Metallocene polypropylene modified material for corrosion-inhibiting coating of steel pipe and preparation method and application thereof

A metallocene polypropylene and anti-corrosion coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of using nano-reinforced materials and other problems that are not mentioned, and achieve outstanding UV aging resistance and thermal resistance. Oxygen aging performance, excellent impact resistance, strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Formulation: 90wt% metallocene polypropylene (mPP), 5.3wt% block copolymerized polypropylene, 0.3wt% metal soap type thermal oxygen stabilizer, 0.5wt% benzophenone type UV absorber and hindered methyl piperidine Light stabilizer, 0.3wt% titanate coupling agent and stearic acid amide dispersant, 0.6wt% nano-CaCO 3 , 3wt% black mother.

[0027] The above components are extruded and granulated by a twin-screw extruder to implement a plasticizing and blending process, the extruder length-diameter ratio is L / D=40:1, and the processing temperature is 160-210°C.

Embodiment 2

[0029] Formulation: 80wt% metallocene polypropylene (mPP), 17.3wt% block copolymerized polypropylene, 0.5wt% metal soap type thermal oxygen stabilizer, 0.7wt% chlorinated benzotriazole type UV absorber and hindered phosphorous acid Ester light stabilizer, 0.5wt% polypropylene dispersant, 1.0wt% nano-talc.

[0030] The above components are extruded and granulated by a twin-screw extruder to implement a plasticizing and blending process, the extruder length-diameter ratio is L / D=40:1, and the processing temperature is 160-210°C.

Embodiment 3

[0032] Formulation: 75wt% metallocene polypropylene (mPP), 21.4wt% block copolymerized polypropylene and random copolymer polypropylene blend, 0.6wt% benzofuranone type thermal oxygen stabilizer, 0.8wt% benzophenone type UV light Absorber and hindered methyl piperidine light stabilizer, 0.7wt% silane coupling agent, 1.3wt% nano-TiO 2 .

[0033] The above components are extruded and granulated by a twin-screw extruder to implement a plasticizing and blending process, the extruder length-diameter ratio is L / D=40:1, and the processing temperature is 160-210°C.

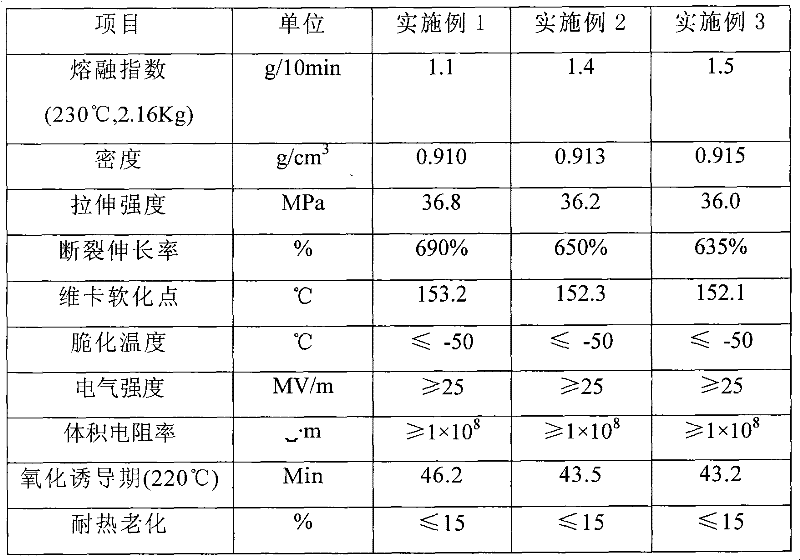

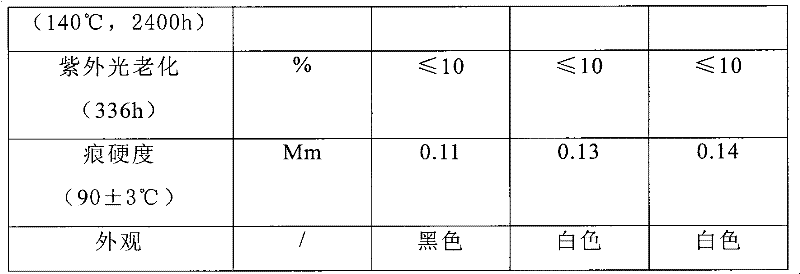

[0034] The properties of the products of Examples 1-3 are shown in Table 1.

[0035] Table 1

[0036]

[0037]

[0038]It can be seen from the table that the products of Examples 1-3 all have outstanding thermal oxygen resistance, photoaging properties and excellent comprehensive properties, which can greatly extend the service life of anti-corrosion steel pipes and broaden the service environment of anti-corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com