Conveying device

A technology of conveying device and conveying mechanism, which is applied to conveyor objects, transportation and packaging, roller tracks, etc., can solve the problem of inconvenient reversing of conveyed objects, and achieve the effect of reducing the demand for site area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

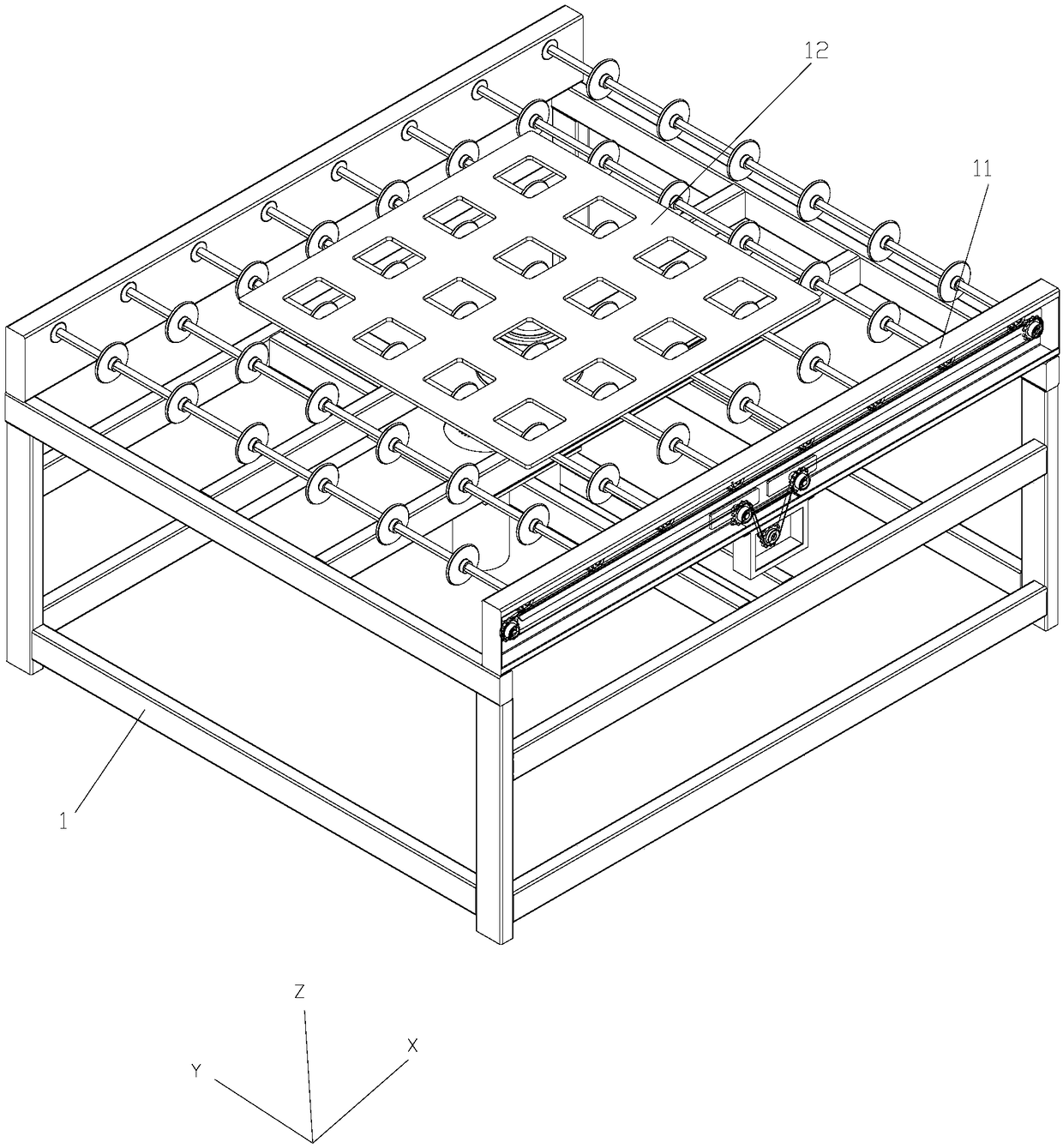

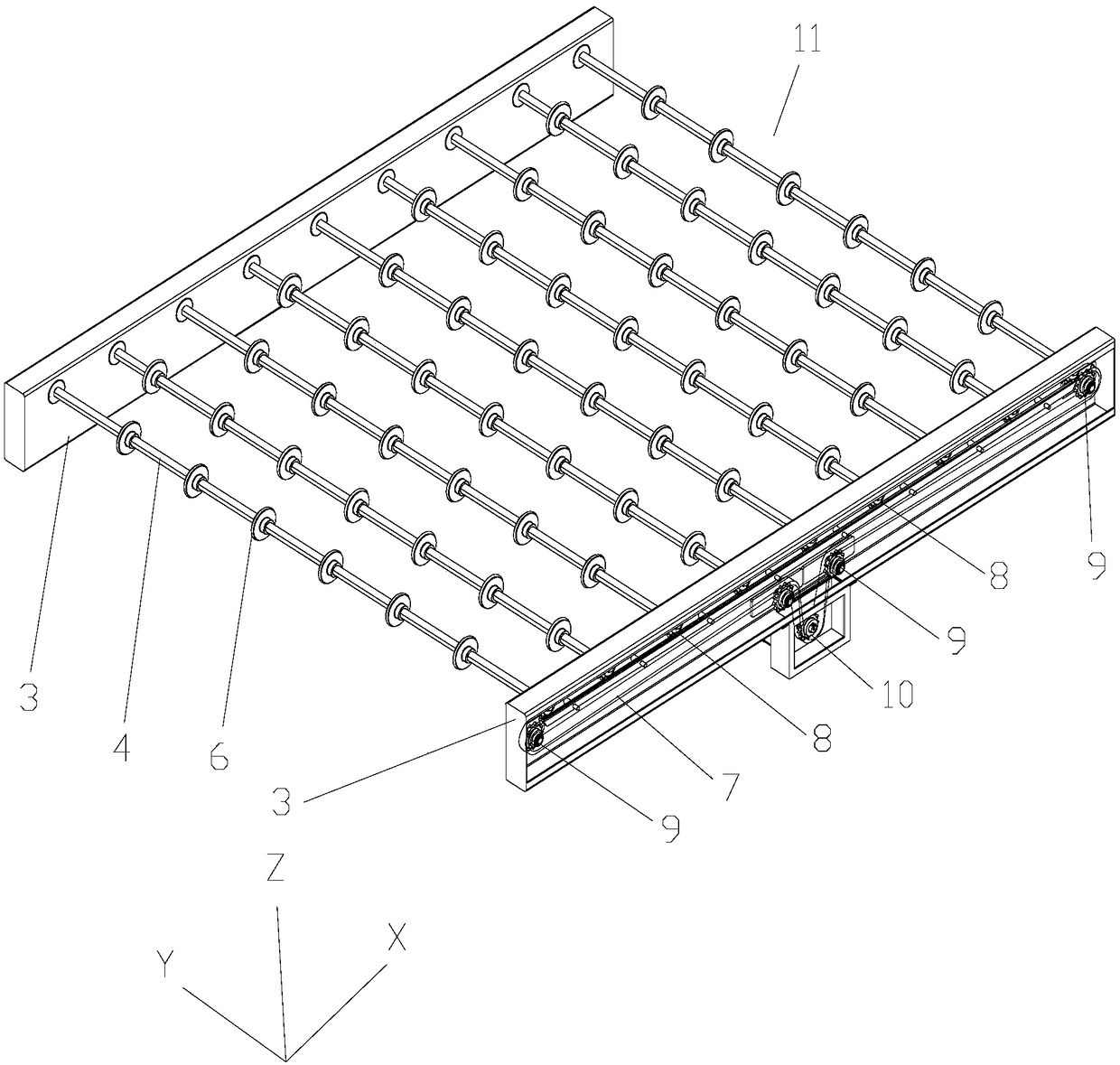

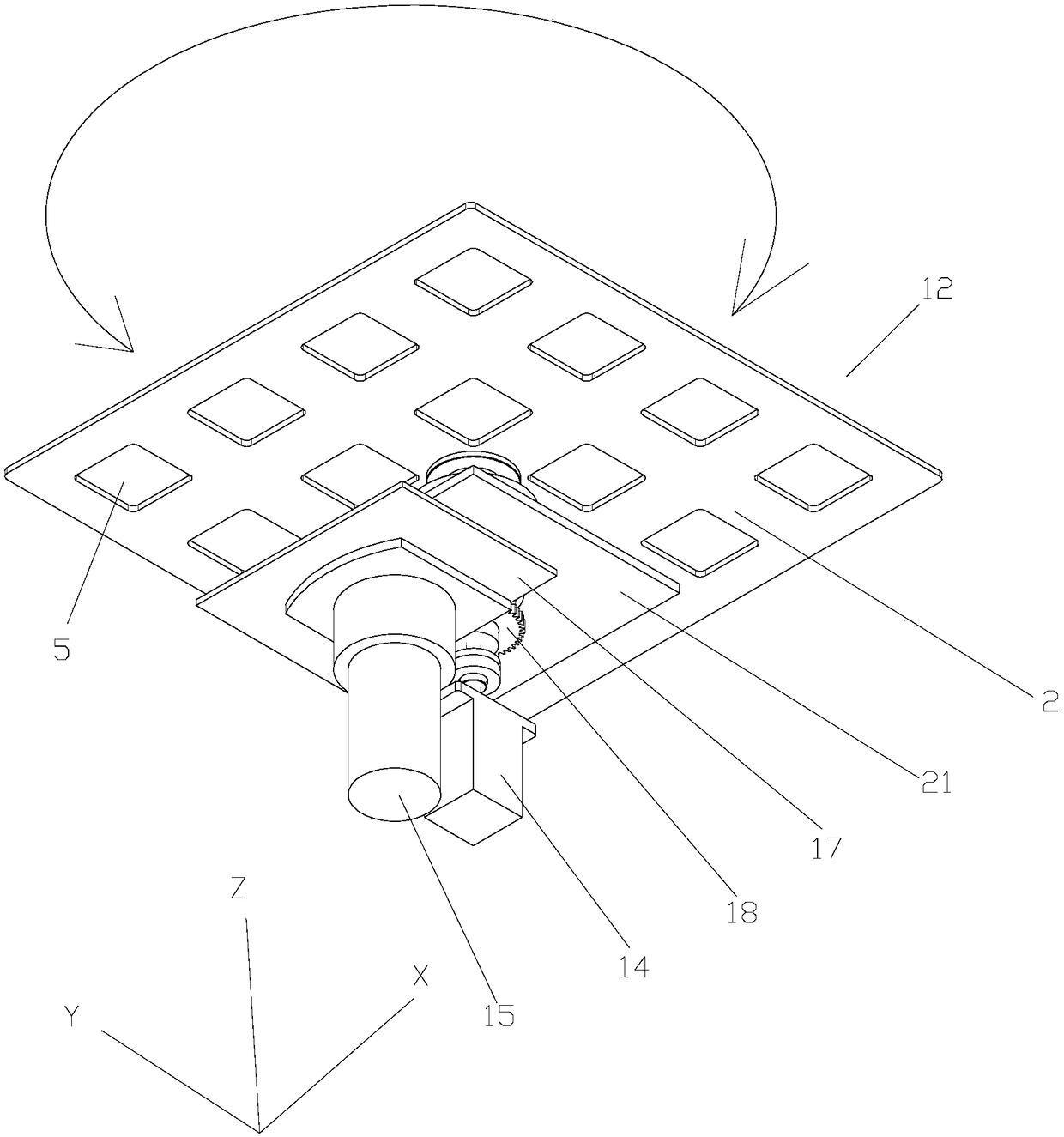

[0021] The present application provides a conveying device, which includes a frame 1 and a first conveying mechanism 11 and a second conveying mechanism 12 arranged on the frame 1, the first conveying mechanism 11 is used to drive objects along the X The second transmission mechanism 12 includes a supporting plate 2, a lifting unit and a rotating unit, the supporting plate 2 can support the object, and the lifting unit can lift the supporting plate 2 along the Z axis so that the The support plate 2 is switched between a first position and a second position higher than the first position, and the rotation unit can drive the support plate 2 to rotate in the plane formed by the X axis and the Y axis, wherein, in During the process of moving from the first position to the second position, the support plate 2 can lift the object on the first conveying mechanism 11, and when moving from the second position to the In the process of the first position, the lifting unit can re-place th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com