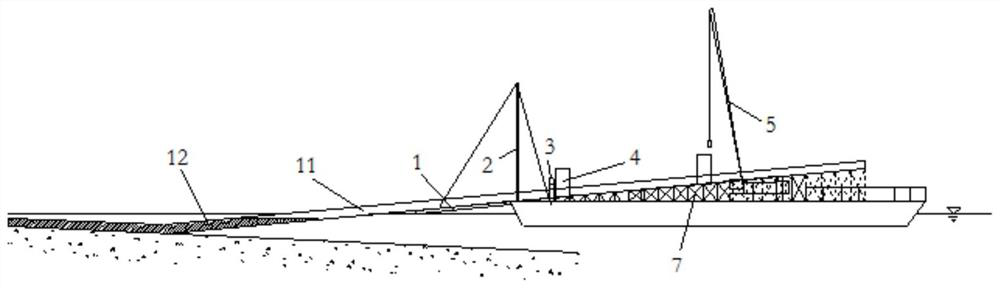

L-shaped shallow sea pipeline laying process

PendingCN112856039AControl slide speedImprove construction efficiencyPipe laying and repairPipe-laying vesselsShallow seaPipe

The invention discloses an L-shaped shallow sea pipeline laying process, and relates to the technical field of pipeline laying engineering. The L-shaped shallow sea pipeline laying process comprises the following steps of towing a pipeline laying ship to a pipeline laying axis position, carrying out anchoring by an anchoring ship, and adjusting the pipeline laying ship to the designed pipeline laying axis center position; hoisting two sections of steel pipes to a guide frame for pipeline laying, enabling the pipe sections to slide downwards to a pipeline welding platform along a track of the guide frame, and welding the two sections of steel pipes into a pipeline; enabling the pipeline to slide downwards to a stinger, and fixing the pipeline through a clamping device; hoisting a next pipe section to the guide frame, and completing welding of the pipe section and the pipeline on the welding platform; loosening the pipe clamping device, and enabling the first two sections of pipelines to enter water by adopting a water injection method; enabling the pipeline laying ship to move backwards and retreat, and enabling the pipeline to slide down to the seabed along the stinger; and repeating the procedures of fixing, hoisting, welding and lowering until all pipelines are laid. According to the L-shaped shallow sea pipeline laying process, the construction efficiency of offshore pipeline laying can be improved, the influence of environmental factors on pipeline laying construction operation is reduced, the effect is good, and the positioning precision is higher.

Owner:CCCC THIRD HARBOR ENG

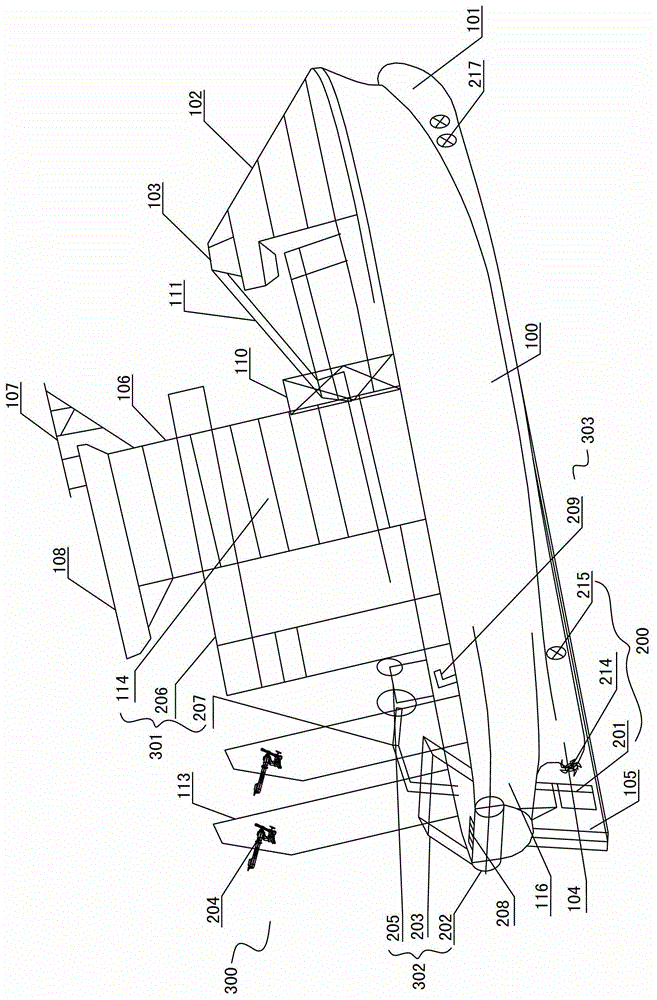

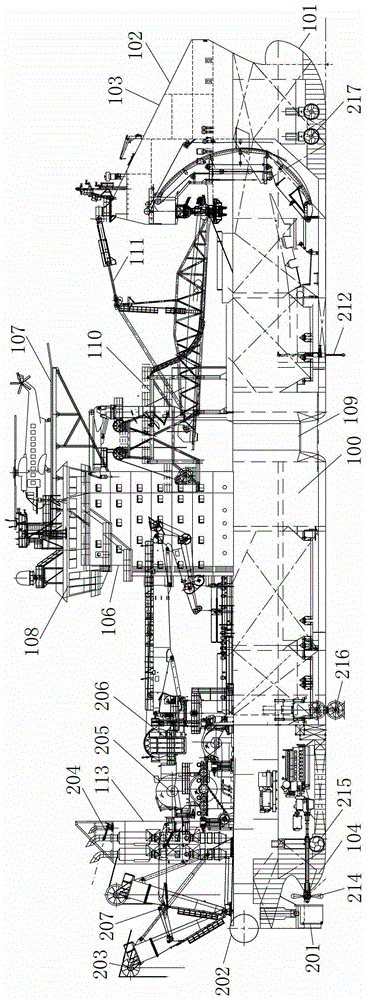

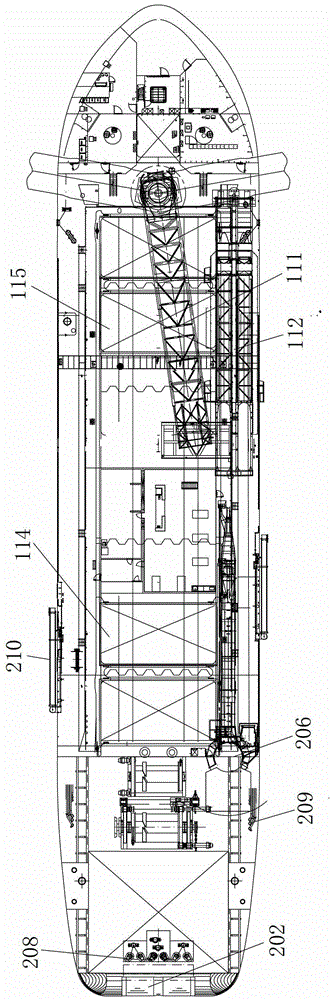

A multifunctional maintenance ship

ActiveCN104097750BImprove the function of marine workMeet the needs of integrated ocean development shipsWaterborne vesselsSpecial purpose vesselsOcean bottomStern

A multifunctional maintenance ship, including a main hull, a power drive system and a plurality of functional units arranged on the main hull, wherein the functional units include a living building, a cargo transport mechanism, a seabed anchor and salvage mechanism and Offshore platform supply mechanism, the bow of the main hull is a spherical nose structure, a conical wave breaking structure is arranged above the spherical nose structure, the stern is a drooping double-push streamlined structure, and the living building is arranged on the main hull On the middle deck, the seabed drag anchor and salvage mechanism are arranged on the stern deck of the main hull, and the offshore platform supply mechanism and the cargo transport mechanism are respectively arranged on the front or rear deck of the main hull superior. Adapted to the needs of the current marine engineering development, it meets the needs of bulk cargo transportation, subsea pipeline stone paving and other operations. offshore development costs.

Owner:深圳智能海洋工程创新中心有限公司 +3

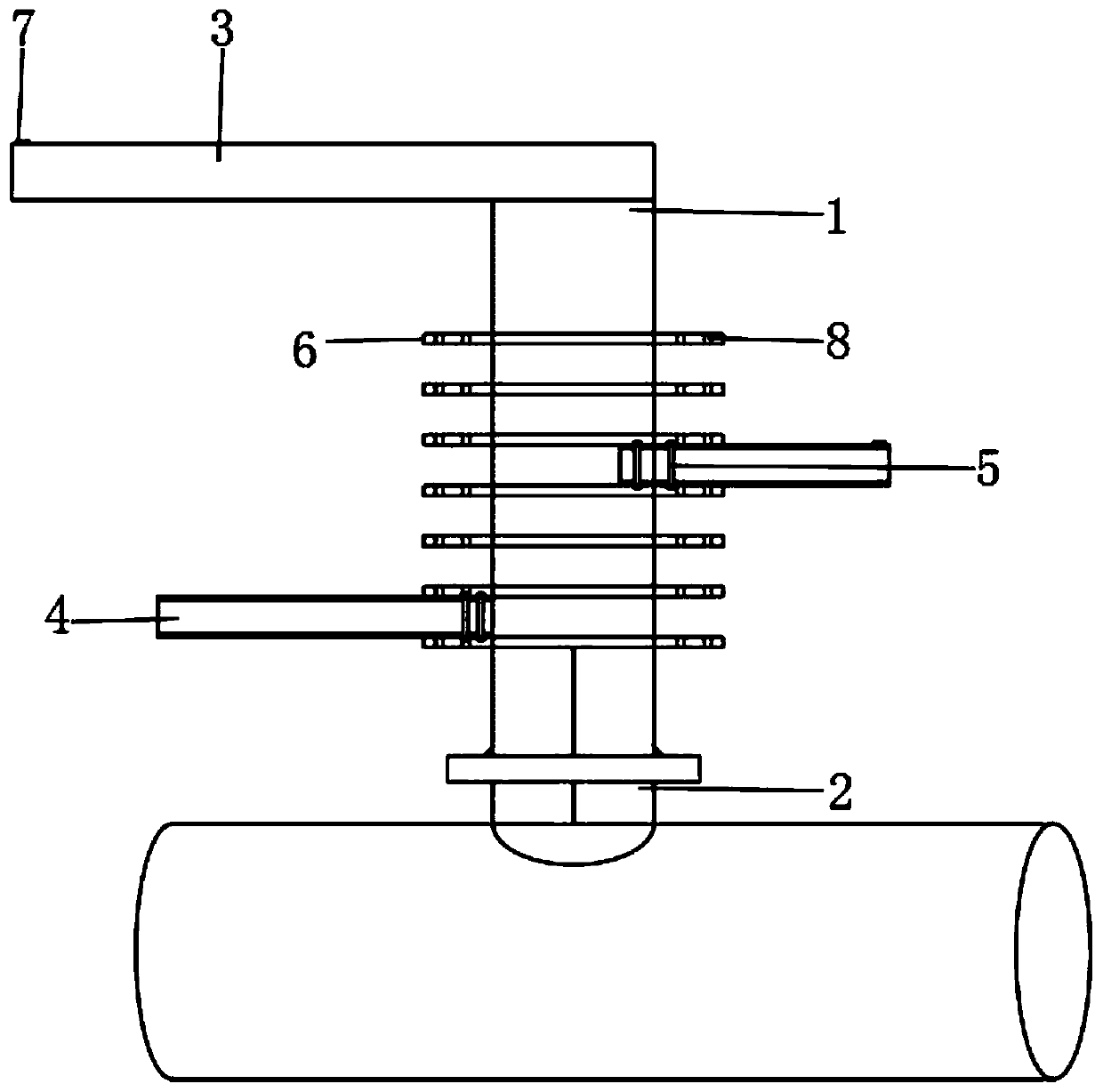

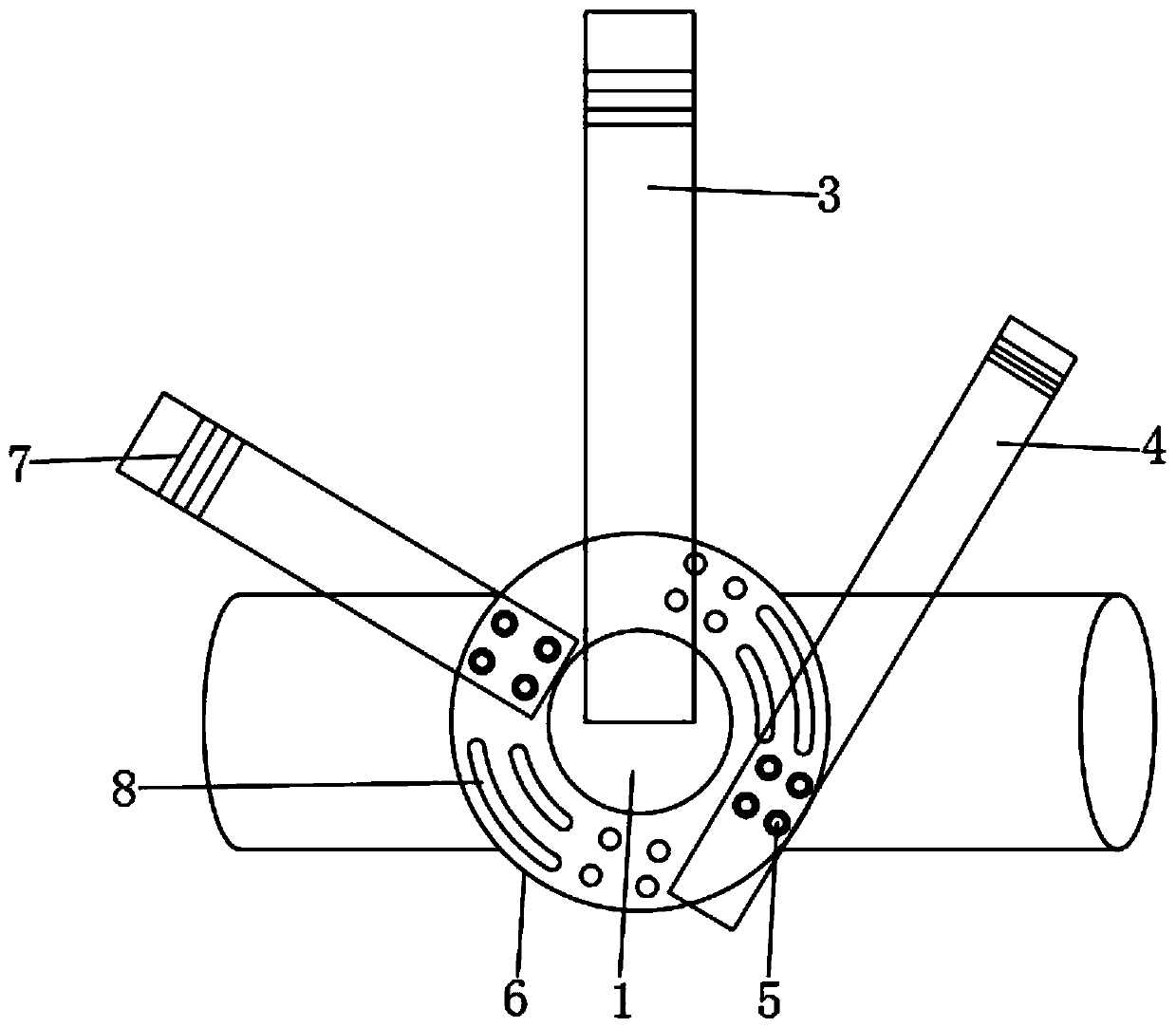

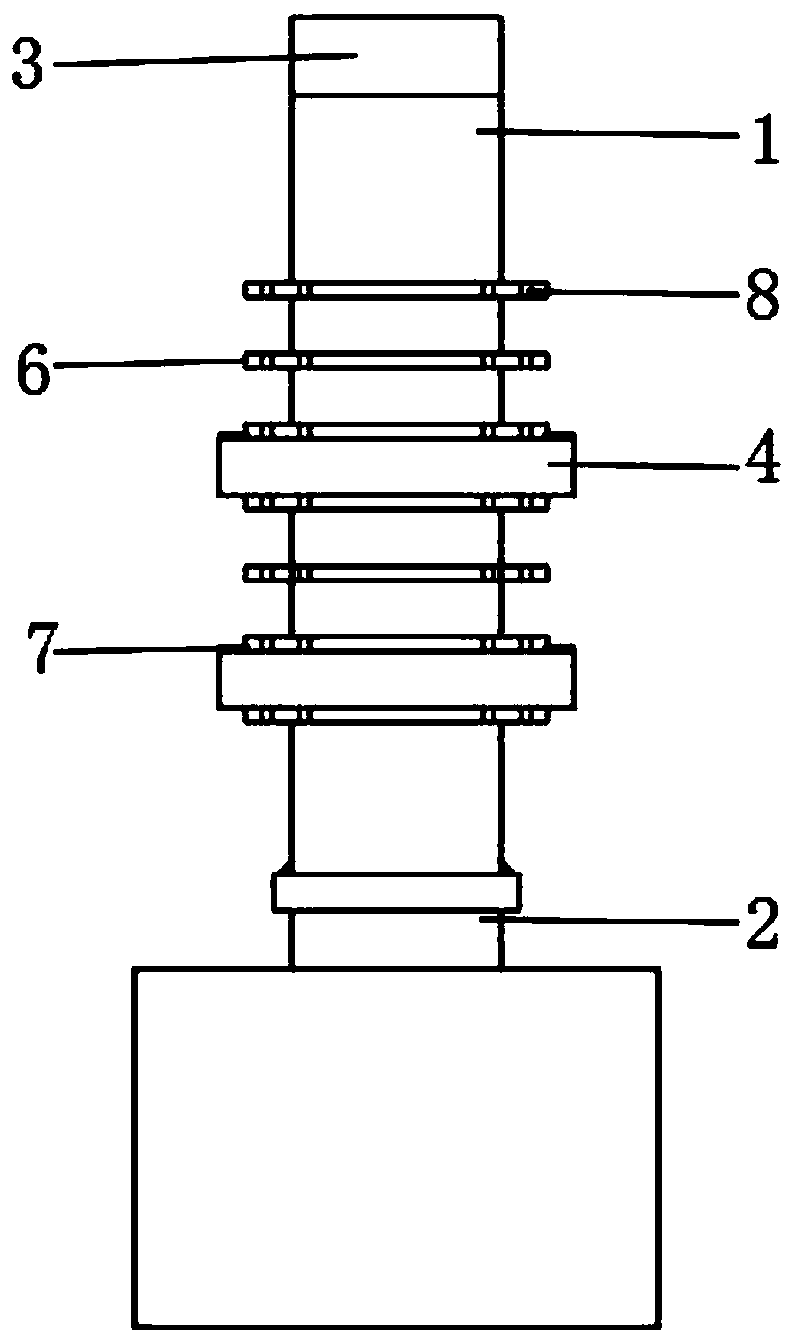

Auxiliary hoisting device for offshore pipeline construction

InactiveCN111336318ASolve installation difficultiesImprove the level of constructionPipe laying and repairLoad-engaging elementsMarine engineeringStructural engineering

The invention belongs to the technical field of auxiliary hoisting devices for construction, in particular to an auxiliary hoisting device for offshore pipeline construction. The auxiliary hoisting device for offshore pipeline construction comprises a hoisting column, wherein a column base is arranged at the bottom end of the hoisting column, a fixed lazy arm is arranged at the top end of the hoisting column, an adjustable lazy arm is arranged on the side wall of the hoisting column, a lazy arm fixing bolt is arranged in the adjustable lazy arm, a direction adjusting ring plate is arranged onthe outer surface wall of the hoisting column, and a rope positioning block is arranged at the top end of the fixed lazy arm. By matching the hoisting column, the column base, the fixed lazy arm, theadjustable lazy arm, the lazy arm fixing bolt, the direction adjusting ring plate, the rope positioning block and a fixed bolt hole, the device body is simple in structure, reasonable in design, convenient to operate and solid and durable, can be used circularly and not only improves the construction level of offshore trestle pipeline construction greatly, but also can solve the problem that it ishard to mount the offshore pipeline when there is no hoisting operation ship to support construction effectively.

Owner:OFFSHORE OIL ENG QINGDAO +1

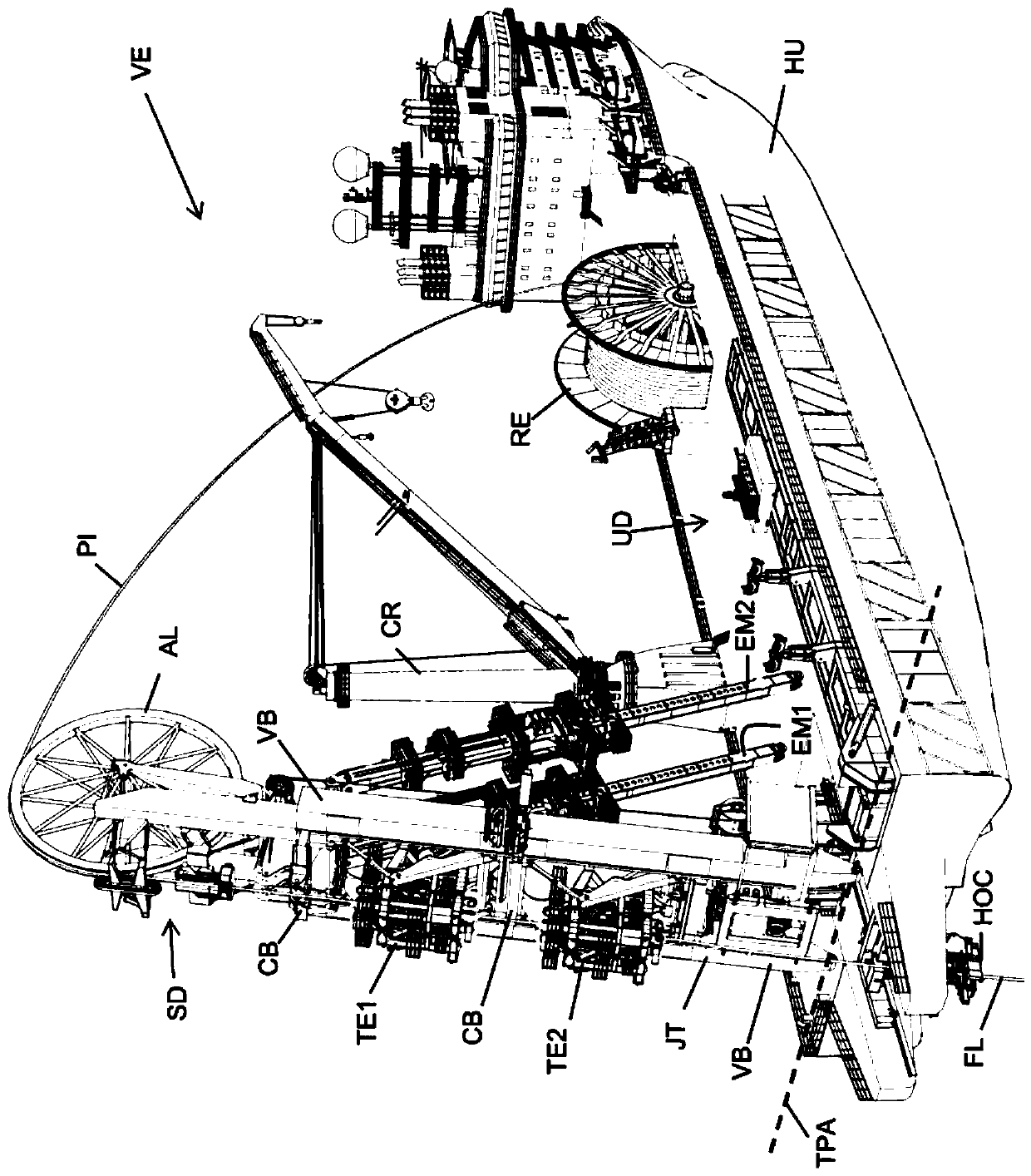

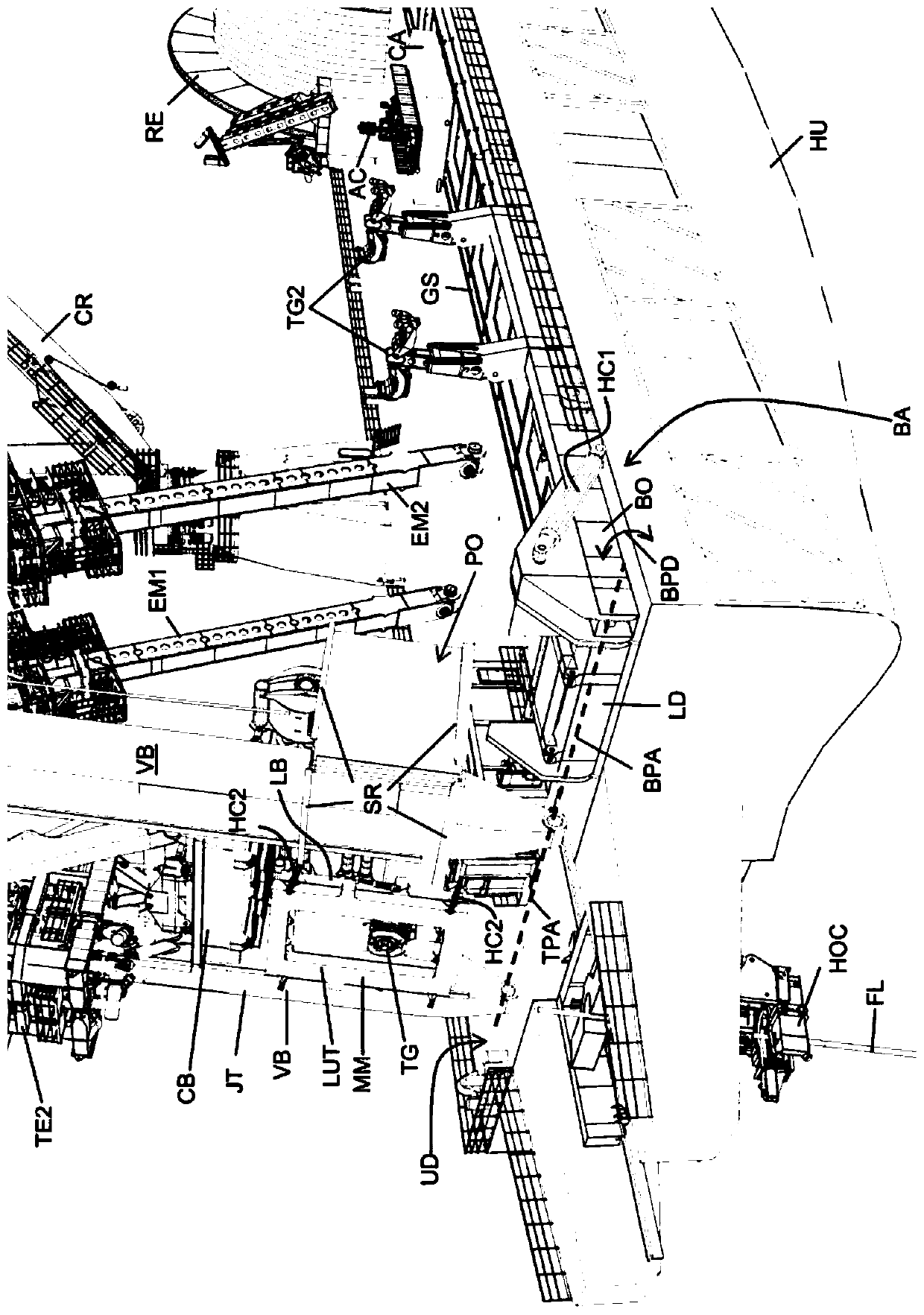

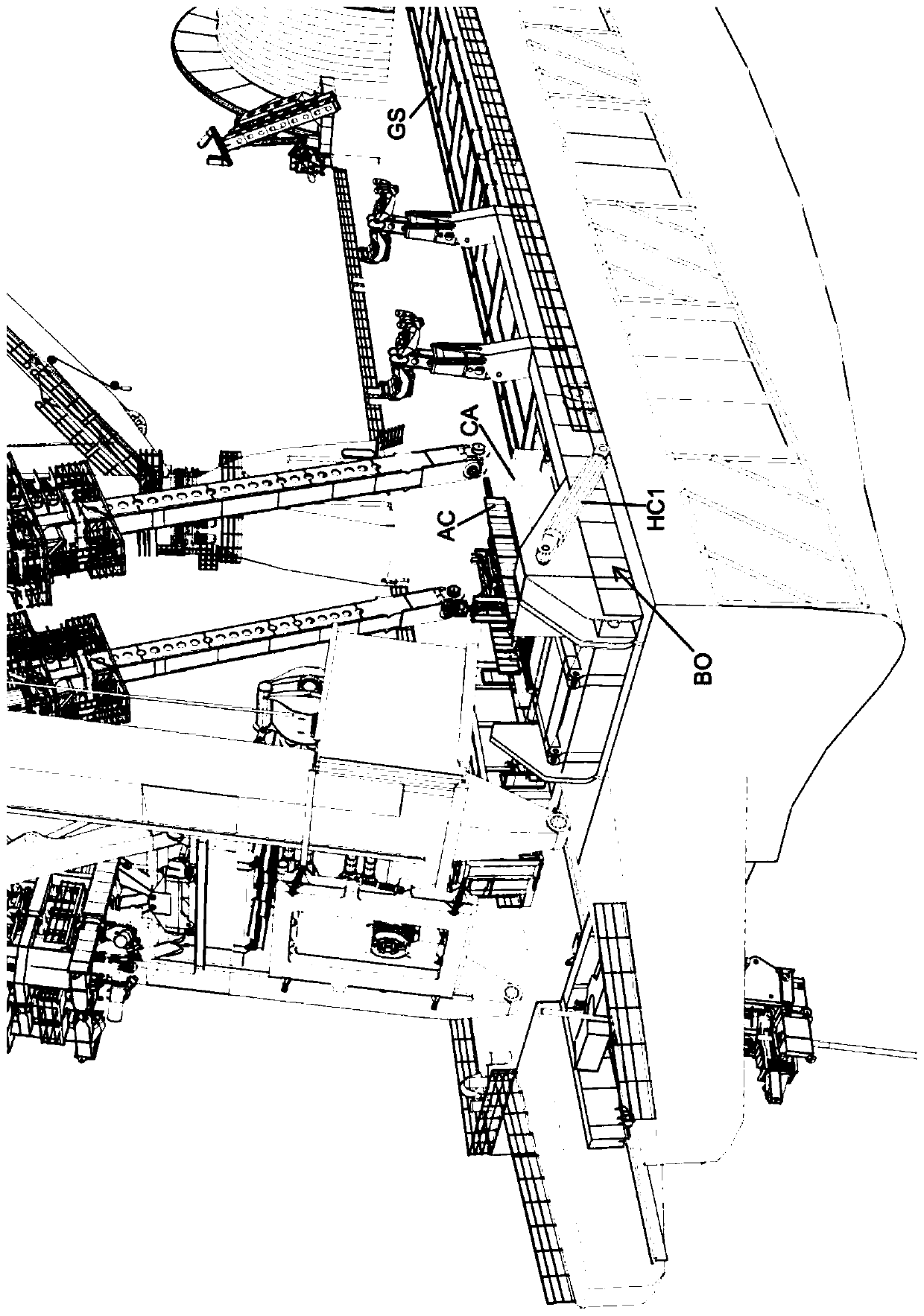

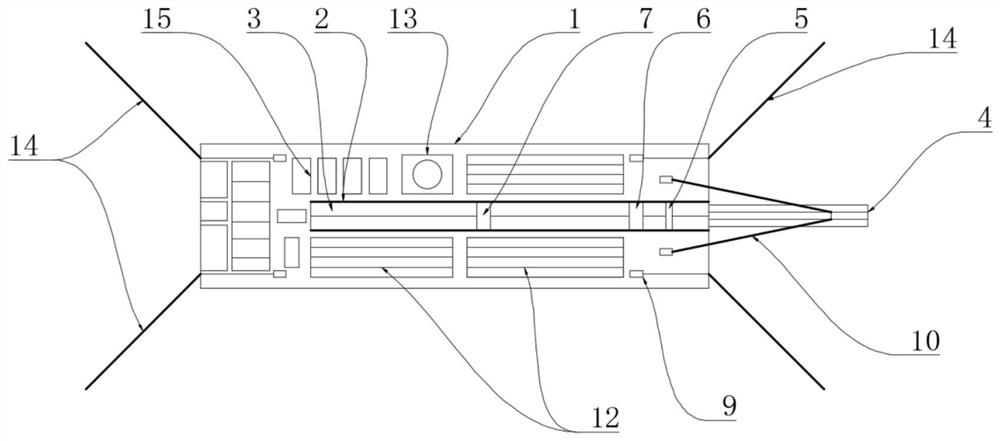

Pipe fitting installation system for j-pipe laying, offshore pipe laying system and method of handling pipe fittings or fittings

The present invention relates to a pipe installation system comprising: a) a J-lay tower structure (JT) for lowering and raising pipes or fittings along a work line (FL); b) a pipe supply system; c) fittings supply system; d) a loading system configured for transporting pipes and fittings between a horizontal pipe supply location and a production line, wherein said loading system comprises a loading device (LD), an alignment device (LUT), said loading The device comprises a base (BA) and a boom (BO) pivotable relative to the base between a lowered position and a raised position for clamping a horizontally located accessory supply position pipes and fittings on the loader, and the elevated position for subsequent transfer to the line; wherein the alignment unit (LUT) is configured to exchange pipes and fittings with the loading unit and to transport the pipes between the loading unit and the line .

Owner:ITREC BV

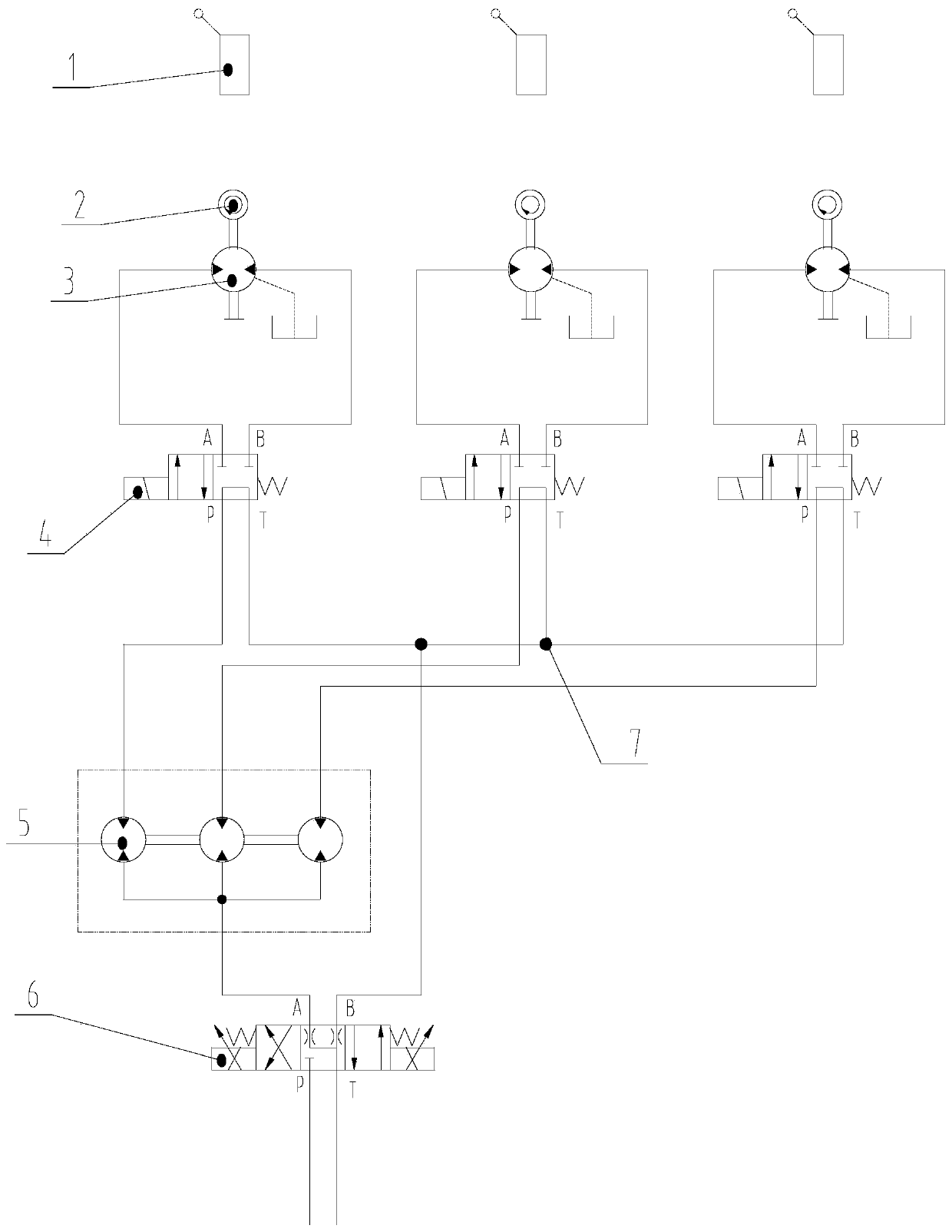

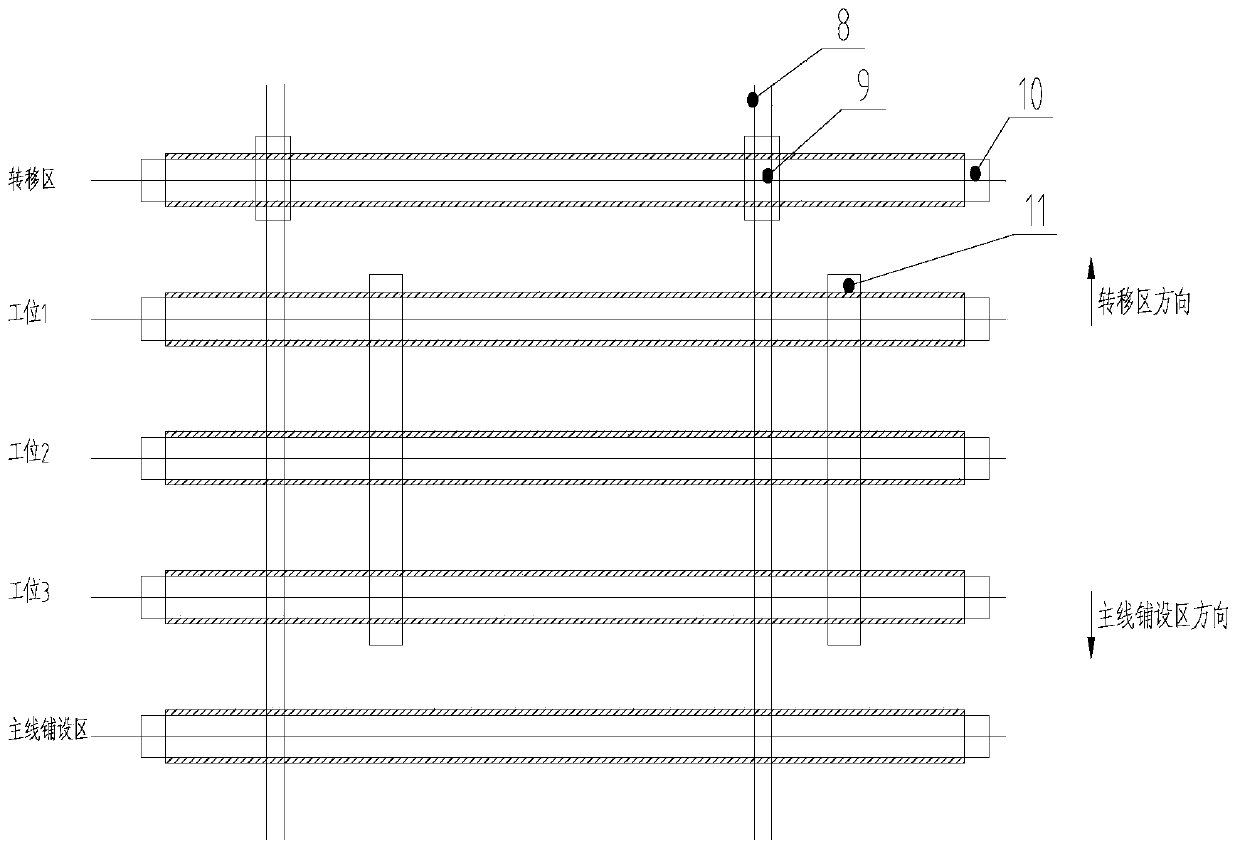

Control system and control method for synchronous positioning of subsea pipeline transverse moving trolley

PendingCN111459173AImprove reliabilityImprove work efficiencyPosition/course control in two dimensionsHydraulic motorControl system

The invention belongs to the field of offshore oil engineering, and particularly relates to a control system and a control method for synchronous positioning of a subsea pipeline transverse moving trolley, the control system for synchronous positioning of the subsea pipeline transverse moving trolley comprises an electrical control module, a hydraulic control module and a driving unit; the drivingunit comprises at least two hydraulic motors mounted on the transverse moving trolley; the hydraulic control module comprises an electric proportional reversing valve, an electromagnetic valve, a hydraulic flow divider, a matched hydraulic pipeline and a matched hydraulic accessory. And the electrical control module comprises a control unit, a master switch and a sensor group. According to the control system and the control method for synchronous positioning of the submarine pipeline transverse moving trolley, accumulated errors and manual deviation rectification adjustment caused by the accumulated errors are avoided, so that the reliability and the working efficiency of the whole transverse moving equipment are improved, and the operation difficulty of the equipment and the offshore pipeline laying operation cost are reduced.

Owner:天津市精研工程机械传动有限公司

Metallocene polypropylene modified material for corrosion-inhibiting coating of steel pipe and preparation method and application thereof

ActiveCN101519513BCoating processing range is wideImproved environmental stress cracking resistanceAnti-corrosive paintsUltraviolet lightsWorking temperature

The invention discloses a metallocene polypropylene modified material for a corrosion-inhibiting coating of a steel pipe and a preparation method and application thereof. A formula of the material comprises 65 to 95 weight percent of metallocene polypropylene, 3 to 30 weight percent of co-polypropylene, 0.01 to 4 weight percent of thermal oxygen stabilizer, 0.03 to 3 weight percent of ultravioletabsorbent and light stabilizer, 0.02 to 5 weight percent of functional additive, 0.01 to 3 weight percent of inorganic nanometer reinforced material, and 0 to 5 weight percent of black color batch, and the material is prepared by adopting a double screw extruder to carry out plasticizing blending technology for extrusion and pelletization. The metallocene polypropylene modified material has wide casting and coating processing range, has strong adaptability to bottom glue of hot melt adhesives, has outstanding ultraviolet light aging resistance and thermal-oxidative aging resistance, and has excellent shock resistance and surface scratch resistance as well as extremely high environmental stress cracking resistance. The material can be suitable for terrestrial pipelines at continuous working temperature high up to 110 DEG C, and is also suitable for offshore pipelines at certain special continuous working temperature high up to 140 DEG C at the same time.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

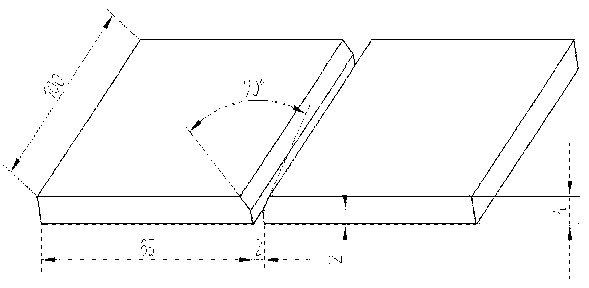

Welding method for dissimilar steel plate MIG welding

PendingCN112620895AImprove mechanical propertiesImprove corrosion resistanceArc welding apparatusWelding/soldering/cutting articlesMetallurgyShielding gas

The invention provides a dissimilar metal X80 pipeline steel and 2507 super duplex stainless steel CMT welding method applied to an offshore pipeline engineering platform. The method comprises the following preparation steps that S1, sections of to-be-welded parts of X80 pipeline steel and 2507 super duplex stainless steel are machined into Y-shaped grooves; S2, surfaces and the grooves of steel plates are polished to remove impurities such as oxide; S3, the steel plates ire fixed to a clamp with a heat dissipation channel, a distance between the plates is 2 mm, the two ends of the plates are fixed through spot welding, an ER2594 duplex stainless steel welding wire is adopted as a filling material, a diameter phi of the welding wire is 1.2, a current is 140 A to 150 A, a voltage is 10 V to 12 V, time is 1 s, mixed shielding gas with 2% of CO2 and 98% of Ar is introduced, and a gas flow is 12 L / min; S4, an MIG welding machine of a cold metal transition welding technology (CMT) is adopted for welding the plates, a welding speed is 45 mm / min, a current is 145 A, a voltage is about 12 V, and a protective gas flow is 12 L / min; S5, a welding table is cooled after welding is completed, and the next batch of samples are welded when the welding table is cooled to 160 DEG C or below; and S6, nondestructive flaw detection and weld joint two-phase proportion detection are conducted on a welded joint, and a welding process is completed after detection is qualified.

Owner:OCEAN UNIV OF CHINA

Offshore pipeline laying system and method for raising and lowering a subsea pipeline and one or more accessories it includes

The present invention relates to a marine pipeline laying system (1) and method for lowering and / or raising a subsea pipeline and one or more accessories (30) it comprises, said system (1) comprising: pipeline entry into the water Device (10), pipe clamps (6a, 6b), accessory connection device and controlled load lifting device (19). The accessory handling device (20) is configured to include an accessory transport track (21) and a cart (23) adapted to engage and support one of the one or more accessories such that the accessory The operating device (20) is adapted to engage said accessory in an engaged position, to position said accessory at a pipe connection location above a pipe clamp (6a, 6b) in a working line (11), wherein said accessory Can be connected to the pipe and support and allow movement of the accessory between an engaged position and a pipe connection position.

Owner:ITREC BV

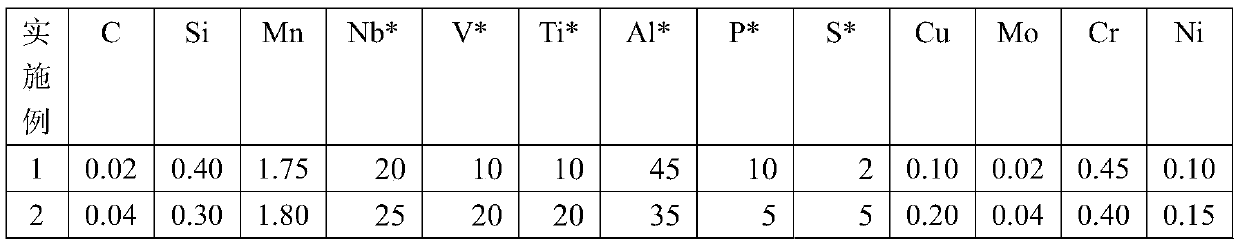

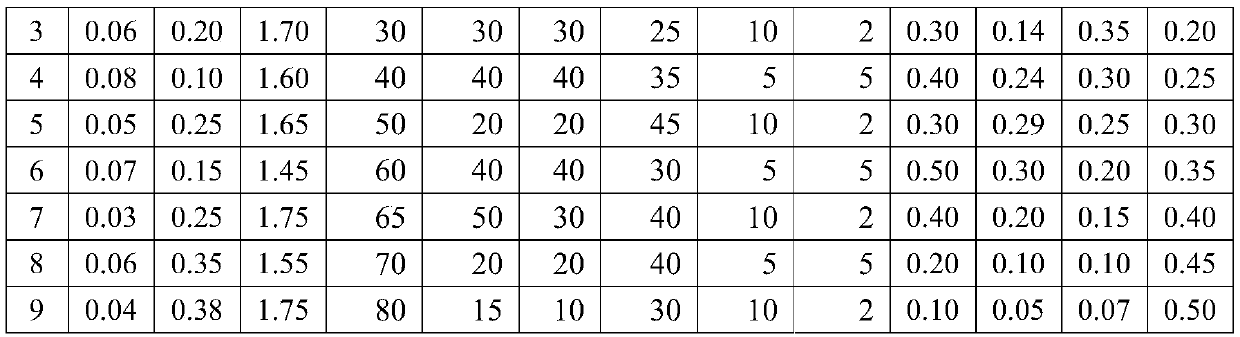

High strain hot rolled steel plate for L485M offshore pipeline pipe and manufacturing method thereof

The invention provides a high strain hot rolled steel plate for an L485M offshore pipeline pipe and a manufacturing method thereof. The steel plate is prepared from the following components in percentage by weight: 0.02 to 0.08 percent of C, 0.10 to 0.40 percent of Si, 1.40 to 1.80 percent of Mn, 0.02 to 0.08 percent of Nb, 0.01 to 0.05 percent of V, 0.01 to 0.04 percent of Ti, 0.025 to 0.045 percent of Al, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.50 percent of Cu, 0.02 to 0.30 percent of Mo, 0.06 to 0.45 percent of Cr, 0.10 to 0.50 percentof Ni, and the balance of Fe and unavoidable impurity elements. The manufacturing method comprises the steps of smelting molten steel, refining out of a furnace, casting, re-heating a plate blank, performing controlled rolling, performing controlled cooling, and performing air cooling to room temperature; the longitudinal mechanical properties of the steel plate produced by applying the manufacturing method are that the UEL (Uniform Elongation of Deformation) is greater than or equal to 10 percent, the yield strength Rt 0.5 is 400 to 550 MPa, the tensile strength Rm is 550 to 700 MPa, and theyield-to-strength ratio Rt0.5 / Rm of the steel plate is 0.70 to 0.80.

Owner:ANGANG STEEL CO LTD

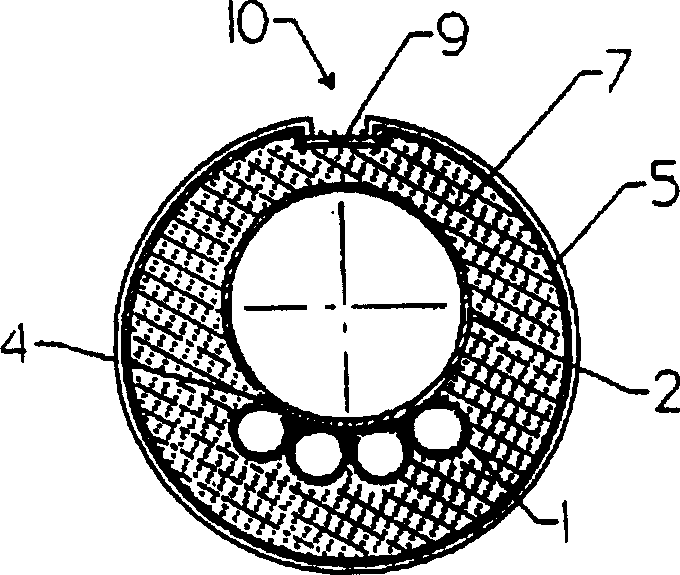

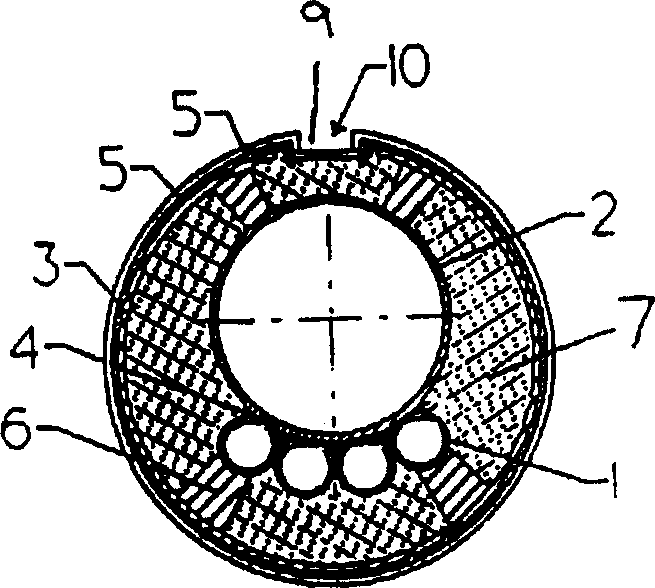

Heated offshore pipeline and method of manufacturing

InactiveCN1120918CEliminates the need for a delivery system that pulls into the casingFirmly connectedDrilling rodsThermal insulationOcean bottomMarine engineering

A submerged marine pipeline (201) is electrically insulated from sea water and is heated by alternating current that flows through the pipeline, where the AC power supply (212) is grounded to ambient sea water (206). The insulating material is cast between an assembled length of a pipeline or bundle of pipelines and molds that are continuous, or directly to one another along and around the assembled length, before it has been placed at its final destination.

Owner:格伦·R·萨姆纳

Ship special for pipeline laying in shoal area

InactiveCN112361080AImprove construction efficiencyThe overall structure is simple and reliablePipe laying and repairPipe-laying vesselsKeelEngineering

The invention discloses a ship special for pipeline laying in a shoal area, and relates to the technical field of offshore pipeline laying engineering. The ship comprises a ship body, wherein a pipeline laying tool is fixedly arranged on the ship body; the pipeline laying tool comprises a guide support, the guide support is provided with a guide sliding groove formed in the keel direction of the ship body, and the guide sliding groove is obliquely formed downwards from the rear end to the front end and extends downwards to the tail end of the ship body; a pipe supporting bracket extending outof the ship body is arranged in front of the guide bracket, and one end of the pipe supporting bracket is hinged with the ship body and butted with the guide sliding groove; a lowering mechanism usedfor lowering the pipe supporting bracket to enable the pipe supporting bracket to correspond to the inclination angle of the guide sliding groove is arranged on the ship body; a pipeline enclasping device is fixedly mounted between the guide bracket and the pipe supporting bracket, and the clamping center line of the pipeline enclasping device is parallel to the guide sliding groove; and a weldingstation is arranged on the guide bracket. According to the ship, construction technology is more efficient, the construction quality is better, stable and continuous pipeline laying operation can beachieved under the complex sea condition of the shallow water area, and the construction efficiency is improved.

Owner:CCCC THIRD HARBOR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com