Patents

Literature

91results about How to "Improved environmental stress cracking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

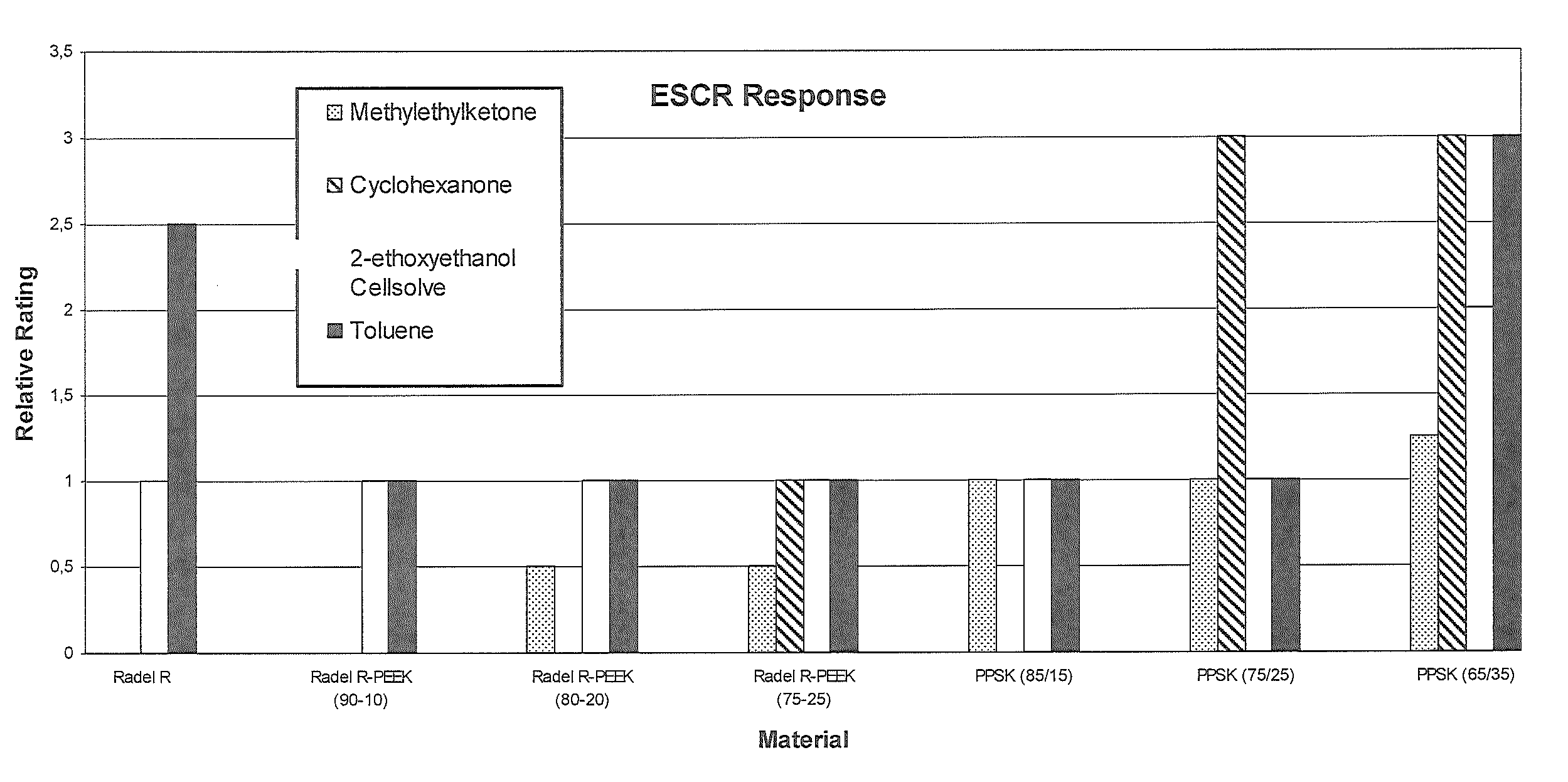

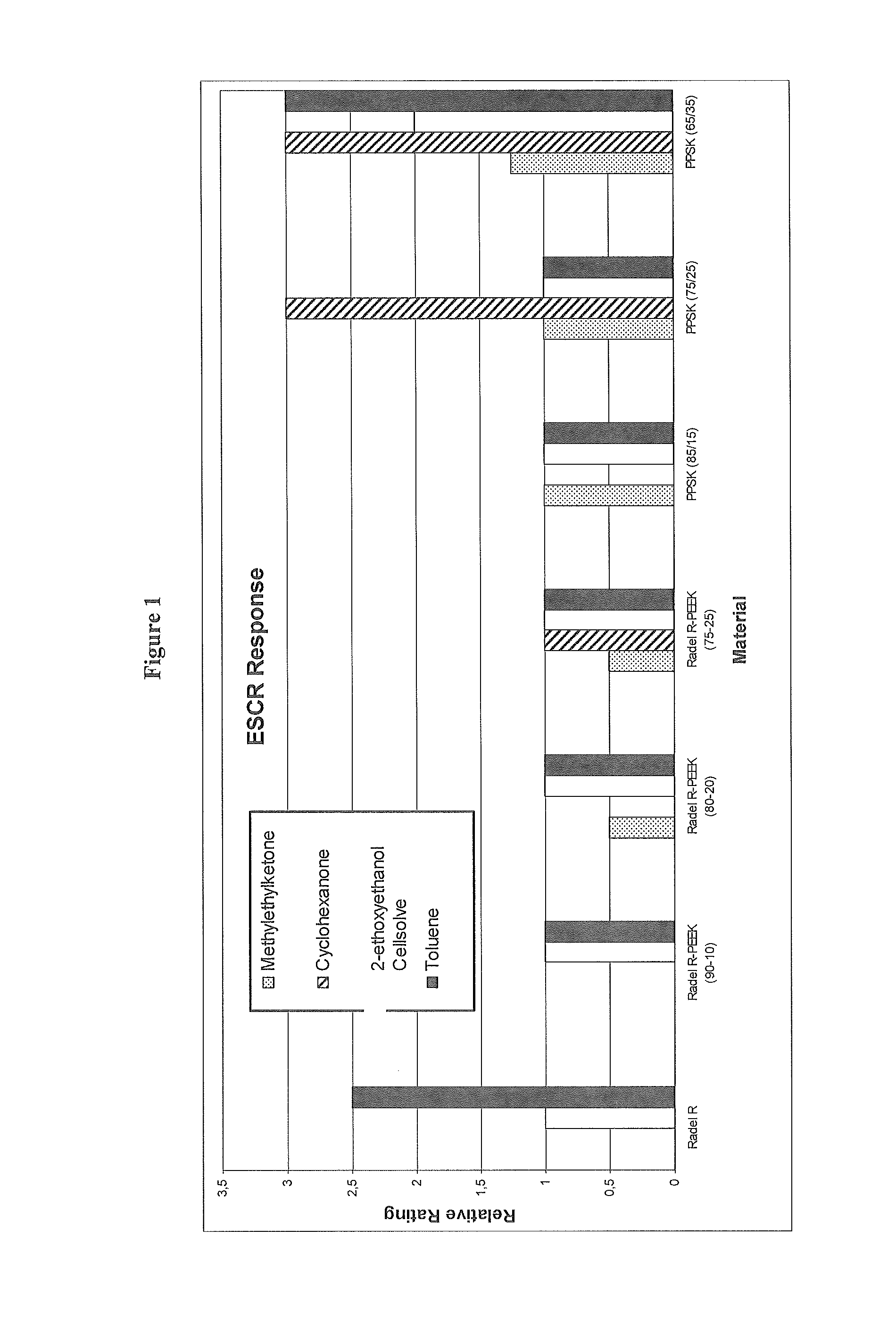

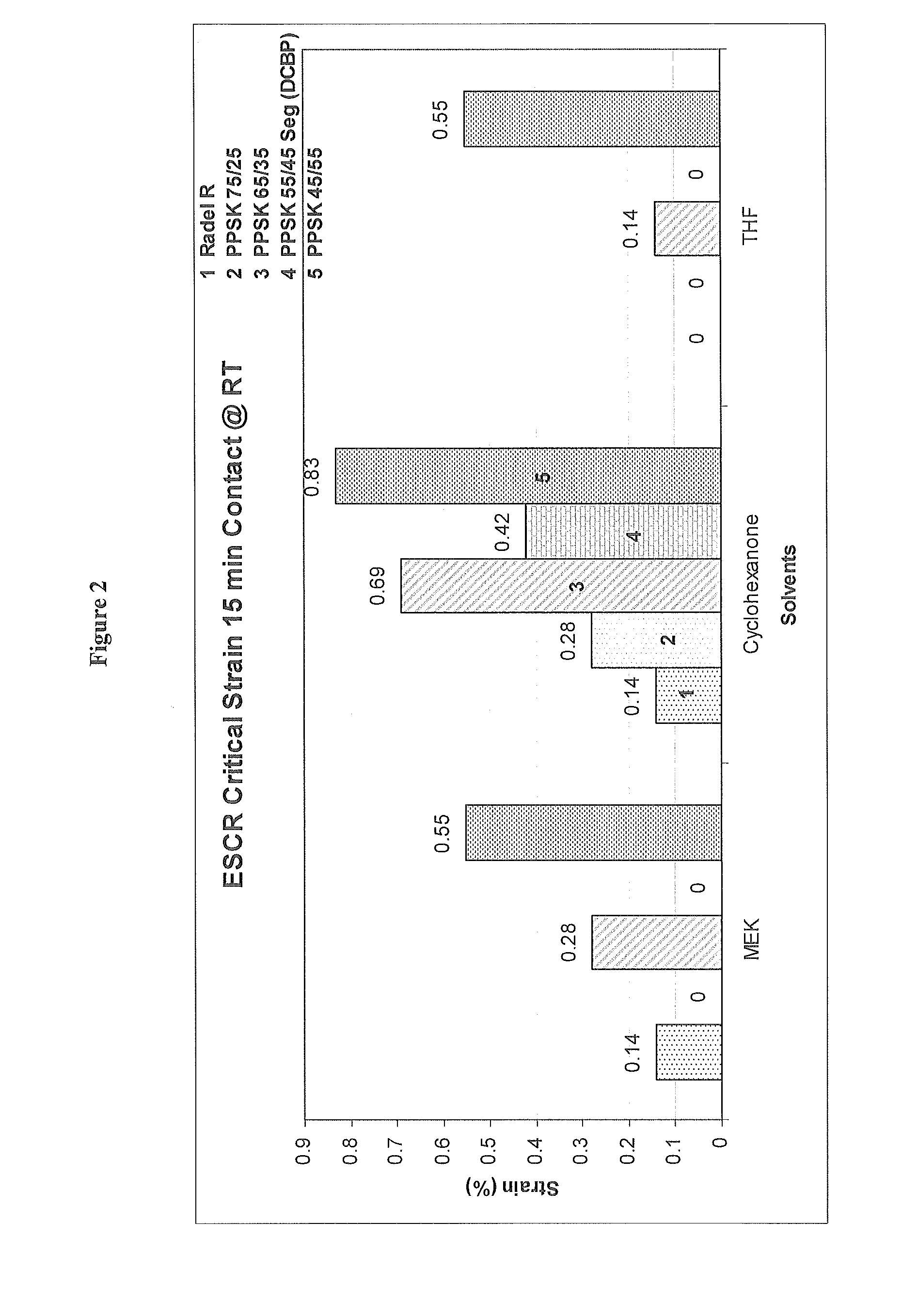

Polyphenyl sulfone ketone copolymers

InactiveUS20100310804A1Improve the immunityLow creepLayered productsThin material handlingPolymer scienceKetone

A polymer comprising sulfone groups, ketone groups and optionally substituted polyarylene groups, wherein the number of moles of sulfone groups over the number of moles of ketone groups ratio is greater than 1. A process for making such polymer, a composition comprising such polymer, and articles made therefrom.

Owner:SOLVAY ADVANCED POLYMERS LLC

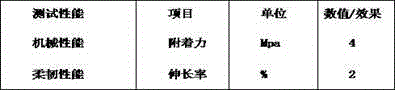

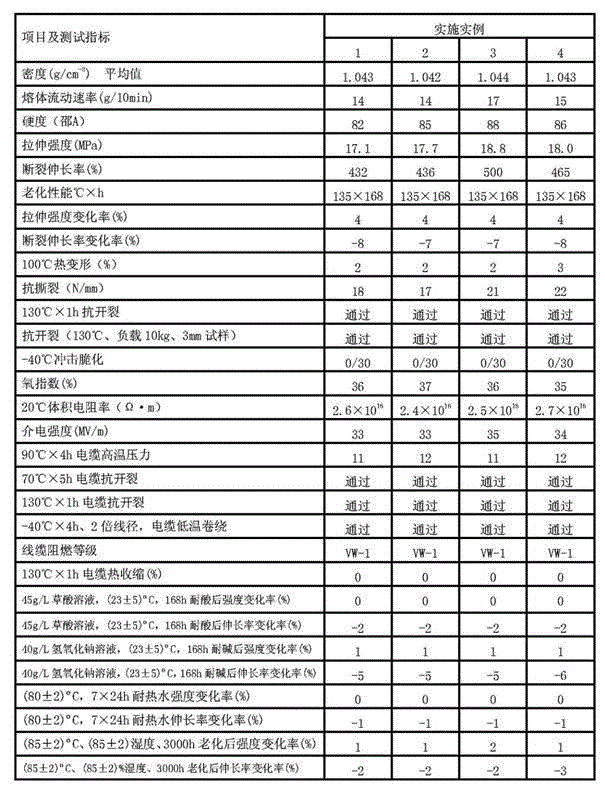

Halogen-free flame retardant thermoplastic elastomer cable material and preparation method thereof

InactiveCN104530626ANo significant change in electrical propertiesGood compatibilityRubber insulatorsPlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the technical field of polymer materials and relates to a halogen-free flame retardant thermoplastic elastomer cable material. The halogen-free flame retardant thermoplastic elastomer cable material is characterized by comprising the following raw materials in parts by weight: 20-60 parts of a styrene type elastomer, 20-60 parts of polyphenyl ether resin, 10-40 parts of polyolefin, 10-50 parts of a polyolefin type elastomer, 10-50 parts of a plasticizer, 20-60 parts of a complex phosphorus-nitrogen flame retardant, 1-5 parts of a lubricating agent, 0.1-1 part of an antioxidant and 0.1-1 part of an anti-ultraviolet absorbent. The invention further discloses a preparation method of the cable material. The cable material disclosed by the invention has the characteristics of excellent processing performance, high flame-retardant grade, no toxicity, light density, good anti-tear performance, good acid and alkali resistance, good weather resistance and the like, as well as particularly prominent water resistance and anti-cracking performance. After high-temperature and high-humidity long-term aging, the cable material has no precipitate, the excellent mechanical and physical properties are kept, and the electrical properties do not change obviously.

Owner:JIANGSU ZHONGLI GRP CO LTD

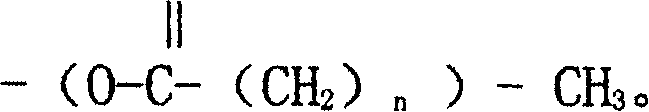

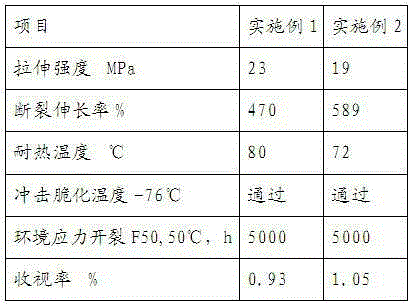

Silane crosslinked polyethylene plastic for low shrinkage anti-crack tube and its preparation method

ActiveCN1876706ASolve the defect of excessive shrinkageOvercome degummingBulk chemical productionTubular articlesCross-linkWater baths

The invention relates the silicon alky cross-linking low-middle-high density vinyon. The components comprises 0.8-3.0wt% silicon alky cross linking agent, 0.02-2.0wt% cross linking initiating agent, 0.02-1.0wt% cross linking catalyst, 0.01-3.0wt% anti-oxidant and 0.05-3.0wt% modified auxiliary agent. The method comprises the following steps: preparing silicon alky grafting material A, mixing A and B materials, handing with extrusion machine to get tubing product, keeping it in water bath at 85Deg.C or vaporium for 8 hours, and getting the product. The invention overcomes the defects of big contraction percentage and degelatinizing phenomena between polythene layer and metal layer; the invention has the advantages of short production circle, stable technology and high rate of finished products.

Owner:上海高分子功能材料研究所

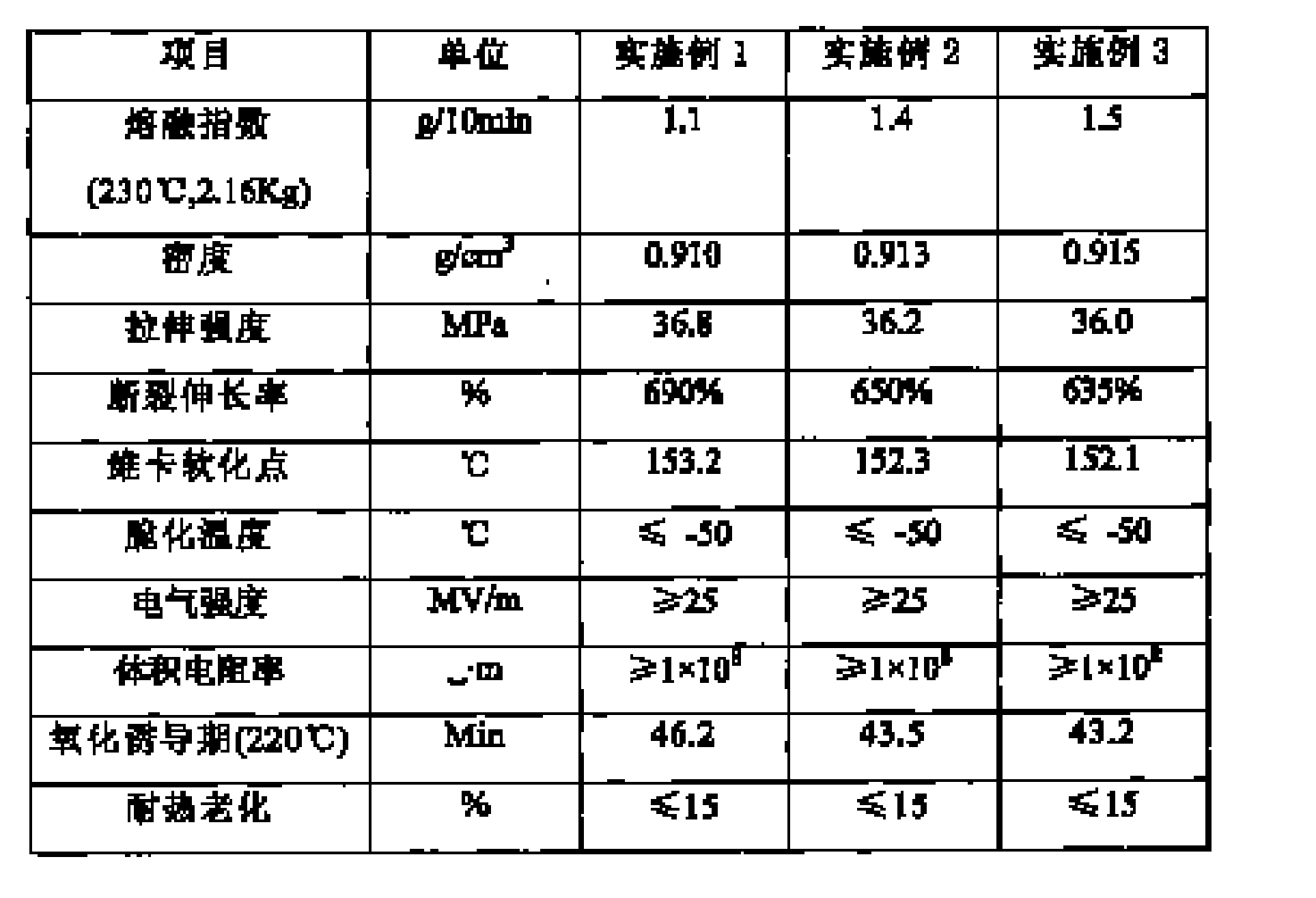

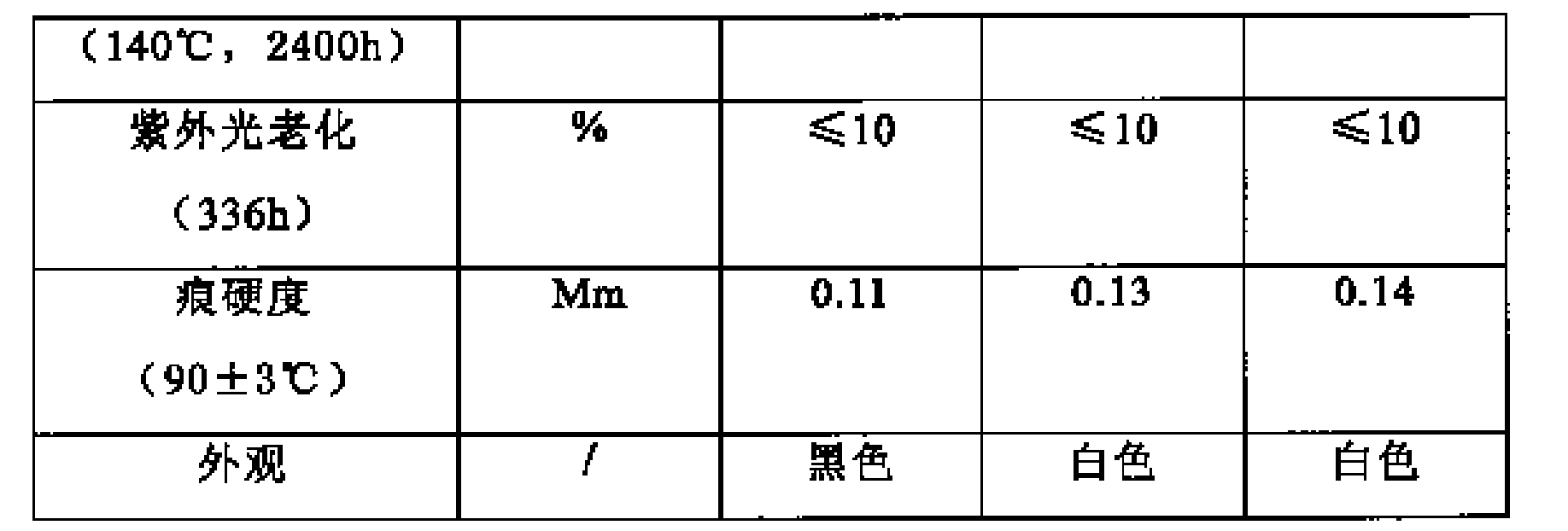

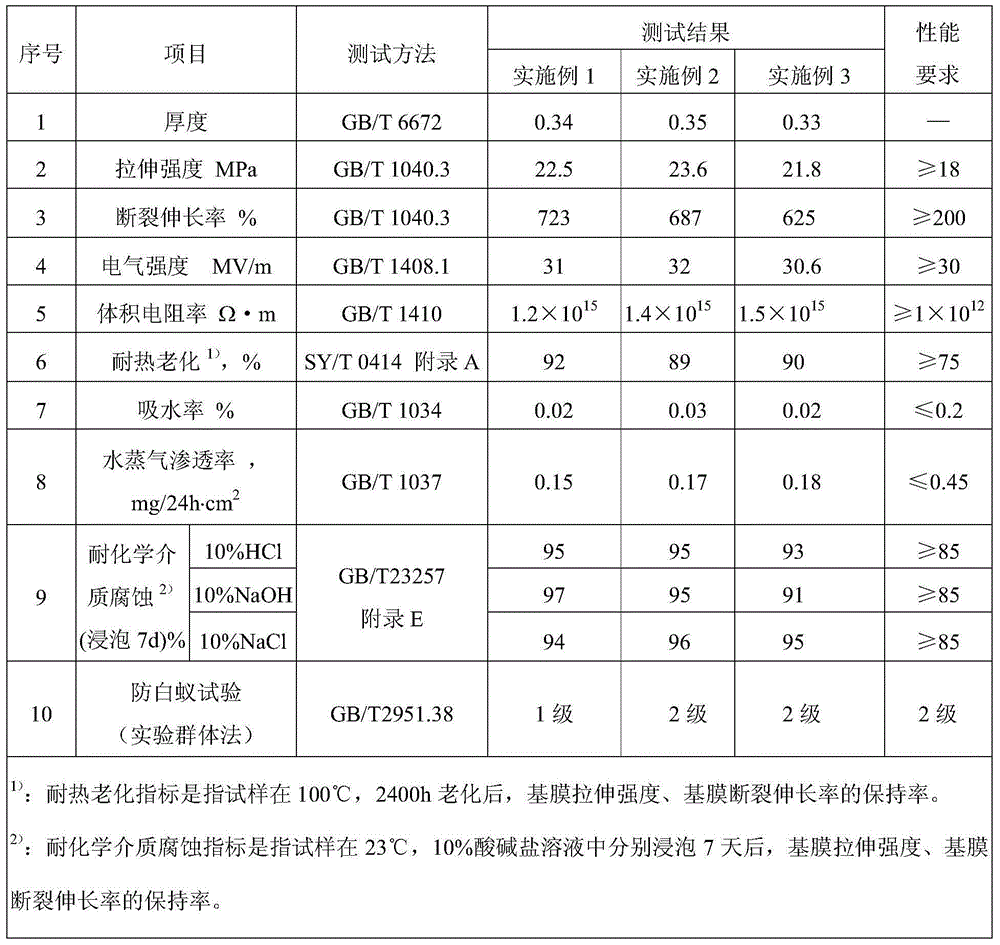

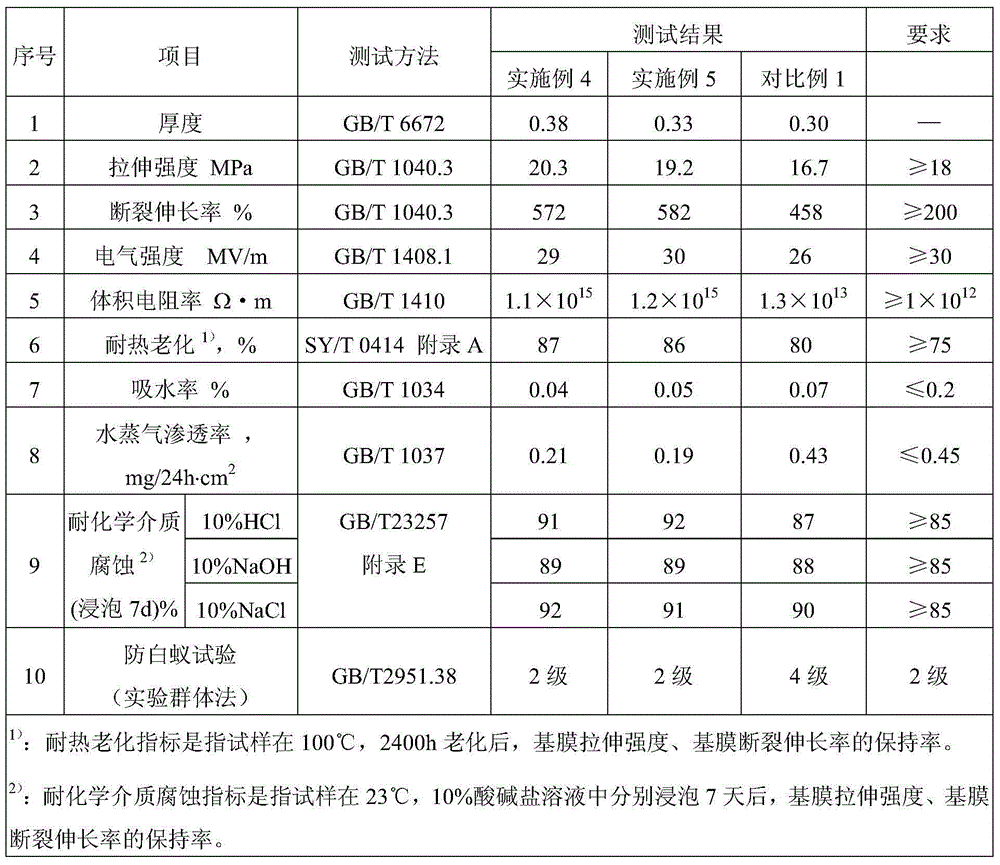

Metallocene polypropylene modified material for corrosion-inhibiting coating of steel pipe and preparation method and application thereof

ActiveCN101519513ACoating processing range is wideImproved environmental stress cracking resistanceAnti-corrosive paintsUltraviolet lightsWorking temperature

The invention discloses a metallocene polypropylene modified material for a corrosion-inhibiting coating of a steel pipe and a preparation method and application thereof. A formula of the material comprises 65 to 95 weight percent of metallocene polypropylene, 3 to 30 weight percent of co-polypropylene, 0.01 to 4 weight percent of thermal oxygen stabilizer, 0.03 to 3 weight percent of ultraviolet absorbent and light stabilizer, 0.02 to 5 weight percent of functional additive, 0.01 to 3 weight percent of inorganic nanometer reinforced material, and 0 to 5 weight percent of black color batch, and the material is prepared by adopting a double screw extruder to carry out plasticizing blending technology for extrusion and pelletization. The metallocene polypropylene modified material has wide casting and coating processing range, has strong adaptability to bottom glue of hot melt adhesives, has outstanding ultraviolet light aging resistance and thermal-oxidative aging resistance, and has excellent shock resistance and surface scratch resistance as well as extremely high environmental stress cracking resistance. The material can be suitable for terrestrial pipelines at continuous working temperature high up to 110 DEG C, and is also suitable for offshore pipelines atcertain special continuous working temperature high up to 140 DEG C at the same time.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Solar-powered back plate and manufacturing method thereof

ActiveCN103050563AHigh temperature resistanceImproved environmental stress cracking resistanceFinal product manufacturePhotovoltaic energy generationSurface layerAging resistance

The invention discloses a solar-powered back plate. The solar-powered back plate comprises an inner surface layer, a core layer and an outer surface layer in the mass ratio of (10-20):(20-40):(40-60) from inside to outside, wherein the inner surface layer is made from vinyl resin, a filler and an additive; the outer surface layer is made from polyamide resin, a filler and an additive; and the core layer is made from a modified polyethylene resin composition. The invention further develops a novel polyethylene resin composition, which comprises 100 parts of crosslinked polyethylene resin, 0-50 parts of grafted polyethylene, 0.1-0.5 parts of catalyst, 0-100 parts of filler and 0-2.5 parts of additive. The novel solar-powered back plate developed by the invention is prepared through a coextrusion process; and a prepared final product has the advantages of superior adhesion, high interlaminar peeling strength, aging resistance, particular damp-heat aging resistance, low saturated water absorptivity, low water vapor transmittance and superior electric insulating property, simple preparation process, low cost and suitability for industrial production.

Owner:SUZHOU DUCHAMPS ADVANCED MATERIALS CO LTD

Composition

InactiveCN101048455AImprove performanceHigh impact strengthTubular articlesVolumetric Mass DensityLow density

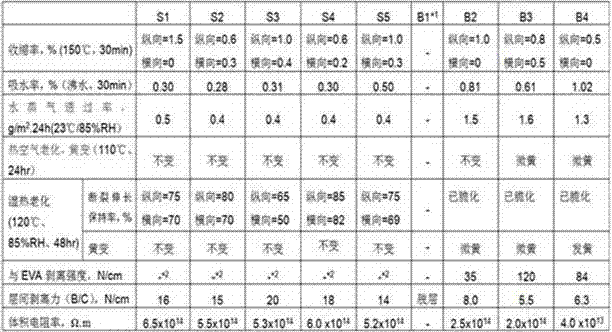

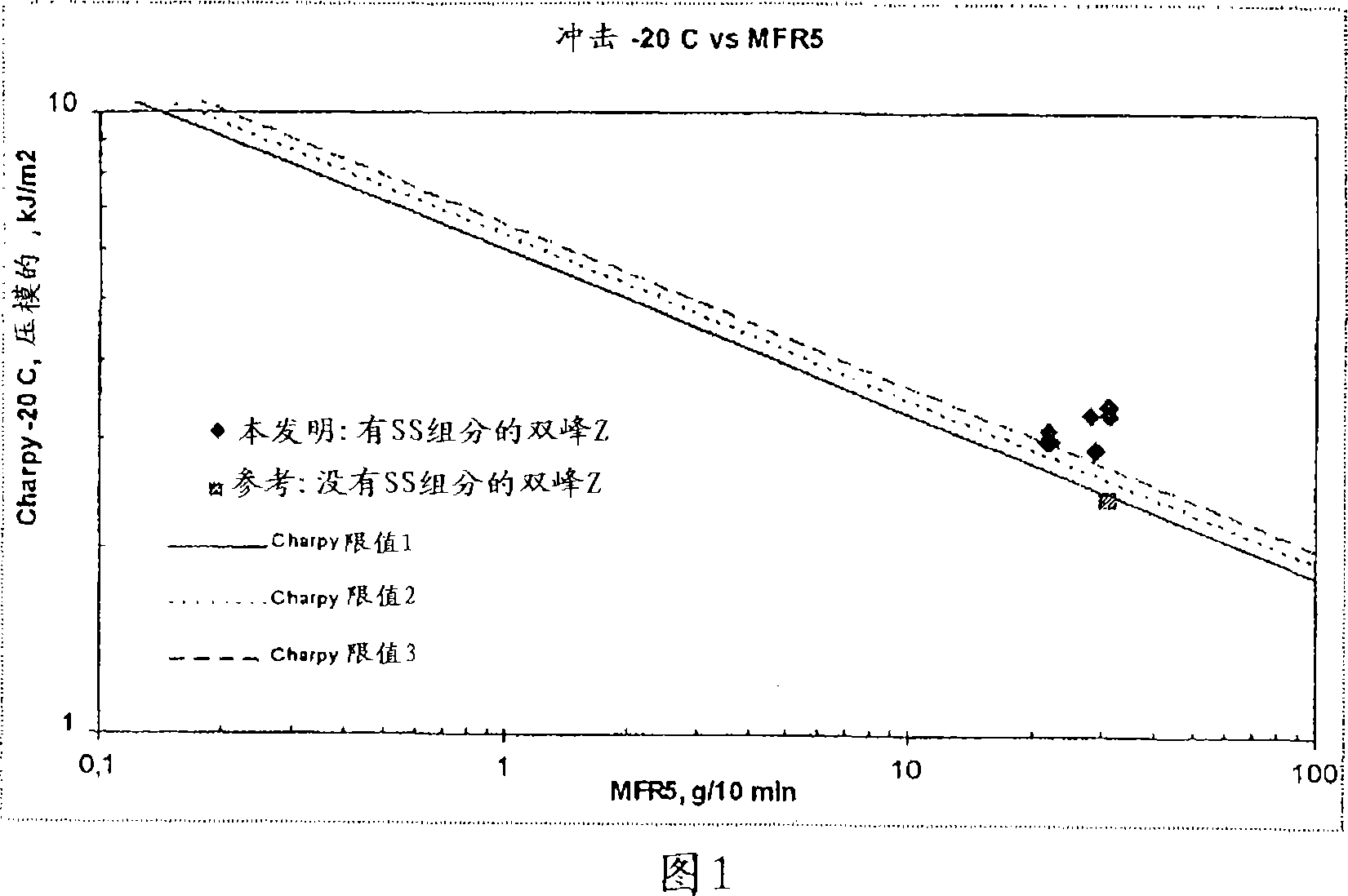

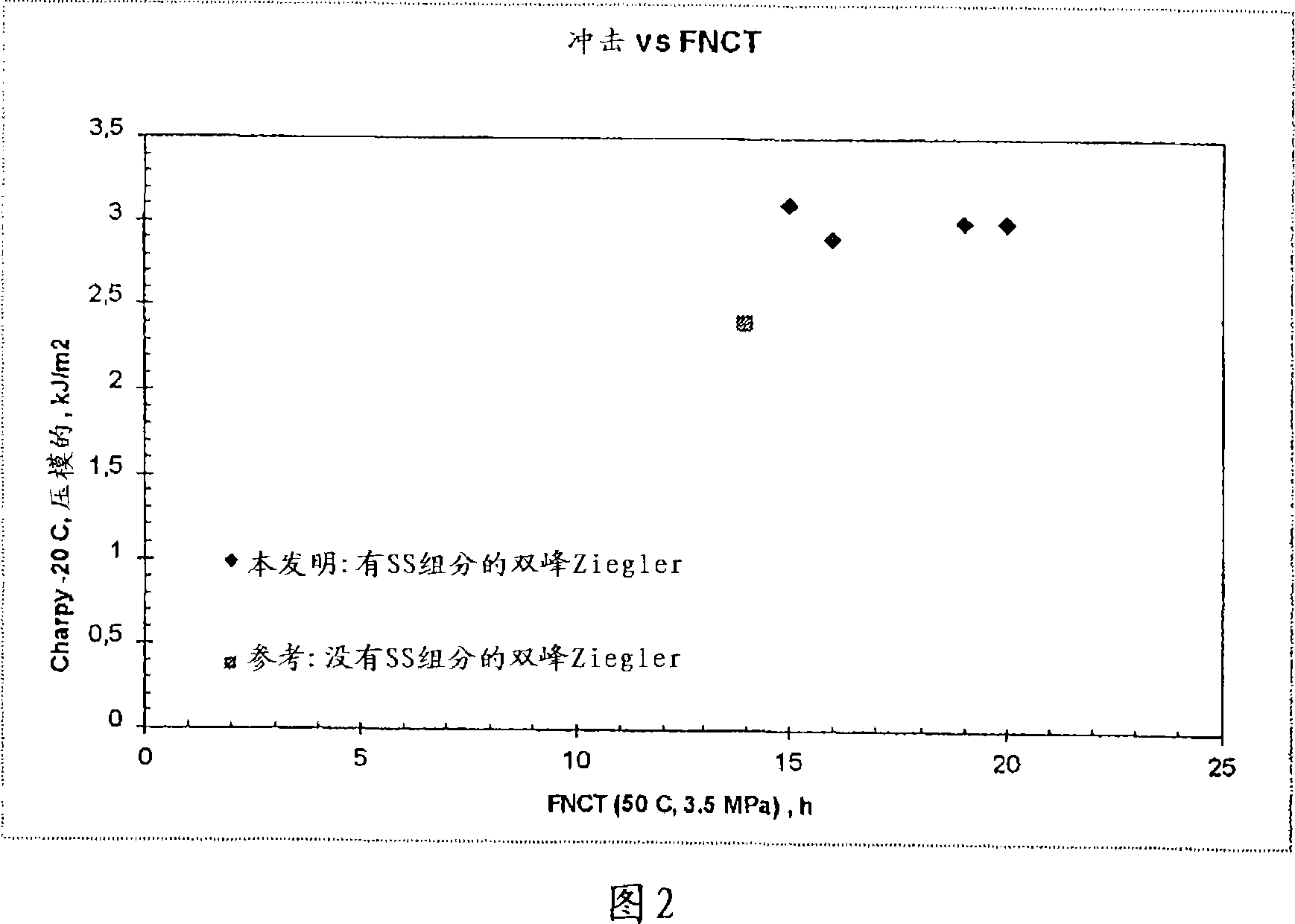

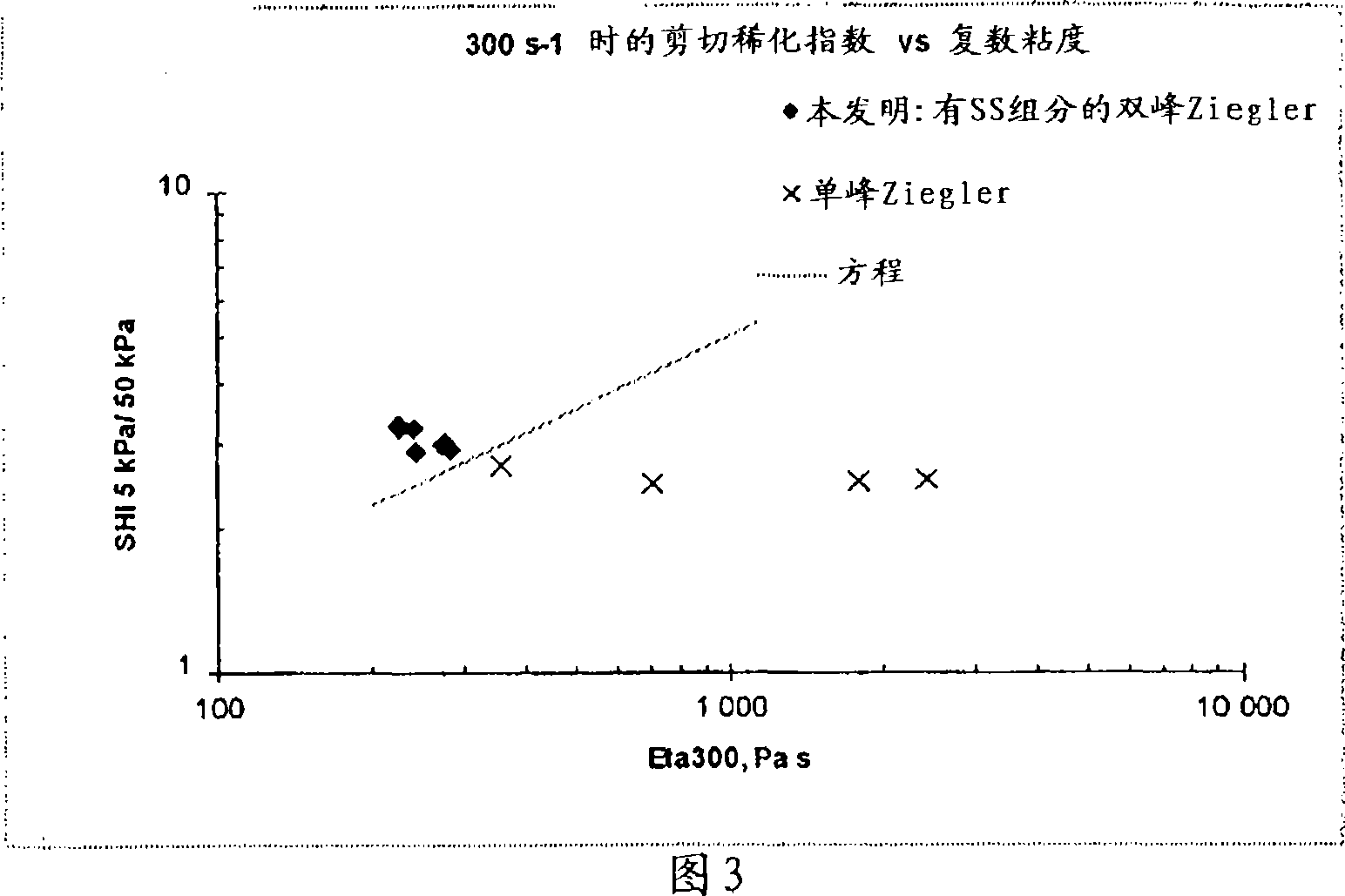

A polyethylene composition comprising at least a first composition and a second composition in amounts of at least 70 wt% of the first composition which comprises at least: (A) up to 60 wt% lower molecular weight (LMW) polyethylene homo or copolymer obtained by Ziegler-Natta catalysis having a density of at least 940 kg / m<3>; and (B) up to 60 wt% higher molecular weight (HMW) polyethylene homo or copolymer obtained by Ziegler-Natta catalysis and having lower density than component (A); and up to 30 wt% of the second composition which comprises: (C) a polyethylene homo or copolymer obtained by single site catalysis (SSC) and having a density of up to 980 kg / m<3>; wherein said polyethylene composition has a charpy impact strength at -20 DEG C, according to ISO 179-3 on compression moulded plates of at least 2.5 kJ / m<2> and density at least 925 kg / m<3>.

Owner:BOREALIS TECH OY

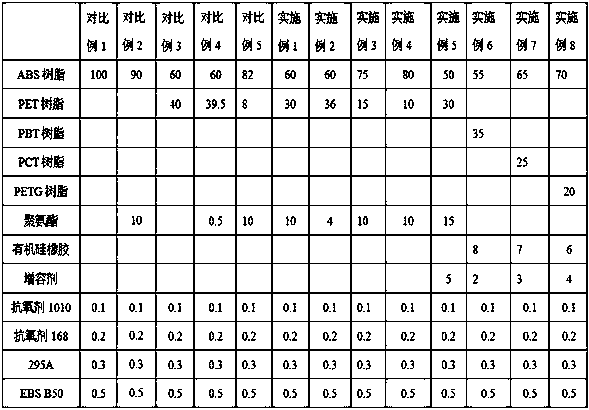

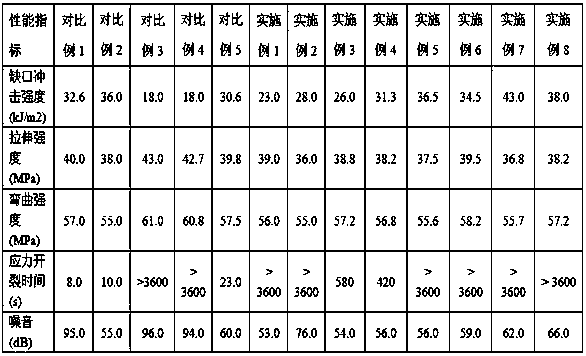

ABS/polyester alloy material as well as preparation method and application thereof

ActiveCN108440892AWith noise reduction effectExcellent resistance to environmental stress crackingElastomerWater leakage

The invention discloses an ABS / polyester alloy material as well as a preparation method and application thereof. The ABS / polyester alloy material comprises the following components by parts: 50-80 parts of styrene-butadiene-acrylonitrile resin, 10-65 parts of polyester resin, and 1.0-15 parts of a high-damping elastomer. According to the method disclosed by the invention, a polyester and high-damping rubber are introduced into an ABS system, so that the prepared ABS / polyester alloy material has excellent environmental stress cracking resistance while having a noise reduction effect, can replace ABS, HIPS or PC / ABS to be used for various plastic parts, can effectively reduce noise made by the parts, can greatly improve environmental stress cracking resistance of the parts, solve the problems of water leakage and cracking caused by the problem, and has significant technical and market value.

Owner:辽宁金发科技有限公司

EVA (ethylene-vinyl acetate) precoating packaging adhesive film and preparation method thereof

InactiveCN104762023AIncrease production speedSimplify process complexityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceAdhesive

The invention provides an EVA (ethylene-vinyl acetate) precoating packaging adhesive film and a preparation method thereof. The adhesive film is composed of three layers, wherein the middle layer is a BOPP (biaxially-oriented polypropylene) film layer, and the upper and lower layers are respectively an EVA adhesive layer. The EVA adhesive layer is prepared from 100 parts of ethylene-vinyl acetate copolymer, 0.5-1 part of crosslinking agent, 0.1-2 parts of antioxidant, 0.01-0.02 part of light stabilizer and 0.02-0.04 part of tackifier. A precoating technique is adopted to produce the EVA packaging adhesive film, i.e. the EVA adhesive layers are coated to the upper and lower surfaces of the BOPP film layer to constitute the EVA packaging adhesive film, thereby greatly enhancing the production rate and simplifying the technique complexity degree under the support of the BOPP film. The bonding firmness between the EVA adhesive layer and BOPP film layer is enhanced, and the shock strength and environmental stress crack resistance of the adhesive film are enhanced.

Owner:ANHUI GUOFENG PLASTIC

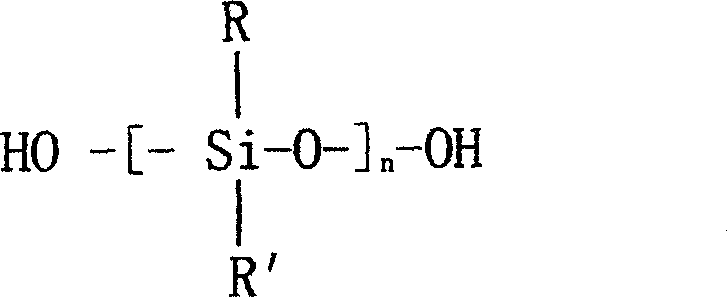

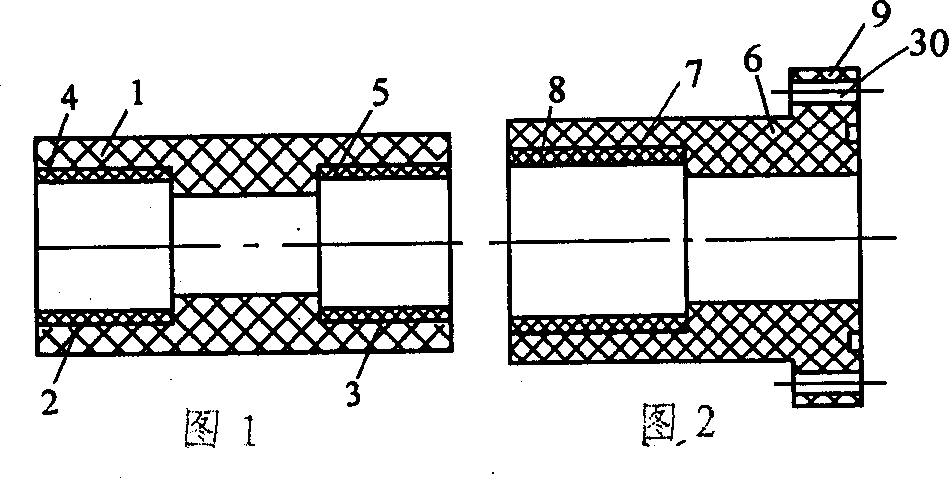

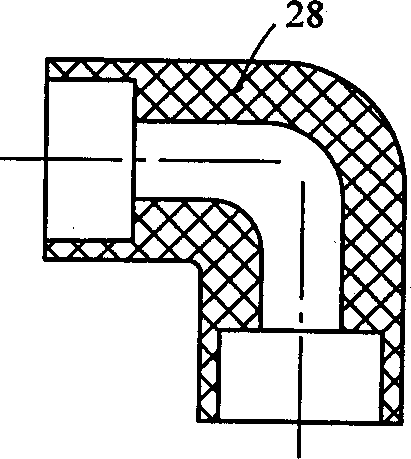

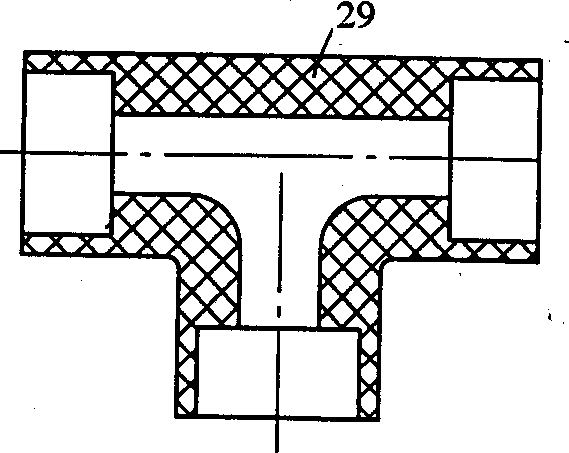

Silane crosslinked polyethylene pipe connecting piece

InactiveCN1344881AOvercoming temperature resistanceOvercoming pressure resistancePipe connection arrangementsPolymer scienceSilanes

The silane crosslinked polyethylene pipe union includes a silane crosslinked polyethylene pipe body produced by using the material comprising at least organosilicon monomer as grafting initiator, hydrolytic polycondensation catalyst and polyethylene as well as through extrusion or injection and reaction of crosslinking polycondensation and with spigots added. It is used to consitute permanent connection with silane crosslinked polyethylene pipe.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Cracking resistance modified polyethylene material and preparation method therefor

InactiveCN105237853AFormula refiningSolve the problem of poor environmental cracking resistanceLinear low-density polyethyleneElastomer

The invention discloses a cracking resistance modified polyethylene material and a preparation method therefor. The cracking resistance modified polyethylene material is prepared from linear low-density polyethylene, high-density polyethylene, POE (Polyolefin Elastomer) and modified masterbatch. Through polyethylene material modification and a micro cross-linking technology, the problem that polyethylene outer layers of composite metal plastic pipes crack is solved.

Owner:山东融汇管通股份有限公司

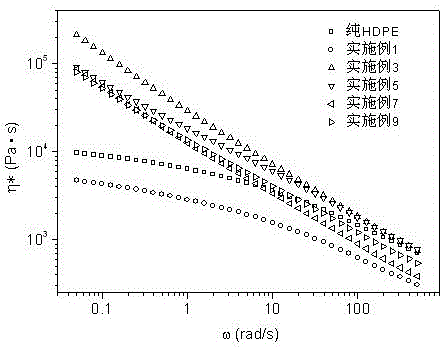

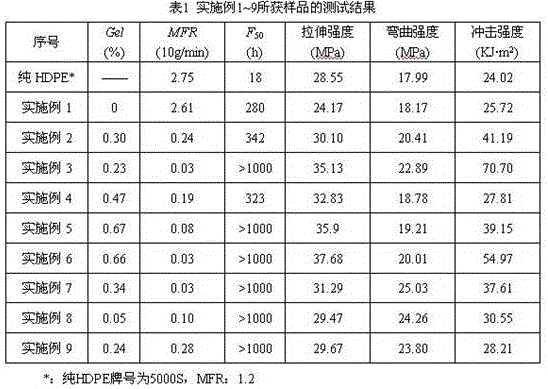

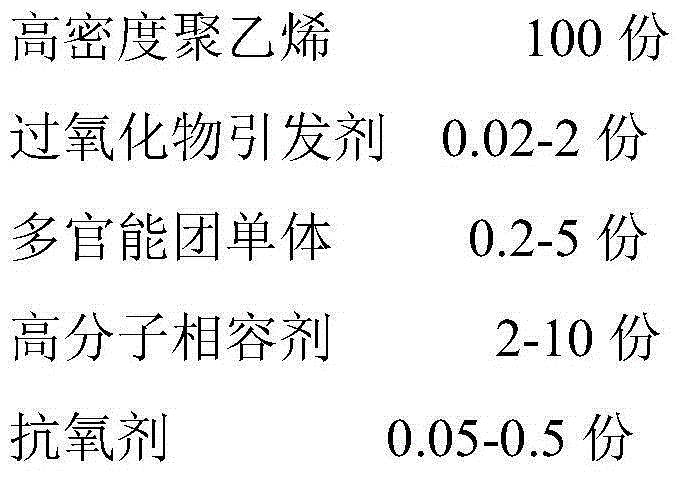

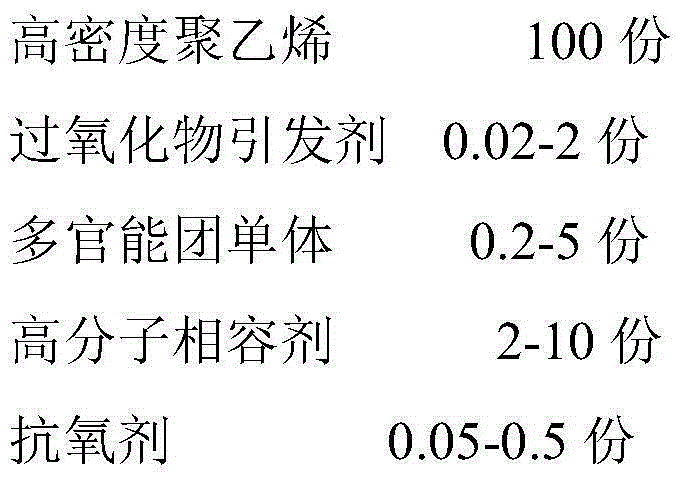

Long-chain branched high-density polyethylene material resisting environmental stress cracking and preparation method thereof

The invention discloses a long-chain branched high-density polyethylene material resisting environmental stress cracking and a preparation method thereof. According to the preparation method, long-chain branched modification is conducted on high-density polyethylene by selecting a melting reaction processing method to improve the environmental stress cracking resisting property of the material, branching generation is promoted by adding two-functionality-degree graft monomers, acrylic ester double bonds are adopted to stabilize the macromolecular free radicals and improve the branching efficiency, and meanwhile an efficient free radical regulating agent is added to regulate and control the activity of the macromolecular free radicals to inhibit crosslinking side reaction; the prepared long-chain branched high-density polyethylene has the low gel fraction, and long-branch-chain high-density polyethylene of which the branch chain length meets the stress cracking resisting requirement is obtained. The long-chain branched high-density polyethylene prepared through the preparation method has the excellent environmental stress cracking resisting property and the good comprehensive mechanical property.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

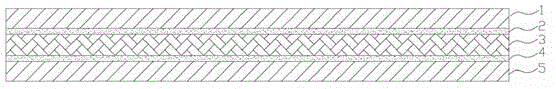

Anti-termite adhesive tape substrate of polyethylene pipeline and preparation method of substrate

ActiveCN104650439AImprove surface adhesionImproved Environmental Stress Cracking ResistanceFilm/foil adhesivesLinear low-density polyethyleneLow-density polyethylene

The invention provides an anti-termite adhesive tape substrate of a polyethylene pipeline and a preparation method of the substrate. The anti-termite adhesive tape substrate of the polyethylene pipeline is prepared from the following components in percentage by mass: 50-75% of ultralow density polyethylene, 10-20% of maleic anhydride modified linear low-density polyethylene, 5-15% of medium-density polyethylene, 5-15% of high-density polyethylene, 1-2% of an antioxidant, 1-2% of color master batch and 1-2% of an anti-termite agent. The anti-termite adhesive tape substrate of the polyethylene pipeline is greatly enhanced in heat resisting stability, heat aging resistance, environmental stress cracking resistance, stretchability, shock resistance and wear resistance, and also has the function of prevention against termites.

Owner:CYG CHANGTONG NEW MATERIAL

Satchel charge packing film and preparation method thereof

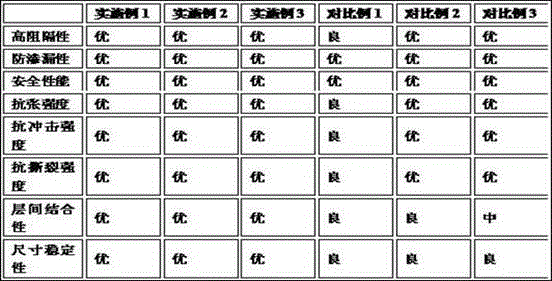

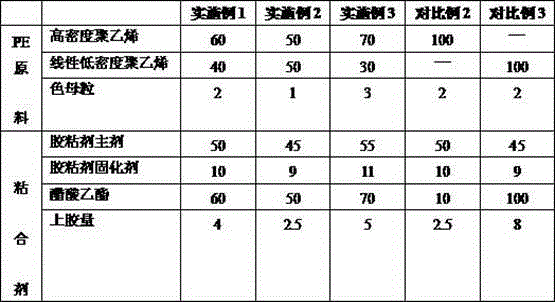

InactiveCN104960766AInterlayer bonding performance and dimensional stability guaranteeHigh tear strengthFlexible coversWrappersSatchel chargeHigh-density polyethylene

The invention discloses a satchel charge packing film and a preparation method thereof. The satchel charge packing film comprises a middle layer, an upper outer layer film and a lower outer layer film, wherein the middle layer is provided with a first surface and a second surface; the upper outer layer film is composited on the first surface of the middle layer; the lower outer layer film is composited on the second surface of the middle layer; the middle layer is a PET (Polyethylene Glycol Terephthalate) film; the upper outer layer film or the lower outer layer film is a PE (polyethylene) film and formed by film blowing of a PE raw material; and the PE raw material comprises a high density polyethylene, linear low density polyethylene and color master batch. The satchel charge packing film has high barrier property, leakage resistance and safety; the chemical stability and the mechanical properties such as the tensile strength, the tearing strength, the environmental stress crack resistance, the low temperature resistance, the heat resistance and the penetration resistance of the satchel charge packing film are improved; and the inter-layer binding ability and the dimensional stability are excellent.

Owner:ZHEJIANG CHANGXING ZIXIN TECH

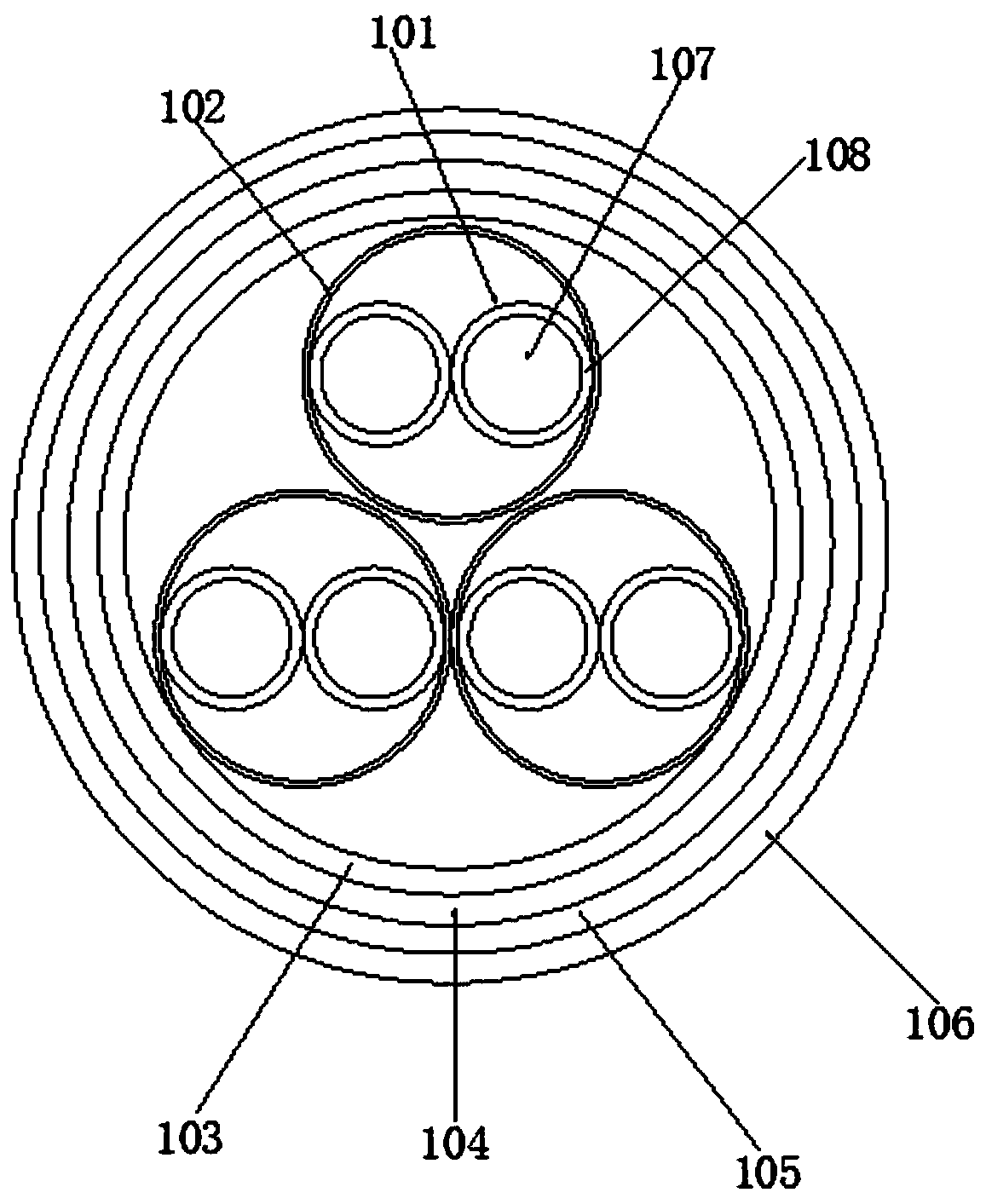

Flame-retardant and high-temperature-resistant computer cable and preparation process thereof

ActiveCN110364294AFlame retardantWith high temperature insulationInsulated cablesInsulated conductorsElectrical conductorCombustion

The invention discloses a flame-retardant and high-temperature-resistant computer cable. The cable comprises core wires, first wrapping layers, a second wrapping layer, a shielding layer, an armor layer and a sheath layer. Each core wire comprises tinned copper core conductors and insulating layers; the outer side of each tinned copper core conductor is wrapped with the corresponding insulating layer; every two core wires are twisted to form a pair wire set; and the outer side of each pair wire set is wrapped with the corresponding first wrapping layer. According to the invention, the quartz fiber maintenance sleeve layer on the outer side of the cable has the advantages of flame retardance, high-temperature resistance, insulationresistance, ablation resistance, corrosion resistance, heatinsulation ability, wave transmission ability, excellent dielectric property and the like; the cable can be protected from combustion in case of a fire; compared with polyethylene insulation, the performance of the the cross-linked polyethylene insulation is greatly improved after cross-linking modification; the comprehensive performance such as the mechanical performance, the environmental stresscracking resistance, the chemical corrosion resistance, the creep resistance and the electrical performance is remarkably improved; and the temperature resistance level is remarkably improved.

Owner:TIANCHANG HUILING ELECTRIC APPLIANCE METER FACTORY

Injection moulding-use high-rigidity linear low-density polyethylene resin and preparation method thereof

InactiveCN104974409AHigh tensile strengthImprove bending strengthLinear low-density polyethyleneLow-density polyethylene

The invention relates to an injection moulding-use high-rigidity linear low-density polyethylene resin which is prepared from following substances, by weight, 100 parts of linear low-density polyethylene, 0.1-1 part of surface-modified nano-carbon fibers, 0.15-0.9 parts of a photo-stabilizing agent, 0.05-0.3 parts of an anti-oxidizing agent and 0.05-0.10 parts of a rheology modifier. The invention also relates to a preparation method of the injection moulding-use high-rigidity linear low-density polyethylene resin. The injection moulding-use high-rigidity linear low-density polyethylene resin is improved in tensile strength, bending strength, impact property and environmental stress cracking resistance, is improved in both rigidity and toughness, is excellent in ultraviolet light aging resistance and processability, and is excellent in comprehensive performance.

Owner:SINOPEC YANGZI PETROCHEM +1

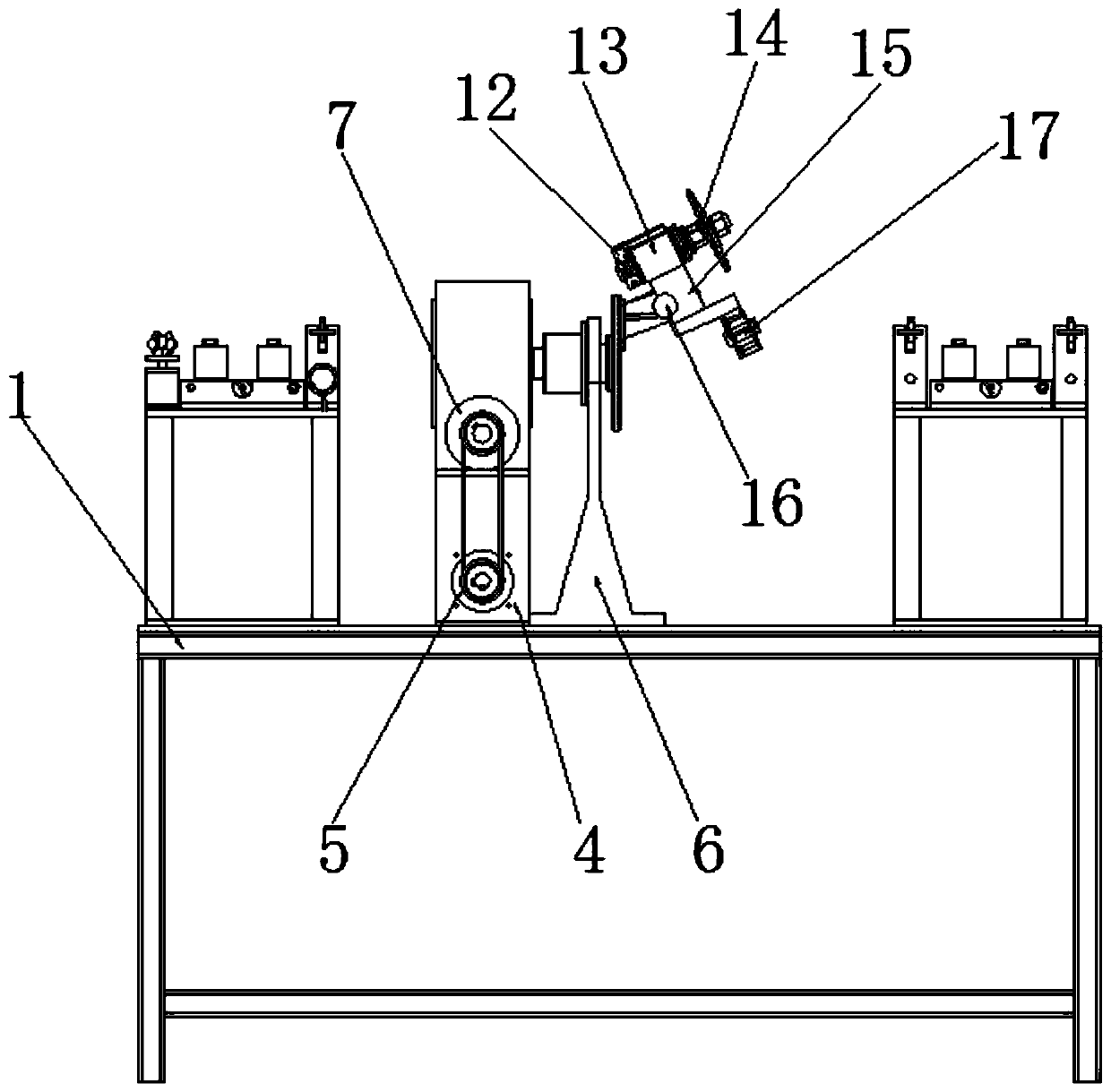

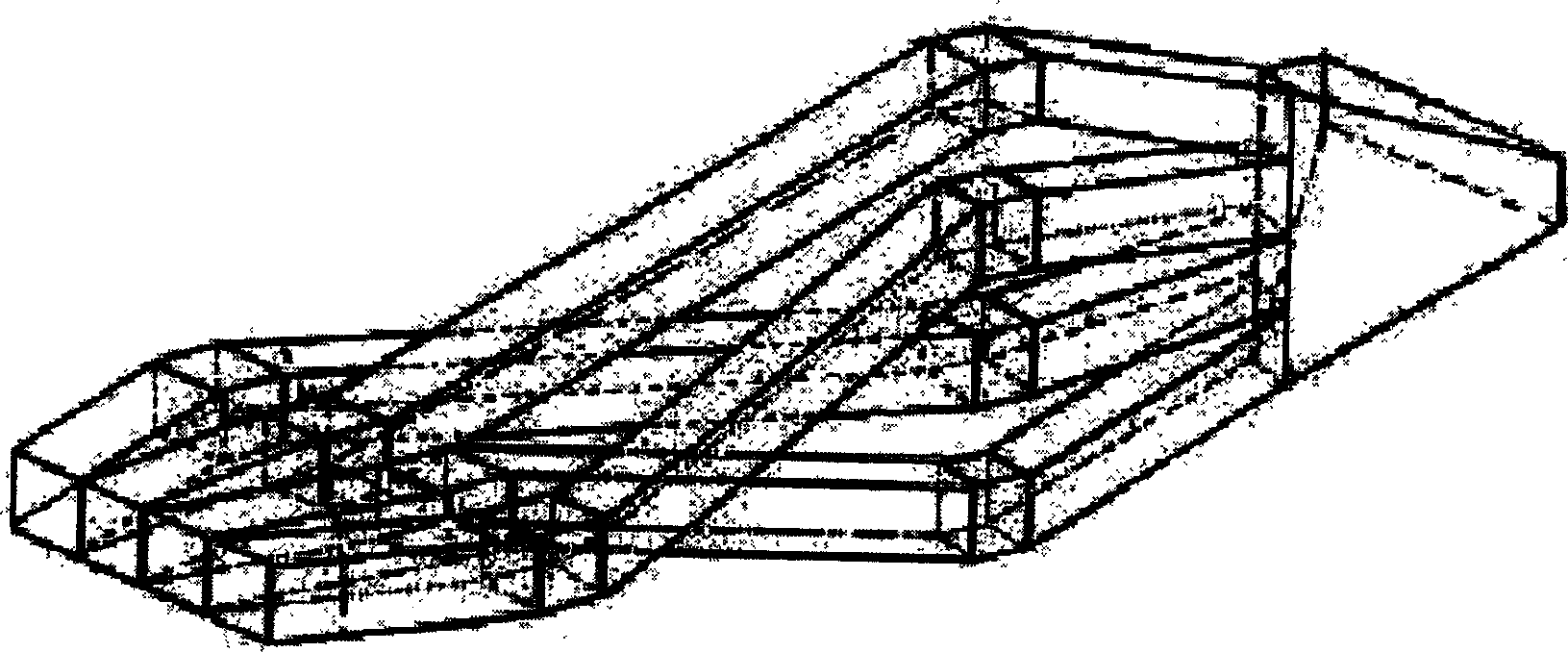

Manufacturing method of carbon fiber reinforced HDPE double-wall winding pipe

The invention discloses a manufacturing method of a carbon fiber reinforced HDPE double-wall winding pipe; firstly, a high-density polyethylene mixture is prepared by high-density polyethylene, a peroxide initiator, polyfunctional group monomers, a high molecular compatilizer and antioxidant; and modified carbon fibers are prepared by carbon fibers and a silane coupling agent. Then, the high-density polyethylene mixture and the modified carbon fibers are reacted and coextruded through a double-screw extruder, and are extruded by a mold and shaped in vacuum to obtain a carbon fiber reinforced HDPE hollow square pipe; and then, the carbon fiber reinforced HDPE hollow square pipe is spirally wound and welded by plastic hot melt adhesive to manufacture the carbon fiber reinforced HDPE double-wall winding pipe. As carbon fiber reinforced HDPE is adopted to manufacture the hollow square pipe, the creep resistance, the modulus, the impact resistance, the scratch resistance, the slow-speed crack expansibility resistance, the environmental stress cracking resistance and the high-temperature resistance are all greatly improved; and the double-wall winding pipe totally has enough gap tensile strength, so that the whole performance of the pipe is effectively improved.

Owner:WUHAN QINGYUAN PIPE CO LTD +1

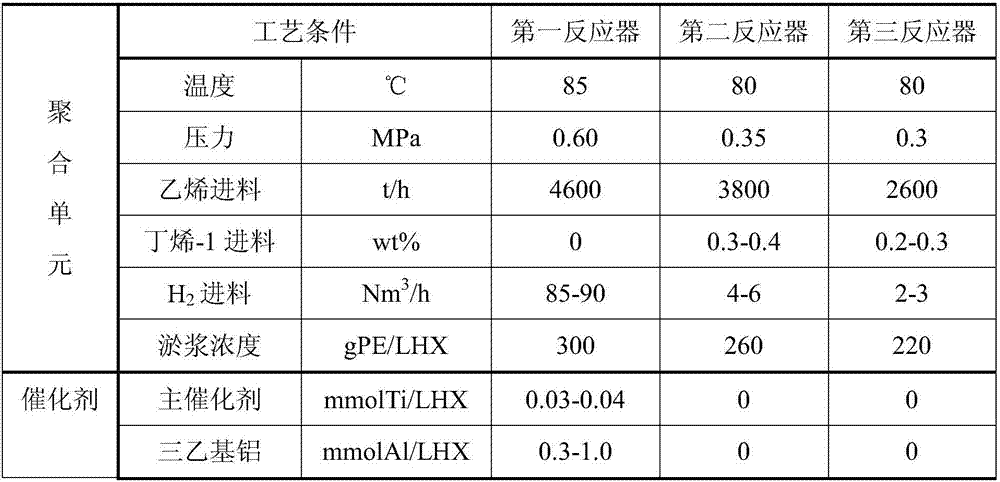

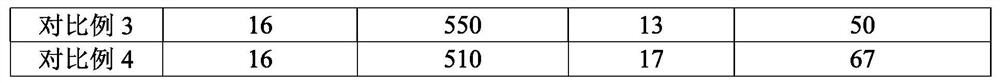

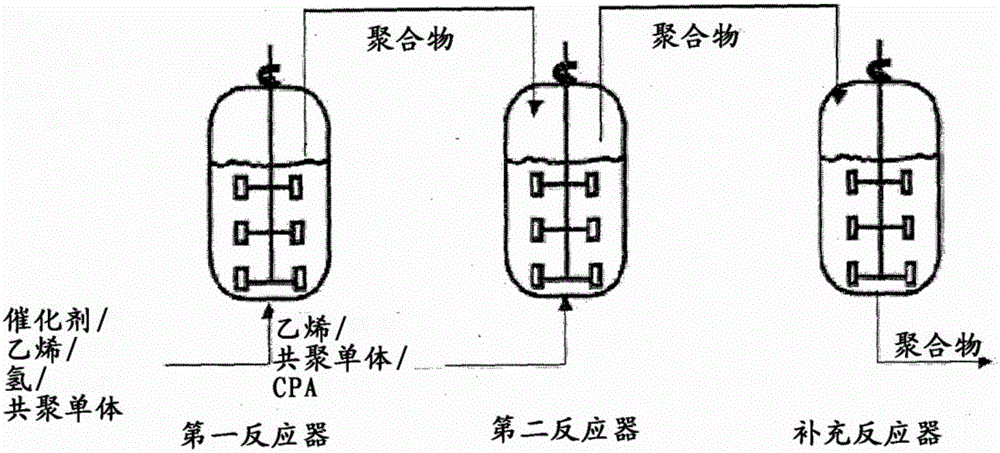

High-density polyethylene resin for preparing small hollow product with extrusion blow molding

InactiveCN107286420AImprove mechanical propertiesIncreased tensile yield strengthBulk chemical productionLow-density polyethylenePolymer science

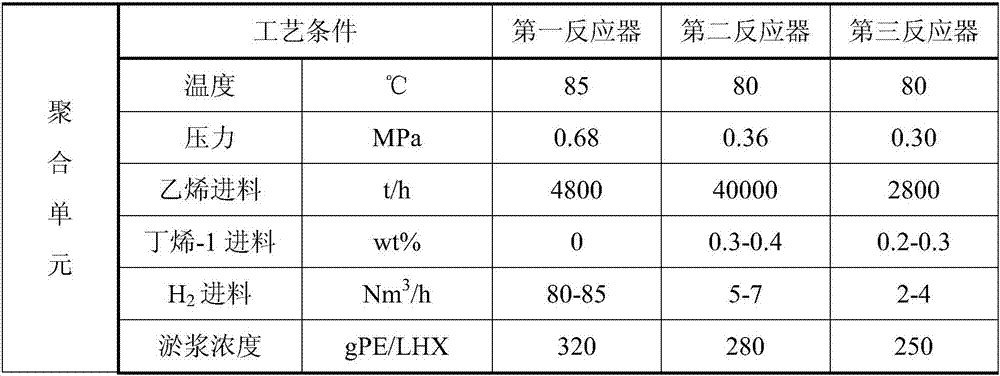

The invention relates to high-density polyethylene resin for preparing a small hollow product with extrusion blow molding. A process of connecting two kettles of a Mitsui slurry polymerization device in series is adopted; then a reaction kettle is connected in series; only ethylene is added into the first reaction kettle; ethylene and butene-1 are added into a second reaction kettle and a third reaction kettle; the molecular weight distribution of HDPE (High-Density Polyethylene) is widened further through the polymerization of the third reaction kettle; meanwhile, the content of the butene-1 as a copolymer monomer of a high-molecular weight part is increased in order to meet the requirement on the HDPE for preparing the small hollow product with the extrusion blow molding. The HDPE has superior mechanical performance, can be up to 28MPa in tensile yield strength to the maximum extent, is over 200h in environmental stress cracking resistance, is improved remarkably in toughness, and can be widely applied to molding and processing of the small hollow product.

Owner:SINOPEC YANGZI PETROCHEM +1

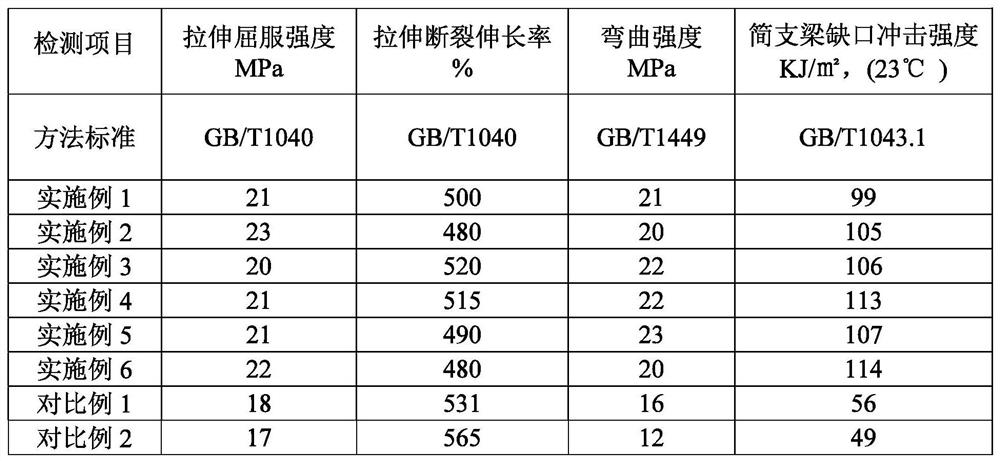

PPR (polypropylene-random) water supply pipe material with high environmental stress cracking resistance and preparation method thereof

ActiveCN104804306AImproved Environmental Stress Cracking ResistanceImprove cold resistanceRigid pipesAntioxidantParaffin oils

The invention relates to a PPR (polypropylene-random) water supply pipe material with high environmental stress cracking resistance. The PPR water supply pipe material comprises raw materials in parts by weight as follows: 15-20 parts of PPB (polypropylene block copolymer), 65-75 parts of PPR, 6-10 parts of low-cis polybutadiene rubber, 6-10 parts of polyisobutene, 2-4 parts of paraffin oil, 0.3-0.5 parts of an initiator and 0.3-0.5 parts of an antioxidant. The invention further provides an application of the PPR water supply pipe material in preparation of PPR water supply pipes. The PPR water supply pipes prepared from the PPR water supply pipe material have excellent environmental stress cracking resistance, cold resistance and low-temperature toughness and can be used in an ultra-low-temperature environment, so that the use range of the PPR pipes is enlarged.

Owner:HENAN LIANSU IND

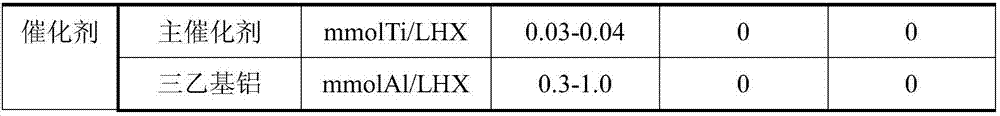

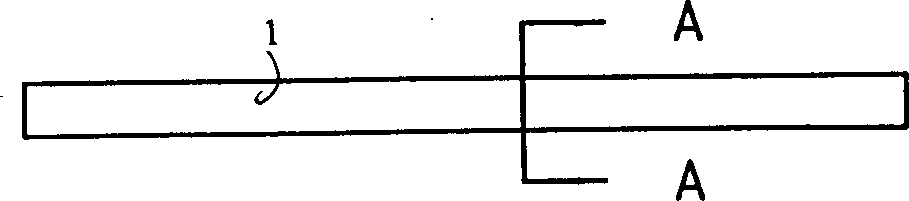

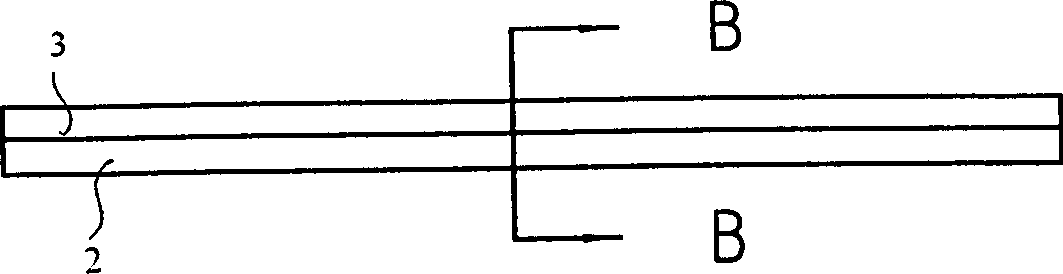

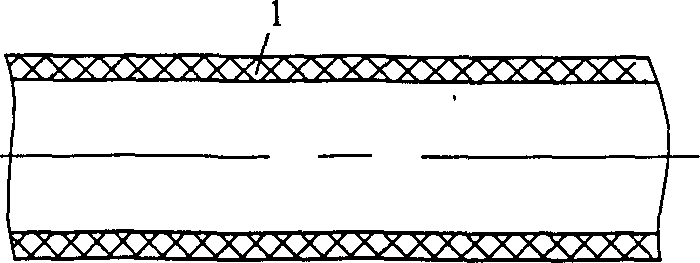

Metal skeleton reinforced non-cross-linking refractory polyethylene pipe

InactiveCN1396400AImproved environmental stress cracking resistanceImprove hot melt effectRigid pipesCross-linkHigh resistance

a non-crosslinked refractory polyethene pipe reinforced by metal skeleton is composed of a main body made of non-crosslinked refractory polyethene and a cylindrical reinforcing metallic skeleton skeleton embedded in the main body and made of curled reticular steel sheet or wound and welded steel wires. Its advantages are high resistance to low temp., high temp. and environment stress, good thermofusibility and long service life.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Cable sheath material for wind power generation

InactiveCN105153520AResistant to twistingGood flexibilityPlastic/resin/waxes insulatorsInsulated cablesActive agentAmorphism

The invention discloses a cable sheath material for wind power generation and belongs to the field of cable sheath materials. The cable sheath material is prepared from, by weight, 70-85 parts of HDPE, 15-30 parts of modifying agent, 15-25 parts of amorphism copolymer, 20-25 parts of acetylene carbon black, 10-20 parts of cold-resistant plasticizer, 20-35 parts of reinforcing filler, 5-15 parts of nano-scale inorganic active agent, 1-3 parts of cross-linking agent, 2-5 parts of auxiliary cross-linking agent, 1-3 parts of anti-aging agent and 10-20 parts of inorganic flame retardant. The cable material has low-temperature resistant and distortion resistant performance and good flexibility, and is suitable for distortion resistant cables, drag chain cables and control cables for wind power generation.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

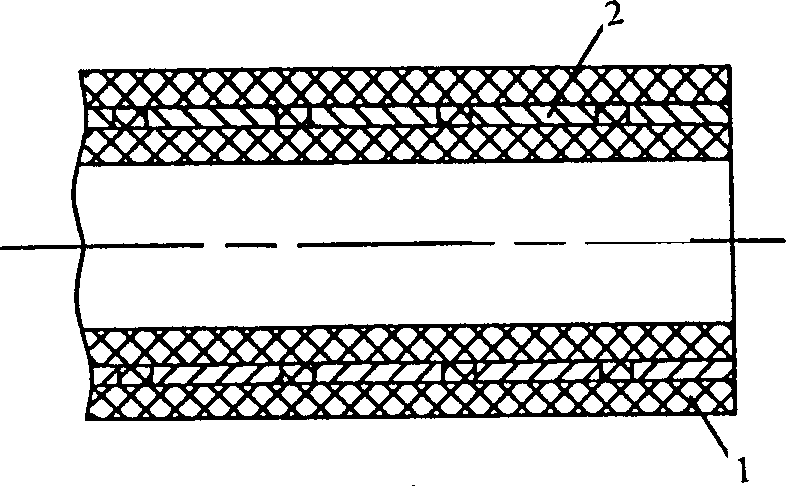

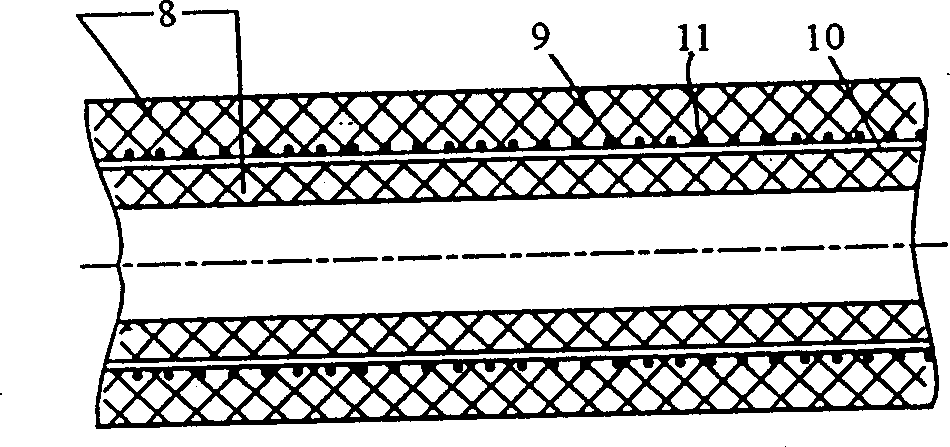

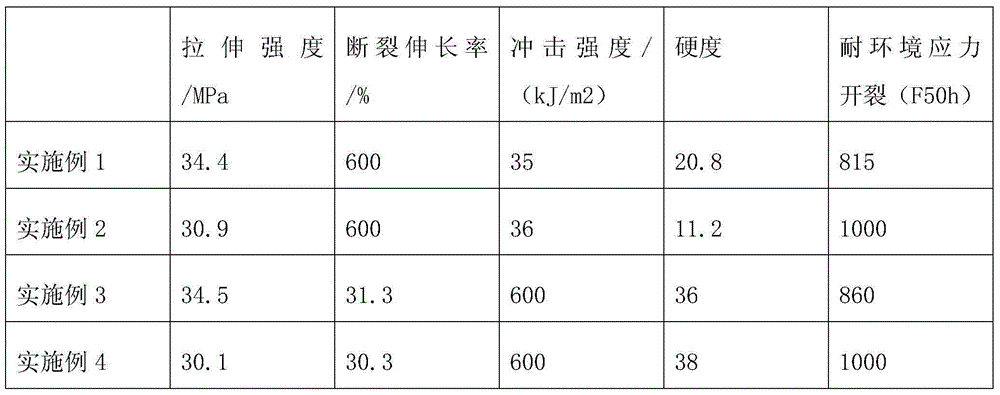

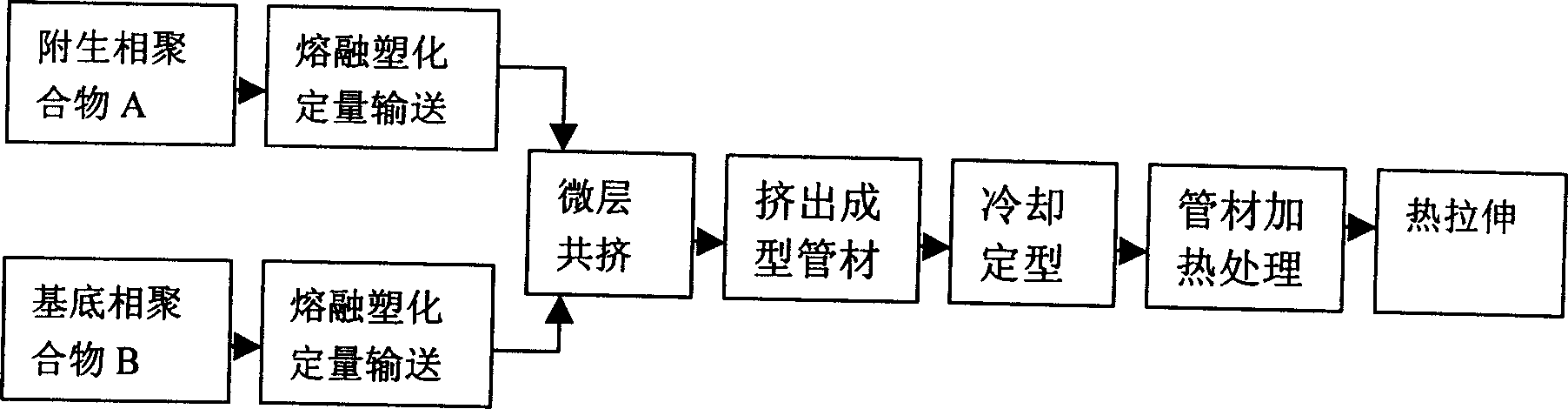

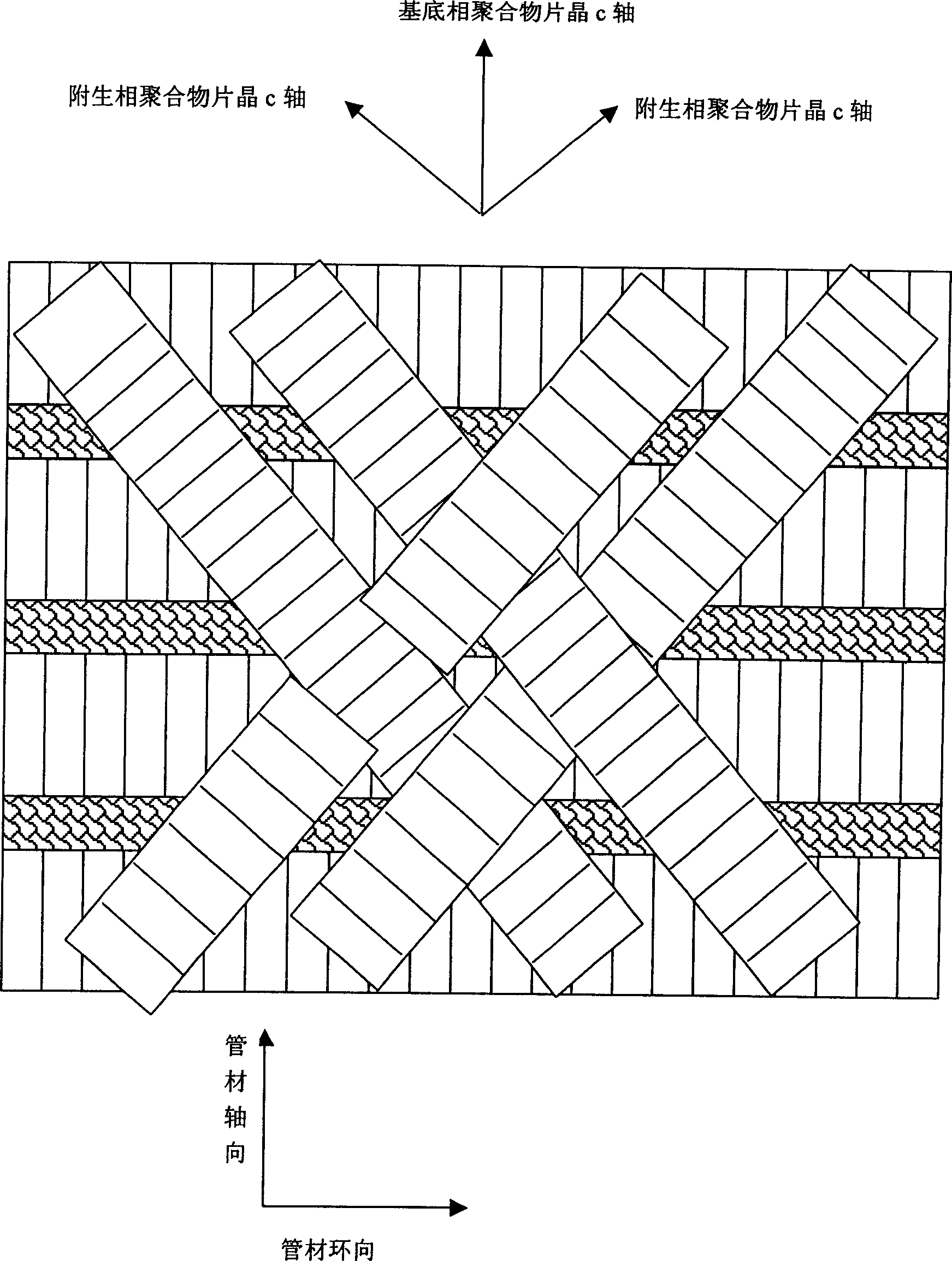

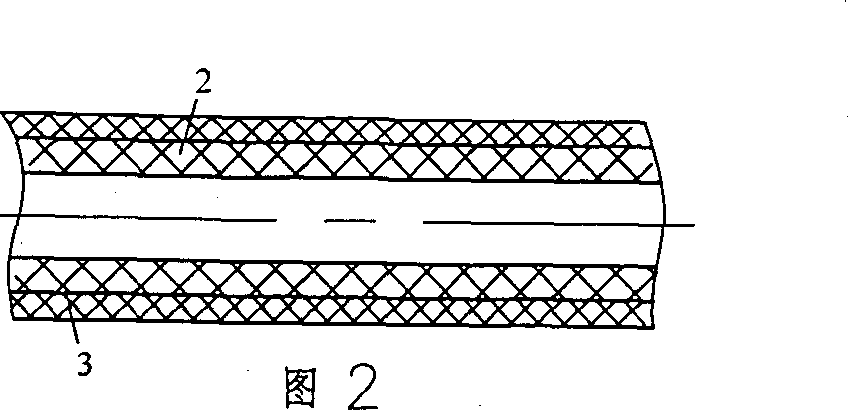

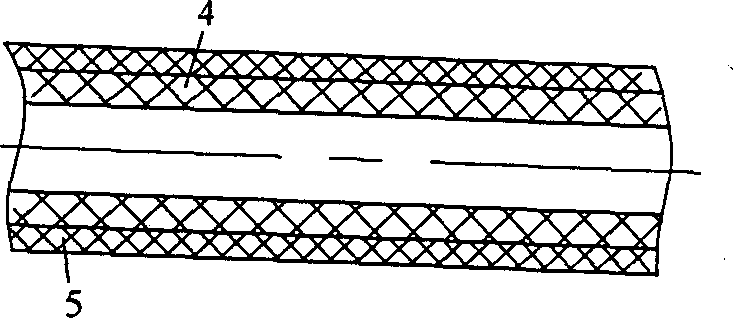

Multiplayer composite tube made from polymer possessing texture in nano layer and making method

InactiveCN1687626AHigh strengthHigh modulusRigid pipesTubular articlesPolymer scienceLayer thickness

The invention discloses the multi-layer polymer composite tubing with nanometer layer structure and its manufacturing method. The composite tubing is formed by the two polymers with non-parallel hetero crossed structure, which passes through the micro-layer coextrusion, the cooled forming, the heat processing and the heat pulling procedures. The c axis of the base polymer layer is along the axial of the tubing, and it accumulative layer thickness is 50-99%of the thickness of the tubing; the c axis of the agglomerative polymer crosses with the axis line of the tubing, and its accumulative thickness is 1-50% of that of the tubing, and the thickness of the single layer of the agglomerative polymer is 50-300 nanometers. The invention forms the reinforcing phase in the tubing in order to strengthen the intensity of the tubing and to improve the expansion of the tubing.

Owner:SICHUAN UNIV

Special impermeable modified epoxy coating for denitrating device and preparation method thereof

InactiveCN104610848AImprove adhesionGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceFirming agent

The invention discloses a special impermeable modified epoxy coating for a denitrating device and a preparation method thereof. The impermeable modified epoxy coating comprises a component A and a component B in a weight ratio of (6: 1)-(5: 1); the component A comprises the following substances: epoxy resin, an inert flaky material, a plasticizer, precipitated barium sulfate, an auxiliary agent, an anti-sagging agent, pigment, a filler and a modifying additive; the component B comprises the following substances: a curing agent, a solvent, an accelerant and a toughening agent. The special modified epoxy coating for the denitrating device, provided by the invention, is high in bonding power, is unlikely to fall off, is good in impermeability and good in chemical agent resistance; the overall protective capability of the coating is improved; the service life of the denitrating device is prolonged; the preparation method has the advantages of simple operation, low cost and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Modified halogen-free flame-retardant thermoplastic elastomer cable material and production method thereof

InactiveCN104830013AEasy to processHigh halogen-free flame retardant gradeRubber insulatorsPlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the technical field of polymer materials and relates to a modified halogen-free flame-retardant thermoplastic elastomer cable material and a production method thereof. The modified halogen-free flame-retardant thermoplastic elastomer cable material is characterized by comprising butadiene-styrene copolymer, polyphenyl ether resin, polyacetylene or polypropylene, polyolefin elastomer, plasticizer, mica, aluminum hydroxide, talcum powder, ethylene vinyl acetate copolymer, polytetrafluoroethylene, lubricant, antioxidant, silicone less than 300 meshes in fineness, and carbon black. The invention further discloses the production method of the modified halogen-free flame-retardant thermoplastic elastomer cable material. The modified halogen-free flame-retardant thermoplastic elastomer cable material has the advantages such as good processability, high flame retarding rating, non-toxicity, low density, good tear resistance, good acid and alkali resistance and good weatherability, with excellent water resistance, cracking resistance and dripping resistance; the modified halogen-free flame-retardant thermoplastic elastomer cable material never ages or separates out under high temperature and high dampness for a long time, the mechanical properties are kept good, and the electrical performances have no evident change.

Owner:JIANGSU ZHONGLI GRP CO LTD

Special coating for modified epoxy denitration device, and preparation method thereof

ActiveCN103992719AImprove adhesionGood chemical resistanceAnti-corrosive paintsPolyamide coatingsPolymer scienceFirming agent

The invention discloses a special coating for a modified epoxy denitration device, and a preparation method thereof. The coating comprises a component A and a component B, the component A comprises modified epoxy resin, an inert sheet material, a flexibilizer, precipitated barium sulfate and an assistant, and the component B comprises a curing agent and a solvent. The preparation method comprises the following steps: adding the epoxy resin, the flexibilizer and the assistant in the component into a dispersion cylinder, stirring, adding precipitated barium sulfate, adding the inert sheet material, filtering to obtain the component A of the coating, dissolving the curing agent by using the solvent in the component B, filtering to obtain the component B of the coating, weighing the prepared component A and the component B according to a mass ratio, uniformly mixing, and curing to obtain the special coating for a modified epoxy denitration device. The special coating for a modified epoxy denitration device has the advantages of strong adhesion, unlikely shedding, good impermeability, chemical reagent resistance, improvement of the whole protection capability of the coating, and prolongation of the service life of the denitration device, and the method has the advantages of simple operation, low cost and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Modified resin for composite material base plate and preparation method thereof

PendingCN111875867AGood size and shape stabilityImprove overload capacityLinear low-density polyethyleneLow-density polyethylene

The invention belongs to the technical field of polyethylene materials, and particularly discloses modified resin for a composite material base plate and a preparation method thereof. The modified resin is prepared from the following raw materials in parts by weight: 50 to 80 parts of high-density polyethylene, 5 to 20 parts of ultrahigh molecular weight polyethylene, 2 to 10 parts of linear low-density polyethylene, 0.1 to 1 part of antioxidant, 0.1 to 1 part of light stabilizer, 0.5 to 3 parts of flow aid, 0.2 to 2 parts of release agent, 0.1 to 1 part of lubricant, 3 to 10 parts of filler and 0.018 to 0.12 part of coupling agent. The filler is modified with the coupling agent, then the filler is blended with the high-density polyethylene, the ultra-high molecular weight polyethylene andthe linear low-density polyethylene, and the formula and the processing technological conditions are reasonably controlled, so that the comprehensive mechanical property of the modified resin is improved, and the prepared composite material base plate is good in size and shape stability and good in mechanical property. In addition, the overload capacity, the environmental stress cracking resistance, the impact strength, the tearing strength and the like are effectively improved.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

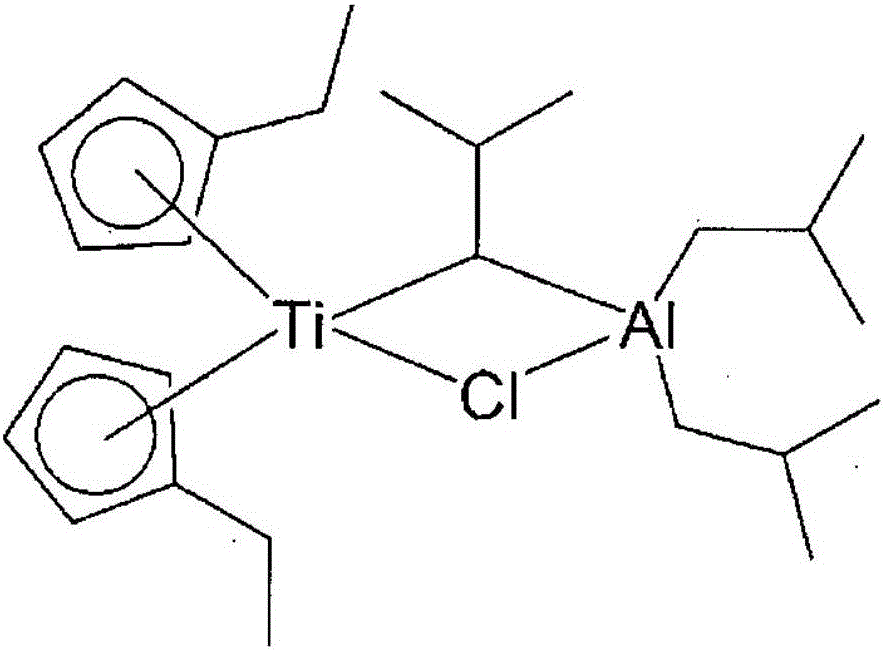

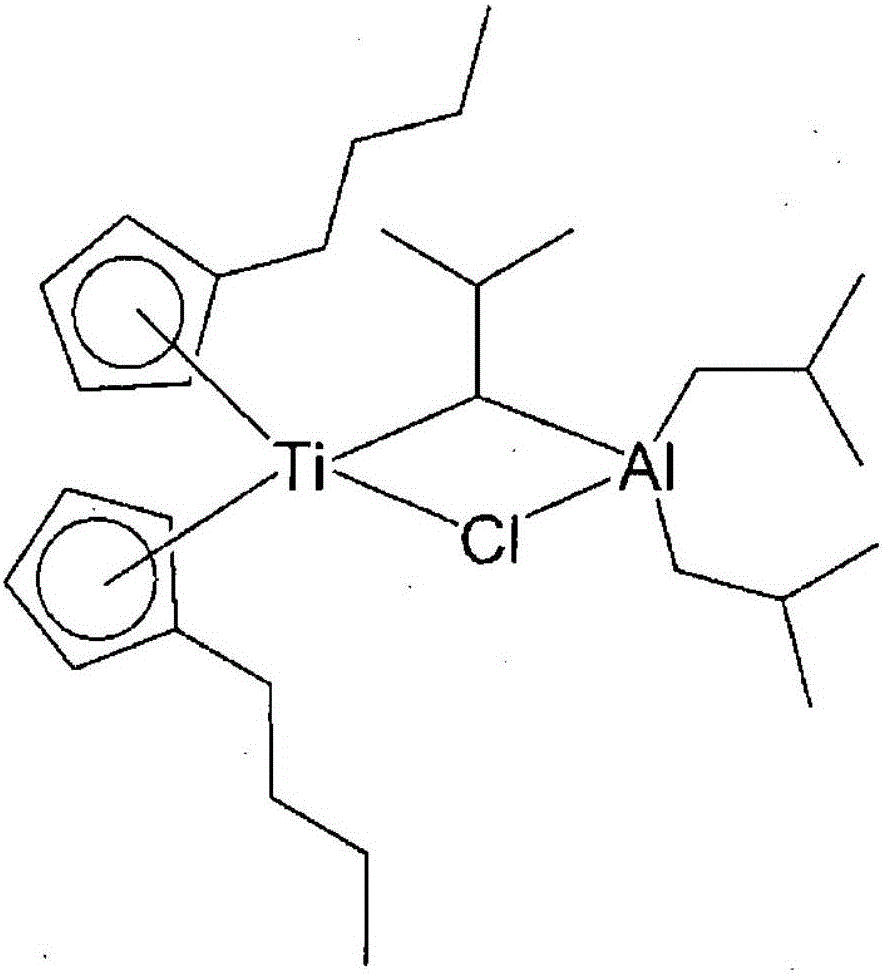

Method for preparing polyolefin and polyolefin prepared thereby

ActiveCN105705527AHigh molecular weightBroad multimodal molecular weight distributionBlow moldingPolyolefin

The present invention relates to a polyolefin preparation method capable of more effectively preparing polyolefin which is preferably useful for blow-molding or the like since the polyolefin has high molecular weight and multimodal molecular weight distribution, and to polyolefin prepared thereby.

Owner:LG CHEM LTD

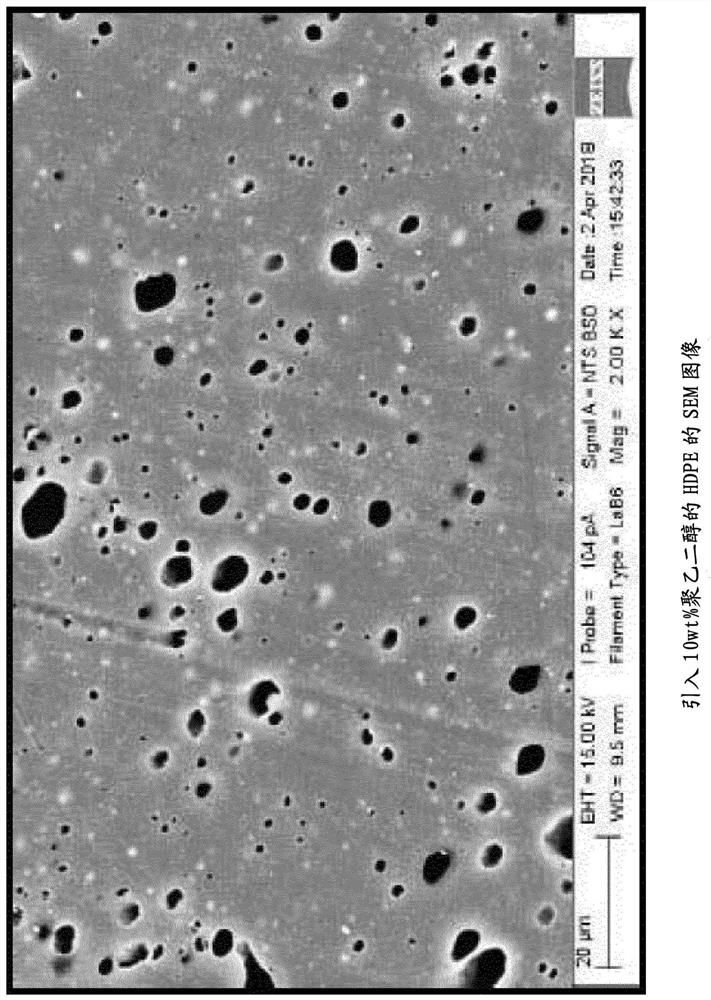

Polyethylene with polyethylene glycol with increased environmental stress crack resistance

ActiveCN112236470AImproved environmental stress cracking resistanceDomestic articlesPolyethylene glycolEnvironmental engineering

A polyethylene composition having increased environmental stress crack resistance (ESCR) is comprised of a polymer blend of a high density polyethylene (HDPE) and polyethylene glycol (PEG). The PEG ispresent in the polymer blend in an amount of from 0.5 wt.% to 15 wt.% by total weight of the polymer blend. The PEG may have an average molecular weight of from 2000 to 40,000. In a method of forminga polyethylene composition having increased ESCR, a HDPE is modified by combining the HDPE with PEG in a polymer blend, the PEG being present in an amount of from 0.5 wt.% to 15 wt.% by total weightof the polymer blend. The polymer blend can be formed into an article of manufacture, such as a bottle cap.

Owner:SABIC GLOBAL TECH BV

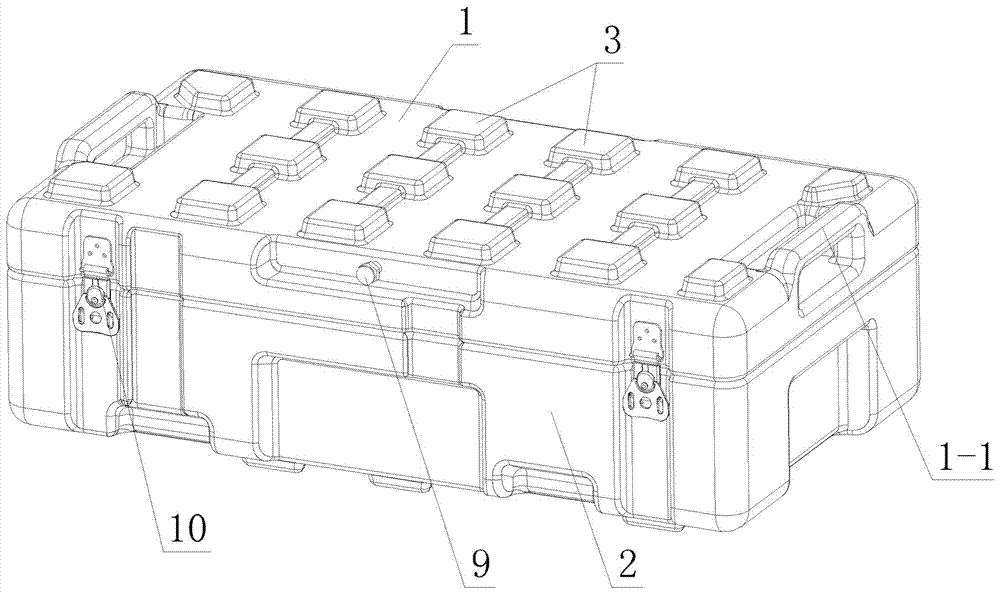

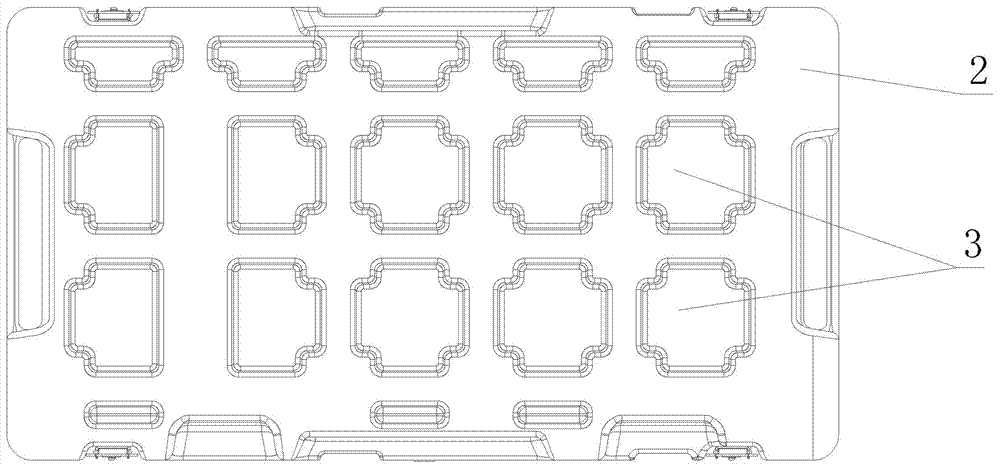

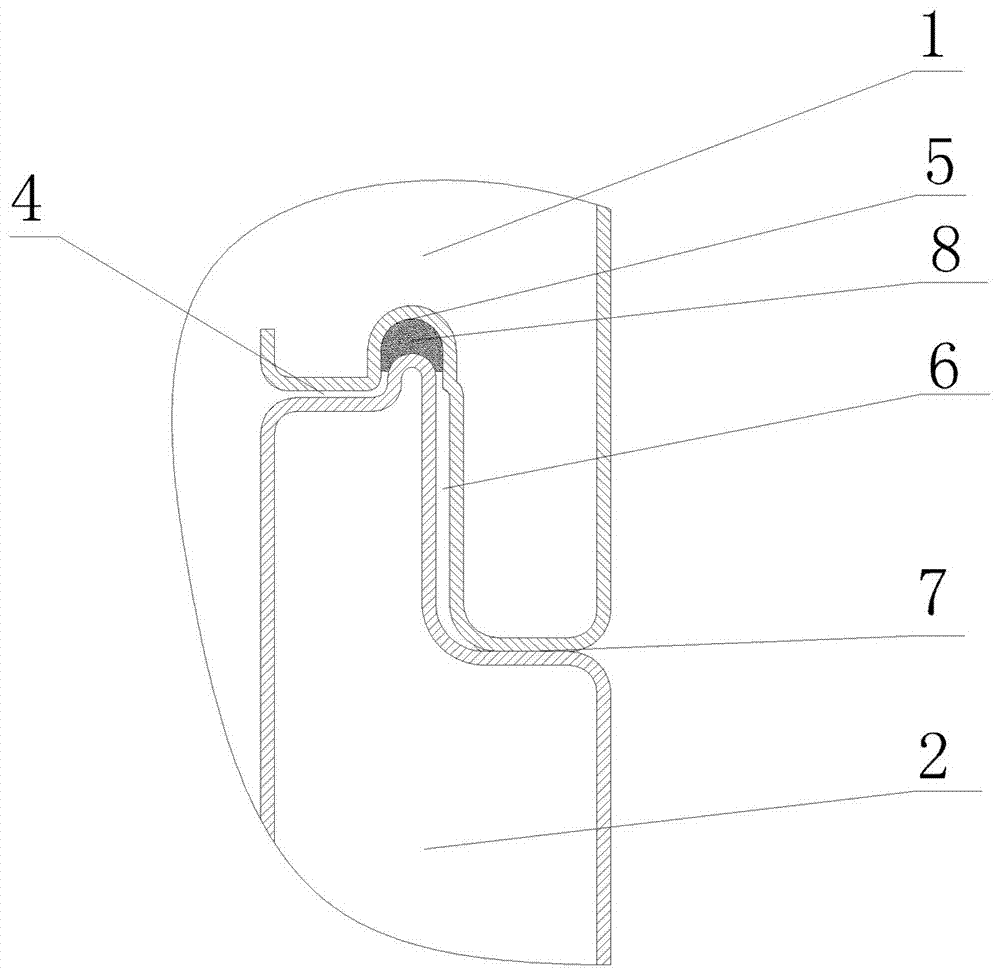

Air-drop type storage-transportation packaging box convenient to stack and preparation method of packaging box

ActiveCN107383579ANot easy to damageImprove toughnessCoatingsRigid containersLinear low-density polyethyleneLow-density polyethylene

The invention relates to an air-drop type storage-transportation packaging box convenient to stack and a preparation method of the packaging box, belonging to the package and transportation fields. The packaging box comprises a box body and a box cover which are mutually buckled, wherein the box body and the box cover are prepared from the following raw materials in parts by weight through rotational molding: 50-70 parts of linear low density polyethylene, 50-70 parts of low density polyethylene, 40-80 parts of high density polyethylene, 10-30 parts of medium density metallocene polyethylene and 1-6 parts of a coupling agent; and rig grids are arrayed at the bottom of the box body or the top of the box body or the box cover in a matrix manner, the rig grids at the top of the box body or the box cover are mutually seamed and clamped with the rig grids at the bottom of the box body on an upper layer so as to form embedding and splicing type anti-dislocation stacking structure. The packaging box is produced from the polyethylene materials with different densities through mixing and rotational molding, and modularized rid grid structures are arranged at the top and the bottom of the packaging box, so that the strength, impact resistance and packaging efficiency of the packaging box are improved, and the mutual stable stacking of different specifications of packaging boxes is realized.

Owner:河北金后盾塑胶有限公司

Silk ribbon of silane-crosslinked high-strength monoway stretched and oriented polymer

InactiveCN1388154AImprove heat resistanceImprove heat aging resistanceFibre treatmentCrack resistancePolymer science

The present invention is polymer band of silane-crosslinked polymer through monoway stretching and orientation and subsequent hydrolysis, polycondensation and crosslinking in wet and hot condition. It has greatly raised heat resistance, heat aging resistance, hydrolysis aging resistance, environment stress resistance, crack resistance, gasoline and arene resistance, and creepage resistance and long service life.

Owner:甘国工

Stretch-orientated silane cross-linked polyethylene pipe and its preparing process

A stretch orientated silane cross-linked polyethene pipe features that its pipe wall contains at least one polyethene layer, which is orientated by radially or both radially and axially stretching and then hydrolytically condensated for cross-linking with silane. Its advantages include high pressure-bearing power and high anticracking performance. Its preparing process is also disclosed.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com