3DP printing method combining hierarchical shifting printing and layered mappable unit partition method

A technology of printing layers and picture frames, applied in the field of 3D printing, can solve the problems of not achieving rapid movement, affecting printing efficiency, and printing module breakage, etc., to avoid printing breakage, efficient and fast printing, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

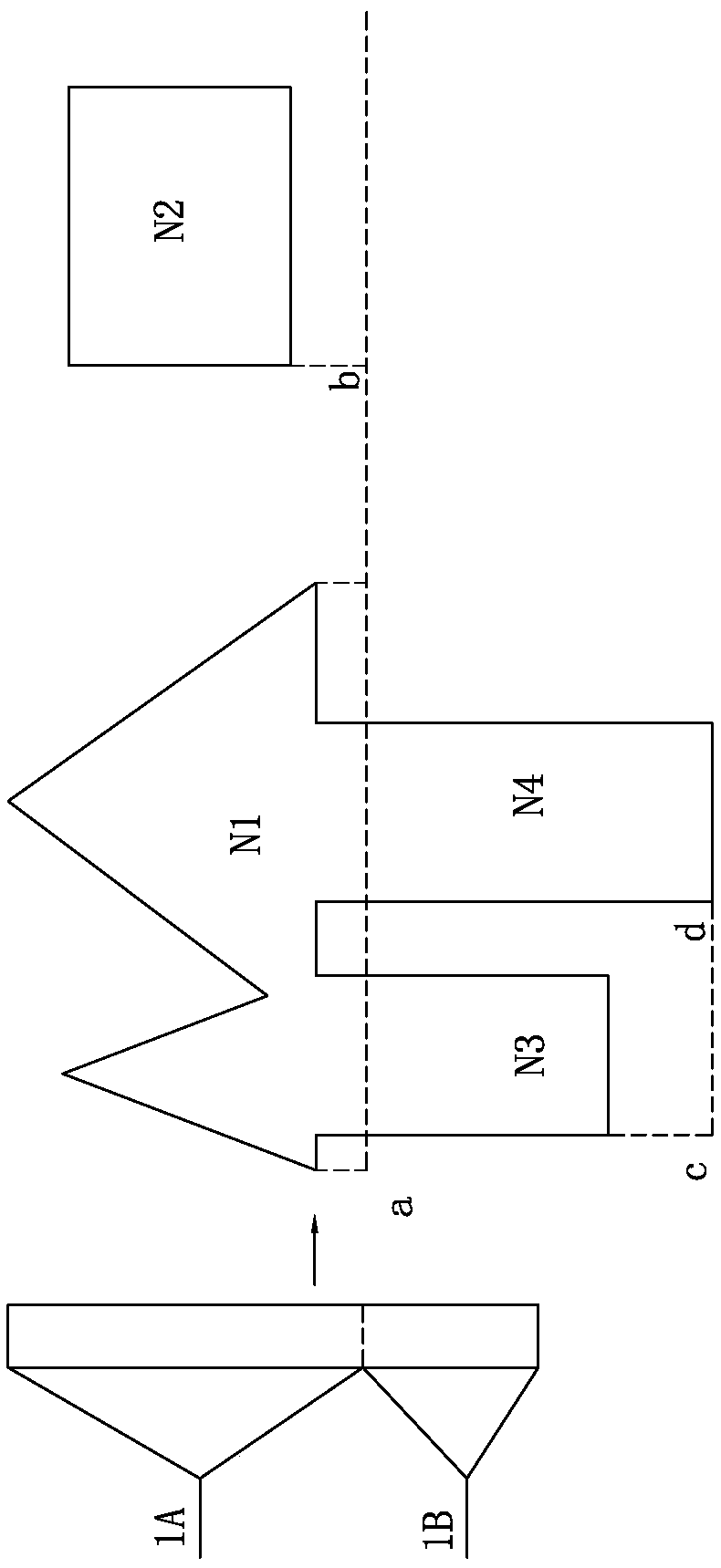

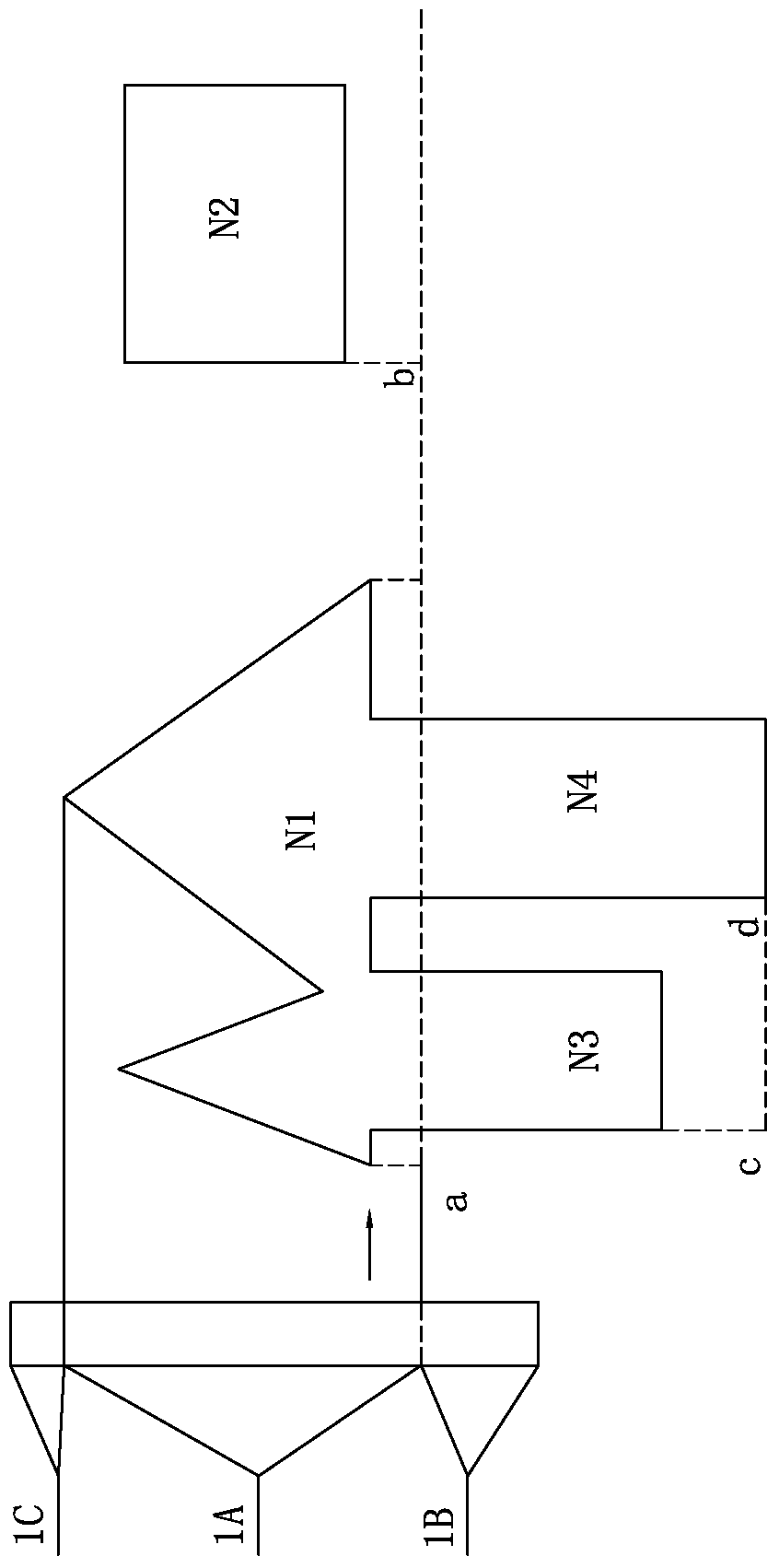

[0021] The following describes the 3DP printing method of the present invention combining the layered dislocation printing and the layered image segmentation method with a specific embodiment in conjunction with the accompanying drawings.

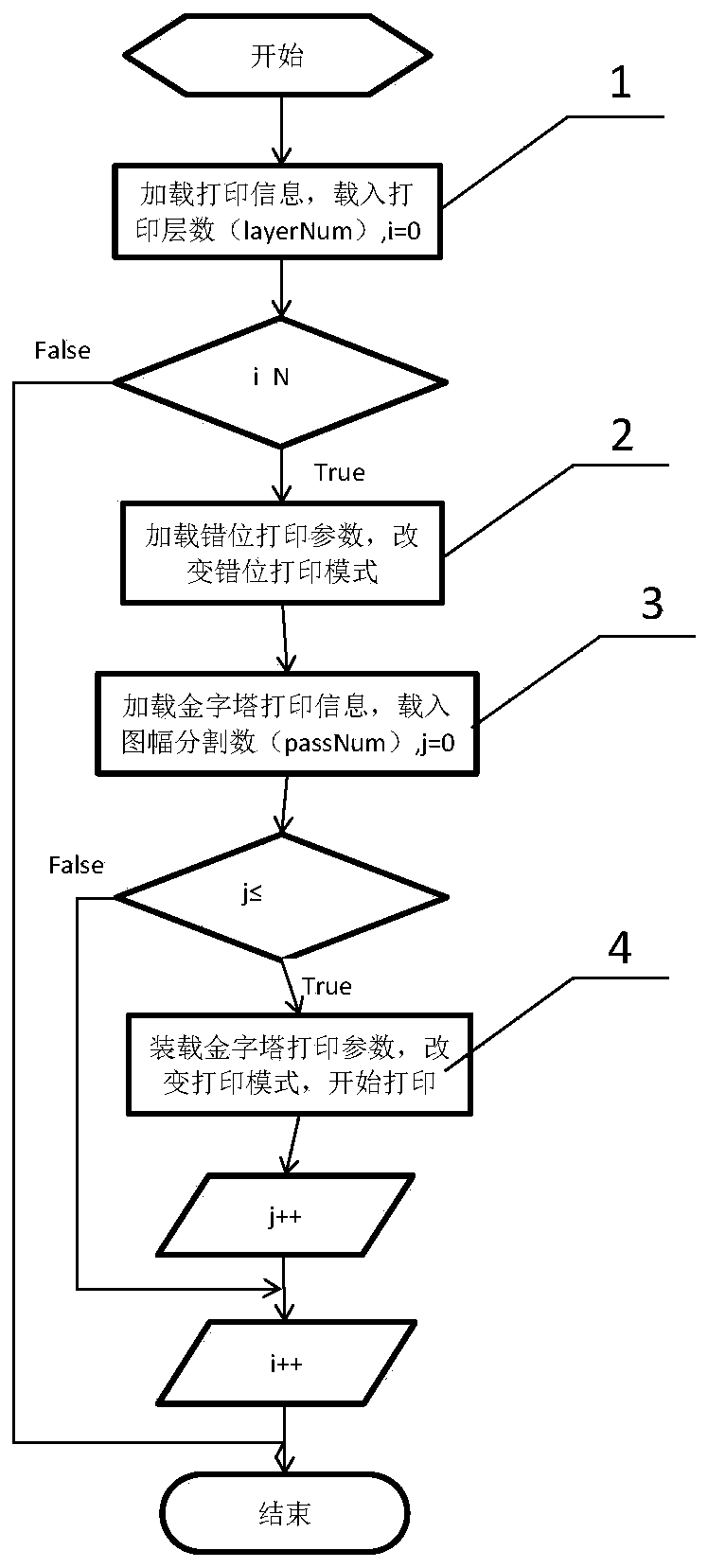

[0022] In this embodiment, the 3DP printing method combining the layered dislocation printing and layer-map-width segmentation method is implemented according to the printing process shown in Figure 1.

[0023] The first step is to read the 3D printing model data information file, load the printing information, analyze the layered information of the 3D model, and obtain the total number N of layers.

[0024] The second step is to judge the printing layer, load the current printing layer from the first layer, and judge whether the number of printing layers i of the current layer is less than the total number of layers N, if i>N is false, exit the printing process, and the printing is over; if i≤ N is True, then enter the third step to execut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com