Wear-resistant material used in drilling application

A technology of bonding materials and drill bits, which is applied in the field of wear-resistant materials, can solve problems such as the difficulty in controlling the uniform thickness, fracture, and uneven distribution of hard surface coatings, and achieve good deposition fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

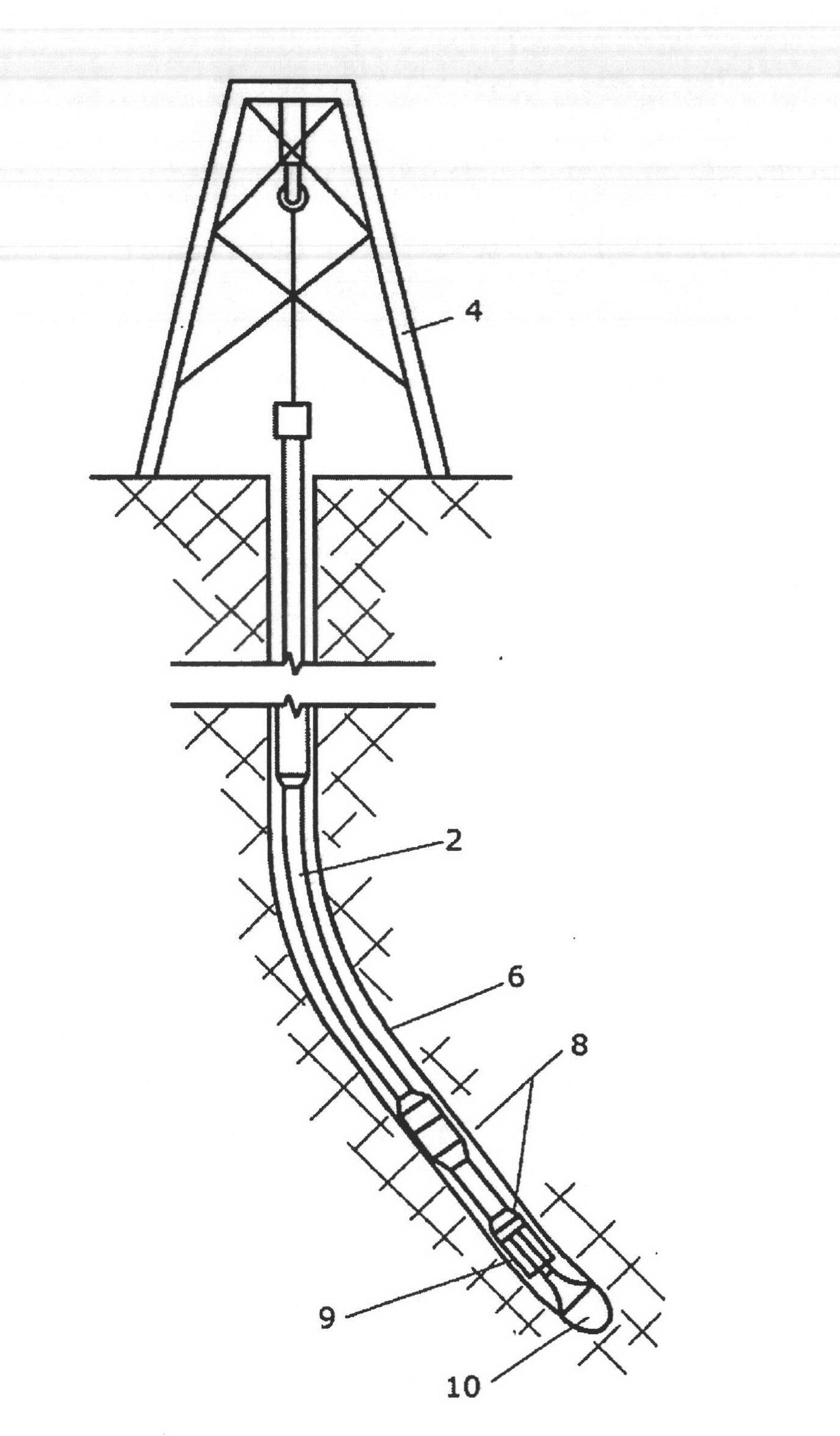

[0024] figure 1 A drill string 2 is shown suspended from a derrick 4 for digging boreholes 6 in the ground for the extraction and recovery of minerals, especially oil. A bottom hole assembly 8 (BHA) is located at the bottom of the drill string 2 . In directional drilling, the BHA 8 has a downhole drive drilling system 9 and includes a drill bit 10 . As the drill bit 10 rotates, it cuts through the formation and advances with the drill string to form the wellbore 6 . In non-directional drilling, the BHA 8 does not include the downhole drive drilling system 9 and may consist of a drill bit, one or more drill collars and optionally other stability enhancing tools.

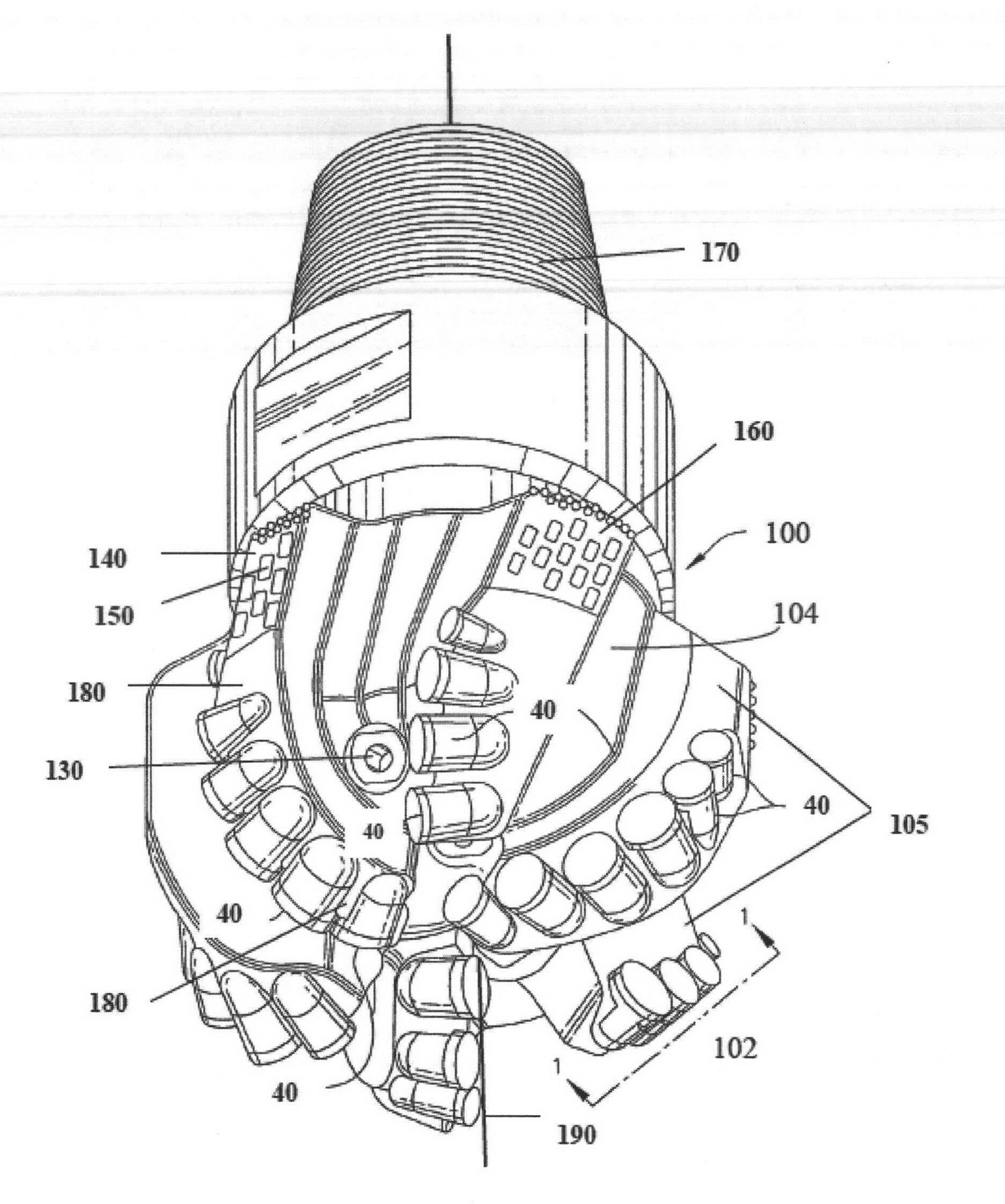

[0025] figure 2 A diamond drill bit is shown with a bit body 100 made of machine steel. The drill bit body 100 has a forward working surface 105 on which a plurality of protrusions and radially spaced blades 102 are arranged. Each blade 102 has a plurality of cutting elements 40 , namely: polycrystalline diamond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com