Patents

Literature

30results about How to "Short foaming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

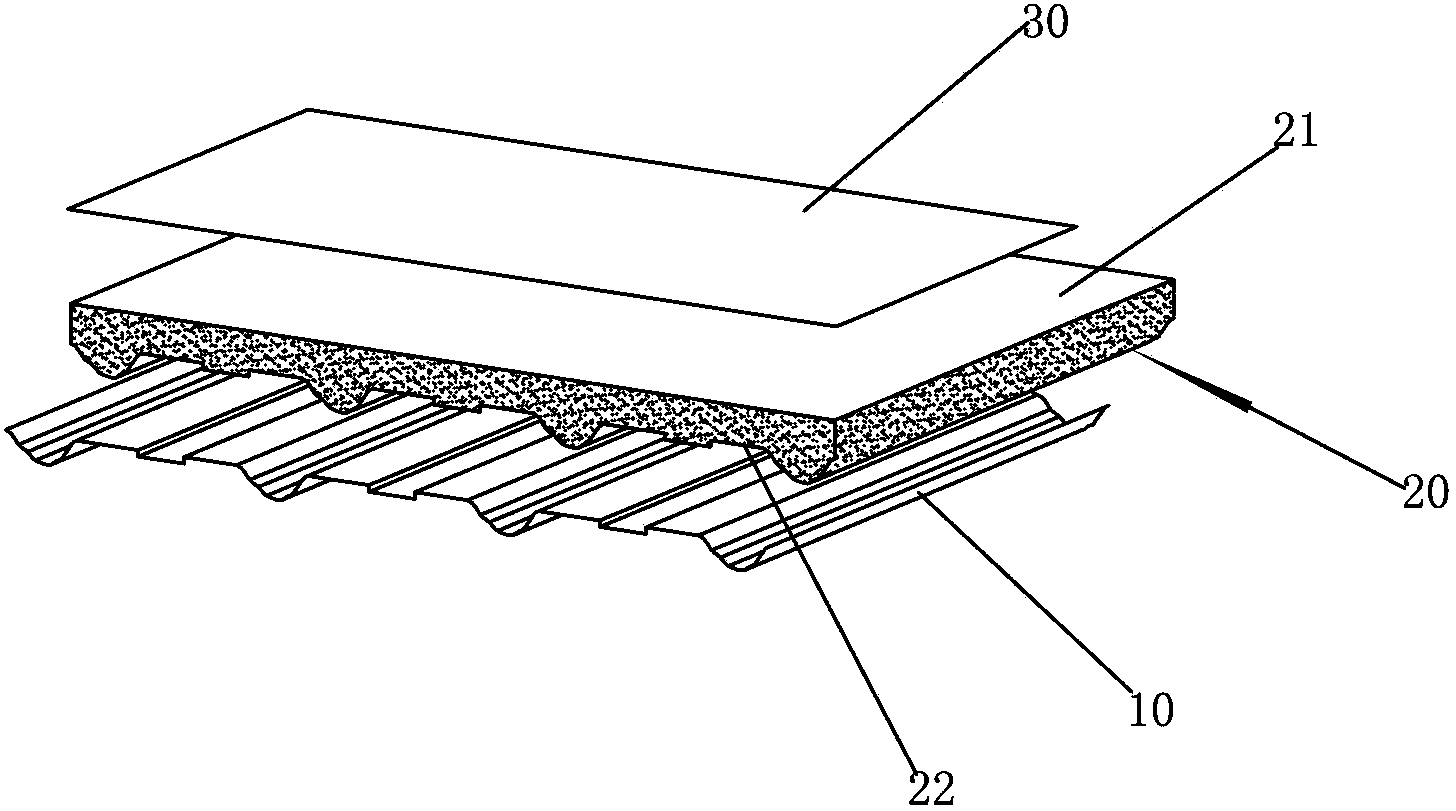

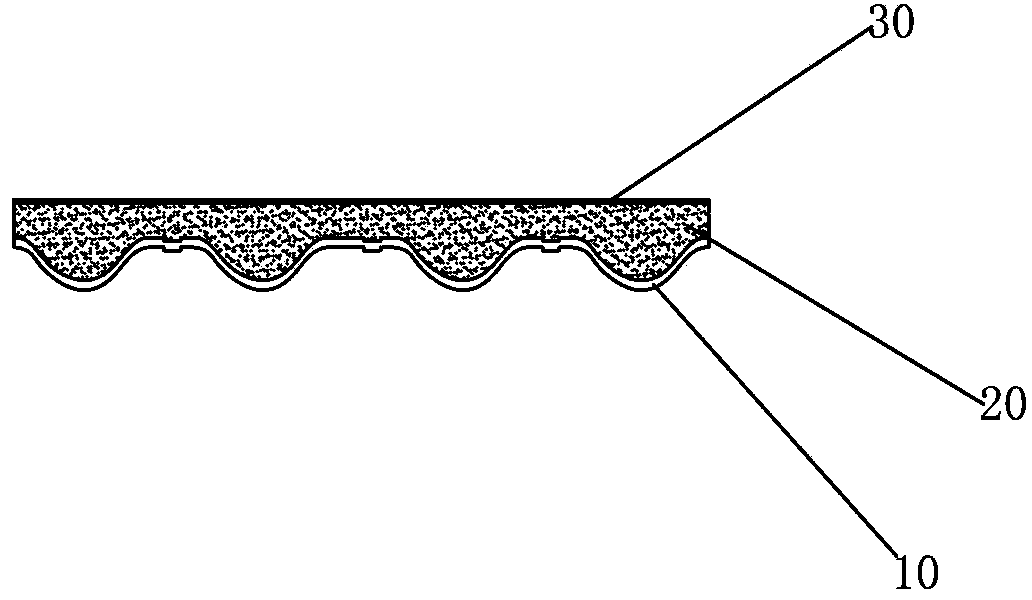

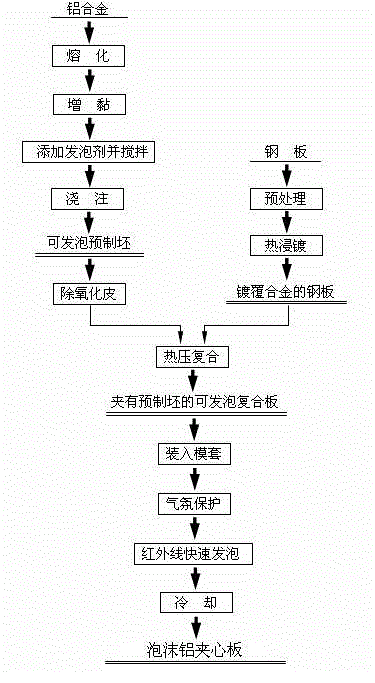

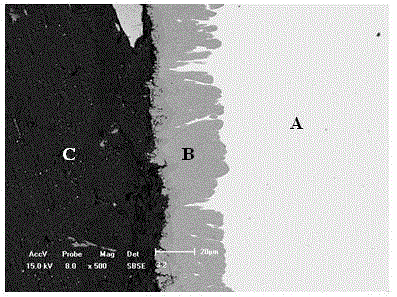

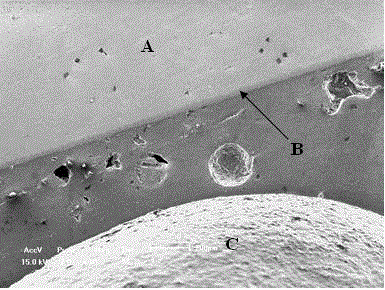

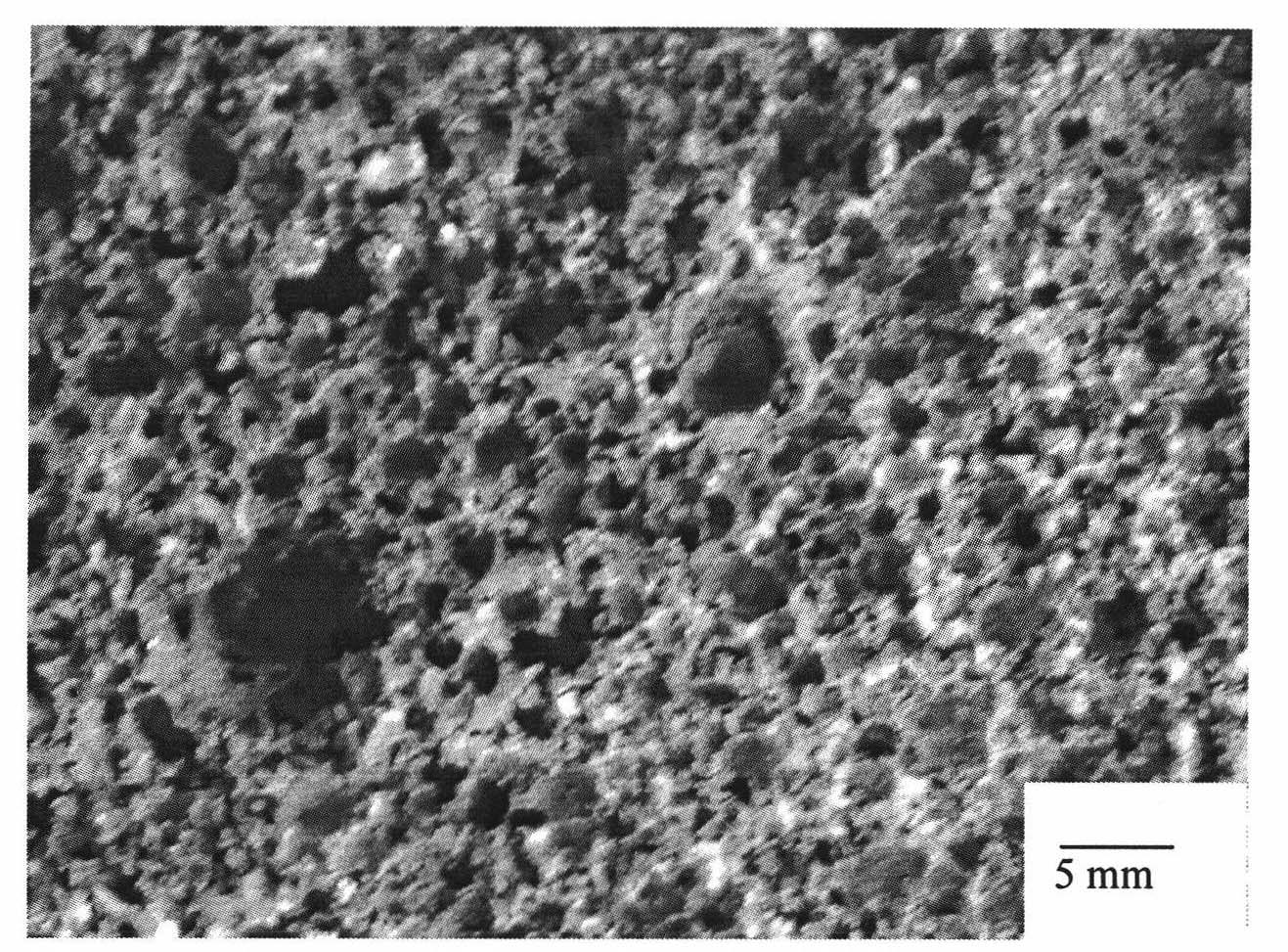

Preparation method of foamed aluminum sandwich plate

ActiveCN102390135AImprove mechanical propertiesAccurate thicknessLaminationLamination apparatusFoaming agentComposite plate

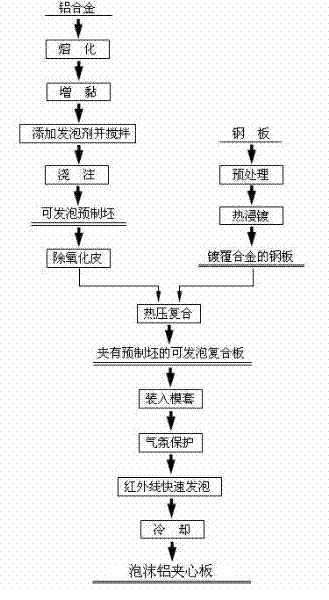

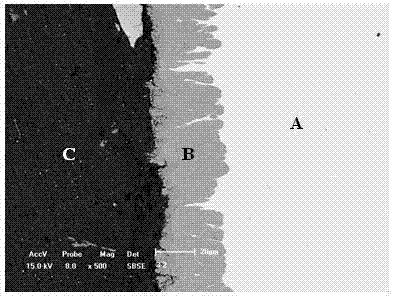

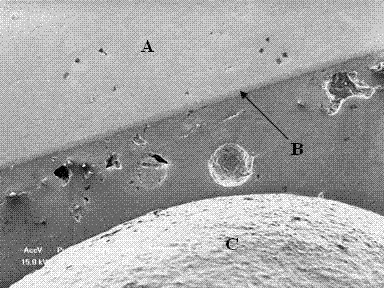

The invention relates to a preparation method of a layered composite material, in particular to a preparation method of a foamed aluminum sandwich plate. The method comprises the following steps of: firstly, uniformly mixing an aluminum alloy, a tackifier and a foaming agent to obtain a platy or blocky foamable precast blank material; then, performing hot-pressing compounding of the precast blankand a steel plate after the surface plating to obtain a foamable composite plate sandwiching the precast blank; placing the foamable composite plate sandwiching the precast blank in a mould sleeve closed around, and delivering into an infrared foaming furnace heating at the upper and lower parts at the same time so as to heat and foam the composite plate sandwiching the precast blank under infrared radiation; and finally, pulling the mould sleeve out of the foaming furnace, and cooling to obtain a foamed aluminum sandwich plate with a fixed thickness. The foamed aluminum sandwich plate prepared by the method provided by the invention has an accurate thickness, a uniform structure and a high yield; and moreover, the preparation processes in the invention can be automatically controlled, thereby being favorable for realizing semi-continuous preparation of the foamed aluminum sandwich plate.

Owner:NORTHEASTERN UNIV

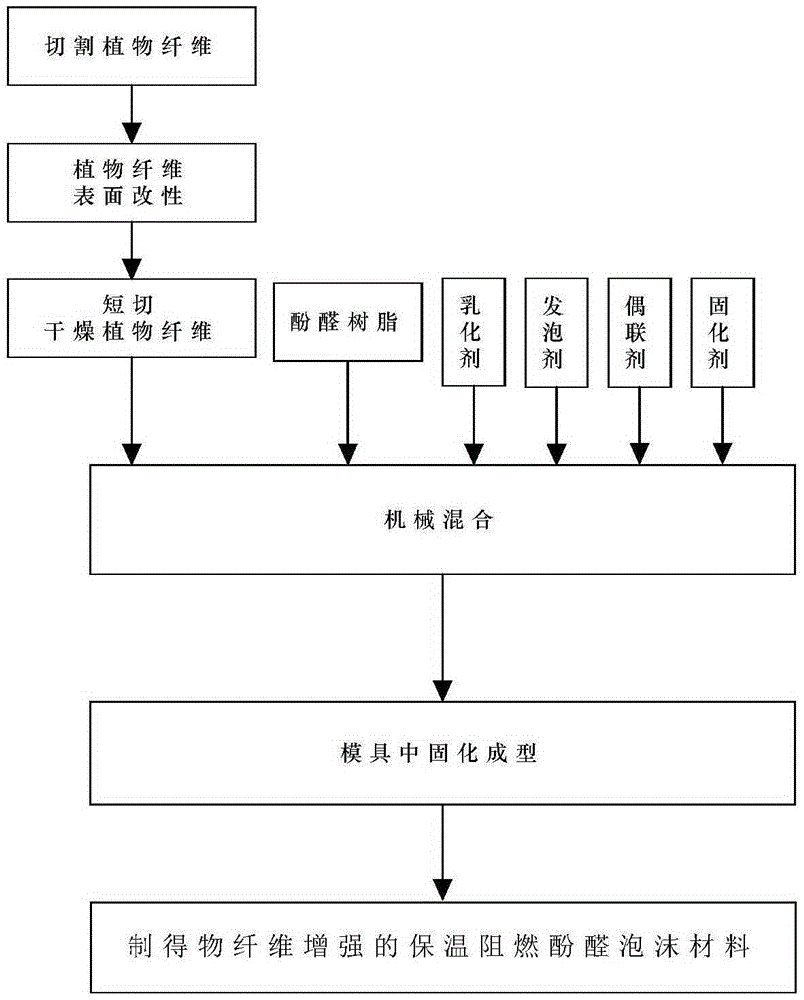

Plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and preparing method thereof

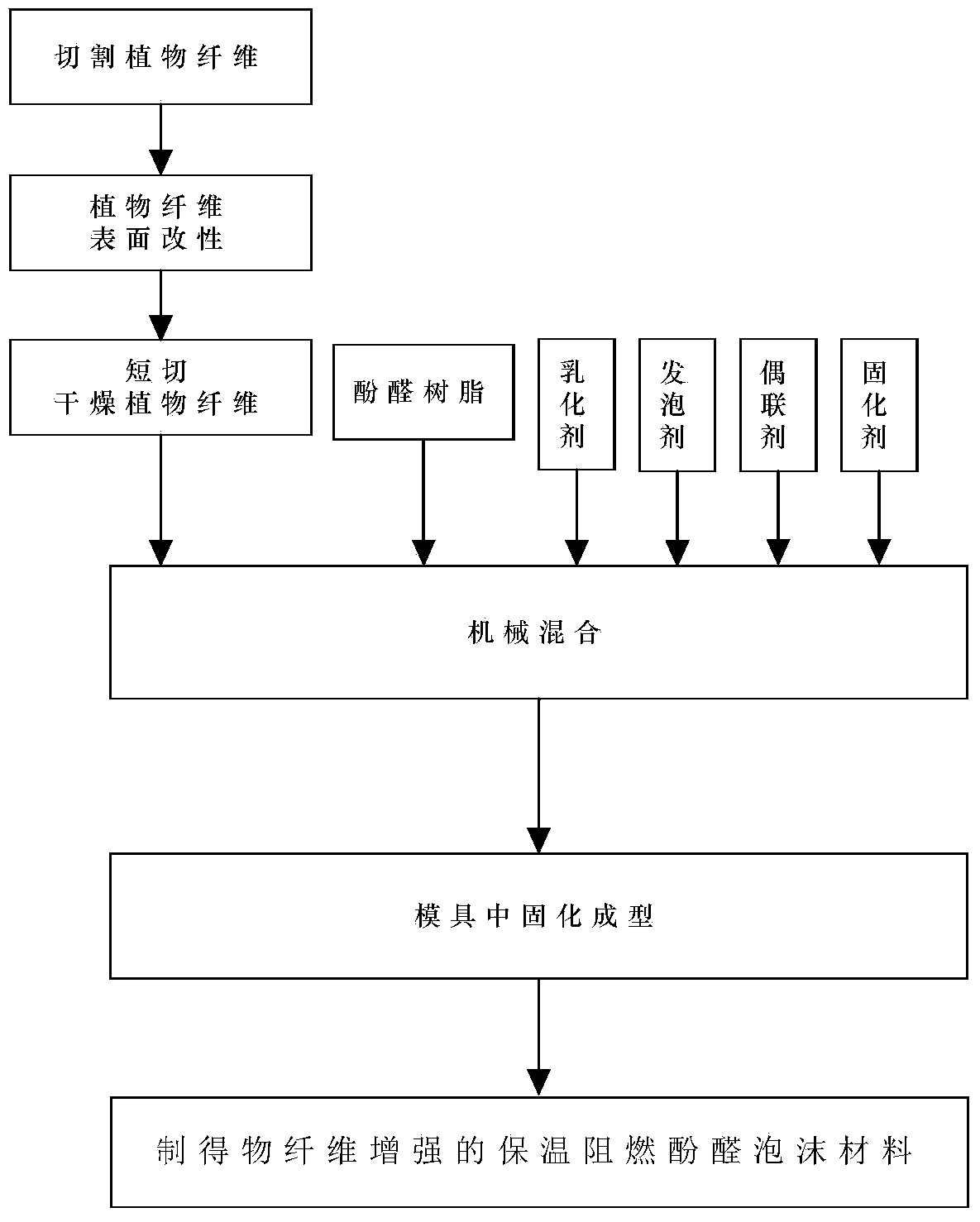

The invention discloses a plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and a preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material. The plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material is formed by adding plant fibers which have different lengths and are of a hollow structure into phenolic resin. The preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material comprises the steps that the dried plant fibers, obtaining through cutting, with the different lengths are mechanically mixed with the phenolic resin, an emulsifying agent, a coupling agent, a foaming agent and a curing agent, the mixture is cured and foamed for 30 min to 120 min at the curing temperature ranging from 45 DEG C to 80 DEG C, and then the plant fiber reinforcing type phenolic foam material used for internal walls and external walls of buildings is obtained after demolding. According to the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and the preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material, phenolic foam is reinforced through the environment-friendly and renewable natural plant fibers, the heat-preservation property and the inflaming-retarding property of the material are good, and the production cost of the phenolic foam material is greatly reduced due to the fact that the plant fibers are cheap and easy to obtain.

Owner:BEIHANG UNIV

Preparation method of plant fiber cushion packaging material

InactiveCN103772733AIncrease the expansion ratioHigh densityFlexible coversWrappersFiberSodium bicarbonate

The invention discloses a preparation method of a plant fiber cushion packaging material. The preparation method comprises the steps of 1) grinding plant fiber, soaking the ground plant fiber in sodium hydroxide for 18-30 hours, filtering and collecting a filter cake, and drying the filter cake; 2) preparing a polyvinyl alcohol solution which is 5-10% in mass concentration, adding the plant fiber dried by the step 1), adding glycerol, sodium bicarbonate, azodicarbonamide and ammonium bicarbonate, and stirring the materials in a stirrer until the materials are completely and uniformly mixed to obtain a mixed sizing material, wherein the mass ratio of the polyvinyl alcohol to the plant fiber to the glycerol to the sodium bicarbonate to the azodicarbonamide to the ammonium bicarbonate is (10-15): (20-30): (3-5): (1-3): (1.2-1.8): (2-6); and 3) adding the mixed sizing agent obtained from the step 2) in a foaming mold and foaming through microwave to obtain the plant fiber cushion packaging material. The prepared foamed material is low in density and high in elastic ratio, and is specifically suitable for cushion packaging.

Owner:NANTONG TIANHE PACKING

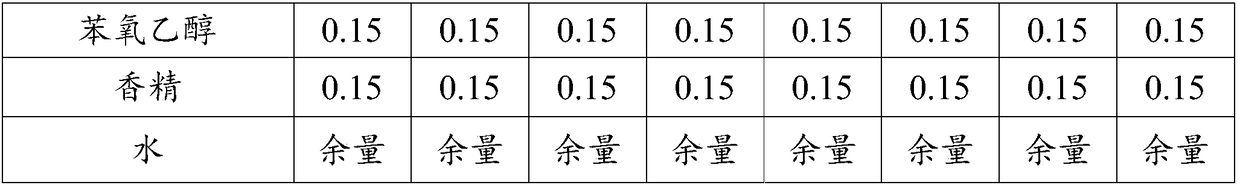

Self-foaming amino acid facial cleanser

ActiveCN108852945AHigh viscosityShort foaming timeCosmetic preparationsToilet preparationsCleansers skinFacial skin

The invention discloses self-foaming amino acid facial cleanser. The self-foaming amino acid facial cleanser comprises an amino-containing surfactant and a self-foaming agent, wherein the self-foamingagent is prepared from perfluorobutyl methyl ether, ethyl perfluorobutyl ether and polydimethylsiloxane; the content of the perfluorobutyl methyl ether in the facial cleanser is 0.1 to 15 percent inpercentage by weight; the content of a mixture of the ethyl perfluorobutyl ether and the polydimethylsiloxane in the facial cleanser is 0.1 to 15 percent in percentage by weight. The facial cleanser disclosed by the invention has a self-foaming effect, the time for self-foaming is short and more foam is generated by self-foaming; the foam is very fine and smooth, is moderate and has no irritation;the facial cleanser can be used for deeply cleaning facial skin and extremely has interestingness.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

Method for producing foam glass by use of glass fiber waste

The invention relates to a method for producing foam glass by use of glass fiber waste, which comprises the following steps of firstly sorting the glass fiber waste, removing impurities and breaking into fine particles; uniformly mixing the raw materials according to the weight percentage in the raw material formula, and performing ball milling to obtain fine powder below 200 meshes; then putting the fine powder into a heat-resistant steel mould box, and performing preheating, foaming, foam stabilization, setting, demoulding, annealing and cooling to obtain a foam glass blank; finally, cutting the blank into a finished product. According to the method provided by the invention, a great quantity of waste raw materials generated by industrial production are made fully used, the production cost is low, the process is simple and easy to implement, the foaming time is short while the foaming is uniform, the energy consumption is remarkably reduced, and the product quality is stable.

Owner:浙江善力高科新材料有限公司

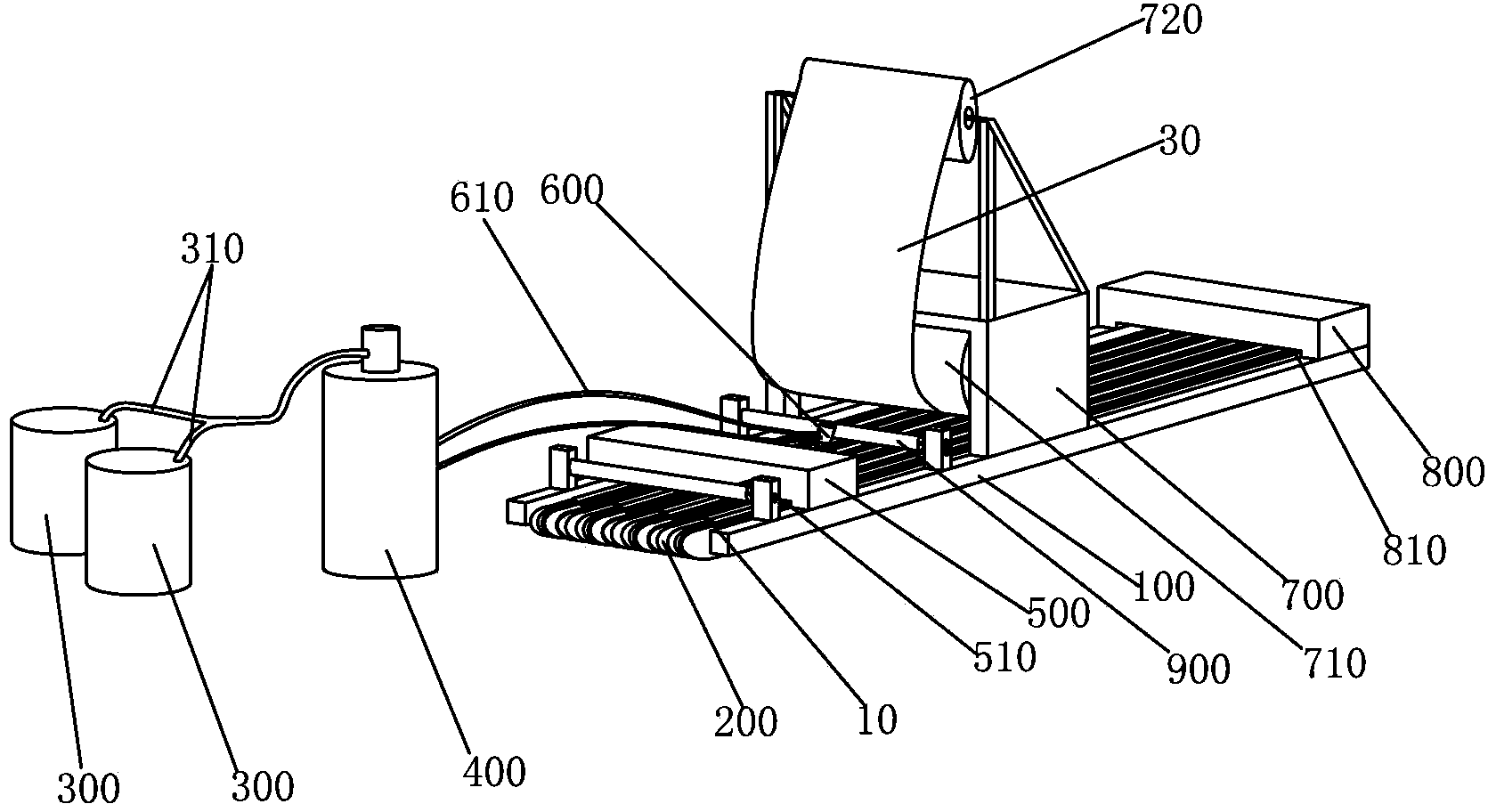

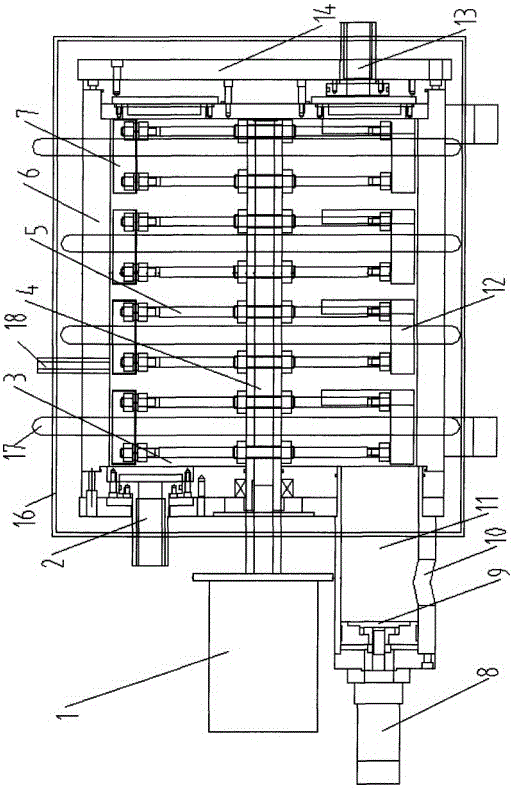

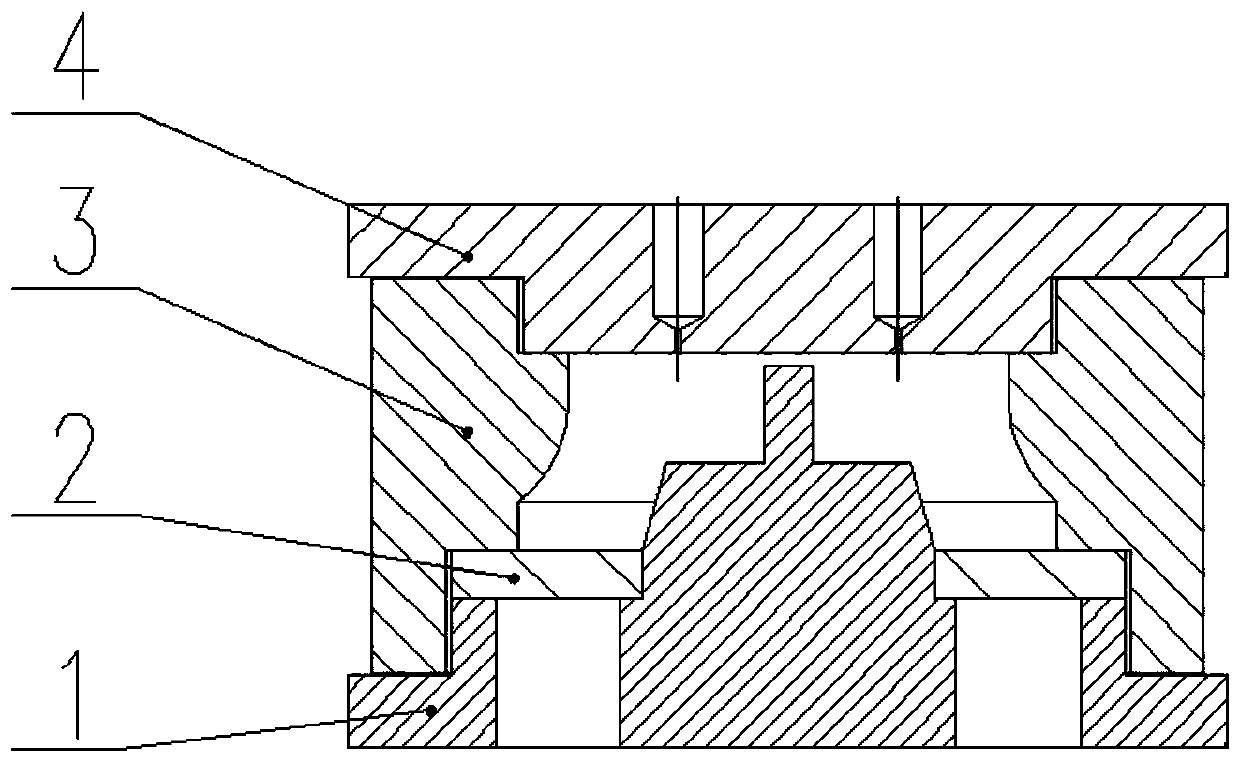

Production technology and equipment for thermal insulating and flame-retardant wall

The invention discloses a production technology and equipment for thermal insulating and flame-retardant wall. The production technology includes: step 10, heating polyisocyanate and polyether respectively to 39-41DEG C; step 20, mixing the polyisocyanate and polyether in a volume ratio of 1:1.1-1.6, and conducting stirring to obtain a foaming agent; step 30, heating a substrate profile to 39-41DEG C; step 40, jetting the foaming agent evenly onto the substrate profile surface to form a foaming layer; step 50, sticking a flame-retardant layer on the foaming layer to obtain a semi-finished product; and step 60, drying the semi-finished product to obtain a finished product. The obtained foaming agent has a short foaming time, which is shorter than the foaming time under room temperature by at least over one time. The rate of finished products is high, and the yield is increased by over 50% compared with the circumstance of not heating the substrate profile. At the same time, the whole production process is simple, and the production equipment is not complex, so that the process and the equipment are suitable for mass production, and the production efficiency is high.

Owner:PUTIAN CHENGXIANG JIN XIN LIGHT STEEL COLOR PLATECO

Production of fine-pored pmma foams using nucleating agents

Fine-cell PMMA foams are produced using a production process including nucleators in addition to suitable blowing agents. It was found that, surprisingly, a simple-to-produce stable PMMA foam having very fine cells and very good properties can be produced.

Owner:EVONIK OPERATIONS GMBH

Quick foaming agent

InactiveCN102070378AFoaming agent, it foams at a moderate temperatureModerate foaming temperatureNon-explosive/non-thermic compositionsHydrogen NitrateSodium thiocyanate

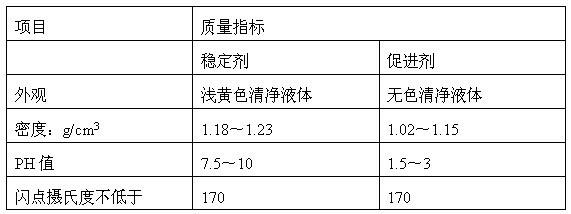

The invention relates to a quick foaming agent for foaming emulsion explosives, which consists of a stabilizing agent and an accelerating agent. The addition amount of the stabilizing agent is 0.3 to 0.5 percent of an emulsion explosive; the addition amount of the accelerating agent is 1.2 to 1.5 times weight of the stabilizing agent of the emulsion explosive; the stabilizing agent consists of the following components in percentage by weight: 0.5 to 1.5 percent of sulfourea, 20 to 30 percent of sodium nitrite, 3 to 5 percent of potassium nitrite, and 63.5 to 76.5 percent of water; and the accelerating agent consists of the following components in percentage by weight: 7 to 11 percent of ammonium nitrate, 2 to 3 percent of hydrogen nitrate, 1 to 3 percent of glacial acetic acid, 0.2 to 0.5 percent of sodium thiocyanate, 0.5 to 0.7 percent of phosphoric acid, 1 to 2 percent of diammonium hydrogen phosphate, 0.5 to 1.2 percent of citric acid, 1 to 3 percent of urea and 75.6 to 86.8 percent of water. The quick foaming agent has the characteristics of high foaming speed, low corrosion, small aftereffect and the like; meanwhile, the ratio of foam materials can be adjusted according to the formula and process conditions of the emulsion explosive and performance requirement, and the continuous production of emulsion explosive packages is realized.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

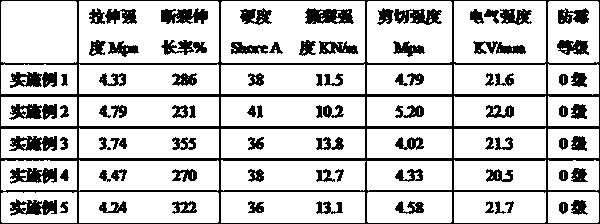

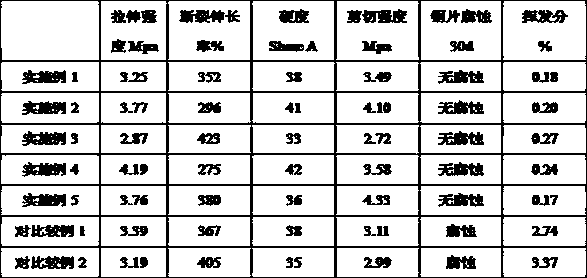

Organosilicon coating rubber for rail transit, and preparation method thereof

The invention discloses an organosilicon coating rubber for rail transit, and a preparation method thereof, and belongs to the technical field of silicone rubber application, wherein the organosiliconcoating rubber comprises: 60-80 parts of hydroxyl-terminated polydimethylsiloxane, 10-20 parts of a reinforcing filler, 10-20 parts of an adhesive film reinforcing agent, 4-8 parts of a cross-linkingagent, 1-5 parts of a chain extender, 0.02-0.5 part of a catalyst, 1-4 parts of a tackifier, and 0.8-3 parts of an antifungal agent, and is prepared through heating drying, vacuum defoaming, vacuum mixing and other steps. According to the present invention, the organosilicon coating rubber is a ketoxime removing type one-component room temperature vulcanized organosilicon elastomer, is used for rail transit, can effectively achieve the effects of water resistance, dust resistance, mildew resistance, insulating protection and the like on the outer layer, can solve the mildew problem of the existing organosilicon coating rubber, can achieve the mildew-resistant grade of 0 grade, does not contain volatile solvents such as petroleum ether, solvent gasoline, toluene and the like, and is safe and environmentally friendly, and the cured rubber layer has good strength and good toughness.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Preparation method of foamed aluminum sandwich plate

ActiveCN102390135BImprove mechanical propertiesAccurate thicknessLaminationLamination apparatusFoaming agentComposite plate

The invention relates to a preparation method of a layered composite material, in particular to a preparation method of a foamed aluminum sandwich plate. The method comprises the following steps of: firstly, uniformly mixing an aluminum alloy, a tackifier and a foaming agent to obtain a platy or blocky foamable precast blank material; then, performing hot-pressing compounding of the precast blank and a steel plate after the surface plating to obtain a foamable composite plate sandwiching the precast blank; placing the foamable composite plate sandwiching the precast blank in a mould sleeve closed around, and delivering into an infrared foaming furnace heating at the upper and lower parts at the same time so as to heat and foam the composite plate sandwiching the precast blank under infrared radiation; and finally, pulling the mould sleeve out of the foaming furnace, and cooling to obtain a foamed aluminum sandwich plate with a fixed thickness. The foamed aluminum sandwich plate prepared by the method provided by the invention has an accurate thickness, a uniform structure and a high yield; and moreover, the preparation processes in the invention can be automatically controlled, thereby being favorable for realizing semi-continuous preparation of the foamed aluminum sandwich plate.

Owner:NORTHEASTERN UNIV LIAONING

Soaping agent and soaping process for high-density patterned pure cotton figured cloth

ActiveCN106118915AWon't happenReduce pollutionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBetaineSodium metasilicate

The invention belongs to the technical field of dyeing and finishing, and specifically relates to a soaping agent and a soaping process for high-density patterned pure cotton figured cloth. The soaping agent for high-density patterned pure cotton figured cloth is prepared from the following raw materials: N-vinyl pyrrolidone, sodium lauryl sulfate, delta-laminated sodium metasilicate, dodecyl dimethyl betaine, etidronic acid, maleic anhydride, polyacrylic acid, compound soaping enzyme, octadecyl amine ethoxylate ether, secondary alkyl sodium sulfonate and thiourea dioxide, wherein the compound soaping enzyme is composed of laccase, lipopenic enzyme, Eurolan RP soaping enzyme and EOQ soaping enzyme. The soaping agent has less foam and short foaming time when used in soaping high-density patterned pure cotton figured cloth; the soaped pure cotton figured cloth can not fade or change color; dyed fabric of the high-density patterned pure cotton figured cloth processed by the soaping agent combined with the soaping process basically has no color difference and strong loss; and compared with the traditional soaping process, the color fastness is higher, working procedures are reduced, and time and energy are saved.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

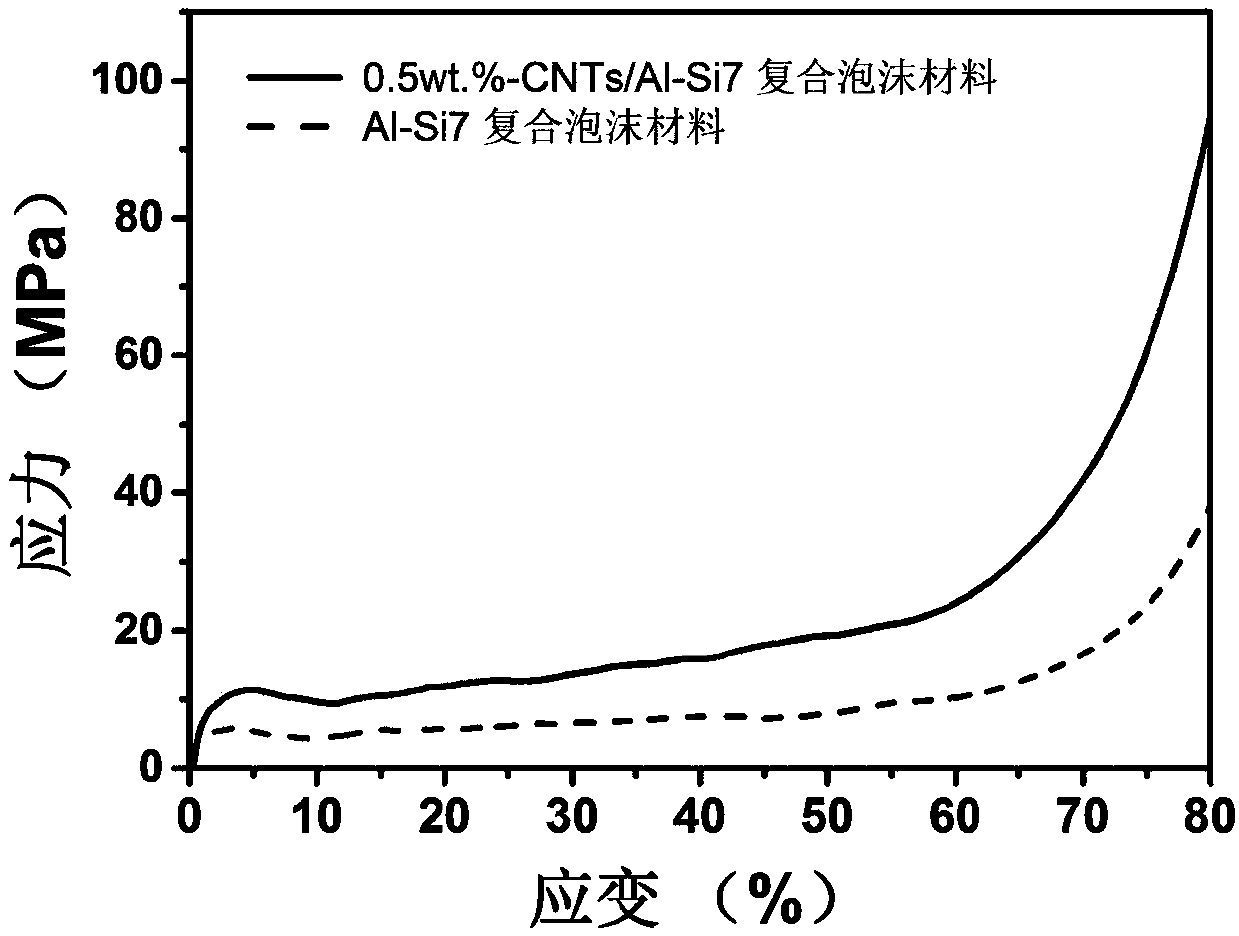

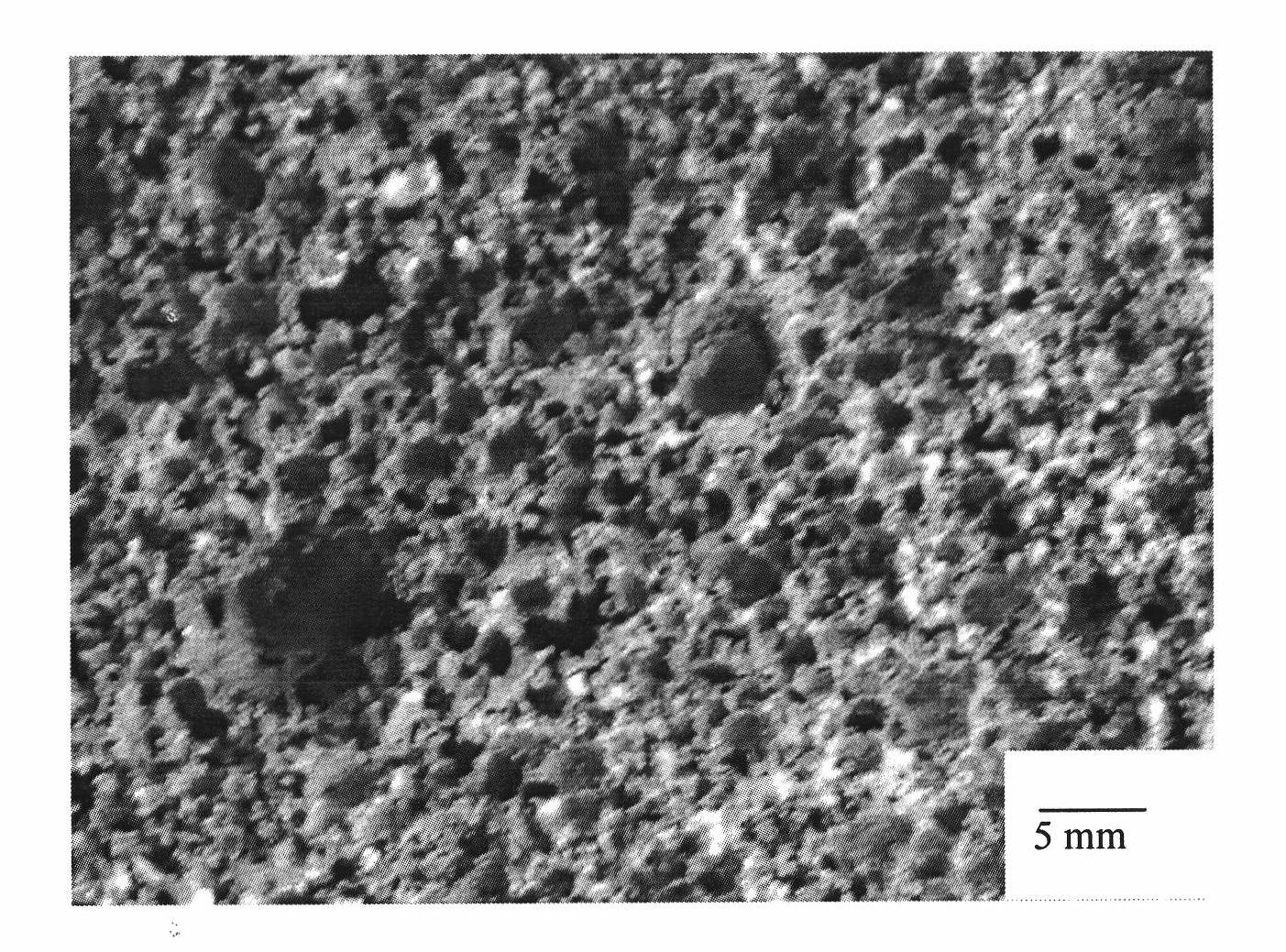

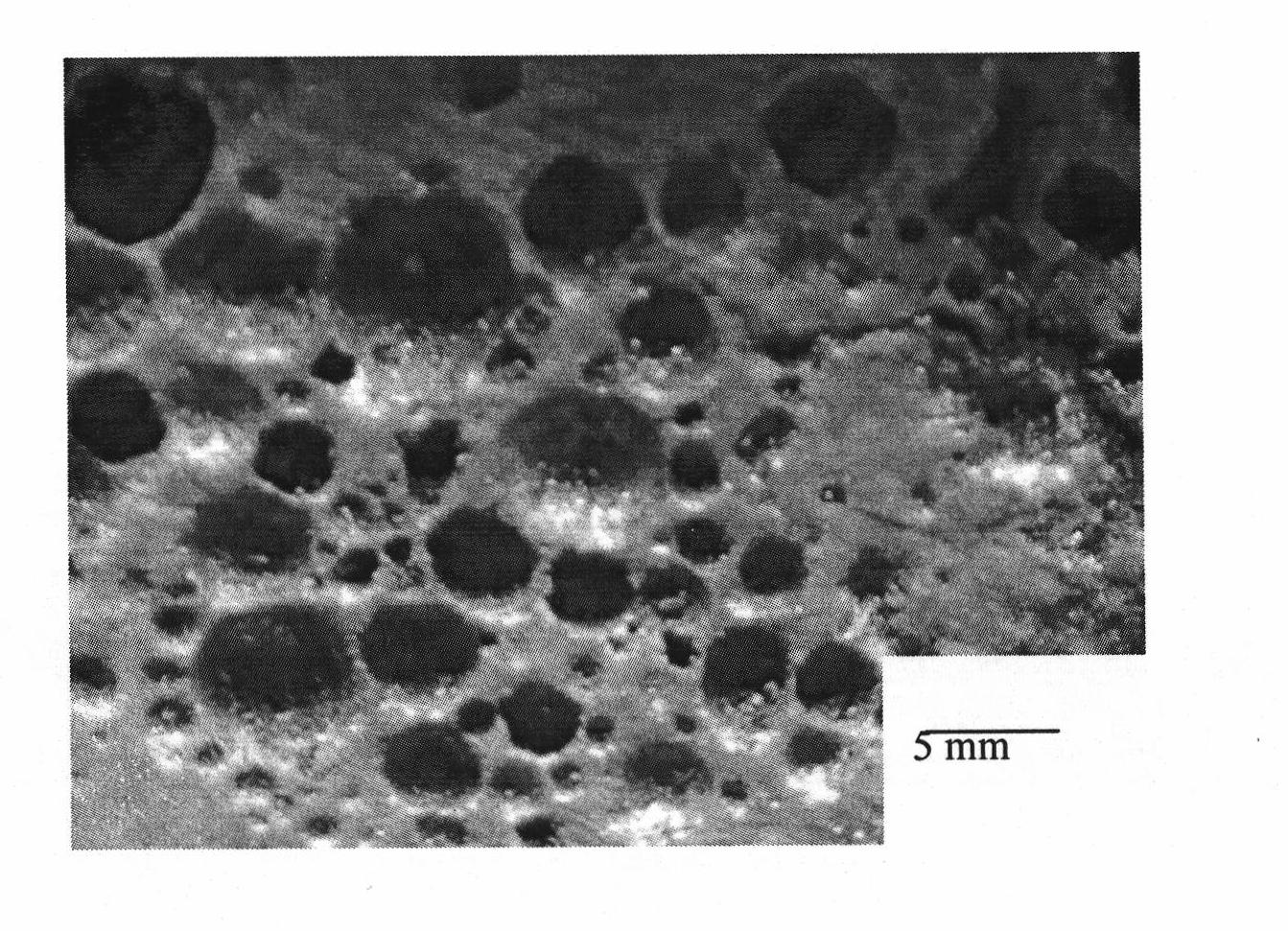

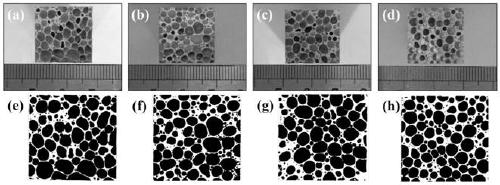

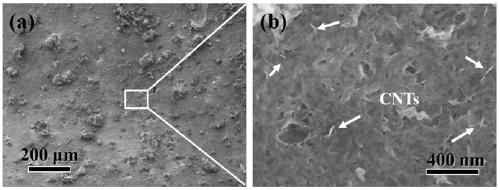

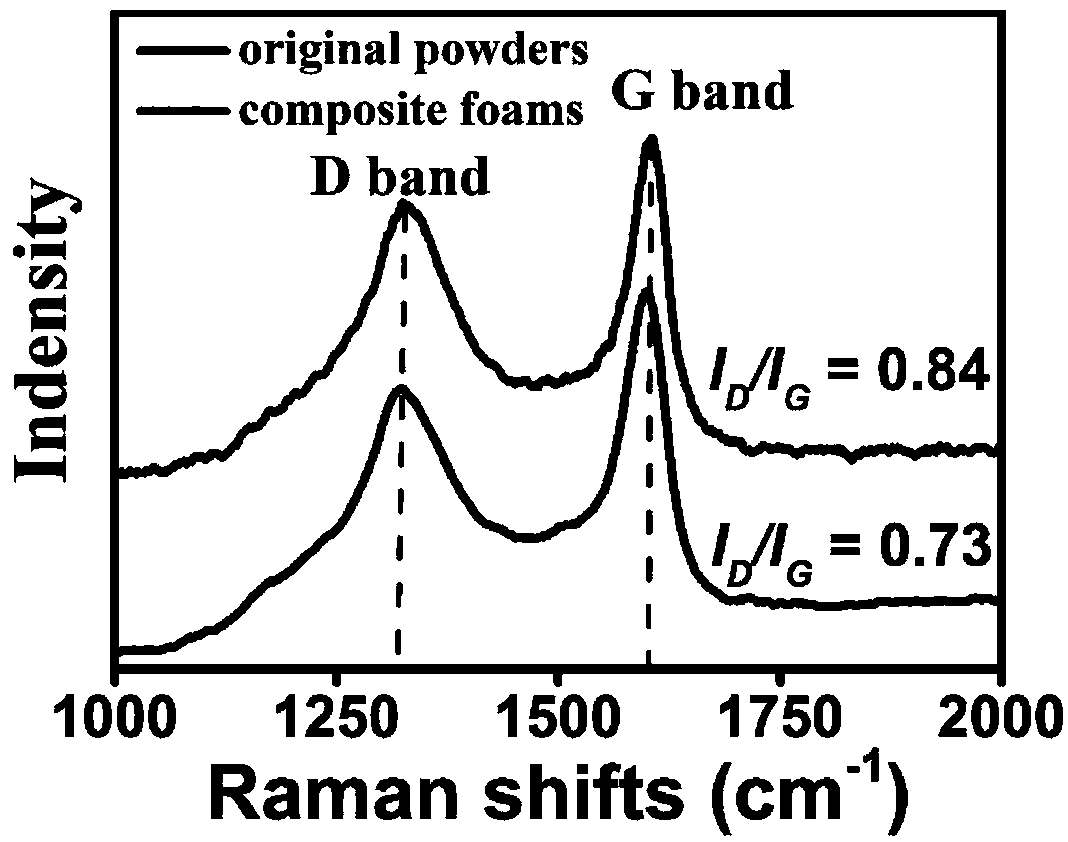

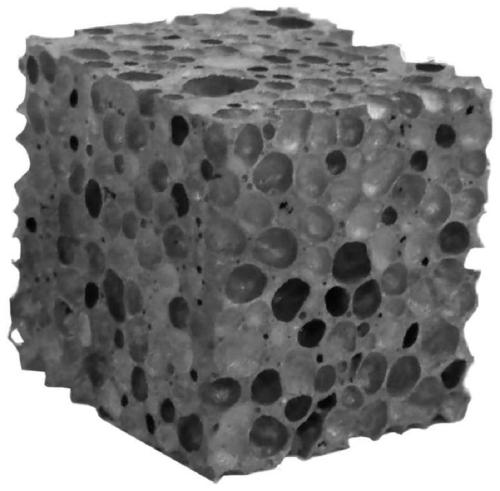

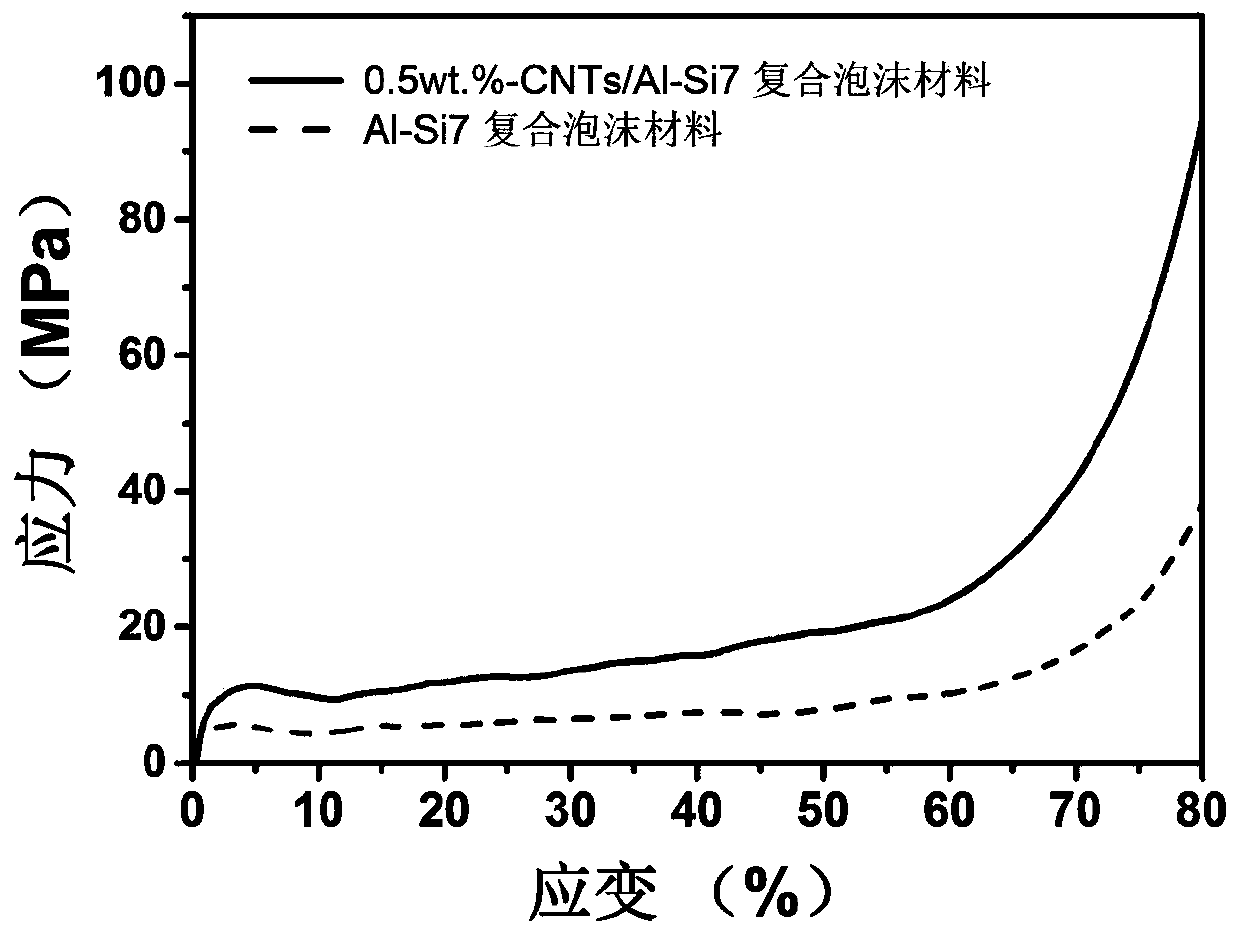

Closed pore CNTs/Al-Si composite foamed material and preparation method thereof

The invention relates to a closed pore CNTs / Al-Si composite foamed material. The closed pore CNTs / Al-Si composite foamed material comprises, by weight, 5%-25% of silicon powder, 0-5% of magnesium powder, 0.15%-1.5% of TiH2 powder and the balance CNTs / Al powder obtained through in-situ chemical vapor deposition. The preparation method includes the steps that the in-situ CNTs / Al powder is subjectedto mechanical ball milling; the CNTs / Al powder obtained through ball grinding is mixed with the silicon powder, the magnesium powder and a foaming agent in a stirring machine; the mixed powder is subjected to cold-press molding, so that a cylindrical precast block is obtained; and the precast block is put into a cylindrical steel mold of a resistance furnace for fast foaming, and accordingly the closed pore CNTs / Al-Si composite foamed material can be obtained. According to the closed pore CNTs / Al-Si composite foamed material, foam pores are evenly distributed, and the size dimensions are uniform; and full-closed holes are formed, the strain rate sensitive effect is low, and the compression stress-strain curve has an obvious platform region. The foamed aluminum material product prepared through the method is stable in quality and excellent in performance, the preparation process is simple and the technological process is fast.

Owner:CIVIL AVIATION UNIV OF CHINA

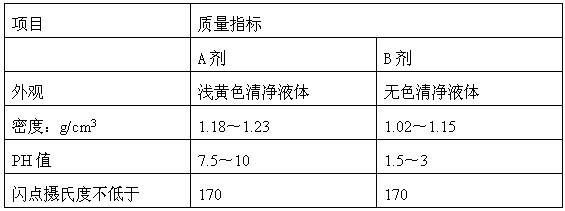

Foaming agent for explosive

InactiveCN102070380AShort foaming timeShort sensitization process timeNon-explosive/non-thermic compositionsSodium bicarbonateSodium thiocyanate

The invention relates to a special sensitizer for explosive, in particular to a foaming agent for emulsion explosive, which comprises an A agent and a B agent, and the A agent and the B agent are mixed according to the weight ratio of 1: 1.2-1.5, wherein the A agent comprises the following components by weight percent: 0.5%-1.5% of thiourea, 3%-5% of potassium nitrite, 20%-30% of sodium nitrite and 63.5%-76.5% of water; and the B agent comprises the following components by weight percent: 7%-11% of ammonium nitrate, 0.2%-0.6% of phosphoric acid, 0.5%-2% of diammonium phosphate, 0.5%-1.5% of sodium thiocyanate, 1.8%-2.5% of citric acid, 0.7%-1.5% of glacial acetic acid, 0.7%-1.5% of sodium bicarbonate, 0.2%-0.9% of thiourea, 0.2%-1% of sodium nitrate, 0.9%-1.5% of urea and 76%-87.3% of water. The foaming agent has the characteristics of short foaming time, appropriate after-effect, easiness in control of density, good safety performance, long natural storage period and the like.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

Preparation of foam magnesium alloy

The invention discloses a foam magnesium alloy preparing method, belonging to the field of the production of an alloy with open or closed pores. The method is particularly a method for preparing a magnesium alloy by means of foaming a powder entity and comprises the following steps: firstly, mixing 150-270-mesh pure magnesium powder and 250-400-mesh pure aluminum powder according to a mass ratio (pure magnesium powder : pure aluminum powder) ranging from 4:1 to 9:1 so as to obtain a metal powder mixture, uniformly mixing the metal powder mixture with 200-325-mesh TiH2 powder vesicant which accounts for 1.0-2.5 percent of the mass of the metal powder mixture, carrying out cold pressing and hot pressing on the mixture obtained from the previous step, and then obtaining a magnesium alloy foaming precast block; and then, under the protection of argon, preparing the foam magnesium alloy with an average aperture ranging from 1 mm to 5 mm by means of heating the foaming precast block in a mould. The method has the advantages of simple and flexible process, short period, high productive rate and no impurity; and the foam magnesium alloy prepared according to the method has a closed-pore structure and the advantages of high porosity, uniform pore structure distribution, regular pore shapes, wide application scope and good comprehensive performance.

Owner:HEBEI UNIV OF TECH

Medical one-component room temperature vulcanization silicone rubber and preparation method thereof

InactiveCN109929505AReduce contentSmall smellNon-macromolecular adhesive additivesCross-linkVulcanization

The invention discloses a medical one-component room temperature vulcanization silicone rubber and a preparation method thereof, and belongs to the technical field of silicone rubber application, wherein the raw materials of the medical one-component room temperature vulcanization silicone rubber comprises, by mass, 100 parts of low volatile hydroxyl-terminated polydimethylsiloxane, 15-25 parts ofa reinforcing filler, 4-10 parts of a cross-linking agent, 1-3 parts of a tackifier, and 0.1-1 part of a catalyst, and is prepared through heating drying, vacuum defoaming, vacuum mixing and other steps. According to the present invention, the medical one-component room temperature vulcanization silicone rubber can greatly reduce the volatilization amount of D3-D10 small molecules; by using the ethyl lactate-based cross-linking agent, the odor during the silicone rubber vulcanization process is reduced, and no corrosion is generated to the metal material; and by using the novel catalyst, thesafety is further improved compared with the ordinary one-component room temperature vulcanized silicone rubber.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Preparation method and application of bath fizzer

InactiveCN110664630AIncrease the amount of foamShort foaming timeCosmetic preparationsToilet preparationsSodium bicarbonateGlycine

The invention discloses a preparation method and application of a bath fizzer. The bath fizzer is composed of sodium bicarbonate, glucose, magnesium oxide, fumaric acid, essence, glycine, isopropyl myristate, sucrose fatty acid ester and pigments. By means of mixing and pressing, the prepared bath fizzer has the advantages of high foaming amount, short foaming time, long foaming maintaining time and small skin impact force, and has a better bathing effect on human skin.

Owner:漳州艾沐日用品有限公司

Preparation method for synthesizing carbon nanotube reinforced foam aluminum composite material based on rapid foaming method

InactiveCN109128174AEvenly dispersedSimple preparation equipmentTransportation and packagingMetal-working apparatusAnhydrous ethanolCarbon nanotube

The invention relates to a preparation method for synthesizing a carbon nanotube reinforced foam aluminum composite material based on a rapid foaming method. The preparation method comprises the following steps that (1) preparation of a catalyst precursor is carried out, particularly, pure aluminum powder and CO (NO3) 26H2O are weighed according to a mass ratio of 18-22:1, a proper amount of anhydrous ethanol solution is added, and precursor powder is obtained after drying; (2) preparation of CNT / Al composite powder is carried out; (3) preparation of foaming precursor is carried out, particularly, the CNT / Al composite powder obtained above is mixed with 7wt.% of Si powder and 0.3wt.% of TiH2 powder in a three-dimensional mixer for 0.5 to 3 hours to obtain uniform mixed powder, and a cold press is used for maintaining pressure at 450 MPa to obtain the foaming precursor; and (4) preparation of foamed aluminum is carried out.

Owner:TIANJIN UNIV

Production of a pmma foam using cross-linking agents, regulators and blowing agents

The present invention relates to novel types of PMMA foams and also to the production thereof. The recipes used in the production process include particularly crosslinkers and chain transfer agents as recipe constituents, mostly in low concentrations, in addition to suitable blowing agents. It was found that, surprisingly, the invention provides a simple-to-produce stable PMMA foam having very good properties.

Owner:EVONIK OPERATIONS GMBH

A kind of microcapsule foamed melamine foam material and preparation method thereof

ActiveCN106750494BHigh closed cell rateImprove insulation effectMicroballoon preparationMicrocapsule preparationFoaming agentPolymer science

The invention relates to microcapsule-foaming melamine foam, which is prepared from a melamine resin prepolymer through microcapsule foaming. A used microcapsule foaming agent is a microcapsule foaming agent with a hydroxy on a wall material; the closed pore rate of the melamine foam is higher, and achieves than 96 percent or more; the heat preservation effect is better, and the heat conductivity coefficient is lower than 0.028W / m.K; the mechanical property is better, and the compression strength achieves 180KPa or more; better flame retardant property is realized, and the oxygen index achieves 37 percent or more. Used foaming liquid has only three components, and no emulsifying agent or foam stabilizer needs to be added in the melamine resin prepolymer, so that the process flow is simple, and the production cost is lower; the prepared microcapsule foaming agent with the hydroxy on the wall material can be applicable to various melamine resin prepolymers with different kinds and different viscosity, the foaming temperature is lower, and the foaming time is shorter.

Owner:HEFEI UNIV OF TECH

A kind of preparation method of closed-cell cnts/al-si composite foam material

Owner:CIVIL AVIATION UNIV OF CHINA

A kind of melamine foam prepared with blocked isophorone diisocyanate as curing agent

The invention relates to melamine foam prepared by taking terminated isophorone diisocyanate as a curing agent. The melamine foam is made from melamine resin prepolymer by taking terminated isophoronediisocyanate as a curing agent. A liquid foaming agent is one of cyclohexane, n-heptane, and isooctane, and the foaming temperature is in a range of 80-120 DEG C. The terminated isophorone diisocyanate takes sodium bisulfite as an end-capping reagent, and has the release temperature being 80-120 DEG C. The released isophorone diisocyanate is taken as a curing agent and can obviously improve the curing rate of the melamine resin prepolymer, thereby matching the curing rate to the foaming rate in the release temperature range. The closed pore rate of melamine foam is no less than 96%, the heatconduction coefficient is lower than 0.029 W / *K, the compression strength is no less than 180 kPa, the oxygen index is no less than 36%, and the density is lower than 50 kg / m<3>.

Owner:HEFEI UNIV OF TECH

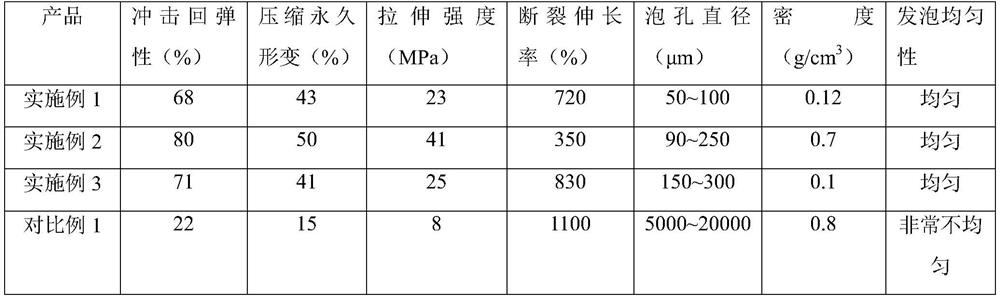

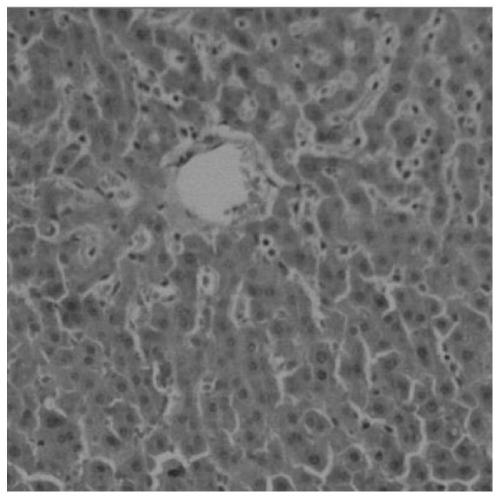

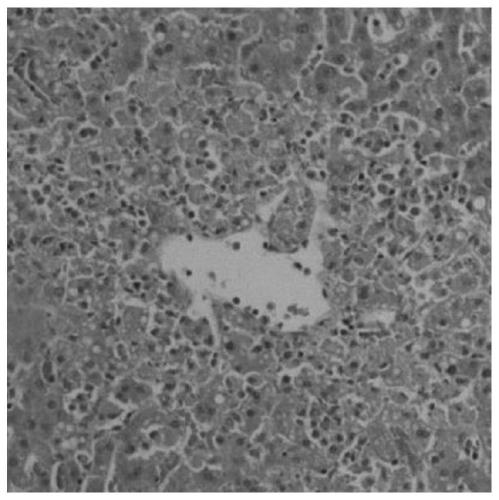

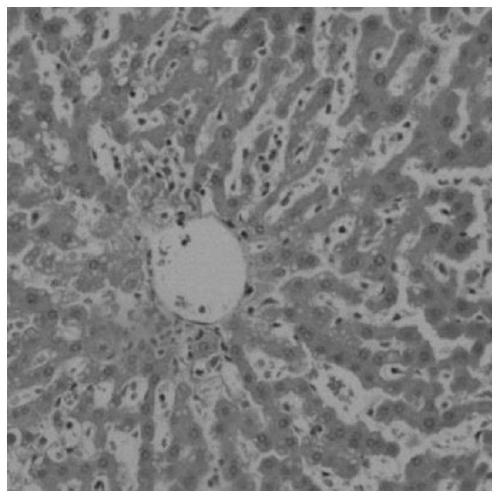

A kind of chemical foaming type polyamide elastomer foaming material and preparation method thereof

The invention discloses a chemically foamed polyamide elastomer foam material and a preparation method thereof. The preparation method comprises the following steps: (1) extruding the mixture of polyamide elastomer, melt viscosity regulator, cell nucleating agent and foaming auxiliary agent through an extruder to obtain foamed particles; (2) foaming Granules, surfactants and chemical foaming agent are mixed in a reaction kettle, stirred and kept warm after heating up in an inert atmosphere; foaming is obtained after continuing to heat up. The polyamide elastomer foaming material provided by the invention has the advantages of good resilience, uniform cell size, low foaming material density, good foaming effect, etc., and at the same time has low melt viscosity and melt strength for polyamide elastomer , The characteristics of difficult foaming, the introduction of melt viscosity modifier to improve the viscosity and strength of the melt is conducive to foaming, suitable for popularization and use; the chemical foaming agent used has low raw material cost, short foaming time, large gas generation, and the introduction of surface activity The agent can promote foaming, control the cell diameter and cell dispersion uniformity, etc.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA

Production of a PMMA foam using cross-linking agents, regulators and blowing agents

The present invention relates to novel types of PMMA foams and also to the production thereof. The recipes used in the production process include particularly crosslinkers and chain transfer agents as recipe constituents, mostly in low concentrations, in addition to suitable blowing agents. It was found that, surprisingly, the invention provides a simple-to-produce stable PMMA foam having very good properties.

Owner:EVONIK OPERATIONS GMBH

Traditional Chinese medicine composition for treating hepatopathy and preparation method and application thereof

PendingCN111420012AConsistent with pathogenesisImprove immunityAnthropod material medical ingredientsHydroxy compound active ingredientsAristolochia mollissimaMyrrh

The invention relates to a traditional Chinese medicine composition for treating hepatopathy and a preparation method and application thereof. The composition comprises the following raw materials: radix paeoniae alba, earthworms, astragalus membranaceus, stiff silkworm, dipsacus roots, radix aconiti, raw radix aconiti kusnezoffii, rhizoma arisaematis, pinellia ternate, rhizoma corydalis, Sichuanpapaya, asarum, scorpio, schisandra chinensis, liquorice, folium artemisiae argyi, processed frankincense, processed myrrh, fructus forsythiae, aristolochia mollissima, rhizoma Sparganii, ground beeltle, rheum officinale, curcuma zedoary, fructus cnidii, fructus gardeniae, semen brassicae, mylabris, herba ephedrae, dature stramonium seedlings, ecliptae herba, fructus evodiae, fructus crotonis, radix clematidis, borneol, radix kansui and poisonous buttercup herb. The traditional Chinese medicine composition for treating hepatopathy can strongly stimulate meridian points and play a role in treating hepatopathy through the meridian points; after being soaked in water, a part of body fluid can be absorbed back again, so that the effect of stimulating autoimmunity can be achieved; and the medicines have the effects of promoting blood circulation to remove blood stasis, dredging meridians, softening hardness to dissipate stagnation, protecting the liver, and removing wind-cold-dampness toxins.

Owner:房纳生

A kind of plant fiber reinforced thermal insulation flame retardant phenolic foam material and preparation method thereof

The invention discloses a plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and a preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material. The plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material is formed by adding plant fibers which have different lengths and are of a hollow structure into phenolic resin. The preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material comprises the steps that the dried plant fibers, obtaining through cutting, with the different lengths are mechanically mixed with the phenolic resin, an emulsifying agent, a coupling agent, a foaming agent and a curing agent, the mixture is cured and foamed for 30 min to 120 min at the curing temperature ranging from 45 DEG C to 80 DEG C, and then the plant fiber reinforcing type phenolic foam material used for internal walls and external walls of buildings is obtained after demolding. According to the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material and the preparing method of the plant fiber reinforcing type heat-preservation inflaming-retarding phenolic foam material, phenolic foam is reinforced through the environment-friendly and renewable natural plant fibers, the heat-preservation property and the inflaming-retarding property of the material are good, and the production cost of the phenolic foam material is greatly reduced due to the fact that the plant fibers are cheap and easy to obtain.

Owner:BEIHANG UNIV

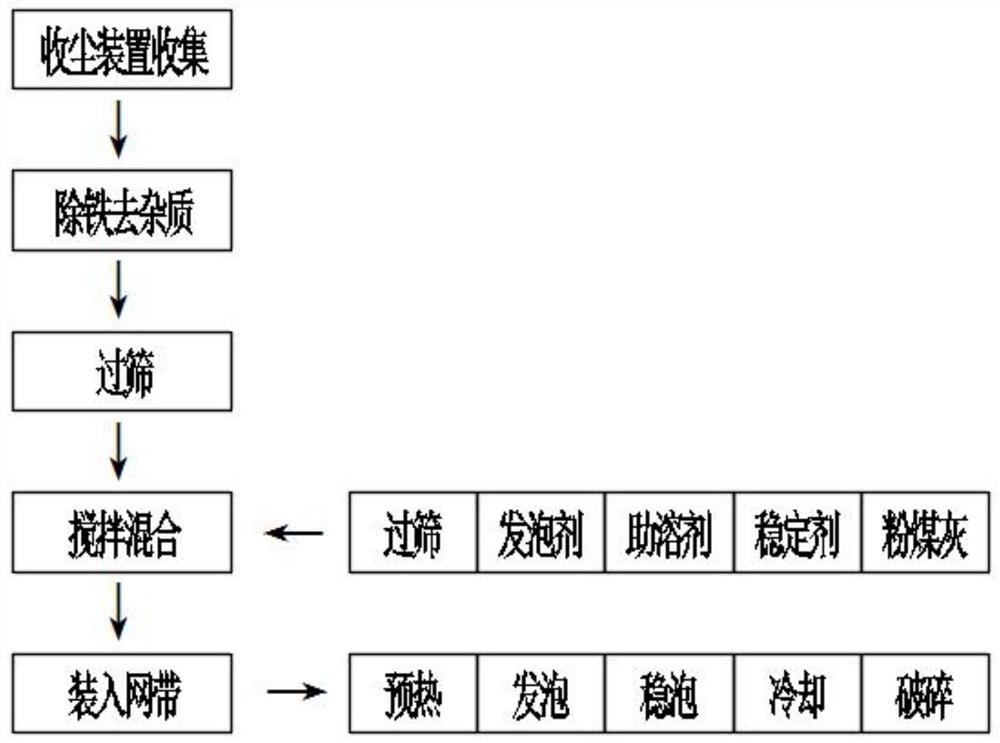

Method for preparing foam glass particles from silica powder

PendingCN111925124AReduce manufacturing costLow costGlass shaping apparatusFoaming agentIron removal

The invention discloses a method for preparing foam glass particles from silica powder, belonging to the technical field of foam glass preparation methods. The method specifically comprises the following steps: step 1, carrying out iron removal and other treatment on silica powder collected by a dust collection device so as to remove impurities; and 2, mixing raw materials consisting of, in percentage by weight, 80-90% of silica powder, 2-4% of a foaming agent, 1-3% of a stabilizer and 1-2% of a cosolvent, with the balance being fly ash. According to the invention, production cost is low, a grinding process is omitted, the method is simple in process and easy to implement, a heat-resistant steel mesh belt is used as a carrier, foaming time is short, foaming is uniform, yield is high, energy consumption is greatly reduced, and product quality is stable. The method overcomes the following problems that waste glass, lava, coal ash and the like are generally adopted as raw materials for foaming of existing foam glass and are high in cost and that the recycling rate of silica powder is extremely low since the silica powder is dust generated in the process of glass cutting and crushing machining, is collected through dust collection equipment and is about 200 meshes.

Owner:湖北大清科技有限公司

A kind of soaping agent and its soaping process for high-density floral pure cotton cloth

ActiveCN106118915BLow costReduce dosageInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateBetaine

The invention belongs to the technical field of dyeing and finishing, and specifically relates to a soaping agent and a soaping process for high-density patterned pure cotton figured cloth. The soaping agent for high-density patterned pure cotton figured cloth is prepared from the following raw materials: N-vinyl pyrrolidone, sodium lauryl sulfate, delta-laminated sodium metasilicate, dodecyl dimethyl betaine, etidronic acid, maleic anhydride, polyacrylic acid, compound soaping enzyme, octadecyl amine ethoxylate ether, secondary alkyl sodium sulfonate and thiourea dioxide, wherein the compound soaping enzyme is composed of laccase, lipopenic enzyme, Eurolan RP soaping enzyme and EOQ soaping enzyme. The soaping agent has less foam and short foaming time when used in soaping high-density patterned pure cotton figured cloth; the soaped pure cotton figured cloth can not fade or change color; dyed fabric of the high-density patterned pure cotton figured cloth processed by the soaping agent combined with the soaping process basically has no color difference and strong loss; and compared with the traditional soaping process, the color fastness is higher, working procedures are reduced, and time and energy are saved.

Owner:SHANDONG JINING RUYI WOOLEN TEXTILE CO LTD

Efficient foaming machine

The invention belongs to an automatic and efficient foaming machine under a high-temperature state. An efficient foaming machine comprises a columnar machine body; a spindle is arranged at the inner axis position of the machine body; rotary rods are arranged on the spindle; at least two rotary rods are arranged; a rotary blade I is welded at one end part with the direction being the same as that of the two adjacent rotary rods and a rotary blade II is welded at the other end part; a stirring motor is fixed on a rear end cover; an output shaft of the stirring motor is connected with the spindle; a discharging mechanism is arranged at the lower part position of the stirring motor on the rear end cover; the rear end cover is further provided with a feeding hole and a gas inlet / outlet; a steam inlet is formed in a front end cover. According to the foaming machine provided by the technical scheme, materials to be foamed and high-temperature steam are rapidly mixed in a stirring process, foaming time is short, foaming is sufficient and the foaming rate is more than 98 percent; in a whole foaming process, automatic feeding is realized by utilizing vacuum pressure and automatic discharging is realized by utilizing an air cylinder and a piston; the efficient foaming machine is simple to operate and high in foaming efficiency.

Owner:曹淅

Production of fine-pored PMMA foams using nucleating agents

Fine-cell PMMA foams are produced using a production process including nucleators in addition to suitable blowing agents. It was found that, surprisingly, a simple-to-produce stable PMMA foam having very fine cells and very good properties can be produced.

Owner:EVONIK OPERATIONS GMBH

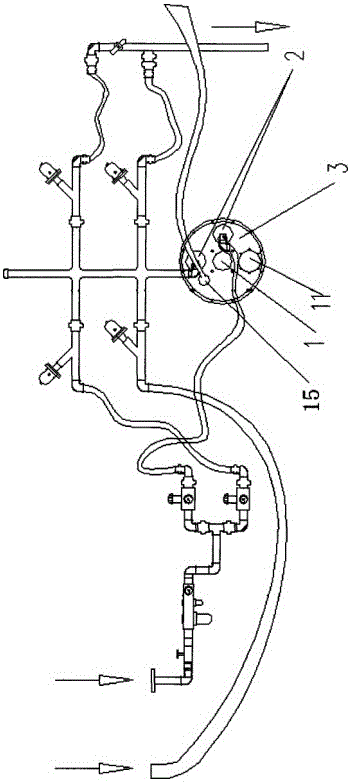

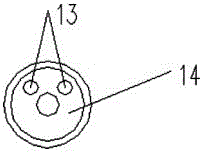

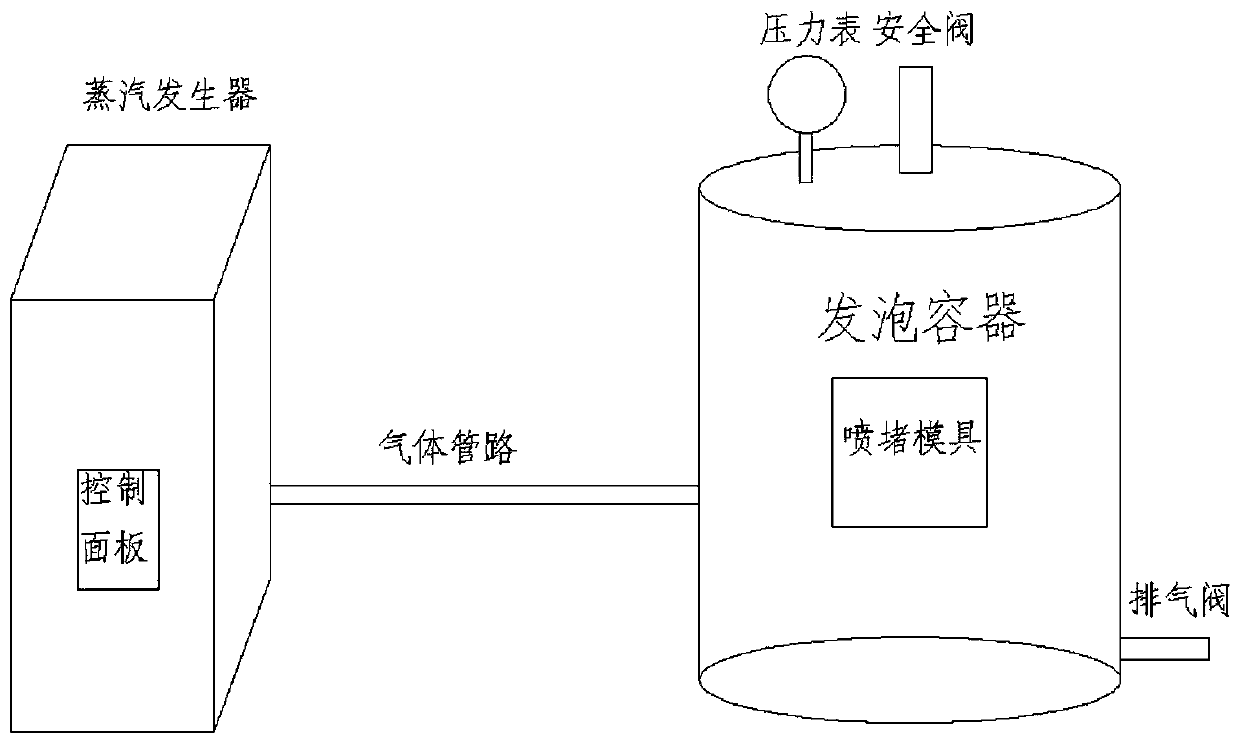

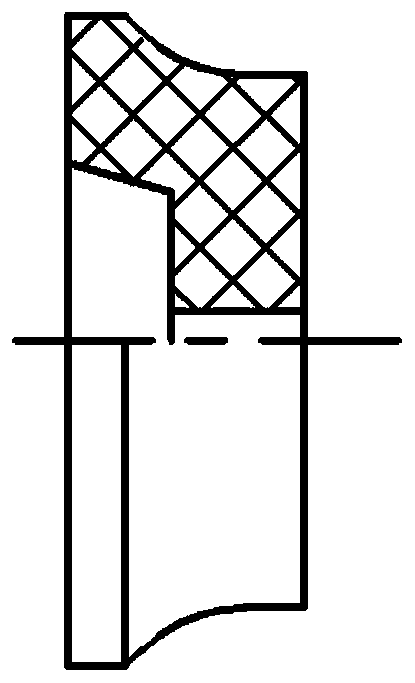

Polystyrene spray plug for solid rocket engine and foaming method thereof

The invention belongs to the technical field of solid rocket engines, and particularly relates to a polystyrene spray plug for a solid rocket engine and a foaming method thereof. According to the method, high-temperature steam generated by a steam generator is used for heating a foaming die, so that expandable polystyrene is heated and foamed into a product shape. Rapid foaming is realized by controlling steam temperature, pressure and flow, and foaming of the low-density spray plug is realized. Compared with a water boiling process, the process has the advantages of high foaming rate, short foaming time and high production efficiency.

Owner:西安现代控制技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com