A method of using the compact layout system of the billet discharge area of the billet continuous caster

A billet continuous casting and compact technology, which is applied to the layout of the billet discharge area of the continuous casting machine, can solve problems such as limited plant space, and achieve the effects of wide adjustment range, improved utilization rate, and smooth production line requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

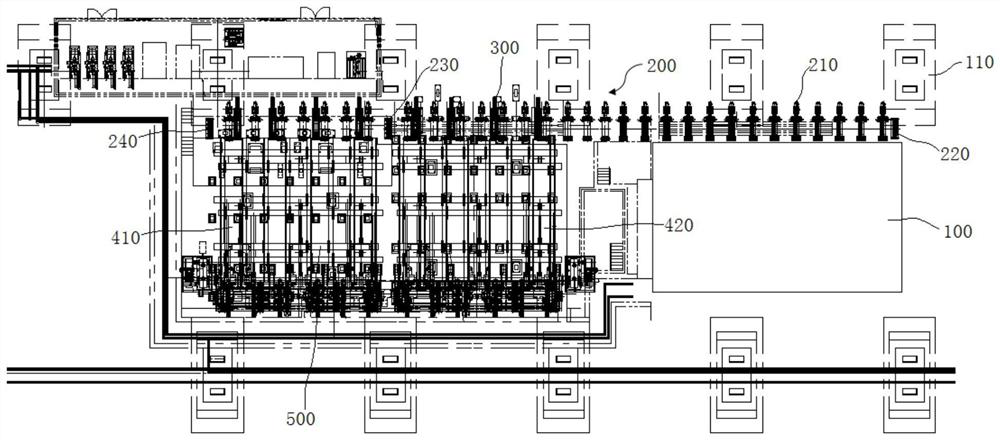

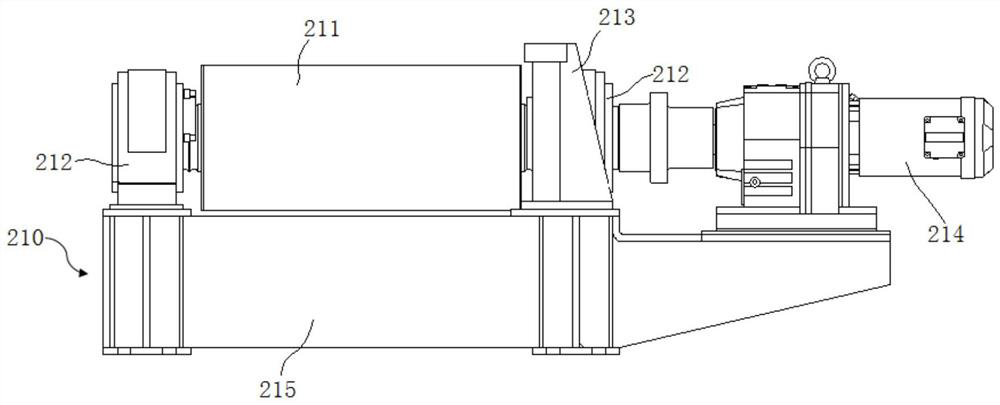

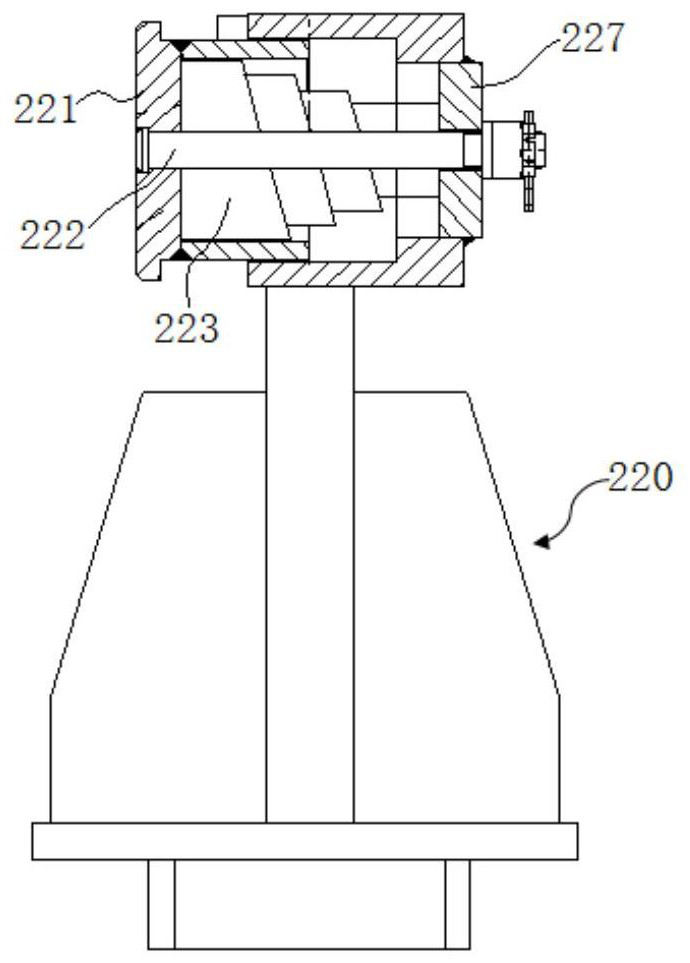

[0048] combine Figure 1-Figure 10 , a method for using the compact arrangement system of the billet discharge area of the billet continuous casting machine in this embodiment, including the lifting baffle 230 arranged on the hot delivery roller table 200 and the two-way cooling panel arranged on the same side of the hot delivery roller table 200 tail. bed A410 and two-way cooling bed B 420, such as figure 1 As shown, in the present embodiment, the two-way cooling bed A 410 and the two-way cooling bed B 420 are all perpendicular to the hot delivery roller table 200, and the two-way cooling bed A 410 is located on the left side of the two-way cooling bed B 420, wherein the two-way cooling bed A 410 and The two-way cooling bed B420 has the same structure and is arranged parallel to each other. In this embodiment, the side of the hot delivery roller table 200 far away from the two-way cooling bed A 410 and the two-way cooling bed B 420 is provided with an alignment steel pushe...

Embodiment 2

[0055] A method of using the compact arrangement system of the billet discharge area of the billet continuous casting machine in this embodiment, the basic structure is the same as that of Embodiment 1, further, as Figure 4 As shown, in this embodiment, the lifting baffle 230 includes a baffle housing arranged above, and the left and right sides of the baffle housing are respectively provided with a fixed end surface 238 and a buffer end surface 231, wherein the buffer end surface 231 is detachably inserted into the baffle On the right side of the plate housing, a second fixed screw 232 is connected between the fixed end surface 238 and the buffer end surface 231, and the fixed end surface 238 is provided with a through hole for the second fixed screw 232 to pass through, and one end of the second fixed screw 232 is fixed On the buffer end surface 231 , the other end of the second fixing screw 232 passes through the through hole on the fixing end surface 238 and is limited b...

Embodiment 3

[0059] A method for using the compact arrangement system of the billet discharge area of the billet continuous caster in this embodiment, the basic structure is the same as that of Embodiment 2, further, as figure 1 with Figure 9 As shown, in this embodiment, the side of the bidirectional cooling bed A 410 and the bidirectional cooling bed B 420 away from the hot delivery roller table 200 is provided with a collection platform 500, and the collection platform 500 includes a receiving part 510 for receiving the casting slab 110 With the steel dial mechanism 520 for pushing the cast slab 110, the receiving part 510 and the steel dial mechanism 520 are arranged in parallel. Specifically, such as Figure 9 As shown, in the present embodiment, the collection platform 500 is provided with a plurality of receiving parts 510 and a steel dial mechanism 520 evenly spaced along the width direction of the two-way cooling bed A 410 and the two-way cooling bed B 420, which is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com