Patents

Literature

88 results about "Bonding alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transcript of Alloys & Metallic Bonding. Metallic bonds are formed when the. valance electrons. of a metal atom become. delocalized. or detached from the rest of the atom.

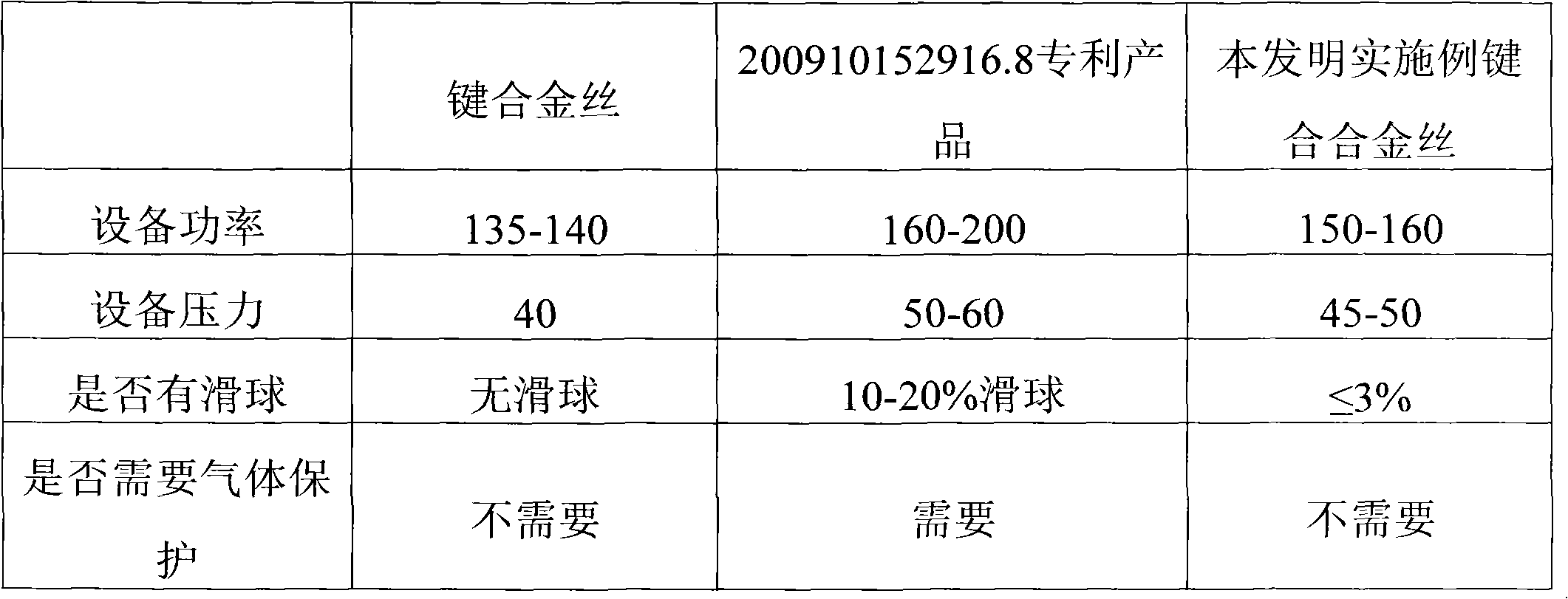

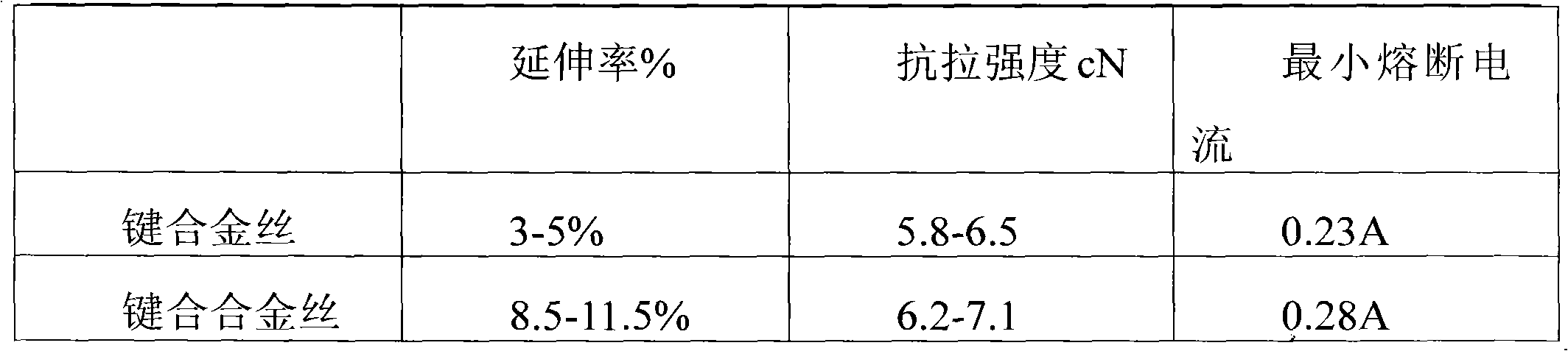

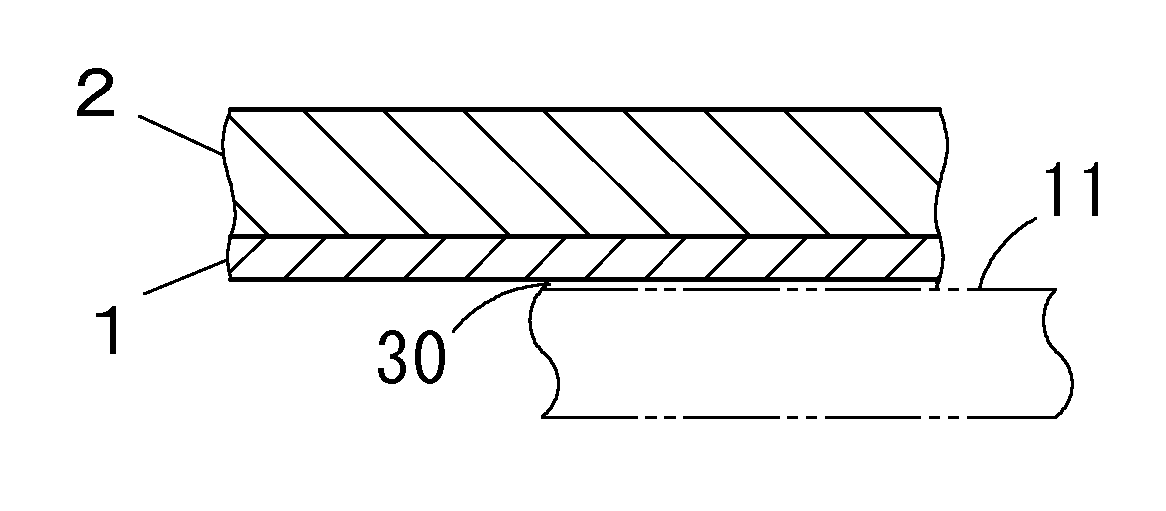

Bonding alloy wire and production technology thereof

ActiveCN102437136AThe production process is convenient and practicalLow costSemiconductor/solid-state device detailsSolid-state devicesMiniaturizationIntegrated circuit

The invention relates to a bonding alloy wire and a production technology thereof. The bonding alloy wire comprises: a base material and a coating plated on a base material surface. The base material is a silver material with a total purity which is greater than or equal to 99.9% and the silver material is added with alloy elements: Ca, Pd and Au. The coating is gold. The production technology ofthe bonding alloy wire comprises the following steps: 1) casting the base material formed by the silver and the alloy elements; 2) performing a large wire drawing to the base material after the fusion casting; 3) plating the gold on the surface of the base material after the large wire drawing; 4) performing wire drawing to the base material whose surface is plated with the gold; 5) performing anannealing process to the gold-plated base material after the wire drawing so as to obtain a needed gold bonding wire. In the invention, the high pure silver material is used as a base, the alloy elements are added and the silver material surface is plated with the gold so that costs can be greatly reduced. An electrical conductivity of the bonding alloy wire whose wire diameter is the same with the wire diameter of the traditional gold bonding wire is higher than the electrical conductivity of the traditional gold bonding wire. The bonding alloy wire of the invention is suitable for an integrated circuit, large-scale integrated circuit miniaturization packaging, a discrete device and LED packaging. The production technology of the bonding alloy wire is convenient and practical.

Owner:浙江佳博科技股份有限公司

Aluminum bonding alloy, and clad material and aluminum bonding composite material each having bonding alloy layer made of the alloy

ActiveUS20120202090A1Improve corrosion resistanceImprove workabilityHot-dipping/immersion processesWelding/cutting media/materialsTitaniumAluminum metal

An aluminum bonding alloy is an Ni—Mg alloy for bonding aluminum and a non-aluminum metal selected from steel, copper, nickel or titanium. The Ni—Mg alloy consists essentially of 0.08-0.90 mass % Mg, and the balance of Ni and inevitable impurities. A clad material includes a non-aluminum metal layer made of the non-aluminum metal and a bonding alloy layer made of the aluminum bonding alloy. The non-aluminum metal layer and the bonding alloy layer are bonded together by pressure welding and diffusion bonding.

Owner:NEOMAX MATERIALS

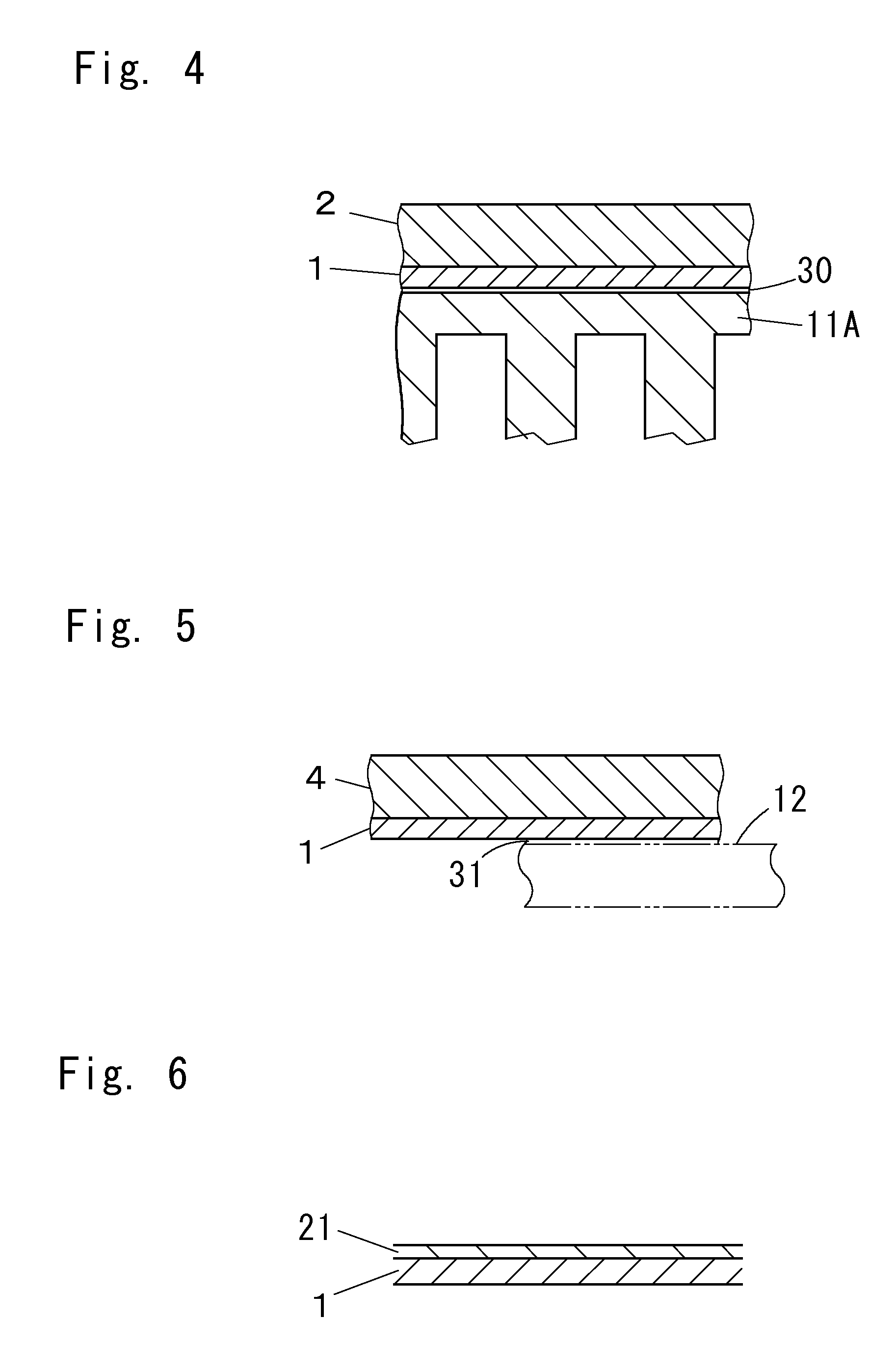

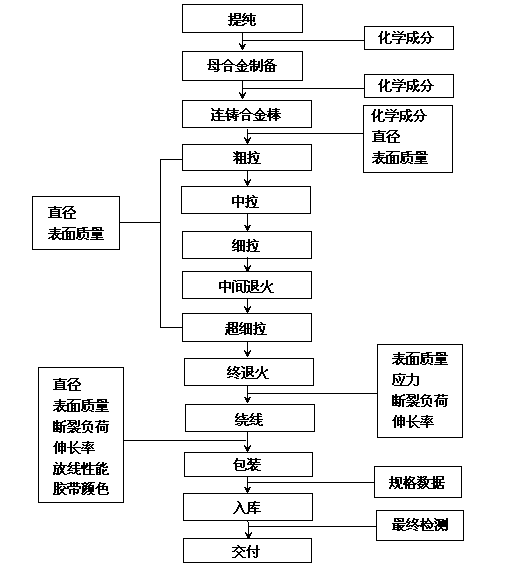

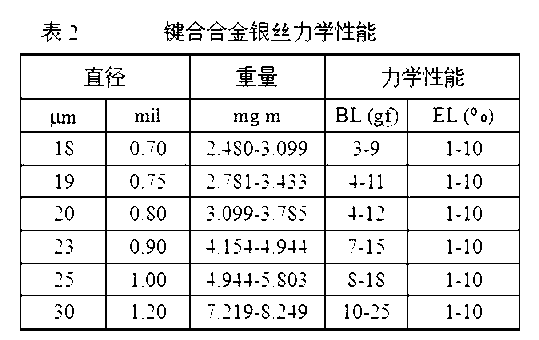

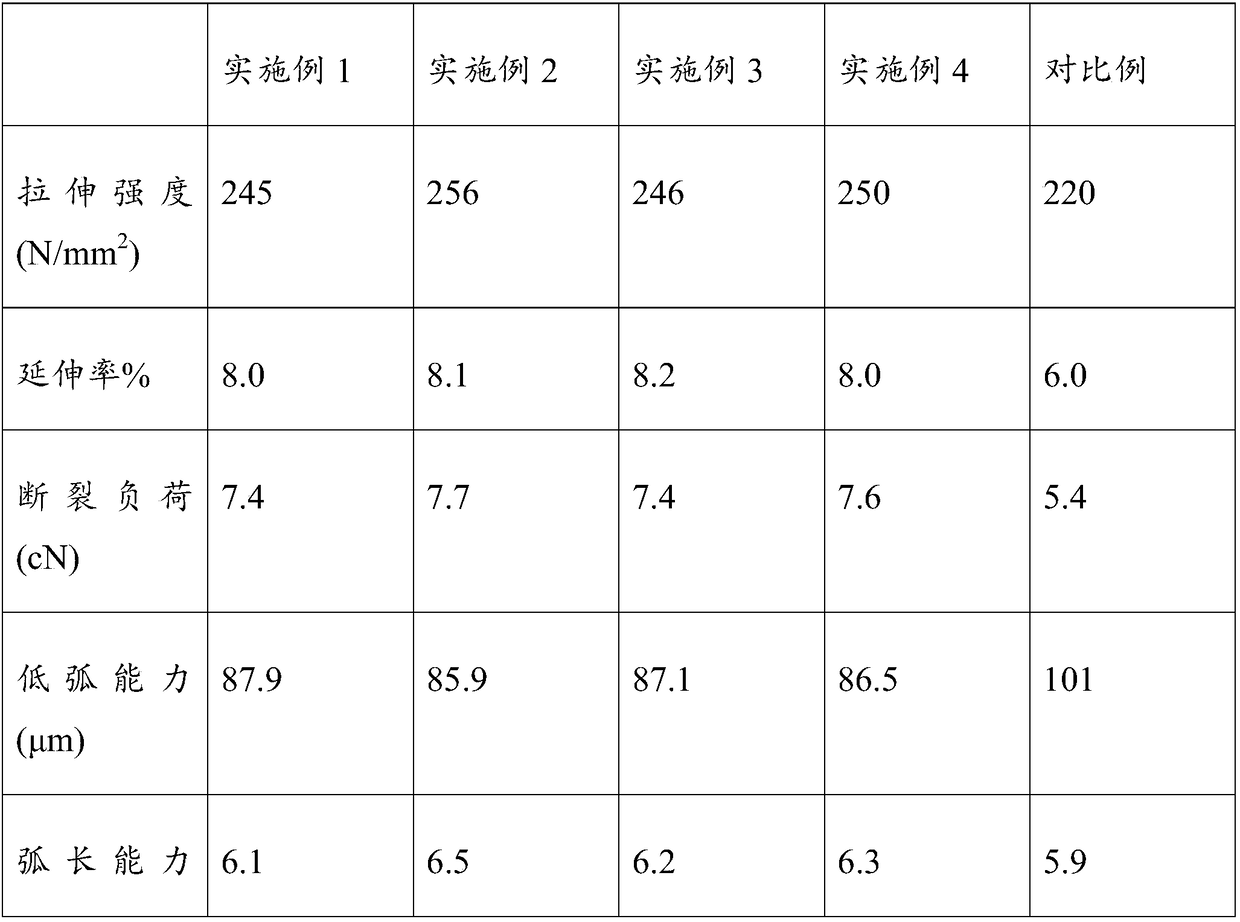

Bonding alloy filamentary silver and preparation method thereof

ActiveCN103194637AImprove conductivityAntioxidantSolid-state devicesSemiconductor devicesCeriumSemiconductor package

The invention relates to bonding alloy filamentary silver and a preparation method thereof, and belongs to the technical field of processing of a bonding wire. The bonding alloy filamentary silver comprises the following metal materials by mass ratio: less than 90wt% of silver, 3.0-10.0wt% of gold, and 3.0-8.0wt% of palladium; and the bonding alloy filamentary silver also comprises at least two of following metals of 10-100ppm of calcium, 4-10ppm of beryllium, 10-100ppm of cerium, and 50-500ppm of copper. The preparation method comprises the steps of 1) preparing materials; 2) smelting mother alloy; 3) continuously casting an alloy rod; 4) roughly working, intermediately drawing, and finely drawing; 5) carrying out middle annealing; 6) ultra-finely drawing; 7) finally annealing; 8) winding; and 9) packaging. The technology disclosed by the invention is specified and reasonable in design, and simple and convenient to operate; the obtained product is strong in electrical conductivity, has certain inoxidizability, good plasticity, high rupturing load, good elongation and low cost, can meet the demands of the semiconductor encapsulation industry and a light-emitting diode (LED) illumination technology on performance of the bonding alloy filamentary silver, and can be used as a substitute for a bonding alloy wire.

Owner:烟台招金励福贵金属股份有限公司

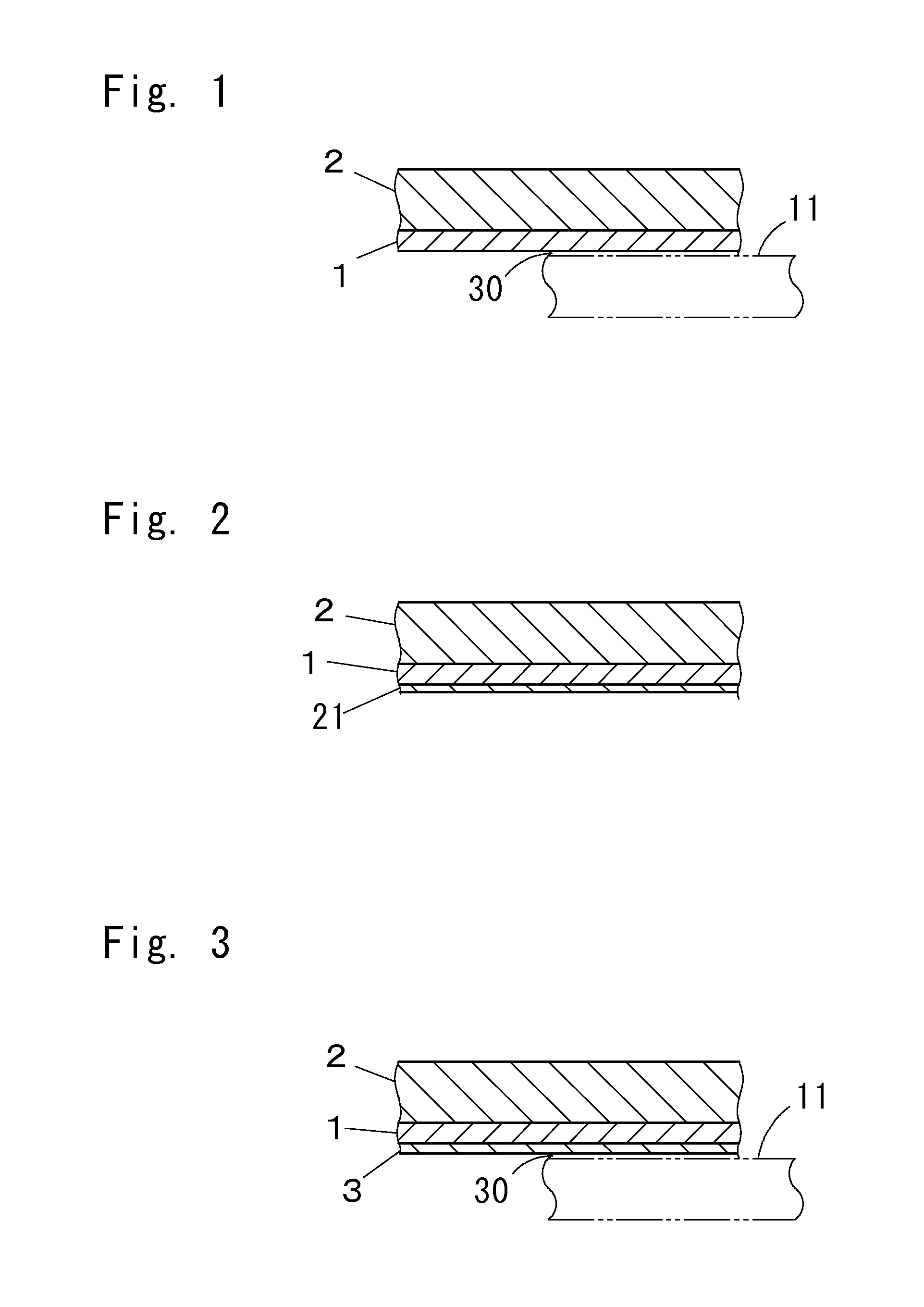

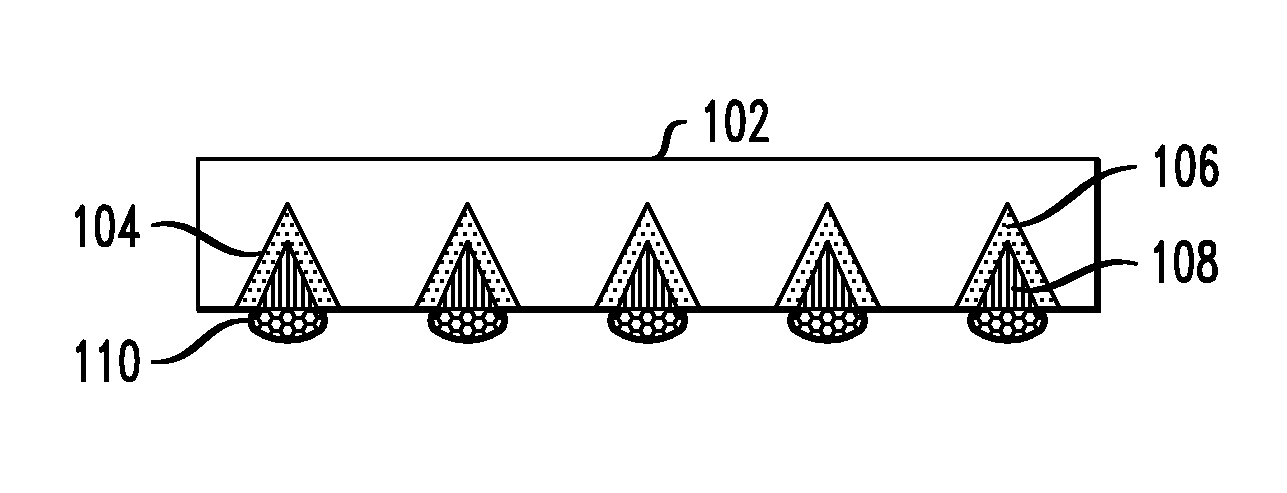

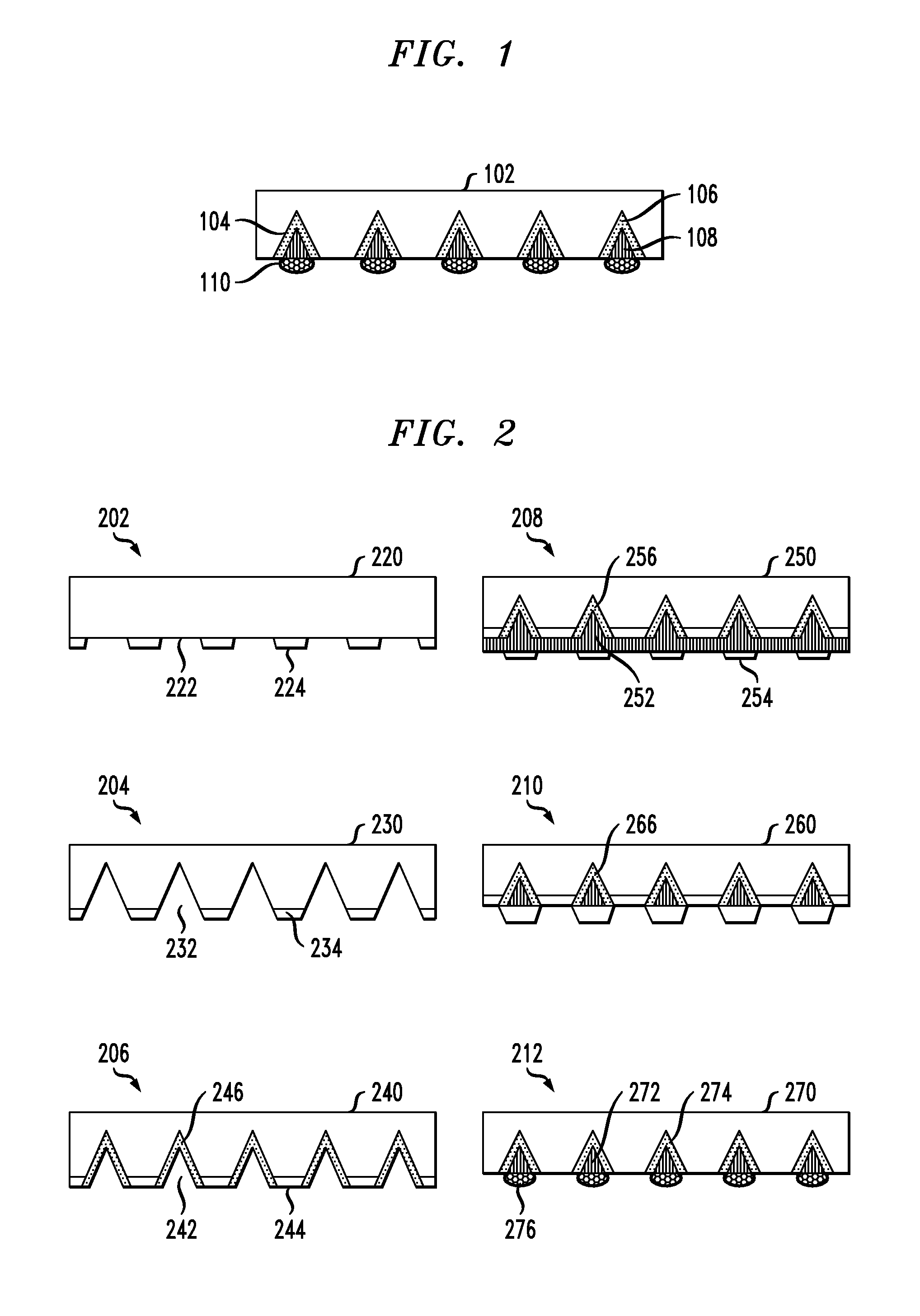

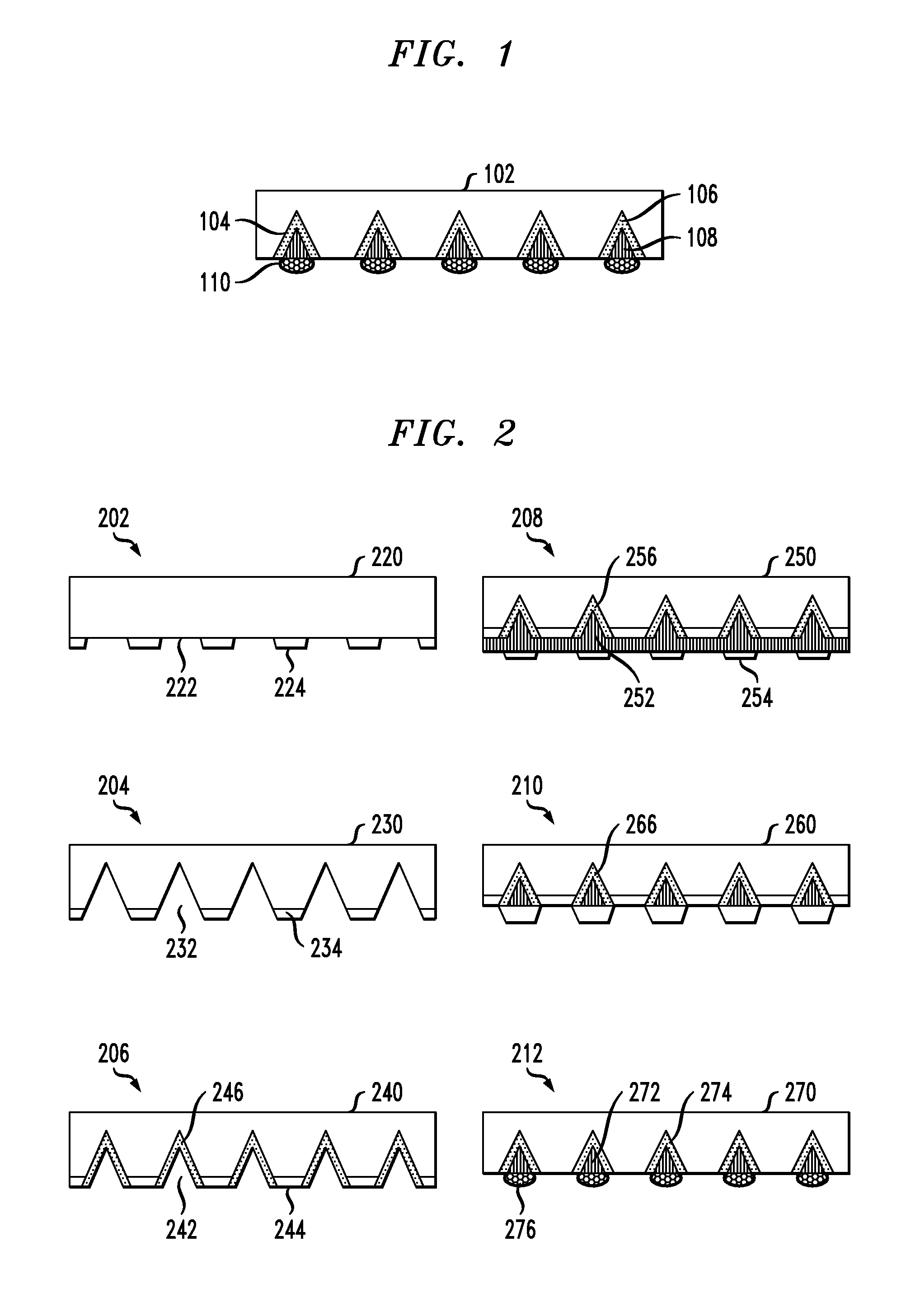

Transferable Probe Tips

ActiveUS20120279287A1Decorative surface effectsElectrical measurement instrument detailsMaterials scienceMicroarray

Transferable probe tips including a metallic probe, a delamination layer covering a portion of the metallic probe, and a bonding alloy, wherein the bonding alloy contacts the metallic probe at a portion of the probe that is not covered by the delamination layer are provided herein. Also, techniques for creating a transferable probe tip are provided, including etching a handler substrate to form one or more via arrays, depositing a delamination layer in each via array, depositing one or more metals in each via array to form a probe tip structure, and depositing a bonding alloy on a portion of the probe tip structure that is not covered by the delamination layer. Additionally, techniques for transferring transferable probe tips are provided, including removing a handler substrate from a probe tip structure, and transferring the probe tip structure via flip-chip joining the probe tip structure to a target probe head substrate.

Owner:IBM CORP

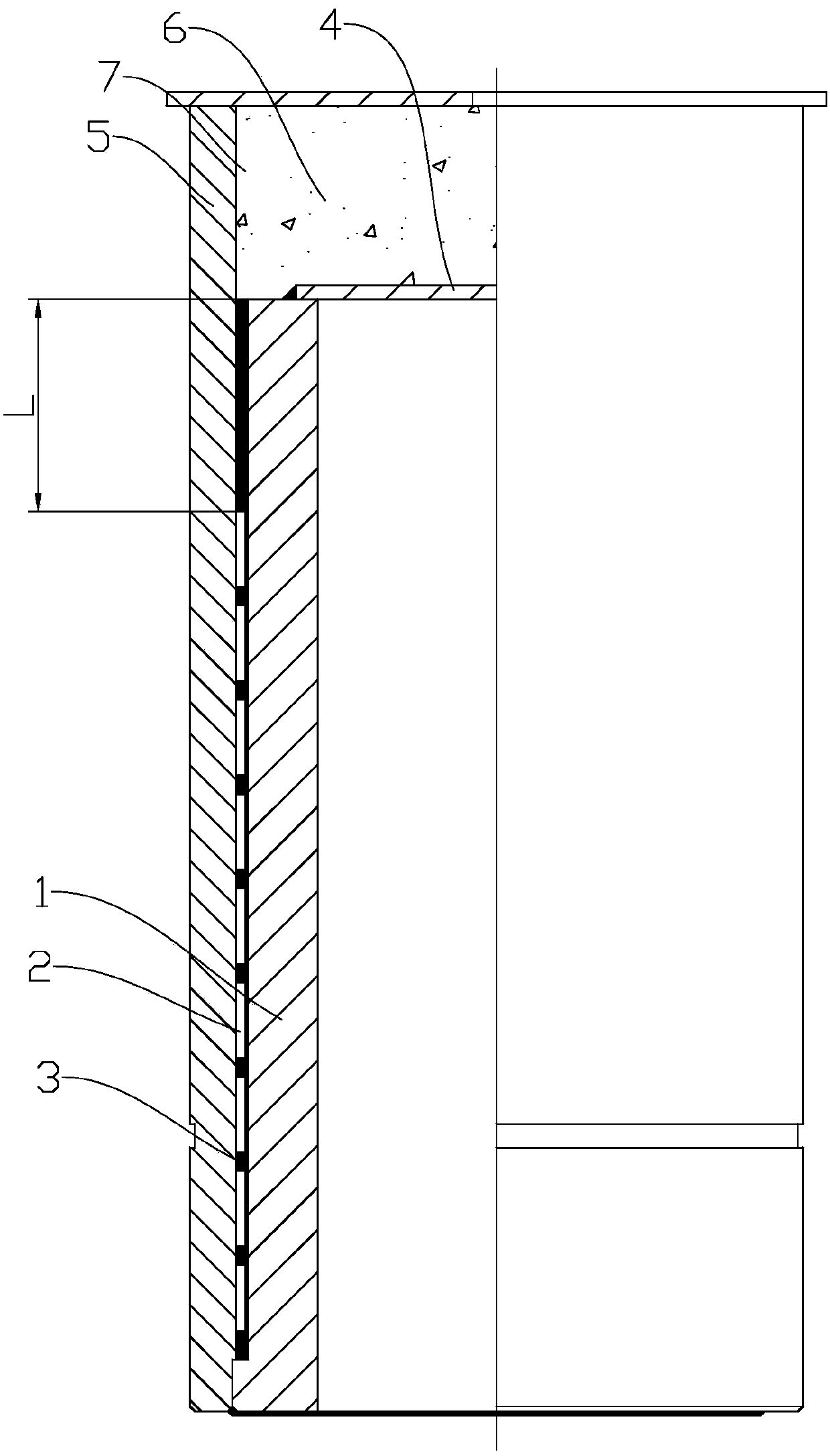

Hard alloy transverse bearing body for spiral drilling rig and production method thereof

ActiveCN103775498ANo change in impact strengthChange in impact strengthBearing componentsNiobiumCobalt

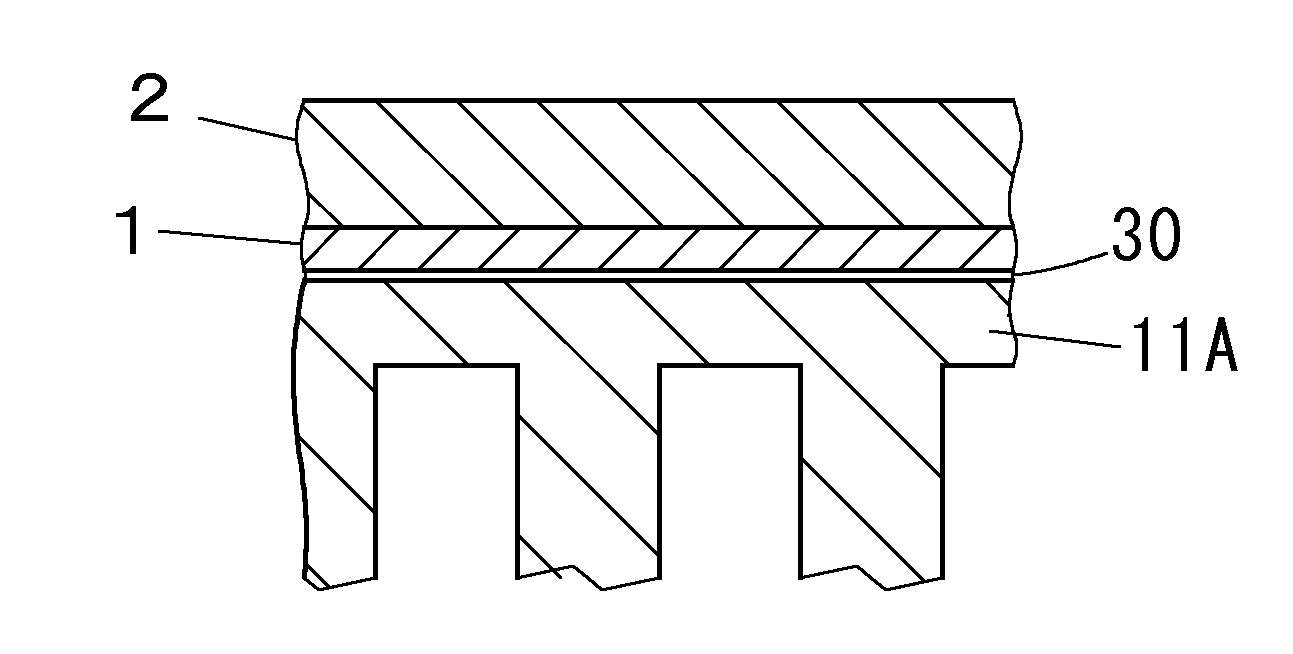

The invention discloses a hard alloy transverse bearing body for a spiral drilling rig and a production method thereof. The production method comprises the steps: producing a hard alloy strip from 8-10 percent by weight of cobalt powder, 0.2-0.3 percent by weight of tantalum and / or niobium rare metal and the balance of tungsten powder, wherein the length distance between the upper top surface of the internal steel body and the hard alloy strip at the uppermost end is not less than 45 mm, and a grain particle size of tungsten carbide powder filled in a gap between the hard alloy strips is not more than 1.0 mu m; placing a bonding alloy in a bushing above a cover plate, wherein the bonding alloy comprises the following components in percent by weight: 13-16 percent of Ni, 9-11 percent of Zn, 25-27 percent of Mn and the balance of Cu, and the total amount of impurities is not more than 0.5 percent; simultaneously placing 5-8 g of borax; then heating to 1150 DEG C in a bell type furnace, discharging out form the furnace after insulating for 1.5 h; immediately air-cooling, cooling to 830-860 DEG C within 2 h, then naturally cooling to a room temperature in air; and machining. According to the production method, the impact strength of the bearing body is changed under the condition of no increase of process complexity, and cracks can be prevented.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

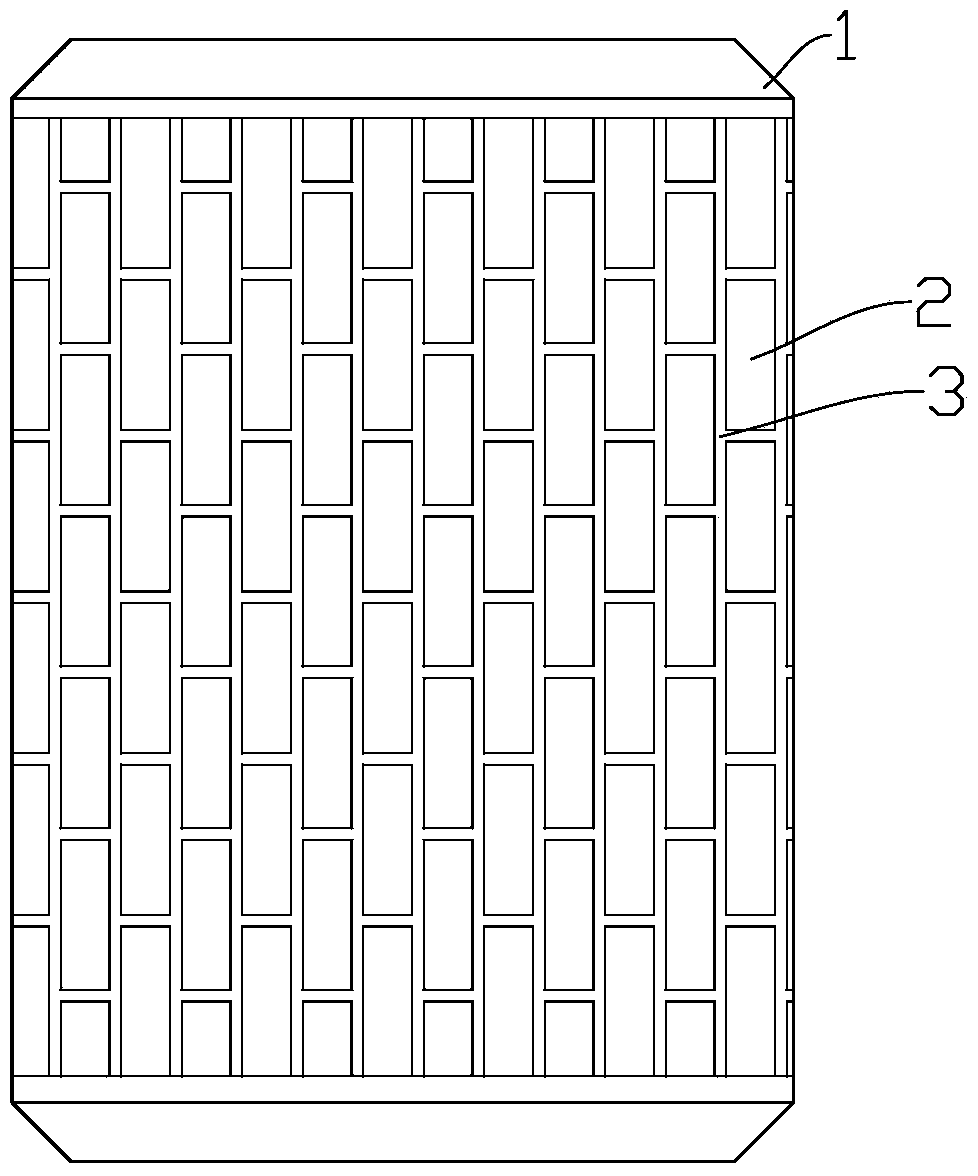

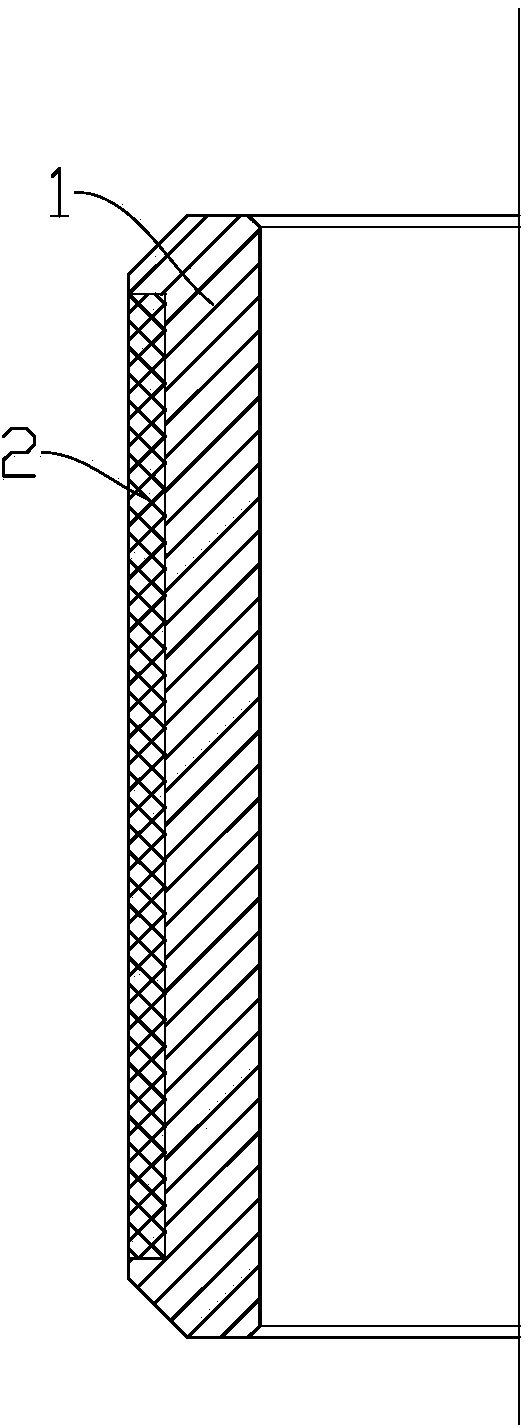

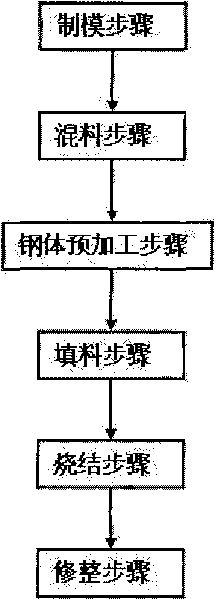

Formula and technique for manufacturing geophysical prospecting bit by powder sintering

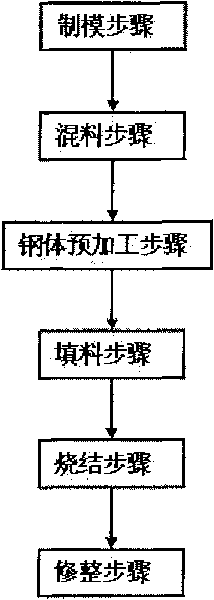

The invention discloses a formula and a technique for manufacturing a geophysical prospecting bit by powder sintering. The formula comprises the following raw materials: in the mixed tungsten carbide powder, 60 to 80 meshes of tungsten carbide powder is 30 percent to 40 percent, 80 to 200 meshes of the tungsten carbide powder is 60 percent to 70 percent, the proportion of the tungsten carbide powder, bonding alloy and dehydrated sodium tetraborate is 100:62.5:5 and the bonding alloy is copper-manganese-nickel alloy, and the proportion of the copper, manganese and nickel is 68:27:11; and the technique comprises the steps of die making, material mixing, preprocessing of steel body, filling, sintering and trimming. At present, the geophysical prospecting bit is mainly processed and manufactured mechanically, and the material and the structure of the bit is more single; and in order to adapt to the exploration of areas with complex formations, the invention adopts powdery materials which are easy to change the material of the bit and can manufacture the bit with complex structure by designing a mold. The formula has low cost, the performance of the finished product is reliable, the technique steps are optimized properly, the technique is simplified and the cost-performance ratio is high.

Owner:SOUTHWEST PETROLEUM UNIV

Aluminum bonding alloy, and clad material and aluminum bonding composite material each having bonding alloy layer made of the alloy

ActiveUS8883318B2Excellent in bondabilityGood weldabilityHot-dipping/immersion processesWelding/cutting media/materialsTitaniumAluminum metal

An aluminum bonding alloy is an Ni—Mg alloy for bonding aluminum and a non-aluminum metal selected from steel, copper, nickel or titanium. The Ni—Mg alloy consists essentially of 0.08-0.90 mass % Mg, and the balance of Ni and inevitable impurities. A clad material includes a non-aluminum metal layer made of the non-aluminum metal and a bonding alloy layer made of the aluminum bonding alloy. The non-aluminum metal layer and the bonding alloy layer are bonded together by pressure welding and diffusion bonding.

Owner:NEOMAX MATERIALS

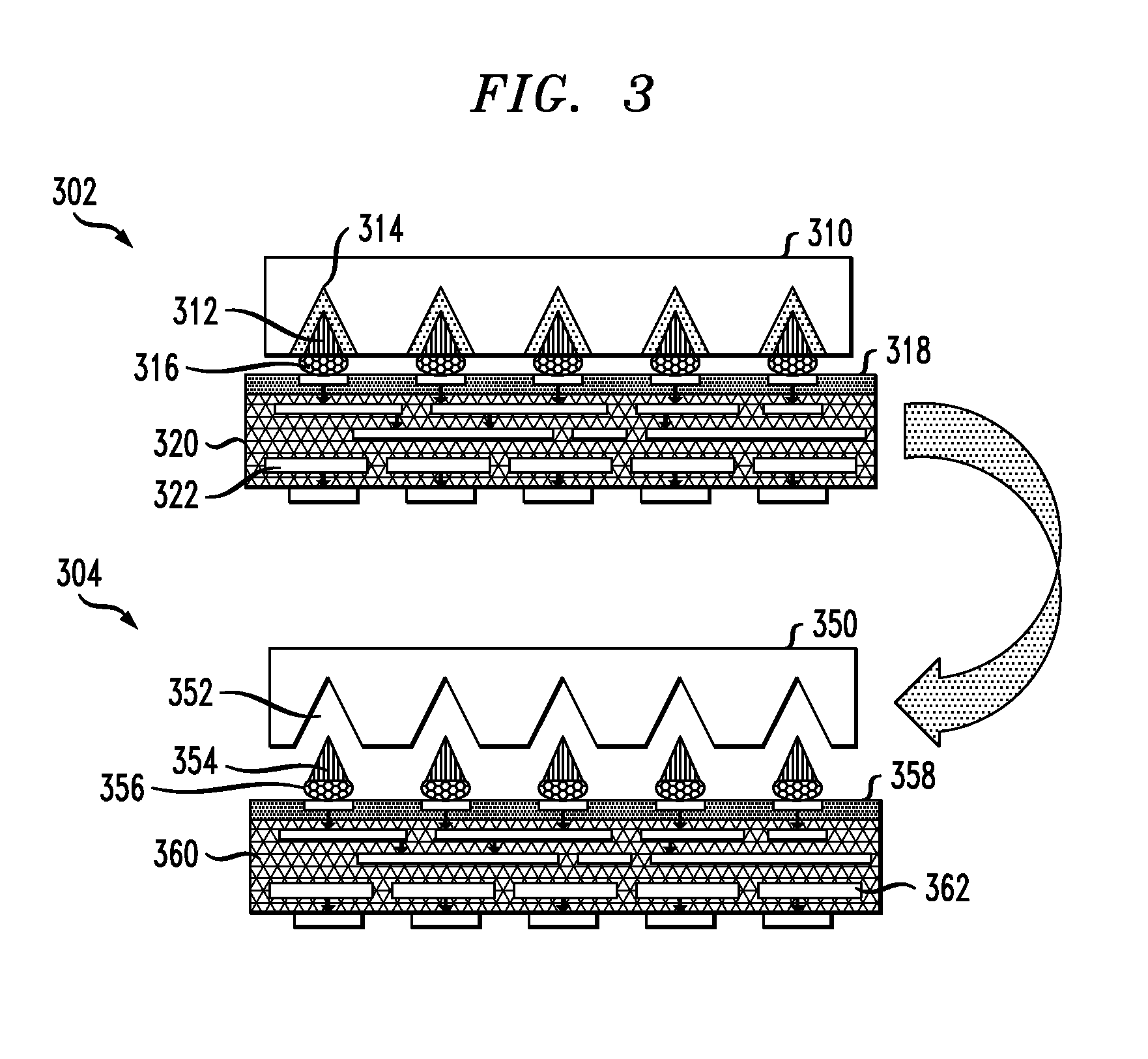

Micromechanical Method and Corresponding Assembly for Bonding Semiconductor Substrates and Correspondingly Bonded Semiconductor Chip

InactiveUS20120280409A1Small distanceHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipPhysics

A micromechanical assembly for bonding semiconductor substrates includes a semiconductor substrate having a chip pattern having a plurality of semiconductor chips, each having a functional region and an edge region surrounding the functional region. There is a bonding frame made of a bonding alloy made from at least two alloy components in the edge region, spaced apart from the functional region. Within the part of the edge region surrounding the bonding frame between the bonding frame and the functional region, there is at least one stop frame made of at least one of the alloy components, which is configured such that when a melt of the bond alloy contacts the stop frame during bonding, the bonding alloy solidifies.

Owner:ROBERT BOSCH GMBH

A bond alloy wire and a preparation method thereof

ActiveCN109003903AGuaranteed service lifeFirmly connectedSemiconductor/solid-state device detailsSolid-state devicesCavitationGold content

A bond alloy wire disclosed in the invention includes the following ingredients in percentage by mass, 1, 99 to 99.5 percent of gold, 0.300 to 0.55 percent of cop, 0.190 to 0.44 percent of palladium,0.001 to 0.002 percent of sil, 0.0005 to 0.003 percent of nickel, 0.0005 to 0.0015 percent of bismuth, 0.0005 to 0.001 percent of beryllium, 0.0005 to 0.001 percent of cerium, 0.001 to 0.003 percent of zinc, 0.001 to 0.002 percent of magnesium, 0.0005 to 0.002 percent of calcium, 0.0002 to 0.0008 percent of aluminum and 0.0009 to 0.0035 percent of lead. Due to the action of palladium and copper, the production of gold and aluminum compounds in isolation, the key alloy wire changes the traditional concept of manufacturing the key alloy wire, From the traditional bonding wire with 99.99% gold content to the wire with 99% gold content, the bonding alloy wire not only improves the strength of the wire, but also does not form Kendall cavitation after being used for more than 4000 hours. The connection between the ball welding and the electrode is good, which ensures the service life of the integrated circuit.

Owner:上杭县紫金佳博电子新材料科技有限公司

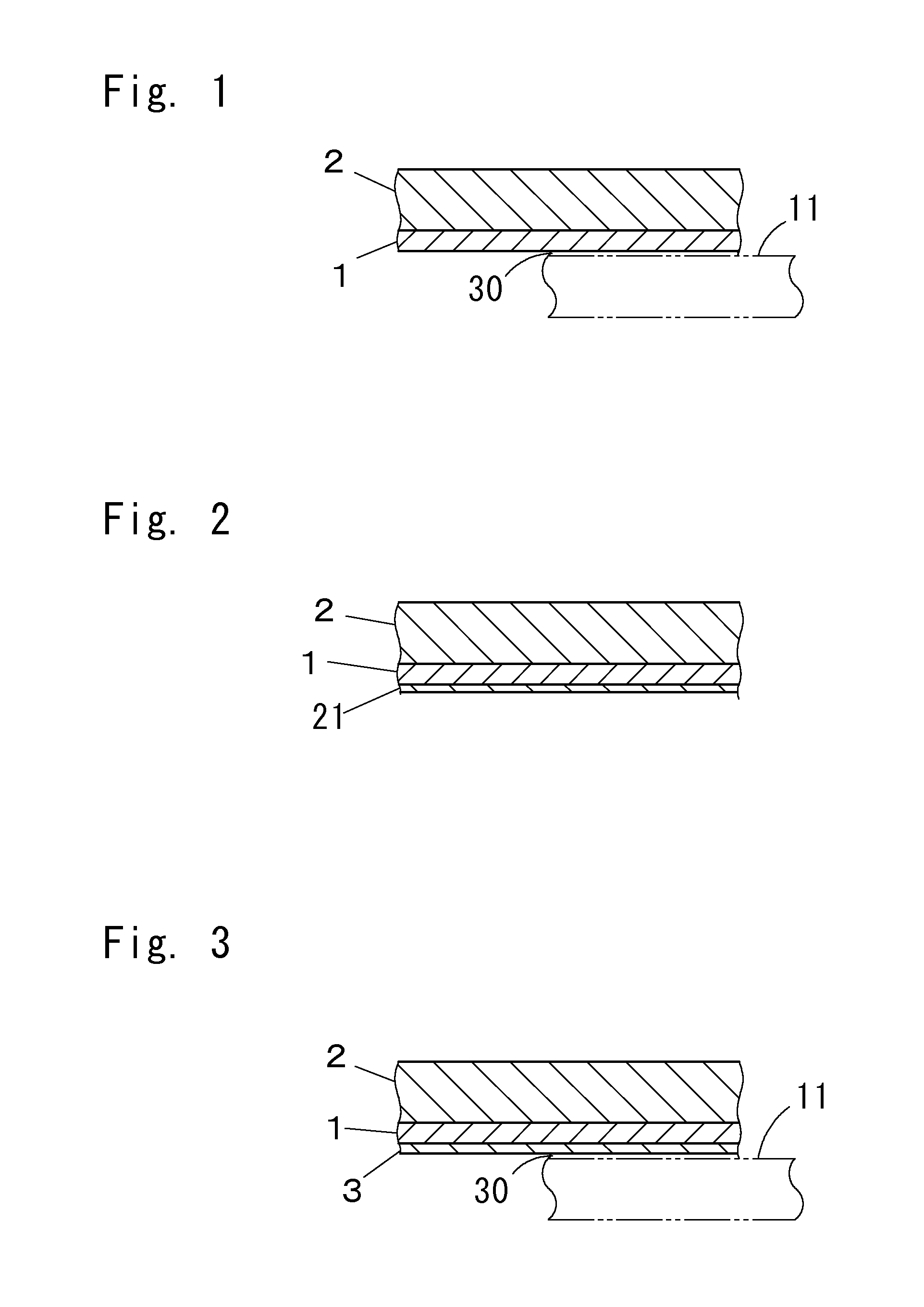

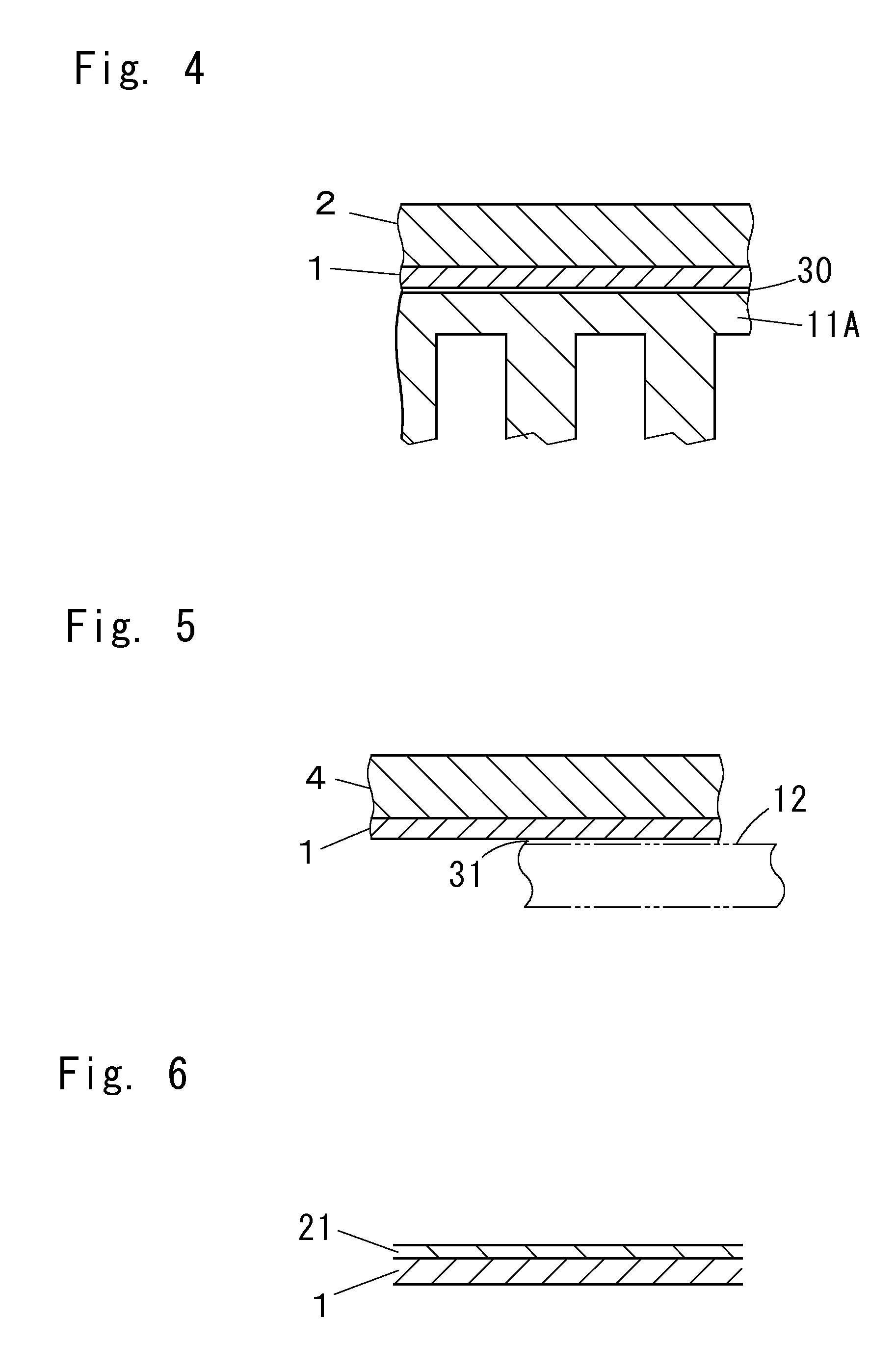

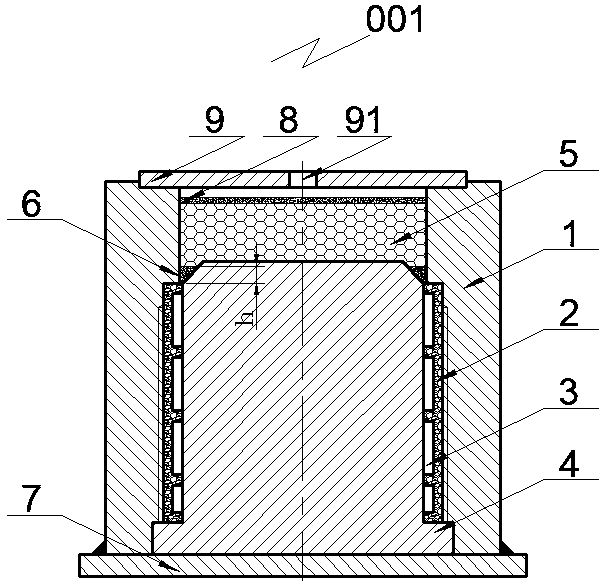

Method for manufacturing composite material of metal/ceramic layer structure

ActiveCN102627007AEasy to manufactureImprove performanceLaminationLamination apparatusMold removalMaterials science

The invention discloses a method for manufacturing a composite material of a metal / ceramic layer structure. The method for manufacturing the composite material of the metal / ceramic layer structure adopts the following technologies: 1, bonding alloy preparation: the bonding alloy is Al-Zn-Fe-Ti alloy and comprises the following components in percentage by mass: 5%-40% of Zn, 0.5%-10% of Fe, 2%-20% of Ti, and the balance is Al; the bonding alloy is composed of a high melting point phase and a low melting point phase, is in solid phase under the normal temperature and is in solid-liquid phases with solid phase being 60%-80% and liquid phase being 40%-20%; and the melting point of the bonding alloy, the interface reaction phase and the phase composition can be adjusted by utilizing the contents of added composition elements of Zn, Ti and Fe; and 2, composite material preparation: heating ceramic and metal to a processing temperature simultaneously, then making the bonding alloy carry out a recombination reaction with the ceramic and the metal, making the ceramic and the metal be in composite molding together under the condition that the temperature is 80-120 DEG C higher than the melting point of the high melting point phase of the bonding alloy, and the composite material of the metal / ceramic structure can be formed by demoulding.

Owner:TIANJIN GONGDA GALVANIZING EQUIP CO LTD

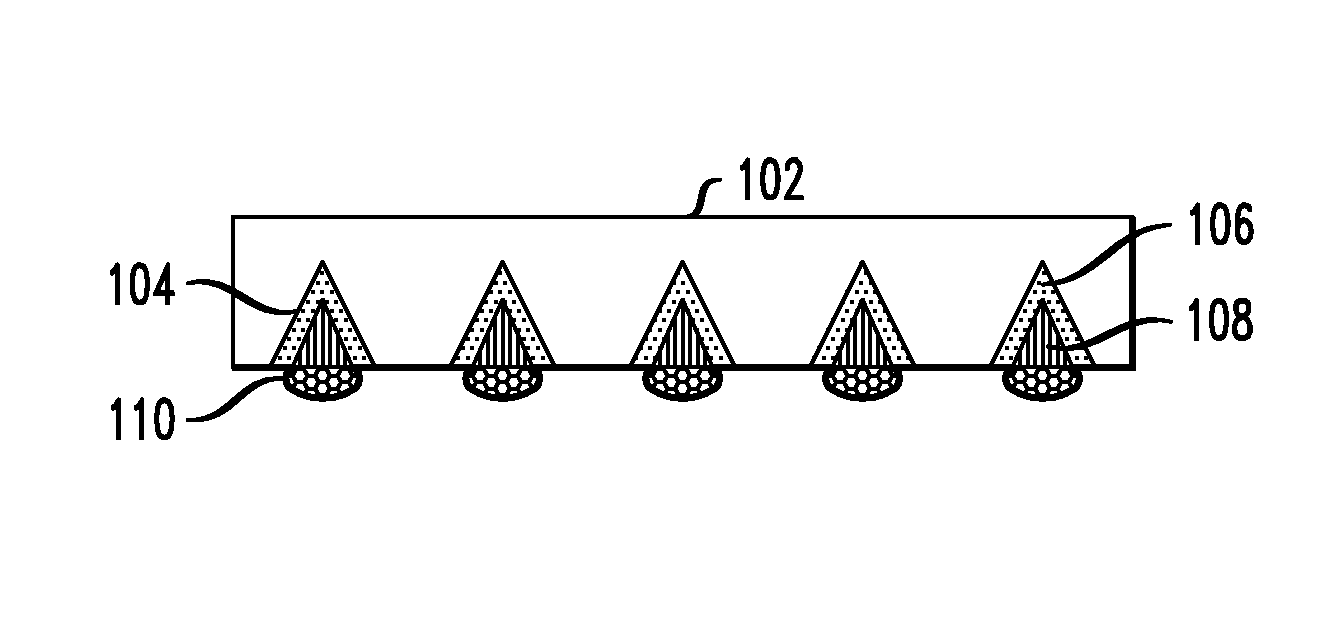

Pixel structure and micro light-emitting diode transfer method

InactiveCN109830191AGuaranteed Alignment AccuracyDoes not affect the driveSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The invention discloses a pixel structure and a micro light-emitting diode transfer method, and belongs to the field of display panel manufacturing. The pixel structure comprises a data line and a scanning line which are arranged crisscross, power lines parallel to the data line, a pixel area defined by the scanning line, the data line and the power lines, a capacitive electrode located in the pixel area, a bonding metal layer which is located in the pixel area and connected with the capacitive electrode and an alignment mark arranged in the bonding metal layer. Accordingly, the alignment markis arranged on the bonding alloy layer, alignment operation is conducted through the micro light-emitting diode and the alignment mark, not only can the alignment precision in the micro light-emitting diode transfer process be guaranteed, but also the drive of the micro light-emitting diode cannot be affected, other structures are not additionally arranged, an existing manufacturing process is changed, new technological processes cannot be additionally added, and economization of production is achieved.

Owner:NANJING CEC PANDA LCD TECH

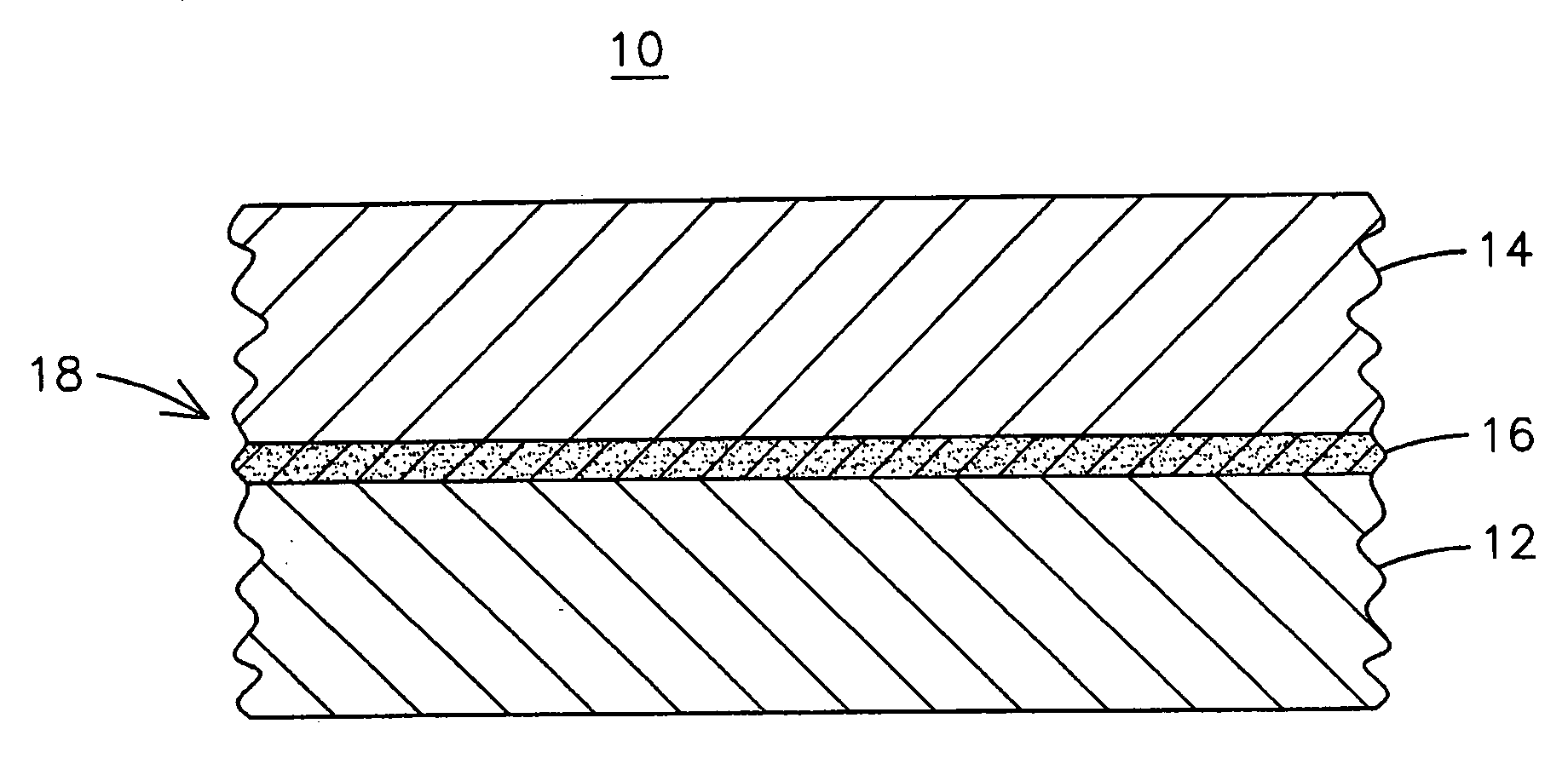

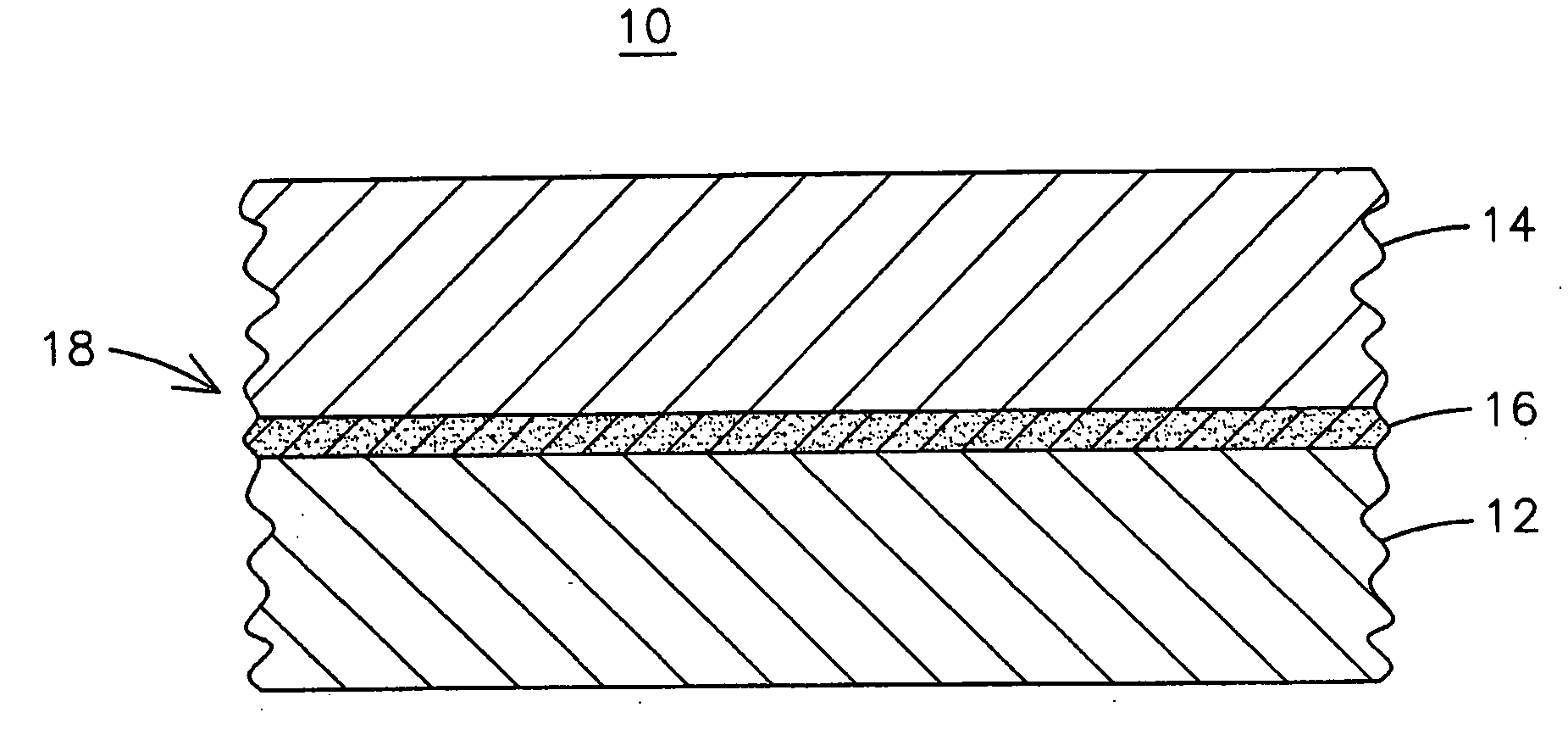

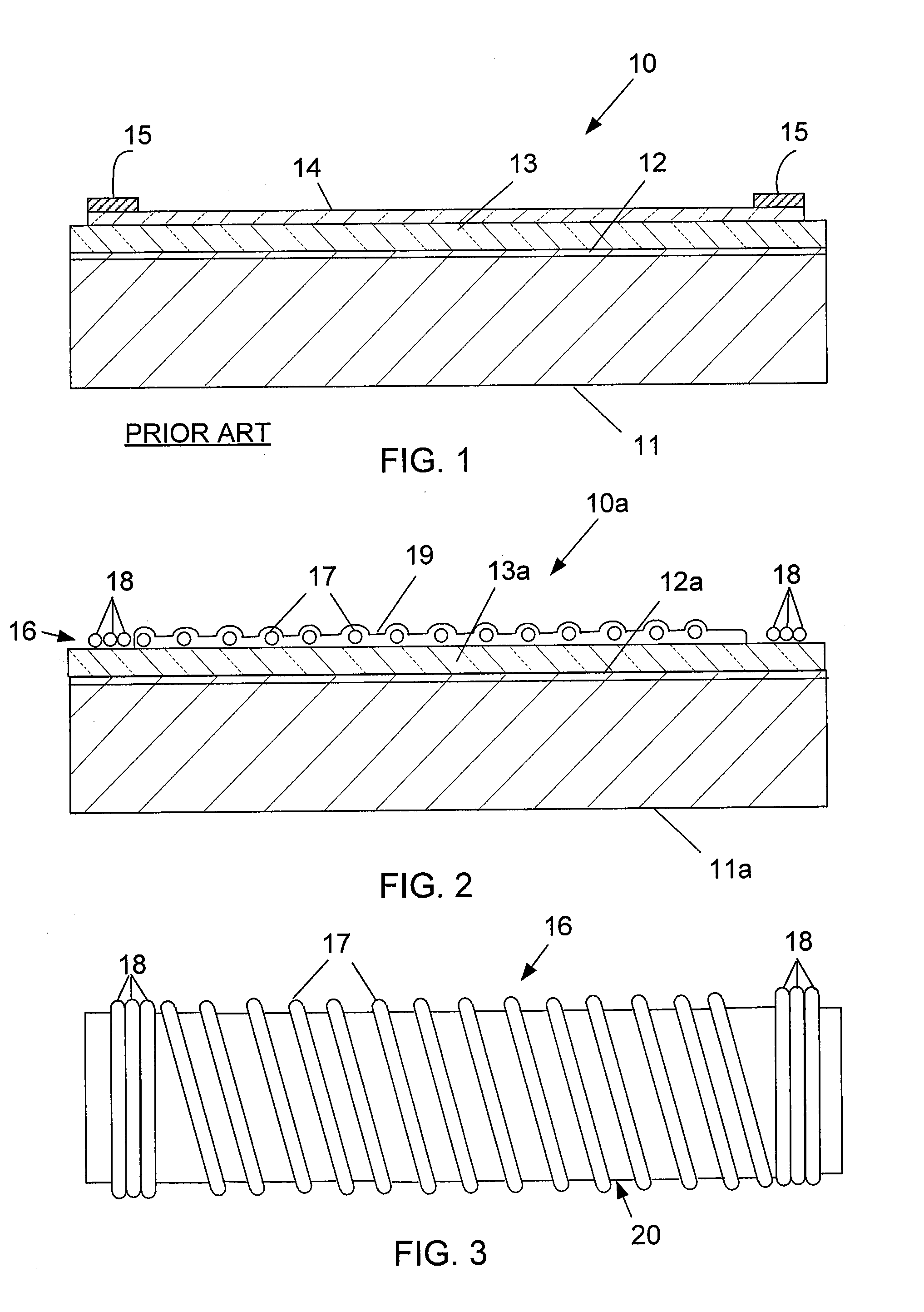

Boron free joint for superalloy component

A boron-free and silicon-free bonding alloy (16) for joining with a superalloy base material (12, 14). The bonding alloy includes aluminum in a concentration that is higher than the concentration of aluminum in the base material in order to depress the melting temperature for the bonding alloy to facilitate liquid phase diffusion bonding without melting the base material. The concentration of aluminum in the bonding alloy may be at least twice that of the concentration of aluminum in the base material. For joining cobalt-based superalloy materials that do no contain aluminum, the concentration of aluminum in the bonding alloy may be at least 5 wt. %.

Owner:SIEMENS ENERGY INC

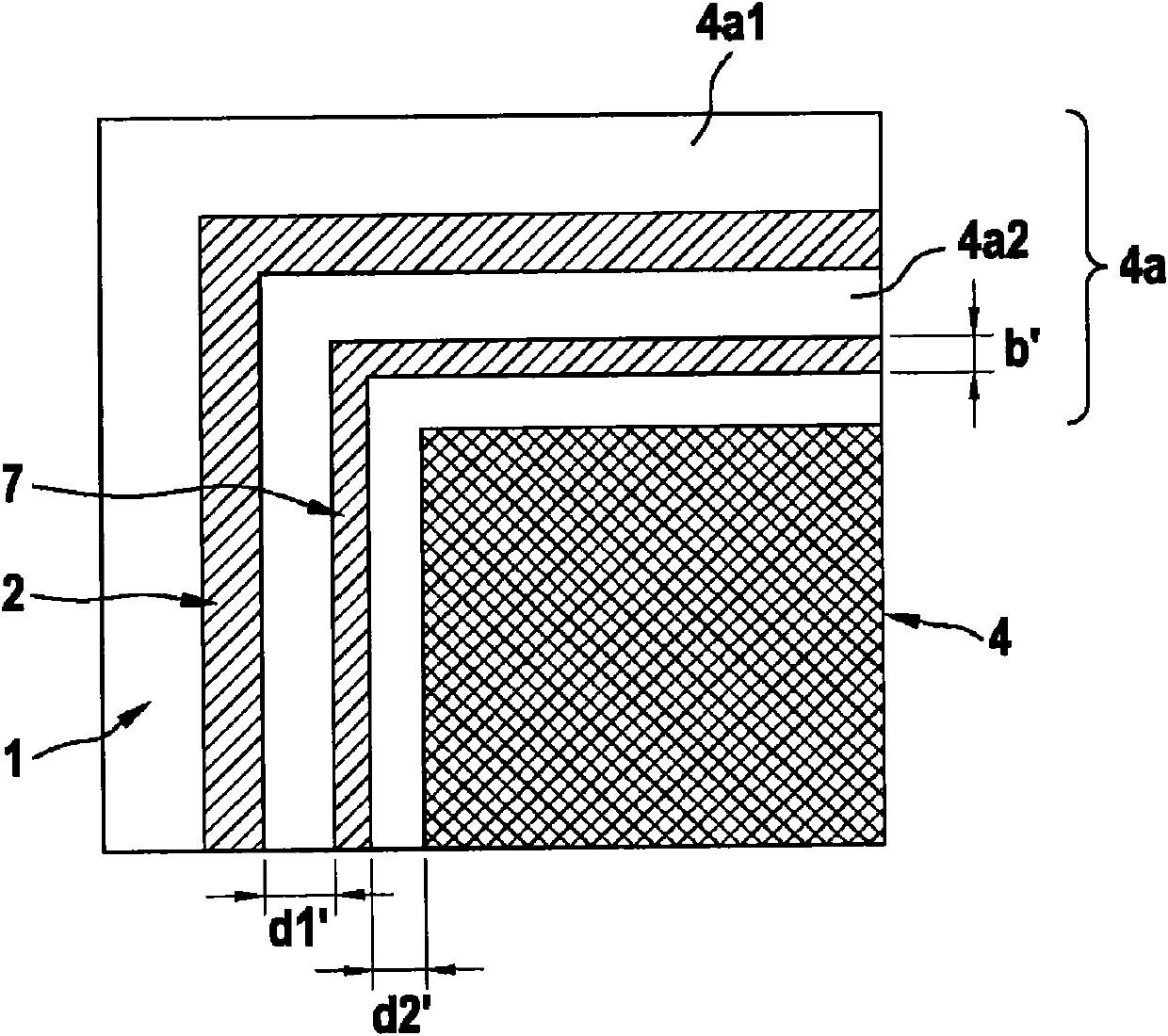

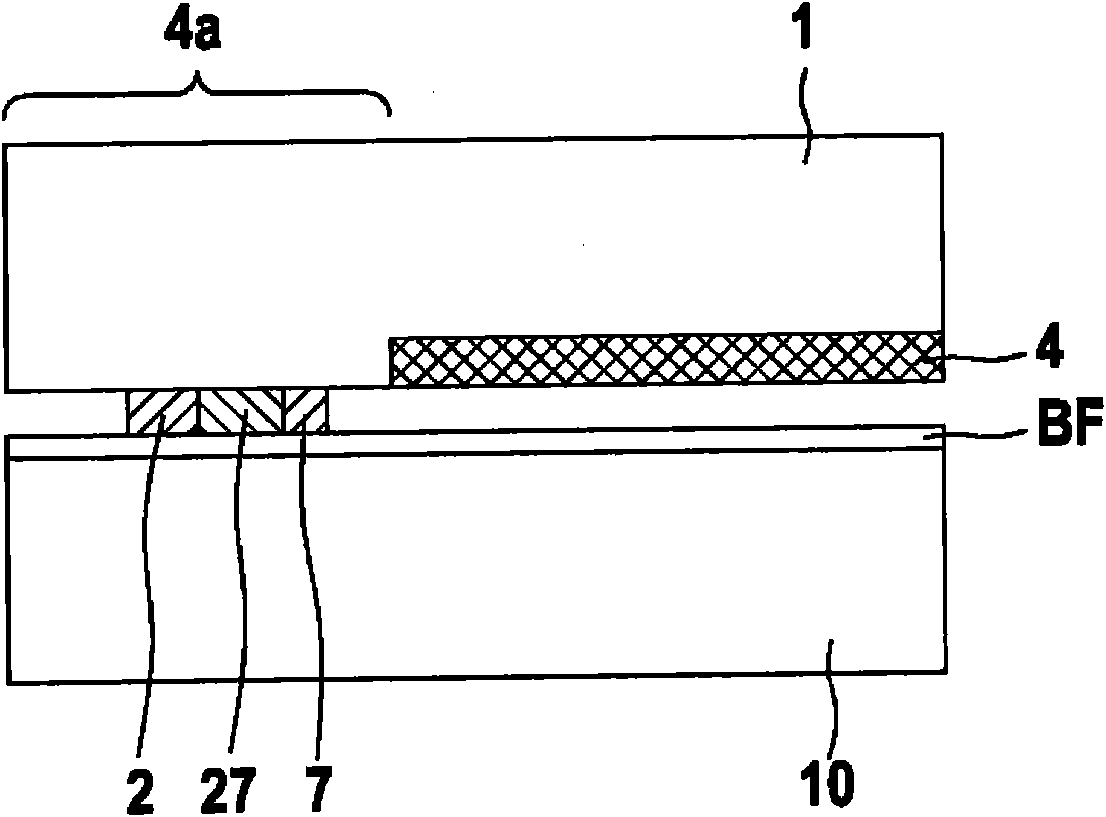

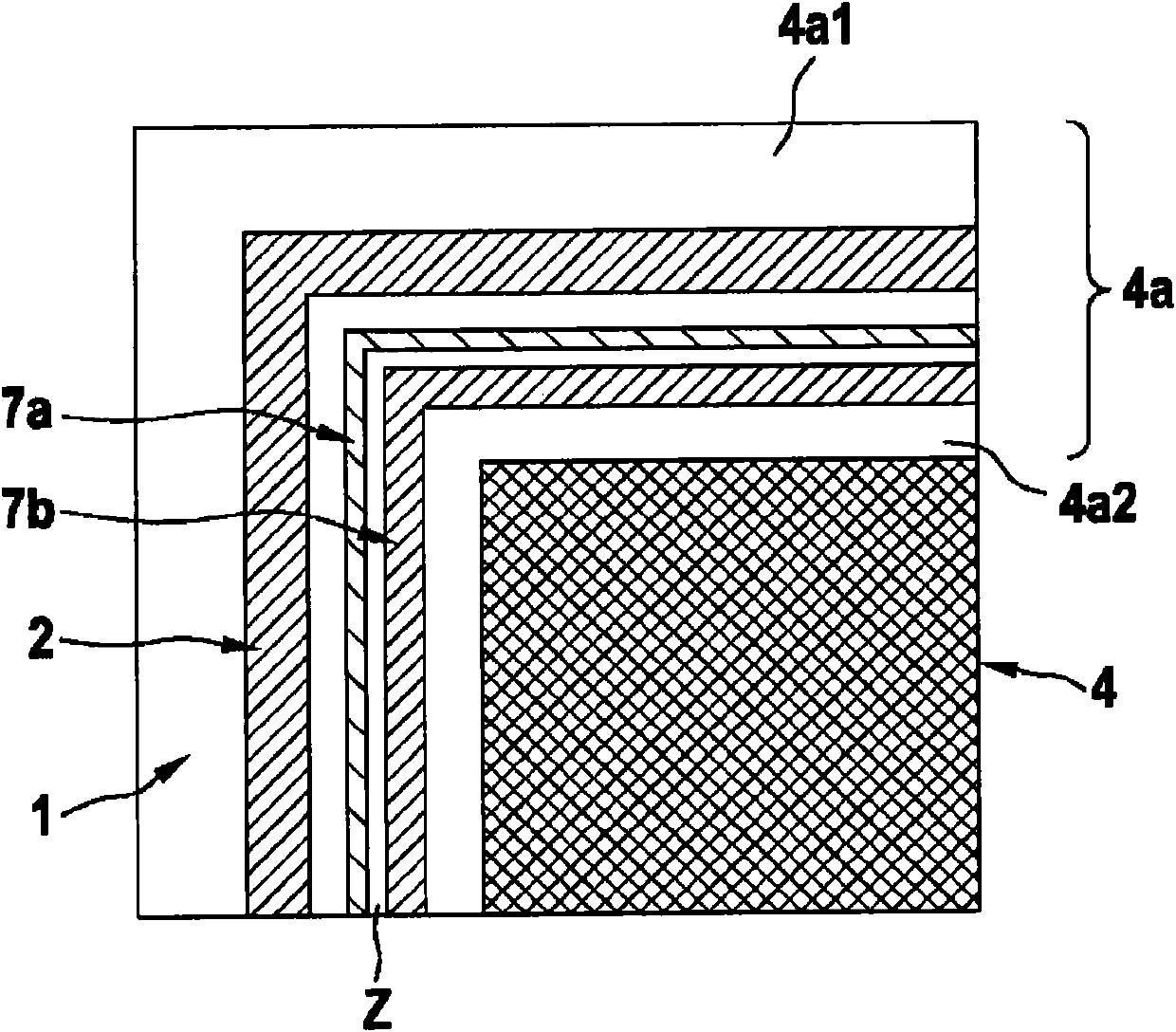

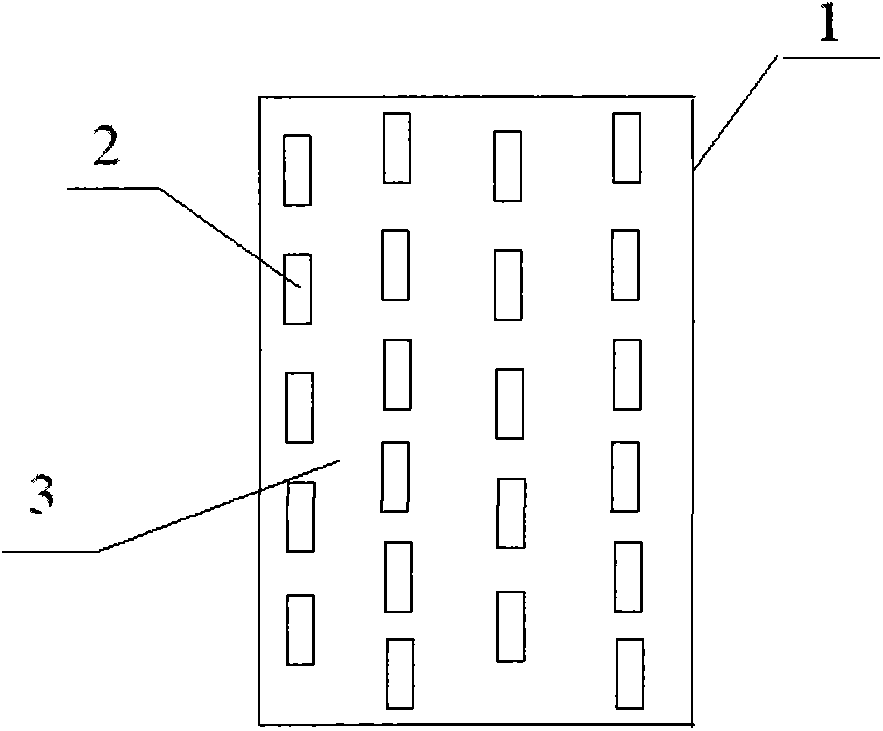

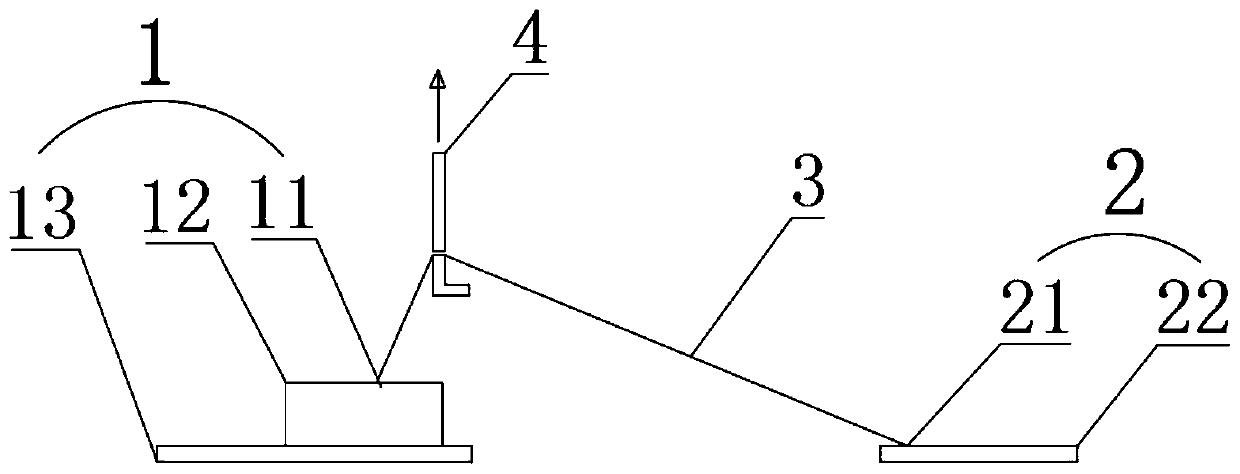

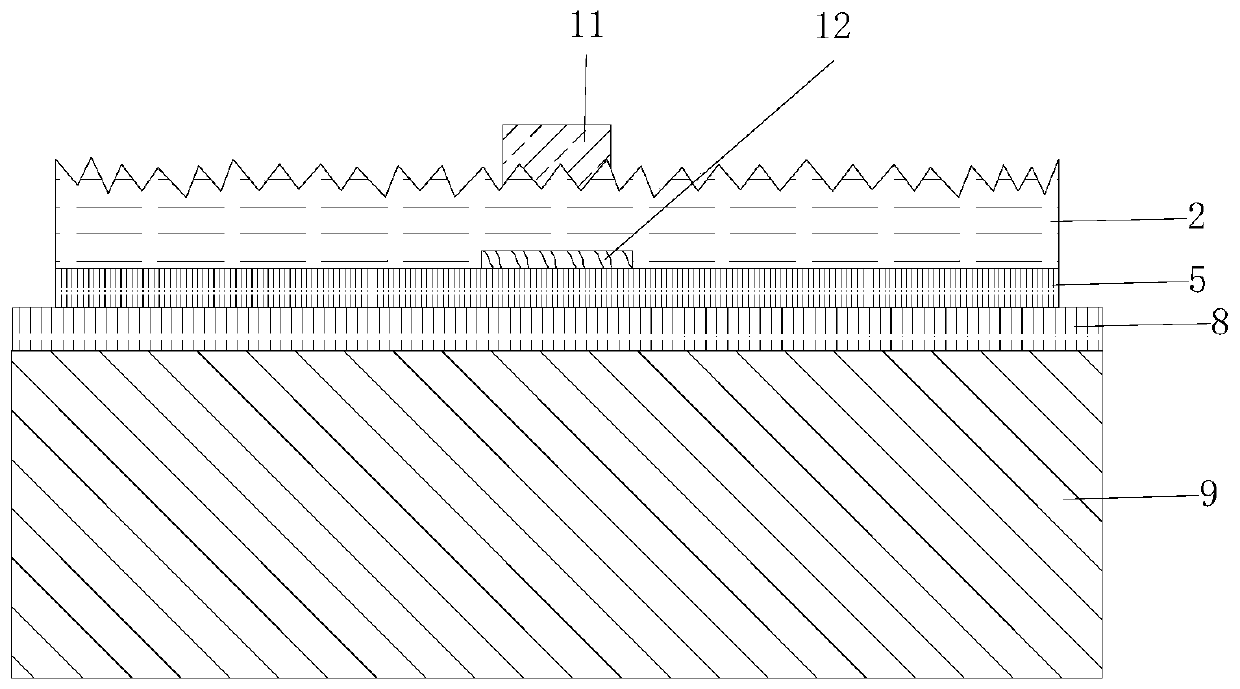

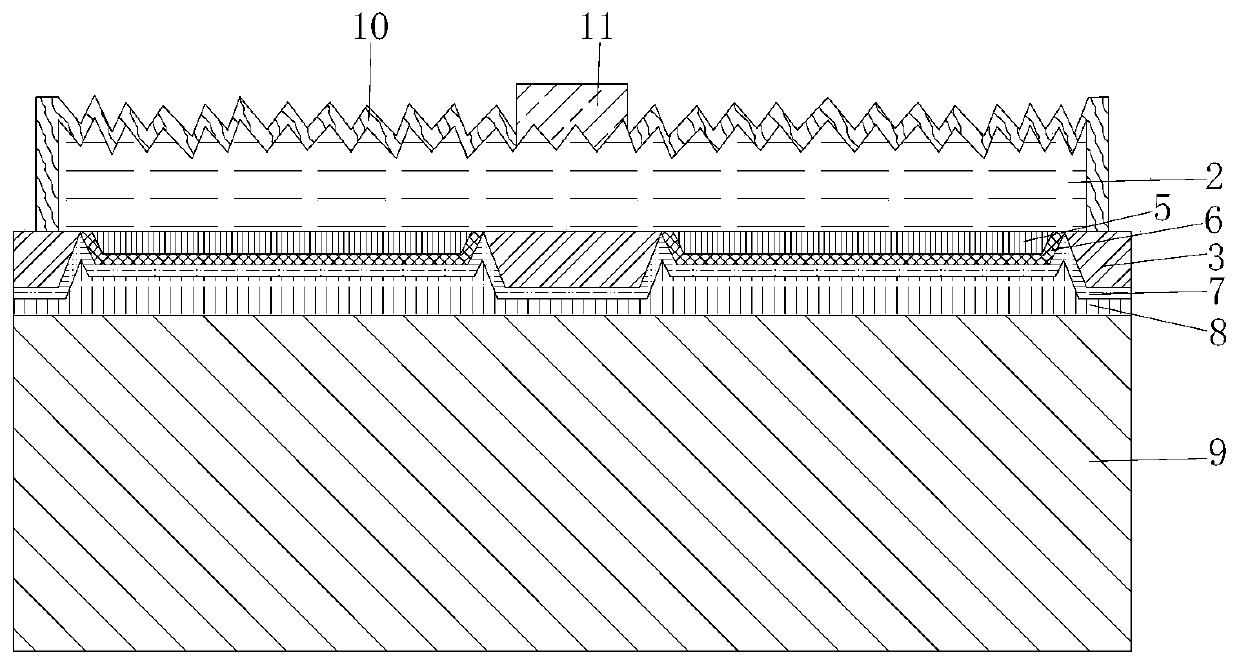

Micromechanical method and corresponding assembly for bonding semiconductor substrates and correspondingly bonded semiconductor chip

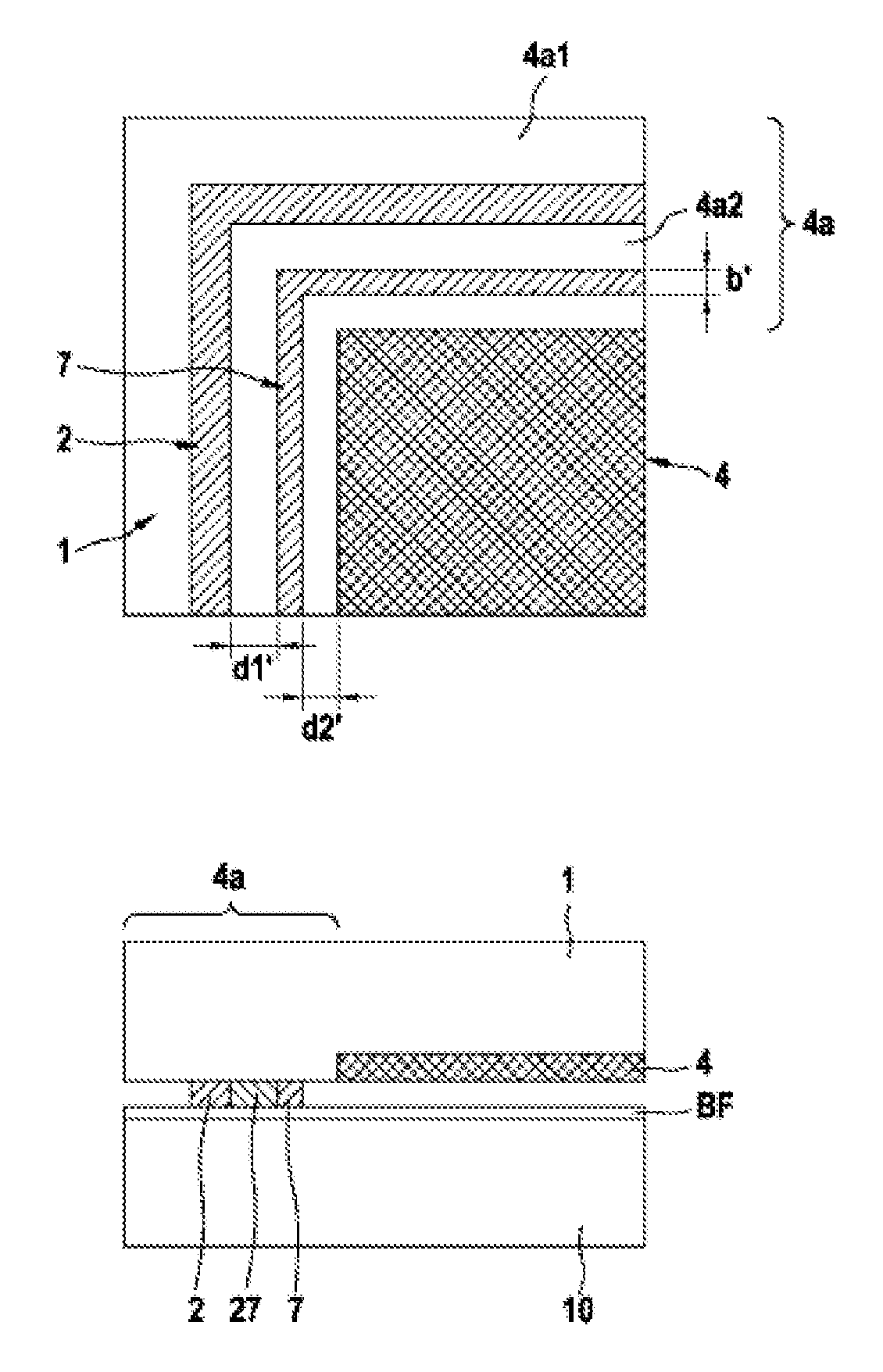

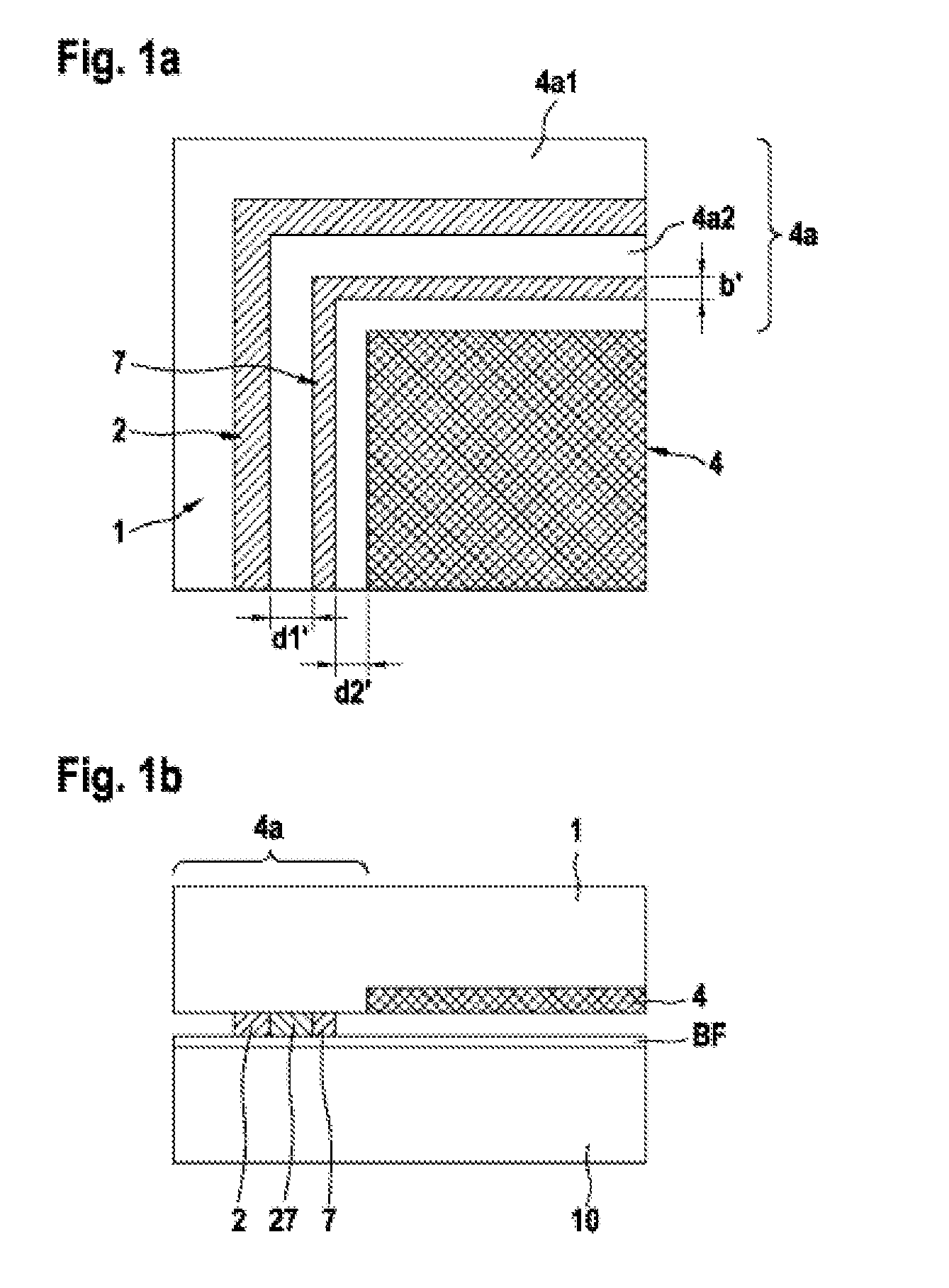

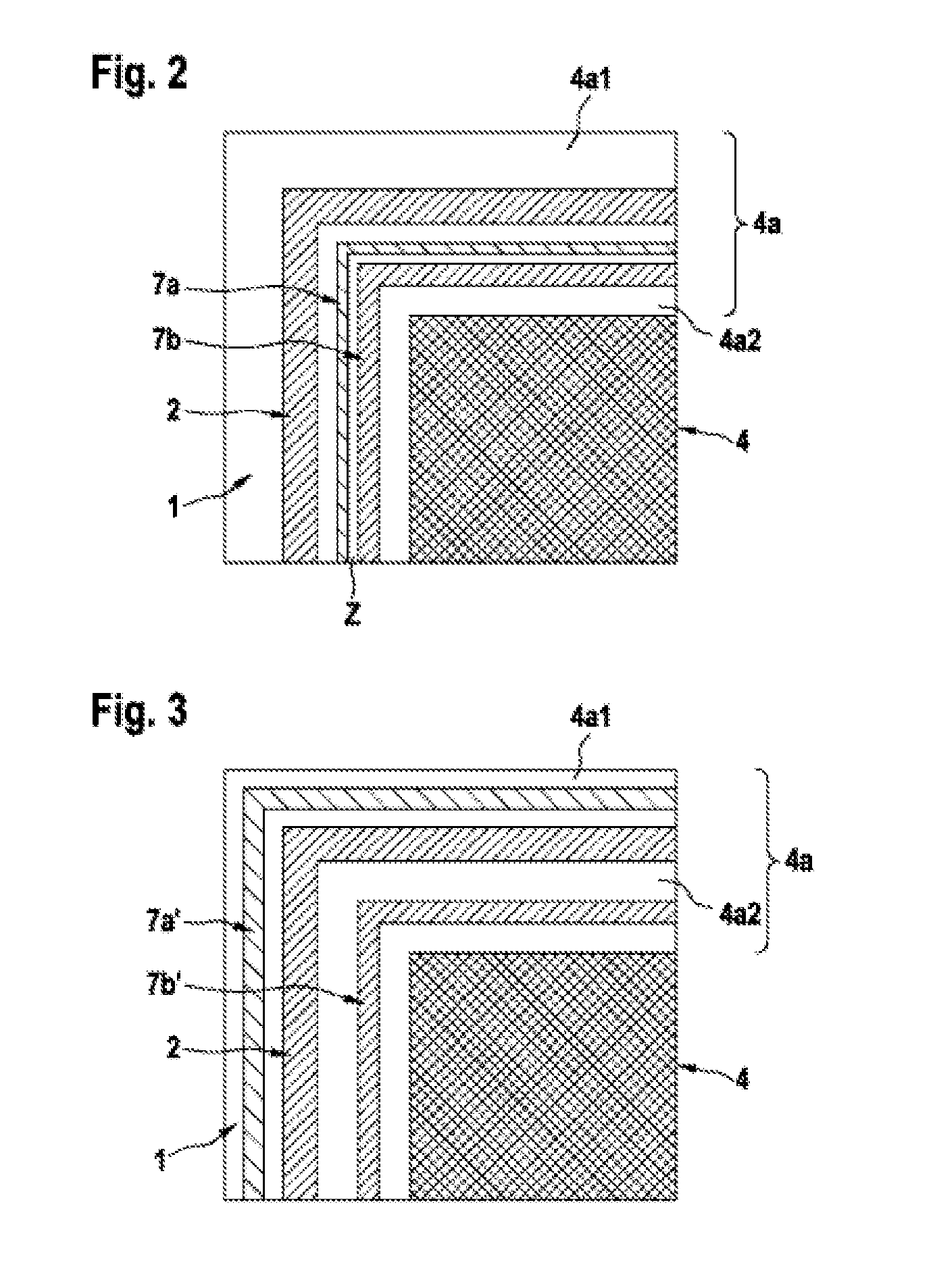

InactiveCN102666368AReduced area requirementsHigh melting pointPrecision positioning equipmentSemiconductor/solid-state device detailsSemiconductor chipEngineering

The invention relates to a micromechanical method and a corresponding assembly for bonding semiconductor substrates and a correspondingly bonded semiconductor chip. The assembly according to the invention comprises a semiconductor substrate having a chip pattern having a plurality of semiconductor chips (1), each having a functional region (4) and an edge region (4a) surrounding the functional region (4), wherein there is a bonding frame (2) made of a bonding alloy made from at least two alloy components in the edge region (4a), spaced apart from the functional region (4). Within the part (4a2) of the edge region (4a) surrounding the bonding frame (2) between the bonding frame (2) and the functional region (4), there is at least one stop frame (7; 7a, 7b; 7b'; 70) made of at least one of the alloy components, which is designed such that when a melt of the bond alloy contacts the stop frame (7; 7a, 7b; 7b'; 70) during bonding, the bonding alloy solidifies.

Owner:ROBERT BOSCH GMBH

Transferable probe tips

ActiveUS9200883B2Semiconductor/solid-state device testing/measurementDecorative surface effectsMaterials scienceBonding alloy

Transferable probe tips including a metallic probe, a delamination layer covering a portion of the metallic probe, and a bonding alloy, wherein the bonding alloy contacts the metallic probe at a portion of the probe that is not covered by the delamination layer are provided herein. Also, techniques for creating a transferable probe tip are provided, including etching a handler substrate to form one or more via arrays, depositing a delamination layer in each via array, depositing one or more metals in each via array to form a probe tip structure, and depositing a bonding alloy on a portion of the probe tip structure that is not covered by the delamination layer. Additionally, techniques for transferring transferable probe tips are provided, including removing a handler substrate from a probe tip structure, and transferring the probe tip structure via flip-chip joining the probe tip structure to a target probe head substrate.

Owner:INT BUSINESS MASCH CORP

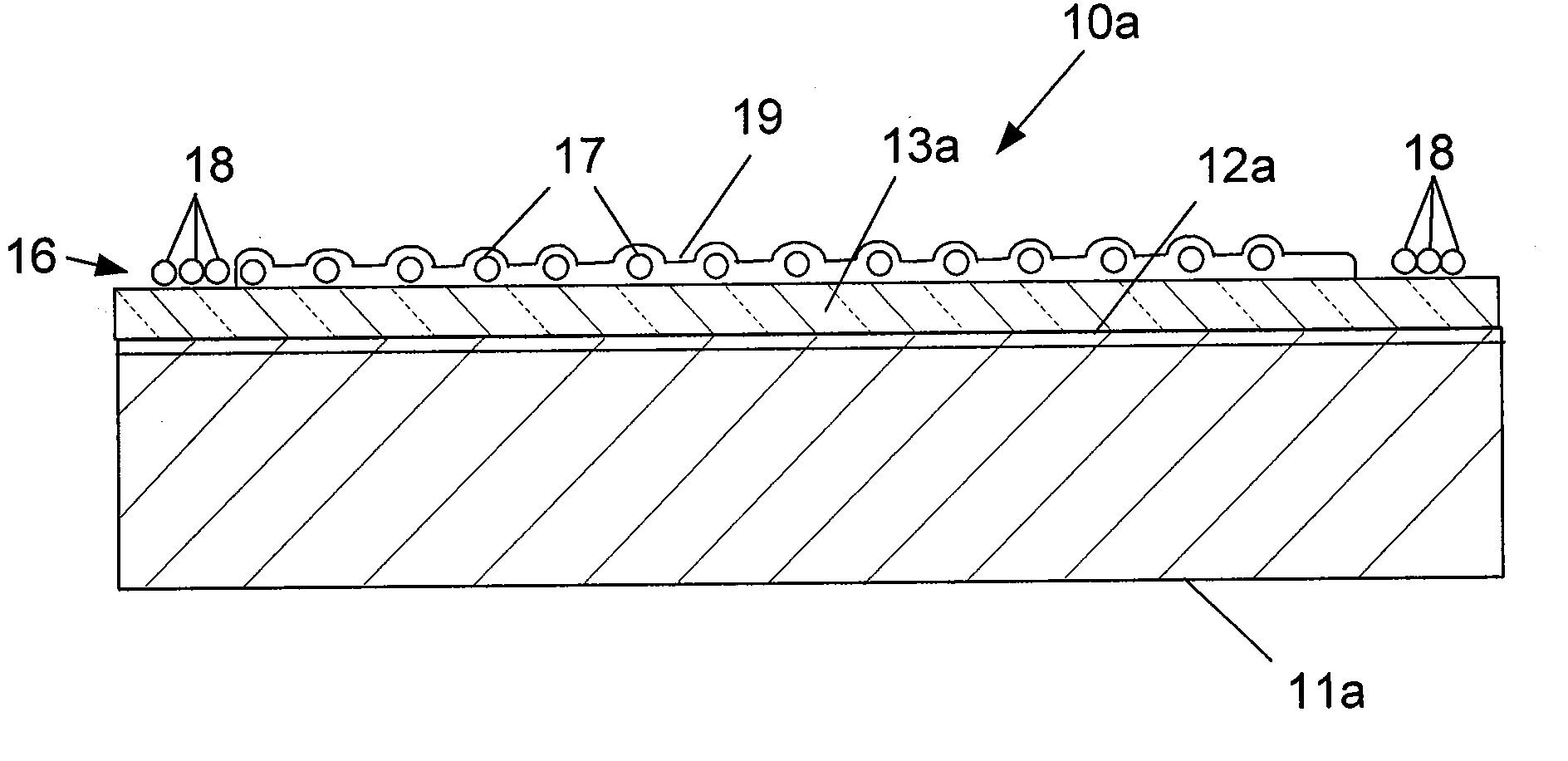

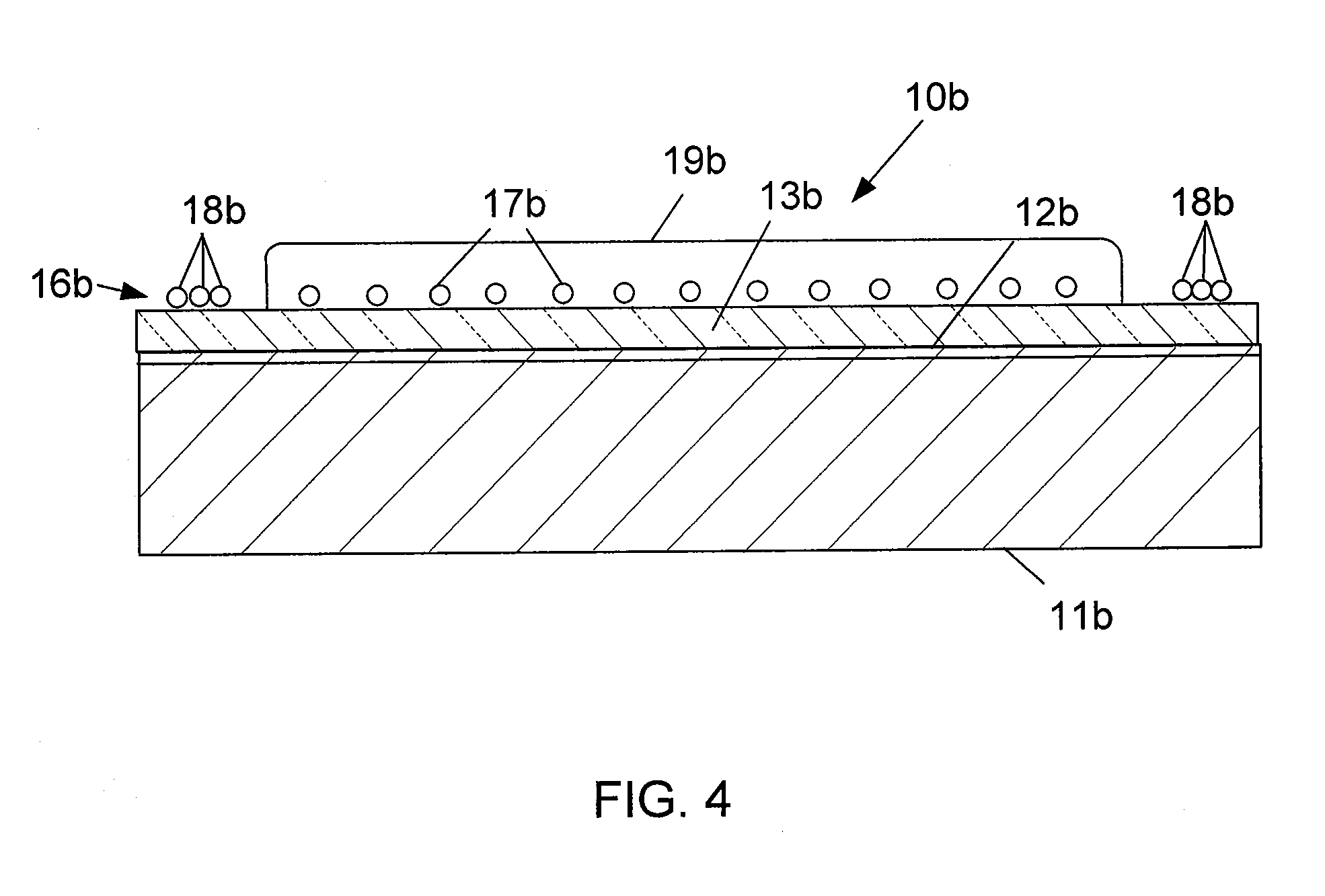

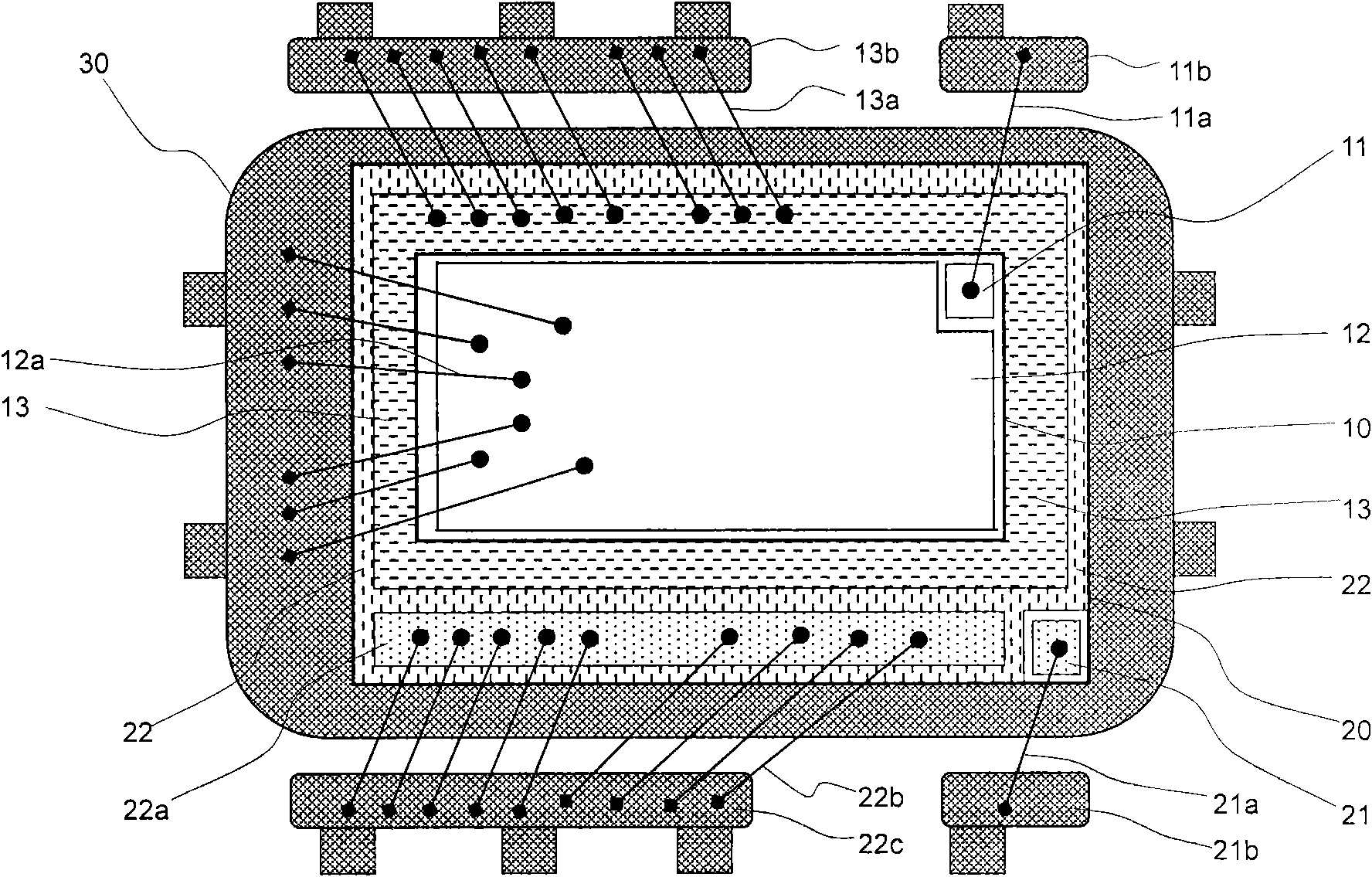

Method and Apparatus for Providing a Machine Barrel with a Heater

InactiveUS20120111851A1Good thermal contactWave amplification devicesHeating element shapesElectrical resistance and conductanceEngineering

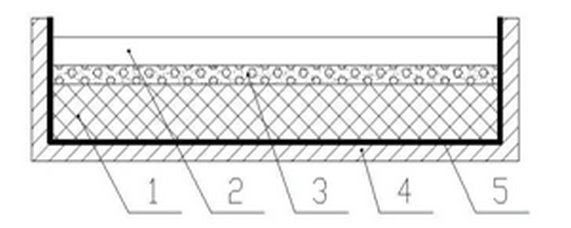

A barrel (11a, 11b) adapted for use in a plastics machine, has an inner layer of insulating ceramic (13a, 13b) disposed over and around the barrel along its length to form an insulated barrel, a wire layer (16, 16b) including a plurality of heating coils (17, 17b) of alloy resistance wire wound around the insulated barrel under tension in a spiral fashion, the wire layer also providing additional termination coils (18, 18b) near opposite ends of the barrel for making electrical contact with a source of electrical power to heat the barrel, and a top layer (19, 19b) of an electrically insulating ceramic disposed over the heating coils A method of making a barrel with a heater, comprises spraying a layer (12, 12b) of a metal bonding alloy over a portion of the barrel to be heated.

Owner:AMERICAN ROLLER

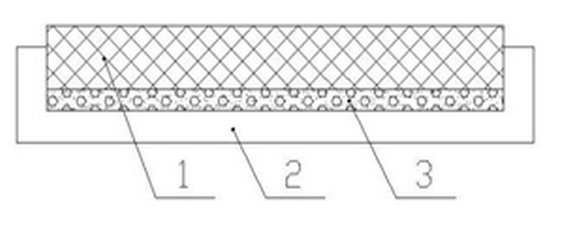

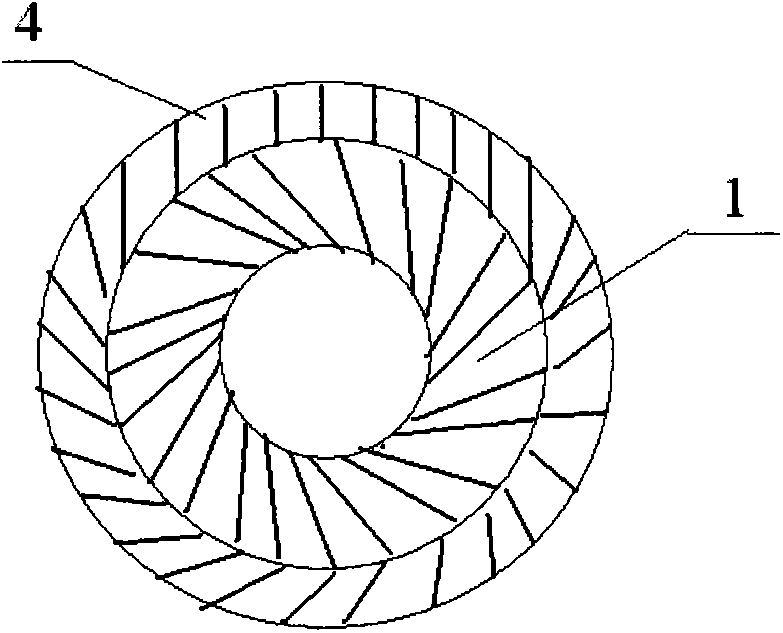

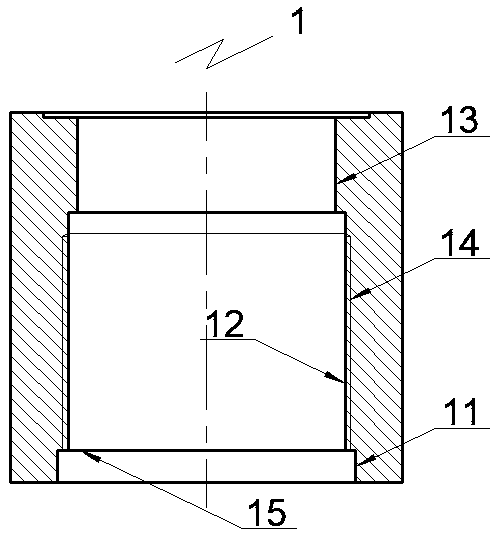

Bearing for oil and gas development drilling

InactiveCN104100638AHigh hardnessGood wear resistanceShaftsBearing componentsWear resistantUltra fine

The invention discloses a bearing for a screw rod drill. The bearing comprises an inner sleeve and an outer sleeve, wherein wear resistant layers are respectively bonded on the outer surface of the inner sleeve and the inner surface of the outer sleeve, and are prepared by arranging hard alloy blocks on a steel main body by certain rules; gaps among the hard alloy blocks are formed by brazing tungsten carbide powder and bonding alloy in a high-temperature furnace; the hard alloy blocks are ultra-fine grain gradient hard alloy blocks rich in cobalt on the surfaces, and comprise the following raw materials: 2-3% of Ti (C, N), 5-5.5% of Co, 0.2-0.4% of VC, 0.3-0.5% of Cr3C2, 0.1-0.3% of carbon black, and the balance of WC; the bonding alloy comprises the following components in percentage by weight: 11-12% of Ni, 12-14% of Zn, 23-24% of Mn, and the balance of copper; and the total amount of impurities is not greater than 0.45%. The wear resistant layers of the bearing have such characteristics as high hardness, good roughness, long wear resistant time and firm combination with a steel matrix.

Owner:江苏长城石油装备制造有限公司

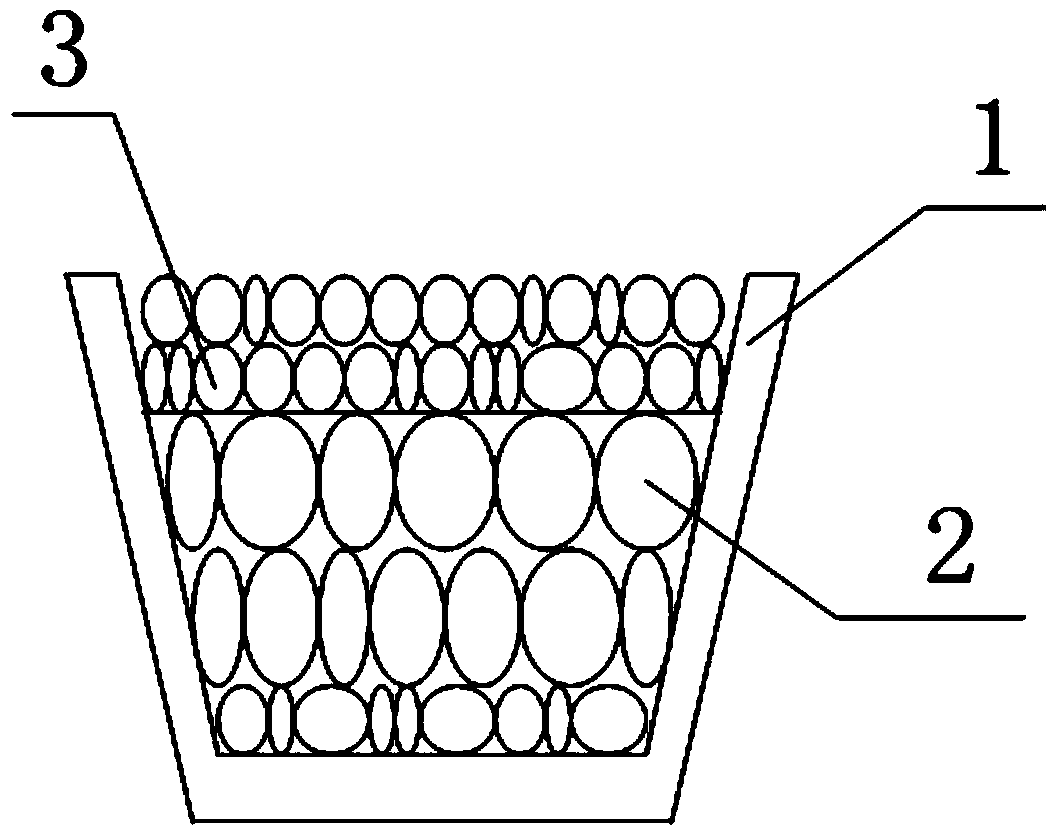

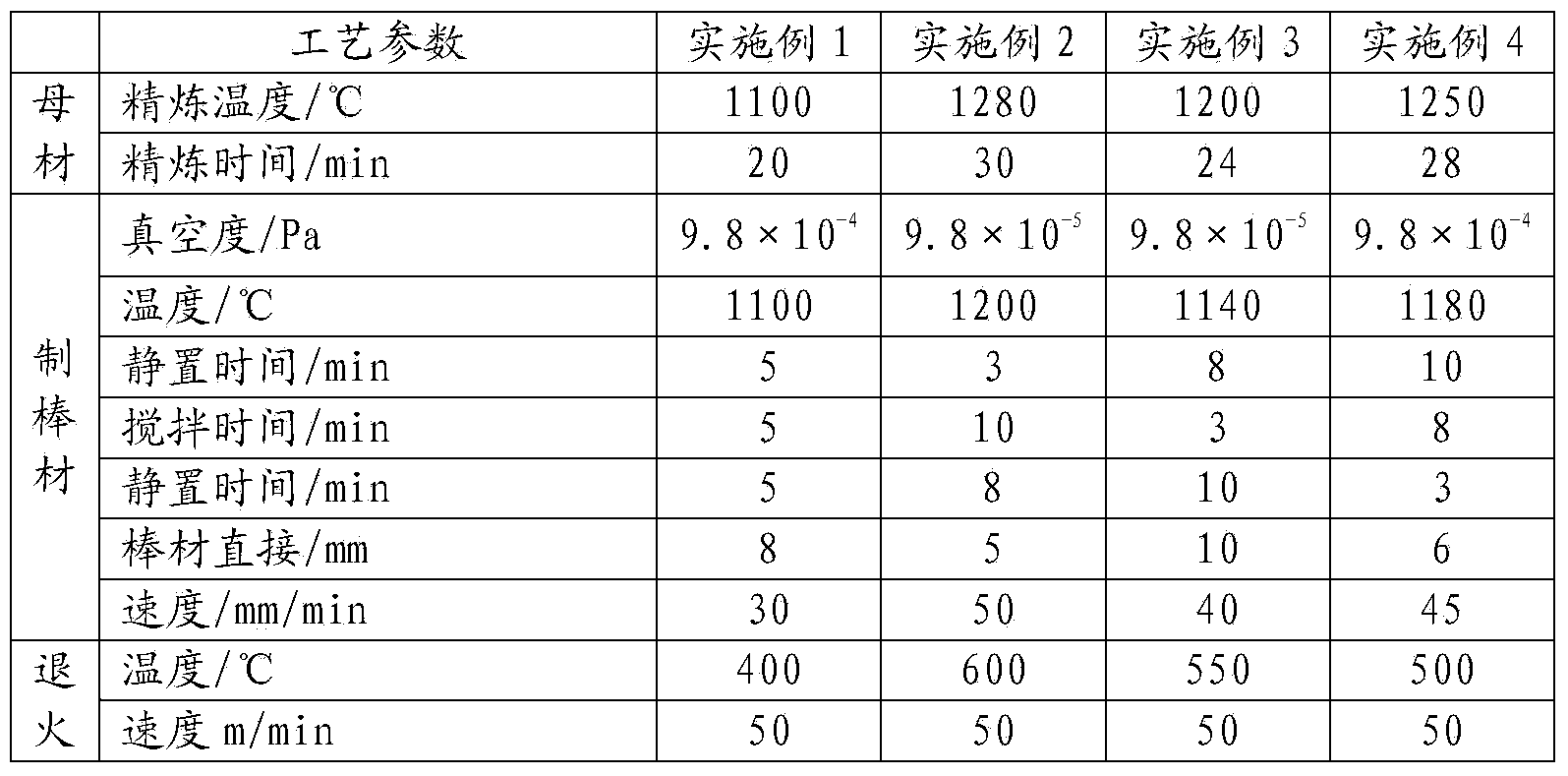

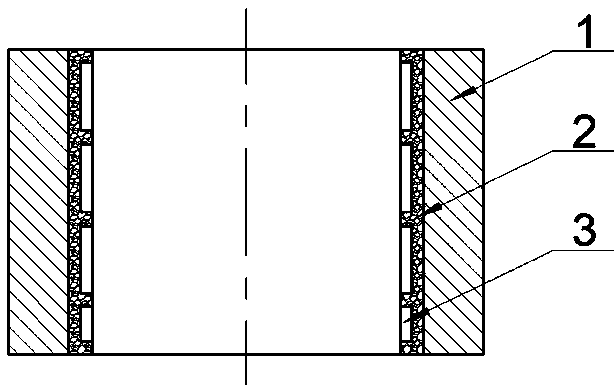

Imitation gold bonding alloy wire and preparation method thereof

ActiveCN103834832ALow costReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesIndiumCopper

The invention discloses an imitation gold bonding alloy wire and a preparation method thereof. The imitation gold bonding alloy wire comprises 65-80wt% of alloy wire silver, 17-32wt% of copper, 0.5-2wt % of indium and 0.5-1wt% of palladium. A certain proportion of copper, palladium and indium are added on the basis of the silver, so that the cost of the raw materials is extremely low. The imitation gold bonding alloy wire has excellent mechanical performance and can meet the welding technique requirements under conventional conditions, and the manufacturing cost of LED (Light Emitting Diode) and IC (Integrated Circuit) encapsulation can be greatly reduced; meanwhile, the color of the appearance of the imitation gold bonding alloy wire is consistent with the color of 22K-18K gold, and the perfect imitation gold is obtained.

Owner:浙江佳博科技股份有限公司

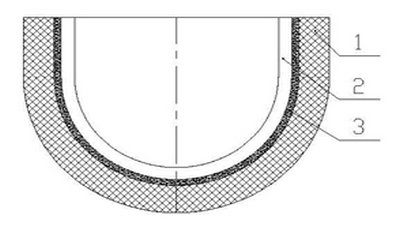

Manufacturing method of radial strengthening sliding bearing static ring

The invention provides a manufacturing method of a radial strengthening sliding bearing static ring. The method comprises the steps that a static ring manufacturing mold is acquired, the mold comprises a core mold and a matrix coaxially placed outside the core mold, annular space is formed between the core mold and the matrix, and containing space is formed among the core mold, the matrix and a cover plate; a locating datum is arranged, a to-be-bonded component is cleaned, and a wear-resisting part is bonded to the outer cylinder face of the core mold; filler is assembled, cast tungsten carbide powder is dumped into the residual clearance of the annular space, locating powder is placed into the position above the cast tungsten carbide powder to form a locating layer, then a certain quantity of a bonding alloy is placed according to the proportion, a certain quantity of a fluxing agent is evenly scattered on the bonding alloy according to the proportion, and the mold is covered with thecover plate; the assembled and filled mold is sintered, and a static ring blank is obtained; and after air cooling, the static ring blank is machined, and the size of the static ring can meet the design requirements. By means of the method, the work life of a radial strengthening sliding bearing can be prolonged, and meanwhile the machining difficulty and manufacturing cost can be reduced.

Owner:BEIJING CHUNLUN PETROLEUM TECH DEV CO LTD

A kind of preparation method of bonding gold-silver alloy

The invention relates to a preparation method of a bonding gold-silver alloy and belongs to the technical field of bonding wire machining process. The bonding gold-silver alloy wire is composed of the following metal materials in a weight ratio: 20-30% of silver, 5-1000ppm of palladium, calcium, beryllium and cerium and the balance of gold; the preparation method comprises the following steps: 1) preparing materials; 2) smelting an alloy ingot; 3) cast-drawing an alloy rod; 4) drawing a wire; 5) performing annealing; 6) performing wiring; and 7) performing packaging. The preparation method of the bonding gold-silver alloy provided by the invention is reasonable and standard in process design and simple to operate. The produced bonding alloy gold-silver alloy wire is good in electric conductivity and stable in chemical property, has good resistance to oxidation, flowability and plasticity, has a relatively high breaking force and relatively good elongation, is moderate in price, and can fully meet the demand of an LED illumination technology in a semiconductor encapsulation industry on performance of the bonding alloy gold-silver alloy wire.

Owner:侯霞

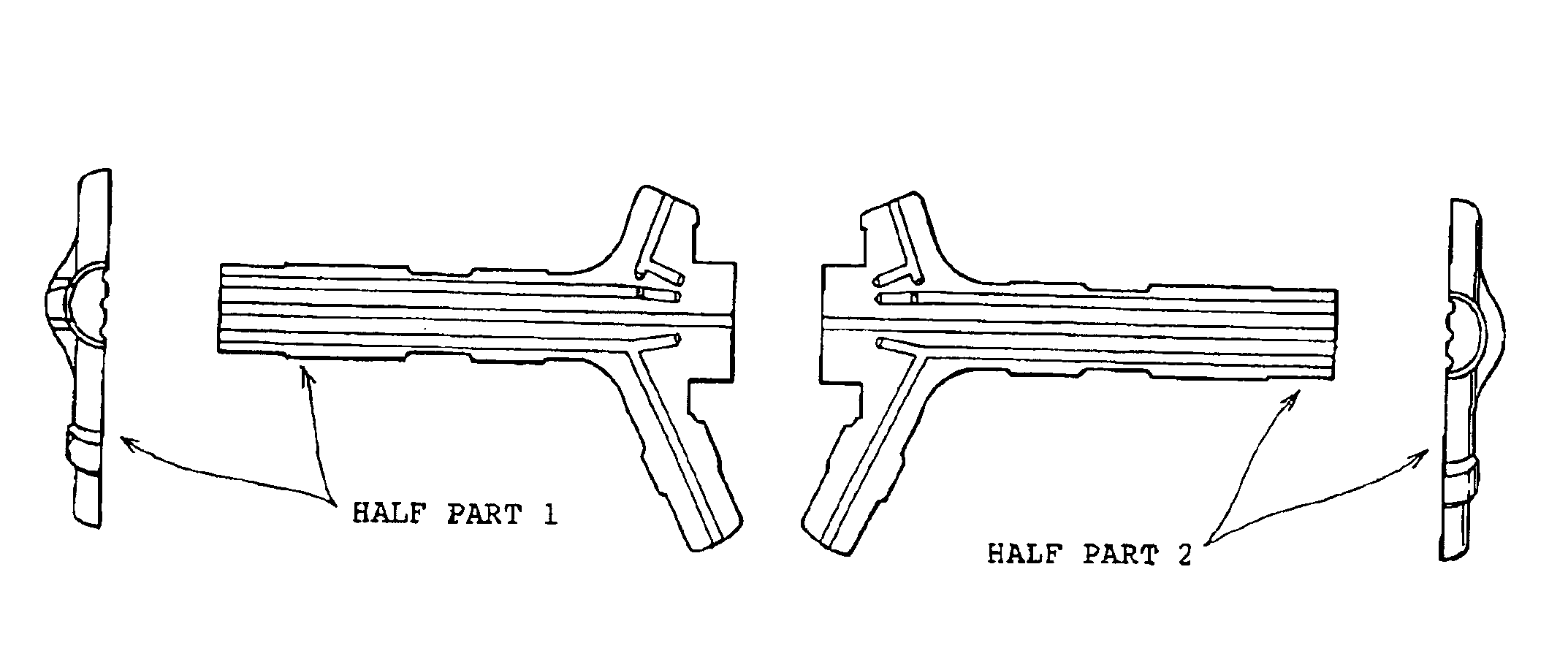

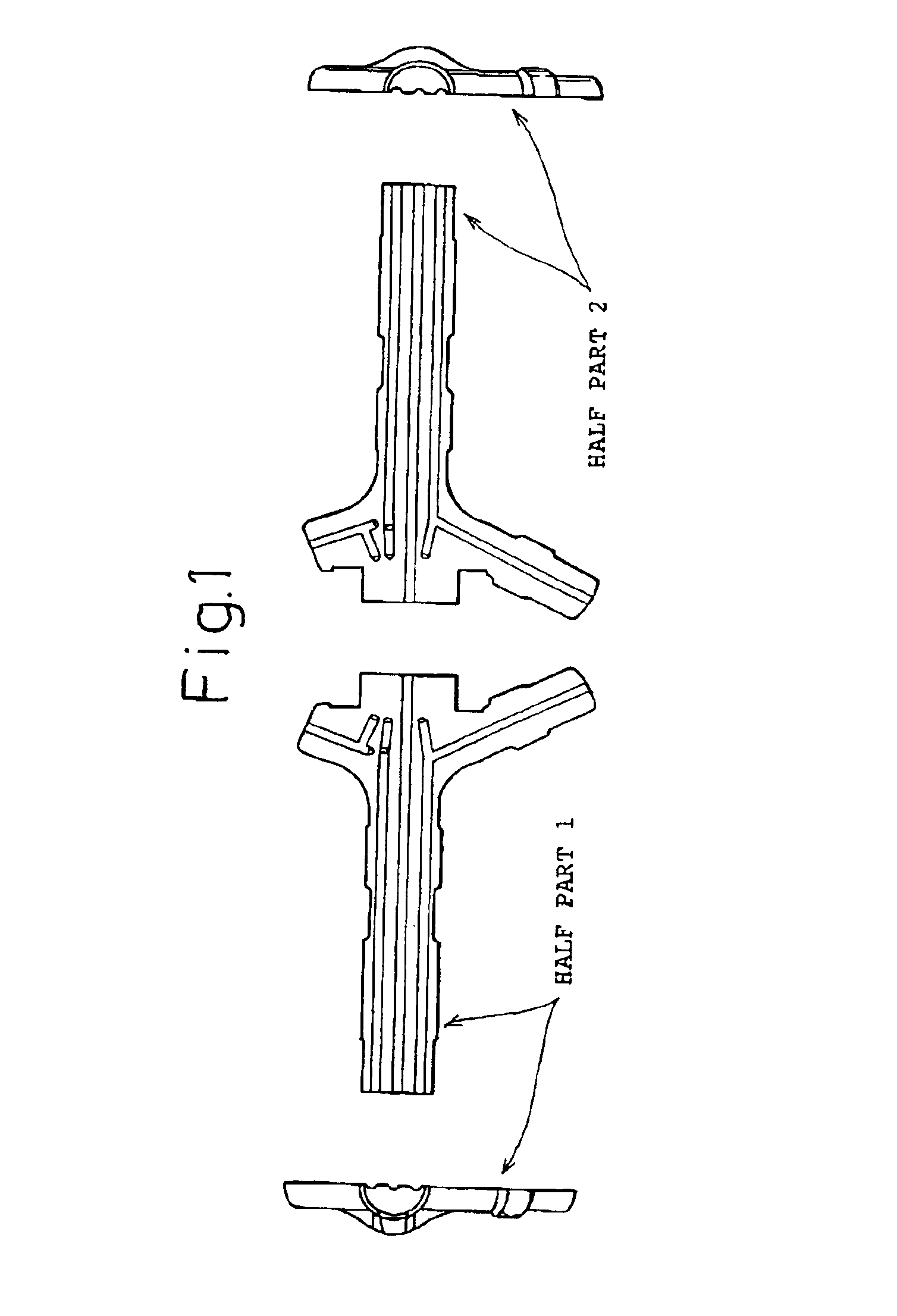

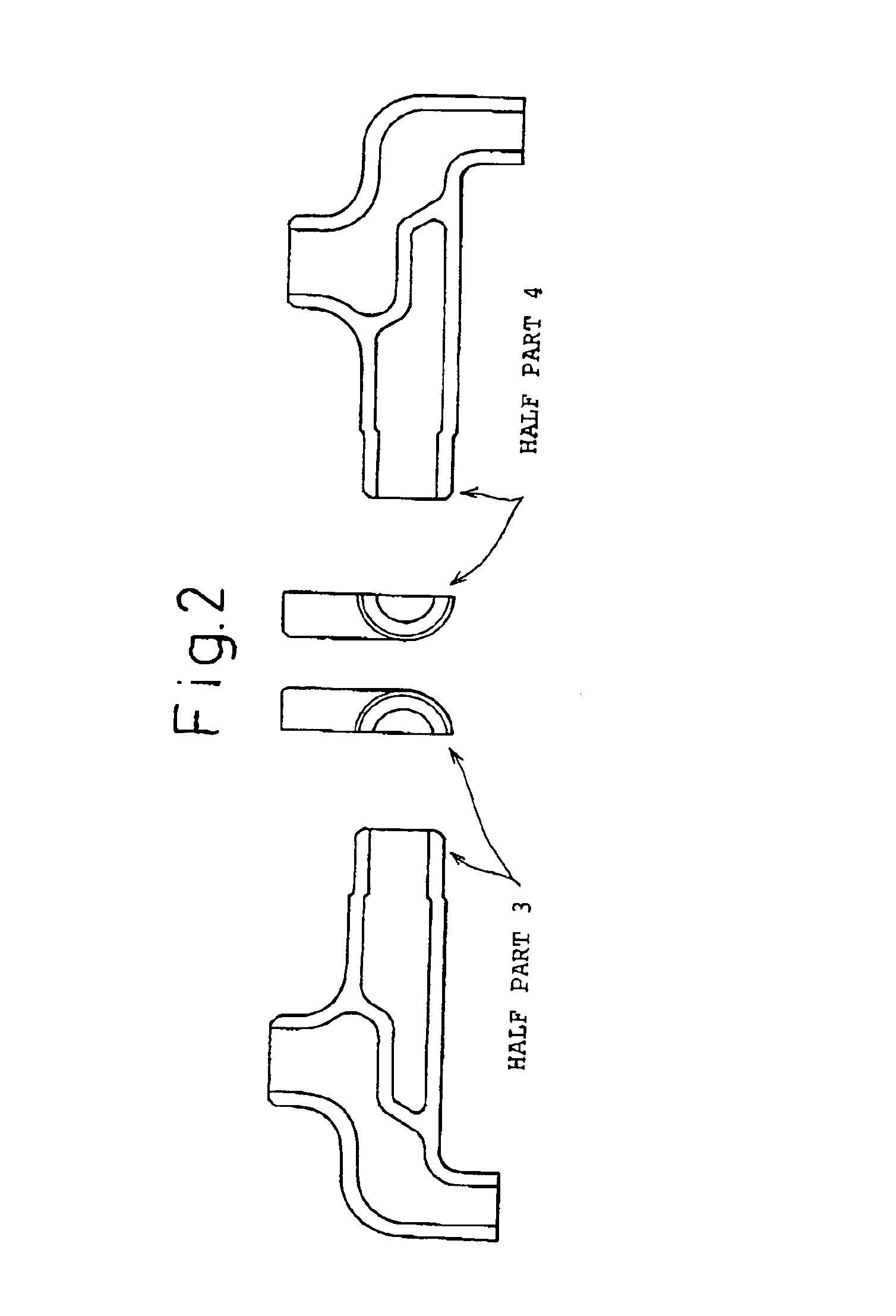

Liquid phase diffusion welded metal-made precision machine component and production method thereof

InactiveUS6913842B2Smooth and precise jointBonding time is constantHigh frequency current welding apparatusWelding/cutting media/materialsMachine partsEngineering

A precision machine part is made of a plurality of pieces with a transient liquid phase diffusion bonding alloy provided between the pieces to bond them together. The precision machine part has one or more conveyance passages formed in it, has a longitudinal axis and is configured to permit passage of liquid or gas through the conveyance passage from a pipe line or cylinder. The pieces of the precision machine part are adhered to each other by transient liquid phase bonding with a ribbon of an amorphous bonding alloy. The bonding alloy can contain 1 to 10 atomic % V or can contain 1 to 15 atomic % of B or P or a mixture of B and P and 1 to 10 atomic % V, the balance being Fe and unavoidable impurities, and can exhibit an amount of contraction in a bonding stress loading direction caused by plastic deformation in the bonding process of not more than 5%. The bonding alloy may be an amorphous Ni-based alloy.

Owner:FUKUJU INDS

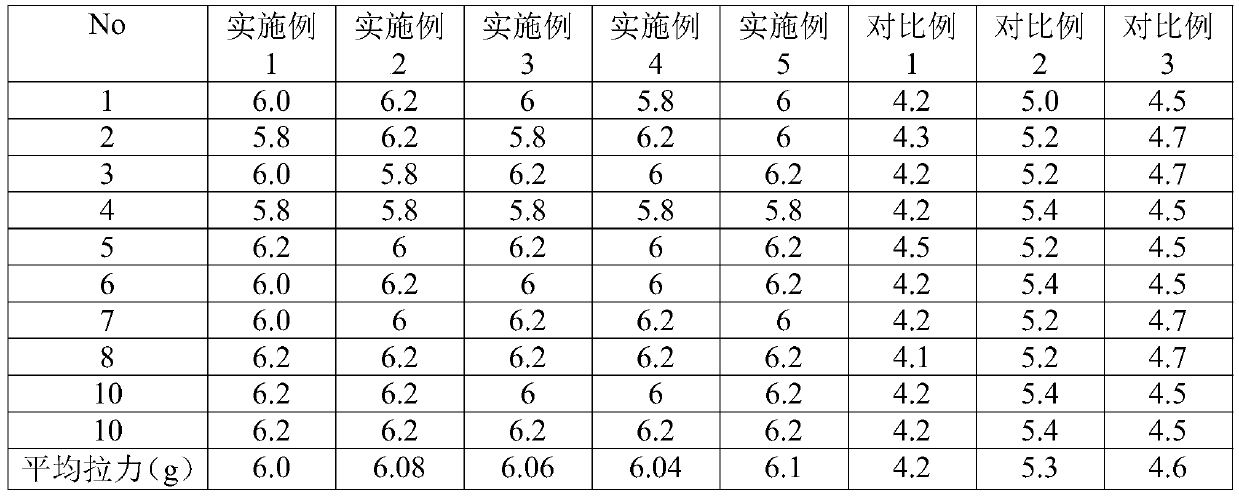

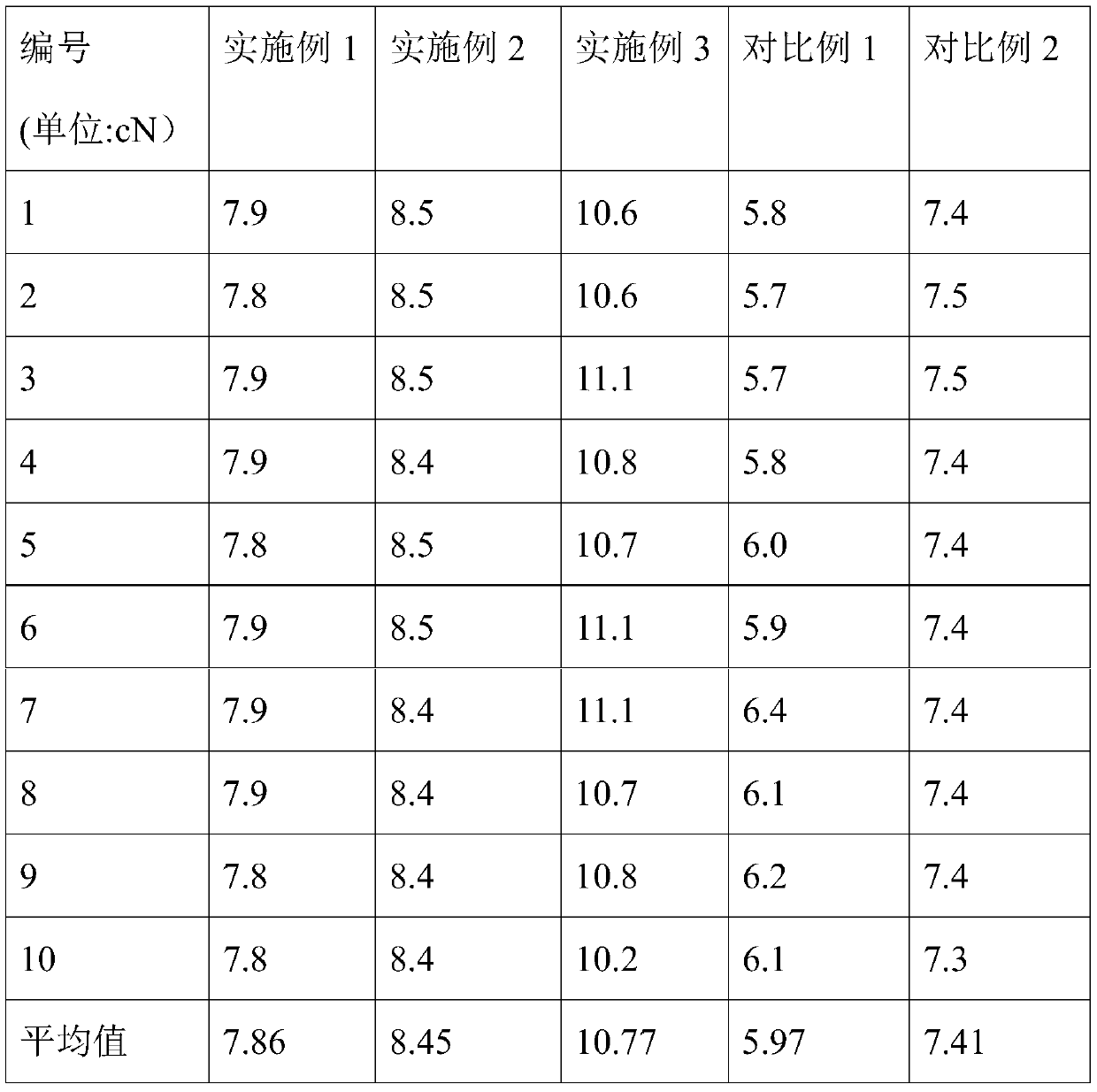

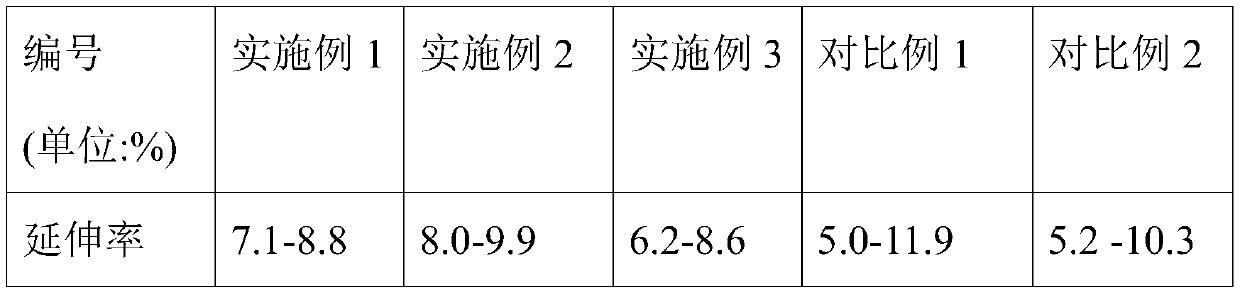

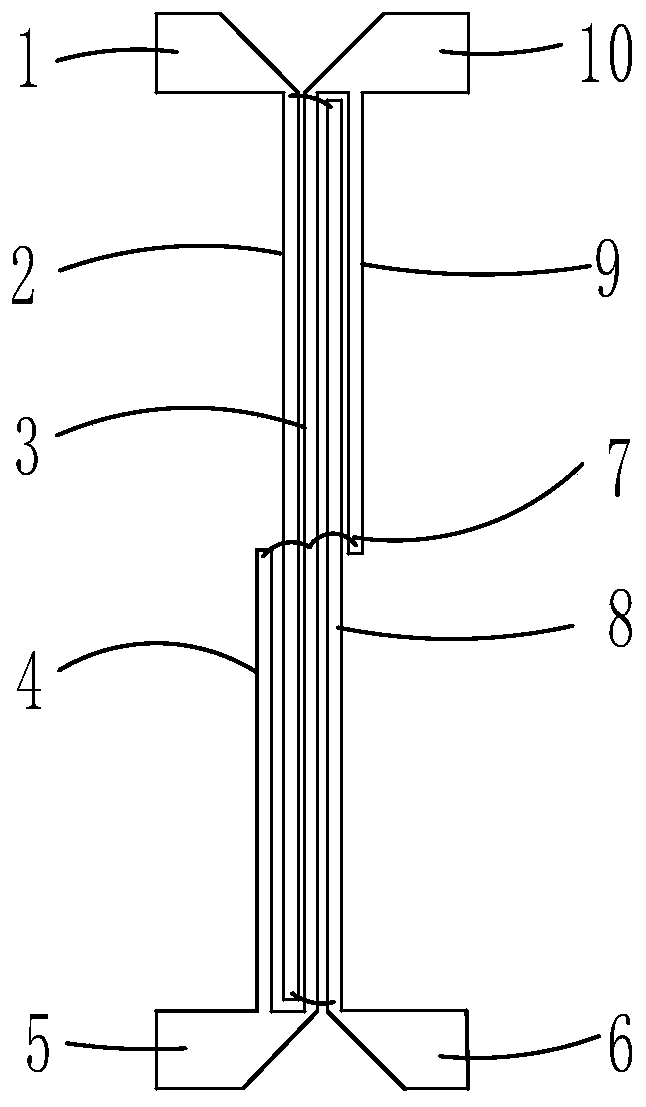

Bonding alloy wire and preparation and application thereof

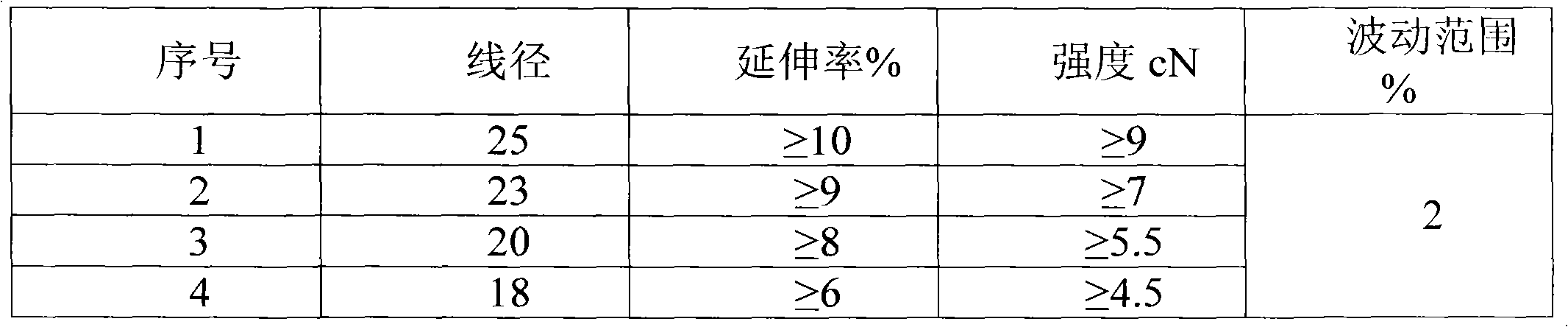

ActiveCN109930020ASmall fluctuation rate of elongationReduce disconnection frequencySemiconductor/solid-state device detailsSolid-state devicesCeriumLanthanum

The invention relates to a bonding alloy wire and preparation and application thereof, and belongs to the technical field of bonding wire processing. Components of the bonding alloy wire include, by mass, 92%-99% of silver, 0.5%-4% of palladium, 0.1%-2% of copper, 0.1%-2% of gold, gallium with the concentration being 20-200 PPM, cerium with the concentration being 20-200 PPM, platinum with the concentration being 20-200 PPM and lanthanum with the concentration being 20-200 PPM. The bonding alloy wire with the section diameter smaller than or equal to 50 micrometers is prepared after casting and wire drawing. According to the bonding alloy wire, the preparation and the application, a high-purity silver material is used as the base, the alloy elements are added, the bonding wire with a smallelongation fluctuation range is prepared, the abnormal short line frequency is decreased, and the bonding productivity and the device operation ratio are increased. The bonding alloy wire, the preparation and the application are suitable for miniaturization packaging of integrated circuits and large scale integrated circuits and are also suitable for packaging of discrete devices and LEDs. The bonding alloy wire is simple in preparation method and good in practicability.

Owner:浙江佳博科技股份有限公司

Low-cost silver-based bonding alloy wire and preparation method and application thereof

InactiveCN111081670AUniform compositionUniform grainSemiconductor/solid-state device detailsSolid-state devicesProduction lineElectronic packages

The invention discloses a low-cost silver-based bonding alloy wire and a preparation method and application thereof, and belongs to the technical field of bonding wire processing. The silver-based bonding alloy wire comprises the following components in percentage by mass: 97.0-99.9wt% of Ag, 0.1-3.0wt% of Cu. The silver-based bonding alloy wire is added with the following microelements: 20-250ppmof Pt, 20-250ppm of Ce, 20-250ppm of Ti, 20-250ppm of Ni and 20-250ppm of Y. The silver-based bonding alloy wire with the wire diameter ranging from 18 micrometers to 50 micrometers is prepared through the procedures of smelting and casting, wire drawing, annealing and cooling. According to the invention, high-purity silver is used as a base material, a small amount of copper and trace alloy elements are added, the raw material cost and preparation energy consumption of the silver bonding wire are reduced, and the production line efficiency is improved. Meanwhile, high breaking load and stable elongation are provided, the mechanical stretching requirements of different electronic packages are met, the bonding abnormal wire breaking frequency is low, and excellent bonding practicability and applicability are achieved. The silver-based bonding alloy wire is suitable for miniaturized packaging of large-scale integrated circuits, and is also suitable for packaging of discrete devices.

Owner:ZHEJIANG UNIV

Ceramal tool processing method

InactiveCN107904426AReasonable workmanshipEasy to operateTurbinesOther manufacturing equipments/toolsCarbideHigh intensity

The invention discloses a processing method of a ceramic alloy cutting tool, which comprises the following steps: selecting Ni as the metal binder phase raw material, Ta, W, Mo, Cr, Ti carbide and TiCN as the hard phase raw material, the mass of each raw material The percentages are as follows: 15% to 20% of the metal binder phase raw material, 80% to 85% of the hard phase raw material; mixed, ball milled, dried and placed in a graphite abrasive tool under a pressure of 10‑15MPa in a hot pressing sintering furnace, Raise the temperature to 1500-1600°C for 2-7min in N2, then raise the temperature to 750-1800°C for 20-40min, then anneal at 1250-1300°C for 1-1.5 hours; then, use the prepared material to produce blank tools , Flat grinding on both sides, wire cutting, grinding, chamfering, and sharpening to make high-strength knives. The processing method of the present invention has reasonable technology, simple operation, low production cost, easy control of the process, and high production efficiency. The surface of the ceramic alloy tool prepared by the method does not contain a metal bonding phase enrichment layer, and the finished product produced has stable quality and high strength. , high temperature resistance, good wear resistance, it is worth promoting.

Owner:JIANGYIN RUYI SCI & TECH DEV

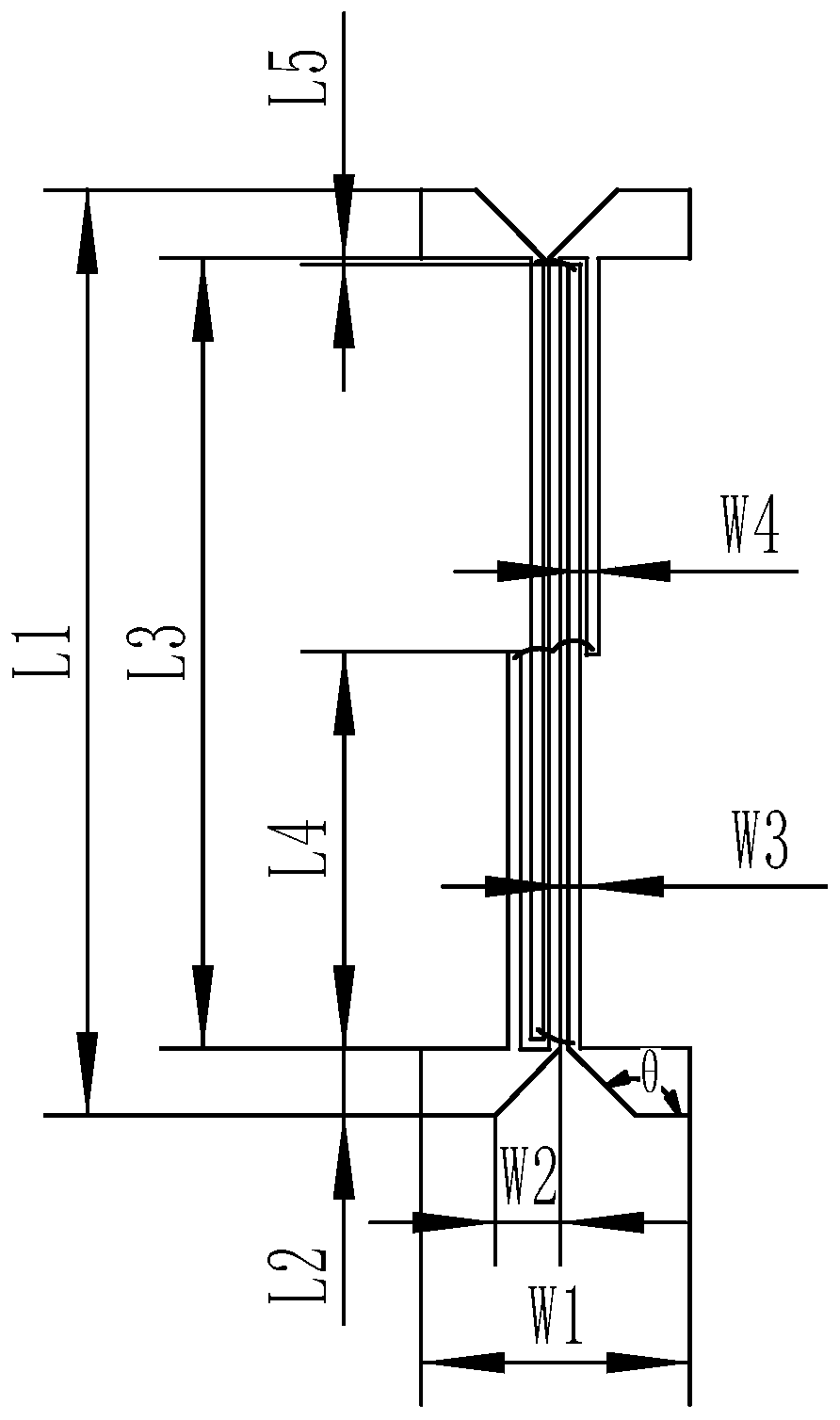

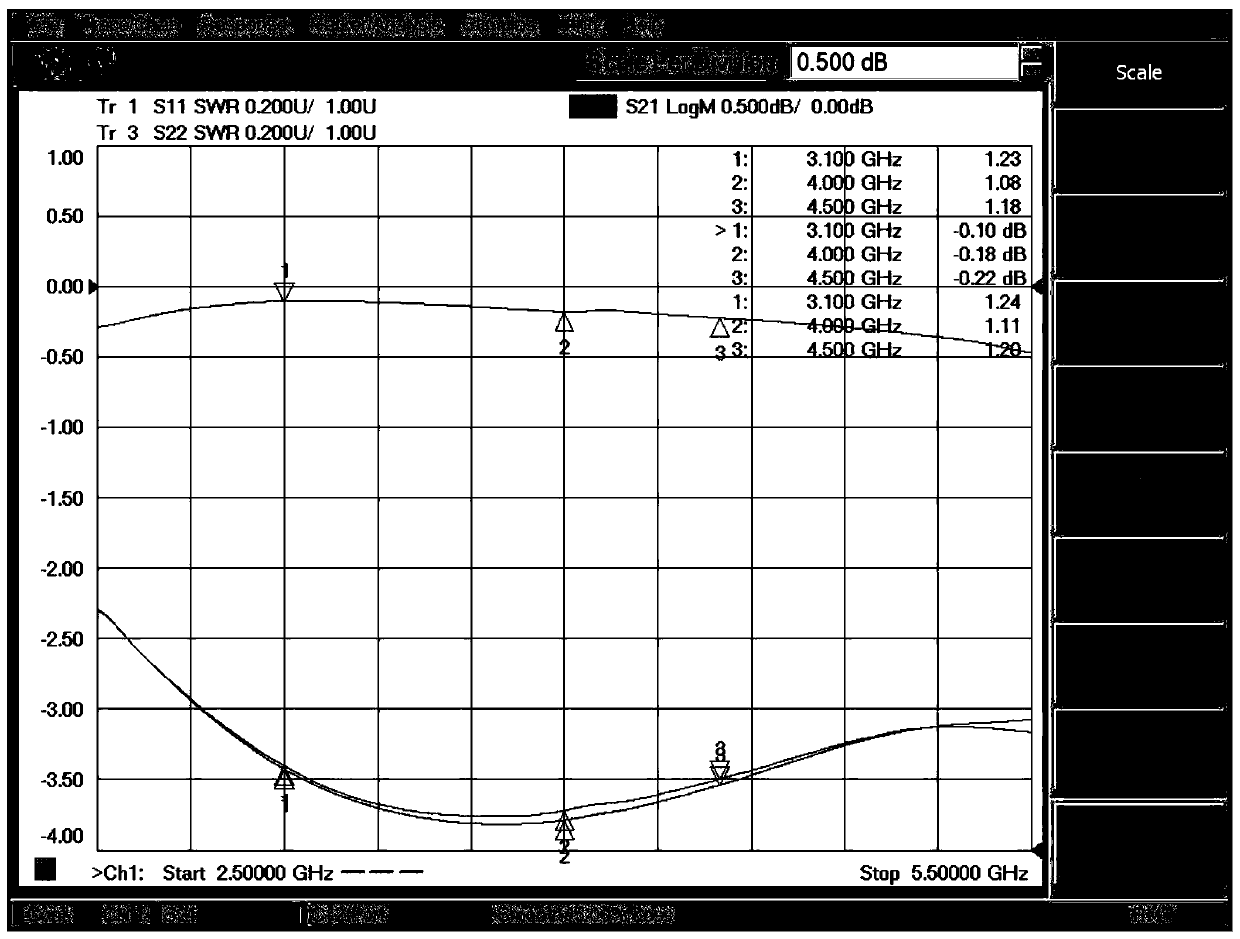

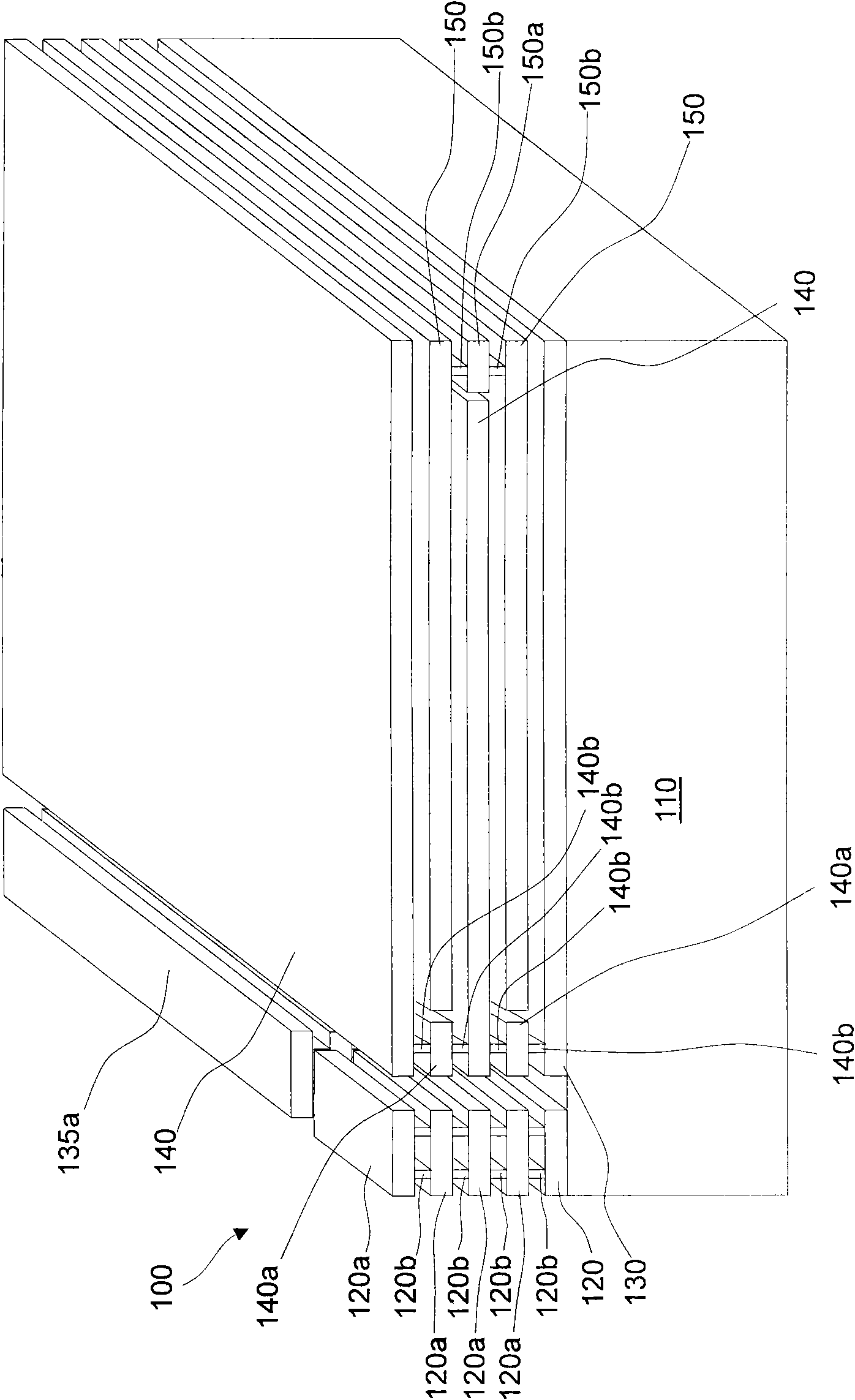

3dB Lange coupler for bearing 1,000W and fabrication method thereof

The invention provides a 3dB Lange coupler for bearing 1,000W and a fabrication method thereof. The 3dB Lange coupler comprises a substrate, wherein an input port, a coupling port, a direct-through port, an isolation port, a plurality of finger-shaped microstrip lines and a plurality of bonding alloy wires are arranged on the substrate, the plurality of finger-shaped microstrip lines are connectedamong the ports, the bonding alloy wires are connected among the finger-shaped microstrip lines, the length L1 between an outer side of the isolation port and an outer side of the input port is 8.634millimeters, the width W1 between an output side of the input port and an outer side of the coupling port is 2.518 millimeters, the height H of the substrate is 1 millimeter, the widths W of the finger-shaped microstrip lines are all 0.100 millimeter, and the distance W4 between adjacent finger-shaped microstrip lines is 0.084 millimeter. The 3dB Lange coupler for bearing 1,000W is small in sizeand can bear 1,000W input power with wide pulse width being 3ms and large duty ratio being 30%.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Copper-plated, pure-nickel and gold-plated bonding wire and fabrication method thereof

InactiveCN109411363APrevent ion migrationGuaranteed electrical conductivitySemiconductor/solid-state device detailsSolid-state devicesIndiumCopper

The invention discloses a copper-plated, pure-nickel and gold-plated bonding wire. The copper-plated, pure-nickel and gold-plated bonding wire comprises the following raw materials based on parts by weight, a four-layer structure is arranged, a copper core is arranged at the innermost layer, pure nickel is plated on a surface of the copper core, gold is plated on a surface of the pure nickel, an ionic migration-prevention agent is plated on a surface of the gold, and the copper core comprises the following raw materials based on parts by weight: 100-110 parts of copper, 2-4 parts of tin, 2-4 parts of aluminum, 1-2 parts of magnesium and 1-2 parts of indium. The invention also discloses a fabrication method of the copper-plated, pure-nickel and gold-plated bonding wire. In the fabricated bonding wire, copper is used as a main raw material to substitute gold, the conductivity can be maintained, and meanwhile, the production cost of a product is greatly reduced; by plating the pure nickel, the gold and the ionic migration-prevention composition on the surface of the bonding alloy wire, an ionic migration phenomenon of the alloy wire is effectively prevented, the product quality is improved, and the service lifetime of a product is prolonged.

Owner:深圳金斯达应用材料有限公司

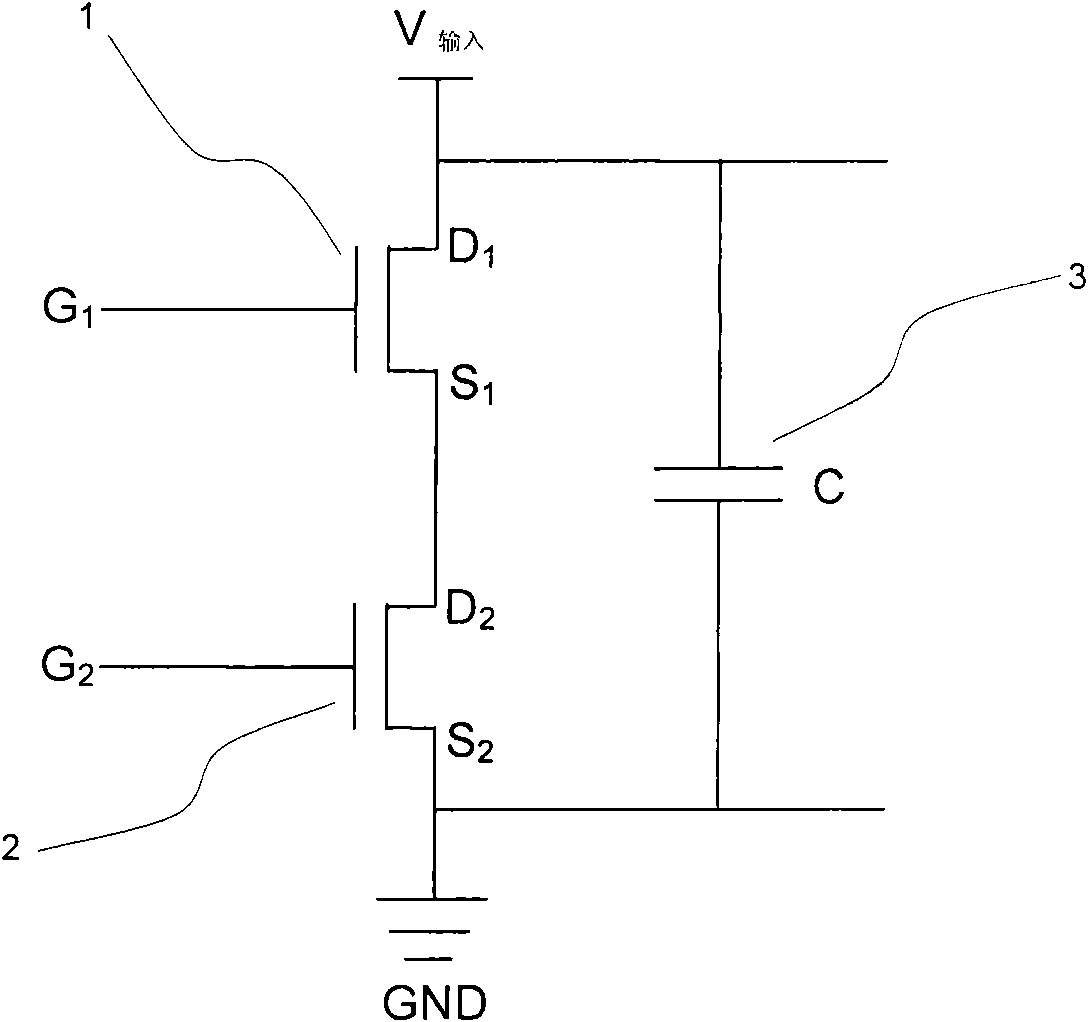

Metal-oxide semiconductor field effect transistor integrated with capacitor

ActiveCN102610608ASolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceField-effect transistor

The invention relates to a metal-oxide semiconductor field effect transistor and particularly relates to the metal-oxide semiconductor field effect transistor integrated with a capacitor, and a manufacturing method of the metal-oxide semiconductor field effect transistor integrated with the capacitor. According to the invention, the capacitor is directly integrated on the metal-oxide semiconductor field effect transistor, so that the mode that the metal-oxide semiconductor field effect transistor tube is connected with an external capacitor by a bonding alloy wire is replaced, and further the discrete inductance in the line connection can be eliminated greatly. Due to the existence of a capacitance pole plate and a dielectric layer, the thickness of a silicon substrate and the mechanical strength of the silicon substrate are improved, and according to the advantages, the silicon substrate can be thinned so as to obtain low resistance of the metal-oxide semiconductor field effect transistor.

Owner:重庆万国半导体科技有限公司

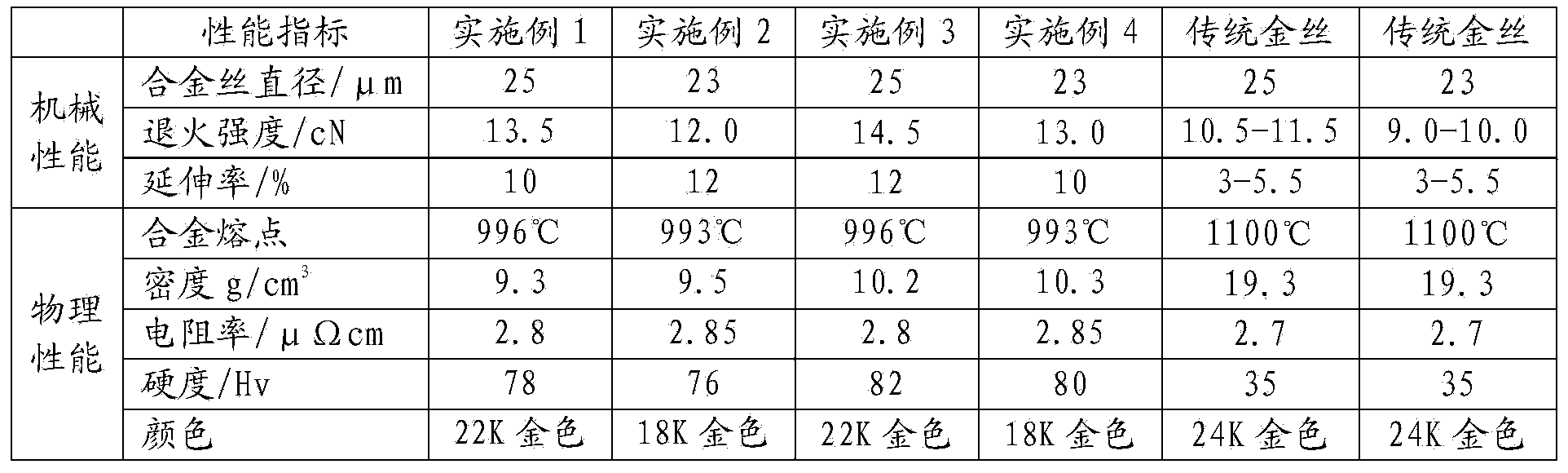

Dispensing structure and process for improving reliability of LED lamp bead

The invention discloses a dispensing structure and process for improving the reliability of an LED lamp bead, and the structure comprises a support bowl cup, a chip, a bonding alloy wire, a die bonding adhesive, a fluorescent adhesive, and a white adhesive, and the chip is fixed at the bottom of the interior of the support bowl cup through the die bonding adhesive. The cathode of the chip is connected to one side of the cathode of the bracket through a bonding gold wire on the other side; the anode of the chip is connected to one side of the anode of the bracket through a bonding gold wire atone side to form a series circuit; the support bowl cup is incompletely filled with fluorescent powder, and a layer of white glue is filled above the fluorescent powder. According to the invention, operation is convenient, design is effect and the process is simple; after the bowl cup is filled with a certain amount of fluorescent glue, the bowl cup is filled with a certain amount of white glue, Mn < 4 + > ions in the fluorescent glue are isolated from hydrolysis reaction with moisture in air, and the effects of improving the reliability of the LED lamp bead and prolonging the service life ofan LED device are achieved.

Owner:JIANGXI HONGLI TRONIC CO LTD

Iron-based bonding alloy for preparing diamond drill bit matrix

The invention discloses an iron-based bonding alloy for preparing a diamond drill bit matrix, relating to a manufacturing technology of petroleum drilling bits. The iron-based bonding alloy contains the following components in percentage by weight: 4-6 percent of silver, 15-20 percent of tin, 8-12 percent of manganese, 10-15 percent of nickel and the balance of ferrum. The iron-based bonding alloyhas the advantages that the strength of the drill bit matrix can be improved by over two times and the cost of the bonding alloy is lower than 20 percent of a conventional bonding alloy.

Owner:CHENGDU DEEP DIAMOND BIT

Vertical-structure LED chip and fabrication method thereof

ActiveCN109768137AImprove reliabilitySimple preparation processSemiconductor devicesOptoelectronicsBlocking layer

Owner:晶能光電股份有限公司

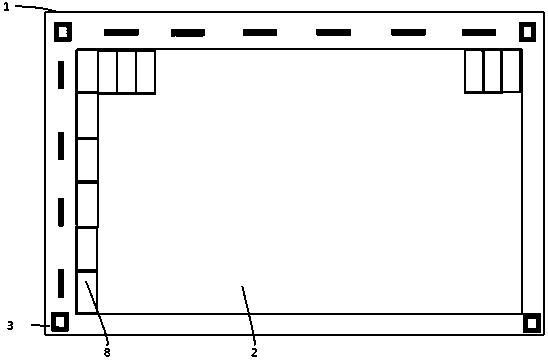

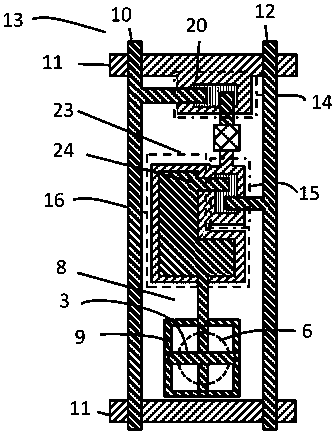

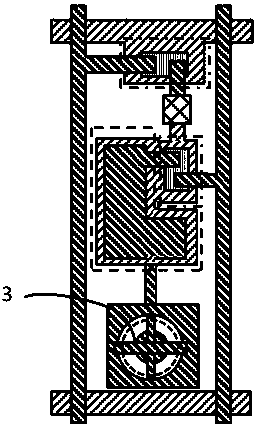

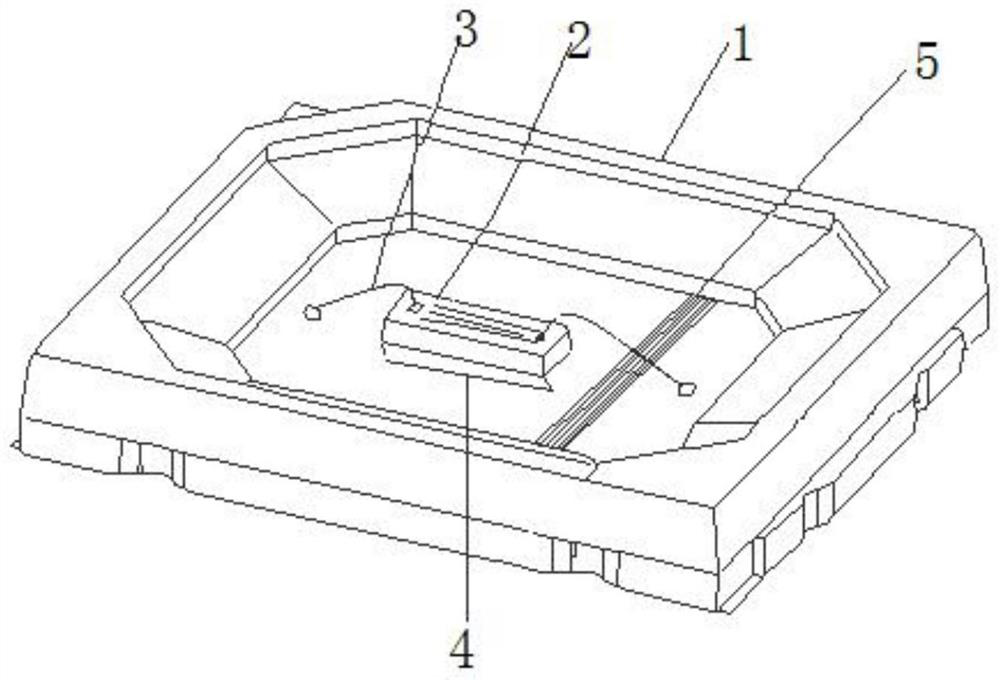

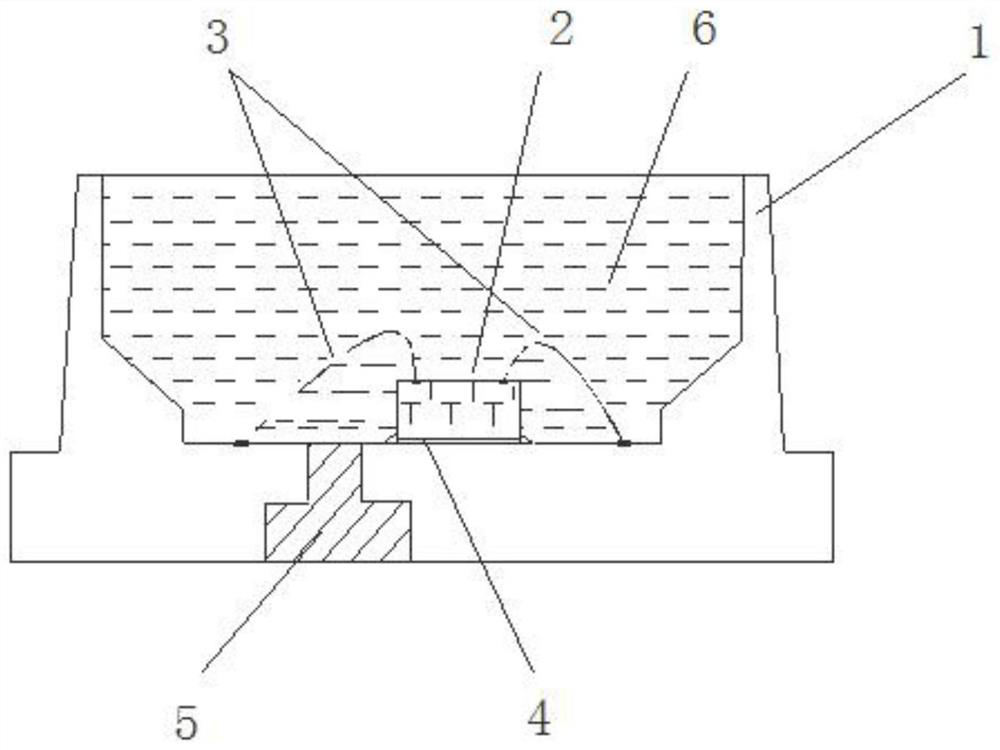

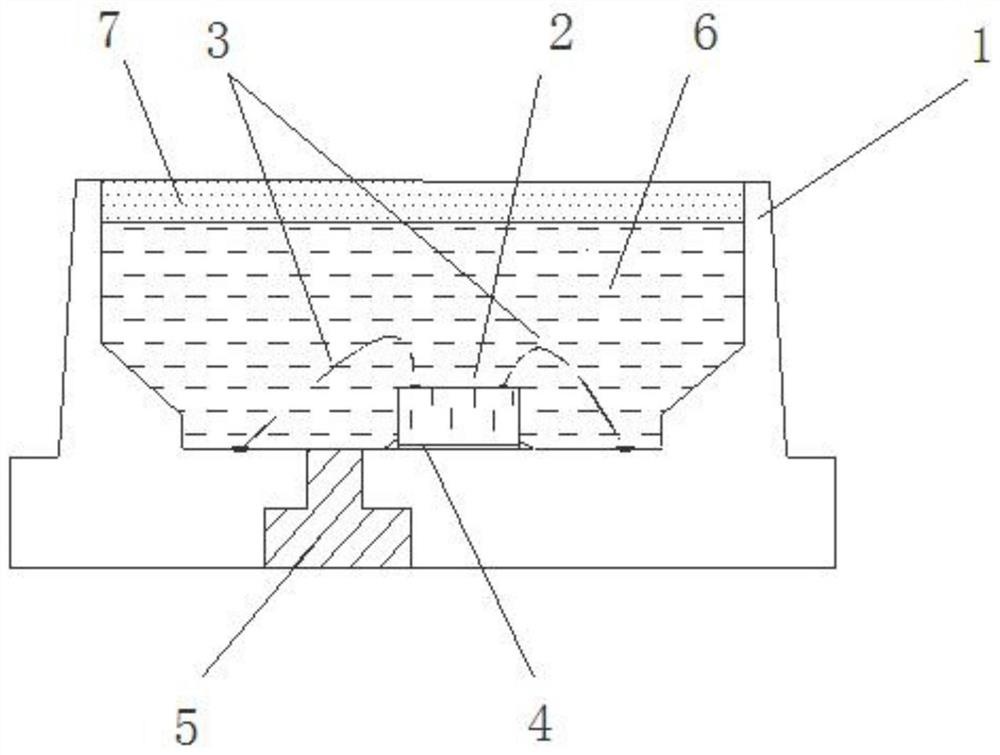

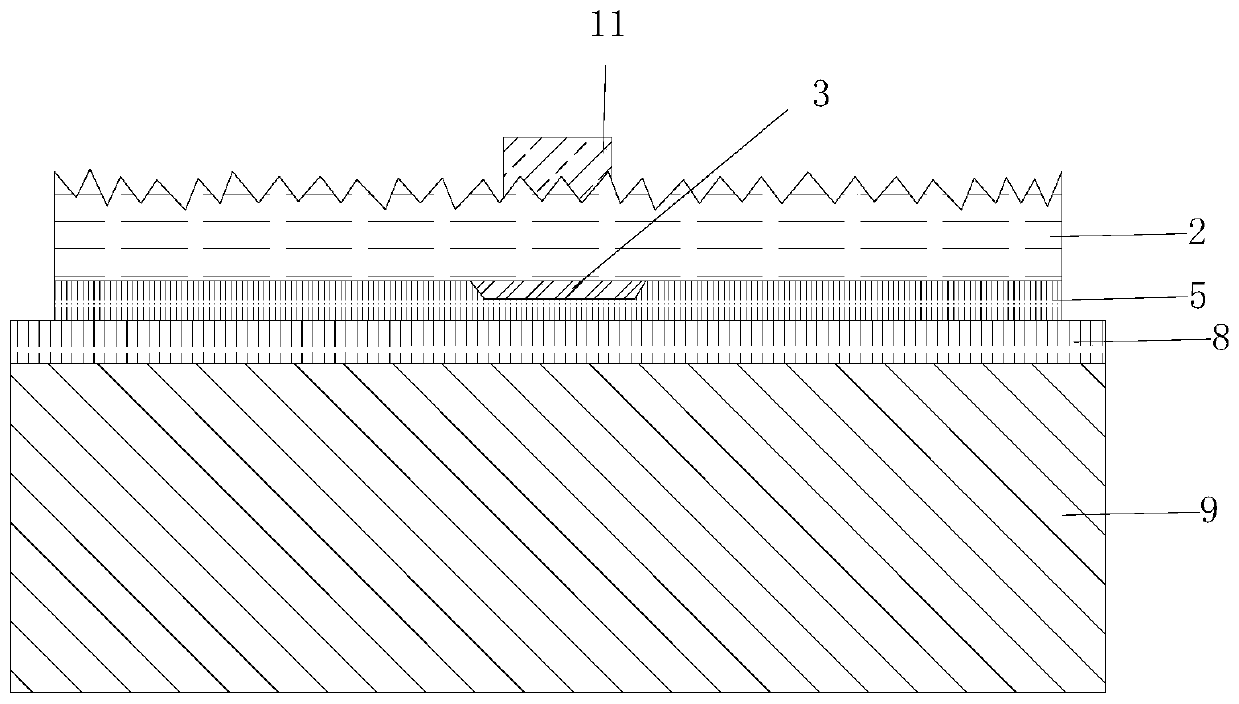

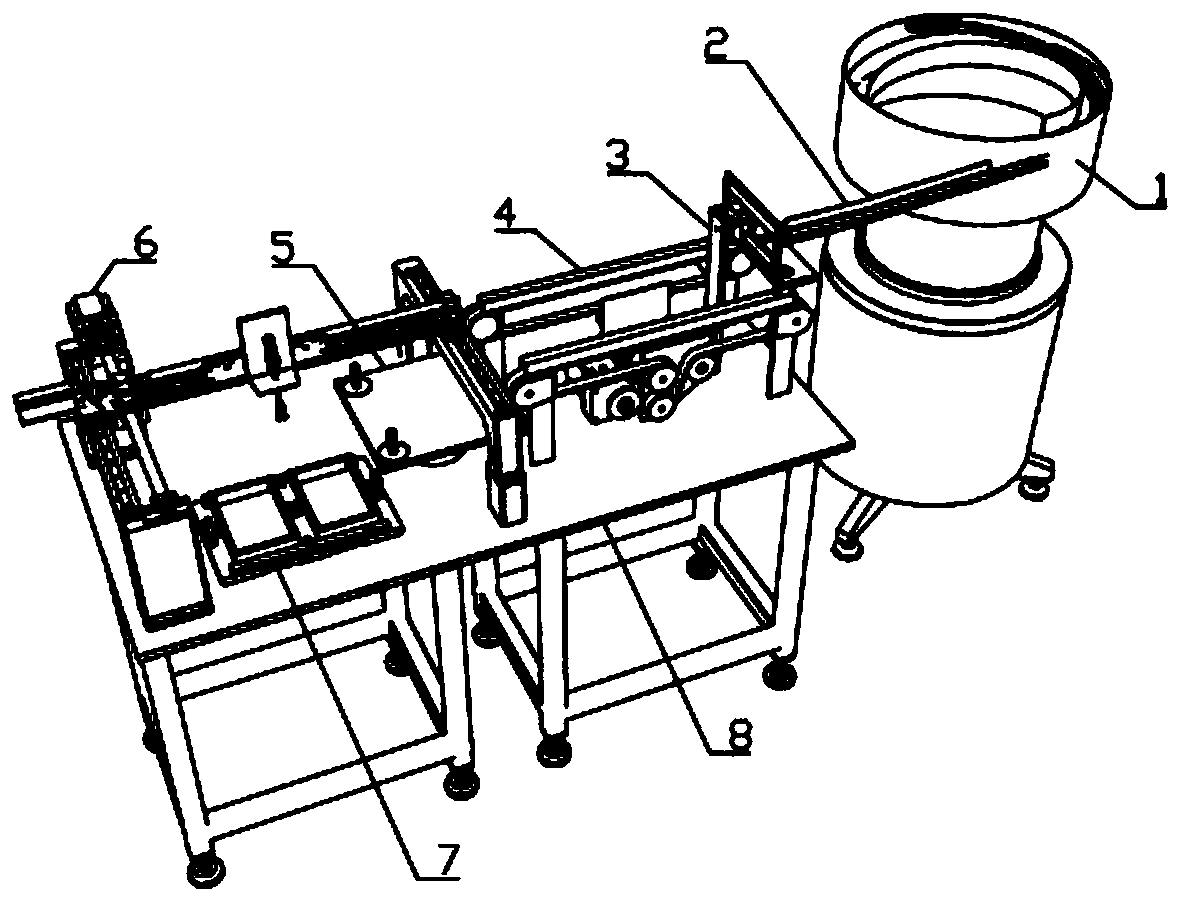

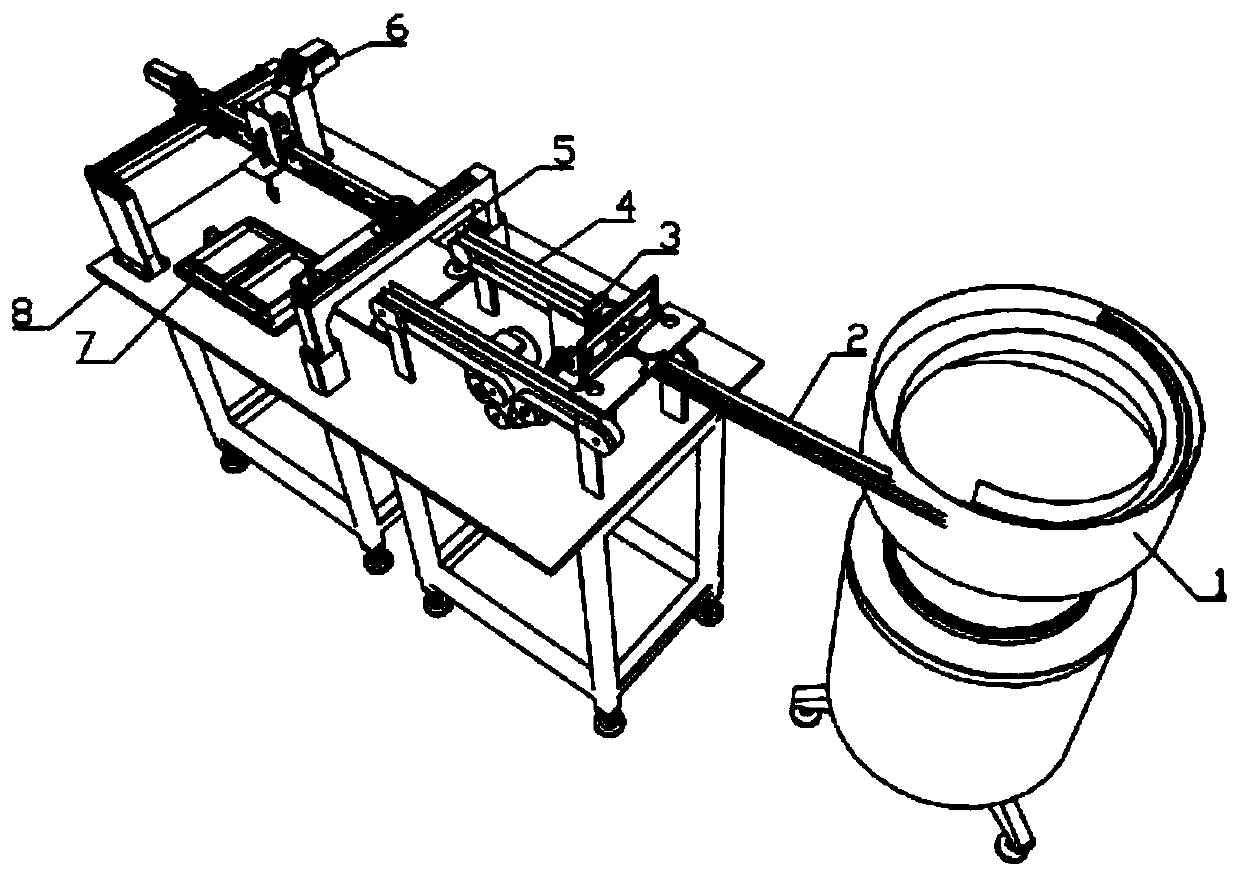

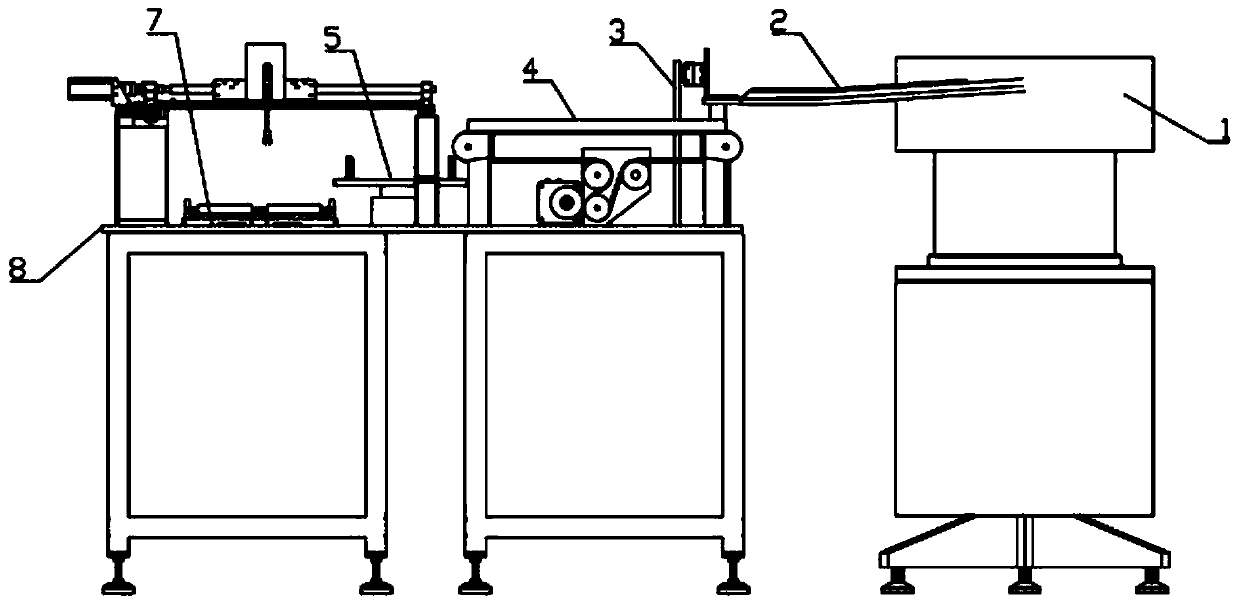

Device convenient for shunting bonding alloy wire reel and using method thereof

The invention belongs to the technical field of bonding alloy wire production, and particularly relates to a device convenient for shunting a bonding alloy wire reel and a using method thereof. The device comprises a vibration feeding mechanism, a feeding channel, a shunting mechanism, a double-channel conveying mechanism, a position exchanging mechanism, a three-dimensional material taking mechanism, a boxing mechanism and a supporting mechanism. The method comprises the following steps of: 1, shunting the bonding alloy wire reels; 2, sleeving the bonding alloy wire reels in strings; 3, exchanging the positions of sleeve rods penetrating the bonding alloy wire reels; and 4, carrying out three-dimensional material taking and boxing. According to the device and the method, the workload of workers is greatly reduced, potential safety hazards are avoided, the production efficiency is greatly improved, and the production cost of enterprises is greatly reduced.

Owner:重庆智荟数创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com