Patents

Literature

63results about How to "Reduced area requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

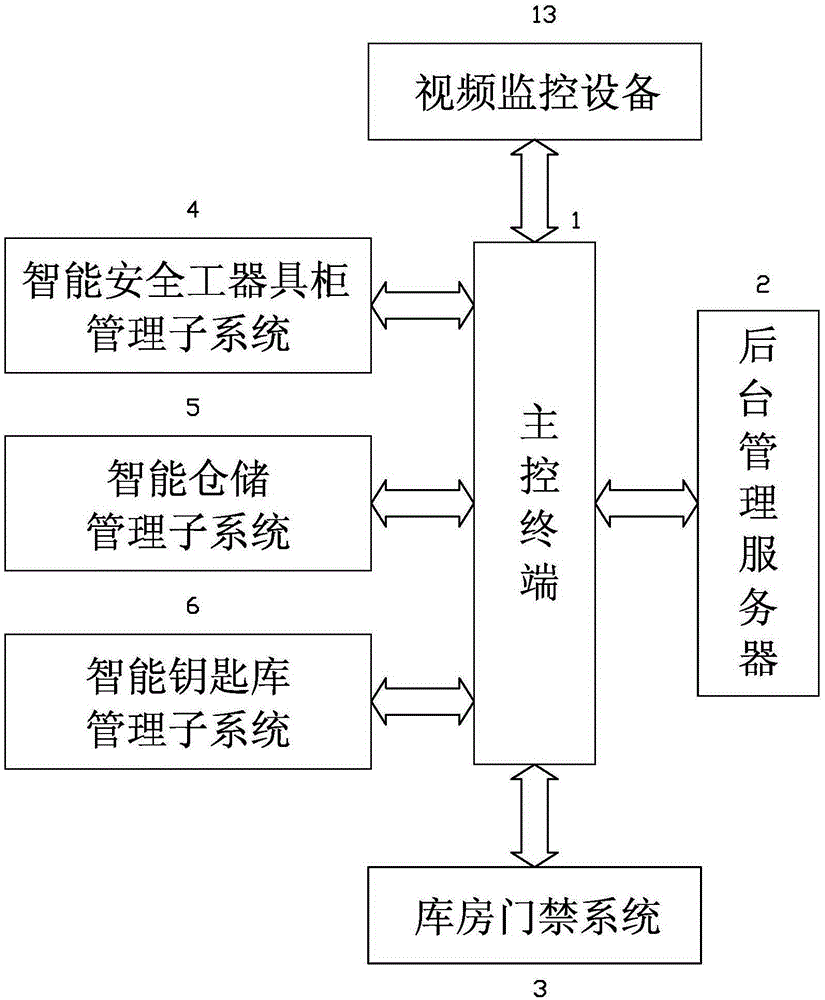

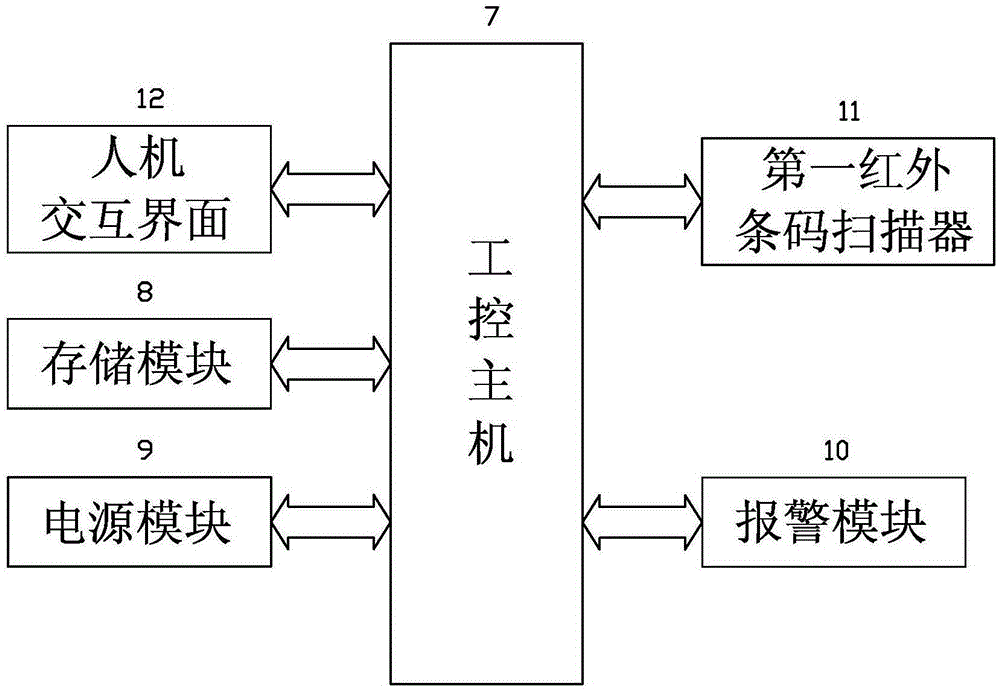

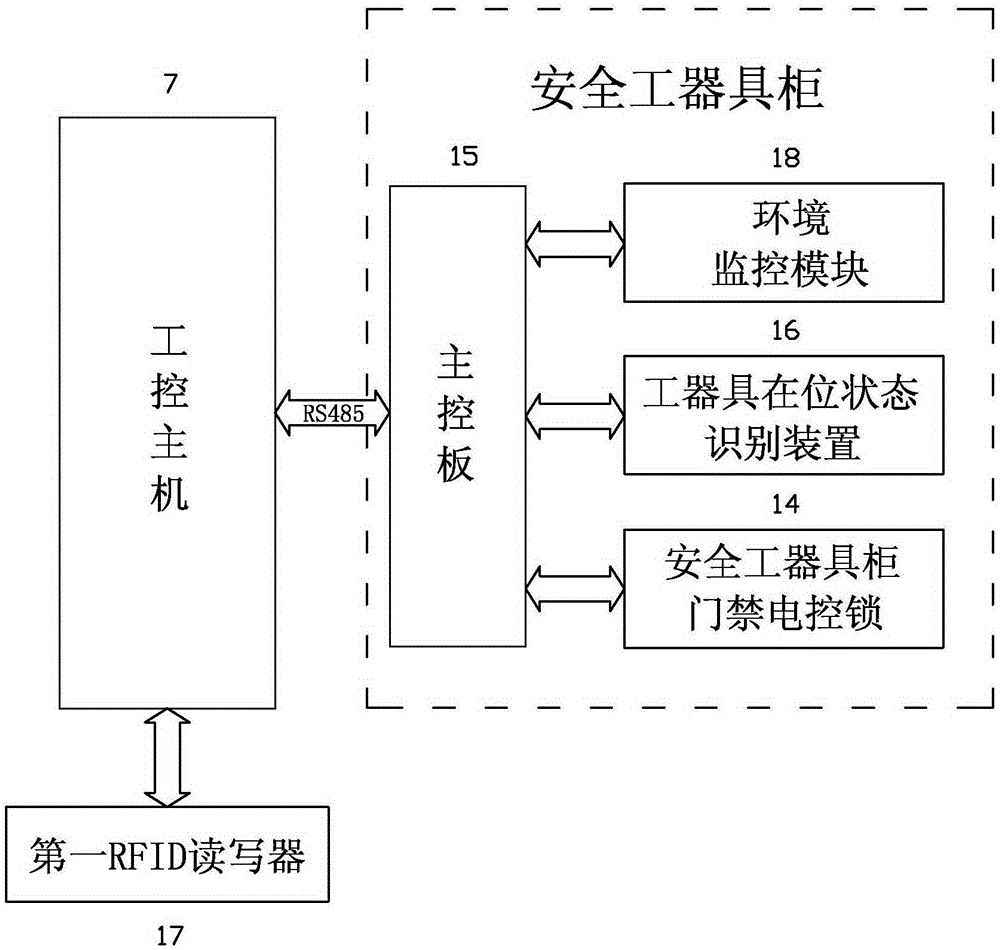

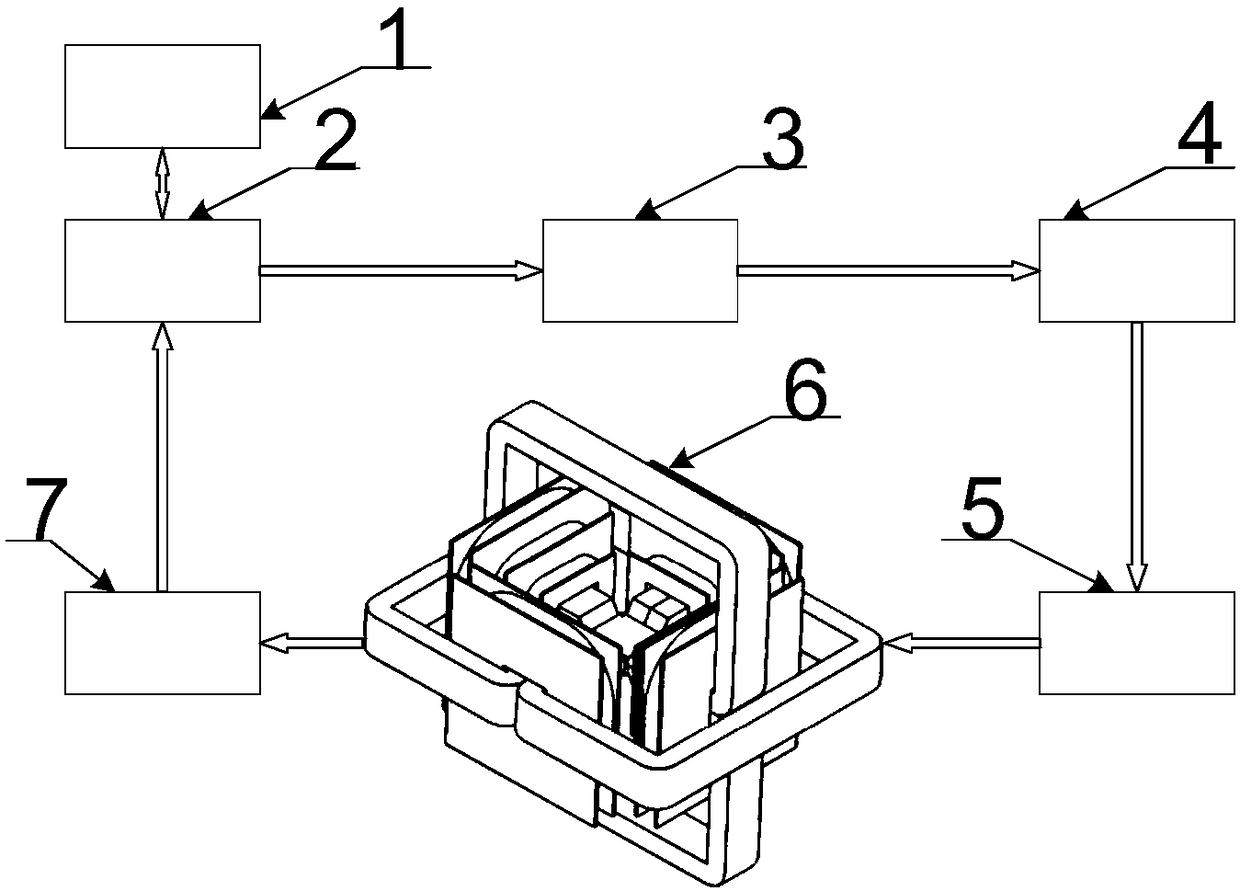

Intelligent power supply station storeroom management system and method based on internet of things

ActiveCN105160748ALearn about usageAvoid abuseData processing applicationsIndividual entry/exit registersThe InternetEngineering

The invention provides an intelligent power supply station storeroom management system and method based on the internet of things. The intelligent power supply station storeroom management system comprises a master control terminal, a background management server connected to the master control terminal, an intelligent security tool cabinet management sub system capable of being connected to the master control terminal in a communication mode, an intelligent warehouse management sub system and an intelligent key library management sub system. The master control terminal is internally provided with intelligent security tool cabinet management system software, intelligent warehouse management software and intelligent key library management system software. A three-in-one comprehensive management model of real-time voice, data and images is adopted for the system, use of a security tool, consumption of spare parts and borrowing of keys are managed through an intelligent means, the failure repair time of a response field can be effectively shortened, the failure reaction speed is increased, the agricultural distribution network construction, overhauling and repairing work efficiency is improved, the work procedure of operation personnel is standardized, the safe production awareness is enhanced, a novel intelligentized power supply station storeroom based on a technology of the internet of things is constructed, and powerful guarantee is provided for safe production of a power enterprise.

Owner:STATE GRID FUJIAN JINJIANG POWER SUPPLY

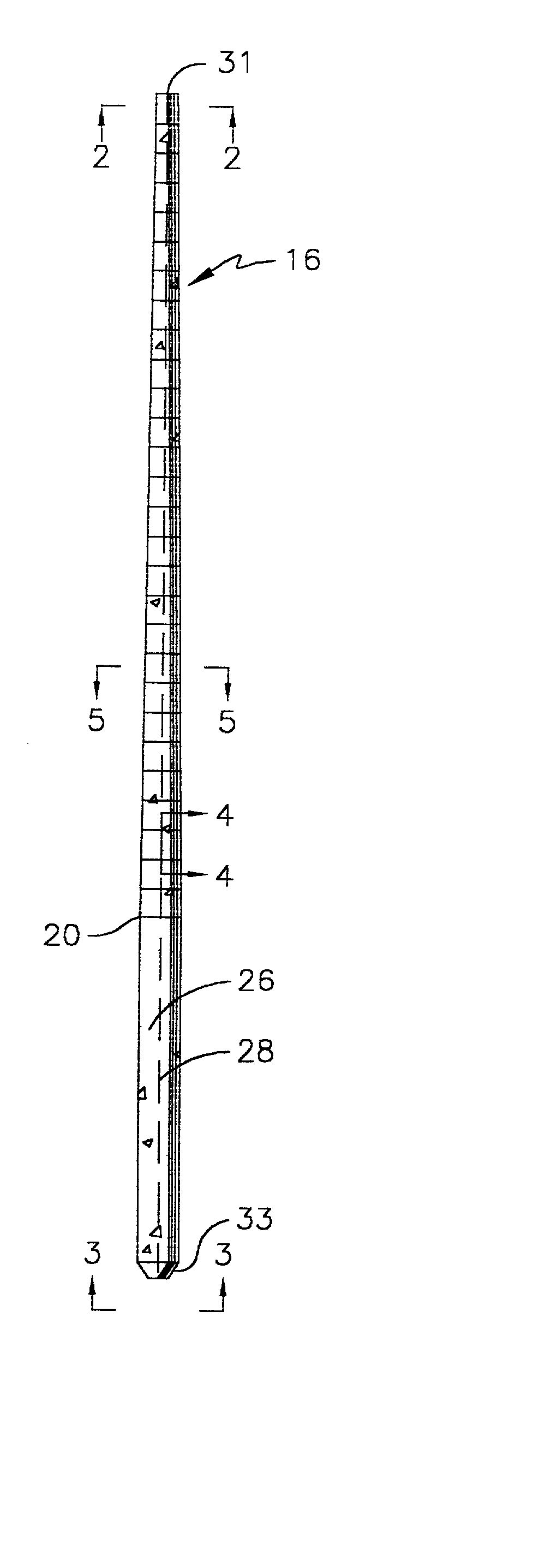

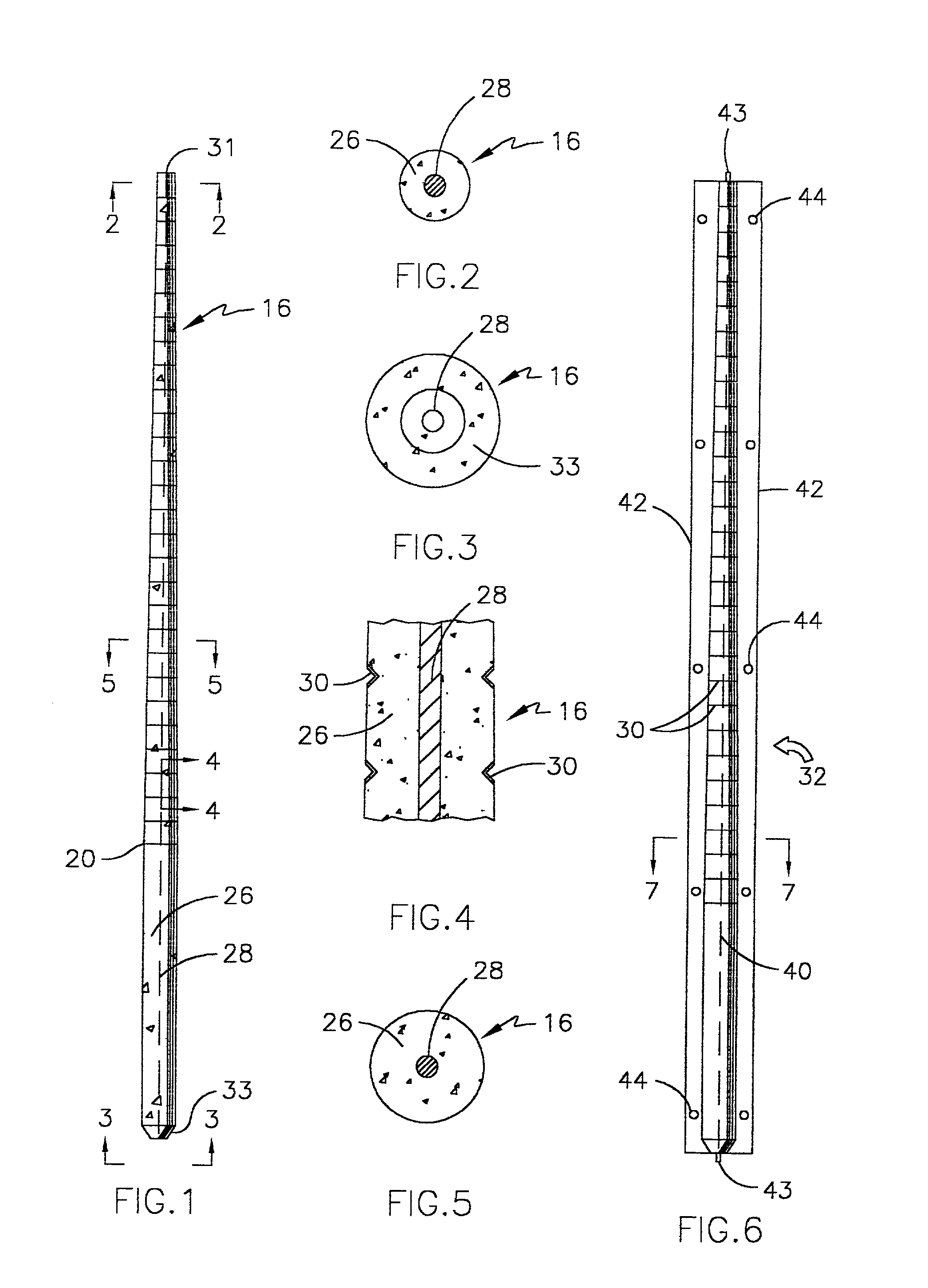

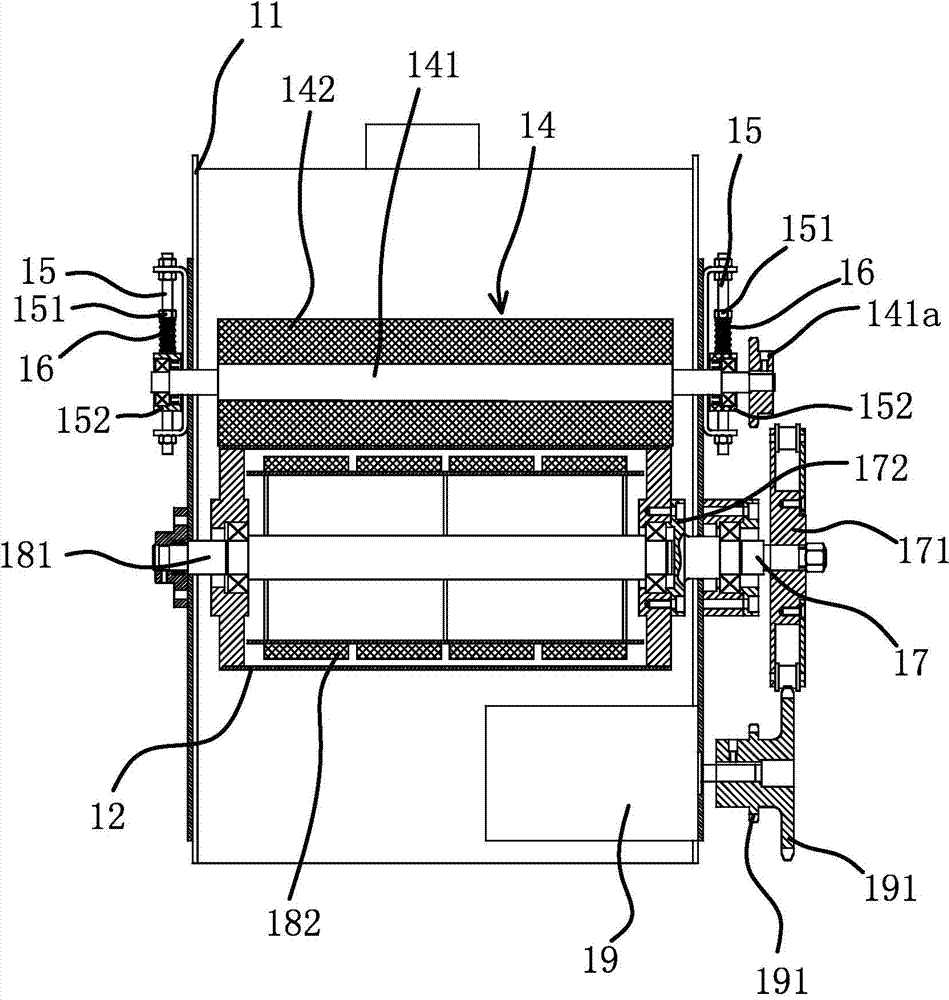

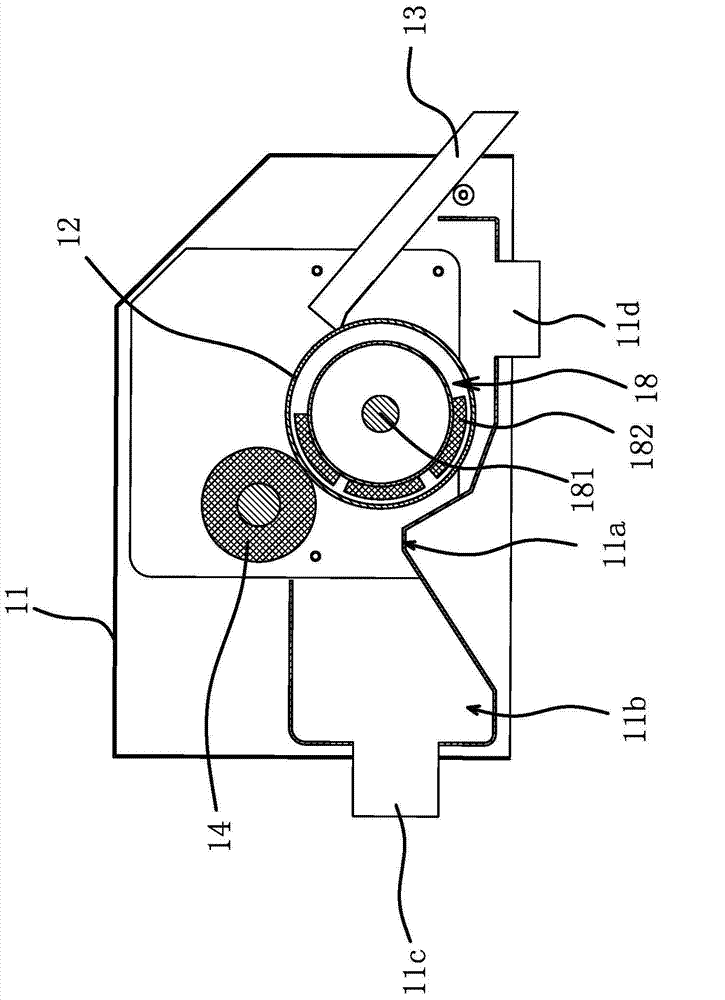

Prestressed concrete fence post assembly and method of construction

InactiveUS20030010969A1Inexpensive to fabricateEasy to useStrutsFencingHigh strength concretePlastic materials

A prestressed concrete fence post assembly, including 1) a main fence post body constructed of a high-strength, concrete grout material; 2) a prestressed high-strength steel tendon member positioned centrally and extended longitudinally of the main fence post body; and 3) a plurality of spaced, parallel concentric connector grooves used with wire tie members to secure fence wire strands against outer surfaces of the main fence post body. Forms, equipment, and method steps for economically casting prestressed concrete post assemblies, poles, towers, or the like. A fence post mold assembly consists of two mating fence post mold half sections, each having an inner plastic material liner to form the desired concrete product. Prestressing is accomplished by pretensioning a centrally located high-strength steel tendon member held at each end by anchor jaw assemblies. A hydraulic tensioning apparatus is connected to one of the anchor jaw assemblies and tension is applied to the tendon member. The prestressing force is retained by extending an anchor nut member into engagement with a top end plate member. A high-strength concrete grout material is forced into the fence post mold assembly near a lower base. A factory arrangement involves a plurality of fence post mold assemblies or a carousel molding assembly may be employed to simplify the logistics of manufacture, increasing the production rate, and reducing the number of personnel and factory space required.

Owner:CRISSEY GLENN C

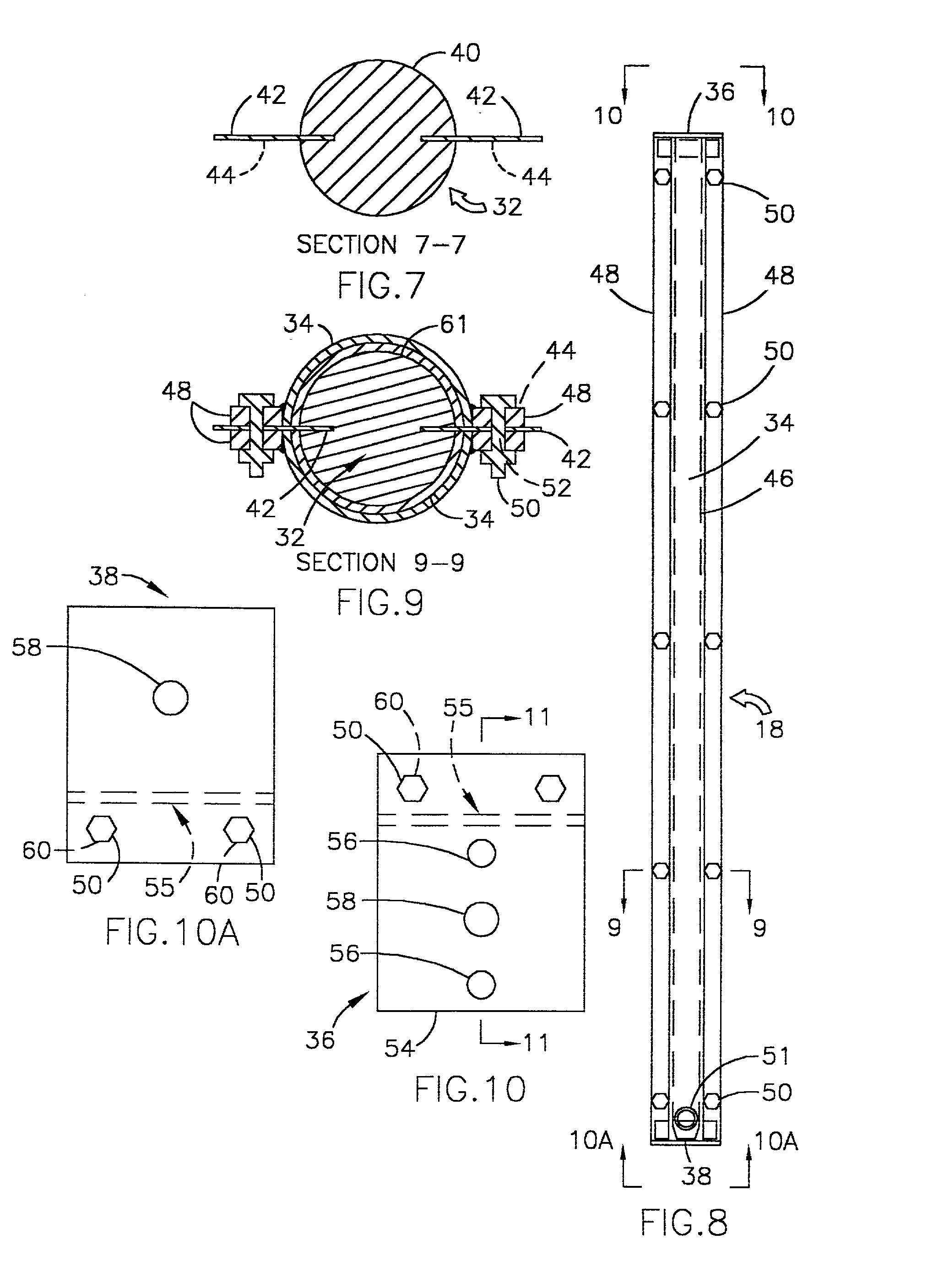

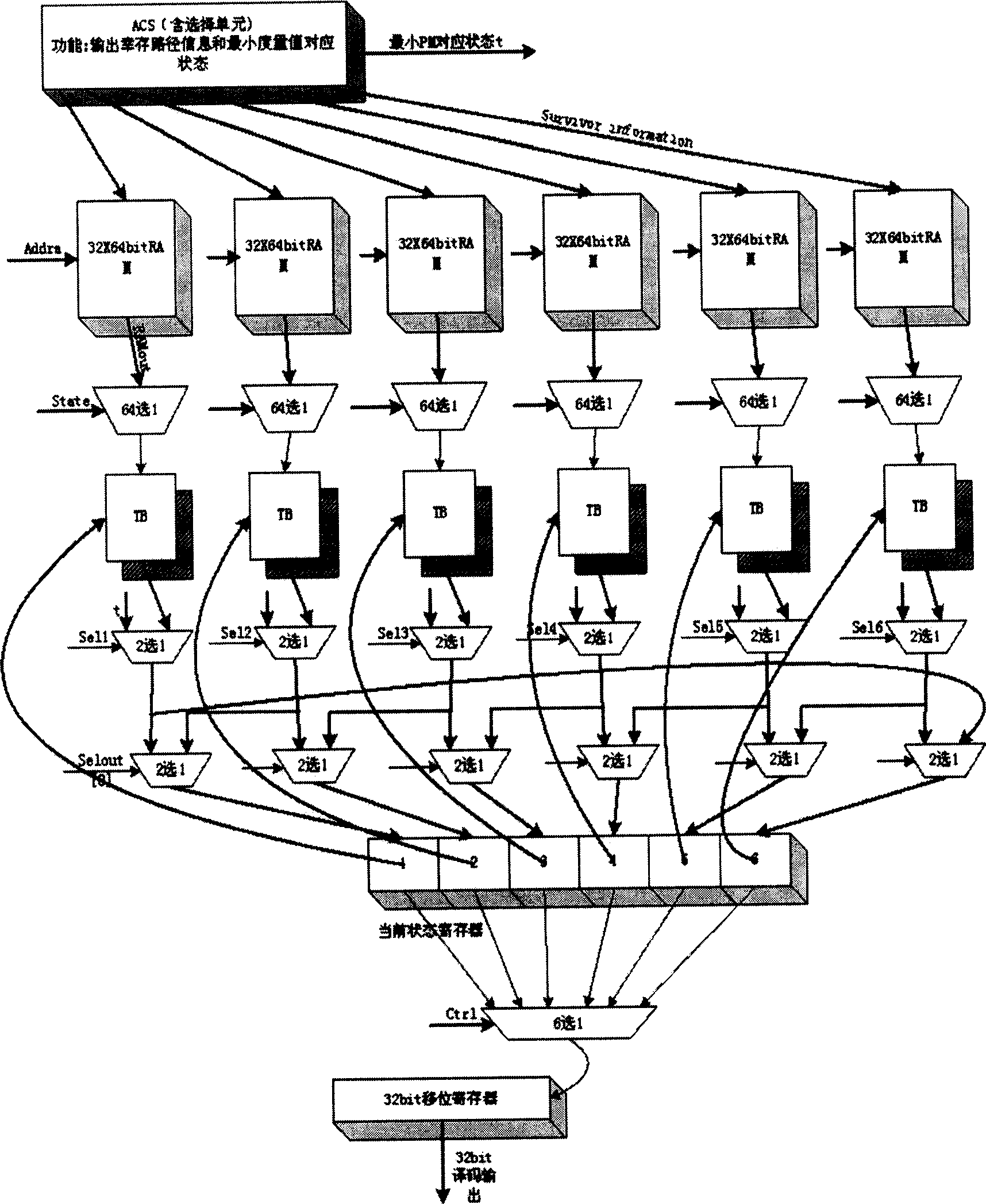

Viterbi decoding based multi-path parallel loop block back trace technique

InactiveCN1671058AReduced Power RequirementsReduced area requirementsError correction/detection using convolutional codesError preventionParallel computingConvolutional code

A Viterbi decoding based multiplex parallel circular block backtracking algorithm, which contains providing a decoding algorithm only needing to collect convolution code coding backtracking, the backtracking algorithm using single or double RAM whose unit number is constantly the product of two times backtracking depth and the sum of convolution code, the RAM is used by divided into blocks whose number determined by backtracking depth and size of backtracking block, each RAM block corresponding a backtracking unit and backtracking gating network, only part of RAM needed to be accessed, the effective parallel backtracking route number the ratio of backtracking depth and size of backtracking block, in backtracking process, the minimum route measurement value corresponded state value is used as the current state value, finally the backtracking result is arranged in inverted sequence and outputted in normal sequence after being stored.

Owner:BEIJING CEC HUADA ELECTRONIC DESIGN CO LTD

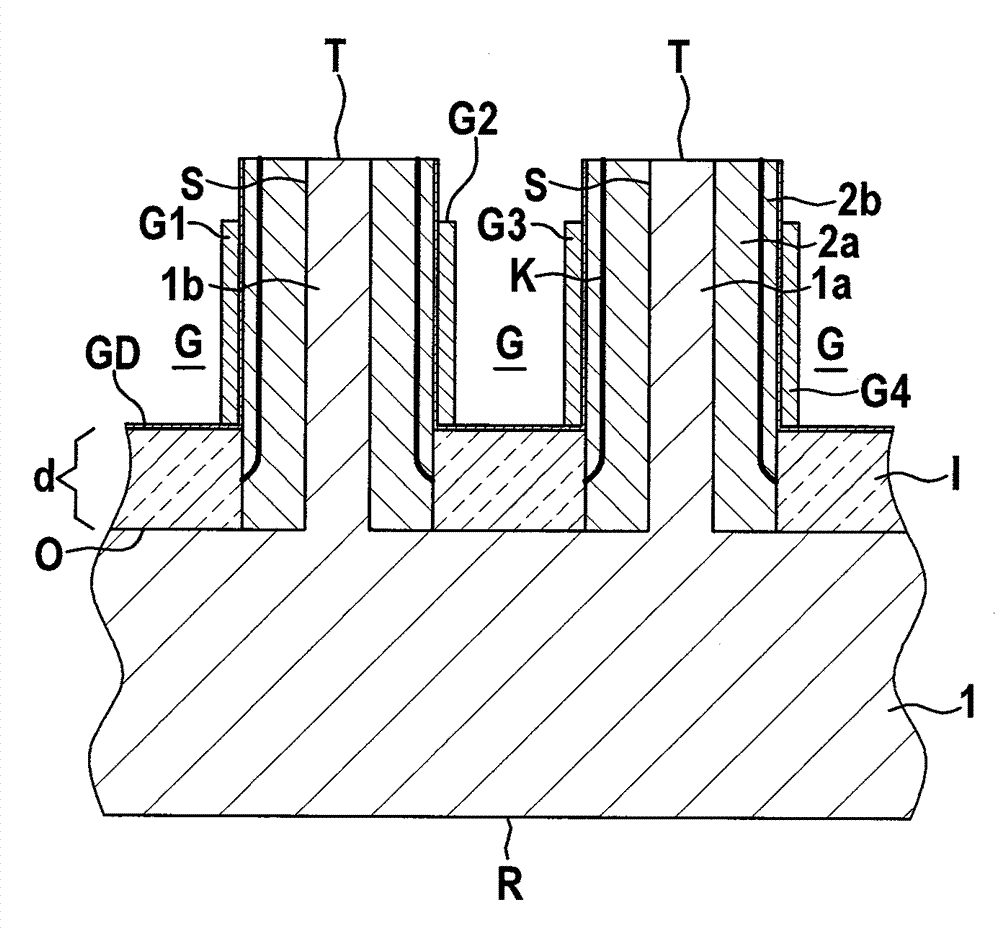

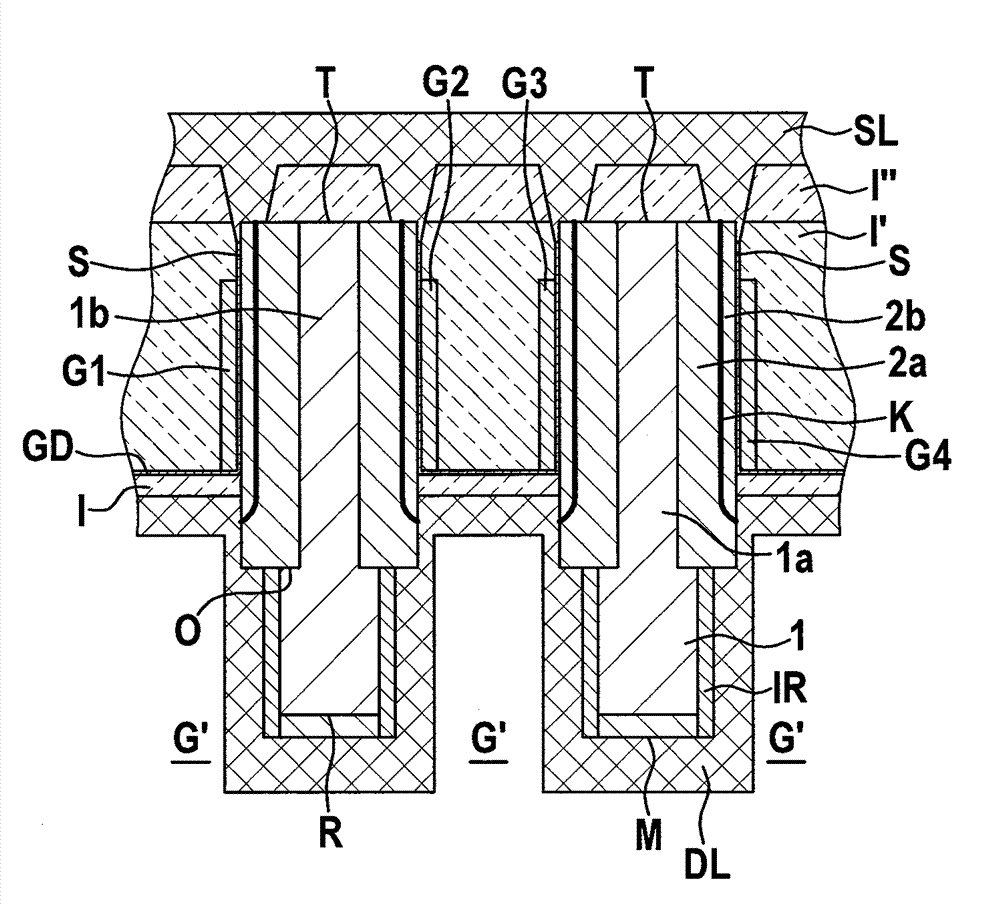

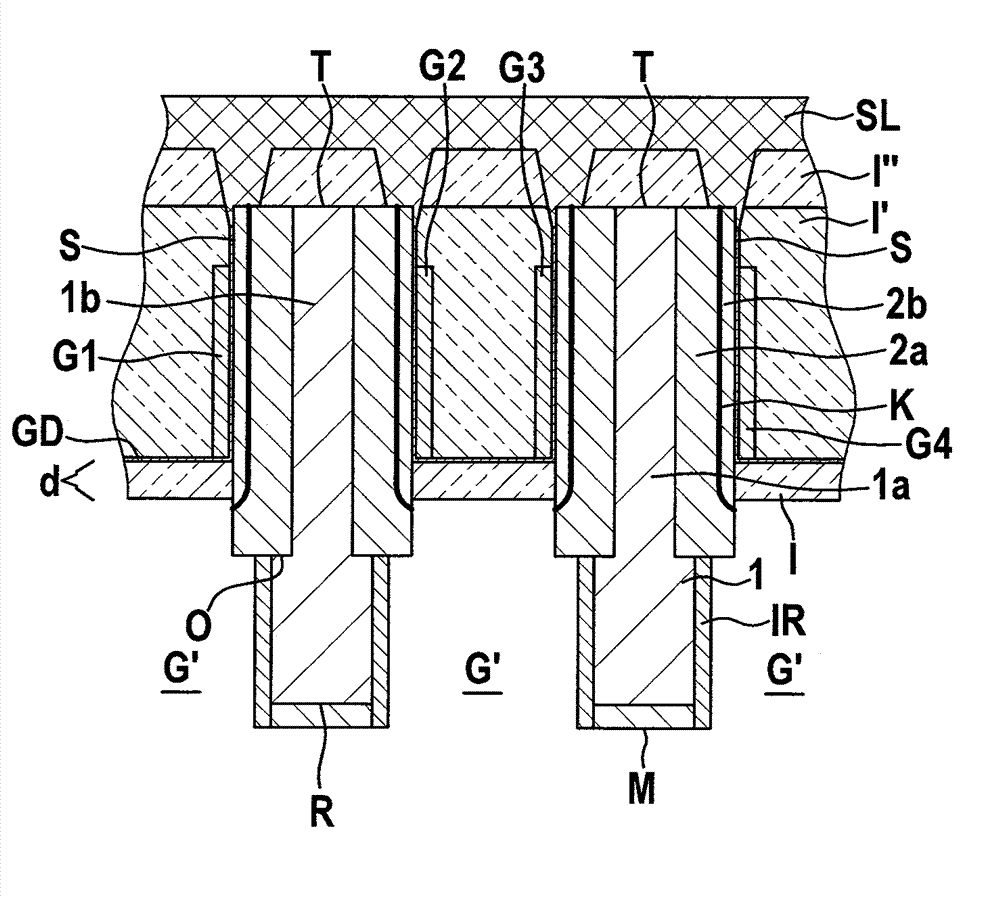

Vertical microelectronic component and corresponding production method

InactiveCN103681836AImprove power densityHigh compressive strengthSolid-state devicesSemiconductor/solid-state device manufacturingCommon drainElectronic component

A vertical microelectronic component and a corresponding production method are realized. The vertical microelectronic component includes a semiconductor substrate having a front side (O) and a back side (R), and a multiplicity of fins (1a, 1b) formed on the front side (O). Each fin has a corresponding side wall (S) and an upper side (T) and is separated from other fins by trenches (G). Each fin includes a GaN / AlGaN heterolayer region formed on the side wall (S)and including an embedded channel region (K) extending essentially parallel to the side wall (S) and at least one gate interface region (G1-G4). The gate interface region (G1-G4) is arranged above the GaN / AlGaN heterolayer region and electrically insulated from the channel region in the associated trench on the side wall (S). A common source terminal region (SL) arranged above the fins is connected to a first end of the channel region (K) in a vicinity of the upper sides (T). A common drain terminal region (DL) arranged above the back side is connected to a second end of the channel region (K) in a vicinity of the front side (O).

Owner:ROBERT BOSCH GMBH

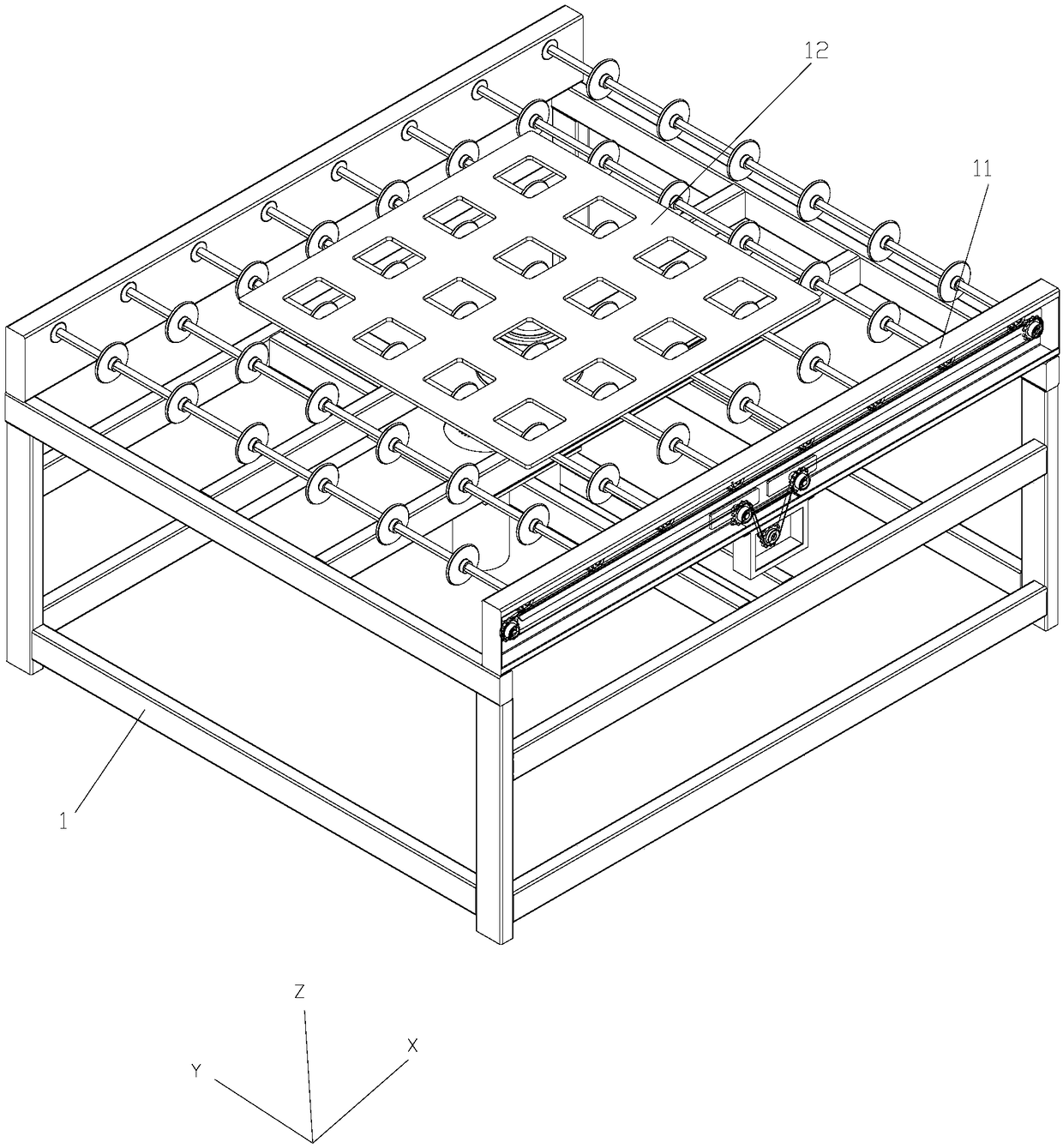

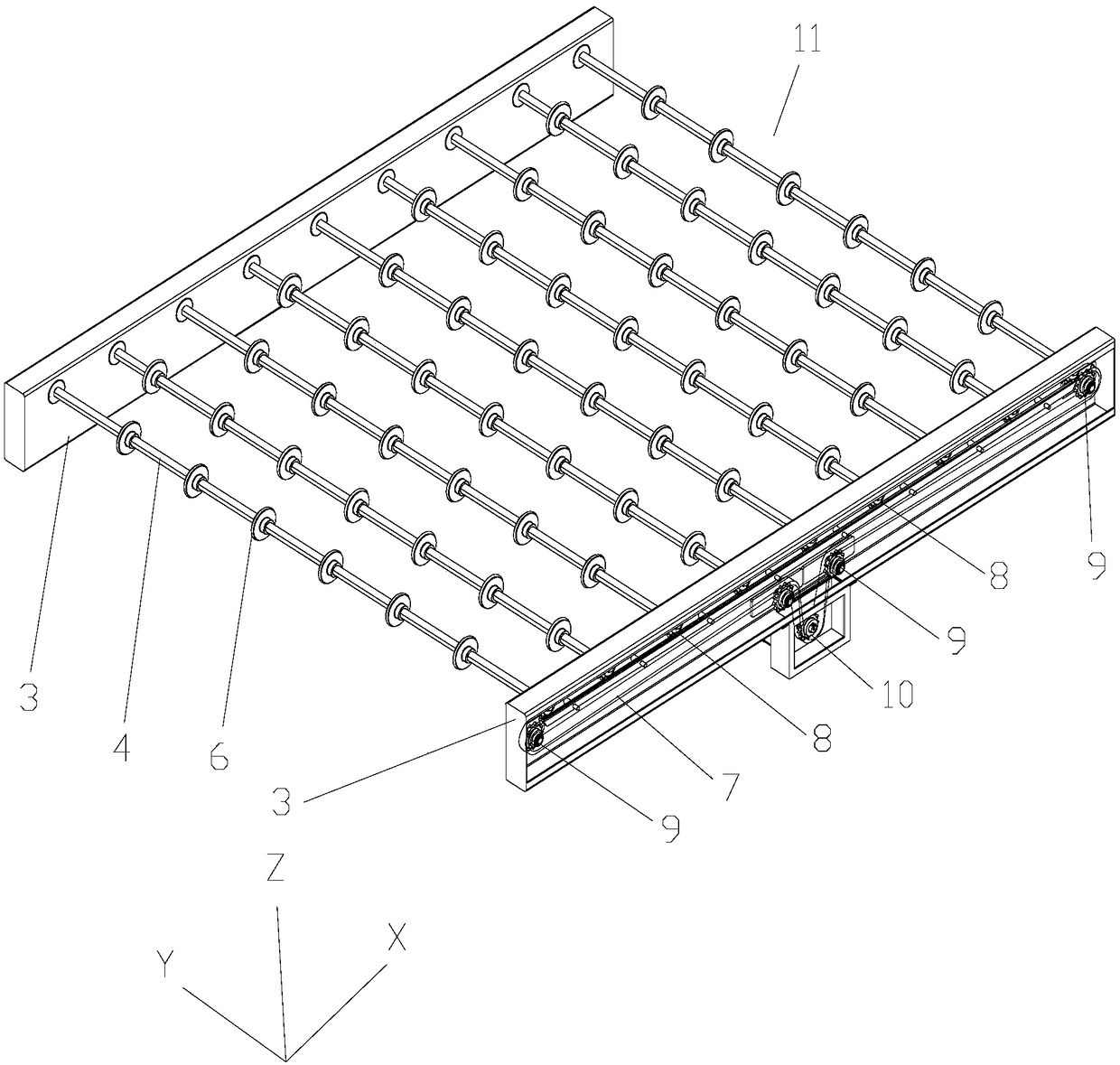

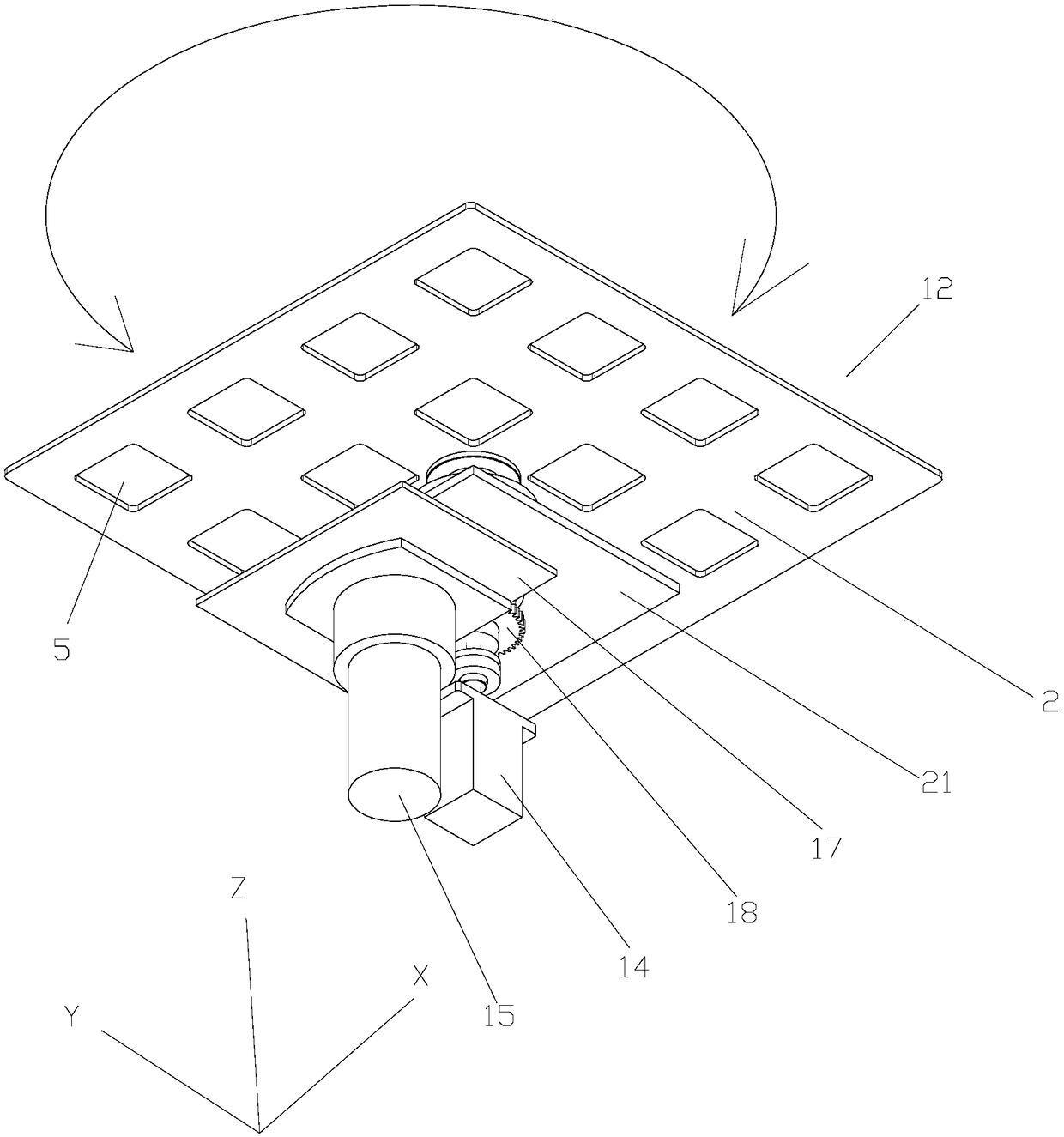

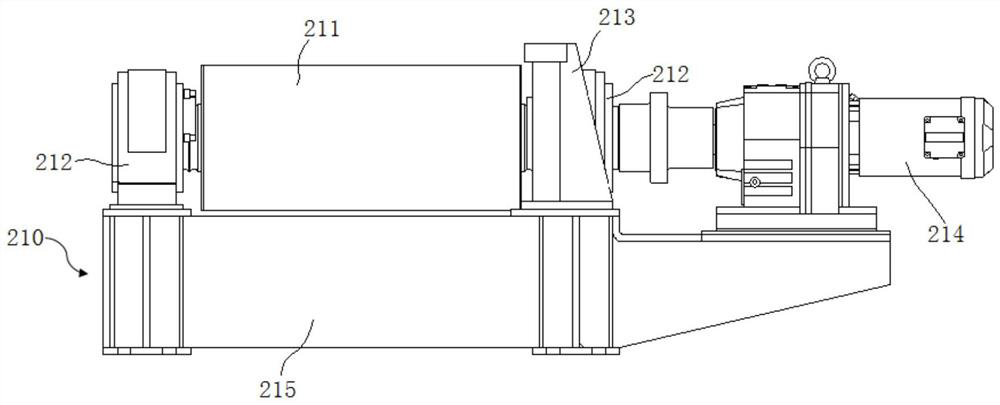

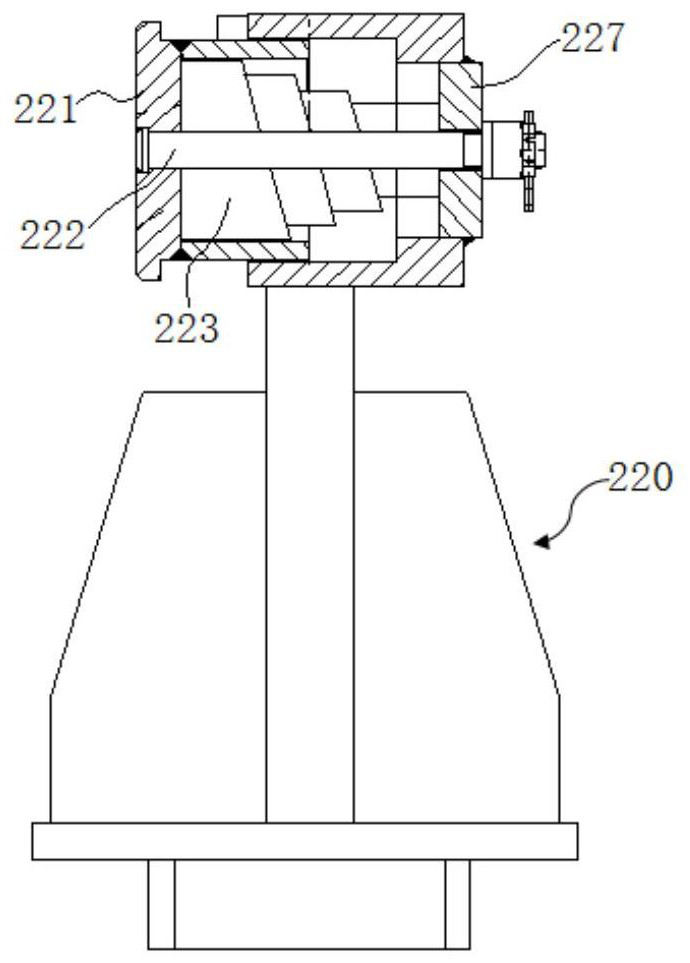

Conveying device

The invention relates to the field of assembly lines of battery packs, and discloses a conveying device. The conveying device comprises a rack (1) a first conveying mechanism (11) and a second conveying mechanism (12), wherein the first conveying mechanism (11) and the second conveying mechanism (12) are arranged on the rack; the first conveying mechanism is used for driving an object to move in an X axis direction; the second conveying mechanism comprises a supporting plate (2), a lifting unit and a rotating unit; the lifting unit is capable of lifting the supporting plate along a Z axis, andthe supporting plate can be driven to rotate through the rotating unit; when moving from a first position to a second position, the supporting plate is capable of propping an object on the first conveying mechanism; and when moving from the second position to the first position, the lifting unit is capable of placing the object on the first conveying mechanism again in order to continuously drivethe object to move in the X axis direction though the first conveying mechanism. With the adoption of the conveying device, the object conveyed on an assembly line can be turned, and moreover, the demand on the field area can be reduced.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

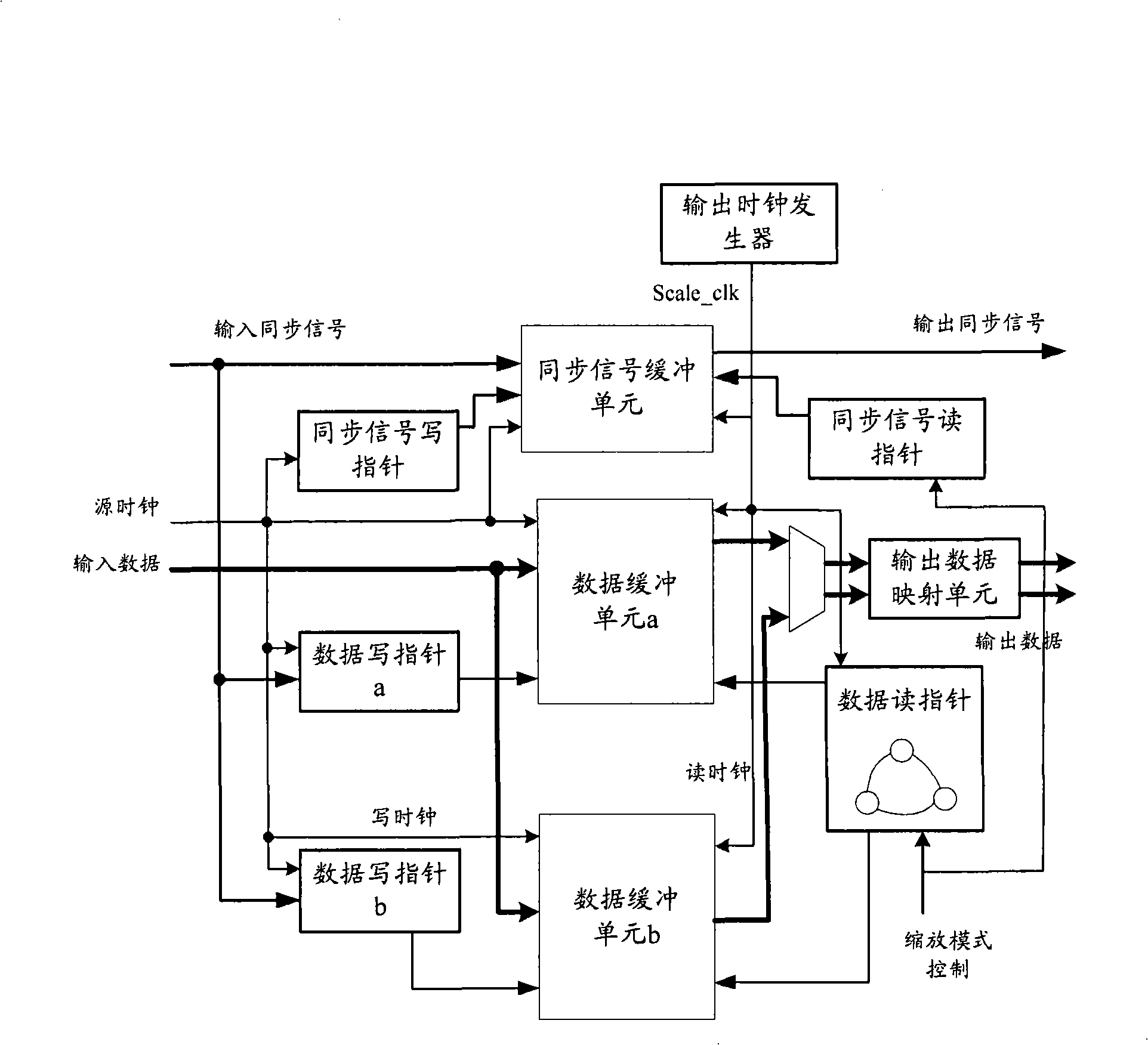

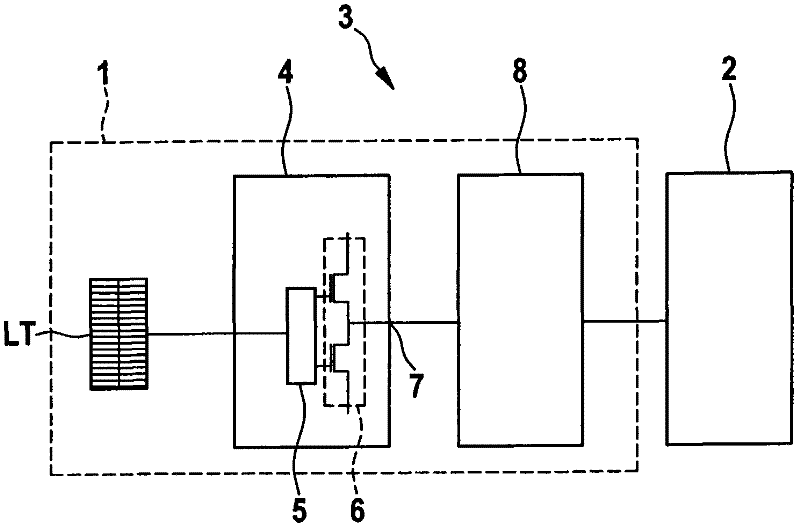

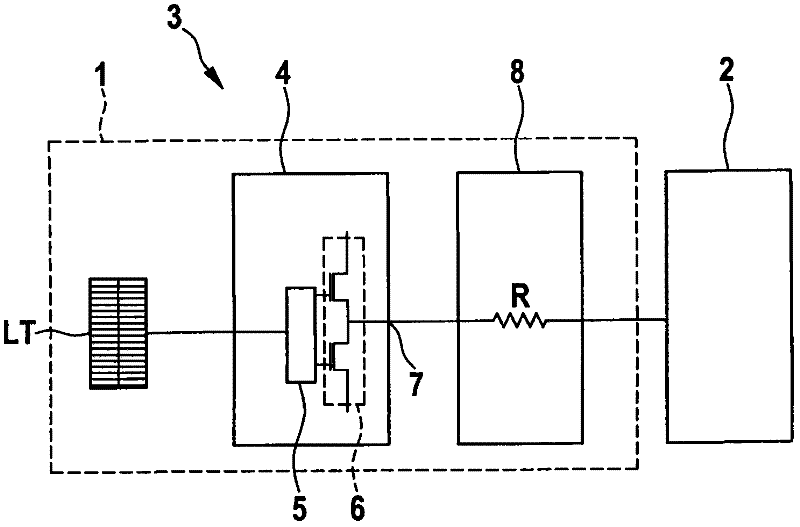

LCD control system

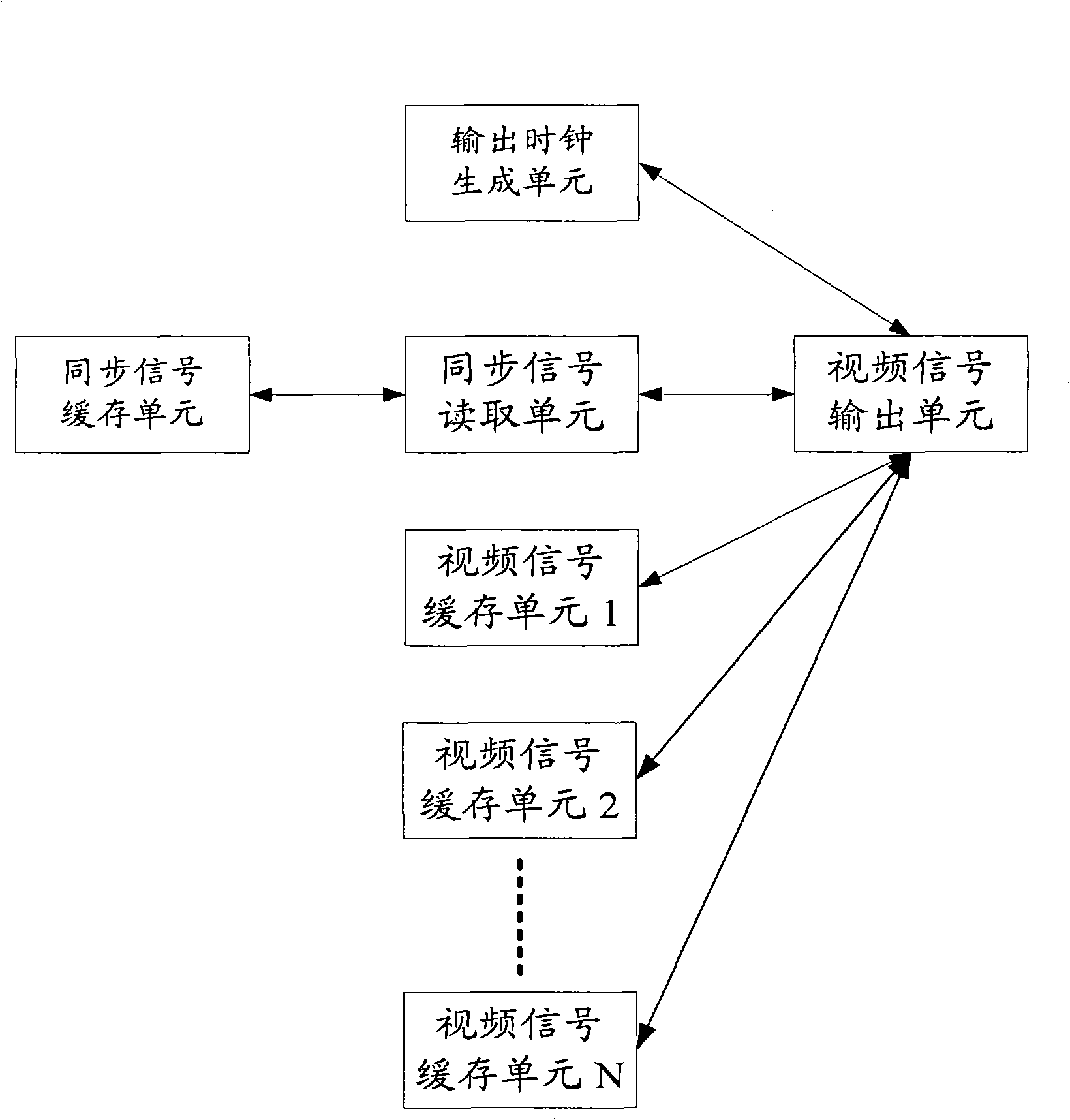

ActiveCN101404145ALine cache unit savingReduced area requirementsTelevision system detailsStatic indicating devicesLiquid-crystal displayControl system

The present invention discloses a liquid crystal display controlling system, which comprises an output clock generating unit, a synchronous signal buffer memory unit, a synchronous signal reading unit, N video signal buffer memory units and an video signal output unit, wherein, the output clock generating unit can generate an output clock signal with a specific scaling according to the working mode of the liquid crystal display controlling system, the synchronous signal buffer memory unit is used for storing a data enabling signal and the like, which are capable of carrying out the signal synchronization on a row or a plurality of rows of video signals, the synchronous signal reading unit is used for reading the data enabling signal and the like, from the synchronous signal buffer memory unit according to the control time sequence requirement of liquid crystal display, and processing the data enabling signal and the like, in a scaling mode according to the specific scaling; the N video signal buffer memory units are used for storing 1 / N parts of a row or a plurality of rows of video signals; the video signal output unit is used for reading 1 / N parts of a row or a plurality of rows of video signals from the N video signal buffer memory units according to the output clock signal, the control time sequence of the liquid crystal display, and the data enabling signal and the like, processed in a scaling mode, processing each 1 / N part in a scaling mode according to the specific scaling, and outputting the signals processed in a scaling mode to outside.

Owner:ANALOGIX CHINA SEMICON

Calibration circuit applied to signal chain analog gain and calibration method thereof

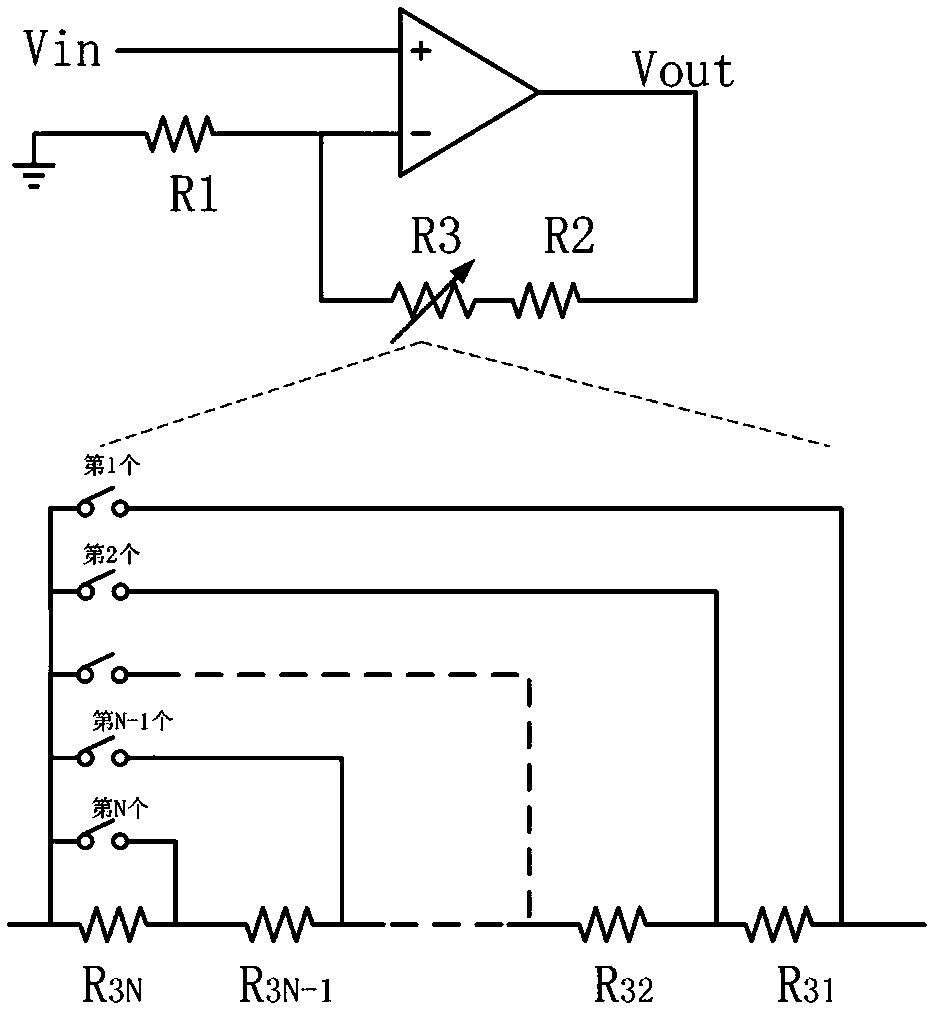

InactiveCN108551343AReduced area requirementsAvoid overheadAnalogue/digital conversion calibration/testingVoltage generatorDigital analog converter

The invention discloses a calibration method for a calibration circuit applied to a signal chain analog gain. The calibration circuit is disposed on the auxiliary path of an amplifier in a signal transmission device and is composed of a first Poly resistor, a second Poly resistor and a calibration voltage generator of a reference voltage Vref; the calibration voltage generator is a digital analogconverter consisting of a string of common resistors and a switch array, and the output of the calibration voltage generator is connected to the substrates of the two Poly resistors for voltage regulation. By applying the calibration circuit and calibration method thereof provided by the invention, the calibration circuit is capable of realizing the calibration of ultra-high precision analog gainby using the voltage coefficient characteristic of the Poly resistor, and the calibration process is not in the signal main path, thereby avoiding the performance impact on the PGA main path, greatlyreducing the area requirement of the calibration circuit, and avoiding the overhead and cost of the unit resistance for calibrating and the chip area occupied by the calibration switch. In addition, the calibration circuit is capable of avoiding the influence of introducing the dynamic performance of the PGA and increasing the voltage linearity of the PGA.

Owner:3PEAK INC

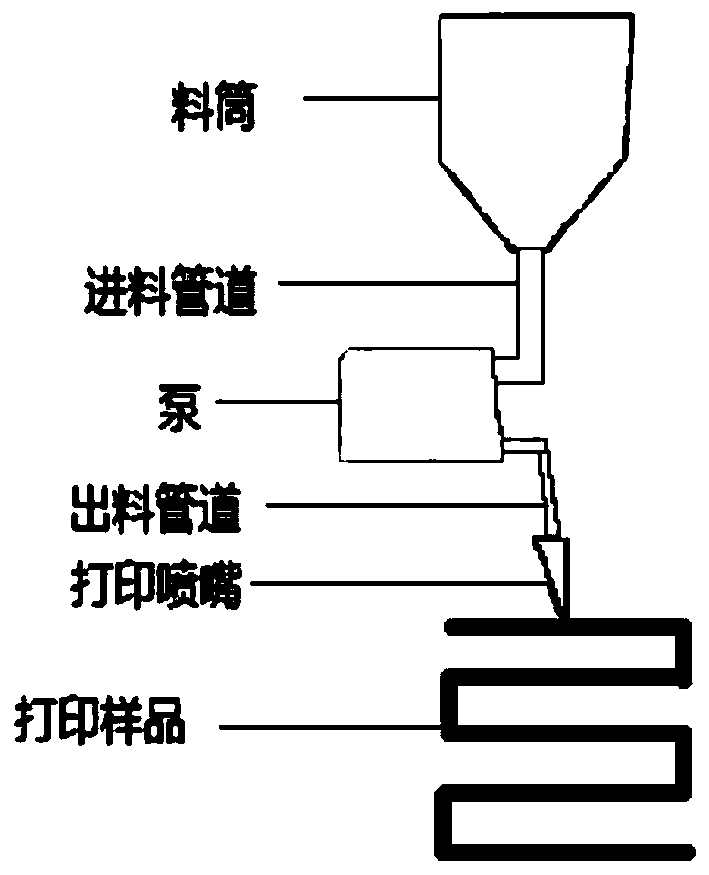

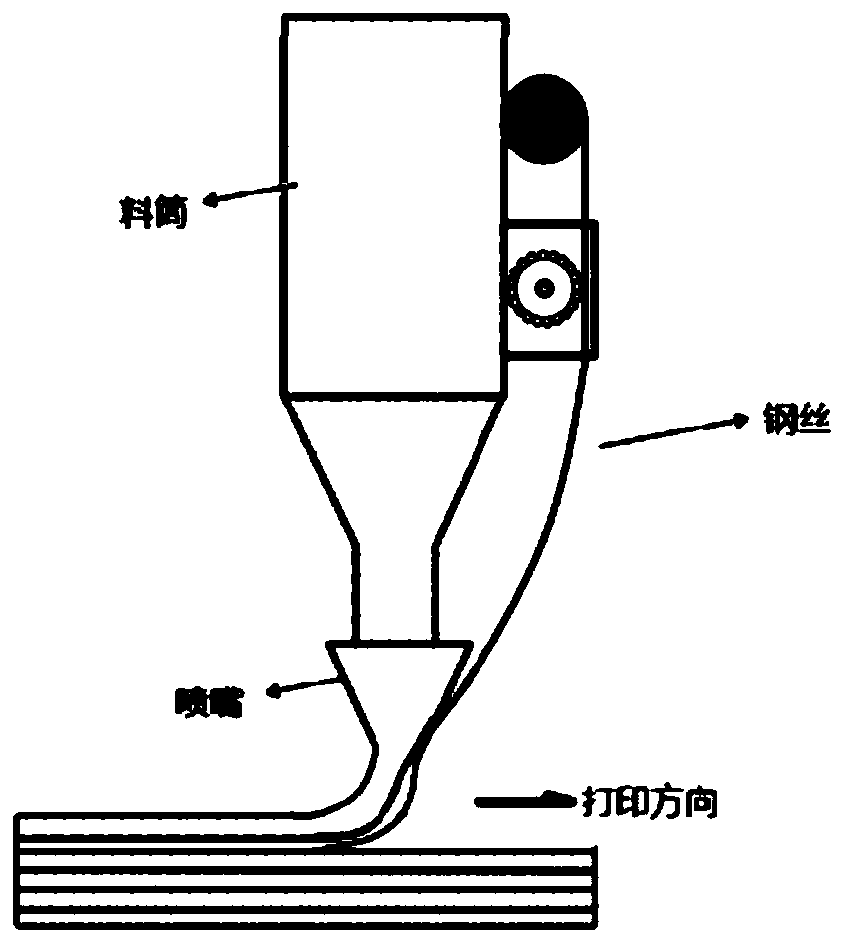

3D printing nozzle for continuous material stirring and extruding and continuous spiral wire feeding

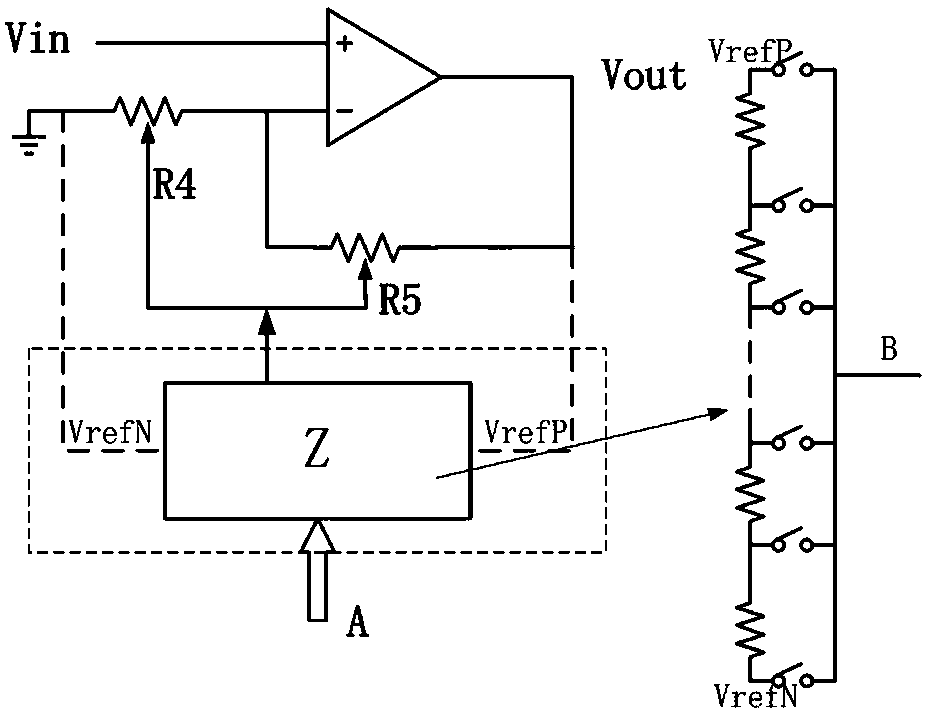

ActiveCN110883901AEfficient printingEasy to assemble and disassembleAdditive manufacturing apparatusCeramic shaping apparatus3d printFiber

The invention discloses a 3D printing nozzle for continuous material stirring and extruding and continuous spiral wire feeding. The 3D printing nozzle comprises a motor, a cylinder, a rotating drum, an upper transmission shaft pipe, a lower transmission shaft pipe, a material equalizing device, a spatula nozzle and a supporting frame, wherein the upper transmission shaft pipe and the lower transmission shaft pipe are arranged on the central axis of the rotating drum. According to the 3D printing nozzle, dry powder enters a spray nozzle and is mixed with liquid to be extruded, so that the usageamount of retarder of traditional 3D concrete can be greatly reduced, and various performance indexes of the 3D concrete can be beneficially improved. Area requirements of a concrete 3D printing siteare reduced. Energy is saved, and the environment is protected. A liquid inlet port has strong flow and slow flow interfaces, and strong water flow can be used for flushing after use. Parts are modular components which are convenient to maintain and replace. An outlet spatula nozzle rotates clockwise to realize the function of smoothing the profile side wall and obtain a smooth lateral side. According to the 3D printing nozzle, a spirally wound steel wire (or long fiber wire) is internally arranged, so that the strength and toughness of 3D concrete materials is effectively enhanced, and the crack resistance of members is obviously improved.

Owner:大连学庆铭锋数控技术有限公司

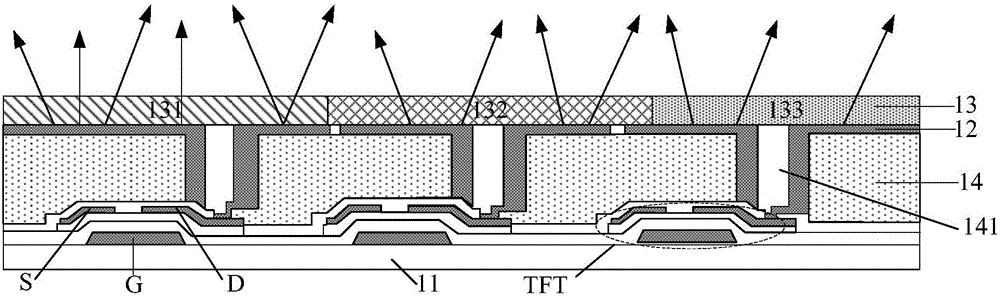

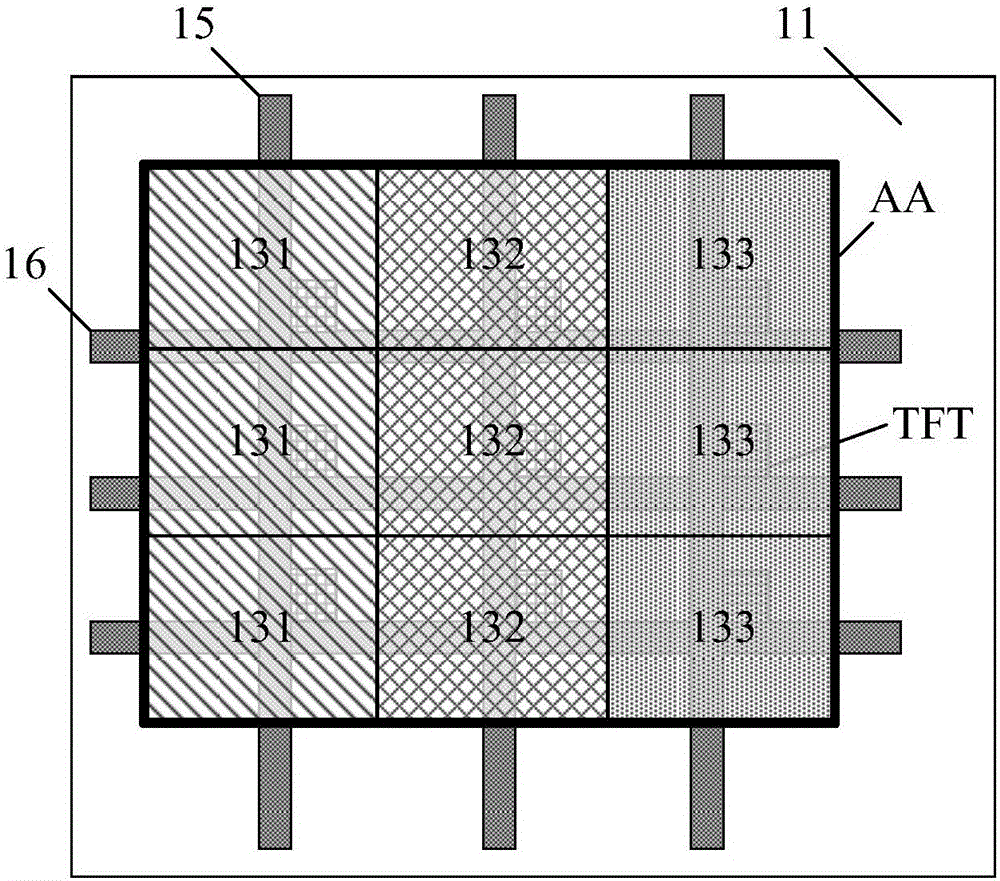

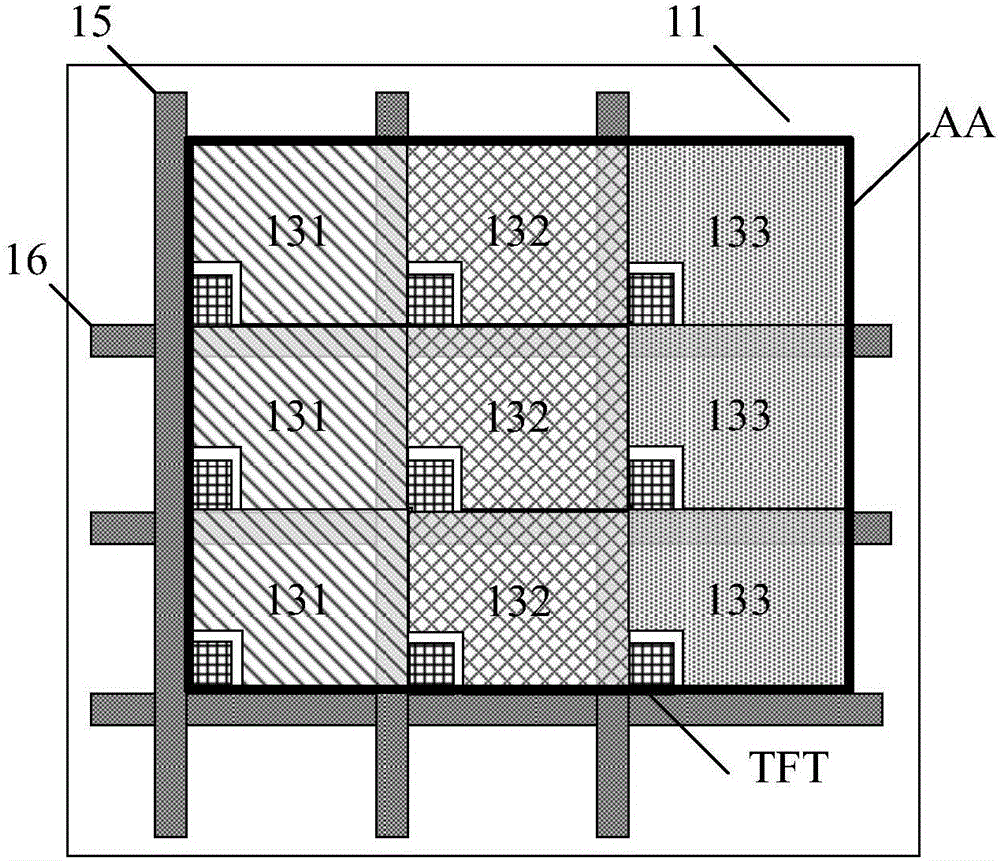

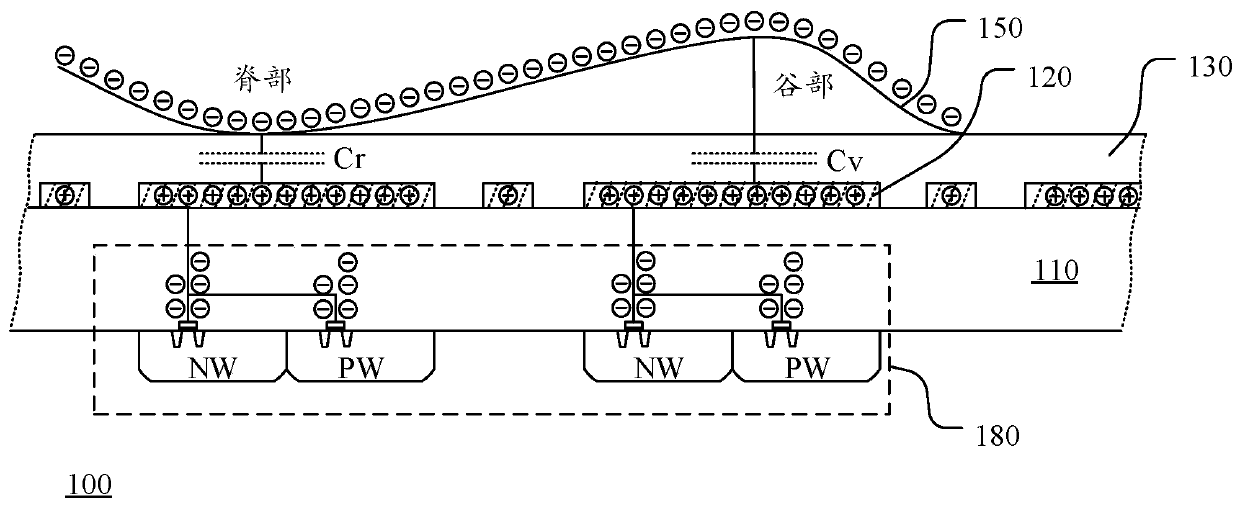

Display substrate, display panel and display device

InactiveCN106483710AReduced lateral transfer pathsReduced area requirementsNon-linear opticsHorizontal transmissionTransistor array

The invention provides a display substrate, a display panel and a display device. The display substrate comprises a substrate base plate, a grid line, a data line, a film transistor array, a reflection pattern and a color filter layer, wherein the grid line, the data line and the film transistor array are located on the substrate base plate; the reflection pattern is located on the grid line, the data line and the film transistor array and used for reflecting incident rays so as to form emergent rays for forming a display frame; and the color filter layer is located on the reflection pattern. According to the scheme provided by the invention, the color filter layer (namely, the pattern of a color filter) is arranged on the substrate base plate for reflecting the pattern, so that the color filter layer is closer to the reflection pattern, the horizontal transmission paths of the reflected rays passing by the color filter layer can be reduced and the cross color phenomenon can be further avoided. Obviously, on the basis of the scheme provided by the invention, the function of a black matrix can be reduced, i.e., the area of the black matrix to be arranged is greatly reduced and the opening rate and reflectivity of the display base plate can be further increased.

Owner:BOE TECH GRP CO LTD

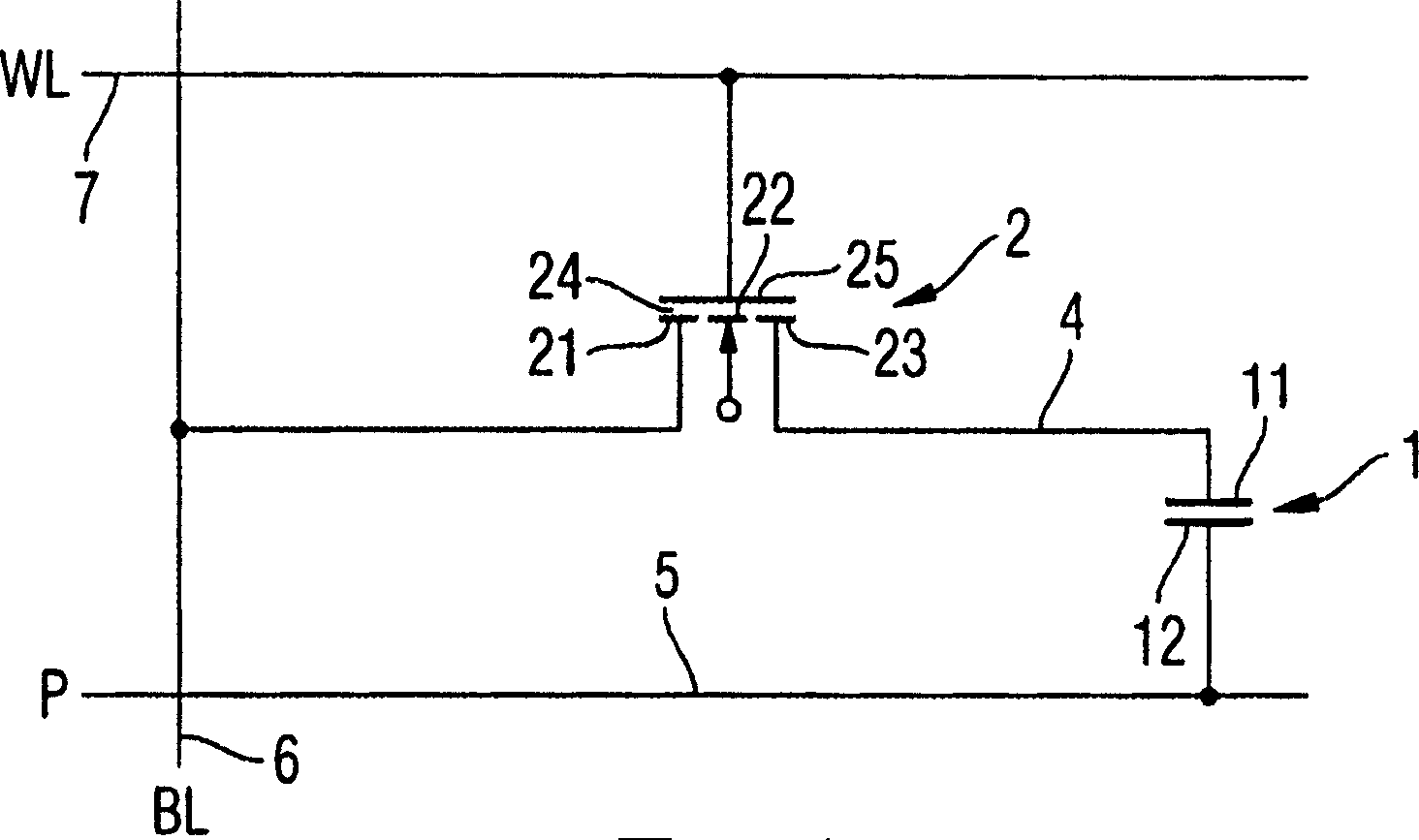

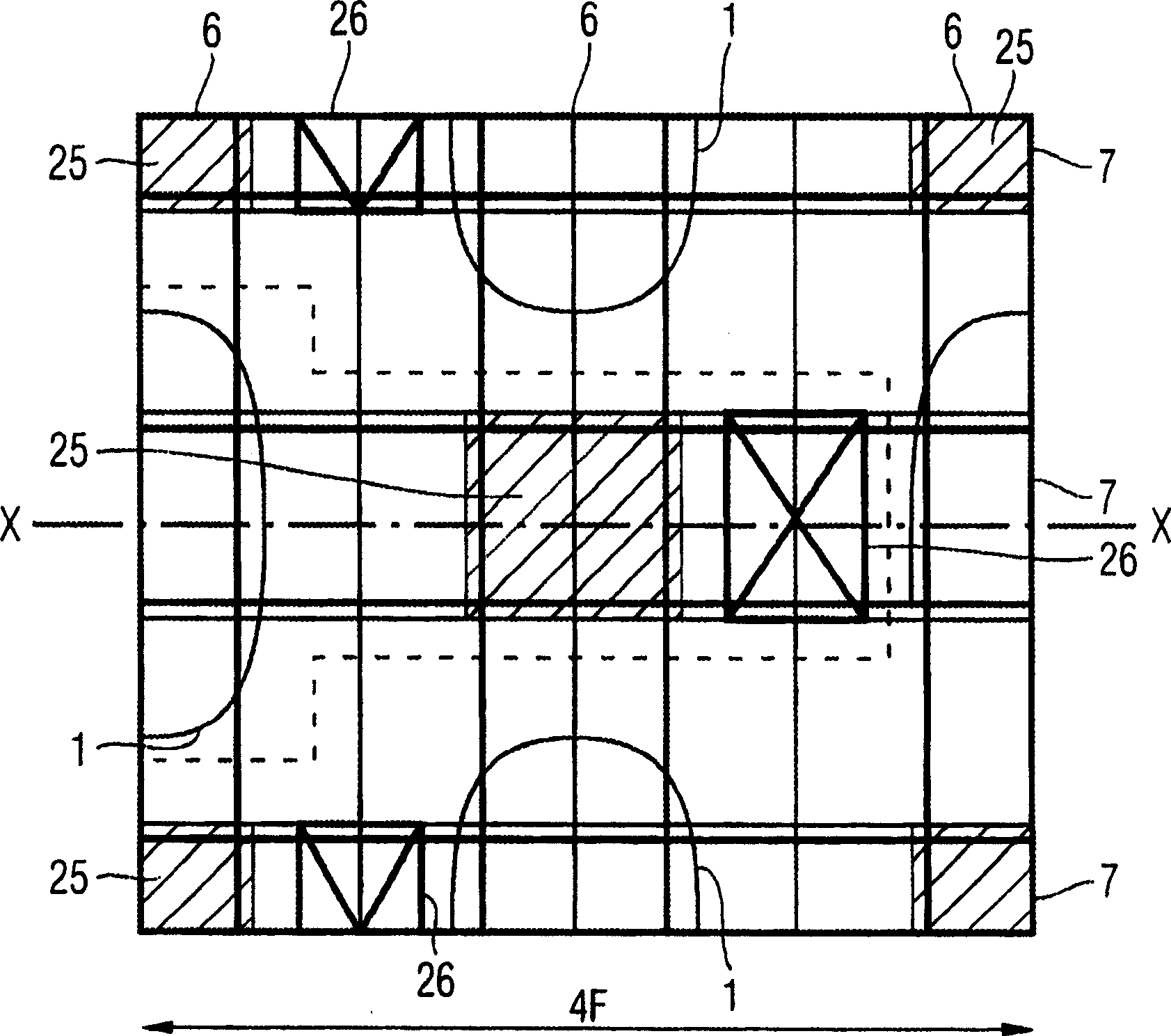

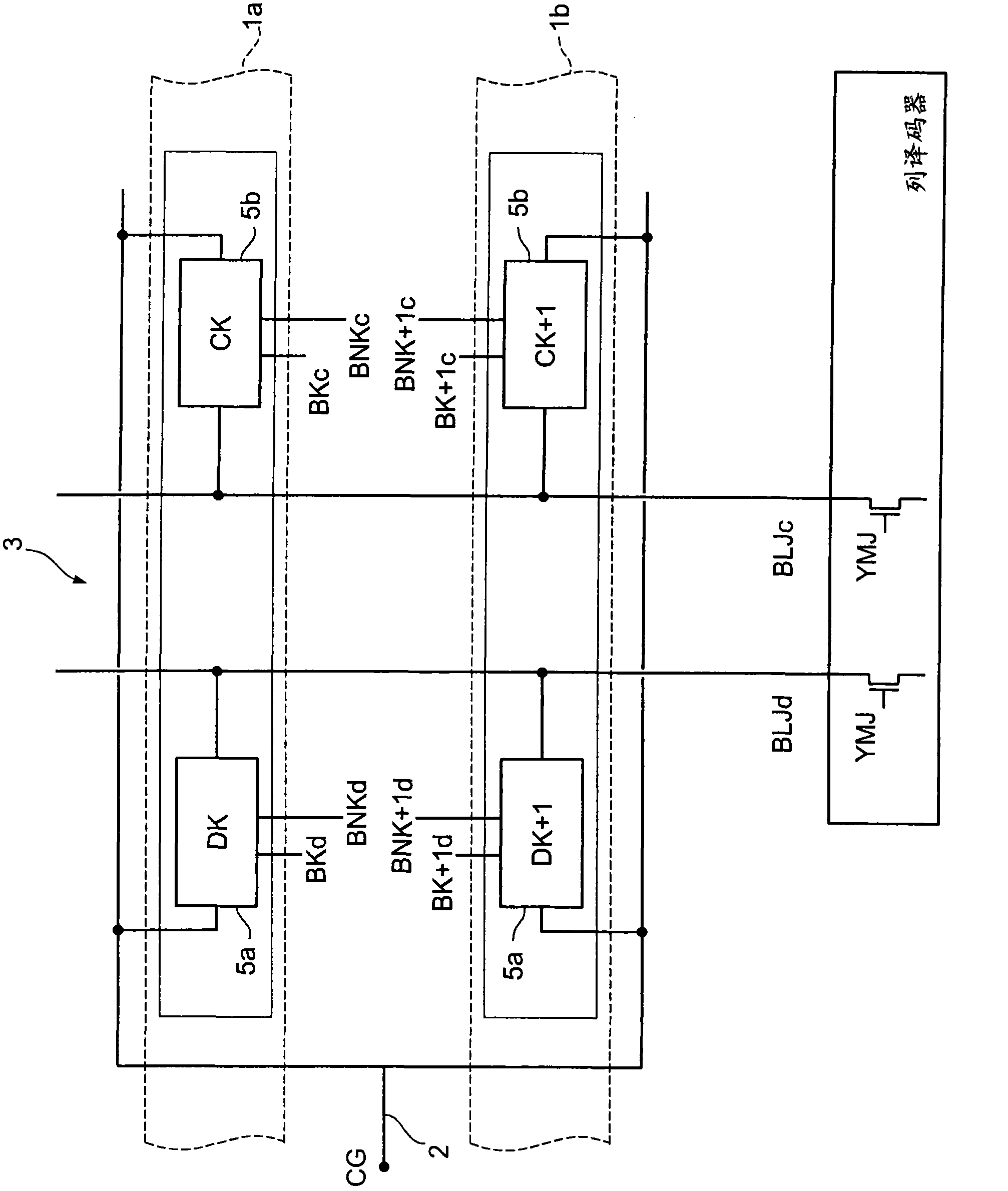

Semiconductor memory cell array having mos transistors and method for forming the same

InactiveCN1917212AReduce intervalReduced area requirementsTransistorSolid-state devicesDielectric layerCapacitor

In a semiconductor memory including an array of memory cells, each memory cell includes a trench capacitor, the trench capacitor including an inner electrode, an outer electrode and a dielectric layer disposed between the inner electrode and the outer electrode, and a selection transistor, the selection transistor including a first source / drain area, a second source / drain area and a channel region disposed between the first source / drain area and the second source / drain area in a recess, the trench capacitor and the selection transistor of each memory cell are disposed side by side, the first source / drain area of the selection transistor being electrically connected to the inner electrode of the trench capacitor, the recess in which the channel region of the selection transistor is formed being located self aligned between the trench capacitor of the memory cell and the trench capacitor of an adjacent memory cell.

Owner:QIMONDA

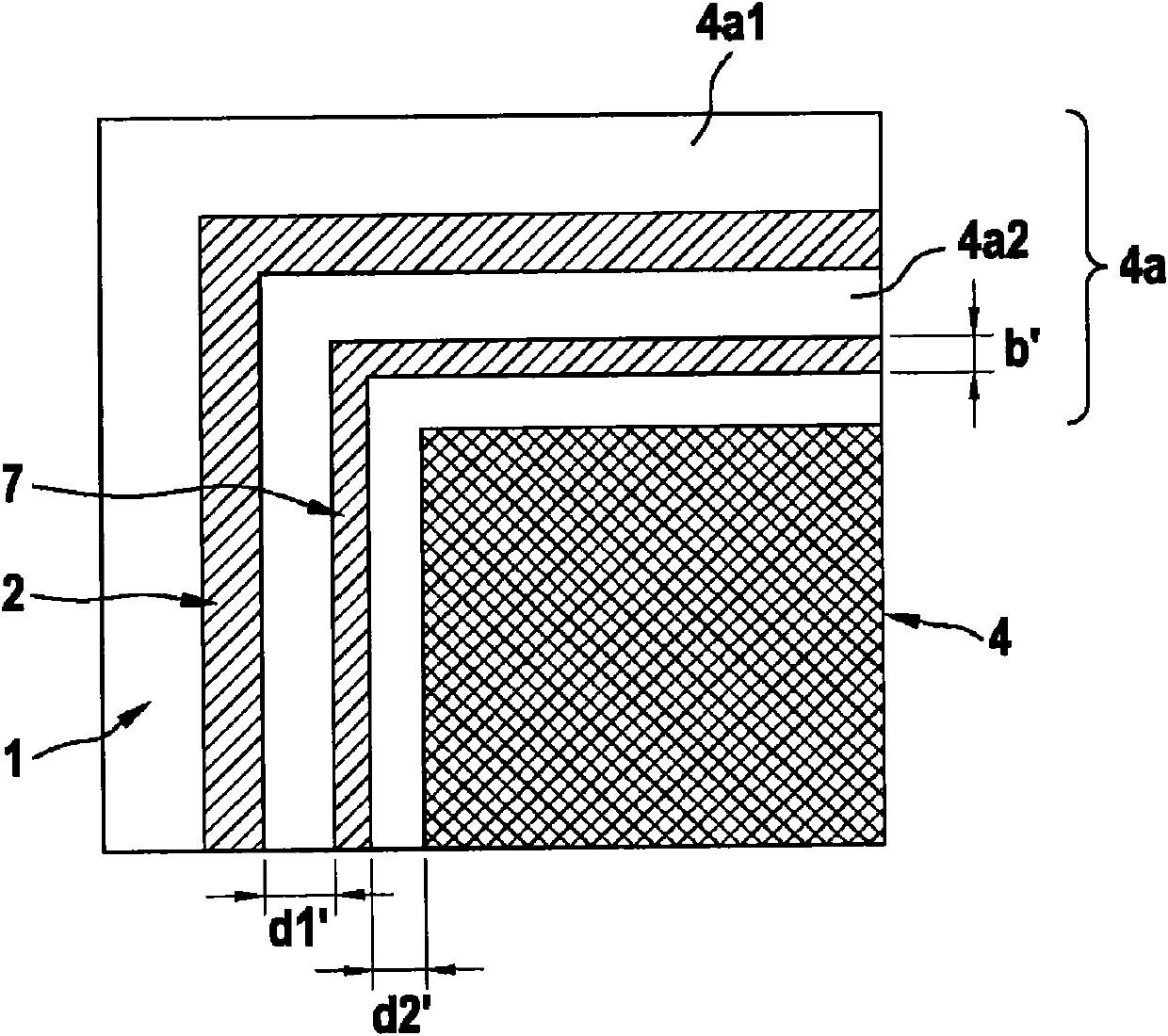

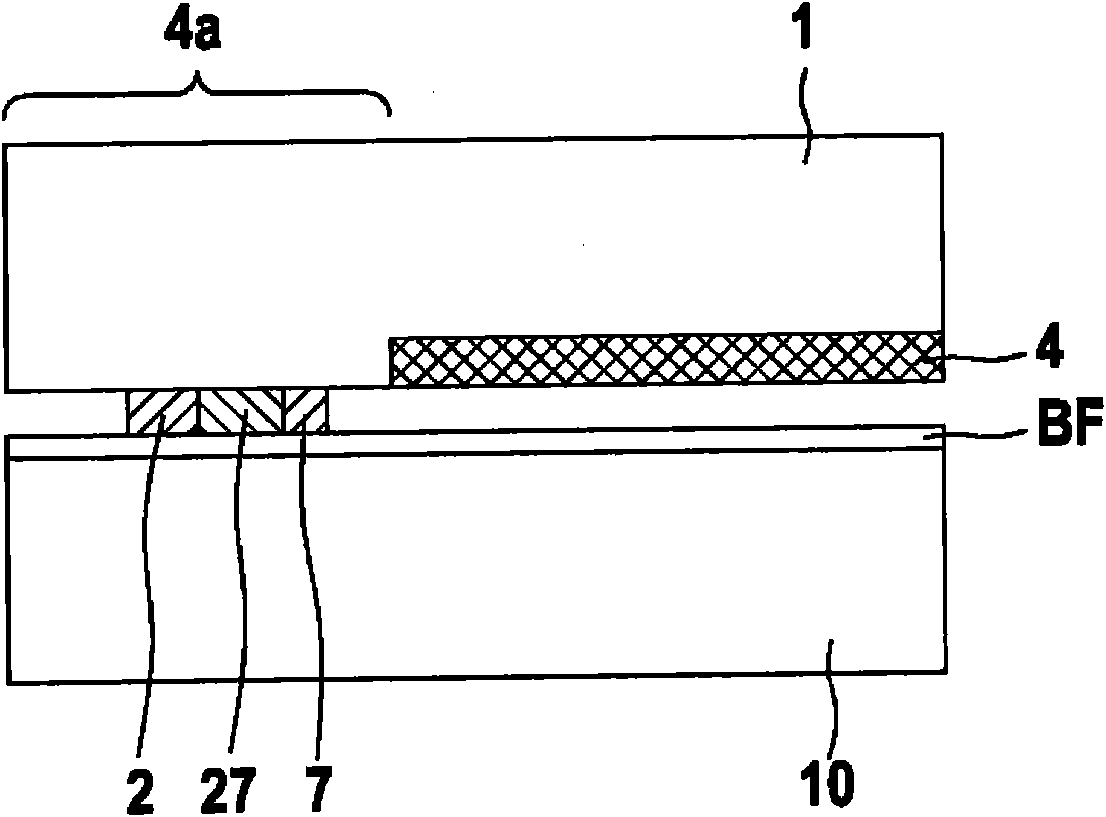

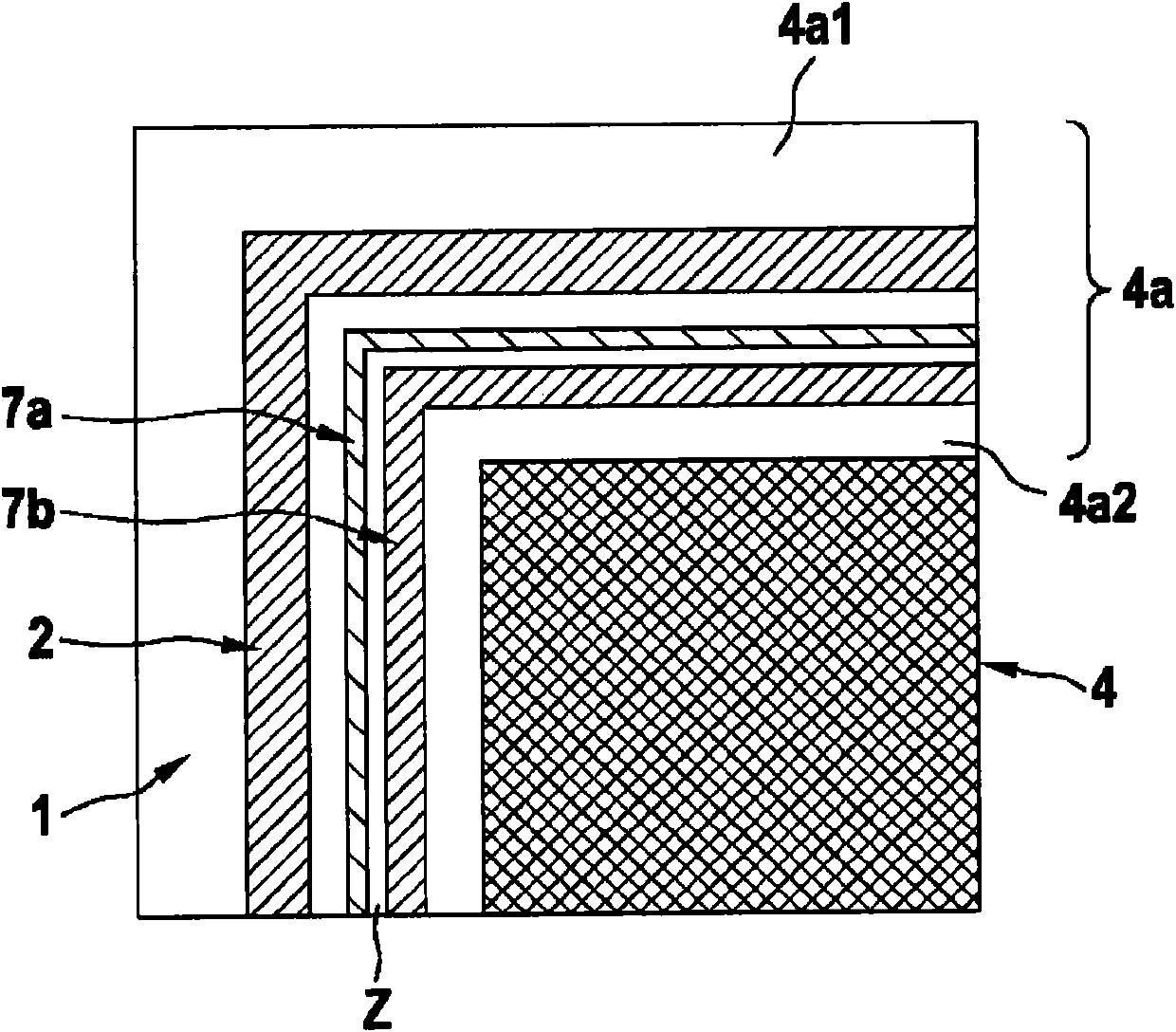

Micromechanical method and corresponding assembly for bonding semiconductor substrates and correspondingly bonded semiconductor chip

InactiveCN102666368AReduced area requirementsHigh melting pointPrecision positioning equipmentSemiconductor/solid-state device detailsSemiconductor chipEngineering

The invention relates to a micromechanical method and a corresponding assembly for bonding semiconductor substrates and a correspondingly bonded semiconductor chip. The assembly according to the invention comprises a semiconductor substrate having a chip pattern having a plurality of semiconductor chips (1), each having a functional region (4) and an edge region (4a) surrounding the functional region (4), wherein there is a bonding frame (2) made of a bonding alloy made from at least two alloy components in the edge region (4a), spaced apart from the functional region (4). Within the part (4a2) of the edge region (4a) surrounding the bonding frame (2) between the bonding frame (2) and the functional region (4), there is at least one stop frame (7; 7a, 7b; 7b'; 70) made of at least one of the alloy components, which is designed such that when a melt of the bond alloy contacts the stop frame (7; 7a, 7b; 7b'; 70) during bonding, the bonding alloy solidifies.

Owner:ROBERT BOSCH GMBH

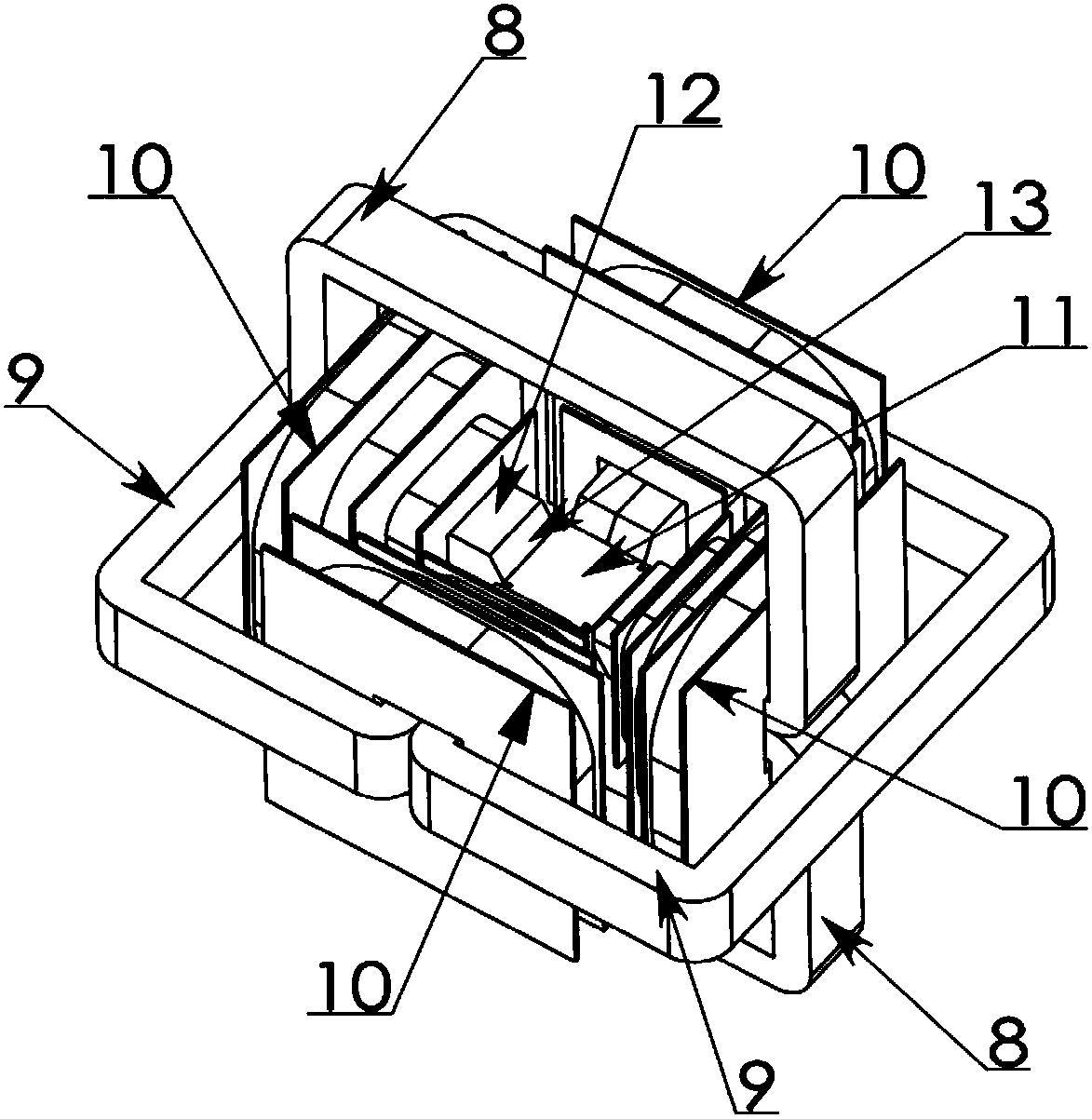

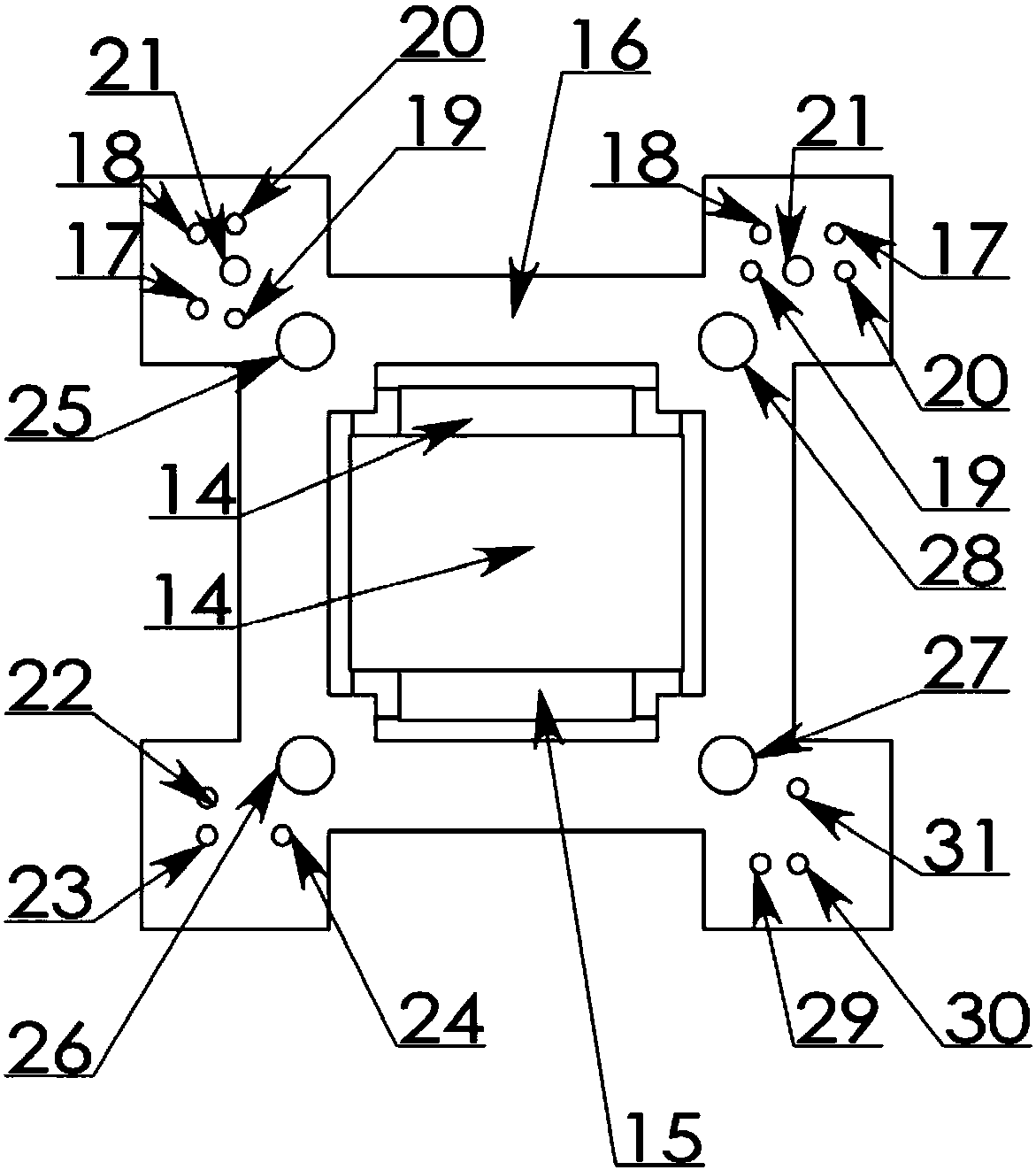

Test system and measurement method for rotary magnetic property of nano-crystalline

ActiveCN109425840AHigh Saturation Magnetic DensityHigh initial permeabilityMagnetic property measurementsCapacitanceTest efficiency

The invention discloses a test system and measurement method for the rotary magnetic property of nano-crystalline, and belongs to magnetic property measurement equipment of nano-crystal materials. Thetest system comprises an NI industrial control computer, a LabVIEW signal generation and collection board, a rotary magnetic property tester, a power amplifier, an impedance matching capacitance box,a B-H composite magnetic sensor and a differential amplification circuit. Two orthogonal magnetic circuits are of a symmetric double-yoke structure, the two magnetic circuits implement excitation independently, and alternate excitation in any direction within a circle, oval and plane can be carried out according to practical condition. The B-H composite magnetic sensor is composed of two H coilsand four probes, the two H coils vertical to the window direction can be wound around a detachable square inner-ring PCB substrate to test the magnetic field intensities H in the two orthogonal directions, the four steel probes are mounted on an outer PCB substrate pairwise, and every two probes in the same pair test the flux density B in one direction. Weld points and lead fixing holes are designed in the outer PCB substrate. Shimming protective layers are arranged in the two sides of a test sample respectively, the uniformity of a test area is ensured, and the test efficiency is improved.

Owner:HEBEI UNIV OF TECH

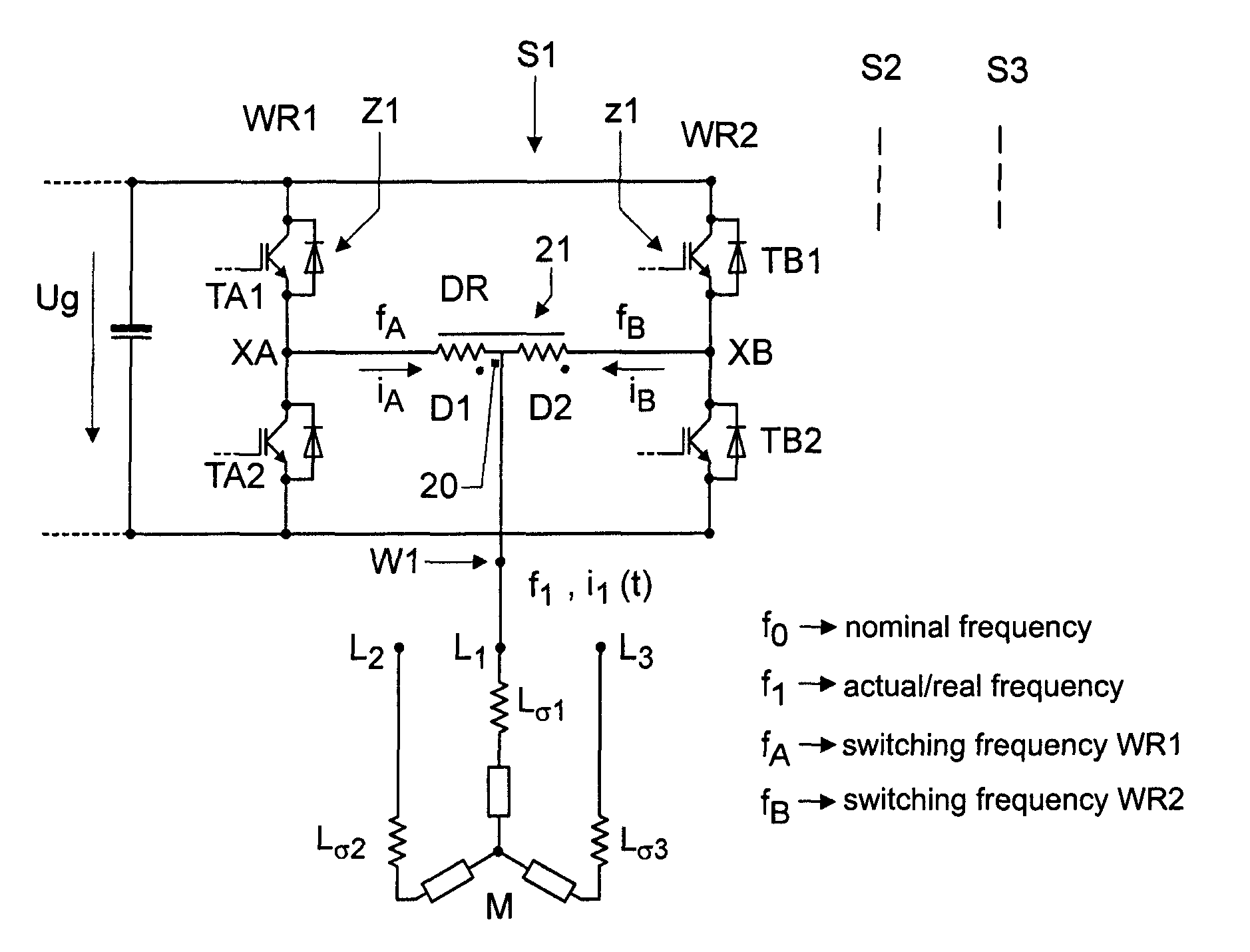

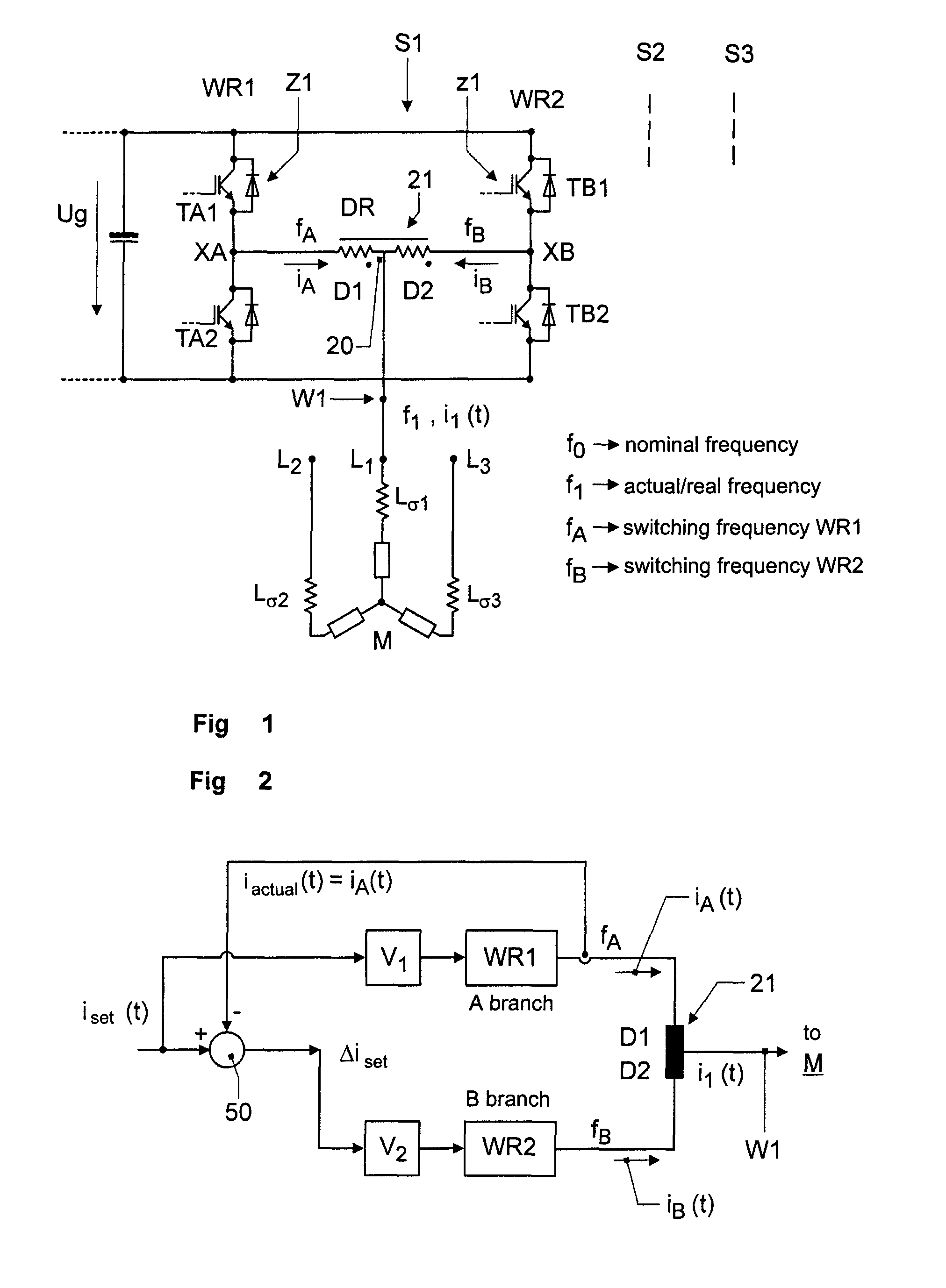

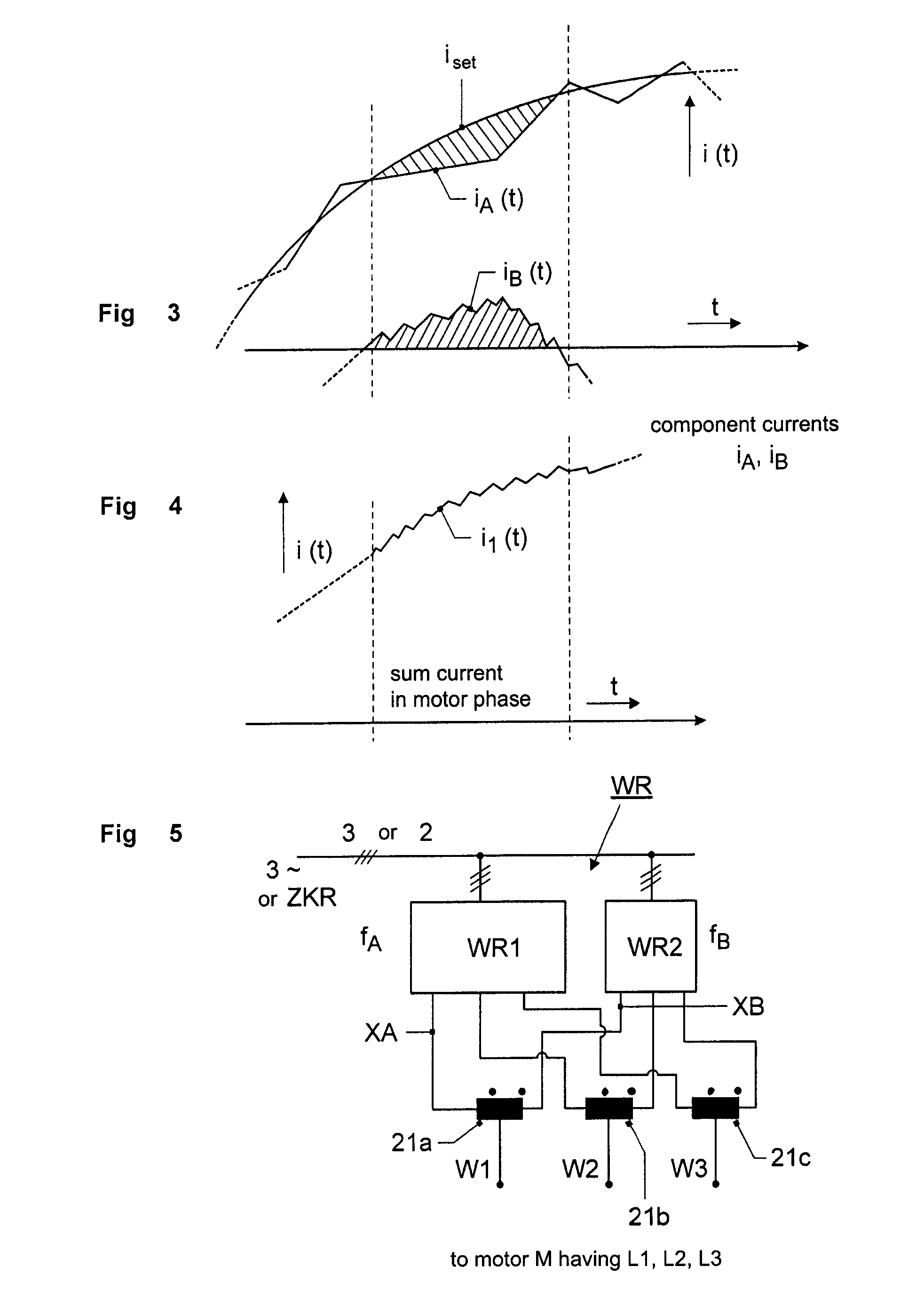

Driving with inverters with low switching losses

ActiveUS8421389B2Lower requirementLow heat generationMotor/generator/converter stoppersSynchronous motors startersPower flowSwitching frequency

Owner:LENZE DRIVES

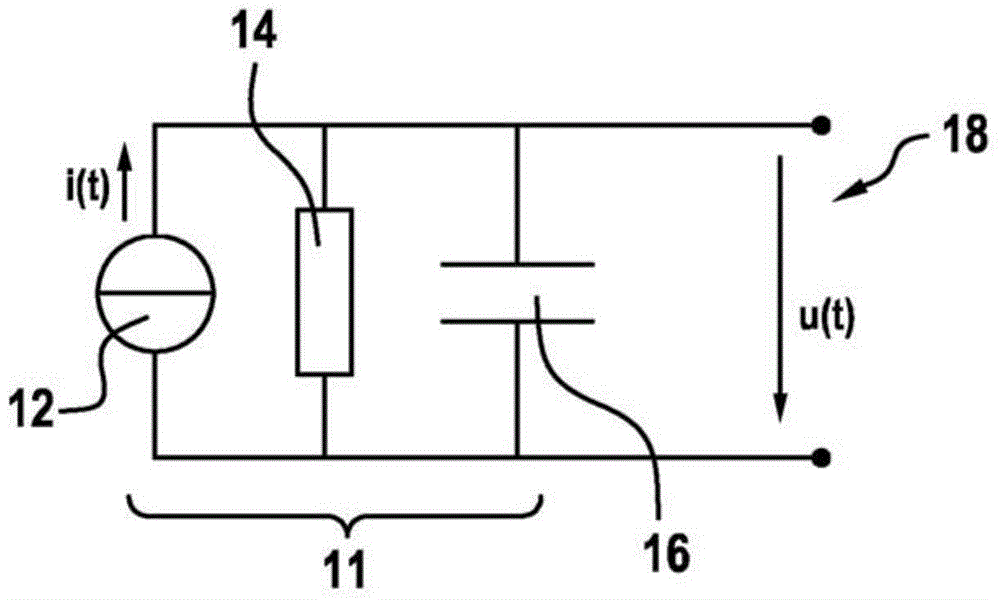

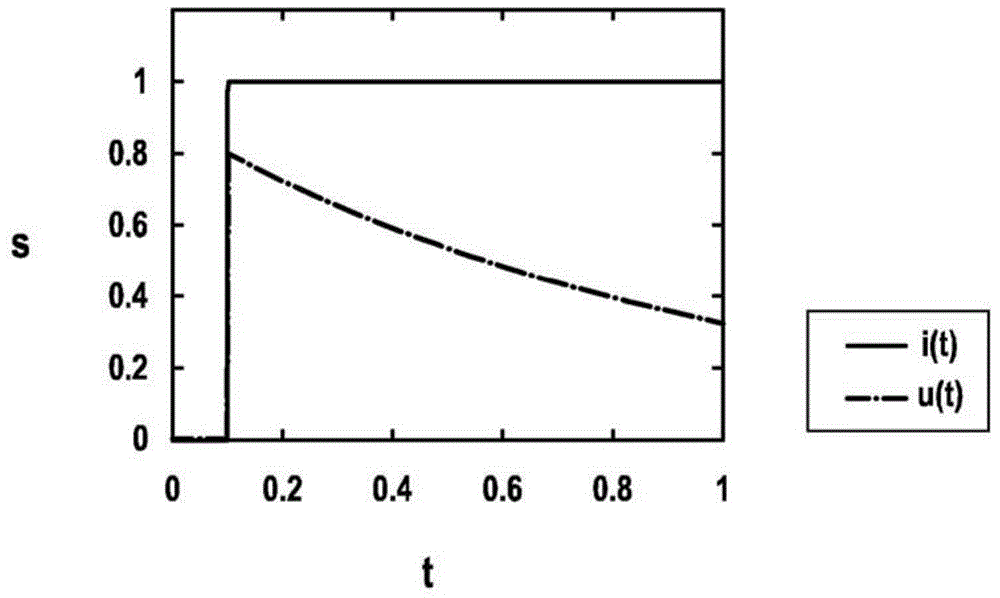

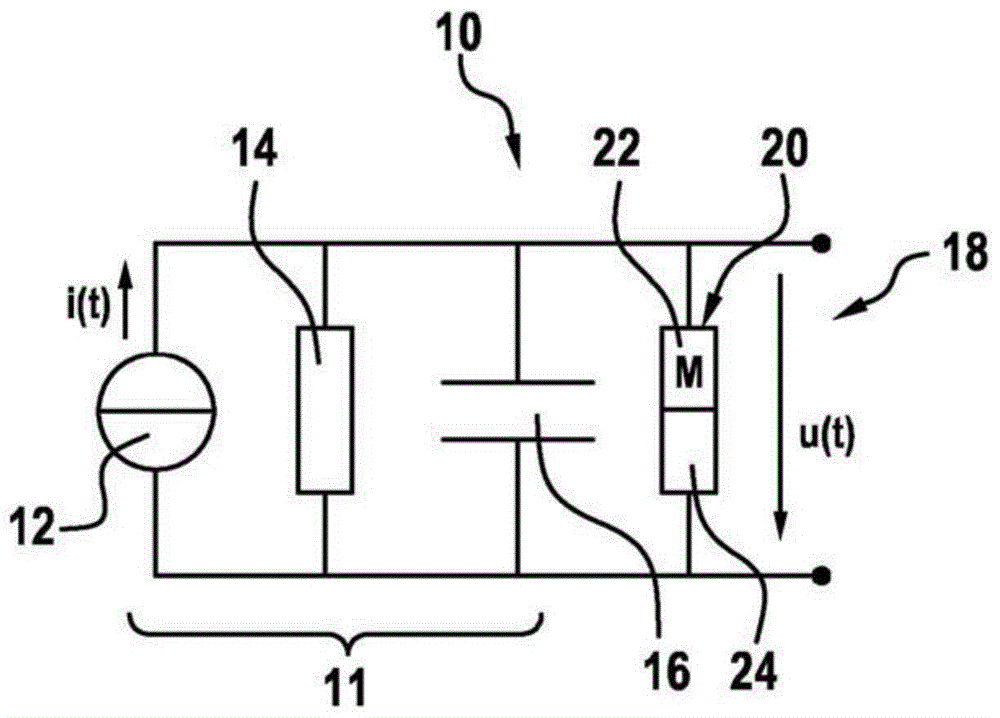

Sensor element having a piezoelectric transducer

ActiveCN103562696AReduced area requirementsReliable readFluid pressure measurement using piezo-electric devicesForce measurement using piezo-electric devicesTransducerMemristor

The invention relates to a sensor element (10) having at least one piezoelectric transducer (11), said piezoelectric transducer (11) being coupled to at least one memristor (20). The invention further relates to a sensor having an array of a plurality of pixels, at least one of the pixels comprising a sensor element (10).

Owner:ROBERT BOSCH GMBH

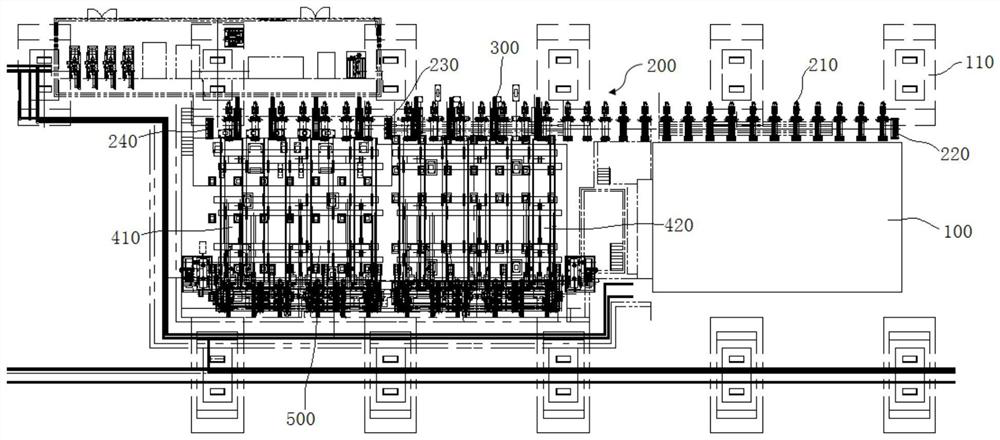

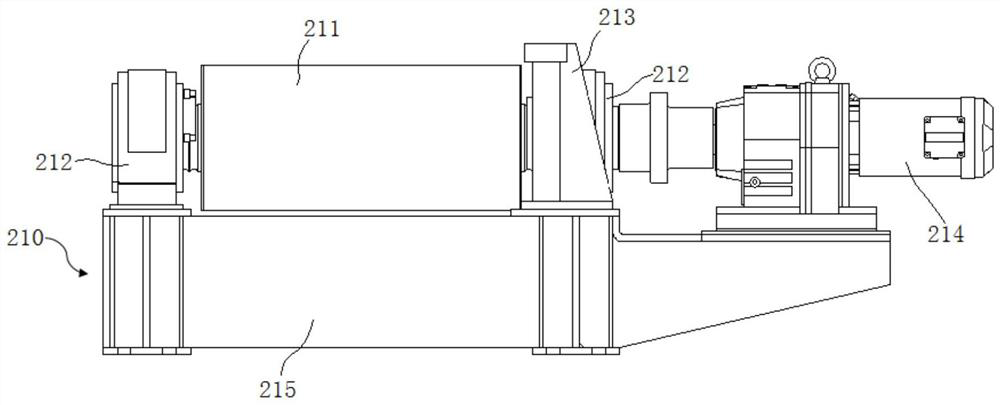

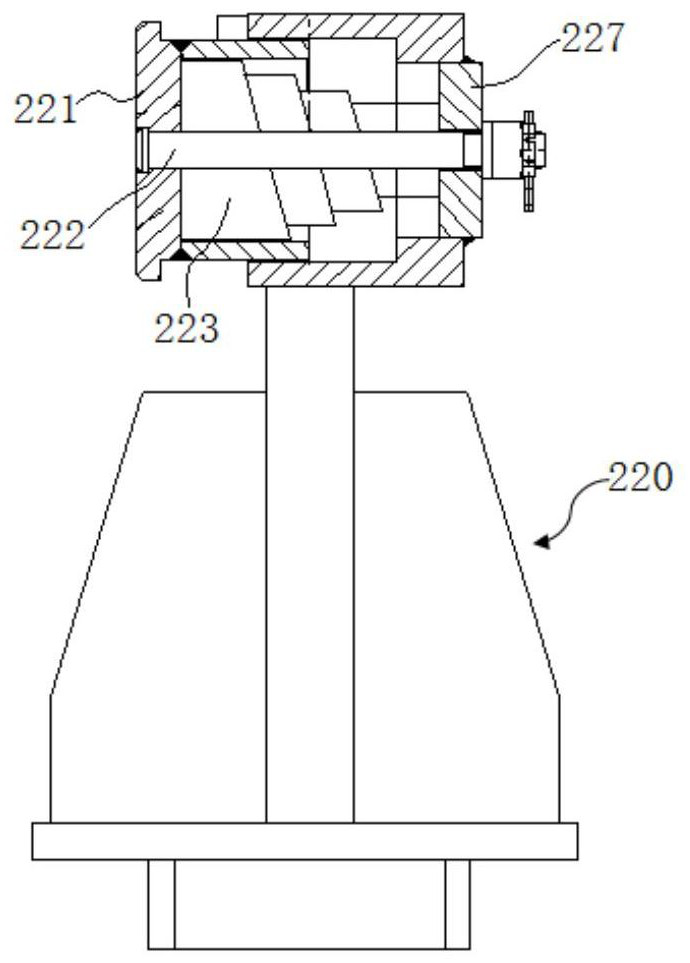

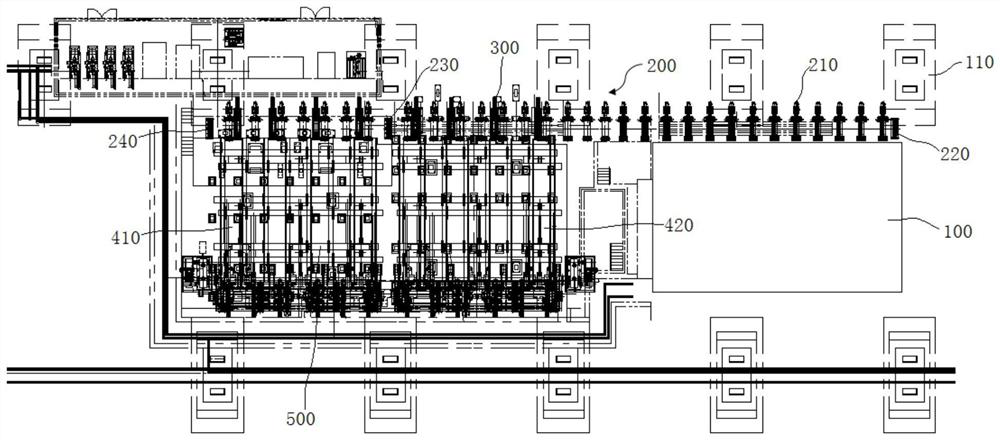

Compact arrangement system for billet discharge area of billet caster

The invention discloses a compact arrangement system for a billet discharge area of a billet caster, and belongs to the technical field of arrangement of billet discharge areas of continuous casting machines. The compact arrangement system comprises a lifting baffle, and a bidirectional cooling bed A and a bidirectional cooling bed B arranged on the same side of the tail of a hot conveying rollerway; the lifting baffle can implement free lifting and is used for performing shunting treatment on casting blanks; the bidirectional cooling bed A and the bidirectional cooling bed B are the same instructure and are arranged in parallel; the operation mode of the bidirectional cooling bed A is alternate operation of forward rotation and reverse rotation; the step number of forward rotation for advancement of the bidirectional cooling bed A is two times of the number of a set of conveyed casting blanks; and the step number of reverse rotation for retreating of the bidirectional cooling bed Ais one time of the number of a set of conveyed casting blanks. Aiming at the problems that the workshop space of a billet discharge area of an existing billet caster is limited and equipment such as cooling beds, a steel moving machine and the like cannot be arranged, the cooling time of the casting blanks on the cooling beds is prolonged when the lengths of the cooling beds are not increased, andthe occupied space area can be effectively reduced.

Owner:马钢集团设计研究院有限责任公司

Actuating device, microsystem device, and method for controlling a micromechanical actuator

InactiveCN102447419AReduced area requirementsReduce power consumptionPiezoelectric/electrostriction/magnetostriction machinesElectrostatic motorsDriver circuitCapacitance

A method, actuating device, and microsystem device are described for controlling a micromechanical actuator, which has a rechargeable capacitor for generating a mechanical motion of the micromechanical actuator, a memory having a lookup table containing previously computed data of signal shapes for controlling the micromechanical actuator, and a driver circuit having a driver circuit control unit for processing the previously computed data, a power stage for generating the signal shapes, and an output for outputting the signal shapes, corresponding to previously computed data, to the micromechanical actuator's rechargeable capacitor. The micromechanical actuator has a limiting device, between the output of the driver circuit and the micromechanical actuator, which is for limiting a voltage excursion of the signal shapes output by the driver circuit, which are usable for generating the mechanical motion by recharging the micromechanical actuator's rechargeable capacitor. The micromechanical actuator's power consumption is reducible by limiting the voltage excursion.

Owner:ROBERT BOSCH GMBH

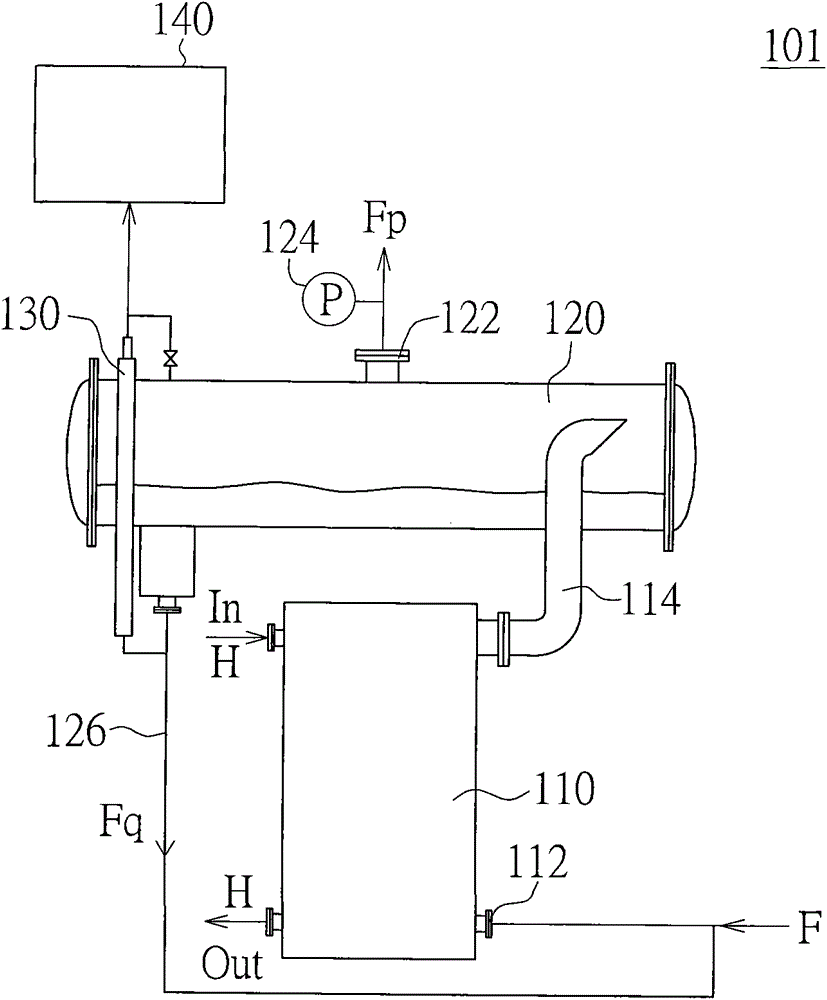

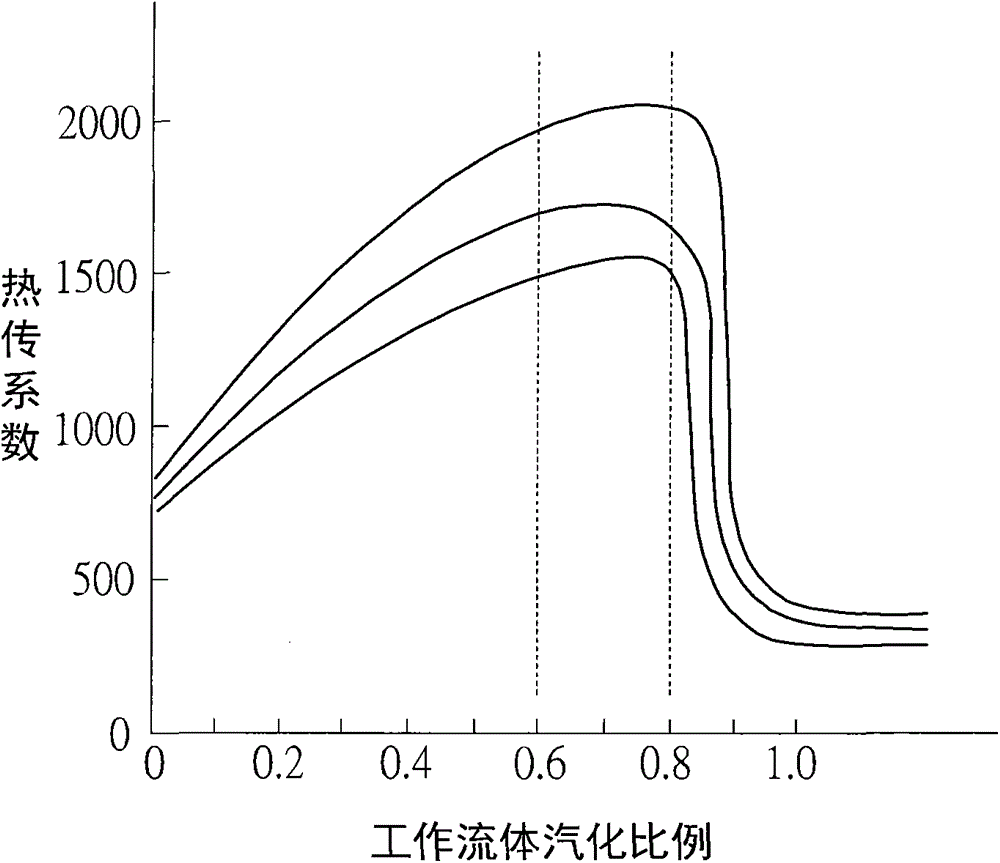

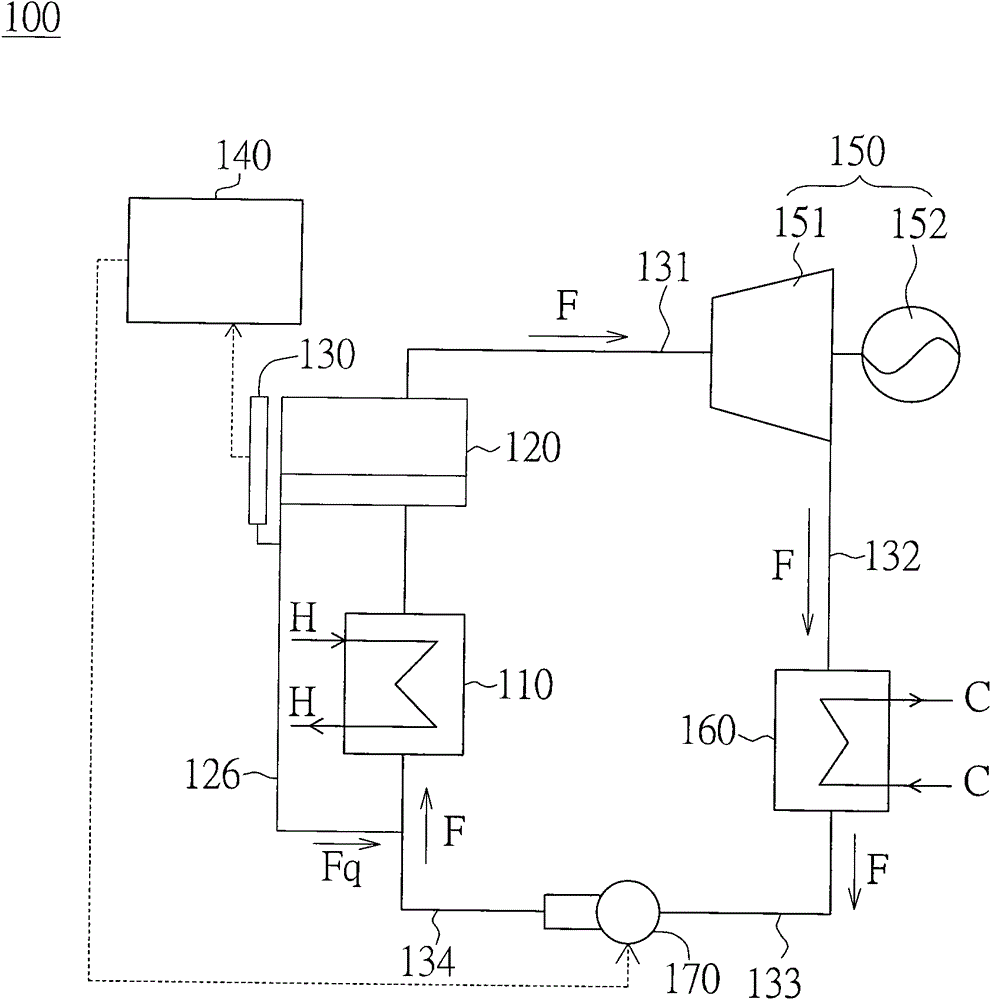

Heat exchanger, heat engine circulating system and control method thereof

ActiveCN104422202AGood heat transfer performanceReduced area requirementsEvaporators/condensersCompression machinesProcess engineeringEvaporator

Provided are a heat exchanger, a heat engine circulating system and a control method thereof. The heat exchanger comprises an evaporator, a gas-liquid separator, a liquid level sensor, and a controller. The evaporator is used to heat a working medium to two phases of gas and liquid. The evaporator is provided with a working medium inlet line and a working medium outlet line. The gas-liquid separator is connected with the working medium outlet line, so as to separate the working medium to a gas state working medium and a liquid state working medium. The liquid level sensor is used to detect height of the liquid state working medium in the gas-liquid separator and output a liquid level signal. The controller is used to receive the liquid level signal, and controls dryness degree of the working medium in the evaporator.

Owner:IND TECH RES INST

Magnetic mud separation system of cutting equipment and separation method

InactiveCN104258992AGuaranteed purityExtended service lifeWorking accessoriesMagnetic separationMagnetic separatorEngineering

The invention provides a magnetic mud separation system of cutting equipment and a separation method, belongs to the operation field, and solves the technical problems that the existing cutting equipment is low in oil sand liquid use efficiency and short in service life. The magnetic mud separation system of the cutting equipment comprises a liquid inlet pipe, a liquid discharge pipe and a magnetic separator, wherein an oil sand inlet and an oil sand outlet are formed in the cutting equipment, the liquid inlet of the magnetic separator is communicated with the oil sand outlet in the cutting equipment through the liquid discharge pipe, the liquid outlet of the magnetic separator is communicated with the sand oil inlet in the cutting equipment through the liquid inlet pipe, and a delivery pump sending the oil sand liquid into the oil sand inlet through the liquid inlet pipe is arranged between the liquid outlet of the magnetic and the liquid inlet pipe. The magnetic mud separation system has the advantages of always keeping the quality of the oil sand liquid. The magnetic mud separation method has the advantage that the oil sand liquid separated from magnetic mud immediately circulates to the cutting equipment, so that the use efficiency of the oil sand liquid is improved.

Owner:TAIZHUO SHUANGHUI MACHINERY EQUIP

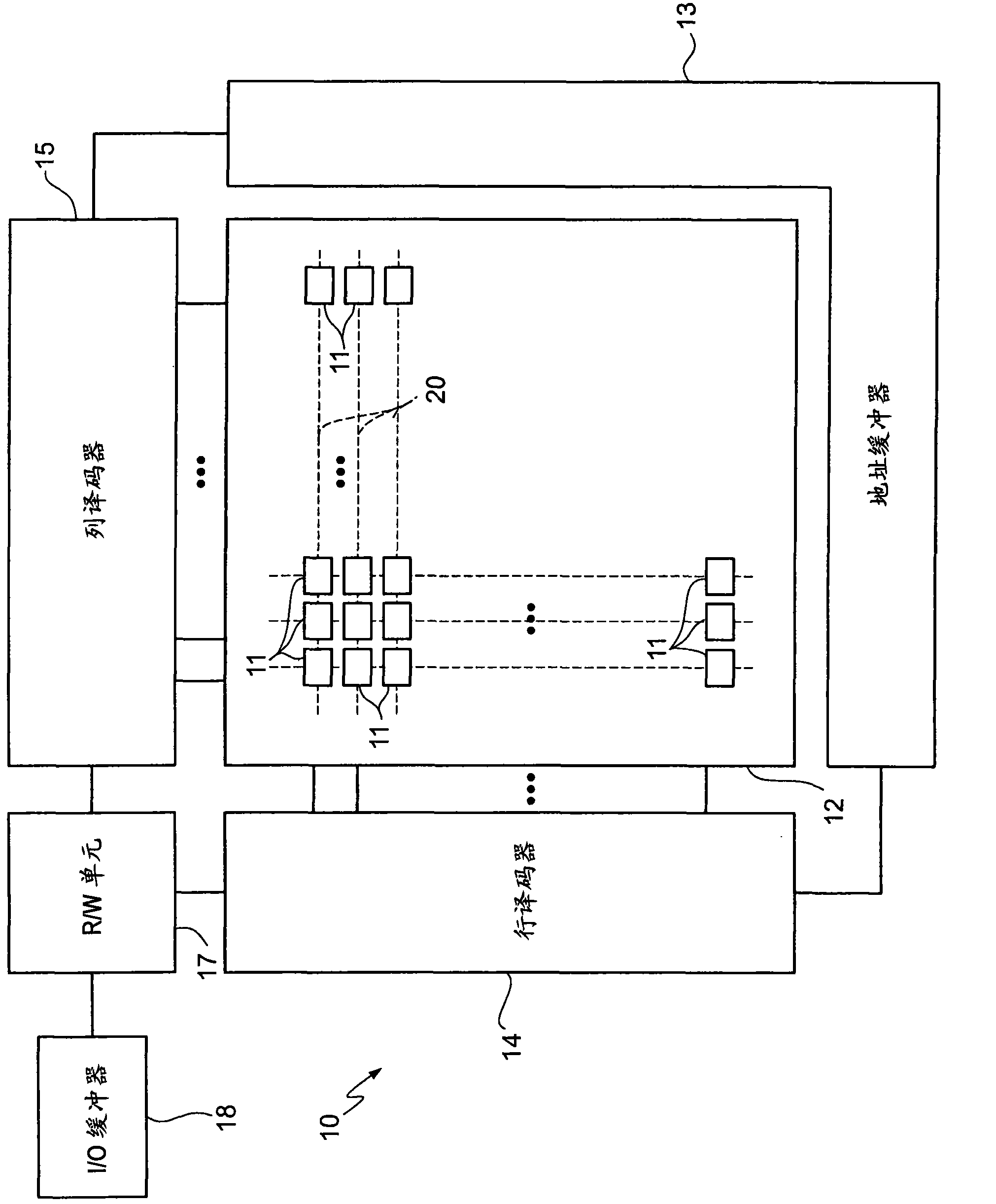

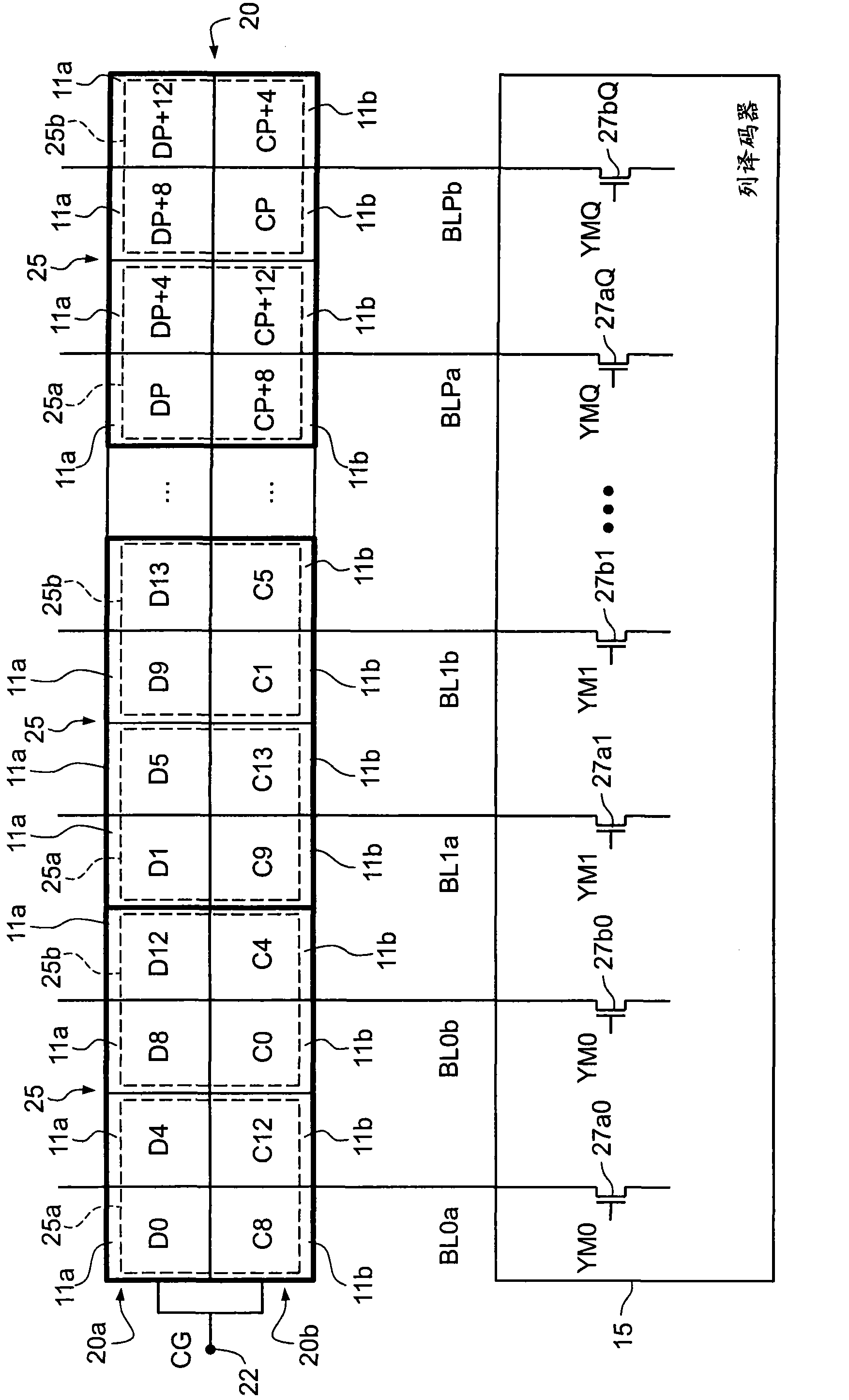

Non-volatile memory device with clustered memory cells

ActiveCN103578545AReduce limitationsReduced area requirementsRead-only memoriesDigital storageControl lineNon-volatile memory

An embodiment of a non-volatile memory device includes: a memory array, having a plurality of non-volatile logic memory cells arranged in at least one logic row, the logic row including a first row and a second row sharing a common control line; and a plurality of bit lines. Each logic memory cell has a direct memory cell, for storing a logic value, and a complementary memory cell, for storing a second logic value, which is complementary to the first logic value in the corresponding direct memory cell. The direct memory cell and the complementary memory cell of each logic memory cell are coupled to respective separate bit lines and are placed one in the first row and the other in the second row of the respective logic row.

Owner:STMICROELECTRONICS SRL

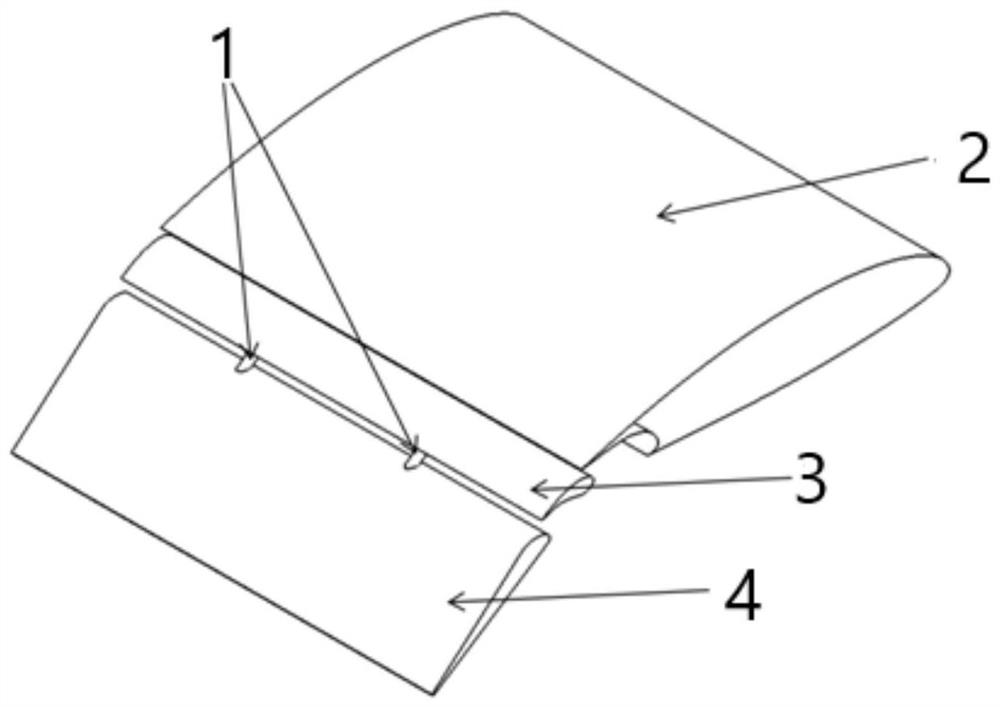

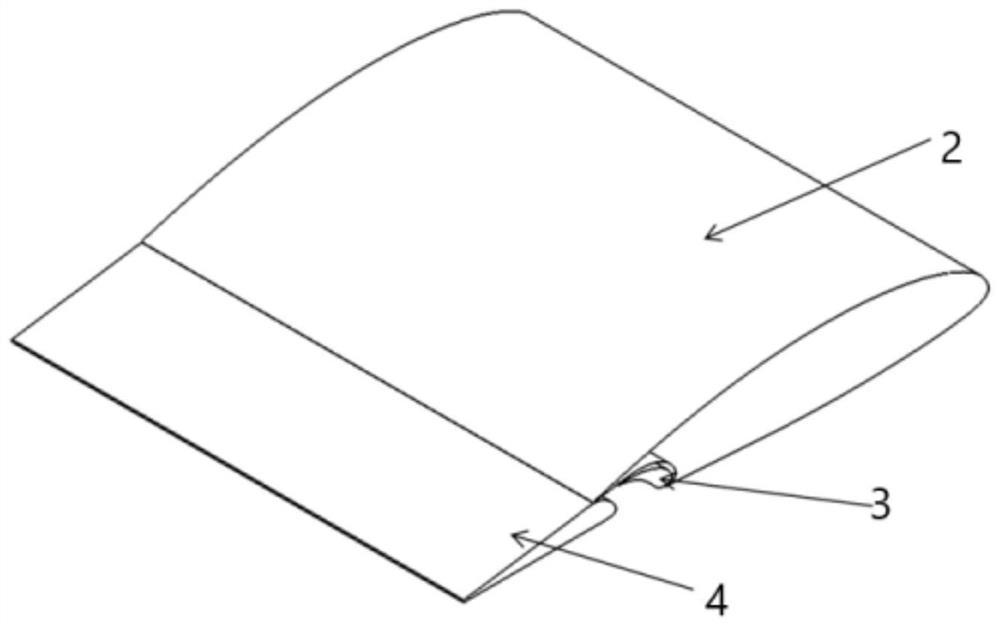

Double-slit flap with flap body fixedly connected with additional wing

ActiveCN112339987AIncreased maximum lift coefficientImprove performanceWingsClassical mechanicsHigh lift

The invention belongs to the technical field of aircraft wings, and particularly relates to a double-slit flap with a flap body fixedly connected with an additional wing. The double-slit flap comprises the additional wing and the flap body, the additional wing and the flap are fixedly connected through a connecting rod, and the fixedly-connected additional wing and flap are taken as a whole to beretracted and released under the effect of a driving connecting mechanism; when the double-slit flap is in a put-down state, a gap exists between the main wing and the additional wing, a gap exists between the additional wing and the flap, and the high lift effect of the double-slit flap is achieved. According to the double-slit flap, through the additional wing flap structure in rigid connection,the high lift effect of the double-slit flap is achieved when the flap body is put down, meanwhile, the structural complexity of the double-slit flap is kept to be equivalent to that of a single-slit / fullerene flap, lift force is improved under the condition of the same structural complexity, and therefore the area requirements of wings and flaps are reduced, the weight of an airplane is reduced,and the aircraft performance is improved.

Owner:中电科芜湖通用航空产业技术研究院有限公司 +1

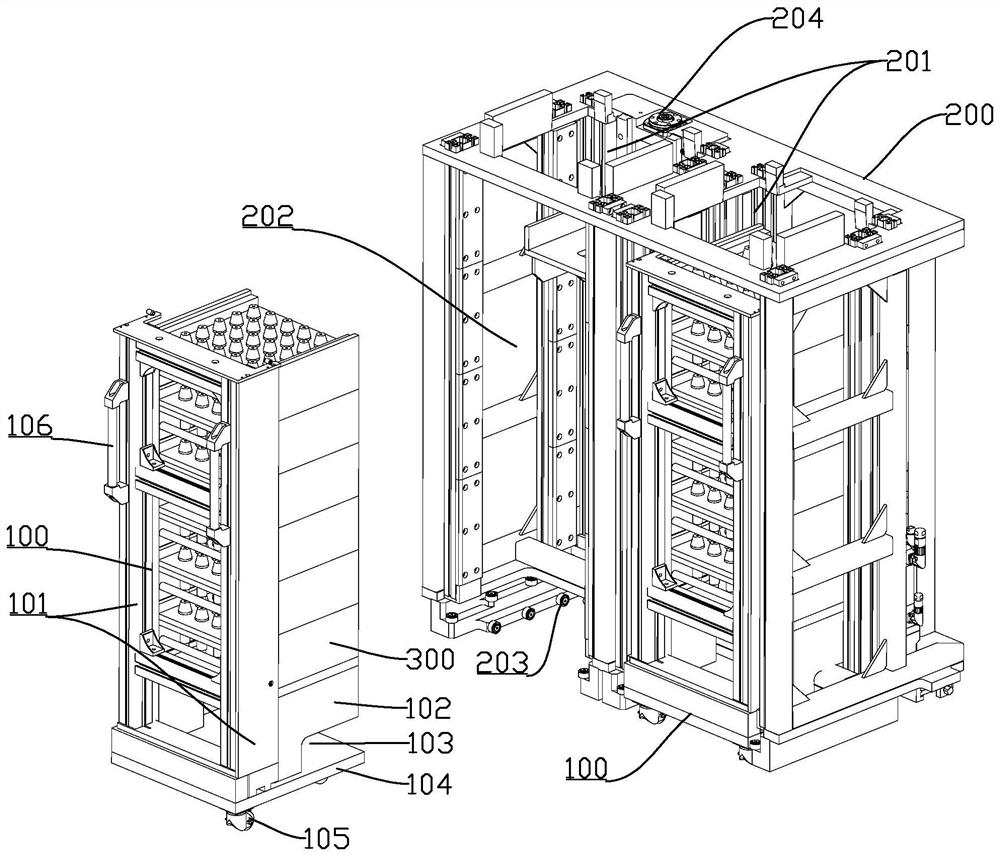

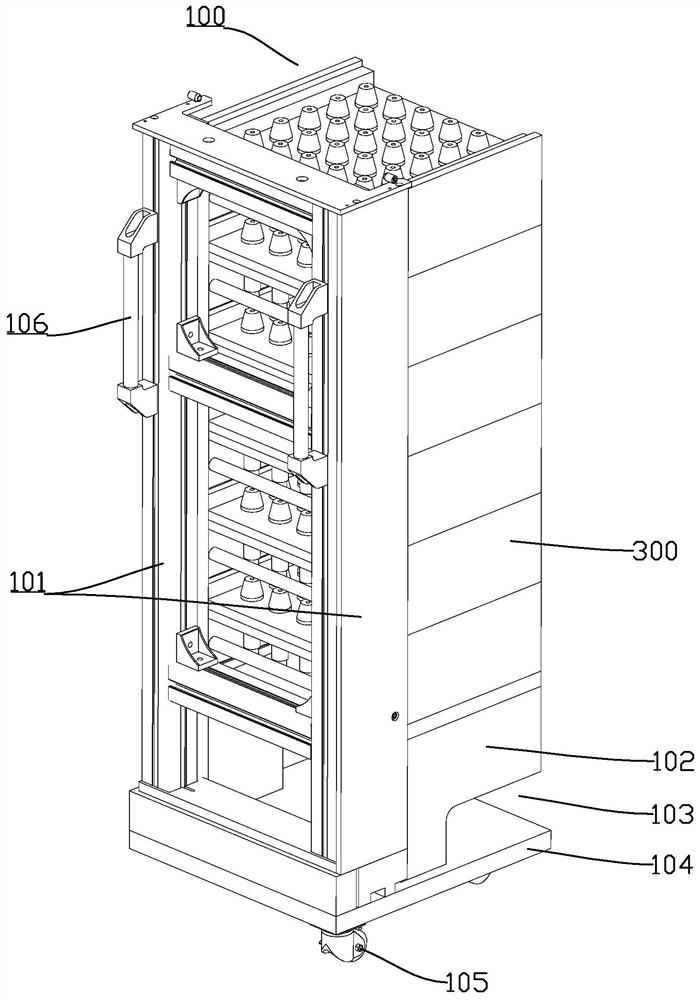

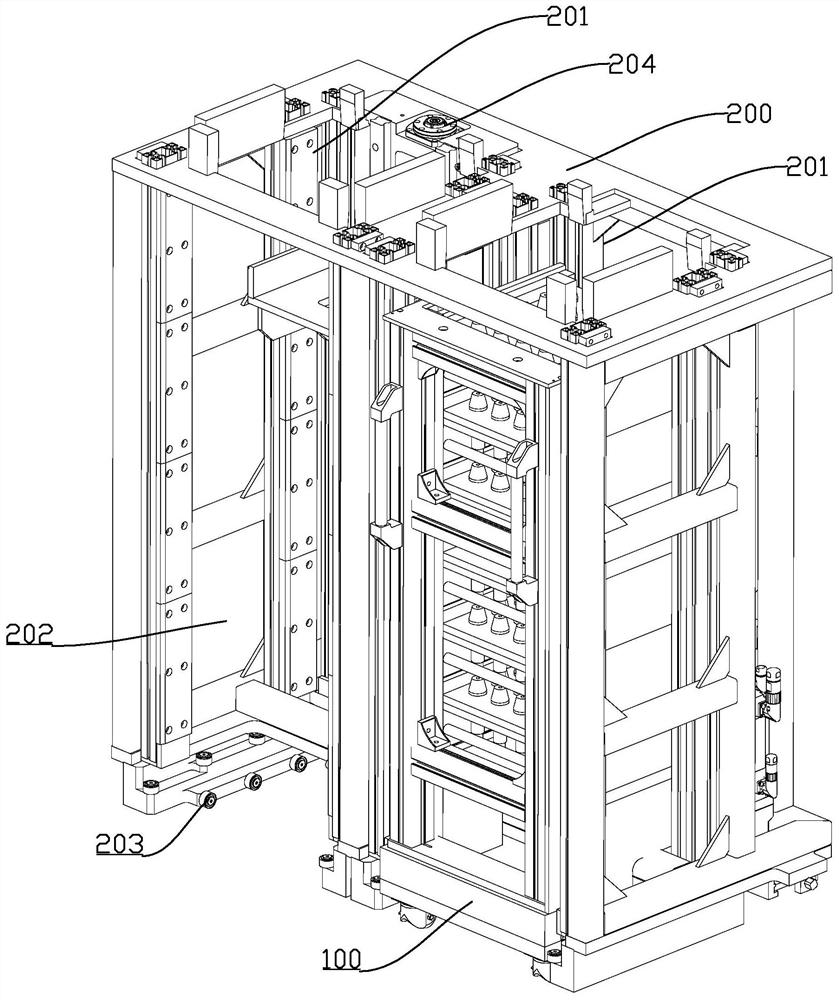

Silo

PendingCN111776564AReduced area requirementsSmall footprintStorage devicesHand carts with multiple axesParking areaStructural engineering

The invention discloses a silo which is provided with at least two pick-and-place positions. A parking area is arranged under each of the pick-and-place positions, and a cart capable of being pushed out is arranged in each parking area. A plurality of material trays are stacked on each cart, the material trays are used to place processed workpieces and / or workpieces to be processed, lifting mechanisms are arranged in the parking areas, and the lifting mechanisms are used to lift the material trays to the pick-and-place positions. The silo can use one pick-and-place position for loading and onepick-and-place position for unloading, the workpieces to be processed and the processed workpieces are integrated into one silo, the floor space is small, the requirement on area of a plant can be reduced, the production cost is reduced, a plurality of material trays are stacked on each cart, so that more workpieces can be placed, only when all the workpieces on the material trays on the cart areprocessed, replacing is needed, so that the production efficiency is greatly improved, and the practicability is high.

Owner:HUNAN ZDCY (ZHONGDA CHUANG YUAN) CNC EQUIP CO LTD

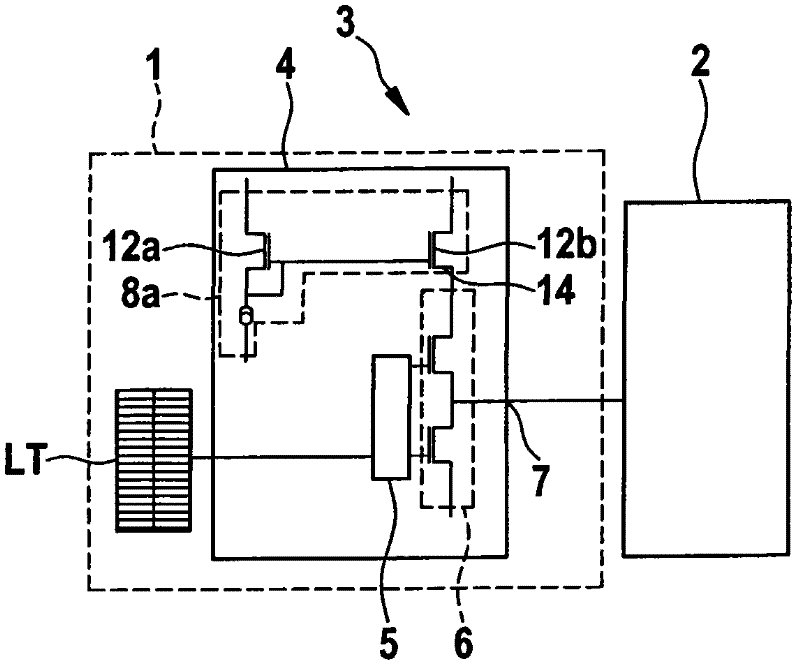

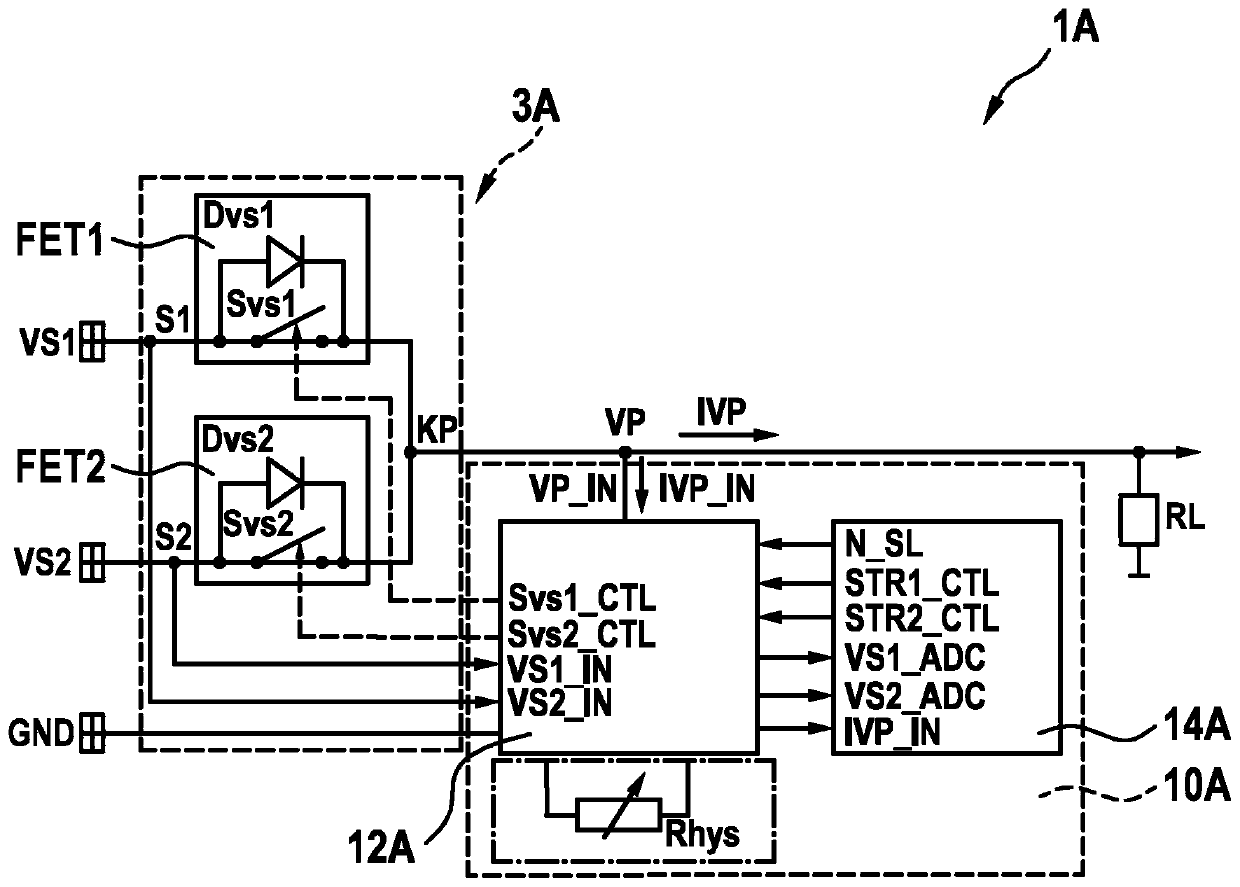

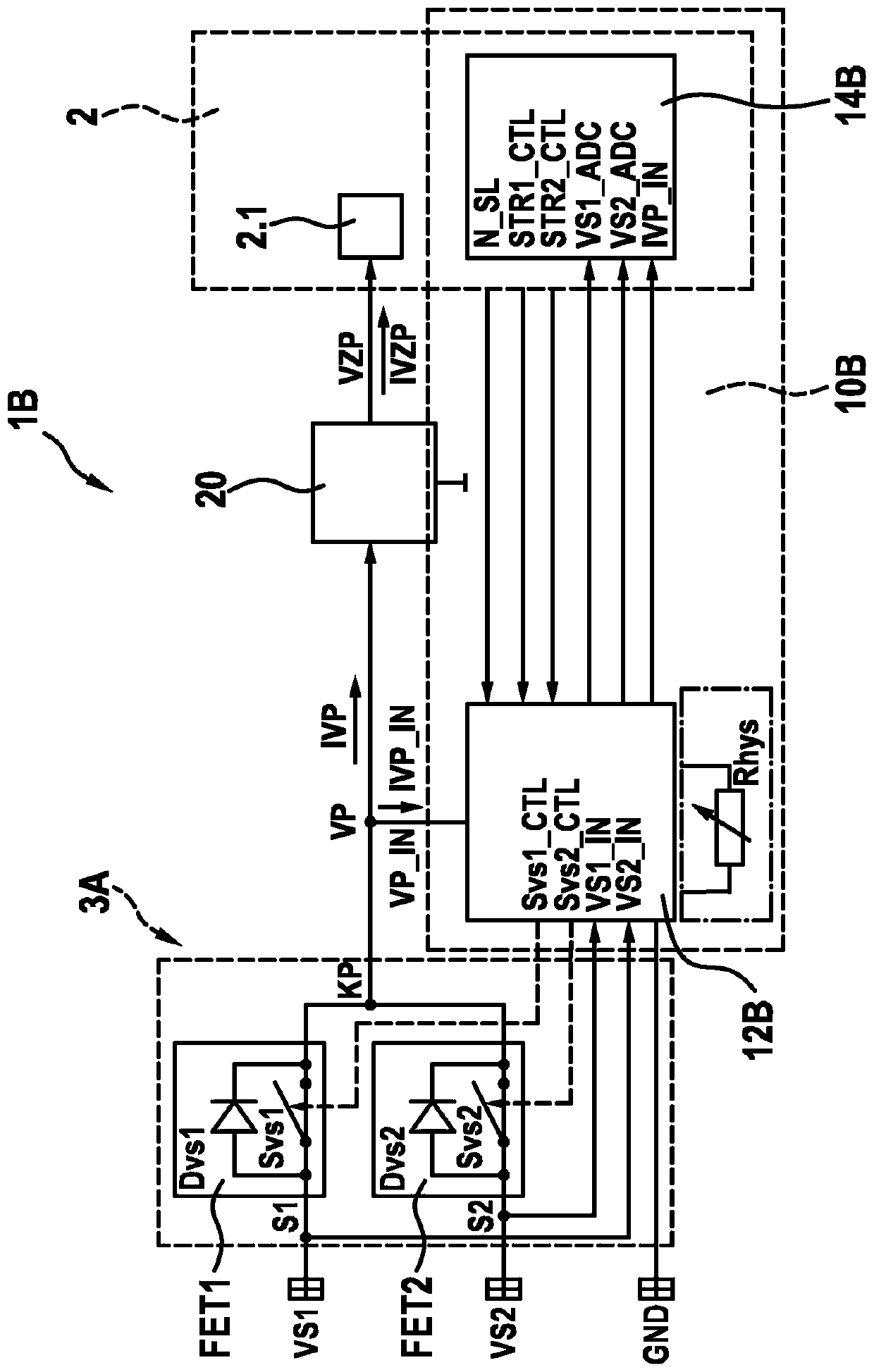

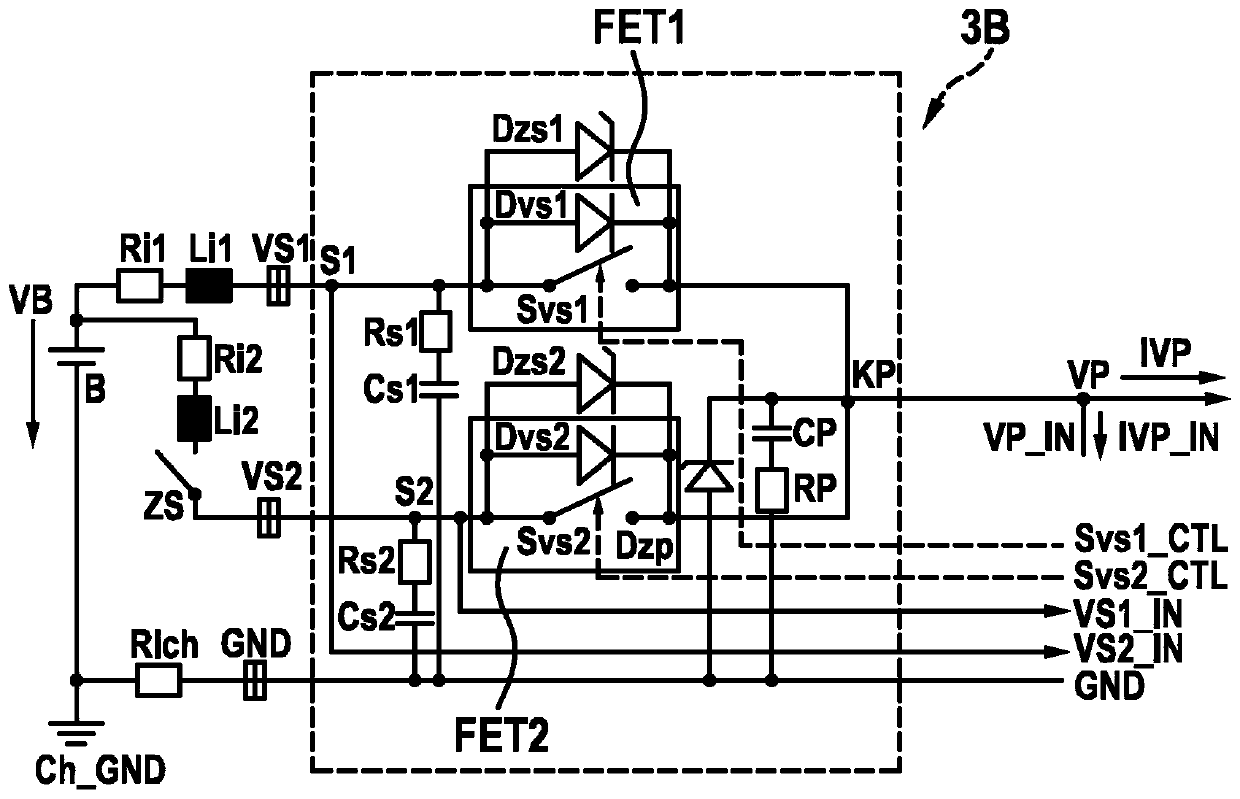

Multi-line supply unit for a vehicle control device

ActiveCN111133650AReduce loadEasy to operateProgramme controlSingle network parallel feeding arrangementsControl cellElectrical polarity

The invention relates to a multi-line supply unit (1A) for a vehicle control device, having at least two supply lines (S1, S2) which are each connected at the input to at least one vehicle voltage source and are joined at the output in a common node (KP), and a protective device (3A) which comprises in each of the at least two supply lines (S1, S2) at least one first protective diode (Dvs1, Dvs2)which is looped into the at least two supply lines (S1, S2) in the conducting direction between the at least one vehicle voltage source and the node (KP). The invention also relates to a method for operating such a multi-line supply unit (1A). In the method, at least one switching element (Svs1, Svs2) is looped into each of the at least two supply lines (S1, S2) parallel to the at least one protective diode (Dvs1, Dvs2), wherein an evaluation and control unit (10A) senses and evaluates a line voltage (VS1, VS2) at the inputs of each of the at least two supply lines (S1, S2) and a supply voltage (VP), protected against polarity reversal, at the common node (KP) and actuates the switching elements (Svs1, Svs2) in the at least two supply lines (S1, S2) via corresponding actuation signals (Svs1_CTL, Svs2_CTL) depending on the evaluation.

Owner:ROBERT BOSCH GMBH

A method of using the compact layout system of the billet discharge area of the billet continuous caster

ActiveCN112122570BImprove cooling efficiencyImprove reliabilityMechanical engineeringContinuous caster

Owner:马钢集团设计研究院有限责任公司

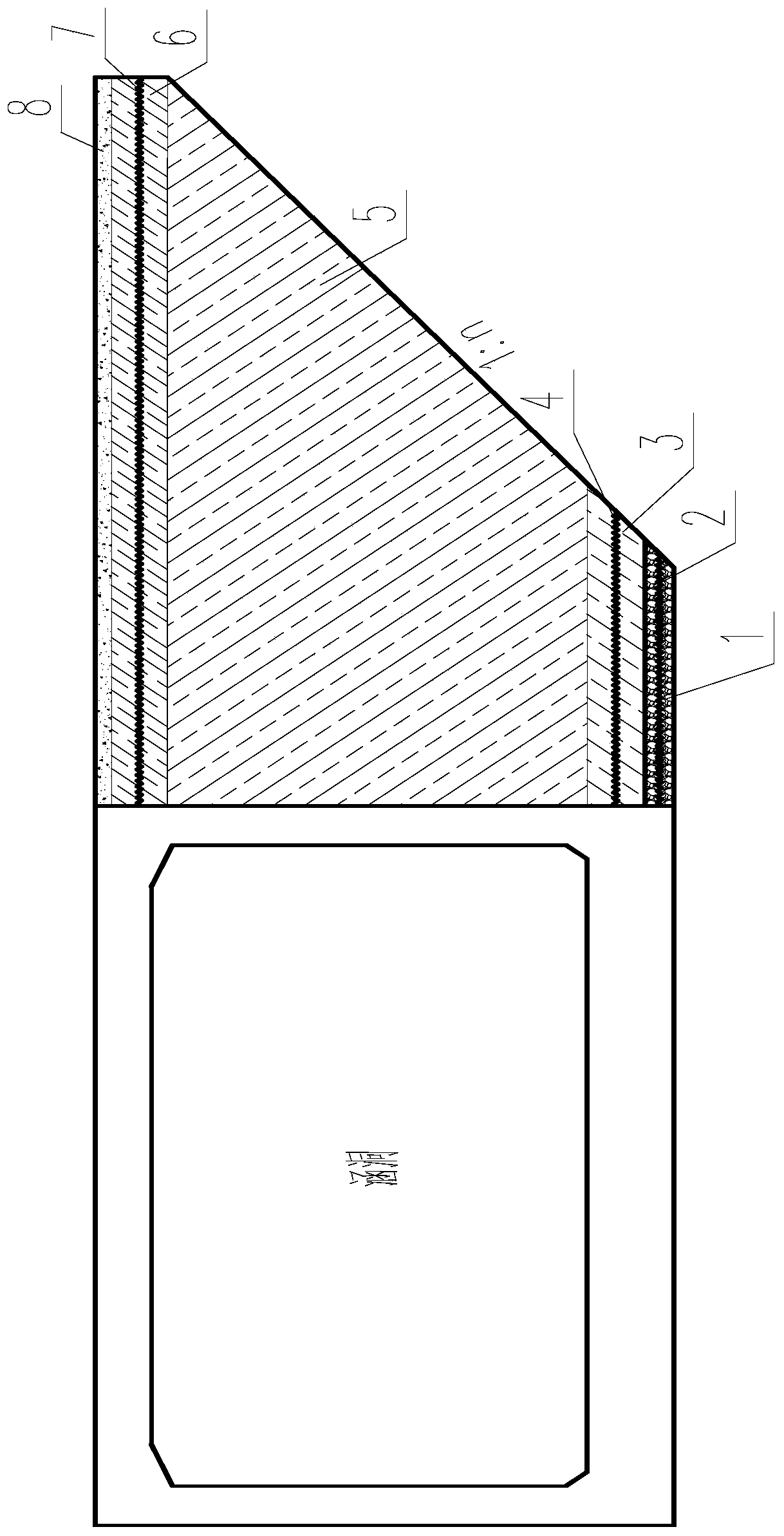

Underneath pass type road culvert transition section foam light soil roadbed structure and construction method thereof

PendingCN111576118AImprove bearing strengthSettling value reductionRoadwaysRailway tracksLand acquisitionCompressive resistance

The invention provides an underneath pass type road culvert transition section foam light soil roadbed structure and a construction method thereof. The roadbed structure comprises a sand cushion layerlocated at a bottom of a roadbed, a concrete cushion layer is laid on the sand cushion layer, three parts of foam light soil with different densities are poured on the concrete cushion layer, and a layer of plain concrete is poured on a contact surface of the foam light soil and a ballast bed. Compared with a traditional filler roadbed, the foam light soil roadbed has advantages that self-weightis light and compressive strength is higher; roadbed bearing strength is improved, and a foundation settlement value caused by a generated additional stress is reduced; and rolling vibration is not needed in a construction process, modes of mechanical stirring and pumping pouring operation are adopted, a needed operation area is small, engineering problems that an underneath pass type transition section construction site is limited, large equipment cannot enter a site, and roadbed rolling is not compact can be solved, vertical slope finishing can be achieved, a land acquisition area is reduced, cultivated lands are protected, and construction cost is saved.

Owner:CREEC WUHAN SURVEY DESIGN & RES

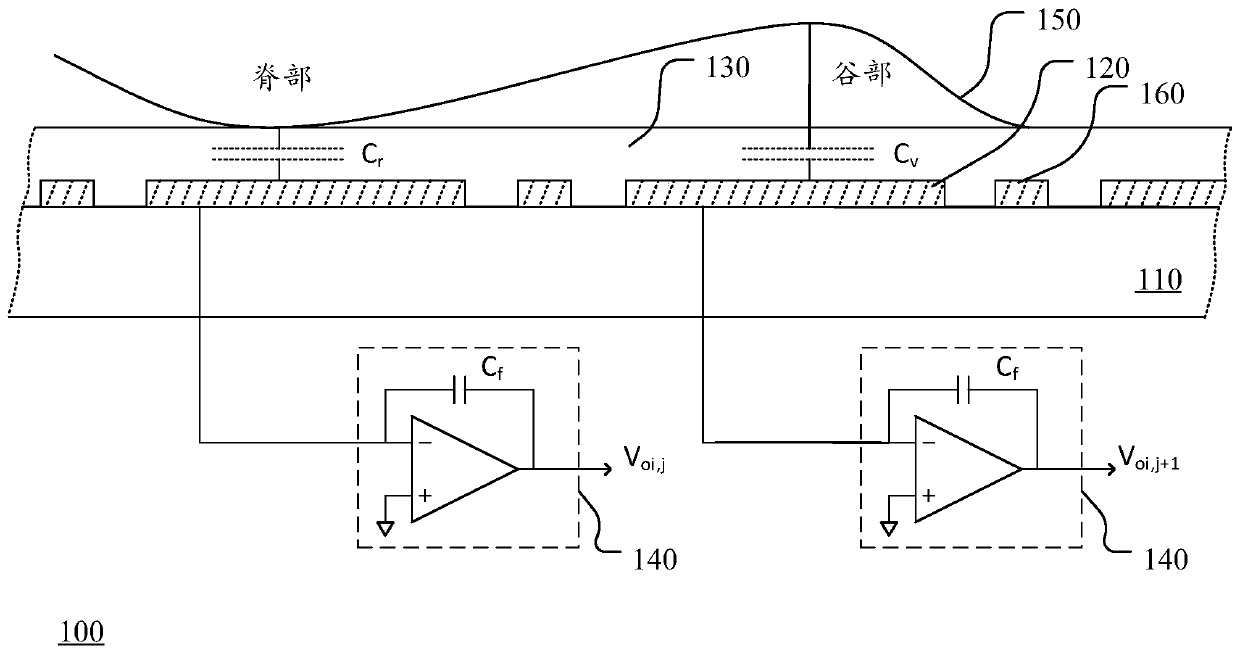

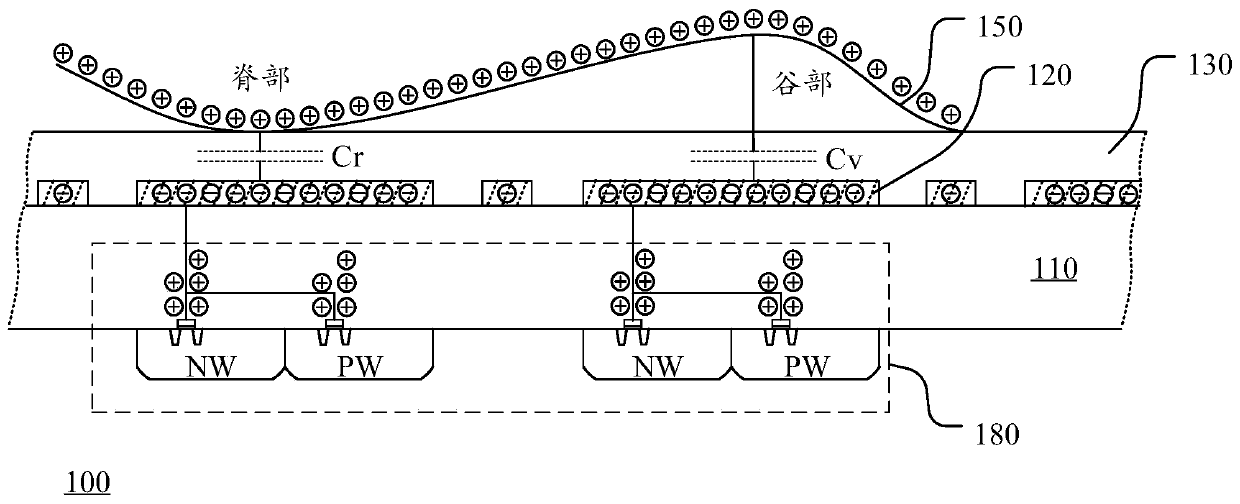

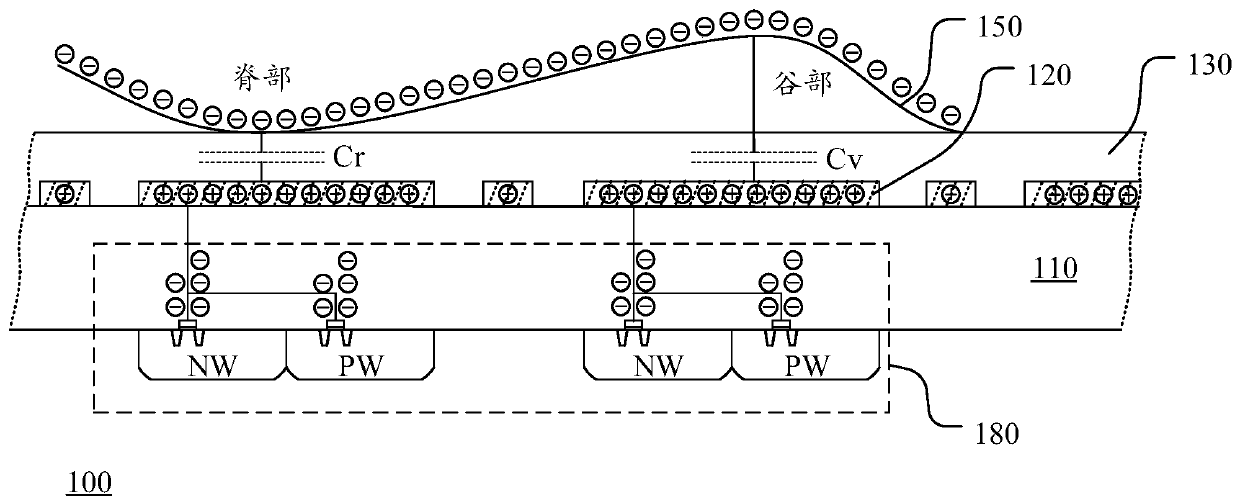

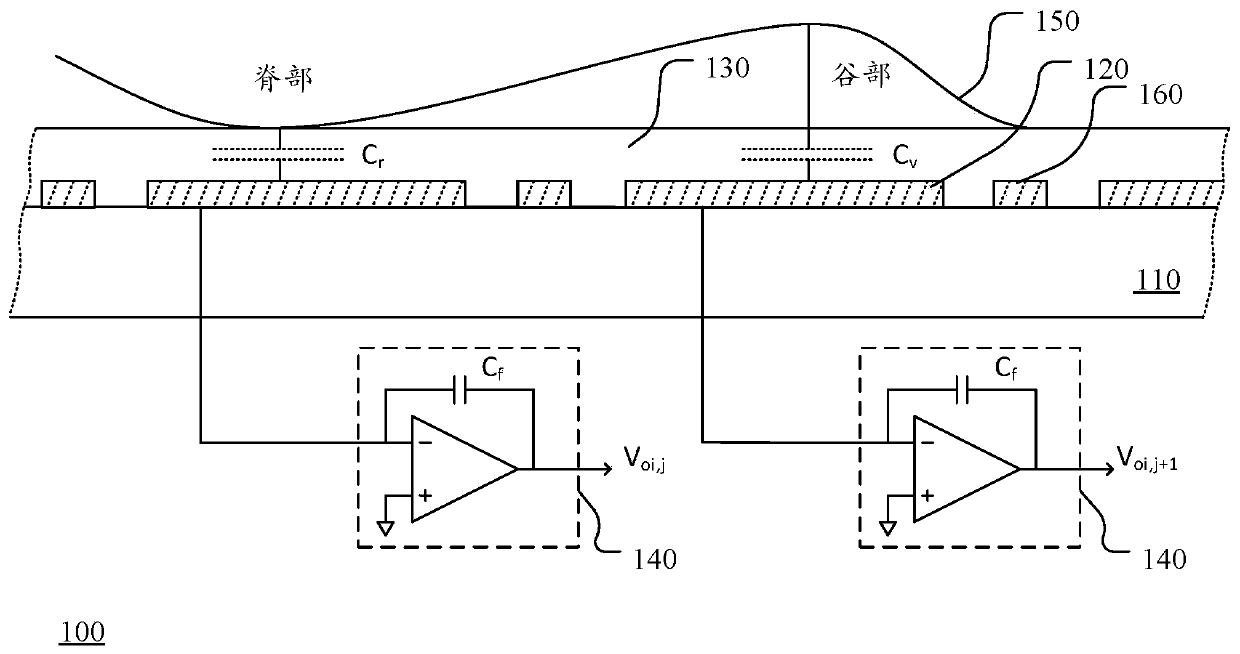

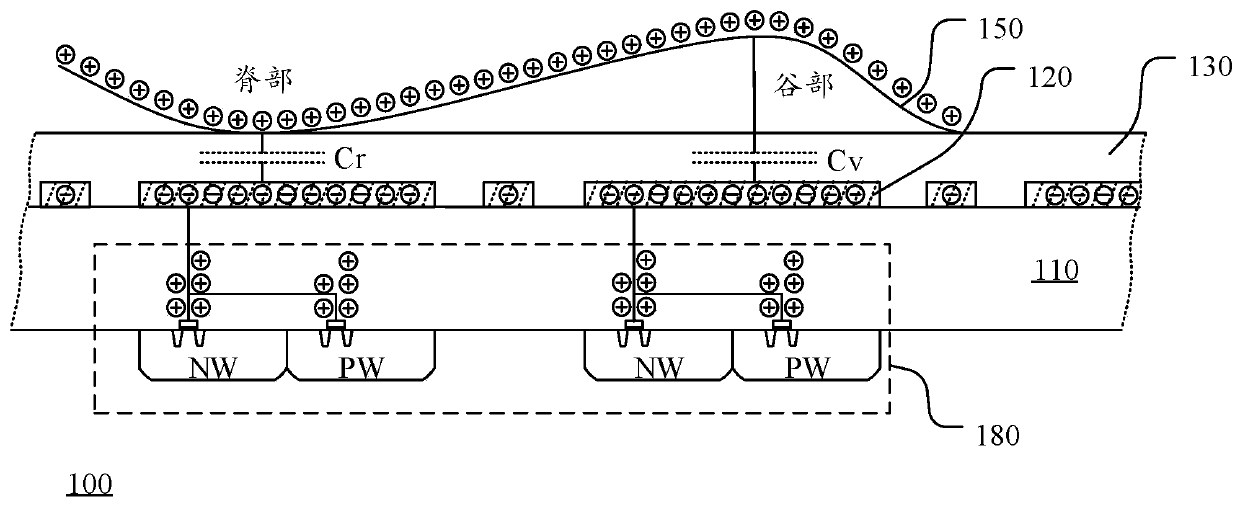

Fingerprint sensing device and electronic equipment

PendingCN110137171AImprove electrostatic protection abilityReduced area requirementsSolid-state devicesDiodeComputer moduleEngineering

The invention discloses a fingerprint sensing device which comprises a first unit, a plurality of second units located on the first unit, and a plurality of fourth units connected to the correspondingsecond units and used for providing a release path of electrostatic charges and a conduction path of sensing signals, wherein each fourth unit includes a voltage adjustment module. By introducing thevoltage adjustment modules to the fingerprint sensing device, the area occupied by the fourth units is reduced, the fourth units can be connected to the corresponding second units respectively, and the electrostatic protection capability of the fingerprint sensing device is improved.

Owner:CHIPONE TECH BEIJINGCO LTD

Fingerprint sensing device and electronic device

PendingCN110164862AImprove electrostatic protection abilitySmall footprintSolid-state devicesDiodeFingerprintStatic Charges

The invention discloses a fingerprint sensing device. The fingerprint sensing device includes a first unit including multiple switch tubes, multiple second units which are arranged on the first unit and are used for providing induction signals, multiple third units used for providing detection signals according to the induction signals, and multiple fourth units which are connected between the corresponding second units and the corresponding third units and are used for providing release paths of static charges and conduction paths of the induction signals, wherein each fourth unit includes atleast one static protection element, and a parasitic diode of at least one of the multiple switch tubes provides at least one of the static protection elements. The fingerprint sensing device is advantaged in that the parasitic diodes of the switch tubes are utilized to form at least one of the static protection elements, the occupation land of a circuit is reduced, the multiple fourth units canbe corresponding connected with the multiple second units, and static protection capability is improved.

Owner:CHIPONE TECH BEIJINGCO LTD

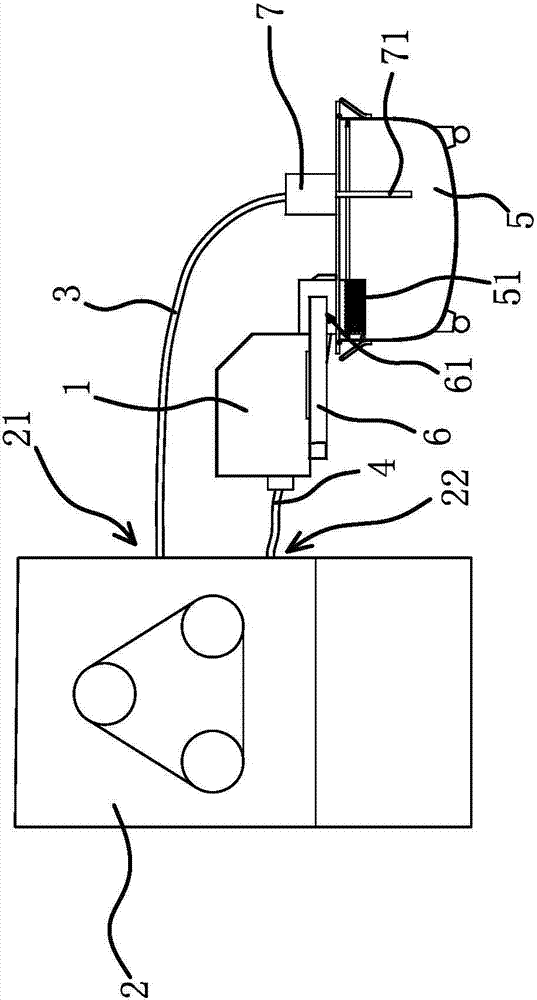

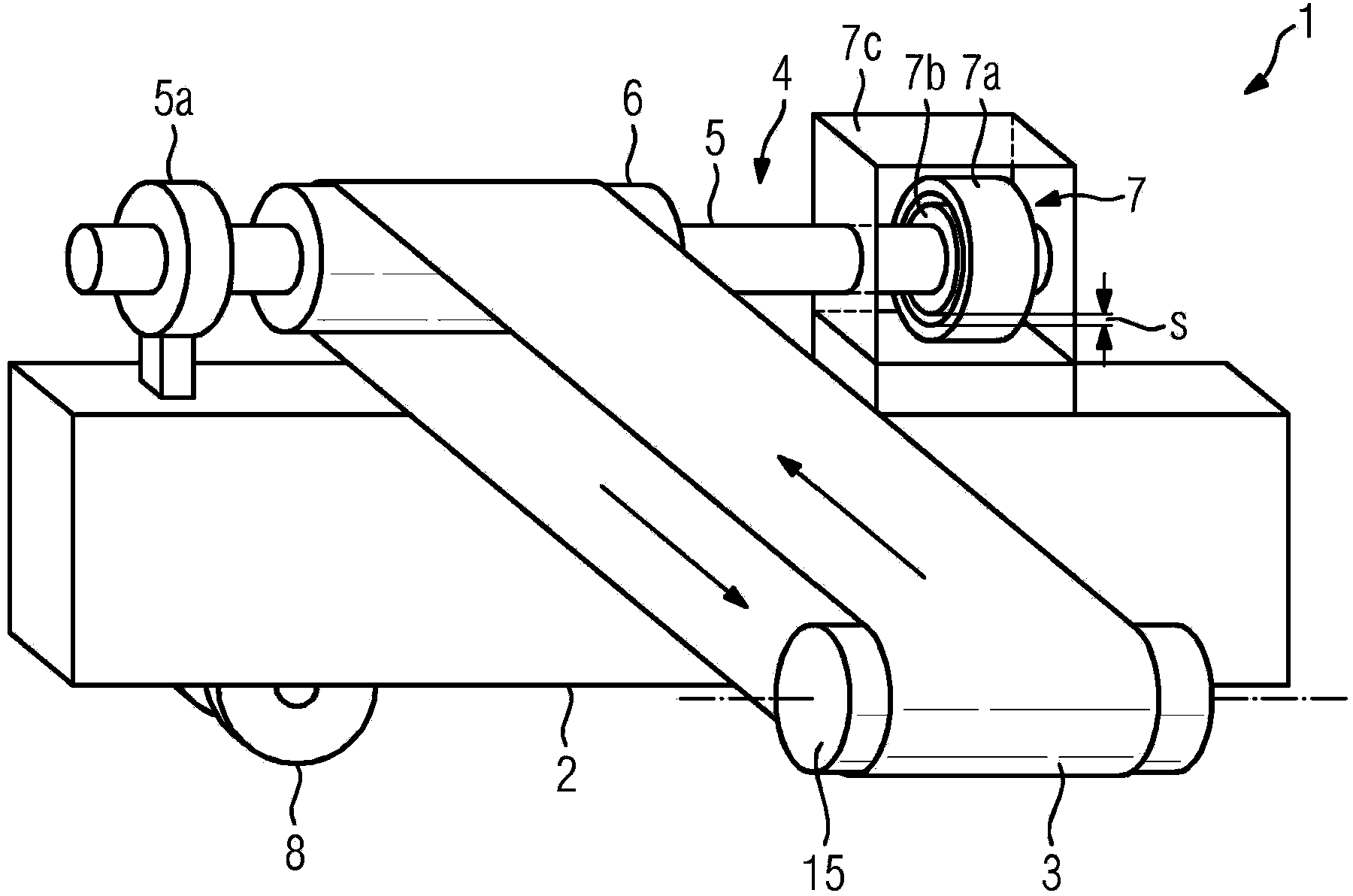

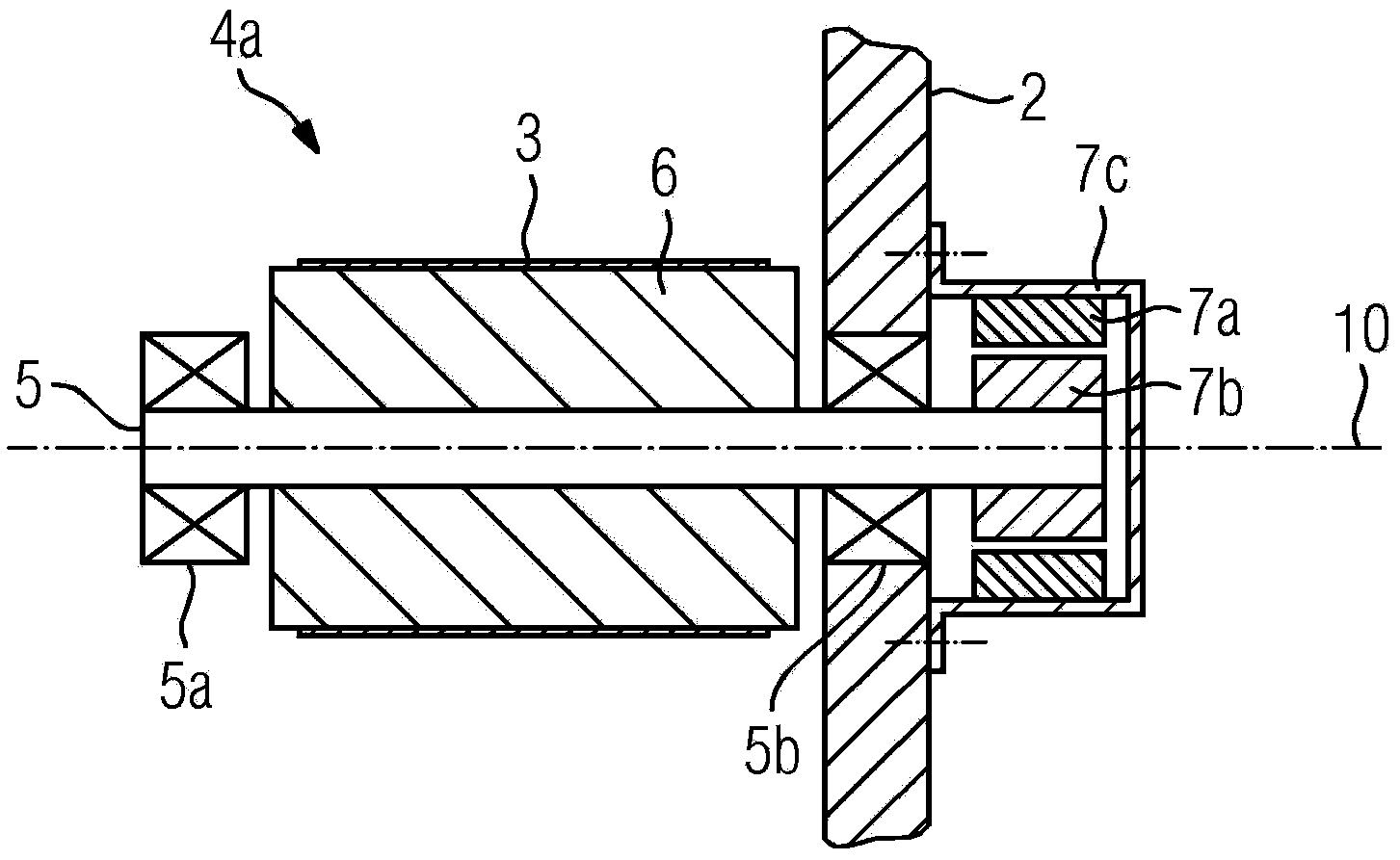

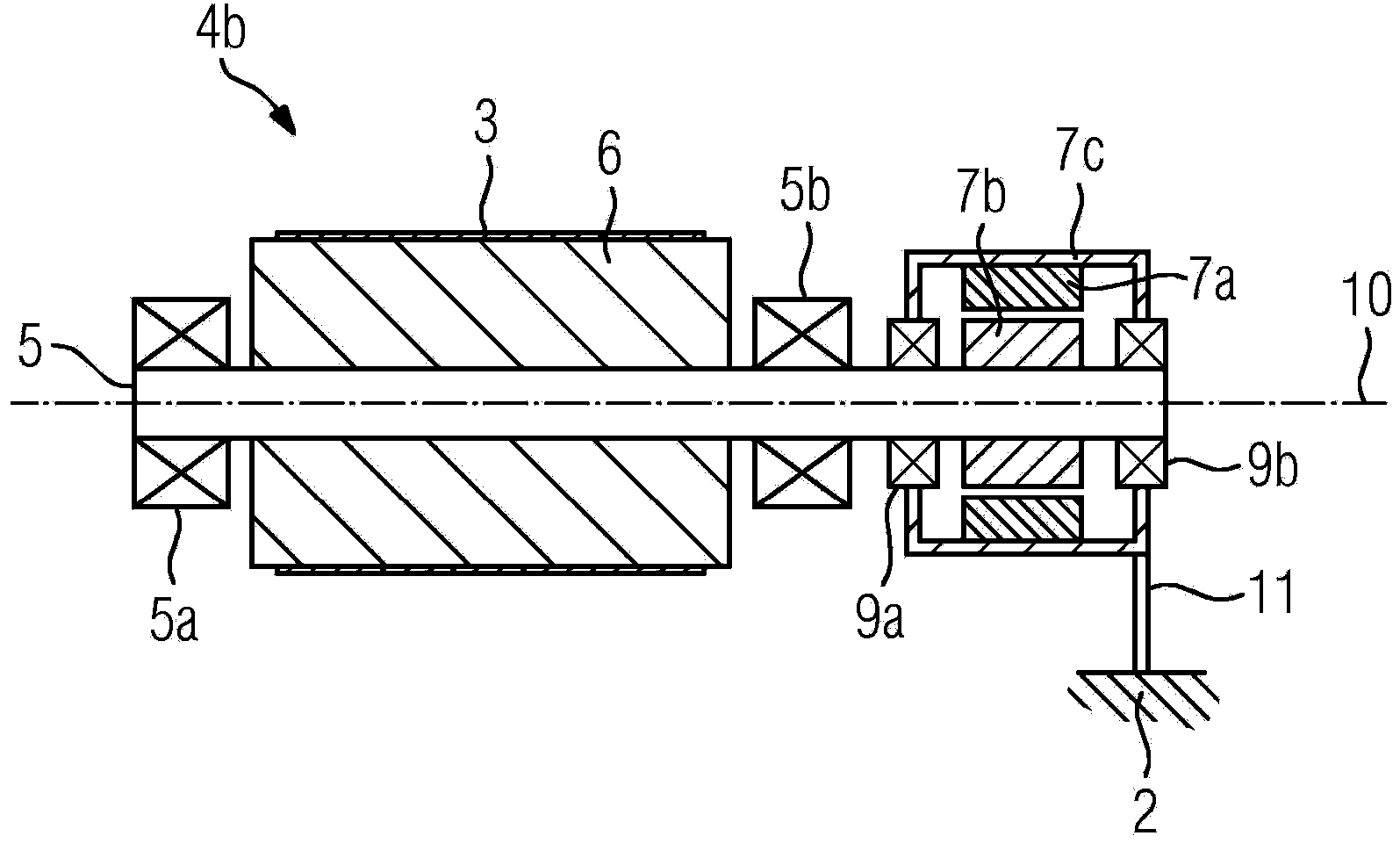

Belt-conveying installation, method for operating the same, and use thereof

ActiveCN103796936AEnabling Disruption-Free ShippingFirmly connectedConveyorsFrequency changerSynchronous motor

The invention relates to a belt-conveying installation (1) for heavy industry, in particular for the extractive or mining industry, comprising at least one carrying structure (2), a conveying belt (3) and at least one drive apparatus (4) for driving the conveying belt (3), wherein the drive apparatus (4) comprises at least one drive shaft (5), at least one drive-shaft-bearing arrangement (5a), at least one drive roller (6) and at least one independently excited drive motor (7) in the form of a frequency-converter-fed alternating-current synchronous motor with a stator (7a) and a rotor (7b). The drive shaft (5) and the at least one drive motor (7) are connected to one another without any gearing, and the rotor (7b) and drive shaft (5) are arranged coaxially, each drive shaft (5) being guided through at least one rotor (7b). The invention also relates to a method for operating such a belt-conveying installation and to the use thereof.

Owner:SIEMENS AG +2

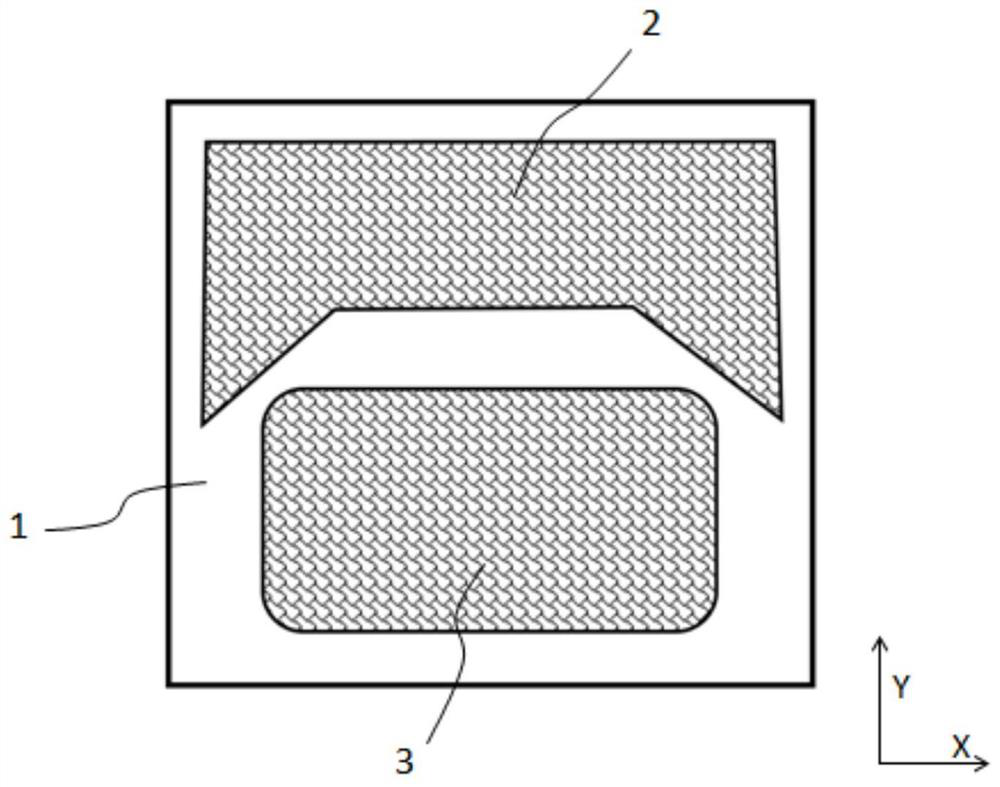

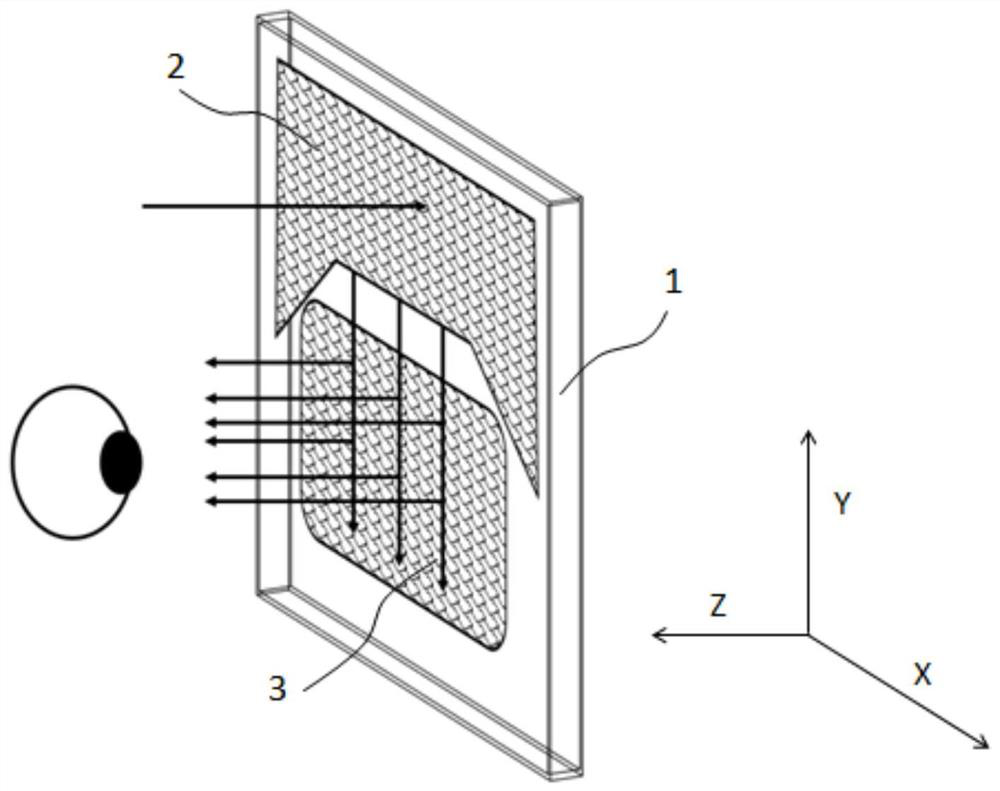

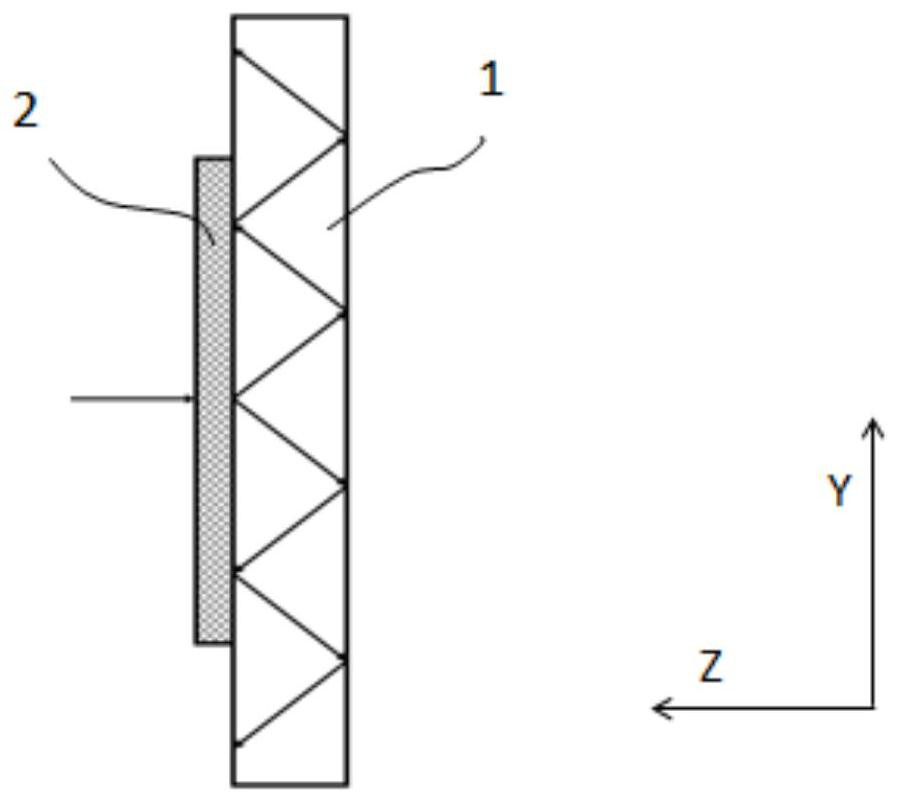

Multidirectional diffraction extension optical waveguide lens and augmented reality display device

PendingCN113325501AReduced area requirementsReduce processing difficultyDiffraction gratingsOptical diffractionDisplay device

The invention provides a multidirectional diffraction extension optical waveguide lens and an augmented reality display device. The multidirectional diffraction extension optical waveguide lens comprises a waveguide; and a functional area which is located on the upper surface or the lower surface of the waveguide, has an optical diffraction function, and at least comprises an incident functional area in which a coupling-in diffraction structure which couples the external image light to the waveguide and realizes the multidirectional diffraction expansion of the image light is arranged, wherein the coupling-in diffraction structure is composed of a plurality of groups of array structures; and an emergent functional area in which a coupling-out diffraction structure used for coupling the image light transmitted from the waveguide out of the waveguide and realizing the multidirectional expansion of the image light is arranged, wherein the coupling-out diffraction structure is composed of a plurality of groups of array structures. According to the invention, the multidirectional diffraction expansion of the image light can be realized, so that an imaging visual angle is increased.

Owner:SVG TECH GRP CO LTD

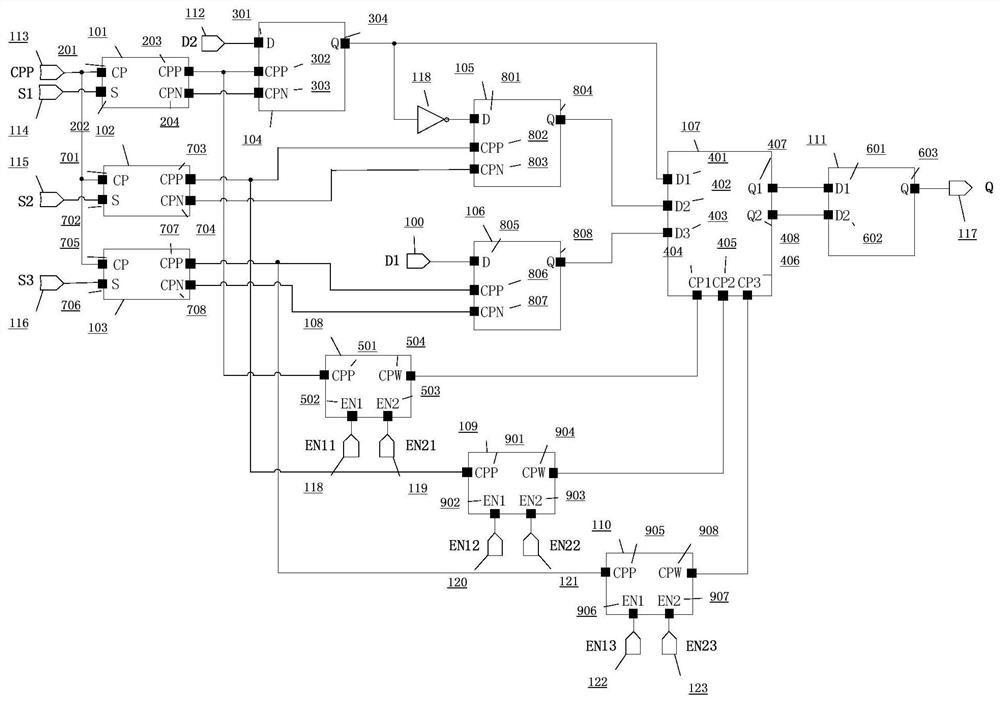

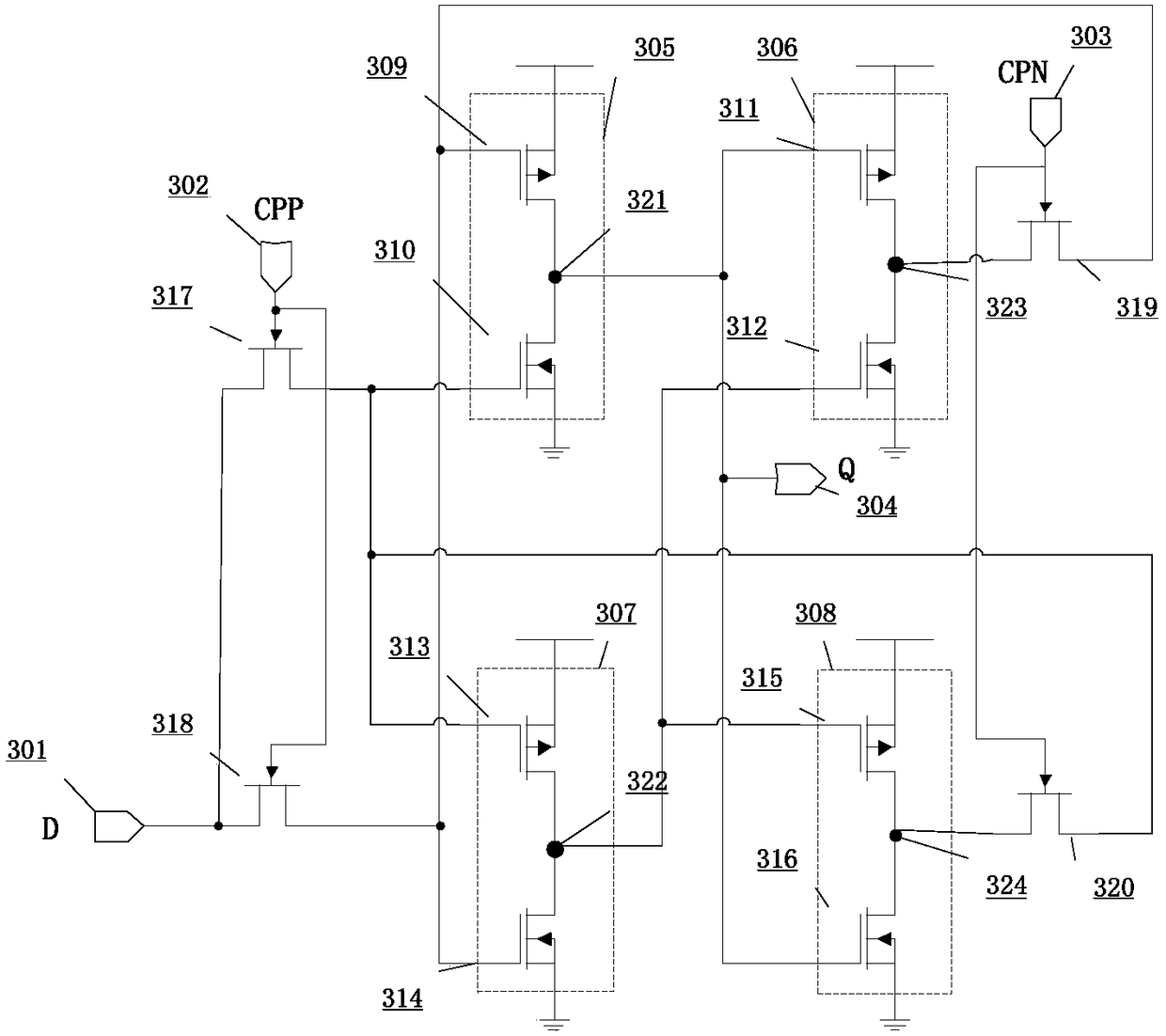

A Single Event Reinforced Programmable Double Data Rate Register Circuit and Control Method

ActiveCN108335708BImproved resistance to single event upsetImprove Flip EffectDigital storageDouble data rateFlip-flop

Owner:BEIJING MXTRONICS CORP +1

Single event hardening-based programmable double-data-rate register circuit and control method

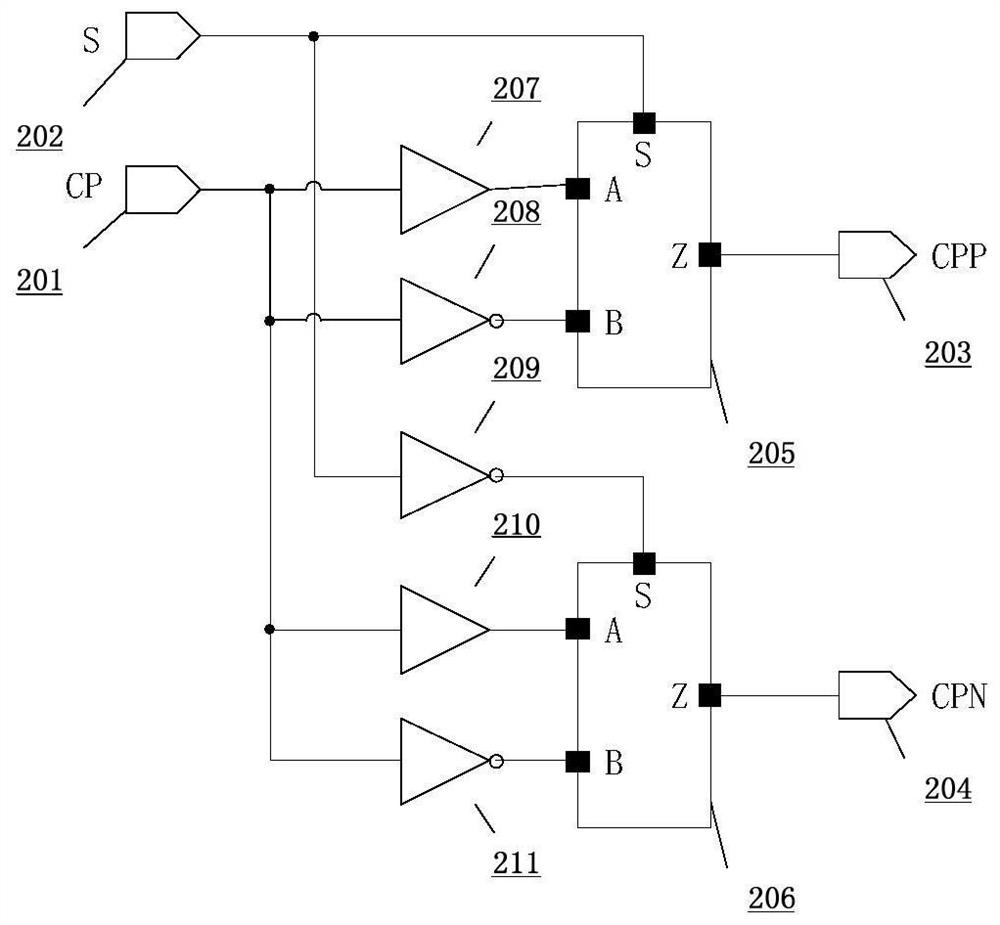

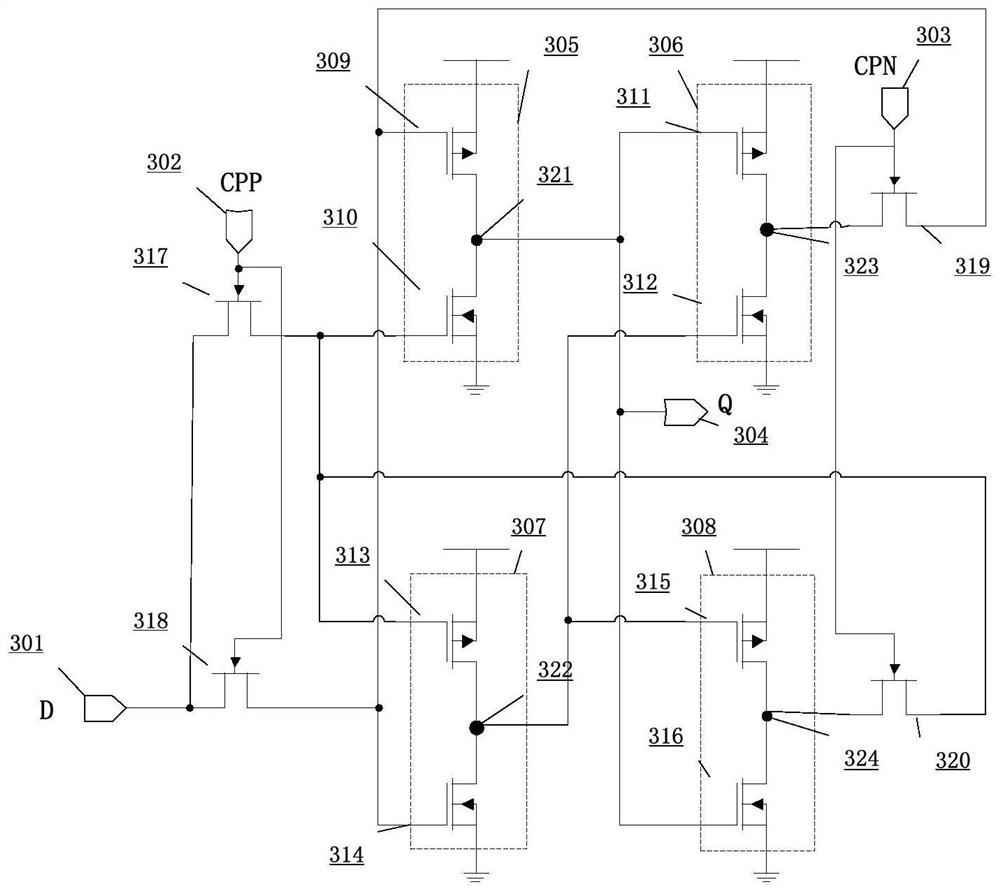

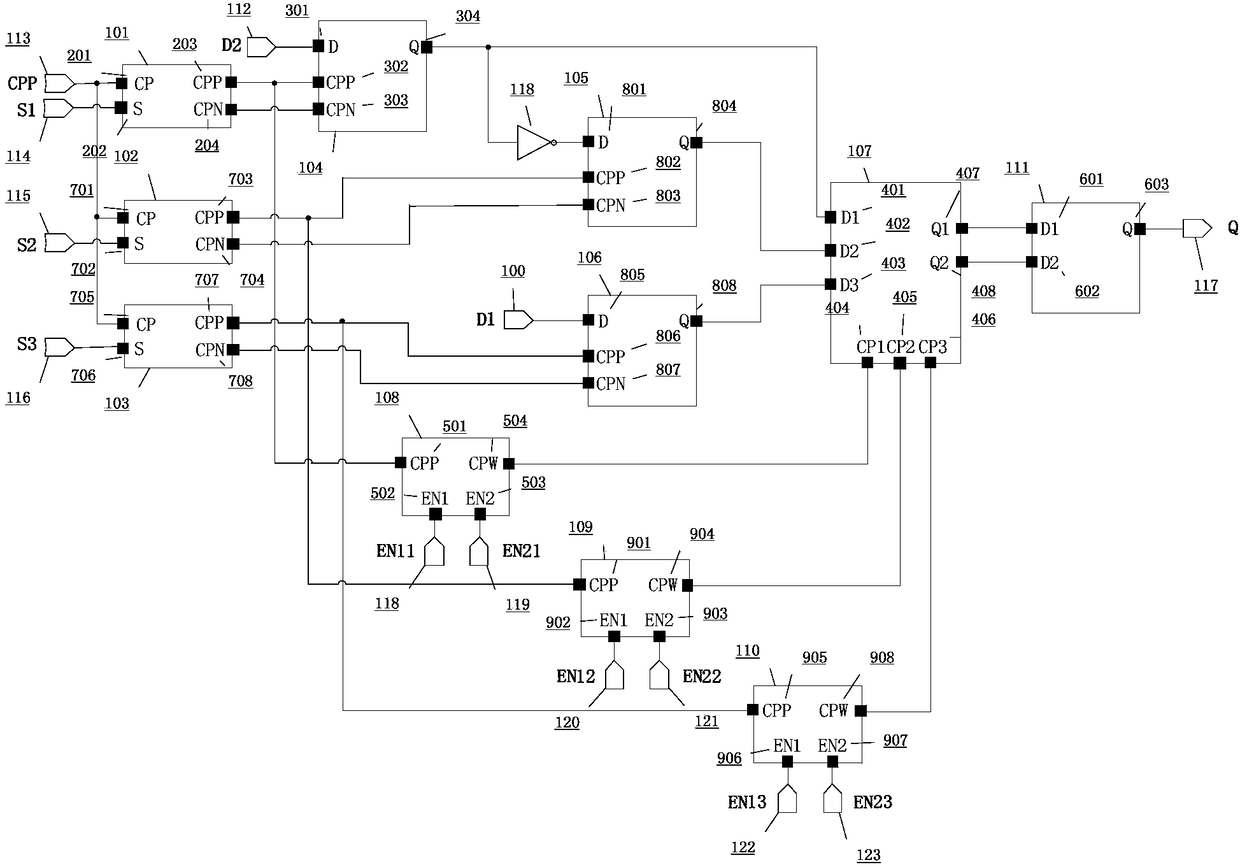

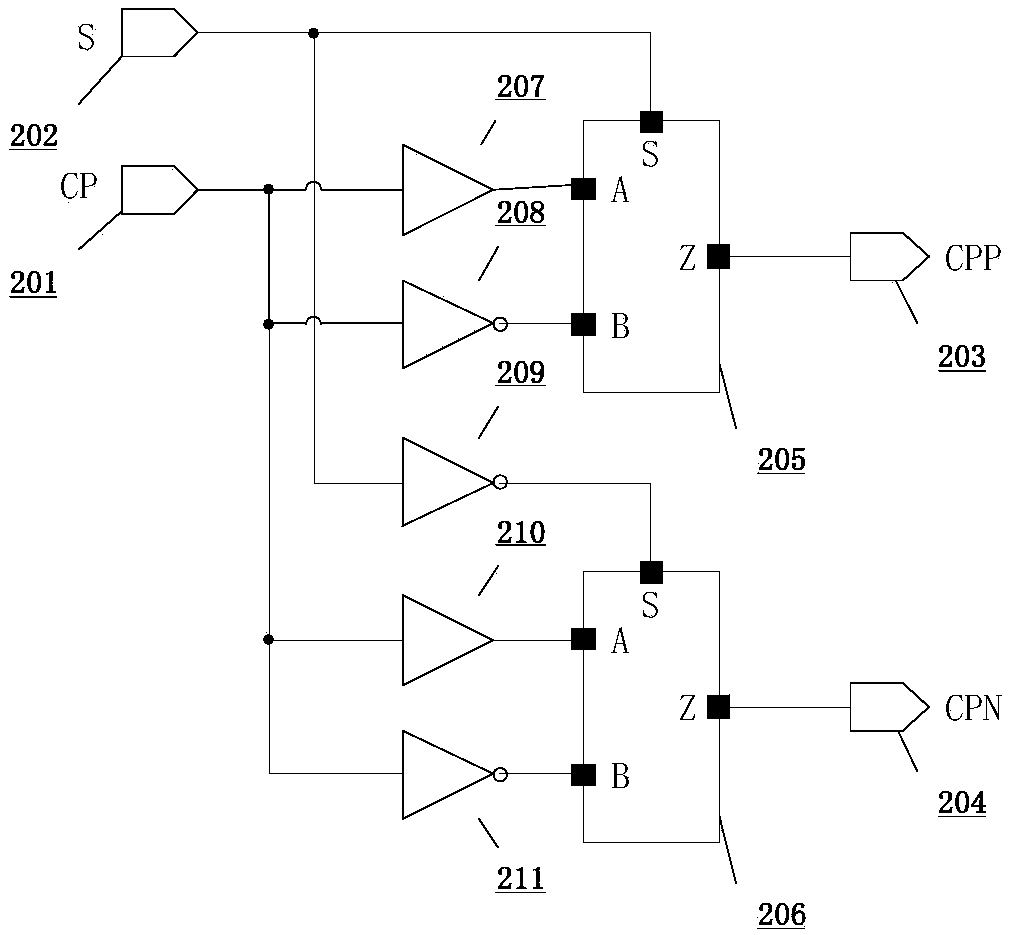

ActiveCN108335708AImproved resistance to single event upsetImprove Flip EffectDigital storageDouble data rateOrder of magnitude

The invention discloses a single event hardening-based programmable double-data-rate register circuit and a control method. A circuit with a dual-redundancy interlocking structure is adopted for a conventional latch to realize single event hardening design of a register storage unit; and based on this, a clock generation circuit, a data multiplexer and a data retaining circuit are added for controlling a time sequence of multiple registers with dual-redundancy interlocking structures, so that multi-mode double-data-rate register functions can be realized. A single event hardening index is improved by three orders of magnitude in comparison with that of a conventional register, and programmable functions of a level latch, a single-data-rate edge trigger, a reverse-edge-mode double-data-rateedge trigger, a same-edge-mode double-data-rate edge trigger and the like can be realized, so that higher flexibility, better time sequence performance and extremely high anti-single event hardeningindex are achieved during use of a programmable user register by a user.

Owner:BEIJING MXTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com