Patents

Literature

616results about How to "Consistent size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous production of silica-based microgels

A continuous process is provided for preparing silica microgels using carbon dioxide as a gel initiator at a pressure of at least about 172 kPa (about 25 psig). Consistent performance of microgel can be produced with varying production rates.

Owner:THE CHEMOURS CO FC LLC

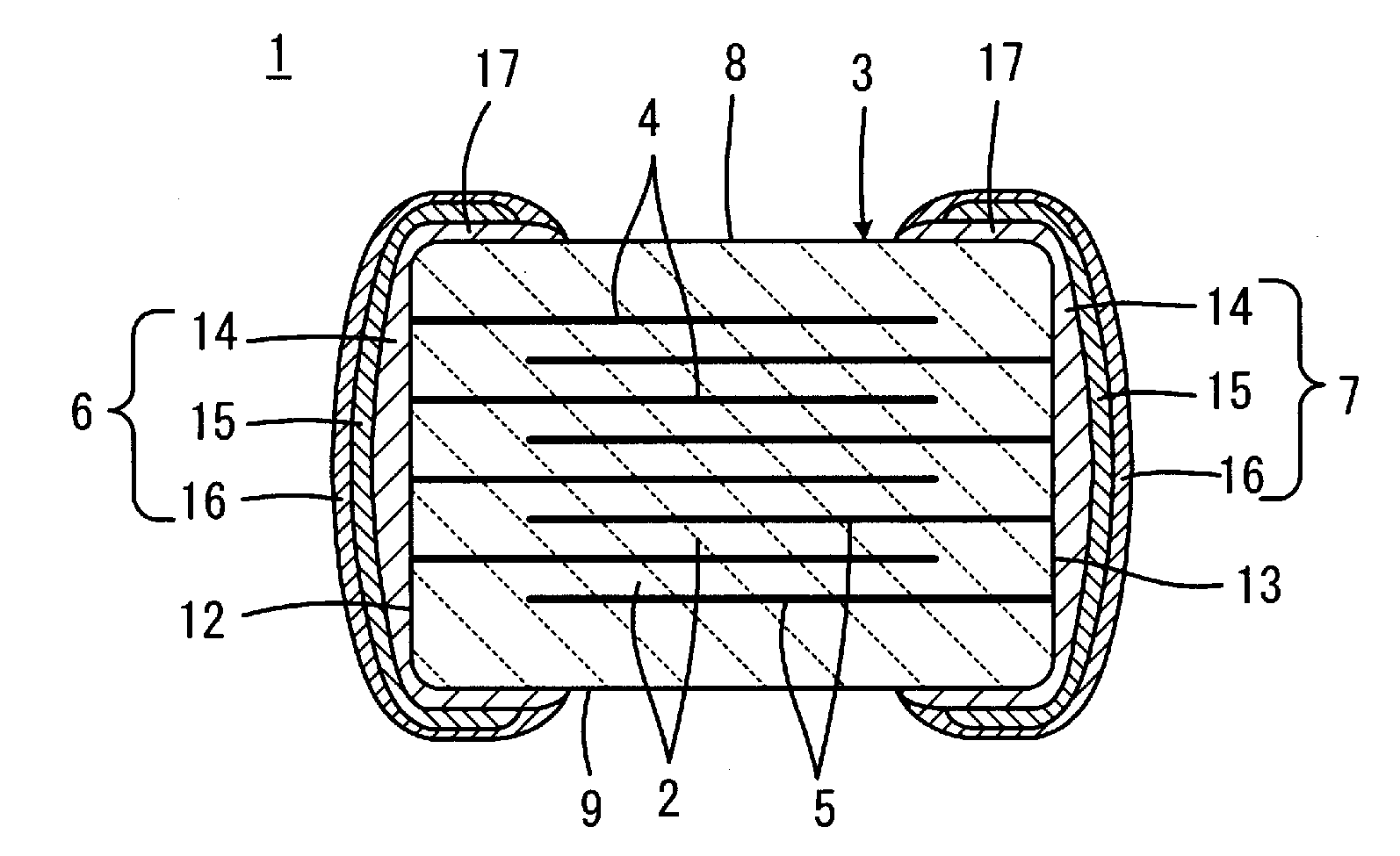

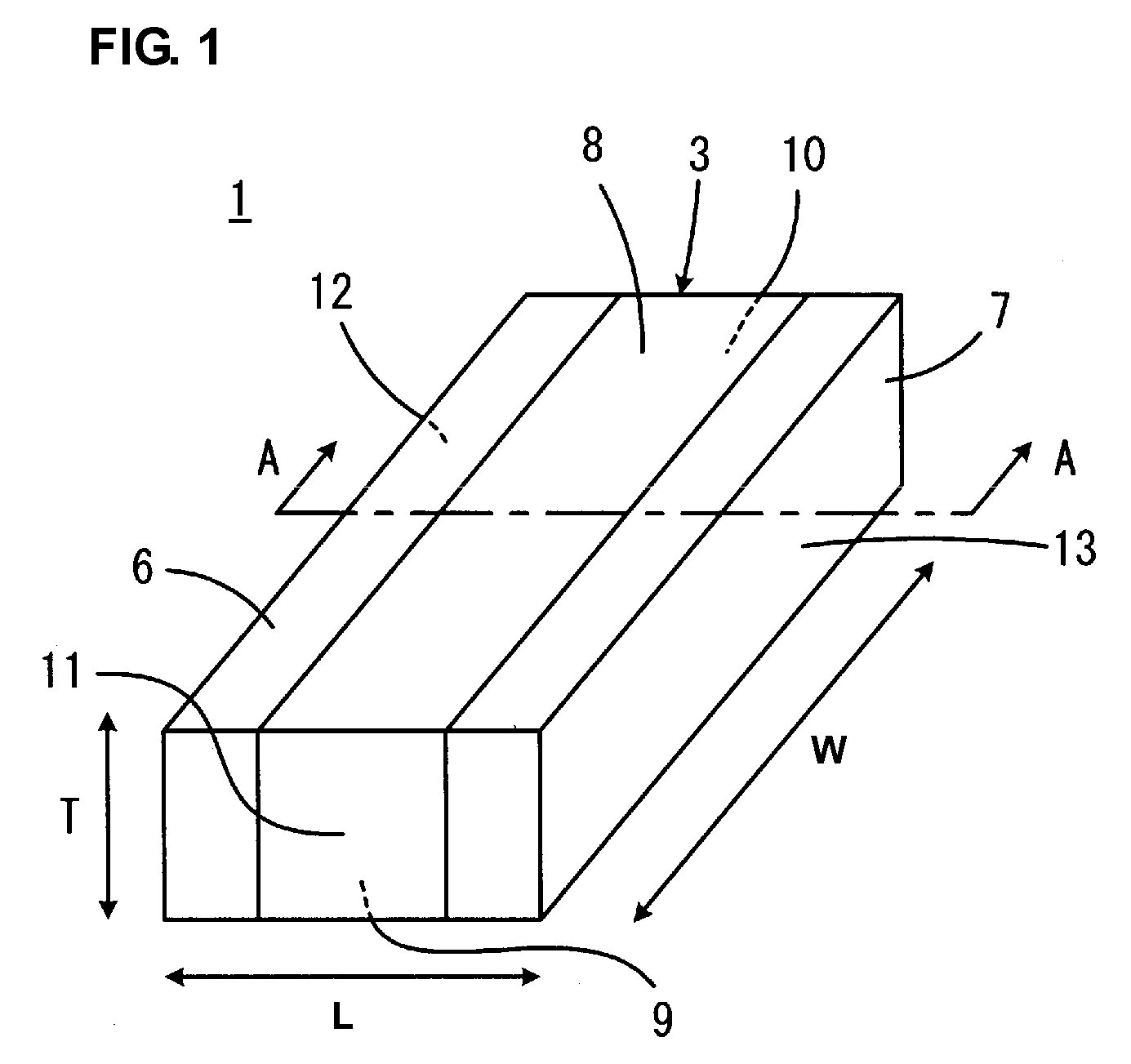

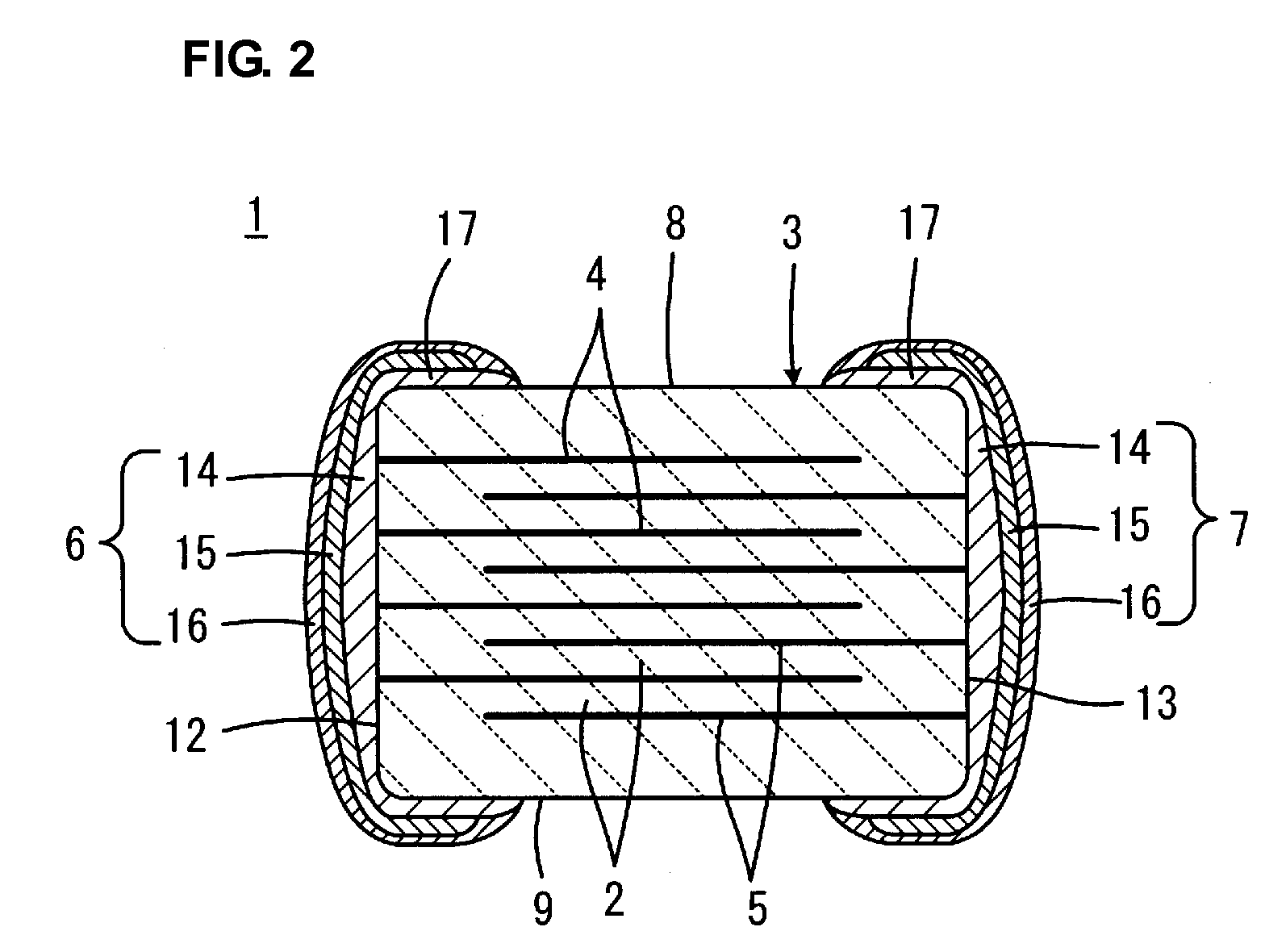

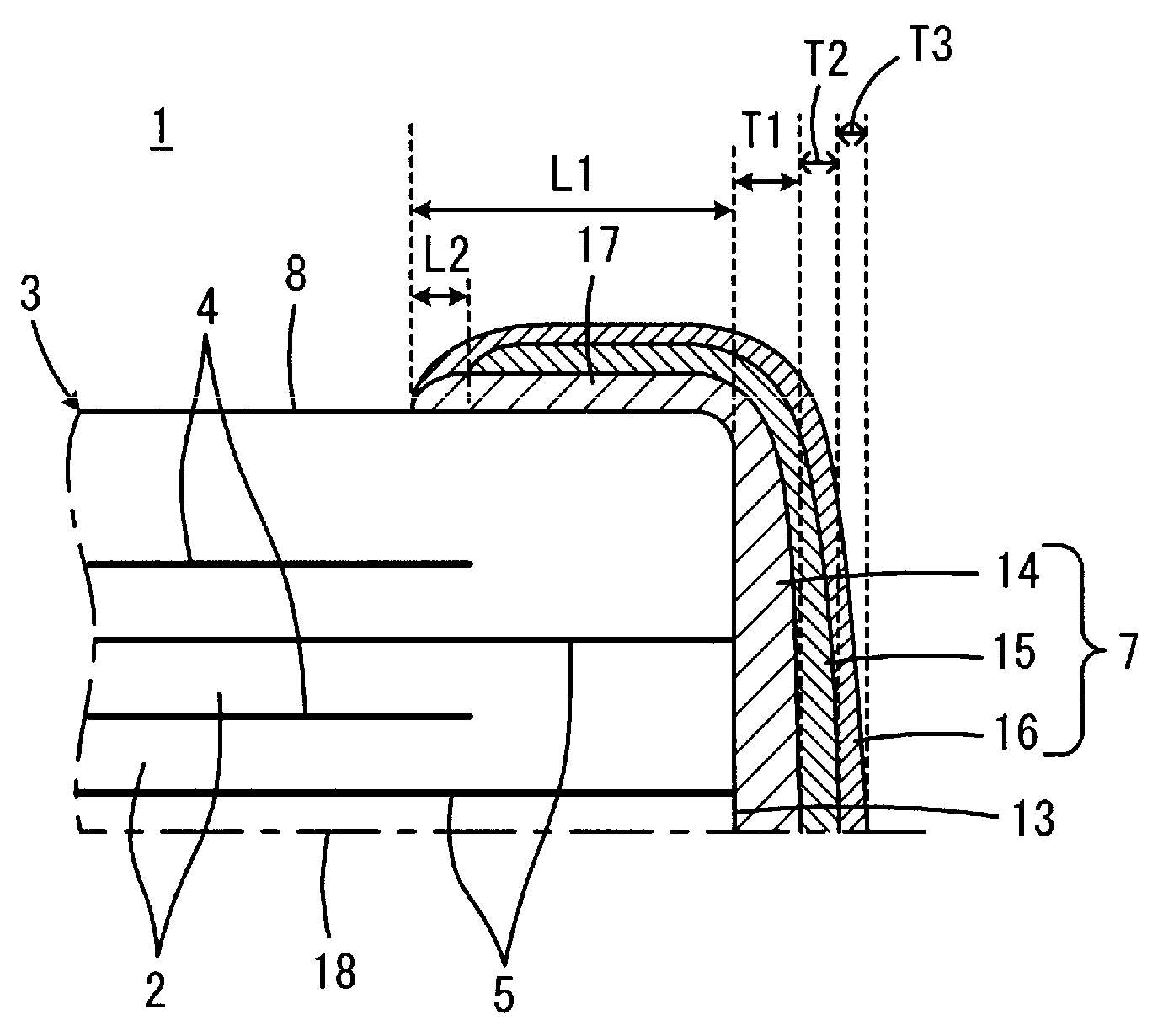

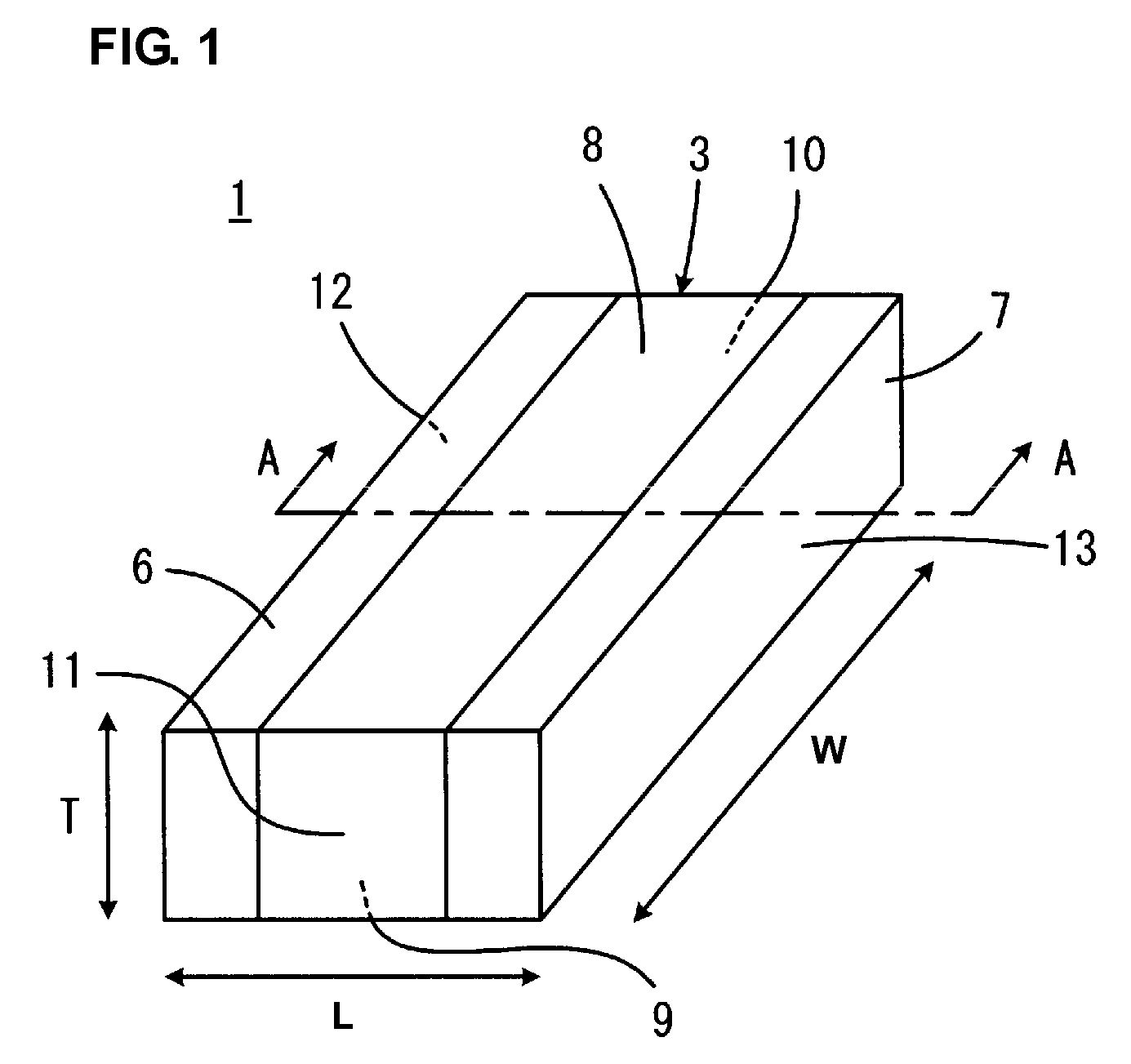

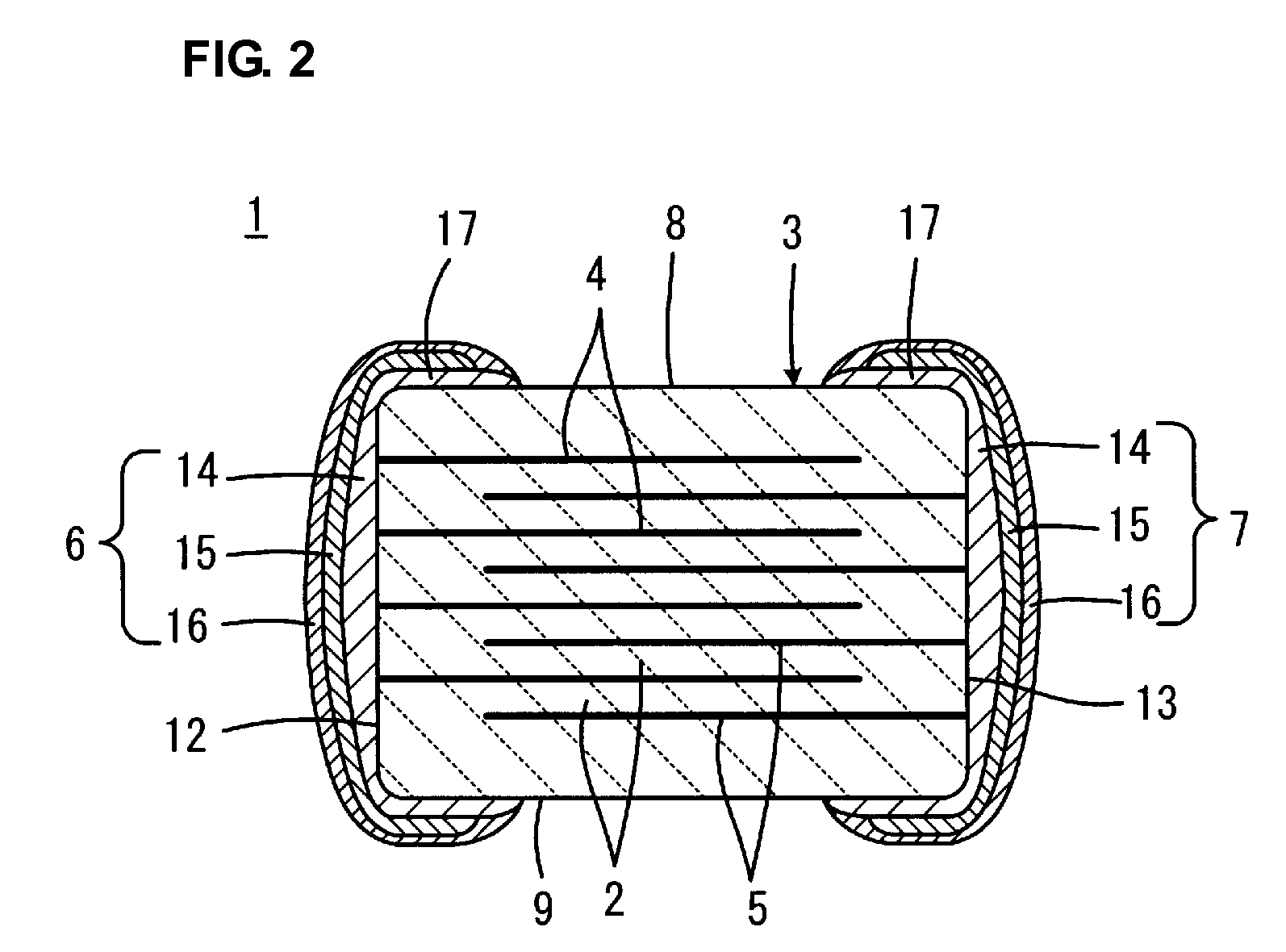

Monolithic ceramic capacitor

ActiveUS20090002920A1Improve installabilityLow reliabilityFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorOptoelectronics

In an LW-reverse-type monolithic ceramic capacitor including external terminal electrodes each including a resistance component, internal electrodes include nickel or a nickel alloy, and the external terminal electrodes each include a first layer, a second layer provided on the first layer, and a third layer provided on the second layer. The first layer has a wrap-around portion extending from an end surface to principal surfaces and side surfaces of a capacitor main body, and contains a glass component and a compound oxide that reacts with Ni or the Ni alloy. The second layer covers the first layer such that the edge of the wrap-around portion of the first layer remains exposed, and contains a metal. The third layer covers the edge of the wrap-around portion of the first layer and the second layer, and is formed by plating.

Owner:MURATA MFG CO LTD

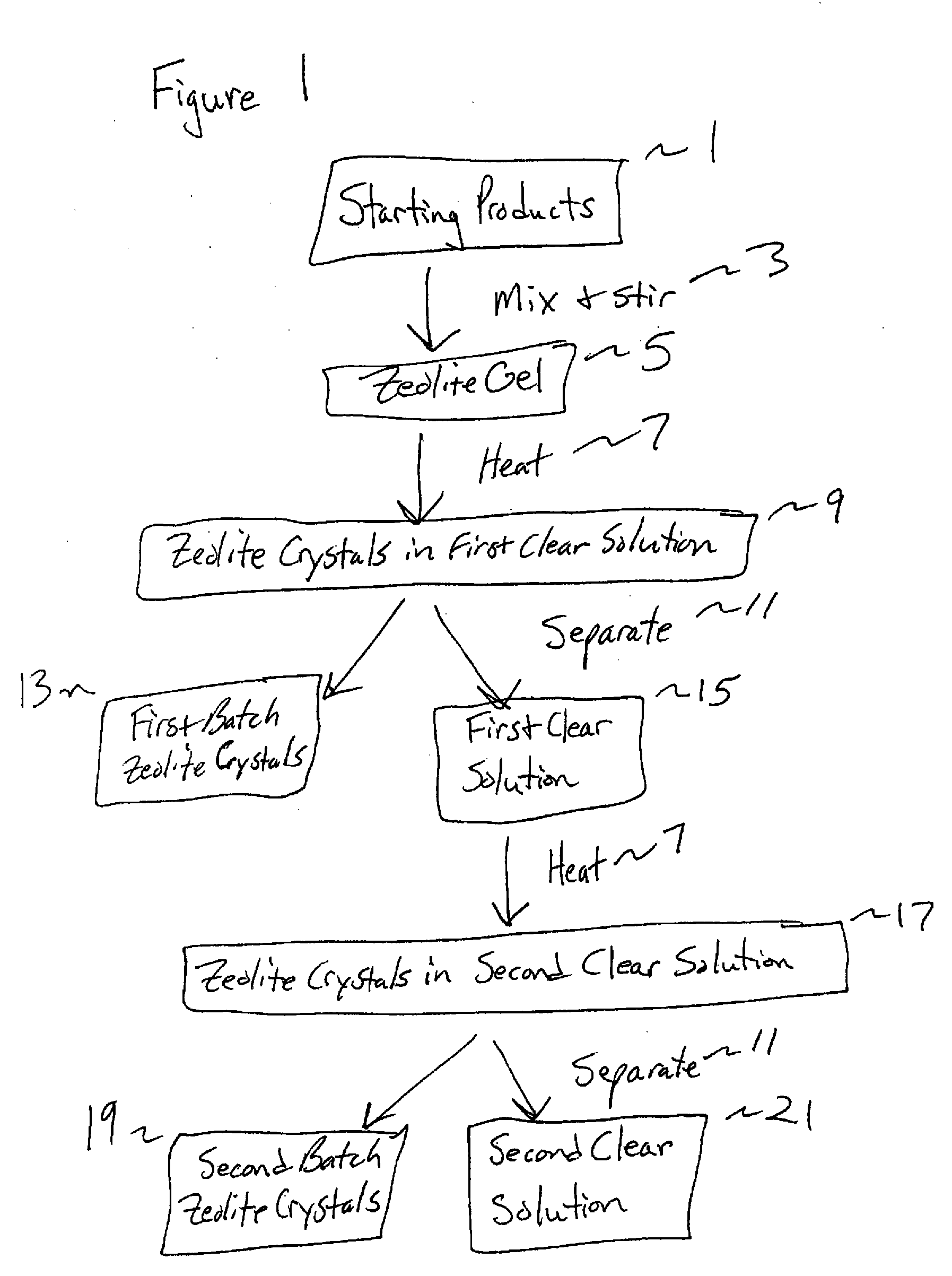

Synthesis and use of nanocrystalline zeolites

InactiveUS20070071666A1High yieldMore consistent crystal sizeNitrous oxide captureMaterial nanotechnologySolventHydrolysis

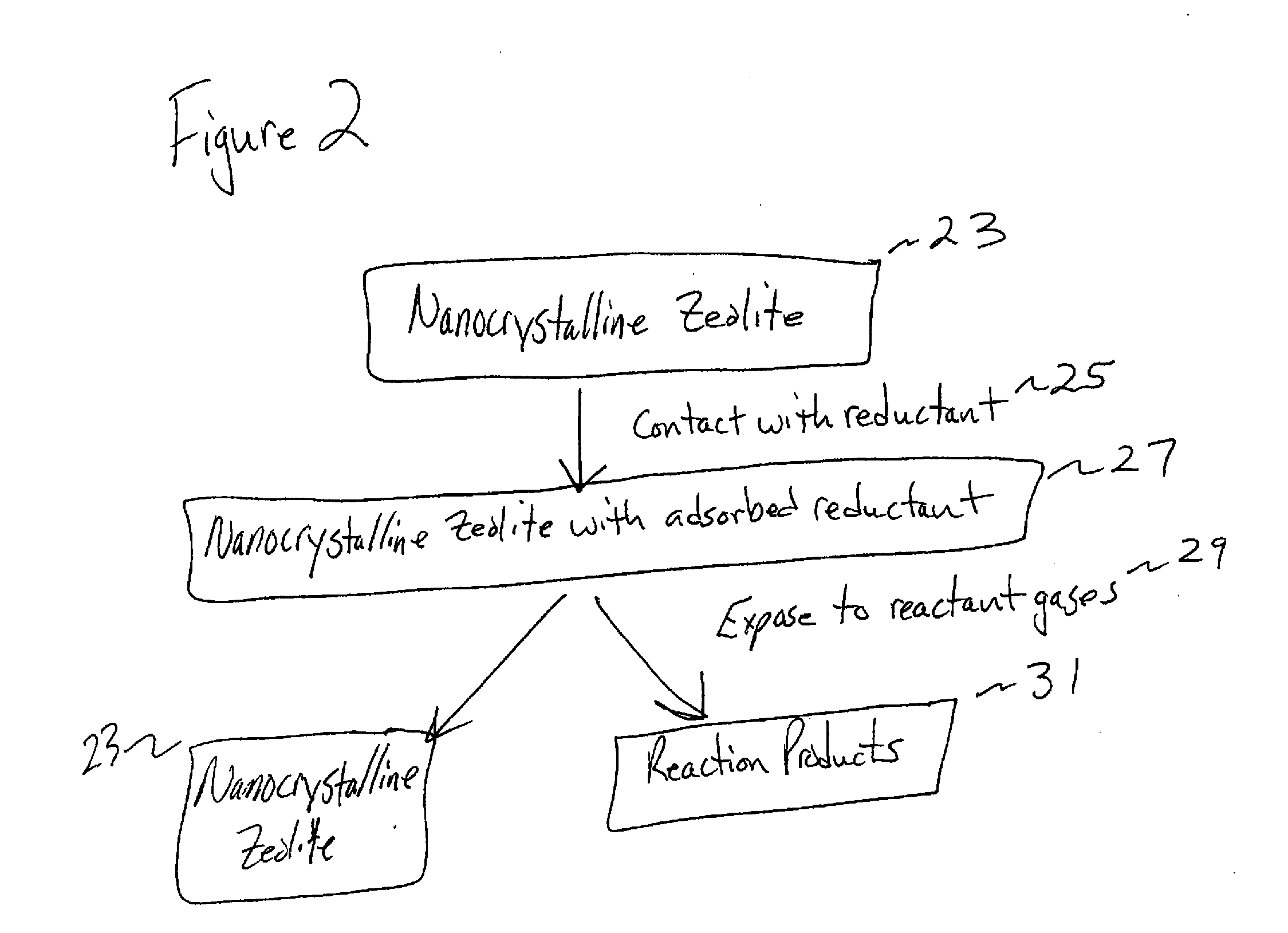

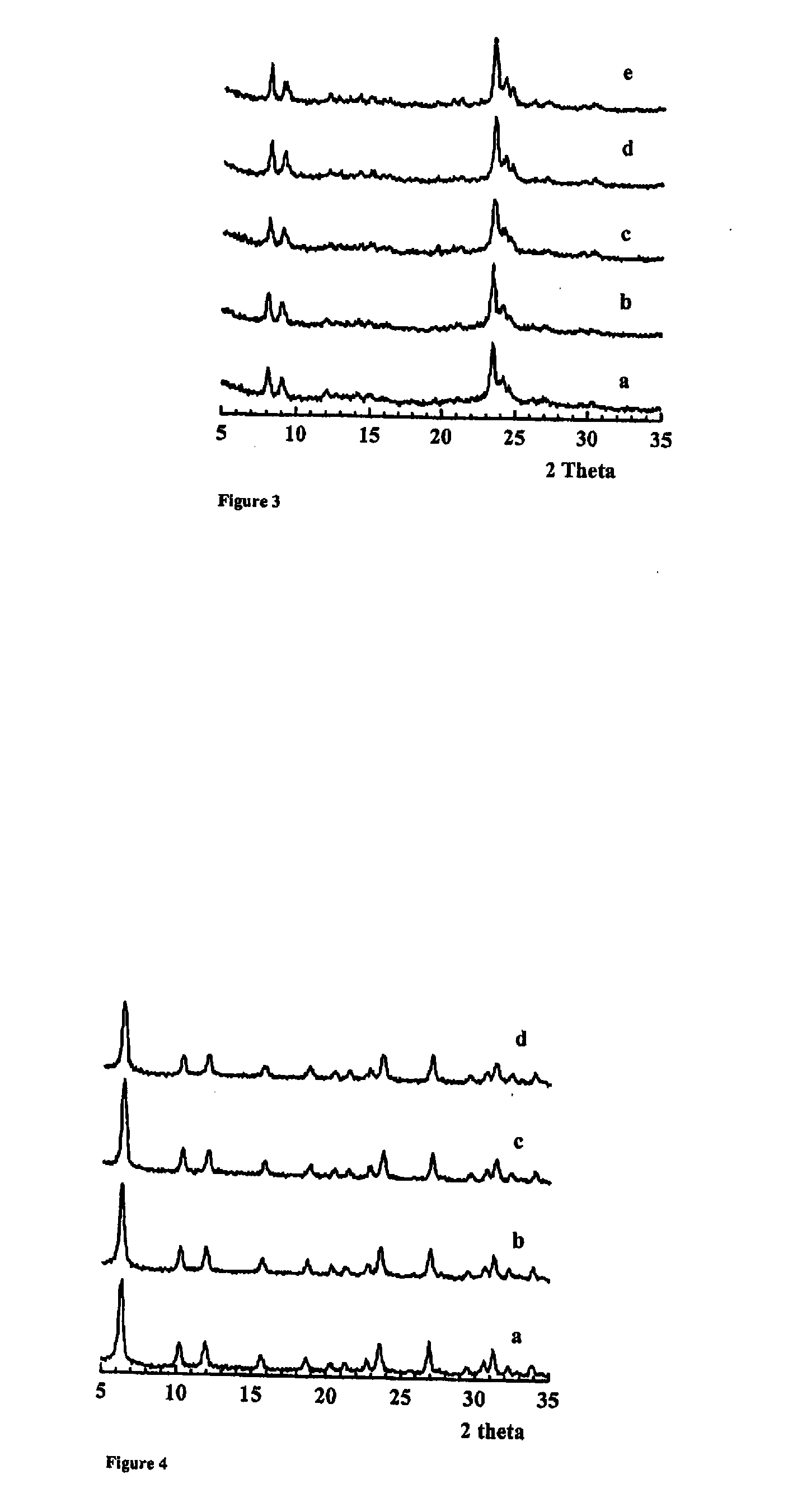

Embodiments of the present invention relate to a method for synthesizing nanocrystalline zeolites, the method comprising contacting starting products that comprise a solvent, a silicon source, a cation base, an organic template, and an aluminum source, or any combination thereof sufficient to produce a zeolite gel by hydrolysis, heating the zeolite gel sufficient to produce a first batch of zeolite crystals and a first clear solution, separating the first batch of zeolite crystals from the first clear solution, heating the first clear solution sufficient to produce a second batch of zeolite crystals and second clear solution and separating the second batch of zeolite crystals from the second clear solution. In addition, embodiments relate to a method of using nanocrystalline zeolites, the method comprising contacting a nanocrystalline zeolite with a reductant sufficient to produce a nanocrystalline zeolite with adsorbed reductant and exposing the nanocrystalline zeolite with adsorbed reductant to reactant gases sufficient to obtain reaction products and the nanocrystalline zeolite.

Owner:UNIV OF IOWA RES FOUND

Through-roll profile unwind control system and method

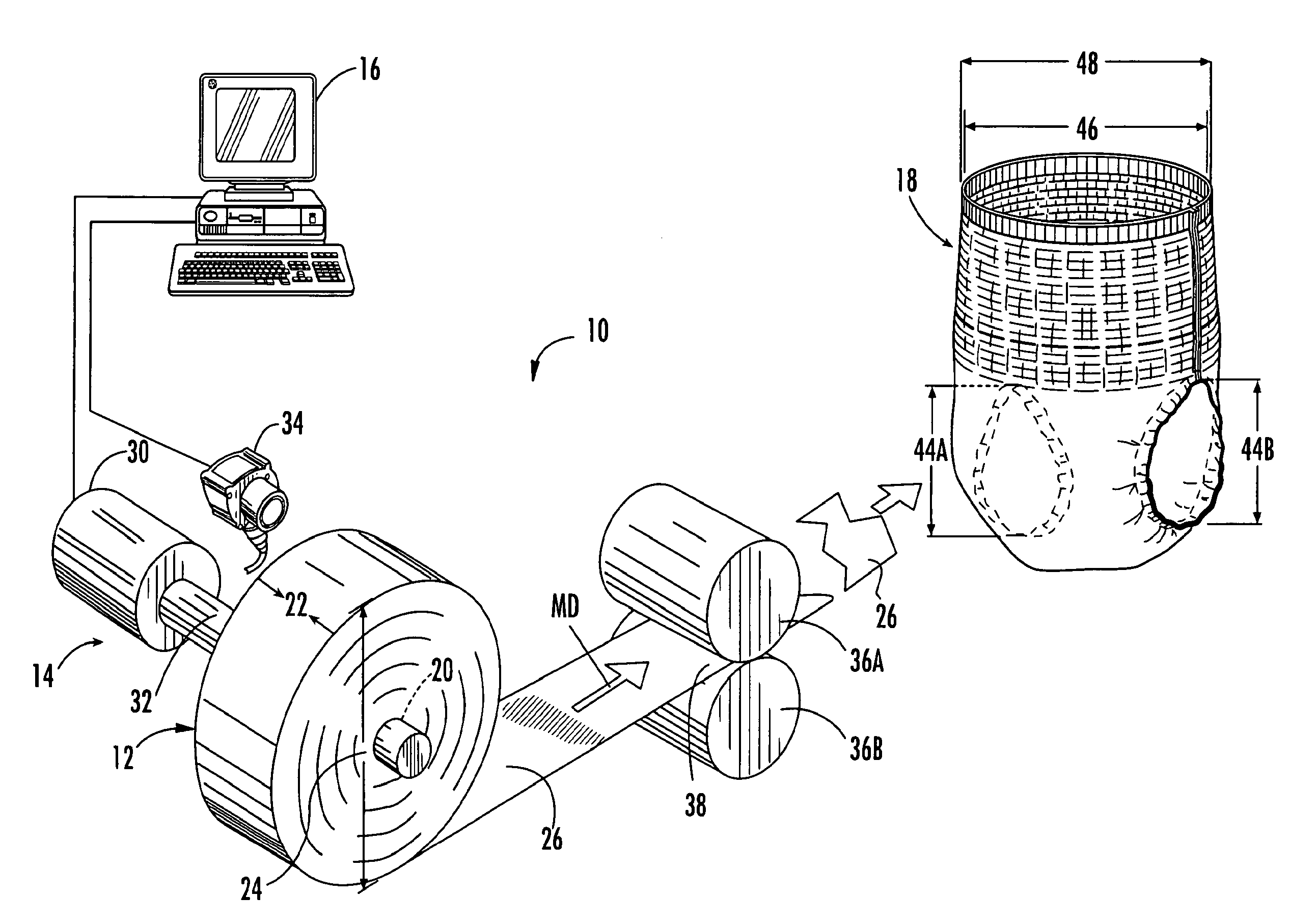

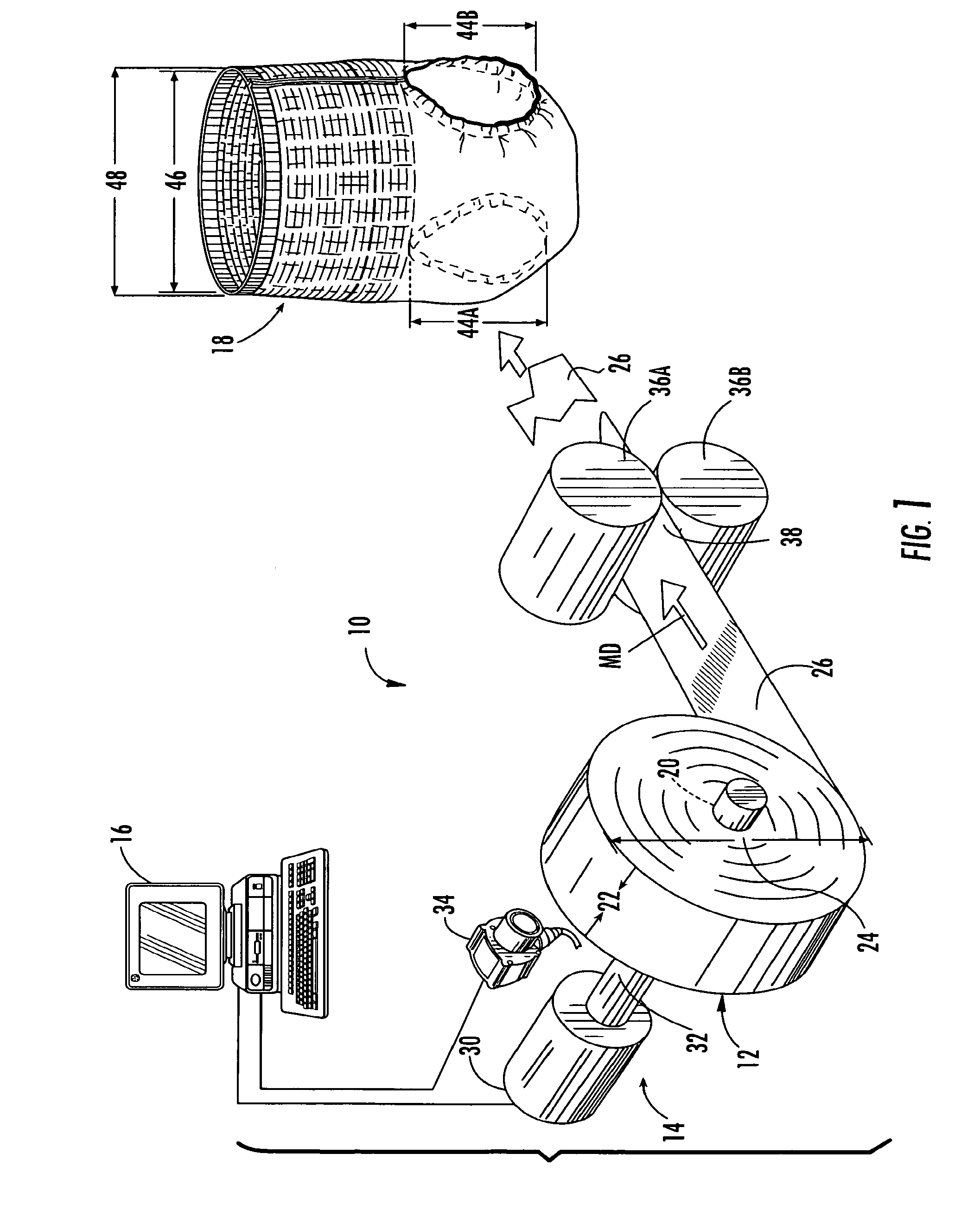

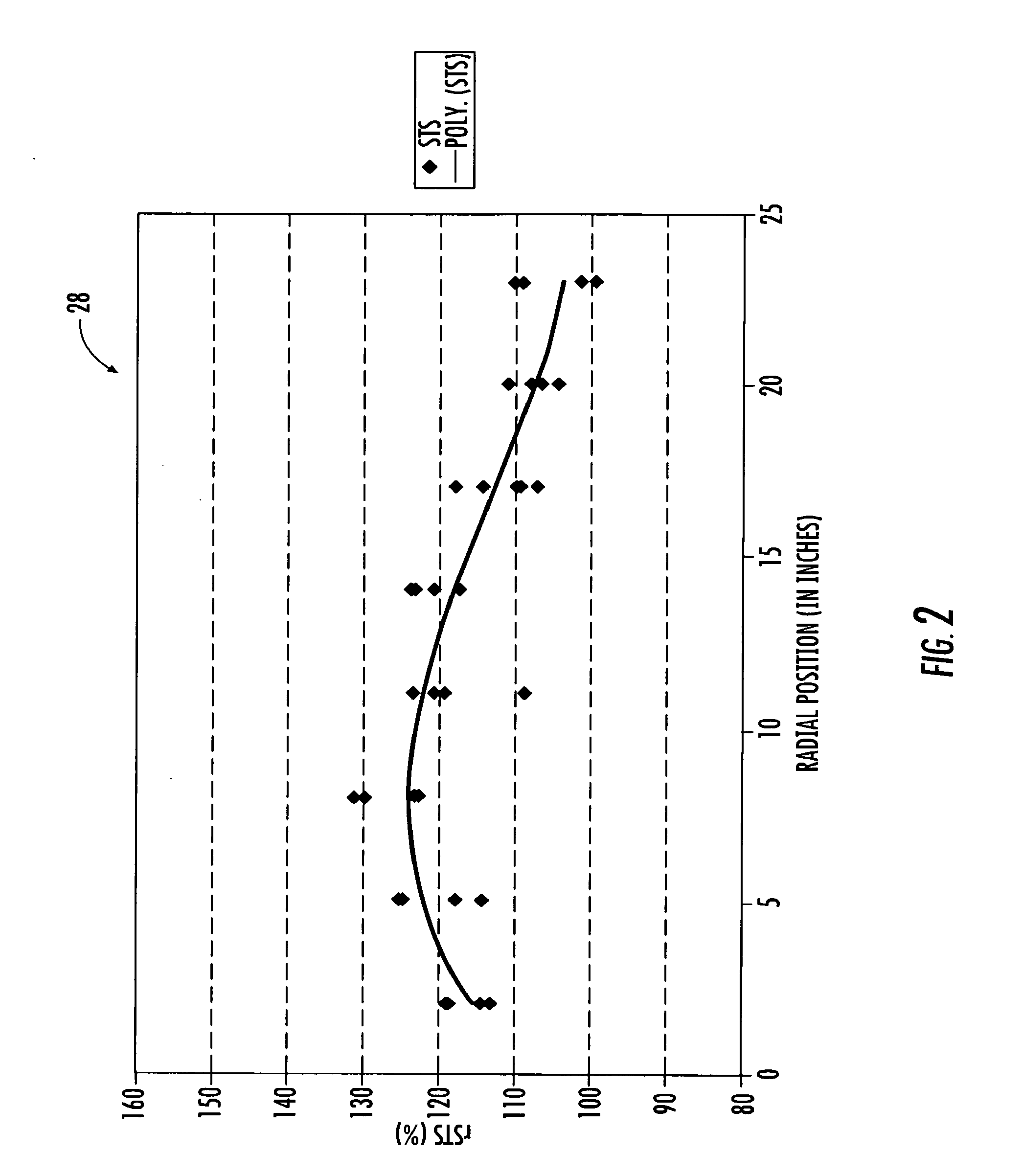

ActiveUS20070131817A1Reduce material consumptionSame sizeFilament handlingAbsorbent padsProcess systemsControl system

A method of unwinding material in a process system for producing a product includes the steps of loading a roll of material in an unwind system, programming a controller with an unwind equation, the controller in communication with the unwind system, computing a material feed rate based on a predetermined product circumference and an average stretch-to-stop roll profile, and putting a diameter of the roll of material and the material feed rate in the unwind equation of the controller, and unwinding a varying amount of material from the roll of material at a varying unwind speed, the controller being responsive to the unwind equation to vary the unwind speed for forming a plurality of products, each product defining a respective circumference substantially equal to the predetermined product circumference.

Owner:KIMBERLY-CLARK WORLDWIDE INC

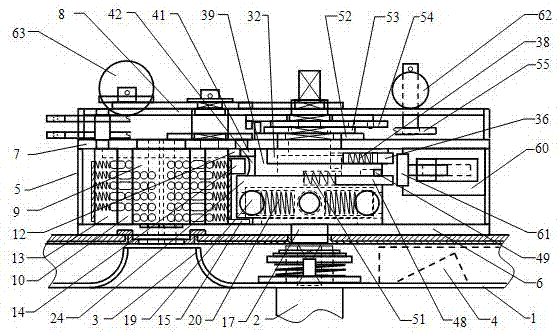

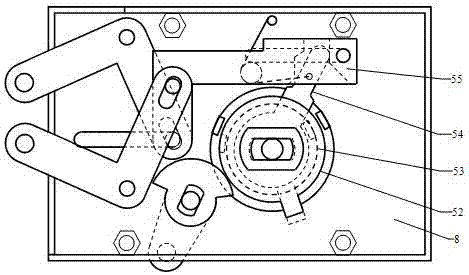

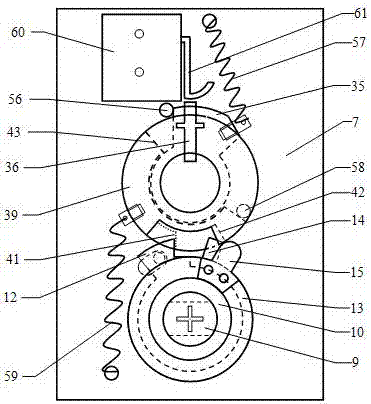

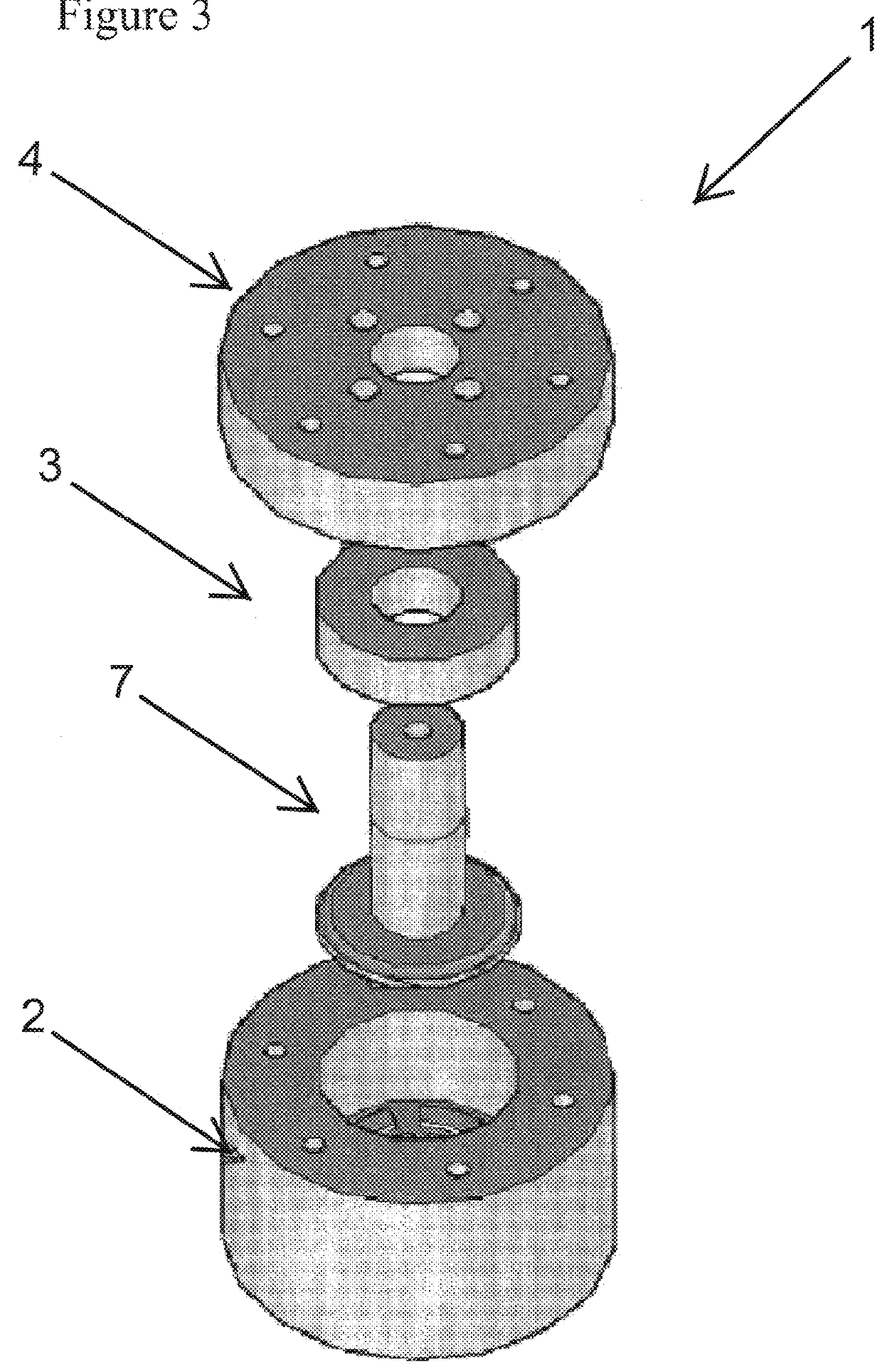

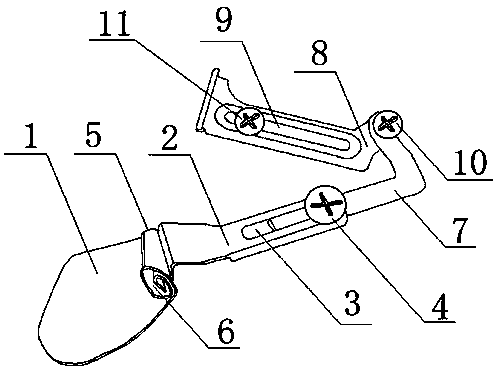

Cam mechanism and rotating ring forced resetting device for fingerprint lock

ActiveCN107035230ANo signs of wear and tearSimple structureNon-mechanical controlsElectric permutation locksEngineeringCam

The invention discloses a cam mechanism and rotating ring forced resetting device for a fingerprint lock and relates to the field of anti-theft locks. According to the cam mechanism and rotating ring forced resetting device for the fingerprint lock, the main improvement is that the specific structure and the assembling mode of an overload protection device of the cam mechanism are changed; a collision bead sliding way, a collision bead spring and the like are radially assembled onto a cam shaft which is amplified locally; meanwhile, a collision bead large in diameter is adopted, on one hand, it is guaranteed that the idle function of the cam mechanism is stable and reliable, and on the other hand, space can be saved; the rotating ring forced resetting device which is simple and easy to implement can be arranged conveniently so that potential dangers can be eliminated; in addition, the resetting device is free of wear in routine operation and low in production cost; and meanwhile, axial dimensions and radial dimensions of main components of a double clutch can be increased so that reliability of the double clutch and safety of the lock can be improved.

Owner:重庆桐雨石科技有限公司

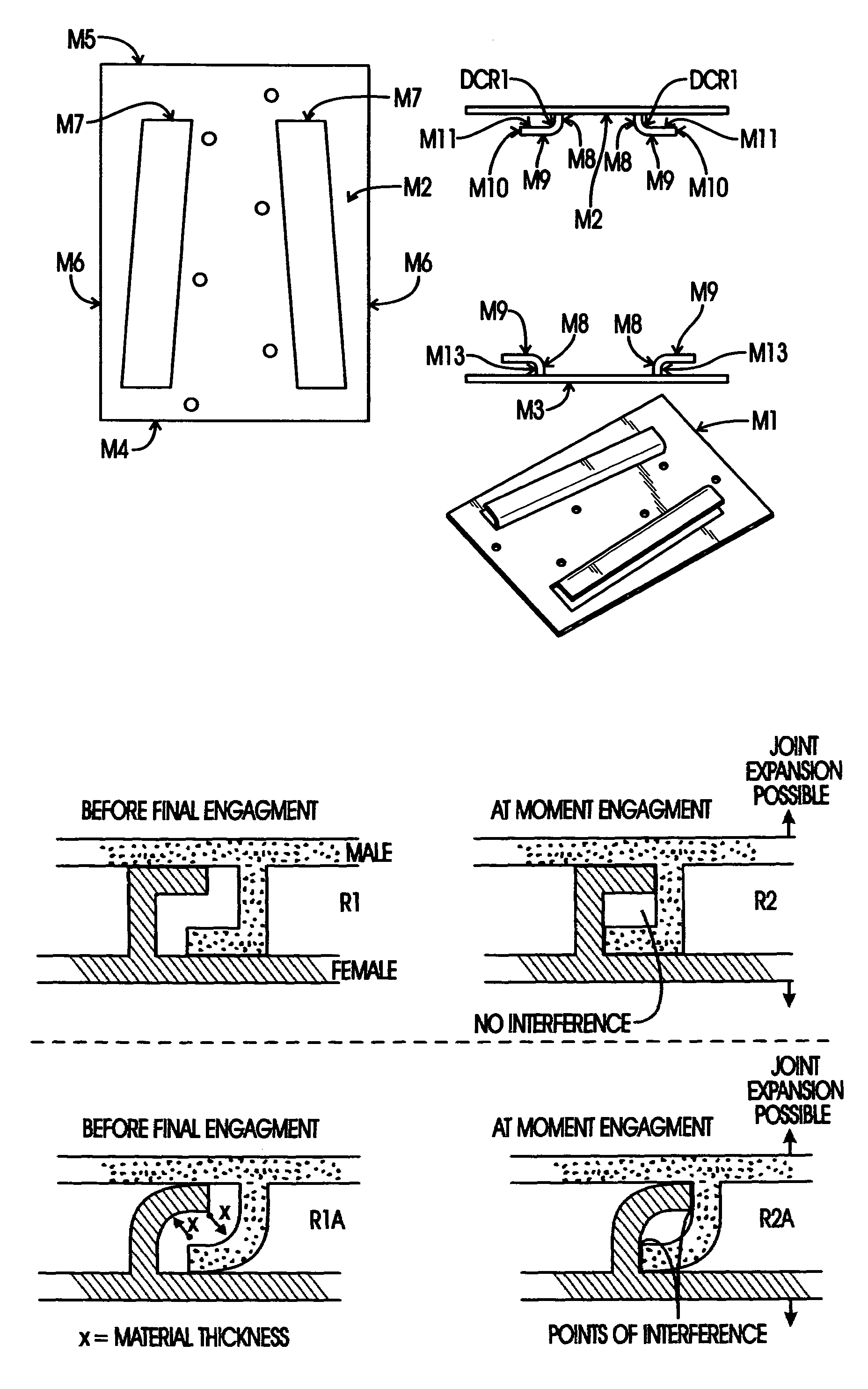

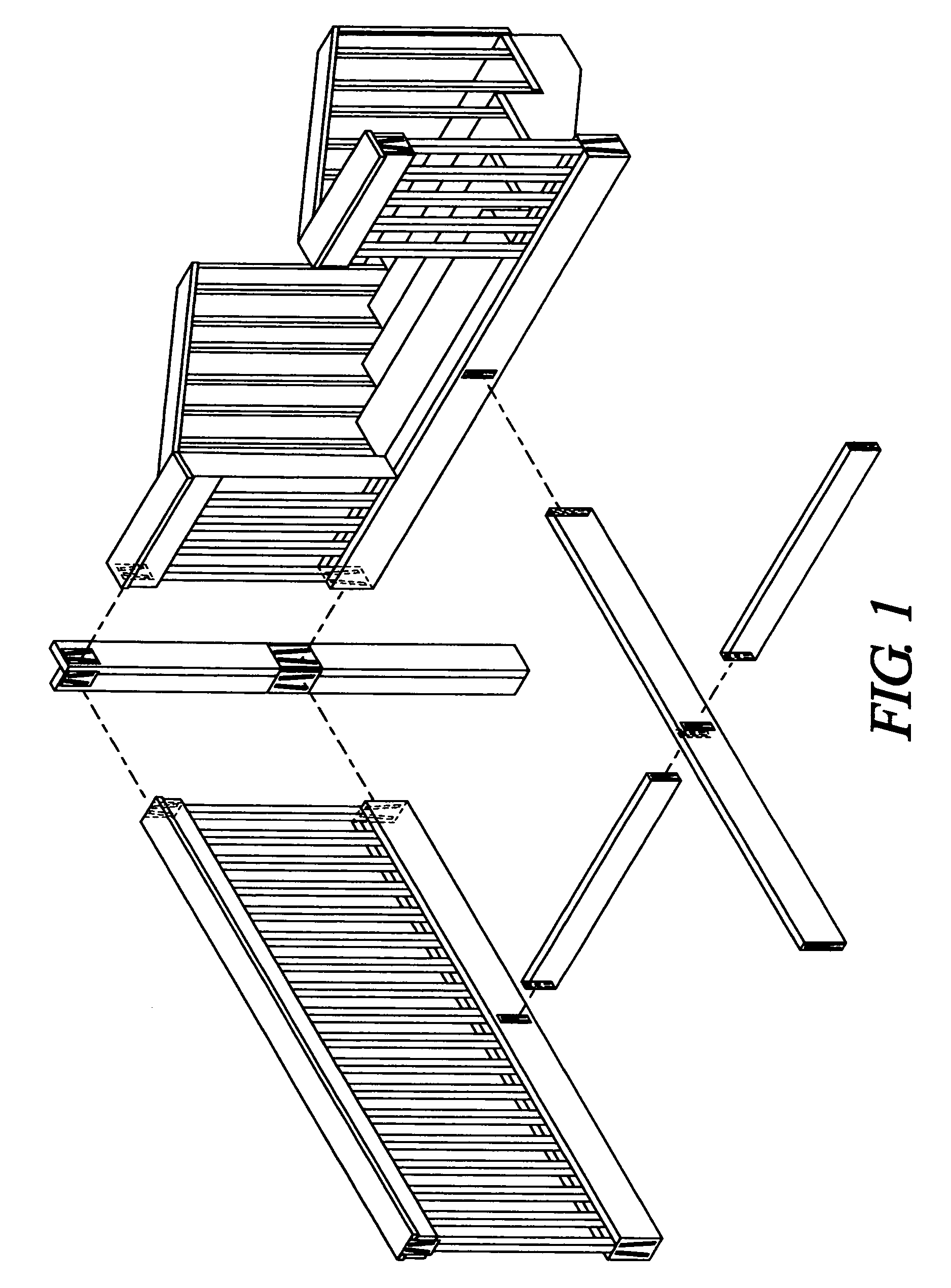

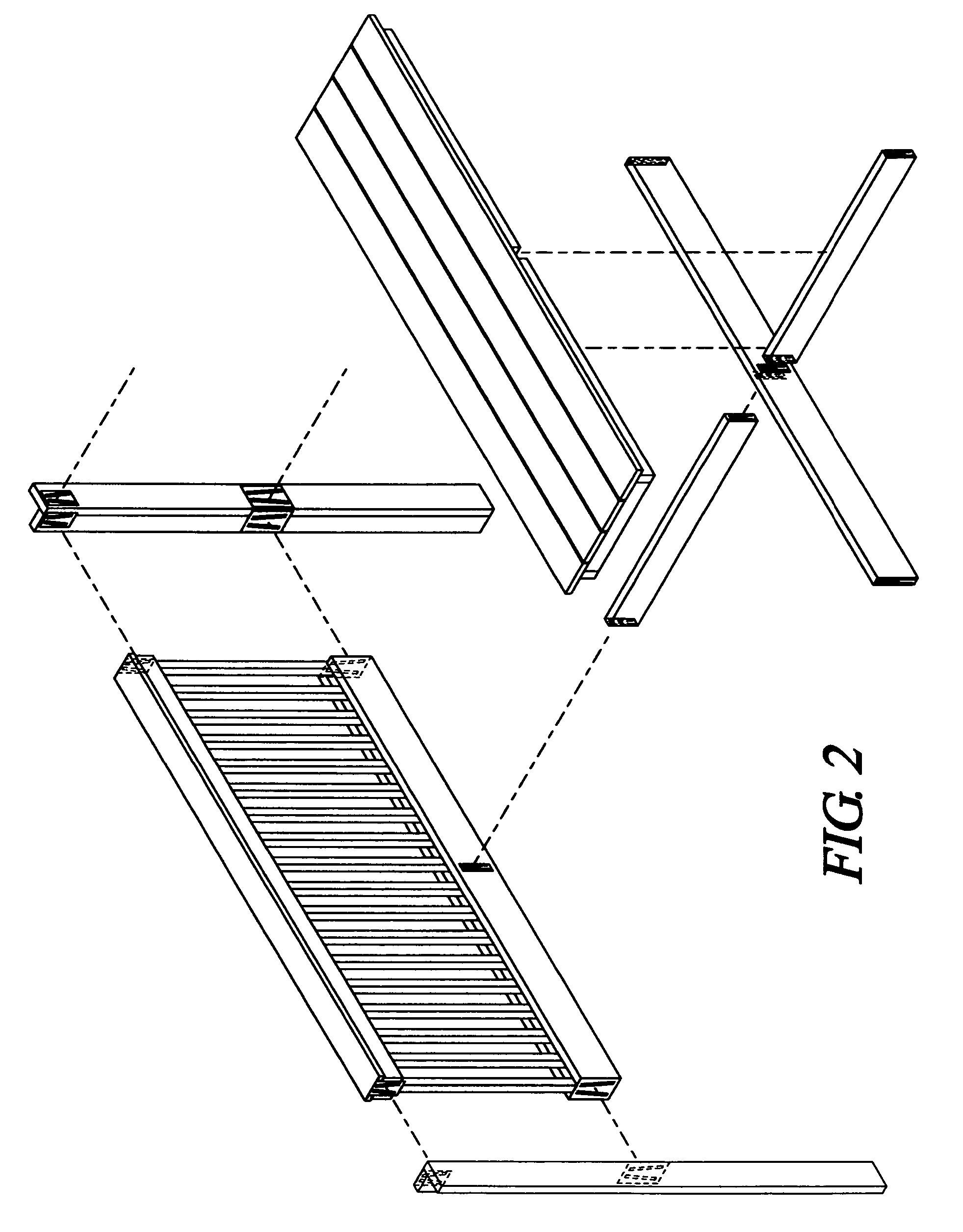

Modular structures and connector assembly apparatus

InactiveUS7007903B2Avoids costly secondary forming operationEasy to assembleCandle holdersCovering/liningsEngineeringMechanical engineering

Disclosed is a modular, knock down structure construction system illustrated by three structures, each having connecting portions detachably secured to one another by Trapezoidal Quick Slide Connector Assemblies, also disclosed, that enable a user to erect, without tools, a pre-designed structure.Additionally disclosed is a manufacturing apparatus for accurately and efficiently mounting connector assemblies on structural parts for later assembly.

Owner:TURNER CAROL SUE

Monolithic ceramic capacitor

ActiveUS7808770B2Improve installabilityLow reliabilityFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorNickel alloy

Owner:MURATA MFG CO LTD

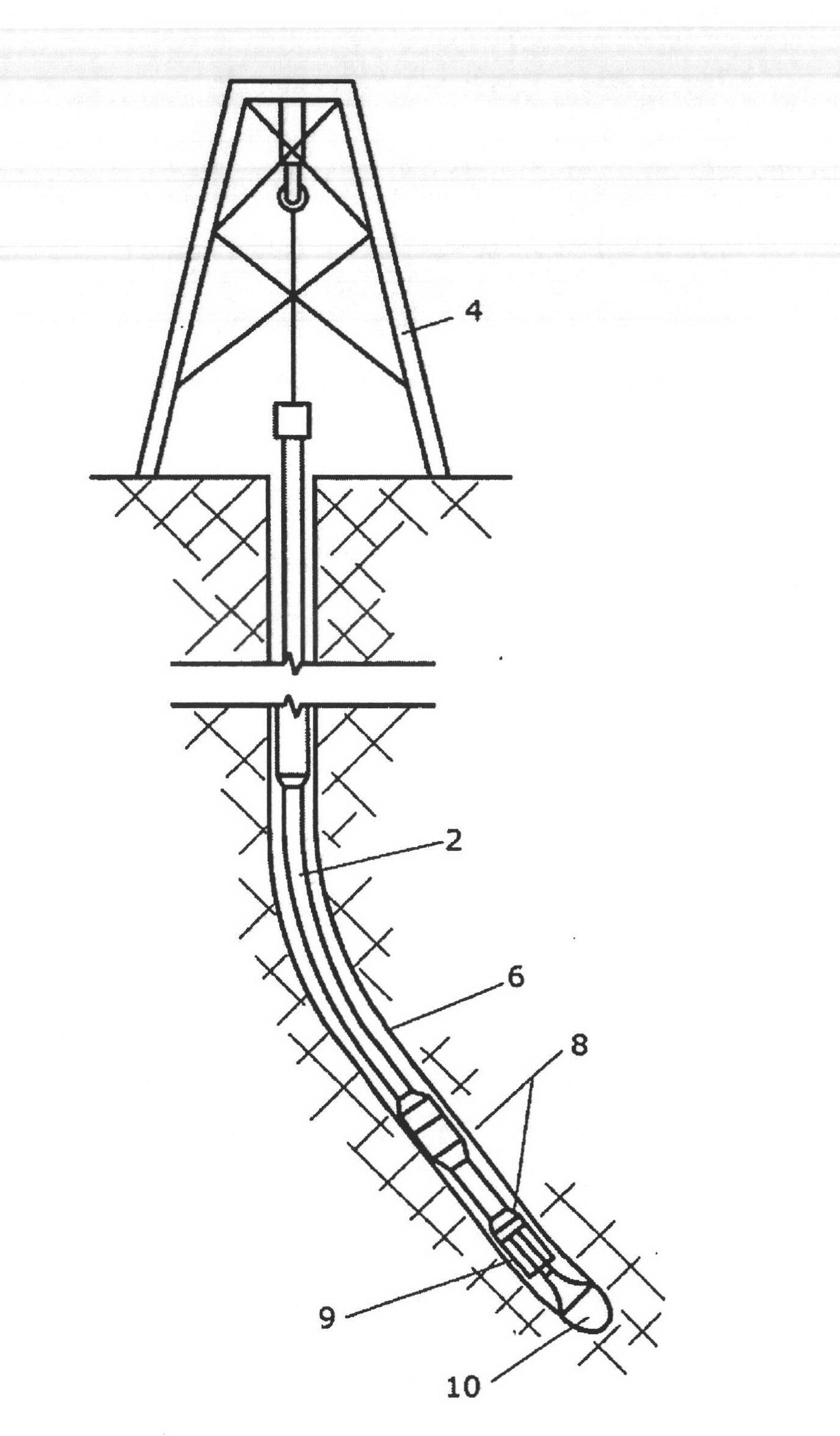

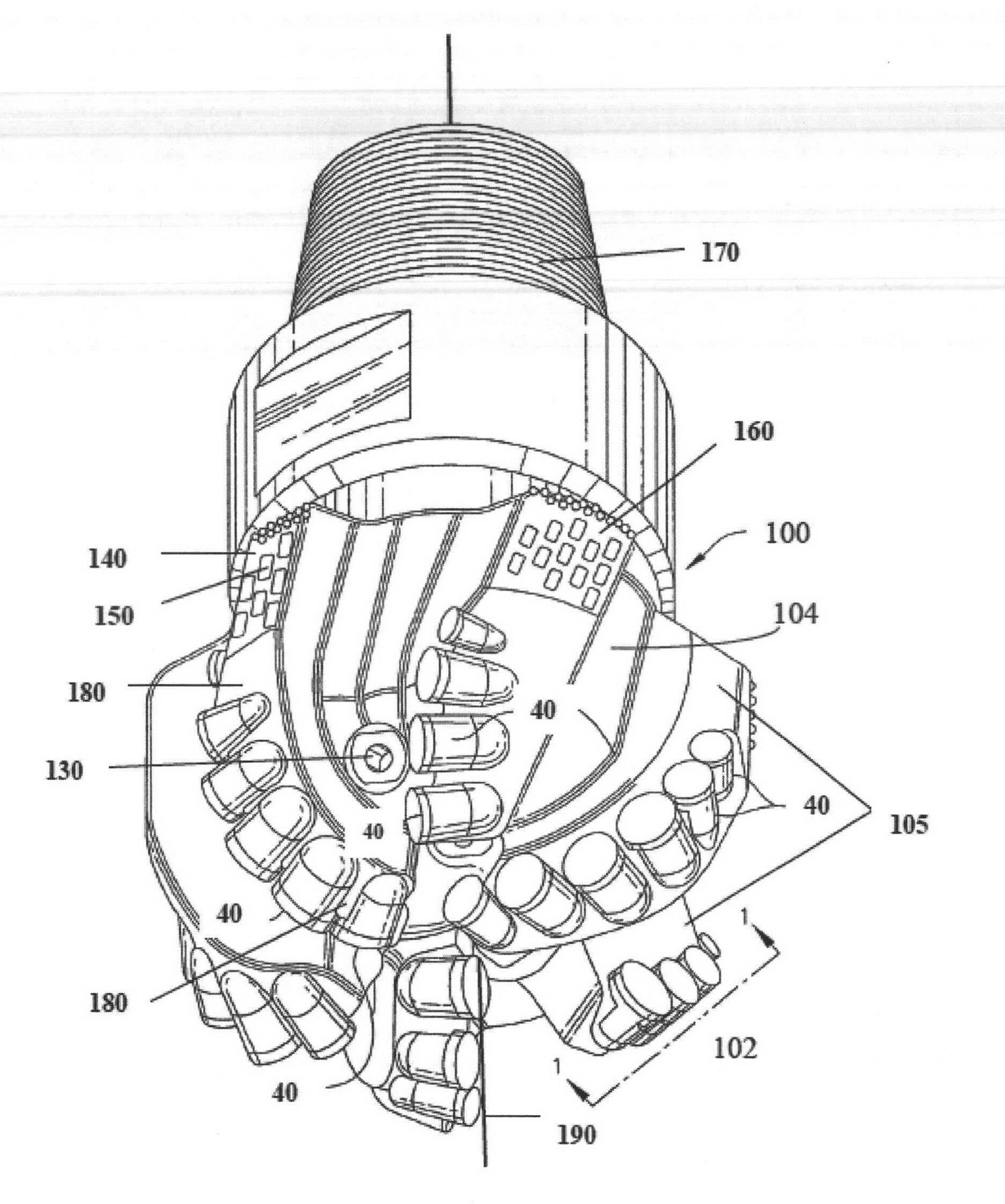

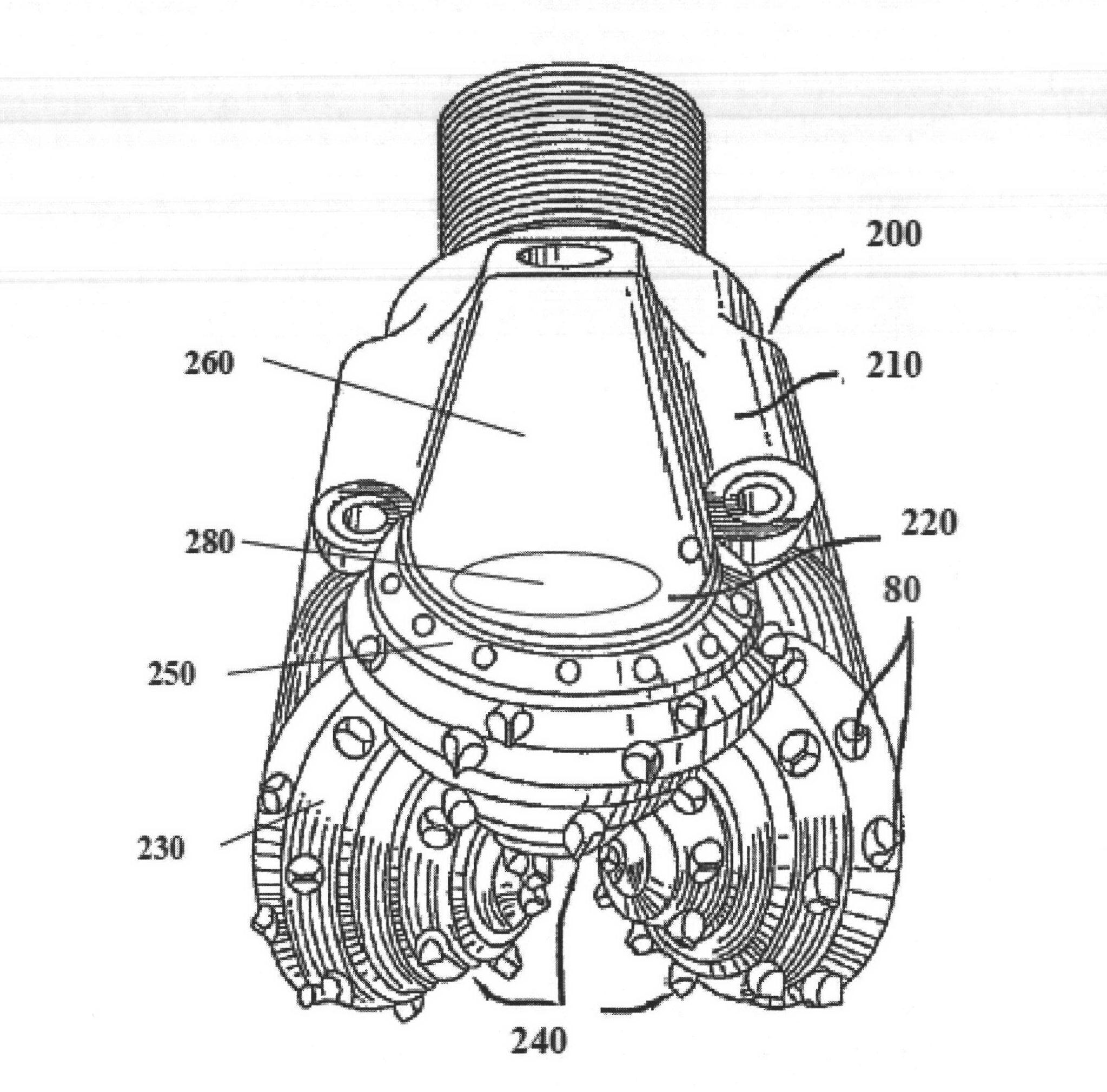

Wear-resistant material used in drilling application

The invention relates to a hard-face metal composition with strong wear resistance and fracture resistance, in particular to a wear-resistant material used in drilling application. The wear-resistant material contains tungsten carbide and a nickel matrix binder, wherein the content of the tungsten carbide in the hard-face metal composition exceeds 50% by weight, and at least 60% by volume of tungsten carbide particles are spherical; and the binder consists of (in weight percent) at least 80% of nickel, 4.5-11% of fusing agent, 3-7% of copper and 1-5% of Cr or Mo or mixture of the Cr and the Mo, wherein the fusing agent is selected from boron, silicon and phosphorus.

Owner:SEED TECH CORP LTD

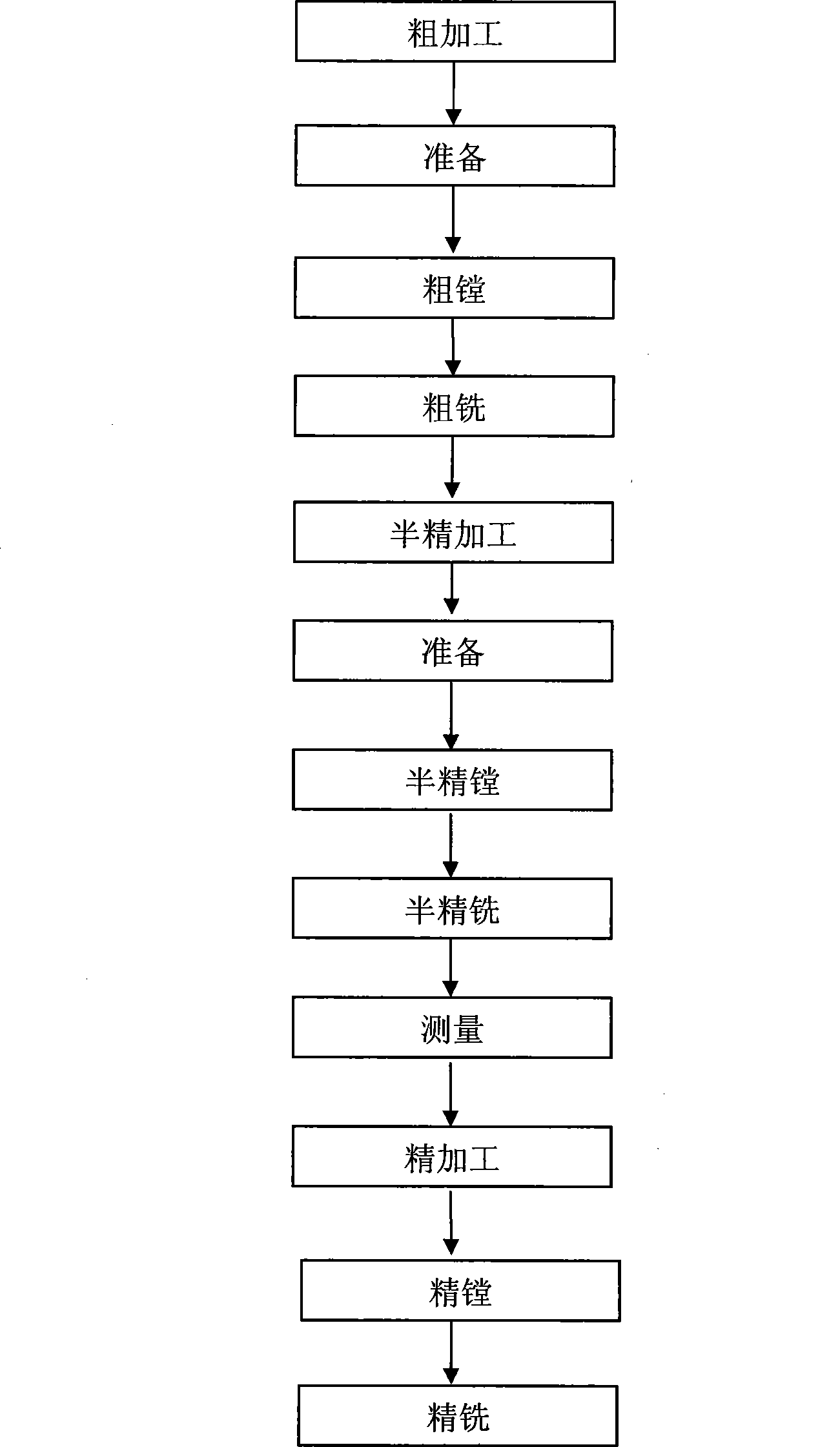

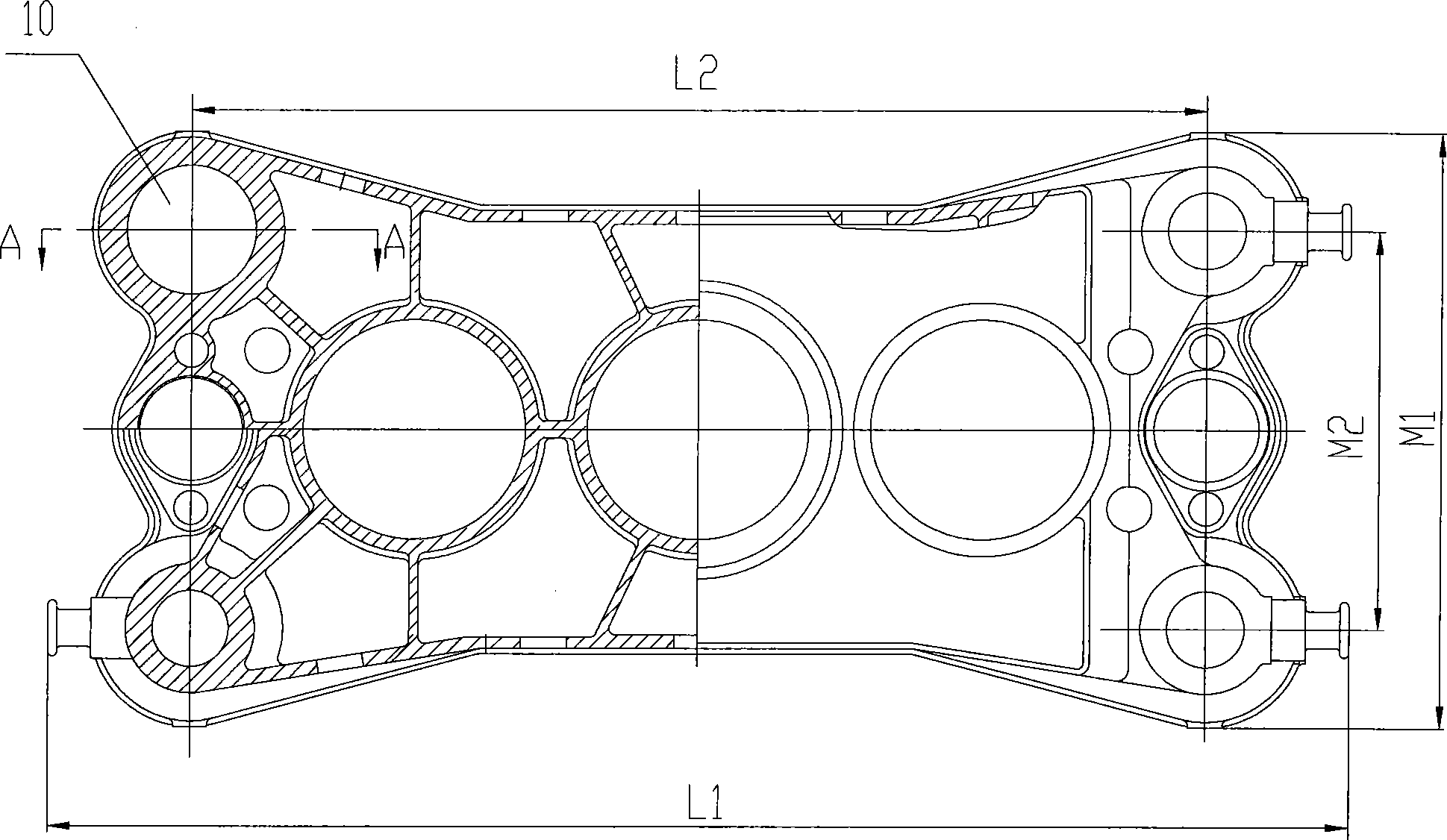

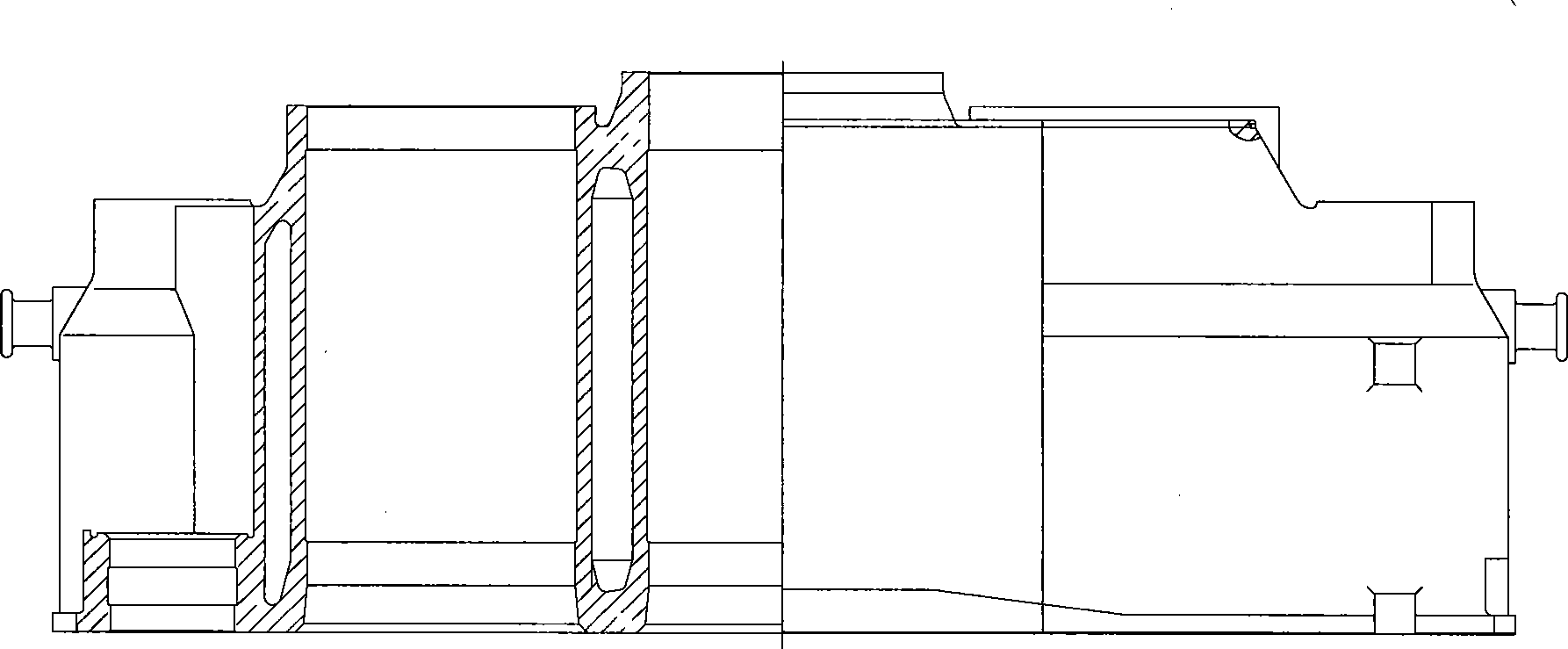

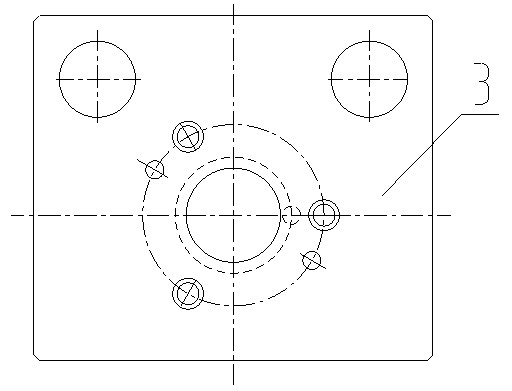

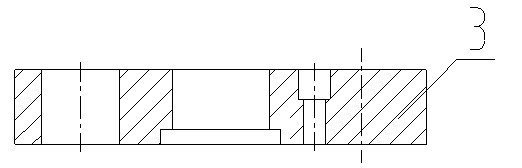

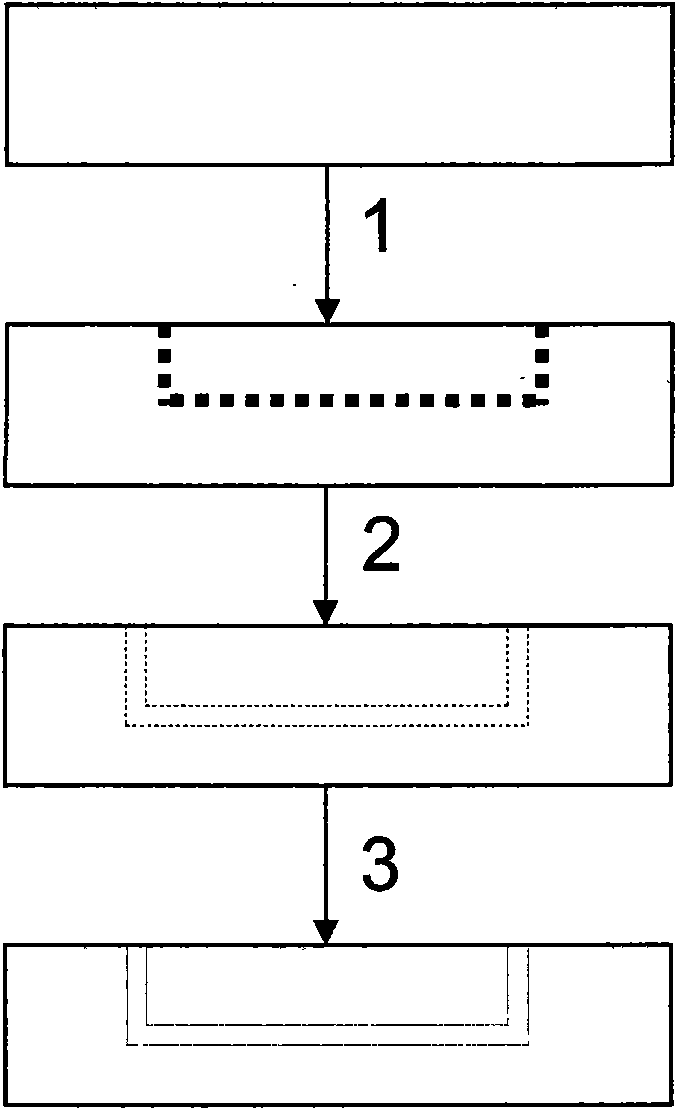

Method for processing pressing sleeve hole of large diameter in top and bottom cross member of oil press

InactiveCN101439457AReduce manufacturing costReduce Tooling CostsMilling equipment detailsBoring/drilling machinesEngineeringMachining process

The invention discloses a processing method used for a large-diameter pressing sleeve hole in the upper and lower crossbeam of an oil hydraulic press. The method is used for processing four pressing sleeve holes (with the design diameter of 1142F9 / 1150F9 and the depth of 2100 plus or minus 0.1mm) of the upper and lower crossbeam in the oil hydraulic press of 165MN; the open size among the four processed pressing sleeve holes is 8950 plus or minus 0.2 multiplied by 3550 plus or minus 0.15mm; furthermore, the diagonal sizes of the four pressing sleeve holes are consistent; the process comprises the steps as follows: step 1: rough machining; a first step is preparation; a second step is that allowance of 10mm on single surface is retained for heavy boring and allowance of 10mm on single surface is retained for rough milling; step 2: semi-finishing; a first step is preparation; a second step is that, allowance of 1mm on single surface is remained for semi-finishing boring by a boring machine, the allowance of 1mm is retained for semi-finishing milling on single surface by a boring machine, a third step is that the allowance of 1mm is retained for semi-finishing milling by a sidecutter head, and a fifth step is that the open size and the diagonal size are measured; step 3: finish-processing; a first step is that the finish-boring is carried out by a boring machine and a second step is that the finish-milling is carried out by the sidecutter head.

Owner:SHANGHAI HEAVY MACHINERY PLANT

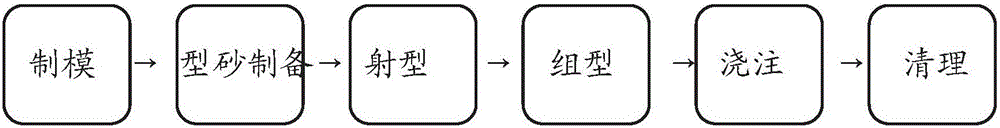

Method for casting large-scale box type castings through precoated sand shell mold

InactiveCN106001453AGood quality instant noodlesSand core surface quality is goodFoundry mouldsMoulding machinesSurface finishSand casting

The invention belongs to the technical field of coated sand casting technology, in particular to a method for casting large-scale box castings with coated sand shell molds. Including mold making, molding sand preparation, core mold making, and core mold combination: After the shell molds and shell cores are combined according to the process card or drawing, the sand box is placed on the outside, the gating system is drawn out, and the gate and the gate are wrapped with plastic film. Riser, then between the shell mold and the sand box, add clay sand layer by layer and solidify, and finally lock the upper and lower boxes; pouring molding and cleaning. The invention has high casting precision, high yield and good surface finish, and is suitable for larger castings.

Owner:东港市永盛铸造有限公司

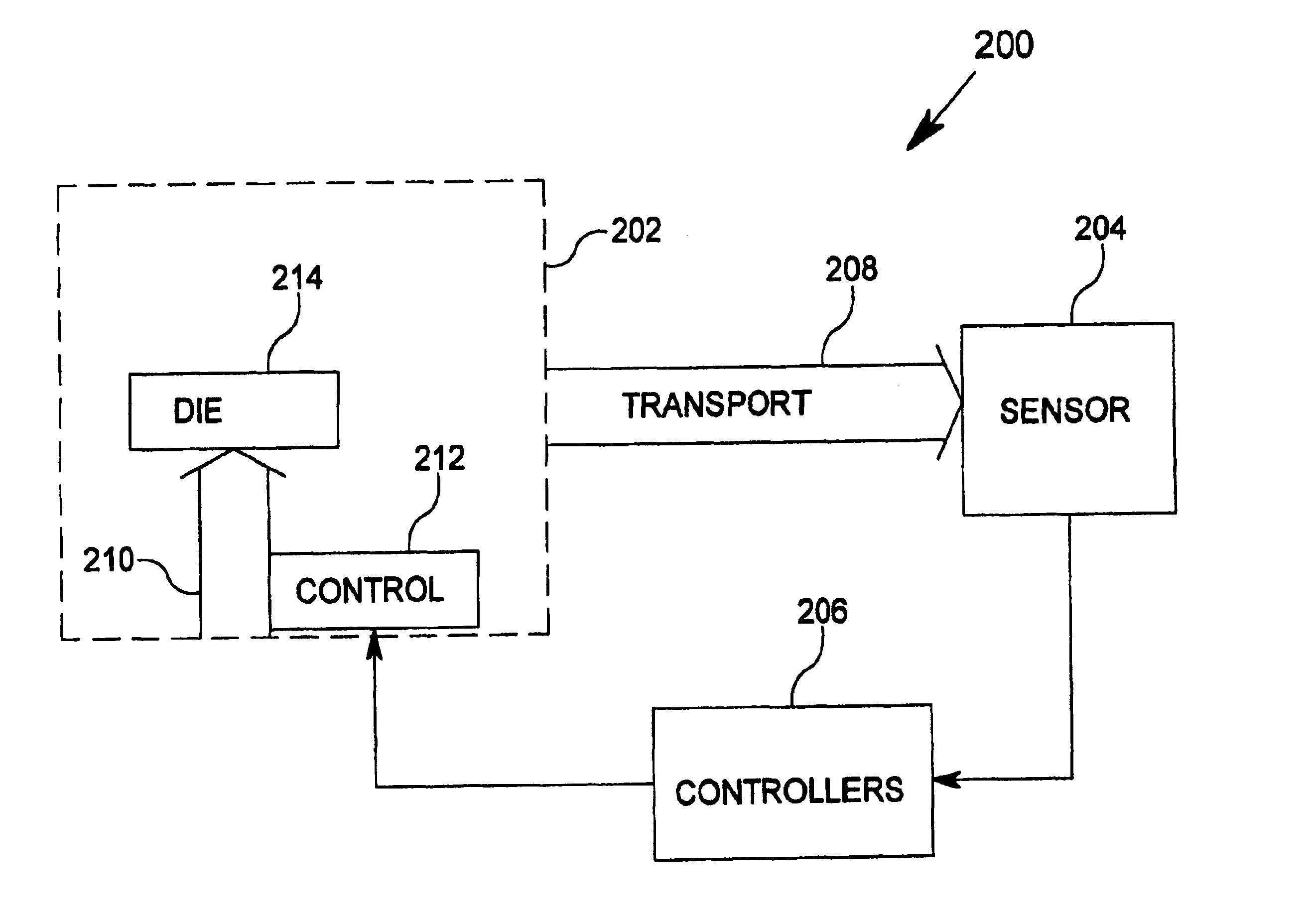

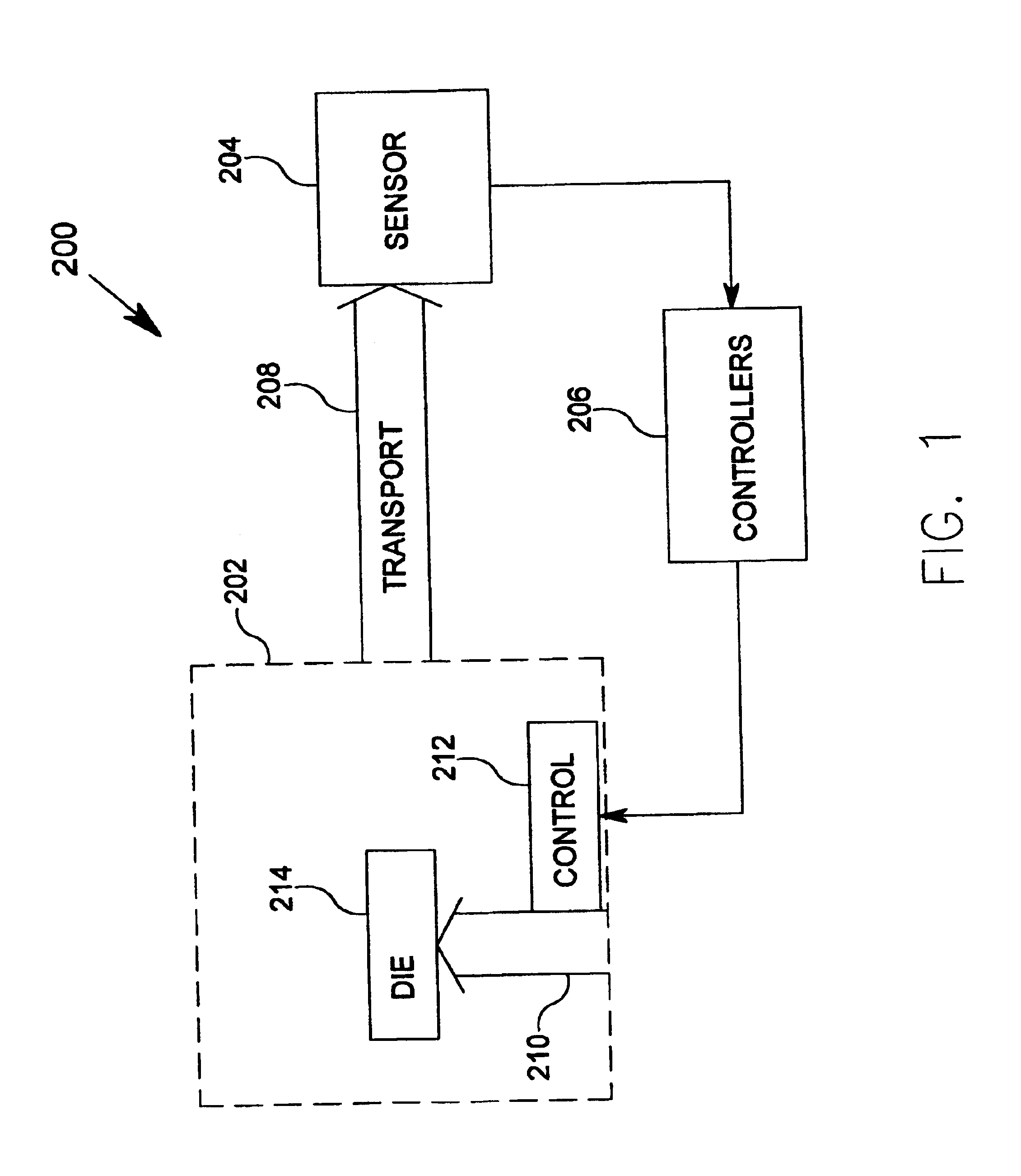

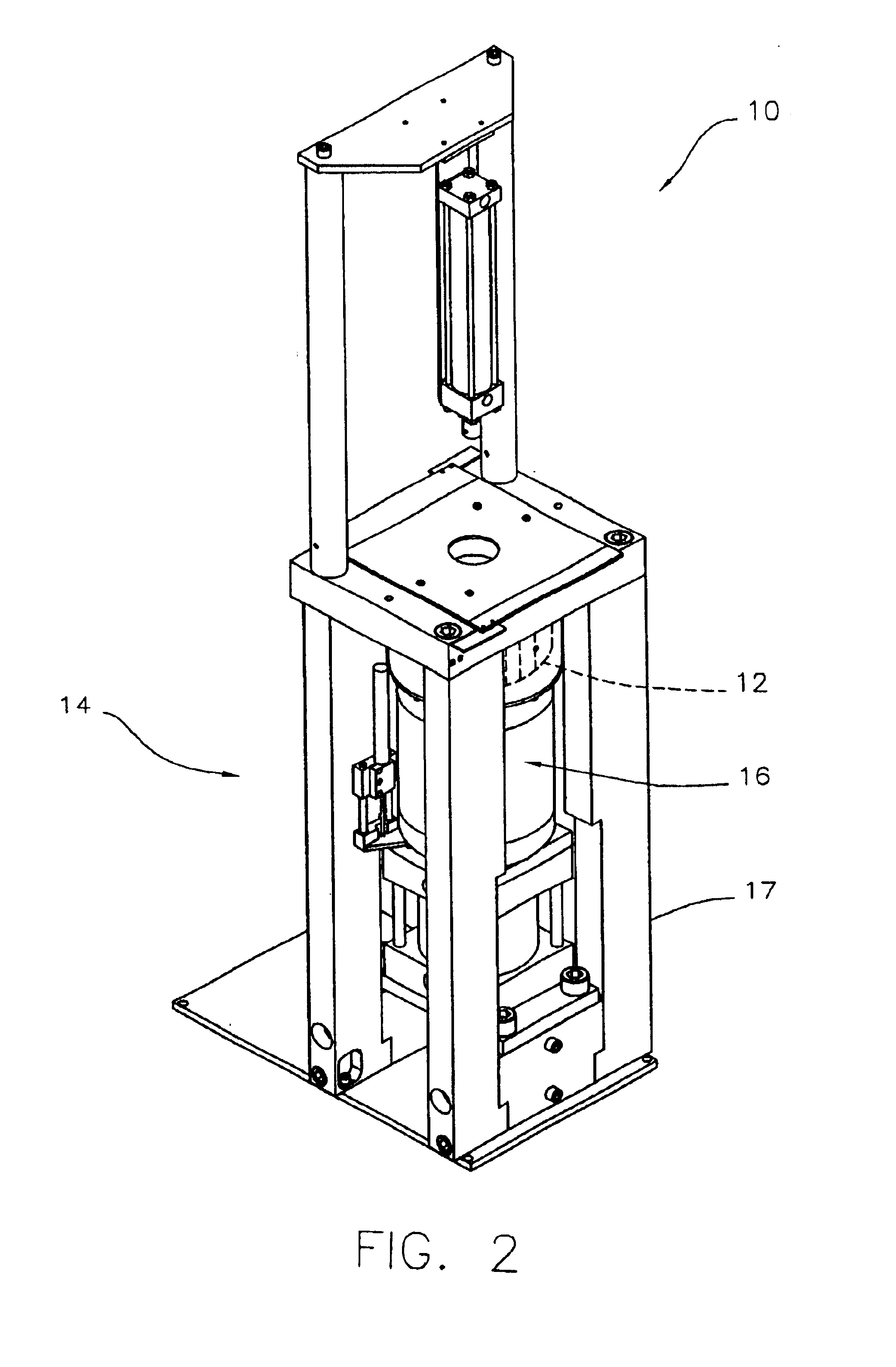

Swaging feedback control method and apparatus

A swaging system includes a swaging assembly, a sensor, and a controller. The swaging assembly includes a movable tool, the movable tool operate to exert force on a die. The die is configured to reduce a dimension of a work piece responsive to the exerted force, the dimension reduction having a relationship to a stroke of the movable tool. The sensor is operable to obtain information including a measurement of the reduced dimension of the work piece. The sensor is operable to generate a measurement signal representative of the obtained information. The controller is operably coupled to receive the measurement signal from the sensor, and is operable to cause adjustment the stroke of the movable tool responsive to the measurement signal.

Owner:BARTROM MICHAEL A +1

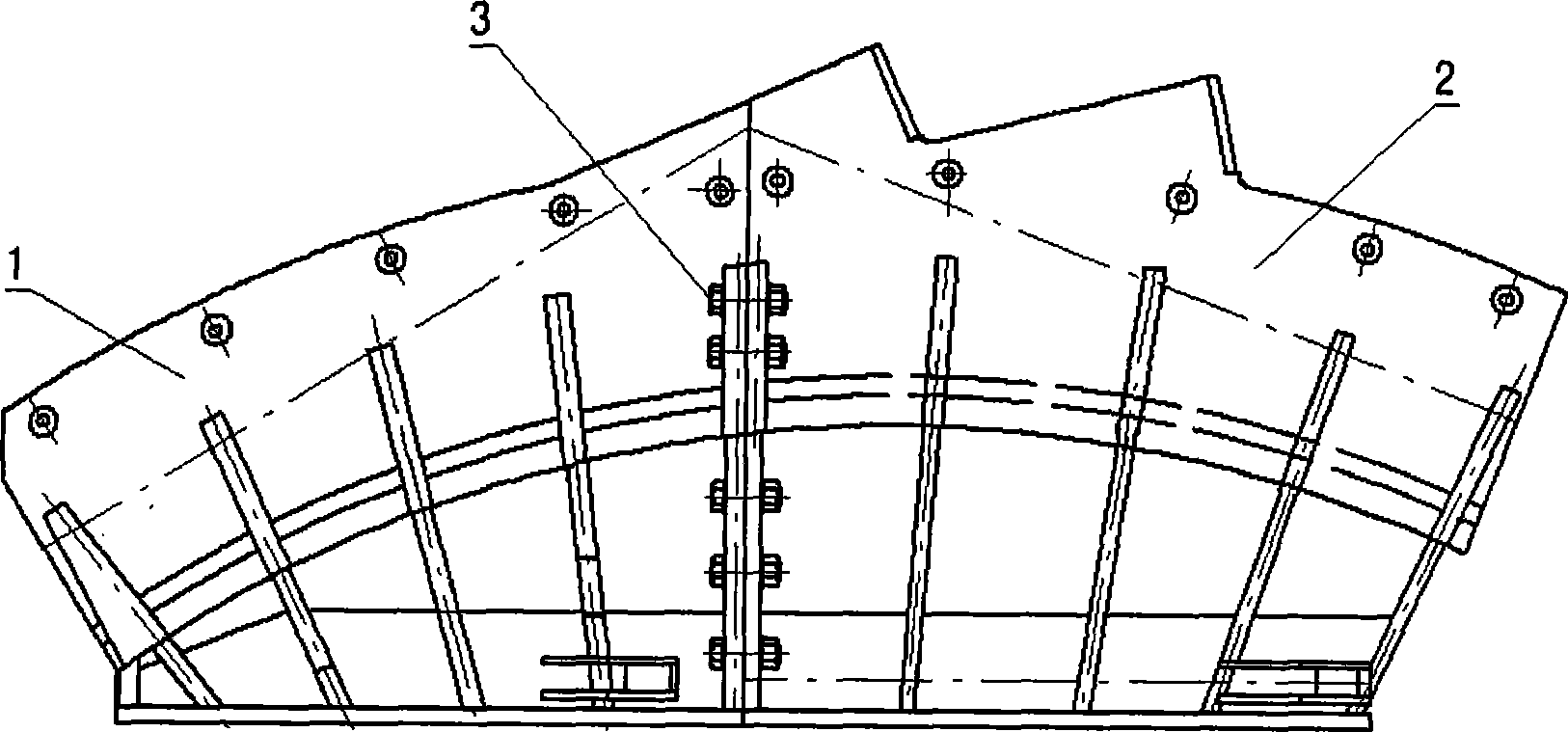

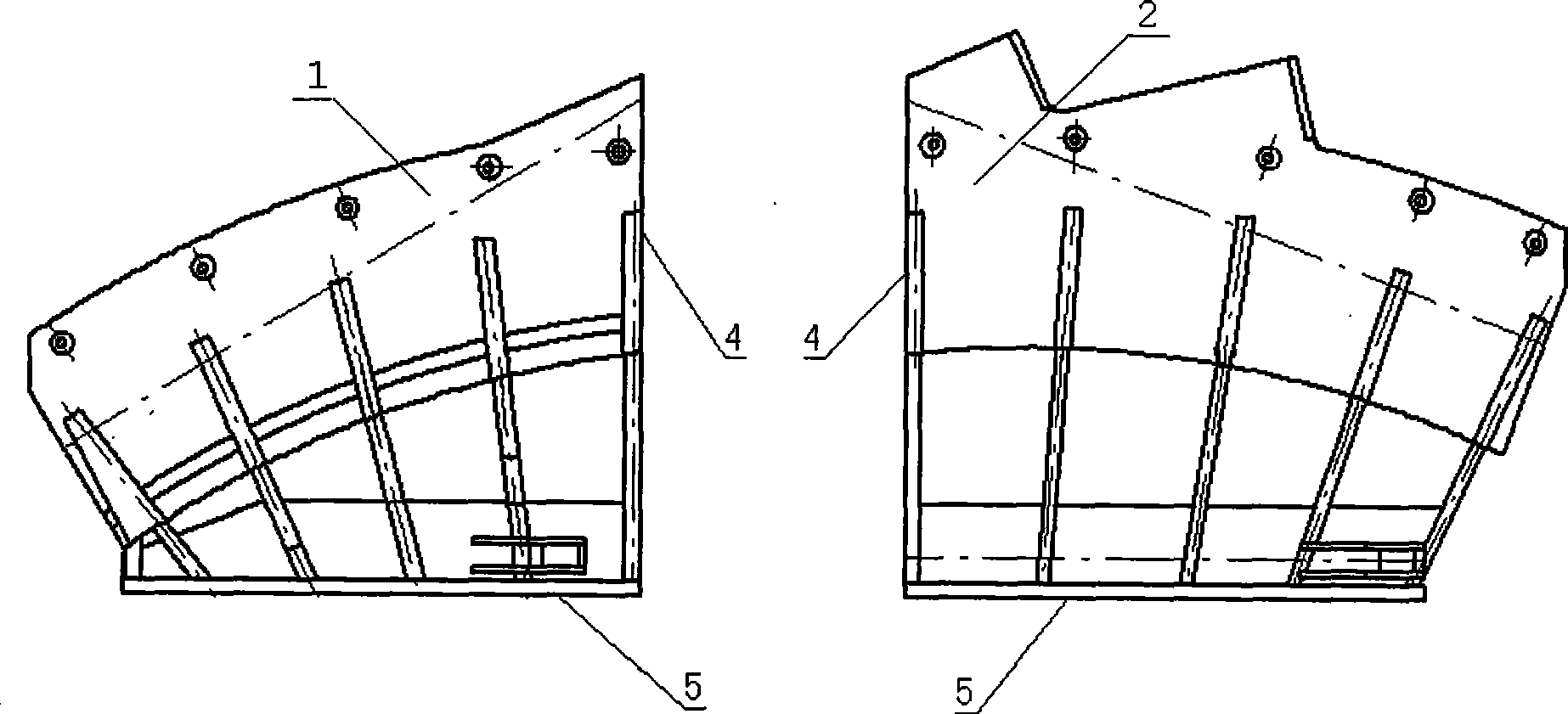

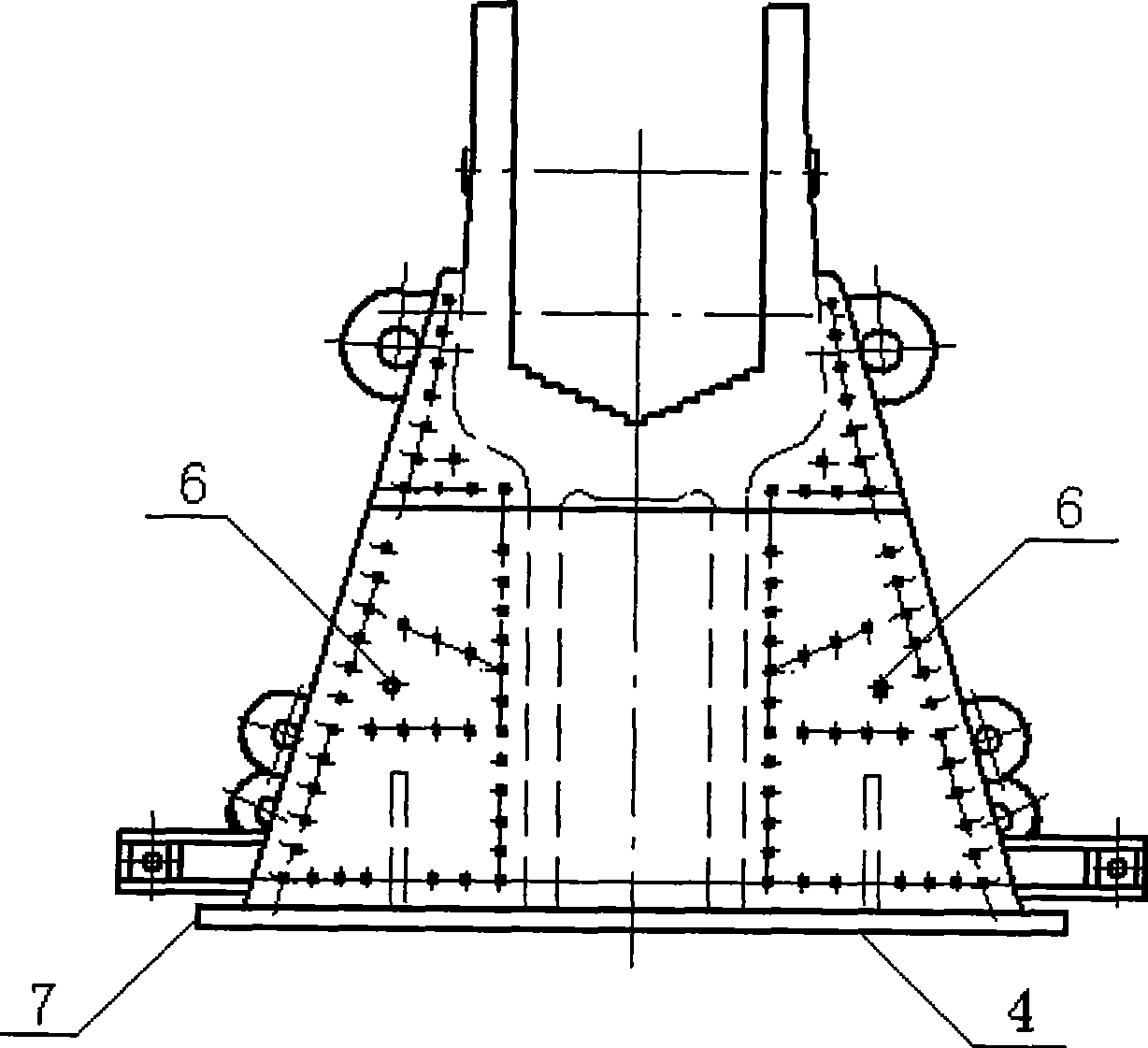

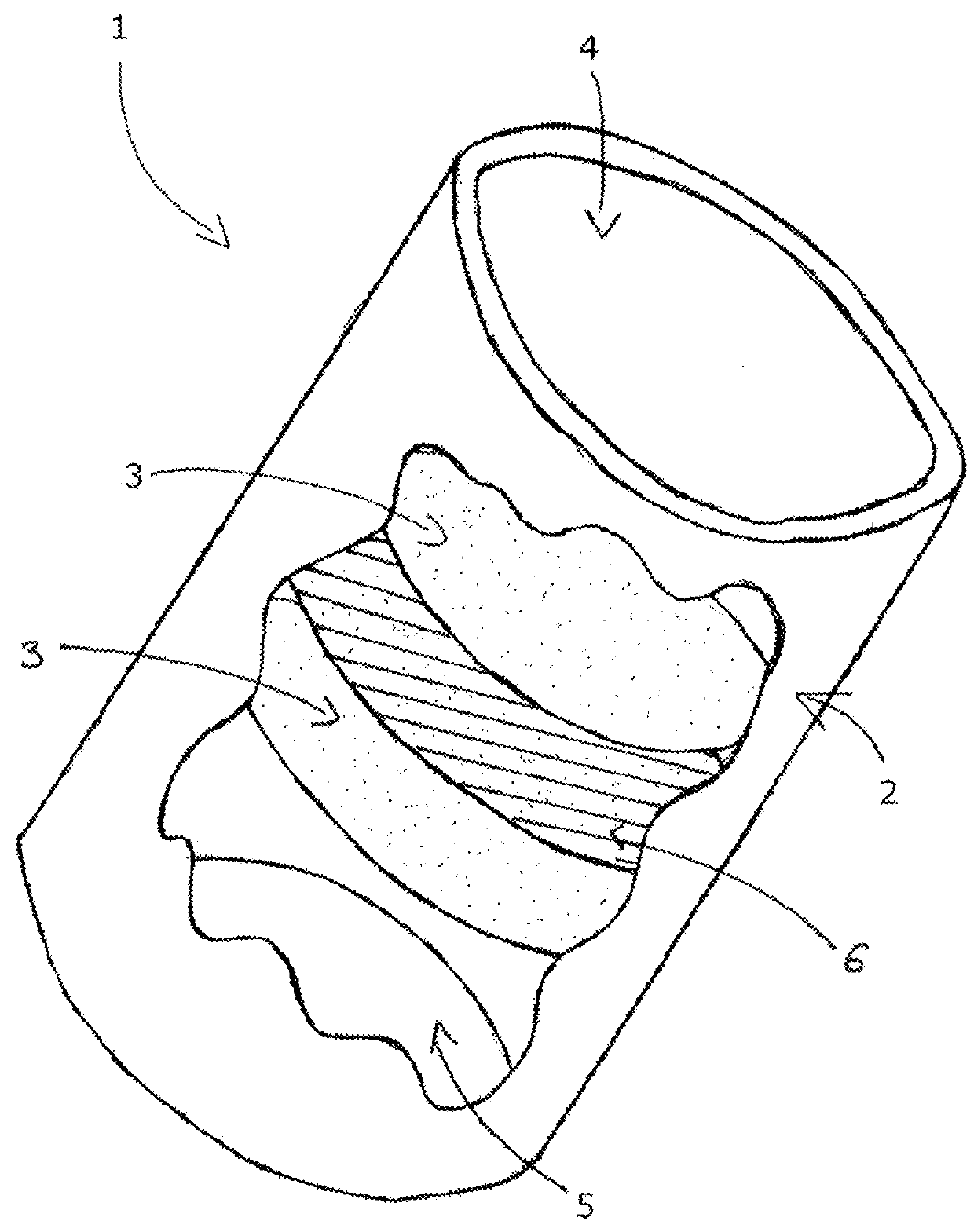

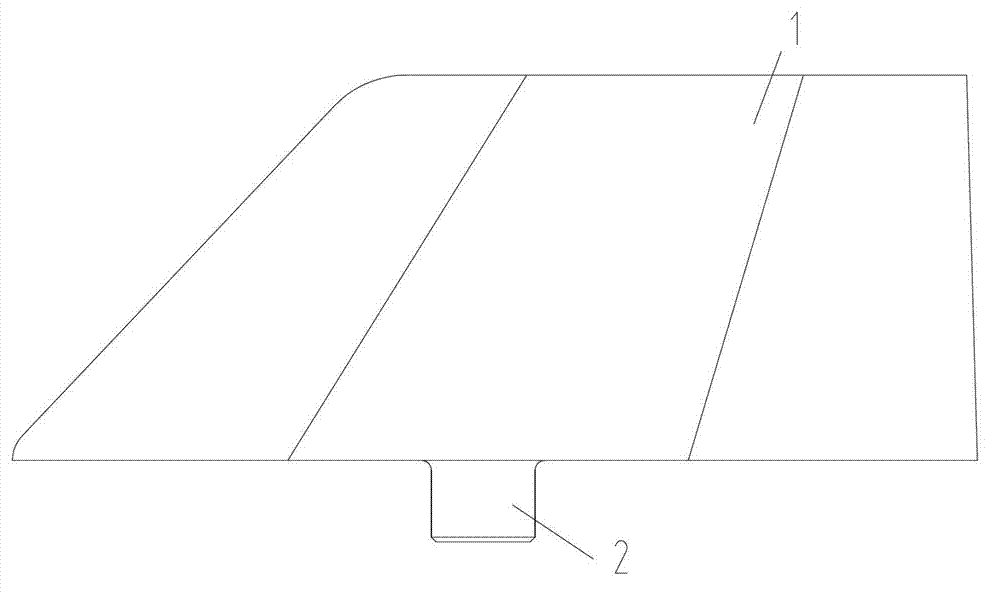

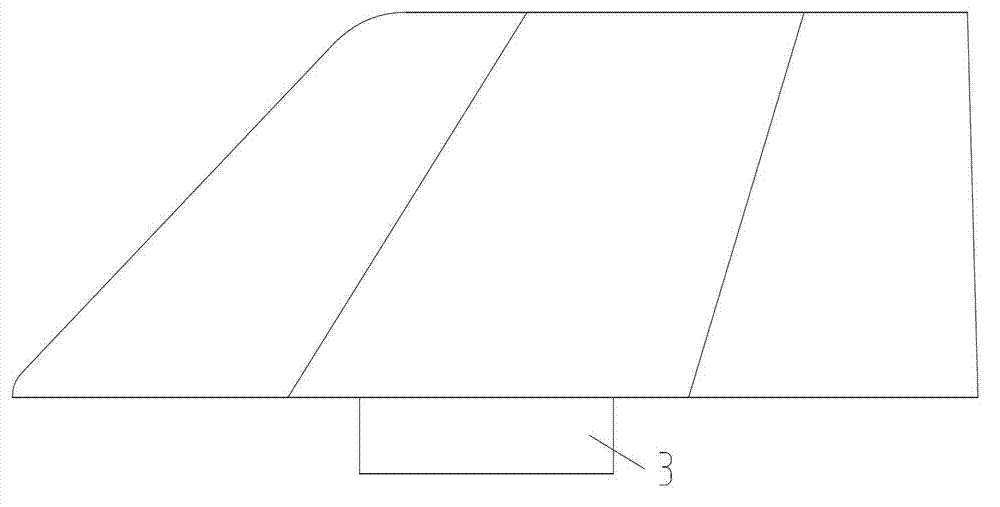

Method for processing main cable saddle of suspension bridge

The invention discloses a method for processing a main cable saddle of a suspension bridge. A side span (1) and a midspan (2) of the main cable saddle are respectively processed, then a bolt (3) is used to connect the side span and the midspan, and a joint surface of the side span (1) and the midspan (2) is provided with a positioning pin hole (6). The method guarantees the consistency of the size of a rope groove after the side span (1) and the midspan (2) are butted, has no alternate edges, high butting accuracy and small error, unifies processing reference, has low requirement on processing equipment, is more convenient for clamping and calibration of workpieces, is easy to guarantee processing accuracy, and improves processing efficiency.

Owner:WUHAN MARINE MACHINERY PLANT

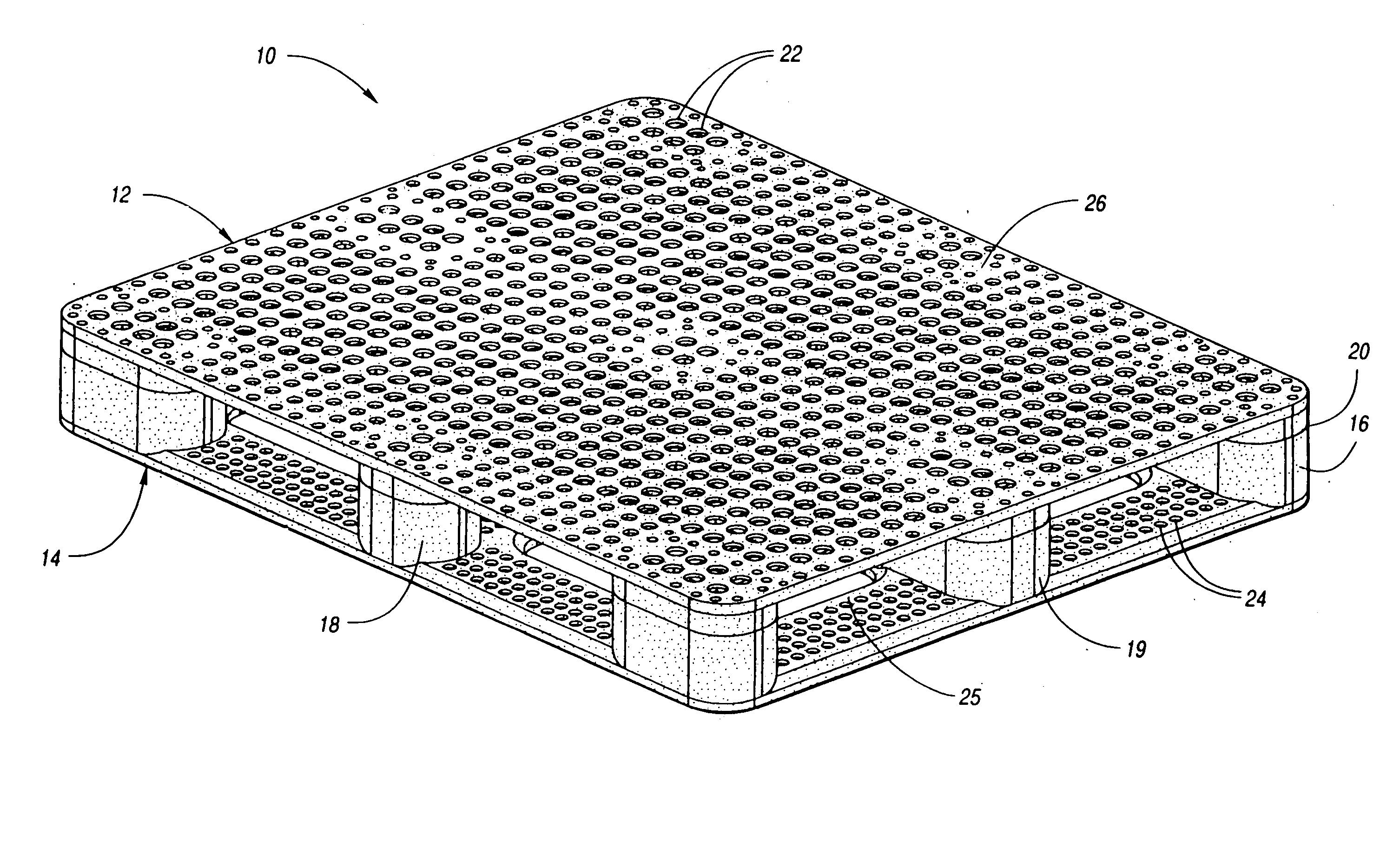

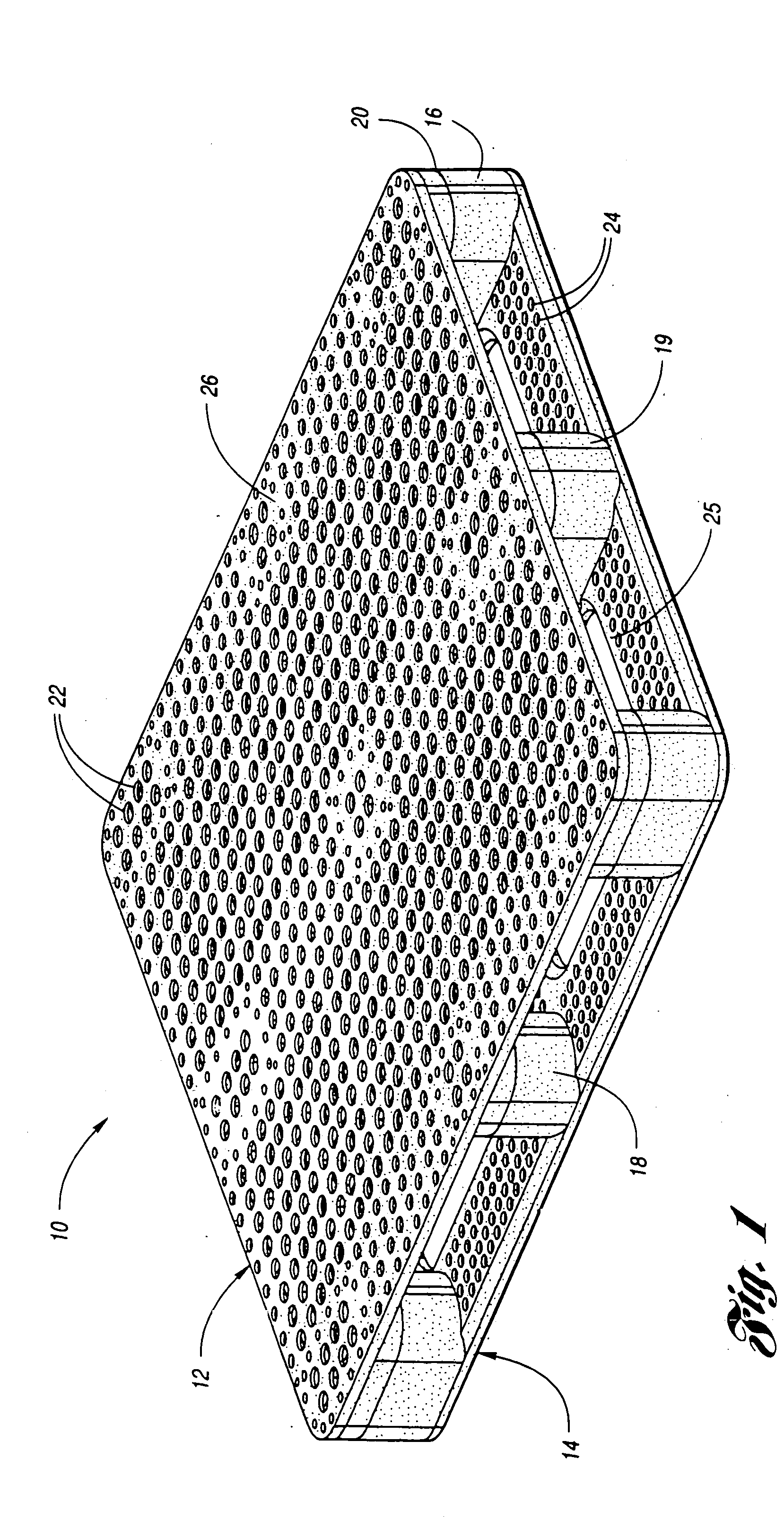

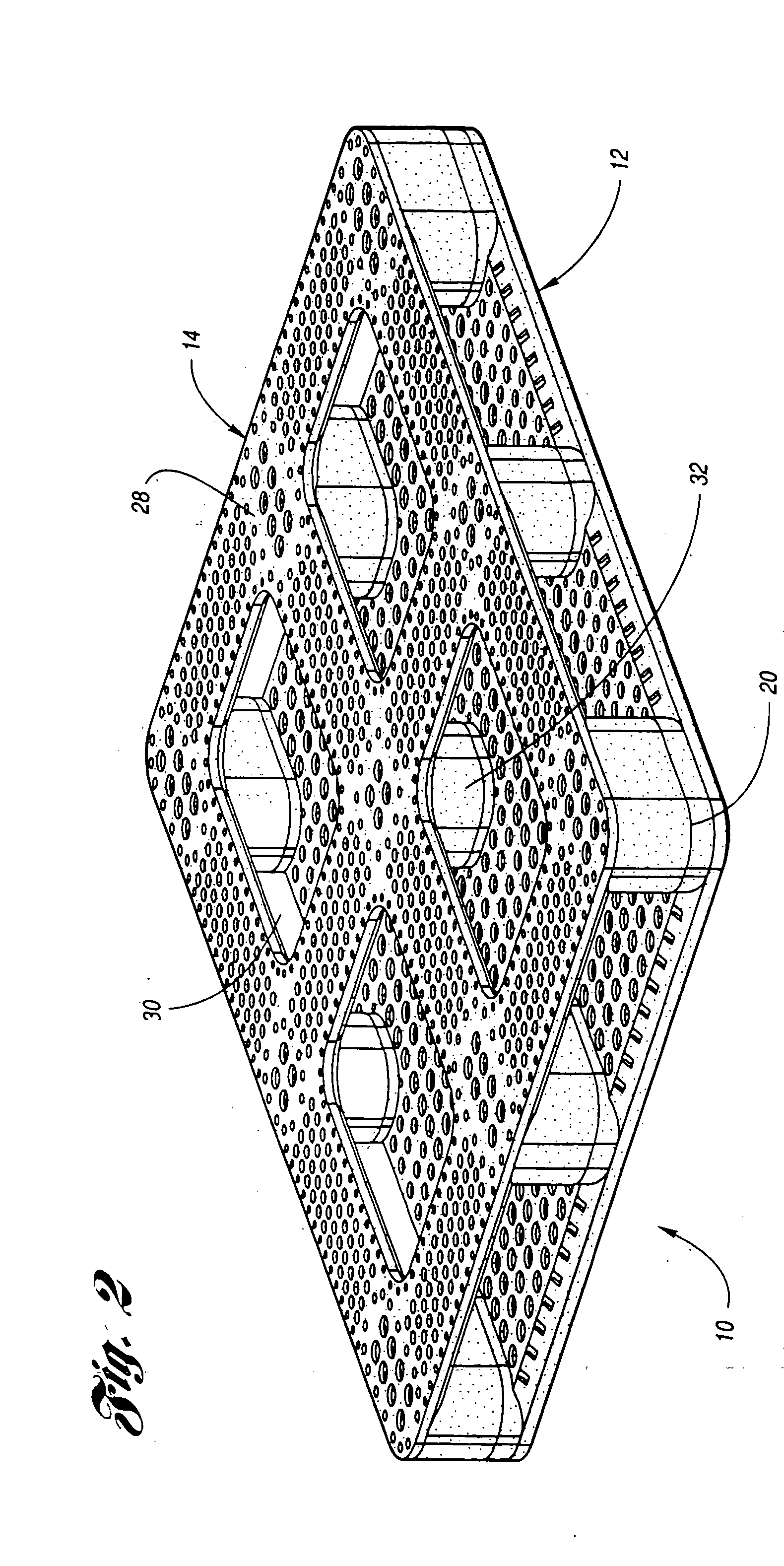

Pallet assembly

InactiveUS20050103236A1Cheap manufacturingInexpensive to assembleDomestic articlesRigid containersPalletCivil engineering

A pallet includes a first component which has a first upper surface, and a first lower surface which includes a first plurality of cross-rib members. A second component has a second lower surface, and a second upper surface which includes a second plurality of cross-rib members corresponding and mounted to the first plurality of cross-rib members. A third component is adjacent the second component and has a third upper surface, and a third lower surface which includes a third plurality of cross-rib members. A fourth component has a fourth upper surface which includes a fourth plurality of cross-rib members corresponding and mounted to the third plurality of cross-rib members. A plurality of intermediate column members extend between the second lower surface and third upper surface.

Owner:REHRIG PACIFIC CO INC

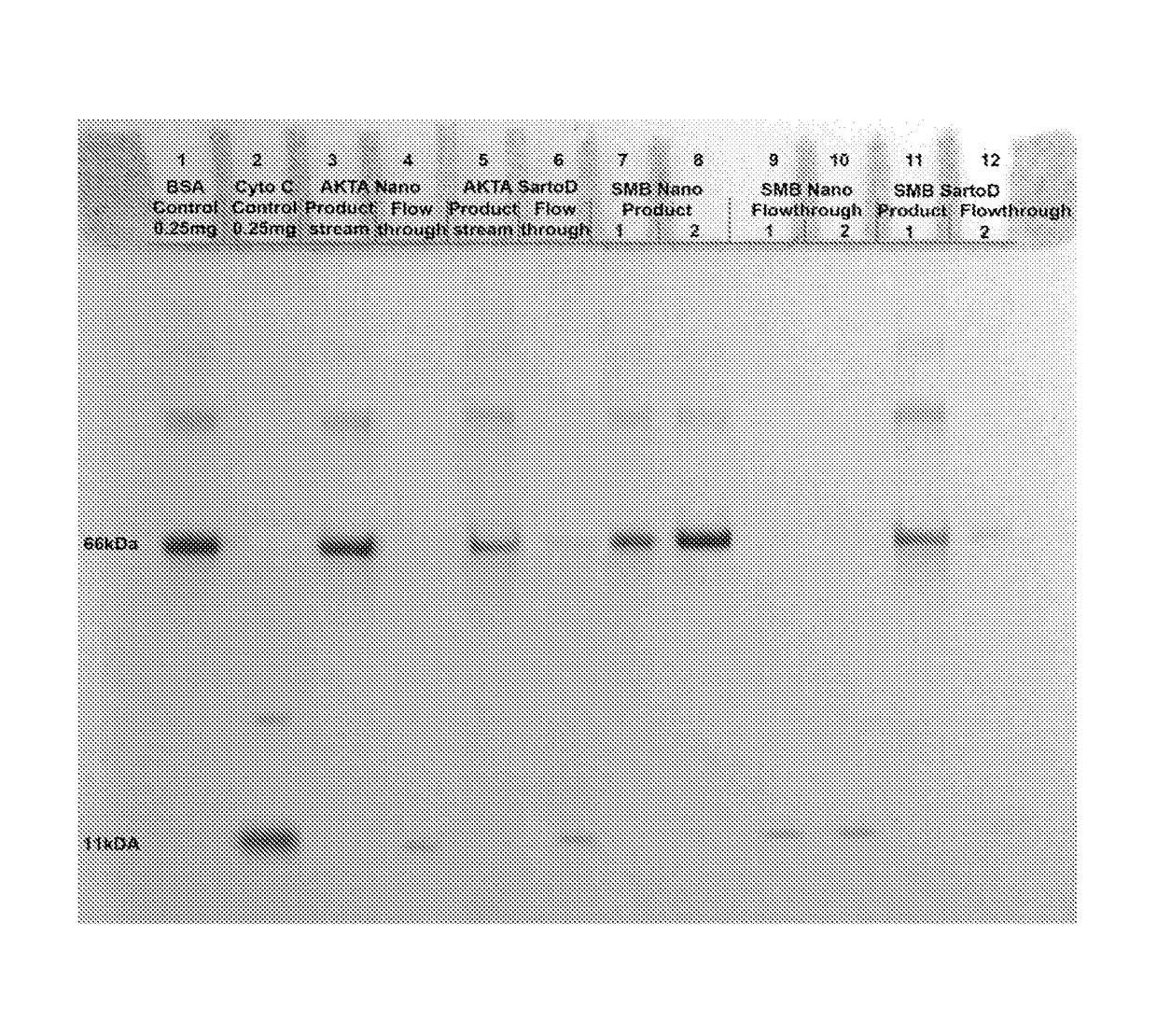

Chromatography medium

ActiveUS20180094022A1Easy to adjustImprove distribution characteristicsMaterial nanotechnologyCation exchanger materialsStationary phaseNanofiber

Owner:PURIDIFY

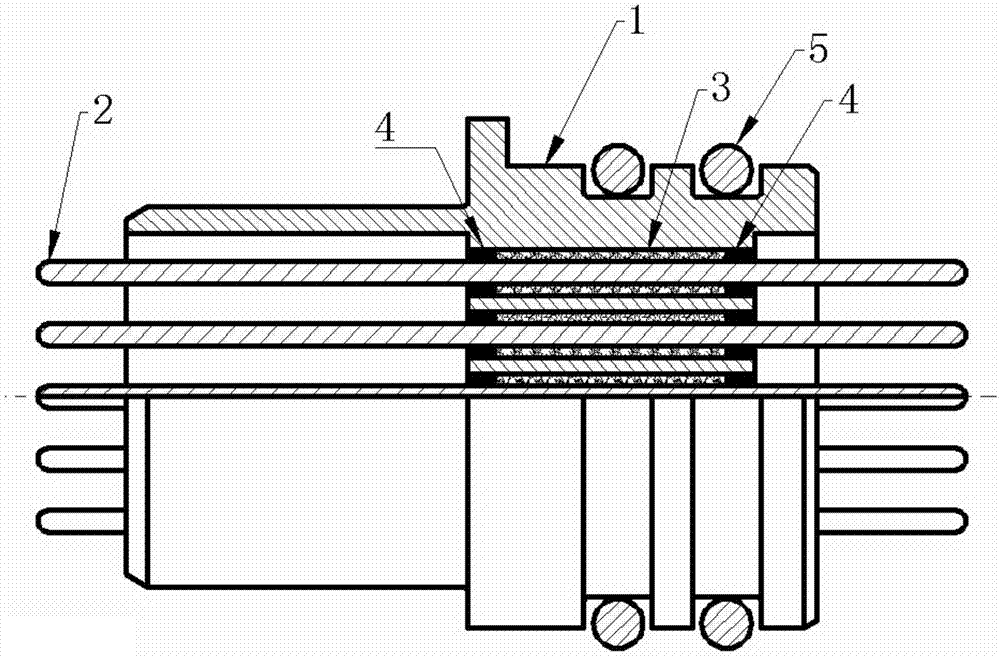

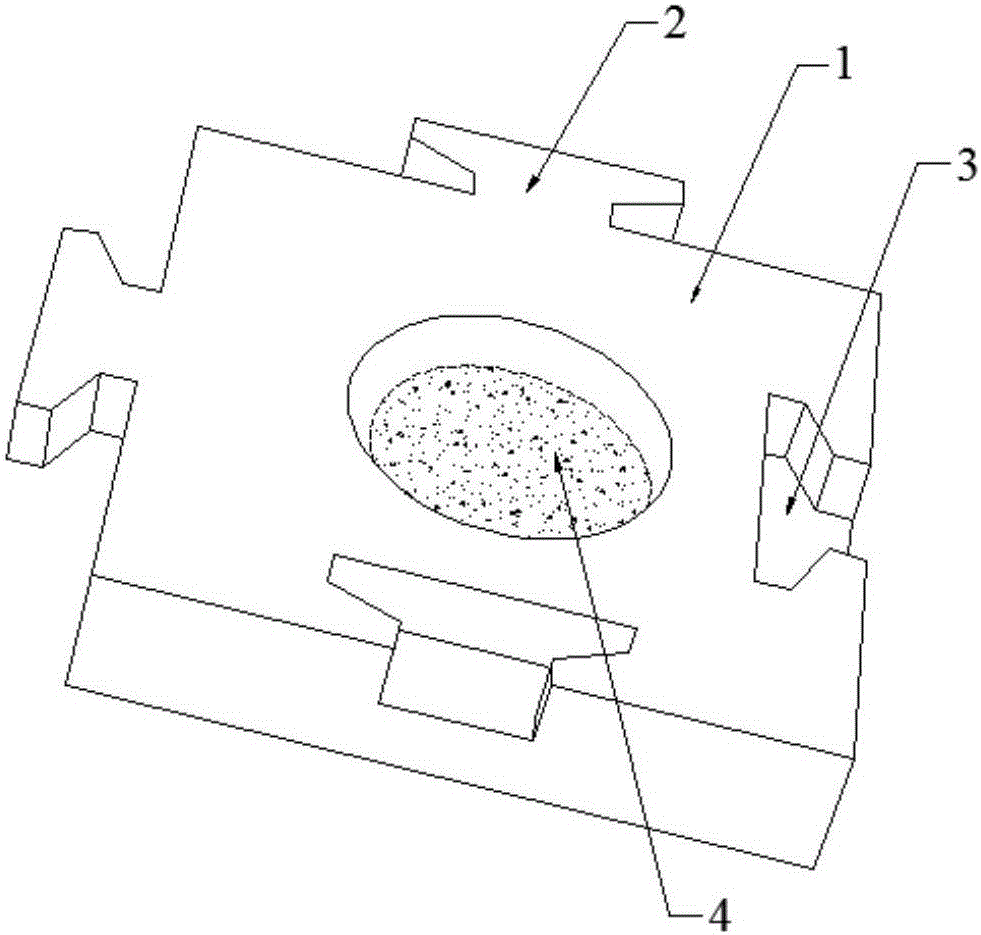

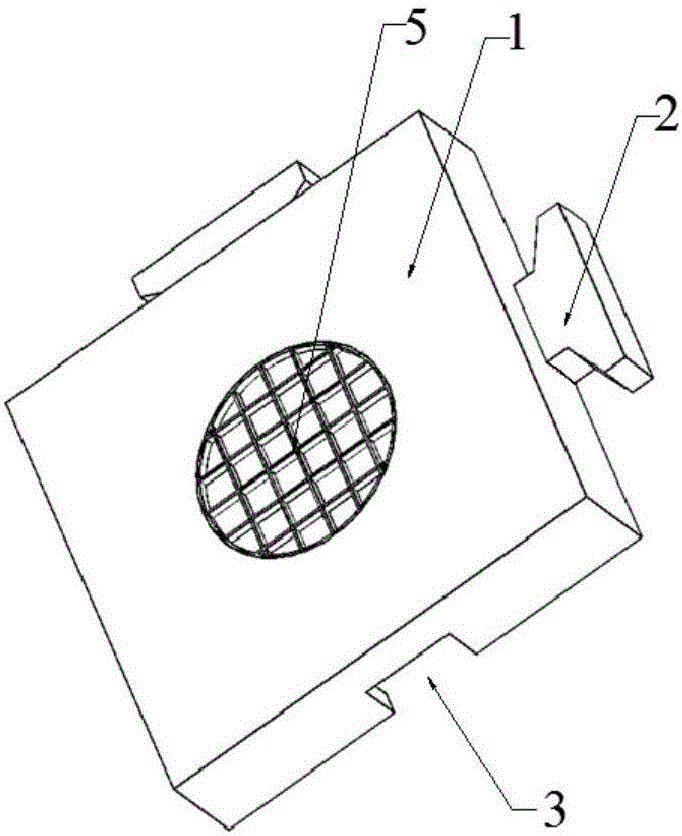

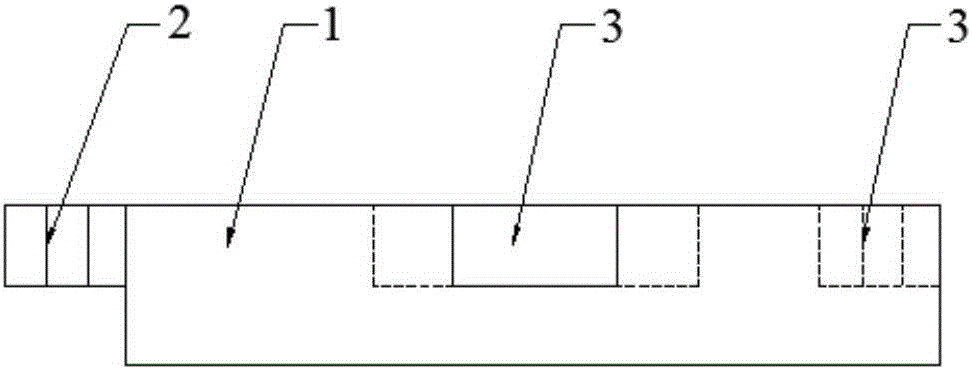

Slender hole glass-sealing multi-pin electrical connector and preparation method of slender hole glass-sealing multi-pin electrical connector

ActiveCN105449420AConsistent sizeGood shape and size consistencyContact member cases/bases manufactureSecuring/insulating coupling contact membersElectrical conductorEngineering

The invention discloses a slender hole glass-sealing multi-pin electrical connector and a preparation method of the slender hole glass-sealing multi-pin electrical connector. The slender hole glass-sealing multi-pin electrical connector comprises a metal housing, wherein a plurality of sealing holes are axially formed in the metal housing; conductor pins are assembled in the sealing holes; glass insulators are clamped between the conductor pins and the sealing hole walls of the metal housing; and epoxy curing layers are sealed at two ends in each sealing hole of the metal housing. The glass insulators are fabricated by a vitreous molten high-pressure tubing technology; sintering is carried out by a mesh-belt high-temperature sintering furnace; fractional potting and curing are carried out in grooves in two ends of the sealing holes of the electrical connector by a high-temperature resistant high-insulation epoxy adhesive, so as to form a compact protection layer; and the glass insulators are prevented from being polluted by external impurities. By the slender glass insulators, glass tubes are consistent in size, smooth in surface and good in boundary dimension; the problems of shrinkage and internal bubbles after a plurality of glass beads are superposed are solved; and two ends are sealed through the epoxy curing layers, so that high air-tightness, high loading capacity and high insulating property are achieved.

Owner:XIAN SEAL ELECTRONICS MATERIAL TECH CO LTD

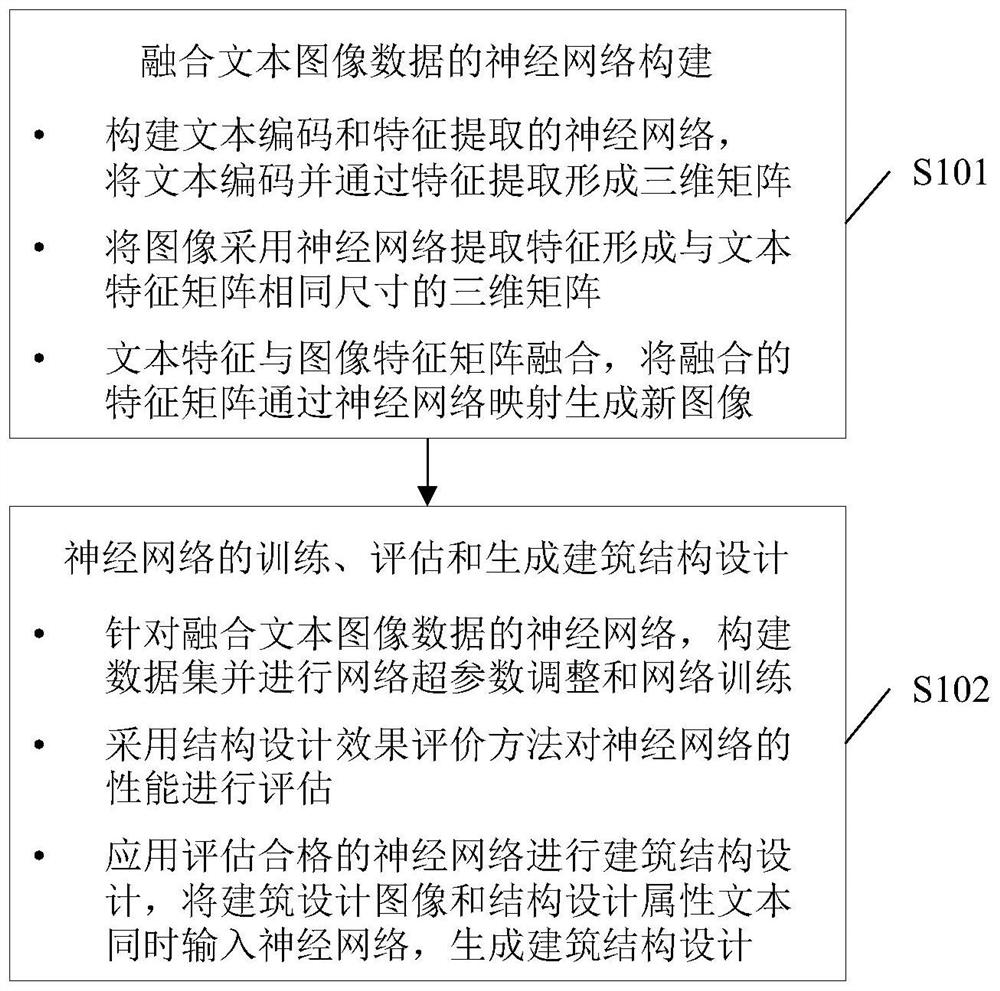

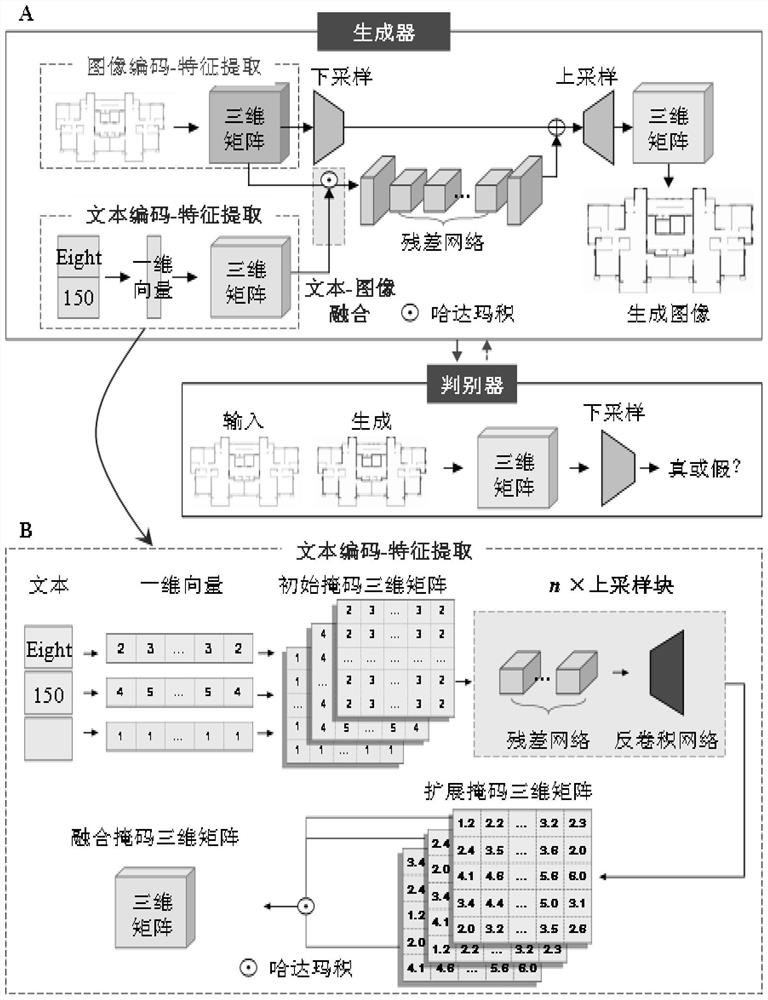

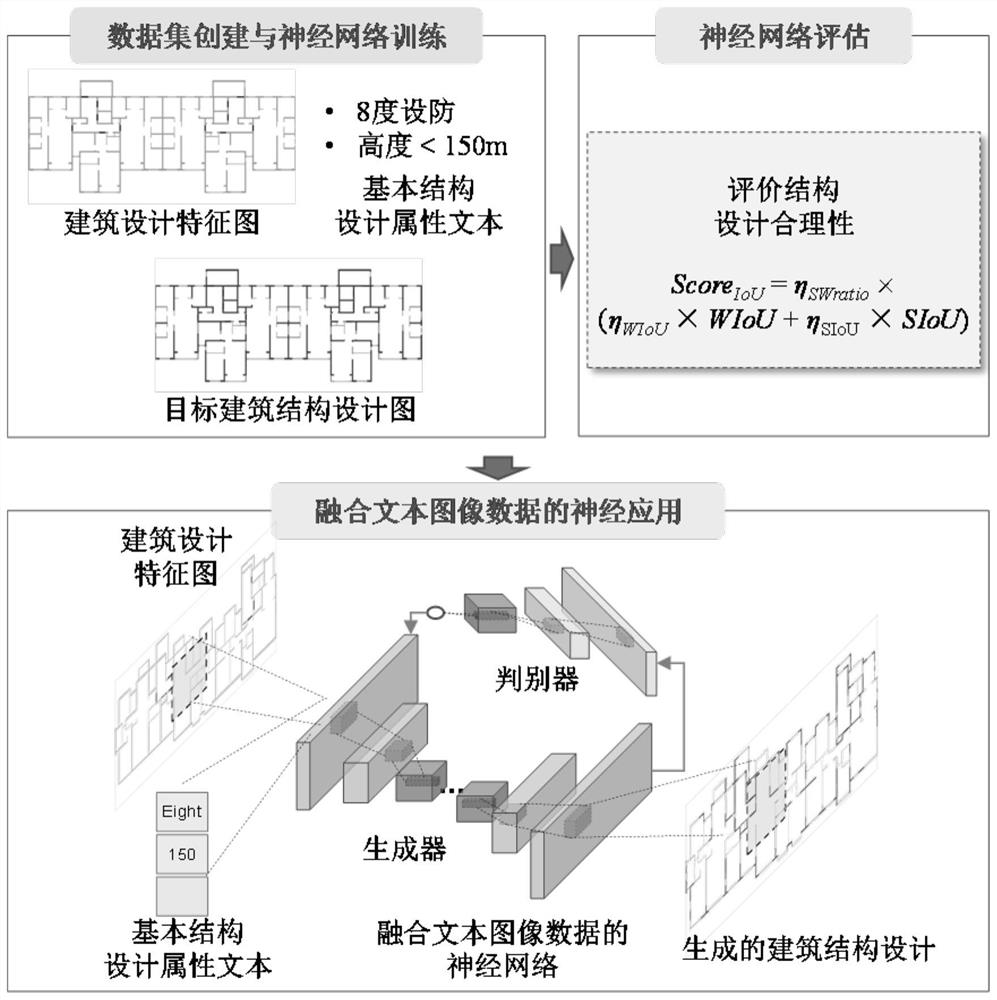

Neural network fusing text and image data and design method of building structure of neural network

ActiveCN112966760AConsistent sizeAutomate building structure designCharacter and pattern recognitionNeural architecturesBuilding designImaging Feature

The invention belongs to the technical field of civil structure engineering and computer deep learning application, and particularly relates to a neural network fusing text and image data and a design method of a building structure of the neural network. A generator in the neural network for fusing the text and the image data generates an image, a discriminator judges the authenticity of the image, the generator comprises a text code and a feature extraction network to obtain a text feature matrix, the text feature matrix and the image feature matrix are fused, and an image network is generated based on fused features. And according to the language description text of the to-be-designed building structure and the pixelated image of the building feature element, the neural network fusing the text and the image data is adopted to complete the design of the building structure. According to the method, the corresponding structural design is quickly output according to the building design image and the structural basic design attribute text, and the automatic building structural design under the guidance of image and text multi-modal data fusion is realized.

Owner:TSINGHUA UNIV

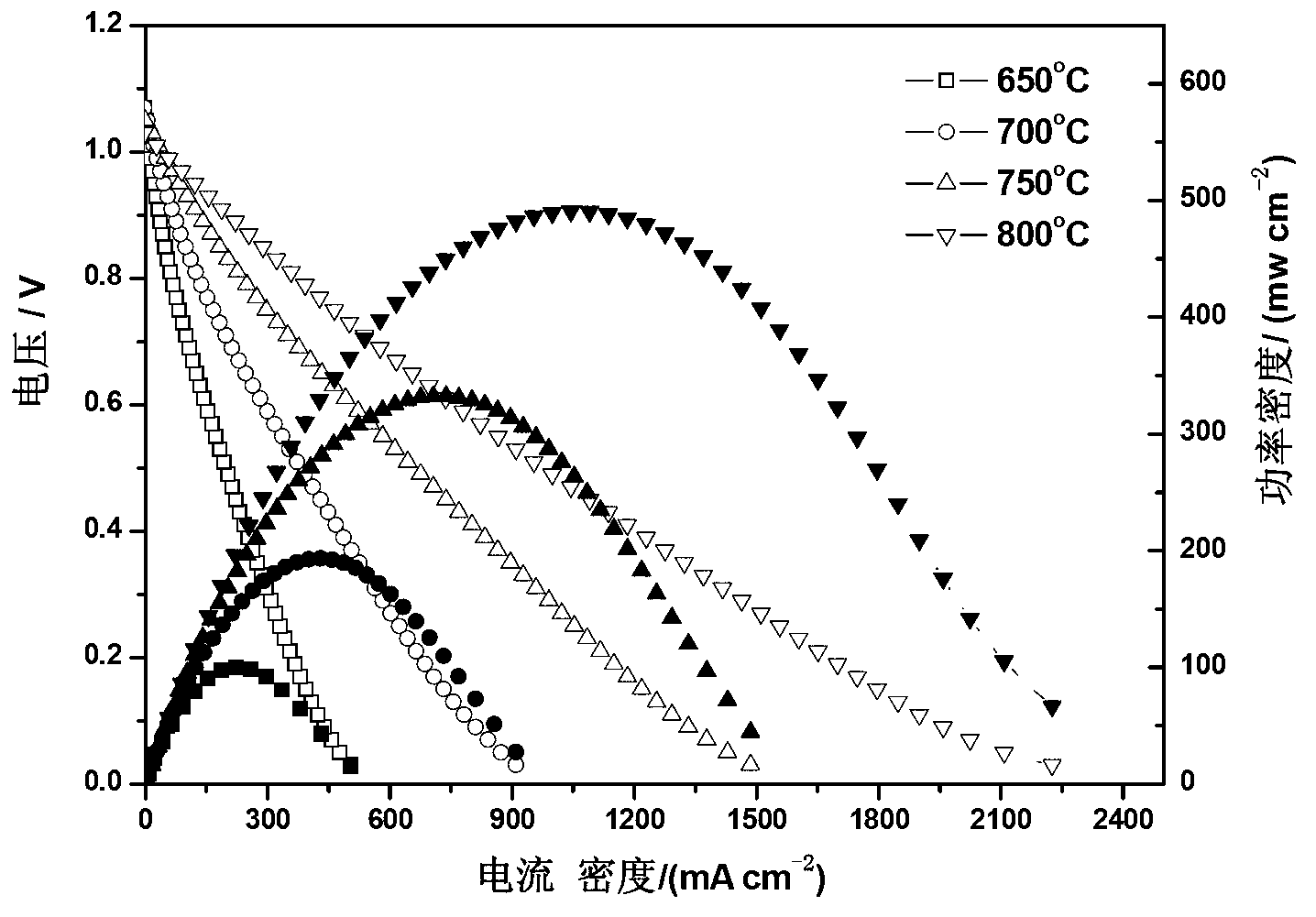

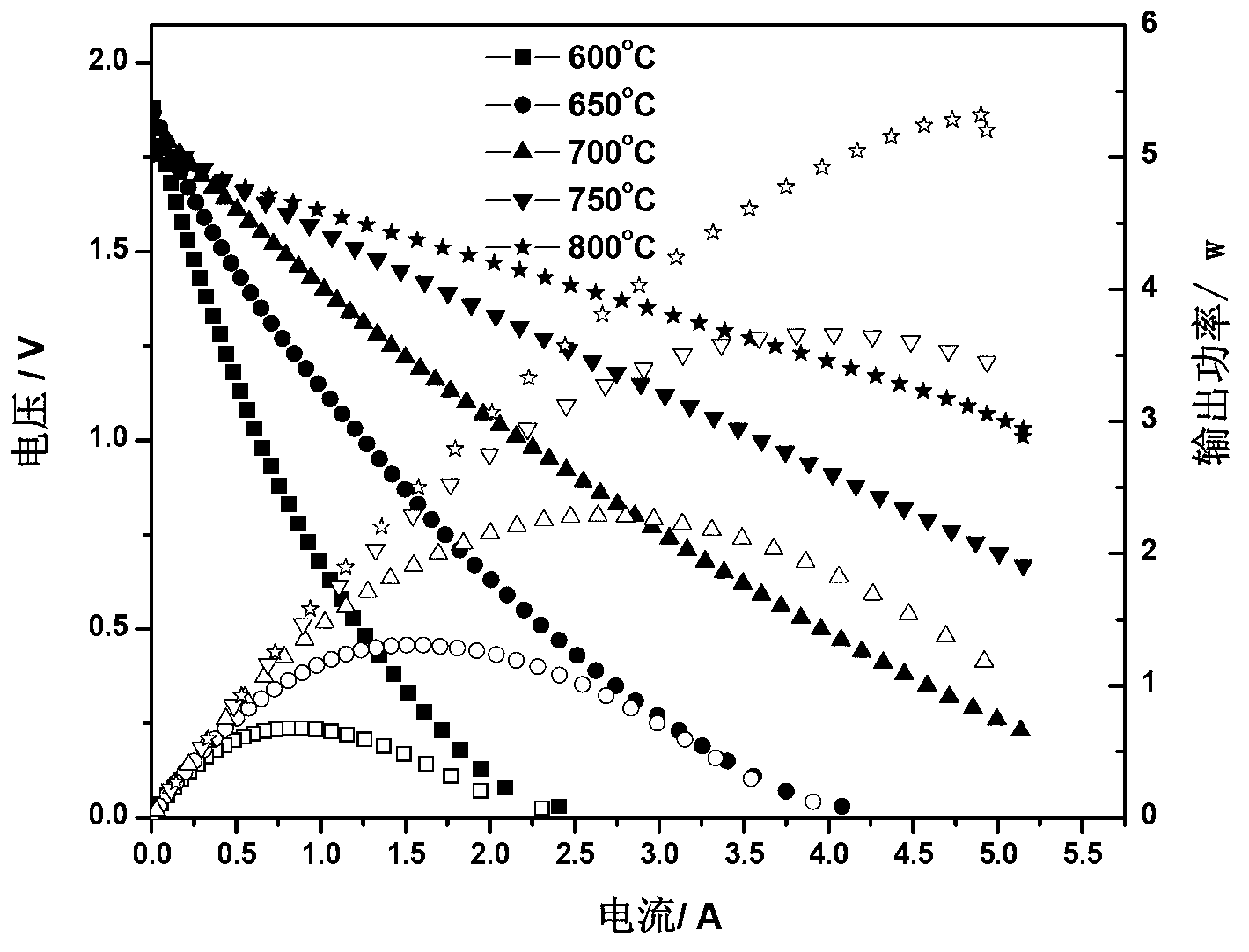

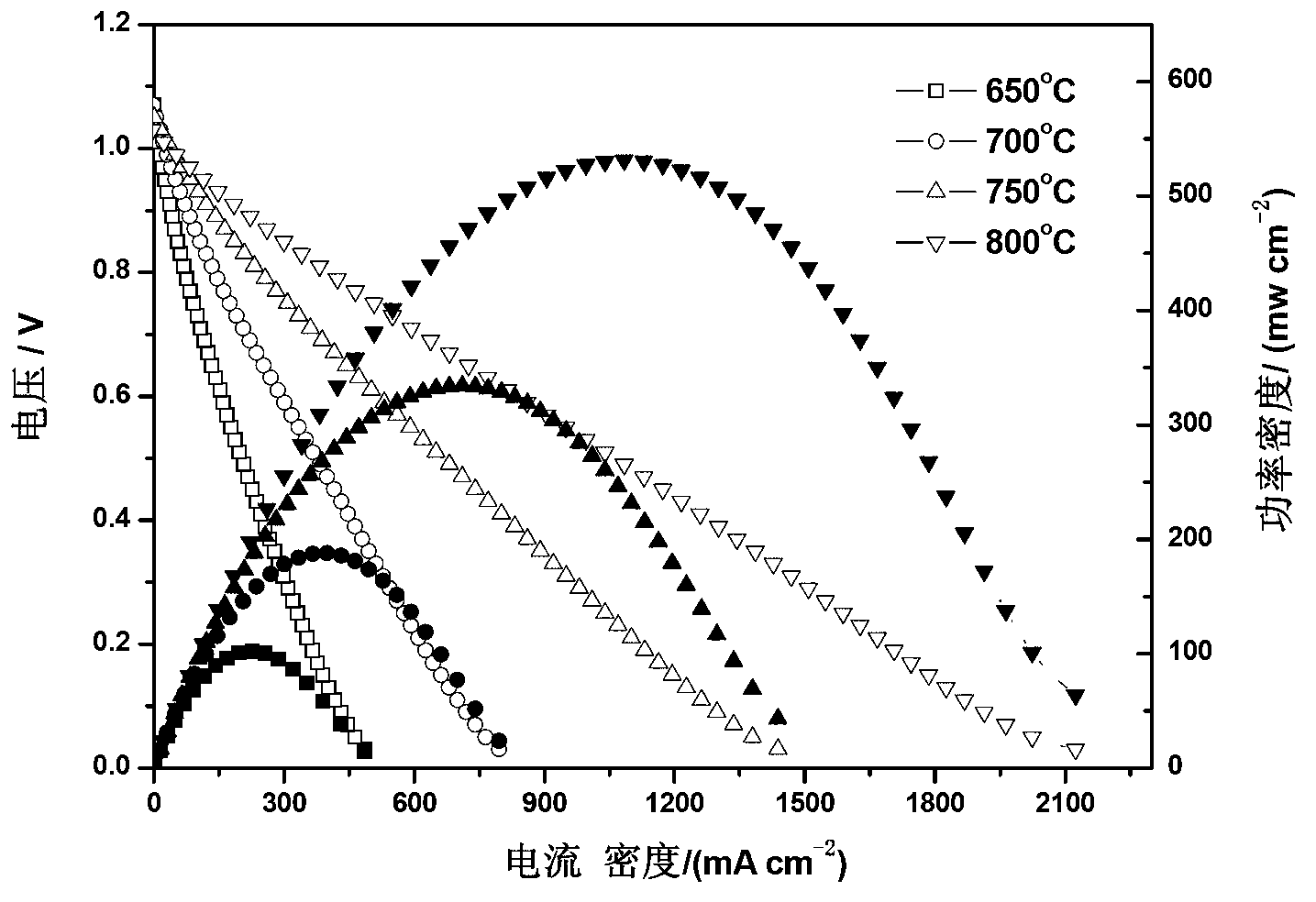

Preparation method of multihole anode support of solid oxide fuel cell

InactiveCN103236548AHigh green strengthHigh dimensional accuracyCell electrodesFinal product manufactureFuel cellsDie casting

The invention discloses a preparation method of a multihole anode support of a solid oxide fuel cell. The preparation method comprises the following steps of: (1) pretreating ceramic powder, (2) preparing slurry, (3) conducting hot die-cast formation, (4) burying, burning, dewaxing and sintering, and (5) preparing an anode functional layer. The preparation method can be used for preparing the multihole anode support in a complicated shape, avoids the problem that uniformly mixed slurry of two powders is difficult to prepare, has the advantages of fast forming, easiness and simplicity in operation, low production cost and high labor productivity, and can realize mass production.

Owner:SOUTH CHINA UNIV OF TECH

Chromatography medium

ActiveUS9802979B2Reduce disruptionEasily replaceMaterial nanotechnologyCation exchanger materialsChromatography columnChemistry

The present invention provides a chromatography medium comprising one or more electrospun polymer nanofibers which form a stationary phase comprising a plurality of pores through which a mobile phase can permeate and use of the same in chromatography, such as the isolation of recombinant proteins, monoclonal antibodies, viral vaccines and plasmid DNA. The invention further provides for the use of the chromatographic medium in a simulated moving bed system.

Owner:PURIDIFY

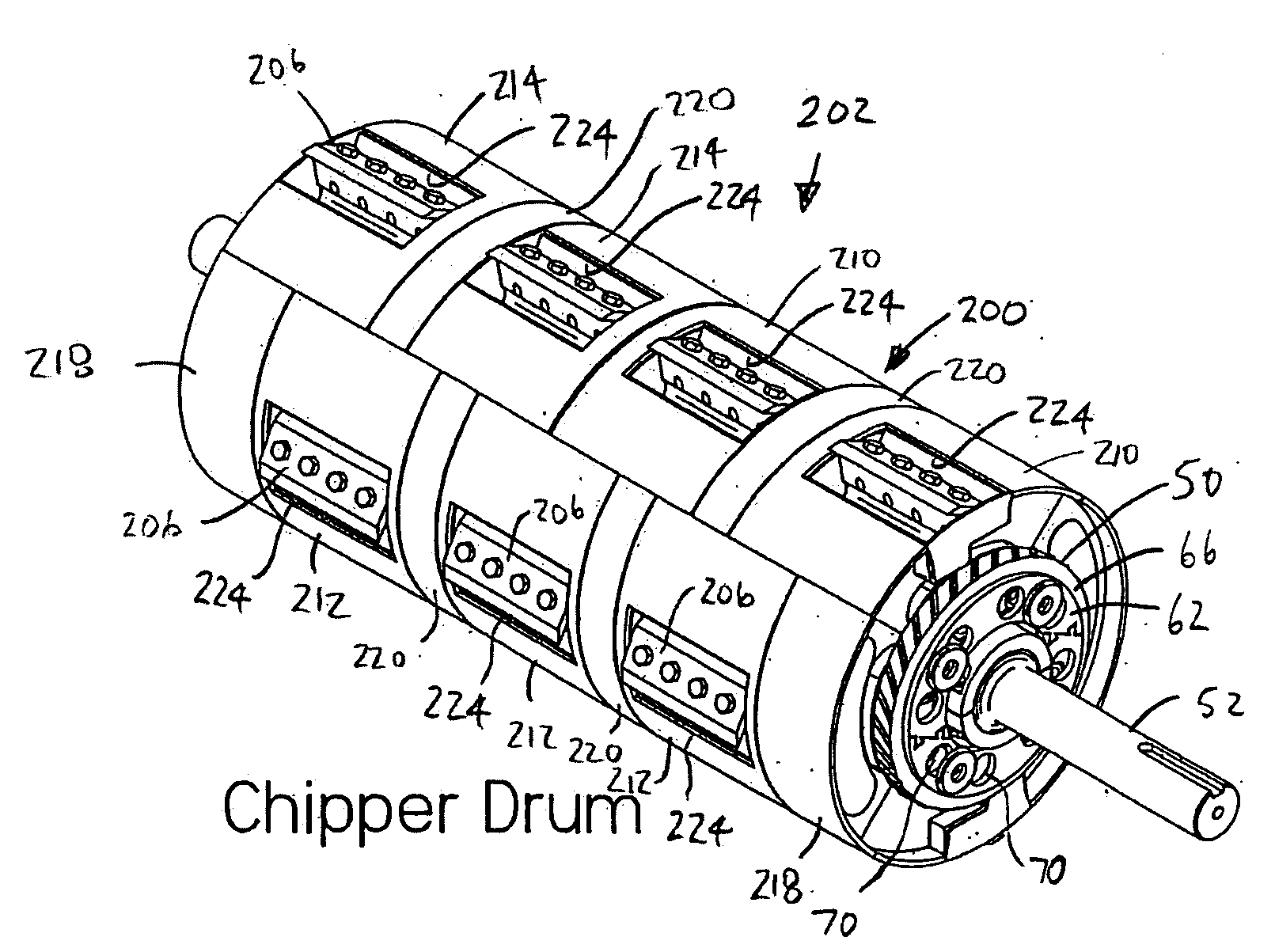

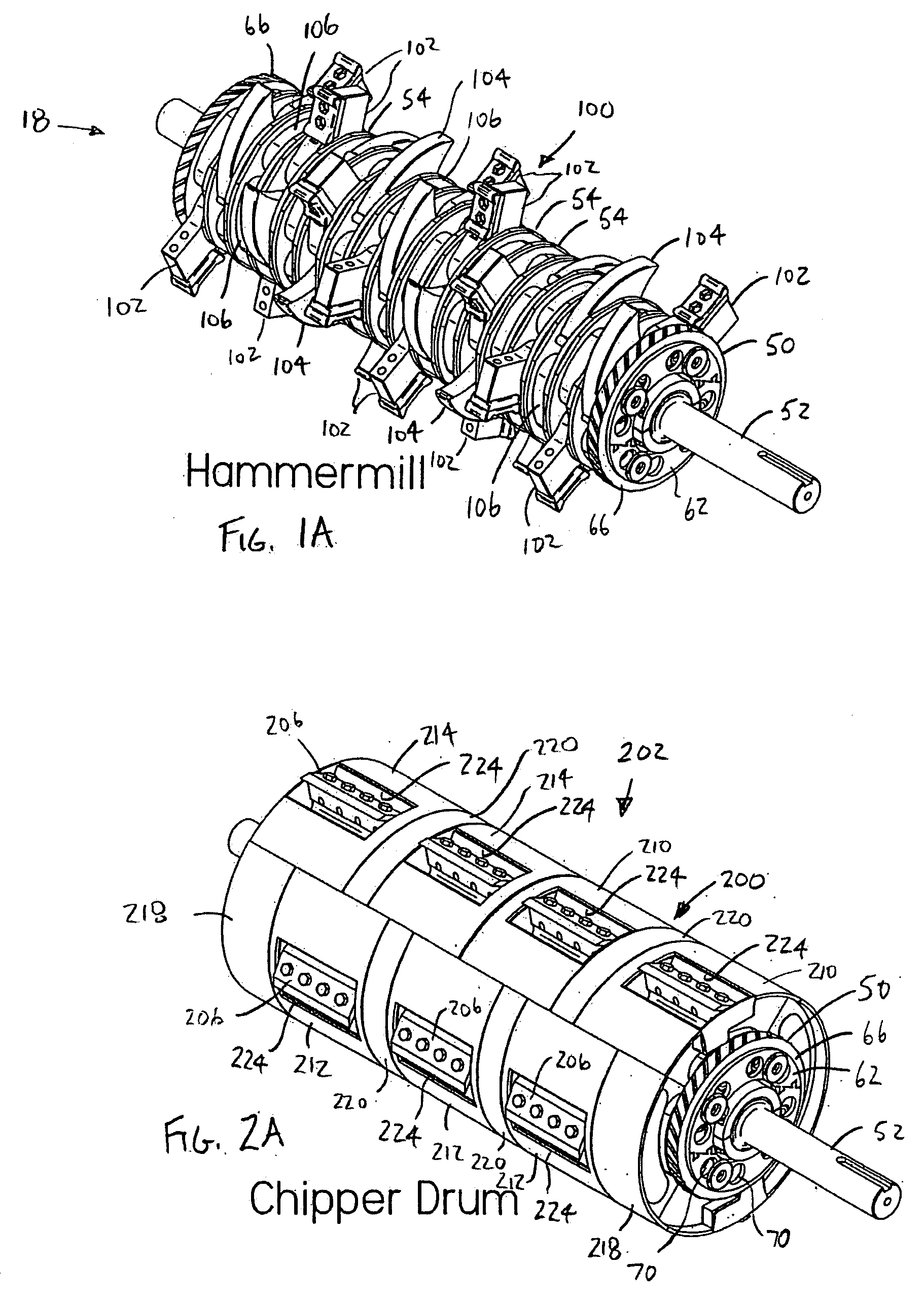

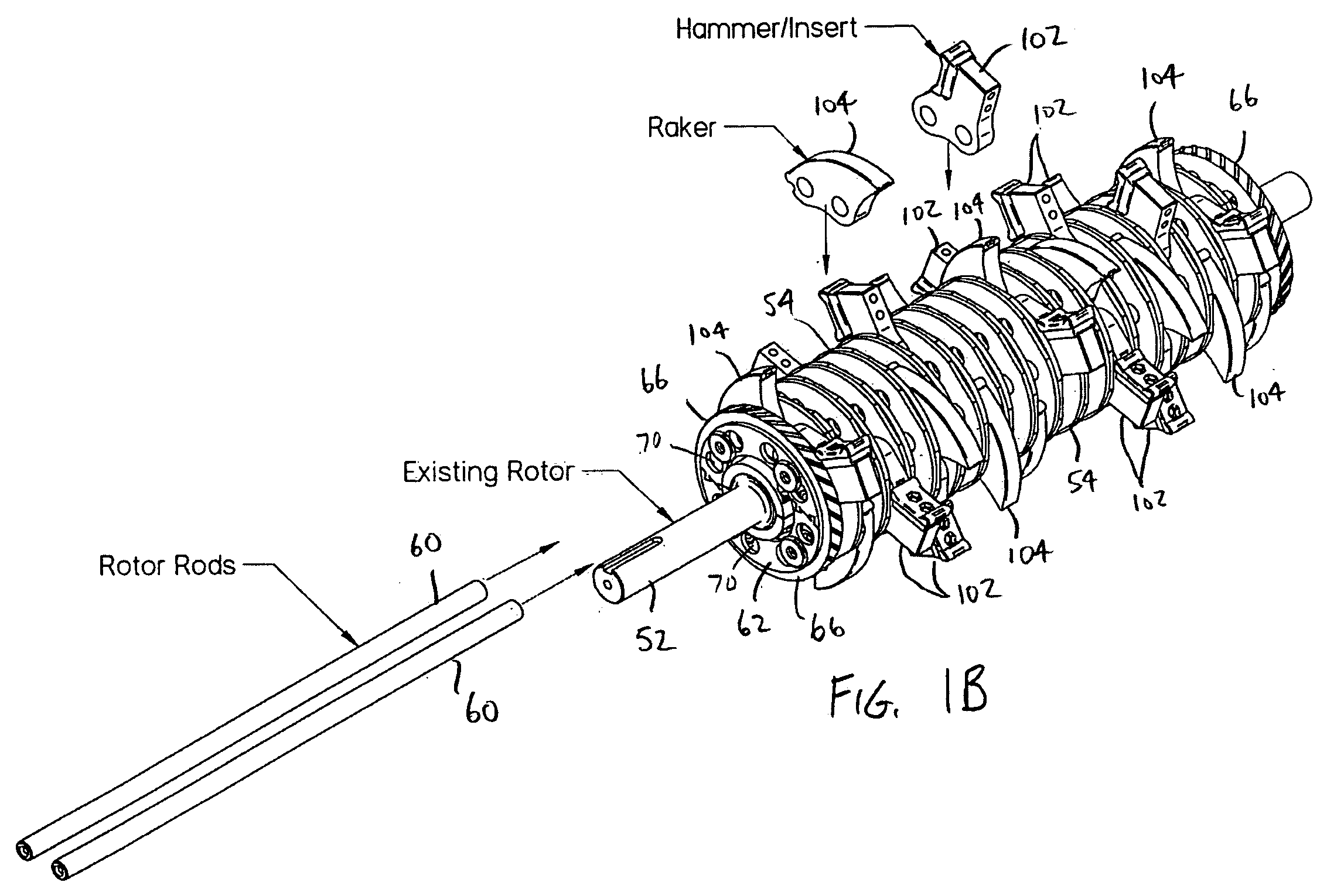

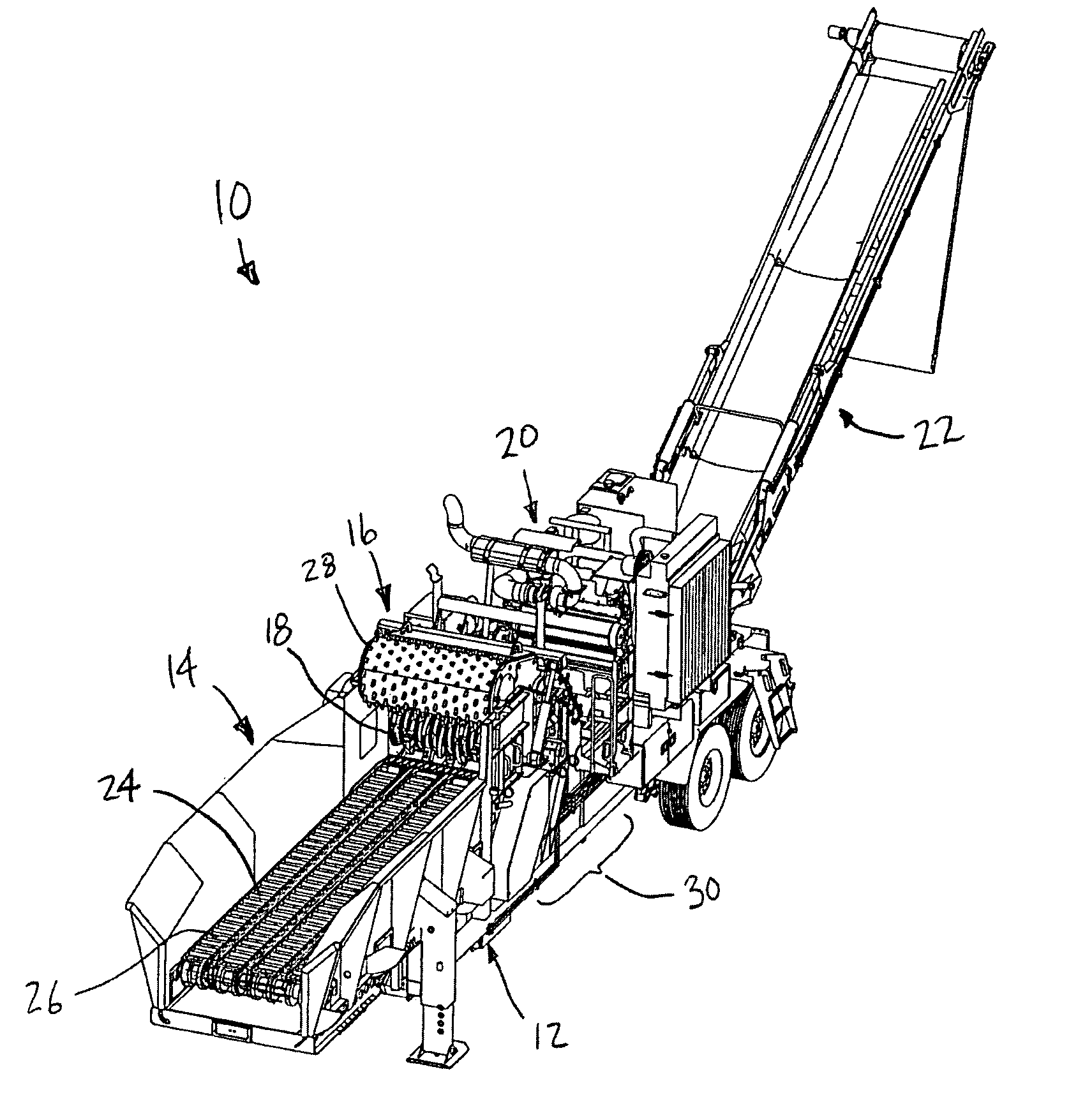

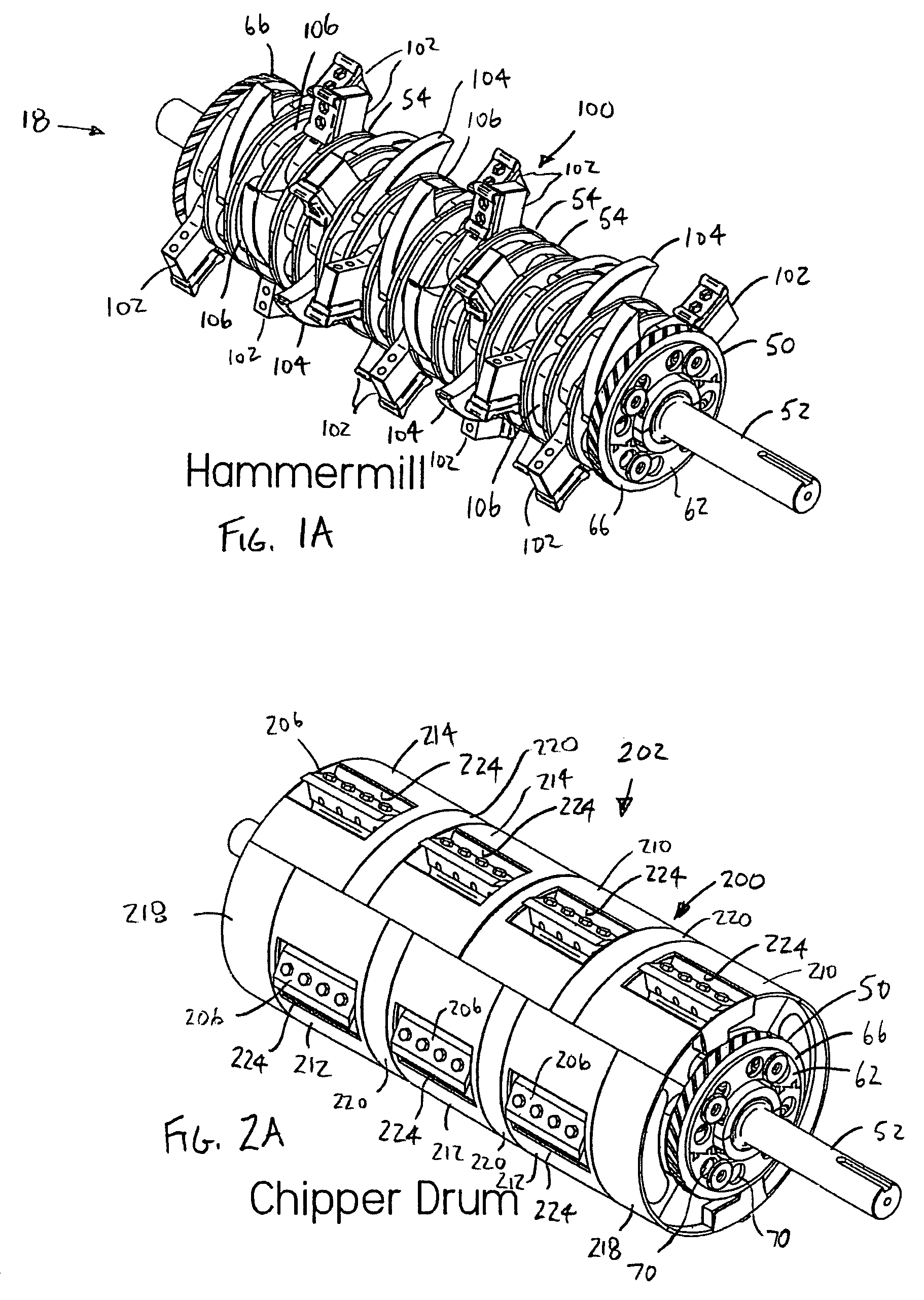

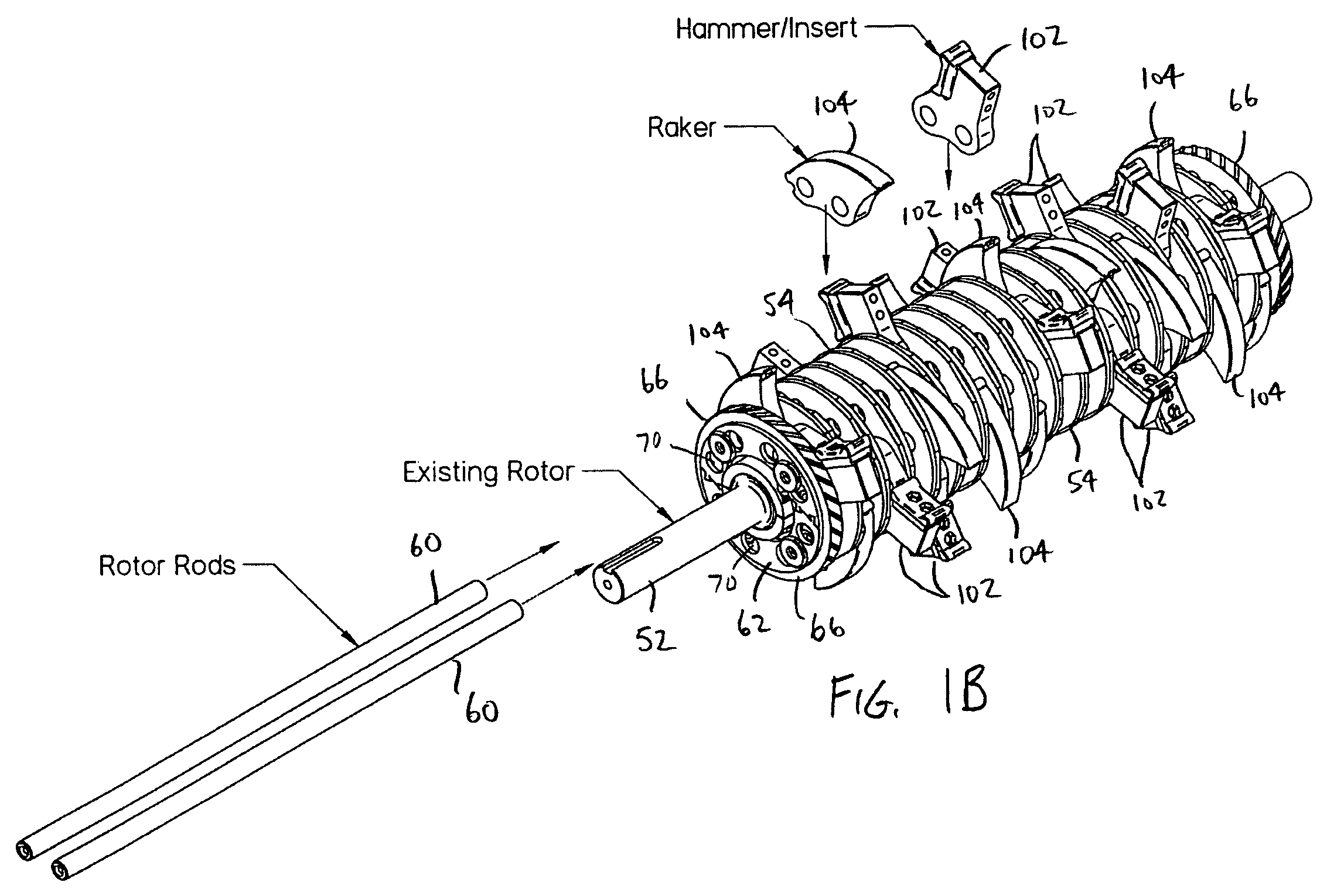

Interchangable chipper inserts for wood grinder

ActiveUS20100206973A1Facilitate quick and easy reversing and replacementEasy to installMetal sawing devicesShearing machinesWood grinderKnife blades

A plurality of chipper inserts that may be installed on a hammermill rotor in place of the hammer inserts to selectively convert the rotor to a chipper. The chipper inserts include drum surfaces that cooperatively define a chipper drum. The chipper inserts may include cutter inserts that have a cutter disposed in a cutter pocket. The chipper drum may be a generally continuous cylindrical interrupted essentially only by the cutter pockets. The cutters and cutter pockets may be positioned in essentially any desired pattern around the drum. The chipper inserts may include a left cutter insert, a center cutter insert, a right cutter insert and three different size spacer inserts. The different types of cutter inserts and spacer inserts may be installed about the rotor with at least one left cutter insert mounted on the left end of the chipper drum and at least one right cutter insert mounted on the right end of the chipper drum. The chipper inserts may be configured in quadrant sections, such that it takes four inserts to extend around the rotor.

Owner:ALAMO GROUP

Interchangable chipper inserts for wood grinder

ActiveUS8061640B2Facilitate quick and easy reversing and replacementEasy to installMetal sawing devicesShearing machinesWood grinderEngineering

Owner:ALAMO GROUP

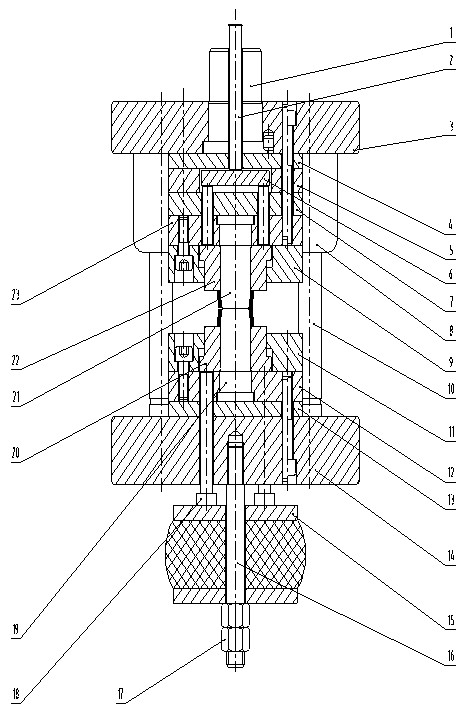

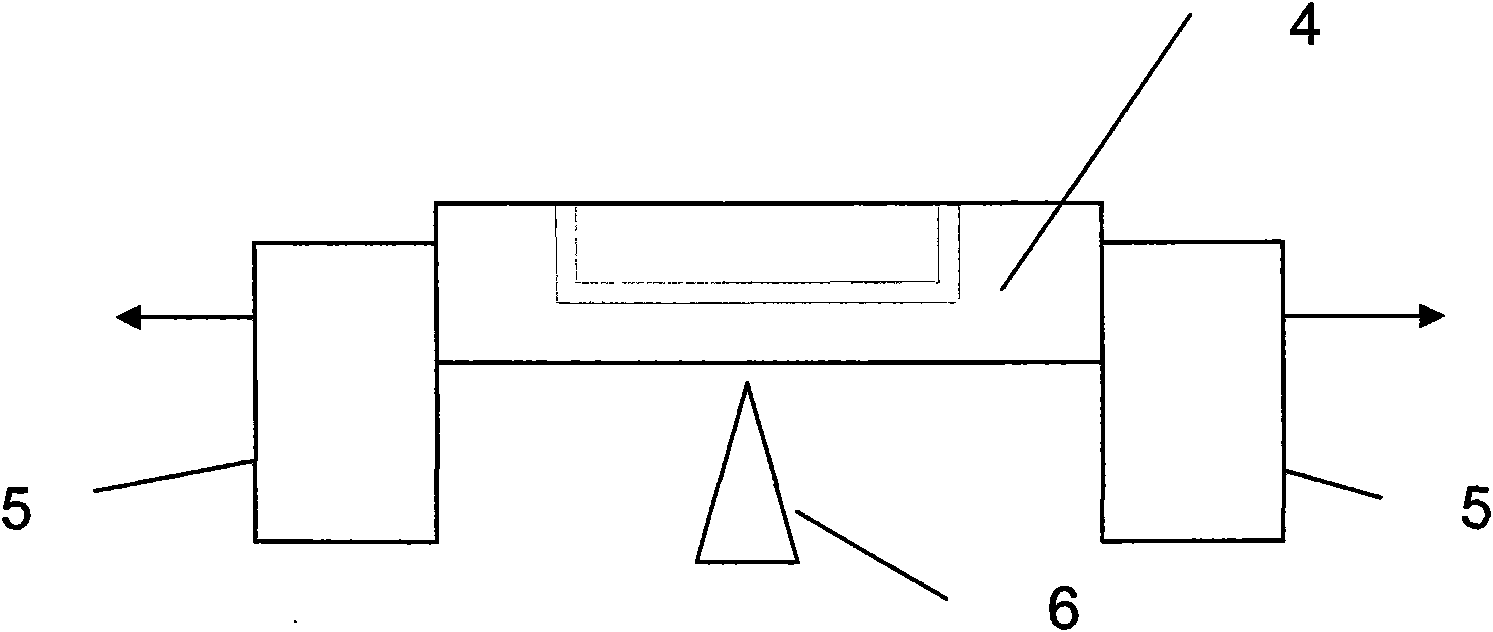

Mould for tubing material forming

The invention discloses a mould for tubing material forming, comprising an upper mould part, a lower mould part and a guide part, wherein the upper mould part comprises a mould handle, a knocking rod, an upper mould seat, an upper cushion plate, an upper cover plate, an upper convex mould, an upper top block and an upper fixed plate; the upper top block is sleeved in the upper cover plate; the upper convex mould passes through the upper top block; the top of the upper convex mould is in contact with the upper cushion plate; the upper convex mould is in sliding fit with the upper top block; the lower mould part comprises a lower cover plate, a lower fixed plate, a lower cushion plate, a lower mould seat, a lower convex mould and a lower top block; the lower top block is sleeved in the lower cover plate; the lower convex mould passes through the lower top block; the bottom of the lower convex mould is in contact with the lower cushion plate; the lower convex mould is in sliding fit with the lower top block; the guide part comprises a guide sleeve and a guide column; the guide sleeve penetrates in the upper mould seat; and the guide column penetrates in the lower mould seat. The mould uses the upper and lower convex moulds to press parts, so that the tubing materials are deformed to necessary shapes; the lengths of products are controlled by the upper and lower top blocks, the sizes of the two ends of each product are ensured to be consistent, the quality requirements of products are ensured, and the material pushing operation is convenient.

Owner:隆昌山川机械有限责任公司

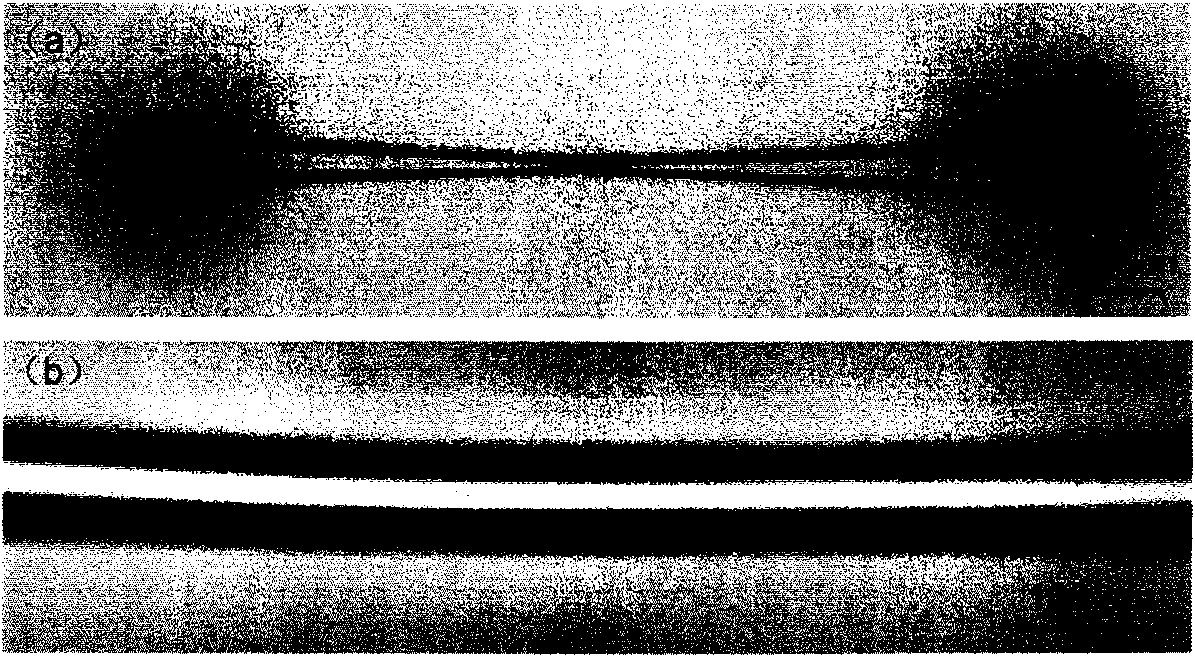

Method for preparing uniform three dimensional nanometer fluid passage by femto-second laser

InactiveCN101549852AUniform longitudinal shapeImprove taperNanostructure manufactureFemto second laserCompound (substance)

A method for preparing uniform three dimensional nanometer fluid passage by femto-second laser comprises the steps of irradiating transparent material by femto-second laser, chemical attacking and hot drawing. the three dimensional nanometer fluid passage prepared by the method in the invention achieves the advantages of uniform longitudinal appearance, good roundness of passage cross section, high smoothness of the passage inner wall and small passage inner diameter to nanometer scale.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

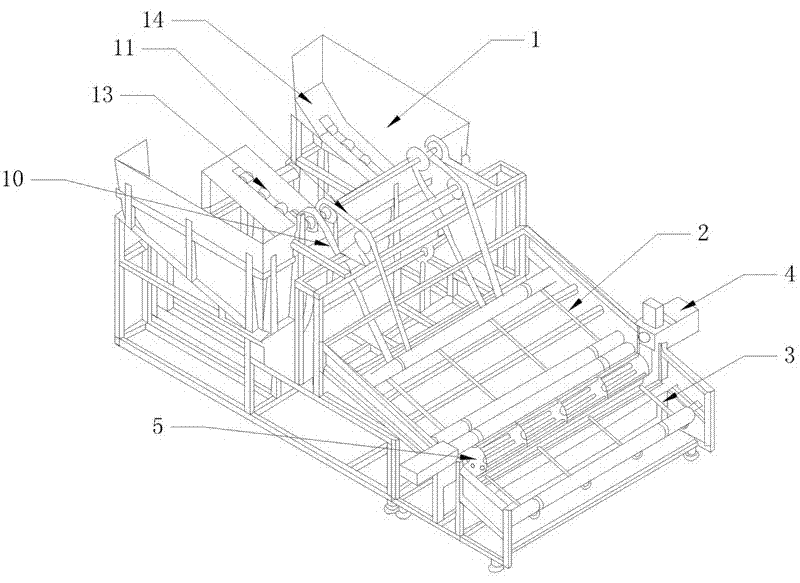

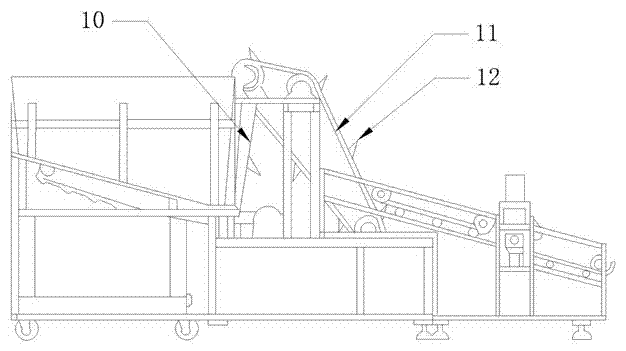

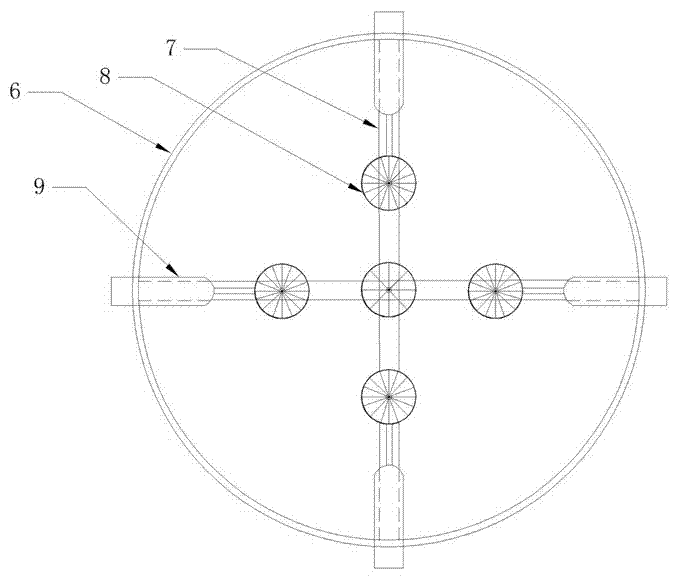

Full-automatic bamboo classifying, breaking and collecting equipment line

ActiveCN107098117APrevent severe unevennessConsistent sizeConveyorsBio-packagingImage detectionEngineering

The invention discloses a full-automatic bamboo classifying, breaking and collecting equipment line. The full-automatic bamboo classifying, breaking and collecting equipment line comprises a bamboo tube feeding device, a bamboo breaking device and a classification collecting device for bamboo chips; the bamboo tube feeding device comprises a feeding frame, a conveying chain set and a detection assembly; the conveying chain set conveys bamboo tubes in the feeding frame to the detection assembly, and the detection assembly comprises a feeding inclined rod, a discharging inclined rod, a rotating clamping ring and an image detection system; the feeding inclined rod and the discharging inclined rod are arranged above and below the rotating clamping ring respectively; the image detection system is arranged at one end of the rotating clamping ring and is connected to a PLC; bamboo breaking knives are connected to hydraulic oil cylinders or air cylinders, and the hydraulic oil cylinders or the air cylinders are fixedly arranged on a circumferential frame or guide rails; and the hydraulic oil cylinders or the air cylinders connected to the bamboo breaking knives are all connected to the PLC. According to the full-automatic bamboo classifying, breaking and collecting device, the diameter and the thickness of the bamboo tubes can be automatically detected, in addition, the different bamboo breaking knives can be selected to break the bamboo tubes with different diameters, and therefore the size of the broken bamboo chips can be ensured to be consistent, and the bamboo chips with different thicknesses can be placed into different collecting boxes.

Owner:益阳竟宁竹业机器人有限公司

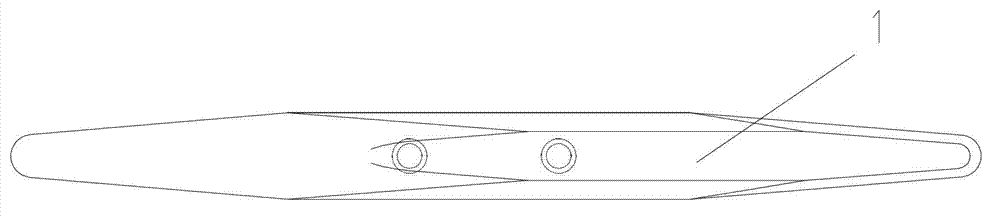

Processing method of nonmetal special-shaped rudder sheet and clamp for processing

InactiveCN102873383AGuaranteed dimensional accuracyGuaranteed surface roughnessMilling equipment detailsPositioning apparatusAbnormal shapedRudder

The invention discloses a processing method of a nonmetal special-shaped rudder sheet and a clamp for processing. The processing method comprises the following steps: 1) designing a nonmetal rudder sheet flat blank according to a product maximum profile dimension; 2) vertically clamping the nonmetal rudder sheet flat blank, symmetrically grinding the two reference surfaces of the nonmetal rudder sheet flat blank; 3) performing rough milling of the profile of the nonmetal rudder sheet flat blank, processing a process chuck for subsequent clamping at a position of a rudderpost; 4) vertically clamping the process chuck, aligning the central planes of the two reference surfaces, performing semi-finish milling of the reference surfaces of the nonmetal rudder sheet flat blank, then performing finish milling one surface to obtain the designed dimension so as to form the rudder sheet; 5) vertically clamping the rudder sheet, performing semi-finish milling of the process chuck to obtain a rudderpost shape; 6) performing finish milling of the rudderpost to obtain the designed dimension so as to finish the processing of the nonmetal special-shaped rudder sheet. With the processing method of the nonmetal special-shaped rudder sheet and the clamp for processing, the processing precision and the form and location tolerance of the nonmetal special-shaped rudder sheet can be effectively ensured.

Owner:湖北三江航天江北机械工程有限公司

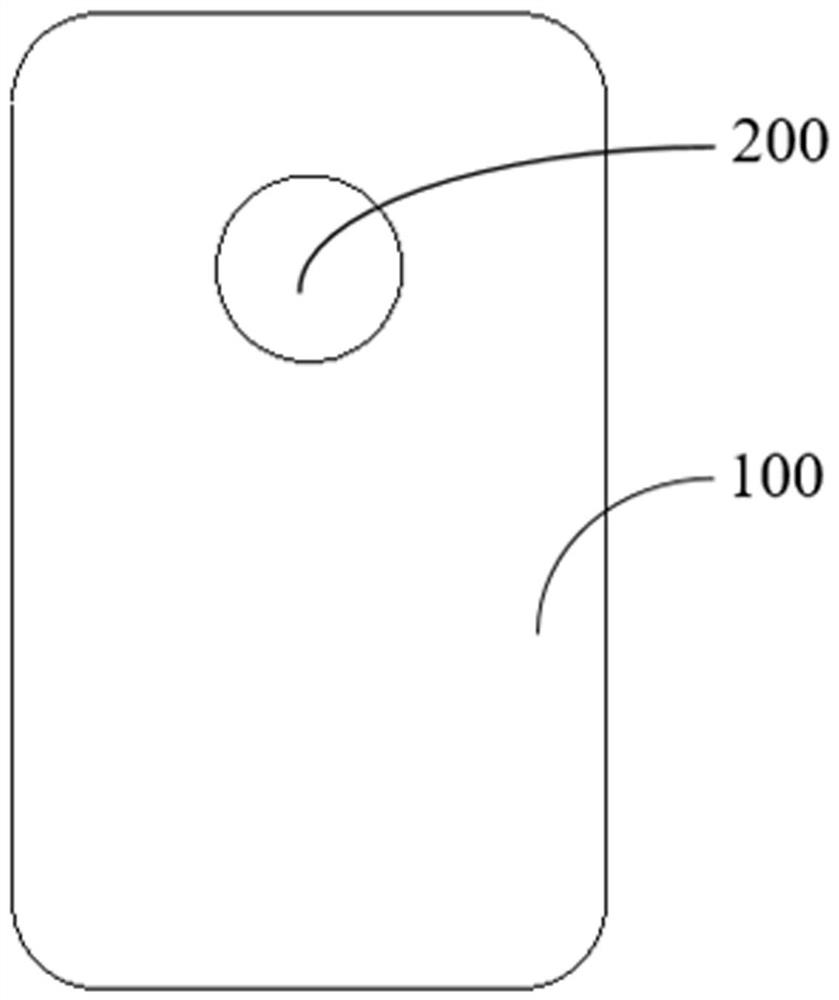

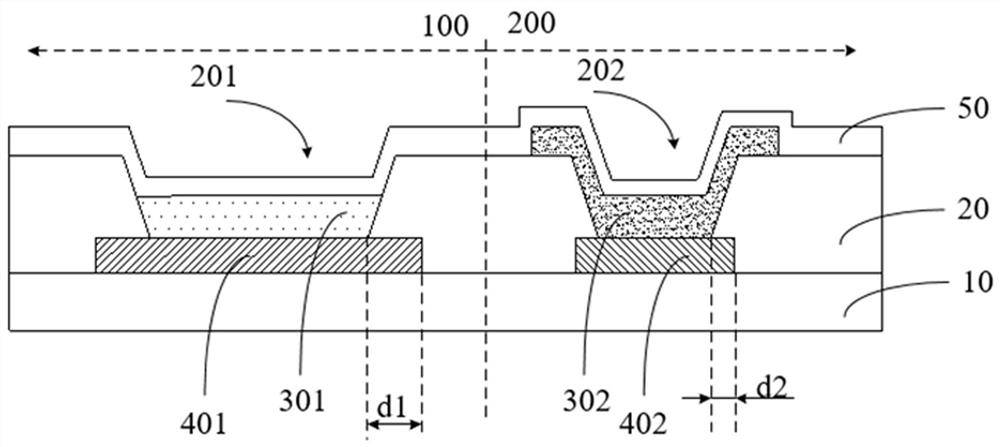

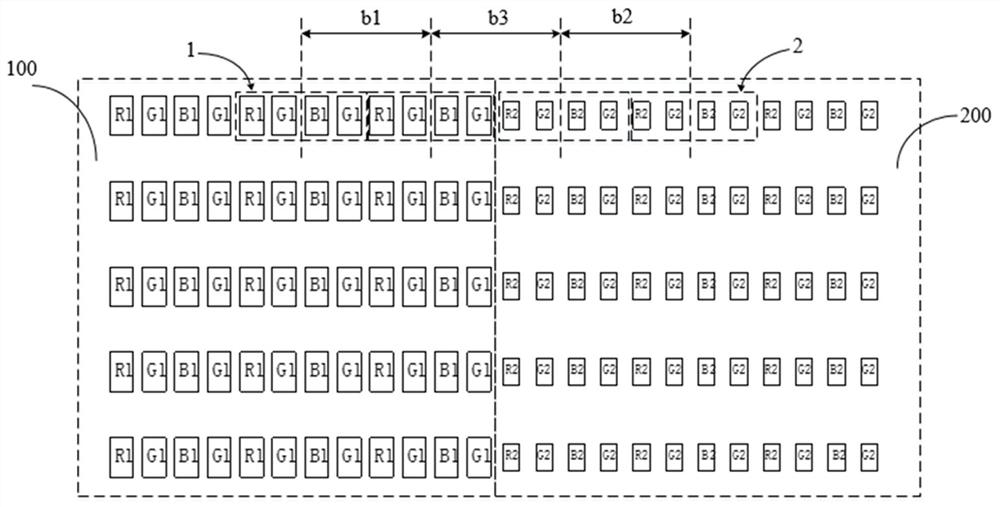

Display panel and display device

ActiveCN112072000AConsistent sizeNo reduction in PPISolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMechanical engineering

The invention provides a display panel and a display device, the display panel is provided with a main display area and at least one display light-transmitting area, the main display area defines a plurality of first pixel openings, and a first light-emitting layer is arranged on the first pixel openings; a plurality of second pixel openings are defined in the display light-transmitting area, andsecond light-emitting layers are arranged on the second pixel openings; the size of each first pixel opening is larger than that of one second pixel opening, the ratio of the orthographic projection area of the first light-emitting layer on the substrate to the orthographic projection area of the second light-emitting layer on the substrate ranges from 95% to 105%, and only the size of the secondpixel opening of the display light-transmitting area is reduced, but PPI of the display light-transmitting area is not reduced. The display effect of the display light-transmitting area is favorably improved; the design of the mask plate adopted by the display light-transmitting area is kept consistent with the design of the mask plate adopted by the main display area, a mask plate stretching netdoes not need to be modified, a mask plate does not need to be specially designed for the display light-transmitting area additionally, the manufacturing procedure is saved, the process cost is reduced, and the production efficiency is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Ecological interlocking slope protection vegetation brick and preparation method thereof

InactiveCN106759108AStrong resistance to cracking and overturningImprove overall stabilityCoastlines protectionCeramic shaping mandrelsEngineeringVegetation

The invention relates to an ecological interlocking slope protection vegetation brick and a preparation method thereof. The vegetation brick comprises a block body and a vegetation disk, the block body comprises a center portion, a mounting clamp block, a mounting clamp groove, the center portion is provided with a center hole, the vegetation disk is arranged in the center hole, the upper surface of the vegetation disk is lower than that of the center portion, the center portion is provided with a front side surface, a rear side surface, a left side surface and the right side surface in the vertical direction, the mounting clamp block is positioned on the front side surface and left side surface and extends to the direction far wary from the center portion, the mounting clamp groove is respectively recessed to the center direction of the center portion from the rear side surface and the right side surface of the center portion, thickness of the mounting clamp block and the depth of the mounting clamp groove are equal and smaller than the thickness of the center portion, and the mounting clamp block and the mounting clamp groove on the adjacent slope protection vegetation bricks are mutually meshed, so that all-directional interlocking is achieved. Bricks are paved without mortar concrete in interlocking and self-embedding manner, and the vegetation brick is simple and easy to operate, low in construction cost, high in construction efficiency and applicable to slope strengthening and ecological restoration.

Owner:CHONGQING UNIV

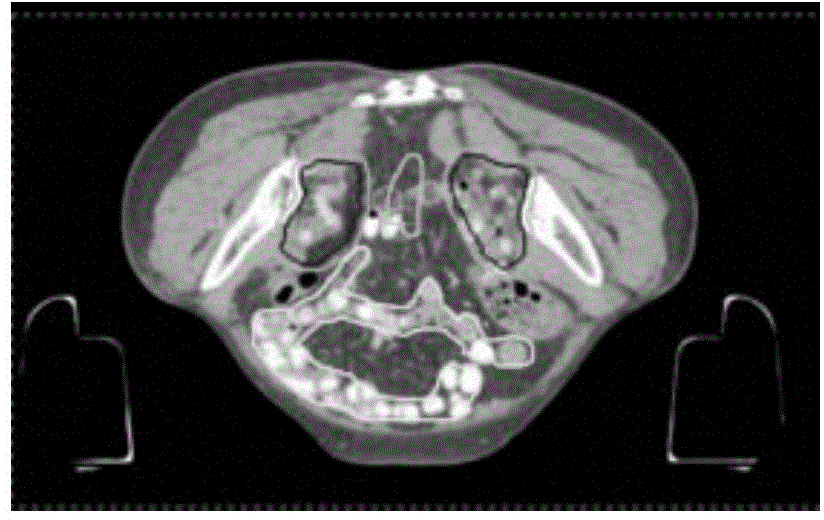

Verification method for ensuring accurate operation of intensity modulated radiation therapy

InactiveCN104888355AHigh precisionImprove accuracyRadiation therapyDose verificationElectronic density

The invention relates to a verification method for ensuring accurate operation of intensity modulated radiation therapy (IMRT). The method comprises the following steps: designing a plan, printing the model of a patient by using a 3D printing technology, scanning the model under the same positioning condition and scanning condition, transmitting the scanned model to a TPS (Therapy Planning System), calling an IMRT therapy plan to be verified, completely copying relevant therapy data of the plan to the model, placing the model on an accelerator therapy bed, adjusting the measurement points of the model to isocenter positions by means of laser rays, and performing absolute dose verification and relative dose verification. The method has the advantages: the verification model is prepared by adopting the 3D printing technology, and the model is completely consistent with the patient in size, physical density and electronic density, so that the precision and the accuracy of the absolute dose verification and the relative dose verification are improved.

Owner:倪昕晔

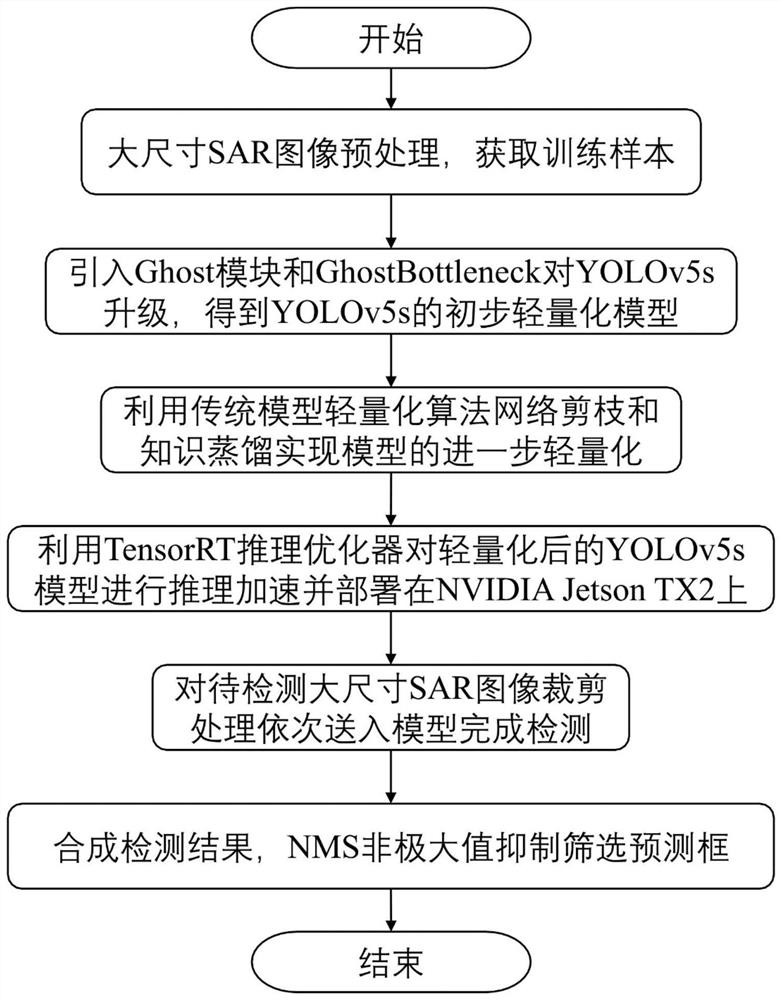

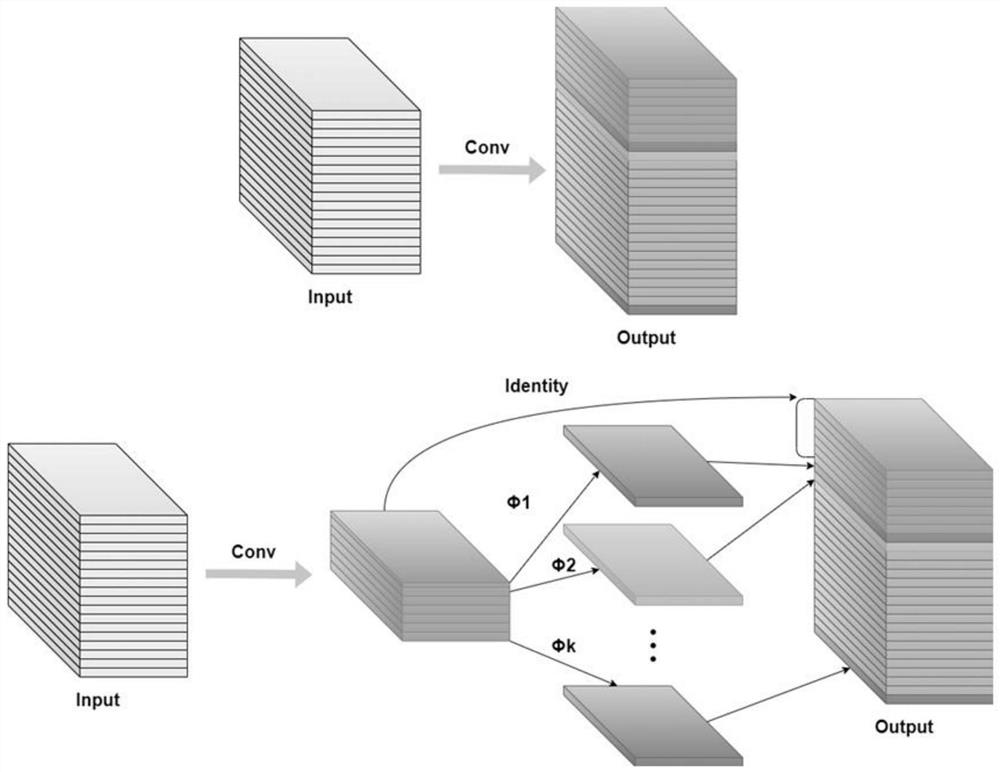

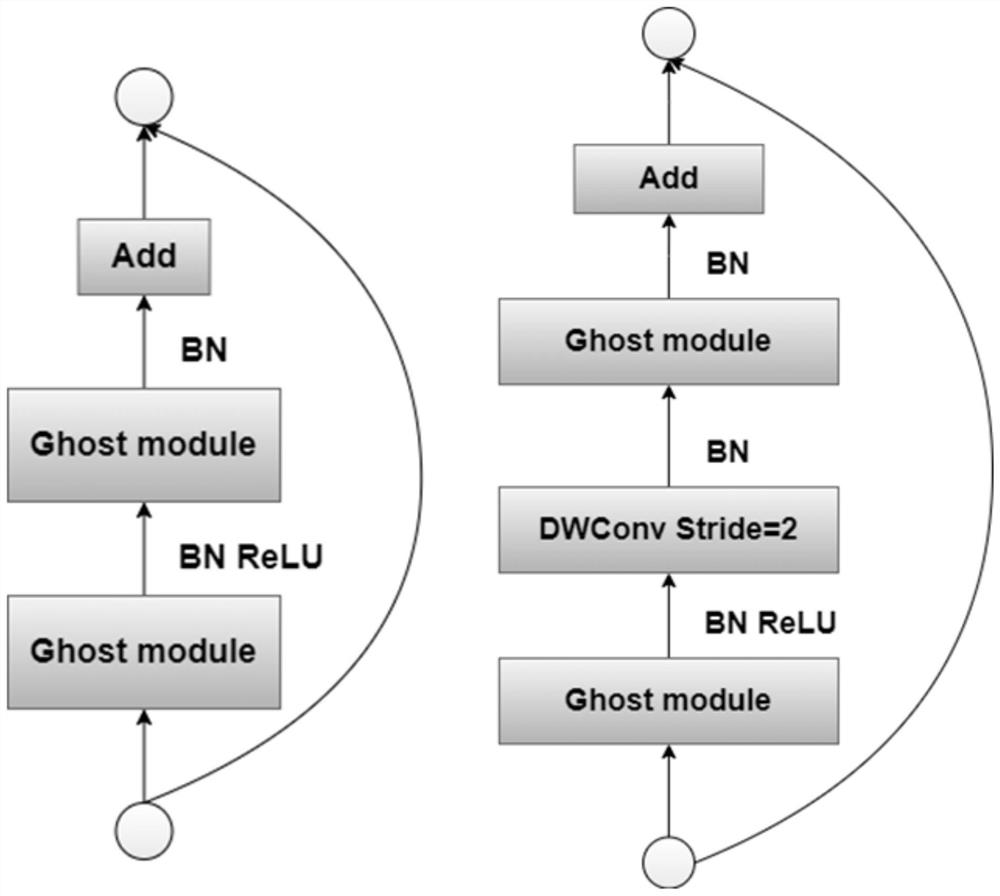

SAR image ship detection method and system based on lightweight deep learning

PendingCN113469073AReduce the amount of parametersAvoid lossCharacter and pattern recognitionNeural architecturesPattern recognitionAlgorithm

The invention discloses an SAR image ship detection method and system based on lightweight deep learning, wherein the method comprises the steps: carrying out the preprocessing of a large-size SAR image, and selecting a training sample; introducing a Ghost module and Ghost Bottleneck to upgrade the YOLOv5s to obtain a preliminary lightweight model of the YOLOv5s; on the basis of the preliminary lightweight model, utilizing the network pruning and knowledge distillation of a traditional model lightweight algorithm to realize further lightweight of the model; using a TensorRT reasoning optimizer for carrying out reasoning acceleration on the lightweight YOLOv5s model, and deploying the lightweight YOLOv5s model on NVIDIA Jetson TX2; cutting large-size SAR images to be detected, and sequentially sending the cut large-size SAR images to the model to complete detection; and synthesizing a detection result, and screening a prediction frame on the final large-size SAR image by using NMS non-maximum suppression. On the premise of satisfying acceptable precision loss, the parameter quantity and the floating point operand of the model are compressed, and the detection speed is improved.

Owner:XIDIAN UNIV

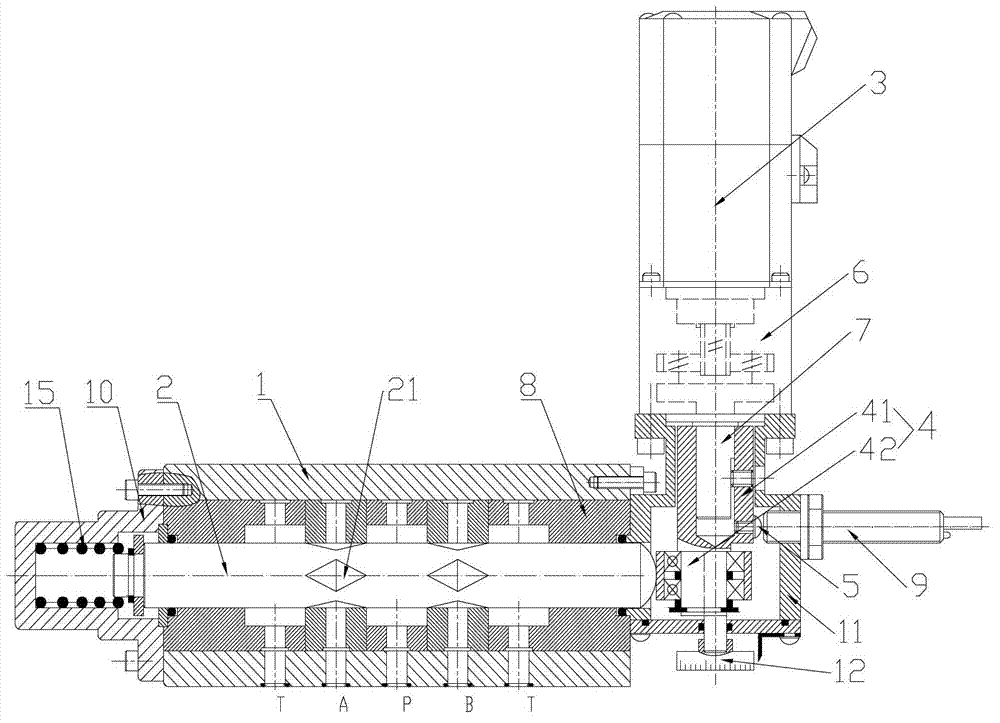

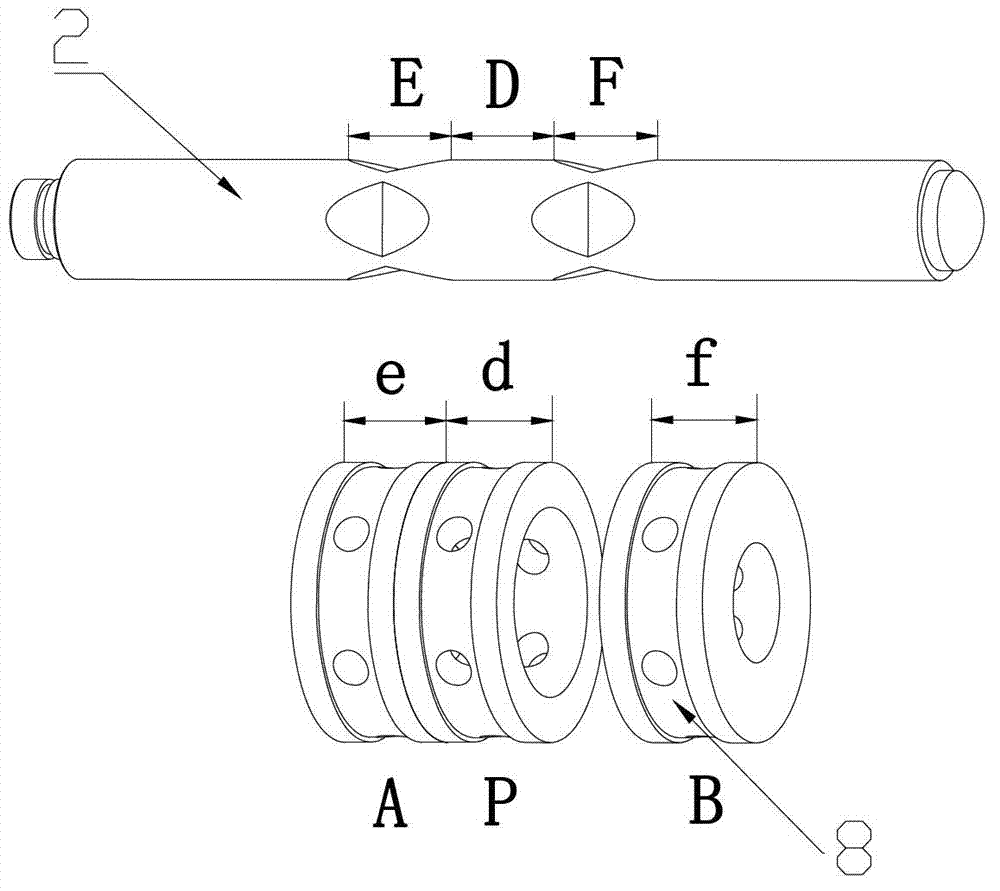

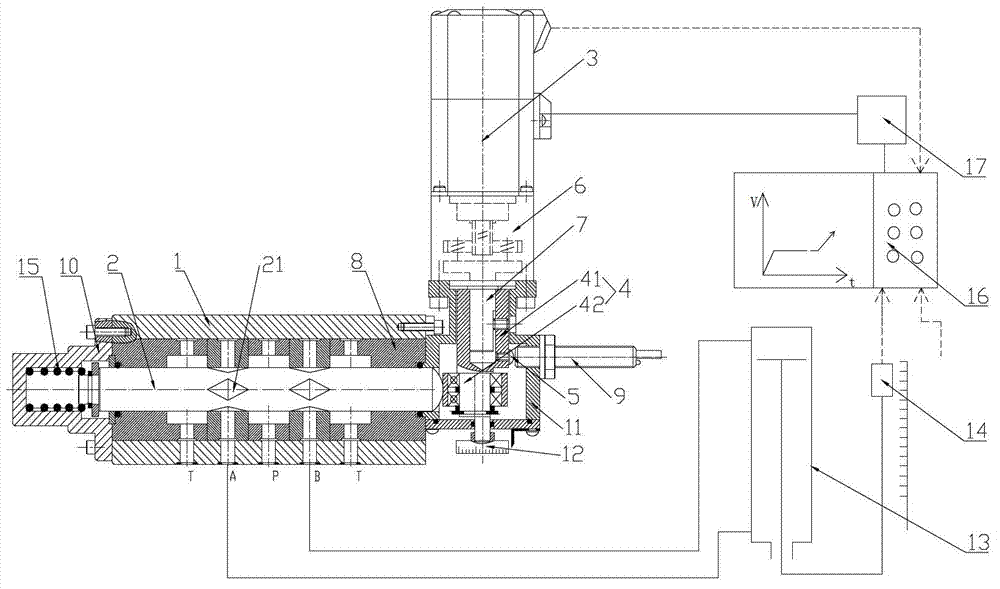

Directly moving type high-flow directional flow servo valve and control system using servo valve

The invention discloses a directly moving type high-flow directional flow servo valve and a control system using the servo valve. A valve core of the servo valve is pushed by a cam shaft driven by a servo motor; the cam shaft comprises an eccentric section and a driving section; one end of the valve core is pressed and leaned against a shaft surface of the eccentric section; a zero position sensing head is arranged on the shaft surface of the driving section; an inductive sensor which is matched with the zero position sensing head is arranged on a cam box; the inductive sensor is connected with a controller; and the controller is used for receiving a signal of the inductive sensor, controlling the servo motor to rotate back and forth in a small scope and performing the zero position positioning on the valve core. The servo valve is high in response speed and high in control precision. Meanwhile, the zero position positioning of the valve core is high in accuracy, is free from temperature null shift and is high in repeating precision. The adjusting time for the zero position positioning is short and a hydraulic system is relative stable when the zero position is adjusted.

Owner:北京润菲利德科技有限公司

Edge rolling tool

The invention relates to an auxiliary device of a sewing machine, in particular to an edge rolling tool. The edge rolling tool comprises an edge rolling device and a support, wherein the edge rolling device is fixedly connected to the support, a slot hole is formed in the support, the support is connected with a connecting rod in a sliding mode through a screw, the connecting rod is further connected with a fixing rod in a rotary mode, a slot hole is formed in the fixing rod, and the fixing rod is installed on a working platform of the sewing machine through the slot hole and a screw. According to the edge rolling tool, due to the fact that edge rolling of the edge of cloth is carried out through the edge rolling tool instead of manual operation, difficulty of operation of edge rolling of the cloth can be reduced, production efficiency can be improved, and edge rolling of the cloth can be even and more reliable.

Owner:中江县四海制衣有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com