Belt-conveying installation, method for operating the same, and use thereof

A technology of belt conveying and equipment, which is applied in the direction of conveyor, transportation and packaging, etc., and can solve the problems such as the location change of belt conveying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

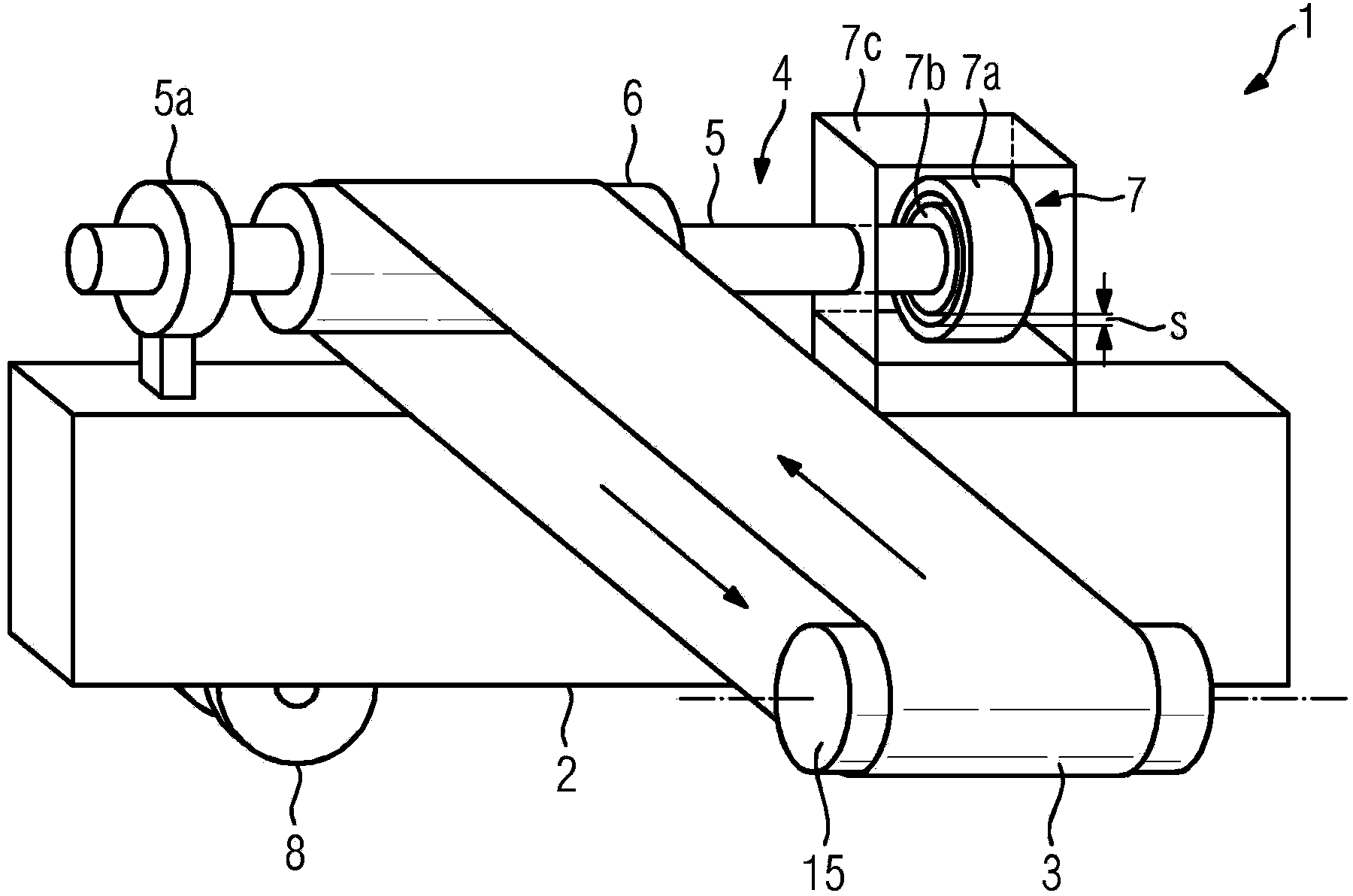

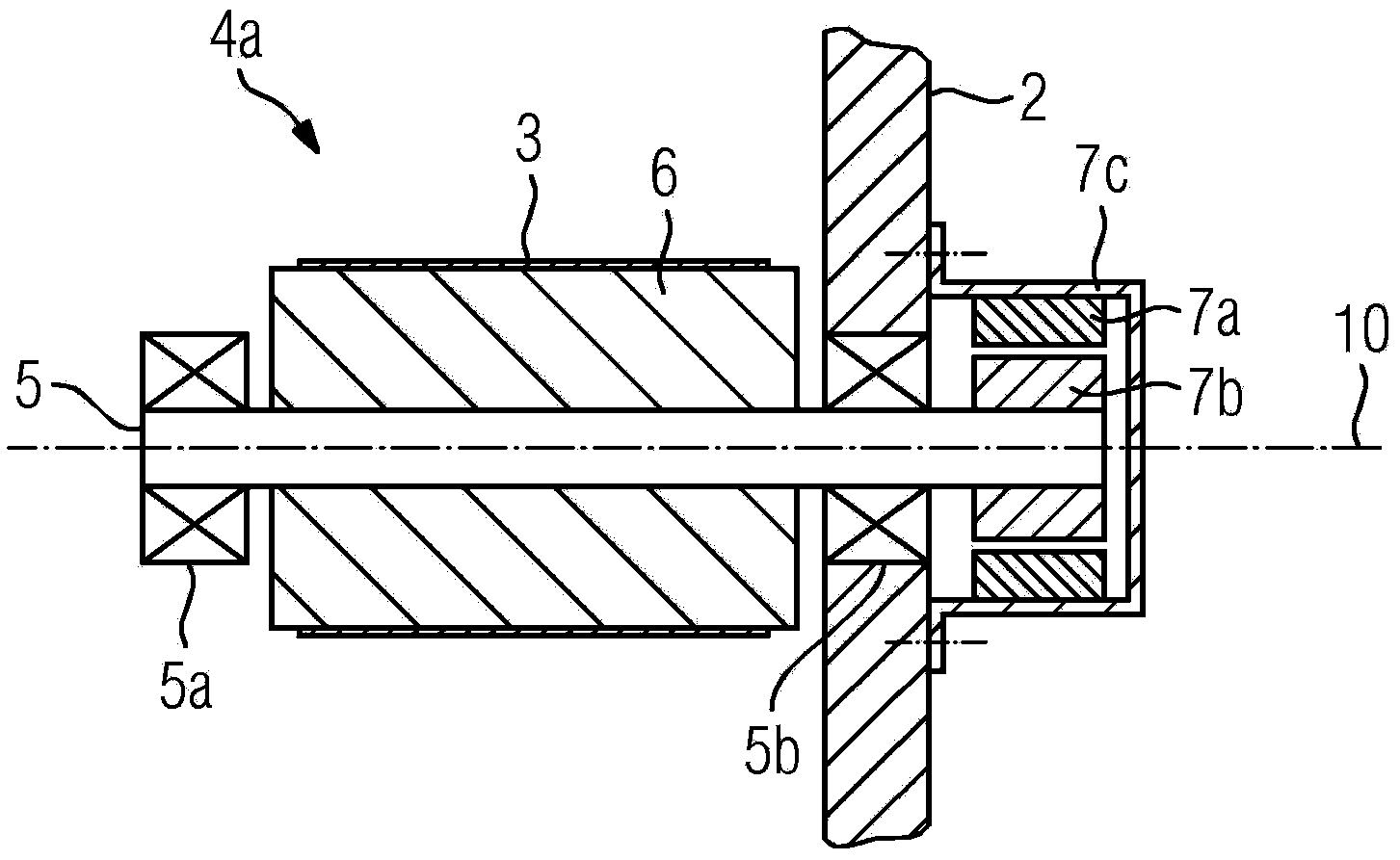

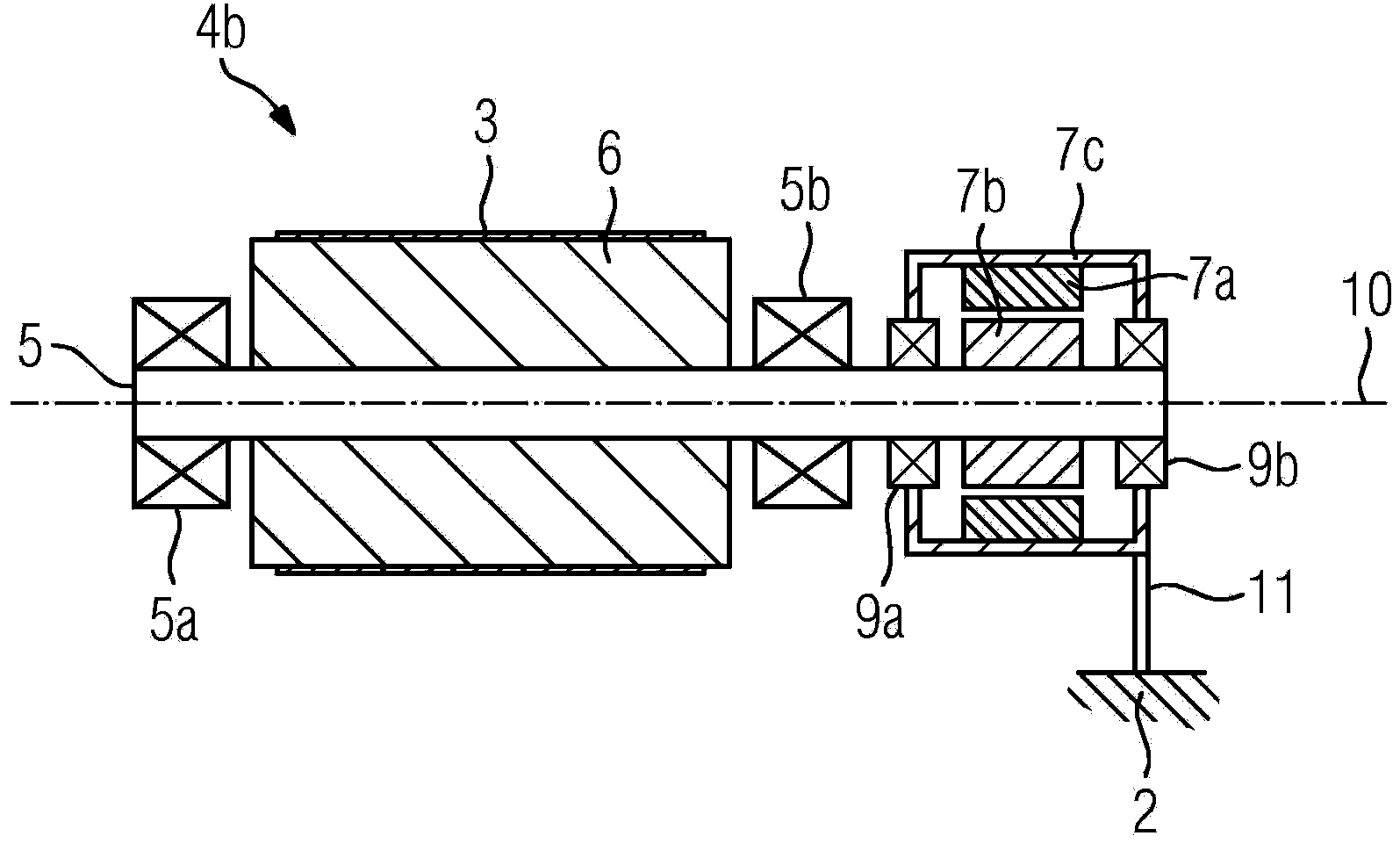

[0047] figure 1 A belt conveyor system 1 for heavy industry, in particular for the raw material industry or the mining industry, is shown schematically and only by way of example in a three-dimensional view. The belt conveyor 1 comprises a carrier structure 2 , a conveyor belt 3 and a drive 4 for driving the conveyor belt 3 . Furthermore, there is at least one guide roller 15 which can likewise be driven and can act as a further drive roller. The drive 4 comprises a drive shaft 5, at least one drive shaft bearing 5a, a drive roller 6 and a separately excited drive motor 7 in the form of an alternating current synchronous motor supplied by a frequency converter, which has a stator 7a and a rotor 7b. The rotor 7 b and the stator 7 a , shown schematically in section, are located in a motor housing 7 c , which is partially transparent here. The drive shaft 5 and the drive motor 7 are connected to one another without gearing, and there is a coaxial arrangement of the rotor 7 b a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com