Satchel charge packing film and preparation method thereof

A technology of packaging film and explosive package, which is applied in packaging, wrapping paper, transportation and packaging, etc. It can solve the problems of poor mechanical properties of composite films and lack of adhesion between three-layer co-extruded PE films of mechanical strength, etc., to improve chemical Effect of Stability and Tensile Strength, Interlayer Bonding Properties and Guaranteed Dimensional Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Prepare the explosive package packaging film as follows:

[0037] (1) First prepare the PE film: mix high-density polyethylene (HDPE), linear low-density polyethylene, and masterbatch

[0038] As a result, the ratio is to add 2 kg of linear low density polyethylene to every 3 kg of HDPE, and the color masterbatch is 0.01 kg. The masterbatch is mainly to increase the color of the film.

[0039] Put the PE raw material into the blown film machine, and then cut the blown film into a tube shape. After being folded flat, it is cut into two separate films, which are wound into rolls.

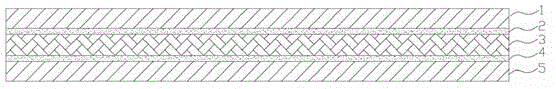

[0040] (2) PE film + PET film + PE film composite There are three layers of packaging film for explosive packs. The middle layer is made of PET film with a thickness of 12 filaments.

[0041]The PET film passes through a plastic printing machine, and the company name, logo, etc. are printed on the surface of the film. After printing, the ink is dried in an oven. The drying uses hot air at a t...

Embodiment 2

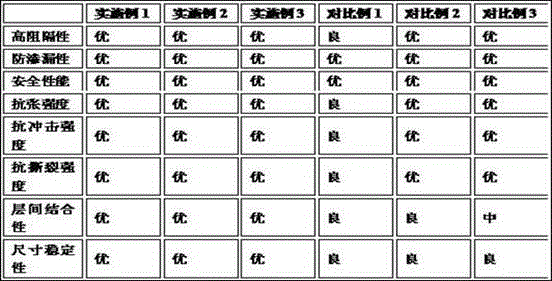

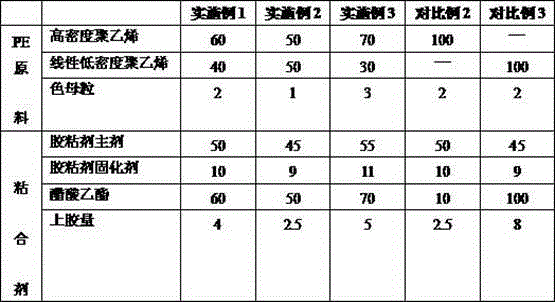

[0050] The process of this example is basically the same as that of Example 1, the difference is that the ratio of PE raw materials used to prepare the PE film is adjusted, see Table 1 for details.

Embodiment 3

[0052] The process of this example is basically the same as that of Example 1, the difference is that the ratio of PE raw materials used to prepare the PE film is adjusted, see Table 1 for details.

[0053] Table 1 Formula ratio

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com