3D printing nozzle for continuous material stirring and extruding and continuous spiral wire feeding

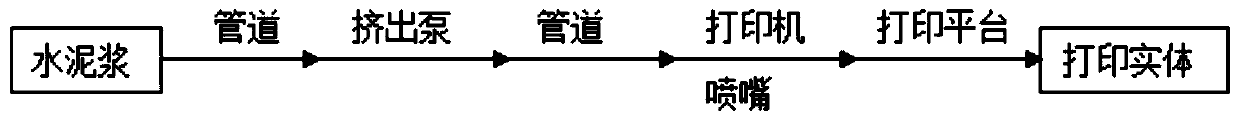

A continuous spiral, 3D printing technology, applied in the direction of ceramic molding machines, manufacturing tools, additive processing, etc., to achieve the effect of reducing site area requirements, enhancing strength, and facilitating assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

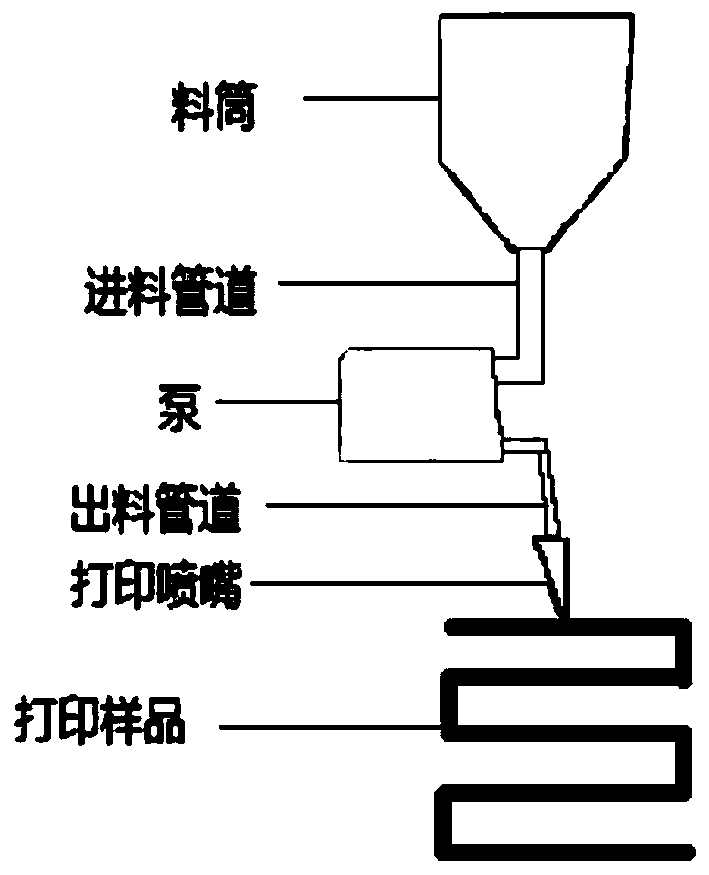

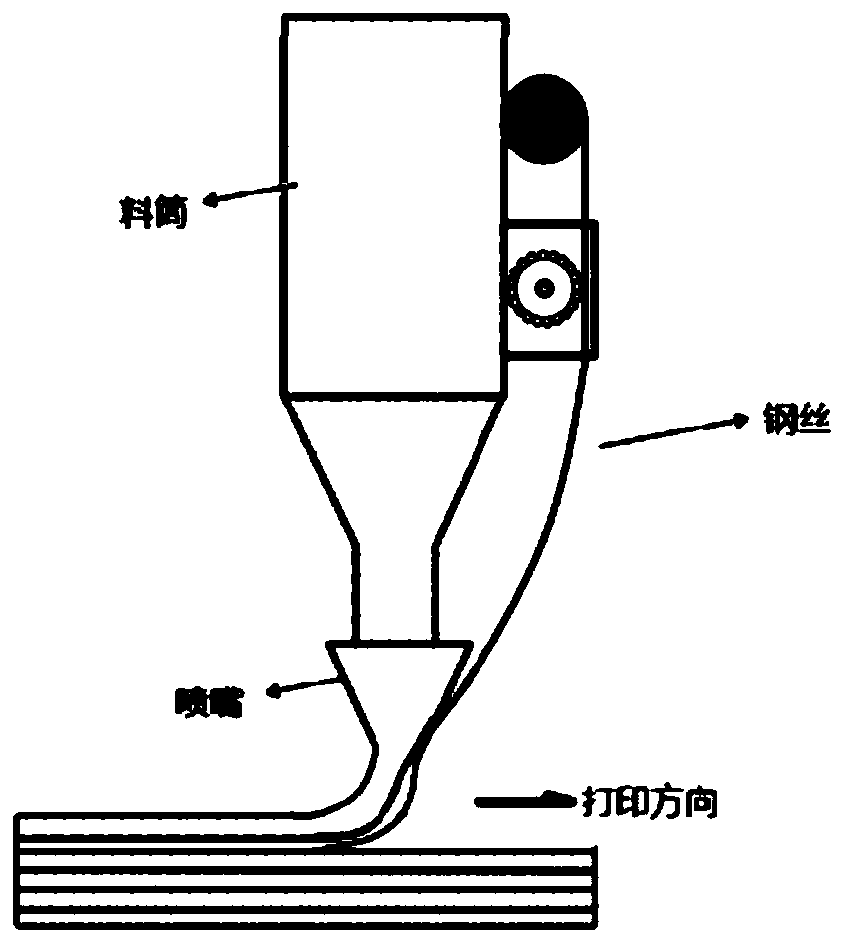

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0038] Such as Figure 4-11 As shown, a 3D printing nozzle with material stirring and extrusion simultaneously and continuous spiral wire feeding, including: motor 100, cylinder 200, rotating drum 300, upper transmission shaft tube 400 and lower driving shaft arranged on the central axis of rotating drum 300 Shaft tube 500, uniform material device 600, spatula nozzle 700 and support frame 800;

[0039] The motor 100 is set on the support frame 800, the output shaft of the motor 100 is connected with the transmission gear set 401, and the transmission gear set 401 is fixedly connected with the upper transmission shaft tube 400, and the motor 100 drives the upper transmission shaft tube 400 counterclockwise through the transmission gear set 401 rotation; the upper transmission shaft tube 400 is fixedly connected with a planetary gear set 402, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com