End fitting handling in a marine pipeline installation system

A technology for submarine pipelines and pipelines, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems such as inability to operate the second end fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

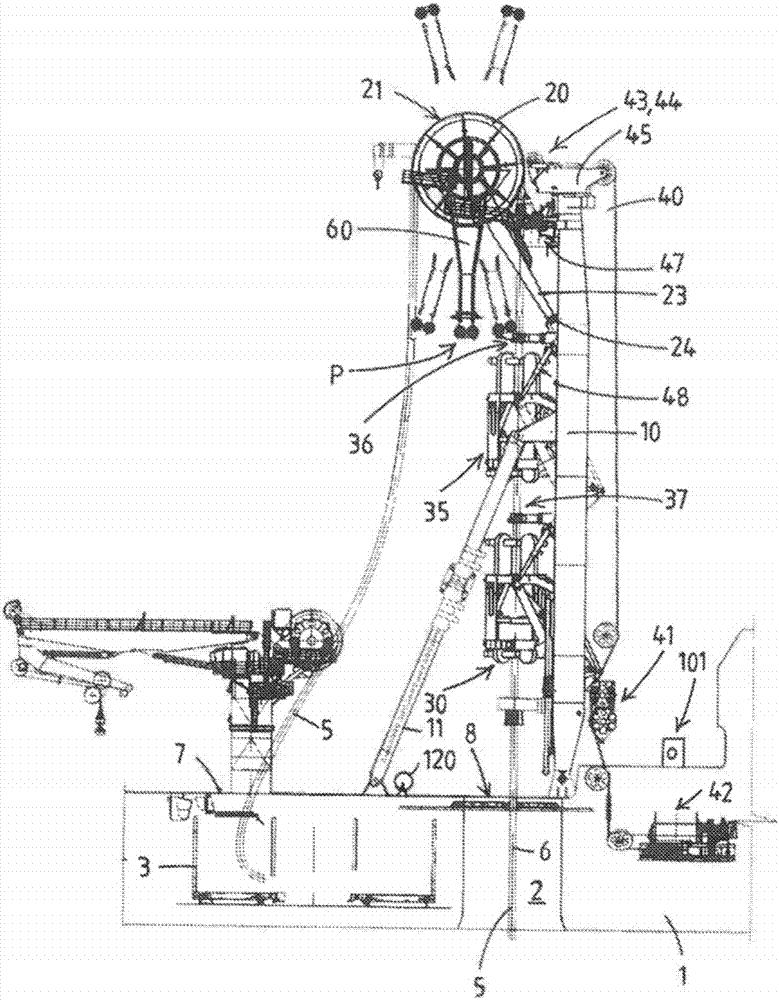

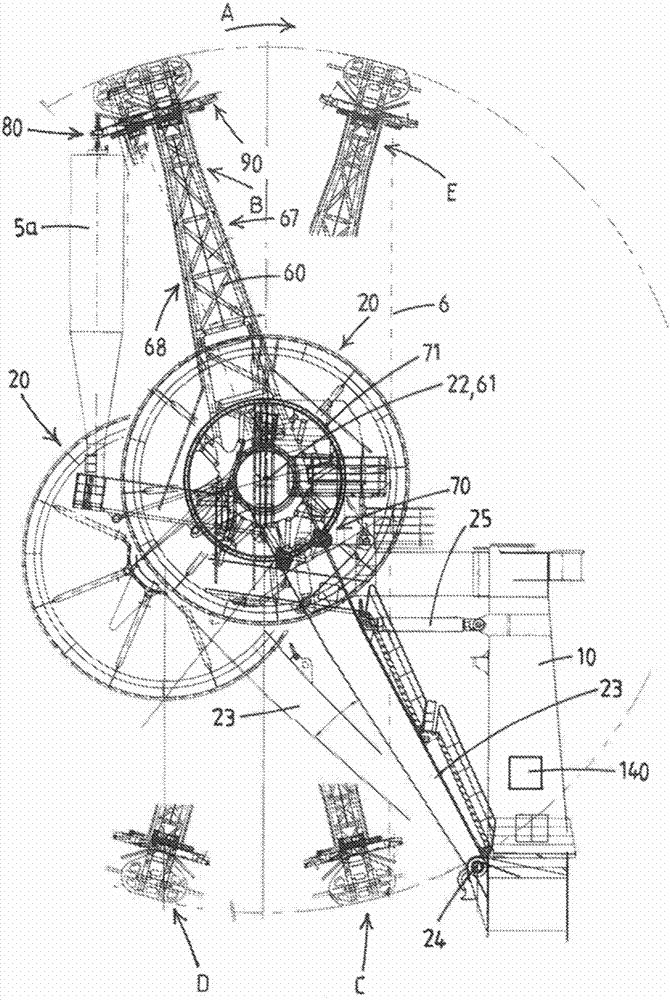

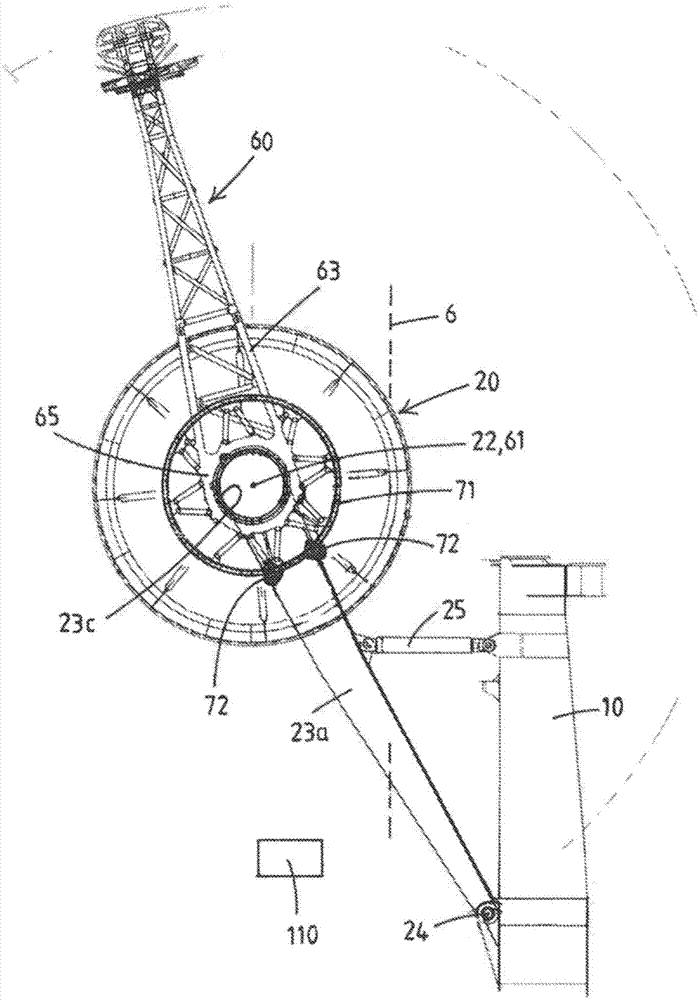

[0200] exist figure 1 shows a part of the hull 1 of a pipe-laying vessel, which here is equipped with a boat well 2 via which the pipe-laying is carried out.

[0201] The vessel supports a storage reel 3 for a flexible pipeline 5 to be installed, for example laid on the seabed and / or as a marine riser or part of a marine riser . In this example, the longitudinal axis drum 3 or the gondola is mounted below the deck 7 of the ship, but such a gondola could also be mounted above the deck if required. In another embodiment, the storage reel 3 is a transverse reel, for example permanently fitted on board the ship or a replaceable reel, for example provided on a slidable tackle on the deck of the ship.

[0202] The water entry tower 10 is arranged on the hull 1, which is close to the boat well 2 here. Said tower 10 is adapted to release the pipeline 5 in the working line 6 into the sea. In this example, the tower 10 is tiltable by means of a telescoping adjuster 11, so that the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com