Actuating device, microsystem device, and method for controlling a micromechanical actuator

A control device and micro-mechanical technology, applied in the direction of micro-structure devices, generators/motors, electrostatic generators/motors, etc., can solve the problems of high area requirements, high current consumption of integrated circuits, etc., and achieve the effect of low area requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

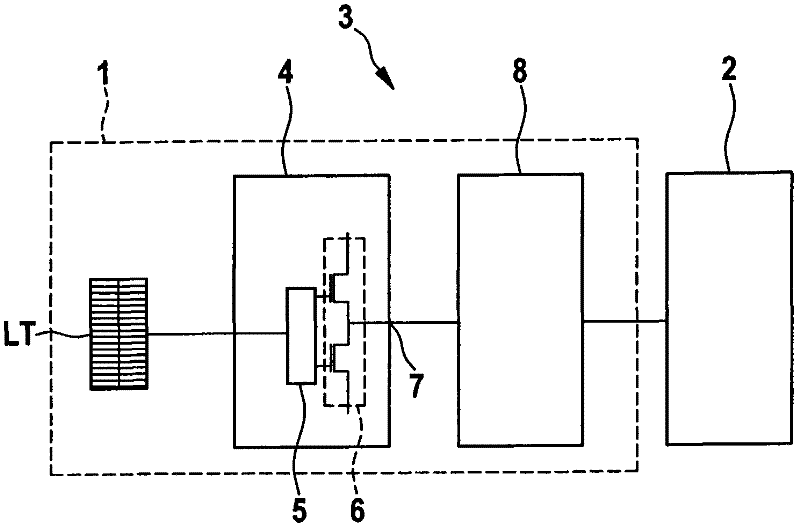

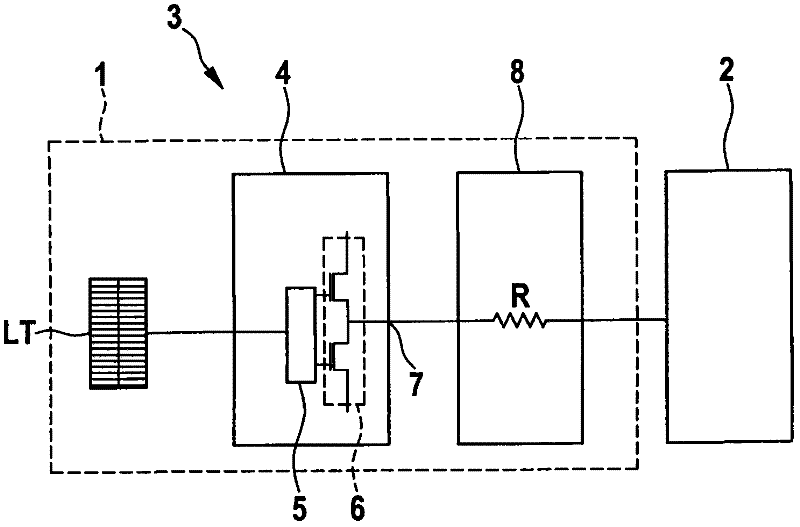

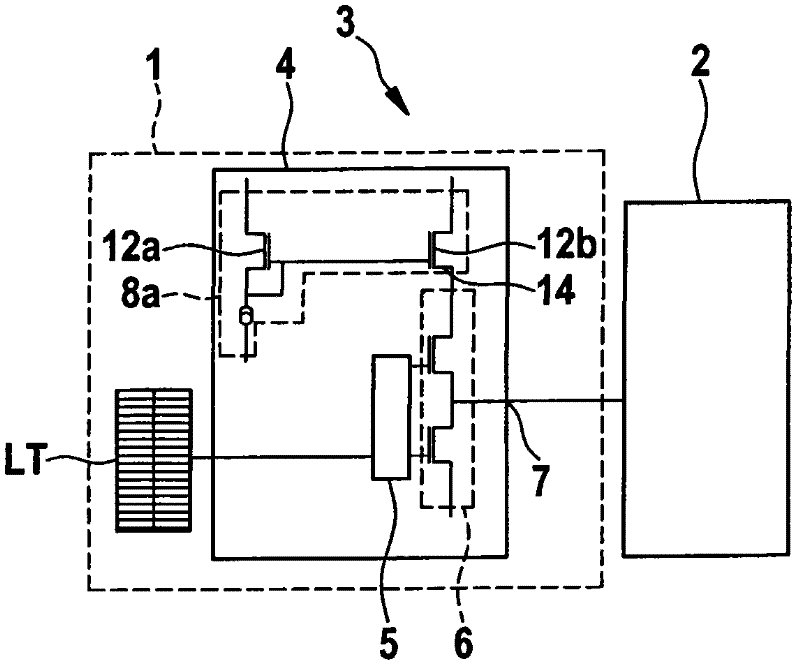

[0043] Before proceeding to the description of the figures, some basic relationships are first explained below so that the exemplary embodiment shown in the figures can be described clearly.

[0044] Micromechanical actuators in MEMS-based microsystems can be modeled as high-ohmic resistors R 致动器 and a capacitor C placed in parallel with it 致动器 , as follows in Figure 7 as stated in the accompanying figure description. Relatively low ohmic series resistance R 导线 Represents all lead resistances. Capacitance C 致动器 including parasitic capacitance C 致 动器P and useful capacitance C 致动器N . A useful capacitance C that has a direct relationship to the mechanical deflection of the micromechanical actuator 致动器N tends to be less than the parasitic capacitance C 致动器P . The value of the useful capacitance of the micromechanical actuator varies dynamically and drops to close to 0F especially in the event of damage to the micromechanical actuator. Independently of this, when elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com