Polystyrene spray plug for solid rocket engine and foaming method thereof

A technology of solid rocket and polystyrene, which is applied in the field of polystyrene injection plugging and foaming for solid rocket motors. It can solve the problems of long foaming time, low heat exchange efficiency, and inability to produce injection plugging, etc., and achieve foaming The effect of short time, high foaming rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In this embodiment, include:

[0057] 1. Use water vapor as the heat source to heat the plugging mold.

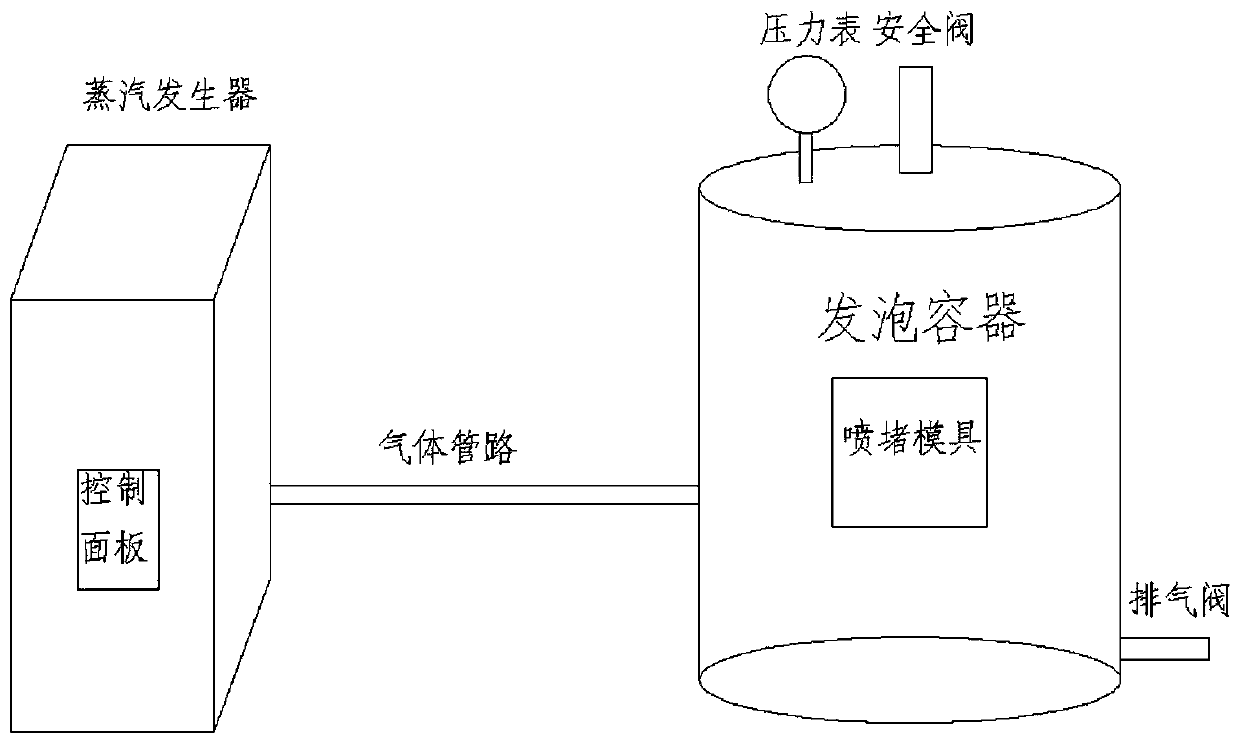

[0058] 2. A steam foaming device is designed to realize spray plugging and foaming molding by adjusting the temperature, pressure and heating time of water vapor. Steam foaming device such as figure 1 As shown, the device is mainly composed of a steam generator and a foaming container. A steam generator is standard equipment and the steam temperature can be controlled via the control panel. The foaming container is equipped with a pressure gauge, a safety valve and a temperature measuring device, which can display the temperature and pressure in the foaming container in real time. The injection plugging mold is placed inside the foaming container, and multiple sets of molds can be placed at the same time. The steam generator and the foaming container are connected by a pipeline, and the gas flow can be controlled by a valve. Regulating the exhaust valve can regu...

Embodiment 2

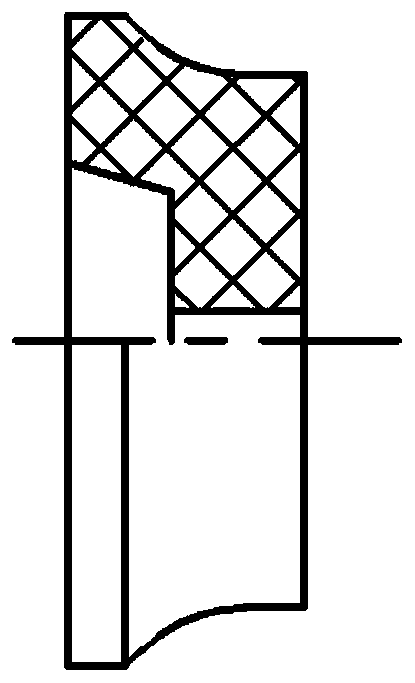

[0060] In this embodiment, a certain type of solid rocket motor injection plugging is taken as an example to introduce the specific implementation mode. The shape of the injection plugging is as follows figure 2 shown.

[0061] 1. Weigh the expandable polystyrene according to the plugging requirements;

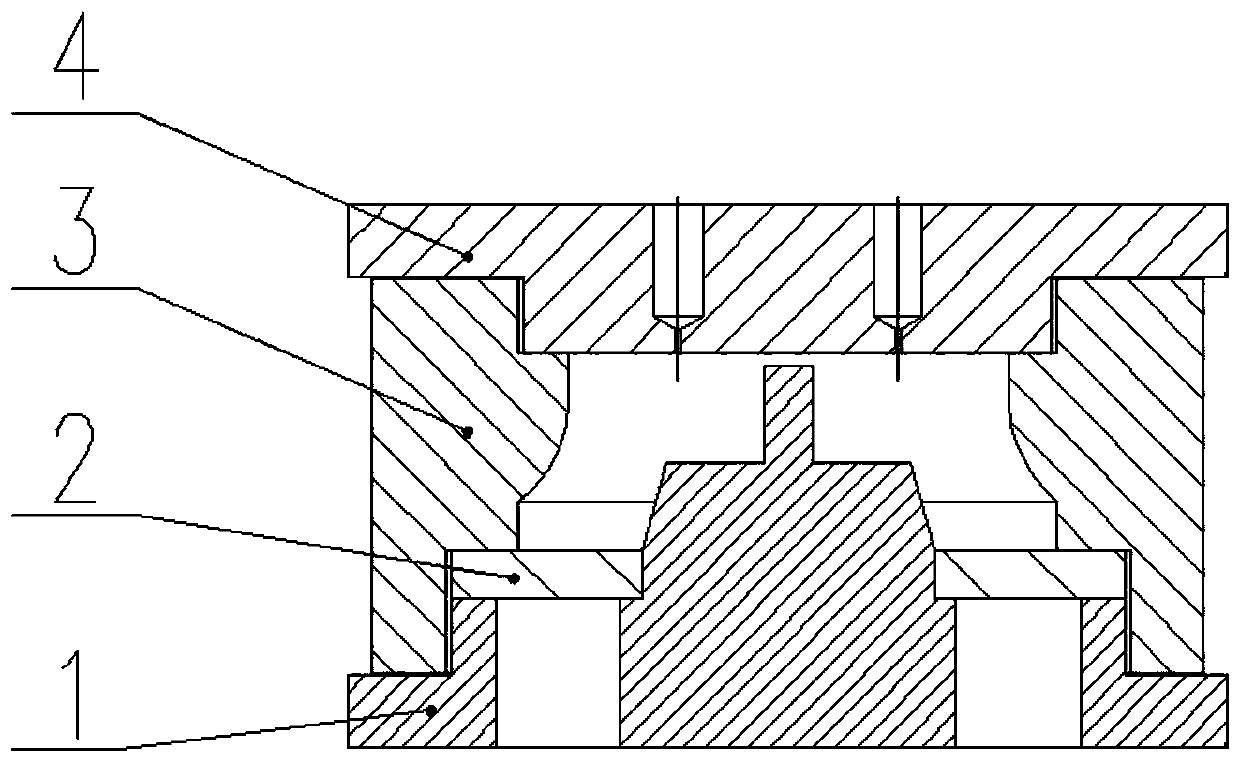

[0062] 2. Put the weighed raw materials into the aluminum foaming mold. The foaming mold is as follows: image 3 shown;

[0063] 3. Put the installed mold into the steam foaming device;

[0064] 4. Adjust the outlet temperature of the steam generator to 108±5°C;

[0065] 5. Adjust the steam pressure in the foaming container between 0.1 and 0.3 MPa;

[0066] 6. Heating for 10 minutes;

[0067] 7. Take out the mold and air-cool, and take out the injection plug after the mold cools down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com