Distributing valve for concrete pump, concrete pump, control method thereof and concrete pump truck

A technology of concrete pump and distribution valve, applied in pump control, pump, piston pump and other directions, can solve the problems of fast wear rate of S-shaped elbow 121, shortening the service life of S-shaped elbow 121, affecting the suction performance of concrete pump, etc. , to achieve high pressure bearing capacity and improve the effect of suction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

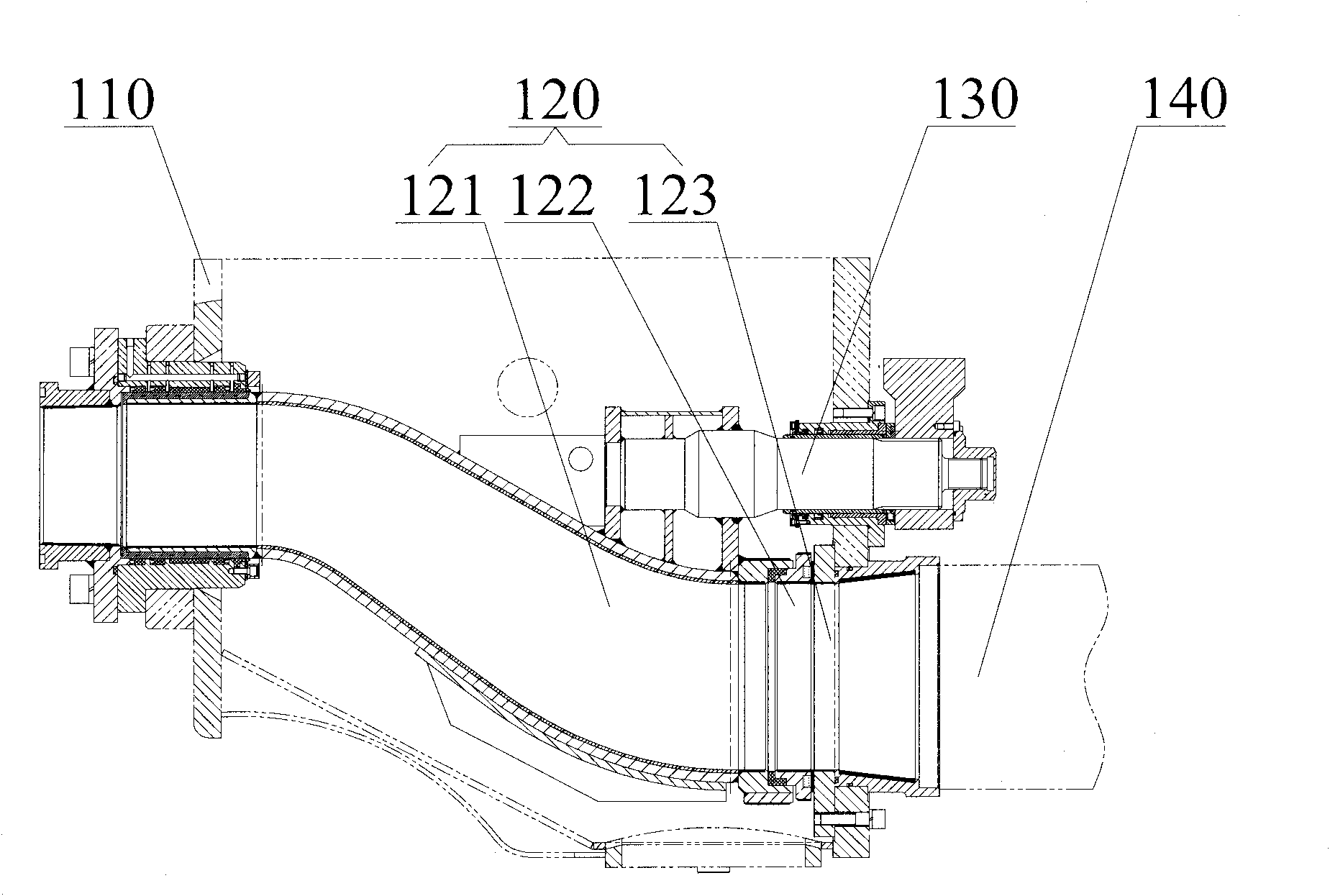

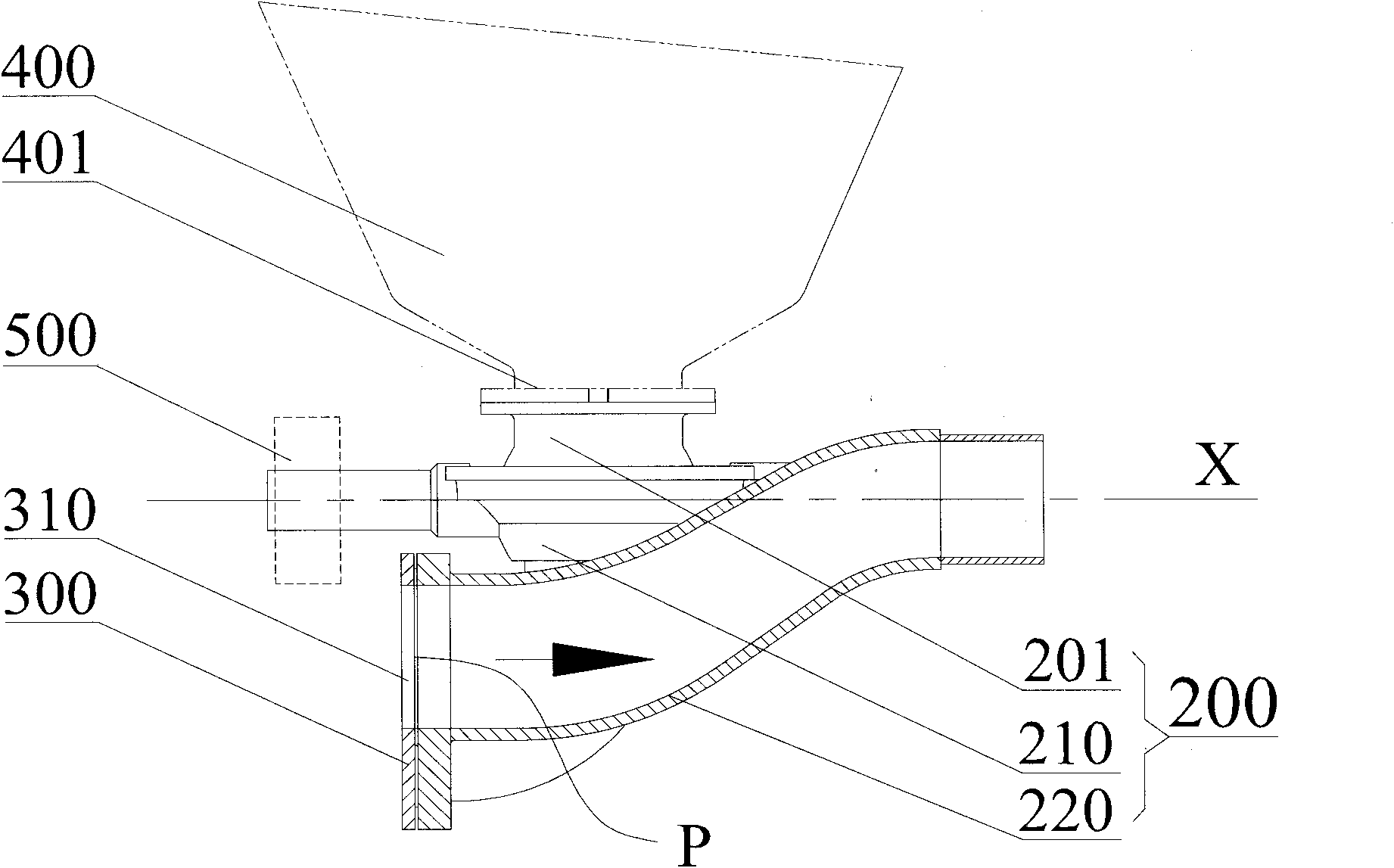

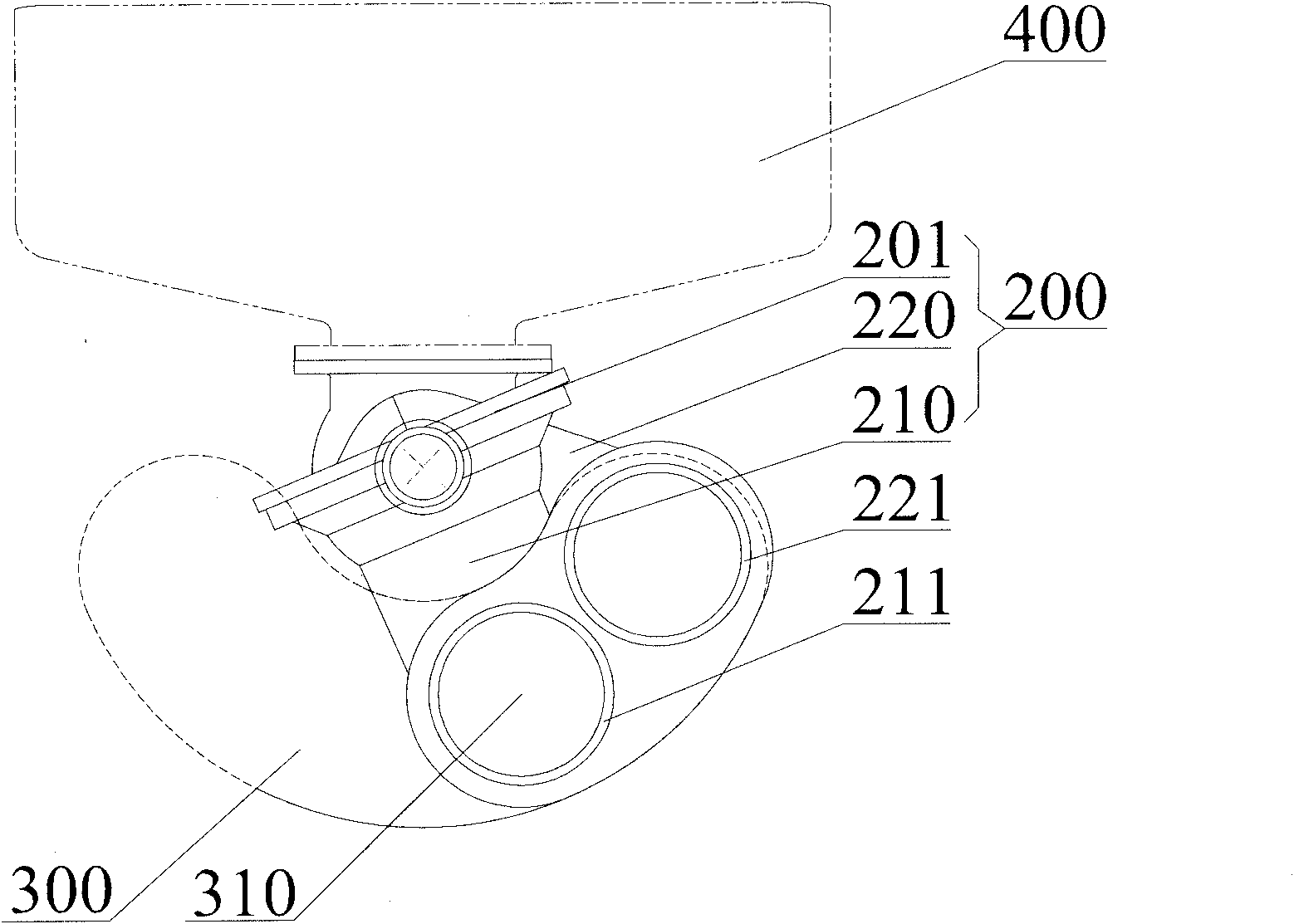

[0059] The distribution valve for a concrete pump provided in Embodiment 1 includes a valve body 200 and a wear plate 300 . The valve body 200 includes a first material suction pipe 210 and a first pump material pipe 220, the front ends of the first material suction pipe 210 and the first pump material pipe 220 respectively have a cutting ring 211 and a cutting ring 221, the cutting ring 211 and the cutting ring The ring 221 is used in conjunction with the wear-resistant plate 300; the wear-resistant plate 300 can have the same material and performance as the spectacle plate in the prior art. When the distributing valve is in state transition, the cutting ring 213 and the cutting ring 214 slide along the working surface P of the wear-resistant plate 220 on the predetermined road section respectively, so that the holes of the cutting ring 213 and the cutting ring 214 respectively contact with the wear-resistant plate at a certain period. The feeding hole 310 on the 300 communic...

Embodiment 2

[0077] The three pipes of the distributing valve body 200 provided in the second embodiment are relatively fixed, and can be driven by the driving mechanism 500 to perform rotary swinging as a whole, and switch from one state to another. This structure has the advantages of simple structure and convenient control. specialty.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com