Silk ribbon of silane-crosslinked high-strength monoway stretched and oriented polymer

A cross-linked polymer, uniaxial stretching technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of aging performance and material engineering life that do not meet the engineering life requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

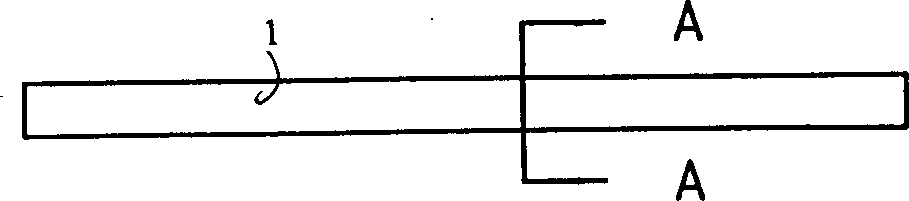

[0040] Figure 1 to Figure 9 Figure 1 of Embodiment 1 of the present invention is given. see figure 1 , Polyethylene material and silane cross-linkable polymer ribbons containing organosilicon monomers, grafting initiators, and hydrolytic condensation catalysts are prepared by unidirectional stretching and orientation, and then hydrolyzed, condensed, and cross-linked under humid heat conditions. The cross-sectional shape of the silane-crosslinked high-strength uniaxially stretched oriented polymer ribbon 1 is as follows figure 2 shown as a rectangle or as image 3 Shown as a diamond or as Figure 4 Shown as round or Figure 5 shown as hollow circular or as Figure 6 Shown as oval or as Figure 7 shown as a triangle or as Figure 8 Groove shape as shown or as Figure 9 The convex shape shown.

Embodiment 2

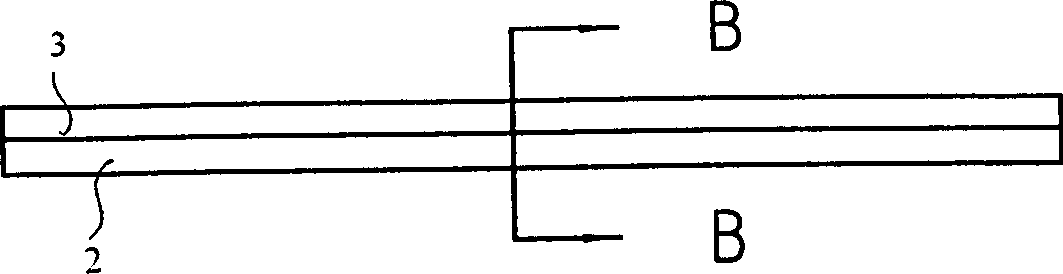

[0042] The two-layer material is polyethylene or polypropylene material, which is composed of silane cross-linked polyethylene layer 2 and silane cross-linked polypropylene layer 3 after extrusion composite uniaxial stretching, and undergoes hydrolysis condensation cross-linking reaction under humid heat conditions. Silane-crosslinked high-strength polymer ribbons. Its cross-sectional shape is as Figure 11 shown as a rectangle or as Figure 12 Shown as a diamond or as Figure 13 Shown as round or as Figure 14 shown as hollow circular or as Figure 15 Oval as shown or as Figure 16 shown as a triangle or as Figure 17 Grooved as shown or as Figure 18 Convex shown.

Embodiment 3

[0044] Figure 19 shows a diagram of Embodiment 3 of the present invention. Referring to FIG. 19 , non-crosslinkable polymer layers 5 and 6 are compositely connected to the top and bottom of the silane crosslinked polymer layer 4 , respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com