Graphene-reinforced titanium-based nanocomposite material and preparation method

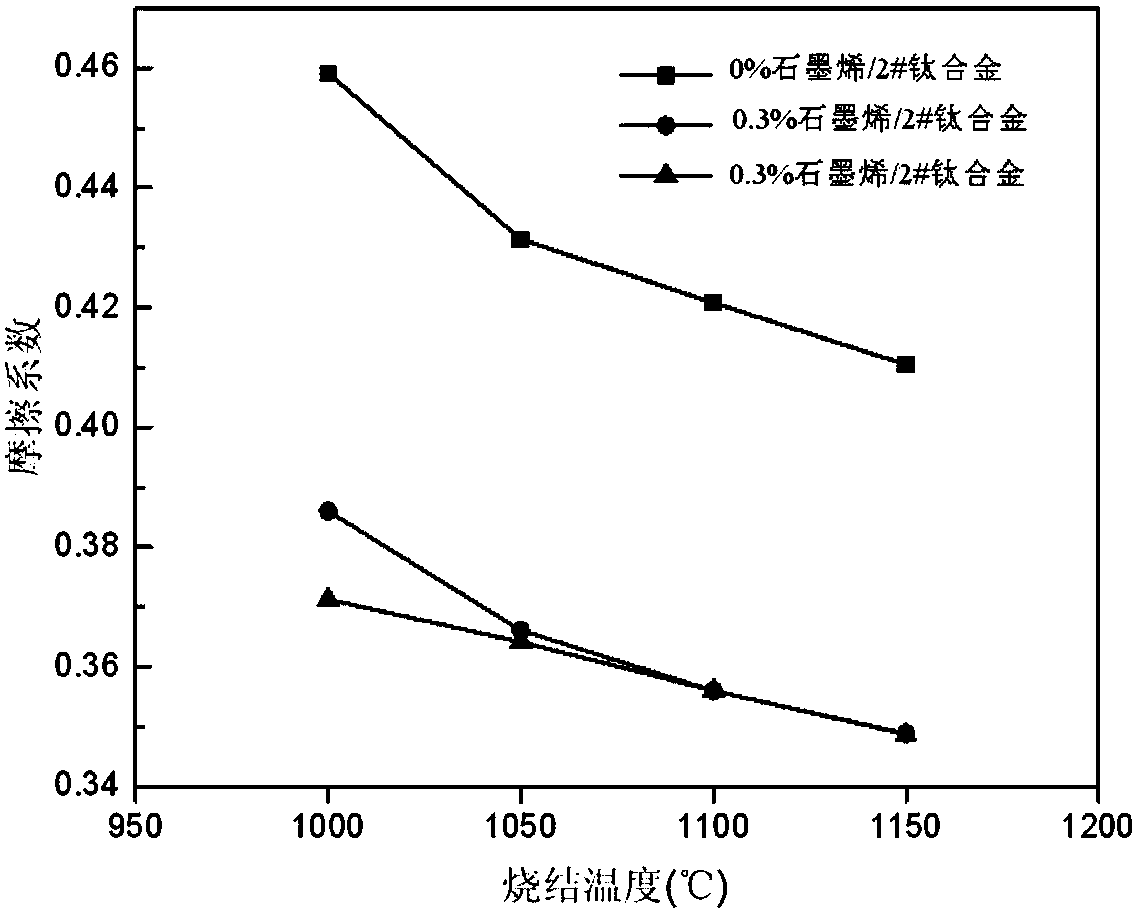

A nano-composite material and composite material technology, applied in the field of graphene-reinforced titanium-based nano-composite materials and its preparation, can solve the problems of difficult compounding of graphene, achieve the effects of increasing bulk density, precise process parameter control, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

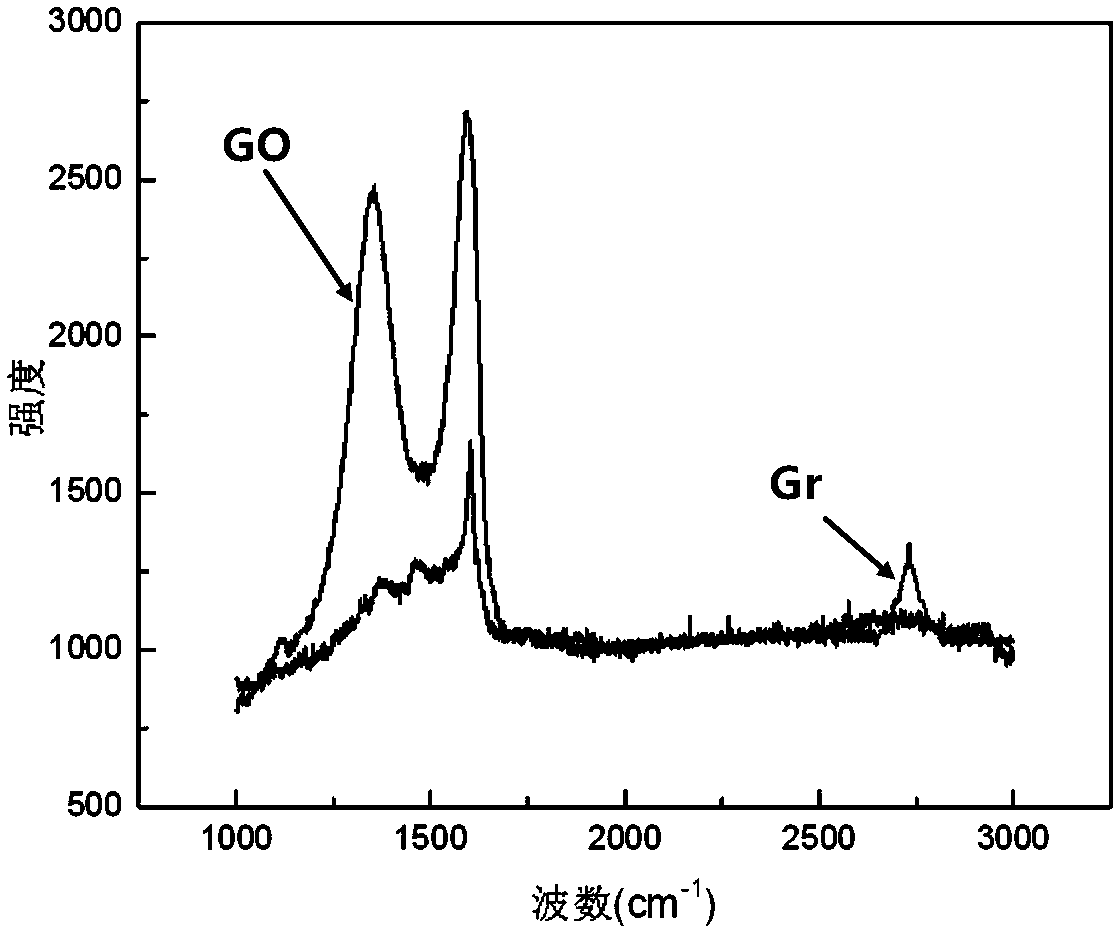

[0032] (1) Add 1.5 g of feathery and translucent graphene oxide nanosheets prepared by redox method to 300 ml of absolute ethanol and stir for 20 minutes, and then use an ultrasonic cell pulverizer to disperse for more than 30 minutes to prepare graphene oxide solution;

[0033] (2) Stir and mix the 1# titanium alloy powder with a particle size of 53 μm to 106 μm and an oxygen content of 800 ppm and graphene oxide solution prepared by the argon atomization method for 30 minutes to 180 minutes under argon protection to form graphene oxide and A mixed slurry of titanium alloy powder, then dried the mixed slurry in an oven at 60° C. for 10 h to obtain graphene oxide and titanium alloy composite powder;

[0034] (3) Put the composite powder into the graphite mold in the cavity of the plasma discharge sintering system, adjust the pressure control button, apply an initial pressure of 1.5KN to the graphene oxide and titanium alloy composite powder, and carry out vacuum treatment at t...

Embodiment 2

[0039](1) Add 3.0 g of graphene oxide nanosheets to 500 ml of absolute ethanol and stir for 25 minutes, then use an ultrasonic cell pulverizer to disperse and process for more than 30 minutes to prepare a graphene oxide solution;

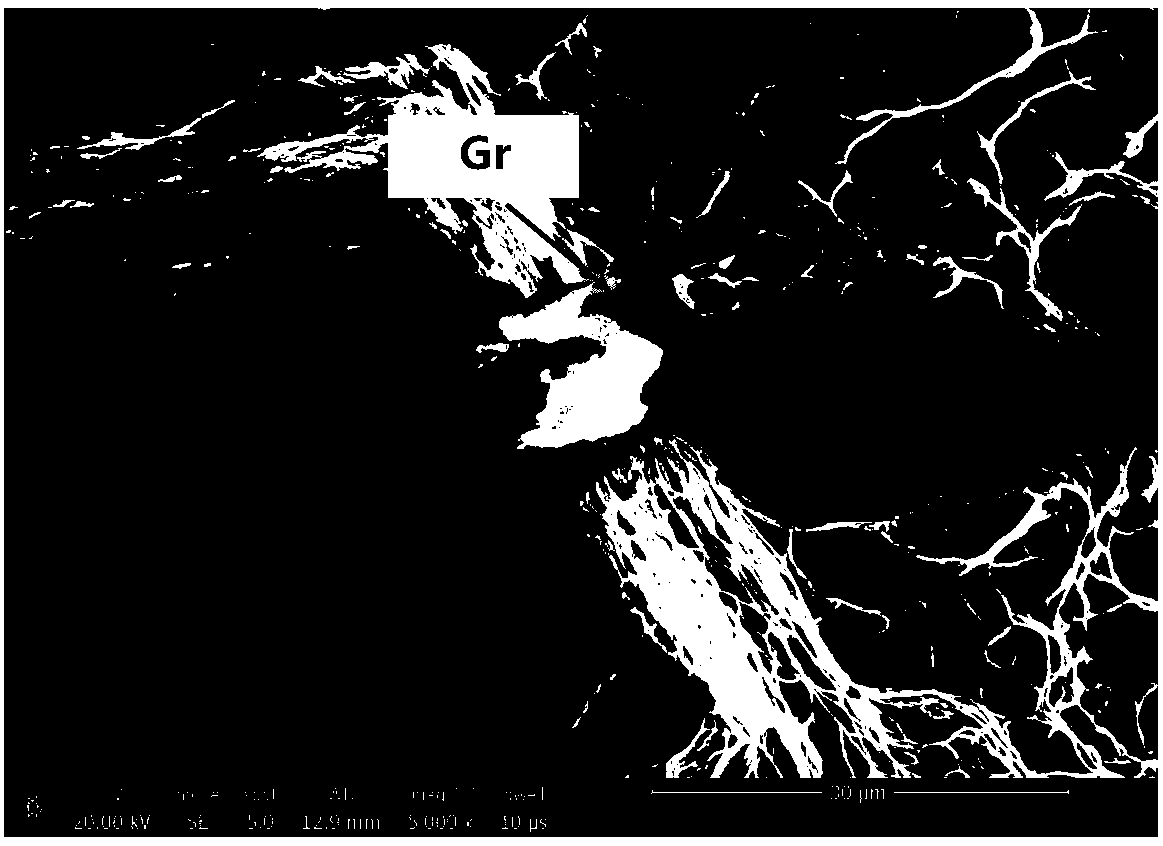

[0040] (2) Stir and mix the 2# titanium alloy powder with a particle size of 100 μm to 200 μm prepared by the argon atomization method and the graphene oxide solution for 30 minutes to 180 minutes under the protection of argon to form a mixture of graphene oxide and titanium alloy powder slurry, and then the mixed slurry was dried in an oven at 60° C. for 10 h to obtain graphene oxide and titanium alloy composite powder;

[0041] (3) Put the composite powder into the graphite mold in the cavity of the plasma discharge sintering system, adjust the pressure control button, apply an initial pressure of 1.5-2.0KN to the graphene oxide and titanium alloy composite powder, and perform vacuuming treatment at the same time: vacuumize at room temperature 30m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com