Patents

Literature

188results about How to "Guaranteed binding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite aluminum oxide /erbium hydrogen resistance coating and preparation thereof

ActiveCN101469409AExcellent self-healing performanceExtended service lifeChemical vapor deposition coatingHydrogenAlloy

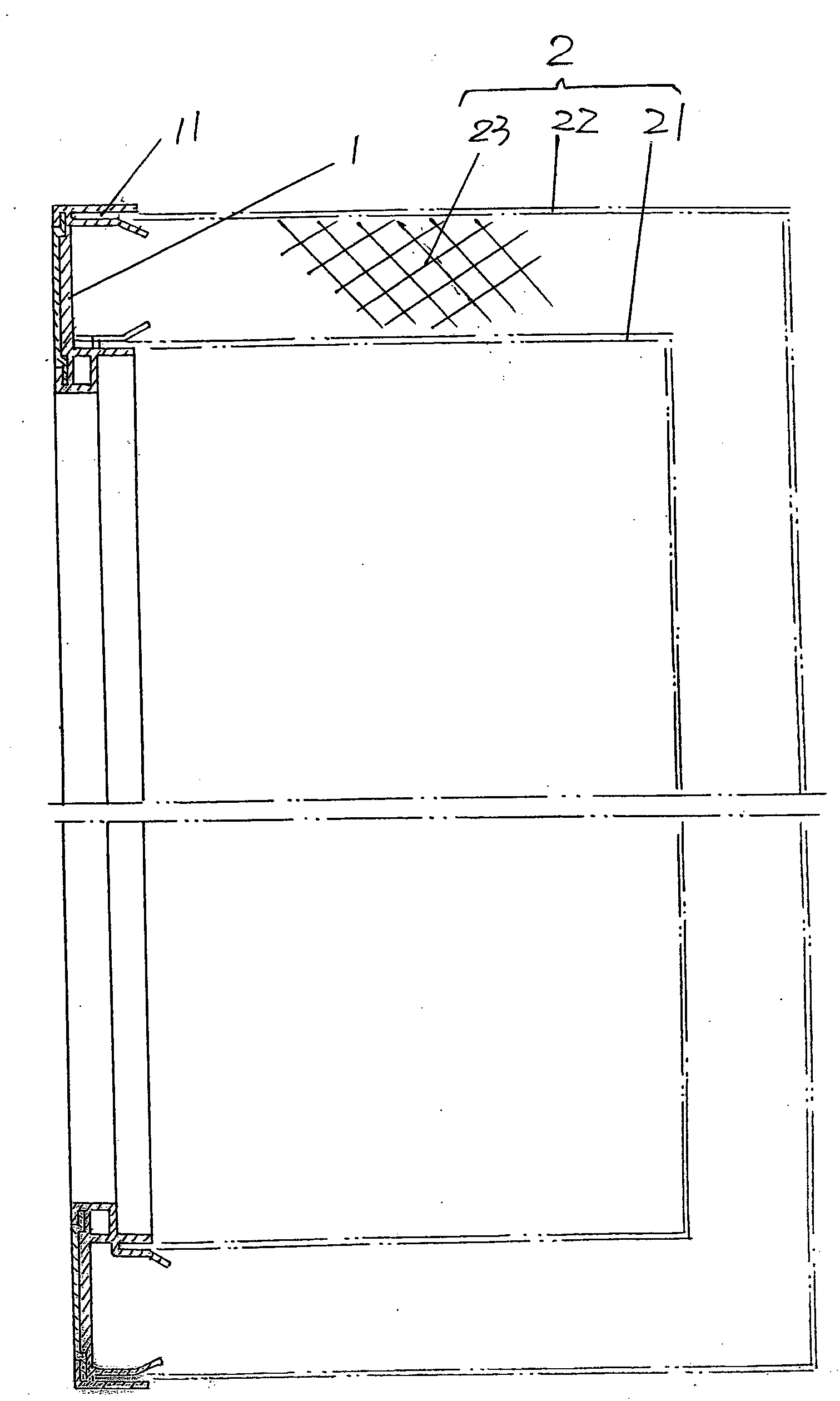

The invention relates to a hydrogen resistant coating and a preparation method thereof, in particular to a hydrogen resistant coating containing an Al2O3Er2O3 composite structure. The coating comprises a basal body, a metal transition layer and an Al2O3Er2O3 composite coating arranged in sequence, wherein the basal body can be made of activated martensite steel; the metal transition layer can be made of FeAl alloy; and the composite coating can be divided into two forms of a single-layer composite coating and a multi-layer gradient composite coating according to different compositions and structures, wherein the single-layer composite coating is formed by preparing a coating on the metal transition layer, the component of the single-layer composite coating is xAl2O3-(1-x)Er2O3, the single-layer composite coating is composited according to the ratio more than 0 and less than 100 percent, the multi-layer gradient composite coating is formed by a plurality of layers of composite coating comprising xAl2O3-(1-x)Er2O3 (x is more than or equal to 0 and less than or equal to 100 percent) with different x values.

Owner:GRIMAT ENG INST CO LTD

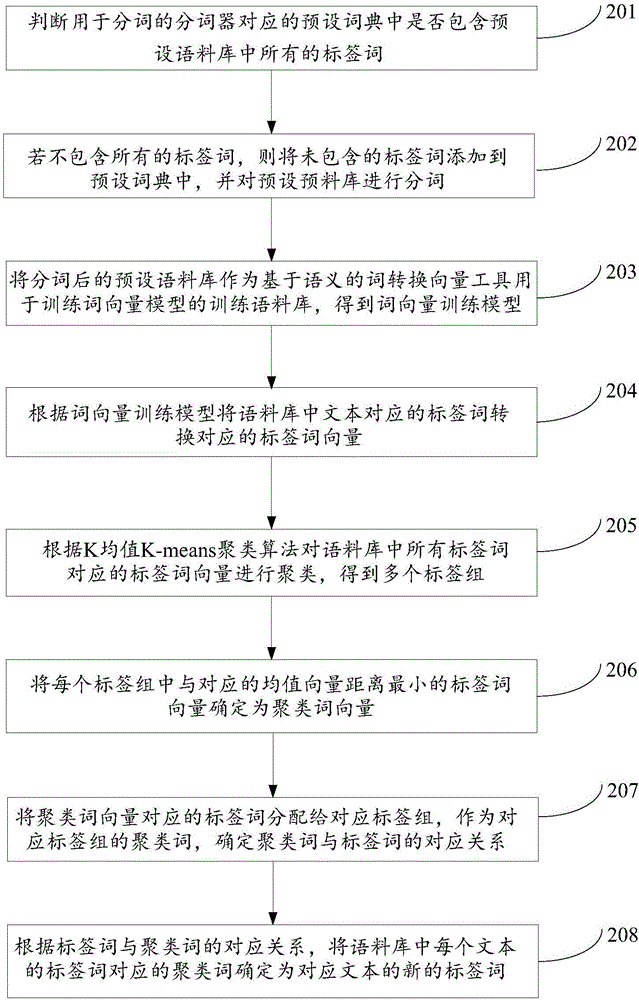

Text label determination method and device

ActiveCN106611052AGuaranteed associativityImprove accuracySemantic analysisCharacter and pattern recognitionCluster algorithmAlgorithm

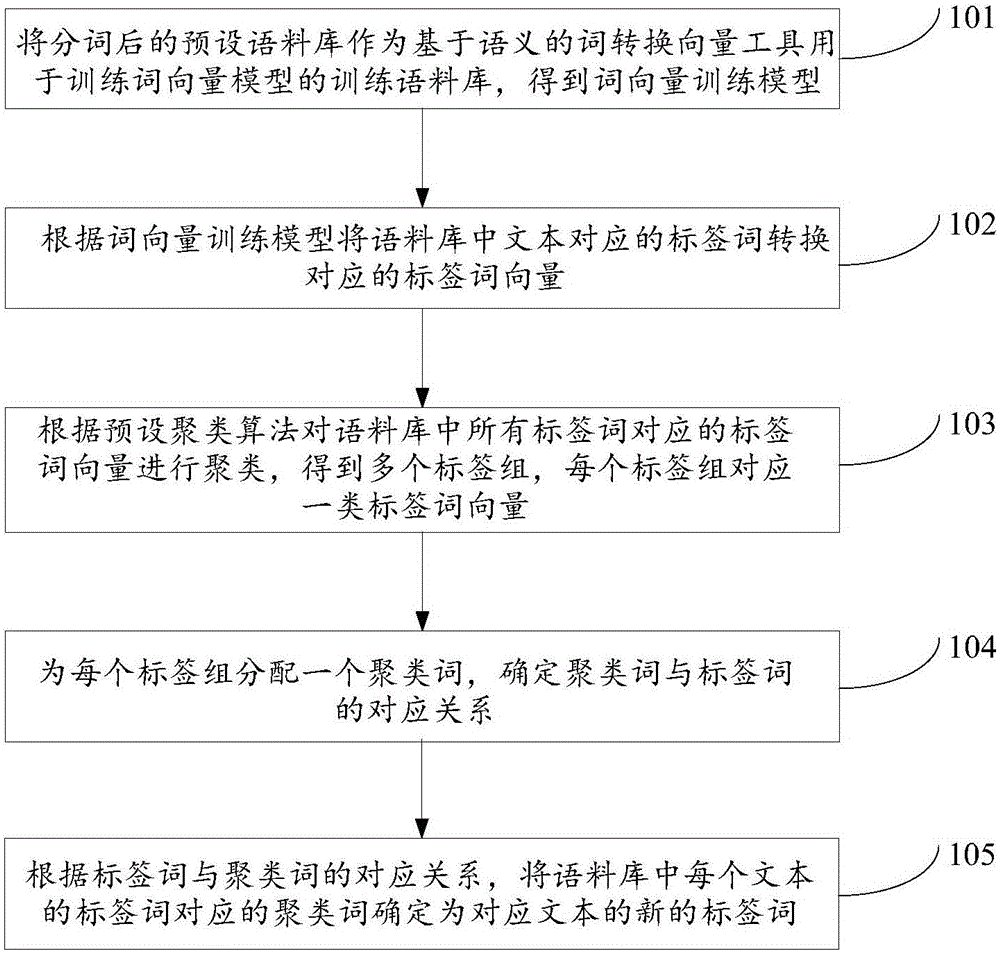

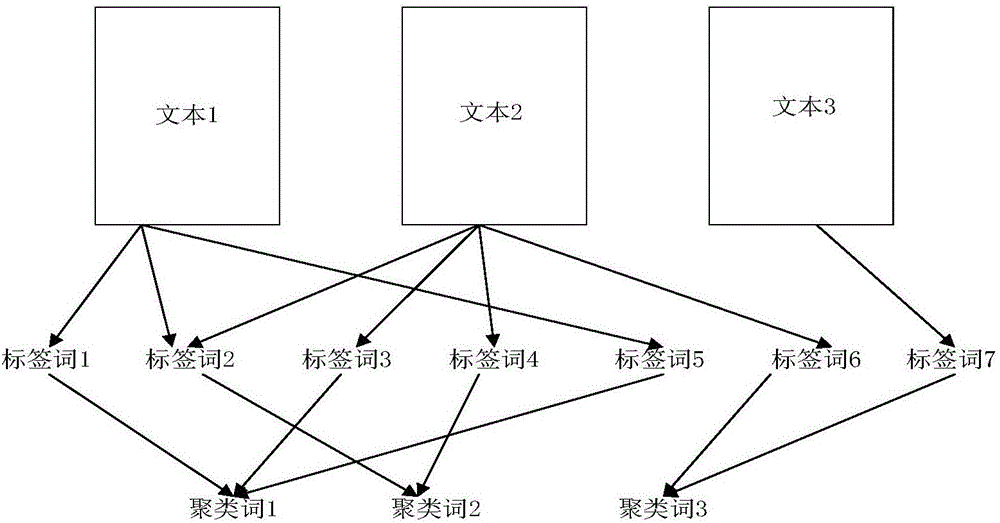

The invention discloses a text label determination method and device and relates to the field of natural language processing technology. The problem that model accuracy is affected because text labels are not standardized is solved. The method comprises the steps that a preset corpus obtained after word segmentation is used as a semantic-based word conversion vector tool training corpus used for training a word vector model, and a word vector training model is obtained; label words corresponding to texts in the corpus are converted into corresponding label word vectors according to the word vector training model; the label word vectors corresponding to all the label words in the corpus are clustered according to a preset clustering algorithm to obtain multiple label sets; a cluster word is distributed for each label set, and the corresponding relation between the cluster words and the label words is determined; according to the corresponding relation between the label words and the cluster words, the cluster word corresponding to the label word of each text in the corpus is determined as a new label word of the corresponding text. The text label determination method and device are applied to the text analysis and processing process.

Owner:NEUSOFT CORP

Rolling method for composite strip of stainless steel and straight carbon steel

InactiveCN102553918AShort process stepsImprove rolling efficiencyMetal rolling arrangementsSS - Stainless steelComposite plate

A rolling method for a composite strip of stainless steel and straight carbon steel belongs to the technical field of rolling of composite strips and comprises the steps of preparing materials; pretreatment; blank overlaying; heating and heat rolling; unreeling; cold rolling and heat treatment; and finishing. Leading an initial rolling plate into a cold-rolling mill for cold rolling to obtain a cold-rolling composite rolling plate, then conveying the cold-rolling composite rolling plate into a heat treatment furnace for heat treatment, and controlling the temperature for heat treatment to obtain a cold composite rolling plate; and performing finishing on the cold composite rolling plate and obtaining the composite strip of the stainless steel and the straight carbon steel. The rolling method for the composite strip of the stainless steel and the straight carbon steel has the advantages that the rolling method is short in process procedure and high in rolling efficiency so as to save energy; enables the integral combination effect of base plate blank made of the straight carbon steel and composite plate blank made of the stainless steel to be fully ensured; is high in finished product rate; and can meet the requirements of industrialized amplification production.

Owner:江苏天成特种金属复合材料科技有限公司

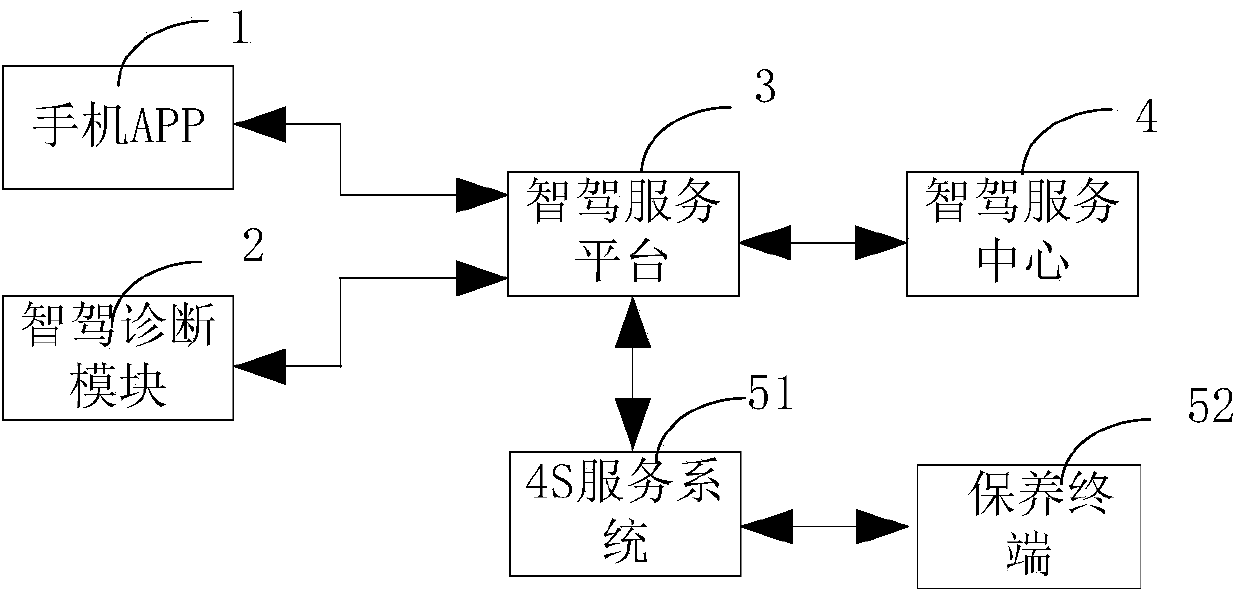

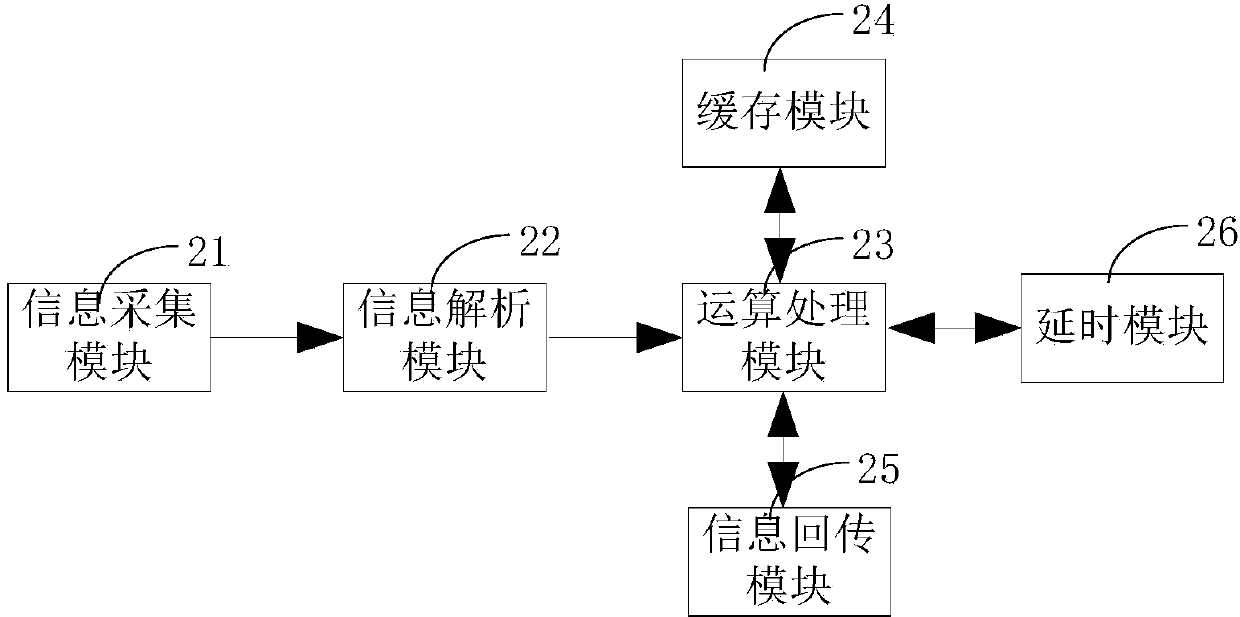

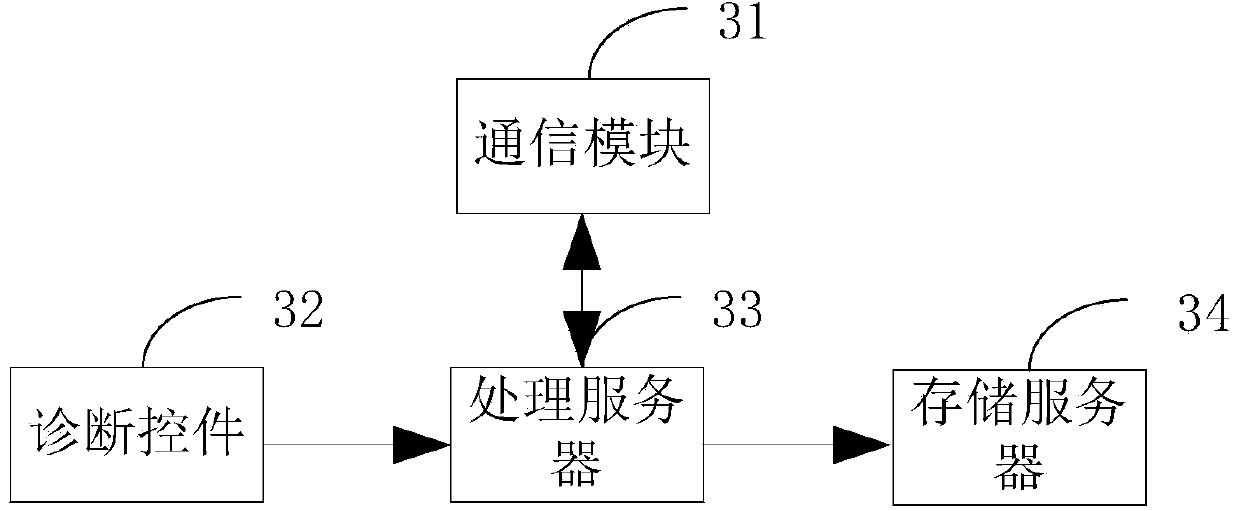

Integrated intelligent driving service system

ActiveCN104184801AGuaranteed maintenanceGuaranteed CompatibilityTransmissionEmergency rescueEngineering

The invention relates to an integrated driving service system, which comprises a mobile phone APP, an intelligent driving diagnosis module, an intelligent driving service platform and an intelligent driving service center, wherein the mobile phone APP is loaded on a mobile phone of a vehicle owner; the intelligent driving diagnosis module is integrated on an intelligent driving diagnostic instrument, the intelligent driving service platform is stored with client serial numbers and intelligent driving diagnostic instrument serial numbers which are sequentially arranged according to the time; and the intelligent driving service platform comprises a diagnostic control, a processing server, a storage server and a communication module. The integrated intelligent driving service system takes an intelligent driving vehicle networking national operation service network as a support, provides functions of one-key navigation, remote diagnosis, security setting, emergency rescue, vehicle removing message passing and maintenance.

Owner:BEIJING YESWAY INFORMATION TECH

Anti-abrasion and anti-corrosion composite functional coating layer

The invention belongs to the technical field of thermal-sprayed coating layers and relates to a composite functional coating layer capable of resisting abrasion and corrosion. The coating layer consists of the chemical components such as NiCrAlY alloy powder, metallurgical TiC powder and rare-earth oxide La2O3 powder, wherein the adding amount of the NiCrAlY alloy powder accounts for 49.5-80 percent of the weight of the powder of the whole coating layer; the adding amount of the metallurgical TiC powder accounts for 19.5-50 percent of the weight of the materials of the coating layer; the adding amount of the rare-earth oxide La2O3 powder accounts for 0.5-5 percent of the weight of the materials of the coating layer. Metallurgical combination is realized, so that the bonding strength of the coating layer is high, and organization is compact; therefore, compared with the common coating layer, the coating layer has the advantages that the abrasion resistance and the corrosion resistance are greatly improved. The coating layer disclosed by the invention is processed by a plasma composite spraying technology such as laser and atmosphere instead of an independent thermal spraying technology; in order to fulfill the aim of realizing coating layer metallurgical combination, due to the metallurgical combination, the coating layer combining strength can be improved, and the high compactness of the organization of the coating layer is realized; due to the high combining strength and the low porosity, the coating layer is long in service life and high in abrasion resistance and corrosion resistance.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

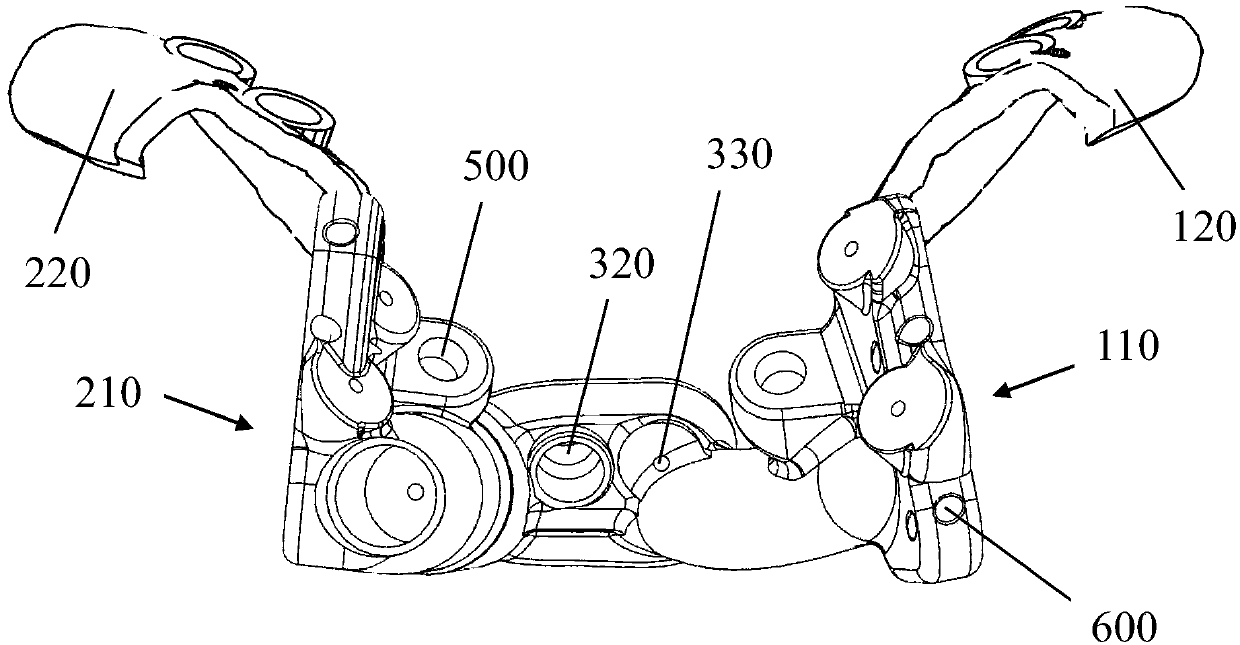

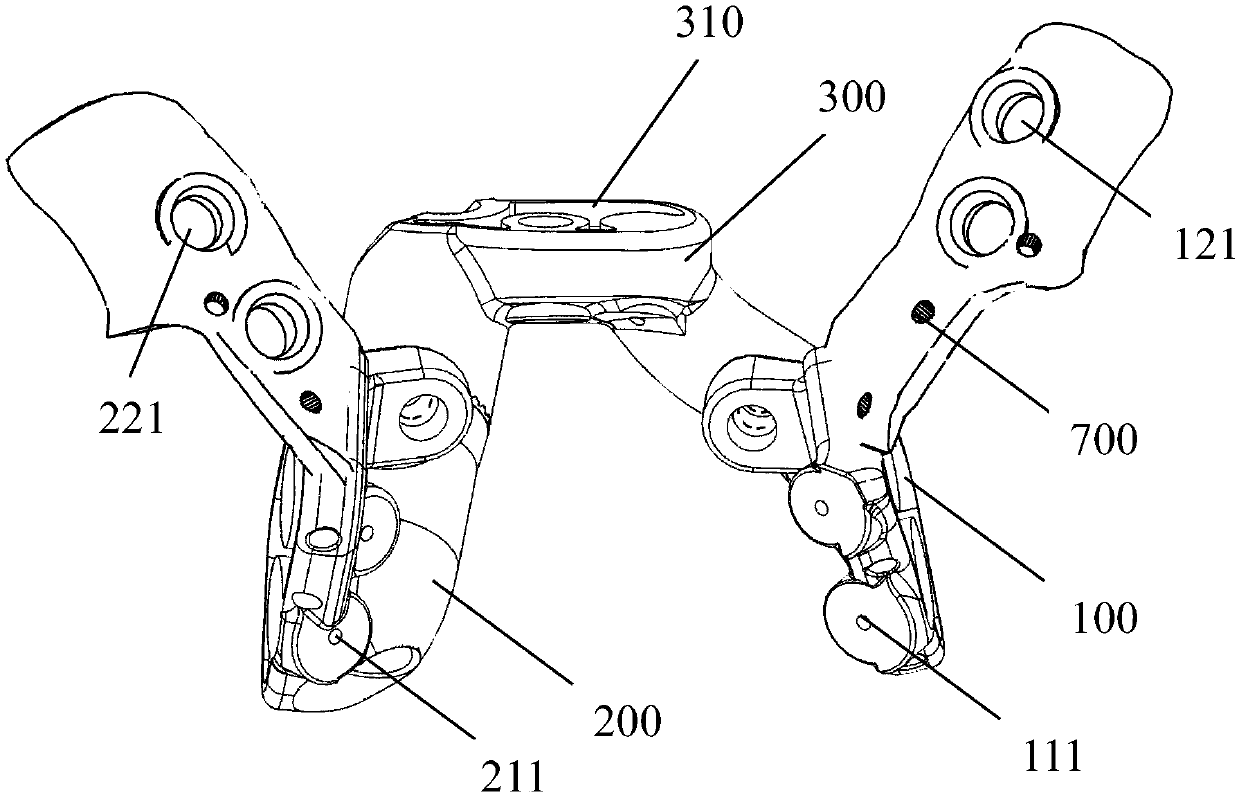

Suspended customized assembly total sacrum prosthesis and customization method

PendingCN108670506AContribute to generationRecovery functionJoint implantsSpinal implantsSacroiliac joint stabilityOsteoblast

The invention discloses a suspended customized assembly total sacrum prosthesis and a customization method. The suspended customized assembly total sacrum prosthesis comprises a prosthesis body, a right ilium wing fastener and a left ilium wing fastener. The suspended customized assembly total sacrum prosthesis has the advantages that the suspended customized assembly total sacrum prosthesis can rapidly promote bone cell generation and bone fusion, restore sacrum functions and achieves reconstructed waist sacroiliac joint stability.

Owner:SUZHOU KANGLI ORTHOPEDICS INSTR +1

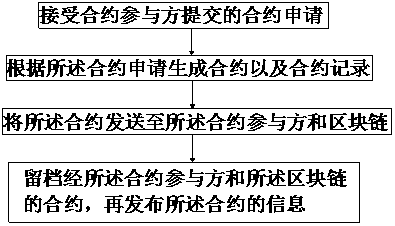

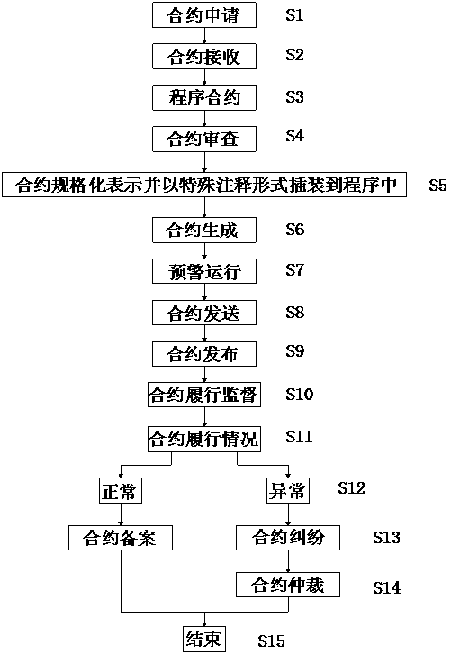

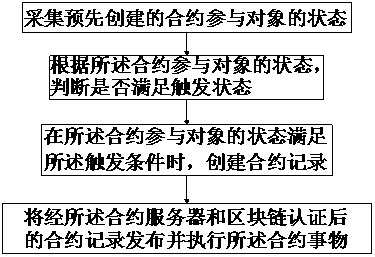

Novel electronic contract and automatic execution method thereof

The invention discloses a novel electronic contract generation method. The method comprises a step of receiving a contract application submitted by a contract participant, wherein the contract application includes involved objects and things of contract participants and a certificate of a legal blockchain approved by the contract participants, a step of generating a contract and a contract recordaccording to the contract application, wherein the contract record comprises a contact signing time, an implementation standard, a purpose, certificates of involved objects of the contract participants and the certificate of the legal blockchain approved by the contract participants, a step of sending the contract to the contract participants and the blockchain, wherein the contract participants can dispute the contract and provide feedback to the blockchain. According to the method, the contract is described in the form of a computer language, then the contract is automatically executed depending on set conditions on a container, signing the contract in a face-to-face way is not needed, a full guarantee is obtained in remote signing, time and labor are saved, the cost is saved, and the security is high.

Owner:深圳市图灵奇点智能科技有限公司

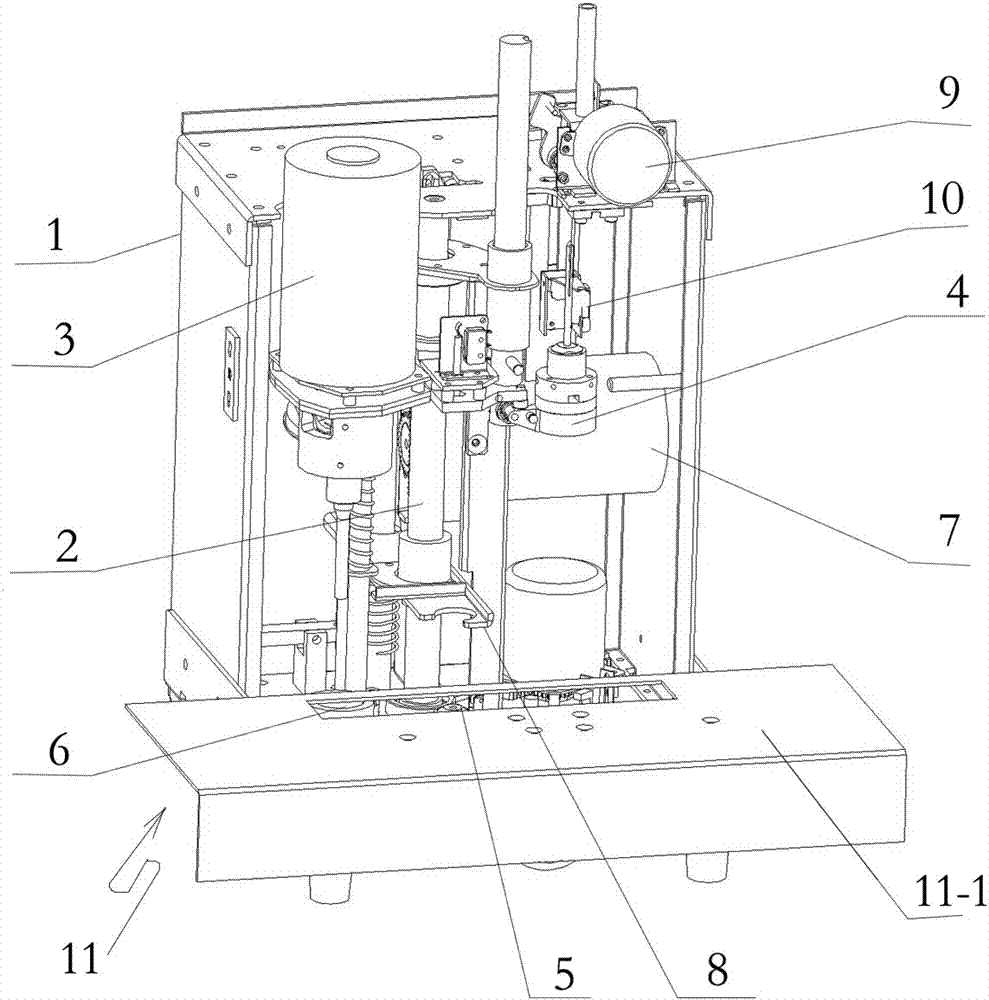

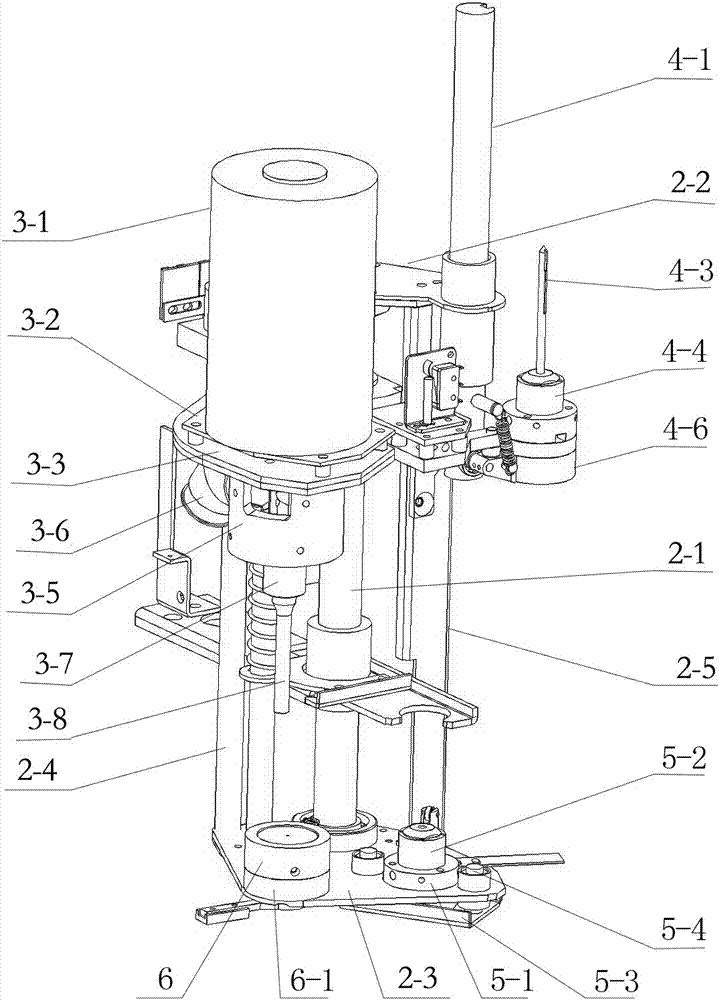

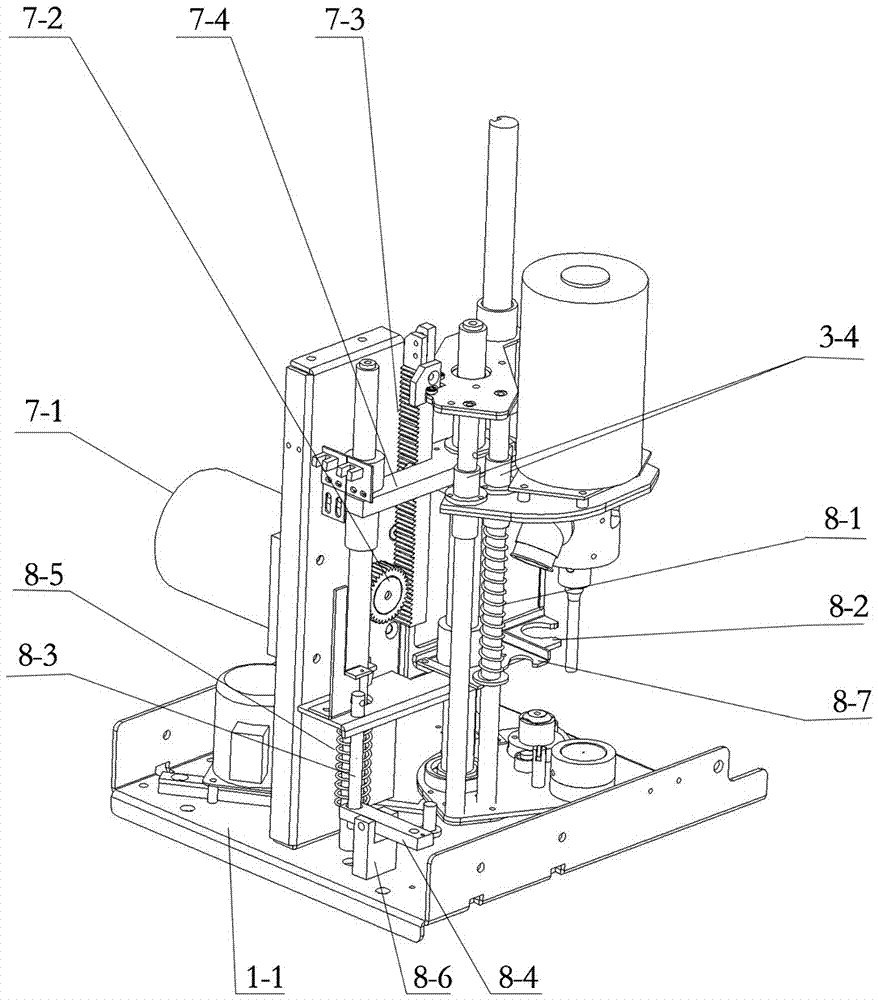

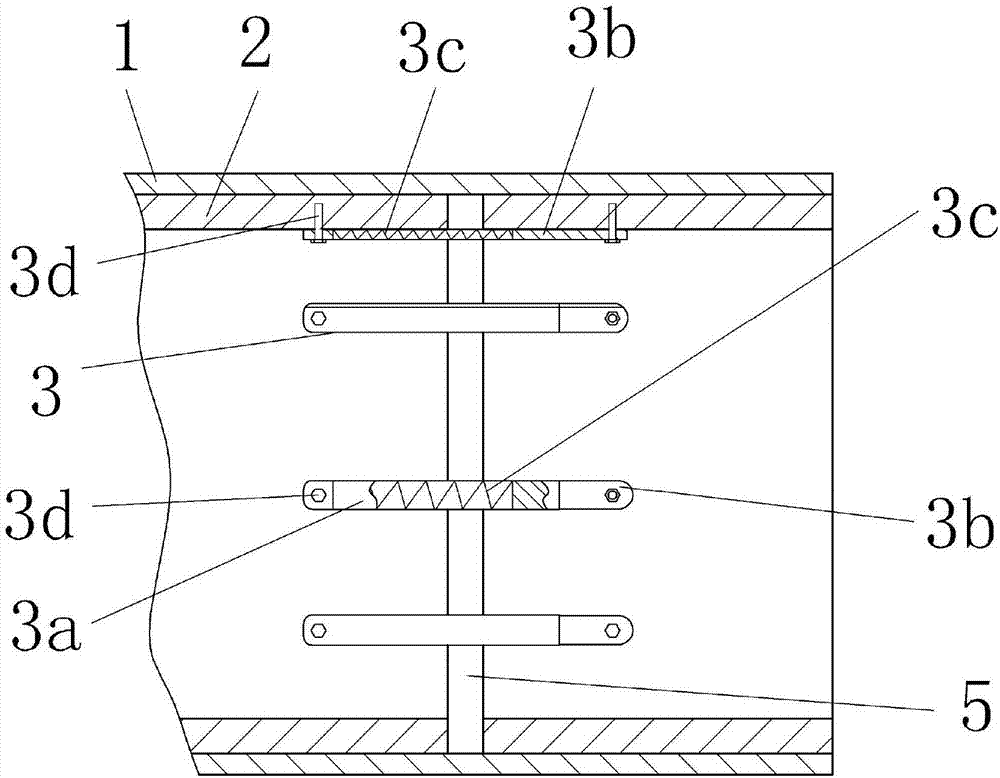

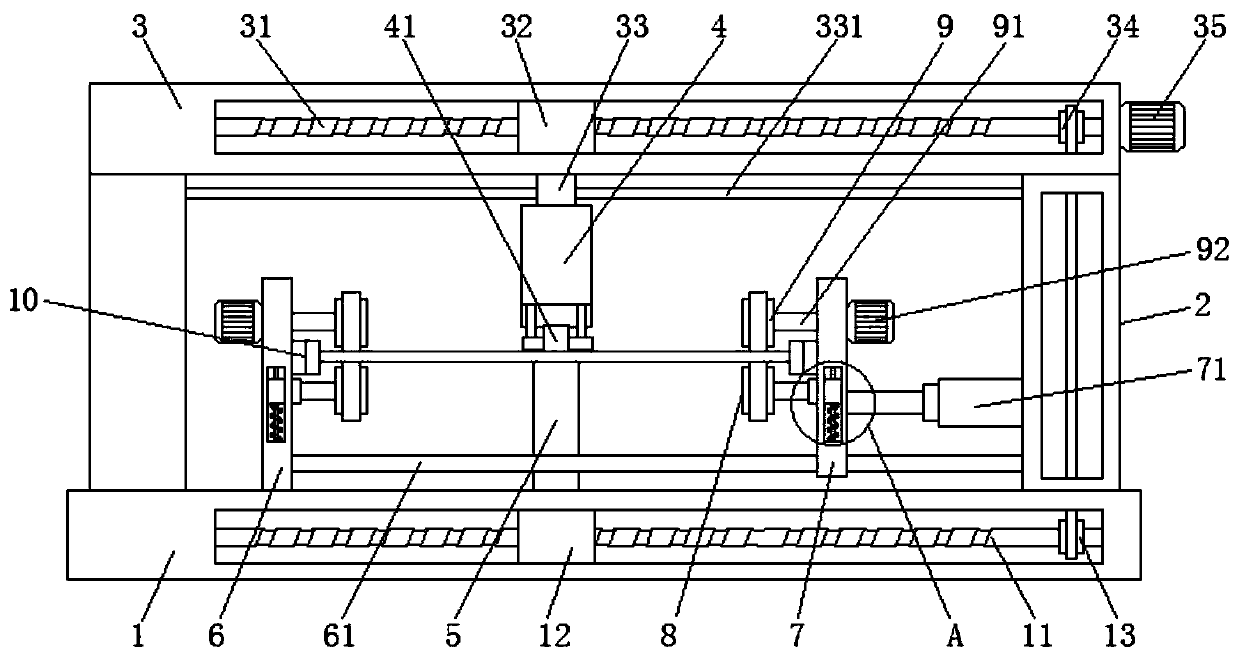

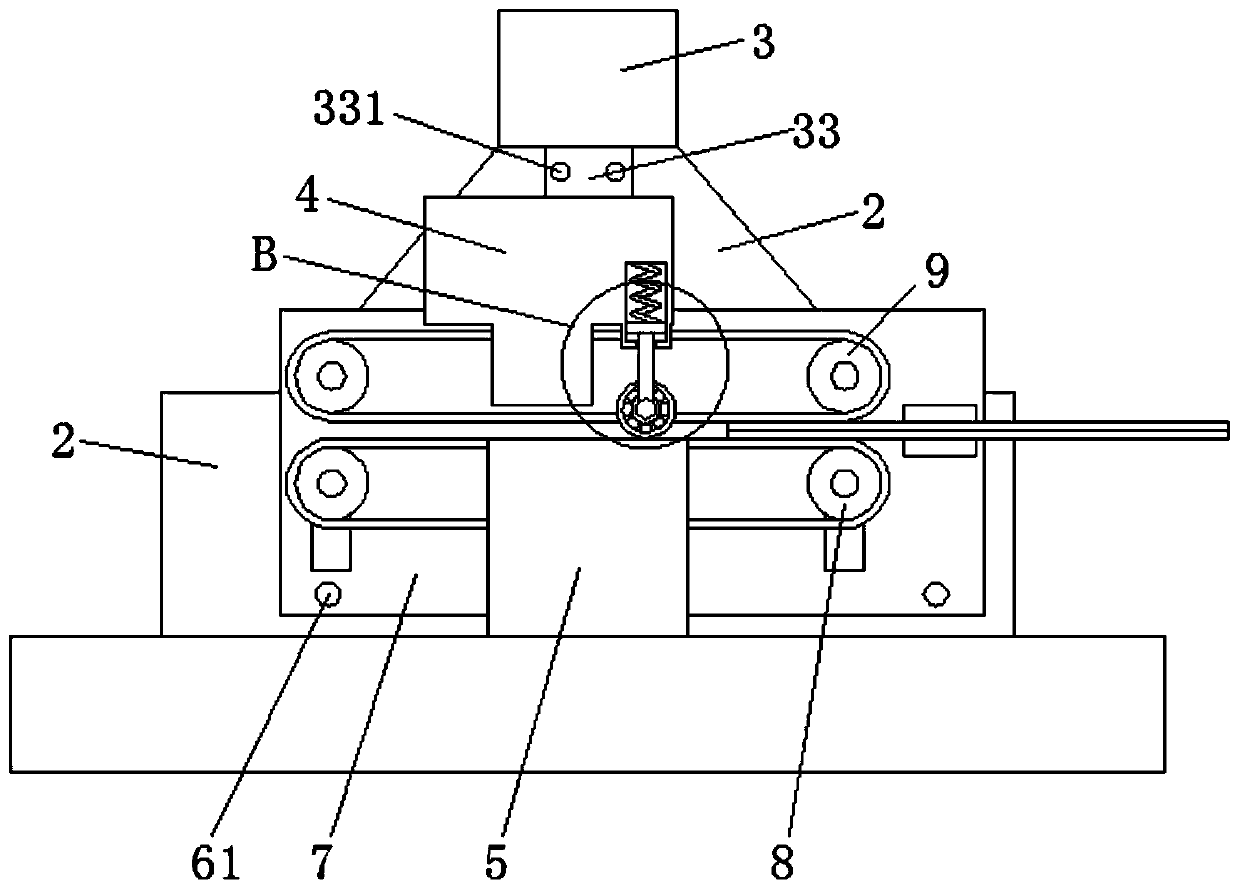

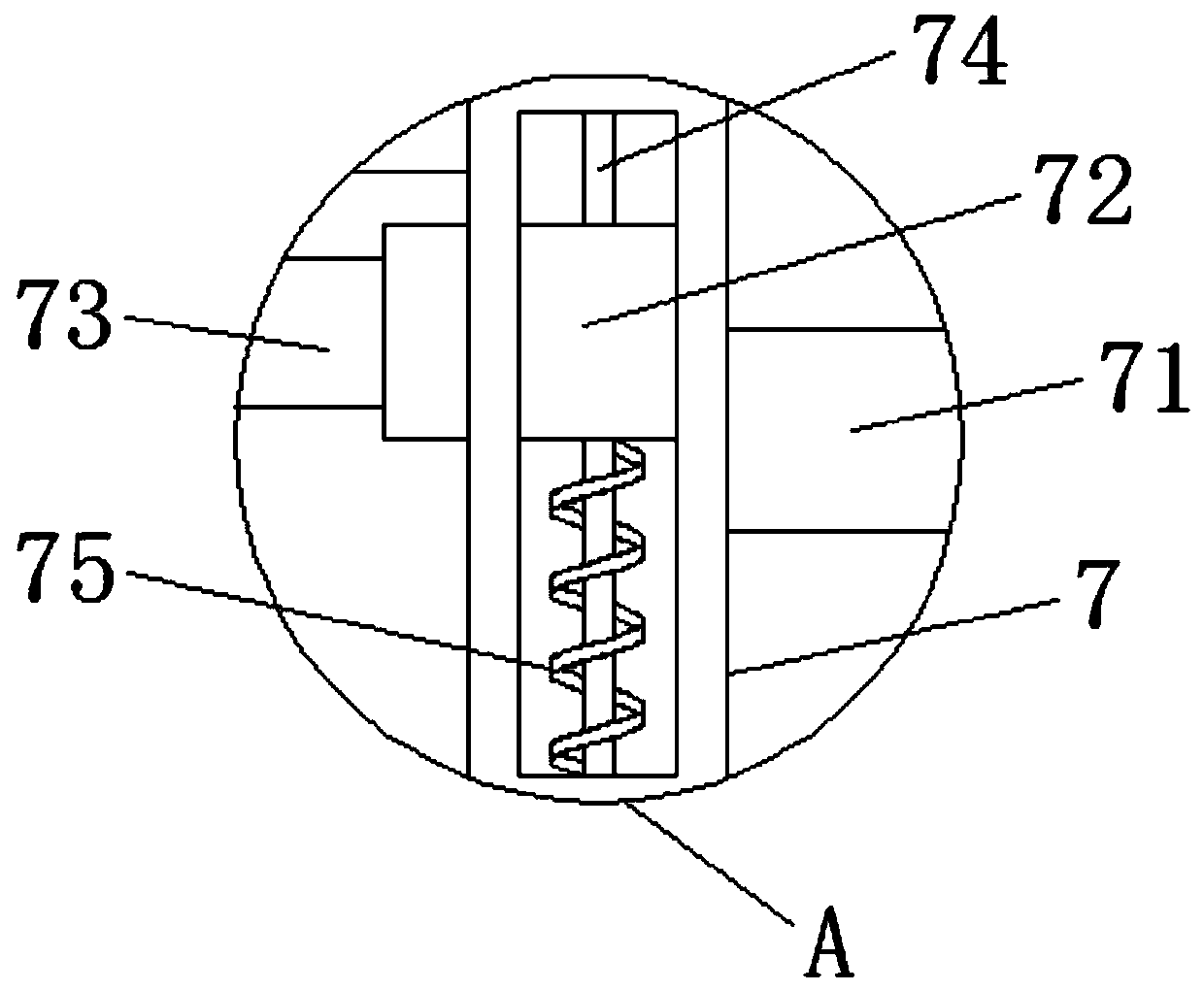

Binding machine for bills and files

ActiveCN108001064AMeet needsSimple mechanical structureSheet bindingEngineeringMechanical engineering

The invention provides a binding machine for bills and files. The binding machine for bills and files comprises a machine frame, a transfer device, a drilling module, an upper hot riveting head module, a lower hot riveting head module, a conductive rubber pad module, a lifting device, a paper pressing device, a binding pipe conveying device, a binding pipe in-place detecting device and a transverse moving workbench. The transfer device comprises a transfer shaft, a rotating support rotating by taking the transfer shaft as the axis, and a rotating driving device for driving the rotating support. The transfer device is arranged in the machine frame, the drilling module, the upper hot riveting head module, the lower hot riveting head module and the conductive rubber pad module are all arranged on the transfer device, and the lifting device, the binding pipe conveying device, the binding pipe in-place detecting device and the transverse moving workbench are all arranged on the machine frame. The machine frame is provided with a paper pressing locking device. The binding machine for bills and files is simple in mechanical structure, has the advantages of small size, low weight, low costand intelligence, has a good assembling process, can effectively improve binding efficiency, and completely meets the requirements of office supplies.

Owner:河北途浩电子科技有限公司

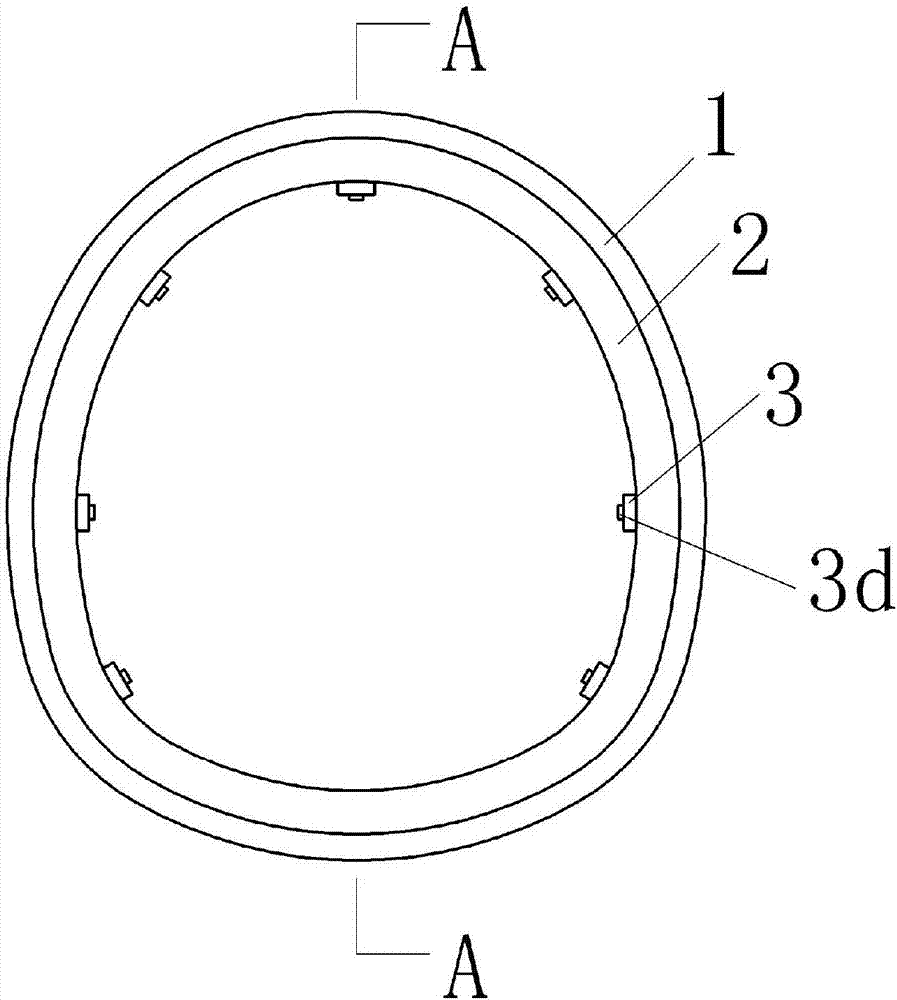

Method for constructing dislocation-resistant tunnel secondary lining passing through active fault

PendingCN107255033AReduce the setting distanceIncrease the number ofUnderground chambersTunnel liningActive faultTension compression

Provided is a method for constructing dislocation-resistant tunnel secondary lining passing through an active fault. The method comprise the steps that A, the segment length of the secondary lining constructed on the active fault crushed zone and in the areas, away from the active fault crushed zone by 20-100 m, of a hanging wall and a heading wall is half to one third that of the secondary lining outside the active fault; and B, seven high-strength tension-compression spring pipes of a crosswise deformation joint are connected with the inner walls of adjacent segments of the secondary lining of the active fault crushed zone through bolts, and the seven high-strength tension-compression spring pipes are located at the positions of an arch crown, a left arch waist, a right arch waist, a left arch springing, a right arch springing, a left wall foot and a right wall foot correspondingly. According to the secondary lining constructed by the method, the dislocation energy of the active fault can be well absorbed, the dislocation-resistant effect is good, the safety of the integral structure of a tunnel can be better guaranteed, and rapid emergency rehabilitation, first-aid repairing and restoring and reinforcing of the tunnel structure after disasters are facilitated.

Owner:URUMQI URBAN RAIL GRP CO LTD +2

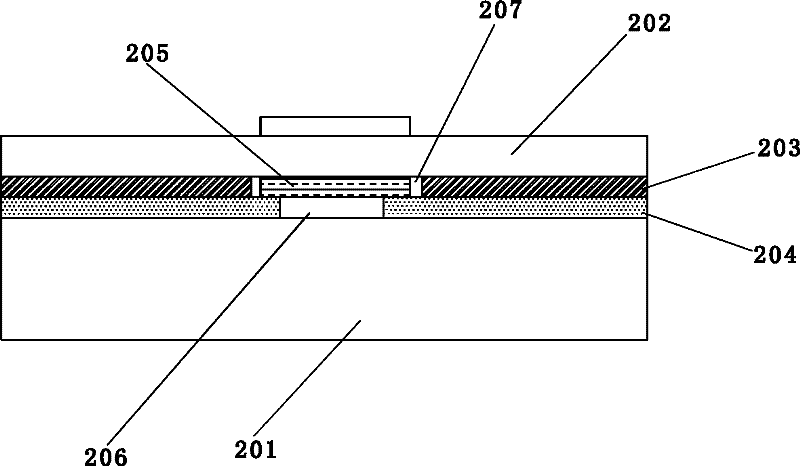

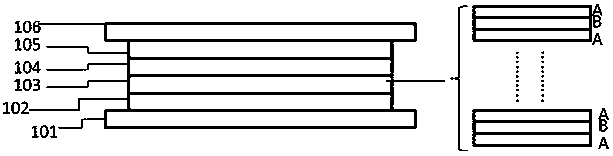

Preparation method of NiAu projection and NiAu projection assembly

ActiveCN105355574AGuaranteed bonding areaGuaranteed binding effectSemiconductor/solid-state device detailsSolid-state devicesGalvanic cellTitanium

The invention provides a preparation method of a NiAu projection. The method comprises that a Ti or TiW metal layer and an Au metal layer are formed between a wafer and the NiAu projection from top to bottom, the Au metal layer outside the projection is removed from top to bottom in a physical dry etching manner, the Ti or TiW metal layer is removed via a wet etching manner, and reaction of a galvanic cell and excessive etching of the Ni material of the projection caused by the wet etching manner are avoided. The invention also provides a NiAu projection assembly which comprises the projection, a seed metal layer and a substrate metal layer, wherein the projection comprises a reserved layer, the Au metal layer and a Ni metal layer are successively from top to bottom, the seed metal layer and the substrate metal layer are arranged at the bottom of the projection, the lateral side of the Au metal layer and the lateral side of the projection are leveled in the vertical direction, and relatively large combination area and combination force between the projection and the wafer are ensured.

Owner:CHIPMORE TECH CORP LTD

Process method for preplating nickel on surface of minuteness aluminum wire before copper plating

InactiveCN102330130AReduce potential differenceReduce corrosionCopper platingVolumetric Mass Density

The invention relates to a process method for electroplating copper on the surface of a minuteness aluminum wire. The process method comprises the following steps of: putting the minuteness aluminum wire which is processed at the front stage into nickel preplating solution, and plating at the temperature of 65 DEG C for 5min by using current at the density of 1A.dm<-2>, wherein the nickel preplating solution is prepared by the following raw materials in part by weight: 100 to 150 parts of NiSO4.6H2O, 20 to 40 parts of NiCl2.6H2O, 120 to 160 parts of Na3C6H5O7.2H2O, 20 to 50 parts of (NH4)2SO4, 10 to 50 parts of sodium gluconate, 0.5 to 1.5 parts of saccharin and 0.02 to 0.08 part of sodium lauryl sulfate; and mixing the solution and water according to weight parts, and adjusting the pH value to be 7.0. By the method, the surface of the aluminum wire which is subjected to nickel preplating and then is subjected to a copper plating process has a smooth and compact surface, fine and tightly-arranged grains and uniform and consistent colors and luster.

Owner:SHENYANG AIRCRAFT CORP

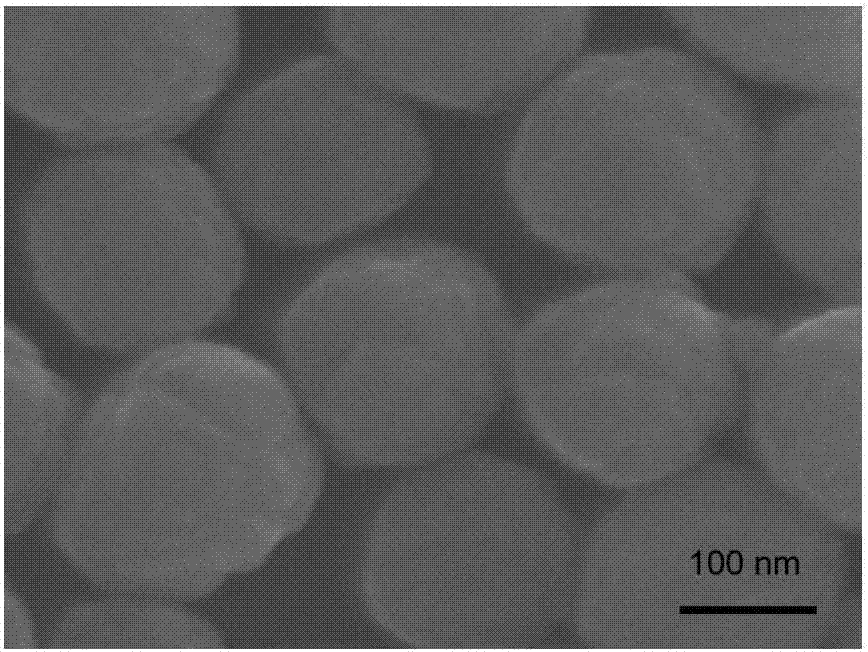

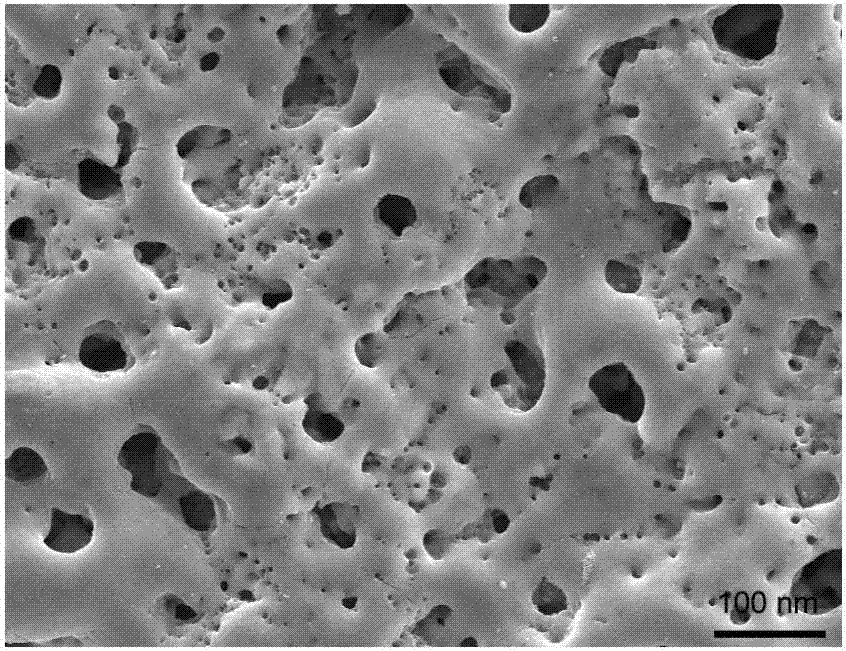

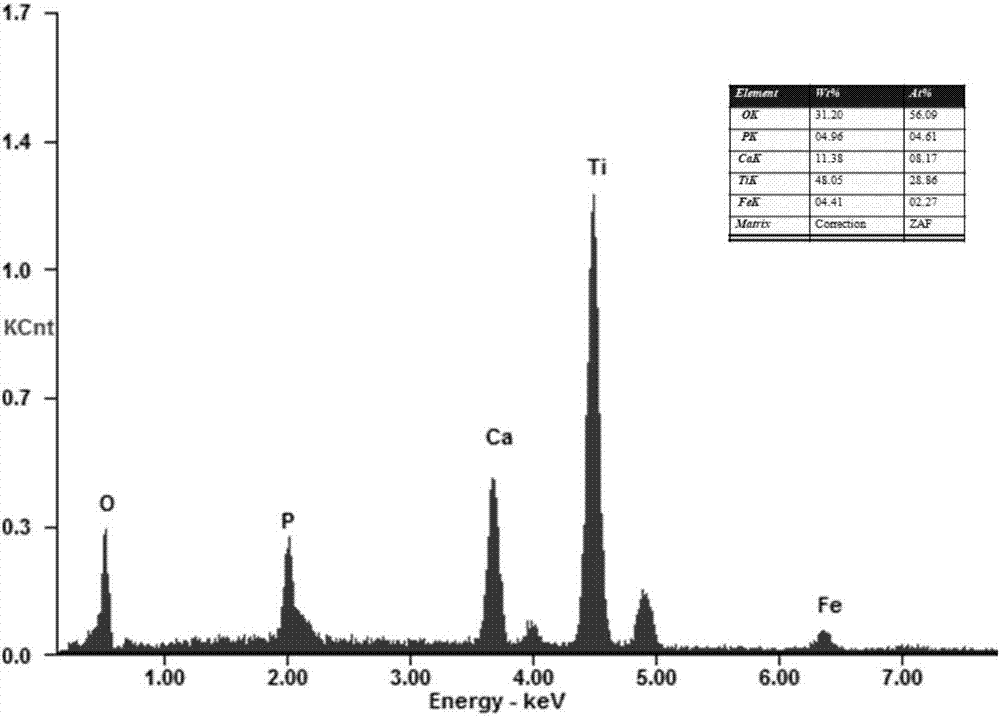

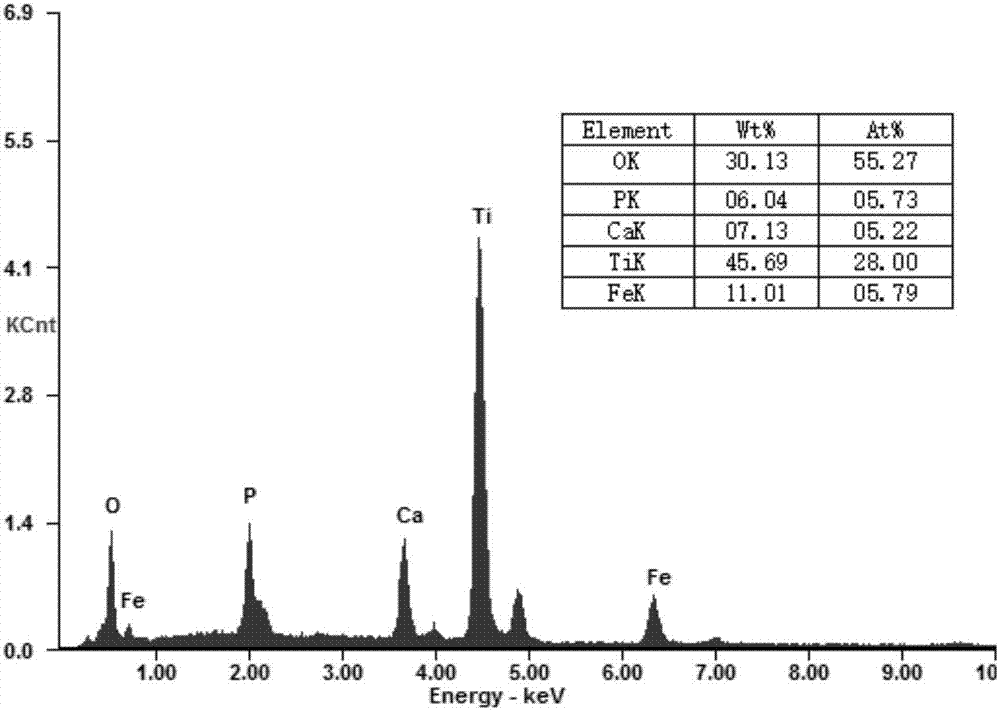

Preparation method of ferroferric oxide/ titanium dioxide magnetic biological activity coating

ActiveCN107236983AGood adhesionPromote proliferationSurface reaction electrolytic coatingProsthesisPlasma electrolytic oxidationMagnetite Nanoparticles

The invention discloses a preparation method of a ferroferric oxide / titanium dioxide magnetic biological activity coating. The preparation method comprises the steps of firstly, utilizing a solvent-thermal method, adopting ethylene glycol as a solvent, adopting 1,6-hexamethylenediamine, ferric trichloride hexahydrate and anhydrous sodium acetate as solutes, reacting in a reaction kettle, and obtaining water-soluble aminated ferroferric oxide magnetic nanoparticles after finishing reaction; secondly, adopting a microplasma oxidation method, adopting water as a solvent, adopting the water-soluble aminated ferroferric oxide magnetic nanoparticles, calcium salt, phosphor salt and weak acid as solutes, and forming an electrolyte solution; and adopting a titanium / titanium alloy sample as an anode and stainless steel as a cathode, adopting a pulse power supply for carrying out microplasma oxidation treatment on the titanium / titanium alloy sample, and after finishing reaction, generating the ferroferric oxide / titanium dioxide magnetic biological activity coating on a surface layer of the titanium / titanium alloy sample. The magnetic material can respond to an external magnetic field, a magnetocaloric effect is produced through the external alternating magnetic field so as to heat up a focus area, and tumor cells are killed, so that the function of bone cancer magnetic hyperthermia is realized.

Owner:汉中艾斯达特新材料科技有限公司

Wear-resistant self-lubricating modified polyphenylene sulfide material and preparation method thereof

The invention belongs to the technical field of polymer materials, and relates to a polyphenylene sulfide material and a preparation method thereof. The composite material is composed of the following raw materials in parts by weight: 45 to 55 parts of polyphenylene sulfide, 5 to 10 parts of anti-wear agent, 0.5 to 1 part of lubricant, 0.2 to 0.4 part of antioxidant, 0.6 to 1 part of coupling agent, and 35 to 45 parts of glass fiber. The preparation method comprises the following steps: adding 45 to 55 parts of polyphenylene sulfide, 5 to 10 parts of anti-wear agent, 0.5 to 1 part of lubricant, 0.2 to 0.4 part of antioxidant, 0.6 to 1 part of coupling agent, and 35 to 45 parts of glass fiber into a high-speed mixer, evenly mixing the materials in a high speed in the high-speed mixer, then pouring the mixture into a screw extruder, extruding the mixture strips, and cutting the strips into granules so as to obtain the finished product. The material has the advantages of high strength, self-lubricating, and wear resistance, and can be made into gears, bearings, and the like.

Owner:HEFEI GENIUS NEW MATERIALS

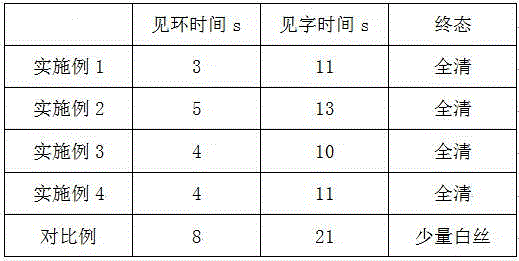

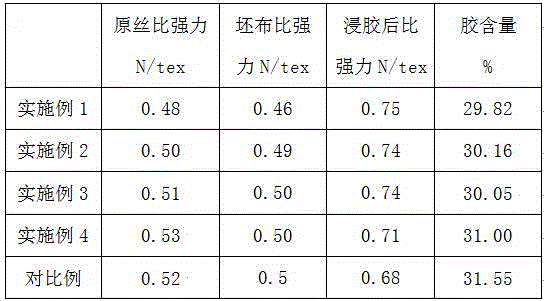

Special alkali-free direct yarn wetting agent for grinding wheel reinforcing sheets and preparation method thereof

The invention discloses a special alkali-free direct yarn wetting agent for grinding wheel reinforcing sheets and a preparation method thereof. The alkali-free direct yarn wetting agent comprises the following components in percentage by mass: 2-6% of epoxy emulsion, 1-5% of polyester emulsion, 0.2-0.6% of water-soluble epoxy resin, 0.2-0.8% of lubricant, 0.05-0.3% of antistatic agent, 0.8-1.4% of coupling agent, 0.2-2% of novel assistant A, 0.1-1% of novel assistant B, 0.1-0.5% of glacial acetic acid and the balance of deionized water. Various components are adopted to endow the yarn with high power and favorable permeation effect in the dipping treatment process. Multiple high-performance lubricants are utilized, and the two novel assistants are introduced, thereby implementing favorable weaving effect on the premise of ensuring favorable permeation effect. The two coupling agents are combined to well ensure the combination effect between the glass fiber and resin.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

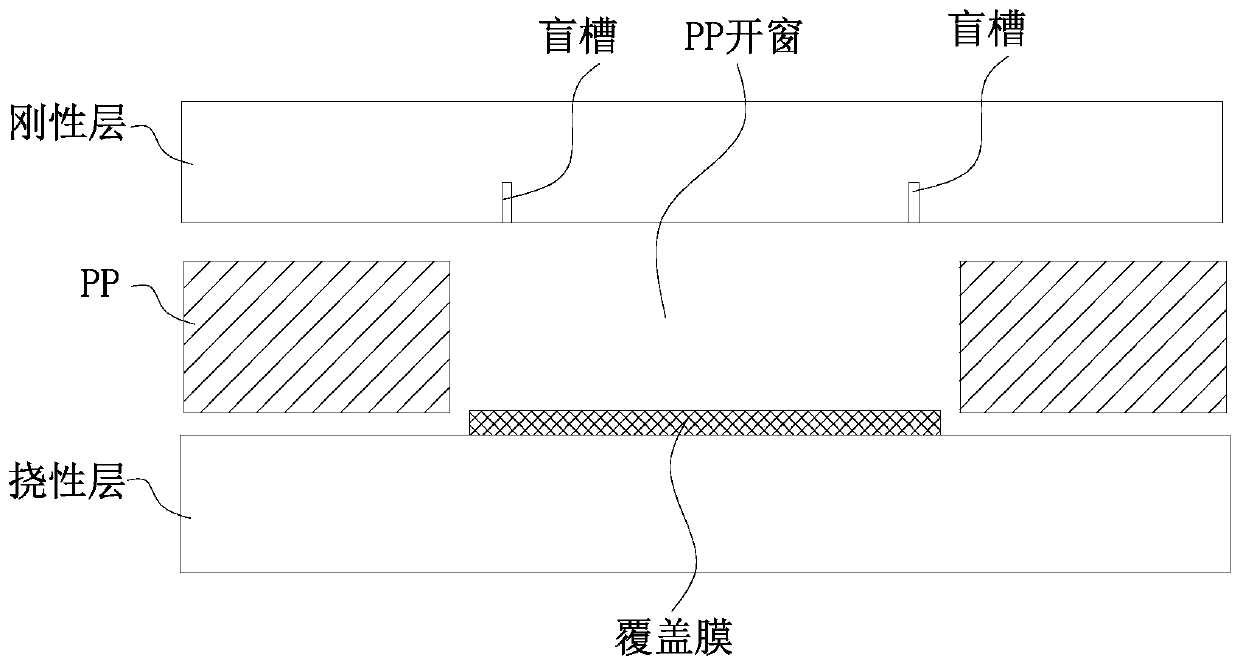

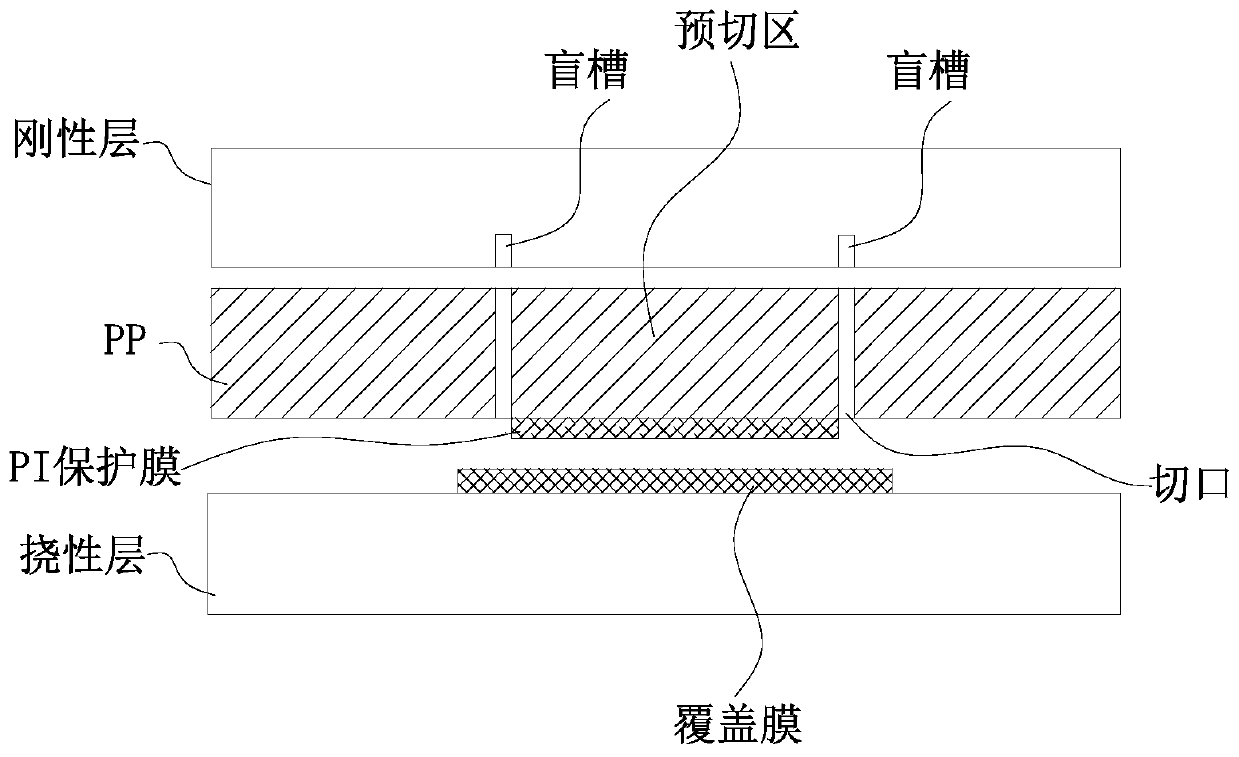

Manufacturing method of rigid-flexible combined board

InactiveCN110678011AGuaranteed binding effectAvoid the formation of protrusions on the pressing surfacePrinted circuit assemblingMultilayer circuit manufactureAdhesiveWindow opening

The invention relates to the technical field of printed circuit boards, in particular to a manufacturing method of a rigid-flexible combined board. According to the invention, the press-fit structureis changed and a pp window does not need to be formed in a prepreg in the press-fit process; a PI protective film is attached to a pre-cutting area. During the press-fit process, the prepreg does notneed to be contracted inwards, so that the sufficient flowing adhesive is provided to ensure the bonding effect of the rigid-flexible layer and a problem of overflowing of the excessive flowing adhesive to the pp window, that is, binding to the flexible area is solved. Besides, with no PP window, a flatness problem of protruding or recession on the press-fit surface due to the window height falling difference caused by the PP window in the prior art is solved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Nano composite plating paste material and its preparation and electroplating method

InactiveCN1414144ASpecial structureExtraordinary corrosion resistanceElectrolytic coatingsMischmetalAlkaline earth metal

A nano-class composite slurry for electroplating is prepared through mixing alpha-Al2O3 with the oxide is alkali-earth metal and / or transition metal and / or rare-earth metal by ball grinding for 6-10 hr transferring phase at 1200-1500 deg.C, proportionally mixing powder, water and cationic surfactant, and dispersing in ball grinder for 60-100 hr. It can be added to traditional plating liquid to obtain decorative-protective-functional plated layer.

Owner:重庆阿波罗机电技术有限公司

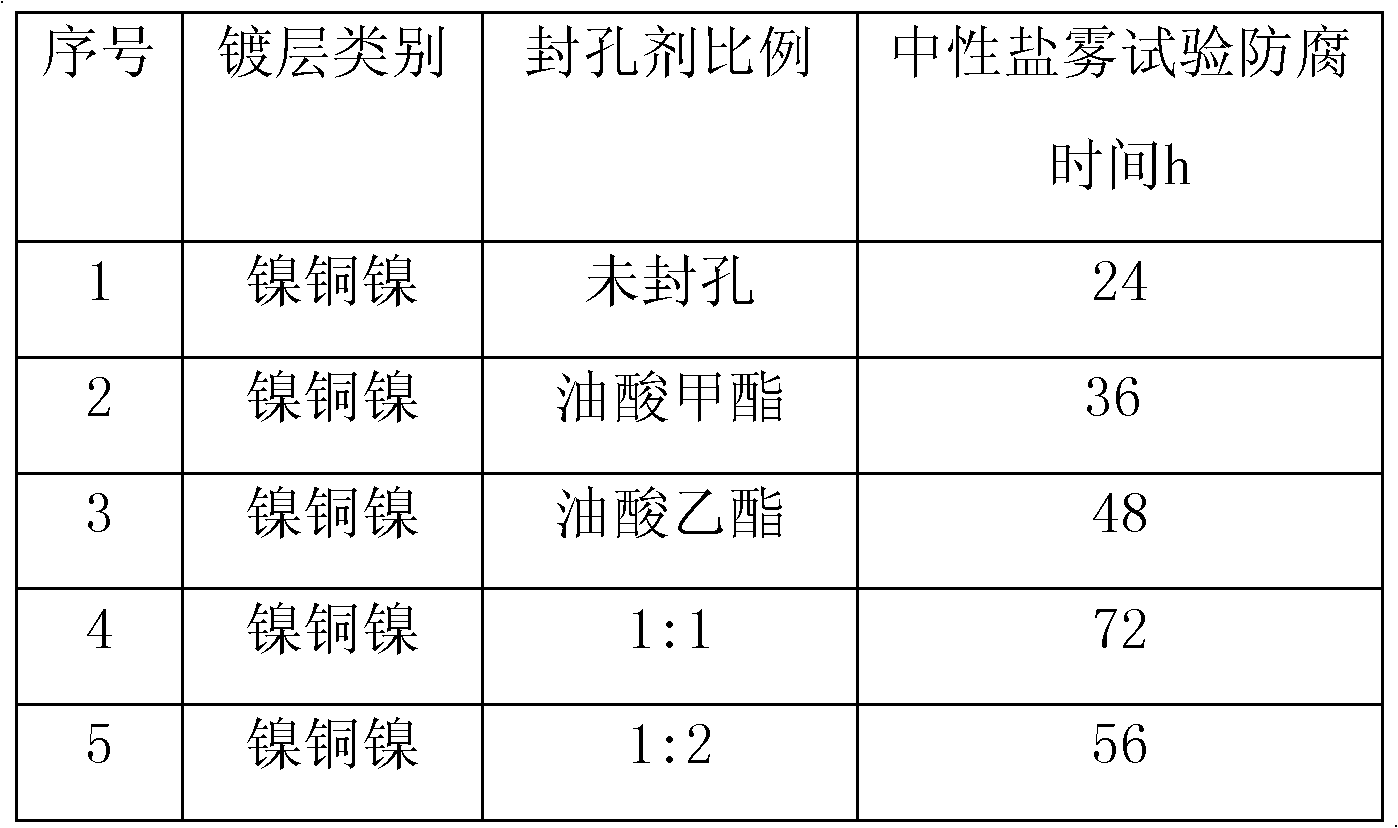

Surface hot dipping and pore sealing method of neodymium-iron-boron permanent magnet material

InactiveCN102581287AReduce erosionGuaranteed binding effectInorganic material magnetismInductances/transformers/magnets manufactureSurface corrosionCorrosion resistant

A surface hot dipping and pore sealing method of a neodymium-iron-boron permanent magnet material belongs to the technical field of surface corrosion protection of neodymium-iron-boron permanent magnet materials. The method comprises the steps of heating a neodymium-iron-boron permanent magnet at 120-240 DEG C for 1-2.5h; and impregnating the heated neodymium-iron-boron permanent magnet in a pore sealing agent and sealing micropores on the surface of the neodymium-iron-boron permanent magnet, and taking out untill the surface temperature of the neodymium-iron-boron permanent magnet is lower than 40 DEG C. The pore sealing agent is methyl oleate and / or ethyl oleate, and the ratio of methyl oleate to ethyl oleate is 1:1 or 1:2 when the pore sealing agent employs a mixture of methyl oleate and ethyl oleate. By adoption of the pore sealing method, after the heated neodymium-iron-boron permanent magnet contacts the low-temperature pore sealing agent, the volume of the surface micropores is reduced and the pressure inside the micropore is reduced, so that the pore sealing agent is sucked into the micropores and plays a role in sealing pores of the neodymium-iron-boron permanent magnet, and the corrosion reduction of acidic and basic solutions to the magnet surface is facilitated in an electroplating process. The neodymium-iron-boron permanent magnet subjected to sealing pore is uniform in surface structure, and ensures the bonding force and the corrosion resistant performance of an electroplating layer in the subsequent electroplating process.

Owner:SHENYANG GENERAL MAGNETIC

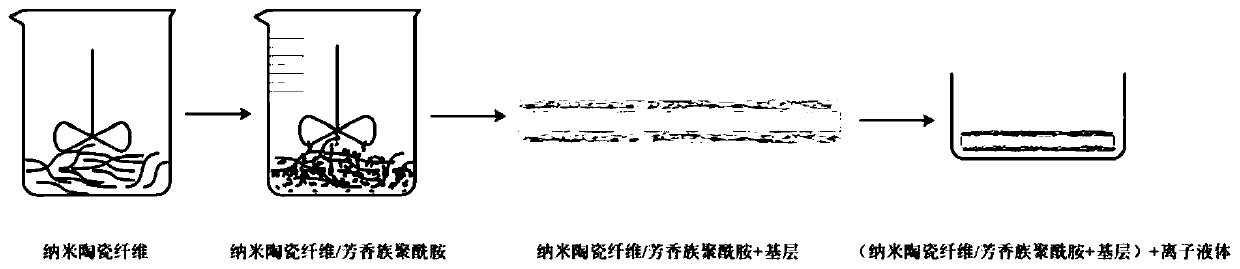

Lithium ion battery diaphragm and preparation method thereof

InactiveCN111477816AEvenly dispersedAvoid reunionSecondary cellsCell component detailsFiberDiaphragm structure

The invention relates to a lithium ion battery diaphragm and a preparation method thereof, and belongs to the technical field of batteries. The diaphragm is a multi-layer composite diaphragm, and comprises a base material and a coating layer formed by coating a single surface or double surfaces of the base material with mixed slurry of nano ceramic fibers and aromatic polyamide, and after ionic liquid modification, a composite diaphragm structure taking the coating layer as a three-dimensional fiber space network framework and taking the base material as a diaphragm thermal shutdown is formed.The preparation method comprises the following steps: 1) performing in-situ polymerization in uniformly dispersed nano ceramic fibers to form aromatic polyamide to obtain mixed slurry; 2) coating thesurface of a base material with the mixed slurry; 3) carrying out drying and water washing on the coated composite diaphragm, placing the composite diaphragm in an ionic liquid, and carrying out vacuum impregnation; and 4) drying the impregnated composite diaphragm to obtain the lithium ion battery composite diaphragm. The lithium ion battery diaphragm provided by the invention has a three-dimensional fiber space network structure skeleton, has good electrolytic solution absorption and retention capability, and is beneficial to improvement of battery safety, cycle and rate capability.

Owner:华鼎国联四川动力电池有限公司

Flex-rigid combined board and manufacturing method of flex-rigid combined board

InactiveCN102523683AAvoid breakingImprove support strengthPrinted circuit assemblingPrinted circuits structural associationsEngineeringHardboard

The invention discloses a manufacturing method of a flex-rigid combined board, comprising the following steps of: A. carrying out grinding and roughening on the surface of a hard board and covering a second prepreg on the roughened surface according to the pin positions on the surface of the board; B. covering a first prepreg on the second prepreg according to the pin positions; C. covering a soft board on the first prepreg according to the pin positions; and D. carrying out lamination on the soft board, the first prepreg, the second prepreg and the hard board. Compared with the prior art, the manufacturing method has the advantages that the fracture of the soft board is effectively avoided, the combining effect of a soft board covering film and the prepregs is improved, the flatness of the flex-rigid combined positions is ensured and the problems of holes and depressions in lamination are avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

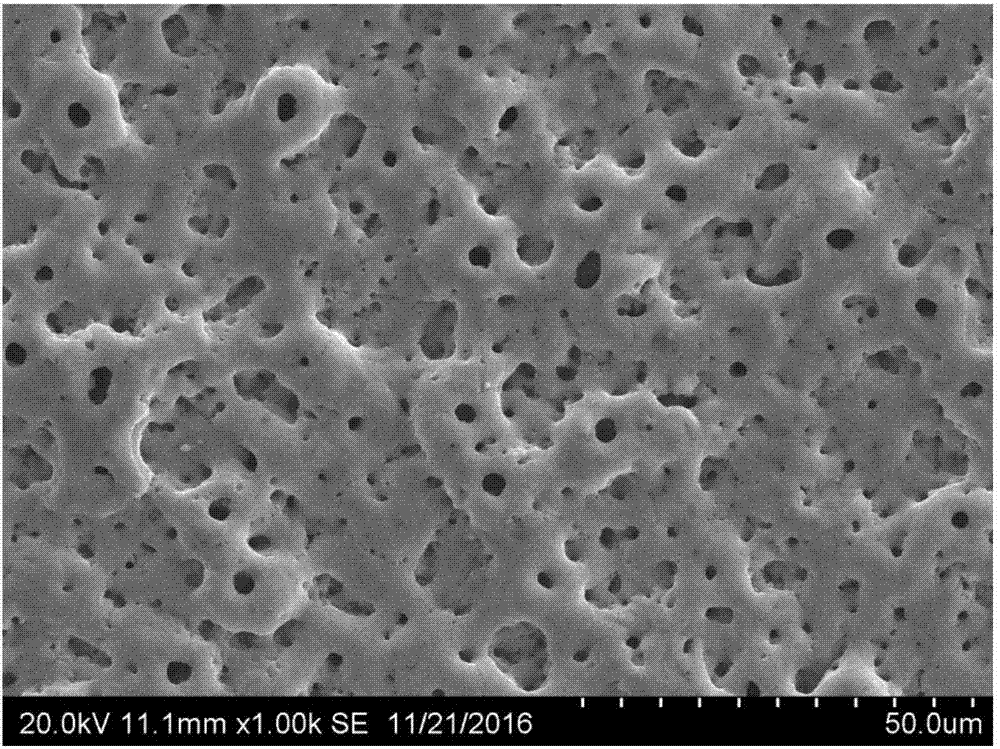

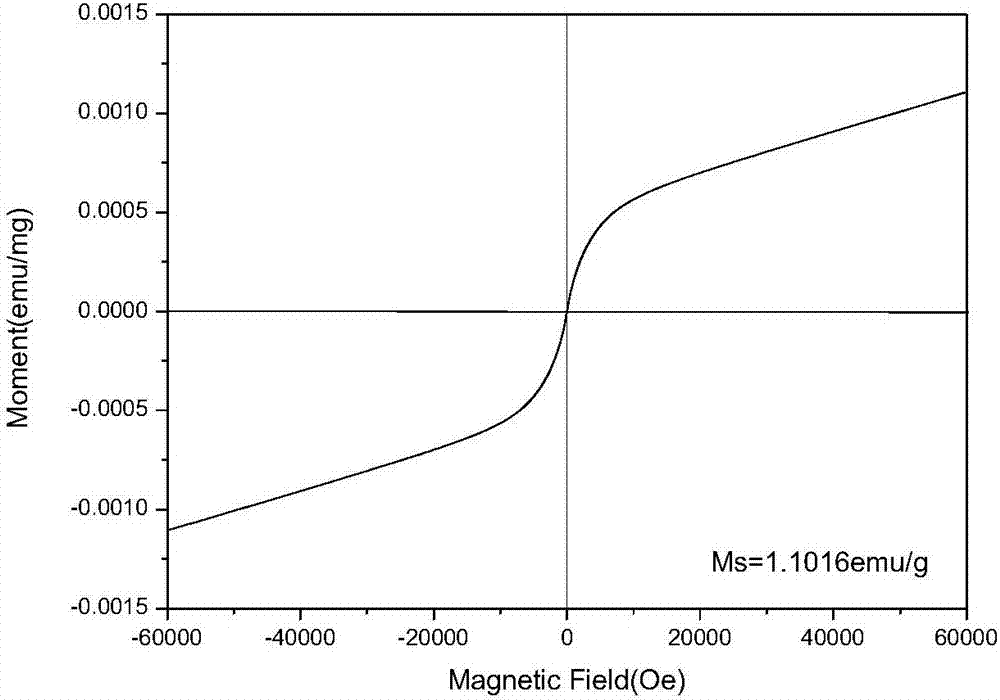

Micro-arc oxidation preparation method of magnetic TiO2 bioactive coating

ActiveCN107119304AMagnetic hasGuaranteed binding effectSurface reaction electrolytic coatingPharmaceutical delivery mechanismPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a micro-arc oxidation preparation method of a magnetic TiO2 bioactive coating. In an air environment, an electrolytic solution containing calcium salt, phosphor salt and molysite is taken, a pH value of the electrolytic solution is adjusted to be 5.0-5.3, titanium or a titanium alloy is taken as an anode, stainless steel is taken as a cathode, and titanium or the titanium alloy is subjected to micro-arc oxidation treatment for 1-8min by adopting a pulsed power supply, with the temperature of the electrolytic solution being kept at 5-25 DEG C, thus the magnetic TiO2 bioactive coating is generated on a surface layer of titanium or the titanium alloy. The magnetic TiO2 coating having magnetism (Ms being 0.2696-1.101emu / g) and good bioactivity can be prepared with the adoption of the micro-arc oxidation preparation method.

Owner:XI AN JIAOTONG UNIV

A method for assembling RGD on the surface of porous pure titanium dental implant

InactiveCN101006944AFavorable for clinical applicationNo damage to shapeDental implantsCoatingsTitaniumEngineering

The invention discloses an assembling method of RGD on the porous pure-titanium tooth plant surface, which comprises the following steps: adopting layer-to-layer electrostatic self-assembling technique to make the surface load positive charge through PEI; immersing plant into RGD solution; using attractive elementary of foreign charge to fix RGD on the PEI surface; crossing PEI and RGD through glutaraldehyde; immersing the plant into RGD solution to seal non-connected aldehydo; increasing RGD quantity; repeating these steps to obtain the product.

Owner:ZHEJIANG UNIV

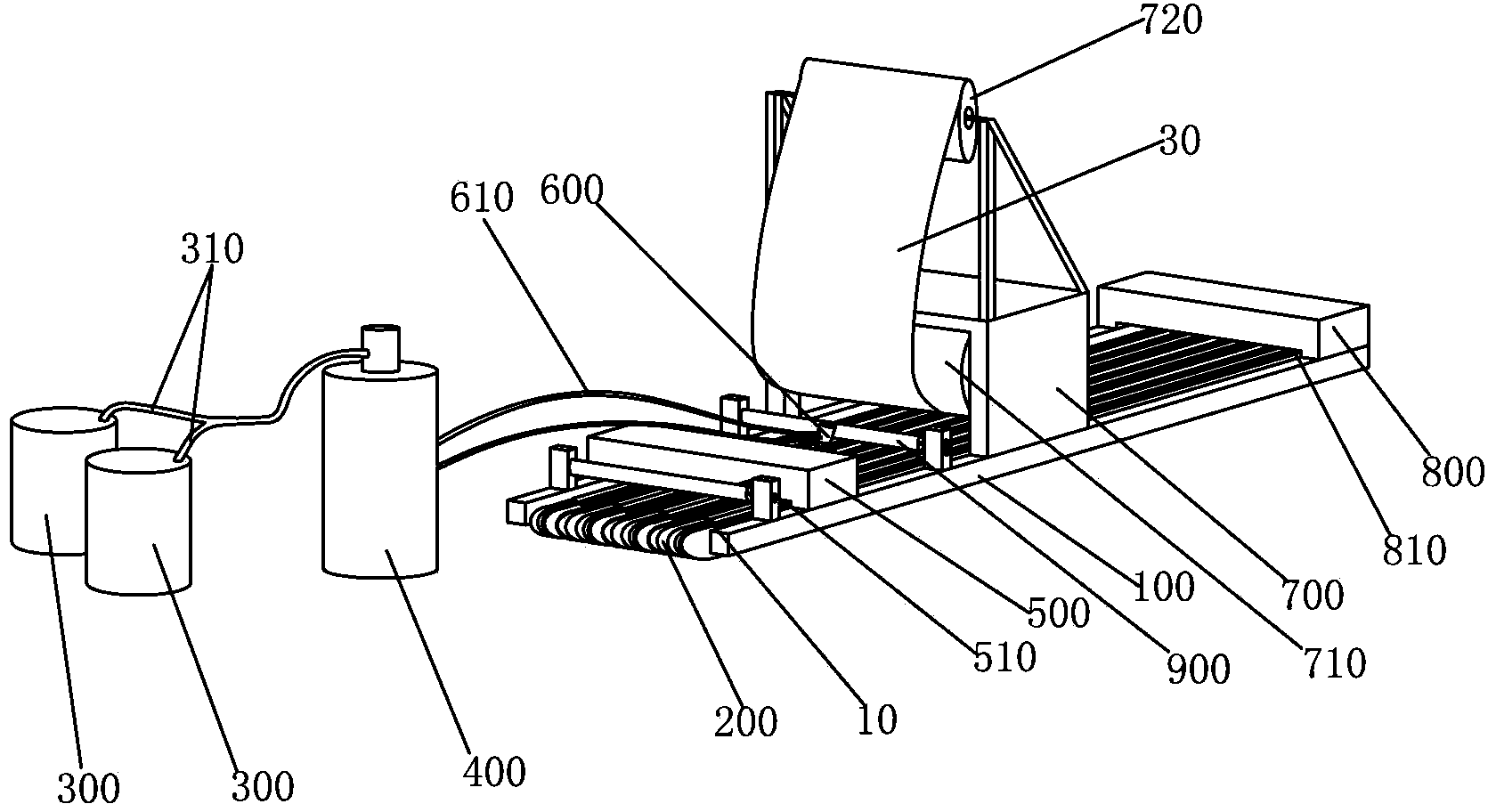

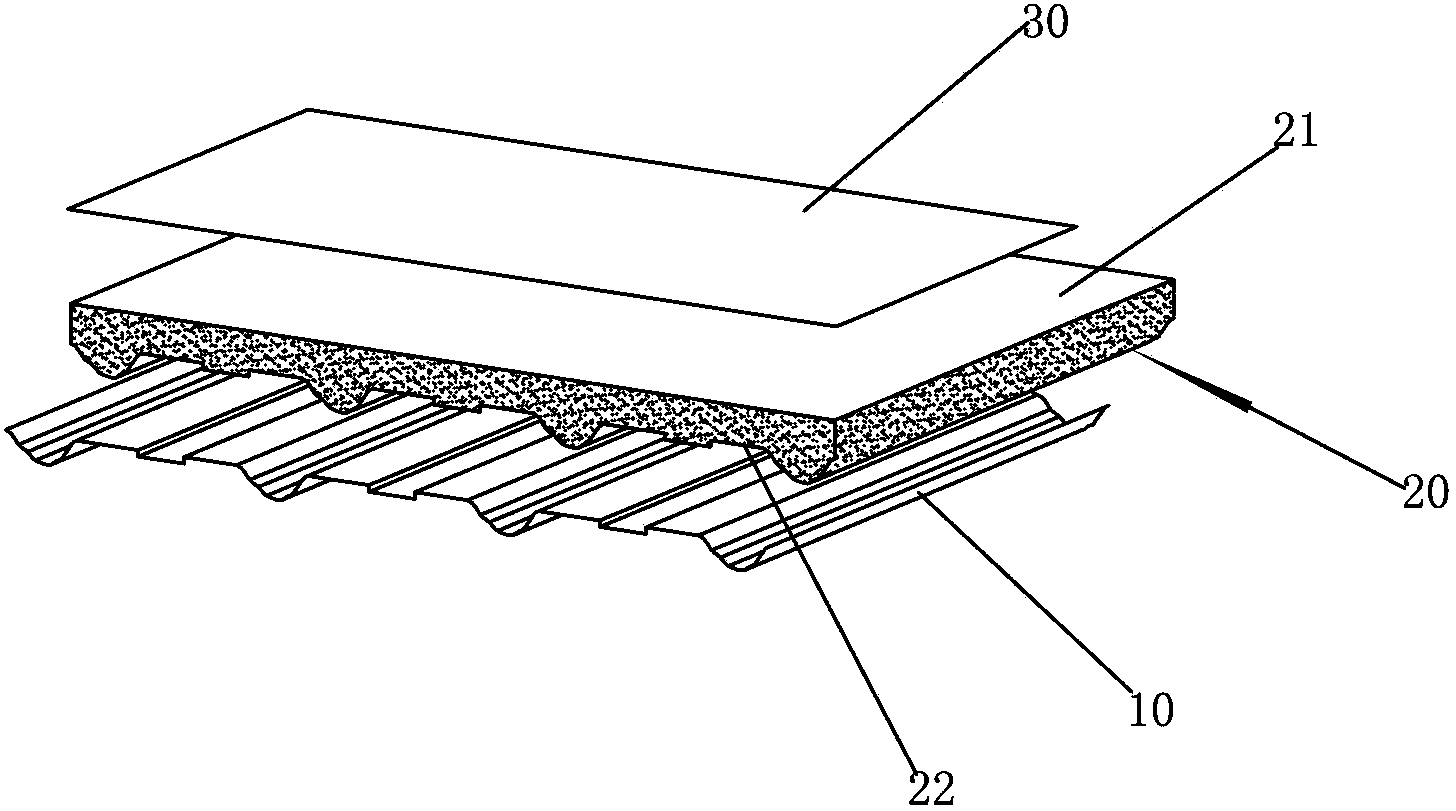

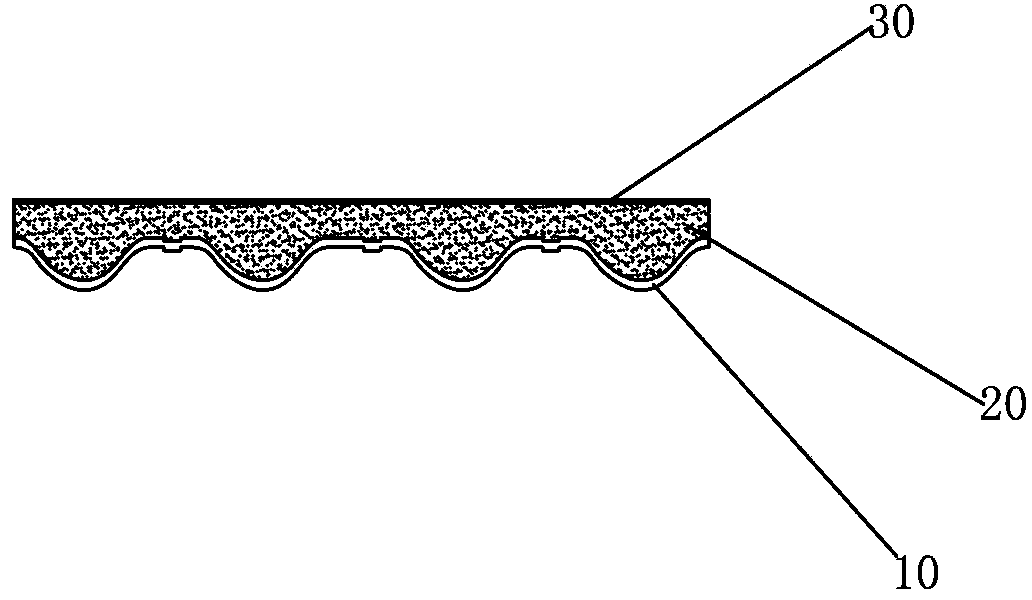

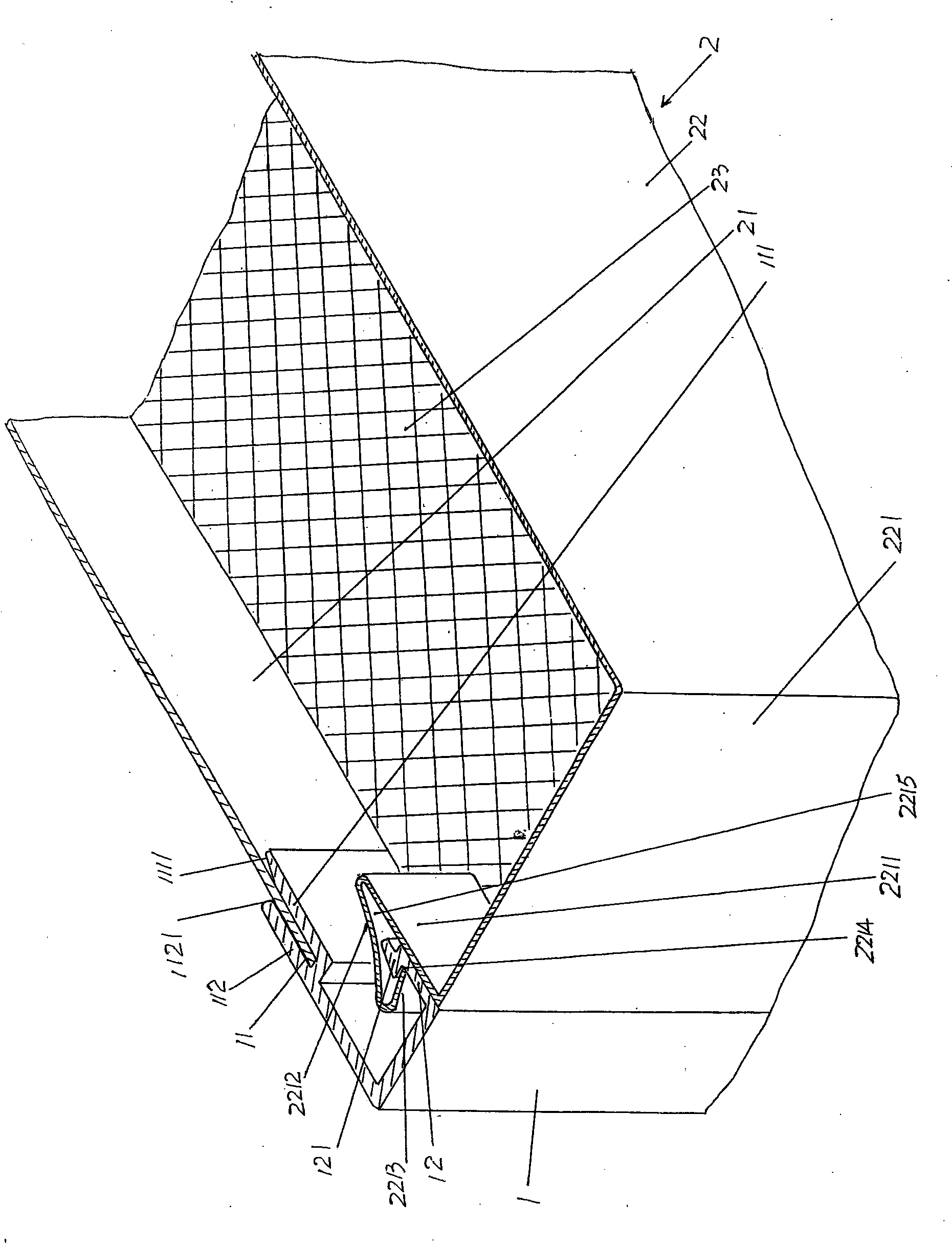

Production technology and equipment for thermal insulating and flame-retardant wall

The invention discloses a production technology and equipment for thermal insulating and flame-retardant wall. The production technology includes: step 10, heating polyisocyanate and polyether respectively to 39-41DEG C; step 20, mixing the polyisocyanate and polyether in a volume ratio of 1:1.1-1.6, and conducting stirring to obtain a foaming agent; step 30, heating a substrate profile to 39-41DEG C; step 40, jetting the foaming agent evenly onto the substrate profile surface to form a foaming layer; step 50, sticking a flame-retardant layer on the foaming layer to obtain a semi-finished product; and step 60, drying the semi-finished product to obtain a finished product. The obtained foaming agent has a short foaming time, which is shorter than the foaming time under room temperature by at least over one time. The rate of finished products is high, and the yield is increased by over 50% compared with the circumstance of not heating the substrate profile. At the same time, the whole production process is simple, and the production equipment is not complex, so that the process and the equipment are suitable for mass production, and the production efficiency is high.

Owner:PUTIAN CHENGXIANG JIN XIN LIGHT STEEL COLOR PLATECO

Electroplating process of circuit board of burning-resistant board

The invention discloses an electroplating process of a circuit board of a burning-resisting board. The electroplating process comprises the following steps: firstly, providing a base plate and coating a copper foil layer at the periphery of the plate surface of the base plate; and then, carrying out boring, first-time plate grinding, copper electroplating, second-time plate grinding, outer circuit manufacturing, and electroplating, wherein the copper foil layer is of a latticed structure; the current density is 15-20ASF during the electroplating process, and the electroplating time is 90-100 minutes. The copper foil layer is arranged at the periphery of the plate surface of the base plate, so that the electroplating is uniform without a plate burning phenomenon; a low-current density long-time electroplating way is adopted to ensure the uniform and stable current of the plate surface, so that the plate is not burnt due to excessive current, the binding force and structural cohesive force of the based copper and electroplated copper of the plate are kept, and the quality of the circuit board is ensured. Moreover, the latticed structure is arranged at the periphery of the plate surface for saving the copper, so that the electroplating area is reduced during the electroplating process, and the copper is further saved.

Owner:SHENZHEN XINGDA PCB

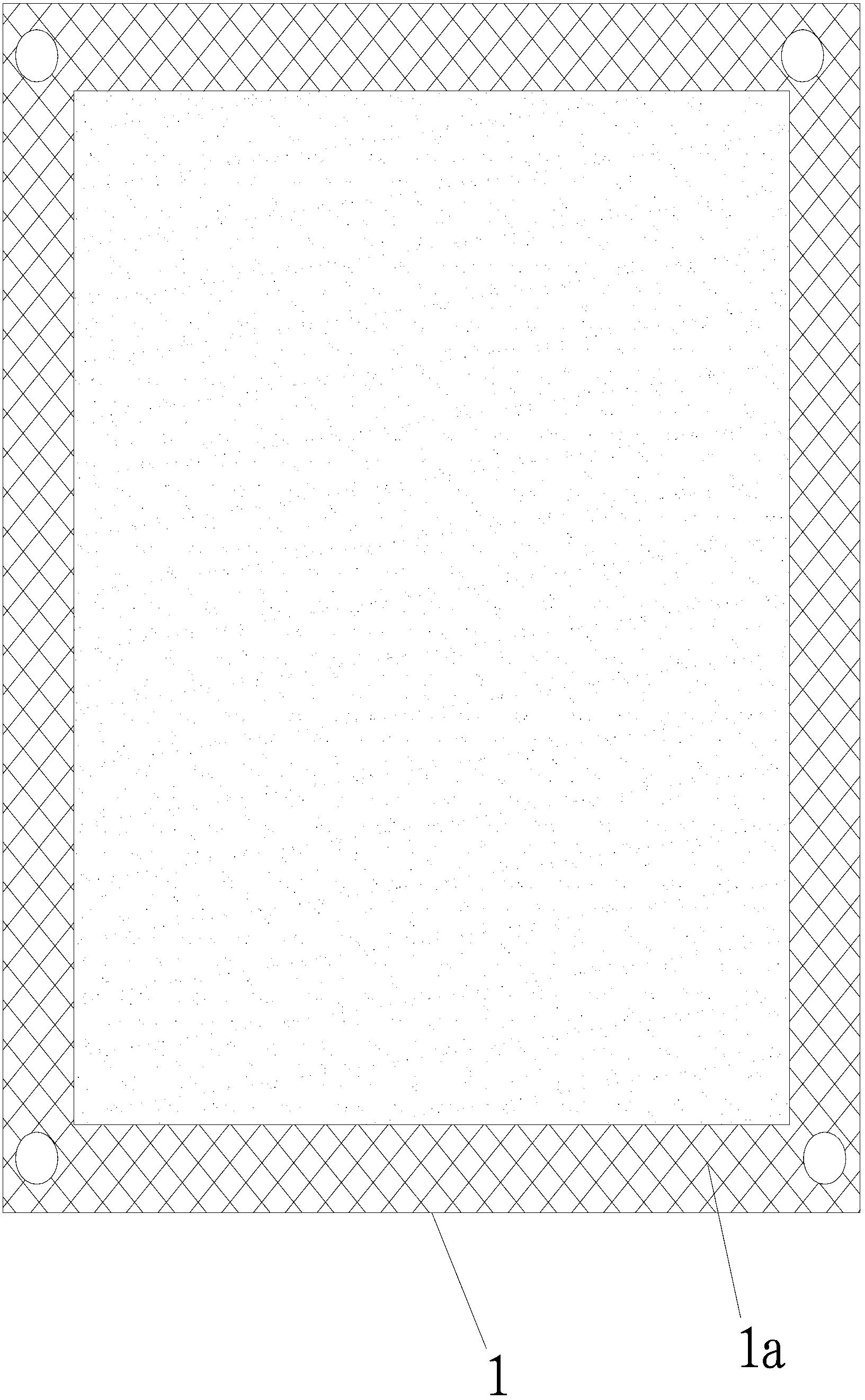

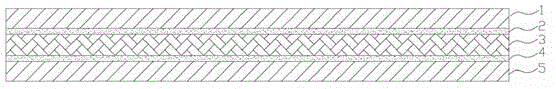

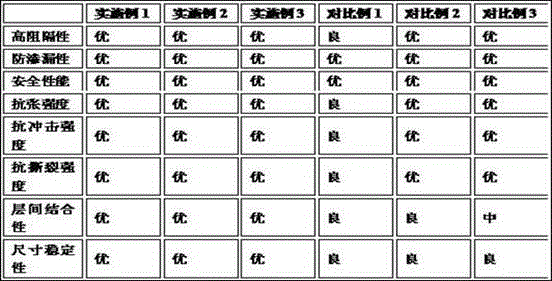

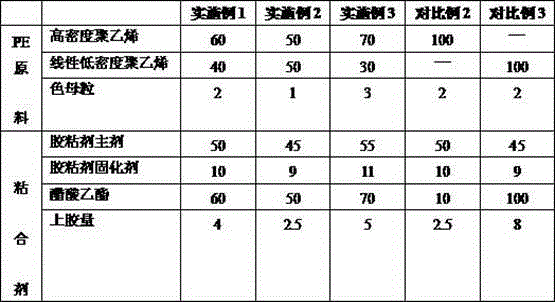

Satchel charge packing film and preparation method thereof

InactiveCN104960766AInterlayer bonding performance and dimensional stability guaranteeHigh tear strengthFlexible coversWrappersSatchel chargeHigh-density polyethylene

The invention discloses a satchel charge packing film and a preparation method thereof. The satchel charge packing film comprises a middle layer, an upper outer layer film and a lower outer layer film, wherein the middle layer is provided with a first surface and a second surface; the upper outer layer film is composited on the first surface of the middle layer; the lower outer layer film is composited on the second surface of the middle layer; the middle layer is a PET (Polyethylene Glycol Terephthalate) film; the upper outer layer film or the lower outer layer film is a PE (polyethylene) film and formed by film blowing of a PE raw material; and the PE raw material comprises a high density polyethylene, linear low density polyethylene and color master batch. The satchel charge packing film has high barrier property, leakage resistance and safety; the chemical stability and the mechanical properties such as the tensile strength, the tearing strength, the environmental stress crack resistance, the low temperature resistance, the heat resistance and the penetration resistance of the satchel charge packing film are improved; and the inter-layer binding ability and the dimensional stability are excellent.

Owner:ZHEJIANG CHANGXING ZIXIN TECH

Binding machine for corrugated paper packaging box

ActiveCN110936659AEnsure normal bindingGuaranteed binding effectBox making operationsPaper-makingCardboardPunching

The invention relates to the field of carton binding equipment, and discloses a binding machine for a corrugated paper packaging box. The binding machine comprises an operation platform, supports arearranged at the two sides of the top of the operation table, a cross beam is fixedly installed between the middles of the top ends of the two supports in a jacking mode, a binding head capable of moving horizontally is arranged at the bottom of the cross beam, a paperboard bracket capable of moving horizontally is arranged on the top of the operation table, and the center of the binding head and the center of the paperboard bracket are located in the same vertical line. According to the binding machine for the corrugated paper packaging box, the two sides of a corrugated board are vertically clamped by a supporting transmission belt and a positioning transmission belt at the two sides of the binding head for transmission, it is guaranteed that the middle of the corrugated board does not protrude when the corrugated board is fixed, it is guaranteed that a drilling tool in the binding head can punch through the corrugated board, the punching position is accurate, and the bookbinding effect of the corrugated paper box is guaranteed; and by synchronously controlling the binding head and the paperboard bracket to horizontally and transversely move, the binding parts of the corrugated cartons can be randomly controlled, so that the corrugated cartons with different qualities can be bound.

Owner:惠州市康宏纸品有限公司

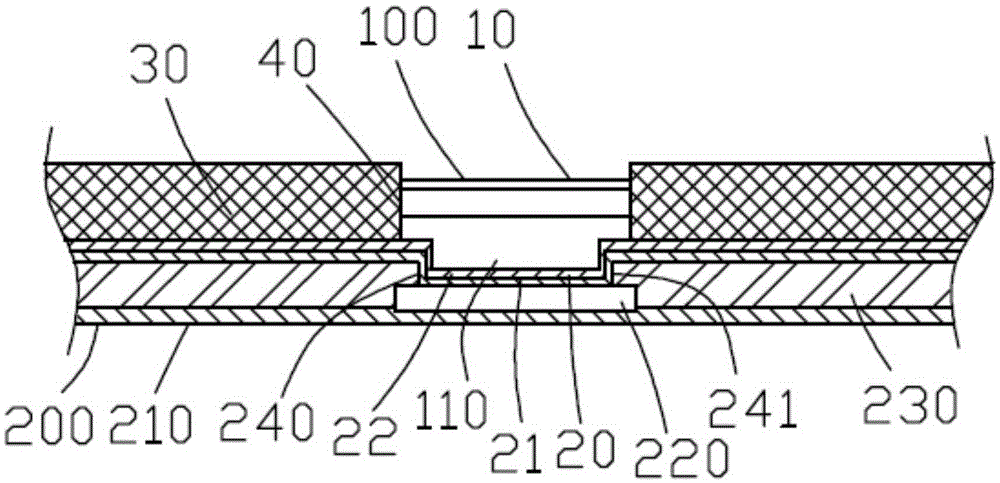

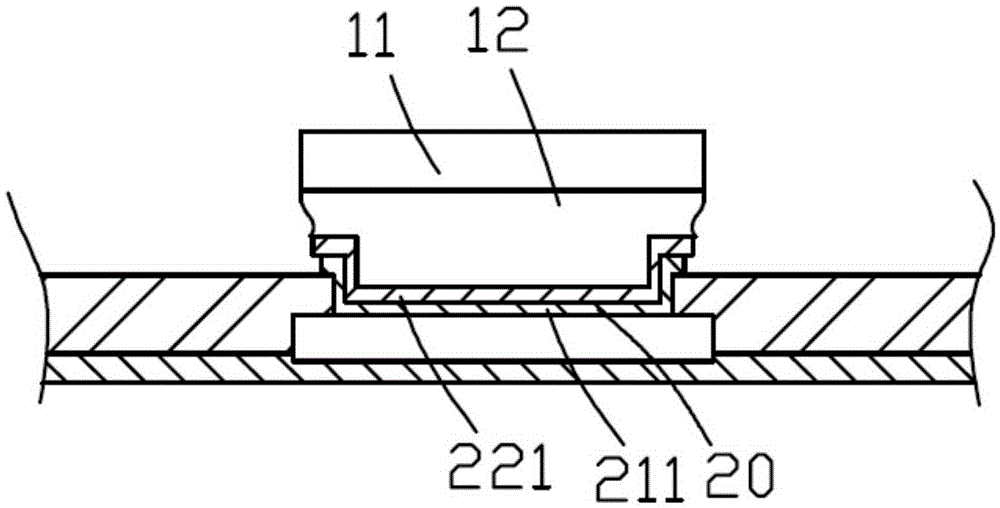

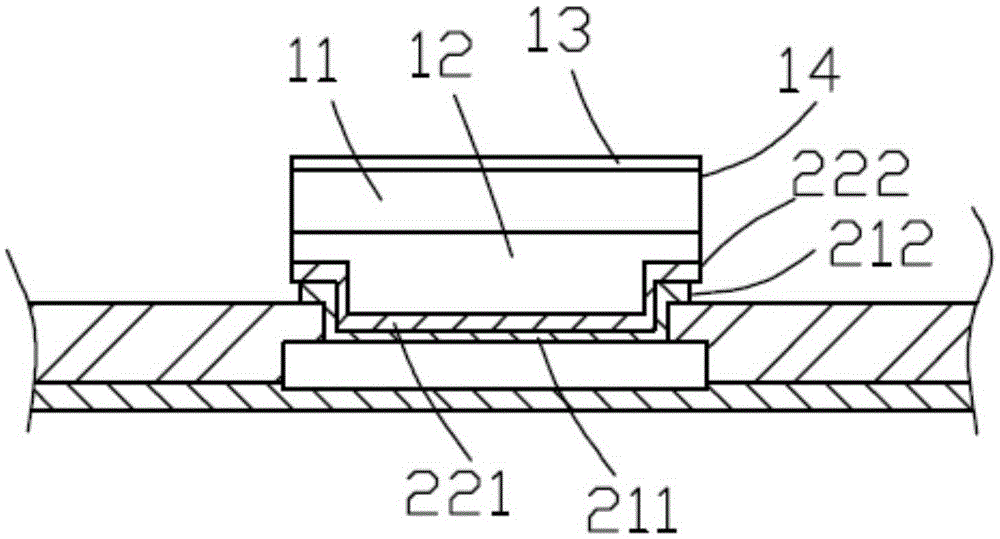

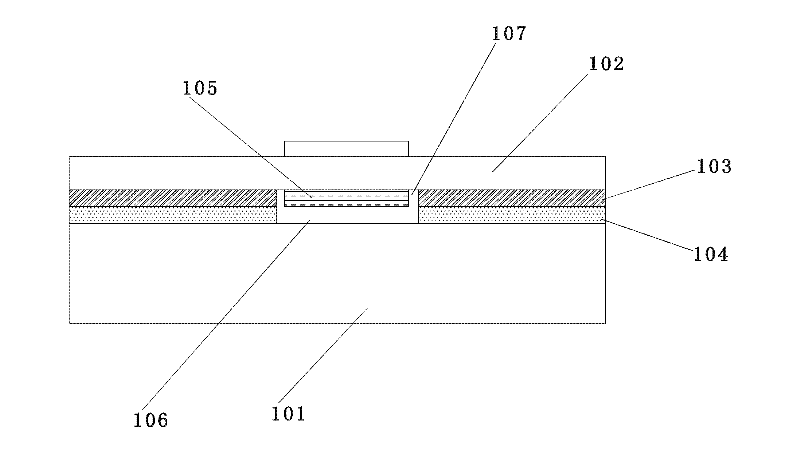

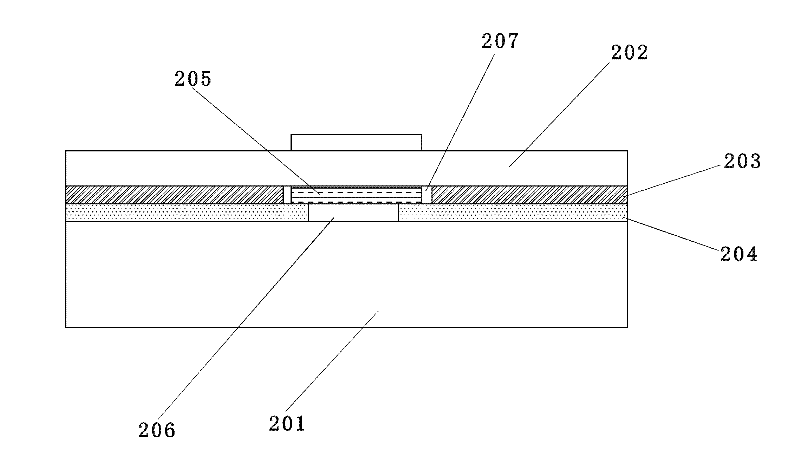

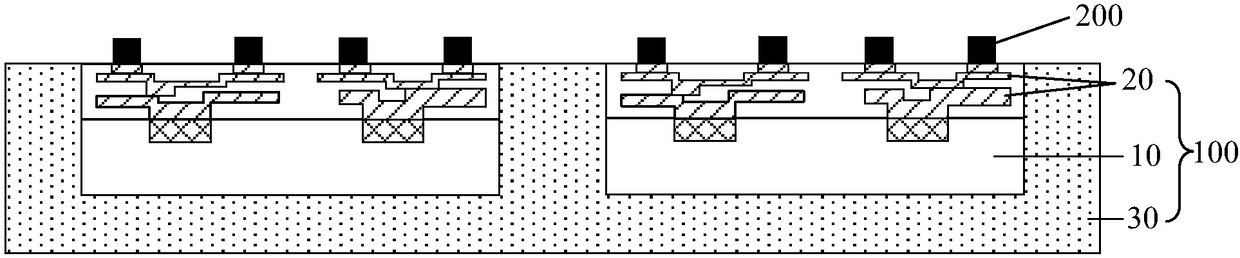

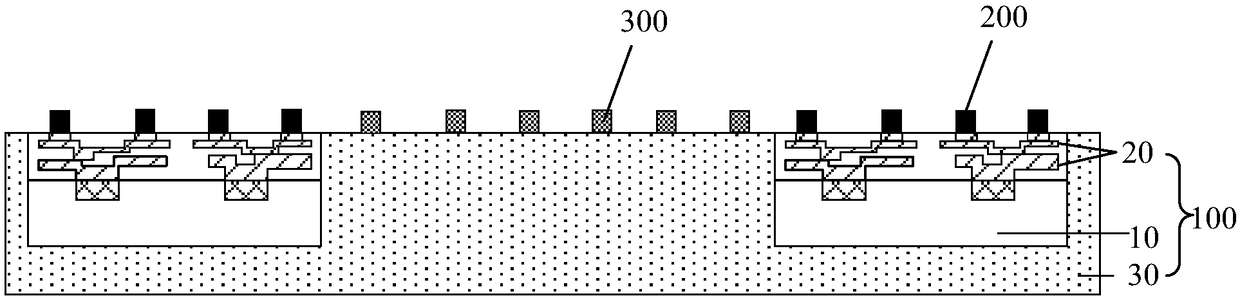

Integrated circuit chip binding structure, preparation method thereof and display device

PendingCN108279517AEven by forceAvoid crackingStatic indicating devicesNon-linear opticsElectricityDisplay device

The invention provides an integrated circuit chip binding structure, a preparation method thereof and a display device, and relates to the technical field of display. The structure can improve the problems that an integrated circuit chip binding structure cannot be flatly fitted with a substrate in the binding process, so that stress of the integrated circuit chip binding structure is uniform, andfurther, a conductive bump cannot stably and electrically contact with other devices or the integrated circuit chip binding structure is cracked in the prior art. The integrated circuit chip bindingstructure comprises a base, a plurality of conductive bumps and at least one supporting bump, the conductive bumps are arranged on the base and electrically connected with a chip in the base, the basecomprises a first area and a second area arranged on the periphery of the first area, the conductive bumps are arranged on the second area, and the supporting bumps are arranged on the base and arranged in the first area.

Owner:BOE TECH GRP CO LTD +1

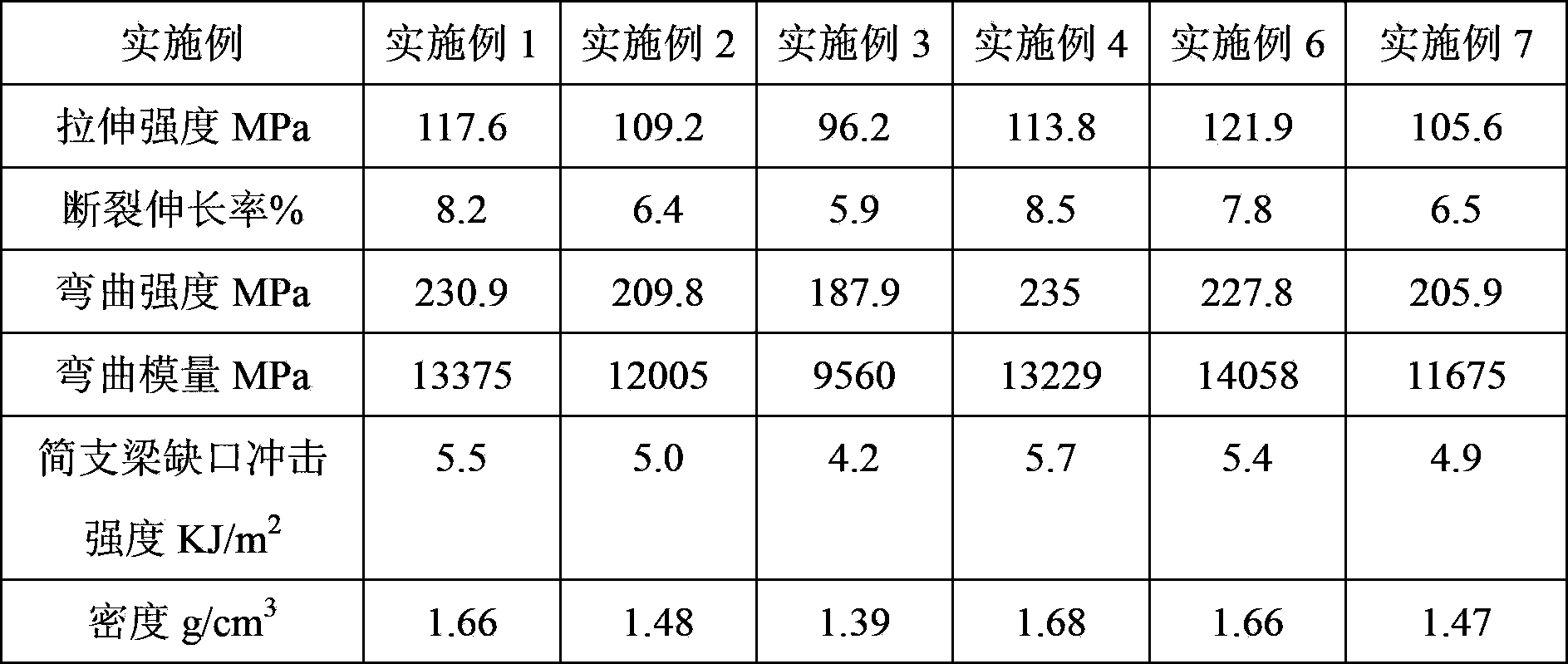

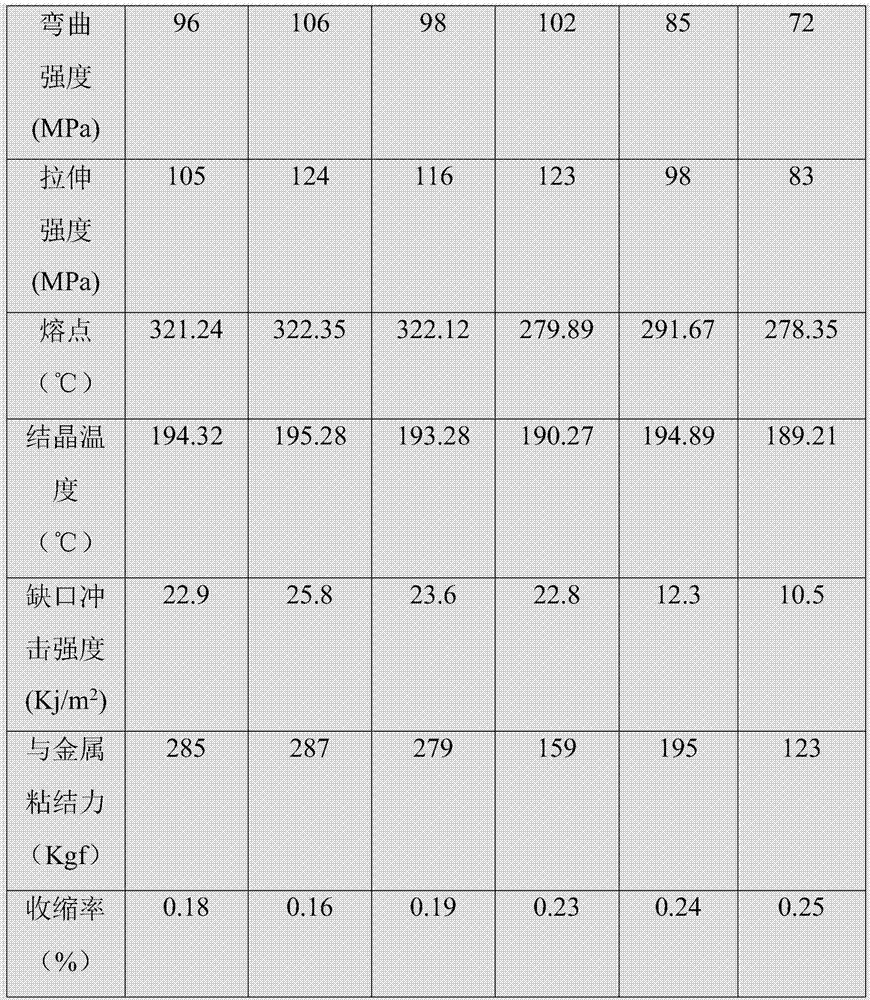

PPS composite material for nanometer injection molding and preparation process thereof

The invention relates to the field of a plastic cement novel material, in particular to a PPS composite material for nanometer injection molding and a preparation process thereof. The PPS composite material for nanometer injection molding is prepared from the following ingredients in parts by weight: 50 to 80 parts of resin, 5 to 35 parts of continuous long carbon fiber, 2 to 10 parts of silicon dioxide, 3 to 8 parts of tougheners, 0.5 to 1 part of antioxidizers, 0.5 to 2 parts of coupling agents and 0.5 to 1 parts of lubricating agents. The toughener is maleic anhydride grafted styrene-ethylene-butadiene-styrene; the laser additive is nanometer copper powder modified by acrylic ester. The PPS composite material for nanometer injection molding has the advantages of good mechanical performance, high bonding force with metal materials and good heat resistance, so that the NMT (nano molding technology) process requirements can be better met.

Owner:深圳市华盈新材料有限公司

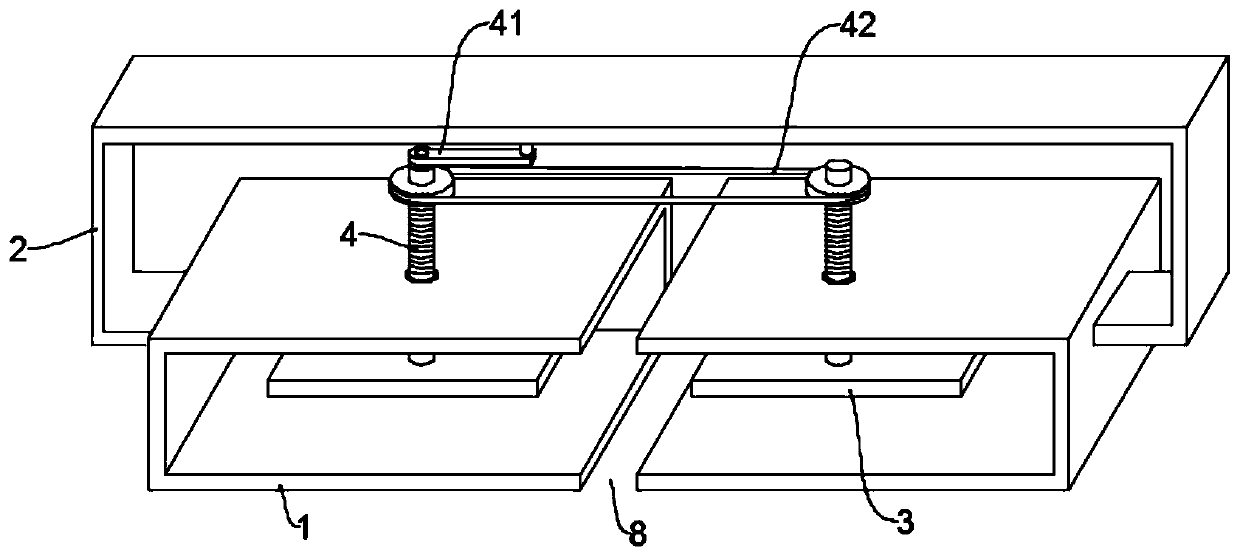

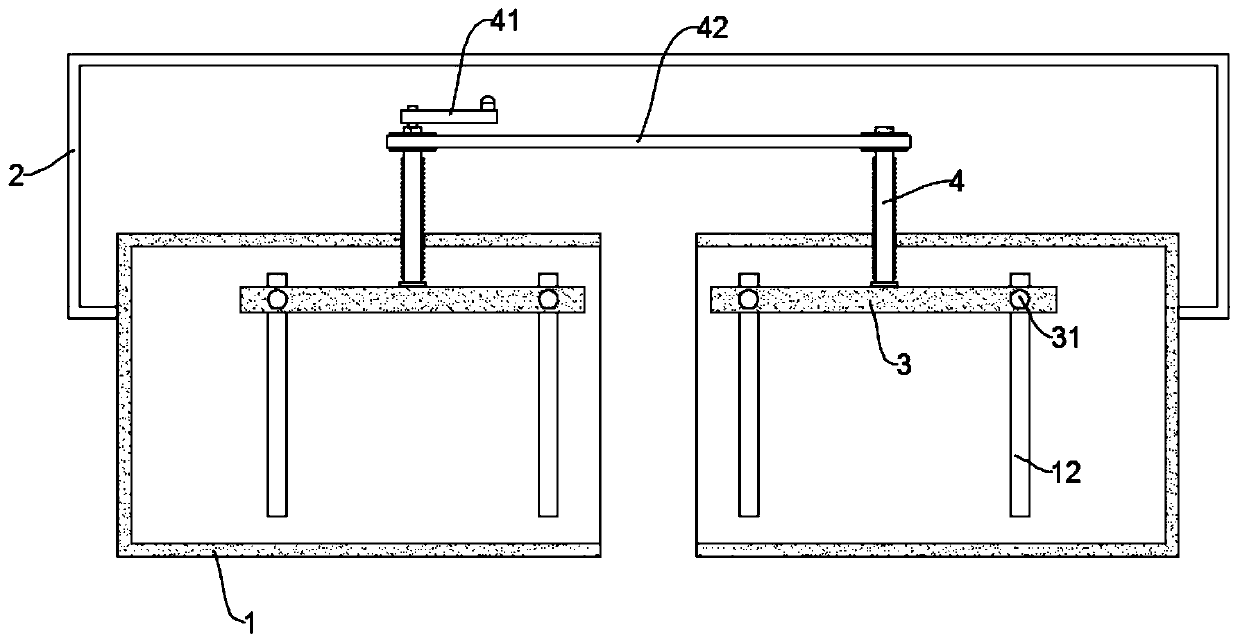

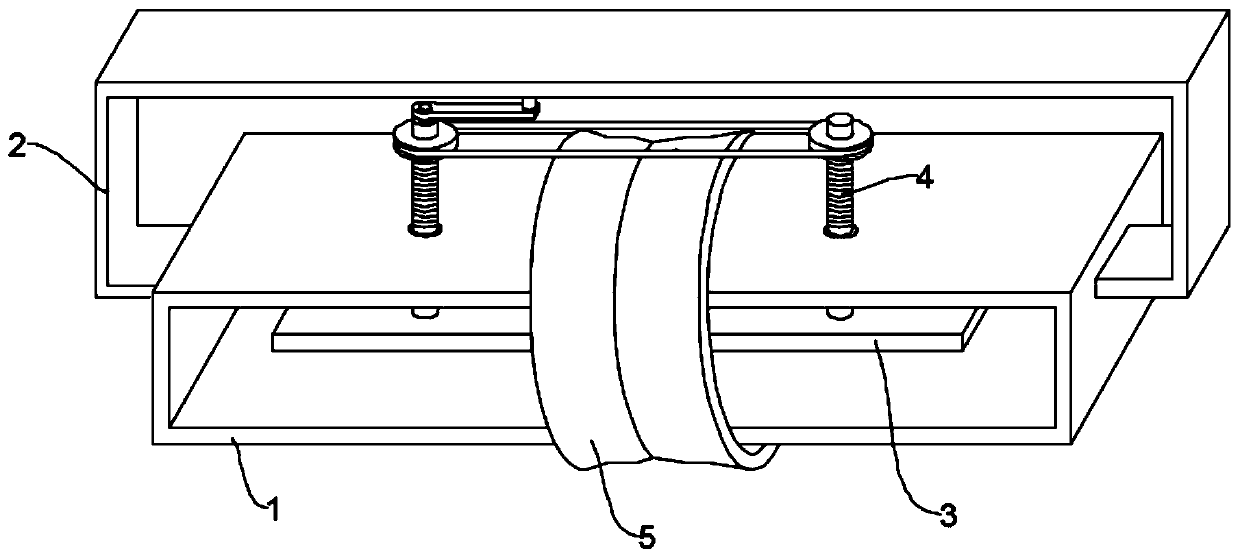

Bill fixing and bundling device for financial accounting

InactiveCN111071537AGuaranteed binding effectPaper article packagingBinding material applicationStructural engineeringMechanical engineering

The invention discloses a bill fixing and bundling device for financial accounting, and relates to the field of office supplies. The device comprises a frame body for placing bills and a flattening assembly for flattening the bills, wherein the frame body comprises two shell bodies which are connected through a connecting frame, and a gap is formed between the side openings of the two shell bodies; and the flattening assembly comprises pressing plates which is arranged in the two shell bodies respectively, the pressing plates are arranged in the shell bodies in a sliding manner, and are drivenby a driving mechanism to move up and down. According to the bill fixing and bundling device, the two shell bodies are arranged at intervals, and the pressing plates are arranged in the two shell bodies respectively, so that the binding work of the bills can be carried out by utilizing the gap on the premise of not taking out the bills, the bills are in a compaction state when being bundled, andthe bundling effect is guaranteed.

Owner:蔡伟

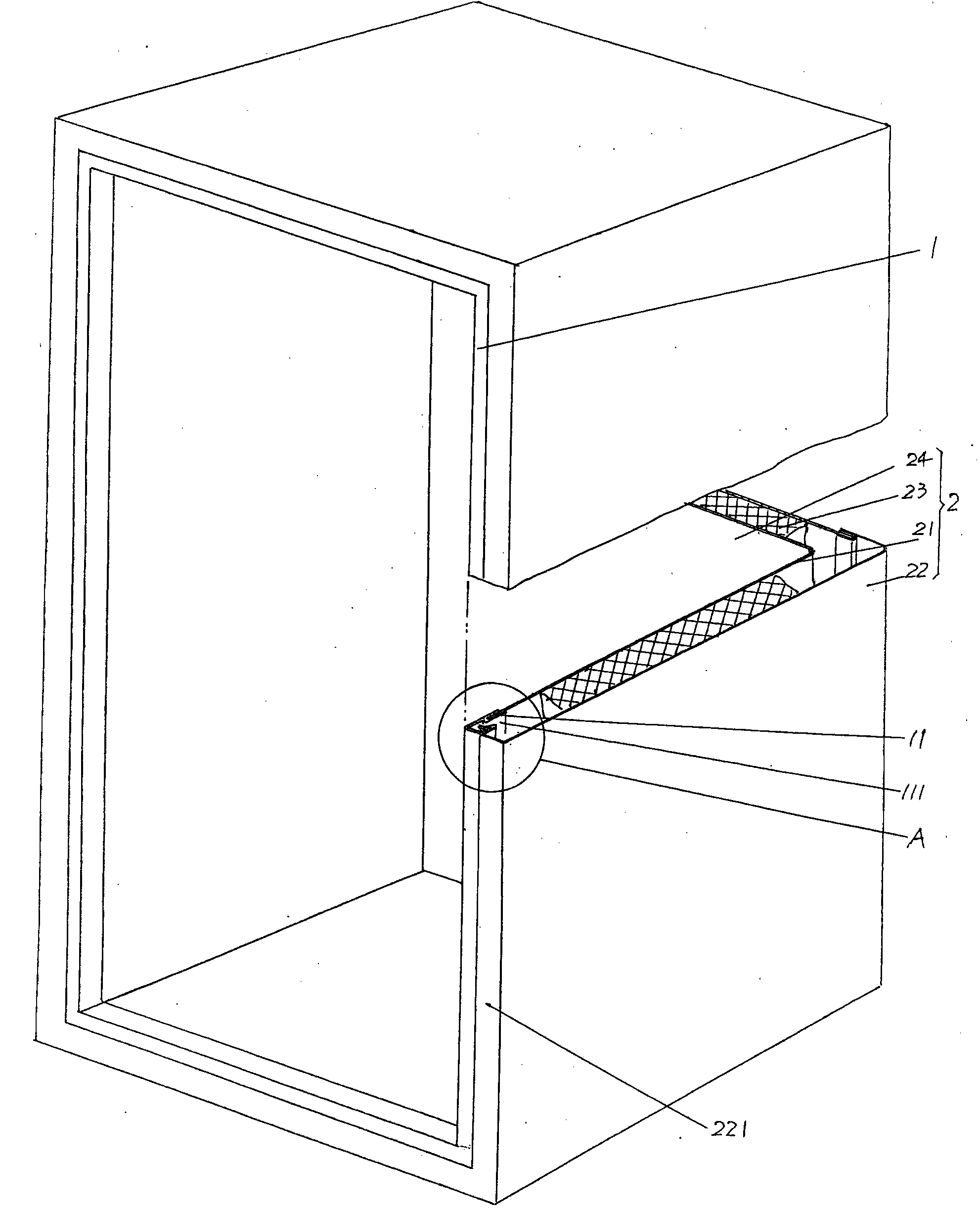

Opening frame and box matching structure of food refrigeration display cabinet

ActiveCN104296465APrevent escapeReduce work intensityDomestic cooling apparatusLighting and heating apparatusInsulation layerUltimate tensile strength

An opening frame and box matching structure of a food refrigeration display cabinet belongs to the technical field of refrigerating devices. An opening frame comprises an opening frame body, and a box slot is formed in the opening frame body. The box comprises a box body, and the box body comprises an inner container, a casing and a foaming heat insulation layer. The matching structure is characterized in that an opening frame matching fold side is bended on one side of the fold side of the casing facing the opening frame body, the opening frame matching fold side is bended to form an inclined fold side in the direction backing to the foaming heat insulation layer, the inclined fold side is bended to form a clamping leg limit fold side towards one side of the opening frame matching fold side backing to the foaming heat insulation layer, and a slot is formed in the space between the clamping leg limit fold side and the opening frame matching fold side. One side of the opening frame body facing the casing fold side is bended to form a casing matching fold side, and one side of the casing matching fold side facing an opening frame embedding leg cavity is bended to form an opening frame embedding leg. The structure effectively prevents foaming materials from escaping to the external from a gap between the casing matching fold side and the casing fold side. The assembly is simplified, the operation intensity is light, the assembly efficiency is high, stress is even, and the whole combination effect is guaranteed.

Owner:苏州雷巴电器有限公司

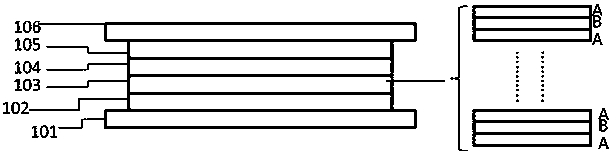

QLED device

ActiveCN109980105AAvoid accumulationGuaranteed binding effectSolid-state devicesSemiconductor/solid-state device manufacturingValence bandConduction band

The present invention provides a QLED device. The device comprises a light emitting layer which is formed by stacking a blue light quantum dot material layer A and a yellow light quantum dot materiallayer B according to a [ABA]n mode, n is 1-3, the valence band difference of the blue light quantum dot material and the yellow light quantum dot material is 0, and the conduction band energy level ofthe blue light quantum dot material is at least 0.5eV higher than the conduction band energy level of the yellow light quantum dot material. A single band difference superlattice structure is introduced in a light emitting layer to improve the recombination efficiency of the quantum dots and the light emitting purification of the device so as to avoid accumulation of charges of the quantum dot layer.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com